Abstract

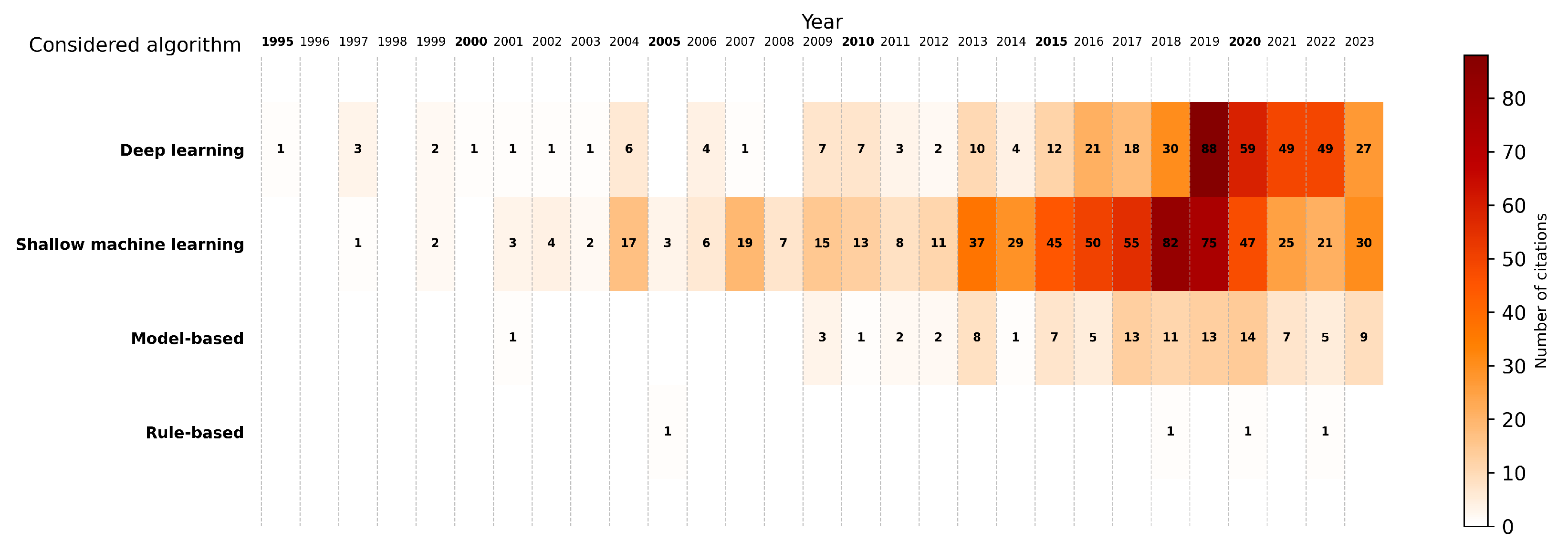

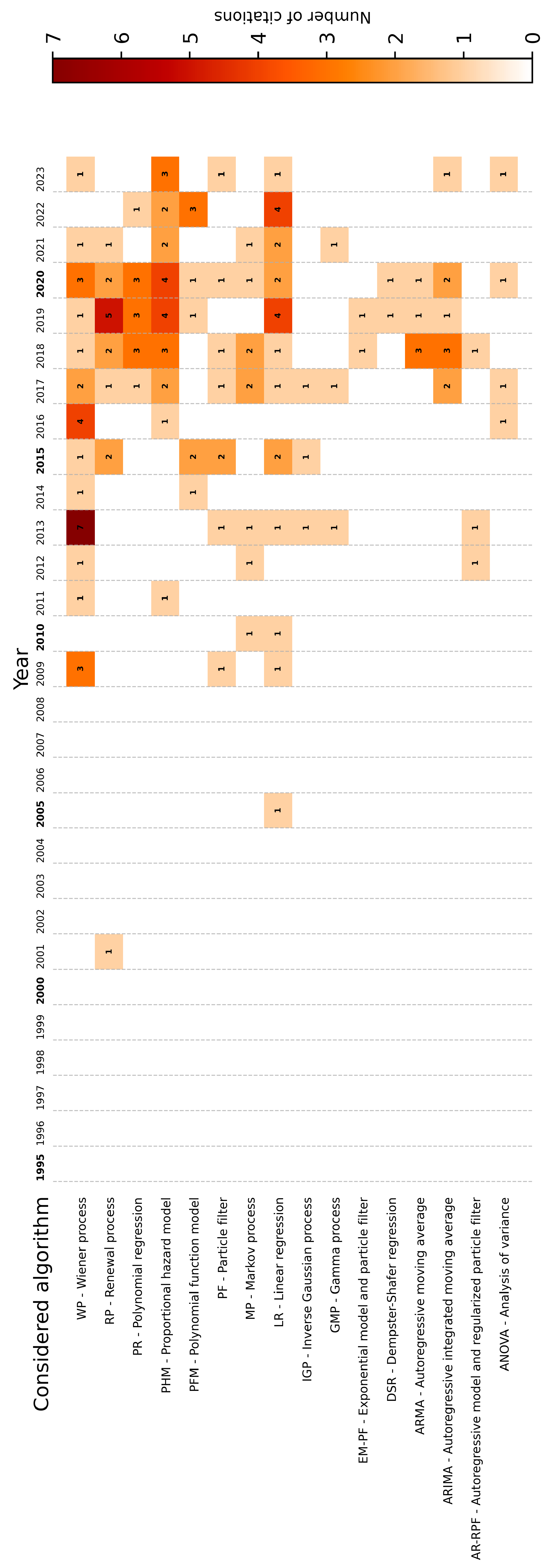

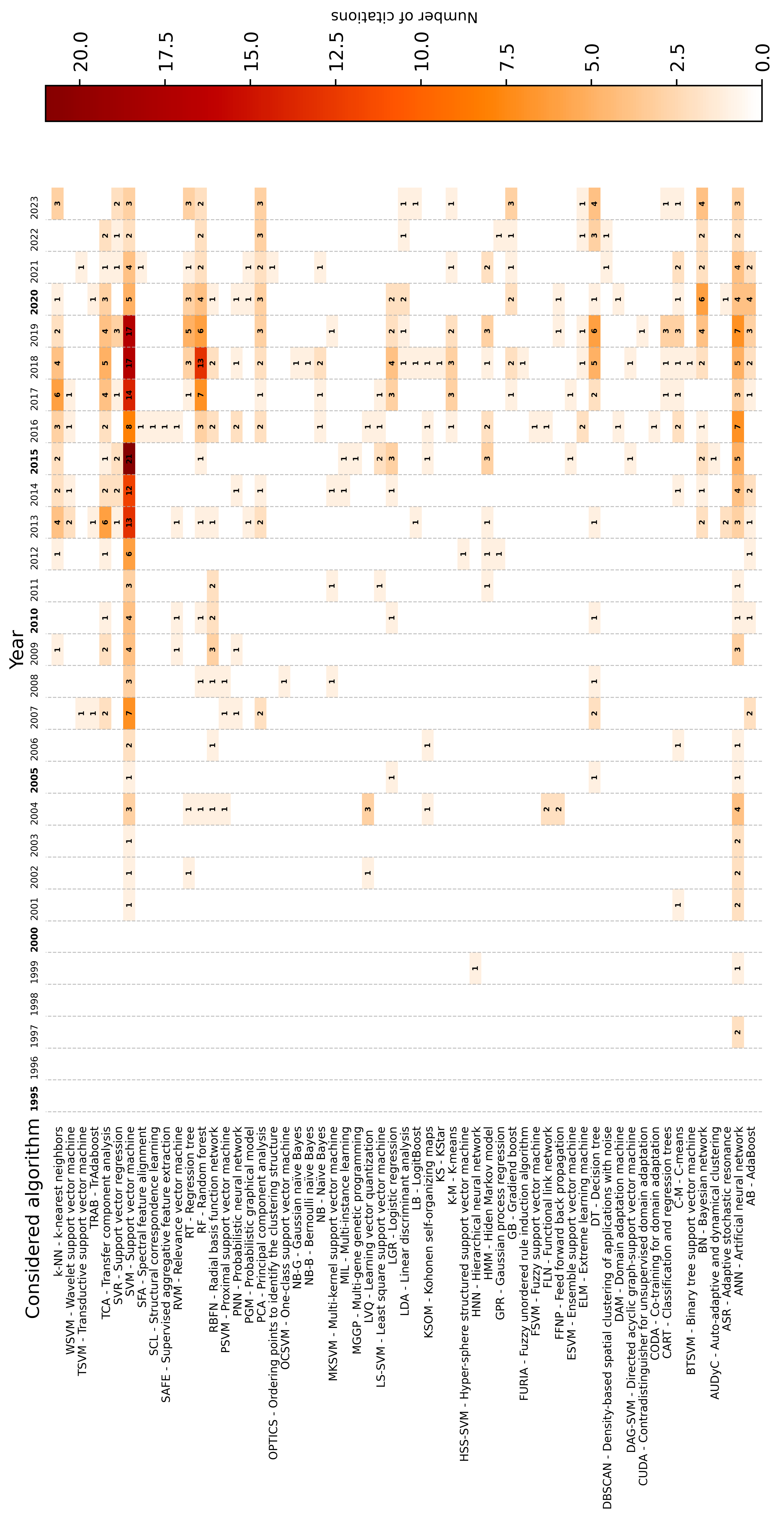

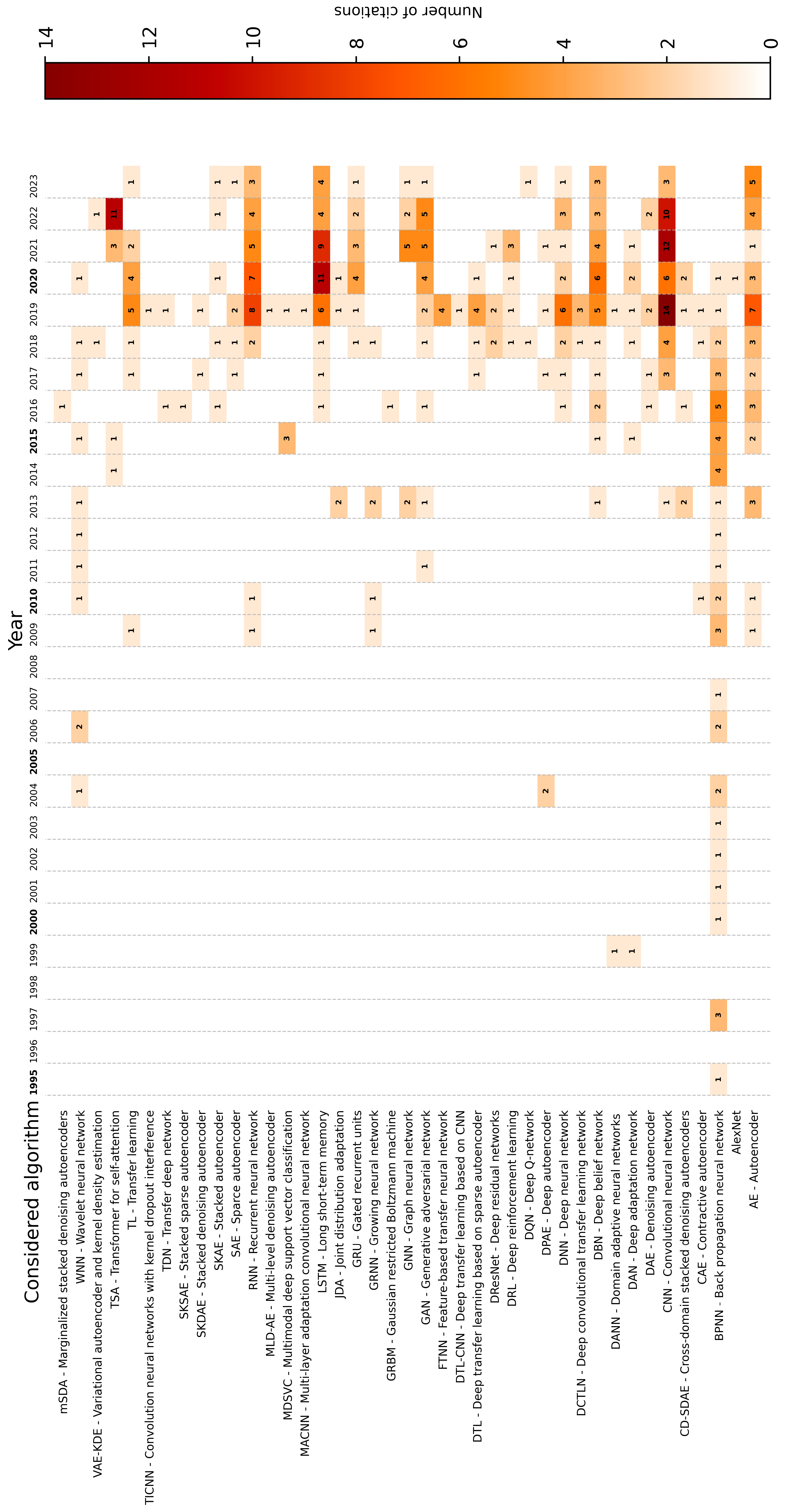

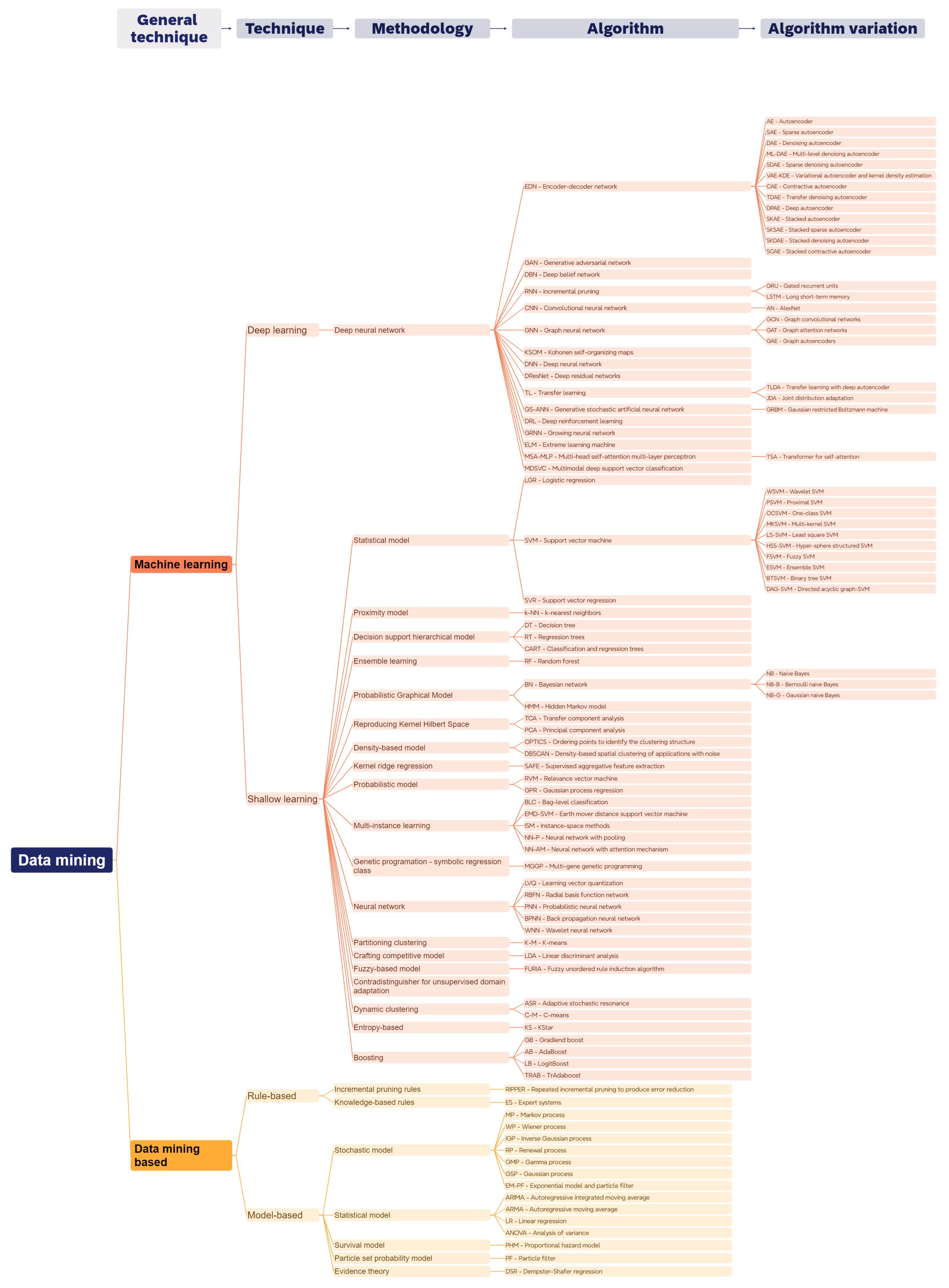

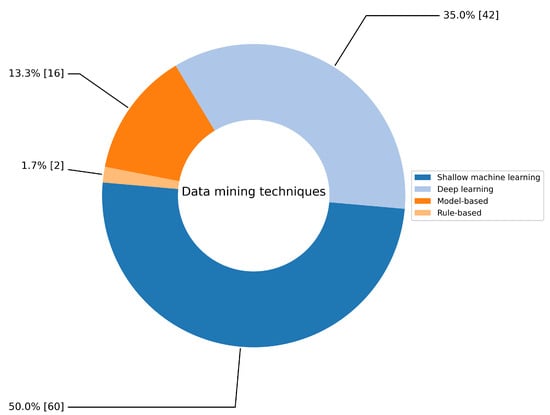

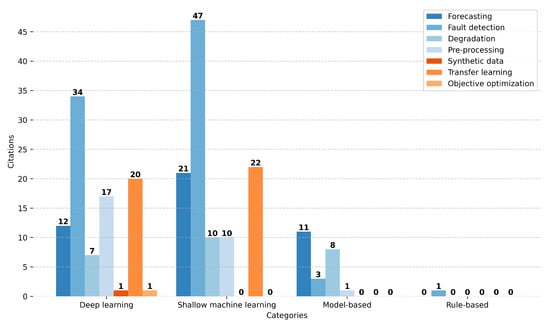

This survey presents a comprehensive review of data-driven approaches for industrial asset maintenance, emphasizing the use of data mining and machine learning techniques, including deep learning, for condition-based and predictive maintenance. It examines 534 references from 1995 to 2023, along with three additional articles from 2024 on natural language processing and large language models in industrial maintenance. The study categorizes two main techniques, four specialized approaches, and 27 methodologies, resulting in over 100 variations of algorithms tailored to specific maintenance needs for industrial assets. It details the data types utilized in the industrial sector, with the most frequently mentioned being time series data, event timestamp data, and image data. The survey also highlights the most frequently referenced data mining algorithms, such as the proportional hazard model, expert systems, support vector machines, random forest, autoencoder, and convolutional neural networks. Additionally, the survey proposes four level classes of asset complexity and studies five asset types, including mechanical, electromechanical, electrical, electronic, and computing assets. The growing adoption of deep learning is highlighted alongside the continued relevance of traditional approaches such as shallow machine learning and rule-based and model-based techniques. Furthermore, the survey explores emerging trends in machine learning and related technologies, identifies future research directions, and underscores their critical role in advancing condition-based and predictive maintenance frameworks.

1. Introduction

The industry faces a huge transformation due to the high automation of systems and processes. This transformation started decades ago with isolated automated systems to solve large process problems with a relatively small amount of digital assets. Nowadays, the variety of digital assets and the complex networking behind them require better and automated monitoring systems, optimized maintenance policies, and advanced analysis to support engineers, technicians, and operators in their daily activities. Many studies are turning their attention to solutions with a focus on resilient architectures, expert systems for decision-making support, and advanced analytic techniques and tools for data mining (DM) and machine learning (ML).

Although DM and ML are generally studied as different areas of computer science, for didactic purposes, this work defines DM as encompassing not only the processes of extracting valuable insights and patterns from large datasets, but also the application of various ML algorithms that leverage these data for predictive and analytical purposes. In short, DM serves as a broad term that includes both the traditional techniques of knowledge extraction and the implementation of the most sophisticated ML algorithms, such as deep learning (DL), to maximize usefulness of available data.

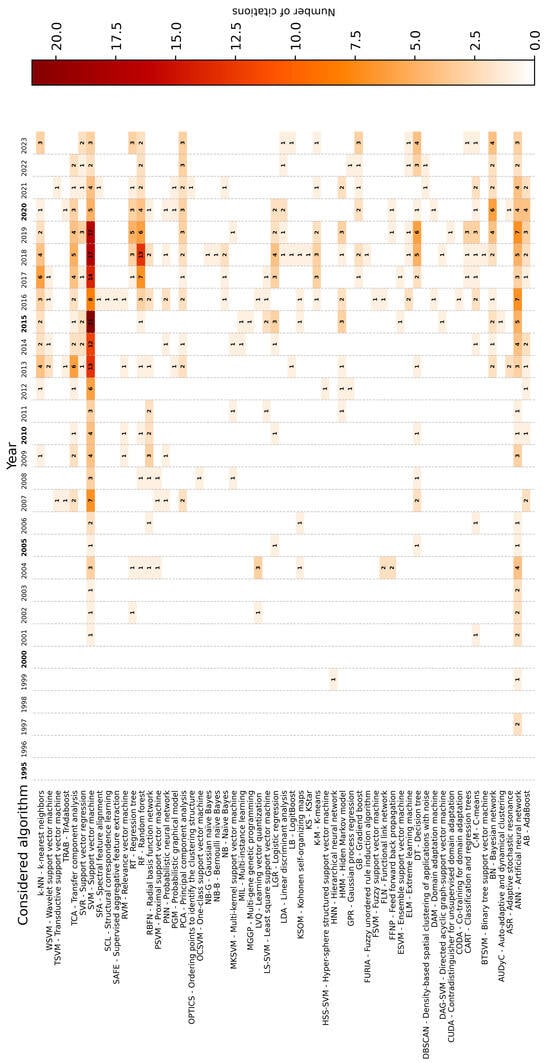

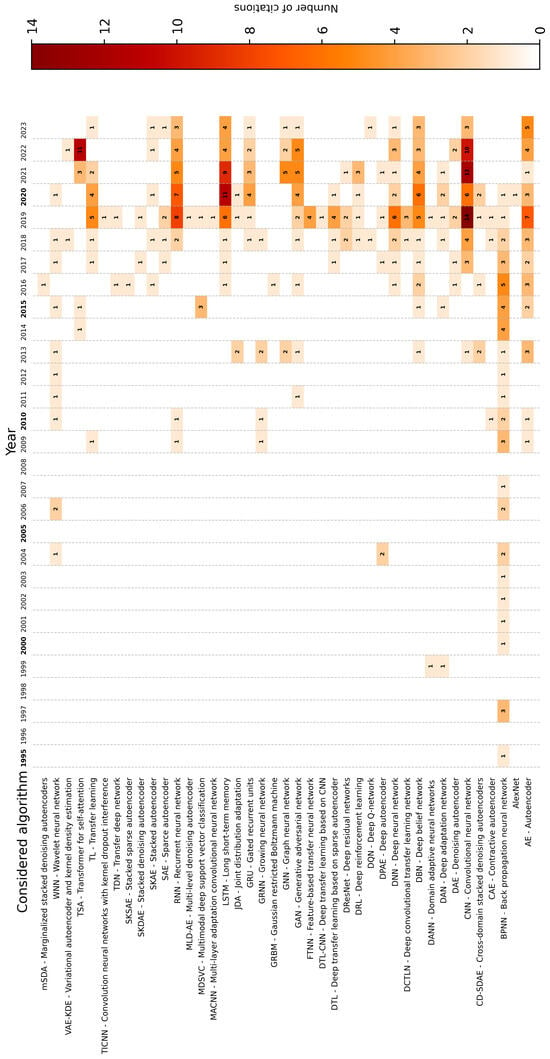

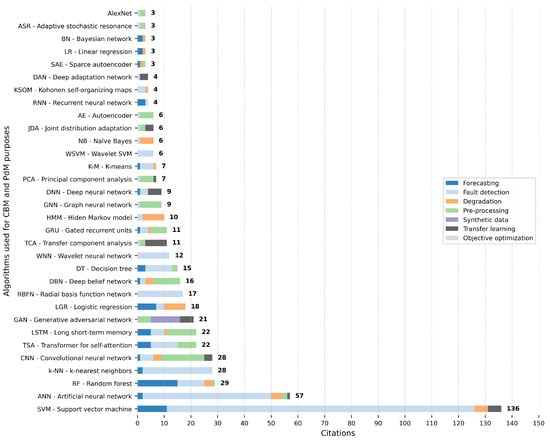

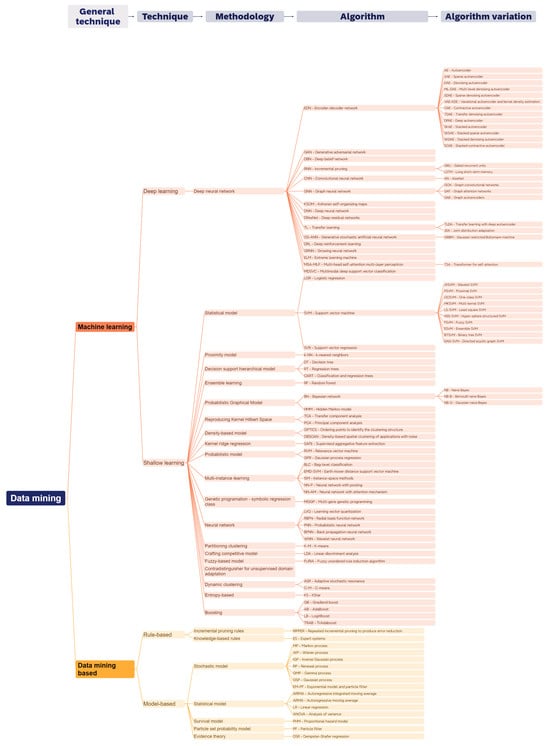

Interesting reviews and surveys explore the field of DM with a focus on maintenance optimization, fault identification, and prognosis such as [1,2,3,4,5,6,7,8,9,10,11,12,13]. Regarding studies with a taxonomy presentation of data science and analytic applications in industrial maintenance, the most comprehensive papers to date are [14,15,16,17,18]. Nevertheless, their focus was based only on mechanic and electromechanic assets.

The revision of survey, review, and taxonomy papers led to the formulation of the following research questions, which define and convey the scope and aim of this paper:

- What techniques are commonly used for analysis in the field of industrial assets maintenance, and how have they evolved over the years?

- Which algorithms are most frequently applied, and what are their specific applications, advantages, and disadvantages?

- Are all types of assets used in the industrial sector adequately studied and analyzed? Is there a review that compiles information across all asset types?

- What categories of asset complexity are typically studied, and which techniques are best suited for analyzing these categories of assets?

- What types of data are considered for analysis? Do the techniques support processing data from assets with multiple variables?

- What are the trending topics in machine learning and the role of emerging technologies in advancing industrial maintenance?

This survey aims to advance the understanding and application of data-driven approaches for industrial asset maintenance by addressing critical gaps and broadening the scope of existing research. The primary contributions of this article are as follows:

- Introduction of data mining (DM) and machine learning (ML) techniques applied to the maintenance of industrial assets;

- Expansion of the study scope to include electric, electronic, and computing assets, in addition to the commonly studied mechanic and electromechanic assets, while proposing four categories of assets based on complexity;

- Analysis of the purposes and applications of DM and ML, with a focus on the most frequently referenced algorithms for condition-based and predictive maintenance;

- Summary of data types and working parameters used in data mining and their relevance to industrial assets maintenance analysis.

To the best of the authors’ knowledge, no existing survey comprehensively addresses all the topics covered in this research study. Therefore, the authors believe that the developed content and findings presented here are of real value for researchers, experts, and decision-makers aiming to venture into the field of industrial asset maintenance.

This work is organized as follows: Section 2 presents the materials and methods used in the research, detailing the methodologies and techniques employed for the search of research studies under interest. Section 3 delves into the application of data mining in industrial maintenance, exploring various maintenance strategies and the purposes of data mining in condition-based and predictive maintenance. Within this section, subsections cover topics such as degradation identification, failure detection, health index forecasting, data pre-processing, synthetic data generation, transfer learning, and objective optimization. Section 4 defines the data types employed in data mining, asset varieties and complexity, providing insights into the types of data utilized and the complexity of assets under consideration. Section 5 presents topics on learning models, types, and algorithms used in industrial maintenance, categorizing them based on their methodologies and techniques. This section also discusses the most cited learning algorithms by technique type. A general discussion is conducted in Section 6. Section 7 presents trending topics of machine learning and emerging technologies in industrial maintenance. Finally, the conclusions of Section 8 synthesize the key findings from the study, highlighting the importance of understanding asset characteristics, employing appropriate analytical methods, leveraging diverse learning techniques, and utilizing suitable tools for effective maintenance strategies. Lastly, as future work directions, suggestions of potential areas for further research and development in industrial maintenance and data mining are presented.

2. Materials and Methods

The primary purpose of this investigation was to identify the most relevant literature on the application of data mining (DM) in industrial maintenance contexts, including industrial asset diagnosis, fault detection, prognosis, and various other applications. To start the exploration, a strategic approach was adopted, starting with the formulation of specific keywords. These keywords were applied within the domains of article titles, keywords, or abstracts, specifically targeting the period spanning from year 2015 to May 2023. Publications and research studies that were not in English and not directly related to the industrial field were excluded from this research. The search revealed a final count of 534 works deemed relevant and included for consideration. Among the considered studies, there are 495 specific research, 22 reviews, 8 surveys, 6 taxonomies, and 3 patents. Additionally, to cover the topics of natural language processing and large language models in the field of industrial maintenance, 3 more articles were considered, being 2 of them specific research studies and 1 review, all of them of the year 2024. Totalizing 537 articles for the general repository.

Table 1 shows part of the keywords under consideration for the exploration of technical studies, focusing on the top 15 most referenced, which are presented as a summary that details their number of mentions within the general repository. The other considered keywords are: remaining useful life (RUL) with 40 mentions, clustering with 40 mentions, preventive maintenance with 32 mentions, forecasting with 30 mentions, deterioration with 26 mentions, industry 4.0 with 26 mentions, internet of things (IoT) with 20 mentions, condition-based maintenance with 21 mentions, big data with 14 mentions, data mining with 11 mentions, industrial systems with 9 mentions, early fault detection with 7 mentions, maintenance planning with 3 mentions, reliability block diagram (RBD) with 2 mentions, failure mode effect and criticality analysis (FMECA) with 2 mentions, natural language processing with 1 mention, language models with 1 mention, and linguistic text mining with 1 mention.

Table 1.

Defined keywords under consideration and the number of occurrences in industrial maintenance research within the overall repository.

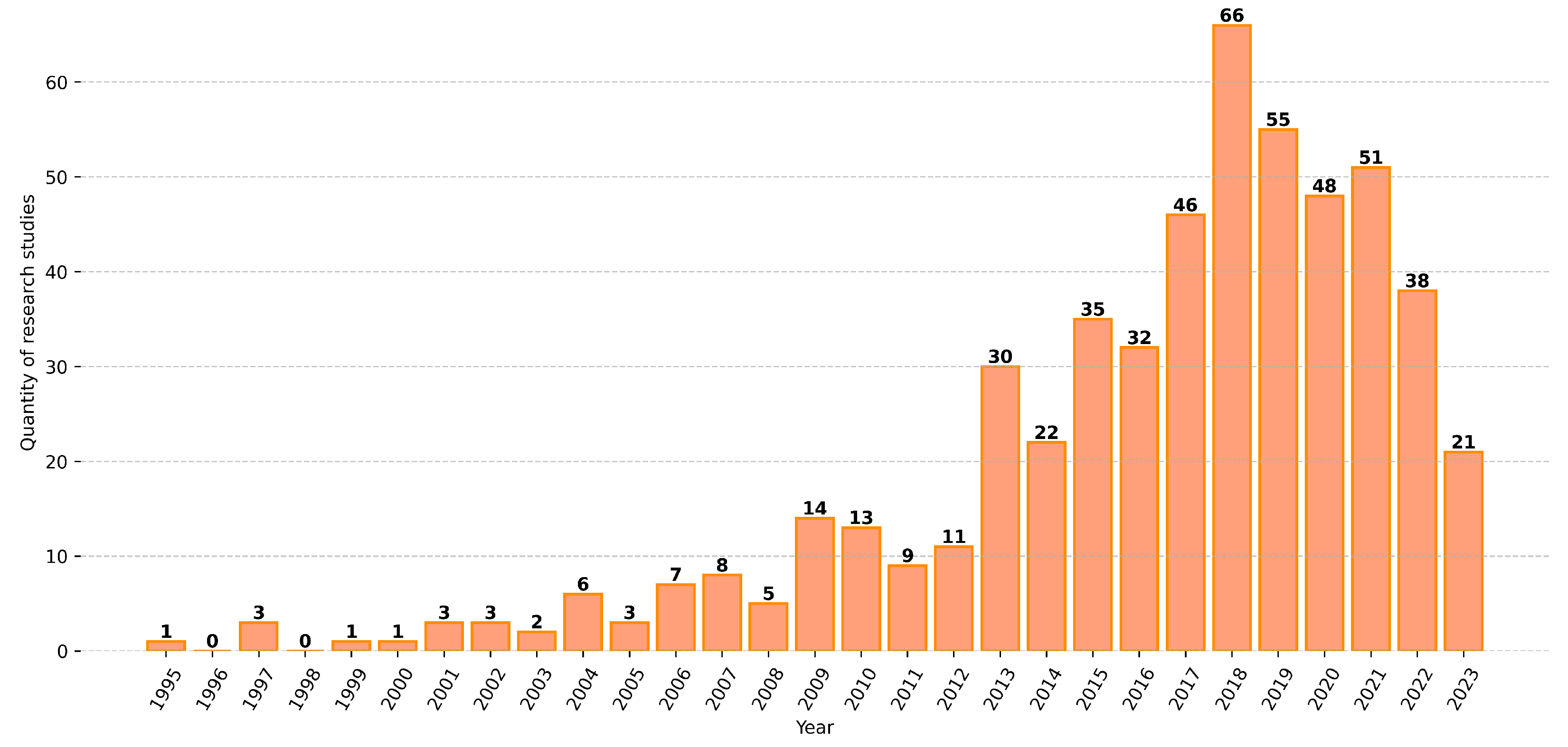

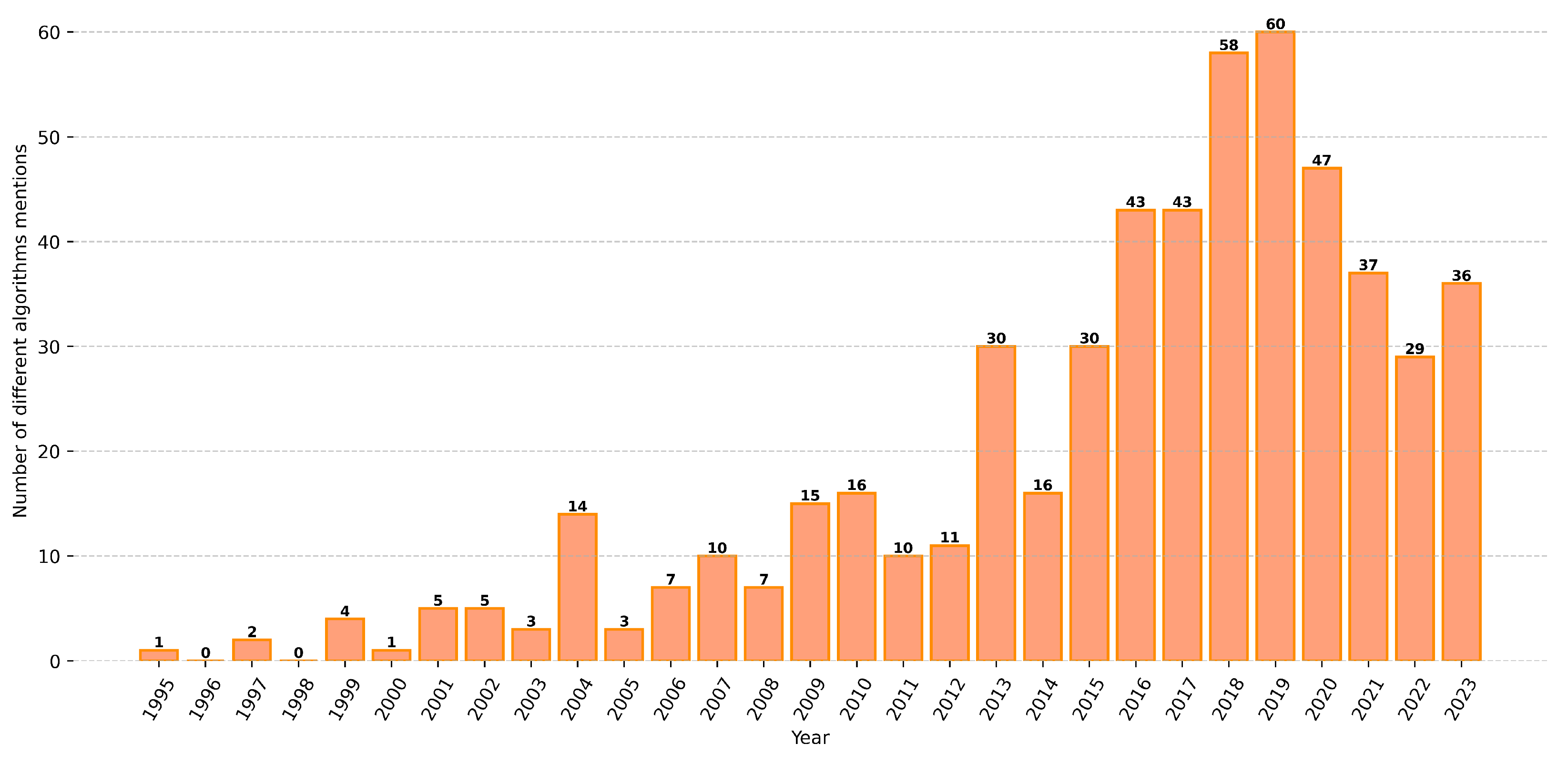

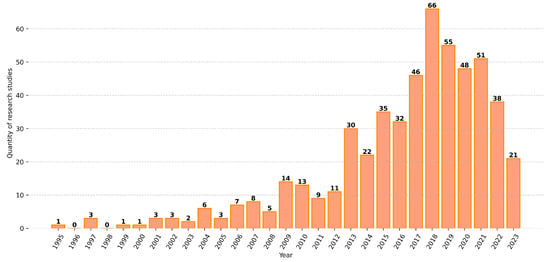

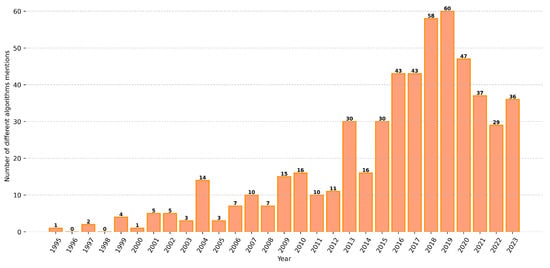

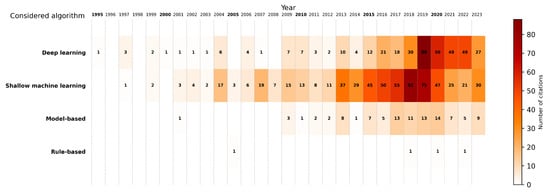

The selection criteria specified the inclusion of studies since the year 2015, whereas the search for specific research studies encompassed a broader timeframe, commencing from the year 1995 up to the year 2023. Articles from 2024 are not considered due to the specific topics defined for the search criteria. Figure 1 illustrates the distribution of the 534 works identified over the entire period under review. There has been a marked increase in studies since 1995, with a rising trend continuing until 2018. Following this peak, a decline in the number of studies is observed in the subsequent years.

Figure 1.

Number of research works found in each year from 1995 to 2023.

The research repository, consisting of 537 articles, was primarily constructed using the following academic databases: Science Direct with 205 studies, IEEE Xplore with 129 studies, Springer Link with 52 studies, MDPI with 39 studies, Sage Journals with 31 studies. An additional 81 studies were sourced from complementary platforms identified through Google Scholar, including Taylor & Francis Online, ACM Digital Library, ResearchGate, IOP Science, HINDAWI, ASME, arXiv, CORE, EXTRICA, Google Patents, WILEY Online Library, IET, IOS Press, BGU, IGI Global, OnePetro, DIVA, WIRES, CERN Document Server, SPIE Digital Library, ARC, AIP Publishing, PHIL Papers, Emerald, and BazTech.

For enhanced readability, refer to Table 2, which lists all the acronyms used in this work.

Table 2.

Used acronyms and their descriptions.

3. Data Mining Application in Industrial Maintenance

This section provides a technical overview of the integration of data mining (DM) techniques in industrial maintenance. It focuses on the strategic application of DM to enhance maintenance practices, beginning with an analysis of maintenance strategies and their integration with DM methodologies. The section further elucidates the role of DM in condition-based and predictive maintenance, emphasizing its significance in enabling proactive interventions and improving operational efficiency. Additionally, it examines the range of DM techniques utilized in industrial maintenance, detailing the sophisticated methods used for insight extraction, failure prediction, and decision-making optimization. A dedicated segment clarifies the foundational models and methods underlying these techniques, providing a comprehensive understanding of their application in industrial maintenance.

3.1. Exploration of Maintenance Strategies for the Application of Data Mining

The utilization of DM in modern industrial maintenance focuses on three widely recognized models: preventive, condition-based, and predictive maintenance.

These models stand as pillars frequently referenced in academic and research studies within the domain of maintenance strategies.

The summary of mentions of these maintenance strategies in the research studies is as follows: preventive maintenance with 22 mentions [4,6,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38], condition-based maintenance with 16 mentions [4,7,13,20,39,40,41,42,43,44,45,46,47,48,49,50], and predictive maintenance with 105 mentions [1,3,4,5,6,7,9,10,14,16,21,23,24,25,26,27,28,29,30,31,32,36,42,43,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127,128,129]. Corrective maintenance is infrequently mentioned in the literature concerning the application of data mining in industrial maintenance, with only 6 references [4,21,29,63,98,130]. Typically, these mentions serve to provide an introductory definition and to highlight its disadvantages in comparison to other maintenance models.

DM in industrial maintenance encompasses the application of advanced analytical techniques to extract valuable insights from maintenance-related data. It involves leveraging historical data, sensor readings, and patterns to enhance maintenance decision-making processes.

Table 3 summarizes, with the corresponding references, these three key maintenance strategies, highlighting their objectives, approaches, benefits, and challenges. Each strategy provides distinct advantages while presenting specific challenges, particularly in data management and advanced analytics.

Table 3.

Overview of definitions, approaches, benefits, and challenges of maintenance strategies considered for data mining application in industrial maintenance.

The studies considered in this research focus on industrial assets maintenance, primarily emphasizing CBM and PdM. Within these maintenance paradigms, DM plays a significant role, following the objectives detailed in the subsection.

3.2. Data Mining Application Purposes in Condition-Based and Predictive Maintenance

Considering condition-based and predictive maintenance strategies, data mining is applied in industrial maintenance mainly for the analysis purposes detailed next. Each analysis purpose and associated terminologies commonly used interchangeably to denote the same concept matter are explained.

3.2.1. Degradation Identification

Degradation refers to the gradual deterioration or decline in the performance, condition, or reliability of a piece of equipment or system over time. It is a progressive process where the performance of the equipment slowly declines due to wear and tear, aging, or other factors. During degradation, the equipment may still be operational, but it may no longer function at its optimal level. A more detailed explanation is presented in [16], based on the ”European Standard of Maintenance” terminology, EN 13306. Maintenance strategies often aim to detect and address degradation early to prevent it from progressing to a failure state. Related terminology and other terms used in research, in alphabetical order, include the following:

- A

- Anomaly detection: The process of identifying abnormal or unexpected deviations in machinery or equipment performance data. It involves using advanced monitoring and analysis techniques to detect potential faults or irregularities that could lead to breakdowns or failures in industrial systems [7,10,13,16,54,55,57,61,63,75,81,84,95,131,132,133,134,135,136,137,138];

- B

- Degradation: The progressive decline in the quality, efficiency, or functionality of industrial machinery or infrastructure due to different factors such as usage, environmental conditions, or lack of maintenance [1,3,7,14,16,20,22,28,29,30,31,39,40,41,43,45,49,52,53,57,61,64,67,69,73,74,83,89,90,91,92,93,99,104,137,139,140,141,142,143,144,145,146,147,148,149,150,151,152,153,154,155,156,157,158,159,160,161,162,163,164,165,166];

- C

- Deterioration: The gradual decline or worsening of machinery, components, or infrastructure within an industrial environment. It encompasses the wear and tear, corrosion, and other factors that lead to reduced performance or functionality over time [1,6,7,10,19,31,43,59,94,109,130,148,167];

- D

- Health condition: Refers to the overall operational state or status of machinery, equipment, or systems in an industrial setting. It involves assessing the well-being and functionality of these assets to ensure they operate efficiently and effectively [3,7,21,23,41,42,55,58,131,141,143,165,168,169,170,171,172,173,174,175,176,177];

- E

- Health monitoring: The continuous or periodic assessment of key parameters, performance indicators, or predictive maintenance data to track the condition of machinery and equipment. This procedure helps to identify potential issues before they lead to breakdowns or failures [1,2,7,64,75,120,152,159,171,178,179,180,181];

- F

- Health state: The specific operational condition or status of machinery, equipment, or systems at a particular time. It provides insights into the overall operational health and performance of industrial assets [1,3,12,14,23,28,41,45,141,161,181,182,183,184,185,186,187];

- G

- Incipient fault: The initial or early stages of a fault or issue in machinery or systems are not easily detectable in general, but they have the potential to develop into more severe problems if not addressed promptly [7,14,47,106,188,189,190,191];

- H

- Performance evaluation: The assessment of how effectively machinery, systems, or processes function within an industrial setting. It involves measuring key performance metrics to ensure optimal efficiency and productivity [50,84,148,192,193];

- I

- Reliability evaluation: The analysis and assessment of the probability that industrial systems, machines, or components will operate without failure within specified operating conditions. It involves evaluating the reliability and dependability of equipments to minimize downtime [194].

3.2.2. Failure Detection

Failure occurs when a component of the equipment or the system ceases to function as intended. It is the point at which the equipment or system cannot perform its intended function due to a critical malfunction or breakdown. A detailed definition and the formulation of a fault diagnosis are presented in [2]. Failure is usually the result of prolonged degradation that has not been addressed through maintenance activities. Related terminology and other words used in research, in alphabetical order, include the following:

- A

- Fault detection: The process of actively monitoring and detecting deviations, abnormalities or faults within industrial equipment or systems. It relies on sensors, monitoring tools, data analysis and algorithms to identify deviations from normal operational behavior and trigger alerts or notifications for maintenance or further investigation [6,7,30,34,39,45,51,54,57,60,61,75,80,167,169,174,178,188,193,195,196,197,198,199,200,201,202,203,204,205,206,207,208,209,210,211,212,213,214,215,216,217,218,219,220,221,222,223,224,225,226,227,228,229,230,231,232,233,234];

- B

- Fault diagnosis: Involves analyzing and determining the root cause or sources of faults, malfunctions, or problems within industrial equipment or systems. It often employs investigative methods, data analysis, and expertise to pinpoint specific issues causing failures [2,3,4,6,7,12,13,32,34,38,39,45,47,53,58,61,77,96,103,106,111,115,118,119,122,131,137,149,157,158,162,163,164,165,169,170,171,172,173,174,175,176,177,178,179,183,184,185,186,188,189,190,191,192,193,198,200,201,203,204,206,207,208,210,211,212,215,216,218,219,221,222,224,225,226,228,229,230,231,232,235,236,237,238,239,240,241,242,243,244,245,246,247,248,249,250,251,252,253,254,255,256,257,258,259,260,261,262,263,264,265,266,267,268,269,270,271,272,273,274,275,276,277,278,279,280,281,282,283,284,285,286,287,288,289,290,291,292,293,294,295,296,297,298,299,300,301,302,303,304,305,306,307,308,309,310,311,312,313,314,315,316,317,318,319,320,321,322,323,324,325,326,327,328,329,330,331,332,333,334,335,336,337,338,339,340,341,342,343,344,345,346,347,348,349,350,351,352,353,354,355,356,357,358,359,360,361,362,363,364,365,366,367,368,369,370,371,372,373,374,375,376,377,378,379,380,381,382];

- C

- Fault identification: The specific act of recognizing, categorizing, or labeling faults or abnormalities within industrial machines or systems. It involves distinguishing among different types of faults or failures to facilitate targeted troubleshooting and corrective actions [7,45,103,192,208,234,236,267,321,353,366,383,384,385,386,387,388,389].

3.2.3. Health Index Forecasting

Health index forecasting involves predicting future condition or health of equipment or machinery based on historical data and various sensor measurements. It helps maintenance teams anticipate when maintenance or repairs will be needed, enabling proactive maintenance and minimizing downtime. A comprehensive definition is presented in [2]. Related terminology and other terms used in research, in alphabetical order, include the following:

- A

- Early fault detection: The capability to identify and detect potential faults or anomalies in industrial machinery or systems at an early stage. It involves the use of monitoring tools, sensors, and predictive algorithms to catch abnormalities before they escalate into severe failures [7,34,80,188,203,230];

- B

- Fault prognosis: This focuses on predicting and forecasting potential faults or failures in industrial equipment or systems before they occur. It uses advanced analytics, machine learning, and diagnostic techniques to anticipate and mitigate impending problems [2,7,53,123,152,356];

- C

- Forecasting: This involves the use of historical data and statistical techniques to predict future trends or conditions related to machinery health, performance, or maintenance needs. It assists in planning maintenance schedules and resource allocation [14,16,30,41,58,67,79,85,92,95,115,137,153,390,391,392,393,394];

- D

- Regression: A statistical method for analyzing the relationship between variables, often employed in predictive maintenance models. Regression analysis helps in understanding how changes in one variable relate to changes in another one and it can be used to predict future outcomes based on historical data patterns [2,3,7,8,10,12,14,16,27,28,41,49,53,58,59,69,72,73,75,76,78,85,91,101,138,149,158,159,160,161,162,171,182,197,269,271,289,290,293,321,346,353,382,391,395,396,397,398,399,400,401,402,403,404,405,406,407];

- E

- Remaining life assessment: This involves the evaluation and estimation of the remaining operational lifespan of industrial machinery. It considers various factors such as usage patterns, environmental conditions, and maintenance history to estimate how much lifespan is left in a system [3,38,71,82,91,147,181,392,395,401,408,409,410,411,412];

- F

- Remaining useful life (RUL): This refers to the estimated time or remaining operational lifespan of a piece of equipment or system before it is expected to fail or become unreliable. Estimating RUL helps in scheduling maintenance activities to maximize asset utilization while minimizing unplanned downtime [2,3,7,9,10,14,16,17,26,43,45,52,53,57,61,62,69,71,74,78,82,88,89,91,93,94,97,120,139,142,144,147,153,156,161,165,166,180,198,392,395,401,402,404,408,410,411,412,413,414,415].

3.2.4. Data Pre-Processing

Data pre-processing refers to the steps taken to clean, transform, and prepare raw sensor and maintenance data for analysis. This includes noise removal, missing value handling, data normalization, and other data cleaning and formatting tasks to ensure the quality and consistency of the data used for the learning model. A brief description is presented in [12]. For more details, refer to [16], which summarizes an extensive use example. Related terminology and other terms used in research, in alphabetical order, include the following:

- A

- Data fusion: This involves the integration or combination of data from different sources or sensors to provide a more complete and accurate representation of the state or condition of industrial machinery. It aims to improve decision-making by using multiple data streams [3,4,7,10,16];

- B

- Dimension reduction: Similar to feature reduction, it involves techniques to reduce the number of dimensions or variables in a dataset. It aims to retain essential information while reducing the dimensionality of the dataset, making it more manageable for analysis [191,250,308]. In industrial maintenance, dimensionality reduction is applied for the following activities:

- (a)

- Dimensionality reduction of sensor data: In predictive and condition-based maintenance, the principal component analysis (PCA) technique, and other variations of it, can be applied to reduce the dimensionality of sensor data while retaining critical information. This helps to improve the modeling for the equipment failure detection and prediction [63,73,75,231,263,343,416,417];

- (b)

- Feature selection: Feature selection methods, such as filters, wrappers, and embedded methods, are used to choose a subset of the most relevant features to improve the modeling of maintenance prediction and condition-based tasks [12,105,130,333,418,419,420]. Some applied feature selection algorithms are chi-squared, Spearman correlation, mutual information, Fisher score, Pearson correlation, and count-based [395]. Metaheuristic optimization is employed with machine learning algorithms to obtain a new subset of the best features of data, as mentioned in [209,220,252,285,383];

- C

- Feature engineering: This is the process of using domain knowledge to extract and create meaningful features from raw data that improve the performance of machine learning models. It involves selecting, modifying, and creating new features (attributes or variables) to enhance the predictive power of the algorithms. This step is crucial because the quality and relevance of features can significantly impact the accuracy and efficiency of the model. Feature engineering can include techniques like normalization, encoding categorical variables, handling missing data, creating interaction features, and more [3,9,78,395,421];

- D

- Feature extraction: This involves the process of selecting or deriving relevant and meaningful attributes or features from raw data collected from industrial machinery or systems. These extracted features help in building predictive models or performing analysis for maintenance-related insights [2,3,7,8,11,12,14,16,33,40,51,61,75,93,131,137,142,157,158,164,170,171,174,184,192,199,200,204,215,216,222,230,231,235,239,244,246,260,261,267,268,270,275,280,284,286,289,290,293,297,303,315,316,317,320,325,328,329,330,332,333,335,336,337,339,343,347,353,354,356,359,361,362,363,364,365,366,369,370,372,373,374,378,381,389,392,416,422,423,424,425,426,427,428,429,430,431,432,433,434,435,436,437,438]. In industrial maintenance, feature extraction applications are for the following tasks:

- (a)

- Image processing: In visual inspections, image processing techniques such as edge detection or texture analysis can be used to extract relevant features from images of equipment components [254,265,324,424];

- (b)

- Signal processing: In equipment maintenance, signals from machines (such as vibration, acoustic, electric current and voltage, among others) can be processed using the fast Fourier transform (FFT), general interpolated fast Fourier transform (GIFFT), and Hilbert–Huang transform (HHT) to extract frequency domain features [6,7,14,55,142,274,319,328,439] and the wavelet packet transform (WPT) to extract time-frequency domain features [96,164,171,173,188,235,238,239,291,324,347,370,422,433,440,441] that indicate the condition of the equipment;

- (c)

- Statistical summarization of data: Sensor data over time can be summarized using statistical features, such as kurtosis, mean, standard deviation, maximum value, minimum value, skewness, variance, root-mean-square, central moment, and others, to provide a concise representation of the data for anomaly identification or predictive models for fault prognosis [103,250,270,418,419,441,442,443,444];

- E

- Feature fusion: This combines or integrates multiple features or information sources from different sensors or data streams related to industrial machinery or systems. The goal is to create more informative and comprehensive features that can enhance the understanding of equipment health or performance [7,354]. In industrial maintenance, some examples of feature fusion applications include the following:

- (a)

- Multi-modal data fusion: Industrial maintenance often involves diverse data sources, including not only sensor data and text reports but also images, making this different from previous presented data fusion cases. Feature fusion techniques can combine features extracted from these three different modalities to create a unified representation for more accurate fault detection or equipment health assessment [2,16,362];

- (b)

- Sensor data fusion: In predictive maintenance, data from multiple sensors on the same equipment can be fused by concatenating or averaging the sensor readings [3,10]. This provides a holistic view of the equipment condition and has the potential to provide better data analysis tools across all domains, including the maintenance quality and the management field [16];

- (c)

- Temporal and spatial data fusion: In cases where equipment data include both temporal (time series) and spatial information, feature fusion can combine features from these dimensions to model the dynamic behavior and spatial relationships of equipments [137,317,319,359];

- (d)

- Text and numerical data fusion: Maintenance reports and numerical sensor data can be fused to provide a more comprehensive understanding of maintenance events and their impact on equipment performance [16];

- F

- Feature learning: This refers to algorithms or techniques that enable systems to automatically discover or learn informative features from raw data without explicit guidance. This process helps to identify patterns or representations that can be useful for predictive maintenance or fault detection [7,9,157,166,258,260,325,351,354,363,365,372,427];

- G

- Feature reduction: This process consists of reducing the number of features or variables in a dataset while preserving as much relevant information as possible. It helps to simplify models, reduce computational complexity, and improve efficiency in the analysis of industrial maintenance data [2,174,175,191];

- H

- Pre-processing: This refers to the initial phase of data preparation where raw data collected from sensors or other sources are cleaned, normalized, transformed, and other necessary steps are taken to make them suitable for analysis. It includes handling missing values, removing noise, and standardizing data formats [2,12,14,16,28,47,78,95,142,193,197,199,200,206,343,445,446,447].

3.2.5. Data Augmentation

Data augmentation involves the creation of artificial data that simulate real-world conditions. This can be useful when real data is scarce or sensitive. In maintenance, synthetic data can be used to test and validate predictive models. Related terminology and other terms used in research, in alphabetical order, include the following:

- A

- Augmentation: Techniques used to expand or enhance existing datasets by introducing variations, modifications, or transformations to the original data. This process helps to increase the diversity and size of datasets for better model training or analysis [2,7,13,14,153,350];

- B

- Data generation: The process of creating or producing new data points or datasets relevant to industrial machinery, systems, or processes. It involves generating data to supplement existing datasets, improve model performance, or simulate different operational scenarios [2,14,60,89,226,352];

- C

- Synthetic data: Artificially generated data that imitate real-world scenarios and characteristics of industrial machinery or systems, also known as fake data [12]. They are used when access to real data is limited or restricted to help train models, test algorithms, or perform analyses without using sensitive or proprietary information [59,99,168,197].In industrial maintenance, synthetic data generation applications examples include the following:

- (a)

- Imbalanced data augmentation: In predictive maintenance, when the majority of the data represent normal equipment behavior, synthetic data can be generated to create more balanced class distributions, ensuring that models effectively detect rare equipment faults [2,12,13,14,350]. For a production system, failure events are rare due to the unaffordable and severe consequences of running machines under fault conditions and the potentially time-consuming degradation process before a failure happens [7];

- (b)

- Rare event simulation: Industrial equipment may experience rare events such as extreme operating conditions or rare failures. Synthetic data can simulate these scenarios to train models for robust fault detection [14].

3.2.6. Domain Adaptation

Domain adaptation is a technique where knowledge learned from one domain or dataset is applied to improve performance in another related domain. In maintenance, this can involve using pre-trained ML models or algorithms from one type of equipment to enhance the predictive accuracy for another type, leveraging the shared knowledge. Related terminology and other terms used in research, in alphabetical order, include the following:

- A

- Domain adaptation: This refers to the process of modifying or adjusting models or algorithms trained on one domain to perform effectively on a different but related domain. It involves minimizing the effects of domain shift by adapting the learned knowledge or features from a source domain to improve performance on a target domain with different characteristics or distributions [7,131,149,170,183,243,399,448,449,450];

- B

- Domain shift: This occurs when there is a difference or discrepancy between the distribution or characteristics of data from one domain (source domain) to another domain (target domain). In industrial maintenance, this could be observed when the data collected from different machines or systems exhibit variations due to changes in operating conditions, environmental factors, or other variables [351,450];

- C

- Transfer learning: This refers to a machine learning technique in which knowledge or patterns learned from one domain or task are transferred and applied to another related domain or task. In industrial maintenance, it involves using knowledge or models trained on one set of machinery or data to improve learning or performance on a different but related set of machinery or data, especially when the labeled data in the target domain are limited [2,7,12,13,14,118,122,131,170,183,184,241,242,266,349,397,399,426,451].It is most valuable when there is limited data in the target domain. In industrial maintenance, examples of transfer learning applications include the following:

- (a)

- Equipment fault diagnosis: Suppose that the source and target domain data are collected from an identical machine, but with different operation conditions, like different speed and load, or different working environments. In this scenario, transfer learning may be used to adapt fault detection models from a known and labeled source domain. Even when the source and target domain data are collected from different but related machines, like motors and generators, transfer learning may be a feasible technique [12,118,122,131,170,184,241,242,349];

- (b)

- Image data classification: Transfer learning has been established as an effective technique in computer vision for using rich labeled data in the source domain to build an accurate classifier for the target domain [426];

- (c)

- Knowledge transfer across sites: In a multi-site manufacturing environment, knowledge gained from maintenance and quality control at one site (e.g.,: a laboratory) can be transferred to improve operations and maintenance at another site (e.g.,: real-world) with similar processes and equipment. Usually, this is known as a digital twin approach, in which situations and conditions are developed in a laboratory (virtual space) that, in the real world (physical space), would not be easily captured due to the production cost, safety, and other factors of the industrial plant [7];

- (d)

- Time series forecasting: Transfer learning can be used in time series forecasting tasks, where models trained on historical data from one location can be adapted to make forecasts for a different location with similar operating conditions [399].

3.2.7. Objective Optimization

Objective optimization involves finding the best set of parameters or decisions that optimize a specific objective or goal. In the context of industrial maintenance, it refers to finding the optimal maintenance strategy that minimizes costs, downtime, or other relevant objectives while maximizing equipment reliability and performance [7]. It is used to make informed decisions and allocate resources effectively. The main characteristic of objective optimization is that it can improve system performance or decision-making. In industrial maintenance, examples of optimization applications include the following:

- A

- Energy consumption optimization: Optimization techniques can minimize energy consumption in manufacturing processes by adjusting equipment operating parameters, such as temperature and pressure, to meet production targets while minimizing the overall cost [100]. Another important factor that can be analyzed to optimize energy consumption is the distance between the edge equipment where data are produced and the computation center where they are processed [2];

- B

- Maintenance scheduling: Optimization can be used to schedule preventive maintenance tasks or inspection intervals for industrial equipment. It considers factors such as equipment criticality, maintenance costs, and operating downtime to find the most cost-effective schedule [3,6,40,76,91];

- C

- Spare parts inventory management: Optimization models can determine the optimal level of spare parts inventory to minimize costs while ensuring that critical components are readily available for maintenance needs [31,37,69]. This is a good example of the role of data-driven prognostics in maintenance decisions that industries usually face over the life cycle of an asset;

- D

- Supply chain optimization: Optimization techniques can optimize the supply chain by minimizing lead times, reducing transportation costs, and ensuring timely delivery of critical spare parts. The factories of the future will combine the efficiency of mass production with custom production, and will optimize the supply chain in real-time thanks to high Internet connectivity. These factories will handle fluctuations in demand in a fully automated and fault-tolerant manner [4], meaning this important process should have redundancy.

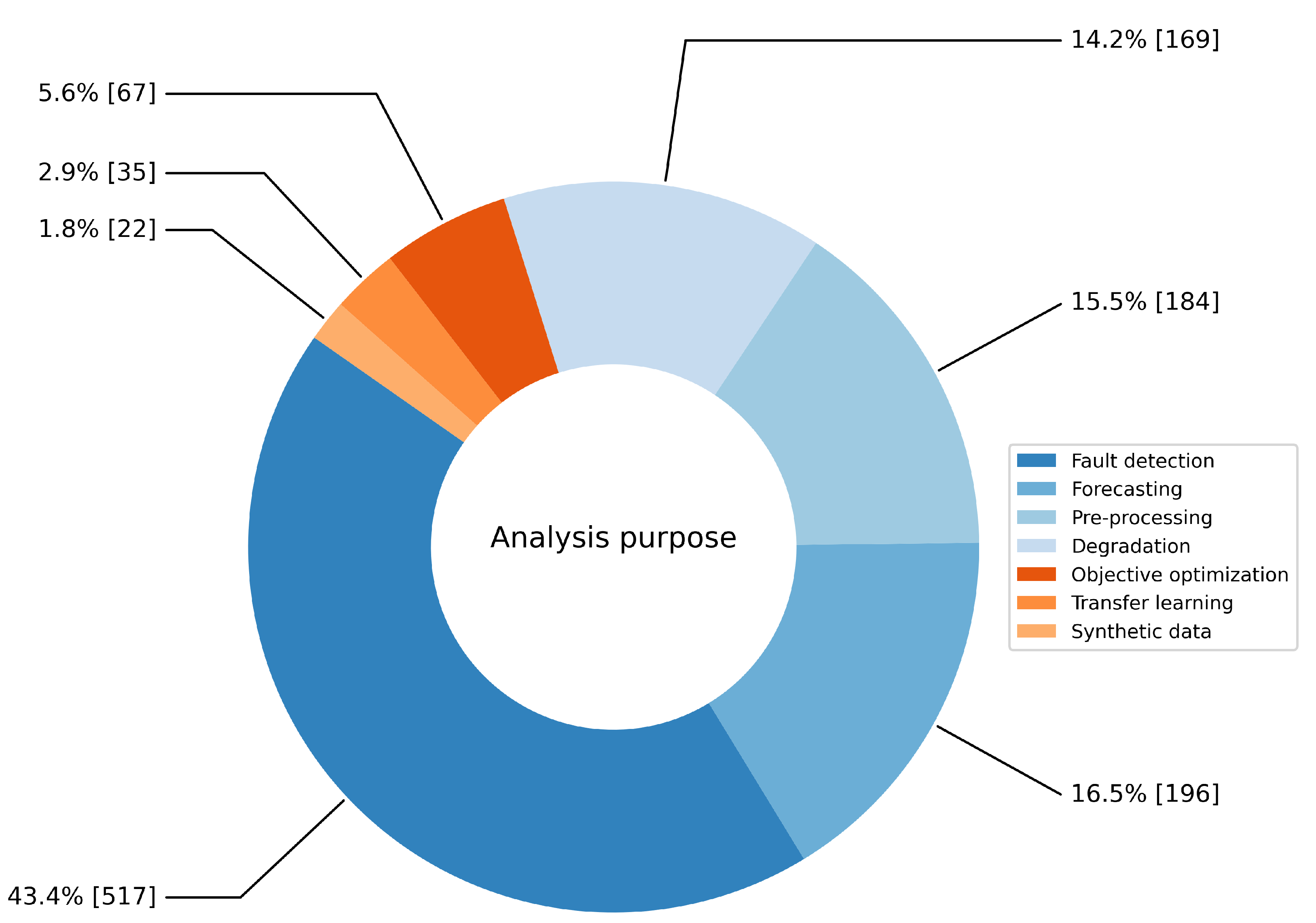

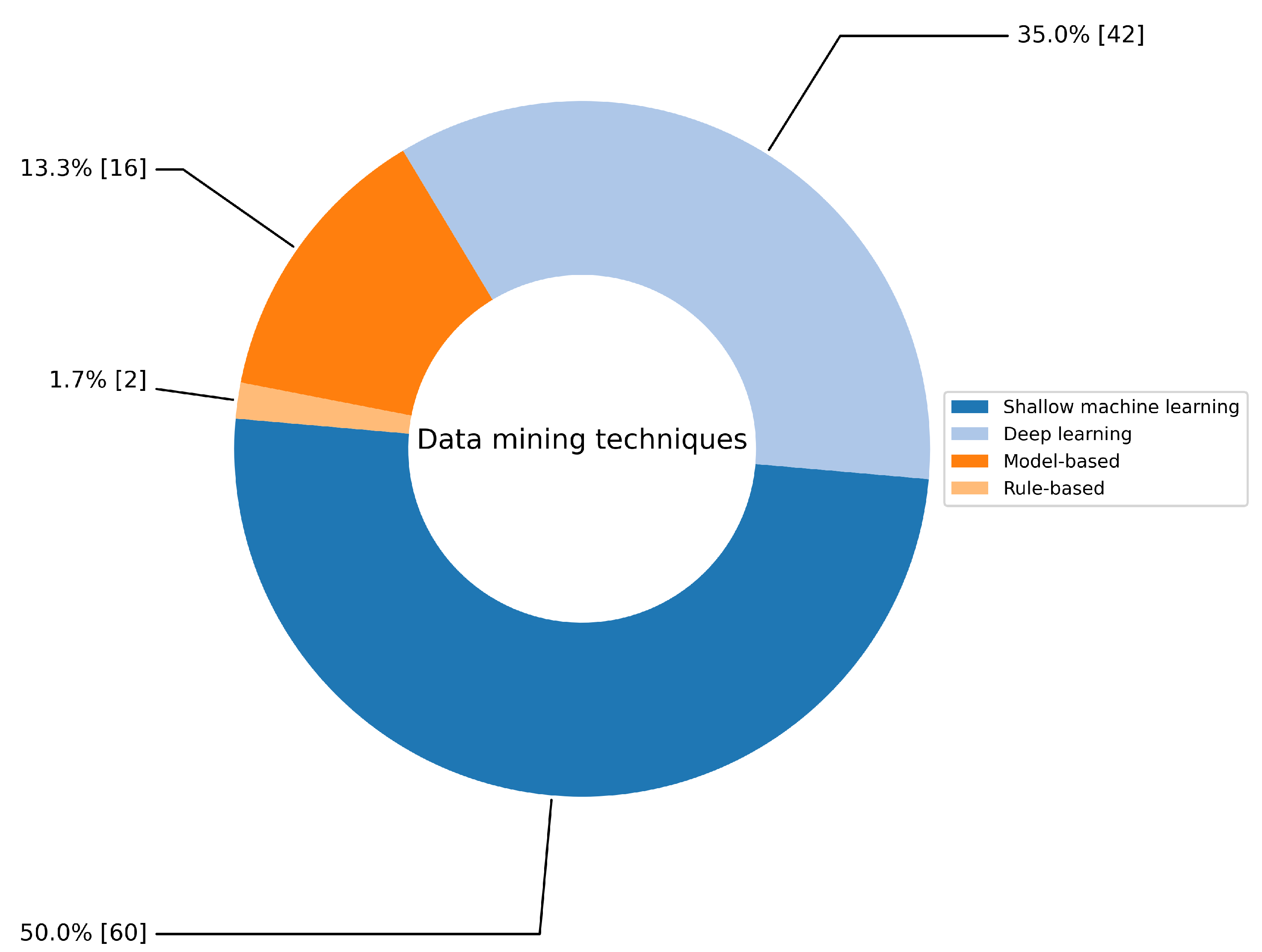

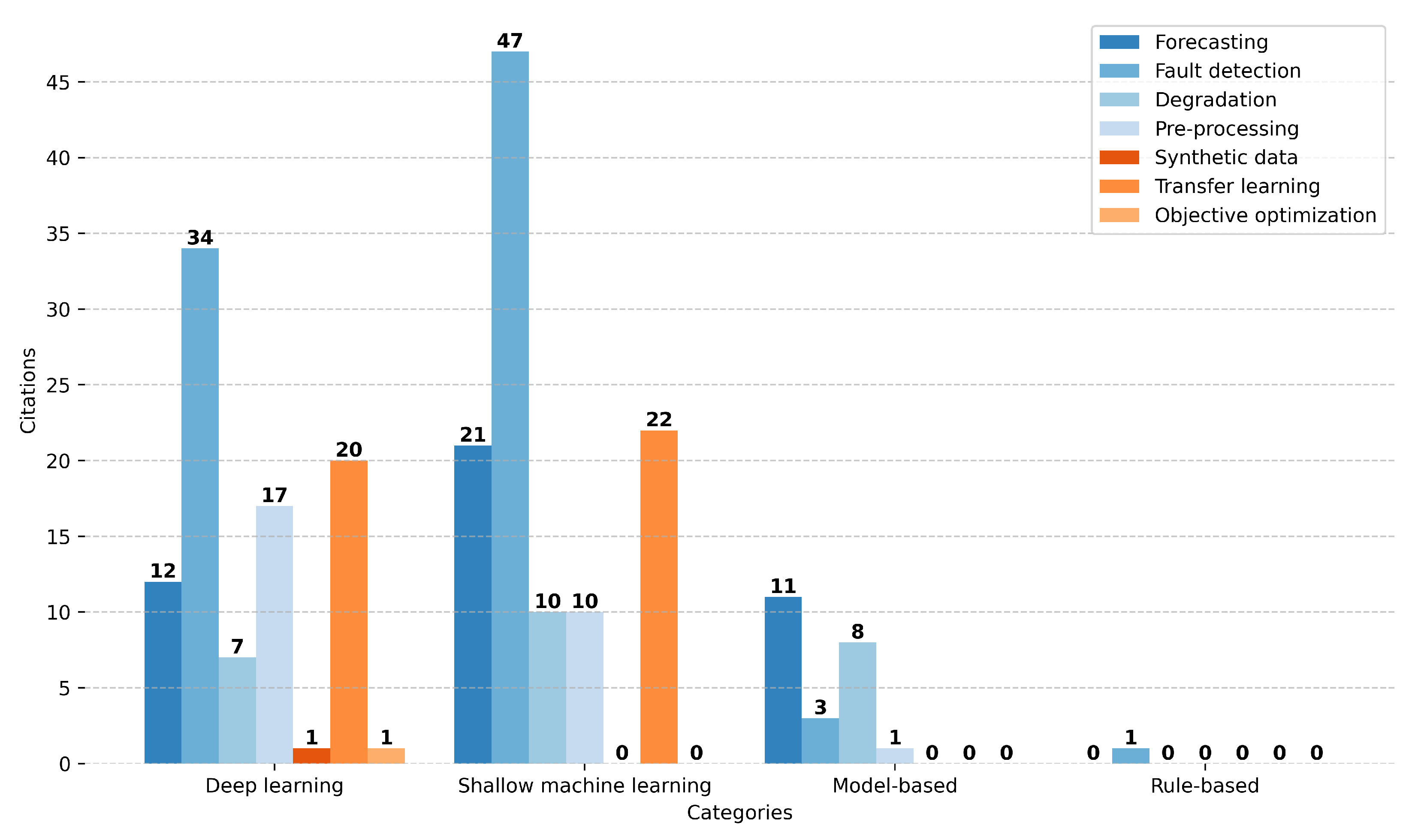

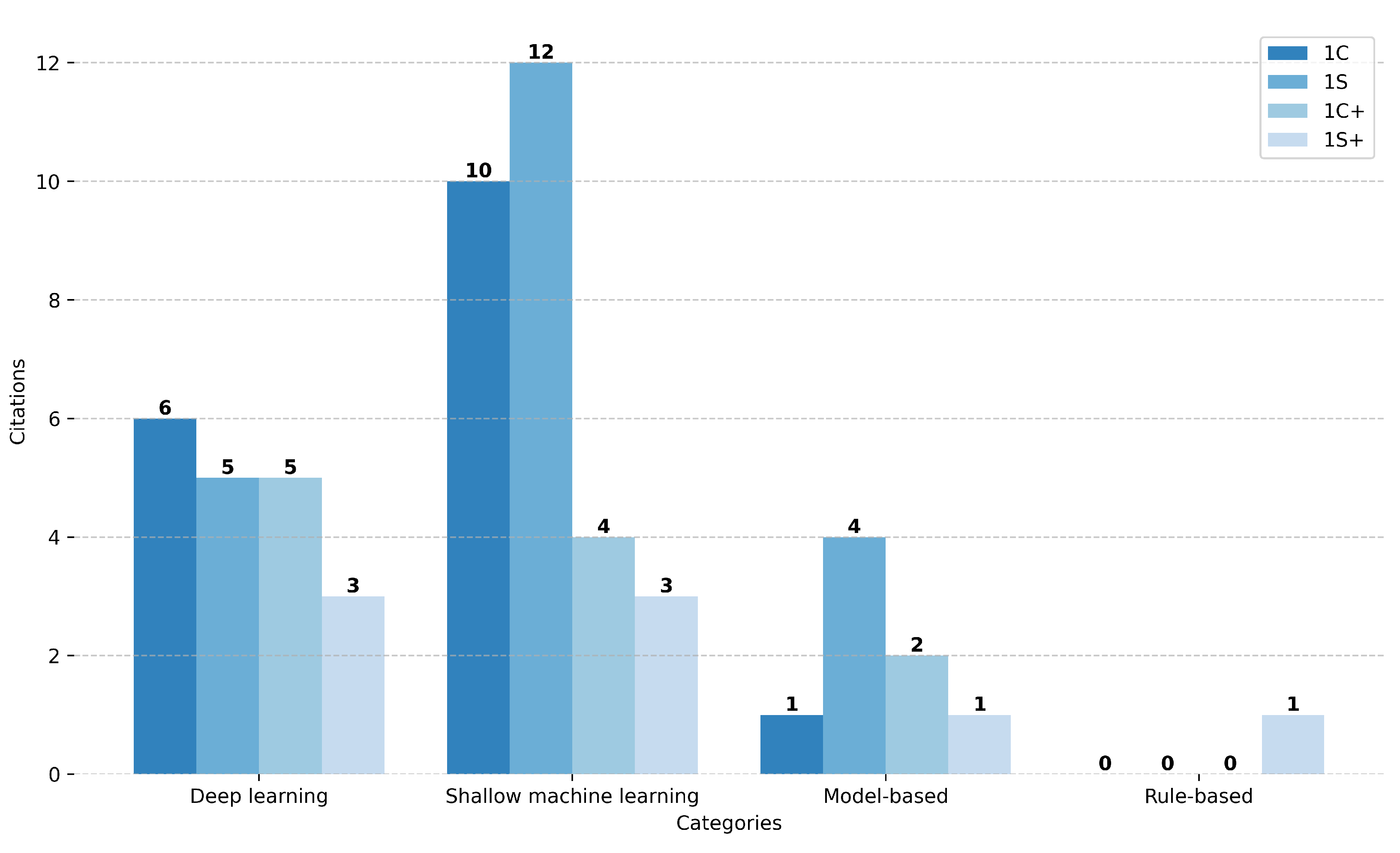

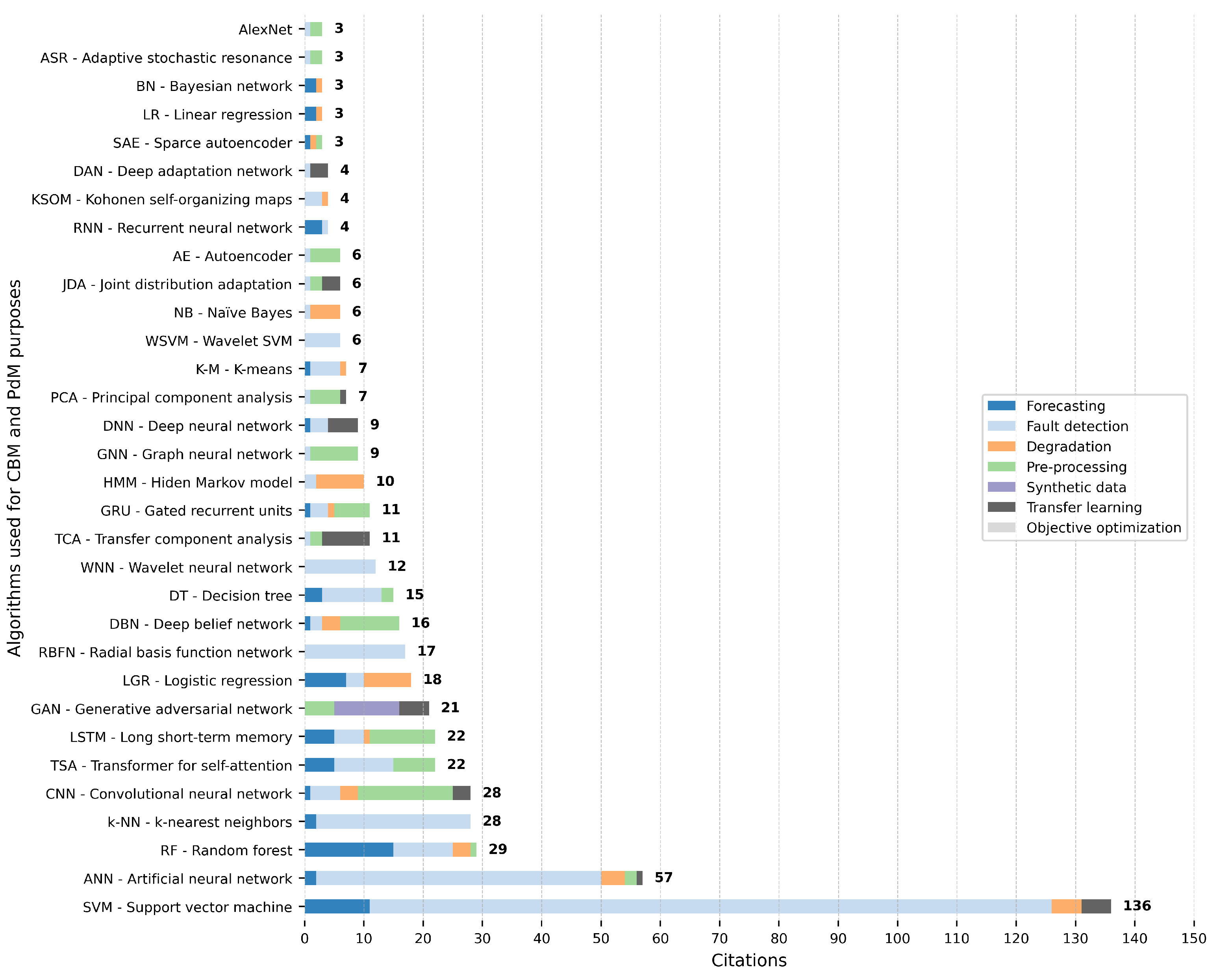

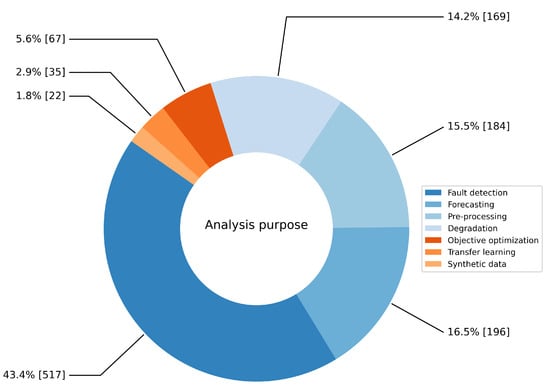

Figure 2 presents and summarizes the number of research works that mention the application of PdM or CBM considering the previously defined purposes, with fault detection, forecasting, pre-processing, and degradation being the most referenced with 517, 196, 184, 169 mentions respectively. The indicated mentions consider the referenced research studies of reviews, surveys, taxonomies, and specific studies, which is why the sum of them exceeds the quantity of the core repository.

Figure 2.

Research works mentioning the application of condition-based or predictive maintenance considering the defined analysis purposes, represented as a percentage [number of papers matching these topics].

3.3. Data Mining Methodologies and Machine Learning Types Applied to Industrial Maintenance

This subsection provides an overview of the wide range of data mining (DM) methodologies, from traditional statistical methods to advanced machine learning algorithms, and highlights their applications in failure prediction, maintenance scheduling optimization, and data-driven decision-making for efficient industrial operations and maintenance.

3.3.1. Data Mining Methodologies

DM encompasses a wide range of methodologies to make extractions, predictions, or decisions based on data. Table 4 summarizes some well-known DM methodologies from the industrial maintenance literature, highlighting their definitions, example algorithms, and applications.

Table 4.

Summary of data mining methodologies, definitions, algorithm examples, and applications.

3.3.2. General Types of Machine Learning

The following is a summary of the general types of machine learning (ML) that support the previous purposes applied to CBM or PdM.

- A

- ClassificationClassification in ML is crucial for solving various problems in industrial maintenance. The main feature of classification is to sort data into categories or classes; hence, it is a problem of automatically assigning a label to an unlabeled example [455,456]. The three most common types of classification are described below:

- (a)

- Binary classification, which can be used to detect a fault (yes/no) based on sensor data and maintenance history, or to predict whether an asset will fail within the next defined period such as 24 h. This helps in proactive maintenance scheduling, preventing costly breakdowns or the damage of dependant systems, as detailed in [14,38,49,83,398,457];

- (b)

- Multi-class classification, which can be used to categorize different types of equipment faults, such as electric, mechanic, or software-related problems, based on fault data and symptoms, as mentioned in [14,38,244,298,312,322,326]. This can enable maintenance teams to identify the root causes of problems and allocate resources efficiently;

- (c)

- Multiple classification (multi-label classification), which helps identify multiple defects or maintenance needs in a manufacturing process, such as categorizing products with defects in color, shape, and size. According to [108], this supports quality control and ensures comprehensive maintenance planning.

- B

- RegressionRegression is an ML technique used to predict the continuous evolution of numerical values based on input features [455,456]. It aims to model the relationship between independent variables (features) and a dependent variable (target) to make predictions. This prediction of signal evolution can serve as input to expert systems or users to trigger alarms related to patterns observed in the future behavior of a system [14].The output of a regression model is a continuous numerical value, such as temperature, pressure, time to failure, or cost.The main characteristic of regression is the forecasting of future outcomes based on historical data. In industrial maintenance, regression models are applied to various scenarios to estimate or forecast continuous outcomes. A summary with examples of applications in industrial maintenance is presented next:

- (a)

- Remaining useful life (RUL): Regression can be used to predict the RUL of industrial equipment based on sensor data. For instance, predicting when a pump or motor will need maintenance to prevent costly breakdowns. Research studies that have estimated the RUL include [2,3,7,9,10,14,16,17,26,43,45,52,53,57,61,62,69,71,74,78,82,88,89,91,93,94,97,120,139,142,144,147,153,156,161,165,166,180,198,392,395,401,402,404,408,410,411,412,413,414,415];

- (b)

- Quality control: Regression analysis can be applied to predict product quality attributes based on various process parameters; for example, predicting the quality of a product based on manufacturing conditions, as described in [390];

- (c)

- Cost estimation: Regression can estimate maintenance or repair costs and the system availability or performance based on factors such as equipment age, usage, and historical maintenance costs. This aids in budget planning, reducing unplanned downtime, extending equipment lifetimes, and maintenance optimization, as detailed in [7,16,25,26,28,29,41,43,50,52,56,73,74,93,104,109,140,458];

- (d)

- Supply chain optimization: Regression can forecast demand for industrial components, helping in supply chain planning and inventory management [4];

- (e)

- Process enhancement: Regression models can optimize manufacturing processes by identifying the ideal operating conditions that lead to the desired output or goal, such as product yield or efficiency [100];

- (f)

- Fault prognosis: Regression analysis can be used to detect abnormal patterns in sensor data that indicate equipment faults or deviations from normal operation, as mentioned in [2,7,53,123,152,356].

- C

- ClusteringClustering is an ML technique used to group similar data points based on certain similarity measures or patterns; hence, it is a problem of learning to assign a label to examples by leveraging an unlabeled dataset [455,456]. It aims to discover inherent structures or patterns in data by grouping data points into clusters, where points within the same cluster are more similar to each other than to those in other clusters. The output of a clustering algorithm is a set of clusters or groups, and it is typically an unsupervised learning technique because it does not require labeled data [56].In industrial maintenance, clustering helps identify similarities or patterns among equipments, processes, or maintenance events. It allows the determination of outliers or identifies erroneous behaviors on machinery or systems [56]. This technique is useful when there is no prior knowledge or understanding of the monitored system [16]. A summary of clustering in ML with examples from industrial maintenance is presented next:

- (a)

- Equipment health monitoring: Clustering can be applied to sensor data from different equipment to group similar machines based on their operating conditions or performance trends. Some examples mentioned in [7] are clustering wind turbine normal states into multiple different clusters for normal behavior identification or the feature fusion of rotary machines for clustering performance improvement;

- (b)

- Maintenance event categorization: Clustering can categorize maintenance events based on their characteristics, such as failure modes. This helps to understand common maintenance challenges and improve response times [14];

- (c)

- Quality control: Clustering can group products or components based on quality attributes. For example, clustering similar products with consistent quality or asset performance can help identify production problems or anomalies [30,390,459,460];

- (d)

- Energy consumption profiling: Clustering can segment energy consumption patterns in a manufacturing facility and identify unusual patterns of energy consumption of different machines. This aids in early fault identification in machines and energy cost savings [24,393,421];

- (e)

- Anomaly detection: In maintenance, clustering can be used for anomaly detection by identifying data points that do not belong to any cluster, which may indicate unusual equipment or system behavior, or potential faults. This helps prevent damage or failure and reduce the malfunctioning time [54,63,132,133,136,138];

- (f)

- Process enhancement: Clustering can group similar processes or production lines, allowing for the identification of maintenance best practices that can be applied across similar assets [100].

In specific cases, some previously explained well-known techniques of ML are combined among themselves, or with other algorithms that are used before or after the data modeling, to allow tasks such as enhanced pre-processing, synthetic data generation, transfer learning, or optimization.

4. Data Types Employed in Data Mining, Asset Variety, and Complexity

The use of data mining (DM) in industrial maintenance requires the exploration and analysis of diverse data types sourced from a large number of assets, each with varying degrees of complexity. These data types cover a broad spectrum, ranging from structured datasets comprising numerical or categorical information to unstructured data such as text, images, or sensor readings. Within industrial settings, assets exhibit multifaceted variations, including machinery, equipment, systems and infrastructure, each characterized by unique operational complexities and unique maintenance requirements. Furthermore, the complexity of these assets ranges from simple standalone machines to interconnected systems within complex industrial ecosystems. The combination of these diverse data types and asset complexities represents significant challenges in extracting valuable insights, requiring sophisticated data processing techniques and analytical methodologies designed to compact and extract valuable information from this diversity. A strategic and valuable factor for the application of data mining and machine learning in data-driven industrial maintenance strategies is their ability to effectively understand and manage the diversity of data types, asset variations, and levels of complexity of these systems.

This section provides an in-depth exploration of the data types utilized in DM, highlighting the most common types used in the field of industrial maintenance. A complimentary overview of data acquisition including the domain of analisys and categorization of data by source are given afterward. Finally, it is discussed the spectrum of asset varieties encountered within industrial environments, and the associated complexity inherent in the operational processes under consideration.

4.1. Data Used for Data Mining

In data mining (DM), various data types are used to represent and analyze information from datasets. In the first segment, an explanation of general data types and their main characteristics is presented. Afterward, the explanation focuses on the most common data types sourced from industrial assets.

4.1.1. General Data Types and Characteristics

This subsubsection details the general data types and their main characteristics. Table 5 outlines, with the corresponding references, the various data types used in industrial maintenance with their definitions, examples, and applications.

Table 5.

Summary of data types, definitions, examples, and applications.

4.1.2. Common Data Types for Data Mining

In the research studies considered for this work, the most frequently mentioned data types can be summarized as follows:

- A

- Time series data: In the industrial field, commonly associated with condition monitoring, time series data contains knowledge in the form of degradation patterns and other types of anomalies in the data that lead to asset degradation. Time-varying features are expected to capture these abnormal patterns, and the models fed with these features are expected to learn to distinguish between normal and abnormal pattern behavior of items and also to forecast the RUL for the monitored items [16]. Time series data have several characteristics that distinguish them from other types of data:

- (a)

- Temporal order: Time series data are collected and recorded in chronological order, where each data point is associated with a specific time or time interval. They are widely used in asset monitoring with periodic inspections [7,20,40,59,81]. The time intervals can be equally spaced, e.g.,: weekly, daily, hourly, minutely, secondly, etc.;

- (b)

- Dependence on time: Time series data exhibit a temporal dependency, meaning that the value of a data point at a given time is often related to the values of previous and/or future data points [359];

- (c)

- Seasonality: Many time series datasets exhibit seasonal patterns, where certain patterns or behaviors repeat at regular intervals, such as daily, weekly, monthly, or yearly cycles. Seasonality can impact data analysis and forecasting [33];

- (d)

- Stationarity: This refers to the characteristic where statistical properties of a time series, such as mean and variance, remain constant over time. Stationary data simplify analysis and modeling. Most signals used for fault pattern recognition are non-stationary, which adds a high complexity for the modeling [45,472];

- (e)

- Trends: Time series data can have underlying trends, which represent long-term changes or movements in the data over time. Trends can be upward (increasing), downward (decreasing), or flat. A very important characteristic in maintenance is the observation of degradation over time to apply early failure detection [20,61] and to evaluate forecasted values [58];

- (f)

- Noise: Time series data often contain noise or random variability that make it challenging to discern underlying patterns. Noise can result from measurement errors, external factors, or other sources of randomness [2,55,57,61];

- (g)

- Irregularities: Time series data may contain irregular or anomalous events, such as peaks [12,308,441], outliers [56,79,84,309] or sudden changes [446], which can disrupt regular patterns and need to be accounted for in analysis.

- B

- Event timestamp data: Often referred to as log data or event data, these data have unique characteristics that make them distinct from other types of data. These characteristics are important when working with event data for various purposes, including monitoring, analysis, troubleshooting and security.Timestamped events include human-generated data that represent information about replaced components and repair activities performed on a certain item or parts of it. Moreover, they also consist of software-generated information, e.g.,: event data information such as alarms and faults messages, which are described in natural language. In addition, they also comprise technical metadata for devices and processes. Event data collection implies a manual or an automatic process and includes qualitative information about the monitored item, such as the description of the installation, breakdown, inspection, repair, overhaul, failure causes, etc., the severity of the failure, and the description of what was done to fix the failure [16]. The main characteristics of timestamped events are as follows:

- (a)

- Timestamps: Event data are associated with specific timestamps, which indicate when each event occurred. These timestamps provide a chronological order, allowing for time-based analysis and tracking of events over time [100];

- (b)

- Event types: Event data typically include different types or categories of events. Each event type represents a specific action, incident, or state change. Examples of event types include error events, system messages, and logs [130];

- (c)

- Granularity: Event data can have different levels of detail, depending on the application. Timestamps can be precise, with high sampling rates (e.g.,: milliseconds, seconds, minutes) [268] or other time units, allowing for fine-grained or coarse-grained analysis;

- (d)

- Volume: Event data often come in large volumes, especially in systems with high levels of activity that generate large datasets [63]. Analyzing and managing large event datasets require scalable and efficient data processing techniques [85,402];

- (e)

- Log levels: Many event logs include log levels that indicate the severity or importance of each event, such as different degrees of fault or system health [7,14,16,96,203,233,280]. Common log levels include INFO, WARNING, ERROR, and CRITICAL. These levels help prioritize events for action or further investigation;

- (f)

- Contextual information: Events often include additional contextual information or metadata, as this information is critical for determining an assertive predictive model, such as source identifiers, event descriptions, user identification, IP addresses, port, repair activities performed, the components replaced, and more [16,67];

- (g)

- Event correlation: Event data may include fields or attributes that allow events to be correlated or grouped, e.g. a correlation identificator can link related events, making it easier to track sequences of events to a particular process instance [100];

- (h)

- Irregularities and anomalies: Event logs can help identify irregular or anomalous patterns and behaviors, such as security breaches [4], forecast system failures based on historical data [92,144,407], or deviations from expected norms [391];

- (i)

- Aggregation and summarization: Event data can be aggregated and summarized over time to extract trends, patterns, and statistics [4,14,72]. This is useful for generating reports and identifying long-term changes;

- (j)

- Real-time monitoring: Event logs are frequently used for real-time monitoring and alerting. Systems can be configured to trigger alerts or notifications based on specific event conditions [30,81].

- C

- Image data: Image data consist of visual information in the form of images or pictures, possessing unique characteristics that distinguish them from other types of data. These characteristics are essential to consider when working with image data in various applications, including computer vision, image processing, machine learning, and multimedia analysis. Some of the challenging characteristics include image quality [30], resolution, and dimension. The basic characteristics of image data are as follows:

- (a)

- Visual representation: Image data are primarily represented visually as two-dimensional arrays of pixels. Each pixel contains color information and contributes to the overall appearance of the image;

- (b)

- Pixel depth: This is often referred to as bit depth or color depth, i.e., the number of bits used to represent each color of pixel information. Common depths include 8-bit (256 colors), 24-bit (16.7 million colors), and 32-bit (including transparency);

- (c)

- Image dimensions: Image data are characterized by their width and height, which define the dimensions of the image in pixels. The aspect ratio, or the ratio of width to height, affects the appearance of an image;

- (d)

- Image formats: Images are stored in specific file formats, such as JPEG (joint photographic experts group), PNG (portable network graphics), BMP (bitmap image file), TIFF (tag image file format), and others. Each format has its own compression, quality, and compatibility characteristics;

- (e)

- Metadata: Images can contain metadata, including information about the image, such as creation date, author, camera settings, and geolocation data;

- (f)

- Color histograms: Image data can be represented by color histograms, which summarize the distribution of colors within an image. Histograms are useful for image analysis and retrieval;

- (g)

- Data size: High-resolution images and image datasets can be large in terms of file size and memory requirements, requiring efficient storage and processing solutions.

Image data can be processed through a wide range of techniques, including filtering [14], resizing, rotation, cropping, enhancement, flattening [424], noise separation [427], and transformation, to extract information or improve image quality.Regarding image features, image data often involve extracting features or patterns, such as edges, textures, shapes, objects, for tasks such as object detection, recognition, and classification [131,204,265,360,424,426], e.g., detecting typical defects such as cracks, stains, or scratches in mechanic assets [459]. Some types of commonly used image features include moment invariants, gray statistical characteristics, texture features, and the differential box-counting fractal dimension [254]. Hence, the key features for processing image data are as follows:- (a)

- Resolution: Images can have different resolutions, which determine the level of detail in the image. High-resolution images contain more pixels and finer details, while low-resolution images have fewer pixels and coarser details [459]. In some research studies, images containing a large number of pixels are known as superpixel images [427];

- (b)

- Color spaces: Images can be represented in various color spaces, such as RGB (red, green, blue) [186,362], grayscale (single-channel) [459], CMYK (cyan, magenta, yellow, key), and others;

- (c)

- Image sensors: Image data originated from image sensors, such as digital cameras, scanners, thermal cameras [5,7,30,204,265,360,473], and satellite imaging devices [453].

The number of mentions for each data type in the research studies is as follows: time series data appear 572 times, event data with timestamps are mentioned 107 times, and image data are referenced 66 times. The indicated number of mentions includes the referenced research studies of reviews, surveys, taxonomies, and specific studies, which is why it exceeds 534—the number of research works of the core repository described in Section 2.

4.1.3. Data Acquisition, Analysis Domain, and Source Categorization

At the core of any analytical effort is the process of data acquisition, which provides the basis for in-depth analysis and decision support. Understanding the intricacies and methodologies surrounding data acquisition is fundamental because it sets the stage for comprehensive and meaningful analyses across diverse domains.

- A

- Data acquisition: There are two main methods of acquisition: embedded or connected sensor, and external sensor. The former refers to a sensor installed inside an asset, i.e., directly connected to the asset, normally included by default for the manufacturer or by request of a customer, measuring voltage, current, vibration, and speed, among other parameters. On the other hand, the latter refers to a sensor installed outside an asset, which is usually performed in the plant to meet engineering or regulatory requirements, including sensors to collect the environment temperature and humidity of a room, the acoustic signal of machinery, or a thermographic camera to verify the working temperature of assets.In the repository under consideration, embedded or connected sensors were mentioned 580 times, making them the most commonly employed sensor type. This widespread use of embedded or connected sensors highlights their importance in monitoring and data collection, particularly in integrated systems where sensors are built into or connected to the equipment. On the other hand, external sensors were mentioned 165 times. Although less prevalent, external sensors still play a crucial role in scenarios where flexibility, retrofitting, or non-intrusive monitoring is required. The significant disparity in usage between embedded or connected and external sensors underscores the preference for integrated solutions, while also acknowledging the critical role of external sensors in specific applications. The reported number of mentions includes the sum of different sensors referenced in research studies of reviews, surveys, taxonomies, and specific studies; for that reason, it excess the number of research works of the core repository.In the analyzed repository, individual sensors were used in 477 research studies, making them the predominant choice for sensor-based data collection. This preference for individual sensors suggests a focus on simpler, more targeted monitoring setups, where a single data stream is sufficient for analysis. However, multiple sensors were utilized in 268 research studies, indicating a significant number of cases where more complex, multi-dimensional data collection was necessary. The use of multiple sensors reflects the growing need for comprehensive monitoring in systems where interactions between different parameters are critical. The difference in the number of studies highlights the balance between simplicity and complexity in sensor deployment, with researchers choosing one or the other depending on the specific requirements of their studies.

- B

- Domain of analysis: For time series data, analyses can be conducted in the time, frequency, and time-frequency domains. The analysis of the repository reveals that time-frequency domain techniques were the most frequently cited, with 114 studies specifically mentioning methods such as wavelet transform and statistical feature extraction. This prominence reflects the importance of capturing both time and frequency information simultaneously, which is crucial for analyzing complex, non-stationary signals. In comparison, 41 studies focused on the frequency domain, often using techniques such as fast Fourier transform (FFT) to analyze the spectral characteristics of the data. These methods are particularly valuable for identifying periodicities and other frequency-based patterns. Finally, 24 studies were conducted in the time domain, where the focus is on analyzing data as they vary over time, without transforming it into other domains. The distribution of these references underscores the variety of analytical approaches employed in research, with a clear emphasis on techniques that can handle more complex, multi-dimensional data.

- C

- Categorization of data by source: The interest in categorizing the data source is to determine whether the dataset is from real-world applications or simulations. A substantial portion of the research, 354 studies, is based on simulated data, encompassing laboratory experiments, simulated public databases, and software-based simulators. This reliance on synthetic data highlights the controlled environments researchers often use to test and validate their models. However, there is a notable gap in the use of real-world data, with only 95 studies utilizing such data, indicating a potential disconnection between theoretical research and practical, real-world applications. The remaining studies in the repository do not explicitly specify their data sources, further emphasizing the need for more transparency and more works on real-world data to ensure the applicability and robustness of the findings.

- D

- Working parameters of assets: Regarding the working parameters data of assets included in the considered research studies for data mining (DM) applications, the most frequently mentioned are as follows: vibration (188 references), speed (65 references), temperature (62 references), mechanical power (53 references), and text data (27 references). Other working parameters with fewer mentions include: acoustic, voltage, current, pressure, sound, acceleration, torque, magnetic field, electrical power, irradiation, displacement, gas concentration, and humidity.

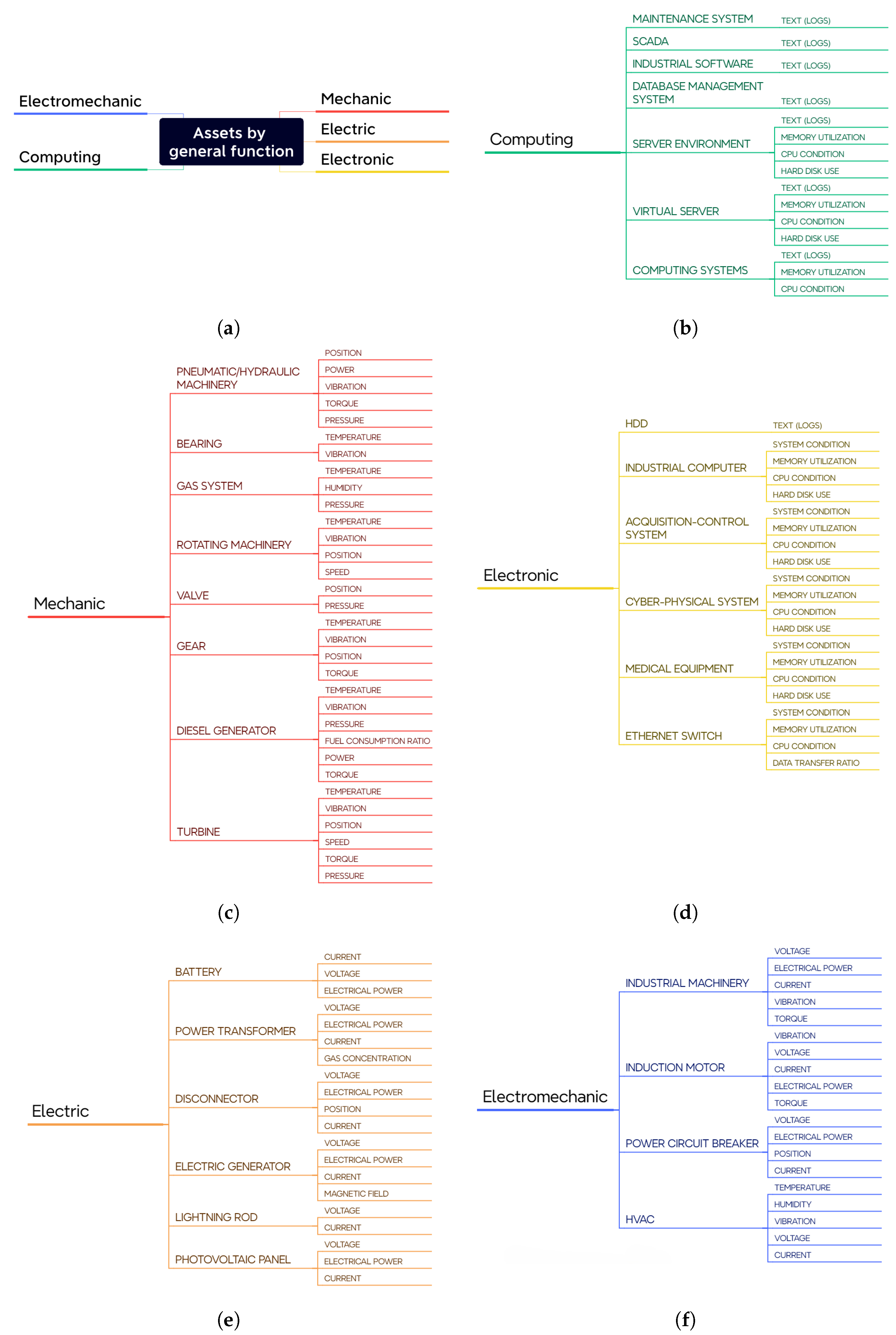

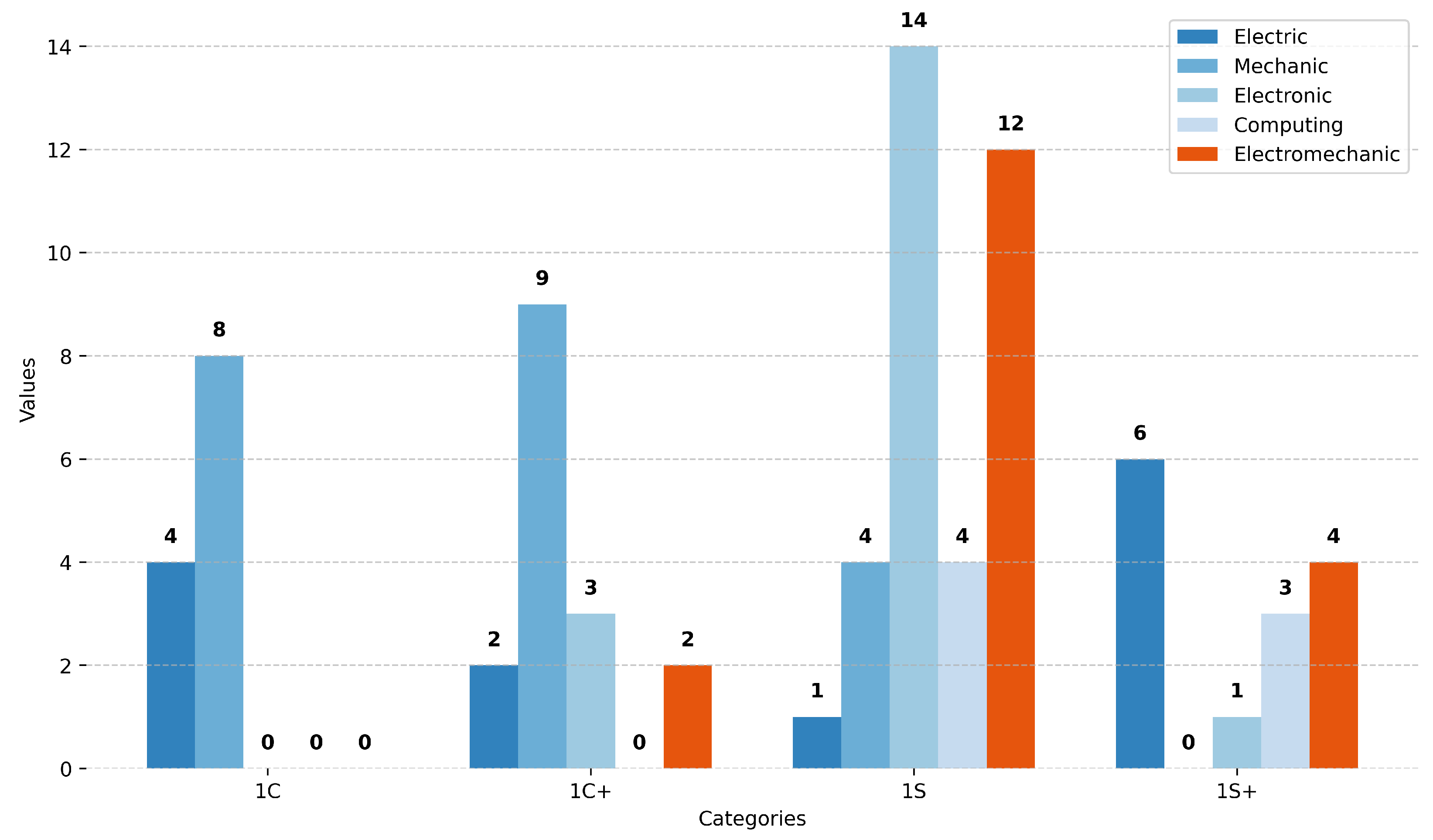

4.2. Types of Assets Considered for Data Mining

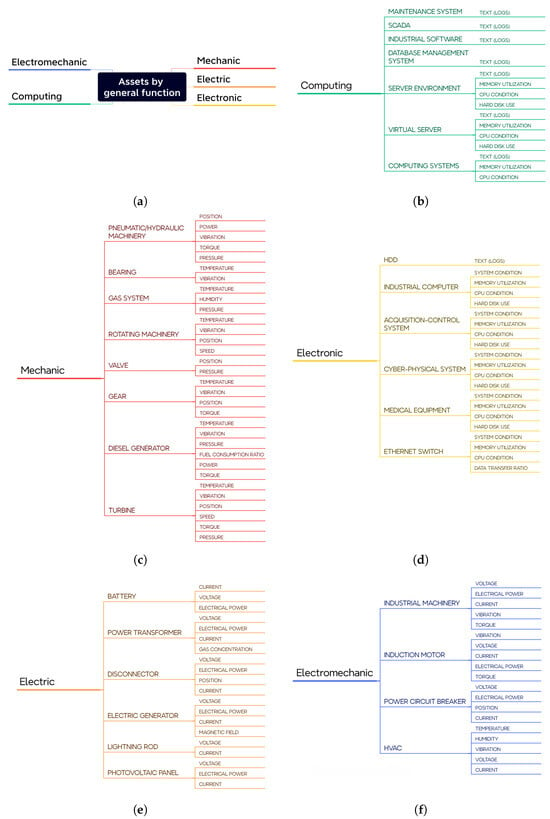

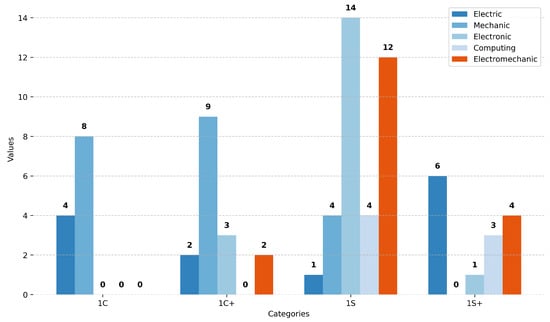

The revision of research studies with the application of PdM or CBM models allowed the identification of five types of assets: mechanic, electromechanic, electric, electronic, and computing.

The total number of unique components or systems mentioned in research studies categorized by asset type is as follows: mechanic (21 different assets), electronic (19 different assets), electromechanic (18 different assets), electric (13 different assets), and computing (7 different assets).

The mechanic category exhibits the highest diversity of assets, while the computing category displays the lowest diversity. Across the mechanic, electronic, and electromechanic categories, the diversity of assets appears to be relatively similar.

Regarding the cumulative mentions of components or systems within defined asset categories, the overall counts are: mechanic (1014), electromechanic (441), electronic (62), electric (42), and computing (25). The indicated cumulative mentions consider the sum of assets of the same category and they could share the same reference, i.e., for mechanic assets of the next subsubsection, the detailed assets (machine, aeroengine, bearing, rotating machinery, gears) total 835 mentions. All these assets are also mentioned in the paper [57], showing that several assets are mentioned in the same reference, which explains why the number of citations exceeds the total number of papers.

4.2.1. Mechanic Assets

Mechanic assets consist of physical components, such as gears, motors, engines, and moving parts. These components are designed to perform specific functions within a mechanical system. These kinds of assets often require regular maintenance to ensure they operate efficiently and safely. This maintenance can include tasks such as lubrication, inspection, repair, and replacement of worn or damaged parts. They are designed to perform mechanical functions, such as generating mechanical power, transmitting motion, or performing a specific task. They are commonly used in various industries, including manufacturing and transportation, to carry out tasks that involve the conversion of mechanical energy [97,360,461,468,474,475].

According to the number of mentions related to mechanic assets, the top five terms with many studies related to industrial maintenance are listed below:

- A

- Machine: This includes various equipment used for manufacturing, processing, or performing specific tasks. There are 328 mentions of this term in the research studies [1,2,3,4,5,6,7,8,9,10,11,12,14,16,17,21,23,24,27,31,33,34,35,36,37,38,41,42,44,47,51,53,54,55,56,57,58,59,60,61,62,66,68,71,72,73,75,78,79,80,81,82,83,84,85,86,87,88,89,90,91,93,95,96,98,99,100,102,103,104,105,106,107,108,109,112,113,114,115,116,119,120,121,123,125,130,131,137,138,148,149,151,158,159,160,162,163,165,166,167,168,170,171,175,176,177,179,181,183,184,185,186,188,189,190,191,192,193,195,197,199,200,201,202,203,205,206,207,208,210,211,217,218,219,220,221,222,223,224,225,228,232,233,235,237,239,240,241,243,244,245,246,247,248,249,250,251,252,253,254,255,257,258,259,260,262,263,266,267,270,272,273,275,276,278,281,285,286,294,296,297,298,299,300,301,302,303,304,305,306,307,308,309,310,311,312,313,314,315,316,317,318,319,320,321,322,323,324,325,326,327,328,329,330,337,338,341,344,345,347,348,349,350,357,360,361,363,365,366,367,369,371,372,373,378,379,380,381,382,383,384,385,386,389,390,391,392,394,395,398,399,400,401,402,403,405,406,407,408,411,412,414,417,418,420,421,422,423,428,429,430,431,432,436,437,438,439,442,443,445,446,447,451,452,454,457,461,463,465,466,469,472,473,474,475,476,477,478,479,480,481,482,483,484,485,486,487,488,489,490,491,492,493,494,495,496,497,498,499,500,501,502,503,504,505];

- B

- Aeroengine: Also known as an aircraft engine, this component generates thrust to propel an aircraft forward. There are 155 mentions of this term in the research studies [2,3,5,7,9,12,16,22,24,25,26,28,29,31,32,34,38,42,45,48,53,57,67,68,71,76,78,82,83,85,91,95,99,106,108,109,110,114,115,116,122,131,137,144,147,152,154,156,162,164,165,166,170,171,174,178,180,181,184,185,197,204,213,214,215,216,221,225,226,230,232,233,235,237,238,239,241,243,245,247,252,254,255,260,262,266,275,286,287,288,289,290,291,292,293,294,297,306,314,325,327,328,336,342,347,348,355,356,357,362,366,367,368,369,370,371,378,382,390,391,395,400,403,405,408,409,410,412,413,419,421,425,433,440,444,454,459,460,471,474,475,477,479,482,498,501,503,506,507,508,509,510,511,512];

- C

- Bearing: These are crucial components found in various machinery and equipment. They facilitate rotational or linear movement by reducing friction between moving parts. There are 151 mentions of this term in the research studies [2,3,6,7,12,44,45,51,53,55,57,58,75,89,92,93,99,106,119,120,141,142,151,153,155,157,160,162,163,171,172,173,174,175,177,183,184,186,188,191,199,200,202,205,207,208,218,219,220,232,233,235,237,240,241,243,244,246,249,250,252,256,257,258,259,260,261,262,263,264,266,269,274,279,280,281,282,283,284,302,306,307,311,312,313,315,316,317,318,321,326,329,330,331,332,333,334,335,336,339,340,341,342,346,348,349,351,352,357,360,363,365,367,369,373,374,378,383,384,386,388,392,393,400,404,410,418,420,430,437,439,441,443,445,446,461,462,463,464,473,481,484,485,493,508,510,512,513,514,515];

- D

- Rotating machinery: This term encompasses various mechanical equipment such as pumps, turbines, compressors, and motors that involve rotating components. There are 103 mentions of this term in the research studies [2,3,6,7,37,51,53,55,57,58,63,86,87,93,119,120,163,165,168,171,175,177,181,185,186,188,189,190,191,192,199,200,206,208,213,219,220,227,233,235,243,246,247,248,250,251,252,257,258,259,260,262,263,266,267,270,272,276,278,281,294,302,306,310,314,320,321,328,341,348,355,359,360,363,365,366,367,372,379,386,389,392,418,420,422,438,441,443,445,446,461,465,473,480,483,486,488,489,493,495,499,516];

- E

- Gears: These are mechanical components that transmit torque and motion between shafts in machinery. There are 84 mentions of this term in the research studies [2,3,6,7,12,35,41,44,45,57,61,89,90,103,106,137,141,142,150,158,174,176,177,183,186,192,197,198,200,209,210,220,221,238,239,243,245,253,258,259,261,262,263,266,268,270,272,273,280,285,301,303,304,319,320,321,337,338,342,351,354,359,361,370,375,376,377,385,416,432,441,442,467,472,492,494,496,497,499,517,518,519,520].

The following mechanic assets are also mentioned in the repository: gearbox, transmission line, gas circulation unit/system, linear motion guides, pump, planetary gearbox, valve, turbine blade, air compressor, railroad track, hydraulic brake, ball screw, exhaust fan, transmission boxes, cooling radiator, and crankshafts.

4.2.2. Electromechanic Assets

Electromechanic assets incorporate both electric and mechanic elements in their design. These assets often include motors, sensors, switches, relays, and other electrical components alongside mechanical parts such as gears, levers, or actuators [192]. This combination allows them to convert electrical energy into mechanical motion or vice versa. Electromechanic assets are typically controlled and operated by electrical systems. They can be automated, monitored, and controlled using electrical signals, often through a programmable logic controller (PLC) or a microcontroller.

According to the number of mentions related to electromechanic assets, the top five terms with many studies related to industrial maintenance are listed below:

- A

- Industrial machinery: This term covers a wide range of machinery, including mechanical and electrical components used in industrial processes, manufacturing, and production. There are 92 mentions of this term in the research studies [2,3,4,5,7,10,13,14,15,16,17,18,23,31,36,41,42,45,47,51,52,53,54,55,56,57,58,60,61,62,63,66,67,71,72,75,76,78,86,87,89,96,99,103,109,115,122,132,133,137,141,159,162,168,176,180,182,186,188,193,206,218,224,227,228,232,233,234,236,257,263,264,272,319,323,352,360,361,367,388,390,396,397,401,408,414,446,459,460,471,479,485];

- B

- Electromechanical equipment: These are devices or systems that have both electrical and mechanical components, such as motors, actuators, and relays. There are 80 mentions of this term in the research studies [1,3,4,6,7,10,14,16,23,27,35,36,37,38,41,44,50,51,53,55,56,59,61,67,70,72,73,74,75,77,79,85,87,89,90,93,97,98,100,104,107,109,114,115,116,124,130,131,132,143,147,152,163,166,181,193,197,204,229,231,236,259,260,263,341,342,349,373,387,393,394,402,414,425,452,473,499,502,505];

- C

- Industrial tool: These include various equipment and devices, with both electrical and mechanical components, used for manufacturing, construction, or repair purposes in industrial settings. There are 76 mentions of this term in the research studies [3,4,6,7,10,16,17,18,28,30,34,41,42,45,47,56,57,59,61,63,66,70,71,72,73,75,78,80,81,87,92,93,94,96,100,113,116,122,124,131,143,144,148,158,161,170,172,182,187,197,233,239,249,253,273,274,286,298,322,341,350,351,352,381,391,397,398,423,425,459,468,475,483,509,517];

- D

- Induction motor: These are commonly used in industrial applications to drive machinery and equipment, having both electrical and mechanical parts. There are 37 mentions of this term in the research studies [3,6,55,60,96,111,179,192,207,211,217,224,229,286,300,322,323,324,325,326,345,350,368,384,386,387,428,429,433,434,438,439,469,486,487,491,514];

- E

- Wind turbine: These are structures equipped with large blades that convert wind energy into electrical power. They have both electrical and mechanical components. There are 27 mentions of this term in the research studies [1,3,6,7,12,53,56,63,67,81,106,110,169,197,221,226,237,272,301,309,334,354,357,358,370,509,521].

The following electromechanic assets are also mentioned in the repository: rotor, hydraulic generator unit, power system, refrigerant flow system, HVAC (heating, ventilation and air conditioning), nuclear power machinery, scooter, power substation, elevator door, high-voltage circuit breaker, washing machine, and circuit breaker.

4.2.3. Electric Assets

Electric assets are equipment, devices, or systems that primarily involve the use or generation of electrical energy. These assets are designed to perform functions that rely on the manipulation or control of electrical energy. They are used for purposes such as power generation, distribution, and control [60].

Based on the number of mentions, the top five electric assets most frequently referenced in the repository are as follows:

- A

- Power transformer: These are crucial components in electrical systems used for voltage regulation and power distribution. There are six mentions of this term in the research studies [2,46,55,67,265,507];

- B

- Photovoltaic panel: These are devices that convert sunlight into electricity. There are seven mentions of this term in the research studies [7,30,53,67,197,203,471];

- C

- Power switch: These are electrical devices used to control the flow of electricity in circuits. There are five mentions of this term in the research studies [31,55,73,100,230];

- D