Comparison of iPad Pro®’s LiDAR and TrueDepth Capabilities with an Industrial 3D Scanning Solution

Abstract

1. Introduction

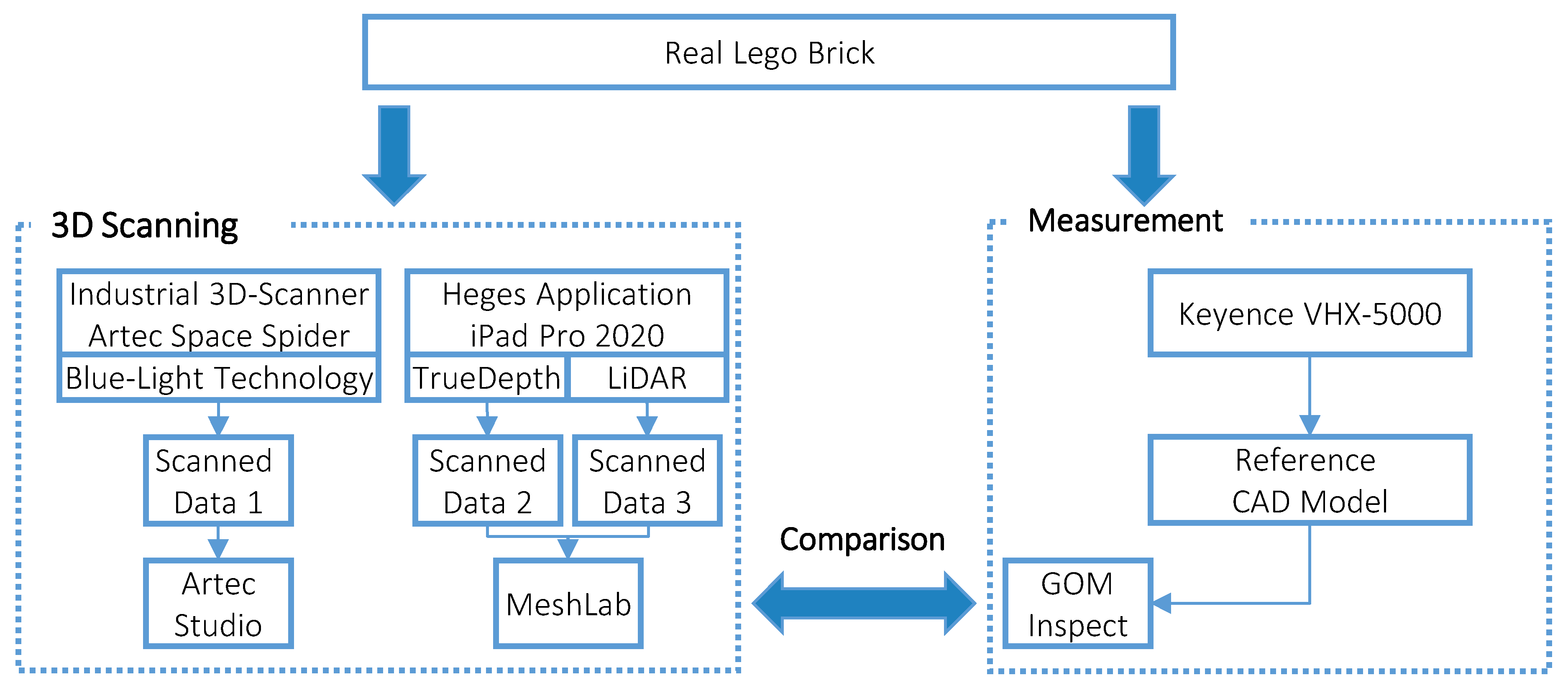

2. Materials and Methods

- (1)

- Scanning

- (2)

- Measurement

- (3)

- Comparison

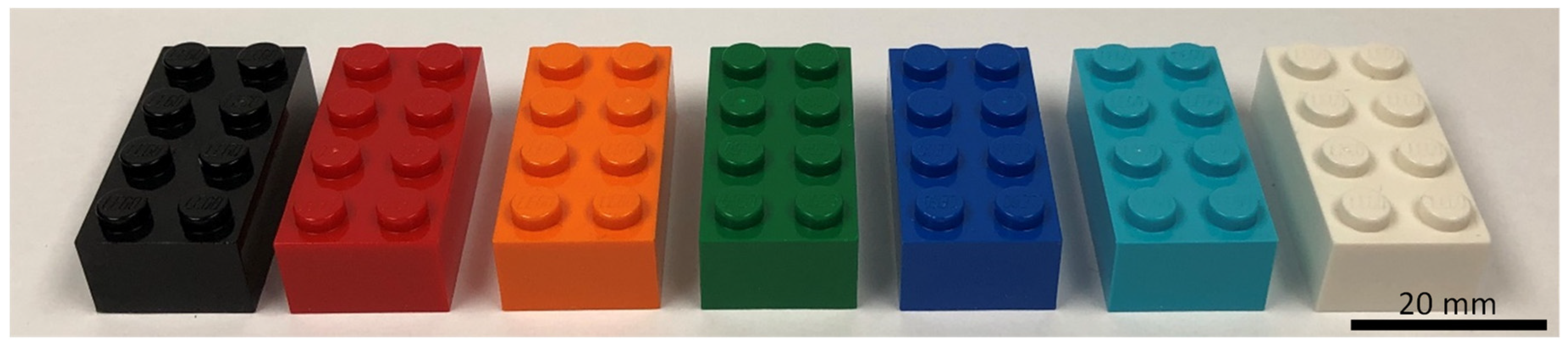

2.1. Scanning

- Material-specific reflectance: all objects are made from the same material

- Surface texture of the underground: constant

- Scanner distance: constant with 300 mm

- Scanning angle: constant with 65°

- Lighting conditions: scanner placed identically in the same environment

- Scanning speed: one rotation of the object per minute

- Relative movements: no movement of the scanning devices

- Post-processing (point cloud, spline, surface model,): same

- Software settings (resolution etc.): same settings

2.2. Measurement

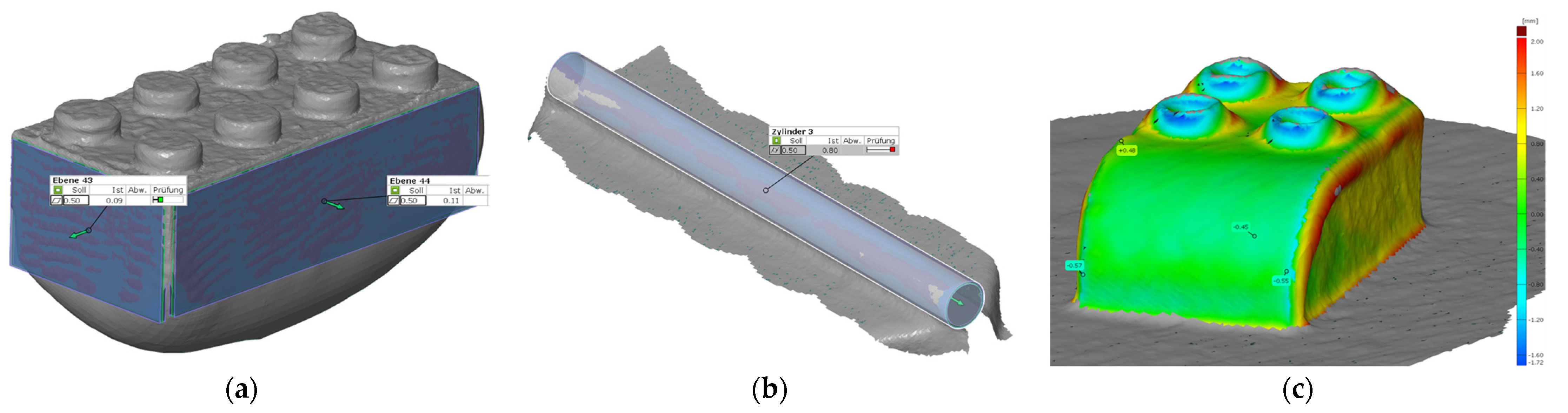

2.3. Comparison

3. Results

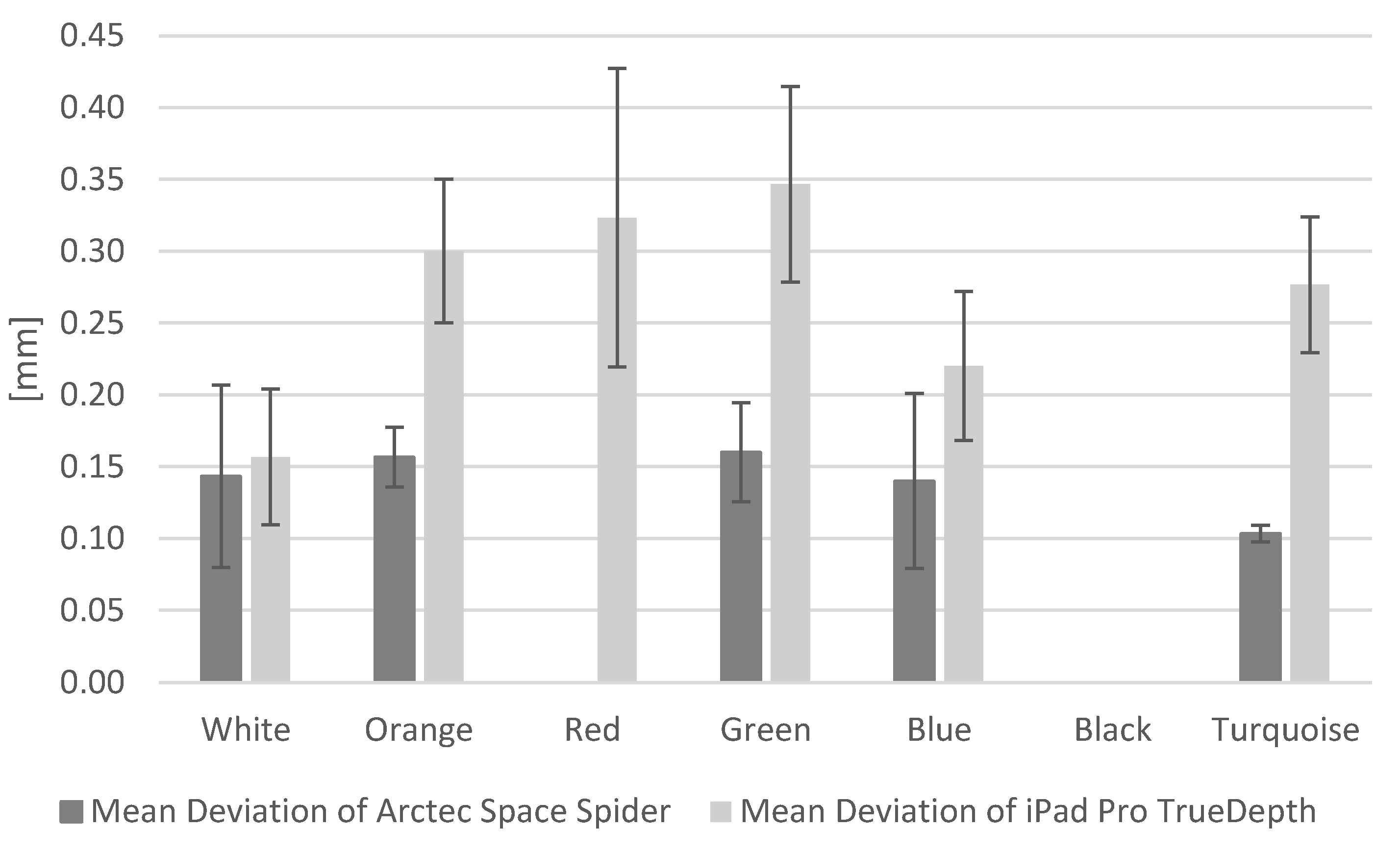

3.1. Impact of Color

3.2. Scanning Accuracy

4. Discussion

4.1. Impact of Color

4.2. Scanning Accuracy

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Artec Space Spider with Blue Light Technology 1 | ||||||

|---|---|---|---|---|---|---|

| Brick Color | Value 1 | Value 2 | Value 3 | Mean | Standard Deviation | Variance |

| White | 0.18 | 0.07 | 0.18 | 0.14 | 0.064 | 0.004 |

| Orange | 0.14 | 0.15 | 0.18 | 0.16 | 0.021 | 0.000 |

| Red | N/A 2 | N/A 2 | N/A 2 | - | - | - |

| Green | 0.14 | 0.20 | 0.14 | 0.16 | 0.035 | 0.001 |

| Blue | 0.21 | 0.11 | 0.10 | 0.14 | 0.061 | 0.004 |

| Black | N/A 2 | N/A 2 | N/A 2 | - | - | - |

| Turquoise | 0.10 | 0.11 | 0.10 | 0.10 | 0.006 | 0.000 |

| iPad Pro 2020 with TrueDepth Camera 1 | ||||||

|---|---|---|---|---|---|---|

| Brick Color | Value 1 | Value 2 | Value 3 | Mean | Standard Deviation | Variance |

| White | 0.12 | 0.21 | 0.14 | 0.16 | 0.047 | 0.002 |

| Orange | 0.25 | 0.35 | 0.30 | 0.30 | 0.050 | 0.003 |

| Red | 0.24 | 0.44 | 0.29 | 0.32 | 0.104 | 0.011 |

| Green | 0.37 | 0.40 | 0.27 | 0.35 | 0.068 | 0.005 |

| Blue | 0.19 | 0.28 | 0.19 | 0.22 | 0.052 | 0.003 |

| Black | N/A 2 | N/A 2 | N/A 2 | - | - | - |

| Turquoise | 0.24 | 0.33 | 0.26 | 0.28 | 0.047 | 0.002 |

| Artec Space Spider with Blue Light Technology 1 | ||||||

|---|---|---|---|---|---|---|

| Form Tolerance | Value 1 | Value 2 | Value 3 | Mean | Standard Deviation | Variance |

| Straightness | 0.15 | 0.14 | 0.15 | 0.15 | 0.006 | 0.000 |

| Flatness | 0.12 | 0.17 | 0.14 | 0.14 | 0.025 | 0.001 |

| Roundness | 1.19 | 0.87 | 0.83 | 0.96 | 0.197 | 0.039 |

| Cylindricity | 0.20 | 0.14 | 0.16 | 0.17 | 0.031 | 0.001 |

| iPad Pro 2020 with TrueDepth Camera 1 | ||||||

|---|---|---|---|---|---|---|

| Form Tolerance | Value 1 | Value 2 | Value 3 | Mean | Standard Deviation | Variance |

| Straightness | 0.42 | 0.29 | 0.61 | 0.44 | 0.161 | 0.026 |

| Flatness | 0.42 | 0.30 | 0.51 | 0.41 | 0.105 | 0.011 |

| Circularity | 0.87 | 1.27 | 1.38 | 1.17 | 0.268 | 0.072 |

| Cylindricity | 0.79 | 0.88 | 0.80 | 0.82 | 0.049 | 0.002 |

| Artec Space Spider with Blue Light Technology 1 | ||||||

|---|---|---|---|---|---|---|

| Target-Actual Comparison | Value 1 | Value 2 | Value 3 | Mean | Standard Deviation | Variance |

| Position | 0.50 | 0.37 | 0.41 | 0.43 | 0.067 | 0.004 |

| Profile of a surface | 0.60 | 0.78 | 0.67 | 0.68 | 0.091 | 0.008 |

| Profile of a line | 4.63 | 4.24 | 4.67 | 4.51 | 0.238 | 0.056 |

| iPad Pro 2020 with TrueDepth Camera 1 | ||||||

|---|---|---|---|---|---|---|

| Target-Actual Comparison | Value 1 | Value 2 | Value 3 | Mean | Standard Deviation | Variance |

| Position | 1.10 | 0.88 | 1.10 | 1.03 | 0.127 | 0.016 |

| Profile of a surface | 1.25 | 1.58 | 0.57 | 1.13 | 0.515 | 0.265 |

| Profile of a line | 4.51 | 5.04 | 5.20 | 4.92 | 0.361 | 0.130 |

References

- Martínez-Olvera, C.; Mora-Vargas, J. A Comprehensive Framework for the Analysis of Industry 4.0 Value Domains. Sustainability 2019, 11, 2960. [Google Scholar] [CrossRef]

- Fathi, M.; Ghobakhloo, M. Enabling Mass Customization and Manufacturing Sustainability in Industry 4.0 Context: A Novel Heuristic Algorithm for in-Plant Material Supply Optimization. Sustainability 2020, 12, 6669. [Google Scholar] [CrossRef]

- Apple Inc. iPad Pro. 2020. Available online: https://www.apple.com/de/ipad-pro/ (accessed on 6 November 2020).

- Hexr. The World’s First Custom Fit Helmet. Available online: https://hexr.com/pages/fitting (accessed on 12 February 2021).

- Raja, V. Introduction to Reverse Engineering. In Reverse Engineering; Raja, V., Fernandes, K.J., Eds.; Springer: London, UK, 2008; pp. 1–9. ISBN 978-1-84628-855-5. [Google Scholar]

- Page, D.; Koschan, A.; Abidi, M. Methodologies and Techniques for Reverse Engineering–The Potential for Automation with 3-D Laser Scanners. In Reverse Engineering; Raja, V., Fernandes, K.J., Eds.; Springer: London, UK, 2008; pp. 11–32. ISBN 978-1-84628-855-5. [Google Scholar]

- Ameen, W.; Al-Ahmari, A.; Hammad Mian, S. Evaluation of Handheld Scanners for Automotive Applications. Appl. Sci. 2018, 8, 217. [Google Scholar] [CrossRef]

- Gerbino, S.; Del Giudice, D.M.; Staiano, G.; Lanzotti, A.; Martorelli, M. On the influence of scanning factors on the laser scanner-based 3D inspection process. Int. J. Adv. Manuf. Technol. 2016, 84, 1787–1799. [Google Scholar] [CrossRef]

- Amornvit, P.; Sanohkan, S. The Accuracy of Digital Face Scans Obtained from 3D Scanners: An In Vitro Study. Int. J. Environ. Res. Public Health 2019, 16, 5061. [Google Scholar] [CrossRef] [PubMed]

- Alexander Duss. Development Capability Profiles of Selected Reverse Engineering Techniques; Stellenbosch University: Stellenbosch, ZA, USA, 2012. [Google Scholar]

- Artec Europe. Artec Space Spider. Available online: https://www.artec3d.com/de/portable-3d-scanners/artec-spider-v2 (accessed on 6 November 2020).

- Schuon, S.; Theobalt, C.; Davis, J.; Thrun, S. High-quality scanning using time-of-flight depth superresolution. In Proceedings of the 2008 IEEE Computer Society Conference on Computer Vision and Pattern Recognition Workshops, Anchorage, AK, USA, 23–28 June 2008; IEEE: Piscataway, NJ, USA, 2008. ISBN 9781424423392. [Google Scholar]

- Alfaro-Santafé, J.; Gómez-Bernal, A.; Lanuza-Cerzócimo, C.; Alfaro-Santafé, J.V.; Pérez-Morcillo, A.; Almenar-Arasanz, A.J. Three-axis measurements with a novel system for 3D plantar foot scanning: iPhone X. Footwear Sci. 2020, 12, 123–131. [Google Scholar] [CrossRef]

- Olade, I.; Liang, H.; Fleming, C. A Review of Multimodal Facial Biometric Authentication Methods in Mobile Devices and Their Application in Head Mounted Displays. In Proceedings of the 2018 IEEE SmartWorld, Ubiquitous Intelligence & Computing, Advanced & Trusted Computing, Scalable Computing & Communications, Cloud & Big Data Computing, Internet of People and Smart City Innovation (SmartWorld/SCALCOM/UIC/ATC/CBDCom/IOP/SCI), Guangzhou, China, 8–12 October 2018; pp. 1997–2004, ISBN 978-1-5386-9380-3. [Google Scholar]

- Carey, N.; Nagpal, R.; Werfel, J. Fast, accurate, small-scale 3D scene capture using a low-cost depth sensor. IEEE Winter Conf. Appl. Comput. Vis. 2017, 2017, 1268–1276. [Google Scholar] [CrossRef] [PubMed]

- Verdaasdonk, R.M.; Liberton, N. The Iphone X as 3D Scanner for Quantitative Photography of Faces for Diagnosis and Treatment Follow-Up (Conference Presentation). In Proceedings of the SPIE 10869, Optics and Biophotonics in Low-Resource Settings V, 1086902, San Francisco, CA, USA, 4 March 2019. [Google Scholar]

- Nermina Zaimovic-Uzunovic, S.L. 10th International Symposium on Measurement and Quality Control (ISMQC 2010): Influences of Surfaces Parameters on Laser 3D Scanning; Curran: Red Hook, NY, USA, 2010; ISBN 978-1-61782-019-9. [Google Scholar]

- The LEGO Group. Company Profile: An Introduction to the LEGO Group. Available online: https://www.lego.com/cdn/cs/aboutus/assets/blt2278c7a21e58e900/LEGOCompanyProfile_2020.pdf (accessed on 6 April 2021).

- Henzold, G. Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME Standards, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2006; ISBN 978-0750667388. [Google Scholar]

- The LEGO Group. Pick a Brick. Available online: https://www.lego.com/de-de/page/static/pick-a-brick (accessed on 6 November 2020).

- Minetola, P.; Iuliano, L.; Calignano, F. A customer oriented methodology for reverse engineering software selection in the computer aided inspection scenario. Comput. Ind. 2015, 67, 54–71. [Google Scholar] [CrossRef]

| Evaluation of Scanned Lego Bricks by Shape Tolerances According to DIN EN ISO 1101 | |||||

|---|---|---|---|---|---|

| Symbol | Geometric Characteristic | Tolerance Type | Lego Brick | Element Number 1 | Control Summary |

| Straightness | Form (No Relation between Features) |  | 4,181,139/44,237 | Controls form or surfaces of a feature in relation to its own perfect form. |

| Flatness |  | 300,123/3001 | ||

| Roundness (Circularity) |  | 6,322,842/98,138 | ||

| Cylindricity |  | 17,715/87,994 | ||

| Position | Location |  | 300,123/3001 | Controls size, form and orientation of scanned surfaces based on datum references. |

| Profile of a surface |  | 230,223 | ||

| Profile of a line |  | 230,223 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vogt, M.; Rips, A.; Emmelmann, C. Comparison of iPad Pro®’s LiDAR and TrueDepth Capabilities with an Industrial 3D Scanning Solution. Technologies 2021, 9, 25. https://doi.org/10.3390/technologies9020025

Vogt M, Rips A, Emmelmann C. Comparison of iPad Pro®’s LiDAR and TrueDepth Capabilities with an Industrial 3D Scanning Solution. Technologies. 2021; 9(2):25. https://doi.org/10.3390/technologies9020025

Chicago/Turabian StyleVogt, Maximilian, Adrian Rips, and Claus Emmelmann. 2021. "Comparison of iPad Pro®’s LiDAR and TrueDepth Capabilities with an Industrial 3D Scanning Solution" Technologies 9, no. 2: 25. https://doi.org/10.3390/technologies9020025

APA StyleVogt, M., Rips, A., & Emmelmann, C. (2021). Comparison of iPad Pro®’s LiDAR and TrueDepth Capabilities with an Industrial 3D Scanning Solution. Technologies, 9(2), 25. https://doi.org/10.3390/technologies9020025