Abstract

The CO2-assisted polymer compression method is used herein to prepare porous polymer materials by bonding laminated polymer fiber sheets using a piston in the presence of CO2. In this work, the CO2 flow line connections were moved from the pressure vessel to the piston to increase productivity, which makes the pressure vessel free-moving and the processing time of sample introduction and removal seemingly zero. In addition, a numbering-up method suitable for CO2-assisted polymer compression is proposed and verified based on the variability of the products. The variability of the product was evaluated using porosity, which is one of the most important properties of a porous material. It is found that the CO2 exhaust process, specific to this method, that uses high-pressure CO2, causes product variation, which can be successfully suppressed by optimizing the CO2 exhaust process.

1. Introduction

Polymers are an essential material in everyday life due to their light and durable characteristics [1,2]. In particular, porous polymer materials are very lightweight and exhibit various functionalities [3] such as sound absorption, heat insulation, adsorption, filtering, moisture permeation, water absorption, drug loading, and sustained release [3]; their applications vary from mass production to advanced functional materials [4].

Considering the advantages of such materials, CO2-assisted polymer compression (CAPC), a method that uses CO2 to adhere fibrous sheets to create a porous polymer material, has been developed [5]. Because the method is a room temperature process and no heater is required, it is a low energy process. As the CO2 used is released into the atmosphere and does not remain in the polymer, impurities do not remain. In addition, CO2 is a very low toxic substance; it is also used in the food industry, e.g., carbonated beverages. CO2 is known as an environmentally friendly solvent; in particular its supercritical state is recognized as a green solvent [6], and its application in various processes has been researched [7,8]. CO2 has also been practically used as an extraction solvent for biomass in the food industry [9]. The demonstrated CO2 process is a suitable method for manufacturing parts used for the food industry, medical treatment, and living environments that demand high purity. Among gases, CO2 is known to dissolve well in polymers and has been reported as a specific interaction between the CO2 and polymer [10], estimation of the solubility of CO2 in polymers [11], measurement of solubility of CO2 in crystalline polymers [12], and measurement of solubility of CO2 in amorphous polymers [13]. CO2 is known to be capable of plasticizing polymers and decreasing their viscosity [14], melting point [15], and glass transition temperature [16]. Many CO2-based processes with polymers have been proposed such as dyeing and polymer particle synthesis [17], foam molding [18], fabrication of carbon nanotube composite foam [19], foam molding of polymer blends [20], molecularly imprinted polymer development in supercritical CO2 [21], and fabrication of two-dimensional porous polymers [22]. As the CAPC process is performed at room temperature with no temperature controller and the pressure of CO2 is also introduced at the vapor pressure, which is the pressure inside the liquid CO2 cylinder, the CO2 is conveniently introduced in the gas phase by opening a valve. As no pump is required, the process is simplified. This technology reduces equipment cost and processing time. Previous work has also shown that material properties, such as porosity, were easily tuned by changing the process conditions, even when using the same raw material [23]. The adhesion strength of the CAPC sample was also evaluated [24]. Others have demonstrated that a drug can be carried in the porous material very easily by loading the drug in the state of the fiber sheet of the raw material, and the sustained release property of the drug when the porous material is immersed in water can be controlled [25]. There are many applications of drug-loaded porous materials in the advanced materials and medical fields, but it is challenging to insert the drug into the center of a thick porous material. The CAPC process facilitates drug carrying by supporting drug insertion at the raw fiber stage.

In my previous studies, only one sample was fabricated in one batch, which is a disadvantage remedied in this work. The CAPC method is used to prepare a porous polymer material by adhering laminated fibrous sheets through a simple apparatus with a short pressing time. Even if it is an overwhelmingly fast process at the laboratory level, when considering mass production, the improvement in the production per unit time is indispensable. Historically, scaling chemical processes up is often challenging. One of the main research goals in chemical engineering is developing ways to smoothly scale up flask-scale reactions to be successful in large reactors.

For processes that cannot be scaled up, numbering-up was proposed. The concept of numbering-up has been structured with a chemical process using a microreactor as shown by numbering-up for multi-phase (gas–liquid) flow microreactor [26], numbering-up for liquid–liquid two-phase capillary microstructured reactor [27], and external numbering-up (parallelized microdevices) [28]. Using a small reactor (microreactor) and a small mixer (micromixer), the microscale chemical process maximizes the heat exchange rate and mixing speed and realizes a high-speed reaction that suppresses by-products. Because the reactors and the mixers must be small, scaling up cannot be performed. Numbering-up that increases the number of reaction lines is important. In manufacturing, it has been common practice to approximate numbering-up conventionally. Adding production lines to increase production is one possible numbering-up strategy. However, a new concept that has emerged in microchemistry is the introduction of the number of reaction lines in an apparatus, wherein numbering-up is considered inside the apparatus.

The micro chemical process is a flow process, but the concept of numbering-up is also adaptable to a batch-type production process in that there is a limit to the amount that can be produced in one reactor. In a batch production process, if the size of the batch is optimized, it is impossible to scale up, and the idea of numbering-up is necessary. When considering production by the CAPC method, scaling up can be applied when large porous polymer materials are fabricated, and the final products are cut into pieces. When it is desired to mold the polymer in the form of a final product, for example, when preparing a drug-loaded tablet, it is necessary to consider numbering-up to increase the production per unit time. The chemical reaction in the flow process and the compression of the polymer fiber sheets are completely unrelated phenomena. Therefore, only the concept of numbering-up for simultaneous production in the same equipment was considered herein.

This study is the first trial to enhance the productivity of the CAPC process. Herein, increasing the productivity of the CAPC process is investigated through two strategies. The flow line of CO2 is improved to hide both sample preparation time and sample removal time. The application of numbering-up such that the cost of equipment is suppressed is also investigated. Product uniformity is evaluated using the porosity of the samples when numbering-up is incorporated. Porosity is an important property of porous materials, and previous research has shown that the sustained release rate of the drug trapped in the porous material is greatly influenced by the fabricated material’s porosity [25]. The cause of sample variation is identified and a solution to suppress sample variation is presented.

2. Materials and Methods

2.1. Materials

A nonwoven fabric spun with a fiber diameter of 8 μm and a basis weight of approximately 30 g/m2 using a melt-blown method (Nippon Nozzle Co., Ltd., Kobe, Japan) was used as a raw material; a polyethylene terephthalate (PET) pellet (Model number: TK3) of Bell Polyester Products Inc. (Yamaguchi, Japan) was used. The procedure of the melt-blown process is very simple. The PET pellets were melted, extruded from small nozzles, and stretched using high-speed blowing air to create a nonwoven fabric. Circular cut samples (18 mm diameter) of the nonwoven fabric were selected such that the same weight (0.257 g) was obtained for each set of 32 sheets.

2.2. Equipment

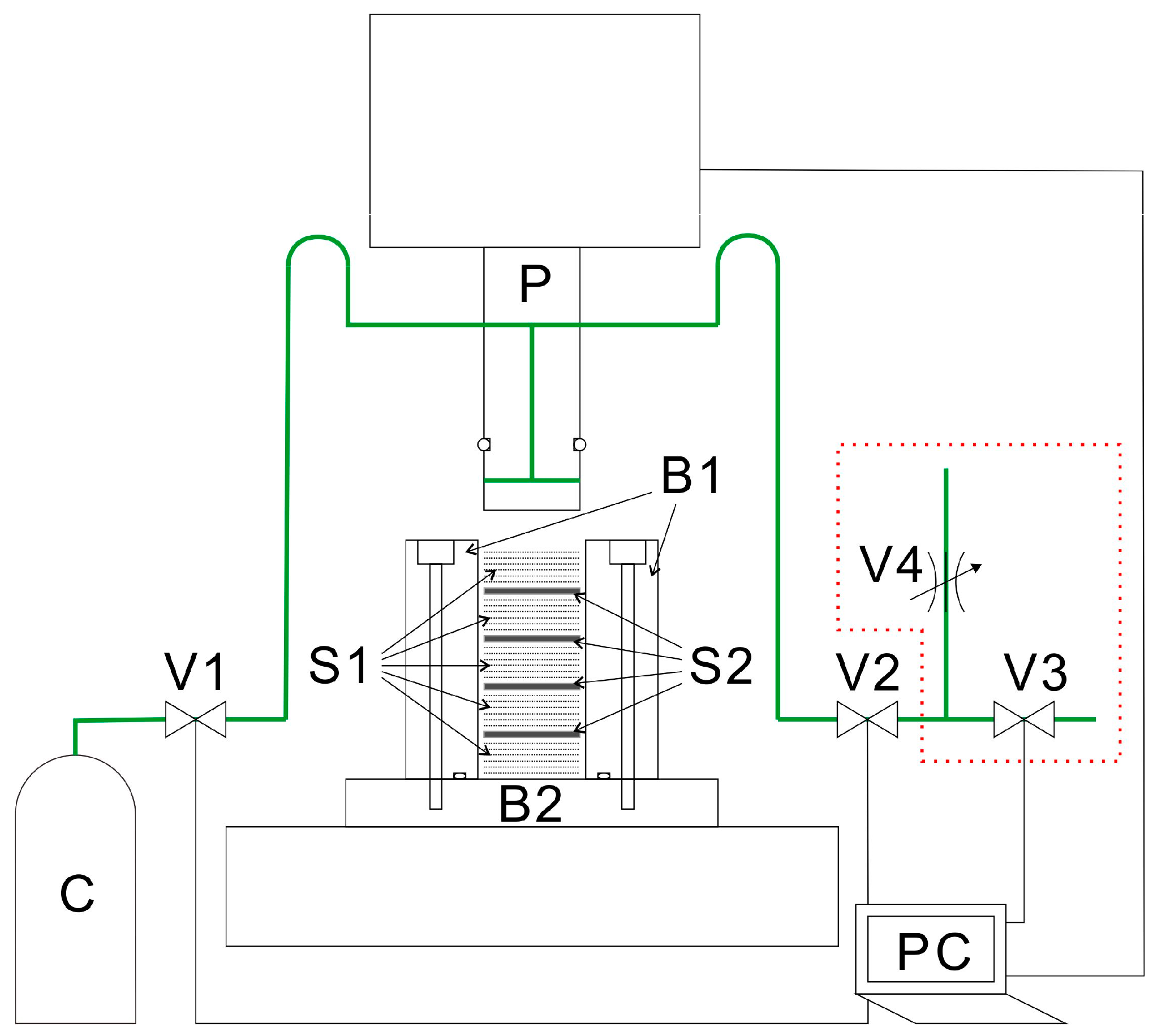

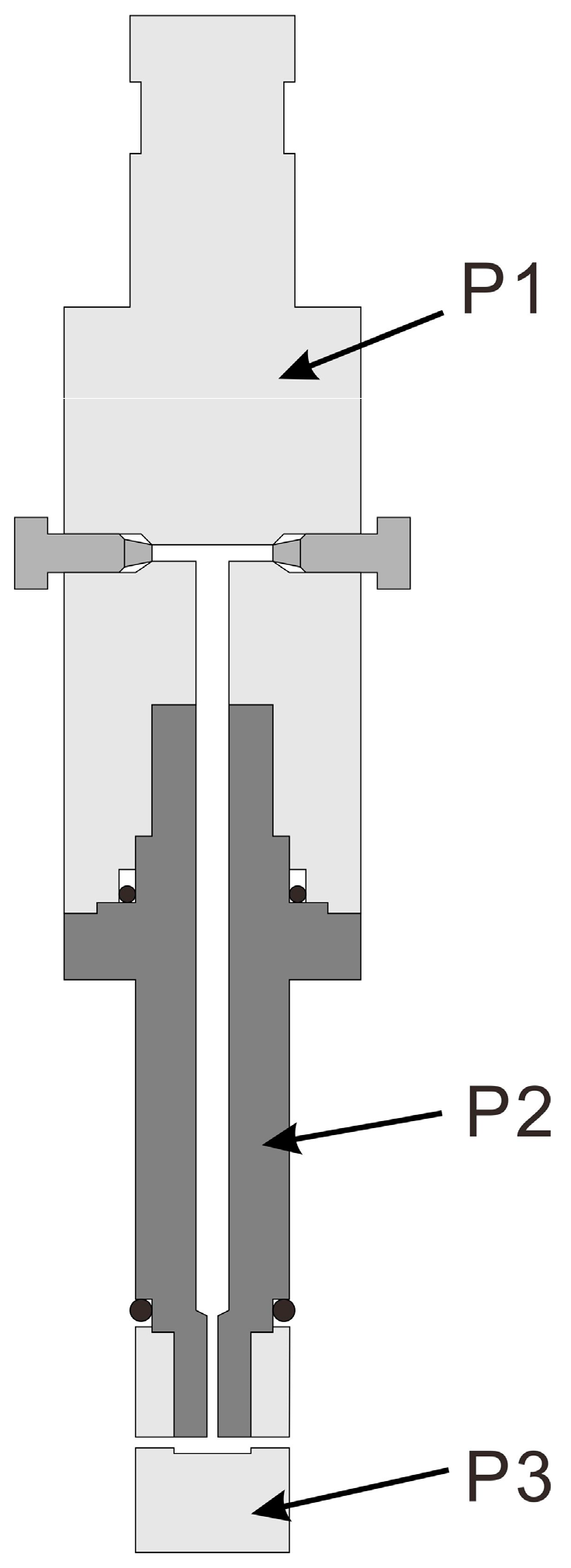

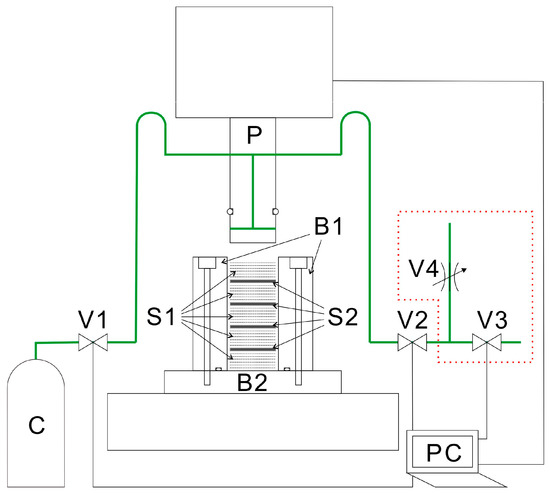

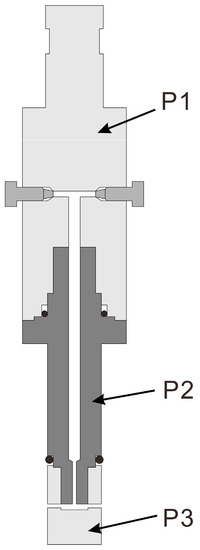

The experimental equipment used in this study is presented in Figure 1. The major difference from previously reported research [5,23,24,25] is found in the connections of the CO2 introduction exhaustion tubes. The position of the tubes was moved from the high-pressure vessel (B1) to the piston (P). The piston area includes a CO2 introduction port and an exhaust port at the top, a flow path for carrying CO2 at the center, and diagonally positioned CO2 introduction and exhaustion ports into the gap between the high-pressure vessel and piston at the bottom. Owing to the difficulty in creating such a shape with one piece, the system comprised mainly three pieces as shown in Figure 2. The inner diameter of component (P2) through which CO2 flows is 4 mm, and the outer diameter of component (P3) is 19.5 mm. Black circles in Figure 2 indicate the O-rings. Component (P1) and component (P2) are sealed with an O-ring. An O-ring between components (P2) and (P3) seals the pressure vessel and component (P2). There is no gas seal between component (P2) and component (P3). The piston was attached to the press machine (Model number: JP-1504), manufactured by Janome Sewing Machine Co., Ltd (Hachioji, Japan). The inner diameter of the pressure vessel is 20.0 mm. Both the piston and the pressure vessel are made of stainless steel (SUS316).

Figure 1.

Schematic illustration of the cross-section of the high-pressure vessel used for CO2-assisted polymer compression. B1: Body of the high-pressure vessel, B2: Base of the high-pressure vessel, C: CO2 cylinder, P: Piston, PC: Laptop computer, S1: Sample, S2: Separator, V1: Intake valve, V2: Exhaust valve, V3: Exhaust valve (optional), and V4: Metering valve (optional).

Figure 2.

Cross-sectional diagram of the piston components. The piston comprises three main components, P1–P3.

The liquid CO2 cylinder was connected to the CO2 inlet of the piston through the introduction valve by a stainless-steel (SUS316) tube. The tube was slacked between the introduction valve and the piston so that the upward and downward movement of the piston was not affected. The stainless-steel tube connected to the outlet of the piston was also connected to the exhaust valve with slack. After the exhaust valve, a T-type branch was provided; one was connected to an additional exhaust valve (V3), and the other was connected to a metering valve (V4). The flow line after the exhaust valve (V2) (dotted red frame in Figure 1) was not provided in the first experiment, and the exhaust was directly released to the atmosphere. Although the introduction valve (V1) was closed during operation, it was temporarily opened when CO2 was introduced. V2 was normally open, but it was closed when CO2 was to be retained in the pressure vessel. In operating V4 and V3, when V2 was open and V3 was closed, CO2 was slowly released through the metering valve. A metering valve (Model number: SS-SS1, Swagelok Inc., Solon, Ohio, United States) was set to the minimum flow rate and used as V4. When V3 was open, CO2 was instantaneously exhausted. When the experiment is performed without the process outlined in the dotted red frame (see Figure 1), it appears that the same result will be achieved as that when V3 is open. After performing the experiment without the dotted red frame line, the flow line in the red frame was added. This has been depicted as the experiment without a dotted red frame line such that the performed experiment is represented accurately.

The high-pressure container is a container with a hole at the top. The structure was made so that the body part (B1) and the base part (B2) could be separated if the system became clogged. By fixing the container filled with the sample just beneath the piston, the setup of the device is complete.

The laptop computer (PC) controlled each valve and piston such that the timing of the valves opening and closing was consistent for all experiments.

2.3. Experimental Procedure

Five sets of 32 laminated samples (S1) were placed in the high-pressure vessel. The laminated samples were separated by stainless-steel spacers (S2), each having a diameter of 19.5 mm and a thickness of 1 mm. As the inner diameter of the pressure vessel is 20.0 mm, there is enough clearance for CO2 to flow between the pressure vessel and the spacers. The inner diameter of the stainless tube from the CO2 cylinder to the piston is 0.8 mm, and the clearance between the pressure vessel and the spacers is much larger than that. The cross-sectional view of the samples when set in the high-pressure vessel is shown in Figure 1. The measured thickness of the center portion of each spacer was, starting from the top spacer, 1.024 mm, 1.009 mm, 1.010 mm, and 1.035 mm. Operation was started when V1 closed and V2 opened. Then, the piston was lowered to the CO2 introduction position, and V2 was closed. The introduction valve and the exhaust valve were alternately opened three times to replace the air in the pressure vessel with CO2. As the internal pressure of the liquid CO2 cylinder is about 6 MPa, once CO2 is introduced at this pressure and released into the atmosphere (0.1 MPa), the amount of existing air is reduced to 1/60, and the remaining air is replaced with CO2. The volume of air is estimated to become (1/60)3 following three trials of the procedure. The CO2 introduction valve was opened again to introduce CO2, and the introduction valve was closed. Then, the piston was lowered to the press position and set to press for 10 s, after which an exhaustion procedure was performed. The exhaustion operation was conducted in two ways depending on the experiment. One exhaust procedure was an experiment without the flow line enclosed by the dotted red line indicated in Figure 1. In this case, CO2 was exhausted instantaneously (<1 s). In the other procedure, the flow line enclosed by the dotted red line was attached; V2 was opened when V3 was closed, and CO2 was slowly exhausted for 30 s by V4. Then, V3 was opened to exhaust CO2 completely. The distances (when the thickness of the spacer is excluded) between the CO2 introduction position and the bottom of the pressure vessel and that between the press position and the bottom of the pressure vessel were 9.75 mm and 6.50 mm, 9.00 mm and 6.00 mm, 8.25 mm and 5.50 mm, 7.50 mm and 5.00 mm, and 6.75 mm and 4.50 mm. The experimental results correspond to press positions from 4.50 mm to 6.50 mm. For evaluating the sample, the thickness of the center was measured with a micrometer and the variation due to the sample position was assessed.

Porosity was evaluated from the polymer density, weight of the fabric sheet, and sample thickness. The datasheet for the PET pellet indicated that the density of the used polymer is 1.34 g/mL. For a solid without any voids, the thickness can be easily calculated using the weight, density, and diameter of the fabric sheet. In this experiment, laminated 0.257 g of circular sheets with an 18.0-mm diameter were used, such that the thickness of the solid (Lsolid) was calculated to be 0.754 mm. The difference between Lsolid and the actual thickness (Lsample) was considered as the total area of the pore, and the porosity α, was calculated as α = (Lsample – Lsolid)/Lsample.

The experiment was performed seven times under each condition and the average value was used for analysis. Error bars are not shown in the plot of the evaluated porosity because the standard deviation of the data was small (maximum 4.9 %); the standard deviation is provided in Table 1 and Table 2.

Table 1.

Product thickness and porosity obtained under rapid CO2 exhaustion.

Table 2.

Product thickness and porosity obtained under slow CO2 venting conditions.

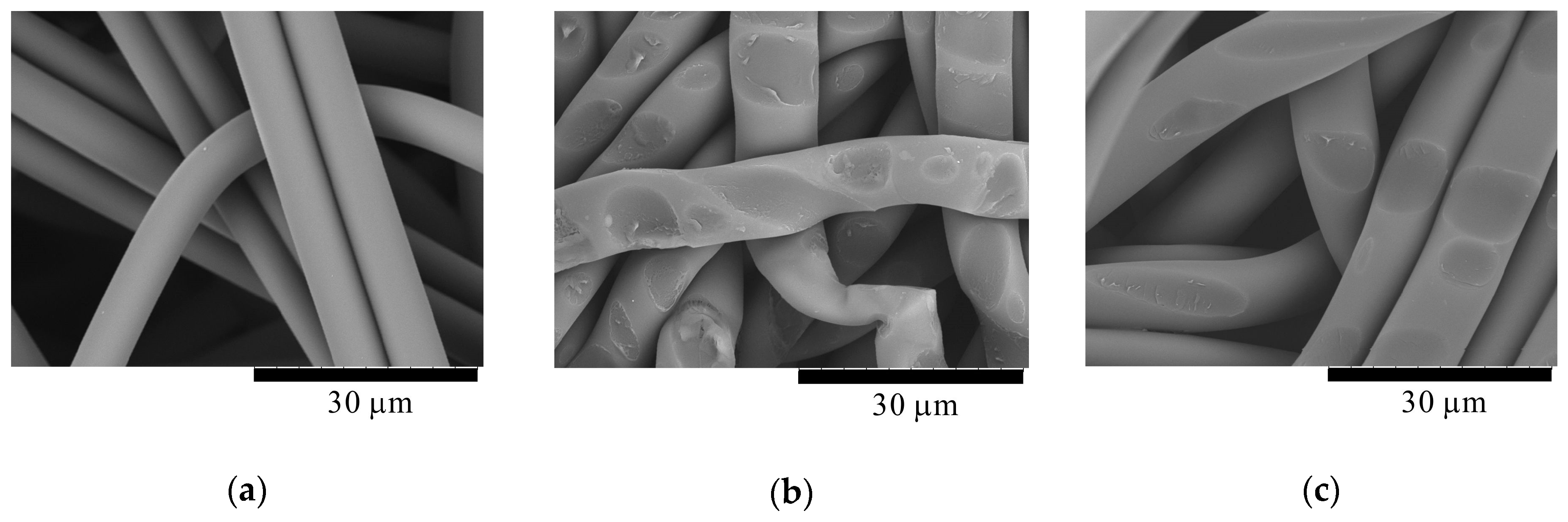

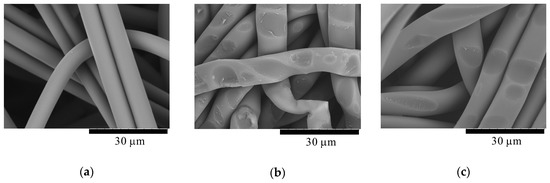

The fiber surface of the central layer of the compressed sample was observed using a scanning electron microscope (SEM; Model number: TM-1000, Hitachi High-Technologies Co., Minato-ku, Japan). The fibrous sheet before compression was also measured using an SEM for comparison.

3. Results and Discussion

First, the design of the system, specifically the effect of connecting the CO2 lines to the piston, is discussed. When they were connected to the high-pressure vessel, the vessel could only be moved within the range that the tubes could extend. To pull the pressure vessel out completely, it was necessary to disconnect the tubes from the pressure vessel, resulting in reduced usability. By connecting the tubes to the piston, the high-pressure vessel became free of this limitation. Moreover, the initial setting (corresponding to the beginning of the operation) was complete by locating the high-pressure vessel including the samples under the piston. If a plurality of high-pressure vessels were set up, it would be possible to prepare and remove samples from the system during press operation, which would greatly improve productivity.

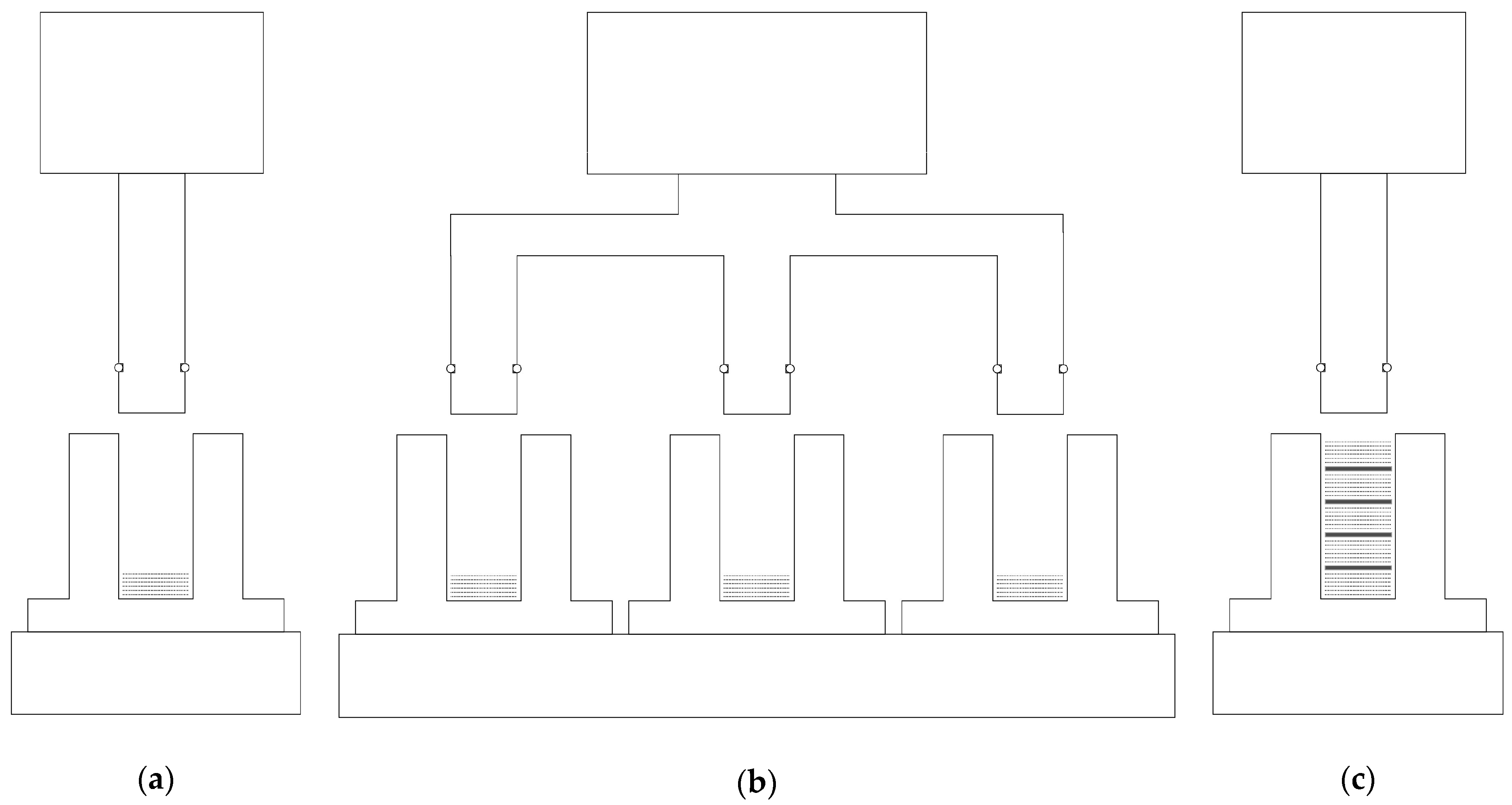

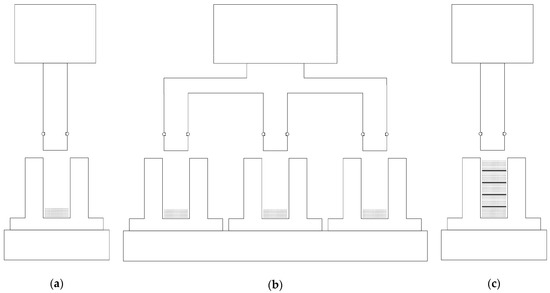

Despite reducing the time for setting and removing the samples, the time required to move the piston, replace the air with CO2, and press remains absolutely necessary time, which is nearly 30 s. If the processing time per sample should be reduced further, multiple samples must be fabricated simultaneously; at this point, the concept of numbering-up is attractive. Figure 3 schematically presents the preparation of one sample and two kinds of numbering-up. Figure 3b shows the concept of preparing a plurality of pressure vessels and pressing a plurality of samples with one press machine. In this case, numbering-up can be realized under the same conditions as the preparation of one sample and it is possible to increase the production efficiency while suppressing variations in the sample. On the other hand, the maximum load determines the performance of the press machine, and when the press area is increased, the required maximum load for the press machine increases, which increases process cost dramatically and should thus be avoided in the practical process. In Figure 3c, numbering-up by stacking samples without changing the press area is shown. Although the stroke of the piston will be long, if the maximum load does not change, the increased cost for the press machine-related owing to the longer stroke will be small; this will be very advantageous. Porosity is an important characteristic of porous materials. When a sample is compressed to fabricate a porous material, the thickness after compression determines the porosity. Thus, to produce samples of the same porosity, the compression rates must be uniform. In the method shown in Figure 3c, the separators are sandwiched between the samples, but the position of the separator is not controlled. Thus, the compression rates of the samples separated by the separators could differ. Owing to low or no uniformity of the raw material sample, the flow of CO2 inside the pressure vessel, and the difference of the distance between the piston (moving device) and the samples, the products may vary. Therefore, product variation was evaluated using the porosity of the product as an index. As the objective here is to increase productivity, first, the experiment wherein CO2 is instantly discarded by opening V2, i.e., without flow line shown within the dotted red line in Figure 1, was conducted.

Figure 3.

Schematic drawings showing the (a) basic process, (b) parallel numbering-up, and (c) serial numbering-up.

Figure 4 shows the SEM images of the raw material sheets and CAPC samples. In the CAPC samples, dents, which are adhesion traces are observed on the fibers. The high compression sample (Figure 4b) has more dents than the low compression sample (Figure 4c), which is caused by strong compression. The origin of the pores is the void between the fibers, implying that the porosity depends on the strength of the compression. As the mechanism of the CAPC process has been previously described [5,23], only a brief explanation is provided herein. The shape of a thermoplastic polymer is maintained by the friction between the polymer chains. The fluidity of the polymer increases when the polymer is impregnated with CO2 as the CO2 molecules reduce the friction between the polymer chains. In the case of PET, CO2 is considered to impregnate the amorphous part of the polymer. By compressing the polymer fibers in a plasticized state, bonding points are formed at the overlapping portions of the fibers. The adhesion of the sample is completed by removing the CO2 and the friction of the polymer chains is recovered.

Figure 4.

Scanning electron microscope images of (a) raw material, (b) sample at 4.5 mm press position, and (c) sample at 6.5 mm press position.

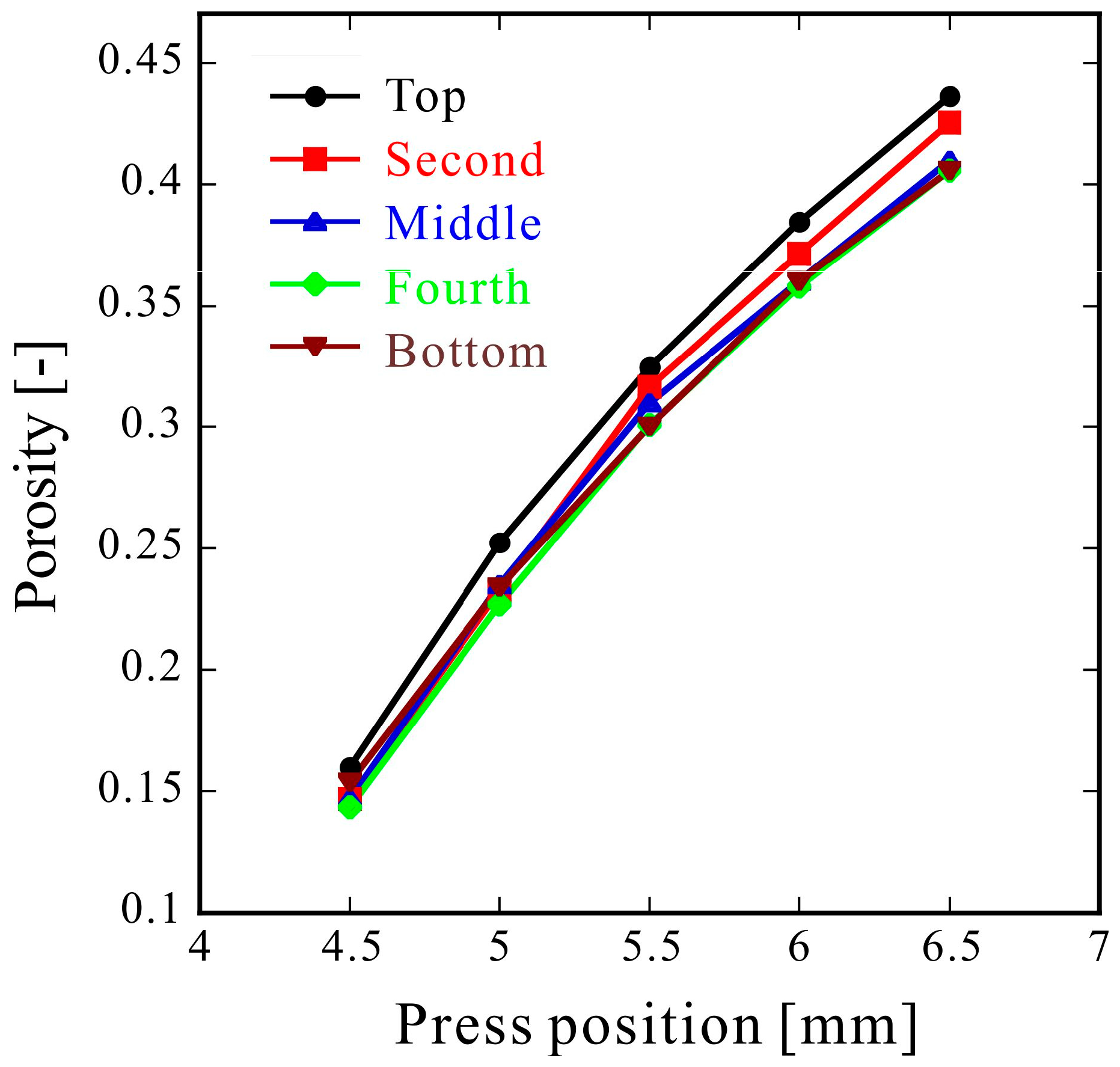

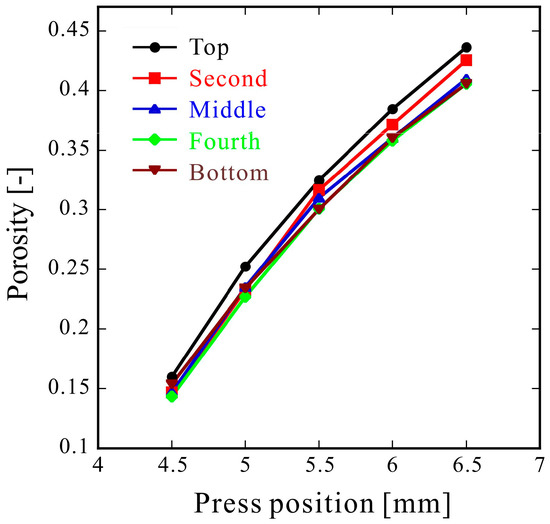

Figure 5 shows the product porosity for different press positions. When the press position was small (high compression), the variation in the sample porosity was small. For larger press positions, larger variation was observed. The top and second samples have higher porosity than the lower samples. The experiments were performed seven times under each condition, and the average thicknesses and porosity are provided along with the standard deviation in Table 1. As seen in Figure 4 and Table 1, the differences in the sample porosity were significant.

Figure 5.

Product porosity at each position for different press positions. Each value is the average thickness based on seven experiments.

I considered the time when variation occurs: When CO2 is introduced, when it is pressed, or when the CO2 exhaust is vented from the system. Introduced CO2 may apply pressure throughout the samples from above by transmitting through the gap between the piston and the high-pressure vessel. However, there is a gap between the spacer and the high-pressure vessel, and CO2 should flow downward instantaneously through this gap. In addition, as the polymer is plasticized only when CO2 is dissolved in it, the effect on the polymer before CO2 is dissolved is expected to be extremely low. When the piston is lowered after introducing the CO2, compression occurs. Considering that the piston moves suddenly when the sample and the spacer are stationary, the upper sample must be compressed more than the lower sample. Another explanation is that the lower sample may be more pressurized by the weight of upper samples and spacers. However, as the pressure of the piston used to compress the sample is about 1 MPa (1 MPa at 4.5 mm press position, 0.9 MPa at 5.0 mm press position, and 0.8 MPa at 5.5 to 6.5 mm press position), the weight of samples and spacers should be negligibly small. The last possibility is to consider how CO2 venting affects the system. When CO2 exhaust is vented by releasing it to the atmosphere, the CO2 trapped in the pores of the porous material and the CO2 dissolved in the polymer are vigorously removed. If this effect differs for each sample layer, the samples may vary. Specifically, CO2 explosively blows out from the upper sample near the outlet, which compresses the lower sample. Because the lower sample, in which CO2 is sufficiently dissolved in the polymer, is still plasticized, the sample is likely to compress. When CO2 is removed from the lower sample, which might compress the upper sample, it seems that the CO2 concentration in the upper sample had already decreased; as decreased CO2 would prohibit plasticization, the upper sample would be difficult to compress, thus leading to it being thicker.

Assuming that the sample variation was most likely due to how the CO2 exhaust was vented from the system, the experiment was conducted with an added metering valve; the metering value should enable even CO2 discharge from each layer by limiting the exhaustion speed. The experiment was performed under the condition of the press position 6.5 mm, for which the dispersion had been largest. As described in the experimental section (Section 2.3), the evacuation operation was performed in a sequence of exhausting the residual pressure instantaneously after exhausting slowly for 30 s. According to the change in the load applied to the piston, the drop in pressure due to CO2 exhaustion for 30 s was about 4 MPa. The measured sample thickness and evaluated porosity versus sample position are listed in Table 2. Although the porosity of the top sample was slightly larger, the variation among the samples was greatly reduced. Therefore, these results indicate that the sample variation was caused by the CO2 venting process. The time required for slow venting doubled the processing time (from 30 s to 60 s), which halves the effect of the 5-fold improvement in the productivity achieved via numbering-up. As the slow venting procedure performed to decrease the sample variation reduces the productivity improvement due to numbering-up, allowable product variation should be considered carefully before adapting slow venting.

4. Conclusions

Two strategies were conducted to improve the productivity of the CAPC method. The CO2 introduction and exhaustion tubes were connected to the piston instead of the pressure vessel, enabling the free movement of the pressure vessel, which removed the processing time otherwise required for sample introduction and removal. The production per unit time was increased by numbering-up vertically and setting multiple samples without changing the load of the piston. This method is very effective because productivity can be improved without a significant increase in equipment cost. However, sample variation in porosity was detected in samples prepared in the numbering-up scheme, which was found to be caused by the CO2 venting process. Although controlling the venting rate was one of the solutions, it was accompanied by a decrease in productivity. Therefore, carefully judging the allowable product variation together with the benefits of numbering-up is necessary. Although not discussed in this article, in the future, the flow of CO2 at the time of exhaustion should be simulated to optimize the high-pressure vessel, spacer, and CO2 flow path, such that CO2 is removed at equivalent levels from all samples. This will potentially allow the sample variations to be lowered without reducing the CO2 venting speed.

Author Contributions

T.A. conceived and designed the experiments, performed the experiments, analyzed the data, and wrote the paper.

Funding

This research received no external funding.

Conflicts of Interest

The author declares no conflict of interest.

References

- Young, R.J.; Lovell, P.A. Introduction to Polymers, 3rd ed.; Routledge: Abingdon, UK, 2011; ISBN 978-0849339295. [Google Scholar]

- Fried, J.R. Polymer Science and Technology, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2014; ISBN 978-0137039555. [Google Scholar]

- Mills, N.J. Polymer Foams Handbook: Engineering and Biomechanics Applications and Design Guide; Butterworth-Heinemann: Oxford, UK, 2007; ISBN 978-0750680691. [Google Scholar]

- Ishizaki, K.; Komarneni, S.; Nanko, M. Porous Materials—Process technology and applications; Springer Science+Business Media: Dordrecht, NL, USA, 2014; ISBN 978-1461376637. [Google Scholar]

- Aizawa, T. A new method for producing porous polymer materials using carbon dioxide and a piston. J. Supercrit. Fluids 2018, 133, 38–41. [Google Scholar] [CrossRef]

- Kerton, F.; Marriott, R. Alternative Solvents for Green Chemistry, 2nd ed.; RSC Publishing: Cambridge, UK, 2013. [Google Scholar] [CrossRef]

- Eldik, R.; Klärner, F.-G. High Pressure Chemistry–Synthetic, Mechanistic, and Supercritical Applications; Wiley-VCH: Weinheim, Germany, 2002; ISBN 978-3527612628. [Google Scholar]

- Jessop, P.G.; Leitner, W. Chemical Synthesis Using Supercritical Fluids; Wiley-VCH: Weinheim, Germany, 1999; ISBN 978-3527613687. [Google Scholar]

- Taylop, L.T. Supercritical Fluid Extraction; Wiley-Interscience: New York, NY, USA, 1996; ISBN 978-0471119906. [Google Scholar]

- Kazarian, S.G.; Vincent, M.F.; Bright, F.V.; Liotta, C.L.; Eckert, C.A. Specific intermolecular interaction of carbon dioxide with polymers. J. Am. Chem. Soc. 1996, 118, 1729–1736. [Google Scholar] [CrossRef]

- Li, M.; Huang, X.; Liu, H.; Liu, B.; Wu, Y.; Wang, L. Solubility prediction of supercritical carbon dioxide in 10 polymers using radial basis function artificial neural network based on chaotic self-adaptive particle swarm optimization and K-harmonic means. RSC Adv. 2015, 5, 45520–45527. [Google Scholar] [CrossRef]

- Shieh, Y.-T.; Su, J.-H.; Manivannan, G.; Lee, P.H.C.; Sawan, S.P.; Spall, W.D. Interaction of supercritical carbon dioxide with polymers. I. Crystalline polymers. J. Appl. Polym. Sci. 1996, 59, 695–705. [Google Scholar] [CrossRef]

- Shieh, Y.-T.; Su, J.-H.; Manivannan, G.; Lee, P.H.C.; Sawan, S.P.; Spall, W.D. Interaction of supercritical carbon dioxide with polymers. II. Amorphous polymers. J. Appl. Polym. Sci. 1996, 59, 707–717. [Google Scholar] [CrossRef]

- Nalawade, S.P.; Picchioni, F.; Janssen, L.P.B.M. Supercritical carbon dioxide as a green solvent for processing polymer melts: Processing aspects and applications. Prog. Polym. Sci. 2006, 31, 19–43. [Google Scholar] [CrossRef]

- Lian, Z.; Epstein, S.A.; Blenk, C.W.; Shine, A.D. Carbon dioxide-induced melting point depression of biodegradable semicrystalline polymers. J. Supercrit. Fluids 2006, 39, 107–117. [Google Scholar] [CrossRef]

- Kikic, I. Polymer–supercritical fluid interactions. J. Supercrit. Fluids 2009, 47, 458–465. [Google Scholar] [CrossRef]

- Tomasko, D.L.; Li, H.; Liu, D.; Han, X.; Wingert, M.J.; Lee, L.J.; Koelling, K.W. A review of CO2 applications in the processing of polymers. Ind. Eng. Chem. Res. 2003, 42, 6431–6456. [Google Scholar] [CrossRef]

- Jacobs, L.J.M.; Kemmere, M.F.; Keurentjes, J.T.F. Sustainable polymer foaming using high pressure carbon dioxide: A review on fundamentals, processes and applications. Green Chem. 2008, 10, 731–738. [Google Scholar] [CrossRef]

- Feng, D.; Liu, P.; Li, L. Fabrication and cell morphology of a microcellular poly(ether imide)-carbon nanotube composite foam with a three-dimensional shape. J. Appl. Polym. Sci. 2019, 136, 47501. [Google Scholar] [CrossRef]

- Heidari, A.; Fasihi, M. Cell structure-impact property relationship of polypropylene/thermoplastic elastomer blend foams. eXPRESS Polym. Lett. 2019, 13, 429–442. [Google Scholar] [CrossRef]

- Viveiros, R.; Rebocho, S.; Casimiro, T. Green strategies for molecularly imprinted polymer development. Polymers 2018, 10, 306. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Yang, C.; Lu, C.; Zhang, F.; Yuan, Z.; Zhuang, X. Two-dimensional porous polymers: From sandwich-like structure to layered skeleton. Acc. Chem. Res. 2018, 51, 3191–3202. [Google Scholar] [CrossRef] [PubMed]

- Aizawa, T. Fabrication of porosity-controlled polyethylene terephthalate porous materials using a CO2-assisted polymer compression method. RSC Adv. 2018, 8, 3061–3068. [Google Scholar] [CrossRef]

- Aizawa, T. Peel and penetration resistance of porous polyethylene terephthalate material produced by CO2-assisted polymer compression. Molecules 2019, 24, 1384. [Google Scholar] [CrossRef] [PubMed]

- Wakui, Y.; Aizawa, T. Analysis of sustained release behavior of drug-containing tablet prepared by CO2-assisted polymer compression. Polymers 2018, 10, 1405. [Google Scholar] [CrossRef] [PubMed]

- Al-Rawashdeh, M.; Yu, F.; Nijhuis, T.A.; Rebrov, E.V.; Hessel, V.; Schouten, J.C. Numbered-up gas–liquid micro/milli channels reactor with modular flow distributor. Chem. Eng. J. 2012, 207–208, 645–655. [Google Scholar] [CrossRef]

- Kashid, M.N.; Gupta, A.; Renken, A.; Kiwi-Minsker, L. Numbering-up and mass transfer studies of liquid–liquid two-phase microstructured reactors. Chem. Eng. J. 2010, 158, 233–240. [Google Scholar] [CrossRef]

- Tonomura, O.; Tominari, Y.; Kano, M.; Hasebe, S. Operation policy for micro chemical plants with external numbering-up structure. Chem. Eng. J. 2008, 135S, S131–S137. [Google Scholar] [CrossRef]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).