In Situ Ceramic Phase Reinforcement via Short-Pulsed Laser Cladding for Enhanced Tribo-Mechanical Behavior of Metal Matrix Composite FeNiCr-B4C (5 and 7 wt.%) Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Powder Materials

2.2. Laser Cladding Process Parameters

2.3. Scanning Electron Microscopy

2.4. X-Ray Diffraction

2.5. Raman Spectroscopy

2.6. Tribo-Mechanical Characterization

- (1)

- Microindentation tests were performed with a loading/holding/unloading time of 20 s each and a maximum load of 250 mN. The vertical and horizontal measurement steps were 50 µm, with a total number of indenter prints of 200 for each coating. The measurement error was determined using standard deviation with a confidence probability of 0.95.

- (2)

- The scratch testing procedure involved creating three scratches per specimen under a constant load of 250 mN and a velocity of 2 μm/s, with scratch lengths of 300–340 μm. A pre-test scratch (1 mN load, 10 μm length) was performed before each test. Surface topography scans (1 mN load) were conducted before and after scratching to evaluate the initial surface condition and measure residual scratch depth. Prior to scratch testing, cross-sections of the specimens were polished to minimize surface roughness effects. The resulting scratches were then analyzed via SEM to identify the dominant failure mechanisms.

3. Results and Discussion

3.1. Microstructure and Chemical Composition

3.2. X-Ray Diffraction Analysis

3.3. Raman Spectroscopy Analysis

3.4. Mechanical Characterization

3.5. Scratch Test Assessment

4. Conclusions

- (1)

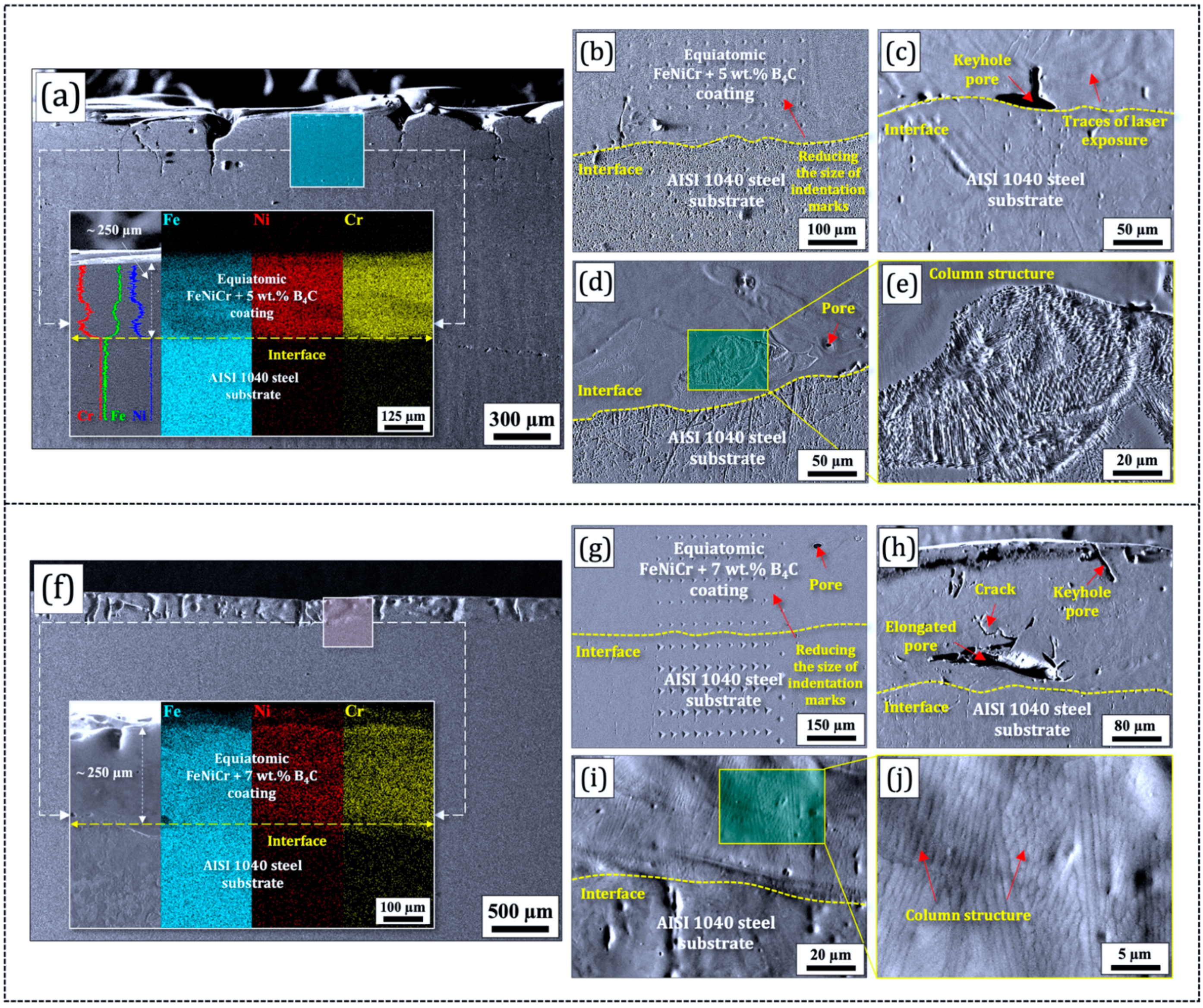

- The FeNiCr-B4C (5 and 7 wt.% B4C) cross-sections are characterized by an average thickness of 250 ± 20 μm and a transition zone of 80 ± 10 μm. Both coatings possess a homogeneous surface texture with a typical column structure and rare defects, such as elongated and keyhole pores, as well as cracks.

- (2)

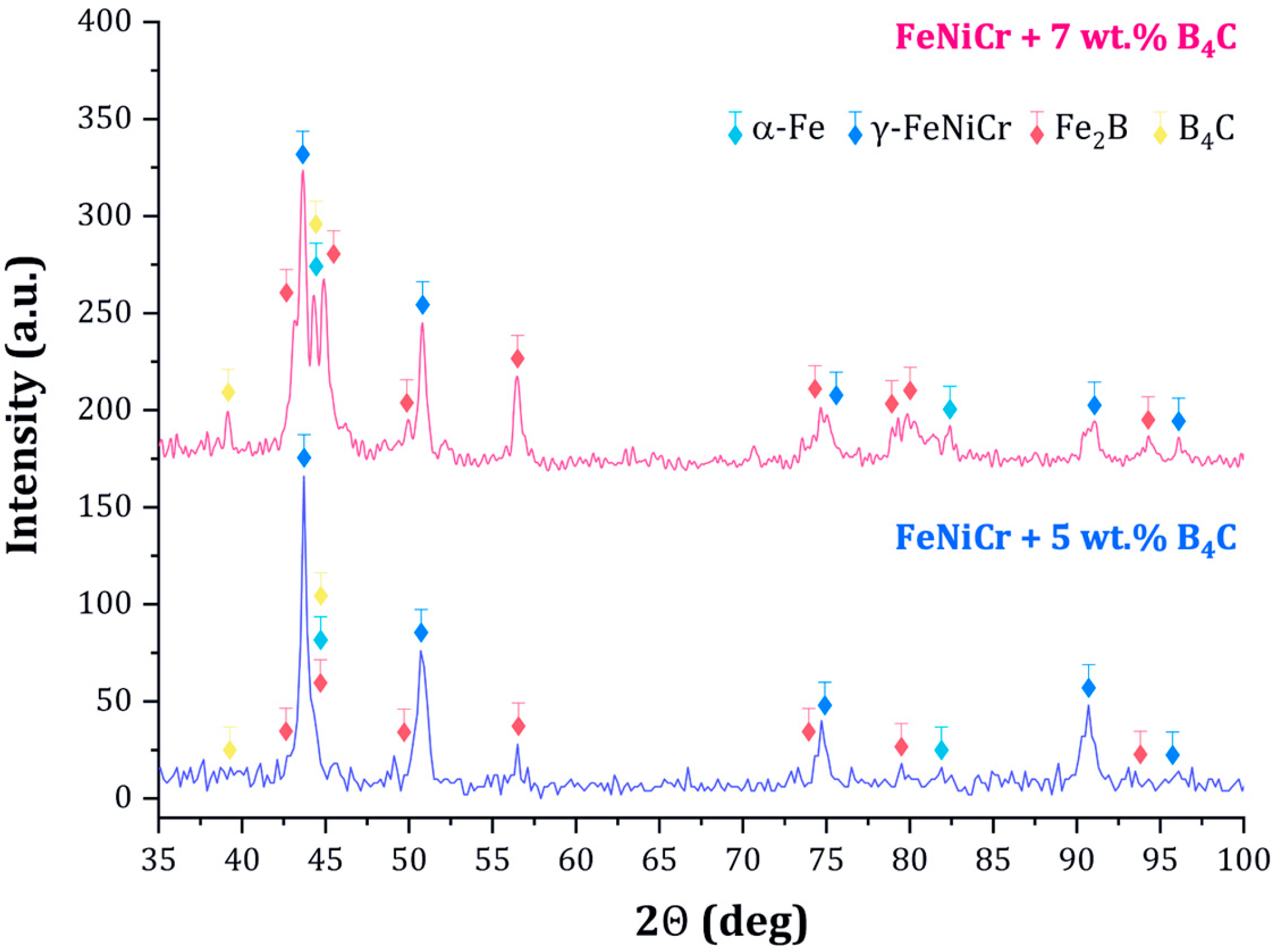

- The XRD analysis confirmed that both FeNiCr-B4C (5 and 7 wt.% B4C) coatings consist of the following phases: α-Fe, space group Im-3m; γ-FeNiCr, space group Fm-3m; Fe2B, space group I-42m; and B4C, space group R-3m.

- (3)

- Raman spectroscopy also revealed the presence of B4C phases inside the FeNiCr + 5 wt.% B4C and FeNiCr + 7 wt.% B4C coatings through detected peaks corresponding to amorphous carbon, stretching C-B-C chains in B4C and vibrational modes of B11C icosahedra. The additional peaks related to intraicosahedral B-B bonds, rotating mode of the C-B-C chain in B4C, and breathing vibrations of B11C icosahedra were identified for both presented coatings. This was an extra indicator of the B4C presence.

- (4)

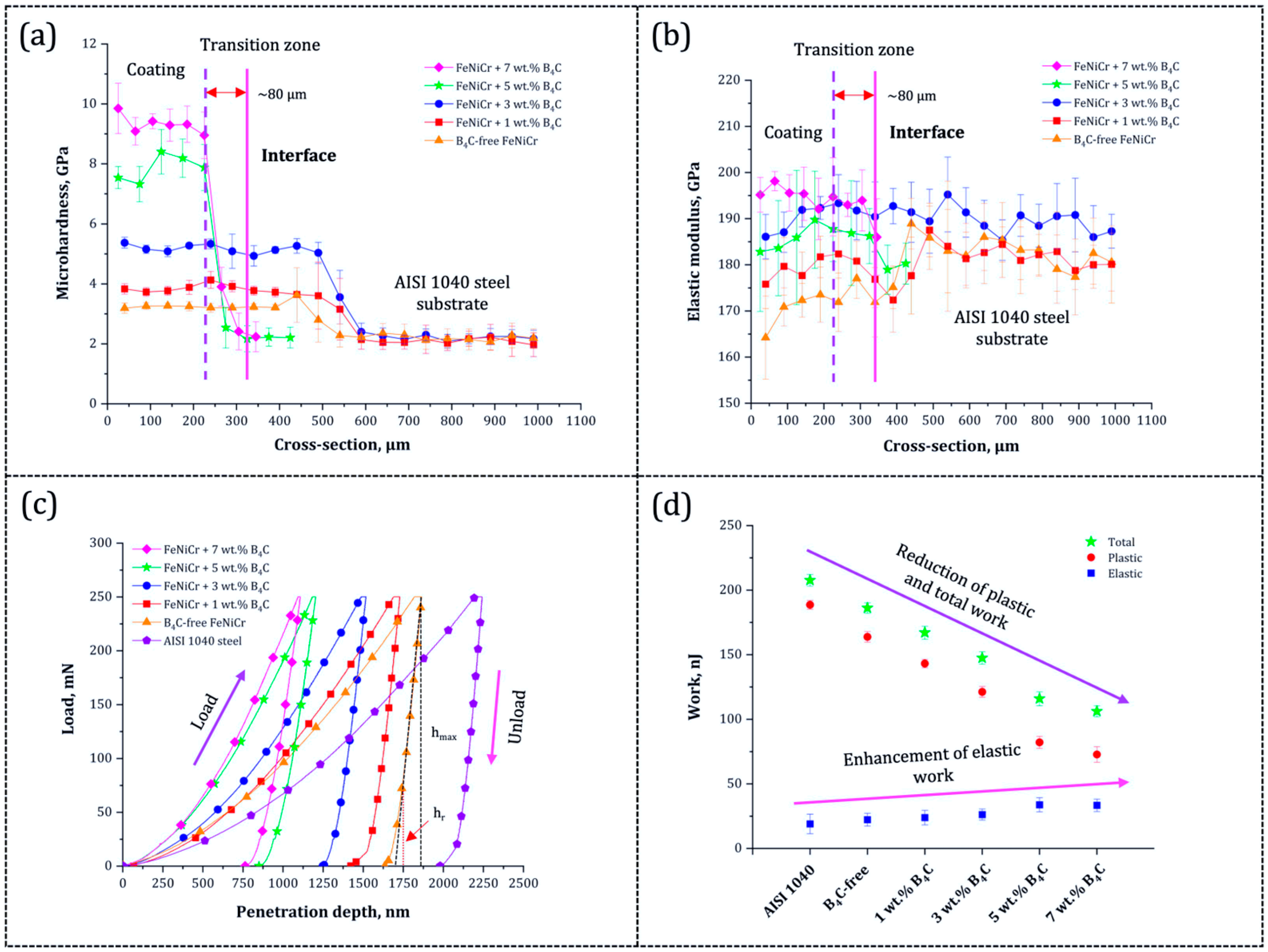

- In situ reinforcement with 5 and 7 wt.% B4C significantly increased microhardness, showing enhancements up to 201% compared to the B4C-free FeNiCr coating, and up to 351% relative to the AISI 1040 steel substrate, respectively. This was promoted by the synergistic strengthening effect between the in situ formed Fe2B and the retained B4C phases.

- (5)

- The comprehensive scratch test analysis demonstrated the enhanced wear resistance and robust mechanical properties of the FeNiCr-B4C coatings. These coatings exhibit excellent adhesion, a beneficial hardness gradient, high cohesive strength, a degree of plasticity, and homogenous B4C dispersion, all contributing to their overall durability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karmakar, R.; Maji, P.; Ghosh, S.K. A Review on the Nickel Based Metal Matrix Composite Coating. Met. Mater. Int. 2021, 27, 2134–2145. [Google Scholar] [CrossRef]

- Sarmah, P.; Gupta, K. Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review. Materials 2024, 17, 4635. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, V.; Mandal, V.; Sarkar, M.; Kumar, A.; Bhagyaraj, J.; Singh, M.K.; Mukherjee, S.; Mondal, K.; Ramkumar, J.; Jain, J.; et al. Enhanced mechanical properties and microstructure of TiC reinforced Stellite 6 metal matrix composites (MMCs) via laser cladding additive manufacturing. J. Alloys Compd. 2025, 1010, 178001. [Google Scholar] [CrossRef]

- Marshall, P. Austenitic Stainless Steels: Microstructure and Mechanical Properties; Elsevier Applied Science: London, UK, 1984; Available online: https://link.springer.com/book/9780853342779 (accessed on 15 April 2025).

- Brassart, L.H.; Besson, J.; Delloro, F.; Haboussa, D.; Delabrouille, F.; Rolland, G.; Shen, Y.; Gourgues-Lorenzon, A.-F. Effect of Various Heat Treatments on the Microstructure of 316L Austenitic Stainless Steel Coatings Obtained by Cold Spray. J. Therm. Spray Technol. 2022, 31, 1725–1746. [Google Scholar] [CrossRef]

- Kaladhar, M.; Venkata Subbaiah, K.; Srinivasa Rao, C.H. Machining of austenitic stainless steels—A review. Int. J. Mach. Mach. Mater. 2012, 12, 178–192. [Google Scholar] [CrossRef]

- Adrian Roberts, J.T. Structural Materials in Nuclear Power Systems; Plenum Press: New York, NY, USA, 1981. [Google Scholar]

- Ehrlich, K.; Konys, J.; Heikinheimo, L. Materials for high performance light water reactors. J. Nucl. Mater. 2004, 327, 140–147. [Google Scholar] [CrossRef]

- Takakuwa, O.; Ogawa, Y.; Yamabe, J.; Matsunaga, H. Hydrogen-induced ductility loss of precipitation-strengthened Fe-Ni-Cr-based superalloy. Mater. Sci. Eng. A 2019, 739, 335–342. [Google Scholar] [CrossRef]

- Ehrnstén, U.; Andresen, P.L.; Que, Z. A review of stress corrosion cracking of austenitic stainless steels in PWR primary water. J. Nucl. Mater. 2024, 588, 154815. [Google Scholar] [CrossRef]

- Hasanzadeh, A.; Hamedani, A.; Alahyarizadeh, G.; Minuchehr, A.; Aghaei, M. The Role of Chromium and Nickel on the Thermal and Mechanical Properties of FeNiCr Austenitic Stainless Steels under High Pressure and Temperature: A Molecular Dynamics Study. Mol. Simul. 2019, 45, 672–684. [Google Scholar] [CrossRef]

- Washko, S.D.; Aggen, G. Asm Handbook: Properties and Selection: Irons, Steels, and High-Performance Alloys, 10th ed.; ASM International: Materials Park, OH, USA, 1990; Volume 1. [Google Scholar]

- Balaji, S.; Upadhyaya, A. Mechanical, corrosion, and sliding wear behavior of intermetallics reinforced austenitic stainless steel composites. J. Mater. Sci. 2009, 44, 2310–2319. [Google Scholar] [CrossRef]

- AlMangour, B.; Baek, M.-S.; Grzesiak, D.; Lee, K.-A. Strengthening of stainless steel by titanium carbide addition and grain refinement during selective laser melting. Mater. Sci. Eng. A 2018, 712, 812–818. [Google Scholar] [CrossRef]

- Li, B.; Qian, B.; Xu, Y.; Liu, Z.; Zhang, J.; Xuan, F. Additive manufacturing of ultrafine-grained austenitic stainless steel matrix composite via vanadium carbide reinforcement addition and selective laser melting: Formation mechanism and strengthening effect. Mater. Sci. Eng. A 2019, 745, 495–508. [Google Scholar] [CrossRef]

- Okulov, A.; Korobov, Y.; Stepchenkov, A.; Makarov, A.; Iusupova, O.; Korkh, Y.; Kuznetsova, T.; Kharanzhevskiy, E.; Liu, K. Mechanical and structural characterization of laser-cladded medium-entropy FeNiCr-B4C coatings. Materials 2023, 16, 5479. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Li, J.; Liu, K.; Xu, G.; Zhu, H.; Wang, J.; Xu, C.; Wang, L.; Okulov, A. Microstructural evolution and corrosion resistance property of in-situ Zr–C(B, Si)/Ni–Zr reinforced composite coatings on zirconium alloy by laser cladding. J. Mater. Res. Technol. 2023, 26, 530–541. [Google Scholar] [CrossRef]

- Okulov, A.; Iusupova, O.; Liu, K.; Li, J.; Stepchenkov, A.; Zavalishin, V.; Korkh, Y.; Kuznetsova, T.; Mugada, K.K.; Moganraj, A. Micromechanical and Tribological Performance of Laser-Cladded Equiatomic FeNiCr Coatings Reinforced with TiC and NbC Particles. Materials 2024, 17, 4686. [Google Scholar] [CrossRef]

- Domnich, V.; Reynaud, S.; Haber, R.A.; Chhowalla, M. Boron Carbide: Structure, Properties, and Stability under Stress. J. Am. Ceram. Soc. 2011, 94, 3605–3628. [Google Scholar] [CrossRef]

- Xie, K.Y.; Domnich, V.; Farbaniec, L.; Chen, B.; Kuwelkar, K.; Ma, L.; McCauley, J.W.; Haber, R.A.; Ramesh, K.T.; Chen, M.; et al. Microstructural characterization of boron-rich boron carbide. Acta Mater. 2017, 136, 202–214. [Google Scholar] [CrossRef]

- Garcıa, J.; Collado Cipres, V.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Liang, D.; Zhao, C.; Zhu, W.; Wei, P.; Jiang, F.; Zhang, Y.; Sun, Q.; Ren, F. Overcoming the strength-ductility trade-off via the formation of nanoscale Cr-rich precipitates in an ultrafine-grained FCC CrFeNi medium entropy alloy matrix. Mater. Sci. Eng. A 2019, 762, 138107. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Lu, W.; Liu, B.; Li, J.; Fang, Q.; Li, Z.; Liu, Y. A novel supersaturated medium entropy alloy with superior tensile properties and corrosion resistance. Scr. Mater. 2020, 186, 381–386. [Google Scholar] [CrossRef]

- Liang, D.; Zhao, C.; Zhu, W.; Wei, P.; Jiang, F.; Ren, F. Significantly Enhanced Wear Resistance of an Ultrafine-Grained CrFeNi Medium-Entropy Alloy at Elevated Temperatures. Metall. Mater. Trans. A 2020, 51, 2834–2850. [Google Scholar] [CrossRef]

- Schneider, M.; Laplanche, G. Effects of temperature on mechanical properties and deformation mechanisms of the equiatomic CrFeNi medium-entropy alloy. Acta Mater. 2021, 204, 116470. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, B.; Guo, W.; Fu, A.; Duan, H.; Li, W. Corrosion behavior and mechanism of FeCrNi medium entropy alloy prepared by powder metallurgy. J. Alloys Compd. 2021, 867, 159094. [Google Scholar] [CrossRef]

- Miranda, R.M.; Gandra, J.P.; Vilaca, P.; Quintino, L.; Santos, T.G. Surface Modification by Solid State Processing; Elsevier: Amsterdam, The Netherlands; Woodhead Publishing Limited: Sawston, UK, 2014; Available online: http://www.sciencedirect.com/science/book/9780857094681 (accessed on 10 April 2025).

- Dezfuli, S.M.; Sabzi, M. Deposition of ceramic nanocomposite coatings by electroplating process: A review of layer-deposition mechanisms and effective parameters on the formation of the coating. Ceram. Int. 2019, 45, 21835–21842. [Google Scholar] [CrossRef]

- Korobov, Y.; Antonov, M.; Astafiev, V.; Brodova, I.; Kutaev, V.; Estemirova, S.; Devyatyarov, M.; Okulov, A. Erosion Wear Behavior of HVAF-Sprayed WC/Cr3C2-Based Cermet and Martensitic Stainless Steel Coatings on AlSi7Mg0.3 Alloy: A Comparative Study. J. Manuf. Mater. Process. 2024, 8, 231. [Google Scholar] [CrossRef]

- Yang, J.; Liu, F.; Miao, X.; Yang, F. Influence of laser cladding process on the magnetic properties of WC–FeNiCr metal–matrix composite coatings. J. Mater. Process. Technol. 2012, 212, 1862–1868. [Google Scholar] [CrossRef]

- Yang, J.; Miao, X.; Wang, X.; Chen, H.; Yang, F. Microstructure, magnetic properties and empirical electron theory calculations of laser cladding FeNiCr/60%WC composite coatings with Mo additions. Int. J. Refract. Met. Hard Mater. 2016, 54, 216–222. [Google Scholar] [CrossRef]

- Li, Y.; Dong, S.; He, P.; Yan, S.; Li, E.; Liu, X.; Xu, B. Microstructure characteristics and mechanical properties of new-type FeNiCr laser cladding alloy coating on nodular cast iron. J. Mater. Process. Technol. 2019, 269, 163–171. [Google Scholar] [CrossRef]

- Zhu, L.; Xue, P.; Lan, Q.; Meng, G.; Ren, Y.; Yang, Z.; Xu, P.; Liu, Z. Recent research and development status of laser cladding: A review. Opt. Laser Technol. 2021, 138, 106915. [Google Scholar] [CrossRef]

- Gokhfeld, N.V.; Okulov, A.V.; Filippov, M.A.; Estemirova, S.K.; Korobov, Y.S.; Morozov, S.O. The Comparative Analysis of the Fe–Cr–C–Ti–Al Coatings Synthesized by Laser, Arc and Hybrid Cladding Methods. Phys. Solid State 2022, 64, 356–361. [Google Scholar] [CrossRef]

- Okulov, A.V.; Iusupova, O.S.; Liu, K. Development of multicomponent hybrid powders based on titanium and niobium carbides as a promising material for laser cladding. E3S Web Conf. 2023, 413, 4012. [Google Scholar] [CrossRef]

- Wang, L.; Liu, K.; Li, J.; Chen, Z.; Wang, J.; Okulov, A. Interfacial microstructure and mechanical properties of diffusion bonded joints of additive manufactured 17-4 PH stainless steel and TC4 titanium alloy. Vacuum 2024, 219, 112709–112716. [Google Scholar] [CrossRef]

- Kishor, G.; Mugada, K.K.; Mahto, R.P.; Okulov, A. Assessment of microstructure development, defect formation, innovations, and challenges in wire arc based metal additive manufacturing. Proc. Inst. Mech. Eng. Part L 2024. [Google Scholar] [CrossRef]

- Giurlani, W.; Zangari, G.; Gambinossi, F.; Passaponti, M.; Salvietti, E.; Benedetto, F.D.; Caporali, S.; Innocenti, M. Electroplating for Decorative Applications: Recent Trends in Research and Development. Coatings 2018, 8, 260. [Google Scholar] [CrossRef]

- Sathish, M.; Radhika, N.; Saleh, B. Duplex and Composite Coatings: A Thematic Review on Thermal Spray Techniques and Applications. Met. Mater. Int. 2023, 29, 1229–1297. [Google Scholar] [CrossRef]

- Alizadeh-Sh, M.; Marashi, S.P.H.; Ranjbarnodeh, E.; Shoja-Razavi, R.; Oliveira, J.P. Prediction of solidification cracking by an empirical-statistical analysis for laser cladding of Inconel 718 powder on a non-weldable substrate. Opt. Laser Technol. 2020, 128, 106244. [Google Scholar] [CrossRef]

- Liu, K.; Wang, H.; Li, J.; Geng, S.; Chen, Z.; Okulov, A. A Review on Factors Infuencing Solidifcation Cracking of Magnesium Alloys During Welding. Met. Mater. Int. 2024, 30, 1723–1742. [Google Scholar] [CrossRef]

- ISO 14577-1:2015; Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method. International Organization for Standardization (ISO): Geneva, Switzerland, 2015. Available online: https://www.iso.org/standard/56626.html (accessed on 12 April 2025).

- Dong, X.L.; Zhang, Z.D.; Xiao, Q.F.; Zhao, X.G.; Chuang, Y.C.; Jin, S.R.; Sun, W.M.; Li, Z.J.; Zheng, Z.X.; Yang, H. Characterization of ultrafine γ-Fe(C), α-Fe(C) and Fe3C particles synthesized by arc-discharge in methane. J. Mater. Sci. 1998, 33, 1915–1919. [Google Scholar] [CrossRef]

- Campos, I.; Ramírez, G.; Figueroa, U.; Martínez, J.; Morales, O. Evaluation of boron mobility on the phases FeB, Fe2B and diffusion zone in AISI 1045 and M2 steels. Appl. Surf. Sci. 2007, 253, 3469–3475. [Google Scholar] [CrossRef]

- Kartal, G.; Timur, S.; Sista, V.; Eryilmaz, O.L.; Erdemir, A. The growth of single Fe2B phase on low carbon steel via phase homogenization in electrochemical boriding (PHEB). Surf. Coat. Technol. 2011, 206, 2005–2011. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, Y.; Xu, S.; Li, J.; Liu, N.; Zhang, Y.; Zhang, Z. Influence of high B4C contents on structural evolution of Al-B4C nanocomposite powders produced by high energy ball milling. Ceram. Int. 2019, 45, 5436–5447. [Google Scholar] [CrossRef]

- Faria, D.L.A.; Silva, S.V.; Oliveir, M.T. Raman microspectroscopy of some iron oxides and oxyhydroxides. J. Raman Spectrosc. 1997, 28, 873–878. [Google Scholar] [CrossRef]

- Kim, J.; Choi, K.J.; Bahn, C.B.; Kim, J.H. In situ Raman spectroscopic analysis of surface oxide films on Ni-base alloy/low alloy steel dissimilar metal weld interfaces in high-temperature water. J. Nucl. Mater. 2014, 449, 181–187. [Google Scholar] [CrossRef]

- Yan, X.Q.; Li, W.J.; Goto, T.; Chen, M.W. Raman spectroscopy of pressure-induced amorphous boron carbide. Appl. Phys. Lett. 2006, 88, 131905. [Google Scholar] [CrossRef]

- Kunka, C.; Awasthi, A.; Subhash, G. Evaluating boron-carbide constituents with simulated Raman spectra. Scr. Mater. 2017, 138, 32–34. [Google Scholar] [CrossRef]

- Brown-Shaklee, H.J.; Neuman, E.W.; Fahrenholtz, W.G.; Hilmas, G.E. Optical characterization of boron carbide powders synthesized with varying B-to-C ratios. J. Am. Ceram. Soc. 2023, 106, 1932–1944. [Google Scholar] [CrossRef]

- Cheng, Y.T.; Cheng, C.M. Relationships between hardness, elastic modulus and the work of indentation. Appl. Phys. Lett. 1998, 73, 614. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Mitterer, C.; Musil, J. Structure-property relationships in single- and dual-phase nanocrystalline hard coatings. Surf. Coat. Technol. 2003, 174–175, 725–731. [Google Scholar] [CrossRef]

- Freitas Rodrigues, P.; Teixeira, R.S.; Le Sénéchal, N.V.; Braz Fernandes, F.M.; Paula, A.S. The Influence of the Soaking Temperature Rotary Forging and Solution Heat Treatment on the Structural and Mechanical Behavior in Ni-Rich NiTi Alloy. Materials 2022, 15, 63. [Google Scholar] [CrossRef]

- Page, T.F.; Hainsworth, S.V. Using nanoindentation techniques for the characterization of coated systems: A critique. Surf. Coat. Technol. 1993, 62, 201–208. [Google Scholar] [CrossRef]

- Petrzhik, M.I.; Levashov, E.A. Modern methods for investigating functional surfaces of advanced materials by mechanical contact testing. Crystallogr. Rep. 2007, 52, 966–974. [Google Scholar] [CrossRef]

- Milman, Y.V.; Chugunova, S.I.; Goncharova, I.V.; Golubenko, A.A. Plasticity of Materials Determined by the Indentation Method. Usp. Fiz. Met. 2018, 19, 271–307. [Google Scholar] [CrossRef]

| Material | Fe | B | Ni | Cr | Mn | C | S | P | Si |

|---|---|---|---|---|---|---|---|---|---|

| FeNiCr | Base | - | 35.6 | 29.8 | - | 0.37 | <0.001 | 0.008 | 1.62 |

| AISI 1040 steel | - | - | - | 0.6–0.9 | 0.37–0.44 | ≤0.05 | ≤0.04 | 0.15–0.35 | |

| B4C | - | 78.3 | - | - | - | 21.7 | - | - | - |

| Parameter | Value |

|---|---|

| Material delivery method | Pre-placed powder bed |

| Shielding gas (Ar), L/min | 10 |

| Laser mode | Pulsed |

| Laser power, W | 50 |

| Laser wavelength, µm | 1.065 |

| Scanning speed, mm/s | 5 |

| Pulse frequency, Hz | 20 |

| Pulse duration, ms | 3.5 |

| Overlap rate, % | ~25 |

| Pulse energy, J | 8.3 |

| Pulse energy density, J/cm2 | 1057 |

| Laser spot area, cm2 | 0.00785 |

| Spot size, mm | 1 |

| Sample | Fe | Ni | Cr | B | C |

|---|---|---|---|---|---|

| FeNiCr + 5 wt.% B4C | 33.45 | 31.26 | 29.04 | 4.65 | 1.60 |

| FeNiCr + 7 wt.% B4C | 31.56 | 29.52 | 30.23 | 6.75 | 1.94 |

| Sample | Phase | Unit Cell Parameters, Å | ||

|---|---|---|---|---|

| a | c | V | ||

| FeNiCr-B4C (5 and 7 wt.% B4C) | α-Fe, Im-3m | 2.87 | - | 23.64 |

| γ-FeNiCr, Fm-3m | 3.591 | - | 46.31 | |

| Fe2B, I-42m | 5.078 | 4.223 | 108.89 | |

| B4C, R-3m | 5.60 | 12.12 (120°) | 329.16 | |

| AISI 1040 Steel | FeNiCr-B4C Coatings | Interpretation | ||||

|---|---|---|---|---|---|---|

| 0 wt.% B4C | 1 wt.% B4C | 3 wt.% B4C | 5 wt.% B4C | 7 wt.% B4C | ||

| 207 | 196 | 194 | 209 | 205 | 208 | α-Fe2O3 |

| 267 | 293 | 279 | 273 | 267 | 271 | α-Fe2O3 |

| - | - | - | - | - | 320 | Stretching C-B-C chains in B4C |

| 380 | - | 377 | 383 | 376 | 378 | γ-Fe2O3 |

| - | - | 469 | 478 | 472 | 462 | Stretching C-B-C chains in B4C |

| 480 | 477 | - | - | - | - | NiO |

| - | 518 | - | - | - | - | Fe3O4 |

| - | - | 533 | 532 | 523 | - | Vibrational mode of B11C icosahedra |

| - | 527 | 528 | 543 | 530 | - | Cr2O3 |

| - | - | - | - | - | 556 | Vibrational mode of B11C icosahedra |

| 578 | - | - | - | - | - | γ-Fe2O3 |

| 645 | 648 | - | - | - | - | γ-Fe2O3 |

| - | 672 | 665 | 657 | 654 | 667 | NiFe2O4/NiCr2O4 |

| - | - | - | - | - | 897 | Intraicosahedral B-B bonds |

| - | - | - | - | 974 | - | Rotating mode of C-B-C chain in B4C |

| - | - | - | - | - | 1098 | Breathing vibrations of B11C icosahedra |

| 1280 | - | - | - | - | - | α-Fe2O3 |

| - | 1330 | 1328 | 1330 | 1330 | 1332 | Amorphous carbon (D peak) |

| - | - | 1560 | 1554 | 1572 | 1562 | Amorphous carbon (G peak) |

| Material | Work, nJ | HIT, GPa | E*, GPa | HIT/E* | HIT3/E*2, GPa | Re, % | δA | ||

|---|---|---|---|---|---|---|---|---|---|

| Total | Plastic | Elastic | |||||||

| AISI 1040 steel | 206.81 | 188.79 | 18.02 | 2.154 | 184.68 | 0.0117 | 0.0003 | 3.85 | 0.90 |

| B4C-free FeNiCr | 186.14 | 163.84 | 22.30 | 3.228 | 172.11 | 0.0188 | 0.0011 | 5.90 | 0.86 |

| FeNiCr + 1 wt.% B4C | 167.04 | 143.15 | 23.89 | 3.825 | 178.34 | 0.0214 | 0.0018 | 6.60 | 0.83 |

| FeNiCr + 3 wt.% B4C | 147.50 | 121.22 | 26.28 | 5.167 | 190.64 | 0.0271 | 0.0038 | 8.30 | 0.78 |

| FeNiCr + 5 wt.% B4C | 115.95 | 82.16 | 33.79 | 8.091 | 181.01 | 0.0447 | 0.0162 | 13.70 | 0.59 |

| FeNiCr + 7 wt.% B4C | 106.23 | 72.79 | 33.44 | 9.711 | 201.17 | 0.0483 | 0.0226 | 14.54 | 0.54 |

| Comparative analysis (change (↓↑) in %) | |||||||||

| 7 wt.% B4C vs. 5 wt.% B4C | 8 ↓ | 11 ↓ | 1 ↓ | 20 ↑ | 11 ↑ | 8 ↑ | 40 ↑ | 6 ↑ | 8 ↓ |

| 5 wt.% B4C vs. B4C-free | 38 ↓ | 50 ↓ | 52 ↑ | 151 ↑ | 5 ↑ | 138 ↑ | 1373 ↑ | 132 ↑ | 31 ↓ |

| 7 wt.% B4C vs. B4C-free | 43 ↓ | 56 ↓ | 50 ↑ | 201 ↑ | 17 ↑ | 157 ↑ | 1955 ↑ | 146 ↑ | 37 ↓ |

| 5 wt.% B4C vs. AISI 1040 steel | 44 ↓ | 56 ↓ | 88 ↑ | 276 ↑ | 2↓ | 282 ↑ | 5300 ↑ | 256 ↑ | 34 ↓ |

| 7 wt.% B4C vs. AISI 1040 steel | 49 ↓ | 61 ↓ | 86 ↑ | 351 ↑ | 9 ↑ | 313 ↑ | 7433 ↑ | 278 ↑ | 40 ↓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okulov, A.; Iusupova, O.; Stepchenkov, A.; Zavalishin, V.; Marchenkova, E.; Liu, K.; Li, J.; Sonar, T.; Makarov, A.; Korobov, Y.; et al. In Situ Ceramic Phase Reinforcement via Short-Pulsed Laser Cladding for Enhanced Tribo-Mechanical Behavior of Metal Matrix Composite FeNiCr-B4C (5 and 7 wt.%) Coatings. Technologies 2025, 13, 231. https://doi.org/10.3390/technologies13060231

Okulov A, Iusupova O, Stepchenkov A, Zavalishin V, Marchenkova E, Liu K, Li J, Sonar T, Makarov A, Korobov Y, et al. In Situ Ceramic Phase Reinforcement via Short-Pulsed Laser Cladding for Enhanced Tribo-Mechanical Behavior of Metal Matrix Composite FeNiCr-B4C (5 and 7 wt.%) Coatings. Technologies. 2025; 13(6):231. https://doi.org/10.3390/technologies13060231

Chicago/Turabian StyleOkulov, Artem, Olga Iusupova, Alexander Stepchenkov, Vladimir Zavalishin, Elena Marchenkova, Kun Liu, Jie Li, Tushar Sonar, Aleksey Makarov, Yury Korobov, and et al. 2025. "In Situ Ceramic Phase Reinforcement via Short-Pulsed Laser Cladding for Enhanced Tribo-Mechanical Behavior of Metal Matrix Composite FeNiCr-B4C (5 and 7 wt.%) Coatings" Technologies 13, no. 6: 231. https://doi.org/10.3390/technologies13060231

APA StyleOkulov, A., Iusupova, O., Stepchenkov, A., Zavalishin, V., Marchenkova, E., Liu, K., Li, J., Sonar, T., Makarov, A., Korobov, Y., Kharanzhevskiy, E., Zhidkov, I., Korkh, Y., Kuznetsova, T., Wang, P., & Jia, Y. (2025). In Situ Ceramic Phase Reinforcement via Short-Pulsed Laser Cladding for Enhanced Tribo-Mechanical Behavior of Metal Matrix Composite FeNiCr-B4C (5 and 7 wt.%) Coatings. Technologies, 13(6), 231. https://doi.org/10.3390/technologies13060231