Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

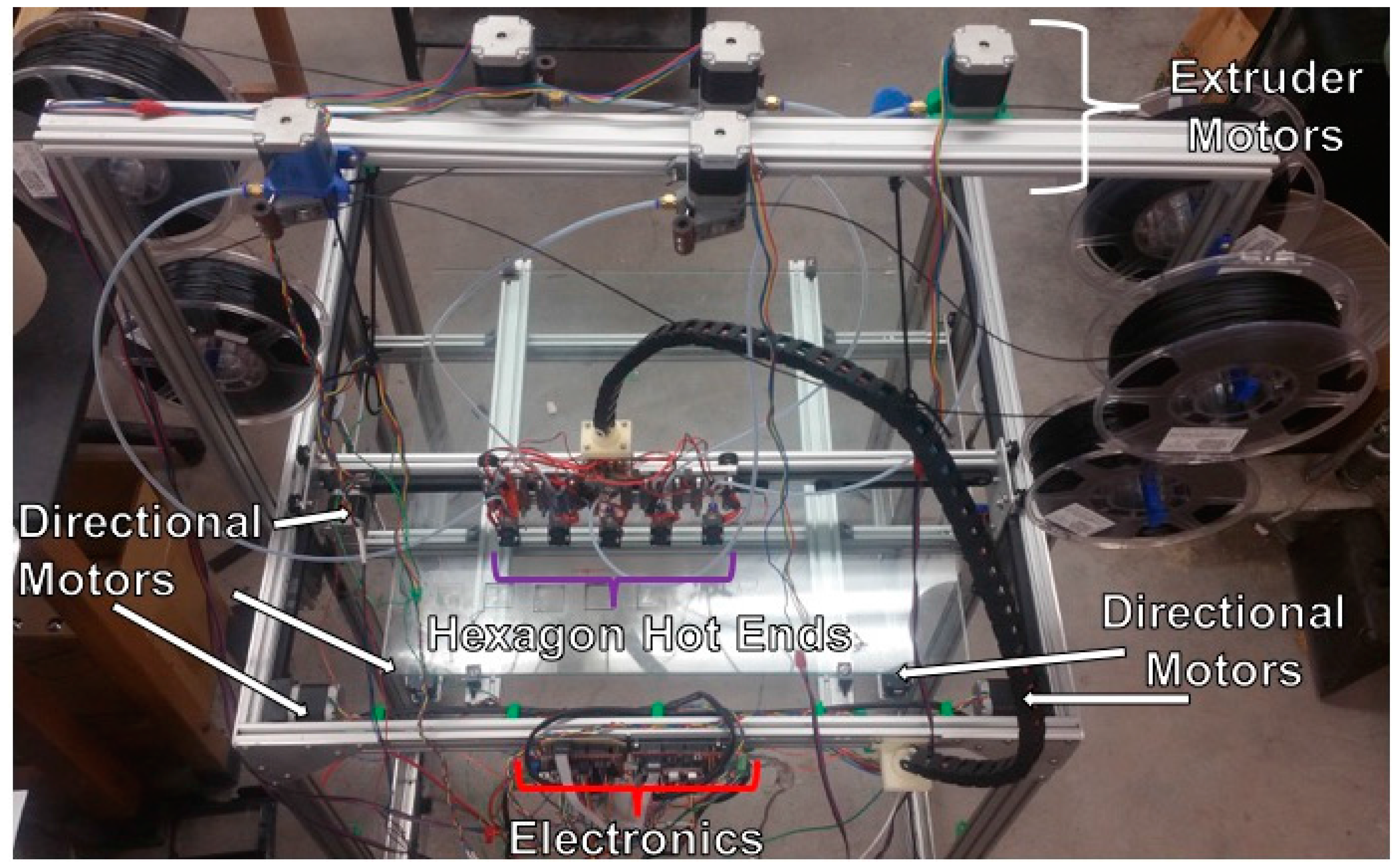

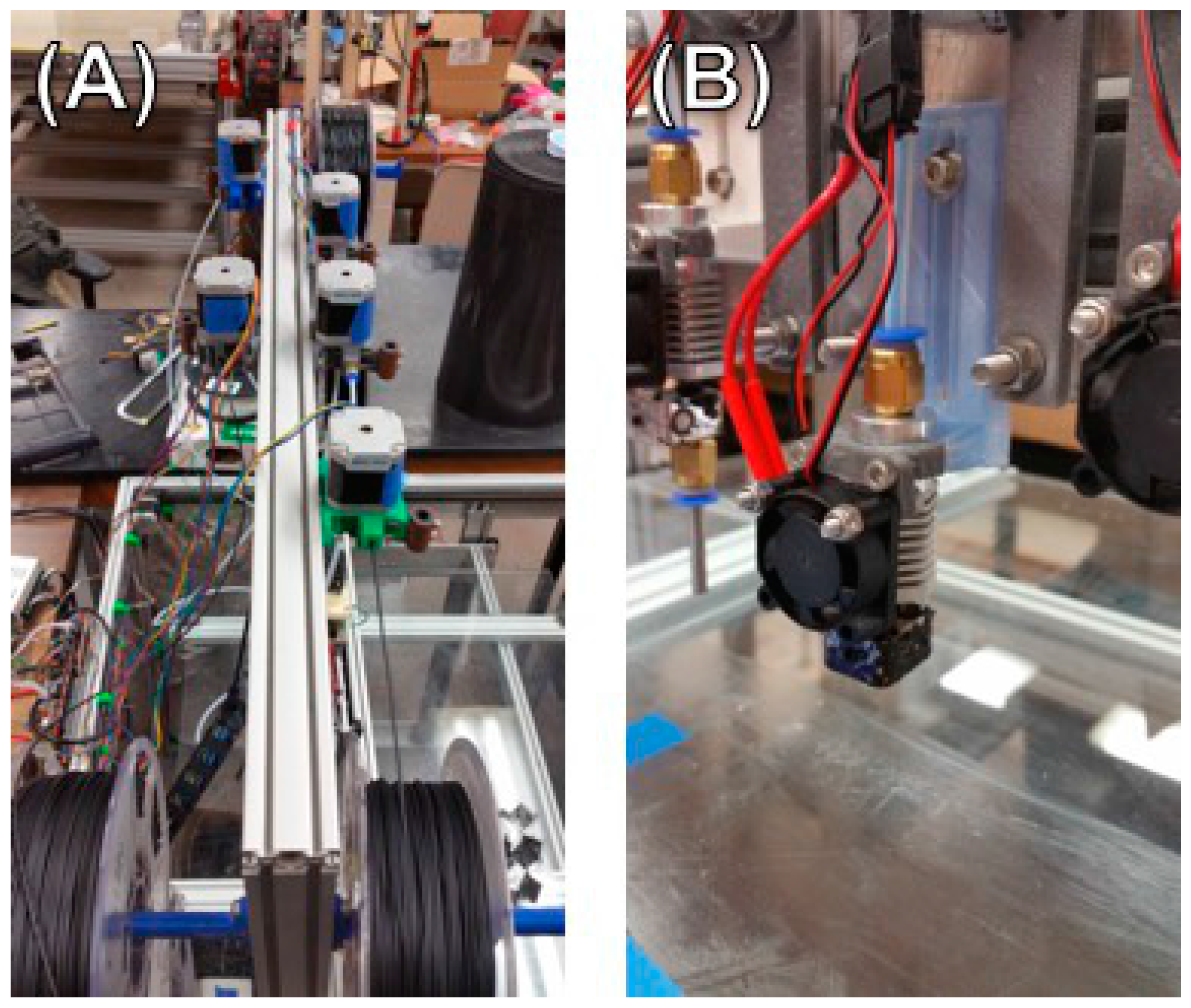

2.1. Fabrication of the Gigabot for Multi-Head Metal-Polymer Composite Printing

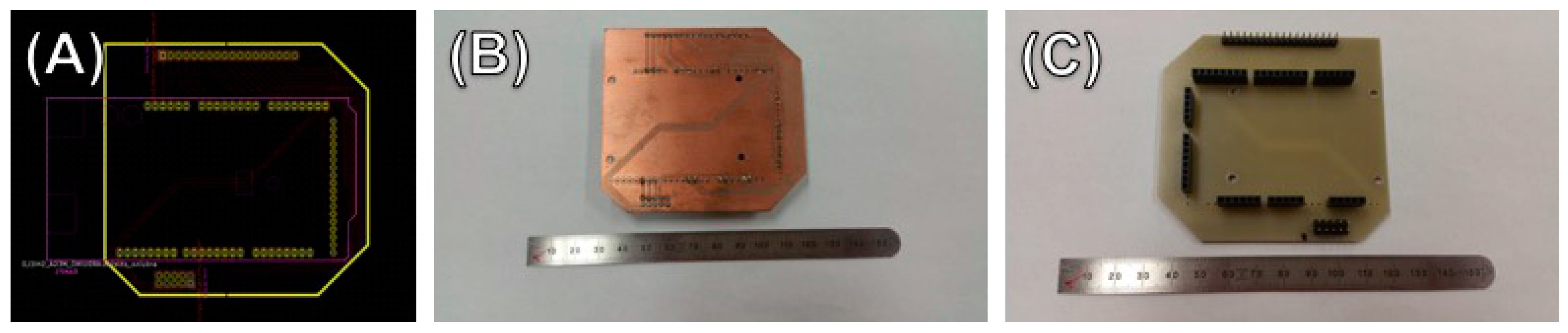

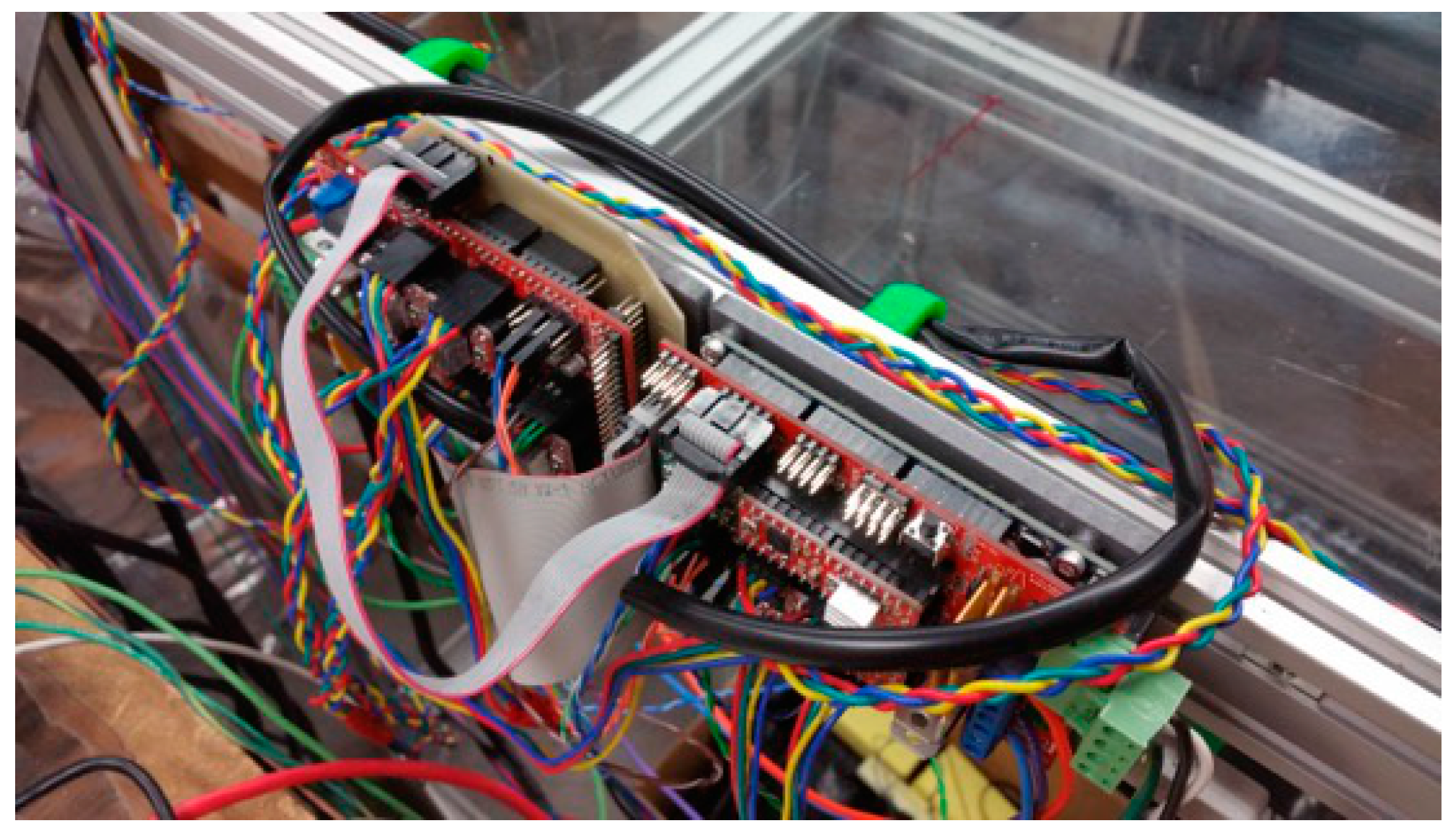

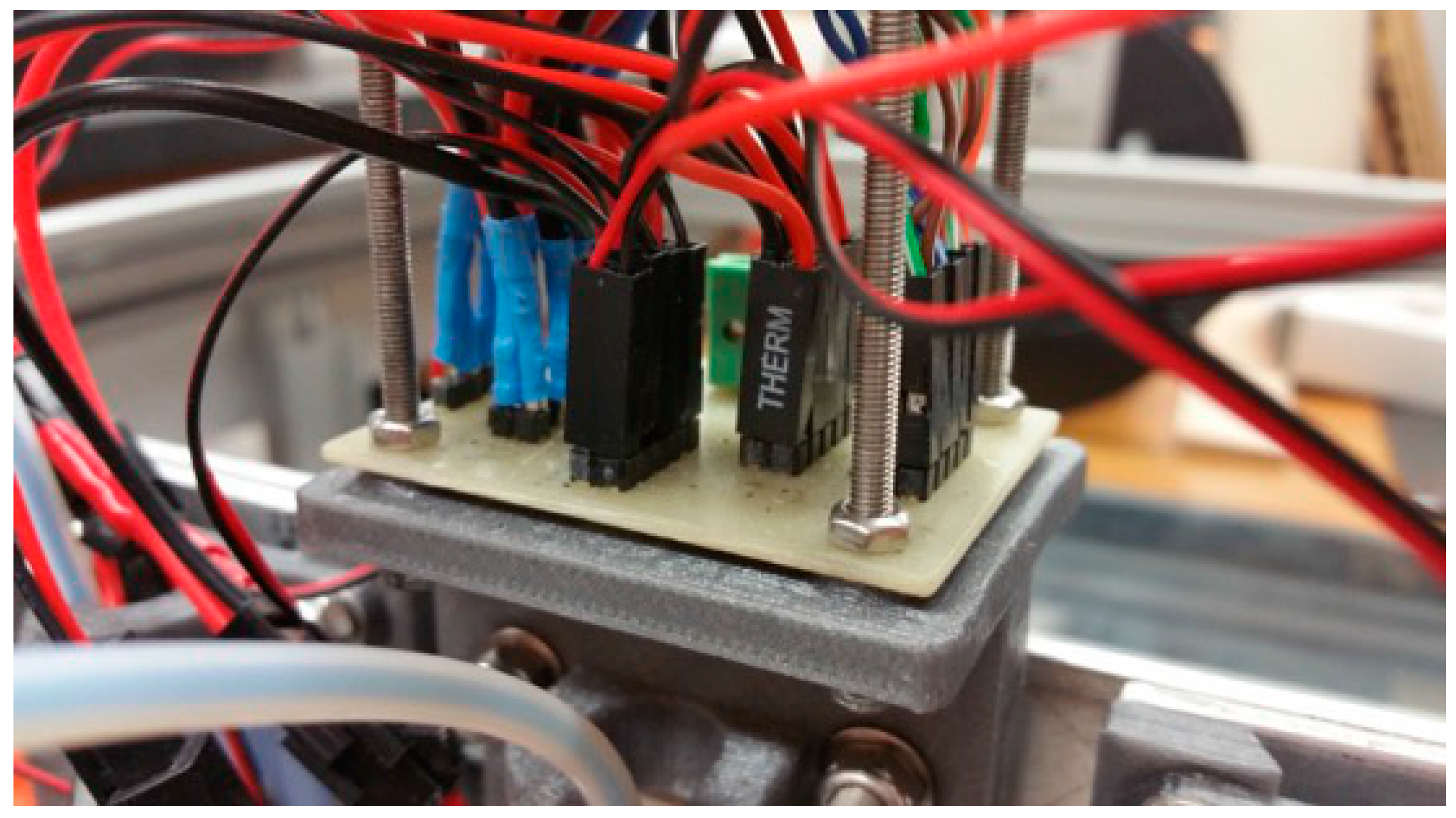

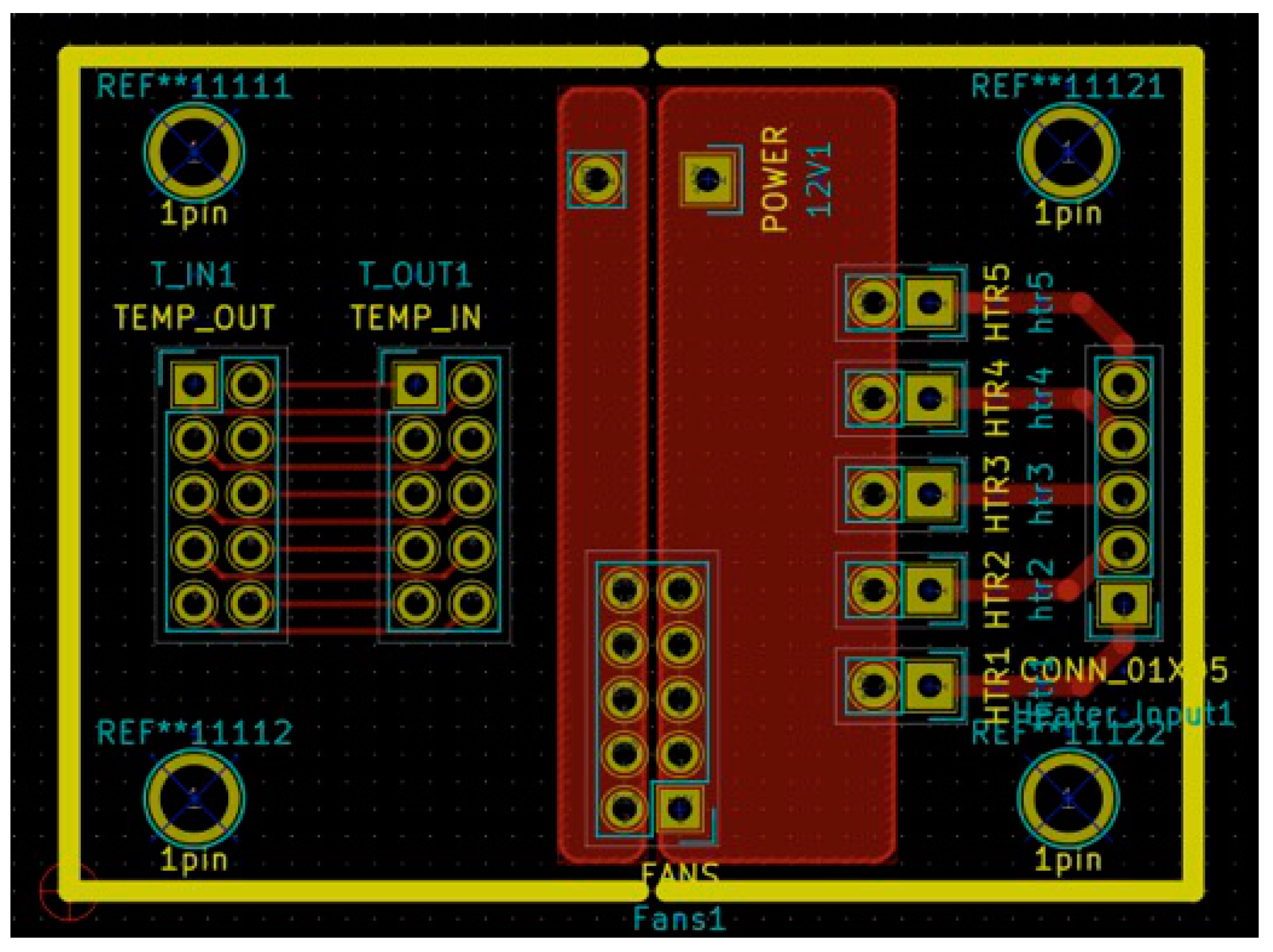

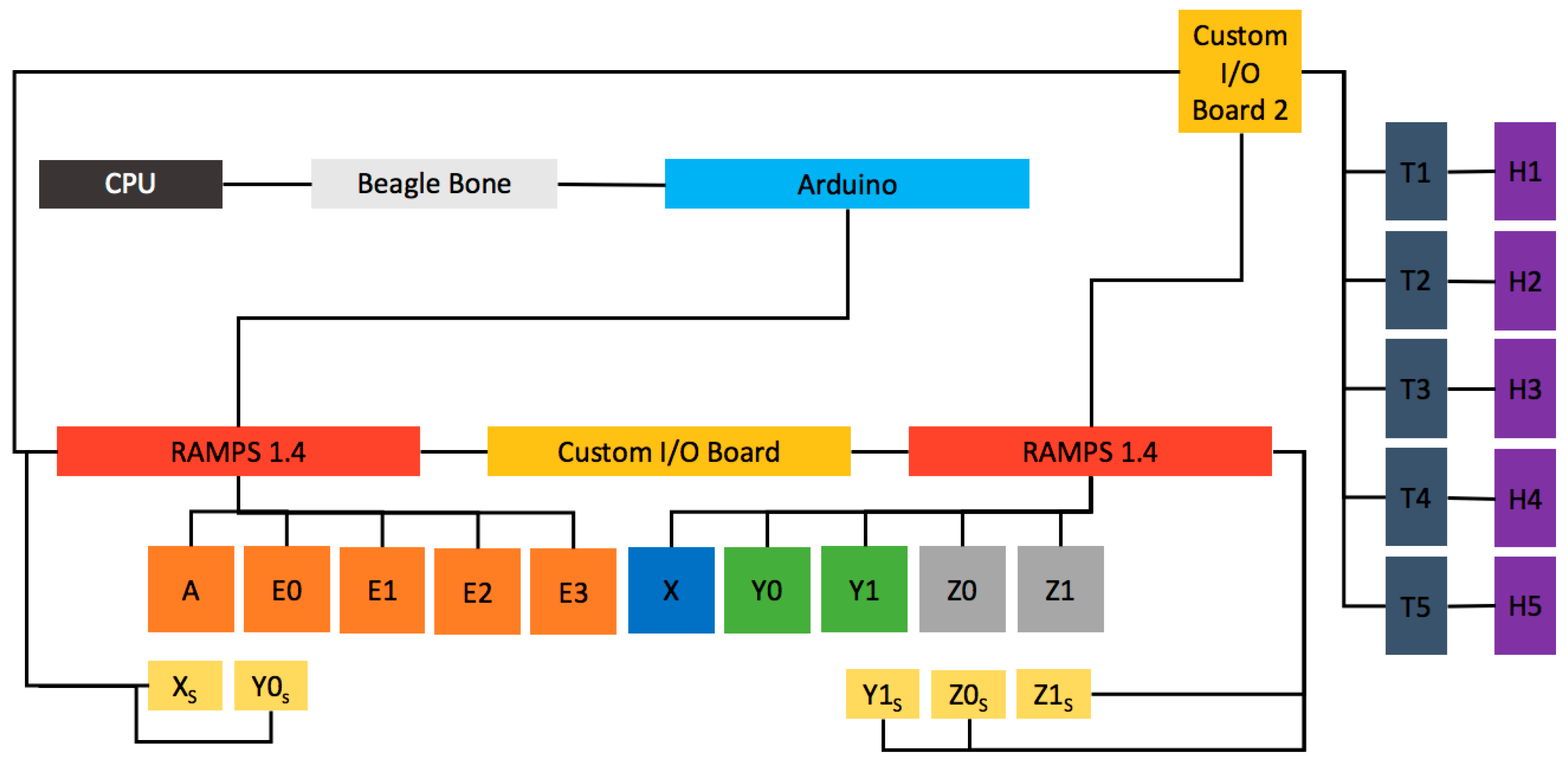

2.2. Circuit Assembly and Printer Control

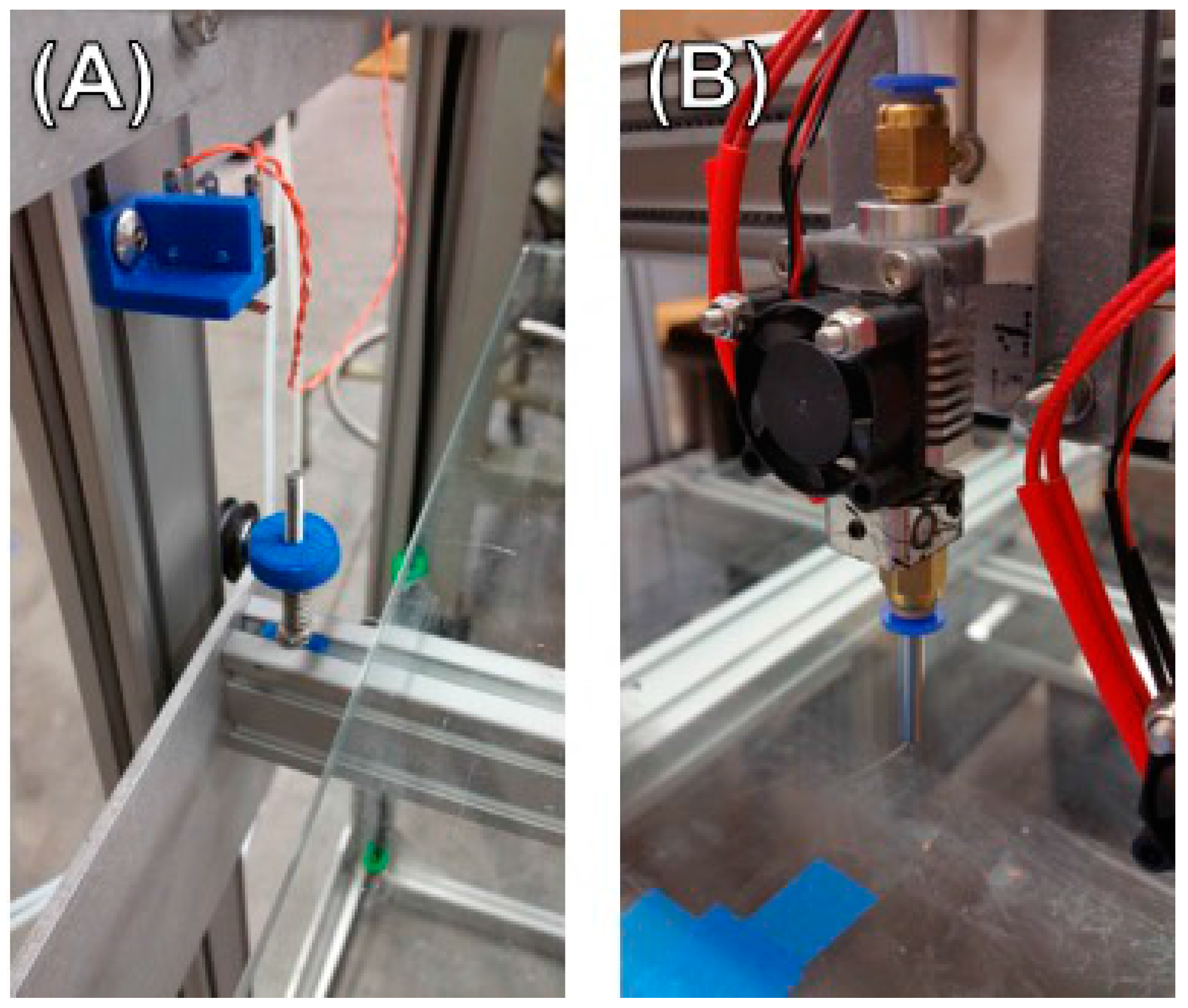

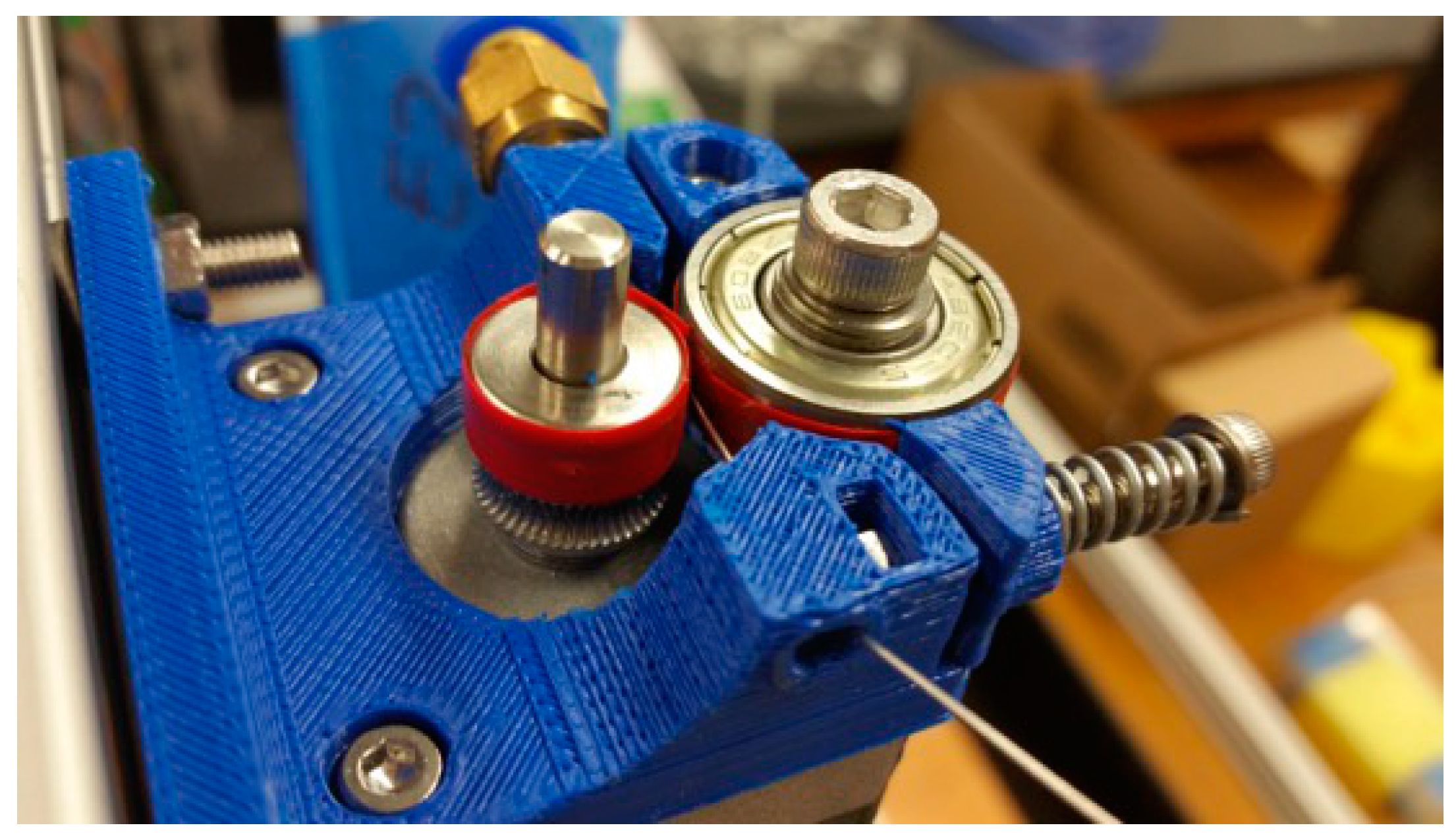

2.3. Modification of Extruder AE for Wire-Feeding

2.4. Composite Printing-Utilizing Wire-Feed Guide and Standard Brass 1.0 mm Extruder Nozzle

2.5. Polymer Filament Material Selection and Printing Parameter Development

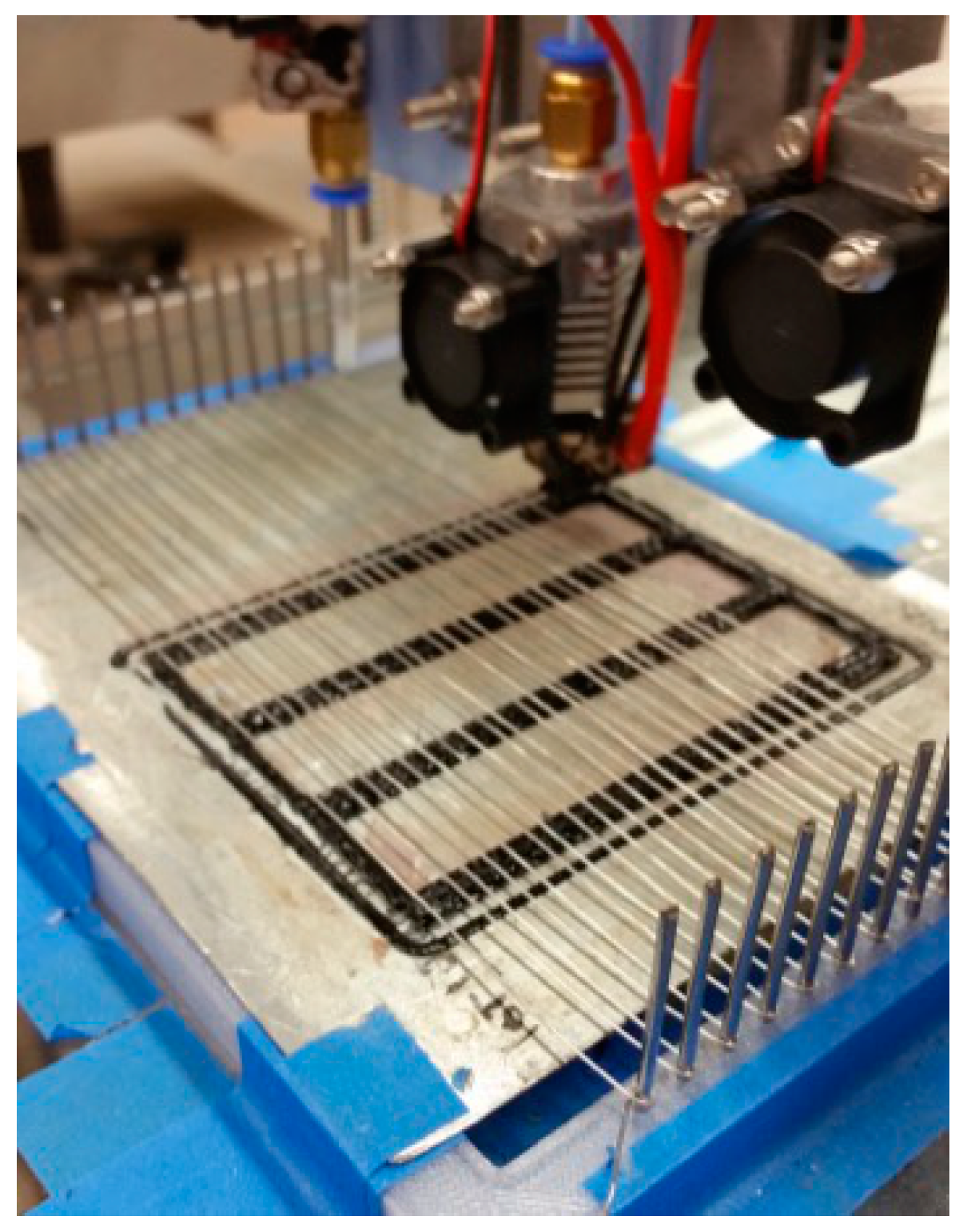

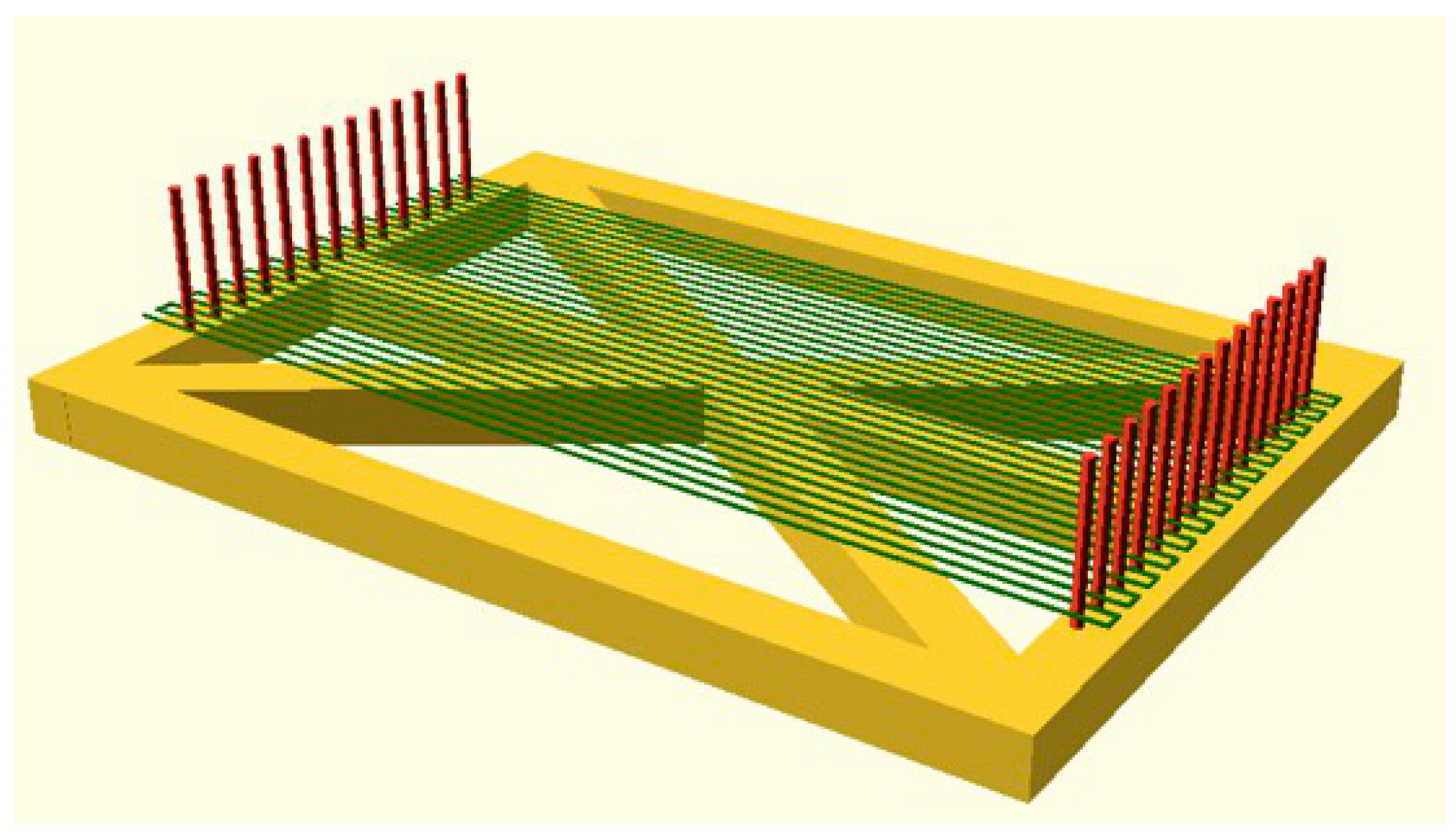

2.6. Composite Printing Tests for Metal-Polymer Composite Gigabot

3. Results

3.1. Resultant Print Quality and Power Consumption Measurements

3.2. Printing Parameter and Material Development

4. Discussion

4.1. Practical Application of the Metal-Polymer Composite Gigabot

4.2. Areas of Improvement and Comparison to Other Technologies

4.3. Future Work

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bowyer, A. 3D printing and humanity’s first imperfect replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Rundle, G. Revolution in the Making: 3D Printing, Robots and the Future; Affirm Press: South Melbourne, Australia, 2014. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. Reprap—The replicating rapid prototype. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The replicating rapid prototyper-maximizing customizability by breeding the means of production. In Handbook of Research in Mass Customization and Personalization; Pillar, F.T., Tseng, M.M., Eds.; World Scientific: Hackensack, NJ, USA, 2009; Volume 1, pp. 568–580. [Google Scholar]

- ASTM F2792-12a. Standard Terminology for Additive Manufacturing Technologies; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Wittbrodt, B.; Pearce, J. M. The effects of PLA color on material properties of 3D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- Tymrak, B. M.; Kreiger, M.; Pearce, J. M. Mechanical properties of components fabricated with open-source 3D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef]

- Afrose, M.F.; Masood, S.H.; Iovenitti, P.; Nikzad, M.; Sbarski, I. Effects of part build orientations on fatigue behaviour of FDM-processed PLA material. Prog. Addit. Manuf. 2015, 1, 1–8. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3D Printing. Unpublished work.

- Kasture, P.V.; Deole, P.; Irwin, J.L. Case Study Using Open Source Additive Manufacturing (AM) Technology for Improved Part Function. In Proceedings of the ASME 2015 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015. [Google Scholar]

- Laureto, J.; Tomasi, J.; King, J.A.; Pearce, J.M. Thermal Properties of 3D Printed Polylactic Acid–Metal Composites. Prog. Addit. Manuf. 2017, 1–15. [Google Scholar] [CrossRef]

- Sugavaneswaran, M.; Arumaikkannu, G. Analytical and experimental investigation on elastic modulus of reinforced additive manufactured structure. Mater. Des. 2015, 66, 29–36. [Google Scholar] [CrossRef]

- Duigou, A.L.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Mater Des. 2016, 96, 106–114. [Google Scholar] [CrossRef]

- Taboas, J.M.; Maddox, R.D.; Krebsbach, P.H.; Hollister, S.J. Indirect solid free form fabrication of local and global porous, biomimetic and composite 3D polymer-ceramic scaffolds. Biomater. 2003, 24, 181–194. [Google Scholar] [CrossRef]

- Seitz, H.; Rieder, W.; Irsen, S.; Leukers, B.; Tille, C. Three-dimensional printing of porous ceramic scaffolds for bone tissue engineering. J. Biomed. Mater. Res. 2005, 74, 782–788. [Google Scholar] [CrossRef] [PubMed]

- Habraken, W.J.E.M.; Wolke, J.G.C.; Jansen, J.A. Ceramic composites as matrices and scaffolds for drug delivery in tissue engineering. Adv. Drug Deliv. Rev. 2007, 59, 234–248. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Ma, P.X. Polymeric Scaffolds for Bone Tissue Engineering. Ann. Biomed. Eng. 2004, 32, 477–486. [Google Scholar] [CrossRef] [PubMed]

- Da Silva, J.R.C.; da Fonsêca, G.F.G.; de Andrade, M.M. Mechanical tests in thermoplastic elastomers used in 3D printers for the construction of hand prosthesis. In Proceedings of the 2014 Pan American Health Care Exchanges (PAHCE), Brasilia, Brazil, 7–12 April 2014; pp. 1–6. [Google Scholar]

- Trachtenberg, J.E.; Mountziaris, P.M.; Miller, J.S.; Wettergreen, M.; Kasper, F.K.; Mikos, A.G. Open-source three-dimensional printing of biodegradable polymer scaffolds for tissue engineering. J. Biomed. Mater. Res. 2014, 102, 4326–4335. [Google Scholar] [CrossRef]

- Wong, J.Y.; Pfahnl, A.C. 3D Printing of Surgical Instruments for Long-Duration Space Missions. Aviat. Space Environ. Med. 2014, 85, 758–763. [Google Scholar] [CrossRef] [PubMed]

- Dimas, L.S.; Bratzel, G.H.; Eylon, I.; Buehler, M.J. Tough Composites Inspired by Mineralized Natural Materials: Computation, 3D printing, and Testing. Adv. Funct. Mater. 2013, 23, 4629–4638. [Google Scholar] [CrossRef]

- Chia, H.N.; Wu, B.M. Recent advances in 3D printing of biomaterials. J. Biol. Eng. 2015, 9. [Google Scholar] [CrossRef] [PubMed]

- Espalin, D.; Muse, D.W.; MacDonald, E.; Wicker, R.B. 3D Printing multifunctionality: structures with electronics. Int. J. Adv. Manuf. Technol. 2014, 72, 963–978. [Google Scholar] [CrossRef]

- Serra, T.; Planell, J.A.; Navarro, M. High-resolution PLA-based composite scaffolds via 3-D printing technology. Acta Biomaterialia 2013, 9, 5521–5530. [Google Scholar] [CrossRef] [PubMed]

- Ma, R.R.; Belter, J.T.; Dollar, A.M. Deposition Manufacturing: Design strategies for multimaterial mechanisms via Three-Dimensional printing and material deposition. J. Mech. Robot. 2015, 7, 021002. [Google Scholar]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Ready, S.; Whiting, G.; Ng, T.N. Multi-Material 3D Printing. NIP Digit. Fabr. Conf. 2014 2014, 120–123. [Google Scholar]

- Anzalone, G.C.; Zhang, C.; Wijnen, B.; Sanders, P.G.; Pearce, J.M. A Low-Cost Open-Source Metal 3-D Printer. IEEE Access 2013, 1, 803–810. [Google Scholar]

- Haselhuhn, A.S.; Wijnen, B.; Anzalone, G.C.; Sanders, P.G.; Pearce, J.M. In situ formation of substrate release mechanisms for gas metal arc weld metal 3-D printing. J. Mater. Process. Technol. 2015, 226, 50–59. [Google Scholar] [CrossRef]

- Haselhuhn, A.S.; Gooding, E.J.; Glover, A.G.; Anzalone, G.C.; Wijnen, B.; Sanders, P.G.; Pearce, J.M. Substrate Release Mechanisms for Gas Metal Arc Weld 3D Aluminum Metal Printing. 3D Print. Addit. Manuf. 2014, 1, 204–209. [Google Scholar] [CrossRef]

- Haselhuhn, A.S.; Buhr, M.W.; Wijnen, B.; Sanders, P.G.; Pearce, J.M. Structure-property relationships of common aluminum weld alloys utilized as feedstock for GMAW-based 3-D metal printing. Mater. Sci. Eng. 2016, 673, 511–523. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Wijnen, B.; Anzalone, G.C.; Haselhuhn, A.S.; Sanders, P.G.; Pearce, J.M. Free and open-source control software for 3D motion and processing. J. Open Res. Softw. 2015, 4. [Google Scholar] [CrossRef]

- Laureto, J.; Dessiatoun, S.; Ohadi, M.; Pearce, J. Open Source Laser Polymer Welding System: Design and Characterization of Linear Low-Density Polyethylene Multilayer Welds. Machines 2016, 4, 14. [Google Scholar] [CrossRef]

- Anzalone, G.C.; Wijnen, B.; Pearce, J.M. Multi-material additive and subtractive prosumer digital fabrication with a free and open-source convertible delta RepRap 3-D printer. Rapid Prototyp. J. 2015, 21, 506–519. [Google Scholar] [CrossRef]

- Pearce, J.M. Applications of open source 3D printing on small farms. Org. Farming 2015, 1, 19–35. [Google Scholar]

- Nilsiam, Y.; Haselhuhn, A.; Wijnen, B.; Sanders, P.; Pearce, J. Integrated Voltage—Current Monitoring and Control of Gas Metal Arc Weld Magnetic Ball-Jointed Open Source 3-D Printer. Machines 2015, 3, 339–351. [Google Scholar] [CrossRef]

- Quan, Z.; Wu, A.; Keefe, M.; Qin, X.; Yu, J.; Suhr, J.; Byun, J.-H.; Kim, B.-S.; Chou, T.-W. Additive manufacturing of multi-directional preforms for composites: opportunities and challenges. Mater. Today 2015, 18, 503–512. [Google Scholar] [CrossRef]

- Bayless, J.; Chen, M.; Dai, B. Wire embedding 3D printer. 2010. Available online: http://www.reprap.org/mediawiki/images/2/25/SpoolHead_FinalReport.pdf (accessed on 19 April 2017).

- Shemelya, C.; Cedillos, F.; Aguilera, E.; Espalin, D.; Muse, D.; Wicker, R.; MacDonald, E. Encapsulated Copper Wire and Copper Mesh Capacitive Sensing for 3-D Printing Applications. IEEE Sens J. 2015, 15, 1280–1286. [Google Scholar] [CrossRef]

- Kim, C.; Espalin, D.; Cuaron, A.; Perez, M.A.; Lee, M.; MacDonald, E.; Wicker, R.B. Cooperative Tool Path Planning for Wire Embedding on Additively Manufactured Curved Surfaces Using Robot Kinematics. J. Mech. Robot. 2015, 7, 021003–021010. [Google Scholar] [CrossRef]

- Saari, M.; Cox, B.; Richer, E.; Krueger, P.S.; Cohen, A.L. Fiber Encapsulation Additive Manufacturing: An Enabling Technology for 3D Printing of Electromechanical Devices and Robotic Components. 3D Print. Addit. Manuf. 2015, 2, 32–39. [Google Scholar] [CrossRef]

- Macdonald, E.; Salas, R.; Espalin, D.; Perez, M.; Aguilera, E.; Muse, D.; Wicker, R.B. 3D Printing for the Rapid Prototyping of Structural Electronics. IEEE Access 2014, 2, 234–242. [Google Scholar] [CrossRef]

- Francia, D.; Caligiana, G.; Liverani, A.; Frizziero, L.; Donnici, G. PrinterCAD: a QFD and TRIZ integrated design solution for large size open moulding manufacturing. Int. J. Interact. Des. Manuf. 2017, 1–14. [Google Scholar] [CrossRef]

- Re:3D. Available online: http://shop.re3d.org/ (accessed on 19 April 2017).

- OpenSCAD. Available online: http://www.openscad.org/ (accessed on 19 April 2017).

- Open Science Framework. Available online: https://osf.io/jvhqt/ (accessed on 19 April 2017).

- GNU General Public License. Available online: http://www.gnu.org/licenses/gpl-3.0.en.html (accessed on 19 April 2017).

- MOST Gigabot. Available online: http://www.appropedia.org/Franklin_Firmware_on_GigabotHX:MOST (accessed on 19 April 2017).

- IC3D Digital Platform. Available online: https://www.ic3dprinters.com/index.html (accessed on 19 January 2017).

- RAMPS 1.4. Available online: http://reprap.org/wiki/RAMPS_1.4 (accessed on 19 April 2017).

- Pololu A4988 Stepper Motor Drive Carrier. Available online: https://www.pololu.com/product/1182 (accessed on 19 April 2017).

- Arduino Mega Board 2560. Available online: https://www.arduino.cc/en/Main/ArduinoBoardMega2560 (accessed on 19 April 2017).

- KiCad–PcbNew. Available online: http://kicad-pcb.org/discover/pcbnew/ (accessed on 19 April 2017).

- Slic3r. Available online: http://slic3r.org/ (accessed on 19 April 2017).

- eSUN–PETG Technical Data Sheet. Available online: http://www.esun3d.net/products/176.html (accessed on 19 April 2017).

- Gizmo Dorks—PP Technical Data Sheet. Available online: http://gizmodorks.com/polypropylene-3d-printer-filament/ (accessed on 19 April 2017).

- Cura. Available online: https://ultimaker.com/en/products/cura-software (accessed on 19 April 2017).

- Petersen, E.; Pearce, J. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Laplume, A.; Anzalone, G.C.; Pearce, J.M. Open-source, self-replicating 3-D printer factory for small-business manufacturing. Int. J. Adv. Manuf. Technol. 2016, 85, 633–642. [Google Scholar] [CrossRef]

- Kreiger, M.; Pearce, J.M. Environmental Impacts of Distributed Manufacturing from 3-D Printing of Polymer Components and Products. MRS Proc. 2013, 1492, 85–90. [Google Scholar] [CrossRef]

- Megan, K.; Pearce, J.M. Environmental life cycle analysis of distributed three-dimensional printing and conventional manufacturing of polymer products. ACS Sustain. Chem. Eng. 2013, 1, 1511–1519. [Google Scholar]

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers. Mechatron. 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Rayna, T.; Striukova, L. From rapid prototyping to home fabrication: How 3D printing is changing business model innovation. Technol. Forecast Soc. Chang. 2016, 102, 214–224. [Google Scholar] [CrossRef]

- Bak, D. Rapid prototyping or rapid production? 3D printing processes move industry towards the latter. Assembl. Autom. 2003, 23, 340–345. [Google Scholar] [CrossRef]

- Hergel, J.; Lefebvre, S. Clean color: Improving multi-filament 3D prints. Comput. Graphics Forum 2014, 33, 469–478. [Google Scholar] [CrossRef]

- Ali, M.H.; Mir-Nasiri, N.; Ko, W.L. Multi-nozzle extrusion system for 3D printer and its control mechanism. Int. J. Adv. Manuf. Technol. 2016, 86, 999–1010. [Google Scholar] [CrossRef]

- Abilgaziyev, A.; Kulzhan, T.; Raissov, N.; Ali, M.H.; Match, W.L.K.; Mir-Nasiri, N. Design and development of multi-nozzle extrusion system for 3D printer. In Proceedings of the 2015 International Conference on Informatics, Electronics & Vision (ICIEV), Fukuoka, Japan, 15–18 June 2015; pp. 1–5. [Google Scholar]

- Song, X.; Pan, Y.; Chen, Y. Development of a Low-Cost Parallel Kinematic Machine for Multidirectional Additive Manufacturing. J. Manuf. Sci. Eng. 2015, 137, 021005–021013. [Google Scholar] [CrossRef]

- Autodesk Project Escher. Available online: http://projectescher.com/ (accessed on 19 April 2017).

- Titan Robotics–Cronus 3D Printer. Available online: http://www.titan3drobotics.com/the-cronus/ (accessed on 19 April 2017).

- Baumers, M. Economic Aspects of Additive Manufacturing: Benefits, Costs and Energy Consumption. Ph.D. Thesis, Loughborough University, Leicestershire, UK, 2012. Available online: https://dspace.lboro.ac.uk/dspace-jspui/handle/2134/10768 (accessed on 4 April 2017).

- Chernov, N.; Stoyan, Y.; Romanova, T. Mathematical model and efficient algorithms for object packing problem. Comput. Geom. 2010, 43, 535–553. [Google Scholar] [CrossRef]

- Bennell, J.; Scheithauer, G.; Stoyan, Y.; Romanova, T. Tools of mathematical modeling of arbitrary object packing problems. Ann. Oper. Res. 2010, 179, 343–368. [Google Scholar] [CrossRef]

- Chernov, N.; Stoyan, Y.; Romanova, T.; Pankratov, A. Phi-Functions for 2D Objects Formed by Line Segments and Circular Arcs. Adv. Oper. Res. 2012, 2012, 26. [Google Scholar] [CrossRef]

- Markforged Composite 3D Printer. Available online: https://markforged.com/why-markforged/ (accessed on 19 April 2017).

- MOST Athena Delta—End Effector. Available online: http://www.appropedia.org/Athena_Effector_Assembly (accessed on 19 April 2017).

| Part Name/Description | Count | Rendered Image | Part Name/Description | Count | Rendered Image |

|---|---|---|---|---|---|

| Extruder Mount Bracket | 5 |  | z-Height End Stop Solenoid Mount | 2 |  |

| z-Height Bed Leveling Adjustment | 5 |  | 80-20 Wire Guides | 10 |  |

| z-Height Bed Leveling Dovetail Mounts | 5 |  | Gantry Cable Supports | 3 |  |

| Filament Spool Holders thing:1269563 | 6 |  | Build Plate Fixturing Brackets | 4 |  |

| 80-20 M4 T-Slot Mount thing:1061769 | 2 |  | Hexagon Hot end Fan Mount | 5 |  |

| z-Height Z1 and Z0 Leveling Screw Knob | 2 |  | MOST Bowden Extruder Drive | 5 |  |

| Gantry Mount Cable Carrier Connection | 1 |  | Arduino Mega 250 Mount Bracket | 1 |  |

| Customized I/O Board Mount Bracket | 1 |  | 80-20 Cable Carrier Mount | 1 |  |

| Gantry Mount Electrical Connection Board | 1 |  | y–Carriage Belt Clamp | 2 |  |

| y-Axis End Stop Solenoid Mount | 2 |  | Compact Bowden Extruder thing:275593 | 1 |  |

| Part Description | Count | Source | Serial/Pat Number |

|---|---|---|---|

| GT2 3MR 9-mm Wide | 1(15 ft) | Gates | - |

| GT2 Timing Pulley | 3 | Gates | - |

| 9-mm Idler Pulley with 625-2RS Bearings | 3 | re:3D | - |

| M5x8 Button Head Cap Screws | 100 | BoltDepot.com | - |

| Hexagon Full Metal Hot-End 1.75 mm, 12 V | 5 | IC3D–Hexagon | X000SV0T0N |

| Cyclemore 1.0-mm Brass Nozzle | 5 | Cyclemore | X000WJAXH5 |

| PC4-M6 Push-In Fitting | 10 | Cyclemore | 30-60007-016-FBA |

| 53 Link Cable Carrier | 1 | Re:3D | - |

| Teflon (PTFE) Bowden Tube 1.75 mm (2.0 mm ID/4.0 mm OD) | 25 ft | 3D CAM | BOWDEN2M |

| 3/8”–8 ACME Threaded Rods | 2 | re:3D | - |

| V-Grove Roller Bearings | 20 | Re:3D | - |

| 67 mm × 60 mm Annealed Glass Build Plate | 1 | Locally sourced | - |

| 80-20 Series 20 T-Slot Nuts | 100 | re:3D | - |

| Threaded Rod Z-Nut Cup | 2 | re:3D | - |

| MXL 18 Tooth Motor Pulley | 2 | re:3D | - |

| MXL 36 Tooth Motor Pulley (Threaded Rod) | 2 | re:3D | - |

| z-Axis MXL Belt | 2 | re:3D | - |

| Aluminum Side Plate | 4 | re:3D | - |

| Aluminum Corner Plate | 8 | re:3D | - |

| Rectangular Brackets for Extruder Motor Gantry | 2 | re:3D | - |

| 3 mm × 9 mm Stainless 18-8 Washer | 100 | BoltDepot.com | 7319 |

| DIY: Gigabot Parts Kit | 1 | re:3D | - |

| M2 Hex Nut | 100 | BoltDepot.com | - |

| Eccentric Wheel Spacer | 4 | re:3D | - |

| Z-Motor Shelf | 2 | re:3D | - |

| Truck Plates (L/R) | 2 | re:3D | - |

| Thermal Tape | 10 | adafruit | 1468 |

| A4988 Pololu Heat Sink | 10 | Pololu Robotics and Electronics | - |

| Part Description | Count | Source |

|---|---|---|

| NEMA 17 Stepper Motor | 10 | - |

| RAMPS 1.4 | 2 | - |

| A4988 Pololu Driver | 10 | - |

| Arduino 250 Mega | 1 | - |

| Custom I/O Board | 1 | - |

| 12 V Power Supply | 1 | - |

| 36 V Power Supply | 1 | - |

| End Stop Solenoid Limit Switches | 5 | re:3D |

| Pin Type | XD | Y0D | Y1D | Z0D | Z1D | Ex0E | Ex1E | Ex2E | Ex3E | AE |

|---|---|---|---|---|---|---|---|---|---|---|

| Step | D32 | D60(A6) | D43 | D46 | D37 | D29 | D36 | D26 | D54(A0) | D35 |

| Direction | D47 | D61(A7) | D41 | D48 | D39 | D31 | D34 | D28 | D55(A1) | D33 |

| Enable | D45 | D56(A2) | D45 | D62(A8) | D45 | D45 | D30 | D24 | D38 | D45 |

| Min Limit | D3 | D14 | D23 | D18 | D0 | D0 | D0 | D0 | D0 | D0 |

| Max Limit | D2 | D15 | D25 | D19 | D0 | D0 | D0 | D0 | D0 | D0 |

| Pin Type | Ex0E | Ex1E | Ex2E | Ex3E | AE |

|---|---|---|---|---|---|

| Heater | D9 | D10 | D42 | D64(A11) | D8 |

| Fan | D0 | D0 | D0 | D0 | D0 |

| Thermistor | A14(D68) | A15(D69) | A10(D64) | A12(D66) | A13(D67) |

| Motor (xD = direction, xe = extruder) | Coupling (steps/mm) | Limit Velocity (mm/s) | Limit Acceleration (mm2/s) |

|---|---|---|---|

| XD | 59.292 | 150 | 250 |

| Y0D | 59.292 | 150 | 250 |

| Y1D | 59.292 | 150 | 250 |

| Z0D | 2133.333 | 4 | 250 |

| Z1D | 2133.333 | 4 | 250 |

| Ex0E | 100 | 200 | 1000 |

| Ex1E | 100 | 200 | 1000 |

| Ex2E | 100 | 200 | 1000 |

| Ex3E | 100 | 200 | 1000 |

| AE | 100 | 200 | 1000 |

| Initial g-code Command Line | G1 F900 X143.487 Y114.988 E0.51434 (A27) | |

|---|---|---|

| Operation 1 | =IF(ISNUMBER(SEARCH(“G1”,A27)),RIGHT(A27,LEN(A27)-SEARCH(“E”,A27,1)+1),”NA”) | E0.51434 |

| Operation 2 | =IF(ISNUMBER(SEARCH(“G1”,A27)),RIGHT(A27,LEN(A27)-SEARCH(“E”,A27,1)),” “) | 0.51434(E27) |

| Operation 3 | =IF(ISNUMBER(SEARCH(“ “,E27)),” “,”A”) | A(F27) |

| Operation 4 | =CONCATENATE(F27,E27) | A0.51434(G27) |

| Operation 5 | =IFERROR(IF(ISNUMBER(SEARCH(“ “,G27)),A27,CONCATENATE(A27&” “&G27)),A27) | G1 F900 X143.487 Y114.988 E.51434 A0.51434 |

| - | eSUN PETG | Gizmo Dorks PP 1 |

|---|---|---|

| Print Temperature (°C) | 230–250 | 230–260 |

| Build Plate Temperature (°C) | 80 or none | 60 |

| Feeding Speed (mm/s) | 30–80 | 90 |

| Dimension | (AE) | ±σ | (E0E) | ±σ | (E1E) | ±σ | (E2E) | ±σ | (E3E) | ±σ |

|---|---|---|---|---|---|---|---|---|---|---|

| X (Width) 1 | 25.82 | 0.08 | 25.86 | 0.08 | 25.93 | 0.06 | 25.94 | 0.06 | 25.93 | 0.18 |

| Y (Length) 1 | 25.77 | 0.06 | 25.80 | 0.04 | 25.79 | 0.06 | 25.88 | 0.01 | 25.70 | 0.04 |

| Z (Height) 1 | 26.42 | 0.09 | 26.66 | 0.05 | 26.39 | 0.06 | 26.45 | 0.04 | 26.25 | 0.03 |

| Operating Condition | Power Draw (Watts) 1 |

|---|---|

| 36 V 10 A Stand Alone | 5.9–6.9 |

| 12 V 20 A Stand Alone | 13.2–14.0 |

| 12 V 20 A with Heaters On | 117–118 |

| 12 V 20 A and 36 V 10 A with Heaters On | 138–144 |

| 12 V 20 A and 36 V 10 A Temp Limit (220 °C) | 138–144 |

| 12 V 20 A and 36 V 10 A with Motors Enabled | 45.9–46.7 |

| 12 V 20 A and 36 V 10 A with no Heaters or Motors | 21–22 |

| 12 V 20 A and 26 V 10 A Motors on Heaters on and Printing | 138–144 |

| Conditions | Metrics | Heat Up | Build | Total kWh |

|---|---|---|---|---|

| 25% In-Fill and ×5 Extruders | Time (min) | 4 | 9 | 0.03 |

| Cycle Power (Watts) 1 | 140–144 | 138–144 | ||

| 100% In-Fill and 5× Extruders | Time (min) | 4 | 20 | 0.06 |

| Cycle Power (Watts) 1 | 140–144 | 138–144 | ||

| 25% In-Fill and 1× Extruders | Time (min) | 4 | 10 | 0.01 |

| Cycle Power (Watts) 1 | 68–69 | 62–65 | ||

| 100% In-Fill and 1× Extruders | Time (min) | 4 | 21 | 0.03 |

| Cycle Power (Watts) 1 | 68–69 | 62–65 |

| Retraction Parameters Type | Corresponding Slic3r Setting |

|---|---|

| Print Temperature (°C) | 220 |

| Print Speed (mm/s) | 40 |

| Layer Height (mm/s) | 0.5 |

| Horizontal Shells (Top) | 2 |

| Horizontal Shells (Bottom) | 3 |

| First Layer Extrusion Width (%) | 200 |

| Extrusion Multiplier | ×2 |

| Parameters Type | Corresponding Slic3r Setting |

|---|---|

| Length (mm) | 10 |

| Lift Z (mm) | 0.5 |

| Speed (mm/s) | 100 |

| Extra length on restart (mm) | 8 |

| Minimum travel after retraction (mm) | 0.1 |

| Retract on layer change | Yes |

| Wipe while retracting | Yes |

| Seam position | Nearest |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laureto, J.J.; Pearce, J.M. Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing. Technologies 2017, 5, 36. https://doi.org/10.3390/technologies5020036

Laureto JJ, Pearce JM. Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing. Technologies. 2017; 5(2):36. https://doi.org/10.3390/technologies5020036

Chicago/Turabian StyleLaureto, John J., and Joshua M. Pearce. 2017. "Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing" Technologies 5, no. 2: 36. https://doi.org/10.3390/technologies5020036

APA StyleLaureto, J. J., & Pearce, J. M. (2017). Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing. Technologies, 5(2), 36. https://doi.org/10.3390/technologies5020036