A Transportable Photovoltaic Power Generation System Utilizing a SiC Inverter and Spherical Si Solar Cells

Abstract

:1. Introduction

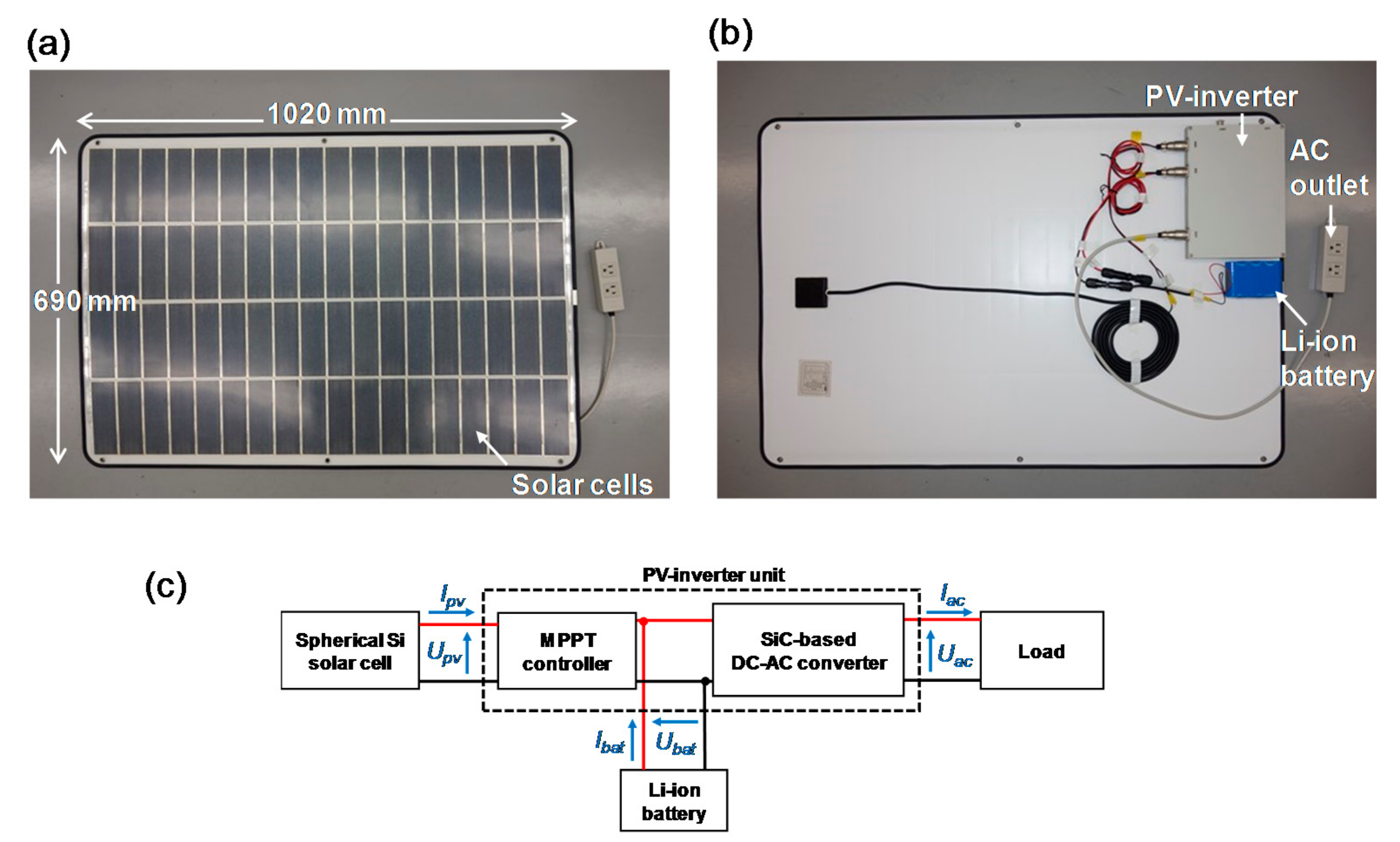

2. Materials and Methods

3. Results

3.1. Conversion Efficiencies of the SiC Inverter

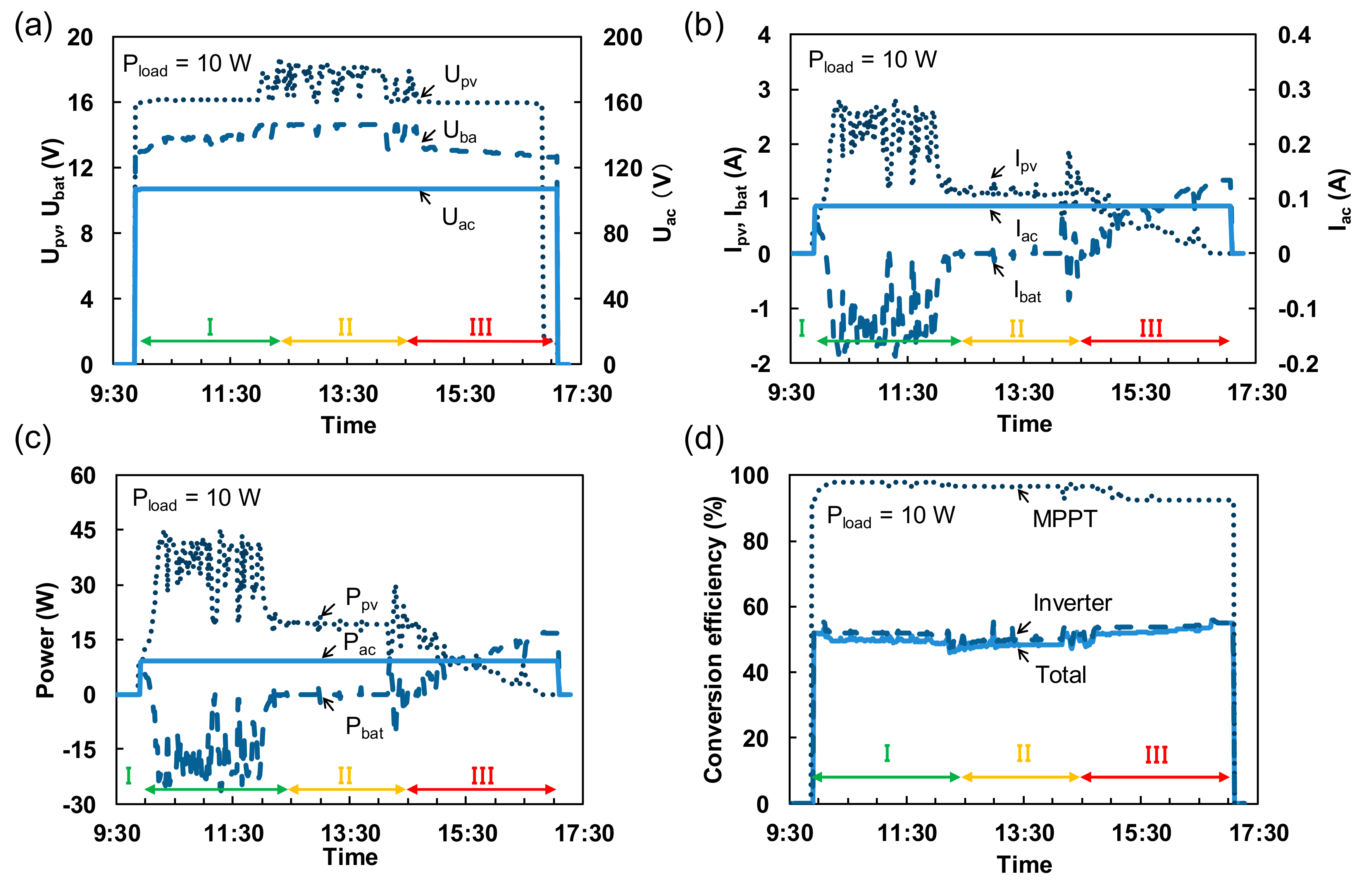

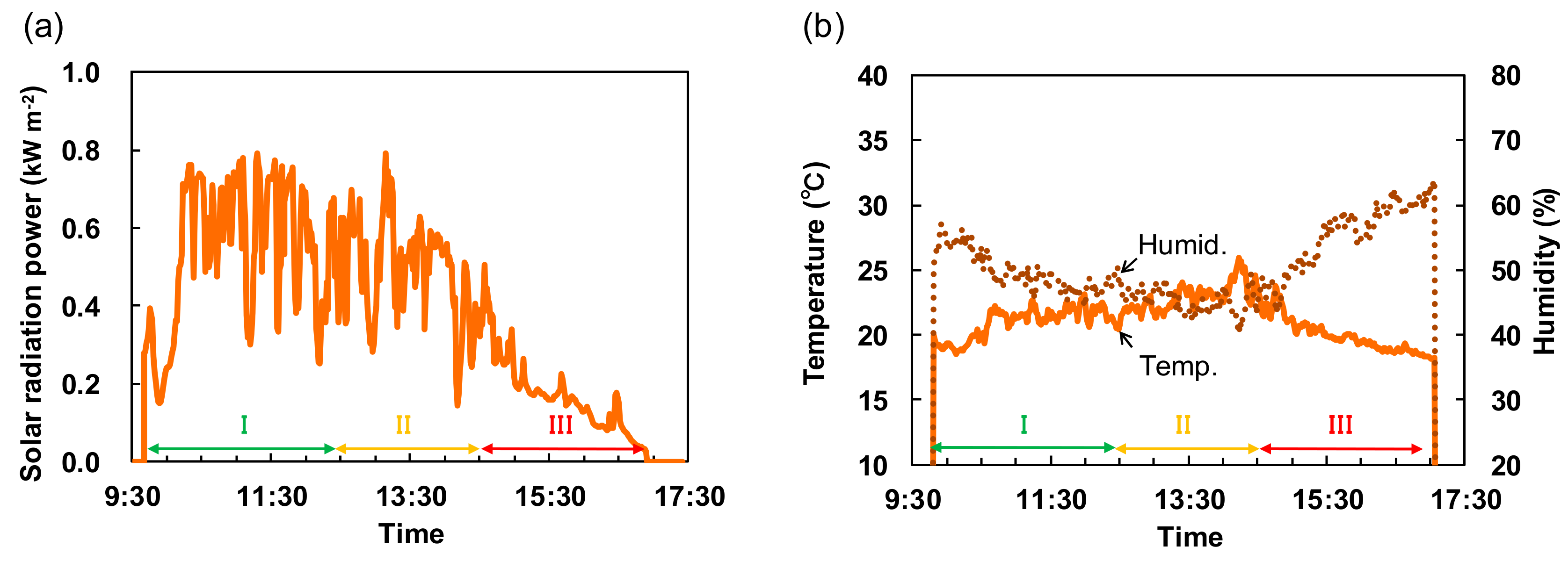

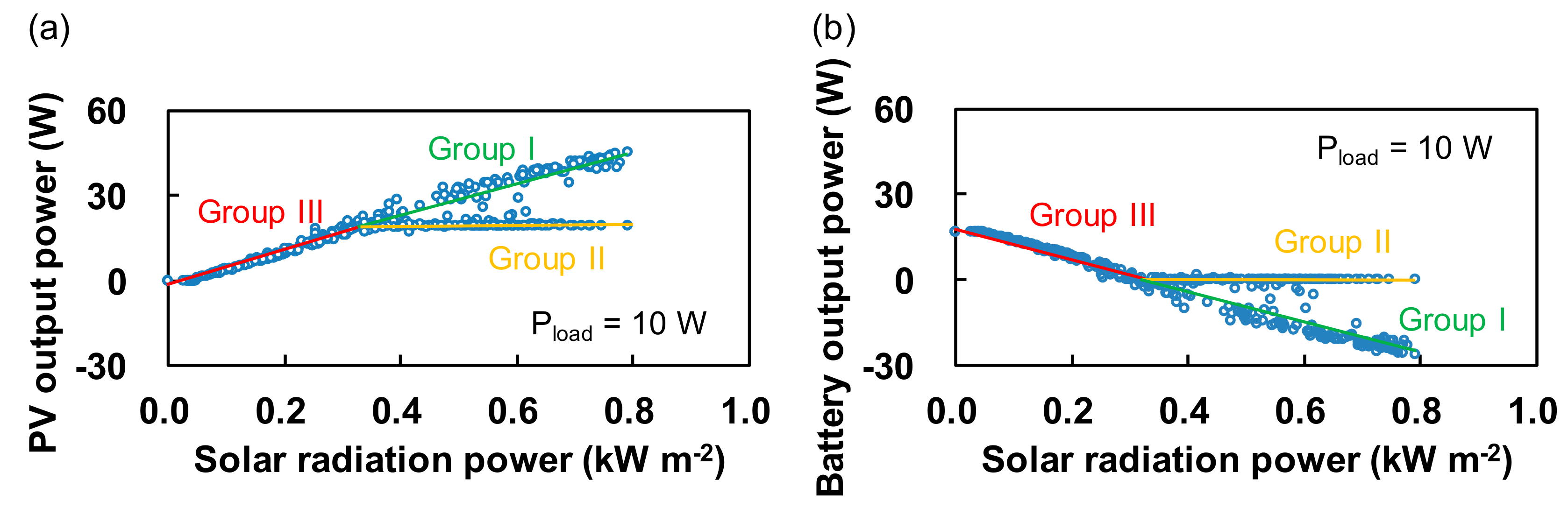

3.2. Electric Power Stability: Measurement Started from a Discharged Condition

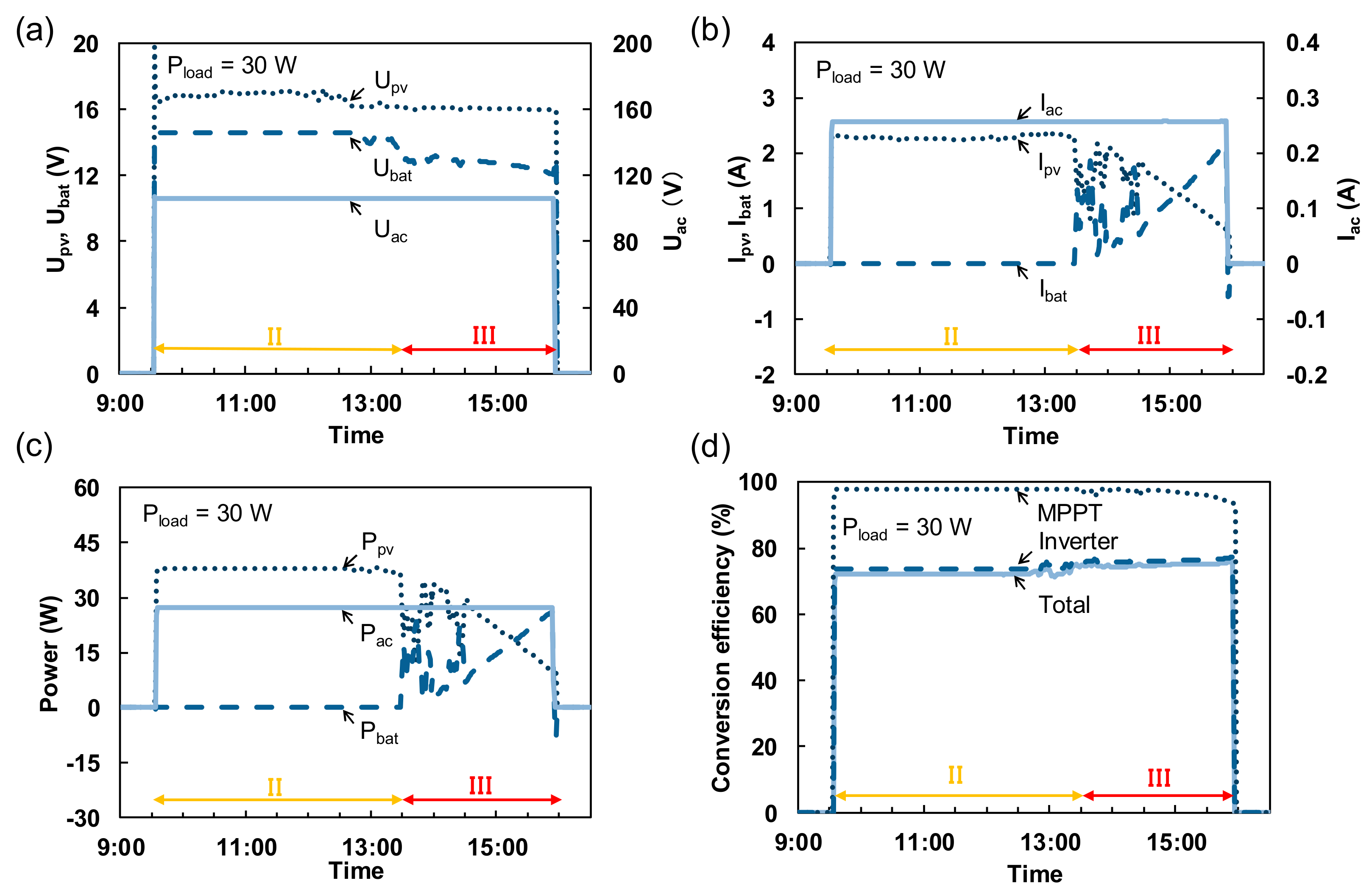

3.3. Electric Power Stability: Measurement Started from a Fully Charged Condition

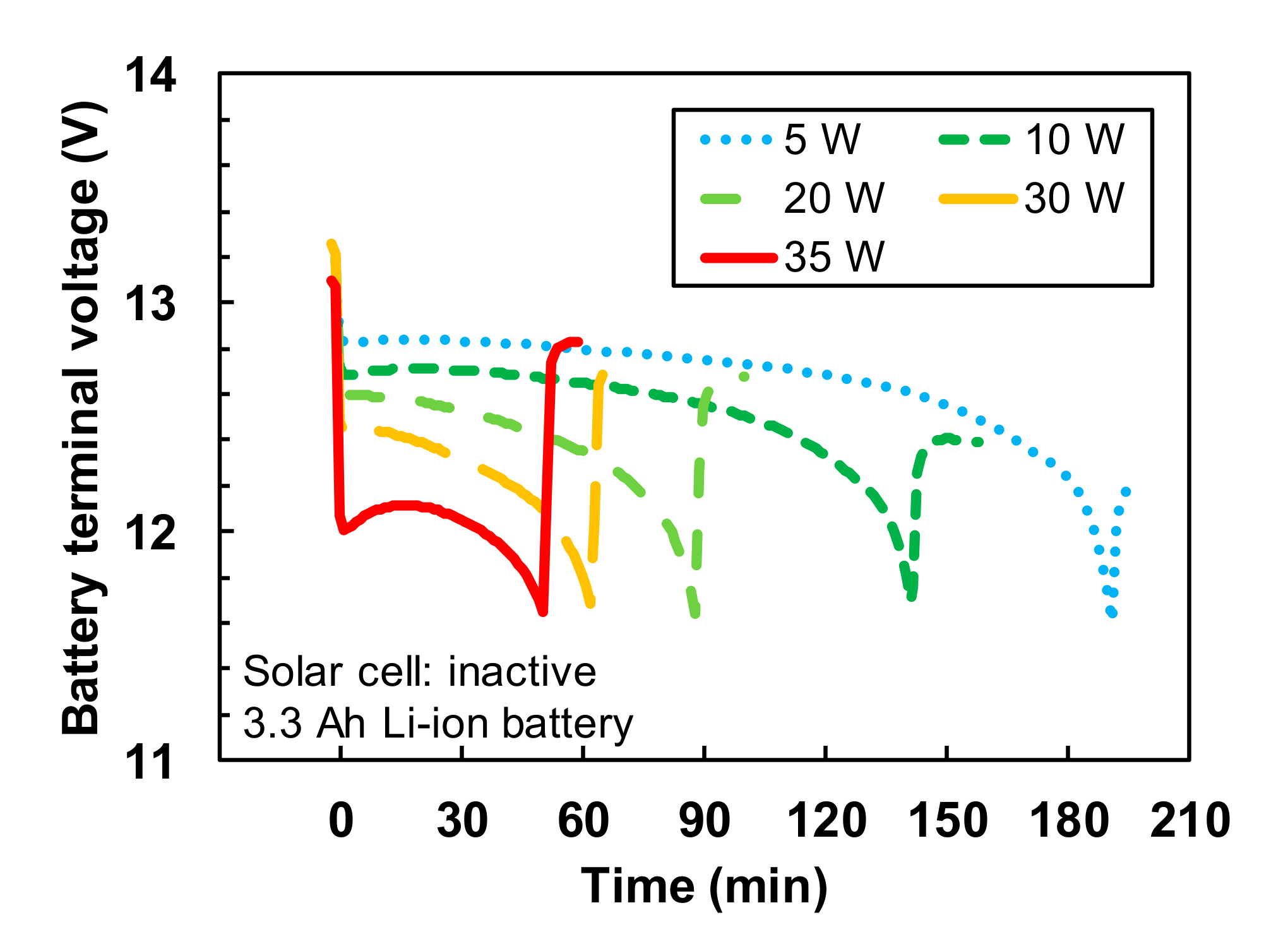

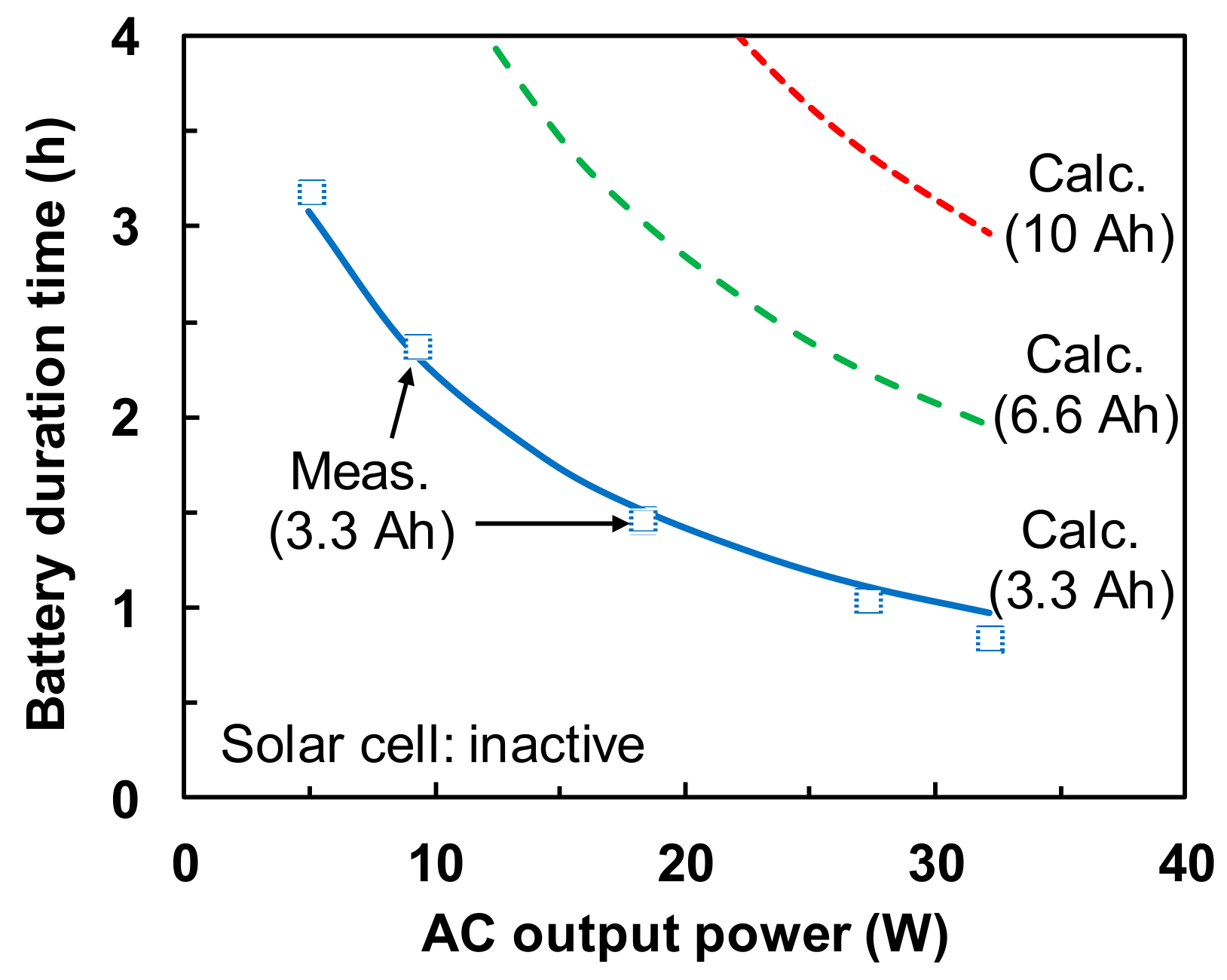

3.4. Battery Duration Time

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Labedev, A.A.; Chelnokov, V.E. Wide-gap semiconductors for high-power electronics. Semiconductors 1999, 33, 999–1001. [Google Scholar] [CrossRef]

- Monroy, E.; Omnès, F.; Calle, F. Wide-bandgap semiconductor ultraviolet photodetectors. Semicond. Sci. Technol. 2003, 18, R33–R51. [Google Scholar] [CrossRef]

- Okumura, H. Present status and future prospect of widegap semiconductor high-power devices. Jpn. J. Appl. Phys. 2006, 45, 7565–7586. [Google Scholar] [CrossRef]

- Phlippen, F.; Burger, B. A new high voltage Schottky diode based on silicon-carbide (SiC). In Proceedings of the 9th European Conference Power Electronics and Applications (EPE 2001), Graz, Austria, 27–28 August 2001; p. 00259. [Google Scholar]

- Stalter, O.; Burger, B.; Lehrmann, S. Silicon carbide (SiC) D-MOS for grid-feeding solar inverters. In Proceedings of the 12th European Conference Power Electronics and Applications (EPE 2007), Aalborg, Denmark, 2–5 September 2007; pp. 1–10. [Google Scholar]

- Chinthavali, M.; Zhang, H.; Tolbert, L.M.; Ozpineci, B. Update on SiC-based inverter technology. In Proceedings of the 2009 Brazilian Power Electronics Conference (COBEP 2009), Bonito, Mato Grosso do Sul, Brazil, 27 September–1 October 2009; pp. 71–79. [Google Scholar]

- Yamane, A.; Koyanagi, K.; Kozako, M.; Fuji, K.; Hikita, M. Fabrication and evaluation of SiC inverter using SiC-MOSFET. In Proceedings of the IEEE 10th International Conference Power Electronics and Drive Systems (PEDS 2013), Kitakyushu, Japan, 22–25 April 2013; pp. 1029–1032. [Google Scholar]

- Li, L.; Li, C.; Cao, Y.; Wang, F. Recent progress of SiC power devices and applications. IEEJ Trans. Electr. Electron. Eng. 2013, 8, 515–521. [Google Scholar] [CrossRef]

- Hensel, A.; Wilhelm, C.; Kranzer, D. Development of a boost converter for PV systems based on SiC BJTs. In Proceedings of the 14th European Conference on Power Electronics and Applications (EPE 2011), Birmingham, UK, 30 August–1 September 2011; pp. 1–7. [Google Scholar]

- Ho, C.N.M.; Breuninger, H.; Pettersson, S.; Escoba, G.; Coccia, A.; Oikonomous, N. Practical implementation of an interleaved boost converter using SiC diodes for PV applications. Proceedings of IEEE 8th International Conference Power Electronics & ECCE Asia (ICPE 2011-ECCE Asia), Jeju, Korea, 30 May–3 June 2011; pp. 372–379. [Google Scholar]

- Kranzer, D.; Wilhelm, C.; Reiners, F.; Burger, B. Application of normally-off SiC-JFETs in photovoltaic inverters. In Proceedings of the 13th European Conference Power Electronics and Applications (EPE 2009), Barcelona, Spain, 8–10 September 2009; pp. 1–6. [Google Scholar]

- Burger, B.; Kranzer, D.; Stalter, O. Cost reduction of PV-inverters with SiC-DMOSFETs. In Proceedings of the 2008 5th International Conference on Integrated Power Electronics Systems (CIPS 2008), Nuremberg, Germany, 11–13 March 2008; pp. 1–5. [Google Scholar]

- Stalter, O.; Kranzer, D.; Rogalla, S.; Burger, B. Advanced solar power electronics. In Proceedings of the 22nd International Symposium Power Semiconductor Devices & IC’s (ISPSD 2010), Hiroshima, Japan, 6–10 June 2010; pp. 3–10. [Google Scholar]

- Burger, B.; Kranzer, D.; Stalter, O. Efficiency improvement of PV inverters with SiC-DMOSFETs. Mater. Sci. Forum 2009, 600–603, 1231–1234. [Google Scholar] [CrossRef]

- De, D.; Castellazzi, A.; Solomon, A.; Trentin, A.; Minami, M.; Hikihara, T. An all SiC MOSFET high performance PV converter cell. In Proceedings of the 15th European Conference on Power Electronics and Applications (EPE 2013), Lille, France, 2–6 September 2013; pp. 1–10. [Google Scholar]

- Nashida, N.; Hinata, Y.; Horio, M.; Yamada, R.; Ikeda, Y. All-SiC power module for photovoltaic power conditioner system. Proceedings of IEEE 26th International Symposium Power Semiconductor Devices & IC’s (ISPSD 2014), Waikoloa, HI, USA, 15–19 June 2014; pp. 342–345. [Google Scholar]

- Burkart, R.M.; Kolar, J.W. Comparative evaluation of SiC and Si PV inverter systems based on power density and efficiency as indicators of initial cost and operating revenue. Proceedings of IEEE 14th Workshop on Control and Modeling for Power Electronics (COMPEL), Salt Lake City, UT, USA, 23–26 June 2013; pp. 1–6. [Google Scholar]

- Sintamarean, C.; Blaabjerg, F.; Wang, H. Comprehensive evaluation on efficiency and thermal loading of associated Si and SiC based PV inverter applications. In Proceedings of the 39th Annual Conference IEEE Industrial Electronics Society (IECON 2013), Vienna, Austria, 10–13 November 2013; pp. 555–560. [Google Scholar]

- Ho, C.N.-M.; Breuninger, H.; Pettersson, S.; Escobar, G.; Canales, F. A comparative performance study of an interleaved boost converter using commercial Si and SiC diodes for PV Applications. IEEE Trans. Power Electron. 2013, 28, 289–299. [Google Scholar] [CrossRef]

- Kim, T.; Jang, M.; Agelidis, V.G. Current status of Silicon Carbide power devices and their application in photovoltaic converters. Proceedings of IEEE ECCE Asia Downunder (ECCE Asia), Melbourne, Australia, 3–6 June 2013; pp. 555–559. [Google Scholar]

- Oku, T.; Matsumoto, T.; Hiramatsu, K.; Yasuda, M.; Shimono, A.; Takeda, Y.; Murozono, M. Construction and characterization of spherical Si solar cells combined with SiC electric power inverter. AIP Conf. Proc. 2015, 1649, 79–83. [Google Scholar]

- Matsumoto, T.; Oku, T.; Hiramatsu, K.; Yasuda, M.; Shirahata, Y.; Shimono, A.; Takeda, Y.; Murozono, M. Evaluation of photovoltaic power generation system using spherical silicon solar cells and SiC–FET inverter. AIP Conf. Proc. 2016, 1709, 020023. [Google Scholar] [CrossRef]

- Oku, T.; Matsumoto, T.; Hiramatsu, K.; Yasuda, M.; Ohishi, Y.; Shimono, A.; Takeda, Y.; Murozono, M. Construction and evaluation of photovoltaic power generation and power storage system using SiC field-effect transistor inverter. AIP Conf. Proc. 2016, 1709, 020024. [Google Scholar] [CrossRef]

- Ando, Y.; Oku, T.; Yasuda, M.; Shirahata, Y.; Ushijima, K.; Murozono, M. A compact SiC photovoltaic inverter with maximum power point tracking function. Solar Energy 2017, 141, 228–235. [Google Scholar] [CrossRef]

- Oku, T.; Ando, Y.; Yasuda, M.; Shirahata, Y.; Ushijima, K.; Murozono, M. Construction of photovoltaic power generation-storage system using an inverter with SiC FET and SBD. Adv. Energy Power 2017, 5, 7–12. [Google Scholar]

- Oku, T.; Kanayama, M.; Ono, Y.; Akiyama, T.; Kanamori, Y.; Murozono, M. Microstructures, optical and photoelectric conversion properties of spherical silicon solar cells with anti-reflection SnOx:F thin films. Jpn. J. Appl. Phys. 2014, 53, 05FJ03-1-7. [Google Scholar] [CrossRef]

- Texas Instruments. Datasheet of BQ24650—Synchronous Switching-Mode Battery Charge Controller for Solar Power with Maximum Power Point Tracking. 2016. Available online: http://www.ti.com/lit/ds/symlink/bq24650.pdf (accessed on 21 April 2017).

- ROHM Semiconductor. Datasheet of SCS210AJ–SiC Schottky Barrier Diode. 2015. Available online: http://rohmfs.rohm.com/en/products/databook/datasheet/discrete/sic/sbd/scs210aj-e.pdf (accessed on 21 April 2017).

- ROHM Semiconductor. Datasheet of SCT2120AF–N-Channel SiC Power MOSFET. 2015. Available online: http://rohmfs.rohm.com/en/products/databook/datasheet/discrete/sic/mosfet/sct2120af-e.pdf (accessed on 21 April 2017).

- Ando, Y.; Oku, T.; Yasuda, M.; Shirahata, Y.; Ushijima, K.; Murozono, M. Comparative study of SiC- and Si-based photovoltaic inverters. AIP Conf. Proc. 2017, 1807, 020020. [Google Scholar] [CrossRef]

- Ando, Y.; Shirahata, Y.; Oku, T.; Matsumoto, T.; Ohishi, Y.; Yasuda, M.; Shimono, A.; Takeda, Y.; Murozono, M. Comparison between SiC- and Si-based inverters for photovoltaic power generation systems. J. Power Eng. 2017, 5, 30–40. [Google Scholar] [CrossRef]

| Unit | Size (mm3) | Weight (kg) |

|---|---|---|

| Inverter | 250 × 180 × 28 | 1.3 |

| Solar cell | 1020 × 690 × 5 | 2.2 |

| Battery | 110 × 66 × 28 | 0.4 |

| Total system | --- | 4.3 * |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ando, Y.; Oku, T.; Yasuda, M.; Ushijima, K.; Murozono, M. A Transportable Photovoltaic Power Generation System Utilizing a SiC Inverter and Spherical Si Solar Cells. Technologies 2017, 5, 18. https://doi.org/10.3390/technologies5020018

Ando Y, Oku T, Yasuda M, Ushijima K, Murozono M. A Transportable Photovoltaic Power Generation System Utilizing a SiC Inverter and Spherical Si Solar Cells. Technologies. 2017; 5(2):18. https://doi.org/10.3390/technologies5020018

Chicago/Turabian StyleAndo, Yuji, Takeo Oku, Masashi Yasuda, Kazufumi Ushijima, and Mikio Murozono. 2017. "A Transportable Photovoltaic Power Generation System Utilizing a SiC Inverter and Spherical Si Solar Cells" Technologies 5, no. 2: 18. https://doi.org/10.3390/technologies5020018

APA StyleAndo, Y., Oku, T., Yasuda, M., Ushijima, K., & Murozono, M. (2017). A Transportable Photovoltaic Power Generation System Utilizing a SiC Inverter and Spherical Si Solar Cells. Technologies, 5(2), 18. https://doi.org/10.3390/technologies5020018