Assessing Operator Wellbeing through Physiological Measurements in Real-Time—Towards Industrial Application †

Abstract

1. Introduction

- (I)

- Which physiological measurements can be used to assess operator wellbeing in real-time?

- (II)

- What risks and possibilities are connected to assessing operator wellbeing in real-time in industry?

2. Materials and Methods

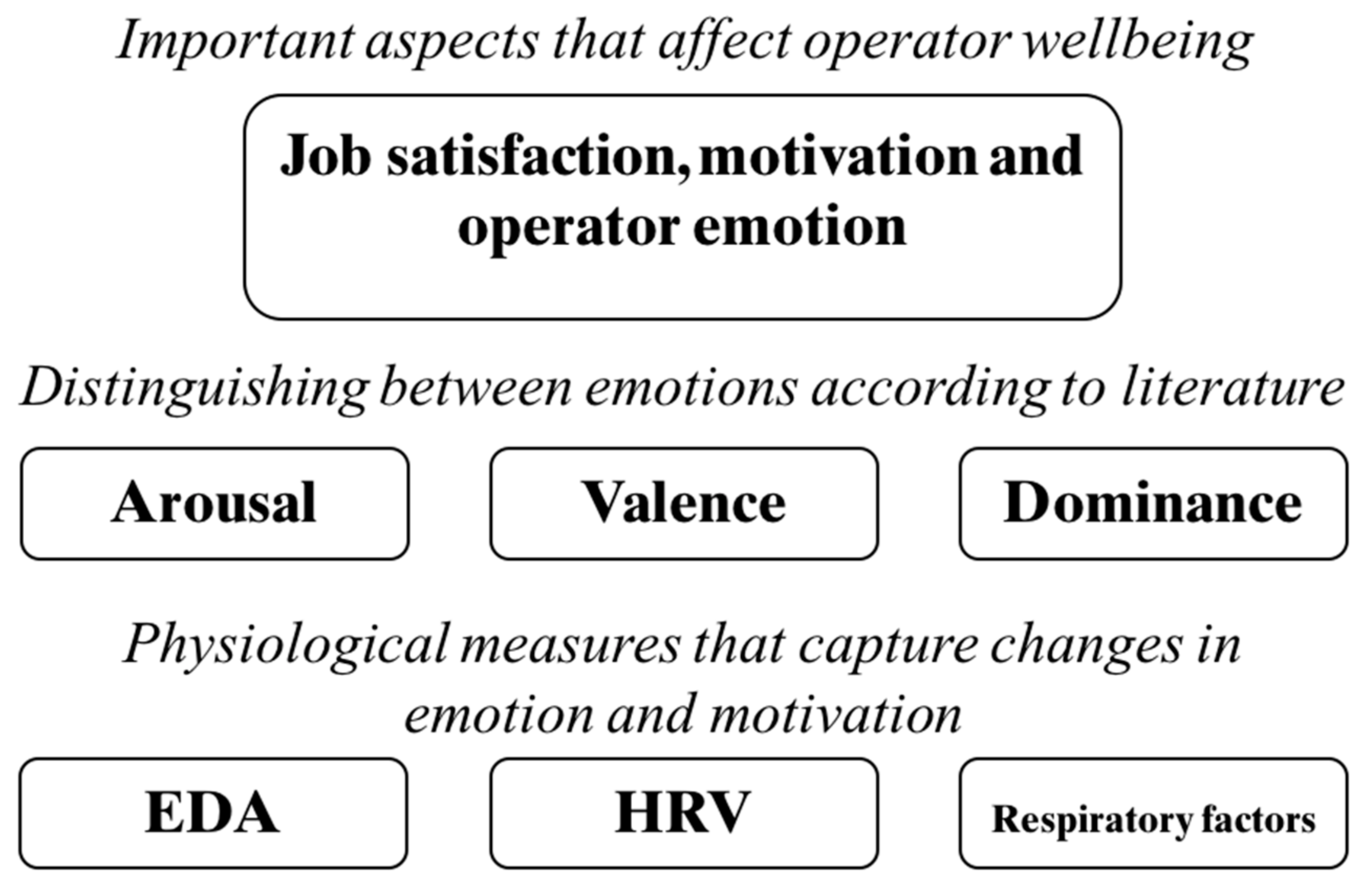

2.1. Literature Study: Identifying Physiological Measures

2.2. Devices Used to Assess Physiological Data

2.3. Laboratory Test Designs

2.4. Case Study Designs

2.5. Workshop on Risks and Possibilities with a Prototype Assessing Operator Wellbeing in Real-Time

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Whitmore, A.; Agarwal, A.; Li, D.X. The Internet of Things—A survey of topics and trends. Inf. Syst. Front. 2015, 17, 261–274. [Google Scholar] [CrossRef]

- Guler, S.D.; Gannon, M.; Sicchio, K. A Brief History of Wearables. In Crafting Wearables: Blending Technology with Fashion; Apress: Berkeley, CA, USA, 2016; pp. 3–10. [Google Scholar]

- Carpanzano, E.; Jovane, F. Advanced automation solutions for future adaptive factories. CIRP Ann. Manuf. Technol. 2007, 56, 435–438. [Google Scholar] [CrossRef]

- Vogel-Heuser, B.; Legat, C.; Folmer, J.; Schütz, D. An Assessment of the Potentials and Challenges in Future Approaches for Automation Software. In Industrial Agents, Emerging Applications of Software Agents in Industry; Elsevier: Amsterdam, The Netherlands, 2015; pp. 137–152. [Google Scholar]

- Mattsson, S.; Partini, J.; Fast-Berglund, Å. Evaluating Four Devices that Present Operator Emotions in Real-Time. In Proceedings of the 26th CIRP Design Conference, Stockholm, Sweden, 15–17 June 2016. [Google Scholar]

- Mattsson, S.; Li, D.; Fast-Berglund, Å.; Gong, L. Measuring Operator Emotion Objectively at a Complex Final Assembly Station. In Advances in Neuroergonomics and Cognitive Engineering; Springer: Berlin, Germany, 2017; pp. 223–232. [Google Scholar]

- Kolbeinsson, A.; Lindblom, J.; Thorvald, P. Missing mediated interruptions in manual assembly: Critical aspects of breakpoint selection. Appl. Ergon. 2017, 61, 90–101. [Google Scholar] [CrossRef] [PubMed]

- Casselman, J.; Onopa, N.; Khansa, L. Wearable healthcare: Lessons from the past and a peek into the future. Telemat. Inf. 2017. [Google Scholar] [CrossRef]

- Schulte, P.; Vainio, H. Well-being at work: Overview and perspective. Scand. J. Work Environ. Health 2010, 36, 422–429. [Google Scholar] [CrossRef] [PubMed]

- European Agency for Safety and Health at Work. Well-Being at Work: Creating a Positive Work Environment; European Agency for Safety and Health at Work: Bilbao, Spain, 2013. [Google Scholar]

- Figner, B.; Murphy, R.O. Using Skin Conductance in Judgement and Decision Making Research. In A Handbook of Process and Tracing Methods for Decision Research; Psychology Press: New York, NY, USA, 2011; pp. 163–184. [Google Scholar]

- Kahneman, D.; Krueger, A.B. Developments in the Measurement of Subjective Well-Being. J. Econ. Perspect. 2006, 20, 3–24. [Google Scholar] [CrossRef]

- Posner, J.; Russell, J.A.; Peterson, B.S. The circumplex model of affect: An integrative approach to affective neuroscience, cognitive development, and psychopathology. Dev. Psychopathol. 2005, 17, 715–734. [Google Scholar] [CrossRef] [PubMed]

- Kallus, K.W.; Barbarino, M.; Van Damme, D. Integrated Task and Job Analysis of Air Traffic Controllers. Available online: https://www.eurocontrol.int/sites/default/files/content/documents/nm/safety/integrated-task-and-job-analysis-of-air-traffic-controllers-phase-1-development-of-methods.pdf (accessed on 21 September 2017).

- Diener, E.; Seligman, M.E.P. Beyond Money. Toward an Economy of Well-Being. Psychol. Sci. Public Interest 2004, 5, 1–31. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, N.; Clore, G.L. Mood, misattribution, and judgments of well-being: Informative and directive functions of affective states. J. Personal. Soc. Psychol. 1983, 45, 513–523. [Google Scholar] [CrossRef]

- Frey, B.S.; Stutzer, A. Happiness and Economics: How the Economy and Institutions Affect Human Well; Princeton University Press: Princeton, NJ, USA; Oxford, UK, 2002. [Google Scholar]

- Health and Safety Executive. Reducing Error and Influencing Behaviour. Available online: http://www.hse.gov.uk/pubns/books/hsg48.htm (accessed on 21 September 2017).

- Mattsson, S.; Fast-Berglund, Å.; Thorvald, P. A Relationship between Operator Performance and Arousal in Assembly. Procedia CIRP 2016, 44, 32–37. [Google Scholar] [CrossRef]

- Wright, T.A.; Cropanzano, R. The Role of Psychological Well-Being in Job Performance: A Fresh Look at an Age-Old Quest. Org. Dyn. 2004, 33, 338–351. [Google Scholar] [CrossRef]

- Ford, M.T.; Cerasoli, C.P.; Higgins, J.A.; Decesare, A.L. Relationships between psychological, physical, and behavioural health and work performance: A review and meta-analysis. Work Stress 2011, 25, 185–204. [Google Scholar] [CrossRef]

- Wright, T.A.; Cropanzano, R.; Bonett, D.G. The moderating role of employee positive well being on the relation between job satisfaction and job performance. J. Occup. Health Psychol. 2007, 12, 93–104. [Google Scholar] [CrossRef] [PubMed]

- Ryan, R.M.; Deci, E.L. Self-determination theory and the facilitation of intrinsic motivation, social development, and well-being. Am. Psychol. 2000, 55, 68–78. [Google Scholar] [CrossRef] [PubMed]

- Grote, G. Uncertainty management at the core of system design. Ann. Rev. Control 2004, 28, 267–274. [Google Scholar] [CrossRef]

- Mavrikios, D.; Karabatsou, V.; Pappas, M.; Chryssolouris, G. An efficient approach to human motion modeling for the verification of human-centric product design and manufacturing in virtual environments. Robot. Comput. Integr. Manuf. 2007, 23, 533–543. [Google Scholar] [CrossRef]

- Muaremi, A.; Arnich, B.; Tröster, G. Towards Measuring Stress with Smartphones and Wearable Devices During Workday and Sleep. Bionanoscience 2013, 3, 172–183. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Landström, A.; Mattsson, S.; Karlsson, M. How changes in cognitive automation can affect operator performance and productivity. In Proceedings of the Sixth Swedish Production Symposium, Gothenburg, Sweden, 16–18 September 2014. [Google Scholar]

- Bohgard, M. Work and Technology on Human Terms; Prevent: Solna, Sweden, 2009; p. 726. [Google Scholar]

- Thorvald, P.; Brolin, A.; Högberg, D.; K. Case, U. Using Mobile Information Sources to Increase Productivity and Quality. In Proceedings of the 3rd International Conference on Applied Human Factors and Ergonomics, Miami, FL, USA, 17–20 July 2010. [Google Scholar]

- Bäckstrand, G.; Brolin, A.; Högberg, D.; Case, K. Supporting Attention in Manual Assembly and Its Influence on Quality. In Proceedings of the 3rd Applied Human Factors and Ergonomics (AHFE) International Conference, Miami, FL, USA, 17–20 July 2010. [Google Scholar]

- Mattsson, S.; Fast-Berglund, Å. How to Support Intuition in Complex Assembly? In Proceedings of the 26th CIRP Conference, Stockholm, Sweden, 15–17 June 2016. [Google Scholar]

- Tang, A.; Owen, C.; Biocca, F.; Mou, W. Comparative Effectiveness of Augmented Reality in Object Assembly. In Proceedings of the SIGCHI Conference on Human Factors in Computing Systems, Ft. Lauderdale, FL, USA, 5–10 April 2003; pp. 73–80. [Google Scholar]

- Thorvald, P.; Lindblom, J. Inital Development of a Cognitive Load Assessment Tool. In Proceedings of the International Conference on Applied Human Factors and Ergonomics, Krakow, Poland, 19–23 July 2014. [Google Scholar]

- Zanchettin, A.M.; Bascetta, L.; Rocco, P. Acceptability of robotic manipulators in shared working environments through human-like redundancy resolution. Appl. Ergon. 2013, 44, 982–989. [Google Scholar] [CrossRef] [PubMed]

- Forsman, M.; Hansson, G.-Å.; Medbo, L.; Asterland, P.; Engström, T. A method for evaluation of manual work using synchronised video recordings and physiological measurements. Appl. Ergon. 2002, 33, 533–540. [Google Scholar] [CrossRef]

- Mendes, W.B. Assessing Autonomic Nervous System Activity. In Methods in Social Neuroscience; Guilford Press: New York, NY, USA, 2009; pp. 118–147. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios: A Literature Review, Technische Universität Dortmund, Fakultät Maschinenbau; Audi Stiftungslehrstuhl Supply Net Order Management. Available online: http://www.snom.mb.tu-dortmund.de (accessed on 21 September 2017).

- Östlund, U.; Kidd, L.; Wengström, Y.; Rowa-Dewar, N. Combining qualitative and quantitative research within mixed method research designs: A methodological review. Int. J. Nurs. Stud. 2011, 48, 369–383. [Google Scholar] [CrossRef] [PubMed]

- Zohrabi, M. Mixed Method Research: Instruments, Validity, Reliability and Reporting Findings. Theory Pract. Lang. Stud. 2013, 3, 254–262. [Google Scholar] [CrossRef]

- Olsen, W. Triangulation in Social Research: Qualitative and Quantitative Methods Can Really Be Mixed. In Forthcoming as a Chapter in Developments in Sociology; Causeway Press: Ormskirk, UK, 2004. [Google Scholar]

- Denzin, N.K. The Research Act: A Theoretical Introduction to Sociological Methods; Aldine: Chicago, IL, USA, 1970. [Google Scholar]

- Saarni, C. Development of Emotional Competence; Guilford Press: New York, NY, USA, 1999. [Google Scholar]

- Russell, J.A. A Circumplex Model of Affect. J. Personal. Soc. Psychol. 1980, 39, 1161–1178. [Google Scholar] [CrossRef]

- Stamps, A.E. In search of dominance: The case of the missing dimension. Percept. Motor Skills 2005, 100, 559–566. [Google Scholar] [CrossRef] [PubMed]

- Mehrabian, A.; Russel, J. An Approach to Environmental Psychology; MIT Press: Cambridge, MA, USA, 1974. [Google Scholar]

- Boucsein, W. Electrodermal Activity, 2nd ed.; Springer: New York, NY, USA, 2012. [Google Scholar]

- Malik, M. Heart Rate Variability: Standards of Measurement, Physiological Interpretation, and Clinical Use: Task Force of the European Society of Cardiology and the North American Society for Pacing and Electrophysiology. Ann. Noninvasive Electrocardiol. 1996, 1, 151–181. [Google Scholar] [CrossRef]

- Stauss, H.M. Heart rate variability. Am. J. Phys. 2003, 285. [Google Scholar] [CrossRef] [PubMed]

- Kreibig, S.D. Autonomic nervous system activity in emotion: A review. Biol. Psychol. 2010, 84, 394–421. [Google Scholar] [CrossRef] [PubMed]

- Braithwaite, J.J.; Watson, D.G.; Jones, R.; Rowe, M. A Guide for Analysing Electrodermal Activity (EDA) & Skin Conductance Responses (SCRs) for Psychological Experiments; Selective Attention & Awareness Laboratory (SAAL), Behavioural Brain Sciences Centre, University of Birmingham: Birmingham, UK, 2013. [Google Scholar]

- Taelman, J.; Vandeput, S.; Spaepen, A.; Huffel, S. Influence of Mental Stress on Heart Rate and Heart Rate Variability. In Proceedings of the 4th European Conference of the International Federation for Medical and Biological Engineering, Antwerp, Belgium, 23–27 November 2008; pp. 1366–1369. [Google Scholar]

- Peper, E.; Harvey, R.; Lin, I.-M.; Tylova, H.; Moss, D. Is there more to blood volume pulse than heart rate variability, respiratory sinus arrhythmia, and cardiorespiratory synchrony? Biofeedback 2007, 35, 54–61. [Google Scholar]

- Söderberg, C.; Johansson, A.; Mattsson, S. Design of Simple Guidelines to Improve Assembly Instructions and Operator Performance. In Proceedings of the Swedish Production Symposium, Gothenburg, Sweden, 16–18 September 2014. [Google Scholar]

- Bradley, M.M.; Lang, P.J. Measuring emotion: The self-assessment manikin and the semantic differential. J. Behav. Ther. Exp. Psychiatry 1994, 25, 49–59. [Google Scholar] [CrossRef]

- Korneliusson, M.; Christensson, K.L.; Saarelainen, A.; Sugumaran, S.; Zinad, E. Designing the Personal Assembly Station of the Future. Bachelor’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2016. [Google Scholar]

- Jacobsson, J.; Nilsson, N.E. Operator-Robot Collaboration-Creation and Evaluation of a Collaborative Operator-Robot Workstation. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2017. [Google Scholar]

- Kotler, P. Marketing Management: Analysis, Planning, Implementation and Control, 6th ed.; Prentice-Hall International: Englewood Cliffs, NJ, USA, 1988. [Google Scholar]

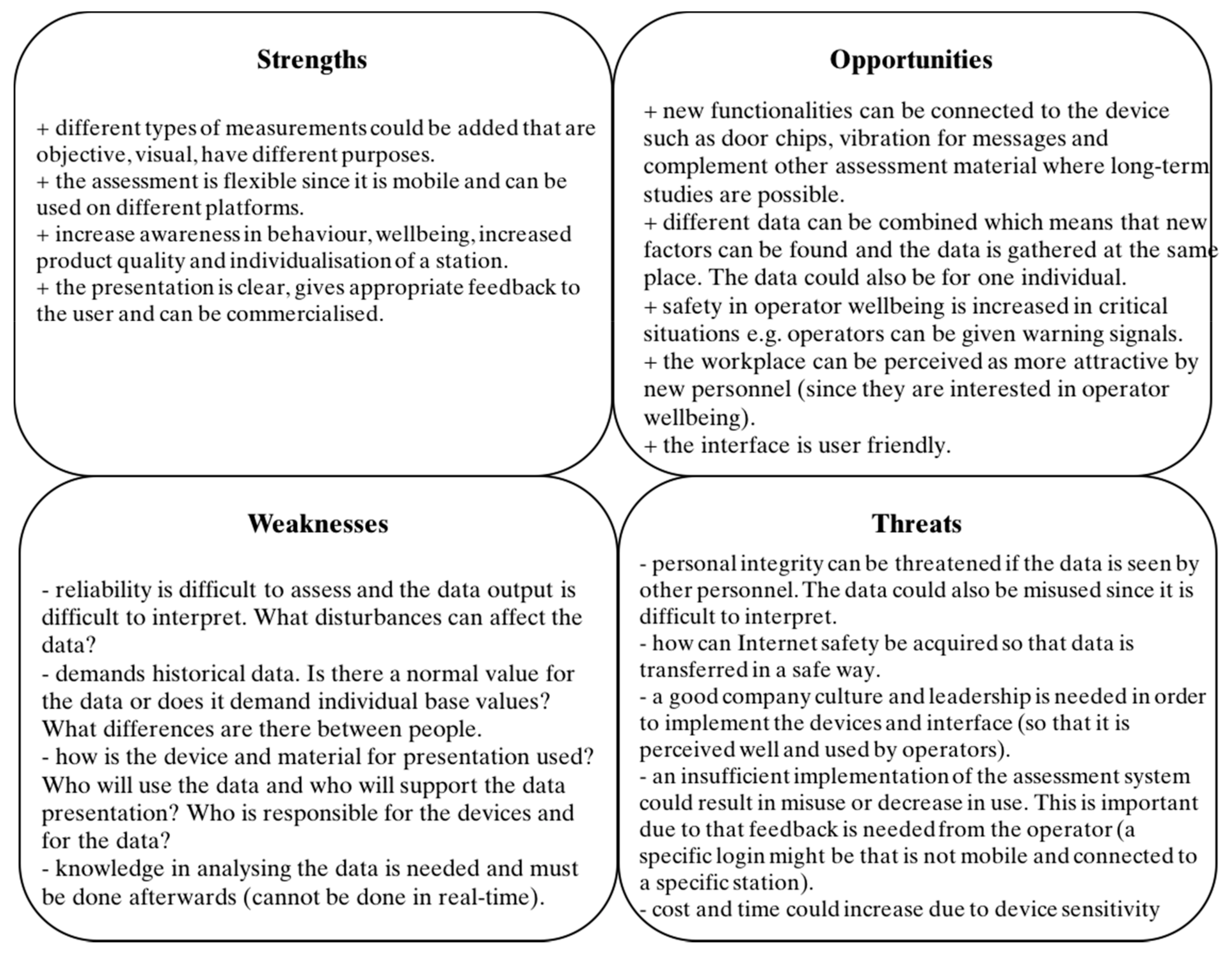

- Ifediora, C.; Idoko, O.; Nzekwe, J. Organization’s stability and productivity: The role of SWOT analysis an acronym for strength, weakness, opportunities and threat. Int. J. Innov. Appl. Res. 2014, 2, 23–32. [Google Scholar]

- Fowles, D.C. The Three Arousal Model: Implications of Gray’s Two-Factor Learning Theory for Heart Rate, Electrodermal Activity, and Psychopathy. Psychophysiology 1980, 17, 87–104. [Google Scholar] [CrossRef] [PubMed]

- Bradley, M.M.; Lang, P.J. Emotion and Motivation, 2nd ed.; Cambridge University Press: Cambridge, UK, 2004; pp. 602–642. [Google Scholar]

- Rasmussen, J. Skills, Rules, Knowledge, Signals, Signs and Symbols and other Distinctions Human Performance Models. IEEE Trans. Man Syst. Cybern. 1983, SMC-13, 257–266. [Google Scholar] [CrossRef]

- Chui, M.; Manyika, J.; Bughin, J.; Dobbs, R.; Roxburgh, C.; Sarrazin, H. The Social Economy: Unlocking Value and Productivity through Social Technologies, McKinsey Global Institute. 2012. Available online: http://www.mckinsey.com/insights/high_tech_telecoms_internet/the_social_economy (accessed on 21 September 2017).

- Endsley, M.R. Designing for Situation Awareness: An Approach to User-Centered Design; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Ropohl, G. Philosophy of Socio-technical Systems. 1999. Available online: http://scholar.lib.vt.edu/ejournals/SPT/v4_n3html/ROPOHL.html (accessed on 21 September 2017).

- Trist, E. The Evolution of Socio-Technical Systems: A Conceptual Framework and an Action Research Program; Ontario Quality of Working Life Centre: Toronto, ON, Canada, 1981. [Google Scholar]

- Hendrick, H.; Kleiner, B. Macroergonomics: An Introduction to Work System Design; Human Factors and Ergonomics Society: Santa Monica, CA, USA, 2001. [Google Scholar]

- Trist, E.L.; Bamforth, K.W. Some Social and Psychological Consequences of the Longwall Method of Coalgetting. Hum. Relat. 1951, 4, 3–38. [Google Scholar] [CrossRef]

- Maguire, M. Methods to support human-centred design. Int. J. Hum.-Comput. Stud. 2001, 55, 587–634. [Google Scholar] [CrossRef]

- Picard, R. Affective Computing: Challenges. Int. J. Hum.-Comput. Stud. 2003, 59, 55–64. [Google Scholar] [CrossRef]

- Smith, C.A.; Kirby, L.D. Appraisal as a pervasive determinant of anger. Emotion 2004, 4, 133–138. [Google Scholar] [CrossRef] [PubMed]

- Hernandez Rivera, J. Towards Wearable Stress Measurement; Massachusetts Institute of Technology: Cambridge, MA, USA, 2015. [Google Scholar]

- Yan, H.; Xu, L.D.; Bi, Z.; Pang, Z.; Zhang, J.; Chen, Y. An emerging technology-wearable wireless sensor networks with applications in human health condition monitoring. J. Manag. Anal. 2015, 2, 121–137. [Google Scholar] [CrossRef]

- Sandulescu, V.; Andrews, S.; Ellis, D.; Bellotto, N.; Martinez-Mozos, O. Stress Detection Using Wearable Physiological Sensors. In Proceedings of the International Work-Conference on the Interplay between Natural and Artificial Computation, Elche, Spain, 1–5 June 2015. [Google Scholar]

- Åkerman, M.; Fast-Berglund, Å.; Ekered, S. Interoperability for a Dynamic Assembly System. In Proceedings of the 6th CIRP Conference on Assembly Technologies and Systems, CATS 2016, Gothenburg, Sweden, 2016; pp. 407–411. [Google Scholar]

- Li, S.; Xu, L.D.; Zhao, S. The internet of things: A survey. Inf. Syst. Front. 2015, 17, 243–259. [Google Scholar] [CrossRef]

- Brown, K.W.; Ryan, R.M. The benefits of being present: Mindfulness and its role in psychological well-being. J. Personal. Soc. Psychol. 2003, 84, 822–848. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods; SAGE: Thousands Oaks, CA, USA, 2009. [Google Scholar]

- Ihantola, E.-M.; Kihn, L.-A. Assessing the quality of case studies. In Proceedings of the 3rd Qualitative Research Conference, Vaasa, Finland, 1–3 June 2010. [Google Scholar]

- Romero, D.; Stahre, J.; Wuest, T.; Noran, O.; Bernus, P.; Fast-Berglund, Å.; Gorecky, D. Towards and operator 4.0 typology: A human-centric perspective on the fourth industrial revolution technologies. In Proceedings of the International Conference on Computers & Industrial Engineering CIE 46, Tianjin, China, 29–31 October 2016. [Google Scholar]

- Romero, D.; Bernus, P.; Noran, O.; Stahre, J.; Fast-Berglund, Å. Advances in Production Management Systems; Springer International Publishing: Basel, Switzerland, 2016; pp. 677–686. [Google Scholar]

- Earthy, J.; Jones, B.S.; Bevan, N. The improvement of human-centred processes-facing the challenge and reaping the benefit of ISO 13407. Int. J. Comput. Stud. 2001, 55, 553–585. [Google Scholar] [CrossRef]

| Research Question | Method | Triangulation Type | Aim |

|---|---|---|---|

| Which physiological measurements can be used to assess operator wellbeing in real-time? | Literature study, laboratory tests and case studies | Data (literature and laboratory results), method (quantitative and qualitative), theory (different theories are combined in the literature study) and investigator triangulation (multiple researchers involved) | Physiological measures are identified and tested |

| What risks and possibilities are connected to assessing operator wellbeing in real-time in industry? | Case studies and workshop | Data (case study and workshop data), method (two types of qualitative data) and investigator triangulation (multiple researchers involved) | Risks and possibilities are identified |

| Device (Developed by Company Name) | Physiological Measurement | Used in Method |

|---|---|---|

| Qsensor (Affectiva) | Electro Dermal Activity (EDA) and body temperature | Laboratory Tests A and B |

| Breathing activity device (Spire) | Respiratory factors (by abdominal and chest movements) | Laboratory Test B |

| SmartBand 2 (Sony) | Heart Rate Variability (HRV) | Laboratory Test B |

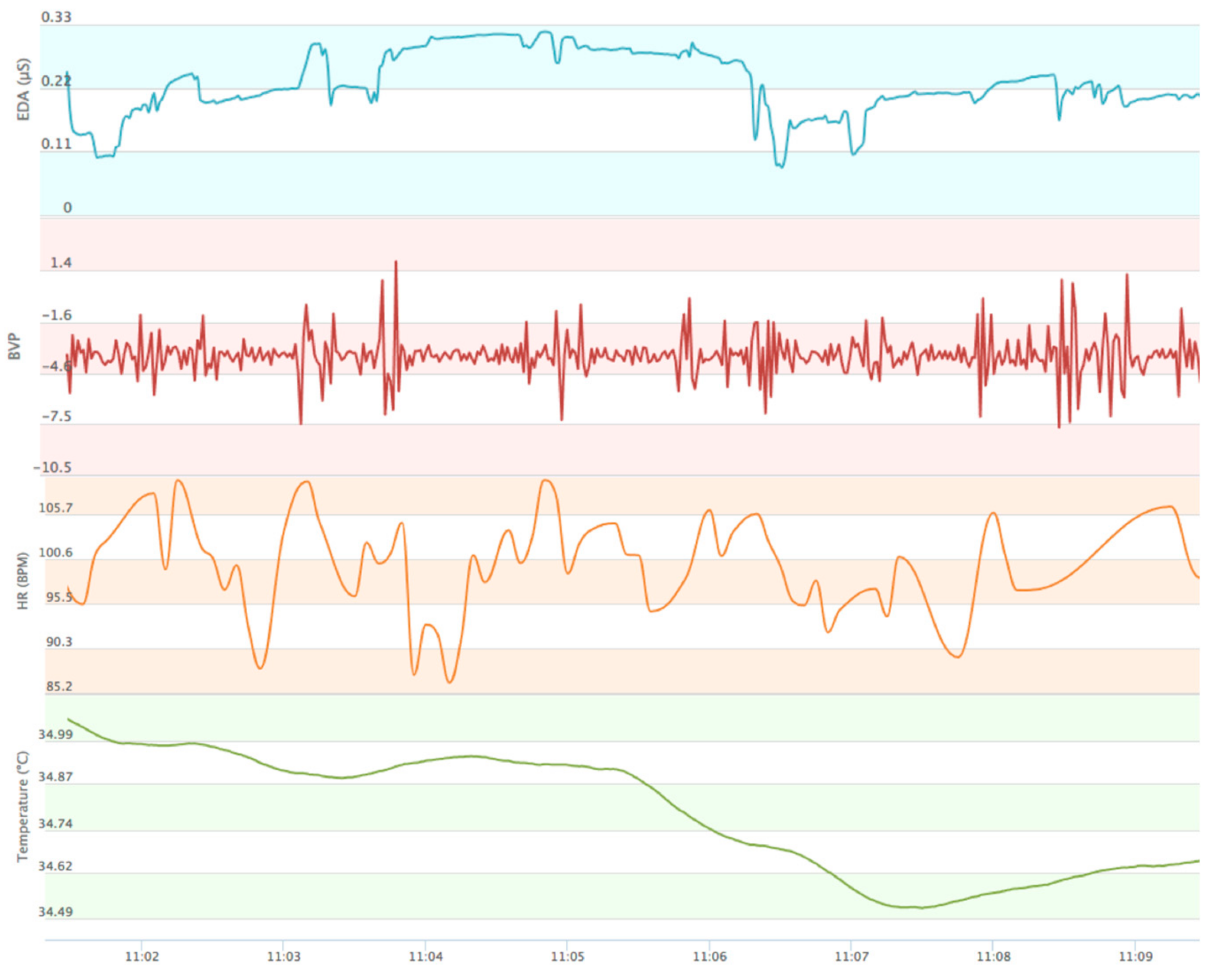

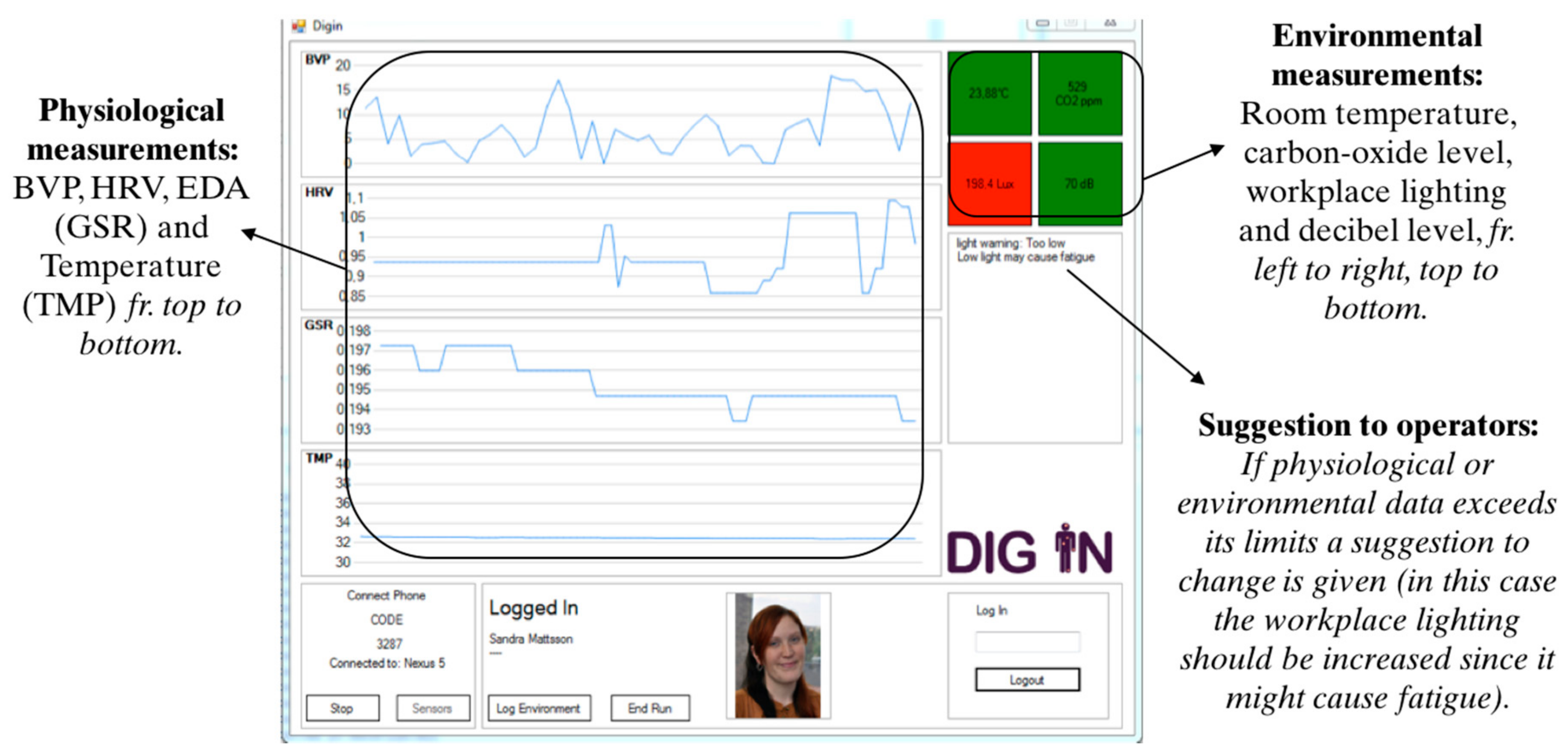

| Activity bracelet E4 (Empatica *) | HRV, Blood Volume Pulse (BVP), EDA and body temperature | Laboratory Test B, workshop and case studies A and B |

| Laboratory Test | A: Emotion Assessments | B: Device Testing |

|---|---|---|

| Number of participants | 60 | 13 |

| Percentage Male/Female (no.) | 52% male (31) | 70% men (9) |

| 48% female (29) | 30% female (4) | |

| Average age | 22 years | 35 years |

| Percentage education (no.) | 86% Bachelor level (52), Masters level 10% (6), Other 4% (2) | Over-graduate 85% (11), Under-graduate 15% (2) |

| Percentage experience in assembling (category, no.) | 56% novice (assembled Lego 8–15 years ago, 33), 18% average (1–7 years ago, 11) and 26% experts (less than one year ago, 16) | 38% novice (5), 31% average (4) and 31% experts (4) in assembling that gearbox |

| Physiological Measurements | Research Methods | Findings | Sources |

|---|---|---|---|

| EDA | Literature Study | EDA was identified as being useful for assessing stress, changes in emotion and motivation | Literature data |

| Laboratory Study A | Weak correlation with operator performance (significant correlation) | Quantitative data | |

| EDA and HRV | Laboratory Study B | 50% of the participants thought it was the most reliable, 50% preferred HRV | Qualitative data |

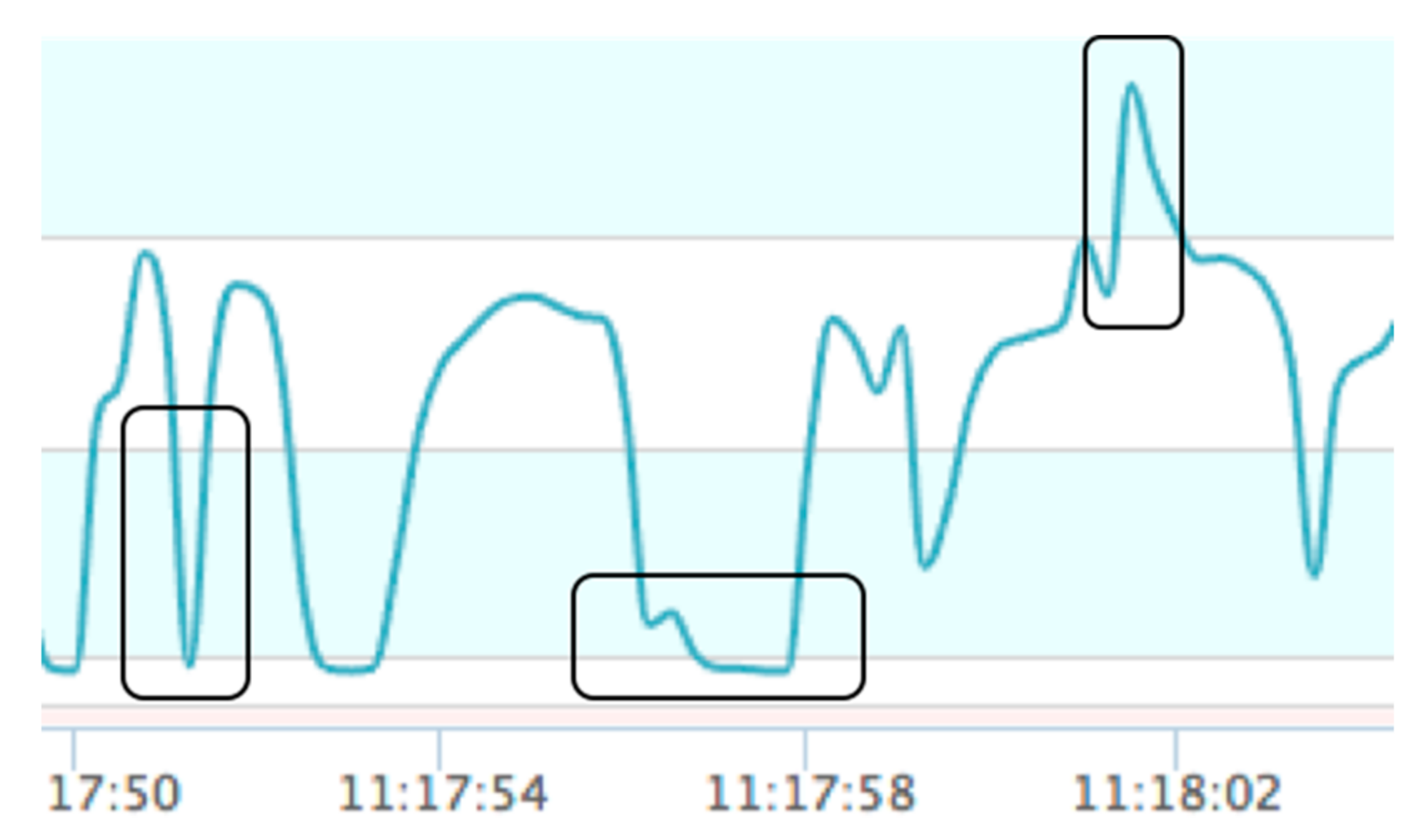

| EDA and HRV | Case Study A | Participants were positive about the graphs | Qualitative |

| EDA and BVP | Case Study B | Project leader thought it was crucial for understanding interaction | Qualitative |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mattsson, S.; Fast-Berglund, Å.; Åkerman, M. Assessing Operator Wellbeing through Physiological Measurements in Real-Time—Towards Industrial Application. Technologies 2017, 5, 61. https://doi.org/10.3390/technologies5040061

Mattsson S, Fast-Berglund Å, Åkerman M. Assessing Operator Wellbeing through Physiological Measurements in Real-Time—Towards Industrial Application. Technologies. 2017; 5(4):61. https://doi.org/10.3390/technologies5040061

Chicago/Turabian StyleMattsson, Sandra, Åsa Fast-Berglund, and Magnus Åkerman. 2017. "Assessing Operator Wellbeing through Physiological Measurements in Real-Time—Towards Industrial Application" Technologies 5, no. 4: 61. https://doi.org/10.3390/technologies5040061

APA StyleMattsson, S., Fast-Berglund, Å., & Åkerman, M. (2017). Assessing Operator Wellbeing through Physiological Measurements in Real-Time—Towards Industrial Application. Technologies, 5(4), 61. https://doi.org/10.3390/technologies5040061