Comparison of Grain Structure, Electrical and Magnetic Properties of BaTiO3 and Ni0.5Zn0.5Fe2O4 Ceramics Sintered Using Microwave and Conventional Techniques

Abstract

:1. Introduction

2. Experimental Procedure

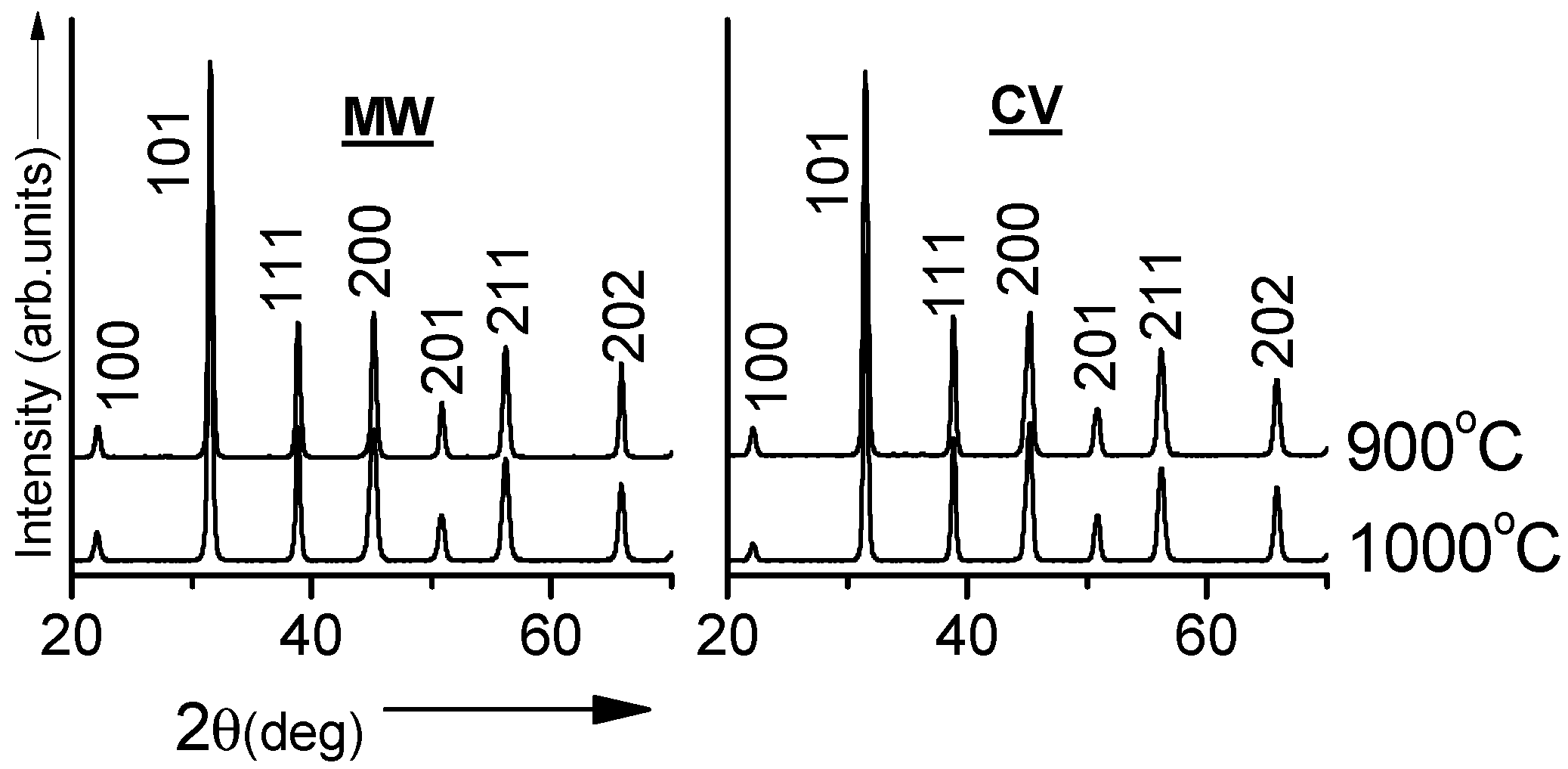

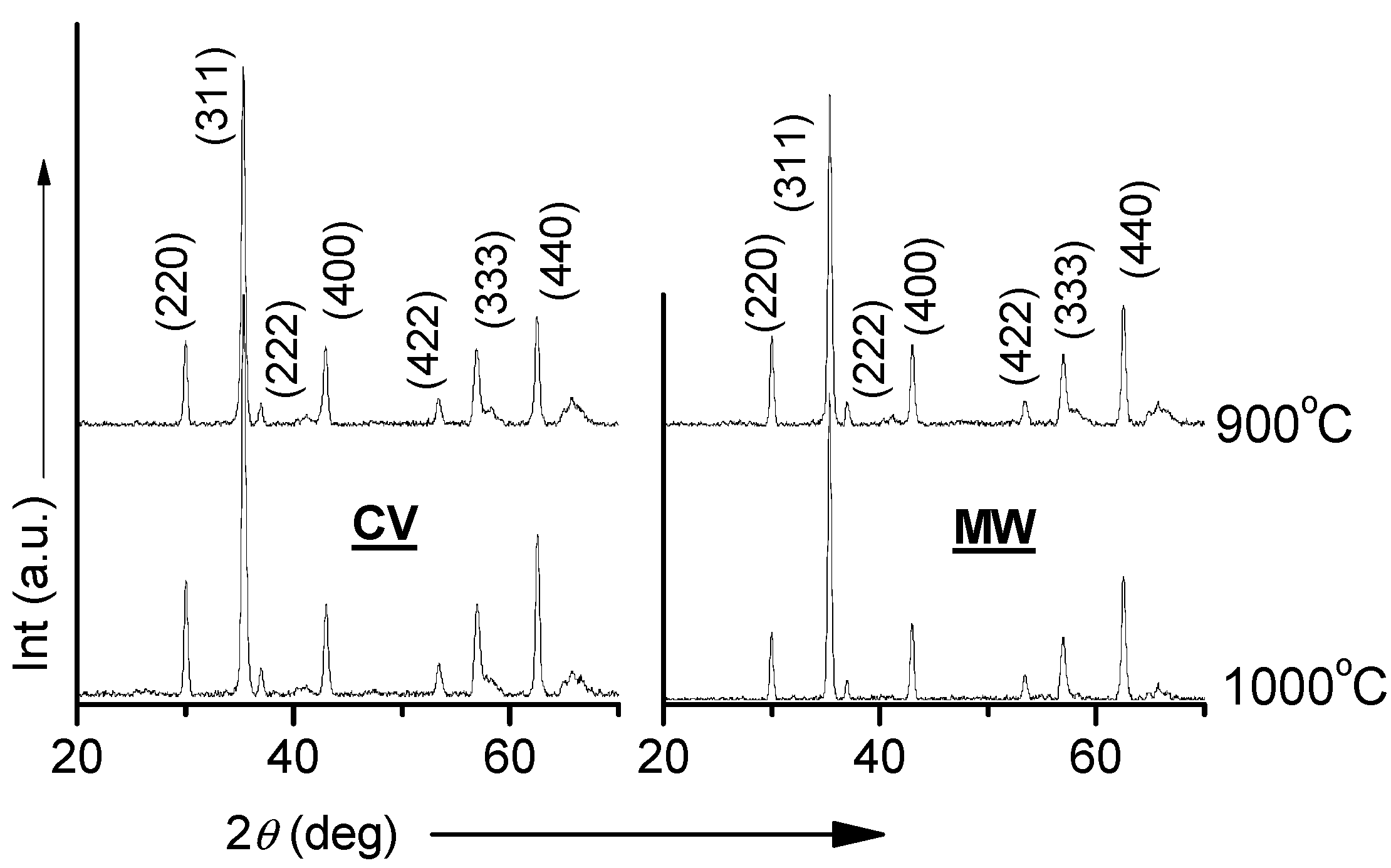

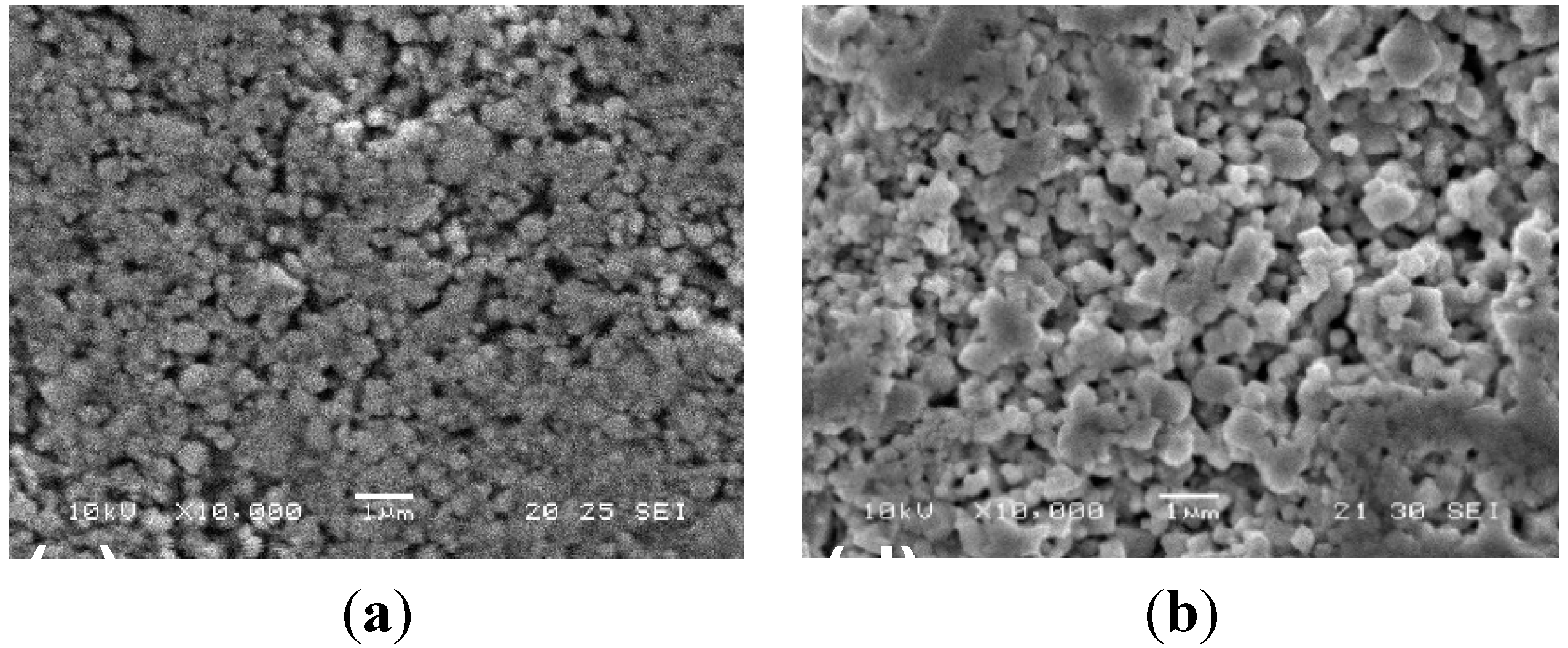

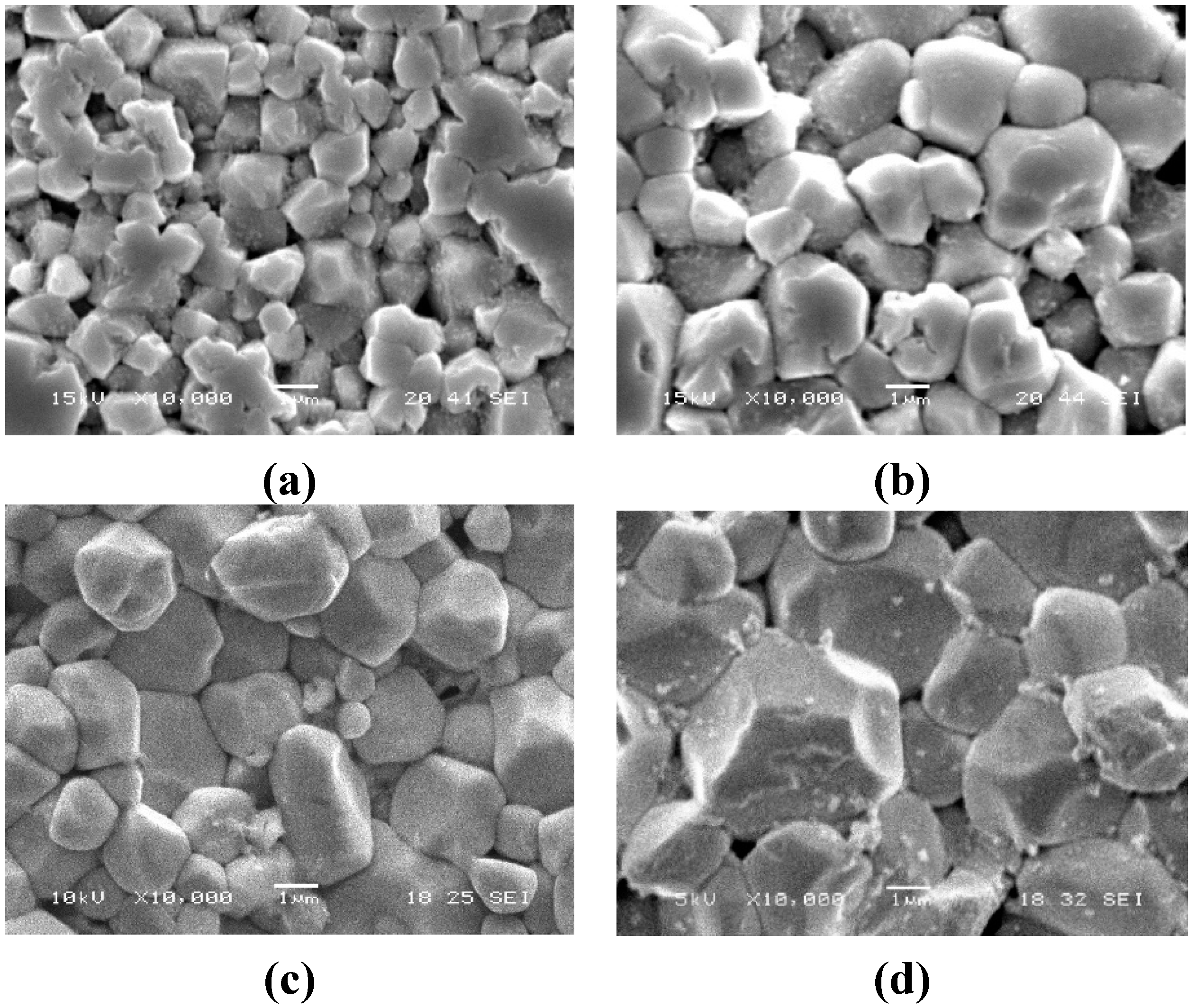

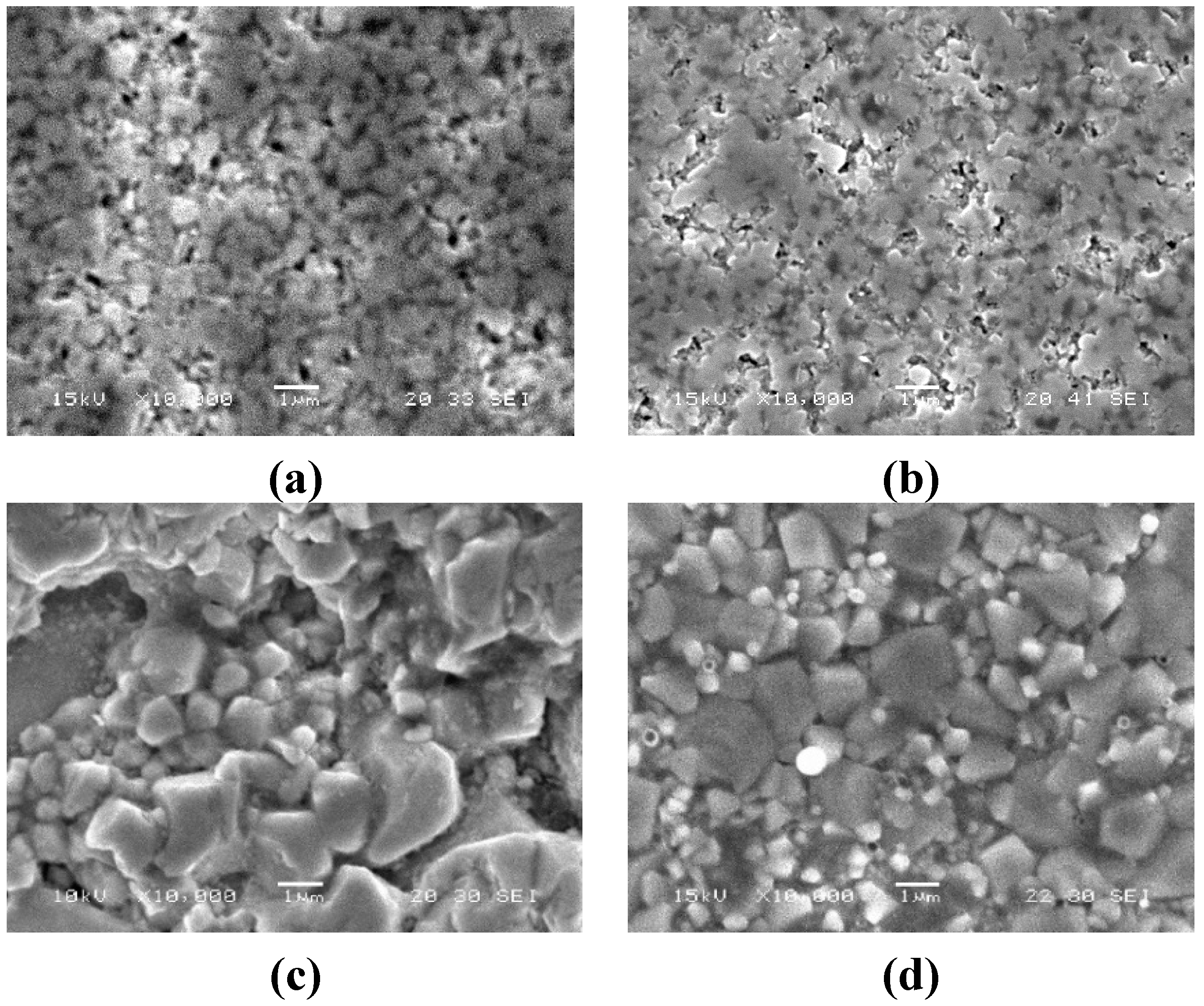

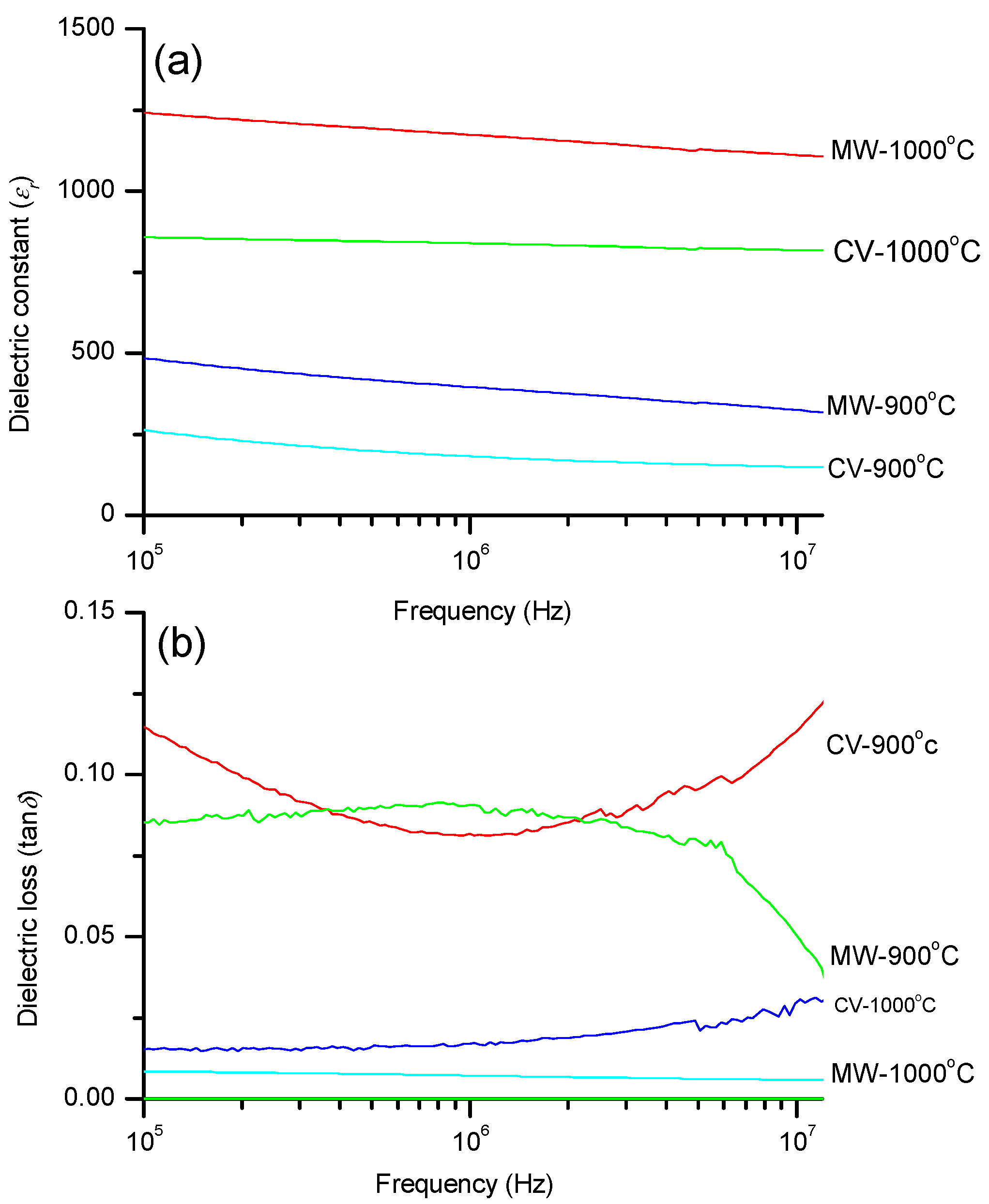

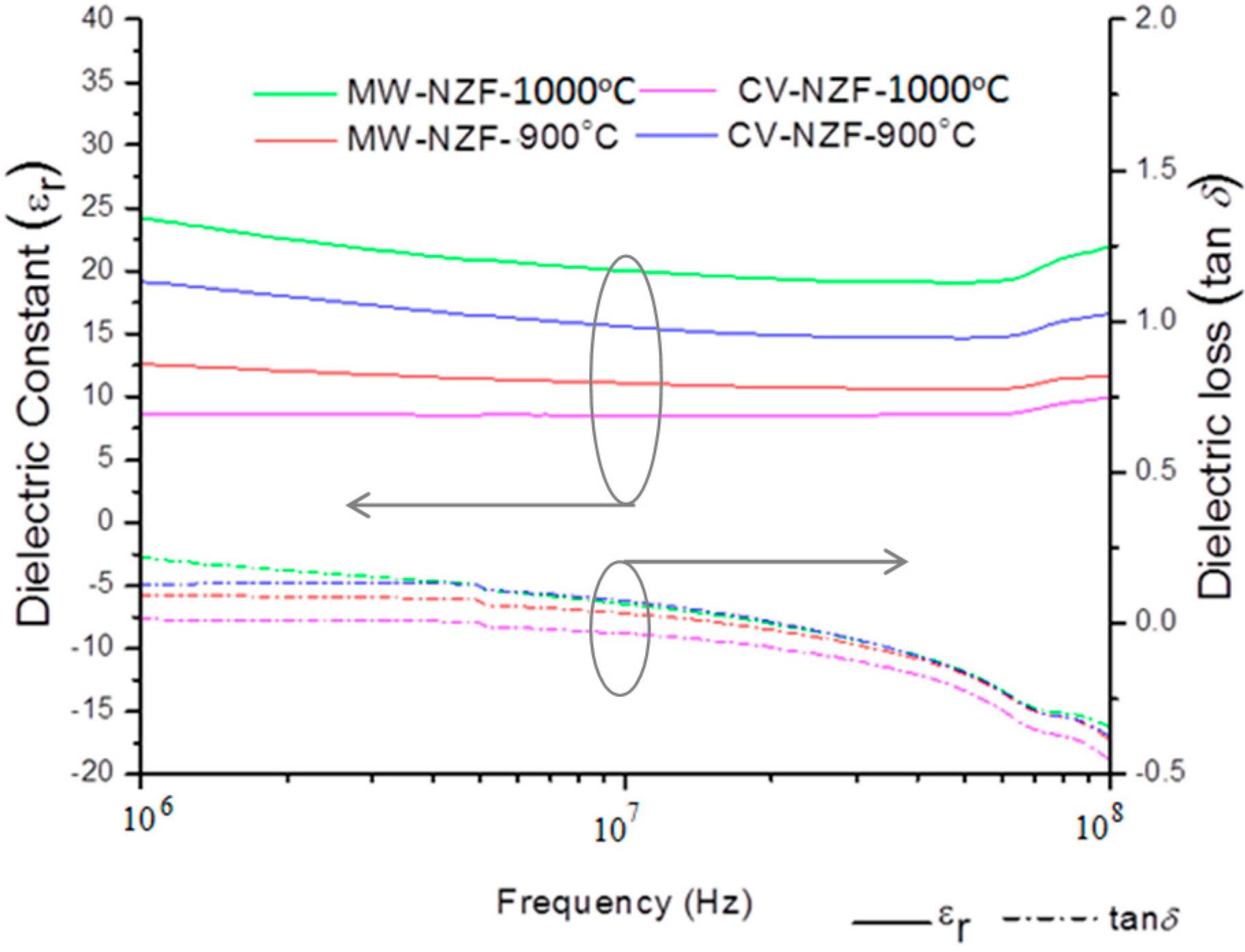

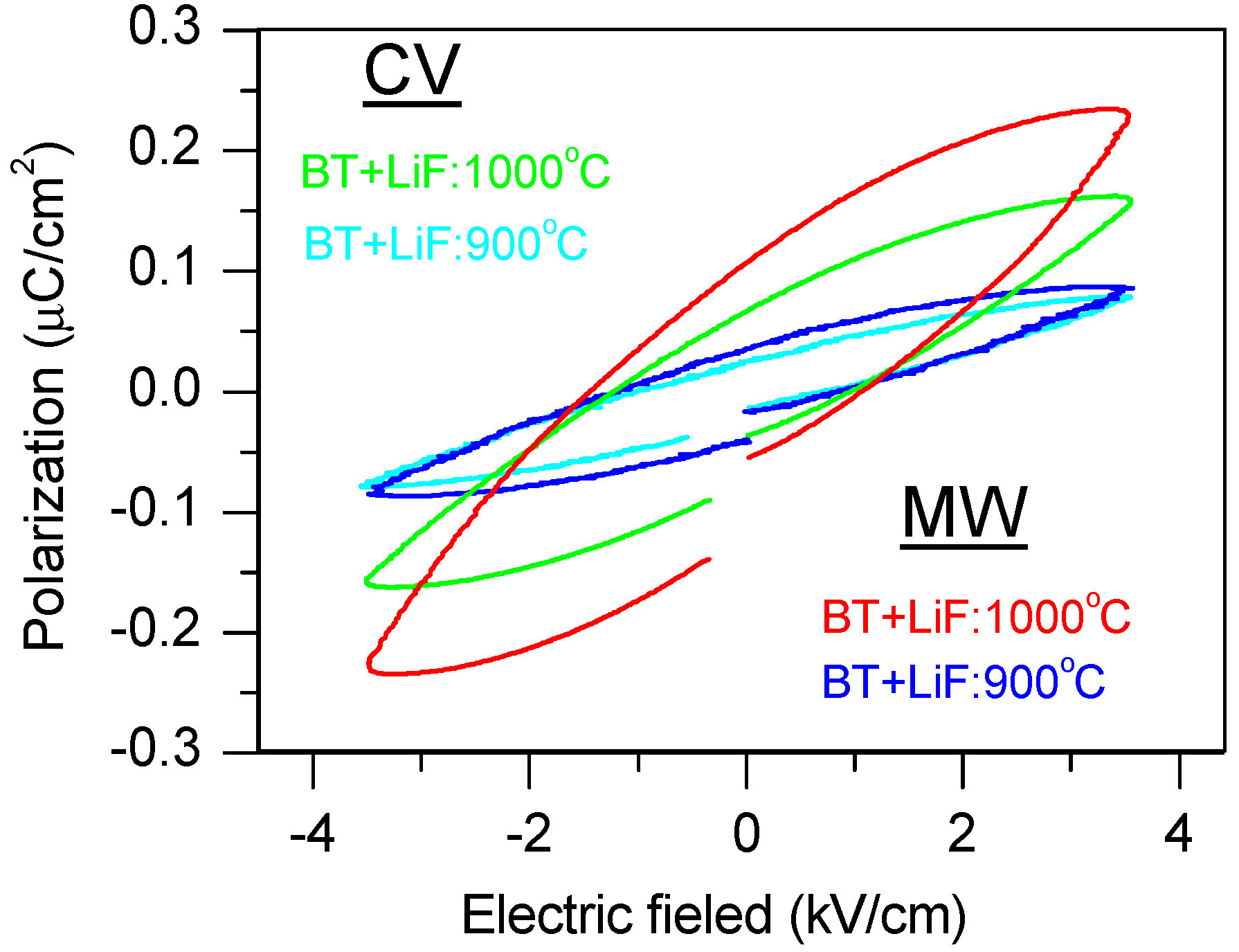

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Reisel, A.D.; Schops, S.; Lenk, A.; Schmutzler, G. Microstructural comparison of conventional and microwave sintered BaTiO3. Adv. Eng. Mater. 2007, 9, 400–405. [Google Scholar] [CrossRef]

- Sadhana, K.; Krishnaveni, T.; Praveena, K.; Bharadwaji, S.; Murthy, S.R. Microwave sintering of nanobarium titanate. Scripta. Materialia. 2008, 59, 495–498. [Google Scholar] [CrossRef]

- Mahboob, S.; Dutta, A.B.; Prakash, C.; Swaminathan, G.; Suryanarayana, S.V.; Prasad, G.; Kumar, G.S. Dielectric behaviour of microwave sintered rare-earth doped BaTiO3 ceramics. Mater. Sci. Eng. B 2006, 134, 36–40. [Google Scholar] [CrossRef]

- Sun, W.; Li, J.; Liu, W.; Li, C. Preparation of fine tetragonal barium titanate powder by a microwave-hydrothermal process. J. Am. Ceram. Soc. 2006, 89, 118–123. [Google Scholar] [CrossRef]

- Yodoji, P.; Peelamedu, R.; Agrawal, D.; Roy, R. Microwave sintering of Ni-Zn ferrites: Comparison with conventional sintering. Mater. Sci. Eng. B 2003, 98, 269–278. [Google Scholar] [CrossRef]

- Ghasemi, A.; Mousavinia, M. Structural and magnetic evaluation of substituted NiZnFe2O4 particles synthesized by conventional sol-gel method. Cerm. Int. 2014, in press. [Google Scholar]

- Shannigrahi, S.R.; Pramoda, K.P.; Nugroho, F.A.A. Synthesis and characterization of microwave sintered ferrite powders and their composite films for practical applications. J. Mag. Mag. Mater. 2012, 324, 140–145. [Google Scholar] [CrossRef]

- Pallathadka, K.P.; Huang, A.; Shannigrahi, S.R. On some properties of PZT–NZF composite films manufactured by hybrid synthesis route. Ceram. Int. 2011, 37, 431–435. [Google Scholar] [CrossRef]

- Sorescu, M.; Diamandescu, L.; Peelamedu, R.; Roy, R.; Yadoji, P. Structural and magnetic properties of NiZn ferrites prepared by microwave sintering. J. Magn. Magn. Mater. 2004, 279, 195–201. [Google Scholar] [CrossRef]

- Peelamedu, R.; Grimes, C.; Agrawal, D.; Roy, R. Ultralow dielectric constant nickel-zinc ferrites using microwave sintering. J. Mater. Res. 2003, 18, 2292–2295. [Google Scholar] [CrossRef]

- Walker, B.E.; Rice, J.R.W.; PohankaR, C.; Spann, J.R. Densification and strength of BaTiO3, with LiF and MgO additives. Am. Cemm. Soc. Bull. 1976, 55, 284–285. [Google Scholar]

- Zadeh, H.N.; Glitzky, C.; Dorfel, I.; Rab, T. Low temperature sintering of barium titanate ceramics assisted by addition of lithium fluoride-containing sintering additives. J. Eu. Ceram. Soc. 2009, 30, 81–86. [Google Scholar] [CrossRef]

- Lange, F.F. Liquid phase sintering: Are liquids squeezed out from between compressed particles? J. Am. Ceram. Soc. 1982, 65, C23. [Google Scholar] [CrossRef]

- Hsiang, H.I.; His, C.S.; Huang, C.C.; Fu, S.L. Sintering behavior and dielectric properties of BaTiO3 ceramics with glass addition for internal capacitor of LTCC. J. Alloys Comp. 2008, 459, 307–310. [Google Scholar] [CrossRef]

- Gao, L.; Huang, Y.; Hu, Y.; Du, H. Dielectric and ferroelectric properties of (1-x) BaTiO3-xBi0.5Na0.5TiO3 ceramics. Ceram. Int. 2007, 33, 1041–1046. [Google Scholar] [CrossRef]

- Gao, S.; Wu, S.; Zhang, Y.; Yang, H.; Wang, X. Study on the microstructure and dielectric properties of X9R ceramics based on BaTiO3. Mater. Sci. Eng. B 2011, 176, 68–71. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.W. Microwave processing: Fundamentals and applications. Composites Part. A 1999, 30, 1055–1071. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shannigrahi, S.; Tan, C.K.I. Comparison of Grain Structure, Electrical and Magnetic Properties of BaTiO3 and Ni0.5Zn0.5Fe2O4 Ceramics Sintered Using Microwave and Conventional Techniques. Technologies 2015, 3, 47-57. https://doi.org/10.3390/technologies3010047

Shannigrahi S, Tan CKI. Comparison of Grain Structure, Electrical and Magnetic Properties of BaTiO3 and Ni0.5Zn0.5Fe2O4 Ceramics Sintered Using Microwave and Conventional Techniques. Technologies. 2015; 3(1):47-57. https://doi.org/10.3390/technologies3010047

Chicago/Turabian StyleShannigrahi, Santiranjan, and Chee Kiang Ivan Tan. 2015. "Comparison of Grain Structure, Electrical and Magnetic Properties of BaTiO3 and Ni0.5Zn0.5Fe2O4 Ceramics Sintered Using Microwave and Conventional Techniques" Technologies 3, no. 1: 47-57. https://doi.org/10.3390/technologies3010047

APA StyleShannigrahi, S., & Tan, C. K. I. (2015). Comparison of Grain Structure, Electrical and Magnetic Properties of BaTiO3 and Ni0.5Zn0.5Fe2O4 Ceramics Sintered Using Microwave and Conventional Techniques. Technologies, 3(1), 47-57. https://doi.org/10.3390/technologies3010047