Methodologies for Technology Selection in an Industry 4.0 Environment: A Methodological Analysis Using ProKnow-C

Abstract

1. Introduction

1.1. Groups in Technology Selection

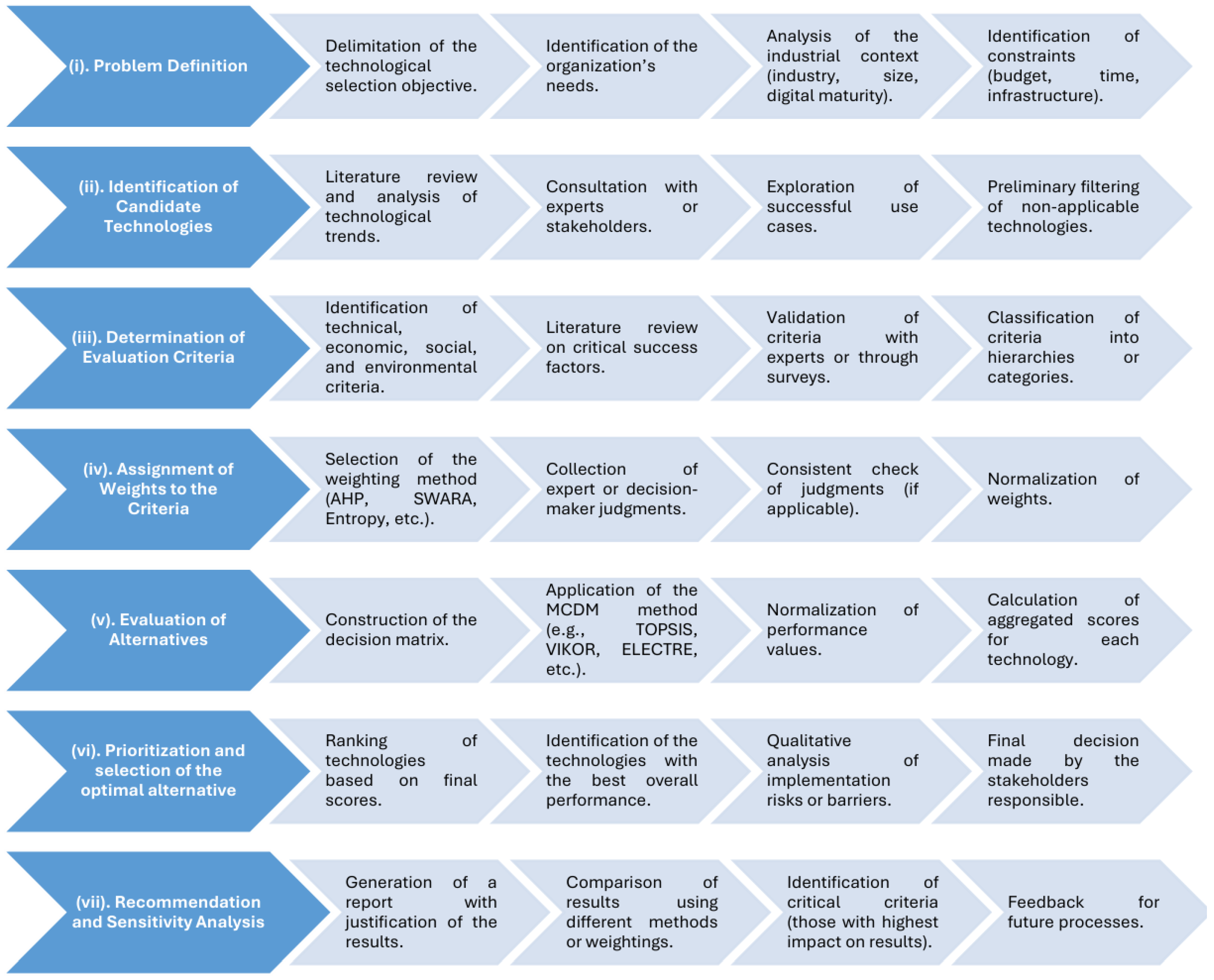

- Problem definition: In this group, the primary objective of the decision is established by identifying the organization’s needs, the challenges of the production environment, and any technical, economic, or strategic constraints that must be considered. A clear and precise problem definition is essential to ensure coherence throughout the evaluation process and to align criteria with the objectives of the manufacturing system [32,33,34].

- Identification of candidate technologies: A systematic exploration is conducted to identify potential Industry 4.0-related technologies applicable to the organization’s specific context. This process may include literature reviews, expert consultations, analyses of relevant use cases, and an initial screening to exclude non-viable options, thereby ensuring a representative and context-relevant set of alternatives [35,36,37].

- Determination of evaluation criteria: This step involves selecting the criteria to be used for evaluating the candidate technologies. The criteria may span technical, economic, organizational, environmental, or social dimensions and should be defined according to the problem’s context. Validation with experts and hierarchical categorization of the criteria help ensure their relevance and applicability [38,39,40].

- Assignment of weights to the criteria: As not all criteria are equally important, weights are assigned using techniques such as AHP, SWARA, or other structured methods. This step requires expert participation and mechanisms to verify the consistency of judgments, ensuring that the assigned weights appropriately reflect strategic priorities [41,42,43].

- Evaluation of alternatives: A decision matrix is constructed in which candidate technologies are quantitatively assessed against each criterion. This information can be normalized and processed using multiple-criteria decision-making (MCDM) techniques such as TOPSIS, VIKOR, and PROMETHEE, among others. The result is a comparative evaluation of the alternatives based on their multidimensional performance [44,45,46,47].

- Prioritization and selection of the optimal alternative: Based on the scores obtained, a ranking of technologies is produced, enabling identification of the most suitable option. This group may also involve a risk analysis, verification of technical feasibility, and discussions with key stakeholders to ensure that the final decision is grounded in a comprehensive perspective [37,48,49].

- Recommendation and sensitivity analysis: Finally, a report is prepared that details the process, the results obtained, and recommendations for implementation. The sensitivity analysis is used to examine how variations in weights or criterion values affect the outcome, contributing to validation of the decision’s robustness and providing feedback for future applications [50,51,52].

1.2. Contributions and Limitations

- Providing a clear understanding of how organizations determine which technologies best suit their specific needs.

- Identifying and analyzing methodologies used by companies for technology selection.

- Examining emerging trends and key factors influencing technological decisions, such as alignment with strategic objectives, integration with existing systems, and adaptability to future changes.

- Clarifying the technology selection process, providing a more detailed understanding

- Providing a reference framework to help companies adopt technologies that enhance their long-term competitiveness and efficiency.

2. Methodology

Filtering Process

- ‘Technology Selection’ OR ‘Industry 4.0 Selection’ OR ‘Technology Prioritization’.

- (‘Project Selection’ AND ‘Technolog* Selection’) OR (‘Project Selection’ AND ‘Portfolio Selection’ AND ‘Technolog*’).

- (‘Strategic Selection’ AND ‘Technolog* Selection’) OR (‘Multi Criteria Decision Making’ AND ‘Technolog* Selection’) OR (‘Strategic Selection’ AND ‘Industry 4.0 Selection’ AND ‘Technolog* Selection’) OR (‘Multi Criteria Decision Making’ AND ‘Industry 4.0 Selection’ AND ‘Technolog* Selection’).

- (‘Multi Criteria Decision Making’ AND (‘Technolog* Selection’ OR ‘Technolog* Prioritization’ OR ‘Industry 4.0 Selection’ OR (‘Project Selection’ AND ‘Technolog*’) OR (‘Portfolio Selection’ AND ‘Technolog*’))) OR (‘Strategic Selection’ AND (‘Technolog* Selection’ OR ‘Technolog* Prioritization’ OR ‘Industry 4.0 Selection’ OR (‘Portfolio Selection’ AND ‘Technolog*’) OR (‘Project Selection’ AND ‘Technolog*’))).

3. Literature Review

Analysis of the Bibliographic Portfolio

4. Analysis of Articles and Discussions

5. Conclusions

Future Research Directions

- Alignment with the company’s overall strategy: Emphasize a strategic approach, focusing on emerging Industry 4.0 technologies and their alignment with business development, innovation, and value creation.

- Long-term integration: Align technology selection with strategic objectives and operational enhancement, ensuring seamless integration with production planning, supply chain management, and product/service development

- Sustainable development: Integrate sustainability criteria into technology selection, including the lifecycle analysis, environmental impact, resource efficiency, and carbon footprint. Promote a circular economy to optimize material use and minimize waste, ensuring responsible technology investments. This balances economic, social, and environmental factors for sustainable technology adoption.

- Flexible methodologies: Develop adaptable and more robust methodologies that may or may not rely on MCDM, considering organizational characteristics such as the size, sector, culture, and resources, while potentially integrating a scenario analysis, simulation, and artificial intelligence.

- Structured comparison: Design a homogeneous conceptual framework to evaluate the performance of hybrid MCDM methods in comparable contexts, considering their robustness, sensitivity, and alignment with strategic manufacturing objectives.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| TS | Technology selection |

| TP | Technology prioritization |

| PS | Portfolio selection |

| PRS | Project selection |

| I4.0 | Industry 4.0 |

| DEA | Data envelopment analysis |

| AHP | Analytic hierarchy process |

| ANP | Analytic network process |

| QFD: | Quality function deployment |

| SSF: | S.T.A.D.T. selection framework |

| SMEs | Small and medium-sized enterprises |

| NRM: | Network relationship map |

| BWM: | Best worst method |

| EDAS | Evaluation based on distance from average solution |

| IVIF: | Interval-valued intuitionistic fuzzy |

| MCDM | Multiple-criteria decision-making |

| MADM | Multi-attribute decision-making |

| MODM | Multi-objective decision-making |

| CODAS | Combinative distance-based assessment |

| VIKOR: | Visekriterijumska optimizacija i kompromisno resenje |

| TODIM: | Tomada de decisão interativa multicritério |

| TOPSIS: | Technique for order preference by similarity to ideal solution |

| CODAS: | Combinative distance-based assessment |

| UTADIS | Utility Additive Discriminant |

| DEMATEL: | Decision-making trial and evaluation laboratory |

| ELECTRE III | Elimination and choice expressing reality |

References

- Abubakar, A.M.; Türkmen, A.; Işik, V.; Mikalef, P.; Turel, O. Exploring the Complementary Effects of Business Analytics Capabilities and π-Shaped Skills on Innovation Outcomes. Eur. J. Inf. Syst. 2025, 34, 146–163. [Google Scholar] [CrossRef]

- Li, N.; Yao, Q.; Tang, H.; Lu, Y. Is Digitalization Necessary? Configuration of Supply Chain Capabilities for Improving Enterprise Competitive Performance. J. Bus. Res. 2025, 186, 114972. [Google Scholar] [CrossRef]

- Weng, Q.; Wang, D.; De Lurgio, S.; Schuetz, S. How Do Small-to-Medium-Sized e-Commerce Businesses Stay Competitive? Evidence on the Critical Roles of IT Capability, Innovation and Multihoming. Internet Res. 2024, 35, 126–151. [Google Scholar] [CrossRef]

- Filatotchev, I.; Lanzolla, G.; Syrigos, E. Impact of CEO’s Digital Technology Orientation and Board Characteristics on Firm Value: A Signaling Perspective. J. Manag. 2023, 51, 875–912. [Google Scholar] [CrossRef]

- Alshaher, A.; Alkhaled, H.R.; Mohammed, M.M. The Impact of Adoption of Digital Innovation Dynamics in Reduce Work Exhaustion in SMEs in Developing Countries: The Case of Cloud of Things Services. VINE J. Inf. Knowl. Manag. Syst. 2025, 55, 113–134. [Google Scholar] [CrossRef]

- Webster, C.; Cain, L. Regulation, Automated Technologies, and Competitiveness in the Hospitality Industry. J. Hosp. Tour. Res. 2025, 49, 268–281. [Google Scholar] [CrossRef]

- Serey, J.; Alfaro, M.; Fuertes, G.; Vargas, M.; Durán, C.; Ternero, R.; Rivera, R.; Sabattin, J. Pattern Recognition and Deep Learning Technologies, Enablers of Industry 4.0, and Their Role in Engineering Research. Symmetry 2023, 15, 535. [Google Scholar] [CrossRef]

- Harikannan, N.; Vinodh, S. State of Art Review on Sustainable Manufacturing and Industry 4.0. Bus. Strategy Environ. 2025, 34, 872–913. [Google Scholar] [CrossRef]

- Fuertes, G.; Zamorano, J.; Alfaro, M.; Vargas, M.; Sabattin, J.; Duran, C.; Ternero, R.; Rivera, R. Opportunities of the Technological Trends Linked to Industry 4.0 for Achieve Sustainable Manufacturing Objectives. Sustainability 2022, 14, 11118. [Google Scholar] [CrossRef]

- Rupp, M.; Schneckenburger, M.; Merkel, M.; Börret, R.; Harrison, D.K. Industry 4.0: A Technological-Oriented Definition Based on Bibliometric Analysis and Literature Review. J. Open Innov. Technol. Mark. Complex. 2021, 7, 68. [Google Scholar] [CrossRef]

- Singh, M.; Goyat, R.; Panwar, R. Fundamental Pillars for Industry 4.0 Development: Implementation Framework and Challenges in Manufacturing Environment. TQM J. 2024, 36, 288–309. [Google Scholar] [CrossRef]

- Bruni, R.; Piccarozzi, M.; Caboni, F. Defining the Metaverse with Challenges and Opportunities in the Business Environment. J. Mark. Theory Pract. 2025, 33, 60–77. [Google Scholar] [CrossRef]

- Anthwal, A.; Uniyal, A.; Gairolla, J.; Singh, R.; Gehlot, A.; Abbas, M.; Akram, S.V. Industry 4.0 Technologies Adoption for Digital Transition in Drug Discovery and Development: A Review. J. Ind. Inf. Integr. 2024, 38, 100562. [Google Scholar] [CrossRef]

- Farrukh Shahzad, M.; Liu, H.; Zahid, H. Industry 4.0 Technologies and Sustainable Performance: Do Green Supply Chain Collaboration, Circular Economy Practices, Technological Readiness and Environmental Dynamism Matter? J. Manuf. Technol. Manag. 2024, 36, 1–22. [Google Scholar] [CrossRef]

- de-Lima-Santos, M.F.; Mesquita, L.; de Melo Peixoto, J.G.; Camargo, I. Digital News Business Models in the Age of Industry 4.0: Digital Brazilian News Players Find in Technology New Ways to Bring Revenue and Competitive Advantage. Digit. Journal. 2024, 12, 1304–1328. [Google Scholar] [CrossRef]

- Arroyabe, M.F.; Arranz, C.F.A.; de Arroyabe, I.F.; de Arroyabe, J.C.F. The Effect of IT Security Issues on the Implementation of Industry 4.0 in SMEs: Barriers and Challenges. Technol. Forecast. Soc. Change 2024, 199, 123051. [Google Scholar] [CrossRef]

- Serey, J.; Alfaro, M.; Fuertes, G.; Vargas, M.; Ternero, R.; Duran, C.; Sabattin, J.; Gutierrez, S. Framework for the Strategic Adoption of Industry 4.0: A Focus on Intelligent Systems. Processes 2023, 11, 2973. [Google Scholar] [CrossRef]

- AL-Khatib, A.W. The Impact of Industry 4.0 Capabilities on Operational Performance: The Mediating Effect of Supply Chain Ambidexterity. TQM J. 2023, 37, 125–149. [Google Scholar] [CrossRef]

- Folgado, F.J.; Calderón, D.; González, I.; Calderón, A.J. Review of Industry 4.0 from the Perspective of Automation and Supervision Systems: Definitions, Architectures and Recent Trends. Electronics 2024, 13, 782. [Google Scholar] [CrossRef]

- Abulibdeh, A.; Zaidan, E.; Abulibdeh, R. Navigating the Confluence of Artificial Intelligence and Education for Sustainable Development in the Era of Industry 4.0: Challenges, Opportunities, and Ethical Dimensions. J. Clean. Prod. 2024, 437, 140527. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Foroughi, B.; Tseng, M.L.; Nikbin, D.; Khanfar, A.A.A. Industry 4.0 Digital Transformation and Opportunities for Supply Chain Resilience: A Comprehensive Review and a Strategic Roadmap. Prod. Plan. Control 2025, 36, 61–91. [Google Scholar] [CrossRef]

- Etzkowitz, H.; Leydesdorff, L. The Dynamics of Innovation: From National Systems and “Mode 2” to a Triple Helix of University–Industry–Government Relations. Res. Policy 2000, 29, 109–123. [Google Scholar] [CrossRef]

- Yoda, N.; Kuwashima, K. Triple Helix of University–Industry–Government Relations in Japan: Transitions of Collaborations and Interactions. J. Knowl. Econ. 2020, 11, 1120–1144. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Sinha, A.K. Digital Economy to Improve the Culture of Industry 4.0: A Study on Features, Implementation and Challenges. Green Technol. Sustain. 2024, 2, 100083. [Google Scholar] [CrossRef]

- Menzies, J.; Sabert, B.; Hassan, R.; Mensah, P.K. Artificial Intelligence for International Business: Its Use, Challenges, and Suggestions for Future Research and Practice. Thunderbird Int. Bus. Rev. 2024, 66, 185–200. [Google Scholar] [CrossRef]

- Aballay-Fredes, C.; Quezada, L.; Marchant-Silva, M.; Fuertes, G.; Vargas, M. Methodology to Generate Strategic Manufacturing Indicators to Support Decision-Making—Case Study of a Food Company. Eng. Manag. J. 2024, 1–13. [Google Scholar] [CrossRef]

- Chen, X.; Chang-Richards, A.; Ling, F.Y.Y.; Yiu, T.W.; Pelosi, A.; Yang, N. Digital Technologies in the AEC Sector: A Comparative Study of Digital Competence among Industry Practitioners. Int. J. Constr. Manag. 2025, 25, 63–76. [Google Scholar] [CrossRef]

- Huy, P.Q.; Phuc, V.K. Changing Times: Does the Critical Success Factors Boosting Green Transition of SMEs Remain Unchanged? J. Innov. Entrep. 2025, 14, 2. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. Critical Analysis of the Impact of Artificial Intelligence Integration with Cutting-Edge Technologies for Production Systems. J. Intell. Manuf. 2025, 36, 61–93. [Google Scholar] [CrossRef]

- Pereira, C.S.; Veloso, B.; Durão, N.; Moreira, F. The Influence of Technological Innovations on International Business Strategy before and during COVID-19 Pandemic. Procedia Comput. Sci. 2022, 196, 44–51. [Google Scholar] [CrossRef]

- Rehman, S.U.; Jabeen, F.; Shahzad, K.; Riaz, A.; Bhatti, A. Industry 4.0 Technologies and International Performance of SMEs: Mediated-Moderated Perspectives. Int. Entrep. Manag. J. 2025, 21, 25. [Google Scholar] [CrossRef]

- Pour, P.D.; Ahmed, A.A.; Nazzal, M.A.; Darras, B.M. An Industry 4.0 Technology Selection Framework for Manufacturing Systems and Firms Using Fuzzy AHP and Fuzzy Topsis Methods. Systems 2023, 11, 192. [Google Scholar] [CrossRef]

- Abdullah, F.M.; Al-Ahmari, A.M.; Anwar, S. A Hybrid Fuzzy Multi-Criteria Decision-Making Model for Evaluating the Influence of Industry 4.0 Technologies on Manufacturing Strategies. Machines 2023, 11, 310. [Google Scholar] [CrossRef]

- Hamzeh, R.; Zhong, R.; Xu, X.W.; Kajati, E.; Zolotova, I. A Technology Selection Framework for Manufacturing Companies in the Context of Industry 4.0. In Proceedings of the World Symposium on Digital Intelligence for Systems and Machines, Košice, Slovakia, 23–25 August 2018; pp. 267–276. [Google Scholar]

- Nouri, S.H.; Sohrabi, T. Investigating and Prioritizing Factors Affecting Technology Selection Using Multi Criteria Decision Making Methods in the National Iranian Petrochemical Company. Teh. Glas. 2021, 15, 449–454. [Google Scholar] [CrossRef]

- Azhar, N.A.; Mohamed Radzi, N.A.; Mustafa, I.S.; Azmi, K.H.M.; Samidi, F.S.; Zulkifli, I.T.; Abdullah, F.; Jamaludin, M.Z.; Ismail, A.; Zainal, A.M. Selecting Communication Technologies for an Electrical Substation Based on the AHP. IEEE Access 2023, 11, 110724–110735. [Google Scholar] [CrossRef]

- Shanmugasundar, G.; Kalita, K.; Čep, R.; Chohan, J.S. Decision Models for Selection of Industrial Robots—A Comprehensive Comparison of Multi-Criteria Decision Making. Processes 2023, 11, 1681. [Google Scholar] [CrossRef]

- Karoui, M.; Mamadou, A.M.; Chalhoub, G. A Novel Distributed Context-Aware Radio Access Technology Selection Scheme for C-ITS Networks Networks. In Proceedings of the International Wireless Communications and Mobile Computing, Dubrovnik, Croatia, 30 May–3 June 2022; pp. 725–730. [Google Scholar]

- Shokatpour, M.H.; Alhuyi Nazari, M.; Haj Assad, M. El Renewable Energy Technology Selection for Iran by Using Multi Criteria Decision Making. In Proceedings of the International Conferences Advances in Science and Engineering Technology, Dubai, United Arab Emirates, 21–24 February 2022. [Google Scholar]

- Moradi, E. Technology Selection in the Steel Industry Based on Multi-Criteria Decision-Making Models: Fuzzy Topsis and AHP. Tech. Soc. Sci. J. 2023, 41, 251–263. [Google Scholar] [CrossRef]

- Alakas, H.M.; Yazici, E.; Ebiri, U.; Kizilay, B.A.; Oruc, O. Selection of 3D Printing Technologies for Prosthesis Production with Multi-Criteria Decision Making Methods. Int. J. Interact. Des. Manuf. 2024, 18, 911–927. [Google Scholar] [CrossRef]

- Petru, C.D.; Breaz, R.E.; Racz, S.G.; Crenganis, M.; Gîrjob, C.E.; Drasovean, P. Decision Support Methodology for the Selection of Industrial Robots Using BWM and TOPSIS Methods. Procedia Comput. Sci. 2024, 242, 43–50. [Google Scholar] [CrossRef]

- Mahdiraji, H.A.; Zavadskas, E.K.; Skare, M.; Kafshgar, F.Z.R.; Arab, A. Evaluating Strategies for Implementing Industry 4.0: A Hybrid Expert Oriented Approach of BWM and Interval Valued Intuitionistic Fuzzy TODIM. Econ. Res. -Ekon. Istraživanja 2020, 33, 1600–1620. [Google Scholar] [CrossRef]

- Buyukozkan, G.; Gocer, F. Technology Selection for Logistics and Supply Chain Management by the Extended Intuitionistic Fuzzy Topsis. In Proceedings of the International Conference on Data Science and Business Analytics, Istanbul, Turkey, 11–12 October 2019; pp. 129–134. [Google Scholar]

- Cristea, M.; Tîrnovan, R.A.; Cristea, C.; Pică, C.S. A Multi-Criteria Decision Making Approach in Lighting Technology Selection for a Production Hall. In Proceedings of the MATEC Web of Conferences, Băile Felix, Romania, 31 May–1 June 2018; Volume 184. p. 04007. [Google Scholar]

- Shen, Y.C.; Lin, G.T.R.; Tzeng, G.H. Combined DEMATEL Techniques with Novel MCDM for the Organic Light Emitting Diode Technology Selection. Expert. Syst. Appl. 2011, 38, 1468–1481. [Google Scholar] [CrossRef]

- Aballay, C.; Quezada, L.; Sepúlveda, C. Model for Technology Selection in the Context of Industry 4.0 Manufacturing. Processes 2023, 11, 2905. [Google Scholar] [CrossRef]

- Nimawat, D.; Gidwani, B.D. Prioritization of Important Factors towards the Status of Industry 4.0 Implementation Utilizing AHP and ANP Techniques. Benchmarking: Int. J. 2021, 28, 695–720. [Google Scholar] [CrossRef]

- Bhadu, J.; Bhamu, J.; Saraswat, P. An Analytic Hierarchy Process (AHP) Approach for Prioritizing the Industries 4.0 Technologies (I4.0T). Evergr. Jt. J. Nov. Carbon Resour. Sci. Green Asia Strategy 2023, 10, 667–675. [Google Scholar] [CrossRef]

- Veljović, M.; Tadić, S.; Krstić, M. Last Word in Last-Mile Logistics: A Novel Hybrid Multi-Criteria Decision-Making Model for Ranking Industry 4.0 Technologies. Mathematics 2024, 12, 2010. [Google Scholar] [CrossRef]

- Erdogan, M.; Ozkan, B.; Karasan, A.; Kaya, I. Selecting the Best Strategy for Industry 4.0 Applications with a Case Study. In Proceedings of the Industrial Engineering in the Industry 4.0 Era, Vienna, Austria, 20–21 July 2018; pp. 109–119. [Google Scholar]

- Tavana, M.; Khalili-Damghani, K.; Abtahi, A.R. A Hybrid Fuzzy Group Decision Support Framework for Advanced-Technology Prioritization at NASA. Expert. Syst. Appl. 2013, 40, 480–491. [Google Scholar] [CrossRef]

- Ensslin, L.; Ensslin, S.R.; Lacerda, R.T.O.; Tasca, J.E. ProKnow-C (Knowledge Development Process-Constructivist). Process. Técnico Com Pat. De Regist. Pendente Junto Ao INPI. Bras. 2010, 10, 2015. [Google Scholar]

- De Carvalho, G.D.G.; Sokulski, C.C.; Da Silva, W.V.; De Carvalho, H.G.; De Moura, R.V.; De Francisco, A.C.; Da Veiga, C.P. Bibliometrics and Systematic Reviews: A Comparison between the Proknow-c and the Methodi Ordinatio. J. Informetr. 2020, 14, 101043. [Google Scholar] [CrossRef]

- Ensslin, S.R.; Ensslin, L.; de Lacerda, R.T.O.; de Souza, V.H.A. Disclosure of the State of the Art of Performance Evaluation Applied to Project Management. Am. J. Ind. Bus. Manag. 2014, 04, 677–687. [Google Scholar] [CrossRef]

- Ensslin, L.; Dutra, A.; Ensslin, S.R.; Chaves, L.C.; Dezem, V.; Ensslin, L.; Dutra, A.; Ensslin, S.R.; Chaves, L.C.; Dezem, V. Research Process for Selecting a Theoretical Framework and Bibliometric Analysis of a Theme: Illustration for the Management of Customer Service in a Bank. Mod. Econ. 2015, 6, 782–796. [Google Scholar] [CrossRef]

- Vieira, E.L.; da Costa, S.E.G.; de Lima, E.P.; Ferreira, C.C. Application of the Proknow-c Methodology in the Search of Literature on Performance Indicators for Energy Management in Manufacturing and Industry 4.0. Procedia Manuf. 2019, 39, 1259–1269. [Google Scholar] [CrossRef]

- MacIel, J.N.; Ledesma, J.J.G.; Ando Junior, O.H. Forecasting Solar Power Output Generation: A Systematic Review with the Proknow-c. IEEE Lat. Am. Trans. 2021, 19, 612–624. [Google Scholar] [CrossRef]

- Ando, J.R.; Salgado, O.H.; Regatieri, H.R.; Hideo, O.; Junior, A.; Ricardo, J.; Salgado, C. Systematic Review of Lithium-Ion Battery Recycling Literature Using ProKnow-c and Methodi Ordinatio. Energies 2022, 15, 1485. [Google Scholar] [CrossRef]

- Lamas, S.A.; Nascimento, E.D.; Mazaro, R.M. Governance and Sustainability in Tourist Destinations. An Analysis of Academic Discourse. Estud. Y Perspect. En Tur. 2019, 28, 1002–1020. [Google Scholar]

- Boonsothonsatit, G.; Vongbunyong, S.; Chonsawat, N.; Chanpuypetch, W. Development of a Hybrid AHP-TOPSIS Decision-Making Framework for Technology Selection in Hospital Medication Dispensing Processes. IEEE Access 2024, 12, 2500–2516. [Google Scholar] [CrossRef]

- Németh, A.; Vitai, V.; Czumbel, M.L.; Szabó, B.; Varga, G.; Kerémi, B.; Hegyi, P.; Hermann, P.; Borbély, J. Clear Guidance to Select the Most Accurate Technologies for 3D Printing Dental Models—A Network Meta-Analysis. J. Dent. 2023, 134, 104532. [Google Scholar] [CrossRef]

- Khan, H.U.; Abbas, M.; Khan, F.; Nazir, S.; Binbusayyis, A.; Alabdultif, A.; Taegkeun, W. Multi-Criteria Decision-Making Methods for the Evaluation of the Social Internet of Things for the Potential of Defining Human Behaviors. Comput. Human. Behav. 2024, 157, 108230. [Google Scholar] [CrossRef]

- Seidenberg, T.; Ayoub, J.; Figge, M.; Anacker, H.; Dumitrescu, R. Method to Support the Selection of Localization Technologies for Industry 4.0. In Proceedings of the International Conference on Information Systems Engineering, Bangkok, Thailand, 16–18 December 2023; Volume 59, pp. 55–60. [Google Scholar]

- Zubiria, A.; Menéndez, Á.; Grande, H.J.; Meneses, P.; Fernández, G. Multi-Criteria Decision-Making Problem for Energy Storage Technology Selection for Different Grid Applications. Energies 2022, 15, 7612. [Google Scholar] [CrossRef]

- Zandi, F.; Tavana, M. A Multi-Attribute Group Decision Support System for Information Technology Project Selection. Int. J. Bus. Inf. Syst. 2010, 6, 179–199. [Google Scholar] [CrossRef]

- Yeung, Y.H.; Lin, R.; Liu, Y.; Ren, J. 3R for Food Waste Management: Fuzzy Multi-Criteria Decision-Making for Technology Selection. In Waste-to-Energy; Academic Press: Cambridge, MA, USA, 2020; pp. 75–110. ISBN 9780128163948. [Google Scholar]

- Upadhyay, Y.; Talib, F.; Zaheen, S.A.; Ansari, M.S. Industry 4.0 Adoption Framework in Msmes Using a Hybrid Fuzzy Ahp-Topsis Approach TOPSIS Methods. Proc. Eng. Sci. 2023, 5, 453–474. [Google Scholar] [CrossRef]

- Ebrahimi, M. A Fuzzy MCDM-Based Approach for Renewable Energy Technologies Prioritisation. Int. J. Energy Technol. Policy 2018, 14, 369–389. [Google Scholar] [CrossRef]

- Biagi, V.; Bollati, M.; Di Gravio, G. Decision Making and Project Selection: An Innovative MCDM Methodology for a Technology Company. In Proceedings of the International Conference on Industrial Engineering and Industrial Management, Barcelona, Spain, 8–11 January 2021; pp. 39–44. [Google Scholar]

- Kim, W.; Han, S.K.; Oh, K.J.; Kim, T.Y.; Ahn, H.; Song, C. The Dual Analytic Hierarchy Process to Prioritize Emerging Technologies. Technol. Forecast. Soc. Change 2010, 77, 566–577. [Google Scholar] [CrossRef]

- Malaga, A.; Vinodh, S. Technology Selection for Additive Manufacturing in Industry 4.0 Scenario Using Hybrid MCDM Approach. In Proceedings of the Industry 4.0 and Advanced Manufacturing, Bangalore, India, 11–12 January 2023; pp. 207–217. [Google Scholar]

- Büyüközkan, G.; Havle, C.A.; Feyziolu, O.; Uztürk, D. Integrated Fuzzy Multi Criteria Decision Making Approach for Sustainable Energy Technology Selection. In Proceedings of the International Conference on Informatics, Environment, Energy and Applications, Amsterdam, The Netherlands, 13–16 March 2020; pp. 93–98. [Google Scholar]

- Ren, J.; Lützen, M. Fuzzy Multi-Criteria Decision-Making Method for Technology Selection for Emissions Reduction from Shipping under Uncertainties. Transp. Res. D Transp. Environ. 2015, 40, 43–60. [Google Scholar] [CrossRef]

- Chemane, L.; Ekenberg, L.; Popov, O.; Cossa, T. MCDM Model for Selecting Internet Access Technologies—A Case Study in Mozambique. In Proceedings of the International Conference on Computer as a Tool, Belgrade, Serbia, 21–24 November 2005; Volume II, pp. 1738–1741. [Google Scholar]

- Ali, T.; Nahian, A.J.; Ma, H. A Hybrid Multi-Criteria Decision-Making Approach to Solve Renewable Energy Technology Selection Problem for Rohingya Refugees in Bangladesh. J. Clean. Prod. 2020, 273, 122967. [Google Scholar] [CrossRef]

- Ferreira, C.C.; Vieira, E.; Gouvea da Gosta, S.E.; Loures, E.R.; de Lima, E.P. Application of MCDM Method for Technologies Selection to Support Energy Management. Procedia Manuf. 2019, 39, 1289–1296. [Google Scholar] [CrossRef]

- Lee, S.; Kim, W.; Kim, Y.M.; Lee, H.Y.; Oh, K.J. The Prioritization and Verification of IT Emerging Technologies Using an Analytic Hierarchy Process and Cluster Analysis. Technol. Forecast. Soc. Change 2014, 87, 292–304. [Google Scholar] [CrossRef]

- Erbay, H.; Yıldırım, N. Technology Selection for Digital Transformation: A Mixed Decision Making Model of AHP and QFD. In Proceedings of the The International Symposium for Production Research, Vienna, Austria, 28–31 August 2018; pp. 480–493. [Google Scholar]

- Azim, A.B.; ALoqaily, A.; Ali, A.; Ali, S.; Mlaiki, N. Industry 4.0 Project Prioritization by Using q-Spherical Fuzzy Rough Hierarchy Process. AIMS Math. 2023, 8, 18809–18832. [Google Scholar] [CrossRef]

- Karasakal, E.; Aker, P. A Multicriteria Sorting Approach Based on Data Envelopment Analysis for R&D Project Selection Problem. Omega 2017, 73, 79–92. [Google Scholar] [CrossRef]

- Quezada, L.E.; López-Ospina, H.A.; Ortiz, C.; Oddershede, A.M.; Palominos, P.I.; Jofré, P.A. A DEMATEL-Based Method for Prioritizing Strategic Projects Using the Perspectives of the Balanced Scorecard. Int. J. Prod. Econ. 2022, 249, 108518. [Google Scholar] [CrossRef]

- Jeng, D.J.F.; Huang, K.H. Strategic Project Portfolio Selection for National Research Institutes. J. Bus. Res. 2015, 68, 2305–2311. [Google Scholar] [CrossRef]

- da Rocha Moro, M.; de Freitas Rocha Loures, E.; Neto, A.A.; Ramos, L.F.P.; Santos, V.; do Amaral, L.M.B. Prioritization of Industry 4.0 Technologies Based on Diagnosis and Performance Indicators Associated with Lean Manufac-turing under Interoperability Requirements. In Proceedings of the Flexible Automation and Intelligent Manufacturing: The Human-Data-Technology Nexus, Detroit, MI, USA, 19–23 June 2023; pp. 408–416. [Google Scholar]

- Fu, Y.; Li, M.; Luo, H.; Huang, G.Q. Industrial Robot Selection Using Stochastic Multicriteria Acceptability Analysis for Group Decision Making. Rob. Auton. Syst. 2019, 122, 103304. [Google Scholar] [CrossRef]

- Karsak, E.E.; Ahiska, S.S. Practical Common Weight Multi-Criteria Decision-Making Approach with an Improved Discriminating Power for Technology Selection. Int. J. Prod. Res. 2005, 43, 1537–1554. [Google Scholar] [CrossRef]

- Dalalah, D.; Bataineh, O. A Fuzzy Logic Approach to the Selection of the Best Silicon Crystal Slicing Technology. Expert. Syst. Appl. 2009, 36, 3712–3719. [Google Scholar] [CrossRef]

- Kafuku, J.M.; Saman, M.Z.M.; Yusof, S.M. Application of Fuzzy Logic in Selection of Remanufacturing Technology. Procedia Manuf. 2019, 33, 192–199. [Google Scholar] [CrossRef]

- Ali, Y.; Pervez, H.; Khan, J. Selection of the Most Feasible Wastewater Treatment Technology in Pakistan Using Multi-Criteria Decision-Making (MCDM). Water Conserv. Sci. Eng. 2020, 5, 199–213. [Google Scholar] [CrossRef]

- Karuppiah, K.; Sankaranarayanan, B.; D’Adamo, I.; Ali, S.M. Evaluation of Key Factors for Industry 4.0 Technologies Adoption in Small and Medium Enterprises (SMEs): An Emerging Economy Context. J. Asia Bus. Stud. 2023, 17, 347–370. [Google Scholar] [CrossRef]

- Torkayesh, A.E.; Malmir, B.; Rajabi Asadabadi, M. Sustainable Waste Disposal Technology Selection: The Stratified Best-Worst Multi-Criteria Decision-Making Method. Waste Manag. 2021, 122, 100–112. [Google Scholar] [CrossRef]

- Qie, X.; Zhang, R.; Hu, Y.; Sun, X.; Chen, X. A Multi-Criteria Decision-Making Approach for Energy Storage Technology Selection Based on Demand. Energies 2021, 14, 6592. [Google Scholar] [CrossRef]

- Loganathan, M.K.; Ming Tan, C.; Mishra, B.; Msagati, T.A.M.; Snyman, L.W. Review and Selection of Advanced Battery Technologies for Post 2020 Era Electric Vehicles. In Proceedings of the Transportation Electrification Conference, Bengaluru, India, 17–19 December 2019. [Google Scholar]

- Hashemkhani Zolfani, S.; Salimi, J.; Maknoon, R.; Simona, K. Technology Foresight about R & D Projects Selection; Application of SWARA Method at the Policy Making Level. Inz. Ekon. -Eng. Econ. 2015, 26, 571–580. [Google Scholar] [CrossRef]

- Ali, T.; Ma, H.; Nahian, A.J. An Analysis of the Renewable Energy Technology Selection in the Southern Region of Bangladesh Using a Hybrid Multi-Criteria Decision Making (MCDM) Method. Int. J. Renew. Energy Res. 2019, 9, 1838–1848. [Google Scholar] [CrossRef]

- El Helou, M.; Lahoudt, S.; Ibrahim, M.; Khawaml, K. Satisfaction-Based Radio Access Technology Selection in Heterogeneous Wireless Networks. In Proceedings of the IFIP Wireless Days, Valencia, Spain, 13–15 November 2013; pp. 1–4. [Google Scholar]

- Li, X.; Liao, H. A Group Decision-Making Method for Technology Selection of Petrochemical Enterprises. Renew. Sustain. Energy Rev. 2024, 198, 114443. [Google Scholar] [CrossRef]

- Wibowo, S.; Grandhi, S. A Group Decision Making Method for High-Technology Projects Selection under Hesitant Fuzzy Environment. In Proceedings of the Chinese Control and Decision Conference, Yinchuan, China, 28–30 May 2016; pp. 167–172. [Google Scholar]

- Apperson, C.; Arefzadeh, F.; Dinsmore, A.; Grabowski, R.; May, D.; Morandi, K.; Tawney, B.; Preston White, K. Project Selection for Technology Investment. In Proceedings of the Design Symposium, Systems and Information Engineering, Charlottesville, VA, USA, 28–29 April 2005; Volume 2005. pp. 151–157. [Google Scholar]

- Heidary Dahooie, J.; Mohammadian, A.; Qorbani, A.R.; Daim, T. A Portfolio Selection of Internet of Things (IoTs) Applications for the Sustainable Urban Transportation: A Novel Hybrid Multi Criteria Decision Making Approach. Technol. Soc. 2023, 75, 102366. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F.; Feyzioǧlu, O. Cloud Computing Technology Selection Based on Interval Valued Intuitionistic Fuzzy Group Decision Making Using MULTIMOORA Approach. In Proceedings of the International Conference on Fuzzy Systems, Naples, Italy, 9–12 July 2017. [Google Scholar]

- Shetty, J.; D’Mello, D.A. Quality of Service Driven Cloud Service Ranking and Selection Algorithm Using REMBRANDT Approach. In Proceedings of the International Conference on Smart Technologies and Management for Computing, Communication, Controls, Energy and Materials, Avadi, India, 6–8 May 2015; pp. 126–132. [Google Scholar]

- de Almeida, A.T.; Duarte, M.D.O. A Multi-Criteria Decision Model for Selecting Project Portfolio with Consideration Being given to a New Concept for Synergies. Pesqui. Oper. 2011, 31, 301–318. [Google Scholar] [CrossRef]

- Isikli, E.; Yanik, S.; Cevikcan, E.; Ustundag, A. Project Portfolio Selection for the Digital Transformation Era. In Industry 4.0: Managing the Digital Transformation; Springer Nature: Cham, Switzerland, 2018; pp. 105–121. [Google Scholar]

- Erbay, H.; Ylldlrlm, N. Combined Technology Selection Model for Digital Transformation in Manufacturing: A Case Study from the Automotive Supplier Industry. Int. J. Innov. Technol. Manag. 2022, 19, 2250023. [Google Scholar] [CrossRef]

- Budak, A.; Ustundag, A. Technology Project Portfolio Selection in Industry 4.0. In Research Anthology on Cross-Industry Challenges of Industry 4.0; IGI Global: Hershey, PA, USA, 2021; pp. 877–894. [Google Scholar]

- De Giovanni, P.; Belvedere, V.; Grando, A. The Selection of Industry 4.0 Technologies through Bayesian Networks: An Operational Perspective. IEEE Trans. Eng. Manag. 2022, 71, 2921–2936. [Google Scholar] [CrossRef]

- Chu, J.; Wu, J.; Chu, C.; Liu, M. A New DEA Common-Weight Multi-Criteria Decision-Making Approach for Technology Selection. Int. J. Prod. Res. 2020, 58, 3686–3700. [Google Scholar] [CrossRef]

- Fasanghari, M.; Dastmardi, M.; Azadnia, M.; Mohammadi, S. Information and Communication Technology Project Selection Based on Fuzzy Agent. In Proceedings of the 2007 International Conference on Convergence Information Technology (ICCIT 2007), Gwangju, South Korea, 21–23 November 2007; pp. 1488–1493. [Google Scholar]

- da Silva, J.F.; da Silva, F.L.; da Silva, D.O.; Rocha, L.A.O.; Ritter, Á.M. Decision Making in the Process of Choosing and Deploying Industry 4.0 Technologies. Gestão Produção 2022, 29, e163. [Google Scholar] [CrossRef]

- Santos, R.C.; de Lima, E.P.; da Costa, S.E.G.; Deschamps, F. Selection of Industry 4.0 Technologies: A Research Agenda. In Proceedings of the Annual Conference, IISE, Online, 22–25 May 2021; Volume 29. pp. 145–150. [Google Scholar]

- Kozłowska, J. Methods of Multi-Criteria Analysis in Technology Selection and Technology Assessment: A Systematic Literature Review. Eng. Manag. Prod. Serv. 2022, 14, 116–137. [Google Scholar] [CrossRef]

- Kim, Y.; Chang, H. A Study on Project Selection Framework for Future ICT Technologies. Wirel. Pers. Commun. 2013, 73, 1591–1600. [Google Scholar] [CrossRef]

- Lehmann, D.; Fekete, D.; Vossen, G. Technology Selection for Big Data and Analytical Applications; University of Münster, European Research Center for Information Systems (ERCIS): Münster, Germany, 2016. [Google Scholar]

- Thomassen, M.K.; Sjøbakk, B.; Alfnes, E. A Strategic Approach for Automation Technology Initiatives Selection. In Proceedings of the Advances in Information and Communication Technology, Ajaccio, France, 20–24 September 2014; Volume 440, pp. 288–295. [Google Scholar]

- Cabrera, D.; Cerrada, M.; Macancela, J.C.; Siguencia, J.; Sánchez, R.V. Technology Selection for Industry 4.0 Oriented Condition-Based Monitoring System: A Case Study in the Paper Mills Industry. IFAC-Pap. 2022, 55, 211–216. [Google Scholar] [CrossRef]

- Raczynski, C.; Mavris, D. A Method for Strategic Technology Prioritization and Portfolio Resource Allocation. In Proceedings of the Aerospace Conference, Big Sky, MT, USA, 5–12 March 2011. [Google Scholar]

- Lee, S.; Cho, C.; Choi, J.; Yoon, B. R&D Project Selection Incorporating Customer-Perceived Value and Technology Potential: The Case of the Automobile Industry. Sustainability 2017, 9, 1918. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, H.; Sutherland, J.W. Development of Multi-Criteria Decision Making Model for Remanufacturing Technology Portfolio Selection. J. Clean. Prod. 2011, 19, 1939–1945. [Google Scholar] [CrossRef]

- Li, T.; Sun, J.; Fei, L. Application of Multiple-Criteria Decision-Making Technology in Emergency Decision-Making: Uncertainty, Heterogeneity, Dynamicity, and Interaction. Mathematics 2025, 13, 731. [Google Scholar] [CrossRef]

- Duan, Y.; Khokhar, M.; Raza, A.; Sharma, A.; Islam, T. The Role of Digital Technology and Environmental Sustainability in Circular Supply Chains Based on the Fuzzy TOPSIS Model. Environ. Dev. Sustain. 2025, 1–32. [Google Scholar] [CrossRef]

- Madanchian, M.; Taherdoost, H. A Comprehensive Guide to the Topsis Method for Multi-Criteria Decision Making. Sustain. Soc. Dev. 2023, 1, 2220. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Goswami, S.S. A Comprehensive Review of Multiple Criteria Decision-Making (MCDM) Methods: Advancements, Applications, and Future Directions. Decis. Mak. Adv. 2023, 1, 25–48. [Google Scholar] [CrossRef]

- Barretta, R.; Taherdoost, H.; Madanchian, M. Multi-Criteria Decision Making (MCDM) Methods and Concepts. Encyclopedia 2023, 3, 77–87. [Google Scholar] [CrossRef]

- Vuković, M.; Pivac, S.; Babić, Z. Comparative Analysis of Stock Selection Using a Hybrid MCDM Approach and Modern Portfolio Theory. Croat. Rev. Econ. Bus. Soc. Stat. 2020, 6, 58–68. [Google Scholar] [CrossRef]

- Ramezanzade, M.; Karimi, H.; Almutairi, K.; Xuan, H.A.; Saebi, J.; Mostafaeipour, A.; Techato, K. Implementing MCDM Techniques for Ranking Renewable Energy Projects under Fuzzy Environment: A Case Study. Sustainability 2021, 13, 12858. [Google Scholar] [CrossRef]

- Lima Junior, F.R.; Osiro, L.; Carpinetti, L.C.R. A Comparison between Fuzzy AHP and Fuzzy TOPSIS Methods to Supplier Selection. Appl. Soft Comput. 2014, 21, 194–209. [Google Scholar] [CrossRef]

- Seyma Yuksel, F.; Kayadelen, A.N.; Antmen, Z.F. A Systematic Literature Review on Multi-Criteria Decision Making in Higher Education. Int. J. Assess. Tools Educ. 2023, 10, 12–28. [Google Scholar] [CrossRef]

- Namin, F.S.; Ghadi, A.; Saki, F. A Literature Review of Multi Criteria Decision-Making (MCDM) towards Mining Method Selection (MMS). Resour. Policy 2022, 77, 102676. [Google Scholar] [CrossRef]

- Bajwa, A.U.R.; Siriwardana, C.; Shahzad, W.; Naeem, M.A. Material Selection in the Construction Industry: A Systematic Literature Review on Multi-Criteria Decision Making. Environ. Syst. Decis. 2025, 45, 8. [Google Scholar] [CrossRef]

| Ref./Quartile | Domain | Contribution | Methodology | Type of Selection |

|---|---|---|---|---|

| 1/Conference | Selection of radio access technologies in vehicular networks [38]. | Multi-criteria framework for optimizing cooperative intelligent vehicular networks. | Technique for order preference by similarity to ideal solution (TOPSIS) | TS |

| 2/Conference | Evaluation and prioritization of renewable energy technologies [39]. | Guide for sustainable energy planning and identification of multi-criteria technologies. | TOPSIS | TS |

| 3/Q1 | Decision-making in medication dispensing processes [61]. | Identification of seven critical factors for technology adoption. | TOPSIS and AHP | TS |

| 4/Q2 | Identification of 3D printing technologies for prosthesis manufacturing [41]. | Expert panel for weighting and ranking alternatives. | TOPSIS, AHP, and PROMETHEE | TS |

| 5/Q1 | Evaluation of 3D printing technologies for dental models [62]. | Network meta-analysis for comparing seven printing technologies by precision. | Literature review | TS |

| 6/Q1 | Multi-criteria methods for assessing the potential of the social Internet of Things [63]. | Evaluation of technologies for modeling and predicting human behavior. | TOPSIS and entropy weighted method | I4.0 |

| 7/Conference | Selection of localization technologies [64]. | Multi-criteria framework for assessing technological alternatives in a balanced and objective manner. | TOPSIS and geometric mean method | I4.0 |

| 8/CiteScore 4.5 | Hybrid methodology for the selection of industrial robots [42]. | Classification of robots based on proximity to the ideal solution and multiple criteria. | TOPSIS and best worst method (BWM) | I4.0 |

| 9/Q1 | Selection of energy storage technologies [65]. | Structured guide for optimizing technology selection under uncertainty. | TOPSIS and triangular fuzzy | TS |

| 10/Q3 | Selection of technology in the petrochemical industry [35]. | Identification and prioritization of key factors in selection using multi-criteria methods. | TOPSIS, Delphi method, and Shannon entropy | TS |

| 11/- | Selection of lighting technologies [45]. | Multi-criteria decision model with technical and sustainable criteria. | Elimination and choice expressing reality (ELECTRE III) | TS |

| 12/Q3 | Project management and decision-making in information technology [66]. | Support system for evaluating and prioritizing projects using multi-criteria and multi-attribute criteria. | TOPSIS, multi-attribute decision-making (MADM) and multi-objective decision-making (MODM) | PRS |

| 13/Conference | Selection of technologies to optimize logistics and supply chain management [44]. | Multi-criteria method for evaluating technological alternatives under uncertainty and ambiguity. | Fuzzy TOPSIS | TS |

| 14/Book chapters | Selection of technologies for food waste management [67]. | Fuzzy multi-criteria method for evaluating technologies under uncertainty. | Fuzzy TOPSIS | TS |

| 15/Q2 | Evaluation of technological impact on manufacturing strategies [33]. | Hybrid method for calculating weights and classifying technological influence. | Fuzzy TOPSIS and Fuzzy AHP | I4.0 |

| 16/Q2 | Selection of technologies for effective manufacturing operations management [32]. | Framework for prioritizing technologies based on economic, social, and environmental criteria. | Fuzzy TOPSIS and Fuzzy AHP | I4.0 |

| 17/Q4 | Identification of key digitalization elements for efficient operations [68]. | Framework for identifying key factors and metrics. | Fuzzy TOPSIS and Fuzzy AHP | I4.0 |

| 18/- | Selection of technologies for competitive markets [40]. | Framework for structuring and defining evaluation indicators. | Fuzzy TOPSIS and Fuzzy AHP | TS |

| 19/Conference | Optimal selection of technological strategies using multi-criteria approaches [51]. | Prioritization of strategies based on human resources and organizational factors. | AHP and VIseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR) | I4.0 |

| 20/Q4 | Selection of renewable energy technologies [69]. | Fuzzy multi-criteria method for classifying categories and criteria. | Fuzzy TOPSIS and PROMETHEE | TP |

| 21/Q1 | Evaluation of technological projects in the aerospace industry [52]. | Fuzzy, hybrid, and structured multi-criteria framework in two modules. | Fuzzy TOPSIS and analytic network process (ANP) | TP |

| 22/Conference | Selection and prioritization of technological projects in business portfolios [70]. | Design of a multi-criteria system integrating strategic objectives and critical success factors. | Fuzzy TOPSIS, PRISMA, and ANP | PRS |

| 23/Q1 | Selection of emerging technologies for R&D at the national level [71]. | Uncertainty management in decision-making without criterion decomposition. | DAHP (Dual AHP or AHP bayesiano) | TP |

| 24/CiteScore. 4.3 | Technological adoption in manufacturing [49]. | Classification of key technologies with expert validation. | AHP | I4.0 |

| 25/Q1 | Selection of communication technologies for electrical substations [36]. | Decision framework with technical, economic, and adaptability criteria. | AHP | TS |

| 26/Conference | Implementation of technologies in additive manufacturing [72]. | Hybrid approach for prioritizing criteria and selecting technologies. | AHP and Fuzzy VIKOR | I4.0 |

| 27/Conference | Selection of sustainable energy technologies [73]. | Reducing uncertainty in perception and weight assignment. | Fuzzy TOPSIS, AHP, and Fuzzy VIKOR | TS |

| 28/Q1 | Selection of technologies to reduce emissions in the maritime sector [74]. | Hybrid multi-criteria evaluation of technologies under uncertainty and incomplete data. | AHP, VIKOR, and Fuzzy AHP | TS |

| 29/Conference | Selection of internet access technologies [75]. | Multi-criteria framework for assessing technologies based on cost, safety, and coverage. | AHP and DecideIT | TS |

| 30/Q1 | Selection of renewable energy technologies [76]. | Hybrid method for weighing technical, economic, and social criteria. | AHP and combinative distance-based assessment (CODAS) | TS |

| 31/- | Selection of technologies for energy management [77]. | Key criteria and framework for technology selection and decision-making. | AHP and literature review | TS |

| 32/Q1 | Forecasting and prioritization of investments in emerging technologies [78]. | Quantitative method based on a multi-criteria tool. | AHP and cluster analysis of factor scores | TS |

| 33/Conference | Selection and evaluation of manufacturing technologies [79]. | Hybrid methodology considering technology, competition, and management. | AHP and quality function deployment (QFD) | I4.0 |

| 34/Q2 | Prioritization of technological projects under uncertainty and expert judgment [80]. | Arithmetic means for evaluating projects with five criteria and four alternatives. | AHP and q-spherical fuzzy rough set | I4.0 |

| 35/Q1 | Evaluation of critical factors for technology implementation [48]. | Prioritization of key factors and industrial sensitivity analysis. | AHP and ANP | I4.0 |

| 36/Conference | Integration of digital technologies in industrial processes [34]. | Technology selection framework with a social and business approach. | Action research with iterative strategic analysis | I4.0 |

| 37/Q1 | Evaluation and selection of R&D projects [81]. | Hierarchy of criteria in five levels and scoring guide. | AHP, data envelopment analysis (DEA), and utility additive discriminant (UTADIS) | PRS |

| 38/Q2 | Selection of technologies in manufacturing [47]. | Three-stage hybrid model for weighting relevant factors. | Fuzzy AHP and Fuzzy ANP | I4.0 |

| 39/Q1 | Ranking and selection of strategic projects [82]. | Modeling relationships between projects and financial objectives of the balanced scorecard. | Decision-making trial and evaluation laboratory (DEMATEL) | PRS |

| 40/Q1 | Selection of emerging technologies using multi-criteria methods [46]. | Hybrid model integrating patent co-citation analysis to identify technological areas. | DEMATEL, Fuzzy Delphi, ANP, and network relationship map (NRM) | TS |

| 41/Q1 | Selection of R&D project portfolios [83]. | Hybrid method for managing interdependence and feedback in decisions. | DEMATEL, modified Delphi method, and ANP | PS |

| 42/Q2 | Optimal selection of industrial robots based on application [37]. | Comparison of multi-criteria methods for selecting criteria in manufacturing. | TOPSIS, simple additive weighing, linear programming technique, VIKOR, ELECTRE III, and net flow method | I4.0 |

| 43/Conference | Enterprise interoperability to optimize performance using Lean indicators [84]. | Technology prioritization framework with diagnostics and performance evaluation. | ELECTRE I and PROMETHEE II | I4.0 |

| 44/Q1 | Selection of robots for industry and manufacturing [85]. | Group decision-making for robot selection with weights and uncertainty. | ELECTRE II, VIKOR, and group decision making | I4.0 |

| 45/Q1 | Technology selection with relative efficiency assessment [86]. | Multi-criteria methodology with common weights that reduces computational cost. | DEA | TS |

| 46/Q1 | Selection of wafer-cutting technology for integrated circuits [87]. | Decision model with static, dynamic, and expert-driven factors. | Fuzzy Logic | TS |

| 47/- | Selection of remanufacturing technologies [88]. | Evaluation of technologies considering key criteria and uncertainty. | Fuzzy Logic | TS |

| 48/Q3 | Selection of technologies for industrial wastewater treatment [89]. | Evaluation framework for decision-making, analyzing five technologies across ten criteria. | Fuzzy VIKOR | TS |

| 49/Q1 | Implementation of technologies in SMEs [90]. | Identification of key factors for implementation using a multi-criteria approach. | Fuzzy complex proportional assessment | I4.0 |

| 50/Q1 | Optimization of last-mile logistics with technology selection [50]. | Weighting of criteria for selecting the best technology. | Fuzzy ANP and Fuzzy ADAM | I4.0 |

| 51/Q1 | Selection of technologies for solid waste disposal [91]. | Incorporating uncertainty into long-term decisions and calculating technology rankings. | BWM | TS |

| 52/Q1 | Selection and prioritization of strategies for technology implementation [43]. | Hybrid approach for identifying key attributes. | BWM, Fuzzy, tomada de decisão interativa multicritério (TODIM), and interval-valued intuitionistic fuzzy (IVIF) | I4.0 |

| 53/Q1 | Selection of energy storage technologies [92]. | Multi-criteria model considering specific storage requirements. | Probabilistic dual hesitant fuzzy set | TS |

| 54/Conference | Selection of advanced battery technologies for electric vehicles [93]. | Multi-criteria model for evaluating emerging technologies based on key performance factors. | Weighted product model | TS |

| 55/Q2 | Selection of R&D projects through technology foresight [94]. | MCDM model for evaluating and weighting criteria. | Stepwise weight assessment ratio analysis | PRS |

| 56/Q3 | Selection of renewable energy technologies [95]. | Integrated model for evaluating and weighting criteria and classifying alternatives. | Evaluation based on distance from average solution (EDAS) | TS |

| 57/Conference | Selection of access technologies in heterogeneous wireless networks [96]. | MCDM model based on operator and user satisfaction. | Satisfaction-based | TS |

| 58/Q1 | Selection of energy conservation and emission reduction technologies [97]. | Model based on rank centrality and differences among experts. | Large-scale group decision-making | TS |

| 59/Conference | Selection of high-tech projects in an uncertain environment [98]. | Algorithm for calculating preferences considering all criteria. | Weighted generalized hesitant fuzzy power average | PRS |

| 60/Conference | Selection and prioritization of R&D projects in the aerospace industry [99]. | Structured questionnaire for experts and decision support system for technology selection. | Scoring algorithm | PRS |

| 61/Q1 | Selection of Internet of Things technologies in urban transportation [100]. | Method for analyzing relationships, weighting criteria, and prioritizing applications. | Fuzzy cognitive map, BWM, and additive ratio assessment | I4.0 |

| 62/Conference | Selection of cloud computing technology [101]. | Method for identifying criteria, managing uncertainty, and conducting multi-criteria evaluation. | IVIF and MULTIMOORA | TS |

| 63/Conference | Selection of cloud services [102]. | Methodology for classifying cloud services based on non-functional properties. | REMBRANDT method | TS |

| 64/Q3 | Portfolio selection analysis for R&D projects [103]. | Multi-criteria model for evaluating projects considering interrelations and synergies. | Nonlinear optimization | PS |

| 65/Book chapters | Selection of digital transformation project portfolios [104]. | Model with multiple constraints, interdependencies, and uncertainty management. | Optimization and integer programming | I4.0 |

| 66/Q3 | Selection of technologies in the context of digital transformation [105]. | Hybrid framework integrating key dimensions through a quantitative approach. | AHP, QFD, and mixed integer programming | I4.0 |

| 67/Book chapters | Selection of technological projects [106]. | Optimization model for maximizing benefits and evaluating scenarios under uncertainty. | Stage-Gate | I4.0 |

| 68/Q1 | Selection and impact of technologies in manufacturing companies [107]. | Technology evaluation, portfolio construction, and operational improvements. | Bayesian network and machine-learning algorithms | I4.0 |

| 69/Q1 | Analysis and selection of technologies in advanced manufacturing [108]. | MCDM approach with common weights and an efficient algorithm. | DEA and mixed integer linear programming | TS |

| 70/Conference | Projects in information and communication technologies [109]. | Agent-based approach for modeling uncertainty with integer linear programming. | Fuzzy Agent | PRS |

| 71/Q3 | Decision-making for the selection and implementation of technologies [110]. | Clustering of key criteria with multi-factor evaluation. | Literature review | I4.0 |

| 72/- | Structured decision-making for technology selection in manufacturing [111]. | Technology identification and strategic roadmap development. | Literature review | I4.0 |

| 73/Q2 | Evaluation and selection of technologies using multi-criteria analysis [112]. | Evaluation of trends, industrial technologies, and their sub-areas. | Literature review | TS |

| 74/Q2 | Selection and evaluation of R&D projects in the communication sector [113]. | Evidence-based approach for R&D prioritization and evaluation. | Literature review | PRS |

| 75/Technical Report | Selection of technologies for big data analysis [114]. | Framework for classifying technologies, identifying key criteria, and guiding technological adoption. | S.T.A.D.T. selection framework (SSF) | I4.0 |

| 76/Conference | Selection of automation technologies in manufacturing [115]. | Framework for technology analysis, computational cost optimization, and investment criteria incorporation. | New methodology | TS |

| 77/CiteScore 1.7 | Selection of technologies for manufacturing [116]. | Quantitative methodology for selecting technology providers based on evaluation dimensions. | New methodology | I4.0 |

| 78/Conference | Selection of technology portfolios in the aerospace industry [117]. | Methodology for resource optimization in commercial and governmental environments. | Strategic planning and prioritization | PS |

| 79/Q1 | Innovation management and selection of R&D projects [118]. | MCDM model considering technology and customer value. | AHP and new methodology | PRS |

| 80/Q1 | Selection of technology for remanufacturing [119]. | MCDM model considering economic benefits, environmental impact, and technological synergies. | AHP and new methodology | PS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quezada, L.; Hermosilla, I.; Fuertes, G.; Oddershede, A.; Palominos, P.; Vargas, M. Methodologies for Technology Selection in an Industry 4.0 Environment: A Methodological Analysis Using ProKnow-C. Technologies 2025, 13, 325. https://doi.org/10.3390/technologies13080325

Quezada L, Hermosilla I, Fuertes G, Oddershede A, Palominos P, Vargas M. Methodologies for Technology Selection in an Industry 4.0 Environment: A Methodological Analysis Using ProKnow-C. Technologies. 2025; 13(8):325. https://doi.org/10.3390/technologies13080325

Chicago/Turabian StyleQuezada, Luis, Isaias Hermosilla, Guillermo Fuertes, Astrid Oddershede, Pedro Palominos, and Manuel Vargas. 2025. "Methodologies for Technology Selection in an Industry 4.0 Environment: A Methodological Analysis Using ProKnow-C" Technologies 13, no. 8: 325. https://doi.org/10.3390/technologies13080325

APA StyleQuezada, L., Hermosilla, I., Fuertes, G., Oddershede, A., Palominos, P., & Vargas, M. (2025). Methodologies for Technology Selection in an Industry 4.0 Environment: A Methodological Analysis Using ProKnow-C. Technologies, 13(8), 325. https://doi.org/10.3390/technologies13080325