Using Plasma Electrolytic Polishing for Post-Processing of Additively Manufactured Ti6Al4V Alloy Products

Abstract

1. Introduction

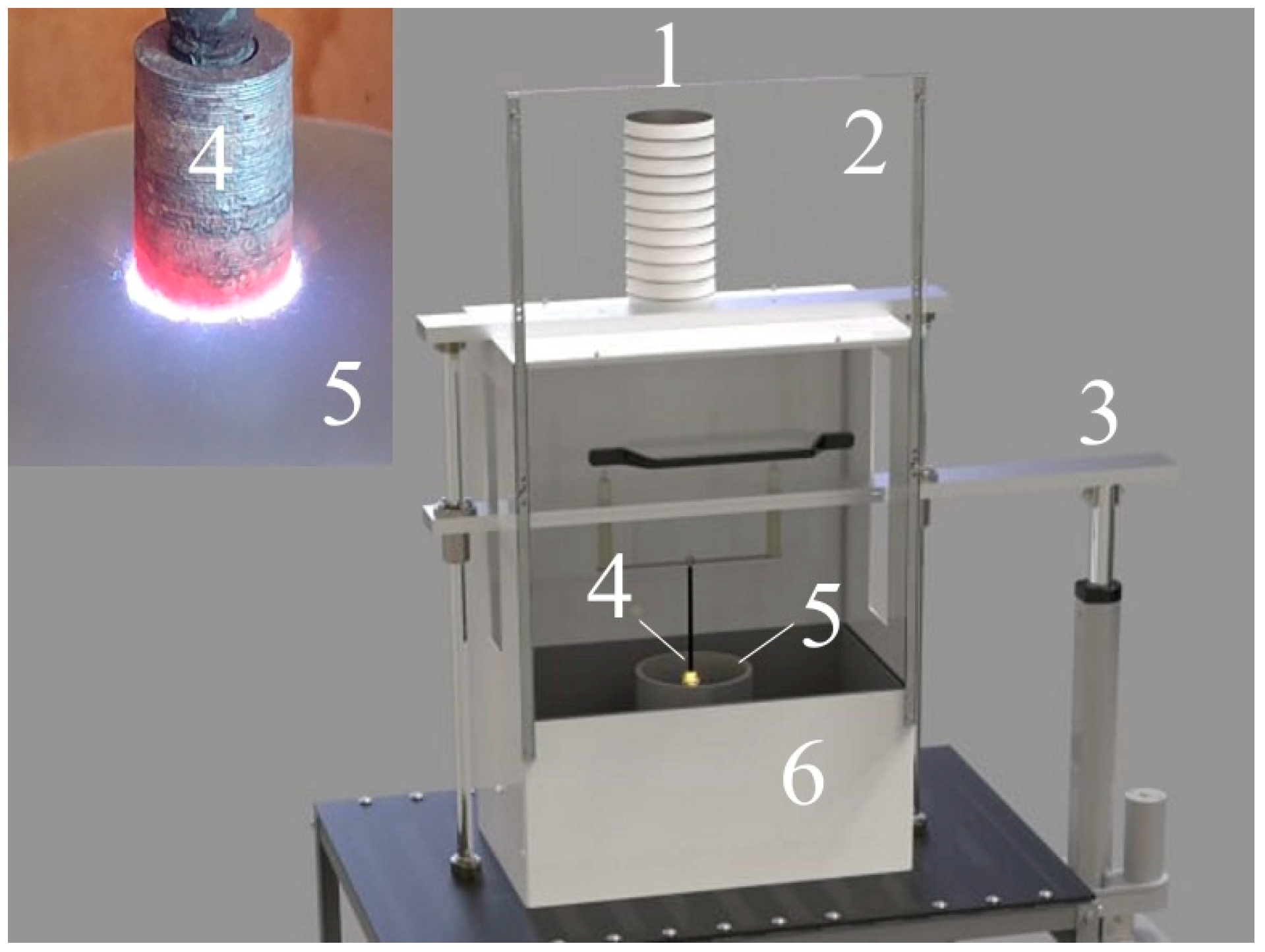

2. Materials and Methods

2.1. Materials

2.2. Processing

2.3. Sample Testing

3. Results

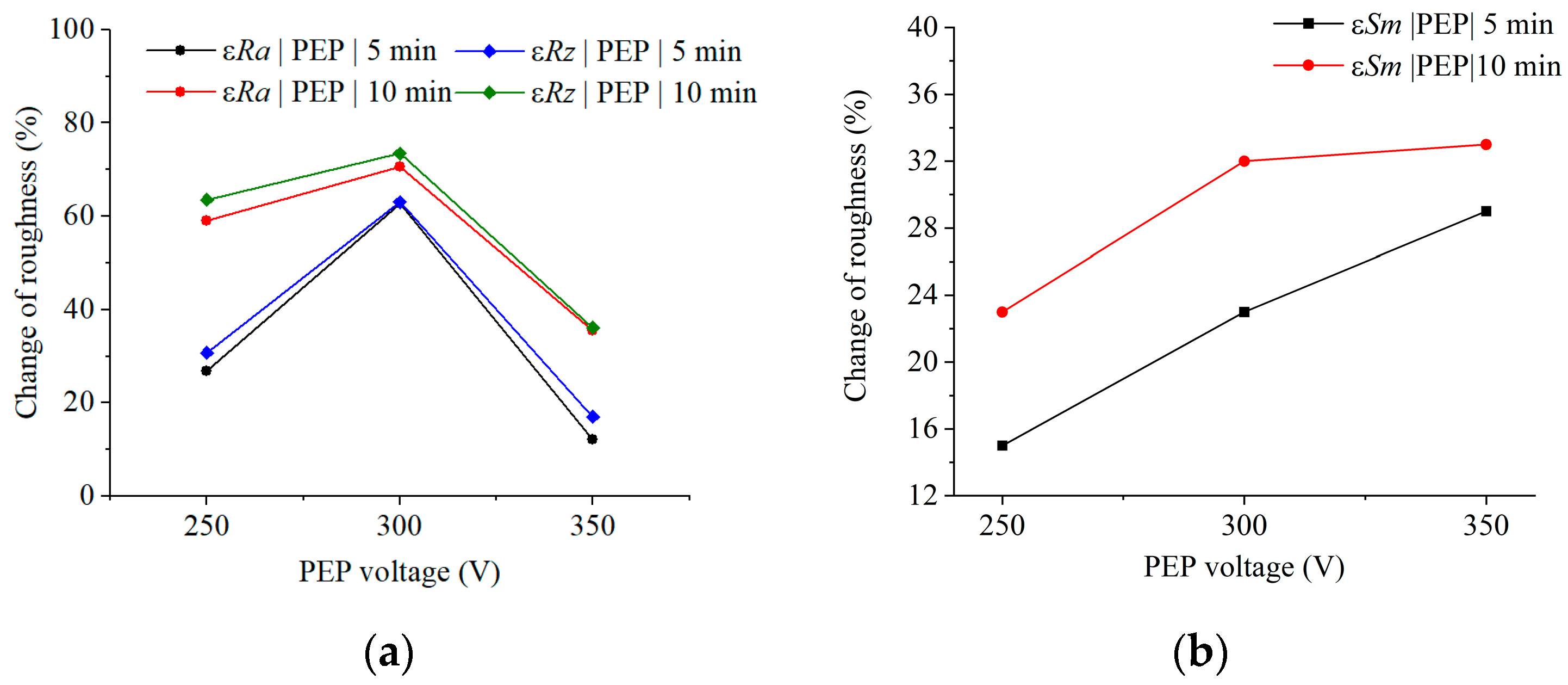

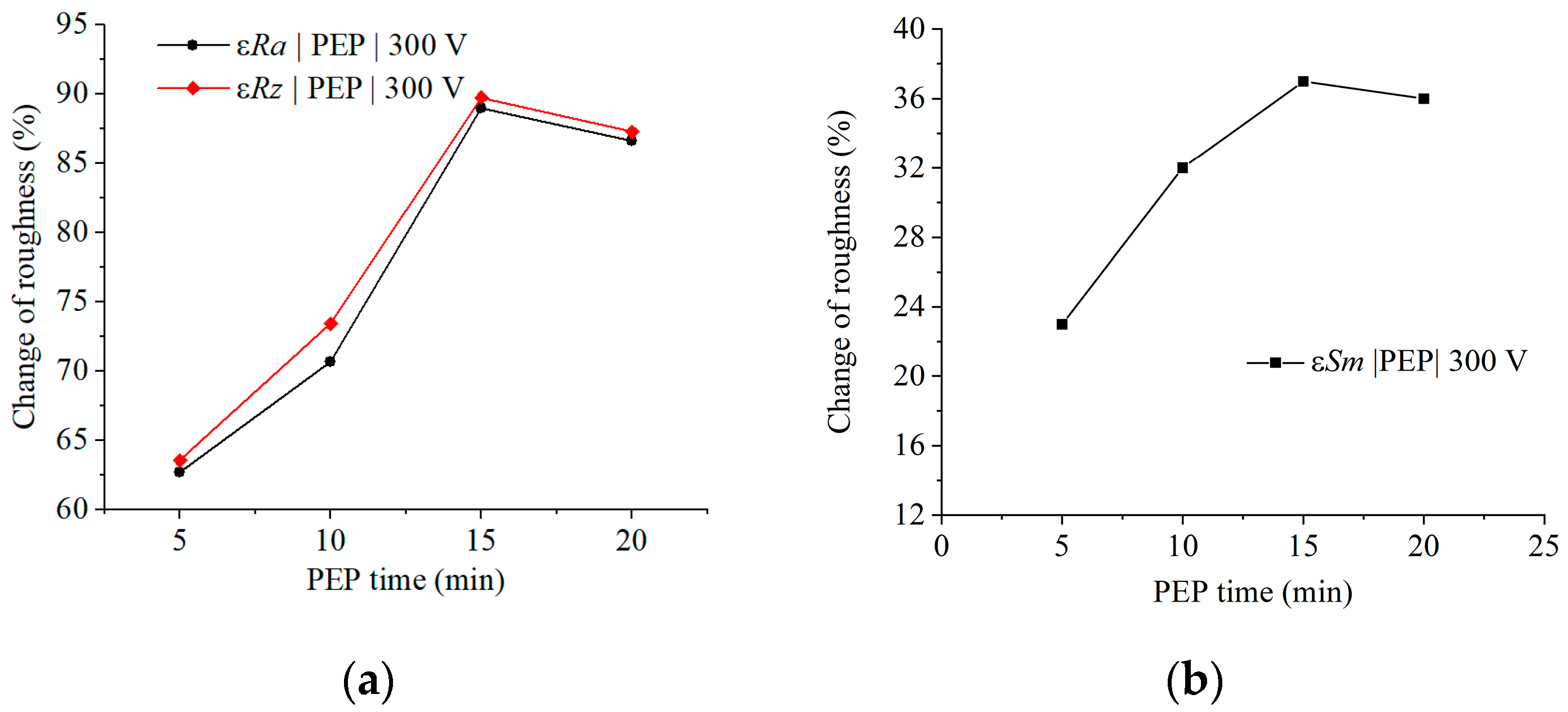

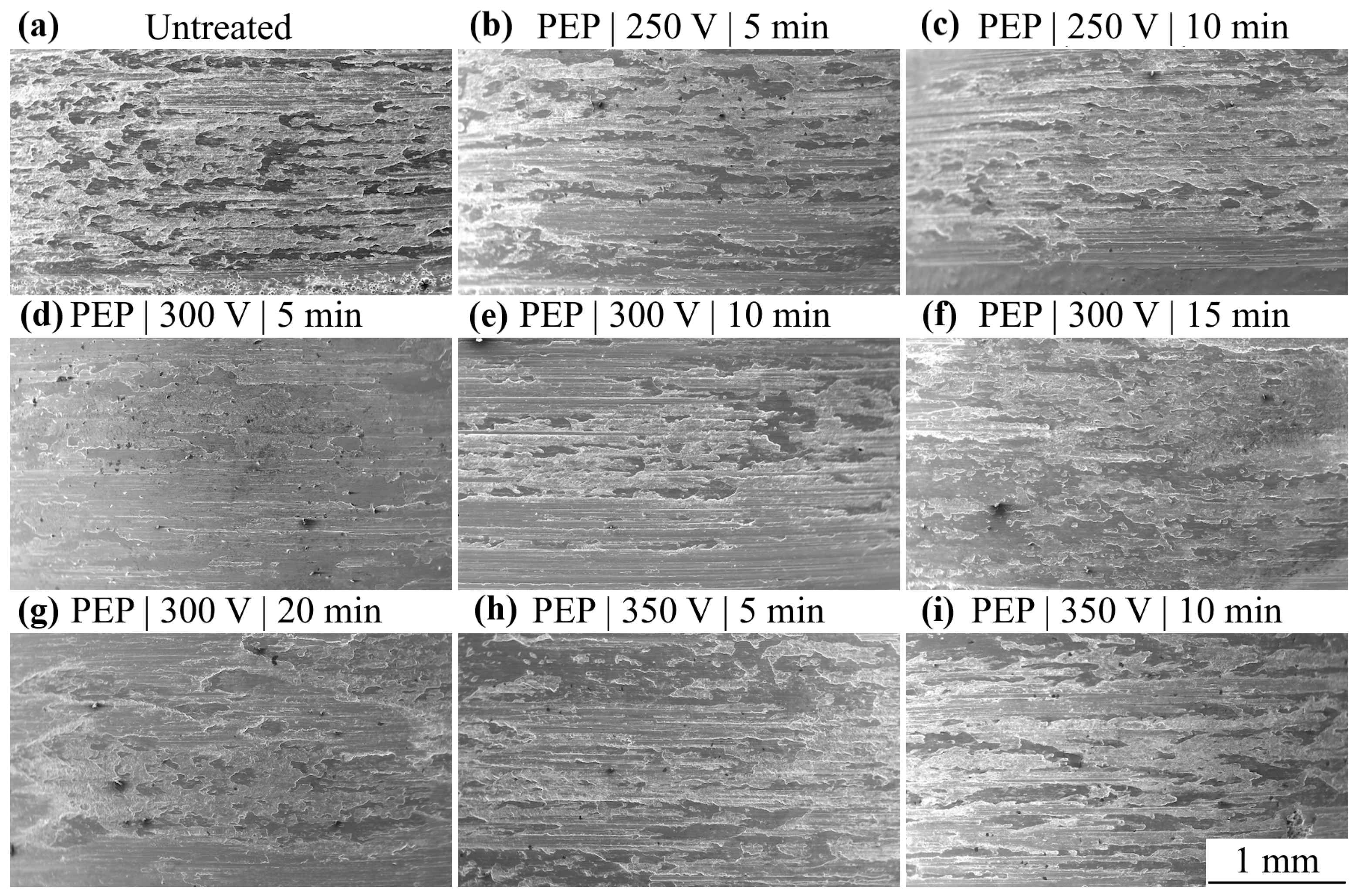

3.1. Surface Morphology and Roughness

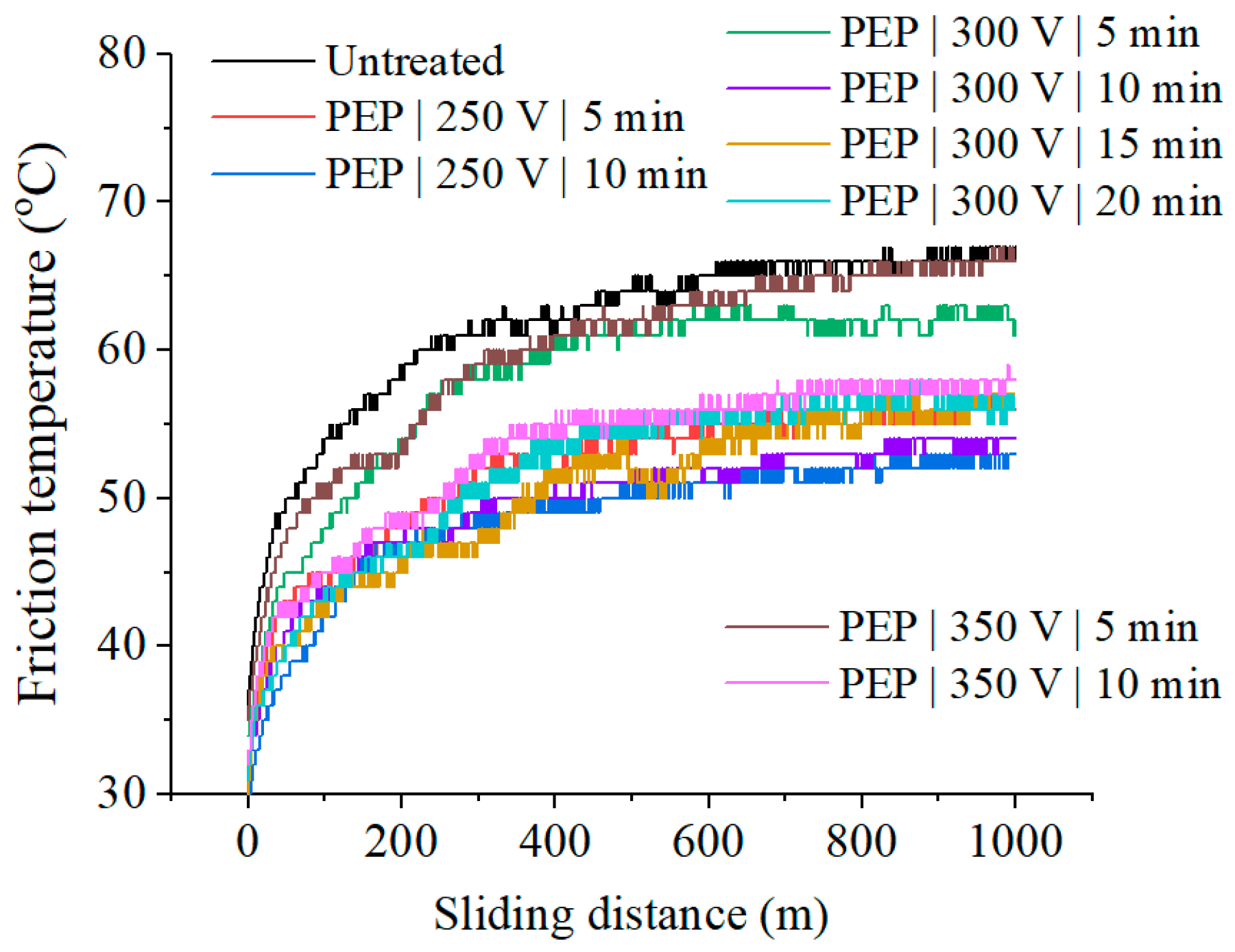

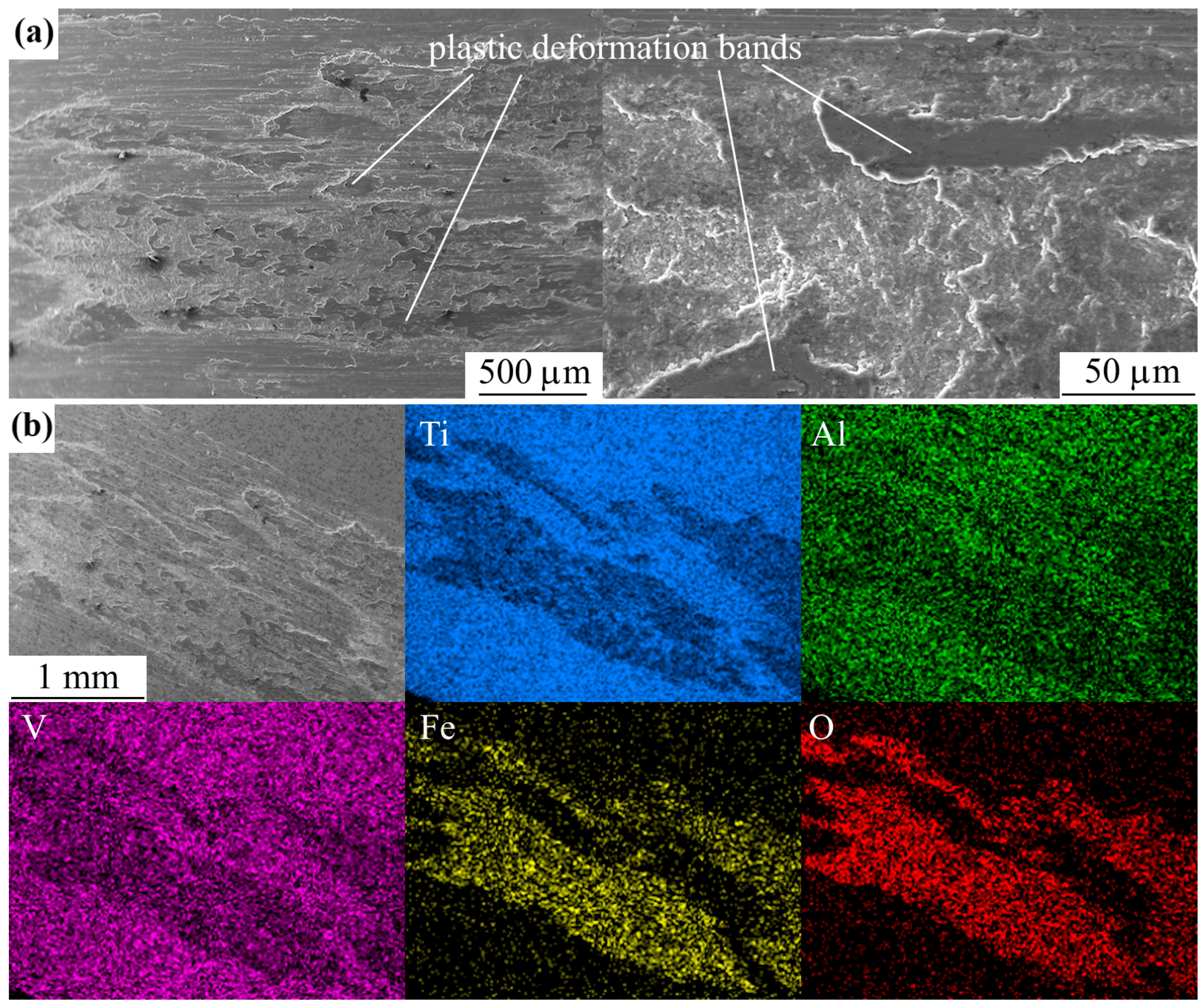

3.2. Tribological Testing

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SLM | Selective laser melting |

| PEP | Plasma electrolytic polishing |

| SEM | Scanning electron microscope |

| EDX | Energy-dispersive X-ray |

References

- Kanishka, K.; Acherjee, B. A systematic review of additive manufacturing-based remanufacturing techniques for component repair and restoration. J. Manuf. Process. 2023, 89, 220–283. [Google Scholar] [CrossRef]

- Leino, M.; Pekkarinen, J.; Soukka, R. The Role of Laser Additive Manufacturing Methods of Metals in Repair, Refurbishment and Remanufacturing—Enabling Circular Economy. Phys. Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef]

- Rahito Wahab, D.A.; Azman, A.H. Additive manufacturing for repair and restoration in remanufacturing: An overview from object design and systems perspectives. Processes 2019, 7, 802. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar] [CrossRef]

- Shrestha, S.; Panakarajupally, R.P.; Kannan, M.; Morscher, G.; Gyekenyesi, A.L.; Scott-Emuakpor, O.E. Analysis of microstructure and mechanical properties of additive repaired Ti–6Al–4V by Direct Energy Deposition. Mater. Sci. Eng. A 2021, 806, 140604. [Google Scholar] [CrossRef]

- Ochonogor, O.F.; Akinlabi, E.T.; Nyembwe, D. A review on the effect of creep and microstructural change under elevated temperature of Ti6Al4V alloy for Turbine engine Application. Mater. Today Proc. 2017, 4 Pt A, 250–256. [Google Scholar] [CrossRef]

- Rack, H.J.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. C 2006, 26, 1269–1277. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Samuel, M.P.; Mishra, A.K.; Mishra, R.K. Additive Manufacturing of Ti-6Al-4V Aero Engine Parts: Qualification for Reliability. J. Fail. Anal. Prev. 2018, 18, 136–144. [Google Scholar] [CrossRef]

- Li, C.; Pisignano, D.; Zhao, Y.; Xue, J. Advances in Medical Applications of Additive Manufacturing. Engineering 2020, 6, 1222–1231. [Google Scholar] [CrossRef]

- Galati, M.; Minetola, P.; Rizza, G. Surface Roughness Characterisation and Analysis of the Electron Beam Melting (EBM) Process. Materials 2019, 12, 2211. [Google Scholar] [CrossRef]

- Wang, P.; Sin, W.; Nai, M.; Wei, J. Effects of processing parameters on surface roughness of additive manufactured Ti-6Al-4V via electron beam melting. Materials 2017, 10, 1121. [Google Scholar] [CrossRef]

- Choudhary, S.; Gaur, V. Study of additively manufactured Inconel 718 with lanthanum zirconate coating. J. Alloys Comp. 2025, 1021, 179710. [Google Scholar] [CrossRef]

- Guo, C.; Wang, J.; Lu, H.; Wang, Y.; Bai, J.; Li, G.; Yin, Y.; Yao, L.; Zhu, Q.; Lu, J. Enhanced oxidation resistance of additively manufactured Inconel 718 superalloy by surface mechanical attrition treatment. Corros. Sci. 2025, 246, 112719. [Google Scholar] [CrossRef]

- Lv, J.; Luo, K.; Lu, H.; Wang, Z.; Liu, J.; Lu, J. Achieving high strength and ductility in selective laser melting Ti-6Al-4V alloy by laser shock peening. J. Alloys Compd. 2022, 899, 163335. [Google Scholar] [CrossRef]

- Yeo, I.; Bae, S.; Amanov, A.; Jeong, S. Effect of laser shock peening on properties of heat-treated Ti–6Al–4V manufactured by laser powder bed fusion. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 1137–1150. [Google Scholar] [CrossRef]

- Lu, H.; Wang, Z.; Cai, J.; Xu, X.; Luo, K.; Wu, L.; Lu, J. Effects of laser shock peening on the hot corrosion behaviour of the selective laser melted Ti6Al4V titanium alloy. Corros. Sci. 2021, 188, 109558. [Google Scholar] [CrossRef]

- Zhou, C.; Yan, X.; Liu, D.; Xu, X.; Cui, J.; Li, M.; Yuan, C.; Li, H.; Liang, Y. Simultaneously achieving strength-ductility in additive-manufactured Ti6Al4V alloy via ultrasonic surface rolling process. Mat. Sci. Eng. A 2025, 920, 147555. [Google Scholar] [CrossRef]

- Tyagi, P.; Goulet, T.; Riso, C.; Stephenson, R.; Chuenprateep, N.; Schlitzer, J.; Benton, C.; Garcia-Moreno, F. Reducing the roughness of internal surface of an additive manufacturing produced 316 steel component by chempolishing and electropolishing. Addit. Manuf. 2019, 25, 32–38. [Google Scholar] [CrossRef]

- Cao, W.; Ghiotti, A.; Bruschi, S. Enhancing the Surface Quality of Additively Manufactured 316 Stainless Steel Revolving Parts through Electrochemical Polishing. Procedia CIRP 2025, 133, 615–620. [Google Scholar] [CrossRef]

- Ferchow, J.; Hofmann, U.; Meboldt, M. Enabling Electropolishing of Complex Selective Laser Melting Structures. Procedia CIRP 2020, 91, 472–477. [Google Scholar] [CrossRef]

- Kiran, K.U.V.; Mahey, V.; Kimbrel, B.; Roy, S. Surface finish enhancement of additively manufactured austenitic steel via novel sustainable electro mechano-chemical polishing. Mater. Today Commun. 2025, 42, 111434. [Google Scholar] [CrossRef]

- Boban, J.; Ahmed, A. Improving the surface integrity and mechanical properties of additive manufactured stainless steel components by wire electrical discharge polishing. J. Mater. Process. Technol. 2021, 291, 117013. [Google Scholar] [CrossRef]

- Yerokhin, A.L.; Nie, X.; Leyland, A.; Matthews, A.; Dowey, S. Plasma electrolysis for surface engineering. Surf. Coat. Technol. 1999, 122, 73. [Google Scholar] [CrossRef]

- Bayatanova, L.; Rakhadilov, B.; Kurbanbekov, S.; Skakov, D.; Popova, N. Fine structure of low-carbon steel after electrolytic plasma treatment. Mater. Test. 2021, 63, 842–847. [Google Scholar] [CrossRef]

- Belkin, P.N.; Dyakov, I.G.; Zhirov, A.V.; Kusmanov, S.A.; Mukhacheva, T.L. Effect of compositions of active electrolytes on properties of anodic carburization. Prot. Met. Phys. Chem. Surf. 2010, 46, 715–720. [Google Scholar] [CrossRef]

- Chongyang, N.; Tianlin, Z.; Yue, X.; Lixia, Y.; Guixiang, W. Study on preparation and friction characteristics of steel 1045 modified layer based on plasma electrolytic carbonitriding. Mater. Today Commun. 2022, 33, 104518. [Google Scholar] [CrossRef]

- Mukhacheva, T.L.; Belkin, P.N.; Dyakov, I.G.; Kusmanov, S.A. Wear mechanism of medium carbon steel after its plasma electrolytic nitrocarburising. Wear 2020, 462–463, 203516. [Google Scholar] [CrossRef]

- Kang, Q.-F.; Yang, W.-M.; Wei, K.-X.; Wang, D.-D.; Liu, X.-L.; Hu, J. Development of a Novel Plasma Aluminum-nitriding Methodology and Its Effect on the Microstructure and Properties for 42CrMo Steel. Surf. Technol. 2023, 52, 394–400. [Google Scholar] [CrossRef]

- Pérez, H.; Vargas, G.; Magdaleno, C.; Silva, R. Oxy-Nitriding AISI 304 Stainless Steel by Plasma Electrolytic Surface Saturation to Increase Wear Resistance. Metals 2023, 13, 309. [Google Scholar] [CrossRef]

- Aliofkhazraei, M.; Macdonald, D.D.; Matykina, E.; Parfenov, E.V.; Egorkin, V.S.; Curran, J.A.; Troughton, S.C.; Sinebryukhov, S.L.; Gnedenkov, S.V.; Lampke, T.; et al. Review of plasma electrolytic oxidation of titanium substrates: Mechanism, properties, applications and limitations. Appl. Surf. Sci. Adv. 2021, 5, 100121. [Google Scholar] [CrossRef]

- Apelfeld, A.; Grigoriev, S.; Krit, B.; Ludin, V.; Suminov, I.; Chudinov, D. Improving the stability of the coating properties for group plasma electrolytic oxidation. Manuf. Lett. 2022, 33, 54. [Google Scholar] [CrossRef]

- Jin, S.; Ma, X.; Wu, R.; Wang, G.; Zhang, J.; Krit, B.; Betsofen, S.; Liu, B. Advances in micro-arc oxidation coatings on Mg-Li alloys. Appl. Surf. Sci. Adv. 2022, 8, 100219. [Google Scholar] [CrossRef]

- Maltanava, H.; Stojadinovic, S.; Vasilic, R.; Karpushenkov, S.; Belko, N.; Samtsov, M.; Poznyak, S. Photoluminescent Coatings on Zinc Alloy Prepared by Plasma Electrolytic Oxidation in Aluminate Electrolyte. Coatings 2023, 13, 848. [Google Scholar] [CrossRef]

- Kim, S.-P.; Kaseem, M.; Choe, H.-C. Plasma electrolytic oxidation of Ti-25Nb-xTa alloys in solution containing Ca and P ions. Surf. Coat. Technol. 2020, 395, 125916. [Google Scholar] [CrossRef]

- Xiang, Y.; Sun, H.; Yang, D.; Ji, G.; Sun, L.; Duan, H.; Wang, J. Material removal model for describing the plasma discharge effect in magnetic-electrolytic plasma polishing. Int. J. Adv. Manuf. Technol. 2021, 131, 5023. [Google Scholar] [CrossRef]

- Danilov, I.; Hackert-Oschatzchen, M.; Zinecker, M.; Meichsner, G.; Edelmann, J.; Schubert, A. Process Understanding of Plasma Electrolytic Polishing through Multiphysics Simulation and Inline Metrology. Micromachines 2019, 10, 214. [Google Scholar] [CrossRef]

- Parfenov, E.V.; Farrakhov, R.G.; Mukaeva, V.R.; Gusarov, A.V.; Nevyantseva, R.R.; Yerokhin, A. Electric field effect on surface layer removal during electrolytic plasma polishing. Surf. Coat. Technol. 2016, 307, 1329–1340. [Google Scholar] [CrossRef]

- Witzke, K.; Kensbock, R.; Willsch, C.U.; Fricke, K.; Bekeschus, S.; Metelmann, H.-R. Mechanical and Plasma Electrolytic Polishing of Dental Alloys. Materials 2023, 16, 6222. [Google Scholar] [CrossRef]

- Kusmanov, S.A.; Tambovskiy, I.V.; Korableva, S.S.; Dyakov, I.G.; Burov, S.V.; Belkin, P.N. Enhancement of Wear and Corrosion Resistance in Medium Carbon Steel by Plasma Electrolytic Nitriding and Polishing. J. Mater. Eng. Perform. 2019, 28, 5425–5432. [Google Scholar] [CrossRef]

- Apelfeld, A.; Borisov, A.; Dyakov, I.; Grigoriev, S.; Krit, B.; Kusmanov, S.; Silkin, S.; Suminov, I.; Tambovskiy, I. Enhancement of Medium-Carbon Steel Corrosion and Wear Resistance by Plasma Electrolytic Nitriding and Polishing. Metals 2021, 11, 1599. [Google Scholar] [CrossRef]

- Yang, D.; Sun, H.; Wang, J.; Ji, G.; Duan, H.; Xiang, Y.; Fan, Y. The formation and stripping mechanism of oxide film on Ti6Al4V alloy surface during electrolytic plasma polishing. Surf. Coat. Technol. 2024, 478, 130469. [Google Scholar] [CrossRef]

- Ma, G.; Li, S.; Liu, X.; Yin, X.; Jia, Z.; Liu, F. Combination of Plasma Electrolytic Processing and Mechanical Polishing for Single-Crystal 4H-SiC. Micromachines 2021, 12, 606. [Google Scholar] [CrossRef] [PubMed]

- Mukhacheva, T.; Kusmanov, S.; Tambovskiy, I.; Podrabinnik, P.; Metel, A.; Khmyrov, R.; Karasev, M.; Suminov, I.; Grigoriev, S. Tribological properties of carbon tool steel after plasma electrolytic nitrocarburizing. J. Manufact. Mater. Process. 2023, 7, 197. [Google Scholar] [CrossRef]

| U (V) | t (min) | μ | Tfr (°C) | Δmfr (mg) | S (mm2) | r (µm) | Δ |

|---|---|---|---|---|---|---|---|

| 250 | 5 | 0.42 ± 0.02 | 56.0 ± 0.4 | 2.1 ± 0.4 | 0.058 | 32 | 0.311 |

| 10 | 0.86 ± 0.04 | 52.8 ± 0.5 | 1.7 ± 0.3 | 0.027 | 9.7 | 0.457 | |

| 300 | 5 | 0.68 ± 0.03 | 62.4 ± 0.7 | 3.6 ± 0.5 | 0.051 | 35.1 | 0.430 |

| 10 | 0.72 ± 0.03 | 53.8 ± 0.4 | 2.1 ± 0.3 | 0.059 | 36.2 | 0.461 | |

| 15 | 0.78 ± 0.04 | 56.2 ± 0.6 | 6.3 ± 0.7 | 0.091 | 12.3 | 0.498 | |

| 20 | 0.28 ± 0.02 | 56.2 ± 0.5 | 2.7 ± 0.5 | 0.064 | 48.4 | 0.370 | |

| 350 | 5 | 0.60 ± 0.03 | 65.9 ± 0.8 | 2.8 ± 0.5 | 0.061 | 34.8 | 0.412 |

| 10 | 0.36 ± 0.02 | 57.7 ± 0.6 | 2.7 ± 0.4 | 0.065 | 41.4 | 0.305 | |

| untreated | 0.60 ± 0.03 | 66.5 ± 0.9 | 2.5 ± 0.4 | 0.067 | 42.8 | 0.481 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigoriev, S.N.; Tambovskiy, I.V.; Mukhacheva, T.L.; Palenov, I.R.; Gaponov, V.A.; Kusmanova, I.A.; Komarov, A.O.; Mitrofanov, A.P.; Suminov, I.V.; Kusmanov, S.A. Using Plasma Electrolytic Polishing for Post-Processing of Additively Manufactured Ti6Al4V Alloy Products. Technologies 2025, 13, 553. https://doi.org/10.3390/technologies13120553

Grigoriev SN, Tambovskiy IV, Mukhacheva TL, Palenov IR, Gaponov VA, Kusmanova IA, Komarov AO, Mitrofanov AP, Suminov IV, Kusmanov SA. Using Plasma Electrolytic Polishing for Post-Processing of Additively Manufactured Ti6Al4V Alloy Products. Technologies. 2025; 13(12):553. https://doi.org/10.3390/technologies13120553

Chicago/Turabian StyleGrigoriev, Sergey N., Ivan V. Tambovskiy, Tatiana L. Mukhacheva, Ivan R. Palenov, Vladislav A. Gaponov, Irina A. Kusmanova, Artem O. Komarov, Artem P. Mitrofanov, Igor V. Suminov, and Sergei A. Kusmanov. 2025. "Using Plasma Electrolytic Polishing for Post-Processing of Additively Manufactured Ti6Al4V Alloy Products" Technologies 13, no. 12: 553. https://doi.org/10.3390/technologies13120553

APA StyleGrigoriev, S. N., Tambovskiy, I. V., Mukhacheva, T. L., Palenov, I. R., Gaponov, V. A., Kusmanova, I. A., Komarov, A. O., Mitrofanov, A. P., Suminov, I. V., & Kusmanov, S. A. (2025). Using Plasma Electrolytic Polishing for Post-Processing of Additively Manufactured Ti6Al4V Alloy Products. Technologies, 13(12), 553. https://doi.org/10.3390/technologies13120553