Open Source 3D-Printable Planetary Roller Screw for Food Processing Applications

Abstract

1. Introduction

2. Materials and Methods

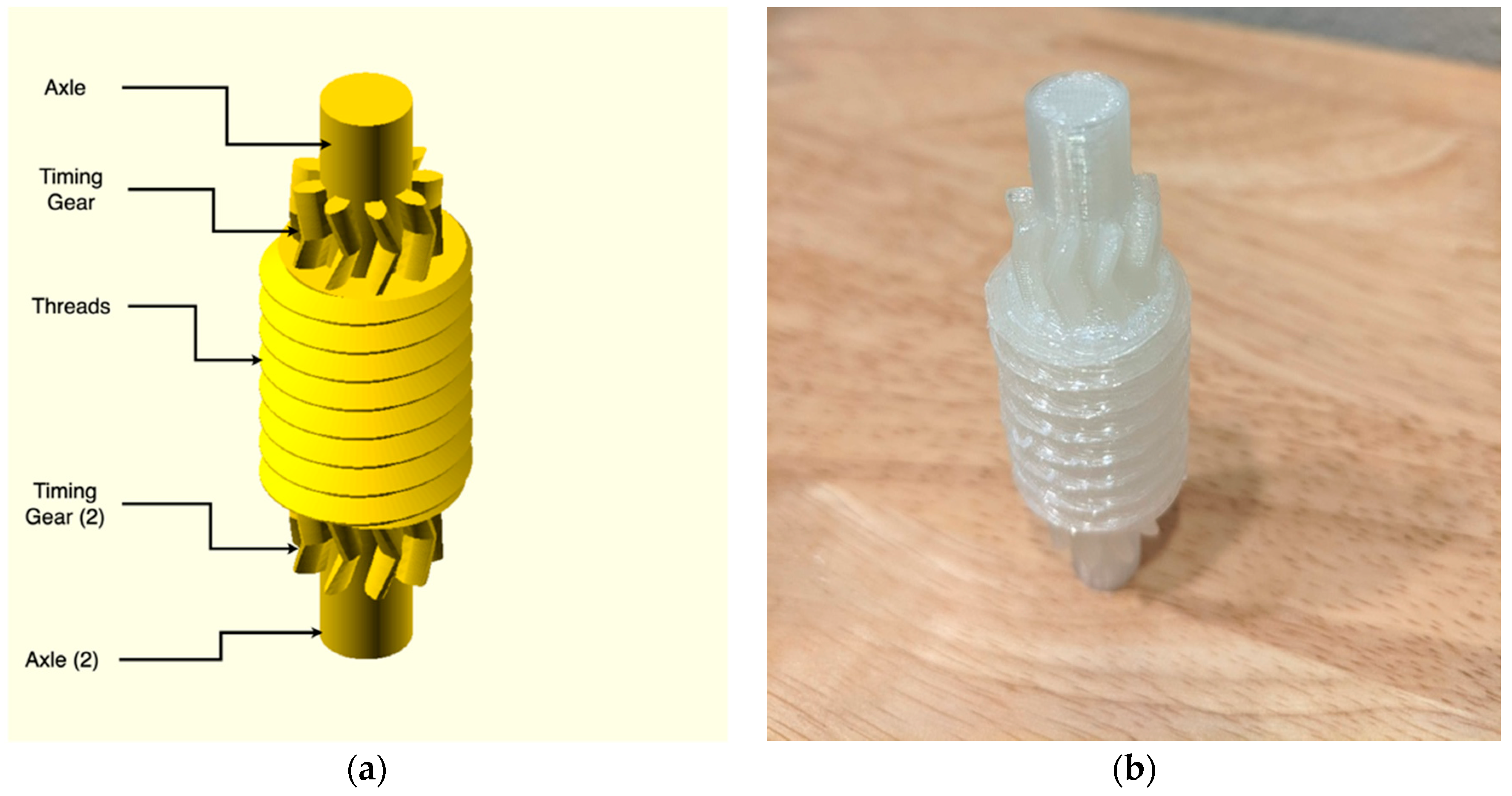

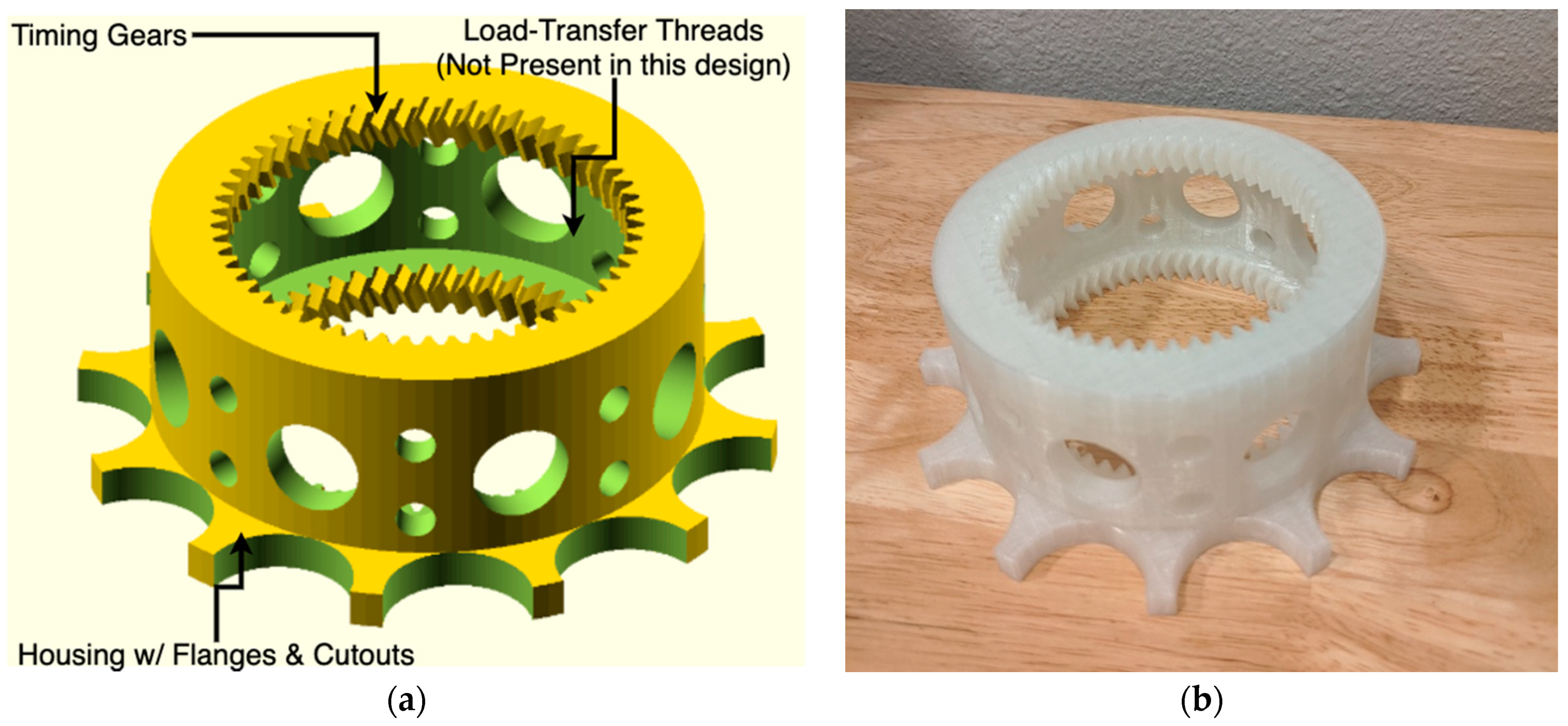

2.1. Roller Screw Design

2.2. Bill of Materials (BOM) for 3D-Printed Parts

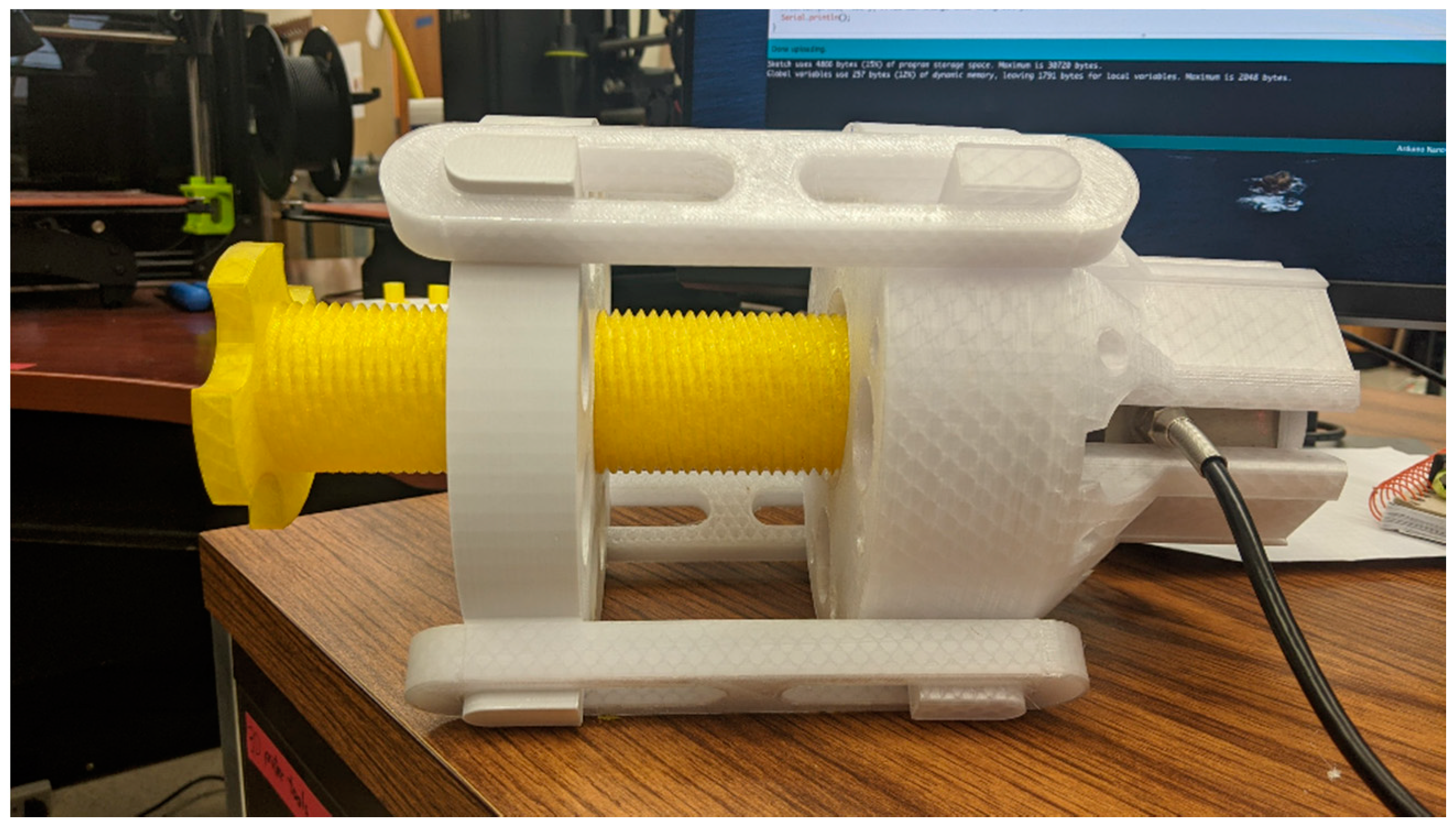

2.3. Roller Screw Assembly

2.4. Roller Screw Testing and Validation

2.5. Validation Testing Versus Control Direct Press Screw

3. Results

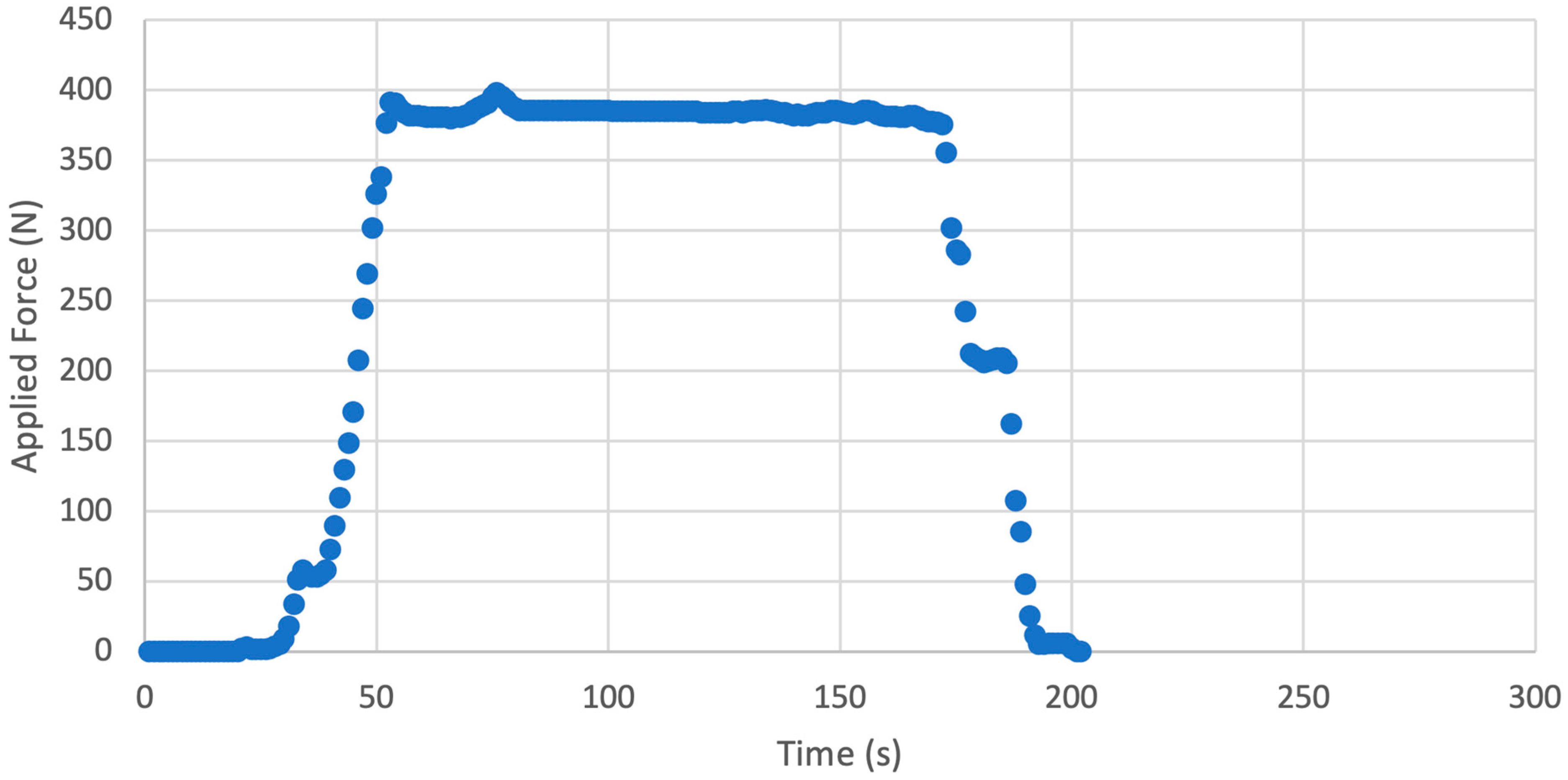

3.1. Maintain a Constant Load without Slipping Test

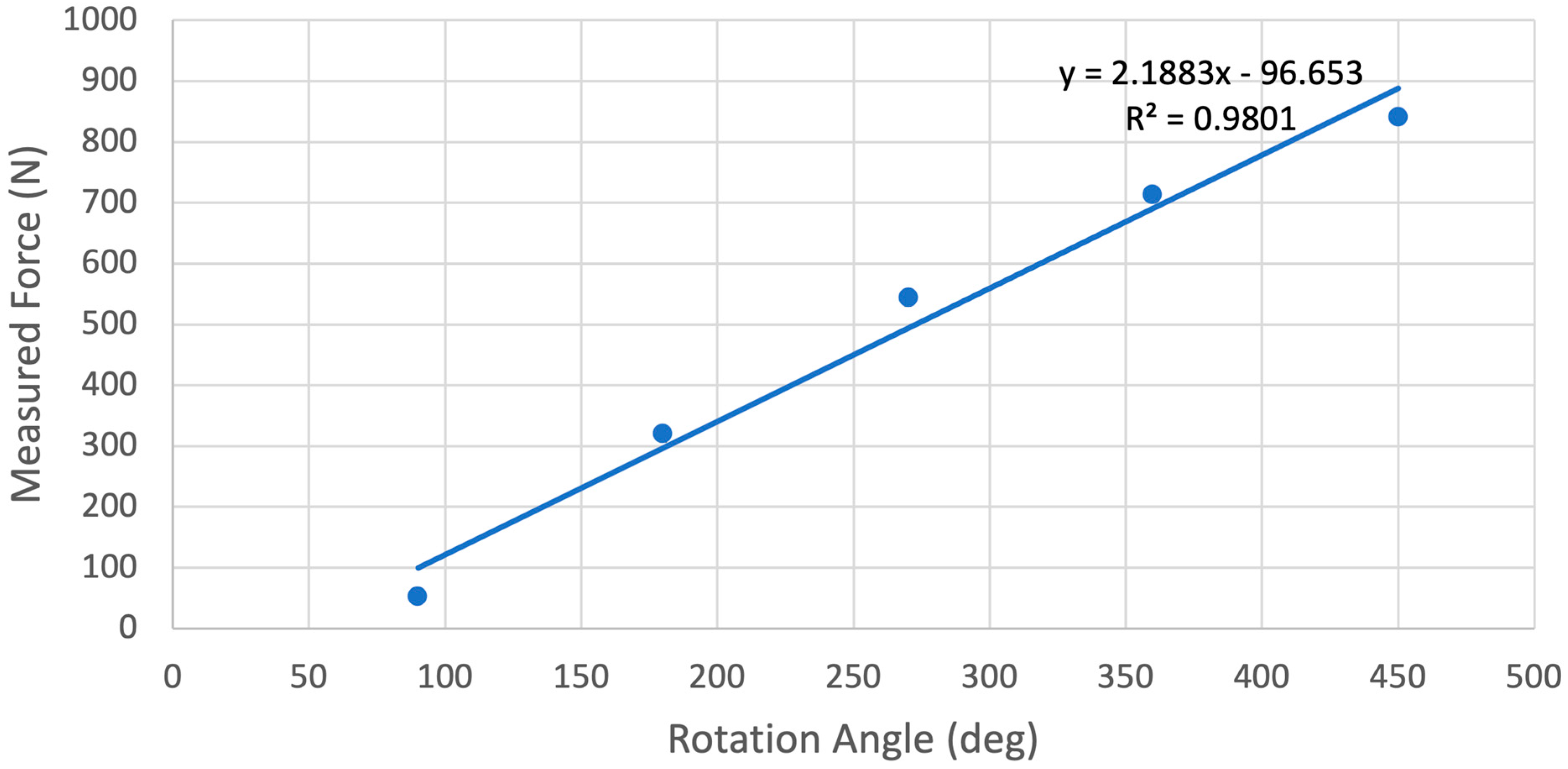

3.2. Increase in Loading Per Rotation of the Collar

3.3. Direct Screw Press Performance

4. Discussion

4.1. Force Exertion and Pressure as a Function of Angle

4.2. Comparison to Conventional Screw Press

4.3. Future Work

4.3.1. Overcoming Mechanism Failures

4.3.2. Increasing Overall Force

4.3.3. Migration to SolidPython

- Graphical User Interface

- Interactive 3D rendering

- Easy import of external thread standards

- Easy import of external housings

- Easy import of alternate gear methods

- Quick-switching between various design features

- Force vs. torque estimations

- Embedded operational simulation

4.3.4. Roller Encapsulation

4.3.5. Food Processing Applications

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix A.1. OpenSCAD Implementation

| File Name | Function |

|---|---|

| “01_pressScrew.scad” | Central Screw Module |

| “02_roller_V4.scad” | Roller Module (Version 4) |

| “03_collar.scad” | Outer Nut Module |

| “04_spacer_V3.scad” | Roller Spacer Module (Version 3) |

| “05_topRetainer_V2.scad” | Top portion of test stand to keep outer nut in place |

| “06_botRetainer_V4.scad” | Bottom portion of test stand to keep load cell and center screw in place |

| “08_loadSensor.scad” | Load cell stand-in for determining size |

| “09_plateBase.scad” | Screws in to bottom of load cell to keep it in place |

| “10_slotAnchor_alt.scad” | Slide-in anchor point for bottom retainer to connect to bracket |

| “11_bracket.scad” | Slotted bracket that holds the bottom and top retainer together |

| “12_presPlate.scad” | Top screw-in plate for load cell. Pressed on by center screw |

| Library | File Name | License | Function |

| Tsmthreads [78] | “tsmthread4.scad” | GNU General Public License v. 3 | Standard Threads Library |

| Giertriebe [79] | “Giertriebe.scad” | Creative Commons—Attribution—Non-Commercial—Share Alike | Convolute Gears Library |

Appendix A.1.1. Central Screw

| Parameter | OpenSCAD Variable | Unit | Description |

|---|---|---|---|

| Screw | |||

| Screw Diameter | d_screw_eff | mm | Major diameter of the central screw |

| Screw Lead | l_screw_lead | mm | Lead of the central screw |

| Screw Thread Starts | n_screw_threads | Ea. | Number of thread starts in the central screw |

| Screw Length | l_screw_length | mm | Length of the central screw. Does not affect overall function |

| Screw Cap | |||

| Outer Diameter | d_cap_outer | mm | Outer diameter of screw cap |

| Cut circles diameter | d_cap_cut_temp | mm | Outer diameter of the circles used to cut holes into the cap |

| Cap thickness | l_cap_thickness | mm | Overall thickness of the cap |

| Cap Cut-ins | n_cap_cuts | Ea. | Number of cuts to be made into the cap |

Appendix A.1.2. Rollers

| Parameter | OpenSCAD Variable | Unit | Description |

|---|---|---|---|

| Assembly Parameters | |||

| Screw Diameter | d_screw_eff | mm | Major diameter of the central screw |

| Screw Lead | l_screw_lead | mm | Lead of the central screw |

| Screw Thread Starts | n_screw_threads | Ea. | Number of thread starts in the central screw |

| Roller Parameters | |||

| Thread Length | l_screw_length | mm | Length of the threads on the rollers |

| Gear Module | h_gear_module | N/A | Module of the timing gears at the top and bottom of the rollers. Needs to be the same as the nut. |

| Gear Teeth Count | n_gear_teeth | Ea. | Number of teeth on the timing gears. Should be set so gears are roughly same diameter as rollers. |

| Gear Height | l_gear_face | mm | Height of gear faces on the timing gears. |

| Gear Pressure Angle | a_gear_press | ° | Pressure angle of the timing gear teeth. Needs to be the same as the pressure angle for the nut. |

| Gear Helix Angle | a_gear_helix | ° | Helical gear angle of the timing gears. Needs to be the same as the nut. |

| Axle Extension | l_axle_extension | mm | Extension of the axle past the gear faces. |

| Axle Radius | L_axle_radius | mm | Radius of the central axle. Note, does not have protective limits. |

| OpenSCAD Variable | Unit | Calculation | Description |

|---|---|---|---|

| d_screw_eff | mm | d_screw_eff = d_central_screw / (n_central_screw_thread_starts − 2) | Major diameter of the roller screw |

| l_screw_pitch | mm | l_screw_lead = l_central_screw_lead / n_central_screw_thread_starts | Pitch of the roller screw |

| axle_length | mm | (l_screw_length+l_gear_face*2)+2 * l_axle_extension | Overall axle length |

Appendix A.1.3. Outer Nut

| Parameter | OpenSCAD Variable | Unit | Description |

|---|---|---|---|

| Assembly Parameters | |||

| Screw Diameter | d_screw_eff | mm | Major diameter of the central screw |

| Screw Lead | l_screw_lead | mm | Lead of the central screw |

| Screw Thread Starts | n_screw_threads | Ea. | Number of thread starts in the central screw |

| Nut Parameters | |||

| Thread Length | l_screw_length | mm | Length of the threads on the nut |

| Ring Gear Module | h_ring_module | N/A | Module of the timing gears at the top and bottom of the rollers. Needs to be the same as the rollers. |

| Ring Gear Teeth Count | n_ring_teeth | Ea. | Number of teeth on the timing gears. Should be set so gears are roughly same diameter as rollers. |

| Ring Gear Height | l_ring_face | mm | Height of gear faces on the timing gears. |

| Ring Gear Pressure Angle | a_ring_press | ° | Pressure angle of the timing gear teeth. Needs to be the same as the pressure angle for the rollers. |

| Ring Gear Helix Angle | a_ring_helix | ° | Helical gear angle of the timing gears. Needs to be the same as the rollers. |

| Ring Gear Rim | d_ring_rim | mm | Rim of extra material around the timing gears. |

| Housing Parameters | |||

| Housing Flange Diameter | d_cap_outer | mm | Diameter of the outer housing flanges. |

| Flange Cut diameter | d_cap_cut_temp | mm | Diameter of the circles cut into the flanges. |

| Flange Thickness | l_cap_thickness | mm | Thickness of the flanges from the bottom of the assembly. |

| Number of Flanges | n_cap_cuts | Ea. | Number of cuts for flanges. |

Appendix A.1.4. Spacer

References

- Giotitsas, C. Open Source Agriculture: A Social Movement? In Open Source Agriculture: Grassroots Technology in the Digital Era; Giotitsas, C., Ed.; Palgrave Advances in Bioeconomy: Economics and Policies; Springer International Publishing: Cham, Germany, 2019; pp. 25–68. ISBN 978-3-030-29341-3. [Google Scholar]

- Meyer, M.; Pantazia, A. Making, Adapting, Sharing: Fabricating Open-Source Agricultural Tools. P2P Found. 2018. Available online: https://blog.p2pfoundation.net/making-adapting-sharing-fabricating-open-source-agricultural-tools/2018/07/06 (accessed on 6 May 2020).

- Lemmens, P. Deproletarianizing Agriculture—Recovering Agriculture from Agribusiness and the need for a Commons-Based, Open Source Agriculture. In Proceedings of the ISDA 2010, Montpellier, France, 28 June–1 July 2010; Coudel, E., Devautour, H., Soulard, C.-T., Hubert, B., Eds.; Cirad-Inra-SupAgro: Montpellier, France, 2010; p. 21. [Google Scholar]

- Nicolosi, G.; Ruivenkamp, G. Re-skilling the Social Practices: Open Source and Life–Towards a Commons-Based Peer Production in Agro-biotechnology? Sci. Eng. Ethics 2013, 19, 1181–1200. [Google Scholar] [CrossRef]

- Giotitsas, C. Beyond Open Source Agriculture. In Open Source Agriculture: Grassroots Technology in the Digital Era; Giotitsas, C., Ed.; Palgrave Advances in Bioeconomy: Economics and Policies; Springer International Publishing: Cham, Germany, 2019; pp. 133–139. ISBN 978-3-030-29341-3. [Google Scholar]

- Group Overview ‹ Open Agriculture (OpenAg). Available online: https://www.media.mit.edu/groups/open-agriculture-openag/overview/ (accessed on 6 May 2020).

- Harper, C. Open-Source Agriculture Initiative—Food for the Future? In LED Lighting for Urban. Agriculture; Kozai, T., Fujiwara, K., Runkle, E.S., Eds.; Springer: Singapore, 2016; pp. 37–46. ISBN 978-981-10-1848-0. [Google Scholar]

- GOAT—Gathering for Open Agricultural Technology. Available online: http://goatech.org/ (accessed on 6 May 2020).

- Sowe, S.K.; Parayil, G.; Sunami, A. Free and Open Source Software and Technology for Sustainable Development; United Nations University Press: Tokyo, Japan, 2012; ISBN 978-92-808-1217-6. [Google Scholar]

- Tsioumani, E.; Muzurakis, M.; Ieropoulos, Y.; Tsioumanis, A. Following the Open Source Trail Outside the Digital World: Open Source Applications in Agricultural Research and Development; Social Science Research Network: Rochester, NY, USA, 2015. [Google Scholar]

- Pearce, J.M. The case for open source appropriate technology. Environ. Dev. Sustain. 2012, 14, 425–431. [Google Scholar] [CrossRef]

- Raymond, E. The cathedral and the bazaar. Knowl. Technol. Policy 1999, 12, 23–49. [Google Scholar] [CrossRef]

- Bonaccorsi, A.; Rossi, C. Why Open Source software can succeed. Res. Policy 2003, 32, 1243–1258. [Google Scholar] [CrossRef]

- Lakhani, K.R.; von Hippel, E. How Open Source Software Works: “Free” User-to-User Assistance. In Produktentwicklung Mit Virtuellen Communities: Kundenwünsche Erfahren und Innovationen Realisieren; Herstatt, C., Sander, J.G., Eds.; Gabler Verlag: Wiesbaden, Germany, 2004; pp. 303–339. ISBN 978-3-322-84540-5. [Google Scholar]

- Söderberg, J. Hacking Capitalism: The Free and Open Source Software Movement; Routledge: London, UK, 2015; ISBN 978-1-135-91639-8. [Google Scholar]

- Bergquist, M.; Ljungberg, J. The power of gifts: Organizing social relationships in open source communities. Inf. Syst. J. 2001, 11, 305–320. [Google Scholar] [CrossRef]

- Pearce, J.M.; Mushtaq, U. Overcoming Technical Constraints for Obtaining Sustainable Development with Open Source Appropriate Technology. In Proceedings of the 2009 IEEE Toronto International Conference Science and Technology for Humanity (TIC-STH), Toronto, ON, Canada, 26–27 September 2009; pp. 814–820. [Google Scholar]

- Zelenika, I.; Pearce, J. Barriers to Appropriate Technology Growth in Sustainable Development. J. Sustain. Dev. 2011, 4, 12. [Google Scholar] [CrossRef]

- Hazeltine, B.; Bull, C. Appropriate Technology; Tools, Choices, and Implications, 1st ed.; Academic Press, Inc.: Cambridge, MA, USA, 1998; ISBN 978-0-12-335190-6. [Google Scholar]

- Rees, W.E. Understanding Sustainable Development. In Sustainable Development and The Future of Cities; Hamm, B., Muttagi, P.K., Eds.; Intermediate Technology Publications Limited: London, UK, 1998; pp. 19–42. [Google Scholar]

- Sianipar, C.P.M.; Yudoko, G.; Adhiutama, A.; Dowaki, K. Community Empowerment through Appropriate Technology: Sustaining the Sustainable Development. Procedia Environ. Sci. 2013, 17, 1007–1016. [Google Scholar] [CrossRef]

- Pearce, J.; Albritton, S.; Grant, G.; Steed, G.; Zelenika, I. A new model for enabling innovation in appropriate technology for sustainable development. Sustain. Sci. Pract. Policy 2012, 8, 42–53. [Google Scholar] [CrossRef]

- Zelenika, I.; Pearce, J.M. Innovation through collaboration: Scaling up solutions for sustainable development. Environ. Dev. Sustain. 2014, 16, 1299–1316. [Google Scholar] [CrossRef]

- Zelenika, I.; Pearce, J.M. The Internet and other ICTs as tools and catalysts for sustainable development: Innovation for 21st century. Inf. Dev. 2013, 29, 217–232. [Google Scholar] [CrossRef]

- Parker, M.; Cheney, G.; Fournier, V.; Land, C. The Routledge Companion to Alternative Organization; Routledge: London, UK, 2014; ISBN 978-1-135-00539-9. [Google Scholar]

- Gupta, A.K. From Sink to Source: The Honey Bee Network Documents Indigenous Knowledge and Innovations in India. Innov. Technol. Gov. Glob. 2006, 1, 49–66. [Google Scholar] [CrossRef]

- Smith, A.; Fressoli, M.; Thomas, H. Grassroots innovation movements: Challenges and contributions. J. Clean. Prod. 2014, 63, 114–124. [Google Scholar] [CrossRef]

- Abrol, D.; Gupta, A. Understanding the diffusion modes of grassroots innovations in India: A study of Honey Bee Network supported innovators. Afr. J. Sci. Technol. Innov. Dev. 2014, 6, 541–552. [Google Scholar] [CrossRef]

- Pattnaik, B.K.; Dhal, D. Mobilizing from appropriate technologies to sustainable technologies based on grassroots innovations. Technol. Soc. 2015, 40, 93–110. [Google Scholar] [CrossRef]

- Harper, C.; Siller, M. OpenAG: A Globally Distributed Network of Food Computing. IEEE Pervasive Comput. 2015, 14, 24–27. [Google Scholar] [CrossRef]

- Boanos, A.; Mothukuri, A.S.; Goettsch, K.A.; Bastola, D.K. Investigation and Utilization of Personal Food Computers for Research in Drug Development and Biomedicine. In Proceedings of the 2017 IEEE International Conference on Bioinformatics and Biomedicine (BIBM), Kansas City, MO, USA, 13–16 November 2017; pp. 2229–2231. [Google Scholar]

- Jakubowski, M. Open Source Ecology. In Kunst, Krise, Subversion; Bandi, N., Kraft, M.G., Lasinger, S., Eds.; Transcript Verlag: Bielefeld, Germany, 2012; ISBN 978-3-8394-1962-5. [Google Scholar]

- Moritz, M.; Redlich, T.; Grames, P.P.; Wulfsberg, J.P. Value Creation in Open-Source Hardware Communities: Case Study of Open Source Ecology. In Proceedings of the 2016 Portland International Conference on Management of Engineering and Technology (PICMET), Portland, OR, USA, 4–8 September 2016; pp. 2368–2375. [Google Scholar]

- Osunyomi, B.D.; Redlich, T.; Wulfsberg, J.P. Could open source ecology and open source appropriate technology be used as a roadmap from technology colony? Int. J. Technol. Learn. Innov. Dev. 2016, 8, 265. [Google Scholar] [CrossRef]

- Macul, V.; Rozenfeld, H. How an Open Source Design Community Works: The case of Open Source Ecology. Available online: https://www.designsociety.org/publication/37745/HOW+AN+OPEN+SOURCE+DESIGN+COMMUNITY+WORKS%3A+THE+CASE+OF+OPEN+SOURCE+ECOLOGY (accessed on 6 May 2020).

- Pearce, J.M.; Morris Blair, C.; Laciak, K.J.; Andrews, R.; Nosrat, A.; Zelenika-Zovko, I. 3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development. J. Sustain. Dev. 2010, 3, 17. [Google Scholar] [CrossRef]

- Canessa, E. Open Book on “Low-cost 3D Printing for Science, Education and Sustainable Development”. Available online: http://sdu.ictp.it/3D/book.html (accessed on 6 May 2020).

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. In Handbook of Research in Mass Customization and Personalization; World Scientific Publishing Company: Singapore, 2009; pp. 568–580. ISBN 978-981-4280-25-9. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The replicating rapid prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Kentzer, J.; Koch, B.; Thiim, M.; Jones, R.W.; Villumsen, E. An Open Source Hardware-Based Mechatronics Project: The Replicating Rapid 3-D Printer. In Proceedings of the 2011 4th International Conference on Mechatronics (ICOM), Kuala Lumpur, Malaysia, 17–19 May 2011; pp. 1–8. [Google Scholar]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Rundle, G. A Revolution in the Making; Simon and Schuster: New York, NY, USA, 2014; ISBN 978-1-922213-48-8. [Google Scholar]

- King, D.L.; Babasola, A.; Rozario, J.; Pearce, J.M. Mobile Open-Source Solar-Powered 3-D Printers for Distributed Manufacturing in Off-Grid Communities. Chall. Sustain. 2014, 2, 18–27. [Google Scholar] [CrossRef]

- Gwamuri, J.; Franco, D.; Khan, K.Y.; Gauchia, L.; Pearce, J.M. High-Efficiency Solar-Powered 3-D Printers for Sustainable Development. Machines 2016, 4, 3. [Google Scholar] [CrossRef]

- Birtchnell, T.; Hoyle, W. 3D Printing for Development in the Global South: The 3D4D Challenge; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 978-1-137-36566-8. [Google Scholar]

- Zhong, S.; Rakhe, P.; Pearce, J.M. Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System. Recycling 2017, 2, 10. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Petersen, E.E.; Pearce, J. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Petersen, E.E.; Kidd, R.W.; Pearce, J.M. Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market. Technologies 2017, 5, 45. [Google Scholar] [CrossRef]

- Ishengoma, F.R.; Mtaho, A.B. 3D Printing: Developing Countries Perspectives. Int. J. Comput. Appl. 2014, 104, 30–34. [Google Scholar] [CrossRef]

- Pearce, J.M. Applications of Open Source 3-D Printing on Small Farms. Org. Farming 2015, 1, 19–35. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Squires, D.A.; Walbeck, J.; Campbell, E.; Campbell, W.H.; Pearce, J.M. Open-Source Photometric System for Enzymatic Nitrate Quantification. PLoS ONE 2015, 10, e0134989. [Google Scholar] [CrossRef]

- Wijnen, B.; Anzalone, G.C.; Pearce, J.M. Open-source mobile water quality testing platform. J. Water Sanit. Hyg. Dev. 2014, 4, 532–537. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- Fernandez-Vicente, M.; Calle, W.; Ferrandiz, S.; Conejero, A. Effect of Infill Parameters on Tensile Mechanical Behavior in Desktop 3D Printing. 3D Print. Addit. Manuf. 2016, 3, 183–192. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Addit. Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef]

- Kung, C.; Kuan, H.-C.; Kuan, C.-F. Evaluation of Tensile Strength of 3D Printed Objects with FDM Process on RepRap Platform. In Proceedings of the 2018 1st IEEE International Conference on Knowledge Innovation and Invention (ICKII), Jeju Island, Korea, 23–27 July 2018; pp. 369–372. [Google Scholar]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef] [PubMed]

- Strandgren, C.B. Screw-Threaded Mechanism. U.S. Patent 2,683,379 A, 13 July 1954. [Google Scholar]

- RollerScrew. (1.0), TheJLo. Available online: https://github.com/TheJLo/RollerScrew (accessed on 4 February 2020).

- LulzBot TAZ 6|LulzBot. Available online: https://www.lulzbot.com/store/printers/lulzbot-taz-6 (accessed on 22 April 2020).

- Susko, A.Q.; Gilbertson, F.; Heuschele, D.J.; Smith, K.; Marchetto, P. An Automatable, Field Camera Track System for Phenotyping Crop Lodging and Crop Movement. HardwareX 2018, 4, e00029. [Google Scholar] [CrossRef]

- Jo Heuschele, D.; Wiersma, J.; Reynolds, L.; Mangin, A.; Lawley, Y.; Marchetto, P. The Stalker: An Open Source Force Meter for Rapid Stalk Strength Phenotyping. HardwareX 2019, 6, e00067. [Google Scholar] [CrossRef]

- Broekman, A.; Steyn, W.J.; Steyn, J.L.; Bill, M.; Korsten, L. SmAvo and SmaTo: A Fruity Odyssey of Smart Sensor Platforms in Southern Africa. HardwareX 2020, 8, e00156. [Google Scholar] [CrossRef]

- Spinelli, G.M.; Gottesman, Z.L.; Deenik, J. A Low-Cost Arduino-Based Datalogger with Cellular Modem and FTP Communication for Irrigation Water Use Monitoring to Enable Access to CropManage. HardwareX 2019, 6, e00066. [Google Scholar] [CrossRef]

- Bentancor, M.; Vidal, S. Programmable and Low-Cost Ultraviolet Room Disinfection Device. HardwareX 2018, 4, e00046. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, W.; Huang, D.; Fuh, J.Y.H.; Hong, G.S. An Overview of 3D Printing Technologies for Food Fabrication. Food Bioprocess. Technol. 2015, 8, 1605–1615. [Google Scholar] [CrossRef]

- Nachal, N.; Moses, J.A.; Karthik, P.; Anandharamakrishnan, C. Applications of 3D Printing in Food Processing. Food Eng. Rev. 2019, 11, 123–141. [Google Scholar] [CrossRef]

- Skrzypczak, N.G.; Tanikella, N.G.; Pearce, J.M. Open Source High-Temperature RepRap for 3-D Printing Heat-Sterilizable PPE and Other Applications. HardwareX 2020, 8, e00130. [Google Scholar] [CrossRef] [PubMed]

- Yanisky-Ravid, S.; Kwan, K.S. 3D Printing the Road Ahead: The Digitization of Products When Public Safety Meets Intellectual Property Rights—A New Model. Cardozo L. Rev. 2016, 38, 921. [Google Scholar]

- Powell, A. Democratizing production through open source knowledge: From open sof.tware to open hardware. Media Cult. Soc. 2012, 34, 691–708. [Google Scholar] [CrossRef]

- Gibb, A.; Abadie, S. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Pearson Education: London, UK, 2014; ISBN 978-0-321-90604-5. [Google Scholar]

- Oberloier, S.; Pearce, J.M. General Design Procedure for Free and Open-Source Hardware for Scientific Equipment. Designs 2018, 2, 2. [Google Scholar] [CrossRef]

- Bonvoisin, J.; Molloy, J.; Haeuer, M.; Wenzel, T. Standardisation of practices in Open Source Hardware. arXiv 2020, arXiv:2004.07143. [Google Scholar] [CrossRef]

- Kintel, M. OpenSCAD. 2020. Available online: https://www.openscad.org/index.html (accessed on 4 February 2020).

- Kirshner, D. Thread-Drawing Modules for OpenSCAD. 2020. Available online: https://dkprojects.net/openscad-threads (accessed on 27 May 2020).

- Janssen, J. Beispiele Für Jedes Modul Befinden Sich Auskommentiert am Ende Dieser Datei. 2020. Available online: https://www.thingiverse.com/thing:1604369 (accessed on 27 May 2020).

- Original Prusa i3 MK3 Kit. Available online: https://shop.prusa3d.com/en/3d-printers/180-original-prusa-i3-mk3-kit.html?gclid=EAIaIQobChMI37S_yc7S6QIVJBh9Ch1-bgDvEAAYASAAEgKIlfD_BwE (accessed on 27 May 2020).

| Parameter | Variable | Units | Description |

|---|---|---|---|

| Central Screw Lead | Linear distance traversed by the central screw per rotation of that central screw | ||

| Central Screw Thread Starts | Each | The number of thread starts on the central screw | |

| Central Screw Major Diameter | mm | The major diameter of the central screw |

| Component | Variable | Relationship | Units |

|---|---|---|---|

| Outer Nut | mm | ||

| Roller Diameter | mm |

| Parameter | Variable | Units | Description |

|---|---|---|---|

| Assembly Height | mm | Linear height of the entire planetary roller screw assembly | |

| Number of Rollers | Each | The number of rollers to place in the assembly. Limited by the diameter of the rollers. Need at least 3. | |

| Timing Gear Height | mm | Linear height of the internal timing gears used on the nut and rollers. | |

| Timing Gear Module | Each | The metric module of the timing gears. Larger values correspond to larger gear teeth. Has no effect on gear ratios. | |

| Timing Gear Helical Angle | ° | Angle of the gear teeth from purely vertical. | |

| Timing Gear Tooth Shape | N/A | Standard shape of gear teeth such as Convolute. | |

| Thread Standard | N/A | Thread standard used such as ACME Square or UTS. | |

| Roller Axle Length | mm | Linear length of the axles extending from the tops and bottoms of the rollers. |

| Name | Qty | Image |

|---|---|---|

| Outer Nut | 1 |  |

| Central Screw (Printed 180 degrees about x-axis) | 1 |  |

| Roller | 4 |  |

| Spacer | 2 |  |

| Name | Qty | Image |

|---|---|---|

| Top Retainer | 1 |  |

| Alternate Top Retainer (for direct screw press test) | 1 |  |

| Bottom Retainer | 1 |  |

| Slotted Brackets | 4 |  |

| Slot Anchor | 4 |  |

| Load Cell Top Plate Screw (Printed 180 degrees about x-axis) | 1 |  |

| Load Cell Bottom Plate Screw (Printed 180 degrees about x-axis) | 1 |  |

| Name | Description | Material | Image |

|---|---|---|---|

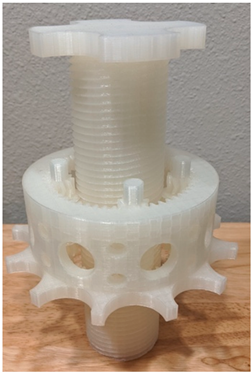

| Roller screw assembly | Unit under test. Mechanical system inserted into test rig assembly. Default high-detail print settings used in TAZ6 3D printer. | 3D-printed PETG (PLA Shown) |  |

| Test Stand Assembly | Encompasses roller screw and holds S-type load sensor in fixed position during use. Default high-detail print settings used in TAZ6 3D printer. Filament profile varied on brand. PETG version of the unit under test is shown. | 3D-printed PETG |  |

| S-Type load cell | Measures compression via change in resistance on strain gauge. Rated to 100 kg. Requires calibration prior to use. | Metal, purchased from Amazon.com |  |

| SparkFun HX711 Load Amplifier | Amplifies measured resistance in load cell to be read by Arduino. Must be soldered to load cell wires. Match wire color to color name on board. | PCB, purchased from Amazon.com |  |

| Arduino | Microcontroller used to run load sensor code. Mount onto breadboard and make connections with jumpers for ease of use. | PCB, purchased from Amazon.com |  |

| Angle (deg) | Pressure (kPa) |

|---|---|

| 90 | 27.09 |

| 180 | 162.78 |

| 270 | 276.86 |

| 360 | 363.45 |

| 450 | 428.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guadagno, M.C.; Loss, J.M.; Pearce, J.M. Open Source 3D-Printable Planetary Roller Screw for Food Processing Applications. Technologies 2021, 9, 24. https://doi.org/10.3390/technologies9020024

Guadagno MC, Loss JM, Pearce JM. Open Source 3D-Printable Planetary Roller Screw for Food Processing Applications. Technologies. 2021; 9(2):24. https://doi.org/10.3390/technologies9020024

Chicago/Turabian StyleGuadagno, Marcello C., Jacob M. Loss, and Joshua M. Pearce. 2021. "Open Source 3D-Printable Planetary Roller Screw for Food Processing Applications" Technologies 9, no. 2: 24. https://doi.org/10.3390/technologies9020024

APA StyleGuadagno, M. C., Loss, J. M., & Pearce, J. M. (2021). Open Source 3D-Printable Planetary Roller Screw for Food Processing Applications. Technologies, 9(2), 24. https://doi.org/10.3390/technologies9020024