Ballistic Testing of an Aerogel/Starch Composite Designed for Use in Wearable Protective Equipment

Abstract

1. Introduction

1.1. Overview

1.2. Background

1.2.1. Prior Work Overview

1.2.2. Extracting Protective Materials

1.2.3. Shear-Thickening Fluids

1.2.4. Aerogels

1.2.5. The Potential for Aerogel-Based STF Composites

1.2.6. Ballistic Impact Testing

2. Materials and Methods

2.1. Experimental Summary

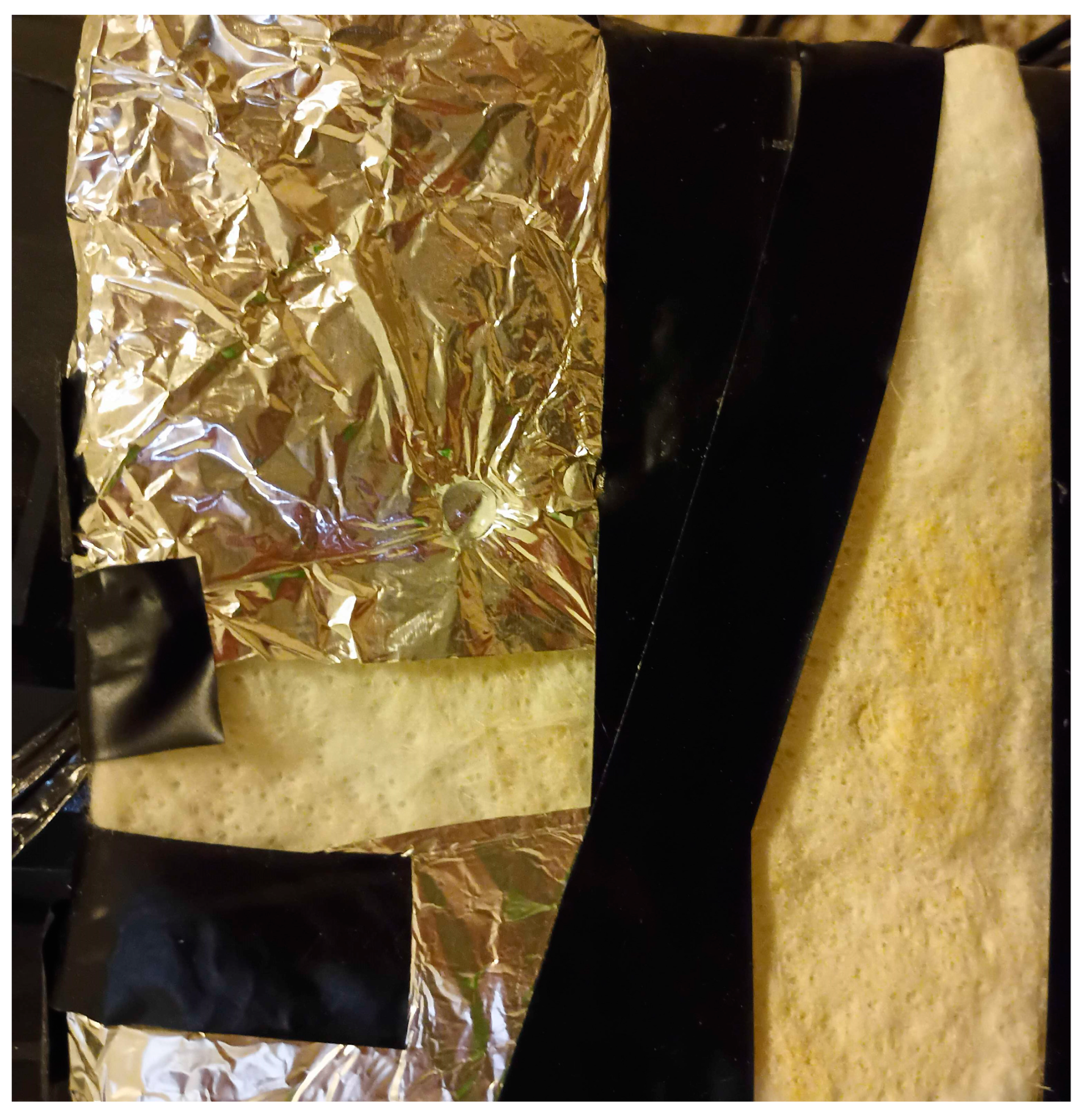

2.2. Material Preparation

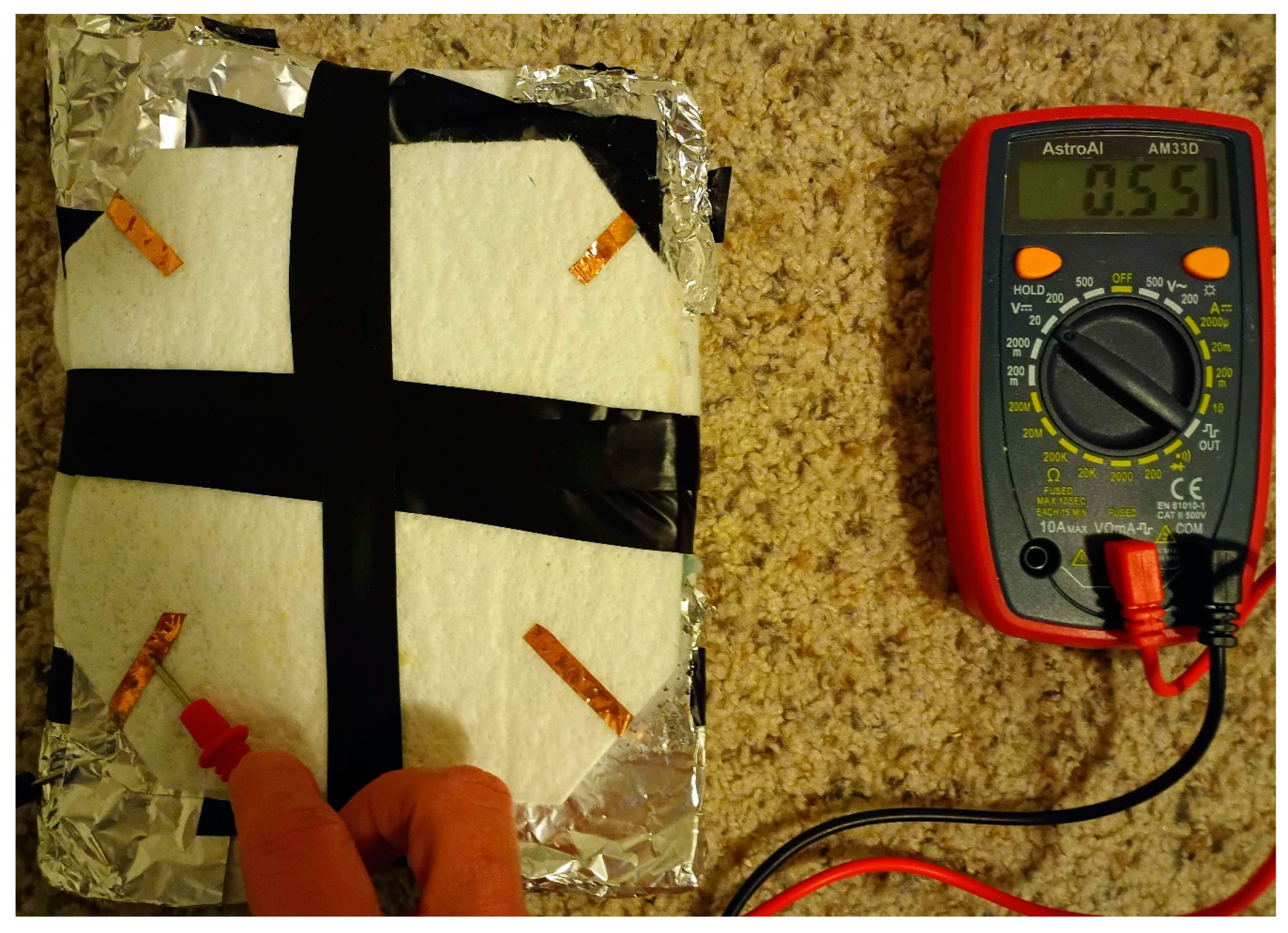

2.3. Ballistic Pendulum Construction

2.4. Pendulum Experimental Setup

2.5. Ballistic Penetration Testing

2.6. Statistical Analysis

3. Results

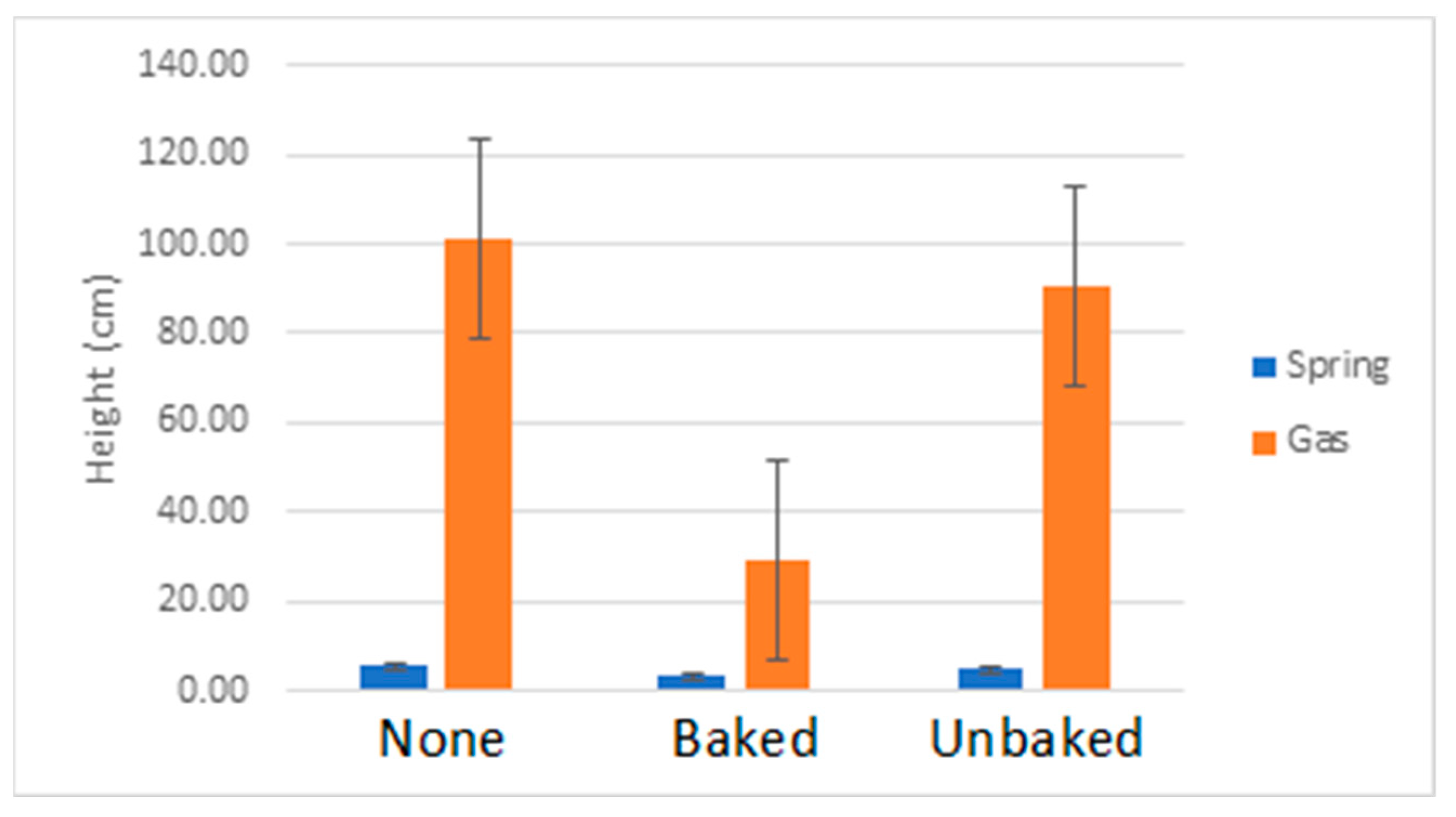

3.1. Ballistic Pendulum Experiments

3.2. Ballistic Pendulum Statistical Analysis

3.3. Ballistic Penetration Tests

4. Discussion

4.1. Summary

4.2. Limitations

4.3. Future Work

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Z.; Yu, Z.; Sun, Y.; Li, Q. Characterization and application of shear thickening fluids. Appl. Mech. Mater. 2013, 405–408, 2503–2506. [Google Scholar] [CrossRef]

- Wang, Y.; Li, S.; Feng, X. The ballistic performance of multi-layer kevlar fabrics impregnated with shear thickening fluids. Appl. Mech. Mater. 2015, 782, 153–157. [Google Scholar] [CrossRef]

- Agnihotri, S.; Penner, S.A.M.; Mallory, K.; Xie, L.; Hickling, A.; Joachimides, N.; Widgett, E.; Scratch, S. Healthcare utilization and costs associated with persistent post-concussive symptoms. Brain Inj. 2021, 35, 1382–1389. [Google Scholar] [CrossRef] [PubMed]

- Graves, J.M.; Moore, M.; Kehoe, L.; Li, M.; Chan, A.; Conrick, K.; Williams-Gilbert, W.; Vavilala, M. Family hardship following youth concussion: Beyond the medical bills. J. Pediatr. Nurs. 2020, 51, 15–20. [Google Scholar] [CrossRef] [PubMed]

- Yengo-Kahn, A.; Kelly, P.; Liles, D.; McKeithan, L.; Grisham, C.; Khan, M.; Lee, T.; Kuhn, A.; Bonfield, C.; Zuckerman, S. The cost of a single concussion in American high school football: A retrospective cohort study. Concussion 2020, 5, CNC81. [Google Scholar] [CrossRef] [PubMed]

- Stanley, E.; Thomson, E.; Smith, G.; Lamb, K.L. An analysis of the three-dimensional kinetics and kinematics of maximal effort punches among amateur boxers. Int. J. Perform. Anal. Sport 2018, 18, 835–854. [Google Scholar] [CrossRef]

- Mayers, L.B. Outcomes of sport-related concussion among college athletes. J. Neuropsychiatry Clin. Neurosci. 2013, 25, 115–119. [Google Scholar] [CrossRef]

- Kerr, Z.Y.; Roos, K.G.; Djoko, A.; Dalton, S.L.; Broglio, S.; Marshall, S.W.; Dompier, T. Epidemiologic measures for quantifying the incidence of concussion in national collegiate athletic association sports. J. Athl. Train. 2017, 52, 167–174. [Google Scholar] [CrossRef]

- Bernick, C.; Hansen, T.; Ng, W.; Williams, V.; Goodman, M.; Nalepa, B.; Shan, G.; Seifert, T. Concussion occurrence and recognition in professional boxing and MMA matches: Toward a concussion protocol in combat sports. Physician Sportsmed. 2021, 49, 469–475. [Google Scholar] [CrossRef]

- Galetta, K.; Barrett, J.; Allen, M.; Madda, F.; Delicata, D.; Tennant, A.; Branas, C.; Maguire, M.; Messner, L.; Devick, S.; et al. The King-Devick test as a determinant of head trauma and concussion in boxers and MMA fighters. Neurology 2011, 76, 1456–1462. [Google Scholar] [CrossRef]

- Kempuraj, D.; Ahmed, M.; Selvakumar, G.; Thangavel, R.; Raikwar, S.; Zaheer, S.; Iyer, S.; Govindarajan, R.; Chandrasekaran, N.; Burton, C.; et al. Acute traumatic brain injury-induced neuroinflammatory response and neurovascular disorders in the brain. Neurotox. Res. 2021, 39, 359–368. [Google Scholar] [CrossRef] [PubMed]

- Ptak, M.; Kaczyński, P.; Wilhelm, J.; Margarido, J.M.T.; Marques, P.A.A.P.; Pinto, S.C.; Alves de Sousa, R.J.; Fernandes, F.A.O. Graphene-enriched agglomerated cork material and its behaviour under quasi-static and dynamic loading. Materials 2019, 12, 151. [Google Scholar] [CrossRef] [PubMed]

- O’Sullivan, D.; Fife, G. Impact attenuation of protective boxing and taekwondo headgear. Eur. J. Sport Sci. 2016, 16, 1219–1225. [Google Scholar] [CrossRef] [PubMed]

- Ramirez, B.; Gupta, V. Energy absorption and low velocity impact response of open-cell polyurea foams. J. Dyn. Behav. Mater. 2019, 5, 132–142. [Google Scholar] [CrossRef]

- Stitt, D.; Kabaliuk, N.; Alexander, K.; Draper, N. Potential of soft-shell rugby headgear to mitigate linear and rotational peak accelerations. Ann. Biomed. Eng. 2022, 50, 1546–1564. [Google Scholar] [CrossRef]

- Chang, C.; Shih, C.H.; You, J.L.; Youh, M.J.; Liu, Y.M.; Ger, M.D. Preparation and ballistic performance of a multi-layer armor system composed of kevlar/polyurea composites and shear thickening fluid (Stf)-filled paper honeycomb panels. Polymers 2021, 13, 3080. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, L.; Lin, J.; Qiu, X.; Wu, C.; Liu, C.; Tian, Y.; Zhang, R.; Huang, W.; Ma, M. Recent developments in polyurea research for enhanced impact penetration resistance and blast mitigation. Polymers 2024, 16, 440. [Google Scholar] [CrossRef]

- Shih, C.H.; Chang, C.; Liu, Y.M.; Chen, Y.L.; Ger, M.D. Ballistic performance of shear thickening fluids (STFs) filled paper honeycomb panel: Effects of laminating sequence and rheological property of STFs. Appl. Compos. Mater. 2021, 28, 201–218. [Google Scholar] [CrossRef]

- Whyte, T.; Stuart, C.A.; Mallory, A.; Ghajari, M.; Plant, D.J.; Siegmund, G.P.; Cripton, P.A. A review of impact testing methods for headgear in sports: Considerations for improved prevention of head injury through research and standards. J. Biomech. Eng. 2019, 141, 070803. [Google Scholar] [CrossRef]

- Ratajczak, M.; Ptak, M.; Chybowski, L.; Gawdzińska, K.; Będziński, R. Material and structural modeling aspects of brain tissue deformation under dynamic loads. Materials 2019, 12, 271. [Google Scholar] [CrossRef]

- Wei, R.; Dong, B.; Wang, F.; Yang, J.; Jiang, Y.; Zhai, W.; Li, H. Effects of silica morphology on the shear-thickening behavior of shear thickening fluids and stabbing resistance of fabric composites. J. Appl. Polym. Sci. 2020, 137, 48809. [Google Scholar] [CrossRef]

- Frizzell, E.; Arnold, G.; Wang, W.; Abboud, R.; Drew, T. Comparison of branded rugby headguards on their effectiveness in reducing impact on the head. BMJ Open Sport Exerc. Med. 2018, 4, e000361. [Google Scholar] [CrossRef] [PubMed]

- Prabhu, R.; Begonia, M.; Whittington, W.; Murphy, M.; Mao, Y.; Liao, J.; Williams, L.; Horstemeyer, M.; Sheng, J. Compressive mechanical properties of porcine brain: Experimentation and modeling of the tissue hydration effects. Bioengineering 2019, 6, 40. [Google Scholar] [CrossRef] [PubMed]

- Nuampakdee, N.; Sinchai, S.; Gamonpilas, C. Effect of alumina addition on the rheological behavior of shear thickening fluids. Key Eng. Mater. 2019, 798, 331–336. [Google Scholar] [CrossRef]

- Wang, L.; Feng, J.; Luo, Y.; Zhou, Z.; Jiang, Y.; Luo, X.; Xu, L.; Li, L.; Feng, J. Three-dimensional-printed silica aerogels for thermal insulation by directly writing temperature-induced solidifiable inks. ACS Appl. Mater. Interfaces 2021, 13, 40964–40975. [Google Scholar] [CrossRef]

- Wang, L.; Feng, J.; Luo, Y.; Jiang, Y.; Feng, J. Versatile thermal-solidifying direct-write assembly towards heat-resistant 3d-printed ceramic aerogels for thermal insulation. Small Methods 2022, 6, 2200045. [Google Scholar] [CrossRef]

- Santos, T.F.; Santos, C.M.; Fonseca, R.T.; Melo, K.M.; Aquino, M.S.; Oliveira, F.R.; Medeiros, J.I. Experimental analysis of the impact protection properties for Kevlar® fabrics under different orientation layers and non-Newtonian fluid compositions. J. Compos. Mater. 2020, 54, 3515–3526. [Google Scholar] [CrossRef]

- Zhu, F. Starch based aerogels: Production, properties and applications. Trends Food Sci. Technol. 2019, 89, 1–10. [Google Scholar] [CrossRef]

- Gong, X.; Xu, Y.; Zhu, W.; Xuan, S.; Jiang, W.; Jiang, W. Study of the knife stab and puncture-resistant performance for shear thickening fluid enhanced fabric. J. Compos. Mater. 2013, 48, 641–657. [Google Scholar] [CrossRef]

- Alaee, P.; Kamkar, M.; Arjmand, M. Fumed silica-based suspensions for shear thickening applications: A full-scale rheological study. Langmuir 2022, 38, 5006–5019. [Google Scholar] [CrossRef]

- Hörz, F.; Cress, G.; Zolensky, M.; See, T.H.; Bernhard, R.; Warren, J.L. Optical Analysis of Impact Features in Aerogel from the Orbital Debris Collection Experiment on the MIR Station (No. S-849); National Aeronautics and Space Administration, Lyndon B. Johnson Space Center: Houston, TX, USA, 1999.

- Zhu, J.; Lv, S.; Yang, T.; Huang, T.; Yu, H.; Zhang, Q.; Zhu, M. Facile and Green Strategy for Designing Ultralight, Flexible, and Multifunctional PVA Nanofiber-Based Aerogels. Adv. Sustain. Syst. 2020, 4, 1900141. [Google Scholar] [CrossRef]

- Simón-Herrero, C.; Gómez, L.; Romero, A.; Valverde, J.; Sánchez-Silva, L. Nanoclay-based pva aerogels: Synthesis and characterization. Ind. Eng. Chem. Res. 2018, 57, 6218–6225. [Google Scholar] [CrossRef]

- Guo, Y.; Qin, S.; Yao, X.; Liu, S.; Ji, Z.; Ma, Z.; Wang, X. Preparation of polyimide aerogels by freeze-extraction and chemical imidization for 3D printing. J. Appl. Polym. Sci. 2022, 139, e52891. [Google Scholar] [CrossRef]

- Li, V.; Mulyadi, A.; Dunn, C.; Deng, Y.; Hu, Q. Direct ink write 3d printed cellulose nanofiber aerogel structures with highly deformable, shape recoverable, and functionalizable properties. ACS Sustain. Chem. Eng. 2018, 6, 2011–2020. [Google Scholar] [CrossRef]

- Yang, J.; Cui, N.; Lu, J.; Han, D.; Shen, J.; Zhang, Z.; Qin, L.; Zhou, B.; Du, A. A facile and versatile post-treatment method to efficiently functionalize 3D-printed carbon aerogels via introducing tailored metal elements. ACS Appl. Energy Mater. 2022, 5, 11970–11976. [Google Scholar] [CrossRef]

- Yao, B.; Chandrasekaran, S.; Zhang, H.; Ma, A.; Kang, J.; Zhang, L.; Lu, X.; Qian, F.; Zhu, C.; Duoss, E.; et al. 3D-printed structure boosts the kinetics and intrinsic capacitance of pseudocapacitive graphene aerogels. Adv. Mater. 2020, 32, 1906652. [Google Scholar] [CrossRef]

- Tetik, H.; Wang, Y.; Sun, X.; Cao, D.; Shah, N.; Zhu, H.; Qian, F.; Lin, D. Additive manufacturing of 3D aerogels and porous scaffolds: A review. Adv. Funct. Mater. 2021, 31, 2103410. [Google Scholar] [CrossRef]

- Tetik, H.; Orangi, J.; Yang, G.; Zhao, K.; Mujib, S.; Singh, G.; Beidaghi, M.; Lin, D. 3D printed MXene aerogels with truly 3D macrostructure and highly engineered microstructure for enhanced electrical and electrochemical performance. Adv. Mater. 2022, 34, 2104980. [Google Scholar] [CrossRef]

- Wang, H.; Hai, M. Highly enhanced electromagnetic wave absorption bandwidth based on reduced graphene oxide-fe aerogel composites. Nanotechnology 2019, 31, 095711. [Google Scholar] [CrossRef]

- Santos-Gómez, L.; Garcı, J.; Montes-Morán, M.; Menéndez, J.; Garcı, S.; Arenillas, A. Ultralight-weight graphene aerogels with extremely high electrical conductivity. Small 2021, 17, 2103407. [Google Scholar] [CrossRef]

- Mannering, J.; Stones, R.; Xia, D.; Sykes, D.; Hondow, N.; Flahaut, E.; Chamberlain, T.; Brydson, R.; Cairns, G.; Menzel, R. Engineering of microcage carbon nanotube architectures with decoupled multimodal porosity and amplified catalytic performance. Adv. Mater. 2021, 33, 2008307. [Google Scholar] [CrossRef] [PubMed]

- Khedkar, M.; Jadhav, S.; Somvanshi, S.; Kharat, P.; Jadhav, K. Physicochemical properties of ambient pressure dried surface modified silica aerogels: Effect of pH variation. SN Appl. Sci. 2020, 2, 696. [Google Scholar] [CrossRef]

- Alwin, S.; Shajan, X. Aerogels: Promising nanostructured materials for energy conversion and storage applications. Mater. Renew. Sustain. Energy 2020, 9, 7. [Google Scholar] [CrossRef]

- Javadi, A.; Zheng, Q.; Payen, F.; Javadi, A.; Altin, Y.; Cai, Z.; Sabo, R.; Gong, S. Polyvinyl alcohol-cellulose nanofibrils-graphene oxide hybrid organic aerogels. ACS Appl. Mater. Interfaces 2013, 5, 5969–5975. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Shen, J.; Estevez, D.; Chen, Y.; Zhu, Z.; Yin, J.; Qin, F. Emi Shielding and Strain-Sensitive Tape Based on Ultraprecise 3D Printed Graphene Oxide Aerogel Microlattices; ResearchSquare: Hangzhou, China, 2022. [Google Scholar]

- Kong, Y.; Lv, Z.; Li, C.; Men, C.; Wu, X.; Wang, J.; Hu, D. Half-full filled aerogels with a 348% increment in energy absorption and a retained high electromagnetic shielding performance. Adv. Funct. Mater. 2020, 34, 2314947. [Google Scholar] [CrossRef]

- Selver, E. Tensile and flexural properties of glass and carbon fibre composites reinforced with silica nanoparticles and polyethylene glycol. J. Ind. Text. 2019, 49, 809–832. [Google Scholar] [CrossRef]

- Qian, K.; Chen, Z.; Qian, K.; Yu, K. Vibration characteristics of shear thickening fluid-based sandwich structures. Adv. Polym. Technol. 2022, 2022, 1–12. [Google Scholar]

- Pan, Y.; Sang, M.; Duan, S.; Li, Z.; Zhang, Z.; Liu, S.; Wu, J.; Chen, H.; Hu, Y.; Gong, X. MXene Assisted Shear Thickening Fluids Reinforced Anti-Impact Composite Aerogel with Superior Electromagnetic Shielding and Flame Retardant Performance. Small 2025, 2025, 2500493. [Google Scholar] [CrossRef]

- Courtney, M.; Courtney, A. Acoustic measurement of potato cannon velocity. Phys. Teach. 2007, 45, 496–497. [Google Scholar] [CrossRef][Green Version]

- Jasperson, C.; Pollman, A. Video measurement of the muzzle velocity of a potato gun. Phys. Educ. 2011, 46, 607–612. [Google Scholar] [CrossRef]

- Frank, M.; Jobski, O.; Bockholdt, B.; Grossjohann, R.; Stengel, D.; Ekkernkamp, A.; Hinz, P. When backyard fun turns to trauma: Risk assessment of blunt ballistic impact trauma due to potato cannons. Int. J. Leg. Med. 2011, 126, 13–18. [Google Scholar] [CrossRef] [PubMed]

- Mungan, C. Internal ballistics of a pneumatic potato cannon. Eur. J. Phys. 2009, 30, 453–457. [Google Scholar] [CrossRef]

- Yan, H.; Liu, Z.; Qi, R. A review of humidity gradient-based power generator: Devices, materials and mechanisms. Nano Energy 2022, 101, 107591. [Google Scholar] [CrossRef]

- Connor, T.; Colgan, N.; Stewart, M.; Annaidh, A.; Gilchrist, M. Inertial properties of a living population for the development of biofidelic headforms. Proc. Inst. Mech. Eng. Part P J. Sports Eng. Technol. 2020, 237, 52–62. [Google Scholar] [CrossRef]

- Yoganandan, N.; Pintar, F.; Zhang, J.; Baisden, J. Physical properties of the human head: Mass, center of gravity, and moment of inertia. J. Biomech. 2009, 42, 1177–1192. [Google Scholar] [CrossRef] [PubMed]

- Milutinovic, J.M.; Hristov, N.; Jerković, D.D.; Marković, S.Z.; Živković, A.B. The application of the ballistic pendulum for the bullets velocity measurements. IOP Conf. Ser. Mater. Sci. Eng. 2019, 659, 012016. [Google Scholar] [CrossRef]

- Larsson, A.; Akyuz, M.; Appelgren, P.; Dingertz, W.; Hurtig, T. Modelling of a coilgun-based plate launcher for active armour applications. In Proceedings of the 17th International Symposium on Electromagnetic Launch Technology, La Jolla, CA, USA, 7–11 July 2014; pp. 1–6.

- Goodwill, S.R.; Kirk, R.; Haake, S.J. Experimental and finite element analysis of a tennis ball impact on a rigid surface. Sports Eng. 2005, 8, 145–158. [Google Scholar] [CrossRef]

- Yarin, A.L.; Rubin, M.B.; Roisman, I.V. Penetration of a rigid projectile into an elastic-plastic target of finite thickness. Int. J. Impact Eng. 1995, 16, 801–831. [Google Scholar] [CrossRef]

- LaRocco, J.; Tahmina, Q.; Simonis, J. Evaluating a Controlled Electromagnetic Launcher for Safe Remote Drug Delivery. Technologies 2024, 12, 69. [Google Scholar] [CrossRef]

| NIJ Level | I | IIA | II | IIIA | III | IV |

|---|---|---|---|---|---|---|

| Round | 0.22 LR | 9 mm P | 0.357 Mag | 0.44 Mag | 0.308 Win | 0.30-06 |

| KE (J) | 200 | 600 | 800 | 2000 | 3600 | 4100 |

| Launcher | Padding | Hardhat | H (cm) | H (std) | V (m/s) | V (std) | KE (J) | KE (std) |

|---|---|---|---|---|---|---|---|---|

| Spring | None | No | 5.43 | 3.52 | 10.73 | 8.64 | 3.42 | 2.22 |

| Spring | Baked | No | 3.01 | 1.03 | 7.99 | 4.67 | 1.90 | 0.65 |

| Spring | Unbaked | No | 4.64 | 1.75 | 9.92 | 6.09 | 2.92 | 1.10 |

| Spring | None | Yes | 2.72 | 1.31 | 7.53 | 5.23 | 1.68 | 0.81 |

| Spring | Baked | Yes | 5.11 | 0.06 | 10.32 | 1.09 | 3.17 | 0.04 |

| Spring | Unbaked | Yes | 5.30 | 0.51 | 10.51 | 3.27 | 3.28 | 0.32 |

| Gas | None | No | 101.20 | 3.10 | 46.32 | 8.11 | 63.73 | 1.95 |

| Gas | Baked | No | 29.41 | 49.86 | 24.97 | 32.52 | 18.52 | 31.40 |

| Gas | Unbaked | No | 90.64 | 18.28 | 43.84 | 19.69 | 57.08 | 11.51 |

| Gas | None | Yes | 52.30 | 2.20 | 33.03 | 6.78 | 32.41 | 1.36 |

| Gas | Baked | Yes | 22.03 | 12.53 | 21.44 | 16.17 | 13.65 | 7.77 |

| Gas | Unbaked | Yes | 148.75 | 1.45 | 55.71 | 5.50 | 92.18 | 0.90 |

| Condition | Df | SumSq | MeanSq | Fvalue | Pr (>F) |

|---|---|---|---|---|---|

| Launcher | 1 | 49,502 | 49,502 | 467.565 | <2 × 103 |

| Padding | 2 | 21,593 | 10,797 | 101.978 | 0.567 |

| Hardhat | 1 | 35 | 35 | 0.329 | <2 × 103 |

| Launcher/Padding | 2 | 21,956 | 10,978 | 103.689 | 0.722 |

| Launcher/Hardhat | 1 | 13 | 13 | 0.127 | <2 × 103 |

| Padding/Hardhat | 2 | 6460 | 3230 | 30.508 | <2 × 103 |

| Launcher/Padding/Hardhat | 2 | 5677 | 2839 | 26.812 | |

| Residuals | 108 | 11,434 | 106 |

| Condition | Diff | Lower | Upper | p_Adjust |

|---|---|---|---|---|

| Baked vs. Unbaked | 32.63253 | 27.16481 | 38.10025 | <0.0001 |

| None vs. Baked | 19.64638 | 14.17866 | 25.1141 | <0.0001 |

| None vs. Unbaked | −12.9862 | −18.4539 | −7.51843 | <0.0001 |

| Sample | Launcher | Average Voltage (V) | Av. V (StD) | Post-Testing Voltage | Test V (StD) | V Change |

|---|---|---|---|---|---|---|

| Unbaked | SGP-35 | 0.58 | 0.01 | 0.57 | 0.04 | 0.01 |

| CA-09 | 0.60 | 0.04 | 0.37 | 0.10 | 0.23 | |

| Baked | SGP-35 | 0.54 | 0.01 | 0.57 | 0.01 | 0.04 |

| CA-09 | 0.60 | 0.01 | 0.59 | 0.01 | 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

LaRocco, J.; Eom, T.; Duggisani, T.; Zalcberg, I.; Xue, J.; Seth, E.; Zapata, N.; Anksapuram, D.; Muzumdar, N.; Zachariah, E. Ballistic Testing of an Aerogel/Starch Composite Designed for Use in Wearable Protective Equipment. Technologies 2025, 13, 199. https://doi.org/10.3390/technologies13050199

LaRocco J, Eom T, Duggisani T, Zalcberg I, Xue J, Seth E, Zapata N, Anksapuram D, Muzumdar N, Zachariah E. Ballistic Testing of an Aerogel/Starch Composite Designed for Use in Wearable Protective Equipment. Technologies. 2025; 13(5):199. https://doi.org/10.3390/technologies13050199

Chicago/Turabian StyleLaRocco, John, Taeyoon Eom, Tanush Duggisani, Ian Zalcberg, Jinyi Xue, Ekansh Seth, Nicolas Zapata, Dheeraj Anksapuram, Nathaniel Muzumdar, and Eric Zachariah. 2025. "Ballistic Testing of an Aerogel/Starch Composite Designed for Use in Wearable Protective Equipment" Technologies 13, no. 5: 199. https://doi.org/10.3390/technologies13050199

APA StyleLaRocco, J., Eom, T., Duggisani, T., Zalcberg, I., Xue, J., Seth, E., Zapata, N., Anksapuram, D., Muzumdar, N., & Zachariah, E. (2025). Ballistic Testing of an Aerogel/Starch Composite Designed for Use in Wearable Protective Equipment. Technologies, 13(5), 199. https://doi.org/10.3390/technologies13050199