Abstract

Development of metal matrix composites (MMCs) with metallic glass/amorphous alloy reinforcements is an emerging research field. As reinforcements, metallic glasses with their high strength (up to ~2 GPa) and high elastic strain limit (~2%) can provide superior mechanical properties. Being metallic in nature, the glassy alloys can ensure better interfacial properties when compared to conventional ceramic reinforcements. Given the metastable nature of metallic glasses, lightweight materials such as aluminum (Al) and magnesium (Mg) with relatively lower melting points are suitable matrix materials. Synthesis of these advanced composites is a challenge as selection of processing method and appropriate reinforcement type (which does not allow devitrification of the metallic glass during processing) is important. Non-conventional techniques such as high frequency induction sintering, bidirectional microwave sintering, friction stir processing, accumulative roll-bonding, and spark plasma sintering are being explored to produce these novel materials. In this paper, an overview on the synthesis and properties of aluminum and magnesium based composites with glassy reinforcement produced by various unconventional methods is presented. Evaluation of properties of the produced composites indicate: (i) retention of amorphous state of the reinforcement after processing; (ii) significant improvement in hardness and strength; (iii) improvement/retention of ductility; and (iv) high wear resistance and low coefficient of friction. Further, a comparative understanding of the properties highlights that the selection of the processing method is important in producing high performance composites.

1. Introduction

Metal matrix composites (MMCs) based on light metals namely Al, Ti, and Mg are developed for aircraft, automotive, sports, and electronics industries due to their light weight and enhanced mechanical properties [1,2,3,4]. Usually, micron-sized ceramic constituents such as Al2O3, SiC, Si3N4, B4C, BN, etc., are incorporated as reinforcements in light metal matrices. The ceramic constituents are strong and stiff; thereby they significantly improve mechanical properties such as hardness, strength, stiffness, wear resistance and high temperature properties, which are not obtainable in conventional alloys. Recently, light metal composites with nano-sized reinforcements such as nano Al2O3, nano SiC, carbon nanotube, nano boron nitride, etc. are being developed so as to improve the ductility of the composites [3,5]. Metal reinforcements are also being explored for the purpose [6,7,8,9,10]. MMCs are synthesized by stir casting, squeeze casting, semi-solid processing and powder metallurgy (i.e., blend-compact-sinter) methods [1,2,3,4]. A method of producing MMCs using novel additive manufacturing techniques is under investigation [11,12,13].

In recent years, metallic glass reinforced light metal composites are being developed. As metallic glasses have unique structure and properties compared to conventional crystalline materials, they are promising as reinforcement phase. In contrast to crystalline materials, metallic glasses do not have long range order [14,15,16]. They exhibit amorphous structure with glass transition and crystallization temperatures. Metallic glasses are also considered as ‘solids with frozen-in liquid structure’ and are meta-stable thermodynamically. These materials possess high strength (~2 GPa), high elastic limit of 2% (elastic limit of crystalline materials: 0.2%), and have superior corrosion resistance owing to the absence of grains and grain boundaries [14,15,16]. They have coefficient of thermal expansion close to those of crystalline metals. With distinctly different structure and properties compared to conventional crystalline materials, metallic glasses are currently being explored as reinforcements for light metal matrices. As they can provide metal–metal bonding at interface with less thermal mismatch, they can serve as better alternatives to conventional ceramic reinforcements [17,18].

In this paper, different methods of processing Al/Mg MMCs with metallic glass reinforcements, examples of composites made, their microstructure and mechanical properties are presented.

2. Processing Methods

2.1. Conventional Methods

2.1.1. Squeeze Infiltration

In this process, the composites are produced by the infiltration of a molten alloy into a ceramic fiber/particle form, followed by solidification [17,18]. The introduction of molten metal into the preform can be achieved either through the application of hydraulic pressure or vacuum. The pressure application increases solidification rate and produces fine-grained material. The method has been widely used to produce conventional metal matrix composites with ceramic reinforcements. Interestingly, this was the first method that was used to synthesize composites with metallic glass reinforcements [18]. Ni-based metallic glass (Ni–Nb–Ta alloy), due to its high thermal stability, was used as the reinforcement in Al–6.5Si–0.25Mg alloy matrix. The microstructure and compressive properties of the novel composites developed were reported [18].

2.1.2. Blend-Compact-Sinter

The widely used solid-state processing method of making metal matrix composites involves the blending of matrix and reinforcements followed by pressure compaction in a die. The compacted green composite billets are sintered in a suitable furnace for a required duration depending on the nature of the matrix and reinforcement. This process is well suited for conventional composites. However, as metallic glasses are metastable, the use of conventional sintering may result in devitrification of the glass due to requirement for long time duration for efficient sintering. Nevertheless, the method has been used by early researchers to produce composites with metallic glass reinforcements containing high volume fraction of reinforcements (40 to 60%) [19,20,21]. Zr-based and Ni-based glassy particles in pure Al matrices were synthesized and the microstructure and properties were reported [19,20,21].

2.2. Advanced Processing Methods

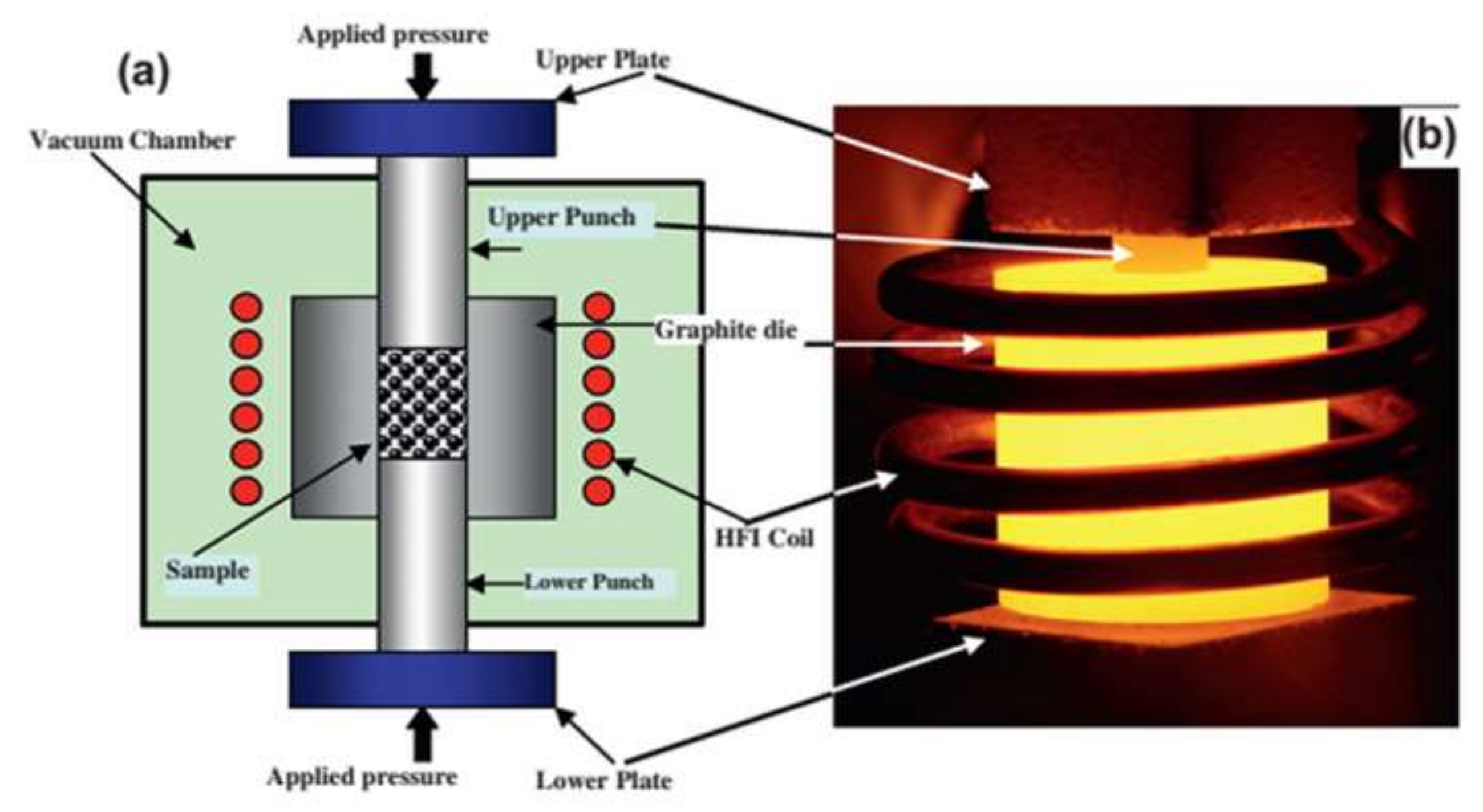

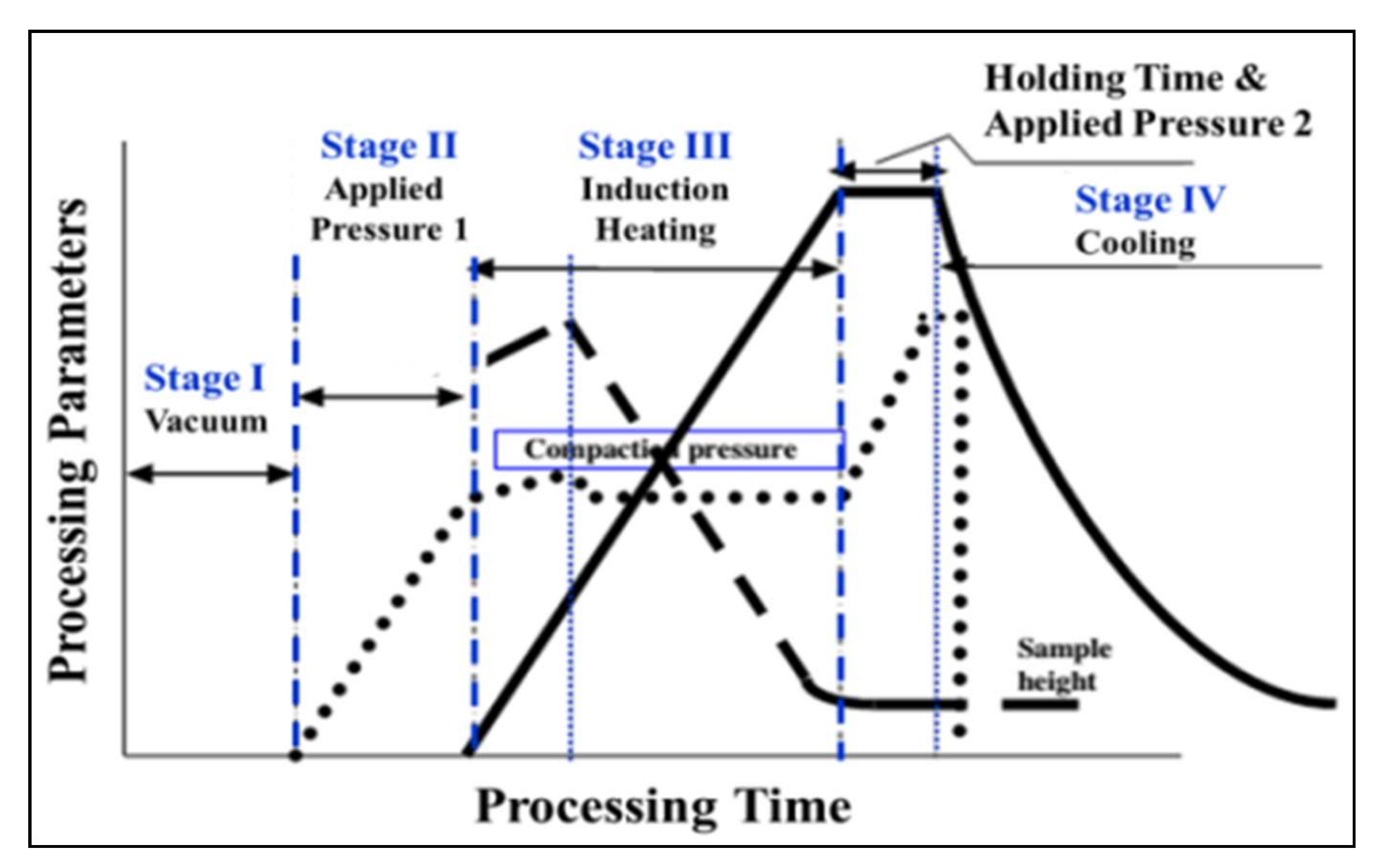

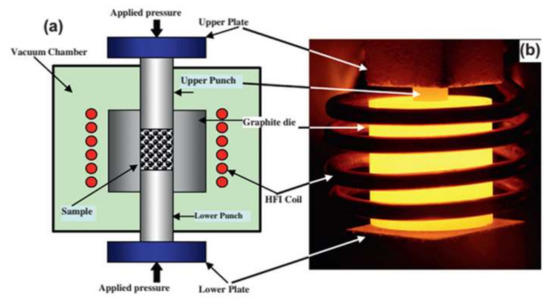

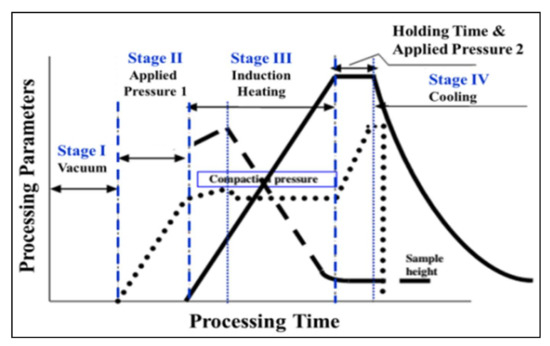

2.2.1. High Frequency Induction Heat Sintering

High frequency induction heat sintering (HFIHS), also known as high frequency induction sintering (HFIS) is a sintering process in which ceramic and metal powders are sintered [22]. In this process, metallic powders are rapidly sintered in a very short period of time, with the assistance of high-temperature and pressure. Due to the high heating and cooling rates involved, grain growth does not occur in the sintered samples. Figure 1a,b shows the configuration of a HFIHS unit [22]. During the operation of the unit, an intense magnetic field is applied through an electrically conducting pressure die that heats the samples. Steps involved in HFIHS process are shown in Figure 2 [22]. Figure 2 shows the four sequential stages of sintering in high frequency induction heat sintering (HFIHS) process. The four stages are: (i) Stage I, evacuation conducted to vacuum level: 1 × 103 Torr; (ii) Stage II, application of uniaxial pressure; (iii) Stage III, activation of induced current for densification and sintering; and (iv) Stage IV, cooling [22].

Figure 1.

(a) High-frequency induction heated sintering apparatus and (b) heated die [22]. (© 2012, Elsevier. Used with permission).

Figure 2.

The four sequential stages of sintering in high frequency induction heat sintering (HFIHS) process [22]. (© 2012, Elsevier. Used with permission).

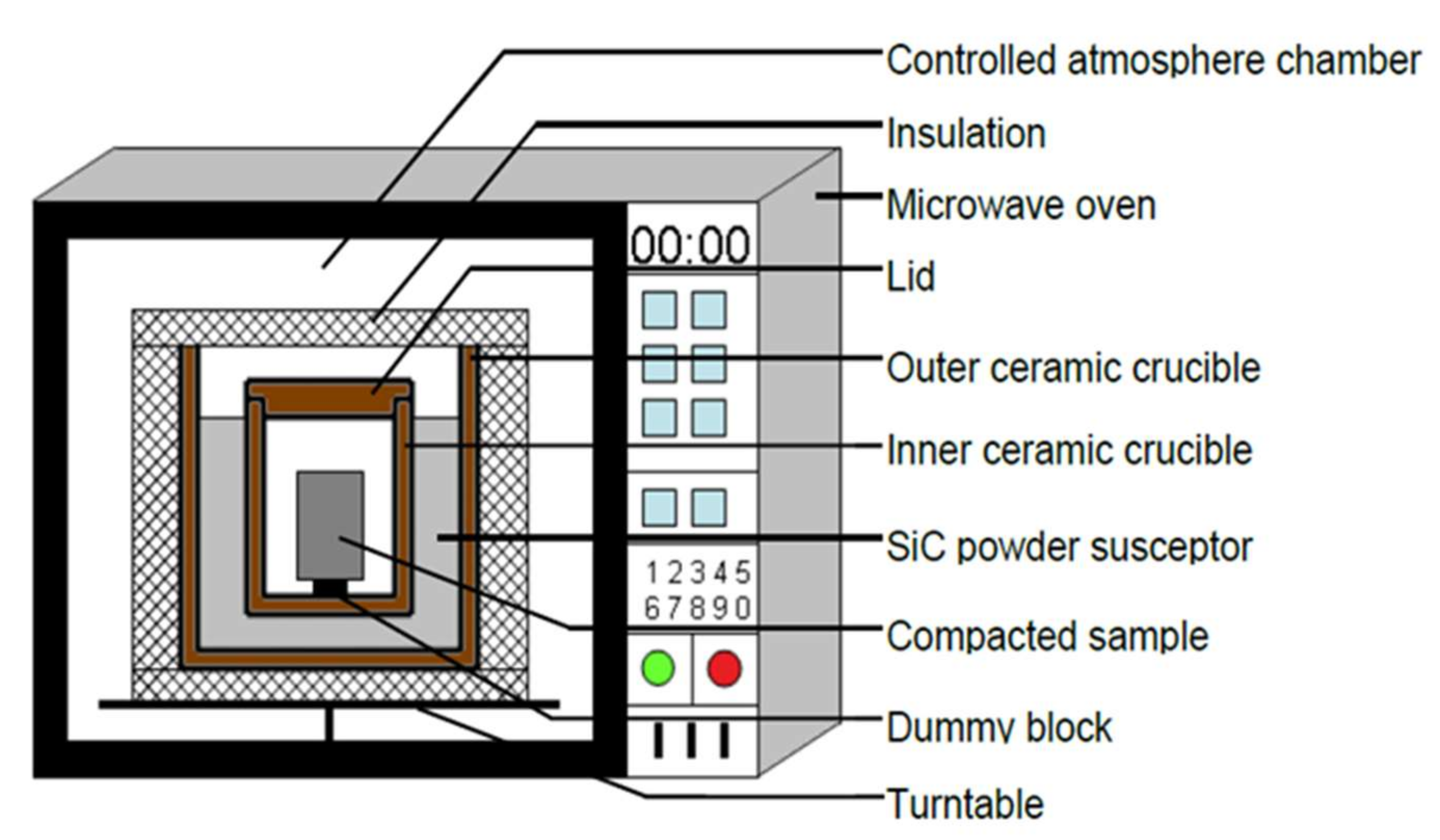

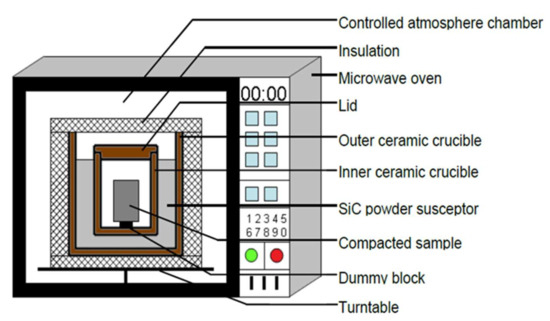

2.2.2. Microwave Sintering

In microwave process, electromagnetic energy gets converted into heat energy. This process is instantaneous and is highly efficient. In conventional sintering process, samples get heated by the transfer of thermal energy from their outer surface to their inner surface. In microwave sintering process, heat is generated by microwaves within materials and radiates outward thereby heating the samples [23]. Given that these two heating processes are distinctly different, in the case of conventional heating, temperatures are found to be higher at the surface than those at the core, and this is vice versa in the case of microwave sintering [23]. Such differential heating in samples causes variation in their microstructure across their thickness and would result in poor properties. To solve the issue of differential heating, the bi-directional hybrid microwave heating technique was developed. Figure 3 shows a schematic of a bi-directional hybrid microwave heating set-up, in which a household microwave oven is used. Here, compacted metal/composite powder billets are kept in the inner crucible for sintering. Between the inner and outer crucibles, SiC powder is kept. SiC powder is a microwave susceptor and it reduces thermal gradient during sintering [24]. The bi-directional heating occurs as SiC powder absorbs microwave and heats billets from outside, whereas billets absorb microwave and get heated from inside. Such bi-directional heating ensures elimination of thermal gradient and eventually result in uniform heating across billets/specimens [23,24].

Figure 3.

Schematic of set-up showing bi-directional microwave sintering.

Advantages of bi-directional microwave sintering method are: (i) it ensures good wettability between reinforcement and matrix (solves the issue of porosity at particle-matrix interface, a major drawback often observed in conventionally sintered materials); (ii) it involves rapid heating rate (note: for materials such as Mg/Mg based materials which are susceptible to oxidation, inert atmosphere in not a necessity during microwave sintering) and high sintering temperatures in short duration of time (close to melting point temperatures of light metals, 620–650 °C); (iii) it eliminates thermal gradient and provides uniform heating; (iv) it generates low porosity, and (v) it gives rise to fine microstructure and therefore better mechanical properties [23,24].

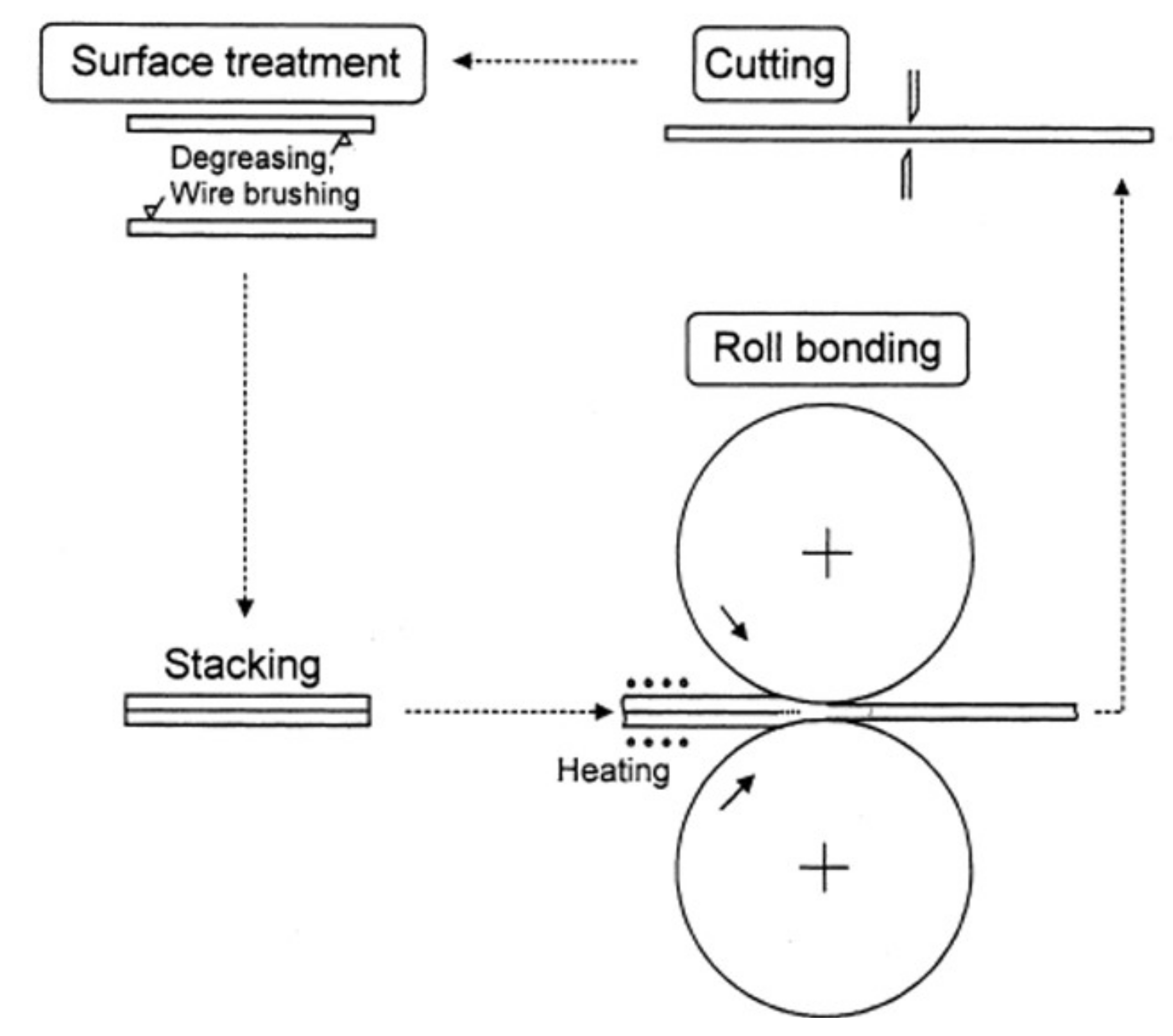

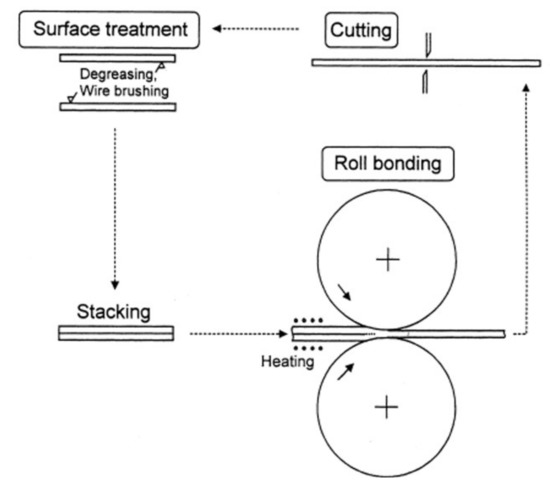

2.2.3. Accumulative Roll Bonding

Accumulative roll bonding (ARB) is a solid state process by which materials are processed in the form of sheets. ARB process includes: (i) stacking of two sheets of same material followed by (ii) heating and rolling of sheets together in a conventional mill so as to bind them (Figure 4). These steps are repeated consecutively [25]. Prior to processing, surfaces should be cleaned to achieve good bonding. For the ARB process, the selection of processing temperature is crucial. The process temperature should be: (i) below recrystallization temperature (as recrystallization removes the accumulated strains) and (ii) high enough to avoid insufficient ductility and low bond strength.

Figure 4.

Schematic of accumulative roll-bonding (ARB) process [25]. (© 1999, Elsevier. Used with permission).

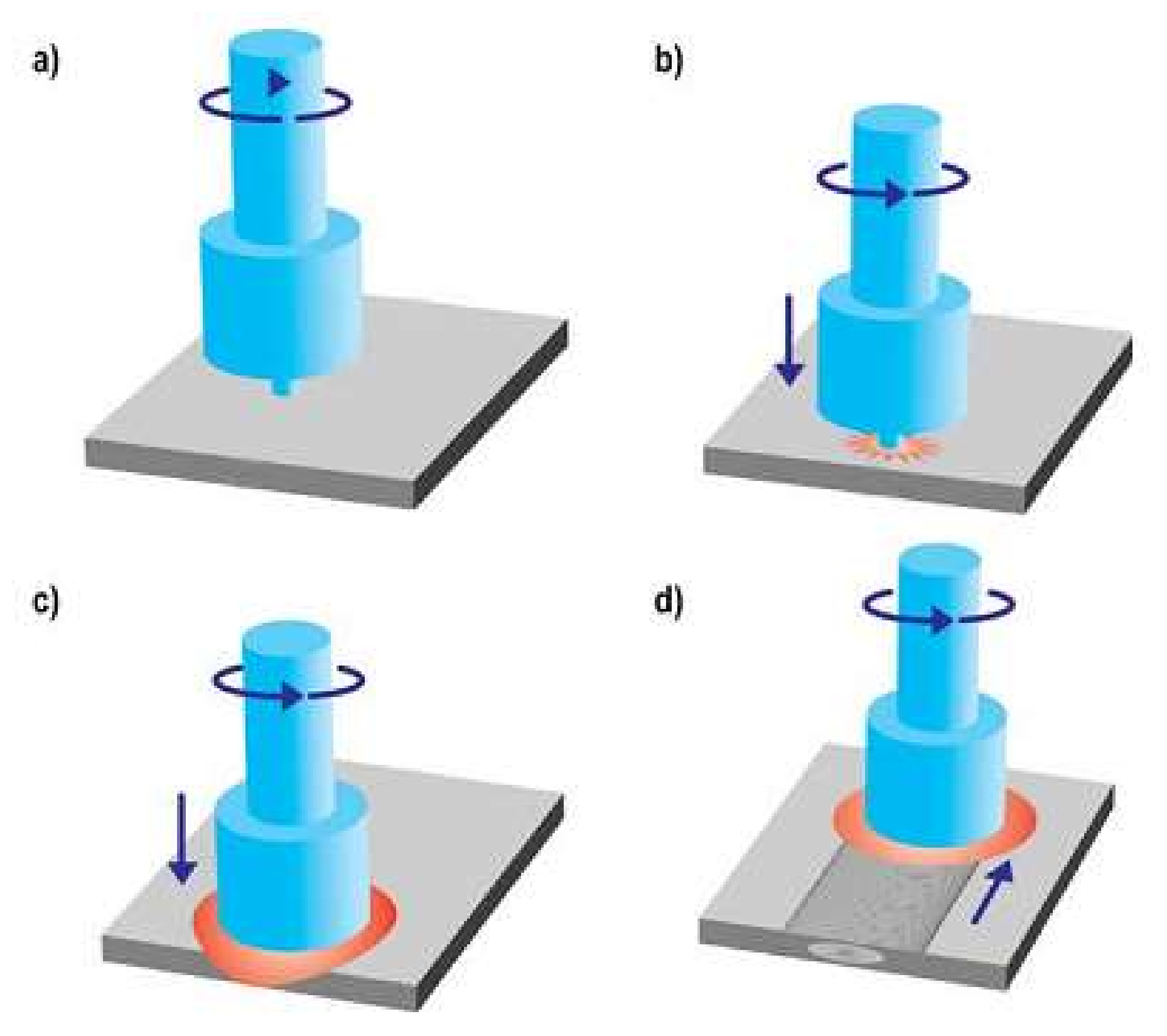

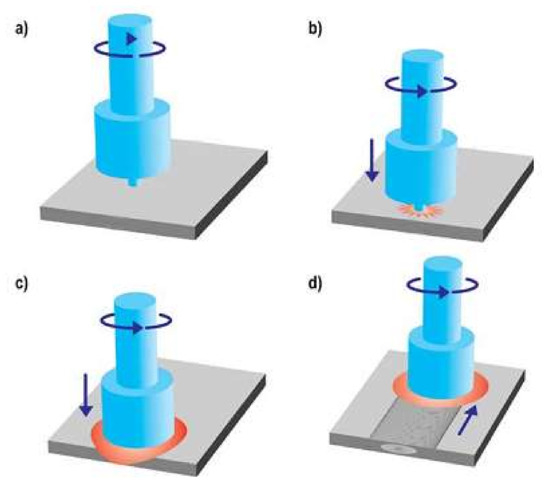

2.2.4. Friction Stir Processing

Friction stir processing (FSP) was developed based on friction stir welding (FSW) process. By the technique of FSP, surface composites can be successfully produced. In this technique, a rotating tool having a shoulder and a pin is brought in contact with the surface of a work piece (here metal matrix) and subsequently the tool is moved over the length and breadth of the surface to be processed. Figure 5 shows the steps involved in the FSP method [26,27]. To create a composite surface on a metal, grooves are made on the metal surface and are filled with reinforcement powder. FSP tool is then passed over the powder filled grooves (steps (a) and (b) in Figure 5), which results in intense plastic deformation and mixing of materials (i.e., reinforcement and matrix materials) assisted by the heat produced as the consequence of friction generated between the tool and the work piece grooves (steps (c) and (d) in Figure 5). This process eventually leads to microstructural refinement and densification at the processed regions on the work piece.

Figure 5.

Schematic showing different steps in friction stir processing [27]. (Open Access).

FSP technique can be effectively used to achieve: (i) fine-grained structures; (ii) surface alloying; (iii) phase modifications; and (iv) surface micro/nanocomposites. FSP modified materials show significant improvement in their mechanical properties such as increased hardness and resistance to wear, corrosion, fatigue, etc.

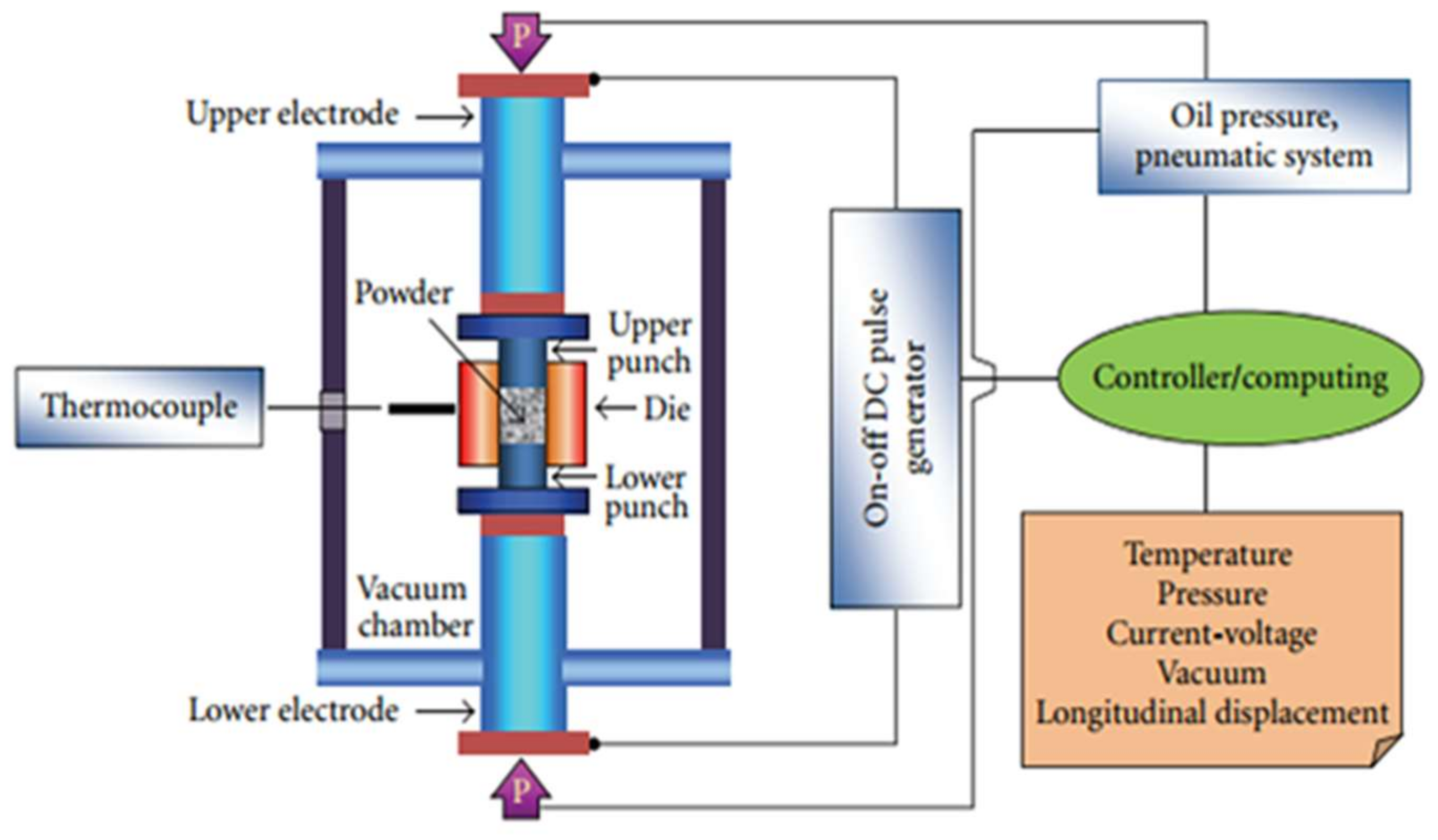

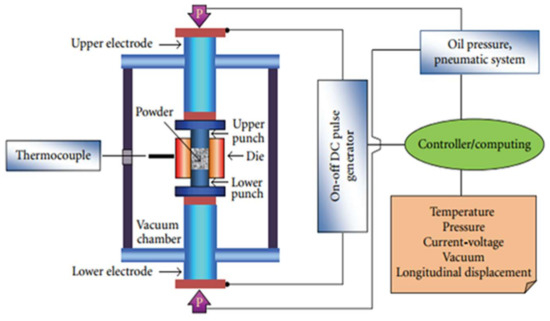

2.2.5. Spark Plasma Sintering

Spark plasma sintering (SPS) is a non-conventional sintering method in which fully dense materials with refined grain size is obtained [28]. A pulsed DC current is directly passed through a graphite die and composite powder compact. The schematic set-up of the process is shown in Figure 6.

Figure 6.

Schematic showing the spark plasma sintering (SPS) process [28]. (Open Access).

The powder compacts with near theoretical density are produced due to the contribution of Joule’s heating effect in densification. Similar to microwave sintering, in SPS, the heat generation is internal, which provides high heating rates (up to ~1000 K/min). The sintering process is hence very fast (within a few minutes). The fast rates enable complete densification of powders without coarsening [28].

3. Microstructure and Properties of Al and Mg Composites Reinforced with Metallic Glass

3.1. Al and Mg Composites Sintered by High Frequency Induction Heat Sintering

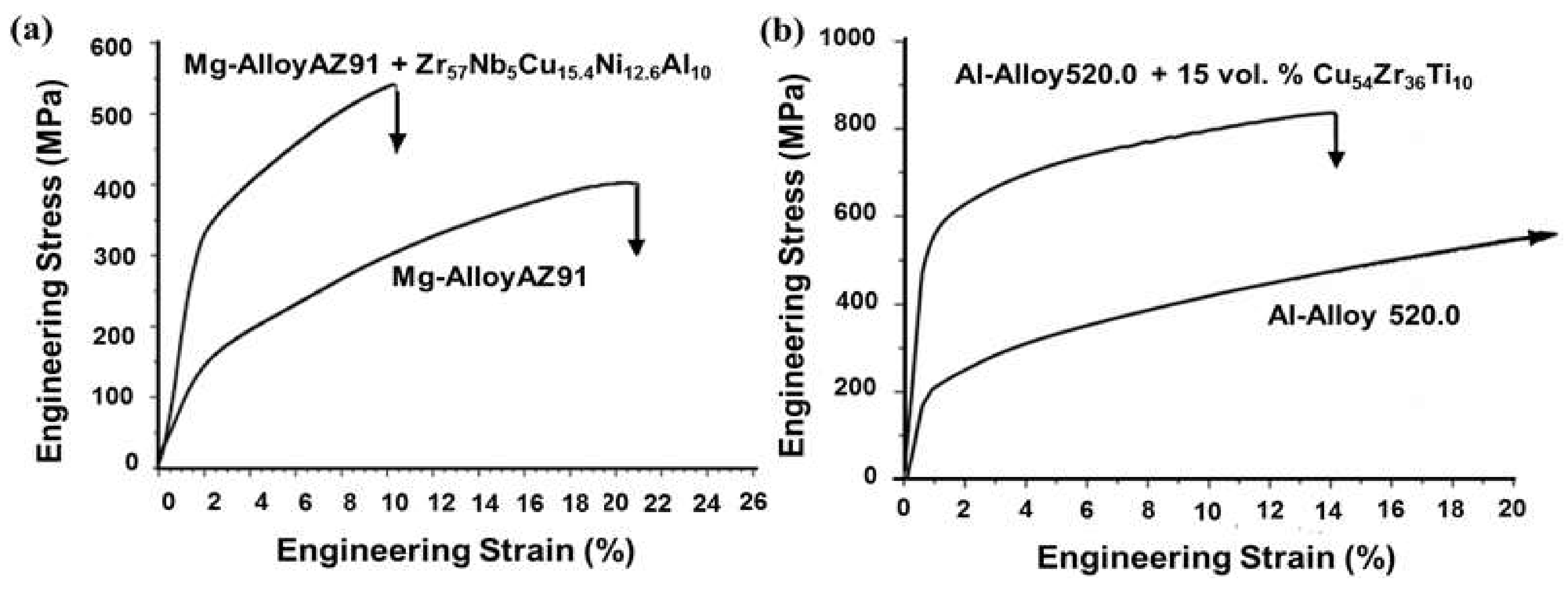

Composites with AZ91 Mg alloy as the matrix and Vitraloy 6 (Zr57Nb5Cu15.4Ni12.6Al10) as the metallic glass reinforcement were synthesized by HFIHS method [29]. Both the matrix and reinforcement materials were taken in ribbon form (AZ91 ingots were melt-spun into ribbons). The ribbons of the materials were cut into small pieces and milled in inert argon atmosphere to convert them into powders. The metal powder was mixed (i.e., reinforced) with 15% Vf of reinforcement powder, and the resulting composite powder was milled. The composite powder was sintered by HFIHS method under vacuum condition (temperature: 713 K, heating rate: 1.6 K/s, pressure: 50 MPa, duration: 126 s) [29]. Microstructural analysis of the synthesized composite showed the retention of the amorphous structure (corresponding to Vitraloy 6) and the crystalline phase (corresponding to Mg and Mg17Al12) [29]. Characterization using scanning electron microscopy (SEM) showed that the metallic glass particles were uniformly distributed in the metal matrix. The synthesized composites exhibited significant enhancement in their hardness and compression strength properties (Figure 7a) [29].

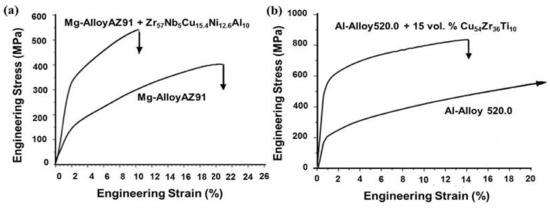

Figure 7.

Comparison of compression stress–strain curves for the high frequency induction heat sintering (HFIHS) sintered: (a) magnesium alloy with Zr57Nb5Cu15.4Ni12.6Al10 metallic glass composite with that of unreinforced AZ91 alloy [29]; and (b) aluminum composite with 15% volume fraction glassy Cu54Zr36Ti10 with that of unreinforced cast aluminum alloy 520 [30]. (© 2009 & 2010, Elsevier. Used with permission).

Using HFIHS, composites containing Aluminum alloy A520 with Cu-based Cu54Zr36Ti10 (at. %) glassy alloy reinforcement (of 15% Vf) were prepared [30]. Using a vibratory mill, the metallic glass and aluminum ribbons were powdered and the mixture was synthesized into a composite by the HFIHS technique (temperature: 720 K, pressure: 50 MPa, duration: 120 s) [30]. XRD analysis revealed no transformation in the amorphous phase. Figure 7b shows the results of compression test conducted on the prepared composite [30]. The significant increase in the compressive strength of the composite was reported to be due to the combination of: (i) the load transfer effect i.e., the ability of the amorphous phase to carry load; (ii) dislocation strengthening effect; (iii) Orowan strengthening; (iv) grain refinement; and (v) solid solution strengthening [30].

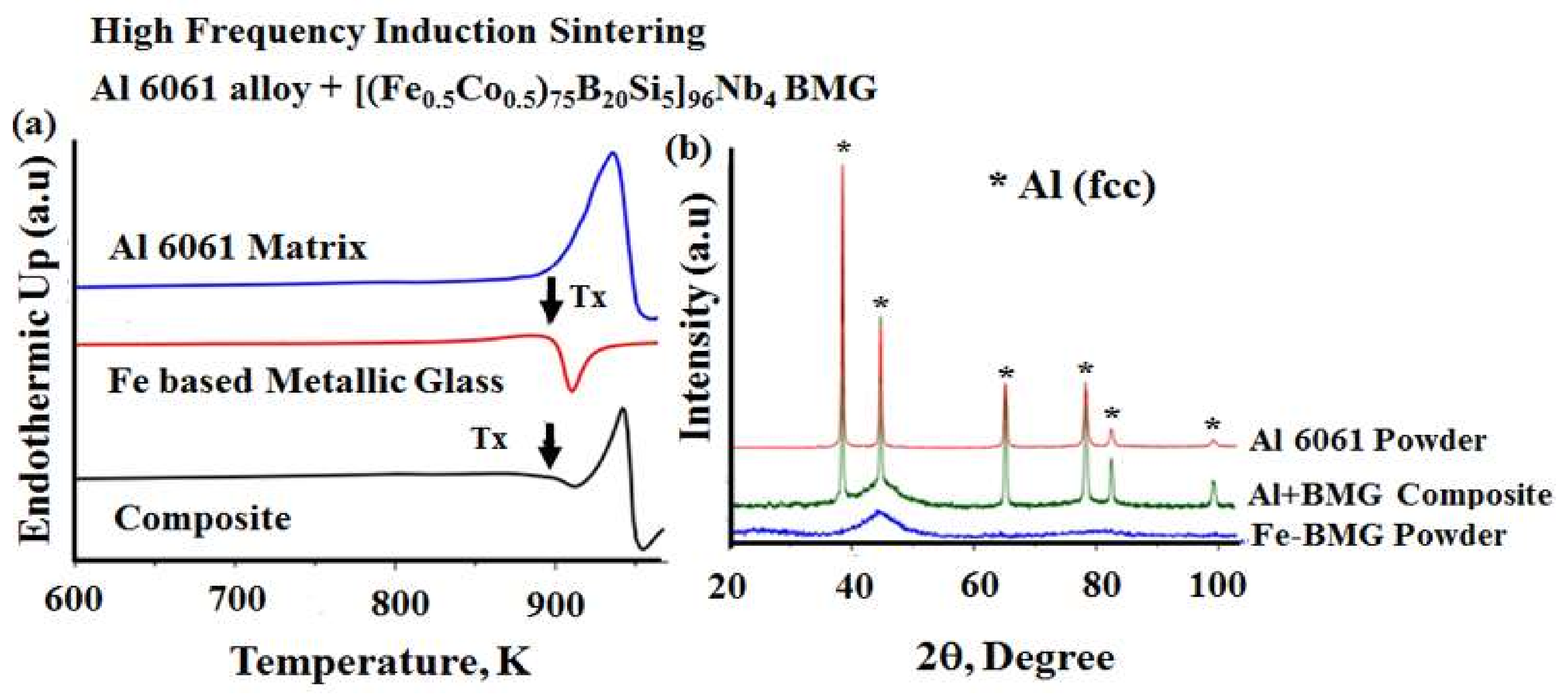

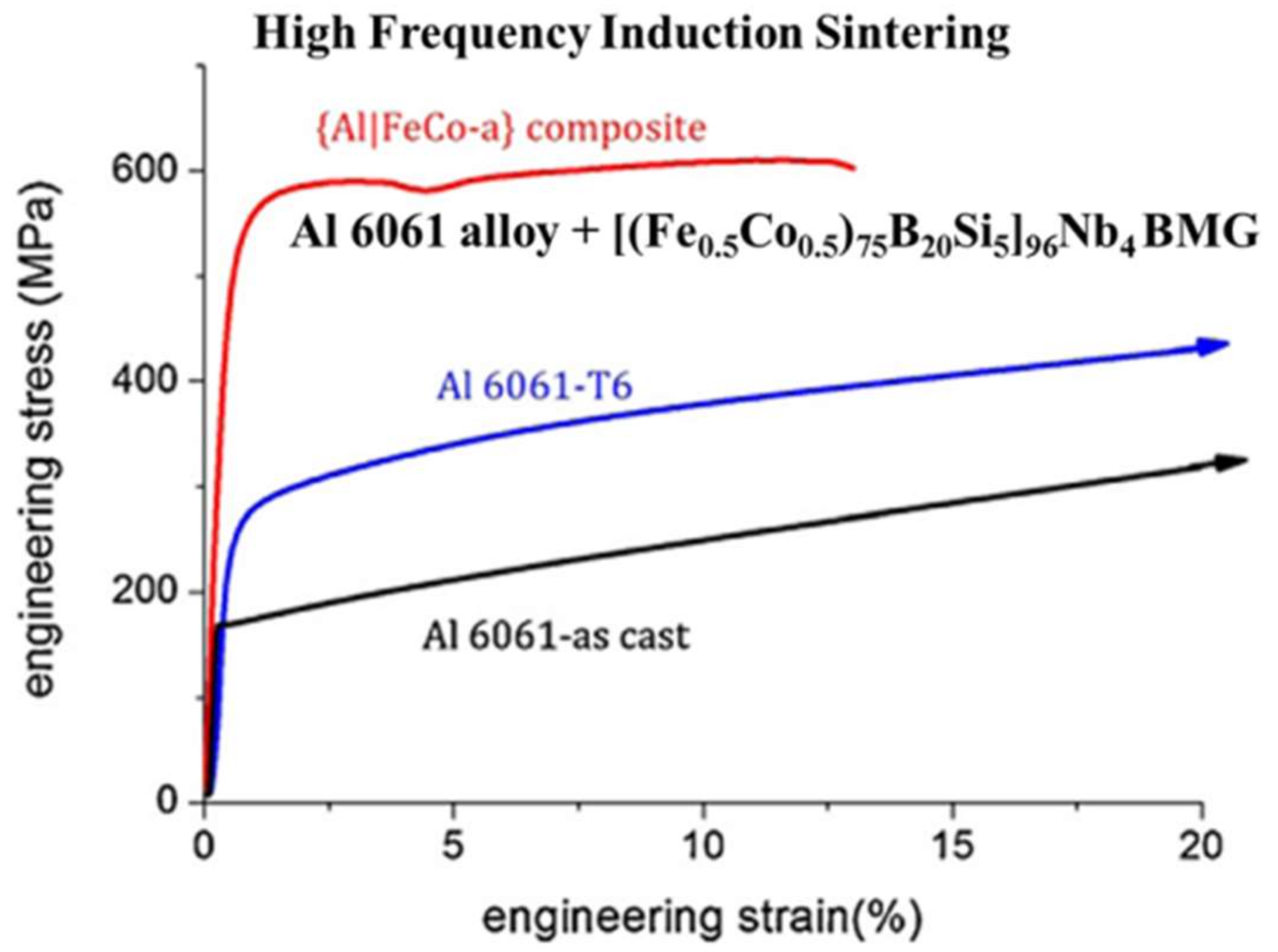

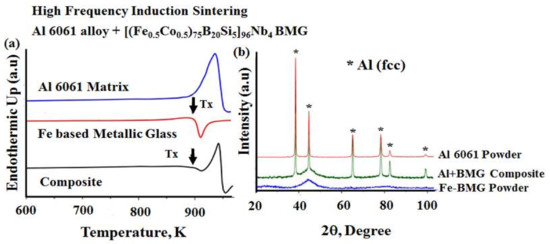

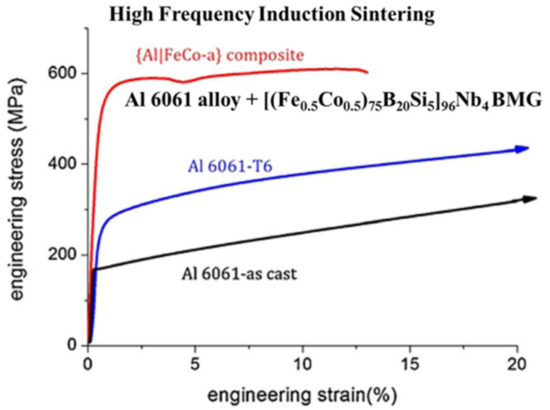

Al6061 Aluminum alloy was incorporated with [(Fe0.5Co0.5)75B20Si5]96Nb4 metallic glassy particles by the HFIHS process (temperature: 828 K, pressure: 70 MPa) [31]. Differential scanning calorimetry (DSC) and XRD analysis of the composites showed that the amorphous structure of the metallic glass remained unchanged. Figure 8a,b show the results of DSC and XRD analysis [31]. Figure 9 shows the stress–strain diagram of the composite, in which excellent increase in the strength properties is evident [31].

Figure 8.

(a) Differential scanning calorimetry thermograms and (b) X-ray diffraction patterns of aluminum 6061 alloy, iron–cobalt (FeCo) based metallic glass and Al6061 alloy with [(Fe0.5Co0.5)75B20Si5]96Nb4 composite prepared by high frequency induction heat sintering [31]. (© 2012, Elsevier. Used with permission).

Figure 9.

Compression stress–strain curves of high frequency induction sintered Al6061 alloy with [Fe0.5Co0.5)75B20Si5]96Nb4 composite compared to those of Al 6061 commercial alloy in the as cast and T6 tempered conditions [31]. (© 2012, Elsevier. Used with permission).

3.2. Al and Mg Composites Produced by Microwave Sintering

Incorporation of metallic glass in light metals such as Al and Mg (i.e., metals with relatively low melting temperature) is a challenge, as metallic glasses are thermodynamically metastable. Therefore, liquid state processing routes can be employed to incorporate only a few metallic glasses (i.e., only those with high amorphous to crystallization transition temperature) [18]. Conventional sintering methods that involve furnace heating are time consuming, which would lead to transformation from amorphous to crystallization state of amorphous reinforcement. Given these reasons, the liquid state and conventional furnace based sintering processes are suitable to synthesize light metal composites with only selective metallic glass reinforcements. Furthermore, it should be recalled that differential heating occurs in samples during sintering by conventional methods that would cause variation in their microstructure across their thickness resulting in poor properties. Thus, the most suitable method by which metallic glasses can be introduced as reinforcements in light metals should (i) generate high sintering temperatures and (ii) sinter powders rapidly. The bi-directional microwave sintering method was developed by incorporating these features, and has thus proved to be a successful and efficient technique to produce metallic glass reinforced light metal composites. Studies on the synthesis of metallic glass matrix composites and metallic glass polymer composites using microwave sintering are reported in [32,33].

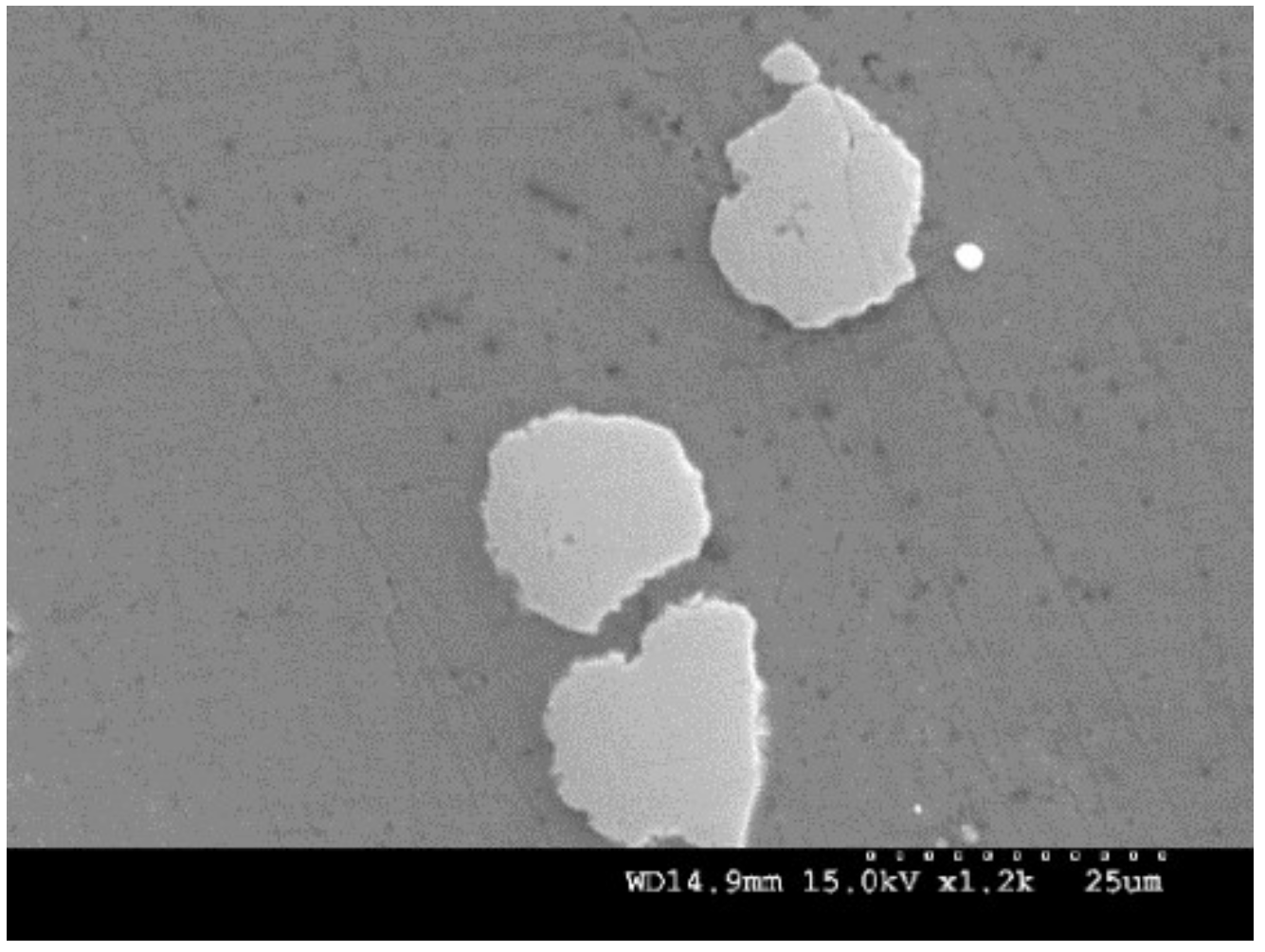

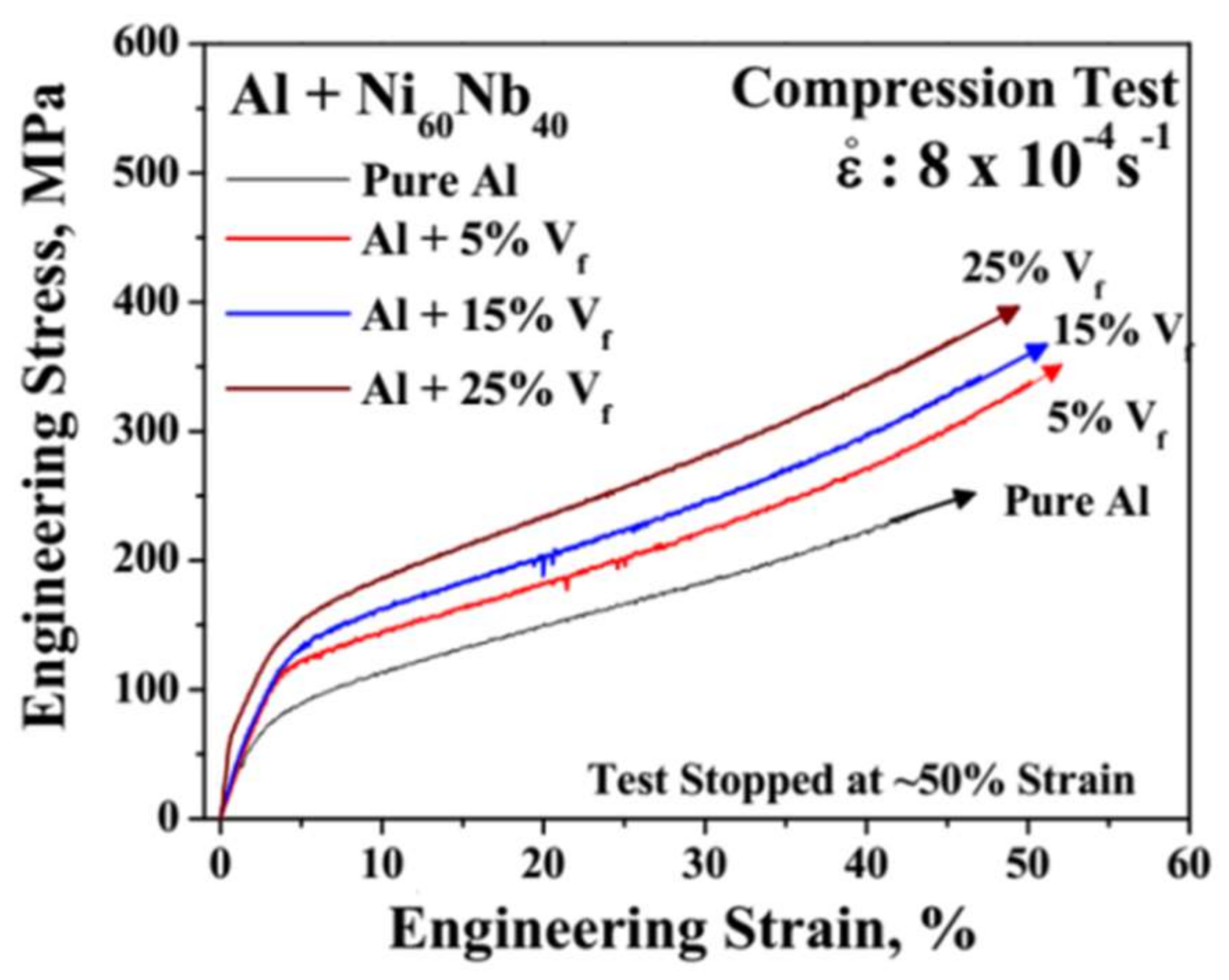

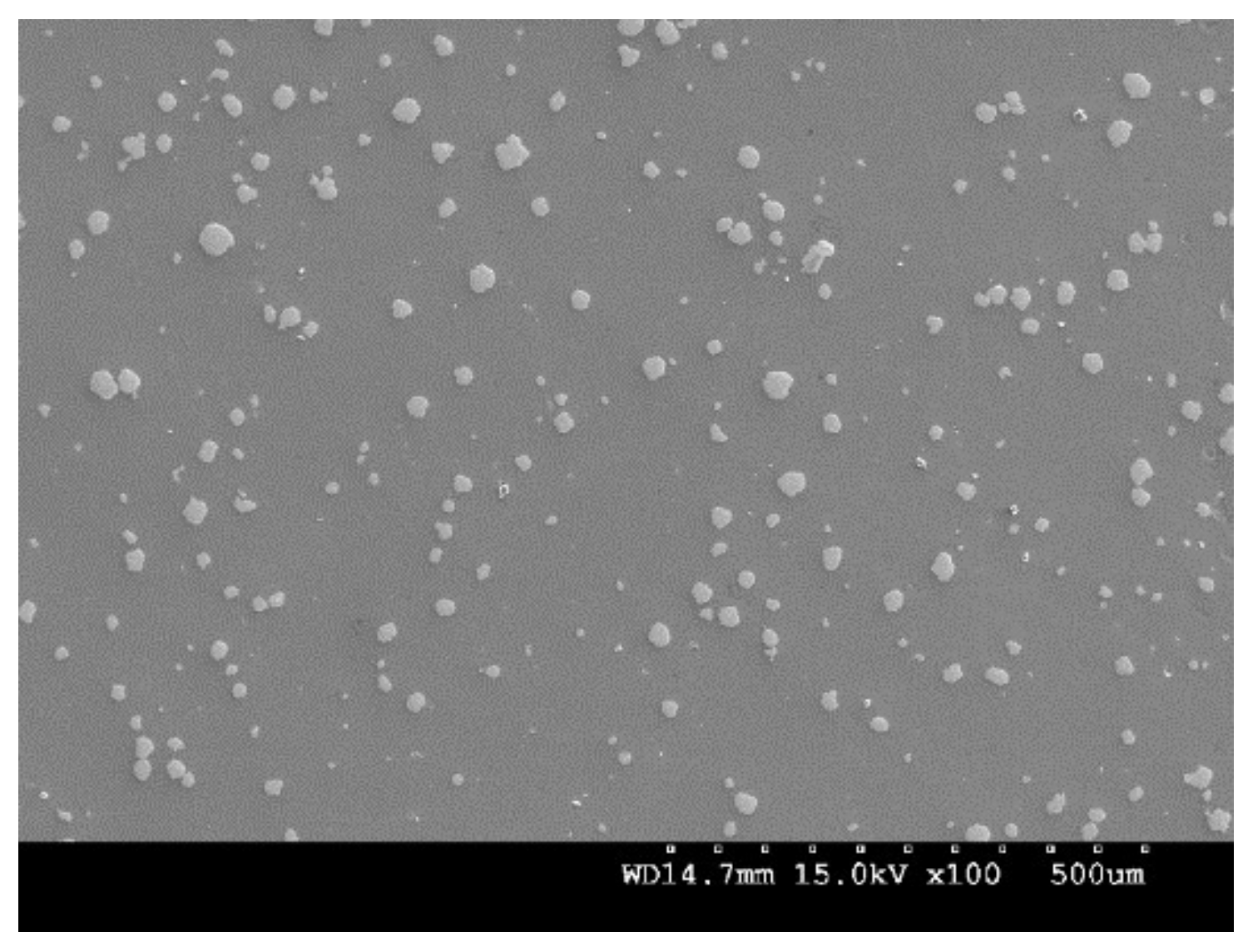

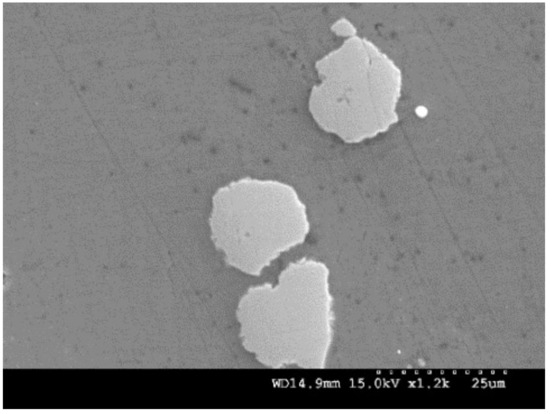

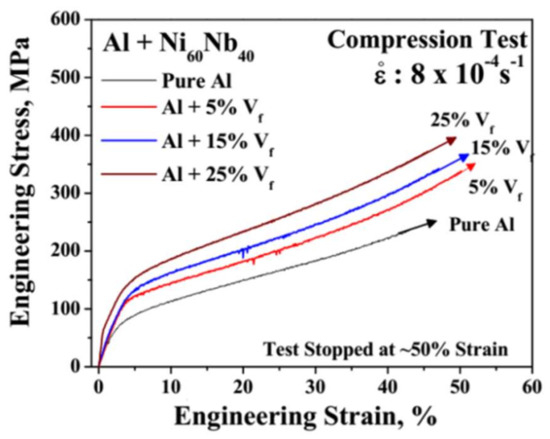

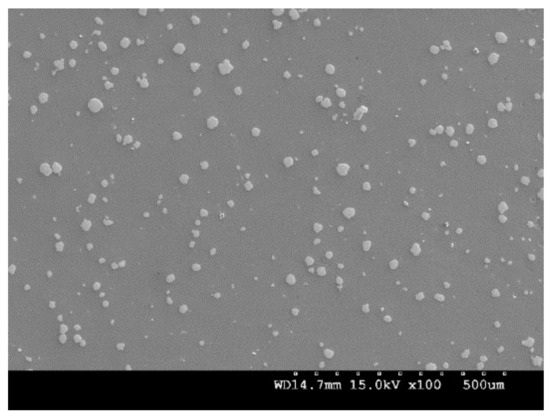

Pioneering works on synthesizing Al and Mg light metal matrix composites with metallic glass particles as reinforcements using the bi-directional microwave sintering were reported in 2013 [34,35]. In one of these works, by using mechanical alloying process Ni60Nb40 (at. %), metallic glass powders were prepared and blended with Al powders [34]. The mixed powders were cold compacted, and subsequently sintered by the bi-directional sintering method (temperature: 550 °C, duration: 750 s). Subsequent to sintering, the composites were hot extruded [34]. Microstructural analysis indicated retention of amorphous structure of the reinforcement, their uniform distribution and absence of interfacial products (Figure 10, [34]). Mechanical properties testing revealed that in comparison to those of the pure Al, the properties of microwave sintered Al composites were superior [34]. The composites recorded 130% increase in the micro-hardness value and 100% enhancement in the compressive strength, as against pure Al (Figure 11 [34]). Results of tensile tests indicated that the Al composites showed 15–60% increase in strength when compared to pure Al. Such composites produced by microwave sintering process outperformed composites produced by other methods in terms of compressive properties, which implies that the microwave process is more efficient in sintering composites than other processes.

Figure 10.

Scanning electron micrograph shows clear interface in pure aluminum reinforced with Ni60Nb40 (atomic pct.) amorphous alloy powder, synthesized by bi-directional microwave sintering.

Figure 11.

Compression properties of pure aluminum reinforced with Ni60Nb40 (atomic pct.) amorphous alloy powder, synthesized by bi-directional microwave sintering [34]. (© 2013, Elsevier. Used with permission).

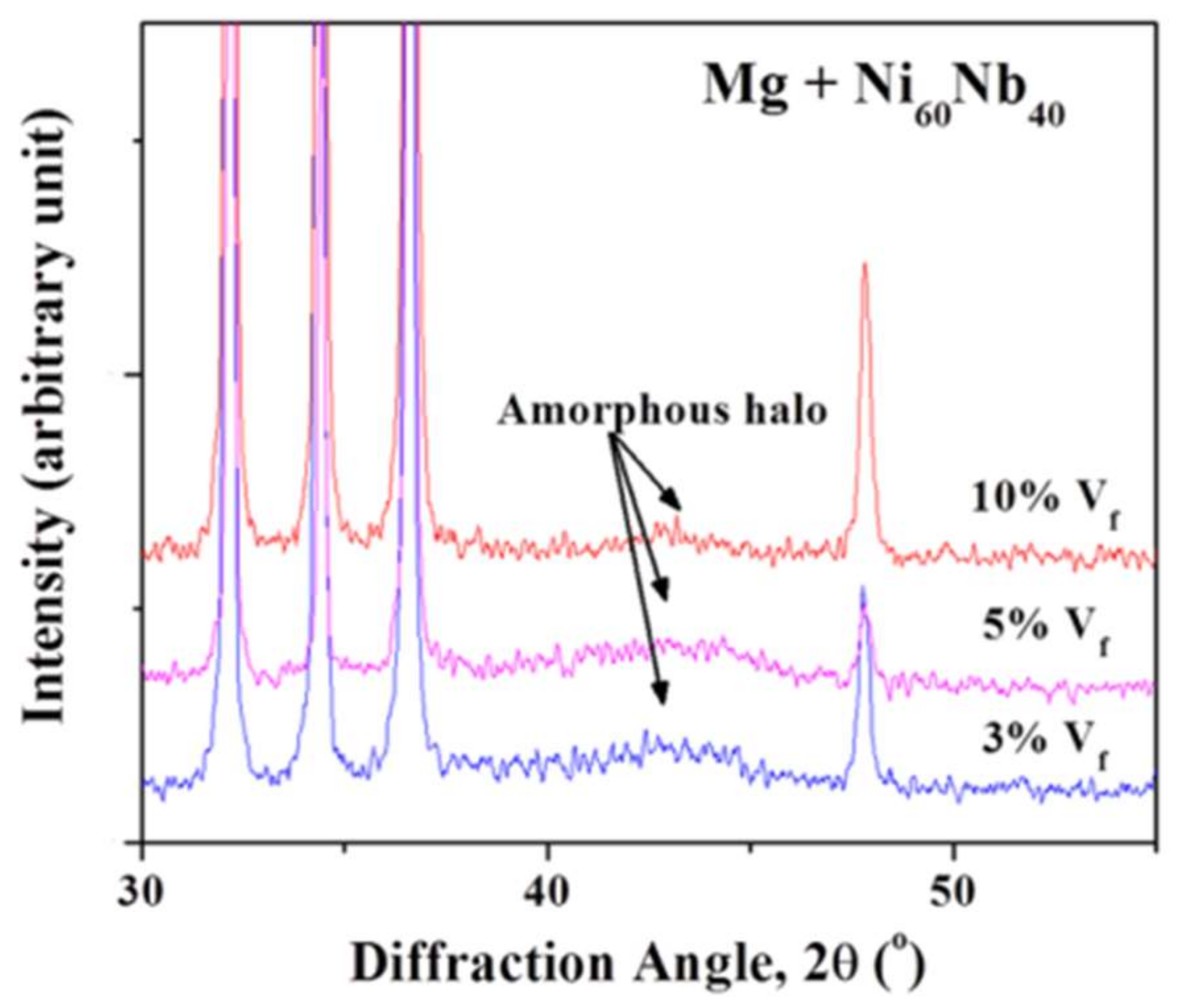

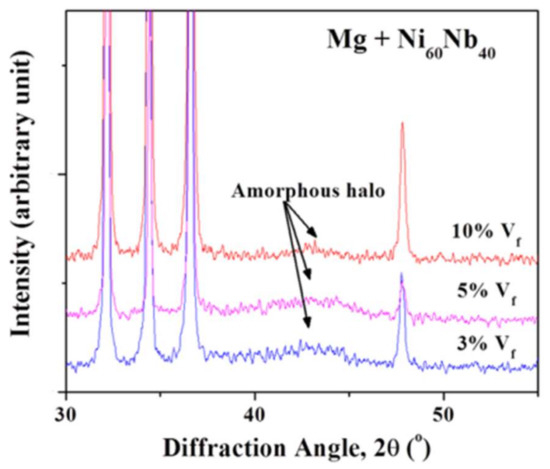

Ni60Nb40 (at. %) metallic glass powder was introduced into Mg metal matrix using bi-directional microwave sintering process [35]. The resulting composite showed uniform distribution of glassy reinforcement, retention of glassy phase and clean reinforcement/matrix interface (Figure 12 and Figure 13) [35]. The composites showed significant improvement in hardness and compression test properties as the volume fraction of the glassy reinforcement was increased [35]. Intrinsic high hardness, strength, and elastic limit of the reinforcement contributed towards the remarkable improvement in the mechanical properties of the Mg composites [35].

Figure 12.

Scanning electron micrograph showing uniform distribution of Ni60Nb40 (atomic pct.) amorphous alloy reinforcement in pure magnesium matrix, synthesized by bi-directional microwave sintering.

Figure 13.

X-ray diffraction pattern showing retention of the amorphous phase in pure magnesium reinforced with Ni60Nb40 (atomic pct.) amorphous alloy powder, synthesized by bi-directional microwave sintering [35]. (© 2014, Elsevier. Used with permission).

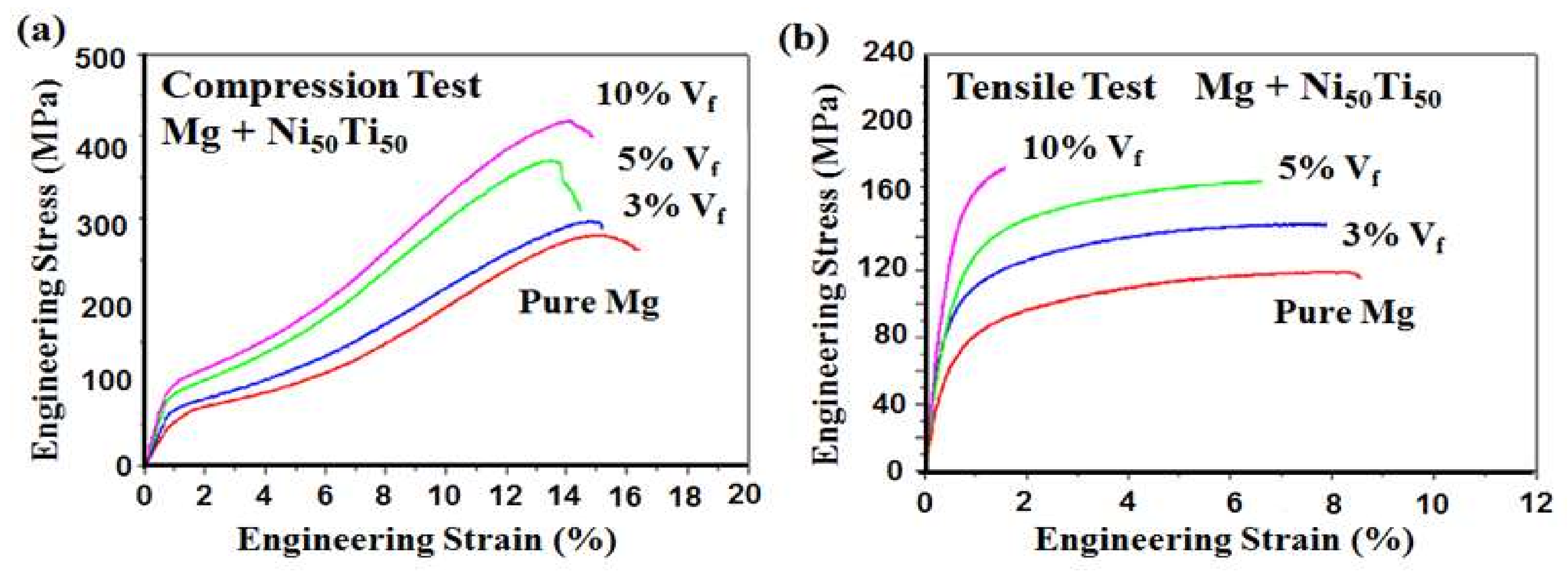

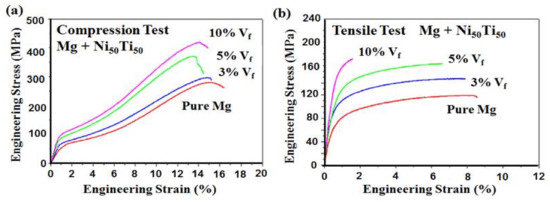

Mg composites with Ni50Ti50 metallic glass reinforcement sintered by bi-directional microwave process showed uniform distribution and retention of the amorphous structure of the metallic glass reinforcement [36]. The Mg composites showed excellent improvement in their mechanical properties, namely microhardness (increased by 80%), compressive strengths (increased by >70%, Figure 14a), and tensile strengths (yield strength: increased by 95%, ultimate strength: increased by 50%, Figure 14b) [36]. Mg composites with Cu50Ti50 glassy particles as reinforcement sintered by microwave technique showed similar improvement in compression strength properties [37]. Microwave sintered Mg-Al85Ti15 composites have shown good damping characteristics [38]. When subjected to damping tests, the composites showed, (i) higher damping capacity; and (ii) 3.75 times higher damping loss rate (i.e., how fast a material stops vibration) than pure magnesium [38].

Figure 14.

(a) Compression and (b) tensile properties of bi-directional microwave sintered pure magnesium reinforced with Ni50Ti50 metallic glass [36]. (© 2015, Elsevier. Used with permission).

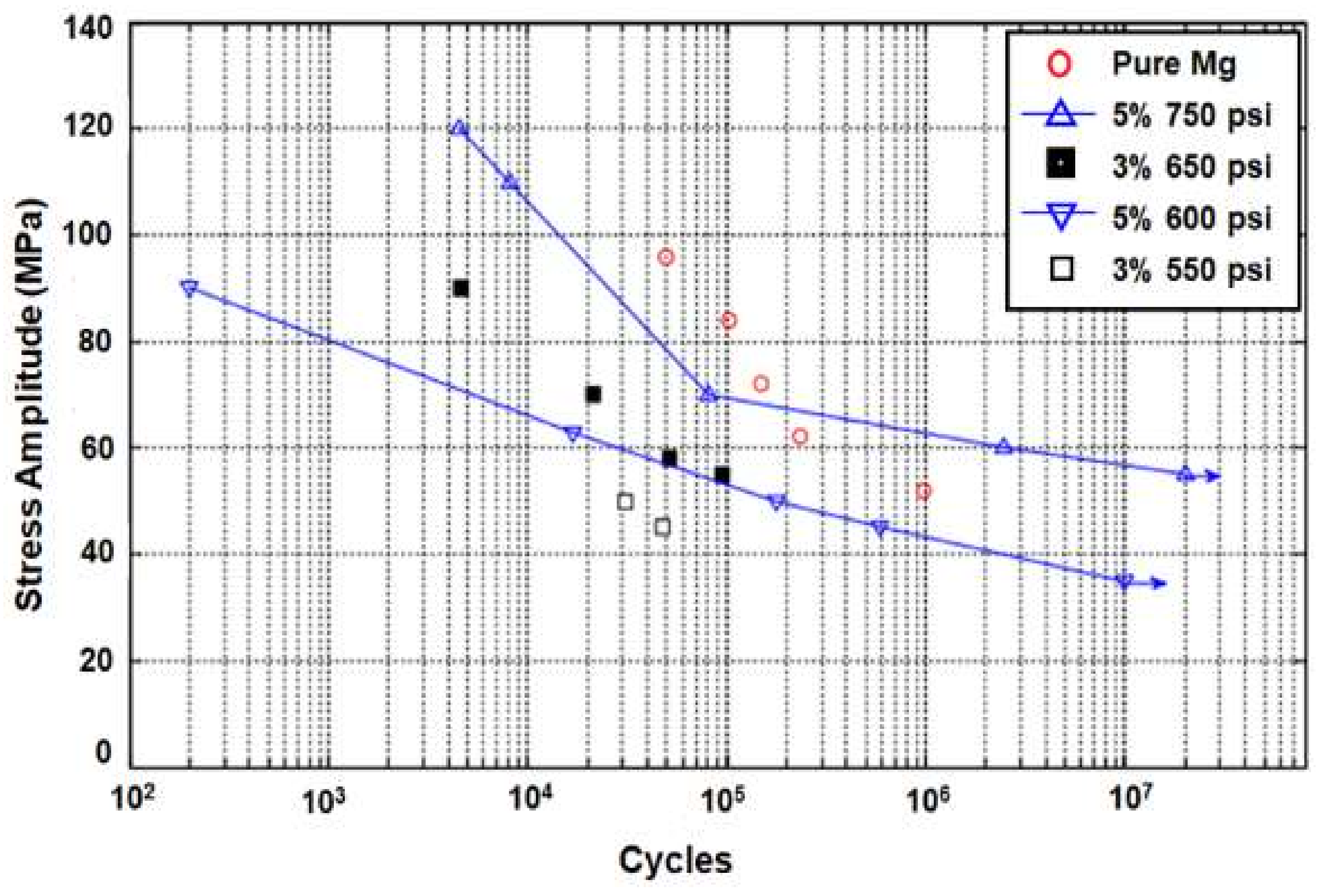

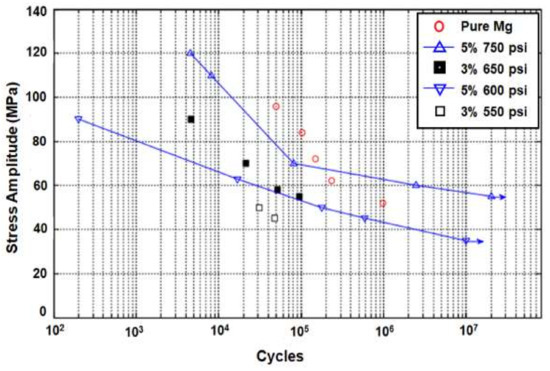

Recently, the high cycle fatigue behavior of pure Mg reinforced with Ni60Nb40 were investigated to understand the fatigue crack growth behavior [39]. It was observed that the fatigue life of amorphous particulate reinforced composite is higher than that of pure magnesium in the high cycle region [39], Figure 15. Further, the fatigue properties and the crack growth phenomenon depended on the microstructure and particle distribution which, in turn, were influenced by the processing conditions. The crack growth in the composites was highly localized and severely influenced by the distribution and microstructure of the reinforcement particles near the vicinity of the crack tip. Depending on the nature and distribution of the particles, the crack growth rate varied, i.e., high crack growth rate was observed in the particle clustered regions when compared to that at the uniformly distributed regions [39].

Figure 15.

S–N curve of Mg-NiNb composites under fatigue loading conditions [39]. (© 2016, Elsevier. Used with permission).

3.3. Al and Mg Composites Synthesized by Accumulative Roll Bonding

ARB is yet another method by which metallic glasses can be successfully introduced into Al matrices. By using ARB method, ultra-fine grained structured composites can be obtained at room temperature. In ARB process, protective atmosphere is not necessary, unlike in the case of sintering methods that involve high temperatures [40]. Al based metal-matrix composites reinforced with Al84Gd6Ni7Co3 glassy powder produced by accumulative roll bonding have shown good improvement in microhardness and tensile strength [40]. Al composites with Al-Ni-Sm metallic glass reinforcement in both amorphous and fully crystallized state showed ultra-fine microstructure [41].

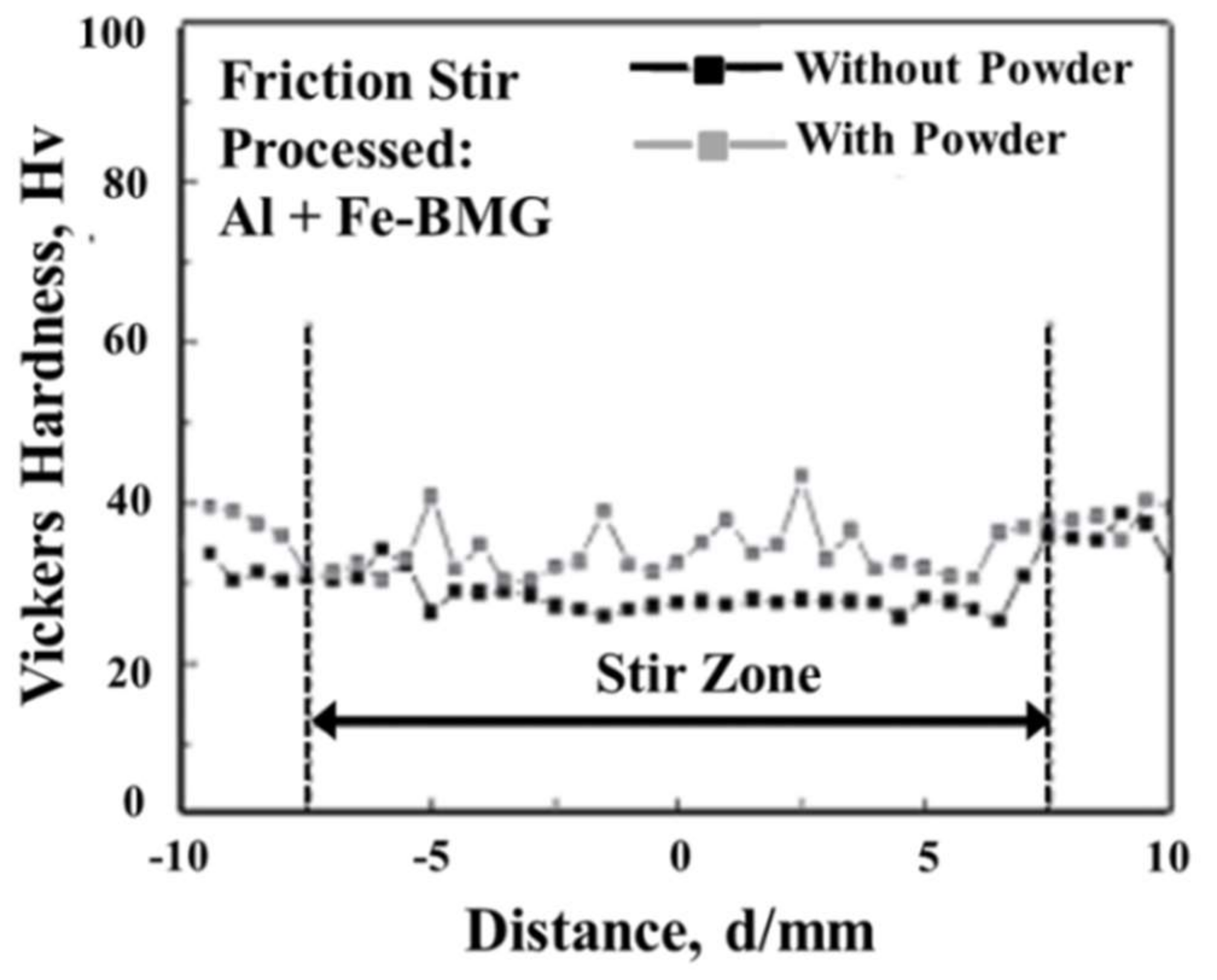

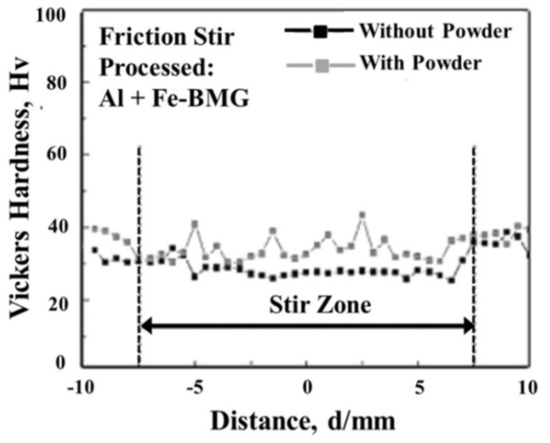

3.4. Al and Mg Composites Produced by Friction Stir Processing

FSP technique is an effective route to produce surface composites with metallic glass reinforcements. Fe72B14.4Si9.6Nb4 particles were introduced in Al metal matrix by FSP [42]. The iron-based glassy particles were chosen as their glass transition temperature was higher than that of the temperature range of the friction stir process (300 to 450 °C) [42]. To spread the reinforcement particles, a gap was made by keeping a shim between two plates. Next, the particles were filled in the gap and the friction stir processing was conducted [31]. Hardness tests revealed that the iron-based metallic glass particles refined the grains and increased the hardness (Figure 16) [42]. Furthermore, the increase in the number of passes resulted in the precipitation of Al13Fe4 that further enhanced the hardness of the composite [42].

Figure 16.

Hardness distribution on a cross section perpendicular to the friction stir processing direction in pure aluminum reinforced with Fe72B14.4Si9.6Nb4 metallic glass [42]. (Open Access).

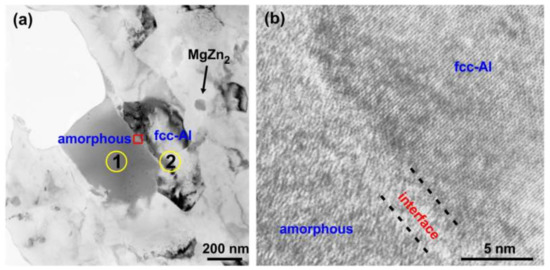

3.5. Al Composites Produced by Spark Plasma Sintering

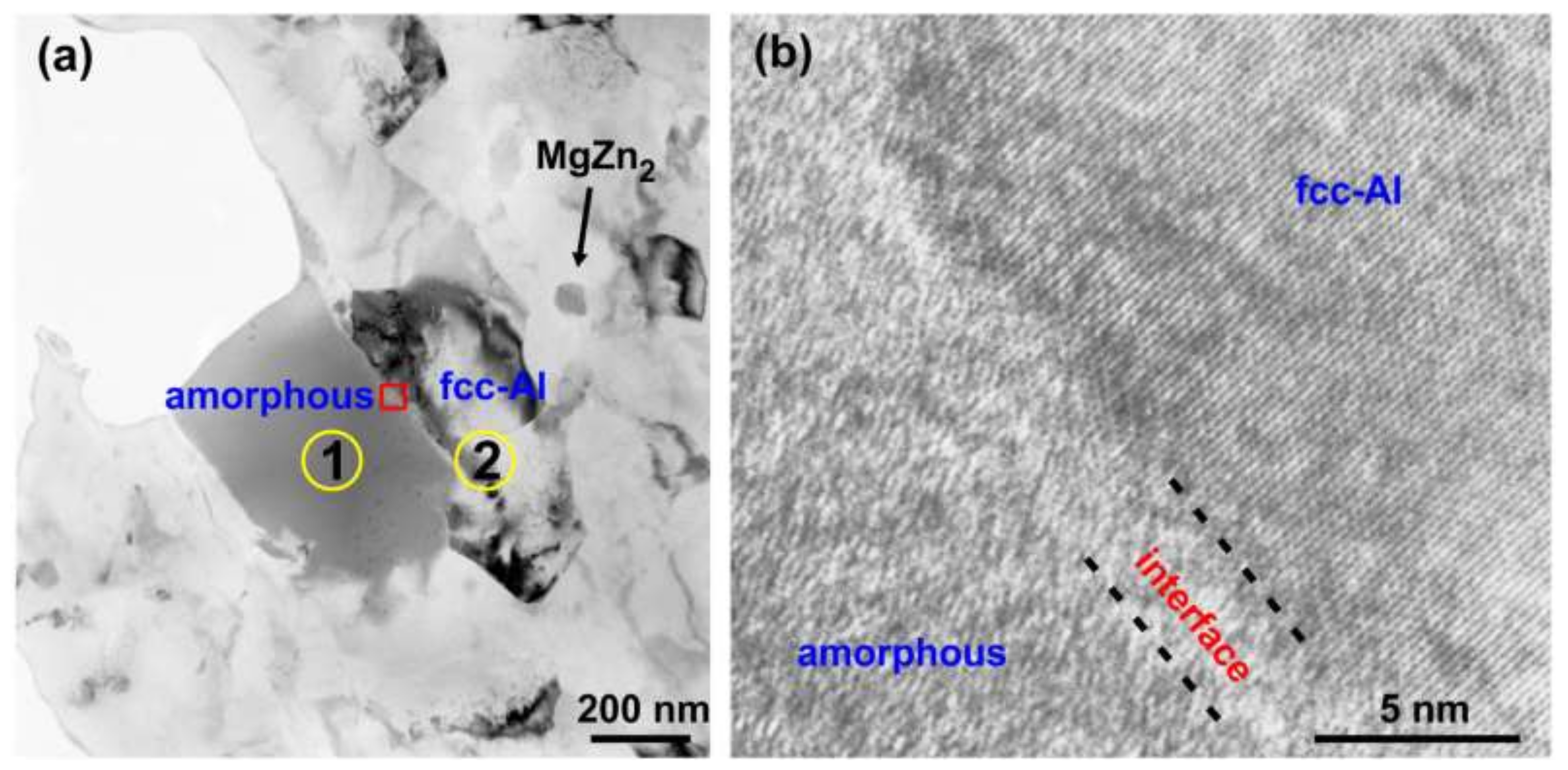

Spark plasma sintering (SPS) has been used to prepare metallic glass reinforced Al-composites [43]. Al7075 (Al-Zn-Mg-Cu alloy) reinforced with 15% volume fraction Zr65Cu18Ni7Al10 (at. %) metallic glass fibers (micro/nano-fibers and micron-sized particles produced by gas atomization) were produced by SPS method. The composites exhibited low porosity, uniform distribution of the reinforcement, and retention of the amorphous structure. The transmission electron microscopic (TEM) images showed the constituent phases, i.e., Al-matrix, amorphous reinforcement and MgZn2 precipitates (Figure 17a). Good bonding between the glassy reinforcement and the Al-matrix occurred due to the formation of ~3 nm thick inter-diffusion layer (Figure 17b).

Figure 17.

(a,b) TEM microstructure of the spark plasma sintered composite showing the interface between the metallic glass and the Al matrix [43]. (Open Access).

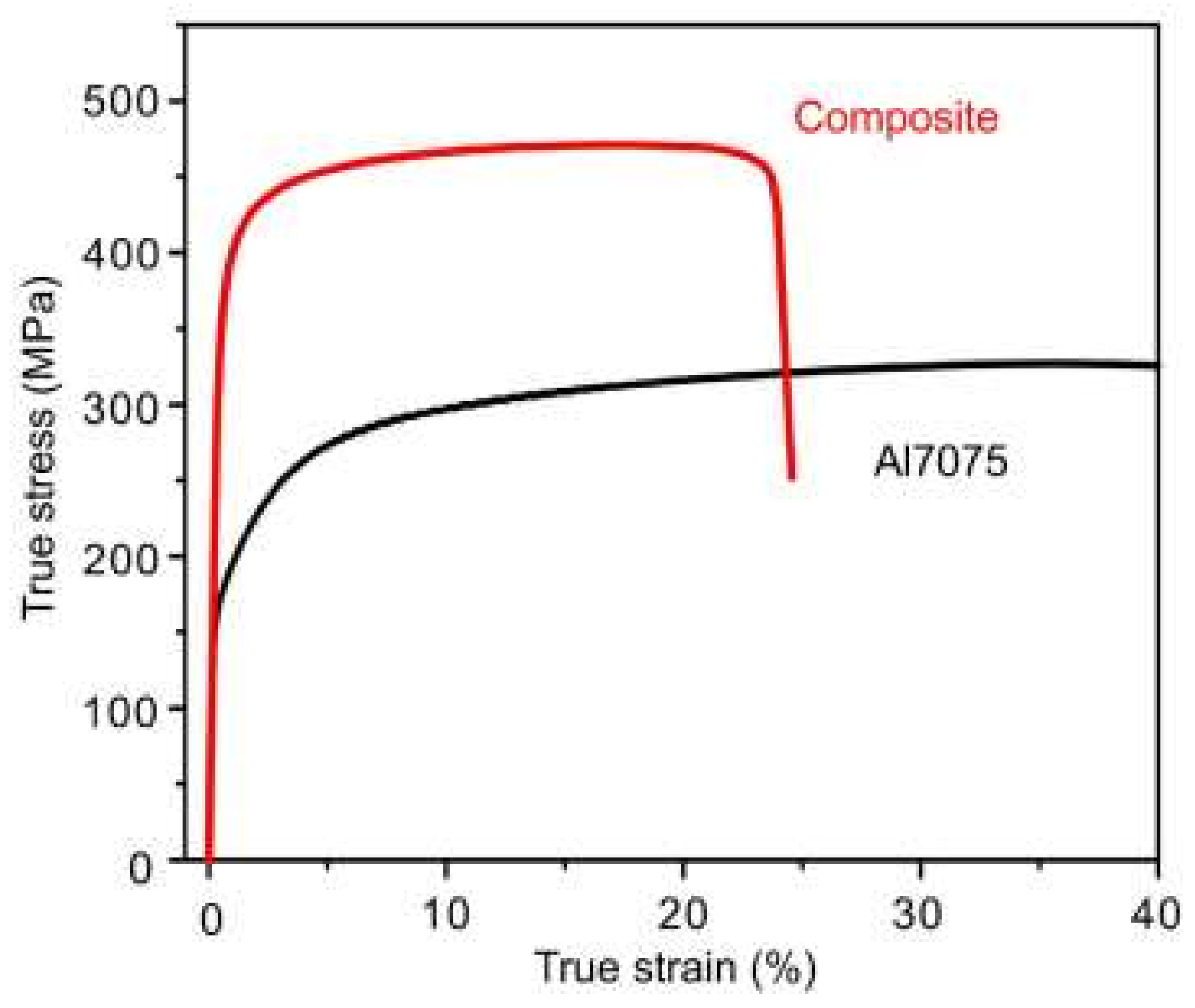

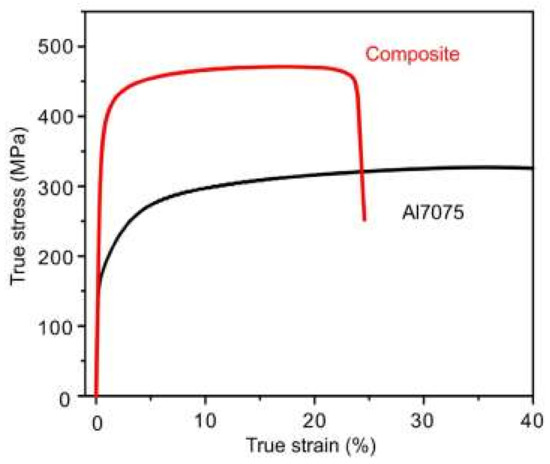

It was observed that the addition of metallic glass reinforcements in the Al-matrix improved the compressive response of the composites, with ~120% increase in compressive yield when compared to the unreinforced matrix (Figure 18). It was identified that the metallic glassy reinforcement impeded plastic deformation by blunting the crack and acted as crack arresters, thereby retarding crack propagation [43].

Figure 18.

Compressive stress–strain curves of 15% volume fraction Zr based glassy fiber reinforced Al7075 composite made by spark plasma sintering. The behavior is compared with that of the unreinforced Al7075 alloy [43]. (Open Access).

3.6. Effect of Processing Method on the Composite Strength Properties

From the investigated mechanical property data it can be observed that the metallic glass reinforced composites exhibit better strength properties when compared to their unreinforced matrix material. Further, the percentage increment in strength properties in the composites seem to depend on the processing method. To understand the effect of processing method on the strength (compressive strength) properties of the composites, comparative strength values in terms of normalized strength (strength ratio, i.e., ratio of the composite strength to that of the unreinforced alloy) are determined from [18,20,21,29,30,31,34,35,36,43] and are listed in Table 1. The values are of the composites with the highest volume fraction.

Table 1.

Comparison of compressive properties (in terms of normalized strength) of amorphous alloy/metallic glass reinforced light-metal composites produced by various methods [18,20,21,29,30,31,34,35,36,43].

From the table, it can be seen that high strength ratio values are observed in the composites made by rapid sintering processes. The composites produced by high frequency induction sintering (HFIS) process showed the highest values of strength ratio when compared to those produced by rest of the methods. High temperatures, pressures, and vacuum/inert gas atmosphere involved during the HFIS process contribute towards better compaction and sintering, eventually giving rise to composites with excellent properties. Among the materials developed by HFIS method, the composite with Fe-based glassy particles showed the highest strength ratio value. This could be due to the enhanced thermal stability of Fe-based glassy particle when compared to the Cu and Zr-based glassy particles [29,30,31], which in turn enhances mechanical properties. Spark plasma sintering and bi-directional microwave sintering, both being rapid sintering processes, also give rise to composites with superior performance. The dimensions of the composites prepared by bi-directional microwave sintering were large enough for the composites to be hot-extruded into rods, such that tension, fatigue and damping properties of the developed composites could be evaluated. These results are the first of their kind and are reported in [34,35,36].

The high strength properties obtained in conventional metal matrix composites, is usually due to the high load bearing capacity of the ceramic reinforcement particles (i.e., inherent high strength of the ceramic reinforcement that can effectively bear the load transferred from the matrix to particles) [44]. On similar lines, the load bearing effect occurs when amorphous particles/metallic glass particles are incorporated as reinforcement in light metal matrices. The amorphous reinforcements have inherent high strength (e.g., the compressive strength of glassy particles are usually >2 GPa), that eventually results in higher composite strength properties. To note, rapid sintering is essential to achieve improved strengthening effect for light metal composites reinforced with amorphous alloy/metallic glass reinforcements. The rapid sintering process (i) minimizes the interaction time with the matrix; (ii) reduces porosity/defects; and (iii) retains the amorphous structure of the reinforcement, thus resulting in an efficient load bearing capacity by the high strength amorphous alloy/metallic glass reinforcements.

In addition to the load bearing capacity, the reinforcements also contribute towards the strengthening of the matrix by various means. Some of the matrix strengthening mechanisms that manifest upon the incorporation of amorphous reinforcement particles include [44,45,46,47,48,49,50]:

- (i)

- Hall–Petch effect: grain boundary strengthening due to fine grain size, which increases the yield strength due to the piling up of dislocations at grain boundaries;

- (ii)

- Orowan strengthening: dislocation bowing that occurs due to the obstruction for dislocation motion owing to its interaction with strong reinforcement particles (amorphous particles have very high hardness, strength and large elastic strain limit);

- (iii)

- Enhanced dislocation density: increase in the dislocation density due to thermal mismatch. The difference in the coefficients of thermal expansion (CTE) between the matrix and reinforcing glassy particles can cause residual plastic strain in the matrix around the particles, resulting in enhanced dislocation density strengthening effect, and (iv) solid-solution strengthening.

4. Summary

Synthesis, microstructure, and mechanical properties of novel light metal composites with amorphous alloy/metallic glass reinforcements were reviewed. The summary from the current review is given below:

- Rapid sintering techniques are more efficient to produce high performing composites, as these methods can (i) prevent devitrification of the reinforcement and (ii) eliminate undesired interfacial reactions. High frequency induction sintering, bidirectional microwave sintering and spark plasma sintering are the rapid sintering methods used to synthesize these composites.

- Amorphous/metallic glass particles effectively bear the load transferred by the matrix due to their inherent high strength. The Hall–Petch effect, Orowon strengthening, solid solution strengthening and enhanced dislocation density due to thermal mismatch are the matrix strengthening mechanisms brought forth by amorphous/metallic glass particle reinforcement.

- Amorphous metallic glass particles are promising as reinforcement materials for light metal matrices, by the incorporation of which composites with superior performance can be realized. It is noteworthy that the discussed composites processing methods have their own unique advantages; and the metallic glass reinforced light metal composites produced by these methods can effectively replace conventional ceramic reinforced light metal composites.

Author Contributions

All authors contributed to the paper. J.S. acquired and interpreted the data. Both J.S. and A.S. provided the analysis for manuscript preparation. M.G. designed the scope of the paper. All authors discussed the conclusions and reviewed the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mortensen, A.; Llorca, J. Metal Matrix Composites. Ann. Rev. Mater. Res. 2010, 40, 243–270. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Alanemea, K.K.; Chown, L.H. Aluminum Matrix Hybrid Composites: A Review of Reinforcement Philosophies; Mechanical, Corrosion and Tribological Characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef]

- Gupta, M.; Sharon, N.M.L. Magnesium, Magnesium Alloys, and Magnesium Composites; John Wiley & Sons: Singapore, 2011. [Google Scholar]

- Huang, L.; Geng, L. Discontinuously Reinforced Titanium Matrix Composites: Microstructure, Design and Property Optimization; Springer: Singapore, 2017. [Google Scholar]

- Bakshi, S.R.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites—A review. Int. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Hassan, S.F.; Gupta, M. Development of ductile magnesium composite materials using titanium as reinforcement. J. Alloys Compd. 2002, 345, 246–251. [Google Scholar] [CrossRef]

- Wong, W.L.E.; Gupta, M. Enhancing thermal stability, modulus and ductility of magnesium using molybdenum as reinforcement. Adv. Eng. Mater. 2005, 7, 250–256. [Google Scholar] [CrossRef]

- Shanthi, M.; Jayaramanavar, P.; Vyas, V.; Seenivasan, D.V.S.; Gupta, M. Effect of niobium particulate addition on the microstructure and mechanical properties of pure magnesium. J. Alloys Compd. 2012, 513, 202–207. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Loh, Z.; Sankaranarayanan, S.; Hamouda, A.M.S.; Gupta, M. Microstructure and Mechanical Properties of Mg-5Nb Metal-Metal Composite Reinforced with Nano SiC Ceramic Particles. Metals 2012, 2, 178–194. [Google Scholar]

- Tian, L.; Russell, A.; Riedemann, T.; Mueller, S.; Anderson, I. A deformation-processed Al-matrix/Ca-nanofilamentary composite with low density, high strength, and high conductivity. Mater. Sci. Eng. A 2017, 690, 348–354. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Monteiro, W.A. (Ed.) Light Metal Alloys Applications; InTech Open: London, UK, 2014. [Google Scholar]

- Janaki Ram, G.D.; Robinson, C.; Yang, Y.; Stucker, B.E. Use of ultrasonic consolidation for fabrication of multi-material structures. Rapid Prototyp. J. 2007, 13, 226–235. [Google Scholar] [CrossRef]

- Chen, M.A. Brief Overview of Bulk Metallic Glasses. Nat. Pub. Group Asia Mater. 2011, 3, 82–90. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Inoue, A. Bulk Metallic Glasses; CRC Press, Taylor-Francis Group: Boca Raton, FL, USA, 2011. [Google Scholar]

- Basu, J.; Ranganathan, S. Bulk Metallic Glasses: A New Class of Engineering Materials. Sadhana 2003, 28, 783–798. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Gupta, M. Metallic Amorphous Alloy Reinforcements in Light Metal Matrices; Springer Briefs in Materials; Springer: New York, NY, USA, 2015. [Google Scholar]

- Lee, M.; Kim, J.-H.; Park, J.; Kim, J.; Kim, W.; Kim, D. Fabrication of Ni-Nb-Ta metallic glass reinforced Al-based alloy matrix composites by infiltration casting process. Scr. Mater. 2004, 50, 1367–1371. [Google Scholar] [CrossRef]

- Scudino, S.; Ali, F.; Surreddi, K.; Prashanth, K.G.; Sakaliyska, M.; Eckert, J. Al-based metal matrix composites reinforced with nanocrystalline Al-Ti-Ni particles. J. Phys. Conf. Ser. 2010, 240, IOP1–IOP4. [Google Scholar] [CrossRef]

- Scudino, S.; Liu, G.; Prashanth, K.; Bartusch, B.; Surreddi, K.; Murty, B.; Eckert, J. Mechanical properties of Al-based metal matrix composites reinforced with Zr-based glassy particles produced by powder metallurgy. Acta Mater. 2009, 57, 2029–2039. [Google Scholar] [CrossRef]

- Yu, P.; Kim, K.B.; Das, J.; Baier, F.; Xu, W.; Eckert, J. Fabrication and mechanical properties of Ni–Nb metallic glass particle-reinforced Al-based metal matrix composite. Scr. Mater. 2006, 54, 1445–1450. [Google Scholar] [CrossRef]

- Khalil, K.A.; Almajid, A.A. Effect of high-frequency induction heat sintering conditions on the microstructure and mechanical properties of nanostructured magnesium/hydroxyapatite nanocomposites. Mater. Des. 2012, 36, 58–68. [Google Scholar] [CrossRef]

- Gupta, M.; Eugene, W.W.L. Microwaves and Metals; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Tun, K.S.; Gupta, M. Development of magnesium/(yttria+nickel) hybrid nanocomposites using hybrid microwave sintering: Microstructure and tensile properties. J. Alloys Compd. 2009, 487, 76–82. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials-development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Weglowski, M.S.; Pietras, A. Friction stir processing-Analysis of the process. Arch. Metall. Mater. 2011, 56, 779–788. [Google Scholar] [CrossRef]

- Mahoney, M.W.; Lynch, S.P. Friction-Stir Processing; Report; Rockwell Sci. Company LLC: Thousand Oaks, CA, USA, 2016. [Google Scholar]

- Saheb, N.; Iqbal, Z.; Khalil, A.; Hakeem, A.S.; Al Aqeeli, N.; Al-Qutub, T.L.A.; Kirchner, R. Spark Plasma Sintering of Metals and Metal Matrix Nanocomposites: A Review. J. Nanomater. 2012, 2012, 983470. [Google Scholar] [CrossRef]

- Dudina, D.V.; Georgarakis, K.; Li, Y.; Aljerf, M.; LeMoulec, A.; Yavari, A.R.; Inoue, A. A magnesium alloy matrix composite reinforced with metallic glass. Compos. Sci. Technol. 2009, 69, 2734–2736. [Google Scholar] [CrossRef]

- Dudina, D.V.; Georgarakis, K.; Aljerf, M.; Li, Y.; Braccini, M.; Yavari, A.R.; Inoue, A. Cu-based metallic glass particle additions to significantly improve overall compressive properties of an Al alloy. Compos. Part A 2010, 41, 1551–1557. [Google Scholar] [CrossRef]

- Aljerf, M.; Georgarakis, K.; Louzguine-Luzgin, D.; Mulec, A.L.; Inoue, A.; Yavari, A.R. Strong and light metal matrix composites with metallic glass particulate reinforcement. Mater. Sci. Eng. A 2012, 532, 325–330. [Google Scholar] [CrossRef]

- Li, S.; Xie, G.Q.; Louzguine-Luzgin, D.V.; Sato, M.; Inoue, A. Microwave-Induced Sintering of Cu-Based Metallic Glass Matrix Composites in a Single-Mode 915-MHz Applicator. Metall. Mater. Trans. A 2011, 42, 1463–1467. [Google Scholar] [CrossRef]

- Li, S.; Louzguine-Luzgin, D.V.; Xie, G.; Sato, M.; Inoue, A. Development of novel metallic glass/polymer composite materials by microwave heating in a separated H-field. Mater. Lett. 2010, 64, 235–238. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Gupta, S.; Sankaranarayanan, S.; Sahu, S.; Gupta, M. Structural and mechanical properties of Ni60Nb40 amorphous alloy particle reinforced Al-based composites produced by microwave assisted rapid sintering. Mater. Sci. Eng. A 2013, 581, 119–127. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Sahu, S.; Sankaranarayanan, S.; Gupta, S.; Gupta, M. Development of novel Mg-Ni60Nb40 amorphous particle reinforced composites with enhanced hardness and compressive response. Mater. Des. 2014, 53, 849–855. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Hemanth Shankar, V.; Jayalakshmi, S.; Bau, N.Q.; Gupta, M. Development of high performance magnesium composites using Ni50Ti50 metallic glass reinforcement and microwave sintering approach. J. Alloys Compd. 2015, 627, 192–199. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Agrawal, N.; Jayalakshmi, S.; Bau, N.Q.; Gupta, M. Synthesis and characterization of novel magnesium materials containing copper-titanium based (Cu50Ti50) amorphous alloy particles. Magnesium Technology. In Proceedings of the TMS Annual Meeting, Orlando, FL, USA, 15–19 March 2015. [Google Scholar]

- Bau, N.Q.; Nai, M.L.S.; Sankaranarayanan, S.; Jayalakshmi, S.; Wong, W.L.E.; Gupta, M. Microstructure and damping characteristics of Mg and its composites containing metastable Al85Ti15 particle. J Compos. Mater. 2016, 50, 2565–2573. [Google Scholar]

- Nafar Dastgerdi, J.; Marquis, G.; Sankaranarayanan, S.; Gupta, M. Fatigue crack growth behavior of amorphous particulate reinforced composites. Compos. Struct. 2016, 15, 782–790. [Google Scholar] [CrossRef]

- Khoramkhorshid, S.; Alizadeh, M.; Taghvaei, A.H.; Scudino, S. Microstructure and mechanical properties of Al-based metal matrix composites reinforced with Al84Gd6Ni7Co3 glassy particles produced by accumulative roll bonding. Mater. Des. 2016, 90, 137–144. [Google Scholar] [CrossRef]

- Anghelus, A.; Avettand-Fènoël, M.N.; Cordier, C.; Taillard, R. Microstructural evolution of aluminum/Al-Ni–Sm glass forming alloy laminates obtained by controlled accumulative roll bonding. J. Alloys Compd. 2015, 631, 209–218. [Google Scholar] [CrossRef]

- Fujii, H.; Sun, Y.F.; Inada, K.; Ji, Y.S.; Yokoyama, Y.; Kimura, H.; Inoue, A. Fabrication of Fe-Based metallic glass particle reinforced Al-based composite materials by friction stir processing. Mater. Trans. 2011, 52, 1634–1640. [Google Scholar] [CrossRef]

- Wang, Z.; Georgarakis, K.; Nakayama, K.S.; Li, Y.; Tsarkov, A.A.; Xie, G.; Dudina, D.; Louzguine-Luzgin, D.V.; Yavari, A.R. Microstructure and mechanical behavior metallic glass fiber reinforced Al alloy matrix composites. Nat. Sci. Rep. 2016, 6, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Kainer, K.U. Metal Matrix Composites; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Ceschini, L.; Dahle, A.; Gupta, M.; Jarfors, A.; Jayalakshmi, S.; Morri, A.; Rotundo, F.; Toschi, S.; Arvind Singh, R. Aluminum and Magnesium Metal Matrix Nanocomposites; Springer: Singapore, 2016. [Google Scholar]

- Arsenault, R.J.; Shi, N. Dislocation generation due to differences between the coefficients of thermal expansion. Mater. Sci. Eng. 1986, 81, 75–87. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect. Mater. Sci. Eng. A 2012, 531, 112–118. [Google Scholar] [CrossRef]

- So, K.P.; Liu, X.; Kushima, A.; Park, J.G.; Kim, H.S.; Ogata, S.; Lee, Y.H.; Li, J. Ton-scale metal–carbon nanotube composite: The mechanism of strengthening while retaining tensile ductility. Extreme Mech. Lett. 2016, 8, 245–250. [Google Scholar] [CrossRef]

- Tian, L.; Russell, A.; Anderson, I. A dislocation-based, strain-gradient-plasticity strengthening model for deformation processed metal-metal composites. J. Mater. Sci. 2014, 49, 2787–2794. [Google Scholar] [CrossRef]

- Rupert, T.J.; Trenkle, J.C.; Schuh, C.S. Solid solution strengthening Enhanced solid solution effects on the strength of nanocrystalline alloys. Acta Mater. 2011, 59, 1619–1631. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).