Self-Powered Electrochemical Humidity Sensor Based on Hydroxylated Multi-Walled Carbon Nanotubes-Modified CeO2 Nanoparticles

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Fabrication and Characterization

2.3. Performance Testing

3. Results and Discussion

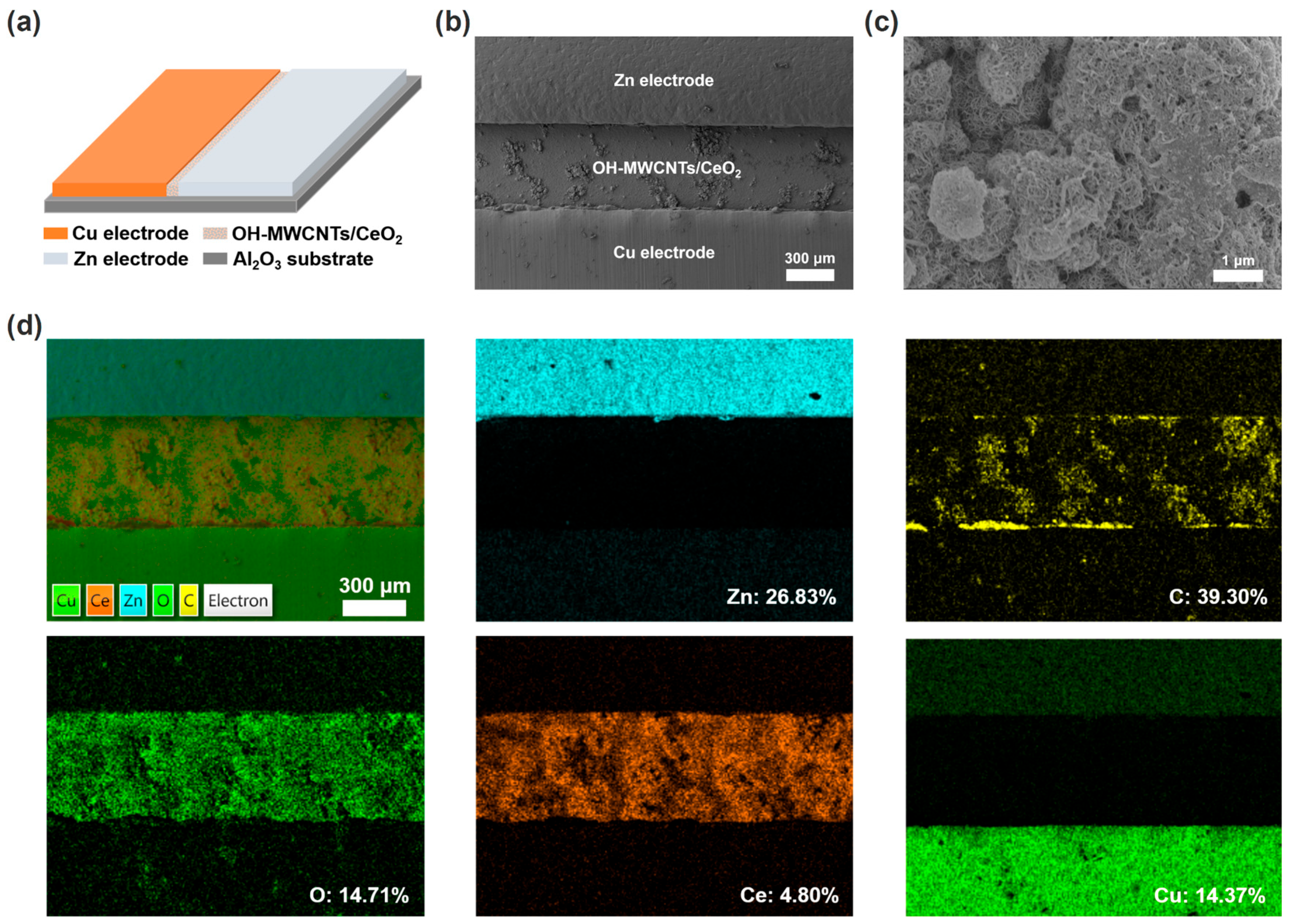

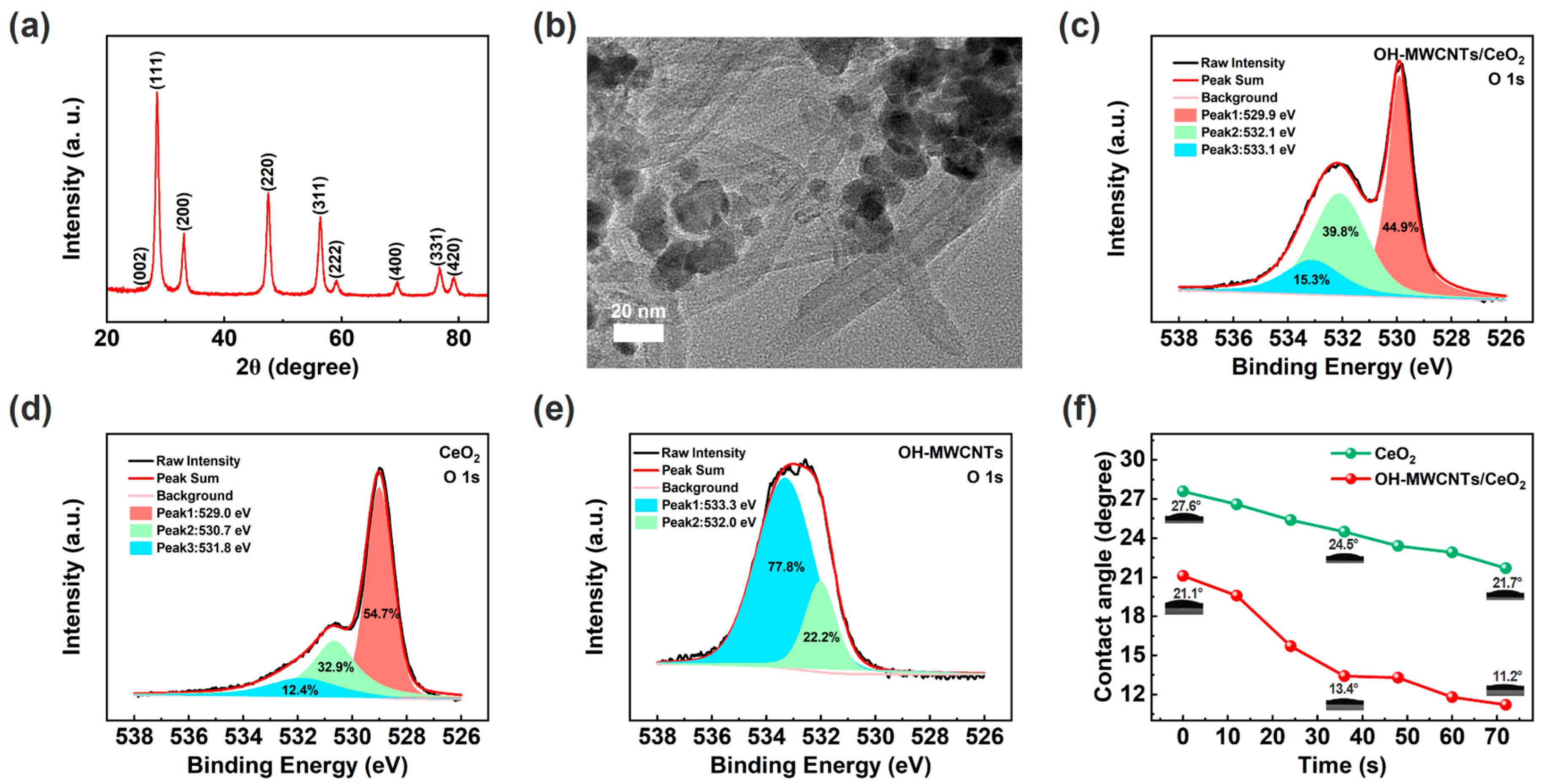

3.1. Characterization

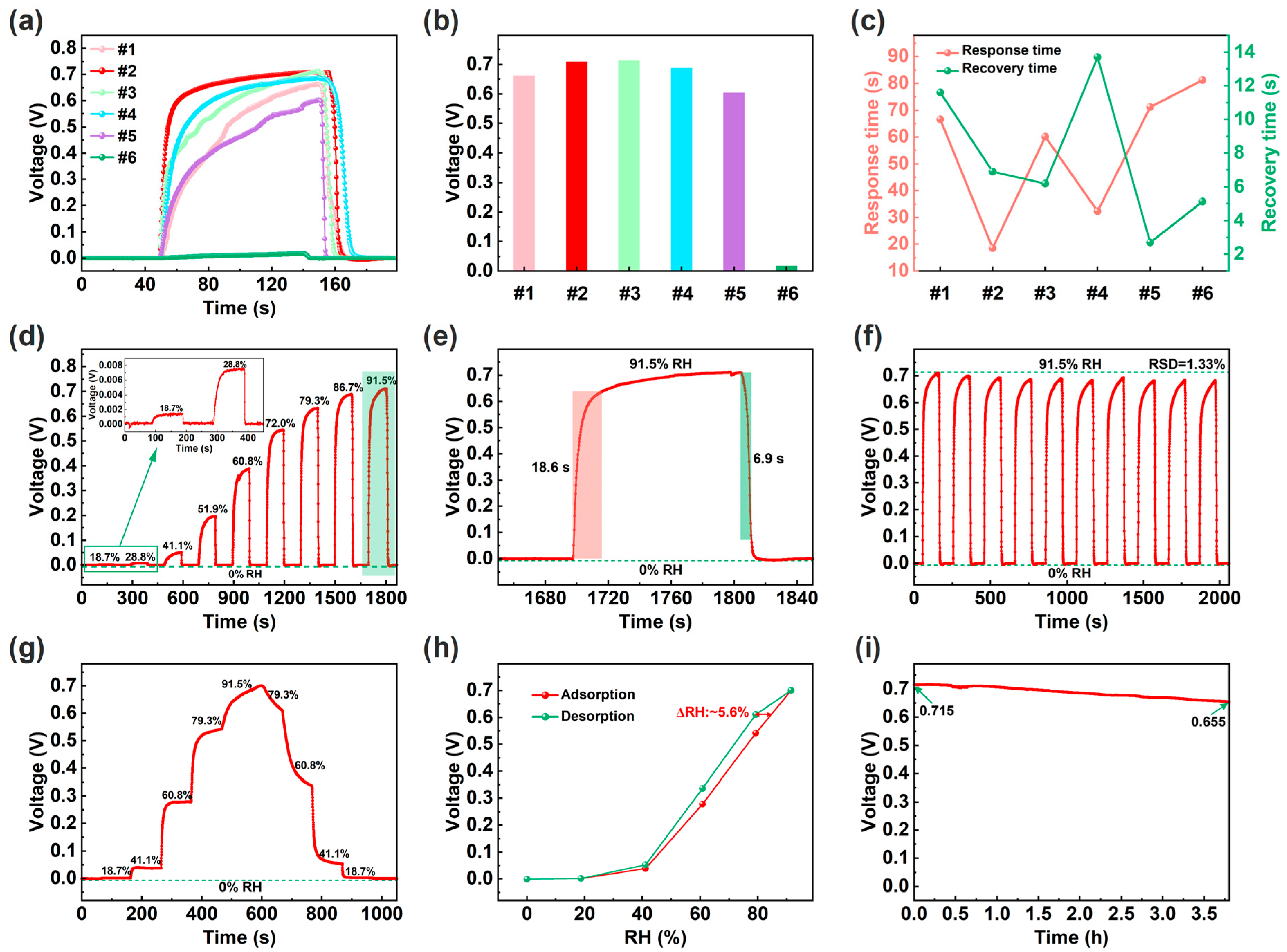

3.2. Performances

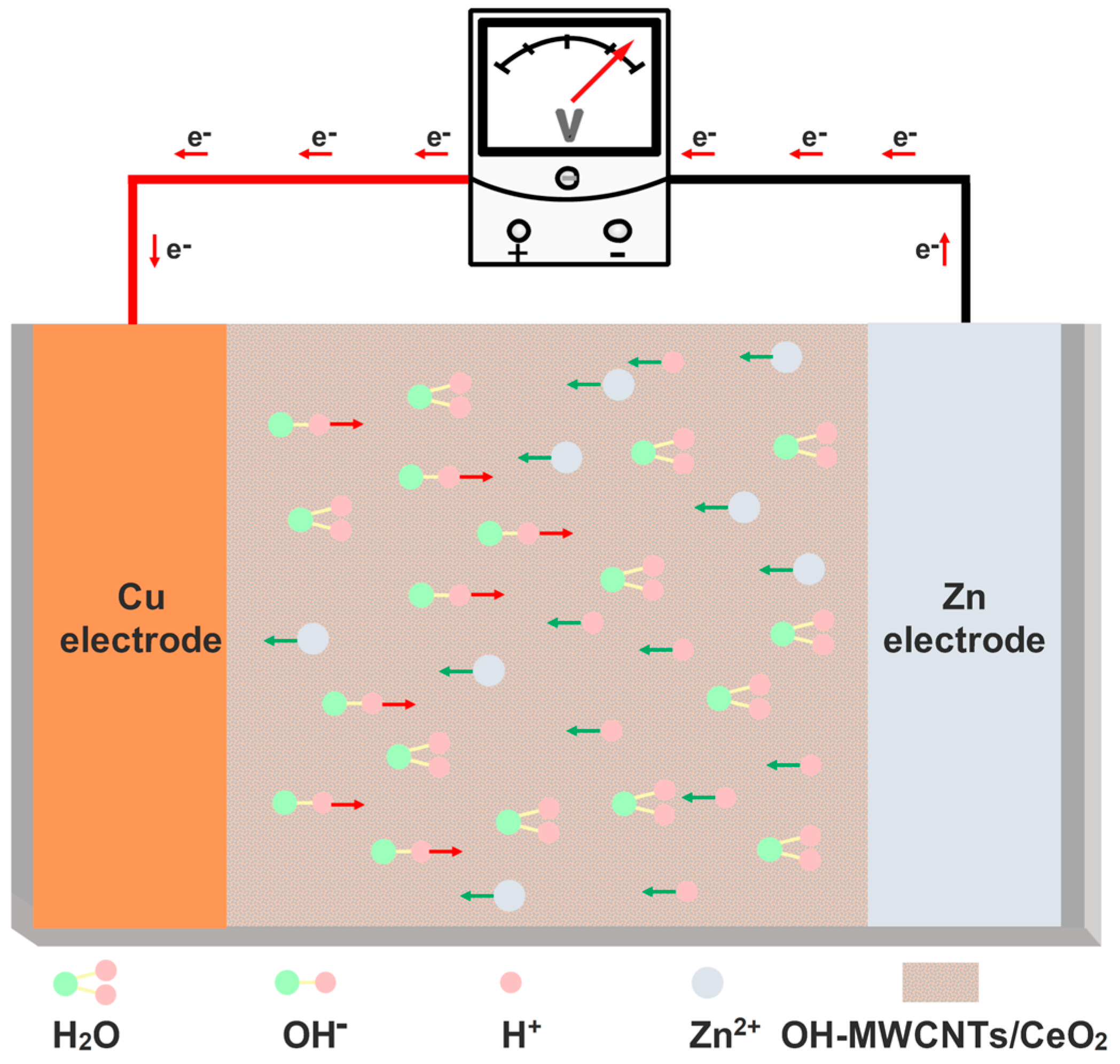

3.3. Working Mechanisms

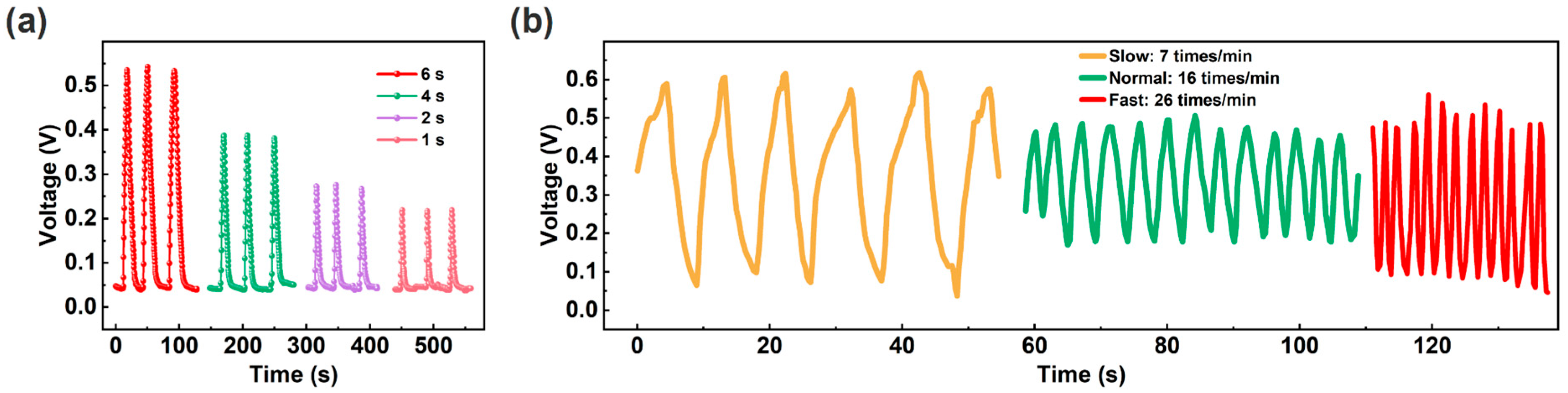

3.4. Applications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zu, Y.; Duan, Z.; Yuan, Z.; Jiang, Y.; Tai, H. Electrospun nanofiber-based humidity sensors: Materials, devices, and emerging applications. J. Mater. Chem. A 2024, 12, 27157–27179. [Google Scholar] [CrossRef]

- Shi, W.; Yang, X.; Lei, L.; Lin, J.; Liang, Q.; Huang, X.; Wu, Q.; Li, W. Human respiration monitoring using humidity and temperature dual-modal sensors for temperature-insensitive humidity sensing and synchronous temperature sensing. Sens. Actuators A Phys. 2025, 395, 117008. [Google Scholar] [CrossRef]

- Zhang, S.; Wei, C.; Li, L.; Cui, J.; Yuan, X.; Hao, D.; Wang, H. A stable and fast-response multifunctional humidity sensor based on a polyanionic liquid containing bromide ions. Chemosensors 2025, 13, 79. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, M.; Tang, M.; Song, X.; Zhang, X.; Kang, Z.; Liu, X.; Zhang, J.; Xue, Q. Recent progress of diversiform humidity sensors based on versatile nanomaterials and their prospective applications. Nano Res. 2022, 16, 11938–11958. [Google Scholar] [CrossRef]

- Laera, A.M.; Cassano, G.; Burresi, E.; Protopapa, M.L.; Penza, M. Flexible humidity sensor based on chemically reduced graphene oxide. Chemosensors 2024, 12, 245. [Google Scholar] [CrossRef]

- Liu, B.; Chen, Q.; Hu, J.; Zhang, Y. Amplifying electron-donor signal of the “water gate” enabled low detection ability of a field-effect transistor-based humidity sensor. Anal. Chem. 2025, 97, 2779–2785. [Google Scholar] [CrossRef] [PubMed]

- Ngokpho, B.; Janphuang, P.; Nijpanich, S.; Chanlek, N.; Wannapaiboon, S.; Siritanon, T.; Ngamchuea, K. Halide-mediated electrochemical modification of copper phthalocyanine for humidity sensing applications. Mater. Adv. 2025, 6, 658–669. [Google Scholar] [CrossRef]

- Lei, D.; Zhang, Q.; Liu, N.; Su, T.; Wang, L.; Ren, Z.; Zhang, Z.; Su, J.; Gao, Y. Self-powered graphene oxide humidity sensor based on potentiometric humidity transduction mechanism. Adv. Funct. Mater. 2021, 32, 2107330. [Google Scholar] [CrossRef]

- Duan, Z.; Yuan, Z.; Jiang, Y.; Zhao, Q.; Huang, Q.; Zhang, Y.; Liu, B.; Tai, H. Power generation humidity sensor based on primary battery structure. Chem. Eng. J. 2022, 446, 136910. [Google Scholar] [CrossRef]

- Jiang, Y.; Duan, Z.; Fan, Z.; Yao, P.; Yuan, Z.; Jiang, Y.; Cao, Y.; Tai, H. Power generation humidity sensor based on NaCl/halloysite nanotubes for respiratory patterns monitoring. Sens. Actuator B, Chem. 2023, 380, 133396. [Google Scholar] [CrossRef]

- Zu, Y.; Hu, J.; Yang, M.; Duan, Z.; Zhang, M.; Yuan, Z.; Jiang, Y.; Tai, H. Electrochemical power generation humidity sensor based on WS2 nanoflakes. Sens. Actuator B, Chem. 2024, 405, 135325. [Google Scholar] [CrossRef]

- Lu, W.; Zhang, Q.; Liu, N.; Lei, D.; Ren, Z.; Yin, J.; Jia, P.; Gao, Y. Nylon fabric/GO based self-powered humidity sensor based on the Galvanic cell principle with high air permeability and rapid-response. Small 2023, 20, 2306463. [Google Scholar] [CrossRef]

- Zhao, W.; Li, Q.; Wang, Q.; Li, Z.; Liang, J.; Wu, W. All-printed flexible self-powered humidity sensor. Sens. Actuator B Chem. 2025, 440, 137868. [Google Scholar] [CrossRef]

- Zhang, M.; Duan, Z.; Yuan, Z.; Jiang, Y.; Tai, H. Observing mixed chemical reactions at the positive electrode in the high-performance self-powered electrochemical humidity sensor. ACS Nano 2024, 18, 34158–34170. [Google Scholar] [CrossRef] [PubMed]

- Dou, Y.; Tang, C.; Lu, Y. Self-powered, highly sensitive, and flexible humidity sensor based on carboxymethyl cellulose for multifunctional applications. Langmuir 2023, 39, 17436–17445. [Google Scholar] [CrossRef]

- Guo, Y.; Xi, H.; Gu, Z.; Li, M.; Li, X.; Gao, D. A self-powered PVA-based flexible humidity sensor with humidity-related voltage output for multifunctional applications. Colloids Surf. A 2023, 658, 130700. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, X.; Wan, Z.; Yin, M.; Ma, L.; Xiao, X. Moisture electricity generation based self-powered humidity sensor for smart agriculture. Mater. Today Chem. 2024, 42, 102416. [Google Scholar] [CrossRef]

- Wang, Z.; Yi, N.; Zheng, Z.; Zhou, J.; Zhou, P.; Zheng, C.; Chen, H.; Shen, G.; Weng, M. Self-powered and degradable humidity sensors based on silk nanofibers and its wearable and human-machine interaction applications. Chem. Eng. J. 2024, 497, 154443. [Google Scholar] [CrossRef]

- Han, M.; Shen, W.; Corriou, J.P. Polydopamine-modified MXene/cellulose nanofibers composite film for self-powered humidity sensing and humidity actuating. Nano Energy 2024, 123, 109445. [Google Scholar] [CrossRef]

- Eryanto, G.; Tseng, S.F. Self-powered paper-based humidity sensors with MgCl2/CNTs composites. Sens. Actuators A Phys. 2024, 376, 115606. [Google Scholar] [CrossRef]

- Tseng, S.F.; Chiu, L.Y.; Hsu, S.H.; Kuo, C.C. High performance flexible and self-powered humidity sensors based on LiCl/LIPG composites. Sens. Actuator B Chem. 2025, 422, 136569. [Google Scholar] [CrossRef]

- Wu, H.; Jin, F.; Ge, H.-L.; Wu, Q.; Wang, Y.; Gao, F. Covalently modified nanocellulose materials: Enhanced performance and stability for self-powered and impedance humidity sensors. Colloids Surf. A 2025, 716, 136681. [Google Scholar] [CrossRef]

- Zhao, Q.; Duan, Z.; Wu, Y.; Liu, B.; Yuan, Z.; Jiang, Y.; Tai, H. Facile primary battery-based humidity sensor for multifunctional application. Sens. Actuator B Chem. 2022, 370, 132369. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Liang, X.; Wang, H.; Lu, H.; Zhu, M.; Wang, H.; Zhang, M.; Qiu, X.; Song, Y.; et al. Humidity-sensitive chemoelectric flexible sensors based on metal-air redox reaction for health management. Nat. Commun. 2022, 13, 5416. [Google Scholar] [CrossRef]

- Hu, J.; Duan, Z.; Tan, C.; Wang, Y.; Yuan, Z.; Jiang, Y.; Tai, H. Self-powered electrochemical humidity sensor based on Cu/(cellulose nanocrystals/NaCl)/Zn structure for respiratory rate detection. Inorg. Chem. Commun. 2025, 180, 114994. [Google Scholar] [CrossRef]

- Cao, L.C.T.; Hakim, L.; Nagao, Y.; Boonruang, S.; Tseng, S.F.; Hsu, S.H. Self-powered humidity sensor based on porous Ti3C2Tₓ MXene: High sensitivity and fast response for real-world applications. Chem. Eng. J. 2025, 523, 168345. [Google Scholar] [CrossRef]

- Huang, Z.; Yao, L.; Lin, S.; Wei, F. Self-powered flexible humidity sensors based on ceramic fiber paper. J. Alloys Compd. 2025, 1040, 183470. [Google Scholar] [CrossRef]

- Liao, K.; Wang, F.; Shen, Q.; Liu, Y.; Mei, Z.; Wang, H.; Zhang, S.; Ma, S.; Wang, L. Advances in humidity sensors based on Self-Powered technology. Chem. Eng. J. 2025, 505, 159480. [Google Scholar] [CrossRef]

- Duan, Z.; Zhang, M.; Jiang, Y.; Yuan, Z.; Tai, H. Emerging electrochemical humidity sensors for zero power consumption and self-powered humidity detection: A perspective. J. Mater. Chem. A 2024, 12, 14975–14985. [Google Scholar] [CrossRef]

- Blank, T.A.; Eksperiandova, L.P.; Belikov, K.N. Recent trends of ceramic humidity sensors development: A review. Sens. Actuator B Chem. 2016, 228, 416–442. [Google Scholar] [CrossRef]

- Pascariu, P.; Tudorache, F.; Romanitan, C.; Serban, A.B.; Koudoumas, E. 1% lanthanide-doped ZnO nanostructures as a versatile approach for state-of-the-art capacitive and resistive humidity sensors. Ceram. Int. 2025, 51, 17090–17100. [Google Scholar] [CrossRef]

- Zahoor, M.T.; Khan, G.A.; Nawaz, M.B.; Farouk, S.; Imran, Z.; Ahmed, W. Rapid dielectrophoresis-assisted deposition of highly concentrated ZnO nanowires for enhanced performance of humidity sensors. Sens. Actuators A Phys. 2023, 362, 114651. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, H.; Chen, C.; Zhang, L.; Ma, X.; Li, X.; Wang, J. Preparation of silver nanoparticles modified SnO2 humidity sensor for tobacco storage environment detection. Sens. Actuator B Chem. 2024, 409, 135612. [Google Scholar] [CrossRef]

- Kumar, A.; Kumari, P.; Kumar, M.S.; Gupta, G.; Shivagan, D.D.; Bapna, K. SnO2 nanostructured thin film as humidity sensor and its application in breath monitoring. Ceram. Int. 2023, 49, 24911–24921. [Google Scholar] [CrossRef]

- Lv, X.; Feng, C.; Lin, T. Enhanced humidity sensing properties of interstitial B-doped TiO2 nanofibers. Sens. Actuators A Phys. 2023, 358, 114412. [Google Scholar] [CrossRef]

- Yu, Z.; Li, J.; Zhang, Q.; Xiang, P.; Lei, J. Laser-induced in situ synthesis and assembly of nano-cotton TiO2 humidity sensors with high sensitivity and fast response for real-time respiratory monitoring. Small Struct. 2025, 6, 2400593. [Google Scholar] [CrossRef]

- Manikandan, M.; Tippo, P.; Singjai, P.; Thongpan, W.; Jumrus, N.; Kumpika, T.; Panthawan, A.; Jhuntama, N.; Thongsuwan, W.; Sroila, W.; et al. Facile design of interdigitated electrode (IDE) based Co3O4 resistive type humidity sensor by a novel spark discharge method. Inorg. Chem. Commun. 2025, 177, 114431. [Google Scholar] [CrossRef]

- Taha, W.M.; Morsy, M.; Nada, N.A.; Ibrahim, M. Studying the humidity sensing behavior of MWCNTs boosted with Co3O4 nanorods. Diamond Relat. Mater. 2022, 121, 108754. [Google Scholar] [CrossRef]

- Yu, H.; Wang, C.; Meng, F.; Xiao, J.; Liang, J.; Kim, H.; Bae, S.; Zou, D.; Kim, E.S.; Kim, N.Y.; et al. Microwave humidity sensor based on carbon dots-decorated MOF-derived porous Co3O4 for breath monitoring and finger moisture detection. Carbon 2021, 183, 578–589. [Google Scholar] [CrossRef]

- Manikandan, V.; Petrila, I.; Vigneselvan, S.; Mirzaei, A.; Mane, R.S.; Kim, S.S.; Chandrasekaran, J. Enhanced humidity sensing properties of Fe-doped CeO2 nanoparticles. J. Mater. Sci. Mater. Electron. 2020, 31, 8815–8824. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Zhang, X.; Guo, C.; Zhang, H.; Zhao, X.; Huo, L.; Dong, X.; Huang, C.; Cheng, X.; et al. Preparation of nest-like CeO2 humidity sensing material and its application in eye strain monitoring. Sens. Actuator B Chem. 2024, 415, 135985. [Google Scholar] [CrossRef]

- Jakhar, S.; Sheoran, G.; Rohilla, B.; Malik, P.; Duhan, S. Structural and sensing insights of CeO2/KIT-6 for humidity detection applications. Mater. Chem. Phys. 2025, 343, 131056. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, H.; Wang, L.; Cai, D.; Liu, B.; Wang, D.; Li, Q.; Wang, T. Electrospun CeO2 nanoparticles/PVP nanofibers based high-frequency surface acoustic wave humidity sensor. Sens. Actuator B Chem. 2016, 223, 730–737. [Google Scholar] [CrossRef]

- Geeta, B.; Bikshalu, K.; Rajendar, V.; Rao, K.V. Nanostructured conducting polyaniline (NSPANI)/CeO2 nanocomposites for humidity sensors application. J. Mater. Sci. Mater. Electron. 2017, 29, 374–381. [Google Scholar] [CrossRef]

- Chani, M.T.S. Fabrication and characterization of chitosan-CeO2-CdO nanocomposite based impedimetric humidity sensors. Int. J. Biol. Macromol. 2022, 194, 377–383. [Google Scholar] [CrossRef]

- Gong, L.; Wang, X.; Zhang, D.; Ma, X.; Yu, S. Flexible wearable humidity sensor based on cerium oxide/graphitic carbon nitride nanocomposite self-powered by motion-driven alternator and its application for human physiological detection. J. Mater. Chem. A 2021, 9, 5619–5629. [Google Scholar] [CrossRef]

- Xie, W.; Liu, B.; Xiao, S.; Li, H.; Wang, Y.; Cai, D.; Wang, D.; Wang, L.; Liu, Y.; Li, Q.; et al. High performance humidity sensors based on CeO2 nanoparticles. Sens. Actuator B Chem. 2015, 215, 125–132. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Xu, H.; Xing, Y.; Chen, J.; Bie, L. Ultrathin CeO2 nanosheets as bifunctional sensing materials for humidity and formaldehyde detection. Rare Met. 2020, 40, 1614–1621. [Google Scholar] [CrossRef]

- Cheng, Y.; Jiang, B.; Chaemchuen, S.; Verpoort, F.; Kou, Z. Advances and challenges in designing MXene quantum dots for sensors. Carbon Neutralization 2023, 2, 213–234. [Google Scholar] [CrossRef]

- Dai, Z.; Lei, M.; Ding, S.; Zhou, Q.; Ji, B.; Wang, M.; Zhou, B. Durable superhydrophobic surface in wearable sensors: From nature to application. Exploration 2023, 4, 20230046. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, G.; Dong, Y.; Wu, Y.; Yu, L.; Bai, Y. Interfacial modulation of polydopamine-reduced graphene oxide for achieving highly conductive and strong graphene/cotton composite yarn toward smart wearable devices. Adv. Fiber Mater. 2024, 6, 1798–1812. [Google Scholar] [CrossRef]

- Rajavel, K.; Lalitha, M.; Radhakrishnan, J.K.; Senthilkumar, L.; Rajendra Kumar, R.T. Multiwalled carbon nanotube oxygen sensor: Enhanced oxygen sensitivity at room temperature and mechanism of sensing. ACS Appl. Mater. Interfaces 2015, 7, 23857–23865. [Google Scholar] [CrossRef]

- Nazir, M.A.; Najam, T.; Ullah, S.; Hossain, I.; Javed, M.S.; Naseer, M.; Rehman, A.; Shah, S.S.A. Recent advances in MXene nanomaterials: Fundamentals to applications in environment sector. EcoEnergy 2024, 2, 505–548. [Google Scholar] [CrossRef]

- Duan, Z.; Jiang, Y.; Yan, M.; Wang, S.; Yuan, Z.; Zhao, Q.; Sun, P.; Xie, G.; Du, X.; Tai, H. Facile, flexible, cost-saving, and environment-friendly paper-based humidity sensor for multifunctional applications. ACS Appl. Mater. Interfaces 2019, 11, 21840–21849. [Google Scholar] [CrossRef]

- Futaba, D.N.; Yamada, T.; Kobashi, K.; Yumura, M.; Hata, K. Macroscopic wall number analysis of single-walled, double-walled, and few-walled carbon nanotubes by X-ray diffraction. J. Am. Chem. Soc. 2011, 133, 5716–5719. [Google Scholar] [CrossRef]

- Singh, D.K.; Iyer, P.K.; Giri, P.K. Diameter dependence of interwall separation and strain in multiwalled carbon nanotubes probed by X-ray diffraction and Raman scattering studies. Diamond Relat. Mater. 2010, 19, 1281–1288. [Google Scholar] [CrossRef]

- Guo, C.; Xin, Y.; Liu, Y.; Na, B.; Meng, W.; Zhang, X.; Cheng, X.; Huo, L.; Wang, T.; Xu, Y. Noncontact sensing for water area scanning identification based on Ho2O3/GO humidity sensor. Sens. Actuator B Chem. 2023, 385, 133683. [Google Scholar] [CrossRef]

- Zhao, R.; Xie, D.; Qing, S.; Zhu, B.; Shen, W.; Wang, L.; Meng, X.; Pang, J. Cellulose acetate and reduced graphene oxide (rGO)-based flexible humidity sensor for monitoring human respiration. Sens. Actuator B Chem. 2025, 429, 137291. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Chen, H.; Wang, H.; Luo, Y.; Si, R.; Xie, R.; Tao, K.; Yang, B.R.; Zhang, D.; et al. Scalable fabrication of uniform fast-response humidity field sensing array for respiration recognition and contactless human-machine interaction. Adv. Funct. Mater. 2025, 35, 2502583. [Google Scholar] [CrossRef]

- You, Q.; Gao, C.; Pan, M.; Wei, T.; Shen, W.; Yao, X.; Yang, X.; Yang, Z.; Li, Y.; Li, X.; et al. A seamlessly integrated device of wireless energy storage and humidity sensing for human-machine interaction of respiration. Small 2025, 21, 2501122. [Google Scholar] [CrossRef] [PubMed]

- Mandal, S.; Mantilla, H.M.; Loganathan, K.; Faber, H.; Sharma, A.; Gedda, M.; Yengel, E.; Goswami, D.K.; Heeney, M.; Anthopoulos, T.D. Ultra-fast moisture sensor for respiratory cycle monitoring and non-contact sensing applications. Adv. Mater. 2025, 37, 2414005. [Google Scholar] [CrossRef] [PubMed]

| Main Humidity-Sensing Materials | Detecting Range (RH) | Low RH Response (RH) | Response/Recovery Time (s) | Maximum Response Voltage (V) | Refs. |

|---|---|---|---|---|---|

| NaCl/paper | 0%–91.5% | 41.1% | 109/113 | 0.58 (91.5% RH) | [9] |

| NaCl/halloysite nanotubes | 0%–91.5% | 10.9% | 11.3/19.5 | 0.537 (91.5% RH) | [10] |

| WS2 | 0%–91.5% | 18.7% | 8.4/5.2 | 0.47(91.5% RH) | [11] |

| sodium alginate/LiCl | 0%–95% | 11% | 46/68 | 1.03 (95% RH) | [13] |

| polystyrene sulfonic acid/PVA/LiCl | 33%–91% | 33% | 52.1/56.8 | 0.67 (91% RH) | [17] |

| silk nanofiber | 30%–90% | 30% | Not mentioned | 0.346 (90% RH) | [18] |

| PDA-Ti3C2Tx/TEMPO-oxidized cellulose/LiCl | 11%–91% | 11% | 13/50 | 0.54 (91% RH) | [19] |

| MgCl2/CNTs | 11%–97% | 11% | 10/46 | 1.07 (97% RH) | [20] |

| bacterial cellulose | 43%–97% | 43% | 28.5/54.1 | 0.53 (97% RH) | [22] |

| LiCl | 0%–91.5% | 10.9% | 36.9/38.0 | 0.4 (91.5% RH) | [23] |

| OH-MWCNTs/CeO2 | 0%–91.5% | 18.7% | 18.6/6.9 | 0.711 (91.5% RH) | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Z.; Tan, C.; Duan, Z.; Jiang, Y.; Tai, H. Self-Powered Electrochemical Humidity Sensor Based on Hydroxylated Multi-Walled Carbon Nanotubes-Modified CeO2 Nanoparticles. Technologies 2025, 13, 467. https://doi.org/10.3390/technologies13100467

Yuan Z, Tan C, Duan Z, Jiang Y, Tai H. Self-Powered Electrochemical Humidity Sensor Based on Hydroxylated Multi-Walled Carbon Nanotubes-Modified CeO2 Nanoparticles. Technologies. 2025; 13(10):467. https://doi.org/10.3390/technologies13100467

Chicago/Turabian StyleYuan, Zhen, Chong Tan, Zaihua Duan, Yadong Jiang, and Huiling Tai. 2025. "Self-Powered Electrochemical Humidity Sensor Based on Hydroxylated Multi-Walled Carbon Nanotubes-Modified CeO2 Nanoparticles" Technologies 13, no. 10: 467. https://doi.org/10.3390/technologies13100467

APA StyleYuan, Z., Tan, C., Duan, Z., Jiang, Y., & Tai, H. (2025). Self-Powered Electrochemical Humidity Sensor Based on Hydroxylated Multi-Walled Carbon Nanotubes-Modified CeO2 Nanoparticles. Technologies, 13(10), 467. https://doi.org/10.3390/technologies13100467