Abstract

Precise control and monitoring systems are essential for efficient energy consumption in food dehydration. This study develops an applied cyber-physical control system to optimize food dehydration in rotary dryers, integrating fuzzy control algorithms through data acquisition. The system architecture utilizes DHT22 transducers for temperature monitoring, a DHT11 for humidity measurement, an IP65 anemometer for dryer wind speed detection, and a load cell weight tracking system, all connected to an Arduino Mega 2560 R3 microcontroller implementing the integrated fuzzy logic library. Experimental evaluations were performed with different carrot loads (1.5, 2.5, and 3.5 kg), demonstrating optimal performance at the initial load of 3.5 kg with an energy consumption of 11,589 kJ for 9.33 h, achieving a final moisture reduction of 10%. The 1.5 kg sample showed optimal dehydration kinetics at an average dryer hot air velocity of 1.5 m/s, while maximum efficiency (86%) was achieved with the 3.5 kg load, compared to 30% and 17% for the smaller batches. These results validate the integration of cyber-physical systems to optimize the dehydration rate (0.301 kg/h), thereby ensuring product quality in agro-industrial drying applications.

1. Introduction

Food dehydration is one of the oldest food preservation techniques and continues to play a fundamental role today. Its importance is further highlighted by the growing global interest in energy sustainability and the reduction in post-harvest losses. Drying processes not only improve product quality and extend shelf life but also optimize energy consumption, addressing critical environmental challenges. Despite significant technological advances, a considerable gap remains between traditional methods and modern technologies in terms of efficiency, quality control, and sustainability. This gap emphasizes the need for innovative solutions that integrate advanced control and monitoring technologies to effectively transform industrial dehydration processes.

Efficient energy use and precise process control are essential for optimizing food dehydration, particularly in the food industry. These processes aim to preserve nutritional and sensory properties while minimizing energy consumption [1]. Dehydration involves removing moisture from products, typically using solar or electric dryers. Although conventional drying methods are widely employed, their energy efficiency can vary significantly sometimes by 50% or more depending on operating conditions and technical design [2].

Recent advances in food processing highlight the critical role of intelligent control systems and real-time monitoring in enhancing drying efficiency. Continuous observation of the biochemical and physicochemical properties of food during dehydration is necessary to ensure high-quality final products [3,4]. Factors such as thermal energy distribution, hot air velocity, and drying time influence both nutrient retention and the microbiological safety of dried foods [4]. Moreover, innovative modeling approaches including predictions based on machine learning and drying kinetics analysis have proven effective for optimizing industrial dryer parameters, allowing precise control of volume reduction and moisture content [1,5].

Solar drying is mainly viable in regions with high solar radiation. Studies indicate that parabolic solar dryers can effectively preserve fruits such as pitahaya and pineapple while maintaining their sensory qualities [5]. The choice of drying method also significantly affects the functional properties of fruit powders, as shown in research on guava pulp [6].

Additionally, the application of non-thermal dehydration techniques combined with vacuum microwave drying has improved mass transfer and preserved heat-sensitive bioactive compounds [7]. In recent years, physical simulations and Monte Carlo methods have gained relevance in optimizing carrot drying processes, leading to better thermal energy allocation and reduced dehydration times [8]. Furthermore, machine learning algorithms, including decision trees, random forests, and AdaBoost, have enabled accurate predictions of dehydration kinetics and energy consumption in temperature-controlled microwave drying [9]. In the case of lucuma powder, mathematical modeling and artificial intelligence techniques have effectively characterized microstructural properties during foam mat drying [10].

Among the latest technological advances are new dehydrator models, such as the fluidized bed dryer, which incorporate predictive systems to optimize dehydration efficiency in modern fluidized bed operations [11]. Additionally, integrating thermal energy storage in indirect solar dryers has proven highly effective for drying red chili peppers, allowing continuous and stable operation even under fluctuating solar radiation [12].

In the field of indirect solar dehydrators, innovative systems employing the Internet of Things (IoT) have emerged, enabling real-time monitoring of variables during the moisture removal process. This technology allows optimization of potato dehydration based on slice thickness within the dryer [13].

Performance analyses of solar chambers for apple dehydration have concluded that both chamber design and the control of internal conditions are critical factors for enhancing drying rates [14]. The integration of multiple sensors in dehydration processes that combine far-infrared radiation with hot air, such as in ginger processing, is essential for precise control of key variables, including temperature, humidity, and product moisture content [15]. Optimizing these parameters not only improves food quality but also promotes more efficient energy use. These developments highlight the growing role of digitalization and automation in dehydration processes and underscore the importance of incorporating advanced technologies to achieve more sustainable and efficient agro-industrial production.

The emergence of Internet of Things (IoT) technologies has substantially transformed the optimization of agricultural drying processes. Real-time monitoring systems enable improvements in both energy efficiency and product quality [16]. Such innovations are particularly critical for the design of forced-convection solar dryers that utilize renewable energy to mitigate the environmental impact of moisture removal. Dehydration methods have been shown to significantly affect the sensory properties of agricultural products, such as coffee, emphasizing the need to select appropriate techniques to preserve postharvest quality [17]. This consideration is equally important for other foods, such as carrots, where maintaining organoleptic properties is essential.

Recent studies on control strategies for dehydration processes have proposed integrating Proportional-Integral (PI) control with fuzzy logic. This hybrid approach has enhanced stability and efficiency in rotary dryers, improving the precision of thermal variable regulation [18]. Moreover, the incorporation of sensing systems with signal conditioning and fuzzy logic has enabled optimal data acquisition, supporting efficient and adaptive real-time decision-making [19].

The application of artificial neural networks to predict drying parameters including dehydration time, energy consumption, and exergy efficiency has proven highly relevant for moisture removal from corn grains in convective infrared rotary dryers [20]. These advancements significantly enhance predictive modeling capabilities in food preservation processes.

A critical aspect of rotary drum dryer performance is the maintenance and durability of internal components, particularly sensors. Estimating their service life using experimental data facilitates preventive maintenance planning and ensures continuous operation [21]. The quality of dehydrated agricultural products is directly influenced by the drying method employed. For example, different techniques applied to Arara Arabica coffee affect both physical and sensory characteristics, highlighting the importance of accurate instrumentation and process control [22]. Recent studies have also proposed methods to measure the overall heat transfer coefficient in rotary drum dryers, providing vital data for thermal energy optimization and industrial scaling [23]. Advances in thermal modeling are therefore crucial for designing innovative and efficient dehydration systems.

Research on dehydration methods has increasingly focused on pretreatments such as osmotic impregnation, edible coatings, and reduced pressure application. These techniques have improved the physical and functional properties of carrots dehydrated with microwave and vacuum methods while minimizing structural damage [24]. Such innovations create opportunities to integrate tailored pretreatments into rotary dryers adapted to specific drying conditions.

Furthermore, modifications of carrot cell walls with pectin, influenced by ultrasound and infrared treatments, have revealed new mechanisms of texture formation that are critical for product quality. These findings support enhanced multivariate control of moisture and temperature during dehydration, which is particularly important for optimizing both sensory and structural properties of low-moisture foods [25].

Controlled-temperature drying has been shown to significantly influence drying rates and key quality parameters in carrots, highlighting the need for method adjustment to preserve bioactive compounds [26]. This research provides essential insights for developing strategies that enable the sustainable use of agricultural waste through drying processes.

Although significant progress has been made in deploying various drying technologies, the implementation of integrated cyber-physical systems with adaptive fuzzy control remains an emerging field. This approach offers substantial potential for optimizing energy consumption and improving the quality of dehydrated products.

This study focuses on the development and evaluation of a cyber-physical system with adaptive fuzzy control. The system is designed to enable direct, real-time multivariate monitoring of temperature, humidity, airflow velocity, and mass loss during carrot dehydration in a rotary dryer. The integration of sensors with a microcontroller allows precise automatic adjustments in response to environmental variations, thereby optimizing drying conditions. It is anticipated that this intelligent control system will reduce specific energy consumption, enhance the thermal stability of the dryer, and preserve the organoleptic properties of the dehydrated product. Ultimately, this work aims to promote resource-optimized drying approaches in the agricultural sector, facilitating the adoption of sustainable, energy-efficient, and intelligent dehydration practices.

2. Materials and Methods

The experimental trials were conducted at the Agroindustrial Processes Laboratory of the National Institute of Technology of Mexico, Celaya, Guanajuato, between January 2024 and February 2025. Fresh carrots (Daucus carota L.) were locally sourced at their optimal stage of commercial maturity, with an initial moisture content of approximately 90% on a wet basis. Prior to each trial, the samples were stored under refrigeration at 4 ± 1 °C to ensure microbiological stability. Drying experiments were then performed using a rotary dryer equipped with a fuzzy control system. This system allows real-time monitoring and continuous analysis of critical variables such as temperature, relative humidity, and sample mass loss. The integration of these parameters into the system design aimed to enhance the energy efficiency of the drying process while maintaining favorable operating conditions to preserve the quality of the final product [27].

2.1. Design and Operational Characteristics of the Drying System Applied in Carrot Dehydration

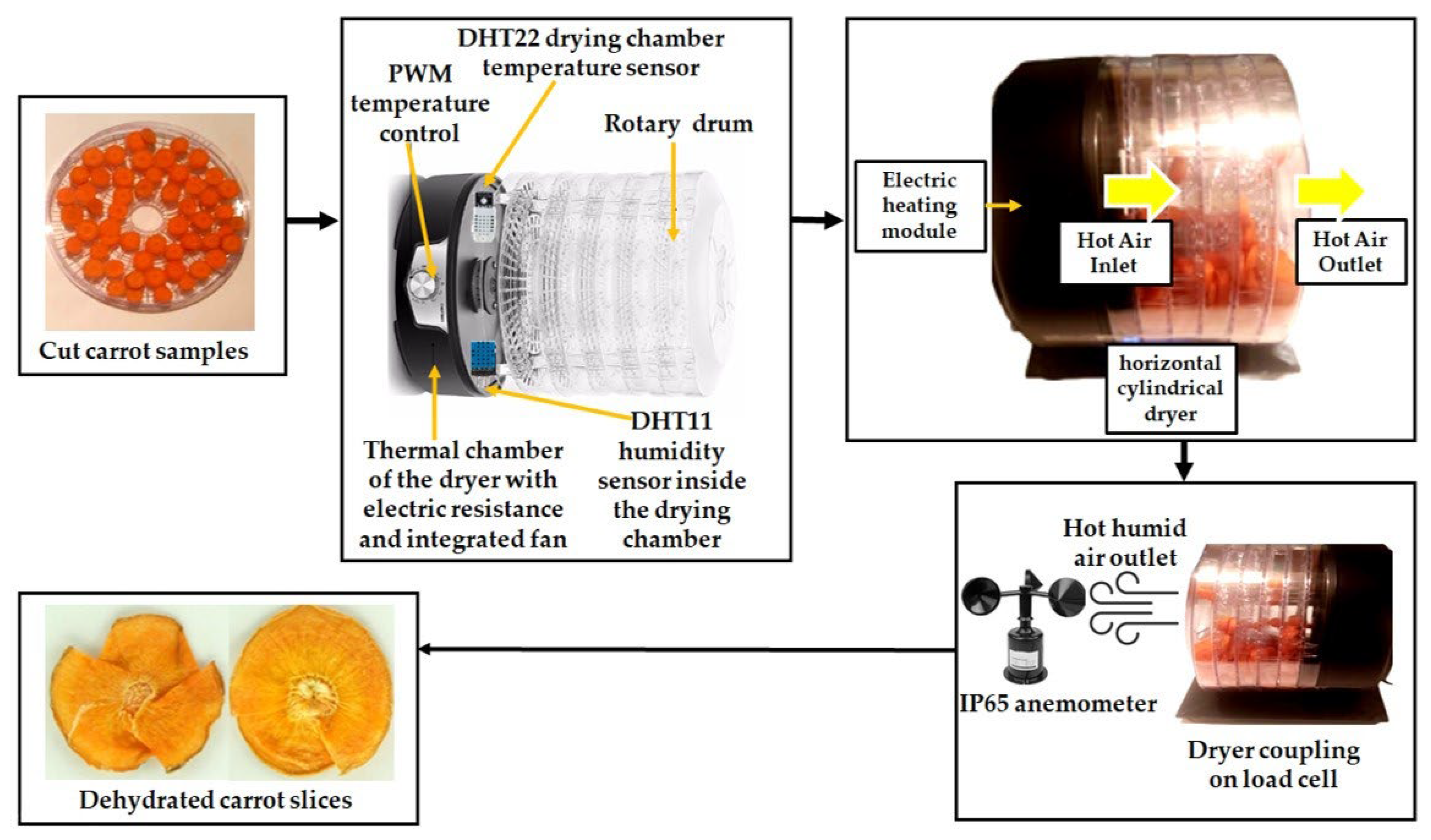

The dehydration system developed in this study consists of a cylindrical rotary dryer measuring 0.35 m in length with an internal diameter of 0.30 m. The drum is driven by a direct current motor that maintains a constant rotation speed of 1.5 revolutions per minute. This steady motion ensures uniform exposure of the product surface to heat and airflow, promoting homogeneous dehydration and generating laminar airflow within the chamber.

The drying chamber is equipped with electric resistance, located at the bottom of the system, to supply heat through forced convection. Heating intensity is regulated by a pulse-width modulator (RobotDyn, Zhuhai, China), which ensures precise temperature control within a range of 50 °C to 75 °C, depending on the food type and specific process requirements. Hot air generation and circulation are provided by a centrifugal fan with a nominal (maximum design) power rating of 200 W, enabling efficient heat transfer while minimizing turbulence. The cylindrical drum used for carrot dehydration is arranged horizontally to guarantee mechanical stability, uniform rotation, and a controlled product residence time. In addition, the system incorporates internal flights that lift and disperse the product during rotation, promoting better mixing and enhancing both heat and mass transfer efficiency. The recorded temperature in the rotary dryer corresponds to the drying air inside the drum, accurately representing the thermal environment to which the carrot samples are exposed during dehydration.

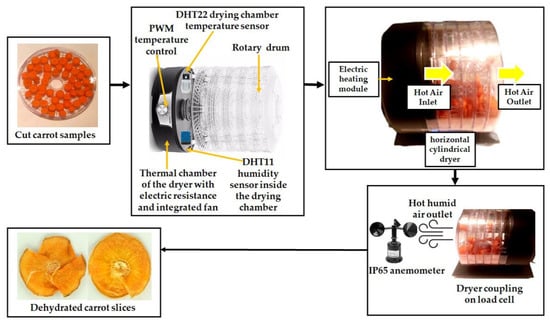

The design of the drying unit is based on recent research on rotary dryers applied to agri-food products, which has demonstrated their effectiveness in preserving thermal stability and key physicochemical and functional properties of vegetables and other food matrices [28,29,30]. Francik et al. [28] used advanced modeling approaches, including artificial neural networks, to accurately predict the drying behavior of onion slices, emphasizing the value of precise process monitoring. Similarly, Bogusz et al. [29] examined the effects of different drying methods on the physical and functional properties of powdered black soldier fly larvae, illustrating that the selection of drying parameters has a direct impact on product quality. In designing the control strategy for the present system, we built upon the foundational work of Mamdani [30], who introduced fuzzy logic algorithms for controlling dynamic processes. His approach allows the integration of expert knowledge into control rules, enabling real-time adjustments in response to changing system conditions. This principle has been applied in our drying system to manage critical variables such as temperature, humidity, air velocity, and mass loss, creating a robust cyber-physical framework with distributed sensors. This instrumentation supports the implementation of fuzzy logic control, which dynamically adjusts operational parameters to optimize drying performance, as illustrated in Figure 1.

Figure 1.

Removing moisture from carrot slices with a rotary dehydrator.

2.2. Preparation of Carrot Samples and Experimental Drying Conditions

During the experimental phase, fresh carrots with high moisture content were selected based on uniform root size. The samples were washed with potable water to remove residues and impurities, then peeled and sliced into discs with a thickness of 5 ± 0.2 mm. Each slice had an average major diameter of 3.7 cm and a minor diameter of 2.2 cm. Prior to each experiment, the samples were weighed and evenly distributed inside the rotary dryer drum. Three load levels (1.5 kg, 2.5 kg, and 3.5 kg) were tested under average operating conditions: a drying temperature of 75 °C and an air velocity of 1.5 m/s, following the optimal parameters reported in the literature for similar processes [31,32].

2.3. Cyber-Physical Monitoring and Control System Applied to Carrot Dehydration

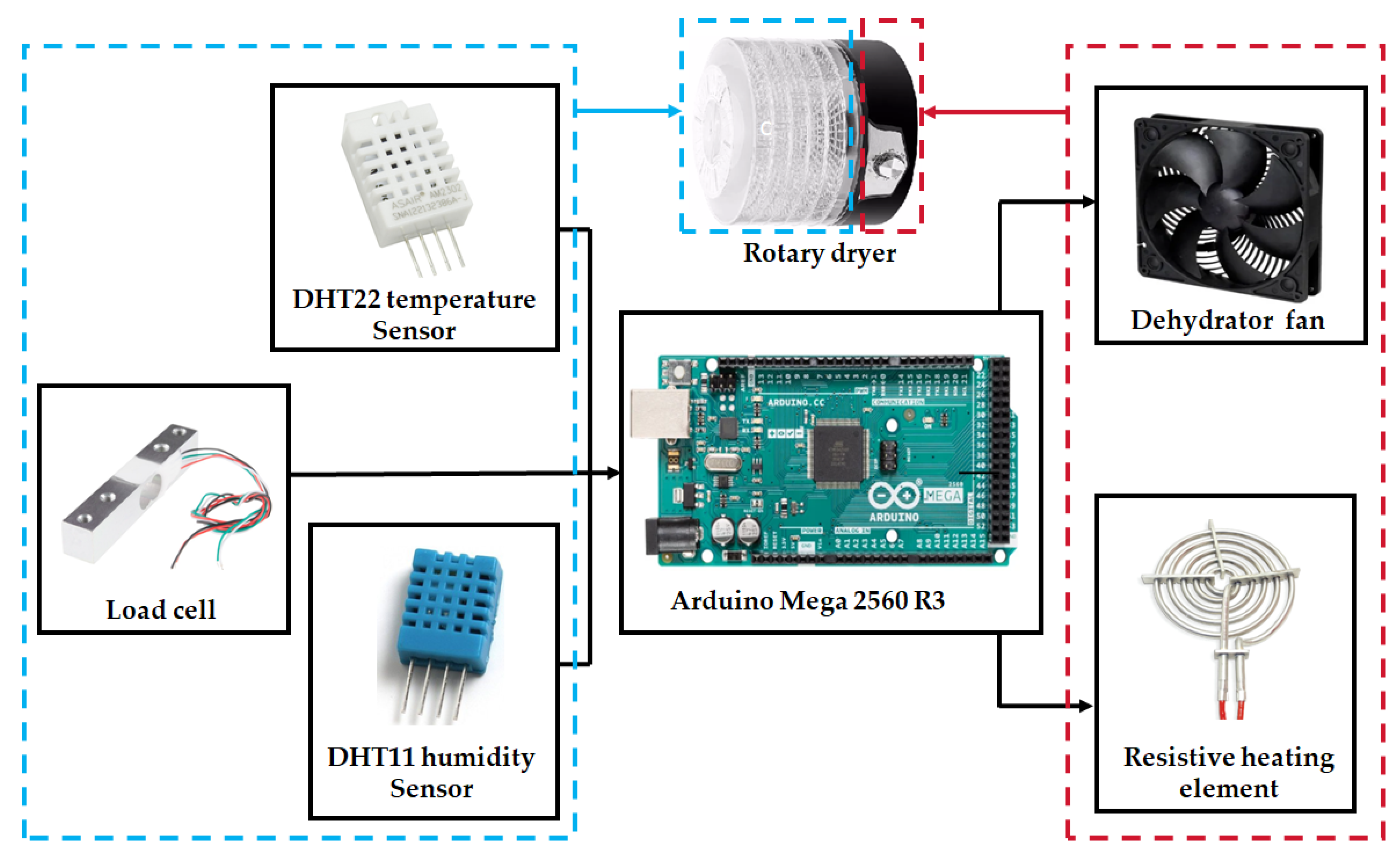

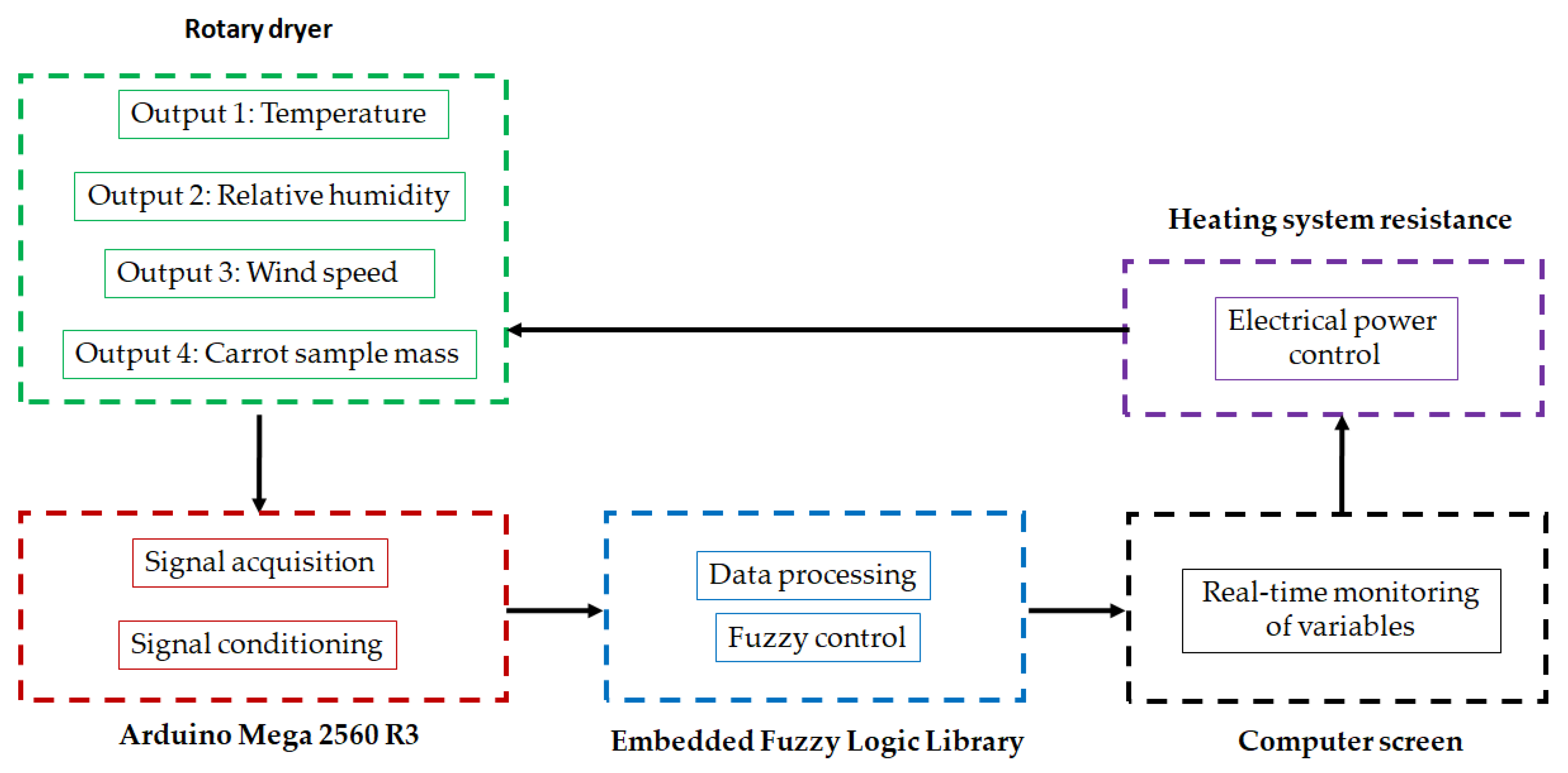

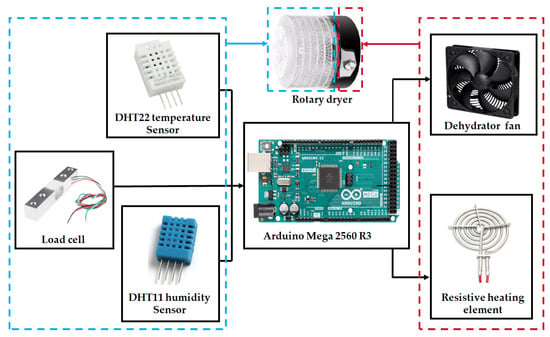

The cyber-physical system was designed to enable real-time monitoring of the main variables involved in the dehydration process using high-precision sensors. Drying air temperature and relative humidity were measured with DHT22 (Aosong Electronics Co., Ltd., Guangzhou, China) and DHT11 (Aosong Electronics Co., Ltd., Guangzhou, China) transducers, respectively. Airflow velocity was recorded with an IP65 anemometer (Davis Instruments, Hayward, CA, USA), while sample mass loss was measured using load cells connected to the data acquisition unit. The analog signals were conditioned and digitized through an Arduino Mega 2560 R3 (Arduino AG, Turin, Italy), which minimized electrical noise and improved signal stability, ensuring reliable data for subsequent analyses of thermal efficiency and process modeling.

The control architecture was based on the Arduino Mega 2560 R3 open-hardware platform, selected for its compatibility with multiple sensors and its capacity to handle real-time applications. Process control was implemented through a fuzzy logic algorithm programmed in C++ using a specialized artificial intelligence library. The developed system integrates multivariable monitoring of temperature, relative humidity, air velocity, and product mass loss, enabling dynamic control of drying conditions and optimizing both dehydration time and energy efficiency. Through fuzzy control based on experimental rules tailored to the specific dehydration kinetics of carrots, the system responds precisely to variations in critical process variables. The combination of multivariable sensors, real-time data acquisition, and fuzzy logic applied to a rotary dryer with mass control minimizes residual moisture zones and reduces energy consumption per kilogram of product [33,34,35].

Experimental trials were conducted, during which the heating and ventilation systems were activated. Temperature, relative humidity, airflow velocity, and product mass were continuously recorded until the samples reached a final moisture content of ≤10% (wet basis) using the sensor-based data acquisition system. At the end of each run, once the drum had cooled, the final mass of the samples and the specific energy consumption were determined, following previously established sensing protocols applied to products with similar characteristics, as illustrated in Figure 2.

Figure 2.

Interconnection architecture between sensors, actuators and dryer control unit.

2.4. Dryer Design and Implementation of Fuzzy Control in Arduino

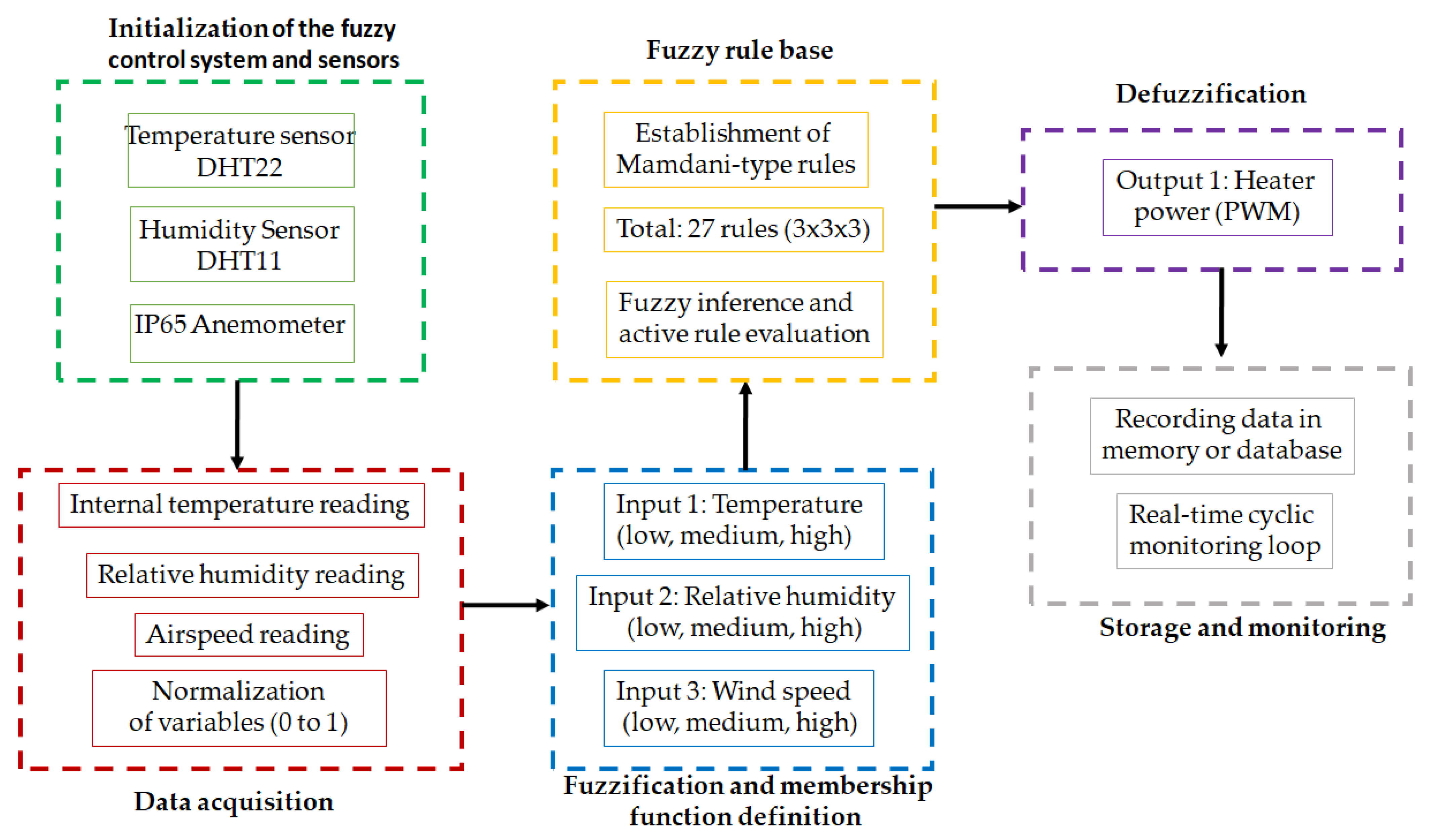

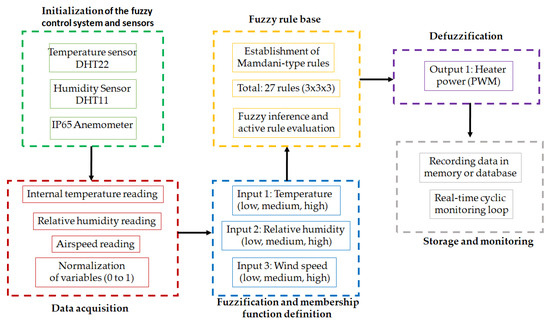

To optimize the dehydration process through intelligent control, a fuzzy control system based on Mamdani logic was implemented on the Arduino Mega 2560 R3 platform. The controller receives real-time measurements from temperature, humidity, and airflow velocity sensors to dynamically regulate the power supplied to the heating element, ensuring uniform drying and stable thermal conditions, as shown in Figure 3 [36].

Figure 3.

Methodology implemented in the design of adaptive fuzzy control applied to dehydration.

The fuzzy controller employed is not adaptive. Unlike an adaptive controller, which adjusts its internal parameters or structure during operation to respond to changes in system dynamics or environmental conditions, the developed system has a fixed rule base, static membership functions, and predefined inference logic, without real-time adjustments to these elements.

The controller allows real-time regulation of the dryer temperature, adjusting the heating element power based on variations in humidity and airflow velocity. This regulation capability ensures precise thermal management, contributing to efficient and uniform drying without the need to modify the controller’s structure or rules.

2.4.1. Mamdani-Type Fuzzy Logic Model

The Mamdani model was selected due to its broad acceptance in industrial applications and its strong ability to represent expert knowledge through “If–Then” rules. This approach is particularly suitable for control systems in environments characterized by high uncertainty and nonlinear behavior, such as thermal processes in food dehydration. The model consists of four stages: (1) fuzzification, which converts crisp input values (temperature, humidity, and airflow velocity) into degrees of membership in linguistic sets; (2) rule evaluation, where logical inferences are applied using minimum and maximum operators; (3) aggregation, which combines the results of all activated rules; and (4) defuzzification, where the centroid method translates the fuzzy results into a precise numerical output. The final value generates the PWM signal that regulates the thermal power applied to the dryer resistance [30,37,38].

2.4.2. Definition of Linguistic Variables and Fuzzy Sets

Three input variables were defined for the fuzzy control system: air temperature (20–85 °C), relative humidity inside the chamber (10–90%), and airflow velocity (0–3 m/s). The output variable was the heating power, expressed as a percentage of pulse-width modulation (PWM) within an operating range of 0–100%. Each variable was represented by three fuzzy sets (low, medium, and high) modeled with triangular membership functions. This formulation provided a more accurate representation of measurement uncertainty and ensured smooth transitions between linguistic levels.

Air temperature was categorized into low (20–40 °C), medium (35–65 °C), and high (60–85 °C). Relative humidity followed similar ranges: low (10–30%), medium (25–60%), and high (55–90%). Airflow velocity was segmented into low (0.0–0.8 m/s), medium (0.6–1.8 m/s), and high (1.6–3.0 m/s). Finally, PWM output power was defined as low (0–40%), medium (35–70%), and high (65–100%) [39].

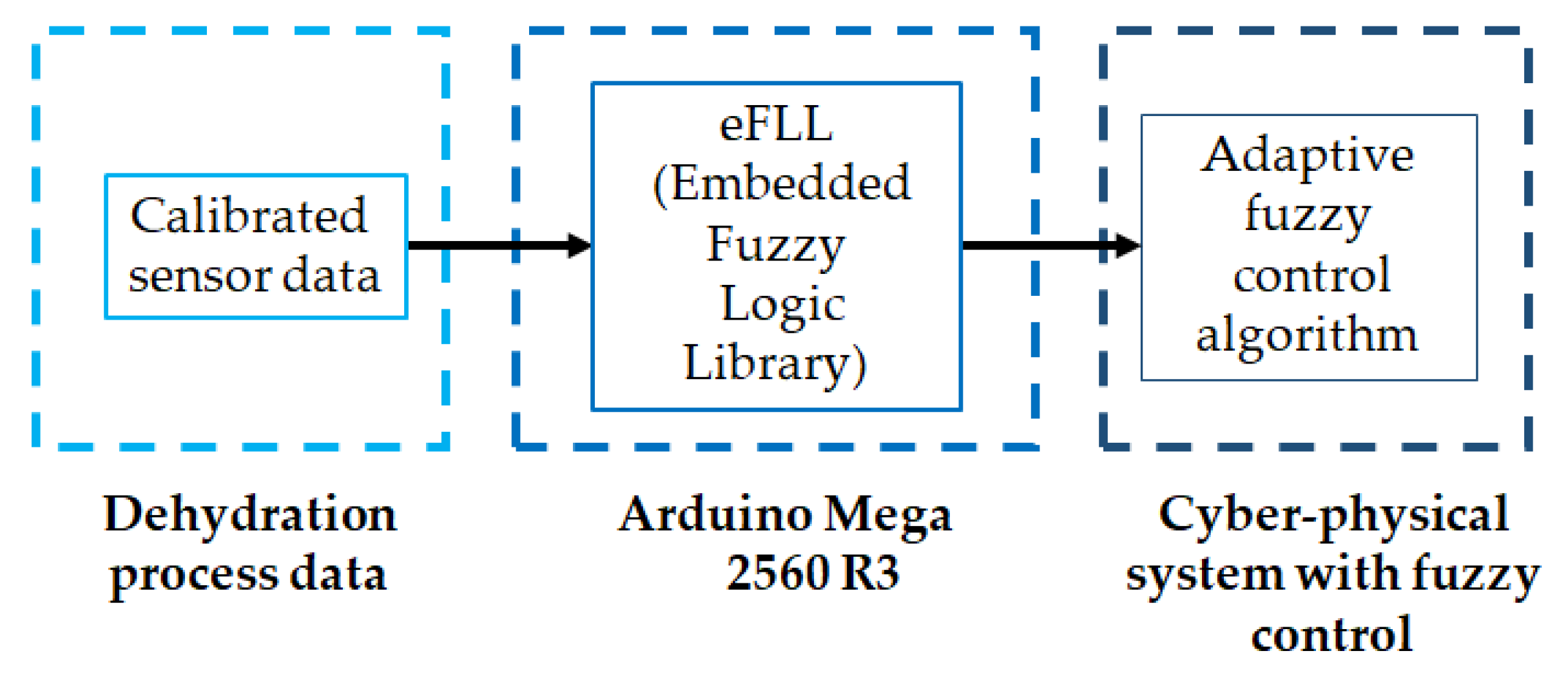

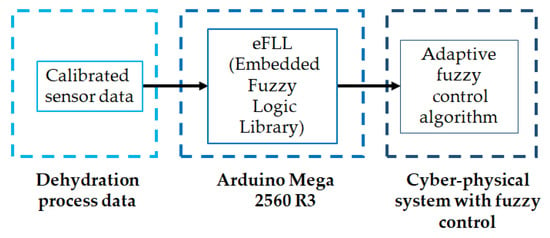

2.4.3. Implementing the Control System in Arduino with eFLL

The fuzzy control algorithm was implemented on an Arduino Mega 2560 R3 using the Embedded Fuzzy Logic Library (eFLL), optimized for embedded systems. This library provides a structured framework for defining inputs, outputs, membership functions, and inference rules. The system was configured with three fuzzy inputs (temperature, humidity, and airflow velocity) and one fuzzy output (PWM power), resulting in a total of 27 rules derived from experimental knowledge of the rotary drying process [40].

The controller logic was constructed using combinations of rules with AND logical operators. These rules encompassed all possible scenarios among the three input variables (3 × 3 × 3), enabling accurate system responses under varying drying conditions. For instance, one representative rule stated: “IF temperature is high AND humidity is low AND airflow velocity is low, THEN output power is high,” as illustrated in Figure 4.

Figure 4.

Integrated fuzzy logic system algorithm.

2.4.4. Fuzzy System Rule Base

The set of 27 rules was directly programmed in Arduino using the structures provided by the eFLL library. A representative example is as follows: when both temperature and humidity are low and the airflow velocity is also low, the output power is set to a medium level (R1). Conversely, if humidity is high while airflow velocity remains low, the output power is increased to a high level (R7). This logic was designed to maximize heat transfer under conditions where moisture evaporation is slower, thereby ensuring efficient dehydration.

It is worth noting that this control scheme can be optimized in terms of both drying time and energy consumption. Optimization is achieved through iterative calibration of the membership functions and adjustment of the fuzzy rules, based on experimental results obtained under different operating conditions. In this way, the parameters that allow for reducing dehydration time without compromising thermal efficiency or product quality are identified.

In this study, optimization was experimentally addressed through controlled tests, comparing the profiles of temperature, humidity, and airflow velocity under different fuzzy system configurations. This approach made it possible to select the rule sets that maximize heat transfer and promote efficient moisture evaporation, ensuring a faster process with lower energy expenditure. The rules were experimentally validated through analysis of the thermal behavior and the system response [41].

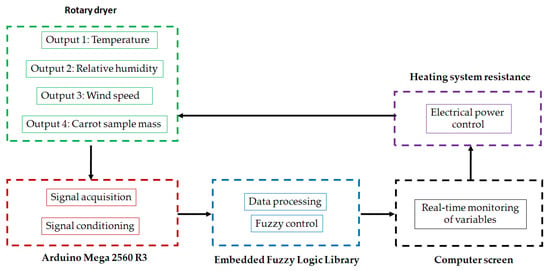

2.4.5. Real-Time Control Cycle: Inference and Defuzzification

After evaluating the rules using Arduino’s Mamdani-type fuzzy inference system, the process moves to the aggregation phase, in which all partial outputs generated by the rules are combined. Aggregation is performed using the maximum union operation (max), enabling multiple rule conditions to contribute to a single output membership function. The result is a composite fuzzy function representing the cumulative degree of membership for each possible level of the output variable in this case, the heating power.

Next, defuzzification is applied to convert the fuzzy representation into a crisp value interpretable and executable by the physical system [42,43]. The centroid method (center of area) is used due to its balance between computational efficiency and dynamic stability. Implemented through the fuzzy library on Arduino, this method generates a single numerical value representing the optimal system performance. This value is then converted into a PWM signal, precisely regulating the power supplied to the rotary dryer’s electrical resistance. This continuous and adaptive control mechanism maintains stable thermal conditions throughout the drying process, as illustrated in Figure 5.

Figure 5.

Operating cycle of the cyber-physical system for carrot dehydration.

2.4.6. Advantages of the Mamdani Approach in Dehydration Processes

The Mamdani-type fuzzy control approach implemented in this study provides several advantages for dehydration processes. It offers high flexibility in handling thermal and environmental variability, demonstrates robustness against noise from low-cost sensors, and allows empirical adjustments based on operator experience without relying on complex mathematical models. Moreover, its scalable structure enables the future integration of additional variables, such as drying time and mass loss, enhancing its applicability in real-world production environments [44,45,46].

2.5. Evaluation of Dehydration Kinetics

During the experimental phase, the dehydration of carrot samples in the rotary dryer was continuously monitored to characterize the drying kinetics under controlled operating conditions. Key parameters recorded included the system’s thermal energy distribution, the total drying time, and the mass loss of the samples. These experimental data allowed the calculation of energy and mass balances to quantify essential drying parameters, such as the energy required for moisture removal, heat transfer between hot air and product surface, drying rate, and overall thermal efficiency. These calculations form a robust basis to validate the performance of the proposed cyber-physical system and its effectiveness in vegetable dehydration [47].

The total energy consumed for moisture removal (, kJ) was calculated as the sum of the energy required to heat the water contained in the carrot to its boiling point () and the latent heat necessary for vaporization (). This formulation allows a clear separation of the contributions of sensible and latent heat [43] and is calculated using Equation (1):

The sensible heat contribution () represents the amount of energy required to increase the temperature of the water contained in the carrot until it reaches its boiling point [48], calculated according to Equation (2):

Here, (kg) denotes the initial carrot mass, (kJ/kg°C) is the specific heat of the carrot, (°C) is the product temperature, and (°C) the ambient temperature.

The latent heat contribution () corresponds to the energy required for vaporization of the water content [48], calculated by Equation (3):

where (kg) is the evaporated water mass, and (kJ/kg) is the latent heat of vaporization. This term reflects the portion of energy effectively used for phase change, which was validated experimentally by monitoring carrot mass reduction throughout the process.

The total energy supplied by the hot air to the product (q, kJ) was estimated considering the properties of air and its flow, according to Equation (4) [49]:

In this expression, (kg/m3) is air density, (kJ/kg°C) is the specific heat of air, and and (°C) are the inlet and outlet air temperatures, respectively.

The total air volume circulating in the dryer, (m3), was derived from airflow velocity, duct cross-sectional area, and total drying time [50], as described by Equation (5):

where (m/s) is airflow velocity measured with an IP65 anemometer, (m2) is the duct cross-sectional area, and (s) is the operating time. This calculation was essential to determine the effective volume of air involved in energy transfer to the product, a critical parameter for estimating dryer efficiency [51].

The moisture content of carrots (, % wet basis) was determined by drying the samples until reaching a constant mass [52], and was calculated using Equation (6):

where (kg) represents the final dry mass. This calculation enabled a direct comparison between theoretical and experimental moisture loss, forming the basis for the kinetic analysis of dehydration.

The dehydration rate (, kg/h) was computed as the ratio between the evaporated water mass (, kg) and the total drying time (, h), as expressed in Equation (7):

This parameter progressively decreased as the moisture content approached equilibrium, consistent with classical drying kinetics. Experimental measurements obtained through load cells confirmed this trend, supporting the ability of the cyber-physical system to maintain controlled drying rates [53].

Finally, the thermal efficiency of the process (, %) was determined as the ratio between the energy effectively used for moisture removal (, kJ) and the total energy supplied to the system (, kJ), according to Equation (8):

This indicator reflects the system’s ability to transform the supplied energy into useful evaporation work. Higher efficiency indicates reduced thermal losses and improved energy utilization. The integration of real-time measurements of temperature, airflow, and mass reduction allowed validation of the dryer’s energy efficiency under different experimental conditions, including variations in carrot load and drying time [53,54].

3. Results and Discussion

3.1. Evaluation of Carrot Dehydration Kinetics

This section analyzes the dynamics of moisture loss in fresh carrots during dehydration in a rotary dryer equipped with a cyber-physical system implementing fuzzy control. Experimental tests were conducted using three initial masses (1.5 kg, 2.5 kg, and 3.5 kg), maintaining an average temperature of 75 °C and an average hot air velocity of 1.5 m/s. The instrumentation included DHT22 and DHT11 sensors, an IP65 anemometer, and load cells, all connected to an Arduino Mega 2560 R3 microcontroller for real-time multivariate monitoring of the drying process.

At the beginning of each experimental trial, the internal temperature of the rotary dryer was stabilized to ensure consistent drying conditions. Pre-weighed carrot samples were evenly distributed within the dryer, and their mass was continuously monitored using load cells. The progressive loss of moisture was recorded throughout the drying process, and the moisture content of the samples was calculated using Equation (6). This approach allowed precise determination of the percentage of moisture remaining in the samples, enabling the construction of accurate drying curves for each tested load and facilitating the analysis of dehydration kinetics under controlled experimental conditions.

The results revealed a clear trend: higher initial loads required longer total dehydration times but exhibited significantly improved energy efficiency. These findings are consistent with recent studies demonstrating that thermal efficiency and heat transfer capacity are optimized when operating with product loads under controlled conditions [32,38,41].

In contrast to traditional methods, such as solar drying or convection drying without intelligent control, the system employed in this study demonstrated responsiveness to variations in process conditions. This capability reduced total operating time without compromising the quality of the final product, aligning with previous research that incorporated fuzzy logic to enhance energy efficiency and preserve the structural integrity of dehydrated foods [29,36,40,44].

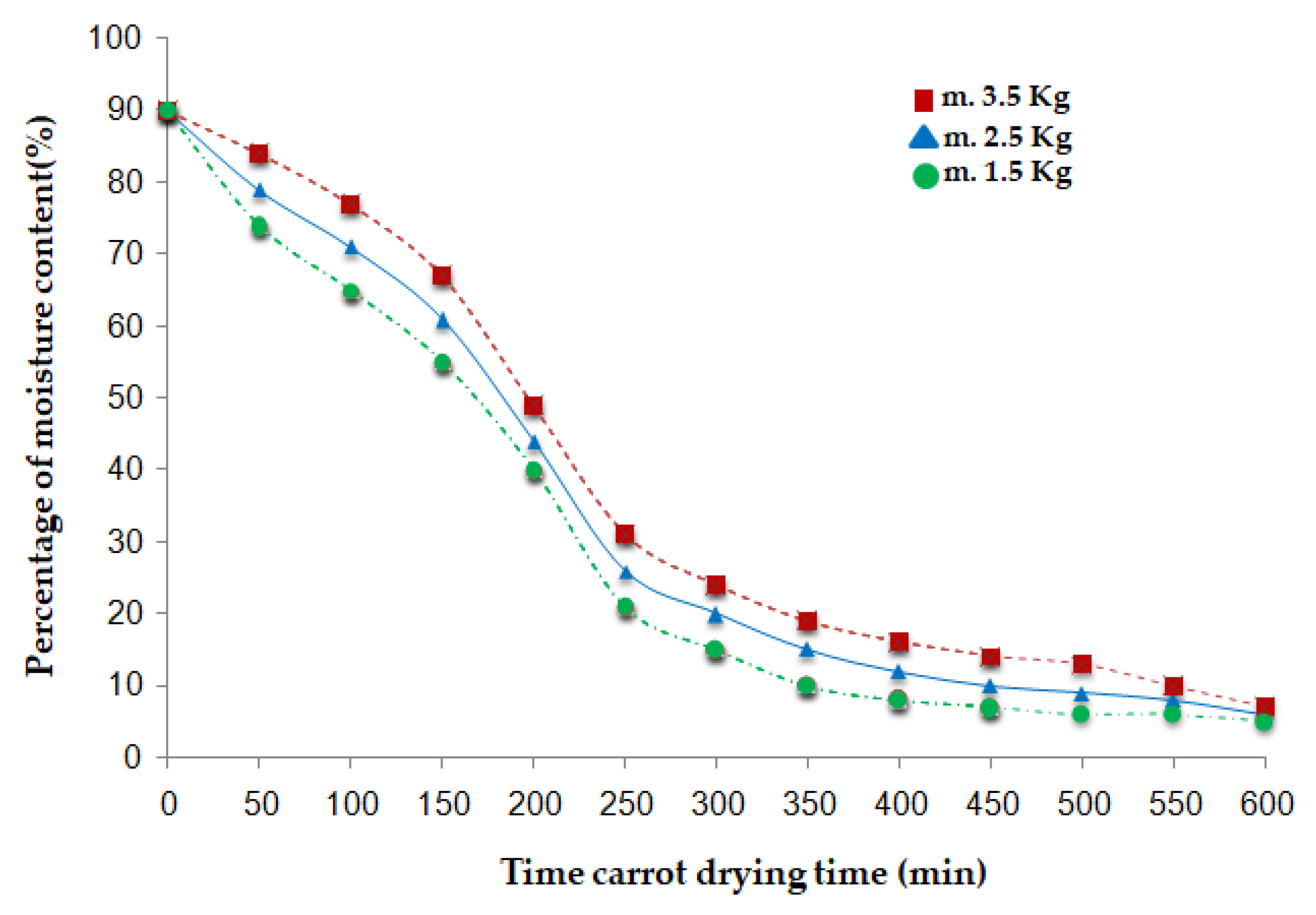

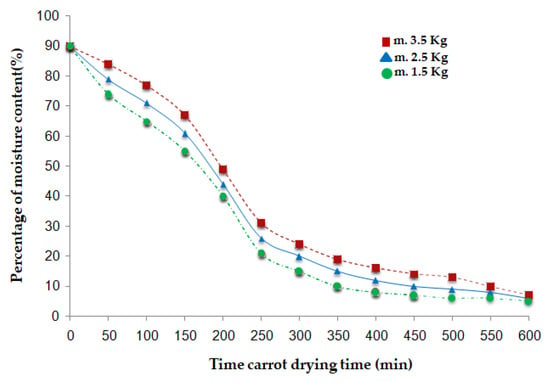

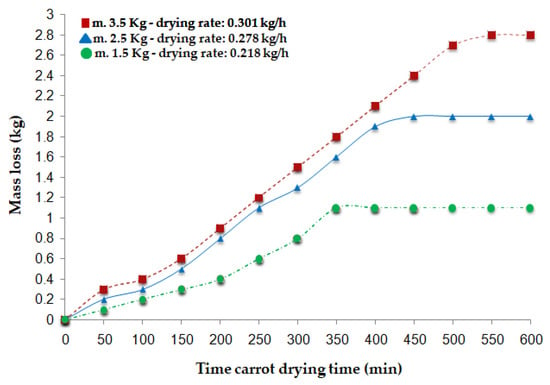

Figure 6 illustrates moisture loss over time for each evaluated load. The 1.5 kg load reached the final moisture content of 10% in approximately 5.5 h, whereas the 2.5 kg and 3.5 kg loads required 7.2 and 9.3 h, respectively. This behavior aligns with mass and heat transfer principles, where temperature gradients and surface area exposed to hot air are key factors influencing drying kinetics [31,35,45].

Figure 6.

Characterization of drying kinetics in carrots with variable initial loads.

The implementation of fuzzy control enabled a dynamic balance among system parameters, optimizing process temperature based on internal humidity, hot air velocity, and product mass monitoring. These results support studies highlighting the potential of intelligent systems to adapt thermal processes in real time, thereby reducing dehydration time [28,30,50].

3.2. Analysis of Temperature Measurements During the Dehydration Process

The experimental tests performed with the cyber-physical system for thermal analysis involved continuous, real-time monitoring of the rotary dryer’s internal environment using multiple sensors: DHT22 for temperature, DHT11 for relative humidity, an IP65 anemometer for air velocity, and load cells for mass loss. This comprehensive monitoring allowed for a precise characterization of the system’s thermal behavior throughout the carrot drying process, ensuring stable and appropriate conditions for efficient moisture removal.

The fuzzy control system, programmed on the Arduino Mega 2560 R3 data acquisition board, processed in real time the signals from all these sensors, dynamically adjusting critical operational parameters, primarily the heater power and the hot air temperature within the dryer. These adjustments are performed via pulse-width modulation (PWM) to control the electric resistance, maintaining the drying air temperature within the cylindrical chamber of the dehydrator.

The adjustment of these parameters is implemented through a fuzzy logic algorithm, which continuously translates sensor readings into real-time control actions. This adaptive capability is essential for maintaining uniform heat distribution and preventing temperature fluctuations that could compromise the quality of the final product, as supported by recent studies on innovative food drying systems [28,30,39].

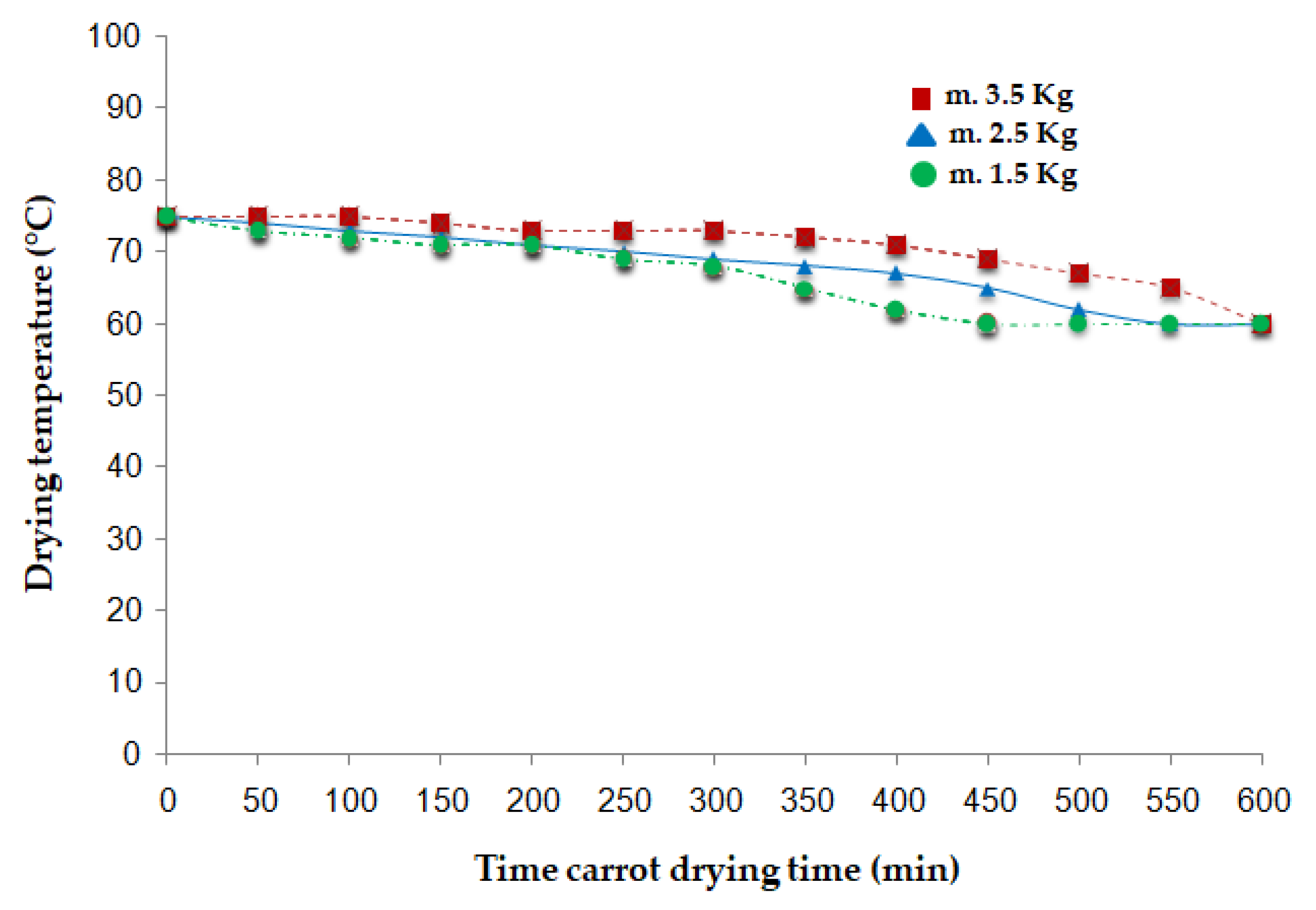

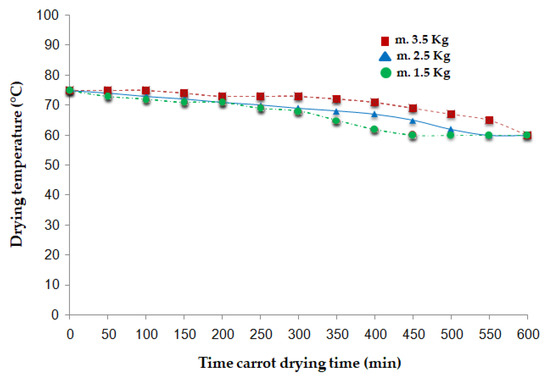

In tests with different initial carrot masses, the average operating temperature was 75 °C, decreasing to around 65 °C at the product’s drying point and stabilizing near 60 °C at the end of the process, as shown in Figure 7. This temperature distribution aligns with thermal analyses reported for convective flow dryers [35], confirming that the system design and fuzzy control maintain an adequate thermal gradient for efficient heat transfer without damaging product structure.

Figure 7.

Temperature distribution behavior during carrot drying.

Thermal fluctuations during dehydration are controlled by the fuzzy system, which mitigates variations caused by hot air flow dynamics. Moderate temperature variations help preserve bioactive compounds in plant products during drying [27,32]. The use of DHT22 digital sensors, instead of analog sensors such as the LM35, provides a significant advantage in terms of measurement accuracy and stability, particularly in environments with variable humidity and temperature, such as inside the rotary dryer. This accuracy is critical for fuzzy logic control, which directly depends on the quality of the input data [36,40].

During the dehydration process, no overheating or cooling zones were observed, ensuring high thermal efficiency. These findings are consistent with similar research where multivariate monitoring was applied to guarantee uniform drying of fruits and vegetables [29,31,45].

The system’s thermal behavior, monitored by DHT22 sensors and integrated into the fuzzy control system, provides stable and adaptive thermal conditions throughout the process. This cyber-physical integration not only improves control over the temperature profile but also represents a significant advancement in the design of smart dryers for agro-industrial applications [33,44,52].

3.3. Analysis of the Energy Used During the Moisture Removal Process in Carrots

Thermal energy consumption during dehydration in a rotary dryer depends on the system’s ability to transfer heat from the hot air to the product, particularly for foods with high initial moisture content, such as carrots. The integration of fuzzy control system with real-time multivariate monitoring enables more precise management of the energy supplied, enhancing drying efficiency [28,36,44].

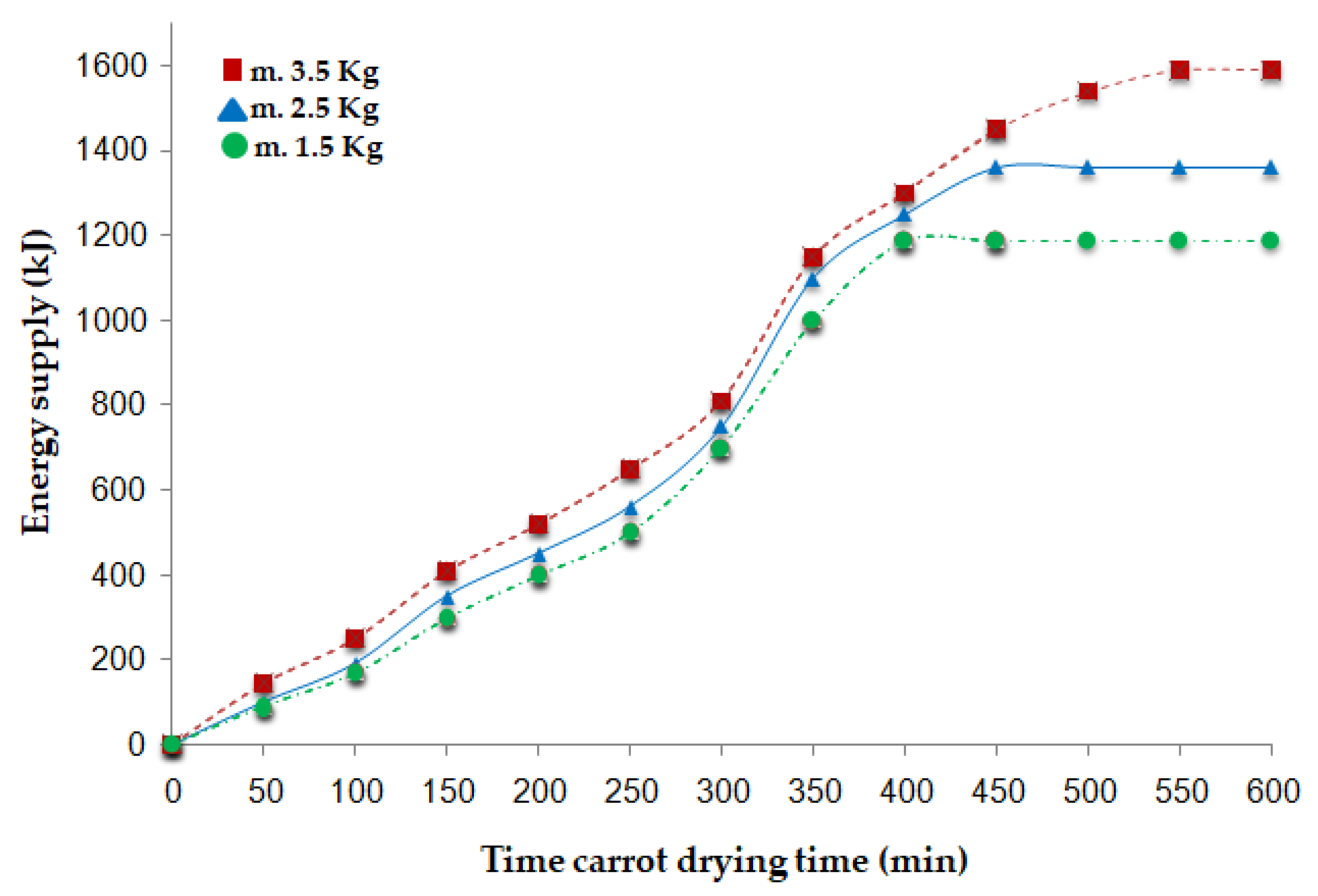

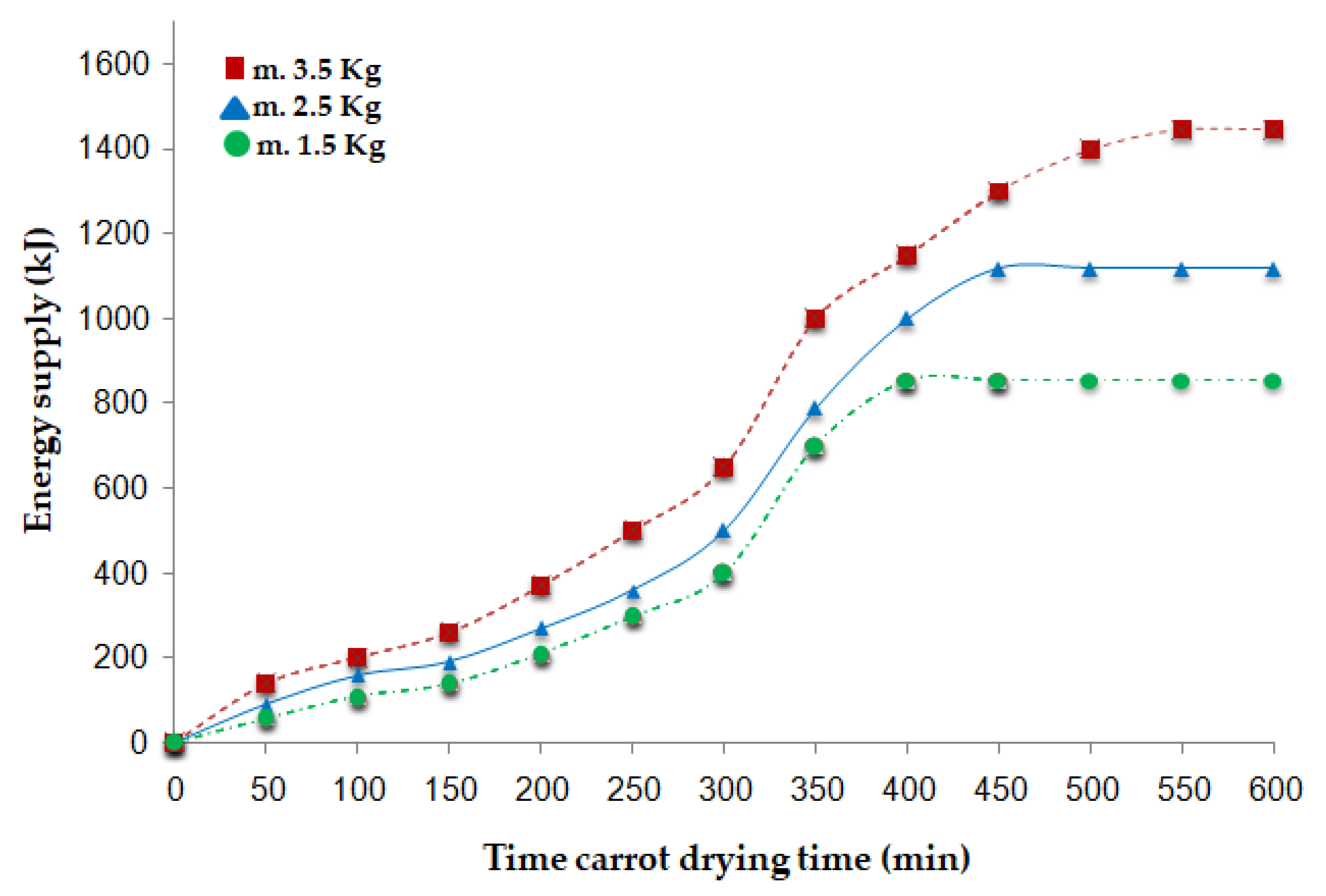

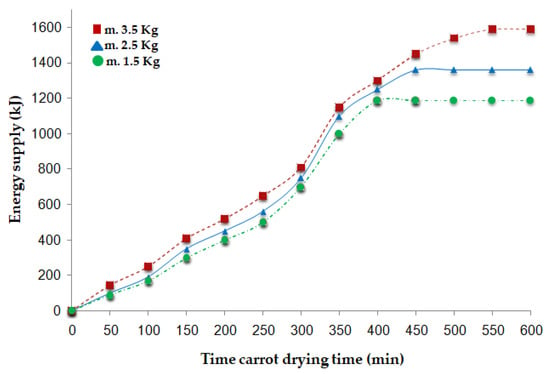

The thermal energy used during product drying is calculated using Equations (1)–(3). Experimental tests showed that a 3.5 kg carrot load required a total of 1589 kJ to reach a final moisture content of 10%, with an average drying time of 9.3 h, as illustrated in Figure 8. This energy demand aligns with studies indicating a proportional increase in required energy as the product mass increases, due to the higher water content that must evaporate and the reduced exposed surface area [35,38].

Figure 8.

Heat transferred by the hot air in the rotary dryer for the carrot dehydration process.

For the intermediate load of 2.5 kg, the system transferred approximately 1360 kJ over a drying period of 7.2 h. This energy was sufficient to achieve uniform dehydration without compromising the product’s physical and chemical properties. This behavior is consistent with previous research showing that moderate loads provide an efficient balance between energy consumption and final product quality [41,50].

The lowest load, 1.5 kg, reached the optimal moisture level in 5.5 h, with an estimated heat transfer of 1187 kJ. The reduced time and energy requirement are attributed to a lower internal resistance to heat flow and a higher surface to volume ratio, which facilitates water evaporation in products such as carrots [27,30,44].

The integration of the cyber-physical system with real-time multivariate monitoring enabled precise energy supply, minimizing the occurrence of under-dried zones through the adaptive fuzzy control system. Several studies have demonstrated that this type of intelligent control offers significant advantages over traditional strategies, such as PID or on-off control, by reducing thermal oscillations and improving drying uniformity [31,48,52].

The temporal profile of electrical energy consumption, recorded and integrated using the Arduino microcontroller during the drying process, reflects the energy supplied to the main components responsible for generating the hot air flow, namely the centrifugal fan and the electrical resistance. The supplied energy was calculated based on the operating power of each component and the drying times recorded for each experiment. Specifically, the fan operated at a power of 14.7 W, corresponding to an average airflow velocity of approximately 1.6 m/s, which represents an operating power significantly below its nominal maximum capacity of 200 W. Meanwhile, the electrical resistance functioned at an average power of 28.5 W to maintain a controlled drying temperature averaging 75 °C throughout the drying process.

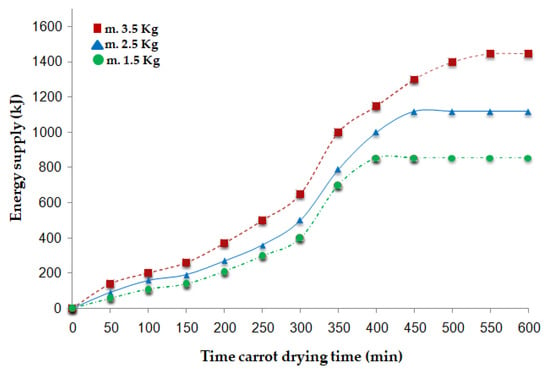

The Arduino system integrated the energy consumption over time, enabling a precise estimation of the total electrical energy supplied. The electrical energy supplied during the drying process and evaluated by Arduino was 1445 kJ (3.5 kg), 1119 kJ (2.5 kg), and 855 kJ (1.5 kg) for their respective cases. These results are clearly illustrated in Figure 9, allowing for a more detailed understanding of the contribution of electrical energy to the overall energy balance of the drying system.

Figure 9.

Temporal profile of the electrical energy supplied during the drying process.

3.4. Evaluation of Carrot Drying Rate Using a Cyber-Physical System

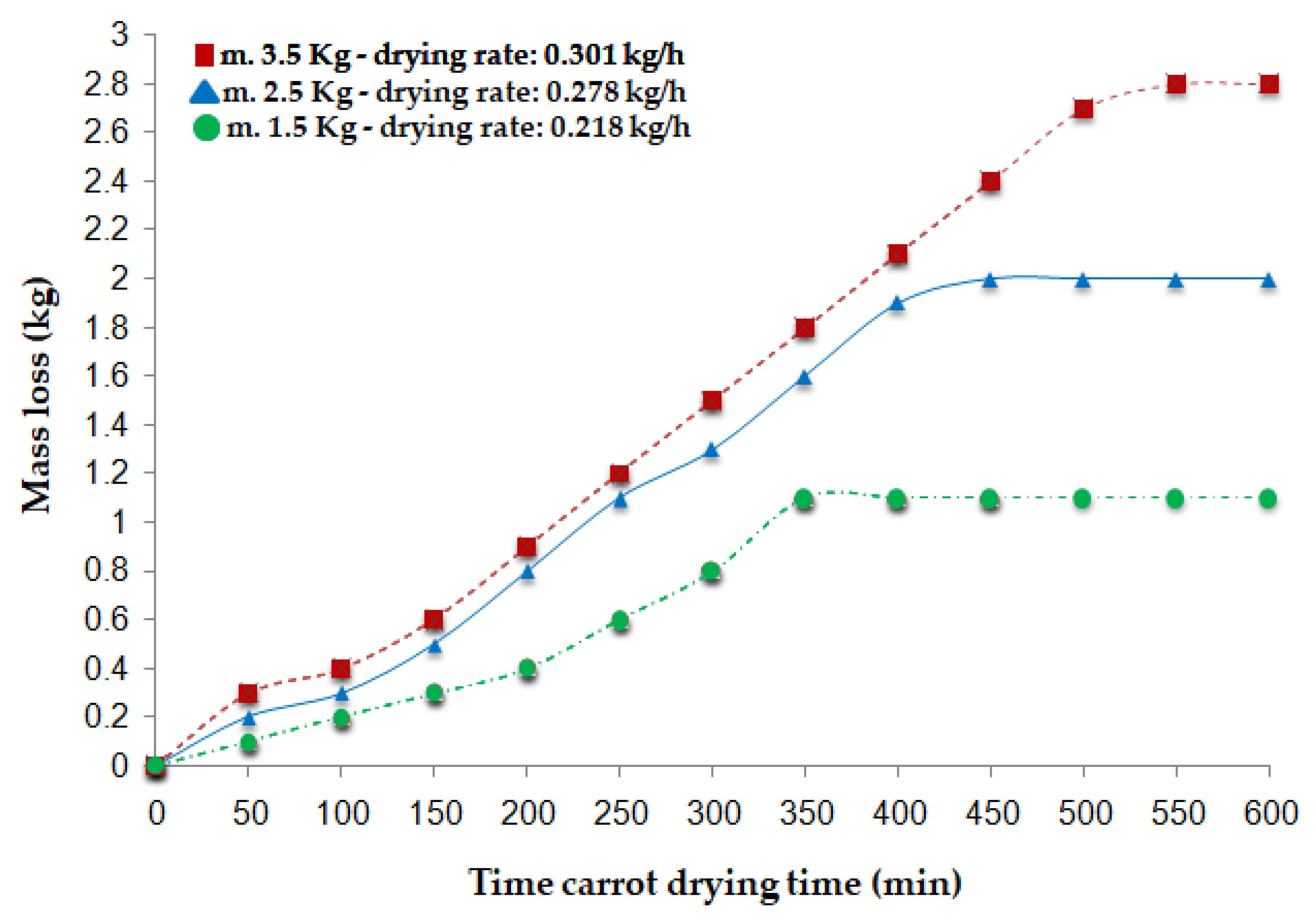

During experimental tests with varying carrot loads, the drying rate was analyzed as a key parameter to evaluate dehydration efficiency. Calculated using Equation (7), it quantifies the mass of water removed per unit time. Continuous monitoring with load cells allowed precise mass-loss measurements and the construction of detailed drying curves for each load. This method reflects the progressive decrease in dehydration rate as the product approaches equilibrium moisture and provides a critical metric for assessing the performance of the cyber-physical drying system [53].

Experimental results indicated that the 1.5 kg load exhibited an average dehydration rate of 0.218 kg/h, the 2.5 kg load reached 0.278 kg/h, and the 3.5 kg load achieved 0.301 kg/h, as shown in Figure 10. These results reflect an increasing trend in the drying rate with larger loads, attributable to higher water content and efficient regulation of the dryer’s internal temperature. However, although the 3.5 kg load presented the highest drying rate, its energy consumption also increased, highlighting the need to balance efficiency, energy use, and drying speed. Accurate measurement of this variable is crucial for establishing control strategies that optimize process operating conditions [30,33,53].

Figure 10.

Evaluation of mass loss through drying rate during the carrot dehydration process.

In compact dryers, both drying rate and efficiency can remain stable if thermal control responds in real time to changes in product moisture [27,39]. In this study, such regulation was achieved through the implemented fuzzy control system, which continuously adjusted heat input based on humidity measurements, thereby enhancing the stability of the dehydration rate.

Comparison of experimental results with theoretical models from the literature revealed strong agreement between drying rates calculated using Equation (7) and actual mass data recorded by the load cells. This validation demonstrates that the drying rate is a reliable metric for establishing optimal operating strategies. The correlation between theory and practice is fundamental for future dehydration applications, where efficiency and speed are critical for process viability [45,47].

Accurate estimation of the dehydration rate, achieved through empirical equations and multivariate monitoring, enabled optimization of operating times while ensuring homogeneously dehydrated products. This capability prevents zones of retained moisture and provides a competitive advantage over traditional control methods, which often respond less accurately under nonlinear system variations [36].

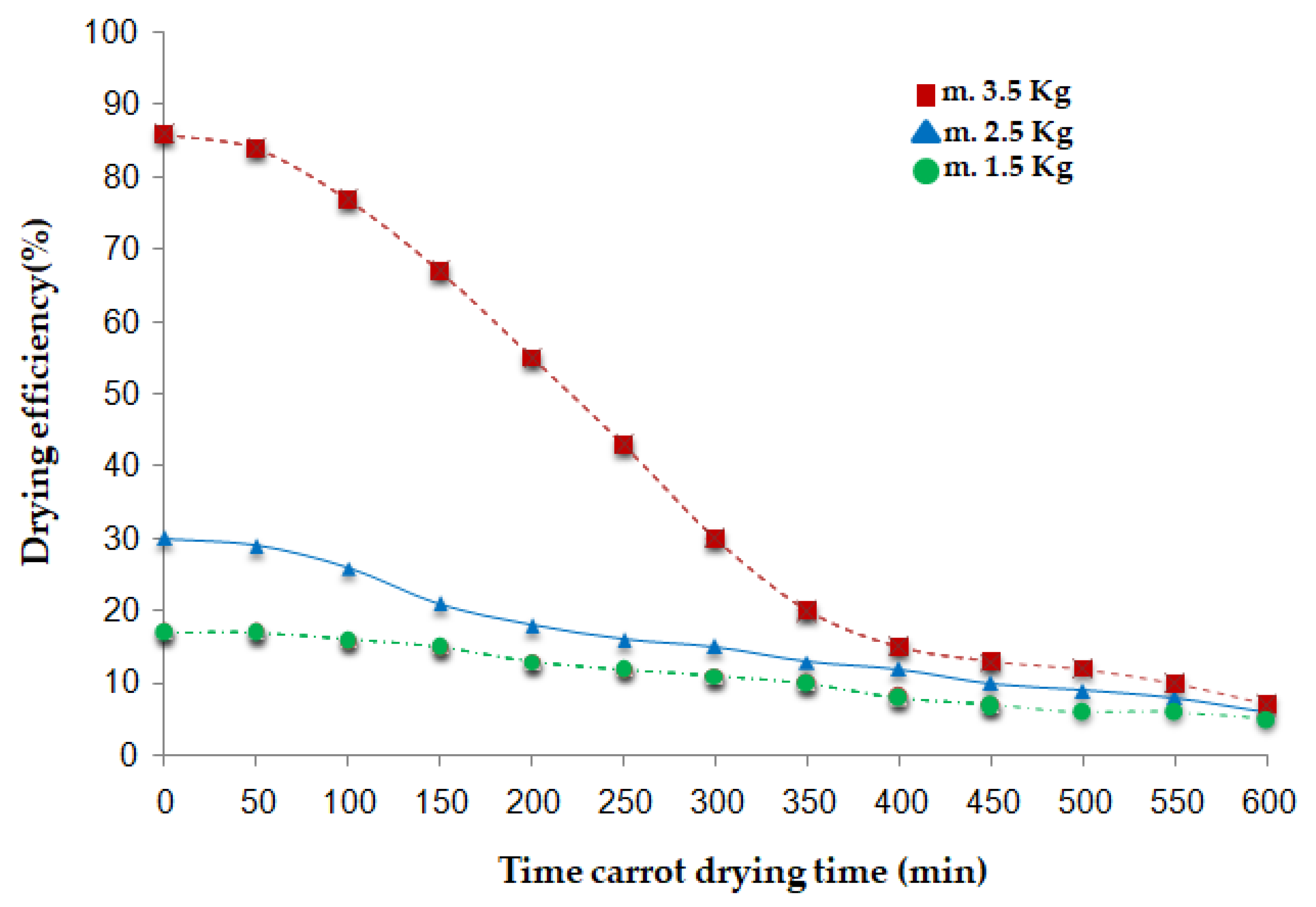

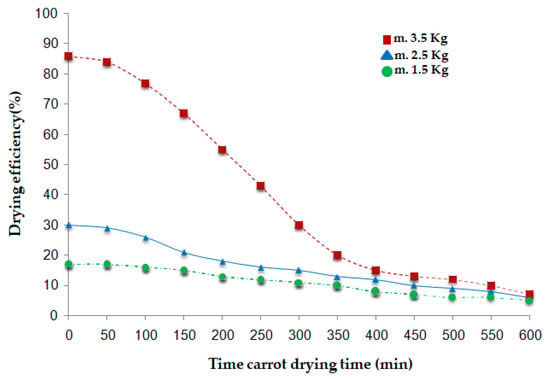

3.5. Evaluation of Drying Efficiency in the Rotary Dehydration Equipment

The thermal efficiency of the dehydration system was evaluated using Equation (8). Continuous experimental monitoring with the developed cyber-physical system allowed real-time recording of critical variables, including temperature, humidity, product mass, and air velocity. Experimental results showed that the 3.5 kg load achieved the highest thermal efficiency at 86%, whereas the 2.5 kg and 1.5 kg loads exhibited lower efficiencies of 30% and 17%, respectively, as shown in Figure 11. These findings demonstrate the direct influence of product mass on energy utilization and overall performance of the dehydration system.

Figure 11.

Drying efficiency in the carrot dehydration process.

During the initial hours of drying, thermal efficiency increased significantly, as most of the supplied energy was used to evaporate free water. However, as the moisture content approached 10%, the efficiency increased gradually at a lower rate, primarily due to heat losses by convection, with limited additional moisture removal, as reported in previous studies on automatically controlled solar dryers [43].

The use of high-precision sensors for temperature (DHT22), humidity (DHT11), mass (load cells), and air velocity (IP65 anemometer) allowed continuous data recording without interrupting the process. This prevented thermal losses associated with system access and further improved efficiency. Such strategies have been recognized as critical factors in intelligent drying systems with multivariate monitoring [28,36,44].

The integration of fuzzy control with real-time data acquisition also minimized signal noise and allowed the system to adapt to variations in product load. These results validate the incorporation of intelligent cyber-physical systems in dehydration processes, demonstrating both technological innovation and enhanced energy sustainability [27,34,49].

These results highlight the effectiveness of fuzzy control in nonlinear industrial processes with high parameter variability. In rotary dryers, Júnior et al. [55] demonstrated that an industrial multivariable fuzzy controller can reduce energy consumption while maintaining product quality by regulating the exhaust gas temperature, achieving significant energy savings and reductions in CO2 emissions. Additionally, self-tuning fuzzy schemes improve drying stability and efficiency [56], and the literature supports the versatility and robustness of fuzzy control compared to traditional methods [57,58].

4. Conclusions

This study validates a cyber-physical fuzzy control system to optimize carrot dehydration in a rotary dryer. By implementing a system with multivariate sensors (temperature, relative humidity, air velocity, and mass loss), real-time signal acquisition and conditioning were achieved, allowing for dynamic control of operating conditions, achieving uniform and efficient dehydration.

Experimental analysis showed that the drying efficiency, defined as the ratio between the enthalpy of the evaporated water and the enthalpy of the electrical energy supplied, depends significantly on the initial product mass. The supplied energy consisted of (a) the power of the heating resistance, measured with the Arduino system, and (b) the operational power of the fan motor, estimated from the measured air velocity, considering that the fan does not operate at its maximum nominal power. Under these conditions, the largest initial mass (3.5 kg) achieved the highest efficiency of 86%, while smaller loads resulted in considerably lower efficiencies. This behavior is explained by the fact that a larger mass increases the thermal inertia of the system, reducing direct heat losses and enabling a more effective transfer of thermal energy from the hot air flow to the product. Additionally, the stable average air velocity of 1.6 m/s favored uniform heat distribution and precise humidity control within the drying chamber [19,26].

The use of fuzzy control demonstrates a significant advantage over traditional methods such as PID or neural networks. Fuzzy logic facilitated the management of uncertainties and dynamic variations in the drying process, such as fluctuations in initial product moisture content or environmental variations, without requiring constant manual adjustment or large volumes of data for pre-training, as is the case with neural networks [27,29,38]. This enabled more flexible and robust control, optimizing temperature based on the actual conditions detected by the sensors.

The implementation of a low-cost hardware-based cyber-physical system, using the Arduino Mega 2560 R3 microcontroller, together with the programming of a fuzzy control system, proved to be highly efficient for food dehydration applications [37,39]. Among the main advantages identified, the system’s ability to optimize operating parameters based on actual drying conditions stands out. This resulted in a notable improvement in energy efficiency and reduction in operating times [29,40]. Furthermore, as it is an open and widely documented development platform, the use of Arduino Mega allows the replicability of the system in different drying applications, thus promoting its technological transfer and potential adoption in communities or small agro-industries with limited resources [34,41,46]. Although the system demonstrates cost-effectiveness, factors such as the limited accuracy of low-cost sensors, the restricted processing capacity of the Arduino Mega 2560, and exposure to harsh industrial conditions (vibrations, dust, humidity, and electromagnetic interference) could affect the precision and response speed of the fuzzy control. To overcome these limitations in high-throughput applications, it is recommended to integrate higher-precision and industrial-grade sensors, employ microcontrollers with greater processing capacity, and consider distributed data acquisition architectures to ensure reliability and uniformity in the drying process, these limitations do not compromise performance in small- or medium-scale scenarios, where the balance between cost, ease of programming and operational efficiency is essential [36,47].

The applied methodology, which includes signal conditioning, noise removal, and real-time fuzzy inference, contributed to improved measurement reliability and process performance, reflected in a significant reduction in dehydration time and a final product moisture content of 10%. For future research, it is recommended to incorporate microcontrollers with higher processing capacity to improve response speed and the handling of complex data and integrate machine learning techniques for real-time prediction and process optimization [16,40]. Expanding the instrumentation to include additional physical variables and implementing cloud-based data storage would also increase the applicability of the system within smart agriculture. Furthermore, comparative evaluations against traditional control schemes, such as PID or manual control, are proposed to analyze differences in drying time, energy efficiency, and process stability. Such comparisons would not only provide a more robust validation of the direct impact of the fuzzy controller but also offer stronger evidence of its advantages over conventional control methodologies.

Finally, this research demonstrates the technical and operational feasibility of a rotary dryer with fuzzy control for efficient carrot dehydration, highlighting the importance of signal conditioning and the flexibility of fuzzy control to optimize energy efficiency and final product quality in drying processes.

Author Contributions

Conceptualization, J.M.T.-M. and M.G.B.-S.; methodology, J.M.T.-M., M.G.B.-S. and A.G.-L.; software, J.M.T.-M., Y.V.P.-P. and S.M.A.-S.; validation, S.M.A.-S.; formal analysis, M.G.B.-S., A.G.-L., Y.V.P.-P. and J.P.A.-Á.; investigation, J.M.T.-M. and M.G.B.-S.; resources, J.M.T.-M., A.G.-L., S.M.A.-S., J.P.A.-Á. and Y.V.P.-P.; writing—original draft preparation, J.M.T.-M., A.G.-L. and M.G.B.-S.; writing—review and editing, J.M.T.-M. and M.G.B.-S.; supervision, A.G.-L., S.M.A.-S., Y.V.P.-P. and J.P.A.-Á.; project administration, J.M.T.-M. and M.G.B.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Thibault, B.; Zeynoddin, M.; Bonakdari, H.; Ratti, C.; Khalloufi, S. Effect of Model Selection Approach Obtained by Machine Learning Tools on Predicting the Volume Reduction of Plant-Based Dehydrated Foods. J. Food Eng. 2025, 391, 112415. [Google Scholar] [CrossRef]

- Jimenez-Garcia, J.A.; Aguilar-Torres, D.; Luque-Zuñiga, G.; Camacho-Martínez, J.L.; Jiménez-Ramírez, O.; Vázquez-Medina, R. Evaluation of the Efficiency and Economic Feasibility of an Indirect Solar Dehydrator and Its Comparison with an Affordable Electric Dehydrator. Therm. Sci. Eng. Prog. 2025, 61, 103505. [Google Scholar] [CrossRef]

- Kominami, Y.; Takase, K.; Ushio, H. Time-Course Analysis of Kobujime Curing of Japanese Flounder (Paralichthysolivaceus): Biochemical Insights into Dehydration Processing of Fish Meat with Kombu. Int. J. Gastron. Food Sci. 2025, 39, 101124. [Google Scholar] [CrossRef]

- Lordi, A.; Conte, A.; Del Nobile, M.A. Nutritional and Antimicrobial Properties of Tomato By-Products as Affected by Dehydration Temperature. Food Biosci. 2025, 63, 105797. [Google Scholar] [CrossRef]

- Yalta Chappa, M.; Angeles, W.G.; Quispe-Sanchez, L.; Mori Servan, D.C.; Santillan Gomez, H.; Oliva-Cruz, M.; Barrena Gurbillón, M.Á. Modeling of Drying Kinetics and Chemical Analysis for Optimal Preservation of Pitahaya, Aguaymanto and Pineapple Fruits Using a Parabolic Solar Dehydrator in the Amazon Region-Peru. J. Agric. Food Res. 2025, 19, 101696. [Google Scholar] [CrossRef]

- Rakariyatham, K.; Boonyapranai, K.; Laokuldilok, T.; Utama-ang, N.; Nutprem, A.; Kaewprasit, K.; Tatongjai, K. Impact of Different Dehydration Methods on Physicochemical and Functional Properties of Guava (Psidium guajava L.) Powder Prepared from White and Pink Pomaces. Appl. Food Res. 2025, 5, 100696. [Google Scholar] [CrossRef]

- Fu, Y.; Ren, Y.; Sun, D.-W. Impacts of Non-Thermal Pretreatments on Banana Slices during Microwave Vacuum Dehydration Using THz-TDS and NIR-HSI Techniques. J. Food Eng. 2025, 394, 112518. [Google Scholar] [CrossRef]

- Schemminger, J.; Raut, S.; Sturm, B.; Defraeye, T. Mapping the Most Effective Measures to Optimize Carrot Slice Tray Drying Using Physics-Based and Monte Carlo Simulations. Int. J. Thermofluids 2025, 27, 101221. [Google Scholar] [CrossRef]

- Malaslı, M.Z.; Akkoyunlu, M.C.; Pekel, E.; Taşova, M.; Dursun, S.K.; Akkoyunlu, M.T. Prediction of Drying Kinetics and Energy Consumption Values of Purple Carrots Dried in a Temperature-Controlled Microwave Dryer by Decision Tree, Random Forest and Ada Boost Approaches. Chemom. Intell. Lab. Syst. 2025, 260, 105352. [Google Scholar] [CrossRef]

- Thuy, N.M.; Hao, H.V.; Duong, L.T.T.; Giau, T.N.; Minh, V.Q.; Tai, N.V. Foam-Mat Drying of Lucuma Powder: Mathematical and Artificial Modeling of Drying Kinetics, Physicochemical and Microstructural Properties. J. Agric. Food Res. 2025, 19, 101656. [Google Scholar] [CrossRef]

- Sukunza, X.; Rojcewicz, K.; Martin, A.; Bolaños, M.; Tellabide, M.; Olazar, M.; Dajnowiec, F.; Oksiuta, Z. A Model for Predicting the Performance and Maximizing the Drying Efficiency of an Innovative Fountain Bed Dryer. Particuology 2025, 102, 251–263. [Google Scholar] [CrossRef]

- Kerse, A.Y.; Embiale, D.T.; Gunjo, D.G. Dehydration of Red Chilli Using an Indirect Type Forced Convection Solar Dryer Integrated with Thermal Energy Storage. Int. J. Thermofluids 2025, 26, 101045. [Google Scholar] [CrossRef]

- Naniwadekar, M.; Walke, S.; Mandake, M.; Tapre, R.; Patil, K.; Komble, S. A Comprehensive Study of Performance Metrics and Potato Dehydration at Various Slice Thickness Using an IoT-Based Indirect Solar Dryer: An Experimental Approach. Sol. Energy 2025, 288, 113269. [Google Scholar] [CrossRef]

- Kidane, H.; Farkas, I.; Buzás, J. Performance Evaluation of Solar Drying Chambers and Drying Kinetics of Apple Slices. Energy Rep. 2025, 13, 4528–4540. [Google Scholar] [CrossRef]

- Pei, Y.; Fan, L.; Wang, C.; Tian, G.; Meng, X.; Li, Z.; Xu, W. Intelligent Control of Ginger Far-Infrared Radiation and Hot-Air Drying Based on Multi-Sensor Fusion Technology. Food Bioprod. Process. 2025, 149, 415–427. [Google Scholar] [CrossRef]

- Villa-Medina, J.F.; Porta-García, M.Á.; Gutiérrez, J.; Porta-Gándara, M.Á. Solar Forced Convection Dryer for Agriproducts Monitored by IoT. Internet Things 2025, 31, 101566. [Google Scholar] [CrossRef]

- Abreu, D.J.M.d.; Lorenço, M.S.; Machado, G.G.L.; Silva, J.M.; Azevedo, E.C.d.; Carvalho, E.E.N. Influence of Drying Methods on the Post-Harvest Quality of Coffee: Effects on Physicochemical, Sensory, and Microbiological Composition. Foods 2025, 14, 1463. [Google Scholar] [CrossRef] [PubMed]

- Ortíz-Yescas, G.; Meléndez-Vázquez, F.; Quezada-Téllez, L.A.; Torres-Mendoza, A.; Morales-Peñaloza, A.; Fernández-Anaya, G.; Macías-Díaz, J.E. A Hybrid PI–Fuzzy Control Scheme for a Drum Drying Process. AppliedMath 2025, 5, 45. [Google Scholar] [CrossRef]

- Tabares-Martinez, J.M.; Guzmán-López, A.; Bravo-Sánchez, M.G.; Barranco-Gutierrez, A.I.; Martínez-Nolasco, J.J.; Villaseñor-Ortega, F. Instrumentation and Evaluation of a Sensing System with Signal Conditioning Using Fuzzy Logic for a Rotary Dryer. Technologies 2025, 13, 83. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Zadhossein, S.; Kaveh, M.; Szymanek, M.; Hassannejad, S.; Wojciechowska, K. Drying Time, Energy and Exergy Efficiency Prediction of Corn (Zea mays L.) at a Convective-Infrared-Rotary Dryer: Approach by an Artificial Neural Network. Energies 2025, 18, 696. [Google Scholar] [CrossRef]

- Petrescu, M.G.; Burlacu, A.; Isbășoiu, G.D.; Dumitru, T.; Tănase, M. Estimating the Lifetime of Rotary Dryer Flights Based on Experimental Data. Processes 2024, 12, 993. [Google Scholar] [CrossRef]

- Coelho, E.G.; Bertarini, P.L.L.; Gomes, M.S.; Amaral, L.R.; Zotarelli, M.F.; Santos, L.D.; Santana, R.C. Physicochemical and Sensory Properties of Arabica Coffee Beans of Arara cv. Dried Using Different Methods. Foods 2024, 13, 642. [Google Scholar] [CrossRef]

- Donoso-García, P.; Henríquez-Vargas, L.; González, J.; Díaz, I.; Fuentes, I. A Study for Estimating the Overall Heat Transfer Coefficient in a Pilot-Scale Indirect Rotary Dryer. Processes 2024, 12, 357. [Google Scholar] [CrossRef]

- Ignaczak, A.; Woźniak, Ł.; Marzec, A.; Kowalska, J.; Chobot, M.; Kowalska, H. The Influence of Osmotic Treatment, Edible Coatings Application, and Reduced Pressure on Microwave–Vacuum-Dried Carrot Properties. Molecules 2025, 30, 1877. [Google Scholar] [CrossRef] [PubMed]

- Gao, K.; Liu, B.; Wu, B.; Guo, Y.; Song, C.; Nan, S.; Dai, J.; Shen, Y.; Ma, H. A Study on the Effect Mechanism of Pectin Modification on the Carrot Cell Wall’s Texture Formation under Ultrasonic and Infrared Drying. Agriculture 2024, 14, 803. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Orellana-Palma, P.; Pasten, A.; Uribe, E.; Cortés, D.; Carvajal, M. Mild Temperature Conditions Applied to Carrot (Daucus carota L.) Waste Using Different Drying Methods: Effect on the Kinetics and Some Chemical Parameters. Processes 2025, 13, 90. [Google Scholar] [CrossRef]

- Mierzwa, D.; Musielak, G. Microwave and Ultrasound Assisted Rotary Drying of Carrot: Analysis of Process Kinetics and Energy Intensity. Appl. Sci. 2024, 14, 10676. [Google Scholar] [CrossRef]

- Francik, S.; Łapczyńska-Kordon, B.; Hajos, M.; Basista, G.; Zawiślak, A.; Francik, R. Modeling the Drying Process of Onion Slices Using Artificial Neural Networks. Energies 2024, 17, 3199. [Google Scholar] [CrossRef]

- Bogusz, R.; Nowacka, M.; Gondek, E.; Delman, M.; Szulc, K. Effect of Drying Method on Selected Physical and Functional Properties of Powdered Black Soldier Fly Larvae. Appl. Sci. 2025, 15, 4097. [Google Scholar] [CrossRef]

- Mamdani, E.H. Application of Fuzzy Algorithms for Control of Simple Dynamic Plant. Proc. IEEE 1974, 121, 1585–1588. [Google Scholar] [CrossRef]

- Carrillo Luis, V.; Beristain Rios, D.; Hernández-Flores, O.A.; Romero-Salazar, C.; Sandoval-Torres, S. Mathematical Modeling of Goat Meat Drying Kinetics with Thermal Oscillations. Foods 2024, 13, 3836. [Google Scholar] [CrossRef]

- Sundarsingh, A.; BhagyaRaj, G.V.S.; Dash, K.K. Modeling and Optimization of Osmotic Dehydration of Wax Apple Slices Using Adaptive Neuro-Fuzzy Inference System. Appl. Food Res. 2023, 3, 100316. [Google Scholar] [CrossRef]

- Dash, K.K.; Sundarsingh, A.; BhagyaRaj, G.V.S.; Pandey, V.K.; Kovács, B.; Mukarram, S.A. Modelling of Ultrasonic Assisted Osmotic Dehydration of Cape Gooseberry Using Adaptive Neuro-Fuzzy Inference System (ANFIS). Ultrason. Sonochem. 2023, 96, 106425. [Google Scholar] [CrossRef]

- Kang, C.; Zhang, G.; Mu, G.; Guo, H.; Yuan, T.; Zhao, C.; Li, X.; Zhang, Q. Solar-Heat Pump Combined Drying with Phase Change Heat Storage: Multi-Energy Self-Adaptive Control. Renew. Energy 2024, 230, 120867. [Google Scholar] [CrossRef]

- Kumar, V.; Devi, M.K. Impact of Different Drying Methods on Sensory and Physicochemical Analysis of Instant Green Bell Pepper Chutney Mix. Meas. Food 2023, 9, 100077. [Google Scholar] [CrossRef]

- Song, F.; Zheng, Y.; Li, R.; Li, Z.; Liu, B.; Wu, X. Intelligent Control of Green Tea Fixation with Microwave Processing. J. Food Eng. 2023, 349, 111481. [Google Scholar] [CrossRef]

- Abioye, A.O.; Hussein, J.B.; Oke, M.O.; Bolarinwa, I.F. Modelling Some Quality Attributes of a Convective Hot-Air Dried Tomato Slices Using ANN and ANFIS Techniques. Meas. Food 2024, 13, 100140. [Google Scholar] [CrossRef]

- Baidhe, E.; Clementson, C.L. A Review of the Application of Modeling and Simulation to Drying Systems for Improved Grain and Seed Quality. Comput. Electron. Agric. 2024, 222, 109094. [Google Scholar] [CrossRef]

- AitHmazi, O.; Bagar, H.; Madani, A.; Mrani, I. A Novel Approach for Modelling and Predicting the Drying Kinetics of Couscous Grains Using Artificial Neural Networks. J. Food Compos. Anal. 2024, 132, 106301. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; Ali, M.; Qenawy, M.; Adelusi, O.A. Application of Artificial Intelligence to Predict Energy Consumption and Thermal Efficiency of Hybrid Convection-Radiation Dryer for Garlic Slices. Eng. Appl. Artif. Intell. 2024, 138, 109338. [Google Scholar] [CrossRef]

- Rojas Vargas, A.; Pérez García, L.; Sánchez Guillen, C.; AlJaberi, F.Y.; Salman, A.D.; Alardhi, S.M.; Le, P.-C. Performance Evaluation of a Flighted Rotary Dryer for Lateritic Ore in Concurrent Configuration. Heliyon 2023, 9, e21345. [Google Scholar] [CrossRef]

- Alshehri, A.A.; Tolba, N.M.; Salama, M.A.; Saleh, M.; Kamel, R.M. Energy Analysis and Quality Characteristics of Flaxseed Oil by Using an Infrared Rotary Dryer. Case Stud. Therm. Eng. 2024, 54, 103988. [Google Scholar] [CrossRef]

- Susana, I.G.B.; Alit, I.B.; Okariawan, I.D.K. Rice Husk Energy Rotary Dryer Experiment for Improved Solar Drying Thermal Performance on Cherry Coffee. Case Stud. Therm. Eng. 2023, 41, 102616. [Google Scholar] [CrossRef]

- Nafisah, N.; Syamsiana, I.N.; Putri, R.I.; Kusuma, W.; Sumari, A.D.W. Implementation of Fuzzy Logic Control Algorithm for Temperature Control in Robusta Rotary Dryer Coffee Bean Dryer. MethodsX 2024, 12, 102580. [Google Scholar] [CrossRef]

- Li, M.; Liu, M.; Xu, C.; Wang, J.; Yan, J. Thermodynamic and Sensitivity Analyses on Drying Subprocesses of Various Evaporative Dryers: A Comparative Study. Energy 2023, 284, 128571. [Google Scholar] [CrossRef]

- Mihret, Y.C.; Hailemesikel, S.T.; Alemu, A.G.; Delele, M.A. Modeling the Drying Kinetics, Performance Evaluation, and Economic Analysis of Rice Drying Using a Rice Husk-Fueled Mixed-Flow Dryer. Energy Convers. Manag. X 2024, 24, 100774. [Google Scholar] [CrossRef]

- Yu, M.; Zou, L.; Yu, J. Experimental Investigation on the Drying Characteristics in a Solar Assisted Ejector Enhanced Heat Pump Dryer System. Solar Energy 2024, 267, 112265. [Google Scholar] [CrossRef]

- Hamdani, N.; Rizal, T.; Muhammad, Z. Fabrication and testing of hybrid solar-biomass dryer for drying fish. Case Stud. Therm. Eng. 2018, 12, 489–496. [Google Scholar] [CrossRef]

- Soponpongpipat, N.; Nanetoe, S.; Comsawang, P. Thermal and Torrefaction Characteristics of a Small-Scale Rotating Drum Reactor. Processes 2020, 8, 489. [Google Scholar] [CrossRef]

- Yang, G.; Yang, X.; Li, C.; Wei, X.; Lu, Z.; Zhang, C.-a.; Wang, Q.; Wu, X. Numerical Study on the Uniform Distribution of Flow Field of Airflow Dryer. Heliyon 2024, 10, e29439. [Google Scholar] [CrossRef] [PubMed]

- van Boven, A.P.; Dubbelboer, A.; Janssen, T.J.A.; Schröder, J.; Sewalt, J.J.W.; Kohlus, R.; Schutyser, M.A.I. Investigating the Impact of Air Distribution on Spray Dryer Operability Using CFD Simulations and Pilot-Scale Experiments. Powder Technol. 2024, 440, 119779. [Google Scholar] [CrossRef]

- Charmongkolpradit, S.; Somboon, T.; Phatchana, R.; Sang-Aroon, W.; Tanwanichkul, B. Influence of drying temperature on anthocyanin and moisture contents in purple waxy corn kernel using a tunnel dryer. Case Stud. Therm. Eng. 2021, 25, 100886. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, C. Effect of Electro hydrodynamic Drying on Drying Characteristics and Physicochemical Properties of Carrot. Foods 2023, 12, 4228. [Google Scholar] [CrossRef]

- Adegbite, S.A.; Asiru, W.B.; Sartas, M.; Tran, T.; Taborda, A.L.; Chapuis, A.; Ojide, M.; Abass, A. Development of a Pilot Scale Energy Efficient Flash Dryer for Cassava Flour. Resour. Environ. Sustain. 2023, 13, 100117. [Google Scholar] [CrossRef]

- Júnior, M.P.; Da Silva, M.T.; Guimarães, F.G.; Euzébio, T.A.M. Energy savings in a rotary dryer due to a fuzzy multivariable control application. Drying Technol. 2020, 40, 1196–1209. [Google Scholar] [CrossRef]

- Pirrello, L.; Yliniemi, L.; Leiviskä, K.; Galluzzo, M. Self-tuning fuzzy control of a rotary dryer. IFAC Proc. Vol. 2002, 35, 125–130. [Google Scholar] [CrossRef]

- Precup, R.; Hellendoorn, H. A survey on industrial applications of fuzzy control. Comput. Ind. 2010, 62, 213–226. [Google Scholar] [CrossRef]

- Pourjavad, E.; Mayorga, R.V. A comparative study and measuring performance of manufacturing systems with Mamdani fuzzy inference system. J. Intell. Manuf. 2019, 30, 1085–1097. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).