5.1. Estimation Results of the Constructed Simultaneous Equation System

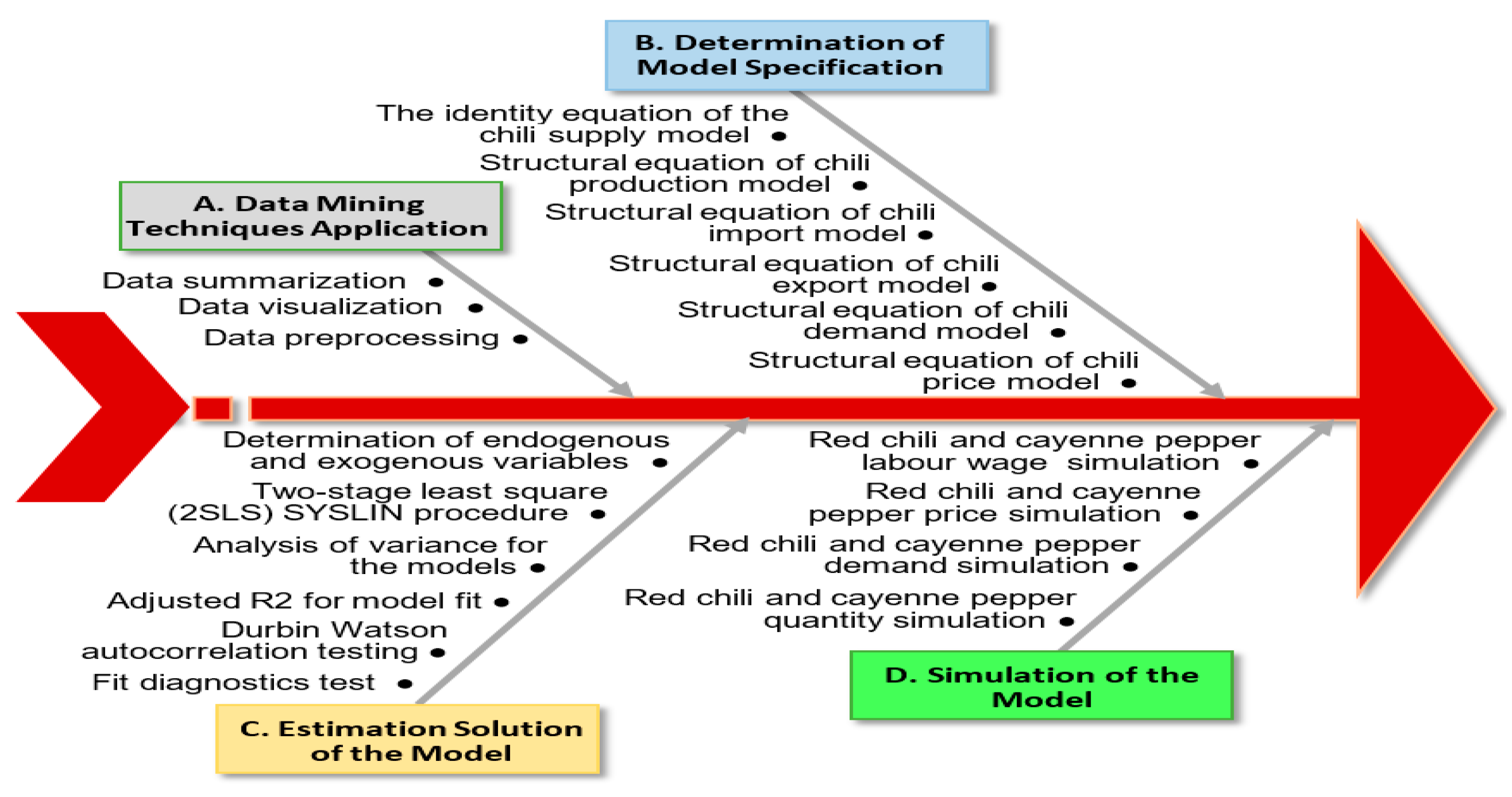

The chili supply model comprises three identity equations: Equation (1) for the total chili supply model, Equation (2) for the red chili supply model, and Equation (3) for the cayenne pepper supply model, which are elaborated into ten equations (

Table 10)—Equations (4) to Equation (13). The identity equation cannot show the behavior of endogenous variables formed by the multiplication, division, addition, or subtraction of several variables (

Gujarati and Porter 2009).

Table 10 summarizes the supply and demand estimation results. Although some adjusted R-square and DW showed reduced values, all the models fit.

Table 10 also shows the two-way relationship between the endogenous and exogenous variables. For instance, the chili price specifies the quantity of its demand and supply; simultaneously, the demand and supply quantities also specify its price. Price and quantity are endogenous variables as they are computed simultaneously from the system of equations. Our verdict aligns with the theories of

Gujarati and Porter (

2009) and

Sativa et al. (

2017).

The analysis of variance in

Table 10 shows that the global F test for all the models is significant (

p-value < 0.1), meaning that the models fit as exhibited by the

p-value < 0.0001 and

p-value < 0.0003. In the red chili production model (QCM), the value of adjusted (Adj.) R-square is 0.95806, which means the model can explain 95.81% of the diversity of the red chili production. The value of Adj. R-square = 0.95806 is close to 1, indicating that the model is excellent (

Forsyth 2018). The remaining values of Adj. R-square in the remaining models were self-explanatory. Our model fit declaration using the Adj. R-square aligned with another study stating the coefficient of determination (R-square) of the average production function was 0.715 for the dry season and 0.652 for the rainy season, which explained, consecutively, 71.5% and 65.2% of the variation of the chili production (

Saidah et al. 2020). This study used an Adj. R-square instead of the R-square. The value of the R-square is the proportion of the variability of the dependent variable described in the model; it is (the ability to predict the model)—the value of the Adj. R-square is a correction to R² that considers the number of variables used in the model (

Ohtani and Tanizaki 2004). Meanwhile, a DW value less than 1.33585 indicates an autocorrelation occurrence, meaning there is a correlation between the i-th observation and the i − 1 observation for i = 1 … 363. Alternatively, it is stated that there is a relationship between e

k,t and e

k,t−1, namely, the error that occurs in an observation k,t influences errors in an observation k,t−1. A DW value of 1.5–2.5 indicates no autocorrelation (

Jeong and Jung 2016).

The chili agro-system in Indonesia involves various factors such as the chili producers (farmers), production center locations, government intervention, supply and demand, price disparities, actors in the trading system, and its environment. With these various constituent factors, the chili agro-system essentially forms an enterprise system, as portrayed in the two-way relationship between the endogenous and exogenous variables shown in

Table 10. These variables interact with one another when discussing the supply and demand models described in the following simulation results. Structural equations in the simultaneous equation system for the supply and demand models describe the structure of the economic model of an economy or the behavior of economic agents (

Gujarati and Porter 2009). An enterprise is a sociotechnical system consisting of interdependent human resources, information, and complex technology interacting in an environment that supports a shared mission (

Giachetti 2016;

Bernard 2012). A system is an interaction that is an essential behavior in an enterprise. An enterprise is a sociotechnical system involving humans and technology, i.e., it is an open system that interacts with its environment to achieve specified goals (

Giachetti 2016).

Worthy sustainable economic development demands monthly inflation stability. For this reason, price stability is a determining factor in achieving inflation under a specified inflation target policy. However, in Indonesia, there are eight main patterns of chili distribution with a varying number of supply chain actors so that, in the end, this will affect the price received by the final consumers (

Rachmaniah et al. 2022). Econometrically, prices can be stable if the supply and demand are balanced. The implication is that a price control mechanism is needed, which means that it is necessary to monitor the production, consumption, and price of fresh chili packaged in a fresh chili enterprise system that considers the factors that make up the Indonesian fresh chili agro-system. Furthermore, to develop an enterprise, it is necessary to select an enterprise architecture framework that is relevant to the conditions of the existing agro-system.

Studies related to the selection of the architecture enterprise framework have been conducted previously (

Sessions and DeVadoss 2014;

Dorohyl et al. 2017;

Bondar et al. 2017;

Mokone et al. 2019). Of the four frameworks compared, the Zachman Framework is very good at taxonomy completeness; TOGAF excels at process completeness, vendor neutrality, and information availability; and FEAF is excellent at reference model guides, partition guides, and prescriptive catalogs. Additionally, the VRF/SIP is very good at practice guidance, business focus, partition guidance, and the time to value (

Sessions and DeVadoss 2014). The ten most popular AE frameworks are the Zachman Framework (25%), SOA (15%), TOGAF (11%), DoDAF (11%), FEAF (9%), Gartner EAF (GEAF) (3%), British Ministry of Defense Architecture Framework (British MODAF) (2%), NATO Architecture Framework (NAF) (1%), TEAF (1%), and the ISO Open Distributed Processing-Reference Model (RM-ODP) (

Dorohyl et al. 2017).

The architectural enterprise framework for chili agro-systems has never been studied, meaning that no previous studies have considered the application of the architectural enterprise framework for chili agro-systems (

Rachmaniah et al. 2022). Meanwhile, the results of research by

Sessions and DeVadoss (

2014),

Dorohyl et al. (

2017),

Bondar et al. (

2017), and

Mokone et al. (

2019) state that the Zachman Framework has various advantages. Therefore, based on previous descriptions, the AE framework for the chili supply and demand model is the Zachman Framework.

5.2. Simulation Results of the Constructed Simultaneous Equation System

The validation results are presented in the column ‘Actual Mean Validation’ in

Table 9, followed by the simulation results in the subsequent columns. Each scenario required specific coding. The simulation coding results were then compared with the validation results to determine the impact of the simulation changes. The formula used to determine the impact of the simulation (% shift) is:

When the real wage of labor (UTK) increases by 10%, it causes an increase of 1.66% and 3.68%, respectively, in the production of red chili (QCM) and the production of cayenne pepper (QCR) models. UTK is an exogenous variable in the QCM and QCR models. The results of the UTK simulation aligned with

Saidah et al. (

2020) in that the increased production of red chili farming was due to an increasing labor use. The increase in UTK also caused an increase in other variables, namely, an increase of:

2.57% in the total supply of fresh chili (QSC),

1.66% in the supply of red chili (QSCM),

3.58% in the supply of cayenne pepper (QSCR),

2.17% in the imports of red chili (MCM),

2.15% in the imports of cayenne pepper (MCR).

The UTK simulation had the highest escalation impact on the export of cayenne pepper (XCR) at 4.05%. On the other hand, the simulation results show that an increase in UTK also caused a decrease in the price of red chilies (HCM) and cayenne peppers (HCR) by −0.66% and −0.14%, respectively. This was probably due to the increase in MCM and MCR, as more supplies were available in the market. The two variables that were not affected were the domestic demand for red chilies (QDCM) and the domestic demand for cayenne peppers (QDCR).

When the price of red chilies (HCM) increased by 50%, the government increased the imports of red chili (MCM) by 5.03% to stabilize the prices (

Table 9). Chili commodities contribute to inflation: a 1% increase of chili prices will increase inflation by 0.01 (

Marpaung et al. 2019). Unfortunately, farmers do not enjoy horticultural crop price increases, whereas the wholesalers and retailers do (

Fitria et al. 2019). An increase in prices occurred due to an increase in demand for red chili (QDCM) by 3.18%; however, the exports of red chili (XCM) increased by 4.09%, but the amount was smaller than the change its imports. On the other hand, when the price of cayenne pepper (HCR) increased by 50%, the government reduced the imports of cayenne pepper (MCR) by 27.85% and its exports (XCR) by 1.25% because cayenne pepper is less prevalent in Indonesia’s main dishes. The price simulation of cayenne pepper’s 50% increase in demand was decreased for cayenne pepper (QDCR) by 16.42%. Here, the price of cayenne pepper increased, causing its purchases to decrease. The per capita consumption of cayenne pepper is relatively lower than that of red chili; hence, an increase in HCR does not cause an increase in the imports of red chili (MCM), the exports of cayenne peppers (XCR), or the demand for cayenne peppers (QDCR), as indicated by the negative value of each simulation on these variables.

The simulations of a 15% increase in demand for domestic red chili (QDCM) and cayenne peppers (QDCR) are in

Table 9. When the QDCM increased, the imports of red chili (MCM) were relatively higher than their exports (XCR). The simulation comparing the value of imports and the value of exports illustrates this. This increase in demand also caused the price of red chilies to increase by 1.38%. Likewise, when the QDCR increased, the import level of cayenne peppers was also relatively higher than its exports. However, recall that the consequences of international price and exchange rate changes are more extensive than tariff rate decreases (

Ahn and Im 2016). An increase in the QDCR also increased the price of cayenne pepper (HCR) by 0.07%. Meanwhile, the demand for red chili or cayenne peppers included their price, their substitutes or complementary prices, and the population and consumer income (

Gusvita and Budaraga 2015).

The last simulation was a 25% reduction in the production of red chilies (QCM) and cayenne peppers (QCR) due to weather conditions or viruses (see

Table 9). Red chili production would increase by 2,557,084 tons with rainfall between 100–250 mm/month; conversely, production would decrease by 2,557,084 tons with rainfall of more than 250 mm/month or less than 100 mm/month (

Sativa et al. 2017). The simulation results show that the supply of both chili types was low, with fewer imports and exports; however, lessening the QCM and QCR supply increased the price of red chili (HCM) by 1.58% and cayenne peppers (HCR) by 1.73%. The simulation results aligned with the basic econometric phenomenon, where less production leads to less supply, so that prices will increase, and a decreased supply can lead to high prices (

Sativa et al. 2017).

5.3. Managerial Implications

This research has managerial implications and a new perspective for monitoring the agro-systems of fresh chili in particular, and the agro-systems of horticultural commodities in general. Chili plants are often harvested, not once, as in rice plants. In addition, fresh chilies are only fresh for a few days, generally approximately 5–10 days after picking; therefore, they must be marketed quickly. Based on discussions with chili farmers in Garut, Sukabumi, and Sleman, fresh chilies are generally harvested (picked) almost twice per week until the harvest season ends. Note that the harvesting age for red chili and curly red chili is 70–80 days, whereas that for cayenne pepper is 100–120 days.

As an implication, the data collection on production, harvested area, and price of fresh chili must occur in each instance or event of production (supply) and procurement (demand/purchase of supply chain actors from farmers). Data collection that is conducted once a month per sub-district will face accuracy problems because farmers will need help to remember their monthly volume, since they do not have the proper tools. The study results regarding the red chili and curly red chili prices imply that the prediction model will be more accurate when using daily time-series data, rather than weekly or monthly time-series data (

Falah and Rachmaniah 2022).

The data were collected directly from each chili farmer in a sub-district per incident and accumulated per district. In this case, it would be necessary to automate data collection forms at the farmer level and to further aggregate them at the sub-district level. The number of rural residents who owned a cellular phone was 54.31% of the rural population (

Badan Pusat Statistik 2021). This means that about 54.31% of rural farmers have the potential to automate their data collection via cell phones; the remainder still require intervention from the District Data Collection Officer.

The theoretical implication affects the size of the estimated parameters generated from the panel data model of the simultaneous equation system. This supports the previous literature on the chili supply and demand model (

Asidawati et al. 2022). The involvement of big data could assist in identifying the chili enterprise system through decision-making in production scheduling, logistics planning, and the supply chains across regions (

Siregar and Suroso 2021).

Generalization of the time-series data units on an annual basis and cross-section at the provincial level eliminates detailed data and produces residuals that are less normally distributed, because the model only examined 363 observations compared to 951,456 observations generated from monthly data sourced from the 7208 sub-districts for the 2010–2020 period. Various data variables that are often needed in modeling should be implemented in a one-gate policy. The authors hope that every government, education, research, and development institution would be able to access these data variables and since collecting data from the root source is not easy, it is necessary to develop an innovative enterprise system for fresh chili. With this enterprise system, the authors hope that the data collection mechanism could be carried out systemically as a part of government institutions’ main tasks and be automated at the micro level.