Development of a Resilient 3-D Printer for Humanitarian Crisis Response

Abstract

:1. Introduction

2. Materials and Methods

2.1. Required Capabilities of a Humanitarian 3-D Printer

2.1.1. The 3-D Printer Must Be Able to Make Useful Parts

2.1.2. The 3-D Printer Must Be Able to Function Independent of Infrastructure

2.1.3. The 3-D Printer Must Be Able to Be Easily Transported

2.1.4. The 3-D Printer Must Be Safe and Easy to Use

2.1.5. The 3-D Printer Must Be Able to Withstand Harsh Environments

2.1.6. The 3-D Printer Must Be Able to Be Procured for Minimal Cost

2.2. The Design of Humanitarian 3-D Printer

3. Results and Discussion

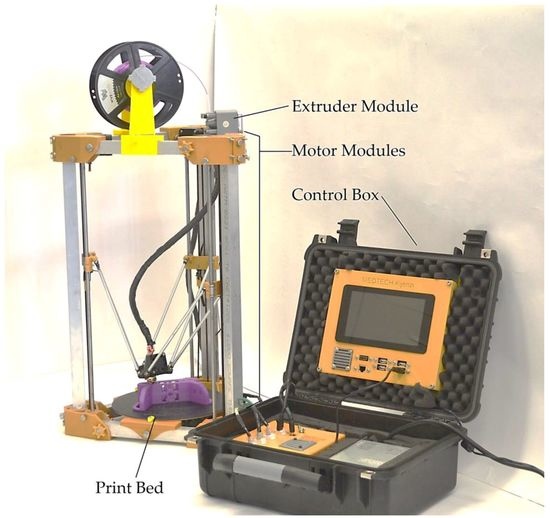

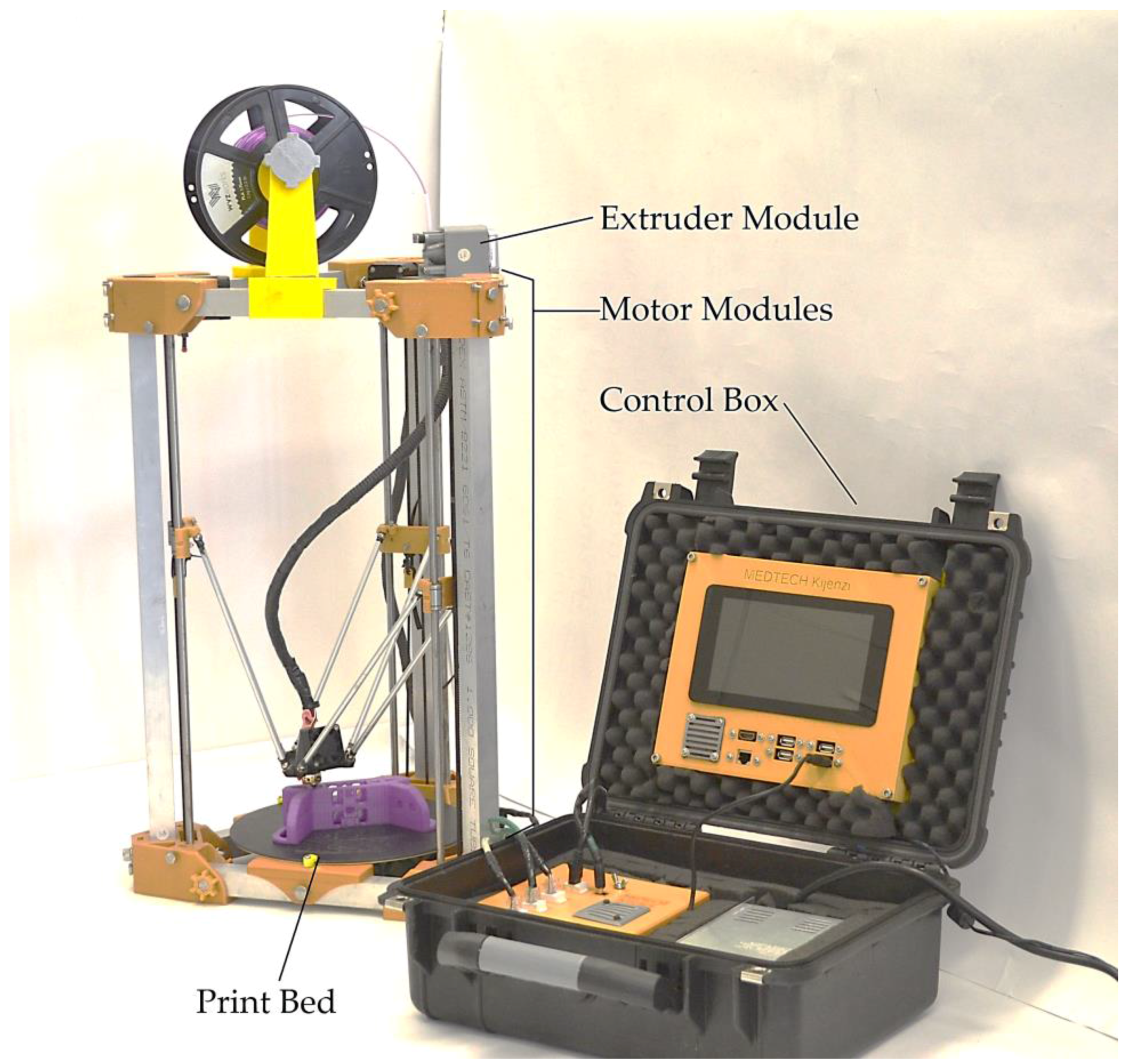

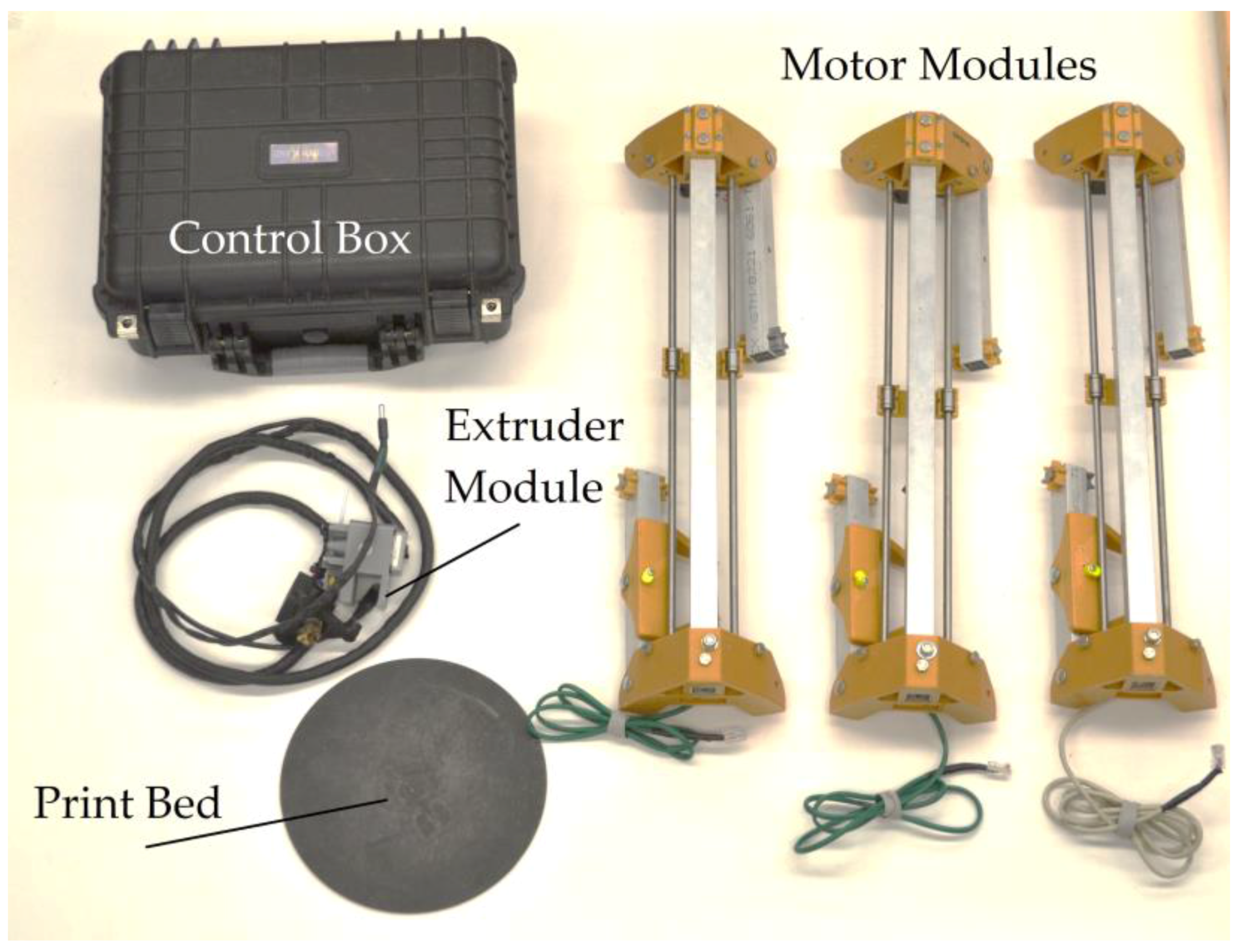

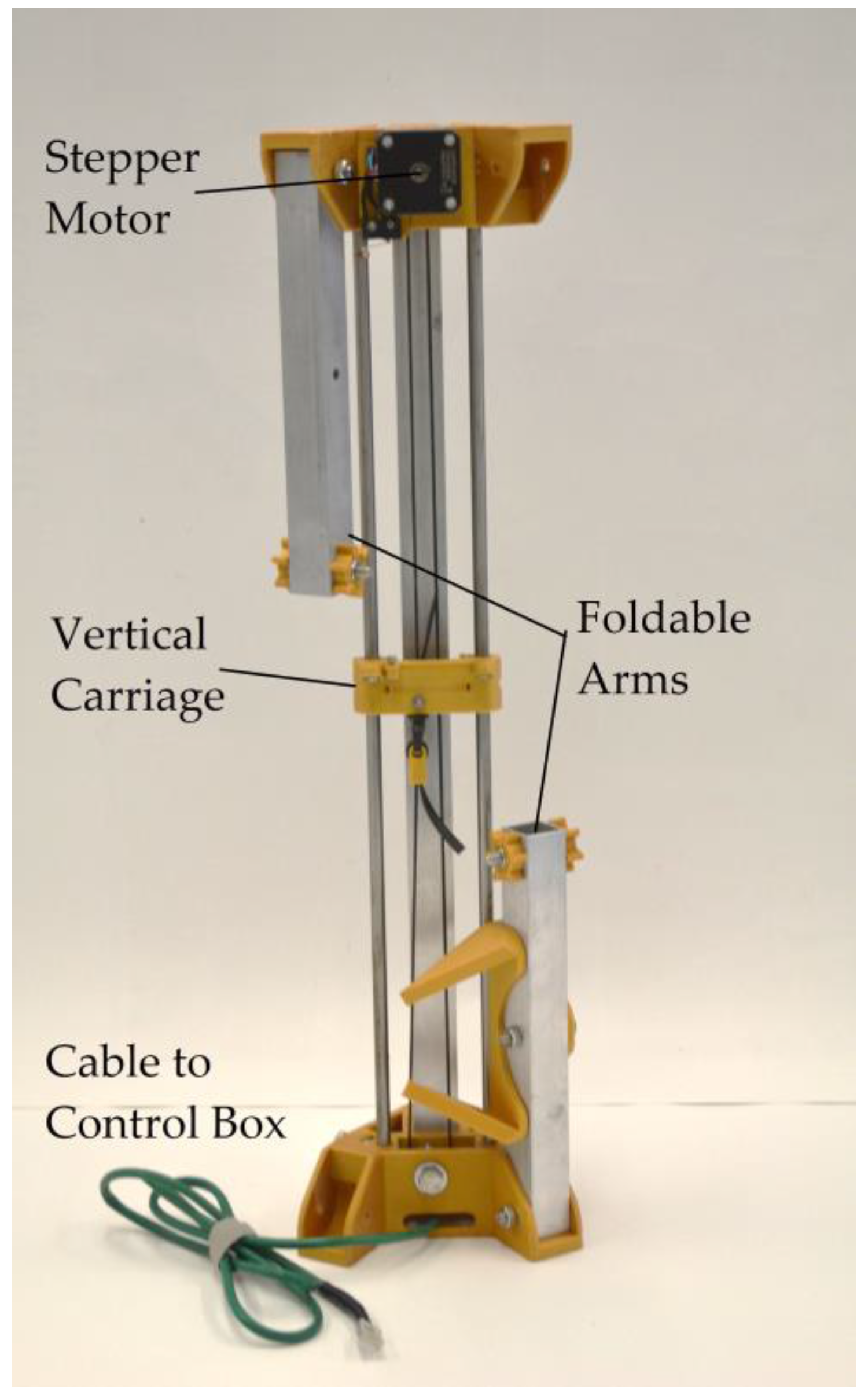

3.1. Design Elements

3.1.1. Fused Filament Fabrication (FFF)

3.1.2. Open-Source RepRap Design

3.1.3. Modular Design

3.1.4. Separable Frame

3.1.5. Protected Electronics

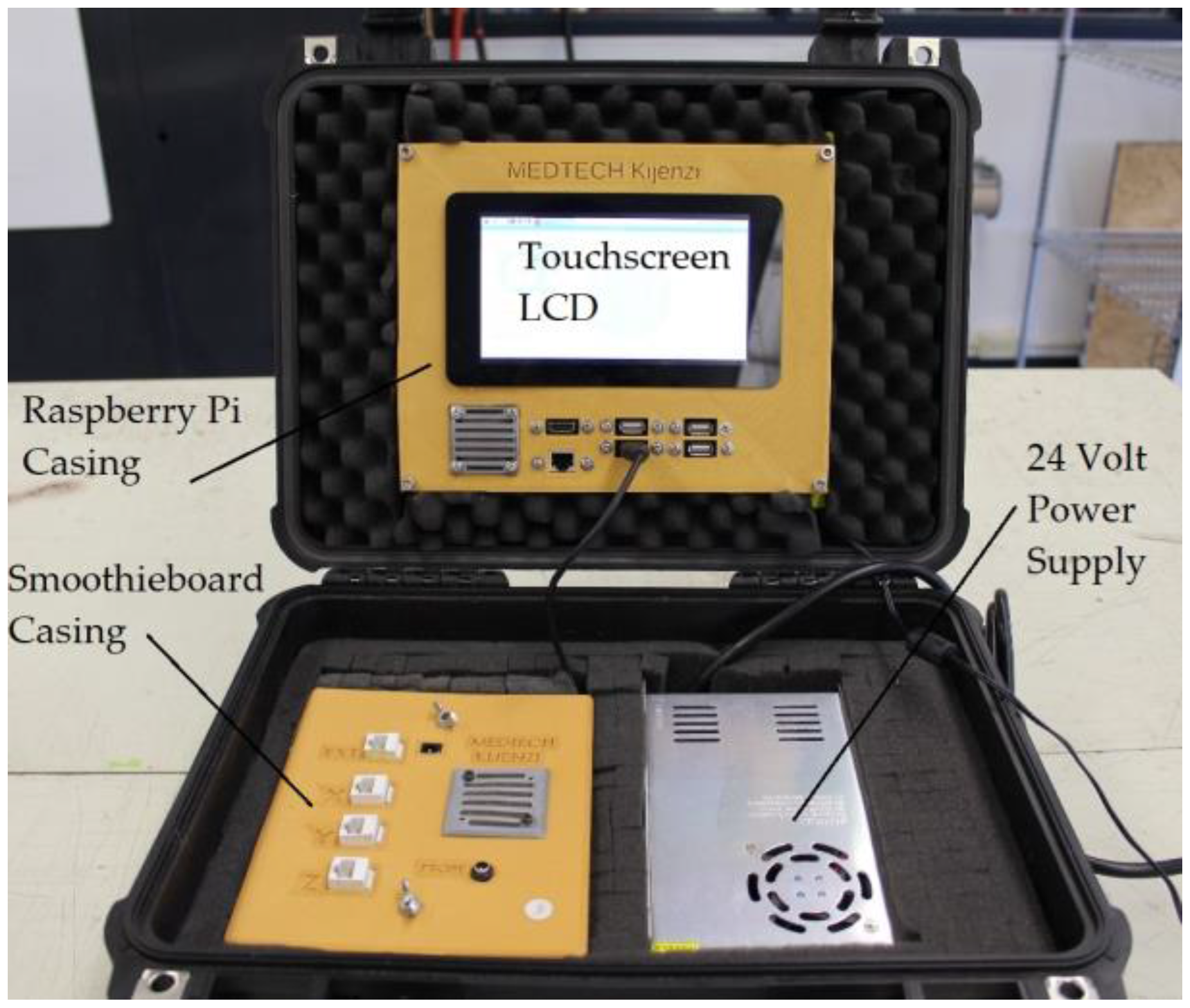

3.1.6. On-Board Computer System

3.1.7. Flexible Power Supply

3.1.8. Climate Control Mechanisms

3.2. Evaluation of the Kijenzi 3-D Printer

3.2.1. Kijenzi 3-D Printer’s Ability to Make Useful Parts

3.2.2. Kijenzi 3-D Printer’s Ability to Function Independently of Infrastructure

3.2.3. Kijenzi 3-D Printer’s Ability to Be Easily Transported

3.2.4. Kijenzi 3-D Printer’s Ability to Be Easily Used

3.2.5. Kijenzi 3-D Printer’s Ability to Withstand Harsh Environments

3.2.6. Kijenzi 3-D Printer’s Ability to Be Procured for Minimal Cost

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Development Initiatives. Global Humanitarian Assistance Report 2017; Development Initiatives: Bristol, UK, 2017. [Google Scholar]

- Loy, J.; Tatham, P.; Healey, R.; Tapper, C.L. 3D Printing Meets Humanitarian Design Research: Creative Technologies in Remote Regions. Creative Technol. Multidiscip. Appl. 2016, 54–75. [Google Scholar] [CrossRef]

- Sniderman, B.; Baum, P.; Rajan, V. 3D Opportunity for Life: Additive Manufacturing Takes Humanitarian Action. Deloitte Rev. Available online: https://www2.deloitte.com/insights/us/en/deloitte-review/issue-19/3d-printing-for-humanitarian-action.html (accessed on 12 October 2017).

- De la Torre, N.; Espinosa, M.M.; Domínguez, M. Rapid Prototyping in Humanitarian Aid to Manufacture Last Mile Vehicles Spare Parts: An Implementation Plan. Hum. Factors Ergon. Manuf. Serv. Ind. 2016, 26, 533–540. [Google Scholar] [CrossRef]

- James, E.; Gilman, D. Shrinking the Supply Chain: Hyperlocal Manufacturing and 3D Printing in Humanitarian Response; OCHA Policy and Studies Series; OCHA: New York, NY, USA, 2015; Volume 14. [Google Scholar]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper-Maximizing Customizability by Breeding the Means of Production. In Proceedings of the World Conference on Mass Customization and Personalization, Cambridge, MA, USA, 7–10 October 2007. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap-the Replicating Rapid Prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Pearce, J.M.; Blair, C.M.; Laciak, K.J.; Andrews, R.; Nosrat, A.; Zelenika-Zovko, I. 3-D printing of open source appropriate technologies for self-directed sustainable development. J. Sustain. Dev. 2010, 3, 17–29. [Google Scholar] [CrossRef]

- Tatham, P.; Loy, J.; Peretti, U. Three Dimensional Printing—A Key Tool for the Humanitarian Logistician? J. Humanit. Logist. Supply Chain Manag. 2015, 5, 188–208. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Petersen, E.E.; Pearce, J. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Gwamuri, J.; Wittbrodt, B.; Anzalone, N.; Pearce, J. Reversing the Trend of Large Scale and Centralization in Manufacturing: The Case of Distributed Manufacturing of Customizable 3-D-Printable Self-Adjustable Glasses. Chall. Sustain. 2014, 2, 30–40. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Laureto, J.; Tymrak, B.; Pearce, J. Distributed Manufacturing with 3-D Printing: A Case Study of Recreational Vehicle Solar Photovoltaic Mounting Systems. J. Frugal Innov. 2015, 1, 1–7. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Savonen, B.L.; Gershenson, J.K.; Pearce, J.M. Viability of distributed manufacturing of bicycle components with 3-D printing: CEN standardized polylactic acid pedal testing. J. Humanit. Eng. 2017, 5, 8–17. [Google Scholar]

- James, E.; James, L. 3D Printing Humanitarian Supplies in the Field. Humanit. Exch. 2016, 66, 43–45. [Google Scholar]

- Franco, D.; Khan, K.Y.; Gauchia, L.; Pearce, J.M. High-Efficiency Solar-Powered 3-D Printers for Sustainable Development. Machines 2016, 4, 3. [Google Scholar] [CrossRef]

- King, D.L.; Babasola, A. Mobile open-source solar-powered 3-D printers for distributed manufacturing in off-grid communities. Chall. Sustain. 2014, 2, 18–27. [Google Scholar] [CrossRef]

- International Federation of Red Cross and Red Crescent Societies. Emergency Items Catalogue. Available online: http://itemscatalogue.redcross.int/ (accessed on 4 February 2018).

- Wong, J.Y.; Pfahnl, A.C. 3D Printing of Surgical Instruments for Long-Duration Space missions. Aviat. Space Environ. Med. 2014, 85, 758–763. [Google Scholar] [CrossRef] [PubMed]

- McBride, A. 3D Printing Takes Emergency Response to Another Level. Policy and Practice Blog, 2014. Available online: https://policy-practice.oxfam.org.uk/blog/2014/05/3d-printing-takes-emergency-response-to-another-level (accessed on 4 February 2018).

- Ott, D. Can Digital Fabrication Revolutionise Humanitarian Action? ICRC Blog, 2016. Available online: http://blogs.icrc.org/gphi2/2016/02/22/can-digital-fabrication-revolutionize-humanitarian-action/ (accessed on 4 February 2018).

- Scott, C. ICRC Enable Makeathon Endeavors to Help People with Disabilities in Remote Areas through 3D Printing and other Technologies. 3D Print, 2015. Available online: https://3dprint.com/tag/icrc/ (accessed on 4 February 2018).

- Liaw, C.Y.; Guvendiren, M. Current and Emerging Applications of 3D Printing in Medicine. Biofabrication 2017, 9, 024102. [Google Scholar] [CrossRef] [PubMed]

- Gregory, M.; Hameedaldeen, S.A.; Intumu, L.M.; Spakousky, J.J.; Toms, J.B.; Steenhuis, H.J. 3D Printing and Disaster Shelter Costs. In Proceedings of the 2016 Portland International Conference for Management of Engineering and Technology, Honolulu, HI, USA, 4–8 September 2016; pp. 712–720. [Google Scholar]

- Angela, W.Y.; Khan, M. On-Demand Three-Dimensional Printing of Surgical Supplies in Conflict Zones. J. Trauma Acute Care Surg. 2015, 78, 201–203. [Google Scholar]

- Michaels, R.E.; Pearce, J.M. 3-D printing open-source click-MUAC bands for identification of malnutrition. Public Health Nutr. 2017, 20, 2063–2066. [Google Scholar] [CrossRef] [PubMed]

- Field Ready. Available online: http://www.fieldready.org/ (accessed on 1 February 2018).

- Refugee Open Ware. Available online: http://www.row3d.org/ (accessed on 1 February 2018).

- Saripalle, S.; Maker, H.; Bush, A.; Lundman, N. 3D Printing for Disaster Preparedness: Making Life-Saving Supplies on-Site, on-Demand, on-Time. In Proceedings of the IEEE Global Humanitarian Technology Conference, Seattle, WA, USA, 13–16 October 2016; pp. 205–208. [Google Scholar]

- James, E. Functional and Technical Specifications for Field Grade 3D Printers Intended for Use in Humanitarian Contexts. Unpublished work. 2016. [Google Scholar]

- Kovács, G.; Tatham, P. Responding to Disruptions in the Supply Network-From Dormant to Action. J. Bus. Logist. 2009, 30, 215–229. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Ramadurai, K.W. 3D Printing of Medical Devices and Supplies. In 3D Printing and Bio-Based Materials in Global Health; Springer: Berlin, Germany, 2017; pp. 63–93. [Google Scholar]

- Meisel, N.A.; Williams, C.B.; Ellis, K.P.; Taylor, D. Decision Support for Additive Manufacturing Deployment in Remote or Austere Environments. J. Manuf. Technol. Manag. 2016, 27, 898–914. [Google Scholar] [CrossRef]

- Wong, J.Y. Applications of 3D Printing in Austere Environments. Aerosp. Med. Hum. Perform. 2016, 87, 423–425. [Google Scholar] [CrossRef] [PubMed]

- Wong, J.Y. Ultra-Portable Solar-Powered 3D Printers for Onsite Manufacturing of Medical Resources. Aerosp. Med. Hum. Perform. 2015, 86, 830–834. [Google Scholar] [CrossRef] [PubMed]

- Wohlers Associates Inc. Wohlers Report 2016: 3D Printing and Additive Manufacturing State of the Industry Annual Worldwide Progress Report; Wohlers Associates Inc.: Fort Collins, CO, USA, 2016. [Google Scholar]

- Anzalone, G.C.; Wijnen, B.; Pearce, J.M. Multi-material additive and subtractive prosumer digital fabrication with a free and open-source convertible delta RepRap 3-D printer. Rapid Prototyp. J. 2015, 21, 506–519. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Additive Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef]

- Rundle, G. A Revolution in the Making; Simon and Schuster: New York, NY, USA, 2014. [Google Scholar]

- Open Science Framework. Available online: https://osf.io/pzxea/ (accessed on 12 February 2018).

- Cruz Sanchez, F.A.; Boudaoud, H.; Muller, L.; Camargo, M. Towards a standard experimental protocol for open source additive manufacturing: This paper proposes a benchmarking model for evaluating accuracy performance of 3D printers. Virtual Phys. Prototyp. 2014, 9, 151–167. [Google Scholar] [CrossRef]

- Raspbian Stretch. Available online: https://www.raspberrypi.org/downloads/raspbian/ (accessed on 26 February 2018).

- Sandvik, K.B.; Jacobsen, K.L.; McDonald, S.M. Do no harm: A taxonomy of the challenges of humanitarian experimentation. Int. Rev. Red Cross 2017, 1–26. [Google Scholar] [CrossRef]

- Ramalingam, B.; Scriven, K.; Foley, C. Innovations in International Humanitarian Action. In Proceedings of the ALNAP 8th Review of Humanitarian Action, London, UK, 13 July 2009. [Google Scholar]

- Betts, A.; Bloom, L. Humanitarian Innovation: The State of the Art; OCHA Policy and Studies Series; OCHA: New York, NY, USA, 2014; Volume 9. [Google Scholar]

- Cruz Sanchez, F.A.; Lanza, S.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. In Proceedings of the Annual International Solid Freeform Fabrication Symposium (ISSF), Austin, TX, USA, 10–12 August 2015; pp. 1591–1600. [Google Scholar]

- Cruz Sanchez, F.A.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical Properties of Specimens 3D Printed with Virgin and Recycled Polylactic Acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- Pakkanen, J.; Manfredi, D.; Minetola, P.; Iuliano, L. About the Use of Recycled or Biodegradable Filaments for Sustainability of 3D Printing. In Sustainable Design and Manufacturing; Smart Innovation, Systems and Technologies; Springer: Cham, Switzerland, 2017; pp. 776–785. [Google Scholar]

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Prototyp. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.-T.; Khalid, M.; Yang, T.C.-K.; Hung, S.-T.; Huang, C.-M. Physical Characterization and Pre-assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Mohan, M.; Das, A.; Johnson, M.D.; Badwal, P.S.; McLean, D.; Gibson, I. A low carbon footprint approach to the reconstitution of plastics into 3D-printer filament for enhanced waste reduction. KnE Eng. 2017, 2, 234–241. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Das, A.; Gomez-Kervin, E.; Wilson, D.; Gibson, I. EcoPrinting: Investigating the Use of 100% Recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing. Solid Freeform Fabrication 2017. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017; Available online: http://sffsymposium.engr.utexas.edu/sites/default/files/2017/Manuscripts/EcoprintingInvestigatingtheUseof100Recycle.pdf (accessed on 3 March 2018).

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Pringle, A.M.; Rudnicki, M.; Pearce, J. Wood Furniture Waste-Based Recycled 3-D Printing Filament. For. Prod. J. 2018. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Nuchitprasitchai, S.; Roggemann, M.; Pearce, J.M. Three Hundred and Sixty Degree Real-Time Monitoring of 3-D Printing Using Computer Analysis of Two Camera Views. J. Manuf. Mater. Process. 2017, 1, 2. [Google Scholar] [CrossRef]

- Gavein, L. Checked Baggage Allowances for Major Airlines: A simple Guide. Sky Scanner. Available online: https://www.skyscanner.net/news/tips/check-in-luggage-size-and-weight-restrictions/ (accessed on 4 February 2018).

- Hsieh, C.T. Investigation of Delta Robot 3D Printer for a Good Quality of Printing. Appl. Mech. Mater. 2017, 870, 164–169. [Google Scholar] [CrossRef]

- Celi, R.; Sempértegui, A.; Morocho, D.; Loza, D.; Alulema, D.; Proaño, M. Study, design and construction of a 3D printer implemented through a delta robot. In Proceedings of the 2015 CHILEAN Conference on Electrical, Electronics Engineering, Information and Communication Technologies (CHILECON), Santiago, Chile, 28–30 October 2015; pp. 717–722. [Google Scholar]

- Soriano Heras, E.; Blaya Haro, F.; de Agustín del Burgo, J.M.; Islán Marcos, M.E. Plate auto-level system for fused deposition modelling (FDM) 3D printers. Rapid Prototyp. J. 2017, 23, 401–413. [Google Scholar] [CrossRef]

- Wachlin, E.; Southerton, L. MOST Delta Autobed Leveling Appropedia. Available online: http://www.appropedia.org/MOST_Delta_Auto_Bed_Leveling (accessed on 5 February 2018).

- Johann; FSR (Force Sensing Resistor). Reprap.org. Available online: http://reprap.org/wiki/FSR (accessed on 5 February 2018).

- Rankin, T.M.; Giovinco, N.A.; Cucher, D.J.; Watts, G.; Hurwitz, B.; Armstrong, D.G. Three-dimensional printing surgical instruments: Are we there yet? J. Surg. Res. 2014, 189, 193–197. [Google Scholar] [CrossRef] [PubMed]

- 3D Hubs. 2018 3D Printer Guide. Available online: https://www.3dhubs.com/best-3d-printer-guide (accessed on 5 February 2018).

| Design Elements | ||||||||

|---|---|---|---|---|---|---|---|---|

| Desired Capabilities | Fused Filament Fabrication | Open-Source RepRap | Modular Design | Separable Frame | Protected Electronics | Flexible Power Supply | On-Board Computer System | Environmental Control |

| Make Useful Parts | X | X | X | X | ||||

| Function Independent of Infrastructure | X | X | X | |||||

| Easily Transported | X | X | ||||||

| Easily Used | X | X | X | |||||

| Withstand Harsh Environments | X | X | X | |||||

| Procured for Minimal Cost | X | X | X | |||||

| Modules | Quantity | Unit Cost ($/Unit) | Module Cost ($) |

|---|---|---|---|

| Alpha-Beta-Gamma | 3 | 49.25 | 147.74 |

| Extruder | 1 | 106.56 | 106.56 |

| Control Box | 1 | 383.13 | 383.13 |

| Print Bed | 1 | 138.86 | 138.86 |

| Kijenzi Deluxe | 776.28 | ||

| Removable Components | |||

| Internal Computer | −1 | 166.11 | −166.11 |

| Heated bed assembly | −1 | 88.86 | −88.86 |

| Kijenzi Basic | 521.32 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savonen, B.L.; Mahan, T.J.; Curtis, M.W.; Schreier, J.W.; Gershenson, J.K.; Pearce, J.M. Development of a Resilient 3-D Printer for Humanitarian Crisis Response. Technologies 2018, 6, 30. https://doi.org/10.3390/technologies6010030

Savonen BL, Mahan TJ, Curtis MW, Schreier JW, Gershenson JK, Pearce JM. Development of a Resilient 3-D Printer for Humanitarian Crisis Response. Technologies. 2018; 6(1):30. https://doi.org/10.3390/technologies6010030

Chicago/Turabian StyleSavonen, Benjamin L., Tobias J. Mahan, Maxwell W. Curtis, Jared W. Schreier, John K. Gershenson, and Joshua M. Pearce. 2018. "Development of a Resilient 3-D Printer for Humanitarian Crisis Response" Technologies 6, no. 1: 30. https://doi.org/10.3390/technologies6010030

APA StyleSavonen, B. L., Mahan, T. J., Curtis, M. W., Schreier, J. W., Gershenson, J. K., & Pearce, J. M. (2018). Development of a Resilient 3-D Printer for Humanitarian Crisis Response. Technologies, 6(1), 30. https://doi.org/10.3390/technologies6010030