Abstract

The transition to a sustainable energy mix is essential to mitigate climate change. Enhanced Oil Recovery (EOR) using low-salinity water (smart water) has emerged as a promising strategy for reducing environmental impacts in the petroleum industry, producing a highly valuable energy source due to both its energy density and market value. This study critically reviews intermediate technological readiness levels (TRL), applying a patent-based approach (TRL 4–5) and a review of articles (TRL 3) to analyze various aspects of smart water for EOR, including its composition. A total of 23 patents from the European Patent Office (Questel Orbit) and 1395 articles from Elsevier’s Scopus database were analyzed, considering annual trends, country distribution, international collaborations, author and applicant affiliations, citation dependencies, and factorial analyses. Both patents and articles show exponential growth; however, international collaboration is more frequent in the scientific literature, while patents remain concentrated in a few countries aligned with their markets. Technologies are focused on wettability, surface complexation, CO2 interactions, emulsification, aerogels, reinjection water treatment, carbonate reservoirs, effluent treatment, nanofluidics, and ASP fluids. Recent topics include CO2 associations, permeability, fractured reservoirs, gels, reservoir water, wettability alteration, and reservoir/oil heterogeneity. The findings indicate the need for multivariated development of customized smart waters to address complex interfacial synergistic mechanisms. International Joint Industry Projects and global regulations on the safe use and composition of hybrid injections are recommended to accelerate development, reduce environmental impacts, and enhance the efficient use of existing fields, alleviating the challenges of finding new reservoirs.

1. Introduction

Humanity requires a responsible energy transition from non-renewable sources, such as oil and gas, which accounted for over 50% of global primary energy consumption in 2022 [1,2], to cleaner energy sources. This transition is necessary to reduce the harmful environmental impacts currently being experienced, such as climate change, and to preserve this planet, our common home [3,4].

Several sustainable energy solutions are emerging in oceanic regions such as the Pre-Salt, including the use of wave and wind energy, as well as the cross-cutting approach of optimizing hybrid energy systems and incorporating solutions enabled by the Internet of Things and generative intelligences [5,6,7].

Pre-Salt production accounts for approximately 5% of global reserves and about 78% of Brazilian output [8,9,10,11,12] and will be essential for achieving the Sustainable Development Goas of Agenda 2023 [13,14]. Its production process not only ensures high productivity but also contributes positively to the SDGs by reducing carbon dioxide emissions to nearly half the global average (SDGs 7, 13) and generating revenues allocated to social and environmental policies. The Social Fund directs resources to education and science (SDG 10), while its economic relevance strengthens strategies for climate adaptation and marine protection (SDG 14). In addition, it supports social programs (SDGs 1, 3, 4), fosters innovation (SDGs 8, 9), and reinforces the energy transition through lower emission intensity (SDGs 7, 13) [10,15,16].

Enhanced Oil Recovery (EOR) with smart water emerges as a potentially environmentally friendly option, as it employs cleaner injection fluids while leveraging the benefits of conventional EOR, which can increase the recovery factor by 30–60% [17,18]. This method requires only minimal adaptations to existing infrastructure, resulting in low capital and operating expenditures. Consequently, it contributes to reducing oil prices and, although influenced by multiple determinants, may stimulate the use of remaining revenues to finance the development of greener energy sources, such as solar photovoltaic deployment in the electricity mix [19].

Traditional EOR methods have significantly contributed to increasing recovery factors but also present important shortcomings and may generate considerable environmental concerns. Chemical flooding typically requires large concentrations of synthetic surfactants and polymers, which in the event of spills, may persist in the environment for long periods, thereby increasing the risk of toxicity to aquatic and terrestrial ecosystems. Gas injection may suffer from gravity override, poor sweep efficiency, and high operational costs. Thermal methods are often energy intensive and costly and, depending on the energy source, may also negatively impact the environment. In addition, issues such as solid and liquid effluent management, brine disposal, and the potential contamination of groundwater highlight the environmental limitations of conventional EOR approaches. These drawbacks have stimulated the search for more sustainable alternatives that address environmental impact, leading to the development of the concept of Green Enhanced Oil Recovery (GEOR), which encompasses EOR technologies that also account for environmental aspects [20,21,22,23].

Nevertheless, technical challenges remain in the cleaner chemical engineering aspects of GEOR, which require creativity and control over the composition of the injection fluid, as well as the treatment of produced water or seawater to be injected.

In this context, low salinity water (smart water) injection has emerged as a promising GEOR strategy.

Among GEOR methods, smart water [24,25,26,27] is a sustainable strategy for the oil industry, capable of increasing production from existing operations while reducing the need to drill new wells and explore new fields. It induces fundamental changes at the oil–brine–rock interface, such as multivalent ion exchange, wettability alteration toward more water-wet conditions, modification of zeta potential, and reduction in interfacial tension. These mechanisms collectively improve microscopic displacement efficiency while requiring only low concentrations of additives, making smart water a cost-effective and environmentally friendlier option compared with conventional EOR approaches.

Smart water EOR, therefore, represents a technology that emerged in 2008 and has since developed rapidly, offering the oil industry an opportunity to meet various SDGs of the 2030 Agenda while maintaining the necessary oil production. The first paper dedicated to smart water focused on low-salinity waterflooding modeling, highlighting a 5 to 38% increase in oil recovery factor [28]. The first patent was filed by British Petroleum in 2008, detailing injection methods involving divalent cation content and zeta potentials in sandstones [29].

Smart waters consist of low salinity aqueous solutions that may or may not include additional additives such as surfactants, polymers, nanoparticles, gels, emulsions, demulsifiers, and nanocomposites, among others. The most critical aspect is that these additives and salts are always present in extremely low concentrations, resulting in minimal environmental impact, typically aligning with the levels at which Life Below Water (SDG 14) and Life on Land (SDG 15) coexist daily.

Recent reviews of EOR methods demonstrated that smart water is one of the emerging techniques [30]. Smart water has also proven to be a relevant and potential method, often associated with environmental preservation technologies. Specifically, patent inventors have shown a commitment to incorporating patent claims for treating and properly disposing of effluents within the EOR patents and there is still a clear global trend toward patenting not only GEOR methods but also the treatment processes for the respective wastes, particularly among the BRICS countries [31].

Technology Readiness Level (TRL) classification is crucial in assessing technological evolution. TRL 1 represents the initial conceptual phase, while TRL 9 indicates that the technology is fully operational. The intermediate TRLs help map technological development and identify potential future technologies that will require careful attention to cleaner chemical engineering aspects [32].

Patents have been used as a metric for evaluating technological systems, allowing for the inference of trends, performance, and structures in technological activities driving innovation [33]. Recently, scientific articles have been employed to map scientific development (TRL 3), while patents have been used to map technological advancements at TRL 4 (academic patents) and TRL 5 (patents licensed to, filed by, or jointly held with companies) [30].

Patents are also an indicator that provides insight into future challenges to be addressed in developing cleaner chemical engineering processes at TRL 6 to TRL 8 (technology demonstration and qualification stages) [32].

Quintella et al. [30] compared BRICS and non-BRICS countries in various EOR methods using patent analysis and composite indicators, employing scientific articles as a metric for TRL 3 and patents for TRL 4–5. Similar TRL metrics have been used in evaluations like biotechnology [34] that is the fifth technological wave preceding the sixth wave of Sustainability, where smart water technologies are inserted, that is crucial for achieving several SDGs [31,35].

This article aims to provide a critical and comparative review of TRL 3 (scientific articles) and TRL 4–5 (patents), identifying opportunities and challenges in smart water EOR to support researchers and decision-makers in advancing this technique with minimal environmental impact. It also seeks to identify future areas that will require solutions to technical challenges aimed at cleaner engineering processes, whether in the formulation of smart water additives or in the treatment of produced water or seawater to be used as injection fluids.

To achieve this, a comprehensive analysis was conducted using internationally published articles and patents, detailing annual trends, country distribution, international collaborations, affiliations of article authors and patent applicants, patent citation dependencies, word clouds of the most frequent relevant terms, and a detailed overview of the topics addressed in articles and in patents. These topics include wettability control, the use of carbon dioxide and carbonation, emulsification, aerogels, effluent treatment, microemulsions and nanofluidics, challenges in low-permeability reservoirs, the use of polymers, surfactants, and alkalis and their combinations, seawater adaptation as an injection fluid, and theoretical simulations.

2. Materials and Methods

2.1. Patents

The patent document search for TRL 4–5 was conducted in the worldwide database of the European Patent Office, covering approximately 100 countries [36]. This database was accessed through Questel Orbit, which has all patents translated into English. To avoid duplicate results due to filings with the same technical content across multiple countries, patent families were considered based on the FAMPAT criterion [37] and will henceforth be referred to simply as “patents.” The search was performed using keywords, truncation characters, and suggestions provided by the database in the fields of title, abstract, object of invention, advantages, and independent claims, employing the following terms:

(eor or ooip or oil recovery or enhanced oil recovery or (“tertiar* oil recov*”) or “secondary petroleum recov*”) AND (smart water or low salinity injection or low salinity flooding or low salinity water flood or low salinity brine injection)

The patent search did not consider the legal status of patents to encompass all potential smart water EOR technologies and avoid specificities related to national patent offices. In fact, some countries, such as Brazil, have encountered patenting obstacles including issues with annual fees, and extended examination periods [38].

The annual number of patents was acquired in September 2024, covering all priority years until 2022, resulting in 23 patents. This approach aimed to circumvent the 18-month patent confidentiality period after filing, focusing solely on the years when the patents were fully published.

The patent graphs and tables were generated using ORBIT outputs, with data downloaded and processed by the authors using Microsoft Excel and PowerPoint. Data cleaning was performed by reading each patent individually, given their small number, and no exclusions were necessary. For the word cloud of the most frequent terms from the patent concepts, the Voyant Tools software v. 2025-08-05 was used [39].

2.2. Articles

The article search for TRL 3 was conducted in the Scopus database. This database was selected because it indexes only peer-reviewed articles, ensuring quality, although it excludes articles published in non-indexed journals. Conference papers were excluded so that only articles that undergo review prior to publication were considered. Keywords and truncation characters were applied in the fields of title, abstract, and keywords, covering English, Portuguese, and Spanish. The search for smart water research articles employed the following terms:

(enhanced AND oil AND recov* OR eor OR ooip OR water AND flooding OR sweep AND efficienc* OR oil AND recovery OR enhanced AND oil AND recovery OR “tertiar* oil recov*” OR “secondary petroleum recov*” OR “primary petroleum recov*”) AND (“low salinit* water*” OR “baixa salinid*” OR “baja* salinidad*” OR “smart water*” OR smartwater*) AND (LIMIT-TO (DOCTYPE, “ar”)

The data were exported to Excel, saved as a CSV file, and processed in RStudio version 2023.12.1 using Biblioshiny from the Bibliometrix package [40]. Keyword-based analyses were conducted following a cleaning process to merge similar terms and exclude irrelevant ones, ensuring that word clouds and keyword co-occurrences were not affected. For this purpose, 5969 keywords were evaluated individually; 495 redundant keywords, which merely repeated terms from the search scope, were removed; and 1056 keywords were standardized. After these procedures, a total of 1395 smart water articles remained.

To compare the annual evolution with smart water EOR, a second dataset of articles on EOR in general was obtained from the Scopus database using the following search terms:

(eor or ooip or oil recovery or enhanced oil recovery or (“tertiar* oil recov*”) or “secondary petroleum recov*”)

Table 1 presents the total number of documents obtained:

Table 1.

Total number of documents obtained.

Graphs and tables for the articles were generated using Biblioshiny tools and export functions and were subsequently processed by the authors using Microsoft Excel and PowerPoint.

3. Results and Discussion

Initially, comparative analyses of TRL 3 (articles) and TRL 4–5 (patents) are performed, focusing on annual evolution and its total percentage distribution, territorial distribution, leading organizations of article authors and patent applicants, international co-authorship of articles, patent co-assignees, citation dependencies, and word clouds of the most frequently relevant terms. Subsequently, the topics of the articles and the contents of the patents are examined in detail.

3.1. General Comparative Analysis

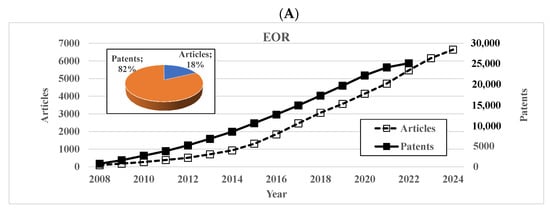

Figure 1 shows the annual cumulative evolution of articles and patents, and their respective percentages, for EOR in general (A) and for smart water EOR (B).

Figure 1.

Annual cumulative evolution of articles (left axis) and patents (right axis), and relative percentages of articles and patents for general EOR (A) and smart water EOR (B).

Figure 1 shows a general annual growth trend in all graphs, indicating that these are still relevant scientific and technological areas. For patents, the last two years lack data due to the 18-month confidentiality period.

For general EOR (Figure 1A), the total number of patents is approximately four times greater than the number of articles. This disparity may be attributed to the high demand for oil within the industry, as it remains a cornerstone of the planet’s energy supply. Proprietary technologies are crucial, with many articles being submitted only after patents are filed. Additionally, this reflects a technology with advanced maturity, requiring TRL 5 (technology validated in a relevant environment) or higher, having already progressed beyond the TRL 3 (experimental proof-of-concept) stage.

Comparatively, for smart water EOR technology (Figure 1B), which is still in its early stages of development, there are only 23 patents, whereas there are nearly 1500 articles showing an exponential growth trend. For the last ten complete years (2014 to 2023), the number of articles was modeled with good fit, resulting in an equation with an R2 value close to unity:

number of articles = 38.069 e0.3753 year R2 = 0.96

In other words, TRL 3, which is represented by articles, has been in full development since 2008, with exponential growth. However, TRL 4–5, represented by patents, is still emerging. For smart water EOR, the number of patents remains relatively small, approximately 2% of the total documents, making it insufficient to fit a meaningful exponential curve.

Another important aspect is the analysis of the impact of the COVID-19 pandemic years on annual trends. A decrease in the growth rate of EOR patents was observed (Figure 1A), consistent with previous findings by Quintella et al. [30]. The number of smart water EOR patents remains insufficient for reliable trend analysis.

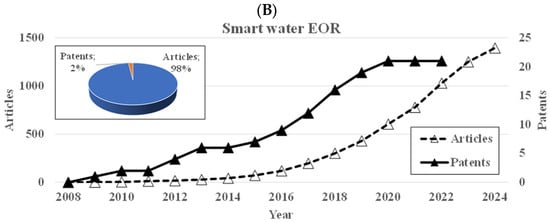

Figure 2 displays the collaborative production between countries concerning smart water. It shows the countries of article authors and their collaborations (Figure 2A), the countries of patent holders who developed the patents (Figure 2B), the countries where these patents were published in order to require exclusive rights for commercialization (Figure 2C), and the annual evolution of accumulated articles for the top five countries (Figure 2D).

Figure 2.

World maps showing the countries of: (A) articles collaborative production; (B) first priority countries according to technology origin; (C) patent protection countries for technology potential markets; (D) annual evolution of accumulated articles for the top five countries (Canada-green; USA—red; India—grey; China—yellow; and Iran—blue).

Smart water is a thriving field for articles. There are 1395 articles with 3330 authors from 63 countries, published in 222 journals, citing 60,547 references with an average citation per document of 20.92. Only 16 authors have single-authored documents, and the average number of co-authors per document is 4.64, with 31.68% international authorship. The total number of authors’ keywords is 2493. The journals with the highest number of published articles are: Journal of Petroleum Science and Engineering (223); Energy and Fuels (135); Fuel (110); Journal of Molecular Liquids (103); Colloids and Surfaces A: Physicochemical and Engineering Aspects (60); Energies (38); Journal of Petroleum Exploration and Production Technology (38); ACS Omega (29); SPE Journal (26); and Geoenergy Science and Engineering (25).

Articles, as expected, are predominantly published in journals focusing on petroleum, fuels, and energy. However, deviations are observed in journals such as Journal of Molecular Liquids, indicating that the technological challenges of smart water EOR are being addressed by scientists specializing in interfaces and chemical strategies for improved EOR formulations with smart water.

The authors of these articles are primarily concentrated in China (371), Iran (318), the USA (197), Canada (86), Saudi Arabia (84), the United Kingdom (86), India (82), Australia (80), and Norway (61). The top five countries are among the ten largest oil producers and are also highly dependent on oil consumption [1]. In the other countries, article output increases largely due to co-authorships with these top oil producers, enhancing their visibility in publication counts (Figure 2A).

In the case of patents, the average family size is 9.8, indicating that smart water EOR is a technology with an export-oriented nature, typically involving around ten countries, with broad market coverage, quite similar to pharmaceutical technologies. Additionally, more than half of the patents are filed with the European Patent Office, suggesting a strategic interest in securing market exclusivity in Europe. Similarly, 86% of the patents are filed under the Patent Cooperation Treaty (PCT), aiming for potential commercialization across various national territories.

When analyzing the article collaborations among authors in detail (Figure 2A), they are primarily centered in China, Iran, and the USA. The most intense group is led by the USA and China, with associations including Saudi Arabia, Norway, Canada, Kuwait, Korea, and Ghana. Another group, led by Iran, has strong collaborations with Australia and the United Kingdom, as well as with Iraq, India, South Africa, Thailand, Mexico, Colombia, and several European countries including Switzerland, Czech Republic, Spain, Denmark, France, Germany, and Austria. A third group, led by Malaysia, includes Nigeria, Netherlands, Pakistan, Sudan, Kazakhstan, Japan, Oman, and Indonesia. Lastly, Egypt and Italy form a fourth group of publication partnerships.

The cumulative annual evolution of articles (Figure 2D) shows that, although publications were initially led by the USA and Canada, China has surpassed all other countries, becoming the leading contributor. The USA has moved to second place, Iran occupies third place after recently overtaking Canada, which is now fourth, while India continues to grow and remains in fifth position.

Regarding patents, ownership of the technological development is concentrated in only four countries: the USA, Great Britain, Korea, and China (Figure 2B). However, these patents have been published in 27 countries (Figure 2C), which are target markets for their use, with the USA (18), Brazil (15), China (12), Mexico (11), and Great Britain (10) leading the list.

There is a significant reduction in the number of countries, from 26 in the article collaboration maps (Figure 2A) to only 4 in the patent maps (Figure 2B). This indicates that only a few of these countries are actively pursuing the commercialization of the technology, all of which are among the major oil producers [1,2].

It is also evident that there is a similarity between the maps in Figure 2A,C. In fact, there is a strong overlap between the map of those producing scientific research and disseminating it internationally through article publications and the map of potential markets for the patents of smart water EOR technology. Is scientific knowledge being given for free so that a small group of countries can patent it with profit potential based on worldwide efforts? Alternatively, could scientific research partnerships serve as a means of increasing human technological readiness for the proper use of imported technologies? Unfortunately, no Joint Industrial Field Projects were observed, which could otherwise accelerate the safe and environmentally responsible implementation of smart water.

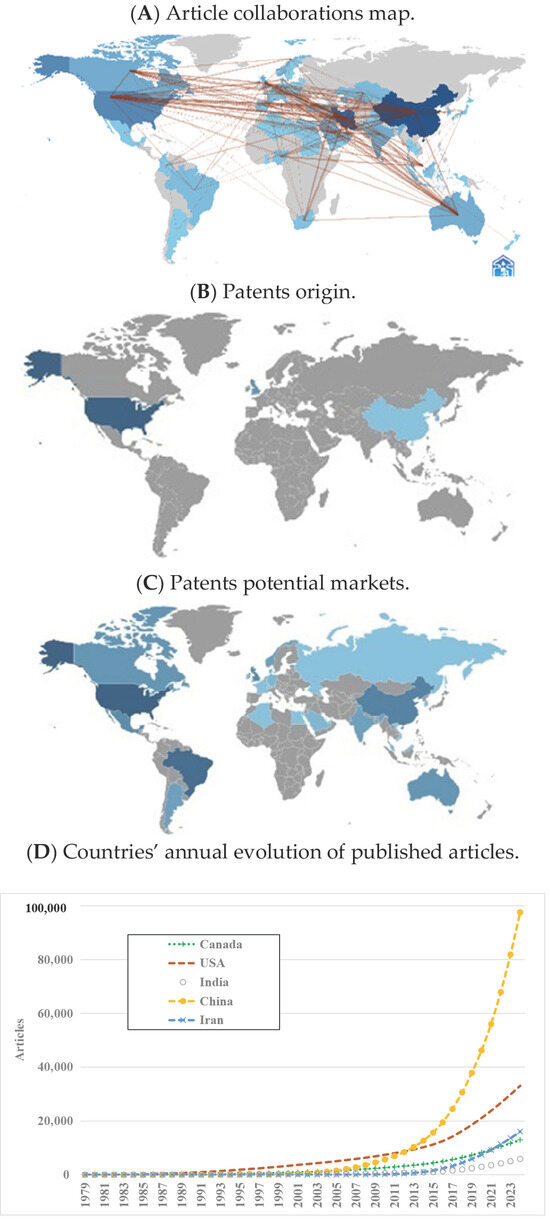

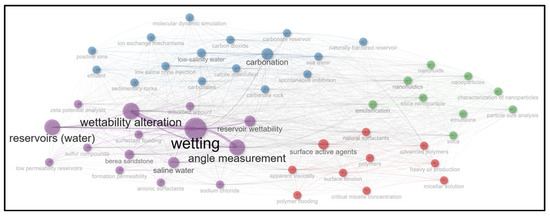

Figure 3 displays the word cloud of the most frequent terms in the keywords plus of the articles (Figure 3A) and the word cloud of the patent concepts (Figure 3B). The search terms used to retrieve the documents were excluded, clarifying the visualization and highlighting the terms most relevant to smart water EOR.

Figure 3.

Word clouds of the most frequent words in smart water EOR documents: (A) cleaned articles’ keywords plus; (B) cleaned patents’ concepts.

In Figure 3A, the majority of articles clearly focus on the interface processes between rock and fluids that define wettability and its alteration, as well as methods for measuring contact angles and agents for wettability alteration, including surface-active agents.

In Figure 3B, the most frequently mentioned concepts in patents relate to water, particularly whether injection water is prepared from produced water, seawater, or estuarine water. The process of desalination to condition and reinject these waters is also prominent, including associated processes such as reverse osmosis, water treatment, nanofiltration, and flocculation. Additionally, there is a focus on the presence and concentration of multivalent ions like calcium and their ratio with anions, as well as the total dissolved solids (TDS). Other relevant keywords include aspects related to reservoir rock formation, such as formation damage, clay, scaling processes, diosmectite, glauconite, and others. The use of carbon dioxide and carbonation is also present.

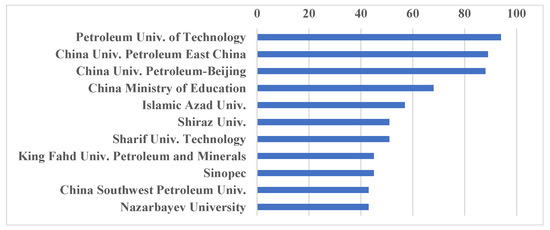

Figure 4 illustrates the top organizations affiliated with the authors of the articles.

Figure 4.

Top 10 organizations of affiliation of article authors.

Table 2 shows the organizations holding the patents with their market indicators. Initially, it is evident that academic organizations are completely absent, indicating that this technology is developed internally by companies. None of the patents have been cited in standards, which may be due to the technology’s relatively recent emergence and the lack of existing national or international regulations governing it. Additionally, no patents have been licensed, which could be attributed to the patents being used for the company’s own consumption or by its service providers, a common business model in the oil industry. However, all patents are still active and have not yet expired.

Table 2.

Patent applicants and market indicators.

In Figure 4, it is observed that most of the affiliations for scientific documents are academic institutions, as expected. Also, the China Ministry of Education is associated with 68 articles. However, there is a company, Sinopec—China Petroleum & Chemical Corporation, with 45 articles, highlights its involvement in research and technological development since TRL 3.

It can be observed (Table 2) that British Petroleum is the leader in the number of patents (10), with an average of 14.6 countries where they are published and an average age of 8.5 years since their filing. In addition to this company, two other firms also clearly target the export of technology, with more than ten family members: Shell (3 patents) and Saudi Arabian Oil (2 patents). Shell began acquiring technologies 10.1 years ago, while Saudi Arabian Oil started 7.3 years ago. Titan Oil Recovery has only one patent filed 9.7 years ago. The recently entering companies that have begun filing patents are Halliburton (3 patents), EPS ENE (2 patents), China Petroleum & Chemical (1 patent), and North China Oil Gas Branch of Sinopec (1 patent).

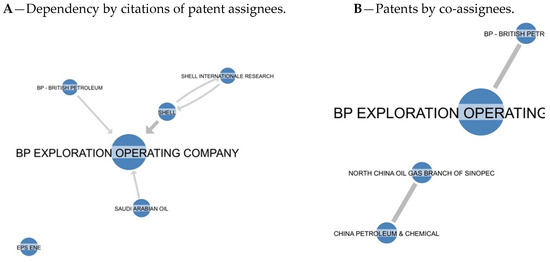

Figure 5 presents the analysis of patents with respect to citations (Figure 5A) and co-assignees (Figure 5B).

Figure 5.

Dependency by citations of patent assignees (A) and patent families by co-assignees (B).

In Figure 5A, it is observed that most patents held by Shell, BP—British Petroleum, and Saudi Arabian Oil cite patents from BP Exploration Operating Company, indicating that the latter was a key originator of significant technological aspects of smart water EOR. There are two patents from EPS ENE [41,42] that do not cite other patents, suggesting they are independent technologies focusing on formation water adjustment methods and a mobile plant for this purpose.

In Figure 5B, two groups of co-assignees are observed: one group includes companies affiliated with BP, and the other includes companies associated with Sinopec. No technological development collaboration between different groups of parent companies is evident, further suggesting that smart water EOR is being developed internally with a focus on commercialization. This technology also does not appear to be part of any Joint Industry Project, which typically involves cross-licensing and collaborative funding for technologies such as Carbon Capture, Utilization, and Storage.

3.2. Articles Analysis

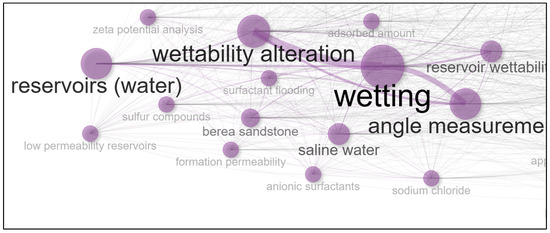

Figure 6 illustrates the co-occurrence network of cleaned keywords plus obtained for smart water EOR articles. There are four distinct clusters.

The largest cluster (purple color in Figure 6, details in Figure 7) is centered on wettability and its alteration, as well as evaluation through contact angle measurements. Wettability is a crucial aspect of smart water and engineered water injections and their applications in sandstone and carbonate rocks [43], including mechanisms of wettability alteration [44]. Chemical mechanisms have been studied by Rezaei-Doust et al. [45]. Various aspects of wettability have been evaluated, such as the presence of anhydrides [46], cation type and concentration [47], brine-rock interactions [48], effects on outcrop and oil reservoir sandstone [49], and the influence of ions such as calcium, carbonate, magnesium, and sulfate [50]. Pilot tests were conducted by Skrettingland et al. [51]. Surface complexation models of oil-brine-sandstone interfaces were developed [52], as well as modeling of low-salinity waterflooding [28]. Several authors have reviewed the various ways in which liquid–solid interfacial interactions can alter wettability and the resulting liquid–liquid interactions, identifying favorable conditions for specific compositions and concentrations while analyzing multiple interfacial mechanisms. However, the general conclusion is that no ideal conditions exist, as outcomes remain highly dependent on actual reservoir conditions [53,54,55,56].

Figure 7.

Purple cluster details of Co-occurrence network of keywords plus for smart water EOR articles from Figure 6.

Contact angle measurements have supported various studies on potential surfactants to be added to smart water EOR fluids, including environment-friendly non-ionic surfactants [57], natural anionic surfactants [58], natural leaf-derived surfactants [59], natural surfactants from Tanacetum and tarragon plants [60], red beet plant surfactants [61], polymer-cationic gemini surfactant systems at high temperatures [62], zwitterionic surfactants [63], synergistic combinations of cationic, anionic, and non-ionic surfactants [64], and carbonated water injection [65]. Some research has also focused on the mechanistic understanding of asphaltenes’ surface behavior [66] and the deformation of microdroplets in crude oil for rapid screening of enhanced oil recovery additives [67]. The most commonly used polymers in smart water EOR are xanthan and HPAM [68,69], while the surfactants can be cationic, anionic, or non-ionic, depending on the combinations of salts and polymers used [70].

Another topic addressed in the literature is the challenge of low-permeability reservoirs, which includes efforts to alter wettability in low-permeability sandstone reservoirs [71], employing in situ emulsification of surfactants [72], using nanoemulsions stabilized by anionic and non-ionic surfactants [73], and surfactant-silica nanoparticles [74], as well as amphiphilic Janus nano-silica [75]. Several studies also explore solutions involving CO2 injection, such as multi-stage gas channeling control systems for CO2 flooding [26,76,77,78].

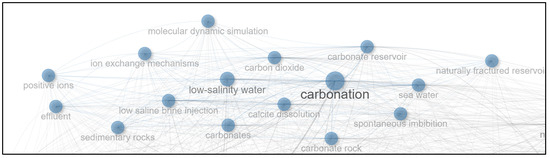

The carbonation cluster (blue color in Figure 6, details in Figure 8) includes articles that employ artificial neural networks for chemical flooding [79], prediction and management of CO2 flooding [80], and evaluation of critical performances [81]. Bisweswar et al. [82] provided a comprehensive review of carbonated water injection. Lashkarbolooki et al. [83] experimentally investigated the effects of temperature, pressure, dynamic swelling, and Bond number of crude oil during carbonated water flooding. Cobos et al. [84] conducted microcalorimetric studies of carbonating produced water as a promising method for CO2 storage and EOR. This cluster also includes articles on water-alternating-gas injection, CO2 injection schemes for extracting oil from low-permeability formations under immiscible conditions [85], 3D radial flow models for controlling gas channeling during CO2 immiscible flooding with complex fractures and heterogeneity [86], and critical reviews of CO2 EOR in carbonate reservoirs [87]. A review of both laboratory and field studies highlights the growing trend of integrating smart water with carbon dioxide for injection and sequestration to enhance carbon neutrality [53]. This topic has become one of the most frequently discussed in articles since 2021–2022 (Figure S1), with initial relevance appearing in 2019 (Figure S2). Although identified as an emerging theme throughout the entire study period (Figure S3), it is absent from the thematic map for 2008–2020 (Figure S4), exhibits low centrality and density in 2021–2022 (Figure S5), and has evolved into a basic theme in 2023–2024 (Figure S6).

Figure 8.

Blue cluster details of Co-occurrence network of keywords plus for smart water EOR articles from Figure 6.

Molecular dynamics simulations have investigated the effects of smart water on the calcite/brine interface [88], the influence of magnesium, sulfite, and sodium ions [89], the effects of temperature on the interaction between water and oil components on the carbonated pore wall [90], and the impact of salinity on the n-decane/water/vapor interfacial equilibrium [91]. Other studies include the effect of surface deprotonation due to resin adsorption at kaolinite edge sites [92], simulations with scaled charges [93], the adsorption behavior of surfactants on carbonate surfaces [94], surface simulations using complementary methods [95], and the nano-structure of hydrolyzed polyacrylamide strengthened ultra stable nitrogen foam [96]. However, very few simulations exist for hybrid smart water methods, particularly models that account for reservoir heterogeneities, consider their size and complexity, and integrate generative intelligence with machine learning [53]. The trend topics map indicates that molecular dynamics simulations began to appear around 2019 (Figure S2), while machine learning approaches have emerged as a recent topic of interest in 2023–2024 (Figure S6).

Studies on seawater adaptation for injection have investigated smart water and high-salinity seawater injection to maintain reservoir pressure without causing damage [97], the effects of magnesium, sulfite, and sodium ions in seawater [89], and the influence of salinity and aging time on carbonate reservoirs [98]. Velusamy et al. [99] examined the effect of imidazolium-based ionic liquids on the interfacial tension of the alkane–water system, while Shojaati et al. [100] studied the impact of salinity on asphaltene precipitation behavior. The stability of silica hydrophilic nanoparticles was analyzed by Puntervold et al. [101], and the application of SiO2–water nanofluid EOR was evaluated by Sofla et al. [102]. Modified seawater approaches were explored for EOR in chalk [101], sandstone reservoirs using EDTA chelating agents/seawater solutions [103], and carbonate reservoirs with modified Fe3O4 magnetic nanoparticles focusing on CO2 absorption capacity [104].

Fluids for EOR in carbonate reservoirs, particularly those analogous to the Pre-Salt formations, have been studied focusing on several factors. Research includes the effects of salinity [47,105,106], binary ionic compounds, and varying brine densities [107], as well as the influence of water-soluble ions on interfacial tension between oil and brine [108] and the impact of sulfate ions [109]. Lashkarbolooki et al. [110] investigated smart water injection into asphaltenic carbonate oil reservoirs. Kumar and Mandal [111] explored the use of zwitterionic surfactants for EOR in both sandstone and carbonate reservoirs. The association of polymers and nanofluids has been studied for application in carbonate reservoirs [112].

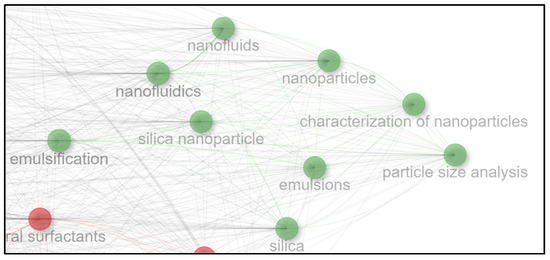

The emulsification cluster (green color in Figure 6, details in Figure 9) includes articles on nanofluids with ZnO nanocrystals induced by electromagnetic energy to increase viscosity [113], single-step silica nanoparticles for rheological characterization of surfactant-based CO2 foam [114], and the use of nanoparticle ferrofluid with magnetic field application [115]. It also covers potential applications of silica-based amphiphilic Janus nanosheets [116] and flooding with complex nanoscale colloidal dispersions through in situ formation of stable oil-in-water Pickering emulsions [117]. Additionally, the cluster includes studies on the EOR effects of graphene oxide/TiO2 nanocomposites, graphene oxide nanosheets, and cedr extraction solutions on carbonate rock [118], as well as amphiphilic graphene oxide flooding for ultralow-permeability reservoirs [119]. Polymers are also examined for their viscoelasticity [120] and the formation and rupture mechanisms of visco-elastic interfacial films in stabilized emulsions [121]. Foam flooding has recently gained prominence (Figure S1), emerging in 2022 (Figure S2) and evolving into a niche theme in 2023–2024 (Figure S6).

Figure 9.

Green cluster details of Co-occurrence network of keywords plus for smart water EOR articles from Figure 6.

Nanofluidics studies include investigations of fluorescent carbon nanoparticles [122], the effects of initial rock wettability on silica-based nanofluids [123,124], and carbonated polymeric nanofluids for sandstone reservoirs [114]. Research also covers the use of nanofluids to control fines migration [125,126], pore-scale investigations of smart water with surfactant nanofluid injection into oil-saturated sandstone using X-ray micro-tomography [127], and polymeric-nanofluids in carbonate reservoirs [128]. Radnia et al. [129] utilized nanofluids based on sulfonated graphene, and Alnarabiji et al. [113] studied nanofluids with induced ZnO nanocrystals via electromagnetic energy. Nanofluid studies related to emulsions [130] focus on optimizing volume fraction and inlet temperature [131], as well as adjustments in viscosity and flow resistance [132,133]. Dibaji et al. [134] developed CNT-TiO2 nanocomposites, while Ranjbar et al. [115] created a green nanofluid based on carbon dots. Nanofluidics was a relevant topic in 2008–2020 (Figure S4), shifting from a central theme to a niche theme in 2021–2022 (Figure S5). A recent review highlights the notable increase in combining smart water containing surfactants with nanotechnological fluids, such as polymer-coated nanoparticles [55].

The results found for microemulsion systems with incorporated nanoparticles indicate that the nanoparticles interact synergistically with surfactant molecules at the oil/water interface, resulting in more stable microemulsions capable of significantly reducing interfacial tension. This leads to the formation of smaller and more easily mobilized droplets [135], demonstrating potential applicability in low and ultra-low permeability reservoirs. Emulsification has been a relevant topic, classified as a basic theme since 2008 (Figure S4).

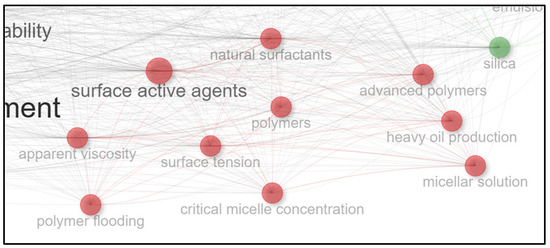

The articles within the surface-active agents cluster (red color in Figure 6, details in Figure 10) investigate various aspects of polymer-enhanced oil recovery that change the wettability as well as increase the piston effect. They include studies on heterogeneous systems after polymer flooding [136], amphoteric hyperbranched polymers [96], particle gel and alkali–surfactant–polymer composite systems for enhanced oil recovery in heterogeneous reservoirs [137], and temperature- and salt-tolerant 2-acrylamide-2-methylpropanesulfonic acid/AM@SiO2 microgel particles [138].

Figure 10.

Red cluster details of Co-occurrence network of keywords plus for smart water EOR articles from Figure 6.

Associations of alkalis, polymers, and surfactants (ASP) [139,140,141,142,143] have been applied to smart water fluids to enhance recovery factors using ionic surfactants [144], nonionic surfactants [145], tragacanth gum as a natural polymeric surfactant [146], clay and fumed silica nanoparticles [147], silica nanoparticles [148,149,150], and Gemini surfactant/polymer/silica-stabilized oil-in-water nanoemulsions [151]. Bacteriology has also recently emerged as a relevant topic (Figure S1), identified as a niche theme in 2023–2024 and associated with biosurfactants and biomolecules (Figure S6).

Effluent treatment remains a relatively underexplored area in the articles. However, some report on the use of biosurfactants derived from fenugreek seeds [152] and geochemical simulations of wettability alteration and effluent ionic analysis during smart water flooding in carbonate rocks [153].

Nonetheless, increased research efforts are expected in the future, in line with the clear exponential growth over the past two decades in the treatment of GEOR-related wastes [31].

Field applications [154], whether using alternating methods or not, have shown highly variable performance, with no reliable patterns yet observable. This is primarily due to the inability to systematically select reservoirs because of intrinsic differences, as well as the lack of data for prior simulations, including heterogeneities, fractures, clay content, and complex structures [53,54,55]. Additionally, intensive data collection increases costs and logistical requirements [53]. A recent trend in field applications is the pursuit of carbon neutrality through the integration of smart water with sequestered carbon dioxide injection [53].

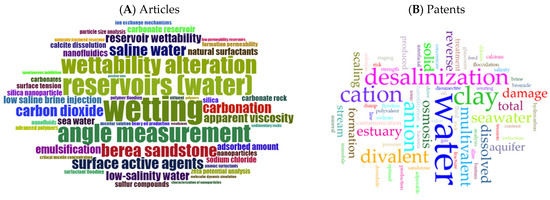

Finally, the thematic map analysis of all published articles, combining degree of development (density) with degree of relevance (centrality), classified the themes as follows (Figure S3):

- Basic Themes: Contact angle measurements; natural surfactants; and surface-active agents.

- Emerging or Declining Themes: Carbon dioxide; formation permeability; and naturally fractured reservoirs.

- Niche Themes: Aerogels; gels; and free radicals.

- Motor Themes: Wetting; reservoir water; and wettability alteration.

Additionally, at the center of the diagram are three promising research areas: emulsions; nanofluidics; and apparent viscosity.

The trend topic analysis (Figure S2) revealed that, in recent years, new research areas have emerged, including activated silica nanofluids, pharmaceutical-inspired procedures applied to EOR such as foam stability and nanofluidics, molecular dynamics simulations, foam flooding, carbon dioxide injection, and carbonation.

3.3. Patents Analysis

In the patents, smart water fluids, utilizing a TDS range of 200 to 10,000 ppm and controlled multivalent cation content, have proven to be a cost-effective method for enhancing the recovery factor in sandstone formations containing at least one mineral with a negative zeta potential under formation conditions [29].

TDS control has also been a significant aspect of patent claims, with various ranges cited such as approximately 8000 ppm in carbonate reservoirs [155] and from 200 ppm to 15,000 ppm [156]. Some patents refer to TDS control in conjunction with the use of demulsifiers to separate oil from produced water, which is then reconditioned for reinjection or disposal [157]. In addition to TDS control, sulfate concentration control has also been referred to in patents [112].

Desalination plants, including their equipment, tanks, and processes, have frequently been referred to in patents, focusing on reconditioning produced water or seawater [41,42,112,155,158,159,160,161,162,163].

Polymers have been incorporated into smart water EOR formulations, including copolymers of acrylamide and acrylate, copolymers of acrylamide, and acrylamide tertiary butyl sulfonate, mixed with metal oxide nanoparticles up to 0.1 wt% and dissolved CO2 [155]. Suijkerbuijk et al. [156] referred to the use of partially hydrolyzed polyacrylamide.

Surfactants have been referred to in patents in compositions involving combinations of phosphonoalkyl moieties and pH treatment fluids, and fatty acid alkoxylates, amine oxides, alkanolamides, alkoxylated alcohols, alkylamine alkoxylates, alkyl glycoside surfactants, or their combinations [164]. Other combinations include aminopolycarboxylic acids with phosphonoalkyl moieties [165]. Additionally, combinations of sulfonate anionic surfactants, quaternary ammonium salt cationic surfactants, and nonionic surfactants have been used at very high concentrations to manage decompression and augmented injection, aiming to prevent increased injection pressure due to crude oil emulsification, particularly in ultra-low permeability oil fields [166]. Recently, Quintella et al. [64,167] patented formulations with quite low surfactant concentrations, utilizing the synergistic effects of surfactant types near their critical micelle concentrations, combining the non-micellar forms of cationic surfactants with the micellar forms of other surfactants.

Other additives have been referred to, like deflocculants (lignite, tannin, polycarbonate, polycarboxylate, polyacrylamide, sodium carboxymethyl cellulose, sodium citrate, sodium silicate, ammonium oxalate, sodium oxalate, arabic gum, humic acid resin, bentonite, and combinations thereof), proppants (sand, clay, bauxite, alumina and aluminosilicates and combinations thereof), and dispersants (lignosulfate, polymethacrylate, hydroxypropyl methacrylate polyacrylamide, sodium vinyl sulfonate, sodium acrylamidomethylpropane sulfonate, phosphonobutane tricarboxylic acid, amino trimethylene phosphonic acid, hydroxyethylidene diphosphonic acid, sodium hydroxyethylidene diphosphonate, diethylenetriamine pentamethylene phosphonic acid and combinations thereof) [168].

Sheehy et al. [169] utilized smart water in Microbial EOR as a vehicle to stimulate resident microorganisms in situ, in order to beneficially change the size or hydrophobic properties of the microorganisms, thereby improving their interaction with the oil contained in reservoir rock formation in the presence of smart water flood treatments.

Advanced methods, such as downhole nuclear magnetic resonance, have been utilized for real-time determination of relative permeability, as well as fluid saturation, mobility, and viscosity [85]. Collins et al. [170] developed a method to detect incremental oil production due to smart waterflood. Other methods employ spectroscopic and interfacial techniques including microscopic, rheometric, and tensiometric methods, such as atomic force microscopy, Brewster angle microscopy, imaging ellipsometry, scanning electron microscopy, cryo-scanning electron microscopy, environmental scanning electron microscopy, transmission electron microscopy, surface force measurements, surface pressure measurements, surface potential measurements, confocal microscopy, molecular structural analyses, magnetic resonance measurements, rheometry, tensiometry, and their combinations [168].

Computer-implemented methods have been patented to develop predictive theoretical models in smart water EOR, focusing on predicting the additional amount of oil recovered, configuring the crude oil displacement system to inject displacement fluids with specific chemical characteristics into one or more reservoirs, and incorporating one or more operating modes of the crude oil displacement system, among other features [171].

In general, smart water patents have followed the trend of GEOR methods, exhibiting a positive Compound Annual Growth Rate ranging from 5% to 15%, with a particular focus on water–oil separation, flotation and sorption processes, solid waste disposal, and multistage treatment systems [31].

4. Conclusions

This article provides a critical comparison between TRL 3 and TRL 4–5 for smart water EOR, along with a comprehensive mapping of this emerging technology, which is undergoing significant development and experiencing a rapid annual increase in both scientific publications and patents. However, the number of patents remains relatively low, suggesting that the technology is primarily being developed internally within organizations.

Despite extensive international collaboration in scientific research, patents remain predominantly concentrated in a limited number of countries, although the target markets for these technologies closely align with the geographic origins of the research publications and their co-authorships.

The citation dependency of patents indicates that the technology was initiated by British Petroleum in 2008 and has since been followed up, with no independent innovations of high content appearing in patents. This contrasts with articles which show the opening of new research avenues. The most common themes are wetting, contact angle measurements, surface complexation models and molecular simulations, carbon dioxide and carbonation, emulsification, aerogels, sea water and formation water treatment for reinjection, carbonate reservoirs, effluent treatment, nanofluidics and its associations with emulsions, low permeability reservoirs, and ASP fluids.

The analysis of documents through word clouds, factor analysis, co-occurrence networks, and thematic maps identified the following themes: basic themes (contact angle measurements, natural surfactants, surface-active agents), emerging or declining themes (carbon dioxide, formation permeability, naturally fractured reservoirs), niche themes (aerogels, gels, free radicals), and motor themes (wetting, reservoir water, and wettability alteration). These findings highlight opportunities to advance cleaner technologies, whether in the recovery and treatment of produced water or seawater, or in more environmentally sustainable remediation and separation processes. They also indicate the need for further studies to advance TRL.

The identified bottlenecks requiring further research and mitigation include the high concentrations of additives in smart water EOR, which deviate from the technology’s environmentally friendly purpose due to their potential to cause harmful environmental impacts. To address this, a greater understanding of the interactions among injected water, oil, and rock is still needed, particularly those involving surfactants and polymers in micellar and aggregate forms, foams, and carbon dioxide injection.

Although smart water EOR is a sustainable approach supporting the transition to greener energy sources, it still requires basic regulatory frameworks for proper implementation by the oil industry. Furthermore, evaluations are needed regarding the payback periods for conditioning plants that treat produced water or seawater for reinjection. This technique presents a strong and robust opportunity for future research and policy development in both the EOR and energy transition fields.

The challenge of multiple coexisting interfacial synergistic mechanisms can only be addressed through multivariate studies that optimize several additives simultaneously, rather than through traditional univariate approaches, which do not capture more complex patterns. Furthermore, reservoir and oil heterogeneity necessitate that multivariate solutions be tailored to specific conditions.

In summary, data analysis reveals an exponential increase in the development of low-salinity water EOR technologies up to TRL 5, indicating the emergence of potential future technologies. These technologies offer substantial environmental and economic benefits; however, challenges remain in developing cleaner technologies necessary to advance their technological maturity beyond TRL 5. Promoting multivariate, customized research and encouraging global adoption of these practices are essential steps toward a more responsible and sustainable energy transition.

It is recommended that international Joint Industry Projects be established to accelerate the technological maturation of smart water EOR. Such initiatives can significantly reduce environmental impacts and enable more efficient utilization of existing oil fields, thereby reducing the need to develop new reservoirs and drill additional wells.

5. Patents

This article was developed by the authors as part of a technological landscape review conducted prior to the filing of three patents. The proposed formulations compete with conventional injection processes using very low concentrations of salts, commercial surfactants, and polymers already employed in EOR for various purposes, whether in traditional or early-stage injection. These formulations increase the Oil Recovery Factor, with the main competitive advantages being lower environmental impact and significantly reduced cost.

Patent BR102024016296-0 refers to optimized low-salinity compositions combined with low concentrations of anionic, cationic, and nonionic surfactants exhibiting synergistic effects that increase oil recovery by up to 20%. The formulation contains at least sodium, calcium, chloride ions, and bicarbonate compounds [167].

Patent BR102025010225-0 refers to formulations of optimized saline compositions at low concentrations, synergistically combined with anionic, cationic, and nonionic surfactants, and comprising at least two polymers containing carbon rings with heteroatoms, which increase oil recovery by up to 28% [172].

Patent BR102025005777-8 refers to formulations based on seawater or formation water, synergistically combined with low concentrations of anionic, cationic, and nonionic surfactants, and polymers with linear conformation or carbon rings containing heteroatoms, which enhance oil recovery by at least 36% compared to seawater and by at least 29% compared to formation water [173].

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/technologies13100457/s1: Figure S1: Thematic evolution of EOR with smart water articles across three temporal slices: 2008–2020, 2021–2022, and 2023–2024. Figure S2: Temporal evolution of the trend topics map for EOR with smart water articles. Figure S3: Thematic map of EOR with smart water articles, showing degree of development (density) versus degree of relevance (centrality) for all years. Figure S4: Thematic evolution of the first temporal slice from Figure S1 (2008–2020). Figure S5: Thematic evolution of the second temporal slice from Figure S1 (2021–2022). Figure S6: Thematic evolution of the third temporal slice from Figure S1 (2023–2024).

Author Contributions

Conceptualization: C.M.Q.; Methodology: C.M.Q.; Literature search: C.M.Q., P.D.R., J.L.N. and S.A.H.; Formal analysis and investigation: C.M.Q. and S.A.H.; Writing—original draft preparation: C.M.Q.; Writing—review and editing: C.M.Q., P.D.R., J.L.N. and S.A.H.; Supervision: C.M.Q.; Funding acquisition: C.M.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Petrogal Brasil S.A., and Agência Nacional do Petróleo, Gás Natural e Biocombustíveis of Brazil-ANP: GALP51.

Data Availability Statement

Most of the data used are available in the Supplementary Materials. Additional raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

C.M.Q. acknowledges a productivity scholarship in technological development research from the National Council for Scientific and Technological Development of Brazil (CNPq). P.D.R. and J.L.N. acknowledge postdoctoral scholarships from Petrogal Brasil S.A., through the Fundação de Apoio à Pesquisa e à Extensão (FAPEX). The Federal University of Bahia is acknowledged for reimbursing the APC fee paid by the authors. Elias Ramos-de-Souza and Edgard Bacic Carvalho are acknowledged for funding acquisition and project administration.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| EOR | Enhanced Oil Recovery |

| GEOR | Green Enhanced Oil Recovery |

| SDG | Sustainable Development Goals |

| TRL | Technology Readiness Level |

| Smart water | Low salinity water |

References

- U.S. Energy Information Administration Oil Producers and Consumers. Available online: https://www.eia.gov/tools/faqs/faq.php?id=709&t=6 (accessed on 4 August 2025).

- Heriot Watt University Statistical Review of World Energy 2023. Available online: https://www.energyinst.org/statistical-review (accessed on 4 August 2025).

- Joseph, J.A. The Ethical Interface of Sustainable Prosperity in the Teachings of Pope Francis. J. Dharma 2021, 46, 279–294. [Google Scholar]

- Fincham, G. “A World Not Our Own to Define”: Ecological Solutions to Global Catastrophe in the Works of Barry Lopez. Engl. Acad. Rev. 2024, 41, 33–46. [Google Scholar] [CrossRef]

- Delgado-Alvarado, E.; Morales-Gonzalez, E.A.; Gonzalez-Calderon, J.A.; Peréz-Peréz, M.C.I.; Delgado-Maciel, J.; Peña-Juarez, M.G.; Hernandez-Hernandez, J.; Elvira-Hernandez, E.A.; Figueroa-Navarro, M.A.; Herrera-May, A.L. Recent Advances of Hybrid Nanogenerators for Sustainable Ocean Energy Harvesting: Performance, Applications, and Challenges. Technologies 2025, 13, 336. [Google Scholar] [CrossRef]

- Ochoa-Correa, D.; Arévalo, P.; Martinez, S. Pathways to 100% Renewable Energy in Island Systems: A Systematic Review of Challenges, Solutions Strategies, and Success Cases. Technologies 2025, 13, 180. [Google Scholar] [CrossRef]

- Govindarajan, U.H.; Zhang, C.; Raut, R.D.; Narang, G.; Galdelli, A. A Review of Academic and Patent Progress on Internet of Things (IoT) Technologies for Enhanced Environmental Solutions. Technologies 2025, 13, 64. [Google Scholar] [CrossRef]

- de Mendonca, M.J.C.; Pereira Junior, A.O.; Pessanha, J.F.M.; Pereira, R.M.; Hunt, J.D. Measuring the Economic Impact of Pre-Salt Layer on the Productivity of the Oil and Natural Gas Sector. Resources 2025, 14, 32. [Google Scholar] [CrossRef]

- Petrobras, S.A. Santos Basin. Available online: https://petrobras.com.br/en/pre-sal? (accessed on 24 September 2025).

- Pooler, M. Brazil Wants to Be a Climate Champion and an Oil Giant. Can It Be Both? Available online: https://www.ft.com/content/8d25d4d5-0258-4676-81ab-30bb711f4fd2? (accessed on 24 September 2025).

- Branco, P.M. Petróleo do Pré-Sal. Available online: https://www.sgb.gov.br/petroleo-do-pre-sal? (accessed on 24 September 2025).

- ANP Brazil 2024 Annual Oil & Gas Production. Available online: https://brazilenergyinsight.com/2025/02/03/anp-brazil-2024-annual-oil-gas-production/ (accessed on 24 September 2025).

- United Nations Sustainable Development Goals. Available online: https://sdgs.un.org/goals (accessed on 18 July 2025).

- United Nations Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/2030agenda (accessed on 18 July 2025).

- Vilardo, C.; Campos, A. Pre-Salt Oil and Its Contribution to Sustainable Development in Brazil: A Preliminary Assessment. Available online: https://conferences.iaia.org/2011/pdf/presentations/IAIA11%20-%20Cristiano%20Vilardo%20-%20Pre-salt%20contribution%20to%20SD%20in%20Brazil.pdf? (accessed on 24 September 2025).

- Petrobras, S.A. Relatório de Sustentabilidade 2024. Available online: https://sustentabilidade.petrobras.com.br (accessed on 25 September 2025).

- Massarweh, O.; Abushaikha, A.S. The Use of Surfactants in Enhanced Oil Recovery: A Review of Recent Advances. Energy Rep. 2020, 6, 3150–3178. [Google Scholar] [CrossRef]

- US Department of Energy Enhanced Oil Recovery. Available online: https://www.energy.gov/fecm/enhanced-oil-recovery#:~:text=However%2C%20with%20much%20of%20the,reservoir’s%20original%20oil%20in%20place (accessed on 5 August 2025).

- Escoffier, M.; Hache, E.; Mignon, V.; Paris, A. Determinants of Solar Photovoltaic Deployment in the Electricity Mix: Do Oil Prices Really Matter? Energy Econ. 2021, 97, 105024. [Google Scholar] [CrossRef]

- Al-Ghamdi, A.; Haq, B.; Al-Shehri, D.; Muhammed, N.S.; Mahmoud, M. Surfactant Formulation for Green Enhanced Oil Recovery. Energy Rep. 2022, 8, 7800–7813. [Google Scholar] [CrossRef]

- Haq, B.; Liu, J.; Liu, K. Green Enhanced Oil Recovery (GEOR). APPEA J. 2017, 57, 150. [Google Scholar] [CrossRef]

- Haq, B.; Liu, J.; Liu, K.; Al Shehri, D. The Role of Biodegradable Surfactant in Microbial Enhanced Oil Recovery. J. Pet. Sci. Eng. 2020, 189, 106688. [Google Scholar] [CrossRef]

- Haq, B. Green Enhanced Oil Recovery for Carbonate Reservoirs. Polymers 2021, 13, 3269. [Google Scholar] [CrossRef]

- Hao, J.; Mohammadkhani, S.; Shahverdi, H.; Esfahany, M.N.; Shapiro, A. Mechanisms of Smart Waterflooding in Carbonate Oil Reservoirs—A Review. J. Pet. Sci. Eng. 2019, 179, 276–291. [Google Scholar] [CrossRef]

- Mwakipunda, G.C.; Jia, R.; Mgimba, M.M.; Ngata, M.R.; Mmbuji, A.O.; Said, A.A.; Yu, L. A Critical Review on Low Salinity Waterflooding for Enhanced Oil Recovery: Experimental Studies, Simulations, and Field Applications. Geoenergy Sci. Eng. 2023, 227, 211936. [Google Scholar] [CrossRef]

- Shen, H.; Yang, Z.; Li, X.; Peng, Y.; Lin, M.; Zhang, J.; Dong, Z. CO2-Responsive Agent for Restraining Gas Channeling during CO2 Flooding in Low Permeability Reservoirs. Fuel 2021, 292, 120306. [Google Scholar] [CrossRef]

- Santos, D.; Barros, V.S.; Silva, M.L.P.; Sales, H.M.M.S.; Borges, G.R.; Franceschi, E.; Dariva, C. Strontium-Based Low Salinity Water as an IOR/EOR Method: Oil-Brine Interaction. J. Pet. Sci. Eng. 2021, 202, 108549. [Google Scholar] [CrossRef]

- Jerauld, G.R.; Lin, C.Y.; Webb, K.J.; Seccombe, J.C. Modeling Low-Salinity Waterflooding. SPE Reserv. Eval. Eng. 2008, 11, 1000–1012. [Google Scholar] [CrossRef]

- Collins, I.R.; Jerauld, G.R.; Lager, A.; McGuire, P.L.; Webb, K. Hydrocarbon Recovery Process. PCT Patent WO2008/029124, 6 March 2008. [Google Scholar]

- Quintella, C.M.; Rodrigues, P.D.; Nicoleti, J.L.; Ramos-de-Souza, E.; Carvalho, E.B.; Hanna, S.A. EOR Technology (Patents) and Science (Articles) Assessment of BRICS and NonBRICS with Growth Rates and Specializations within Responsible Global Energy Transition: A Critical Review. Energies 2024, 17, 3197. [Google Scholar] [CrossRef]

- Quintella, C.M. Environmental Protection in Enhanced Oil Recovery and Its Waste and Effluents Treatment: A Critical Patent-Based Review of BRICS and Non-BRICS (2004–2023). Sustainability 2025, 17, 2896. [Google Scholar] [CrossRef]

- NASA. The TRL Scale as a Research & Innovation Policy Tool. NASA EARTO Recommendations. Available online: https://www.earto.eu/wp-content/uploads/The_TRL_Scale_as_a_R_I_Policy_Tool_-_EARTO_Recommendations_-_Final.pdf (accessed on 5 August 2025).

- Nesta, L.; Patel, P. National Patterns of Technology Accumulation: Use of Patent Statistics. In Handbook of Quantitative Science and Technology Research; Kluwer Academic Publishers: Dordrecht, The Netherlands; pp. 531–551.

- Quintella, C.M.; Hanna, S.A.; dos Santos, S.C. Brazil’s Biotechnology Assessment of Potential to Achieve Sustainable Development Goals, Benchmarking against the USA. World Pat. Inf. 2024, 77, 102275. [Google Scholar] [CrossRef]

- Almgren, R.; Skobelev, D. Evolution of Technology and Technology Governance. J. Open Innov. Technol. Mark. Complex 2020, 6, 22. [Google Scholar] [CrossRef]

- European Patent Office. Worldwide Database. Available online: https://worldwide.espacenet.com (accessed on 5 August 2025).

- Questel Orbit. The Fampat Collection. Available online: https://intelligence.help.questel.com/en/support/solutions/articles/77000436698-fampat-family-construction-rules (accessed on 5 August 2025).

- Gomes Costa, B.M.; Nannini da Silva Florencio, M.; de Oliveira Junior, A.M. Analysis of Technological Production in Biotechnology in Northeast Brazil. World Pat. Inf. 2018, 52, 42–49. [Google Scholar] [CrossRef]

- Voyant Tools. Available online: https://voyant-tools.org (accessed on 5 August 2025).

- Bibliometrix Biblioshiny. Available online: https://www.bibliometrix.org/home/index.php/layout/biblioshiny (accessed on 28 August 2025).

- Jang, J.H.; Park, B.J.; Shin, S.H.; Lee, E.G.; Kim, J.H.; Han, H.S.; Choi, B.G. Movable Smart Water System. Korea Patent KR10-1995822, 27 June 2019. [Google Scholar]

- Park, J.W.; Moon, C.H.; Park, B.J.; Kim, J.H.; Jung, E.T.; Oh, S.H. System for Manufacturing Smart Water. Korea Patent KR10-2338769, 8 December 2021. [Google Scholar]

- Al-Shalabi, E.W.; Sepehrnoori, K. A Comprehensive Review of Low Salinity/Engineered Water Injections and Their Applications in Sandstone and Carbonate Rocks. J. Pet. Sci. Eng. 2016, 139, 137–161. [Google Scholar] [CrossRef]

- Liu, F.; Wang, M. Review of Low Salinity Waterflooding Mechanisms: Wettability Alteration and Its Impact on Oil Recovery. Fuel 2020, 267, 117112. [Google Scholar] [CrossRef]

- RezaeiDoust, A.; Puntervold, T.; Austad, T. Chemical Verification of the EOR Mechanism by Using Low Saline/Smart Water in Sandstone. Energy Fuels 2011, 25, 2151–2162. [Google Scholar] [CrossRef]

- Austad, T.; Shariatpanahi, S.F.; Strand, S.; Aksulu, H.; Puntervold, T. Low Salinity EOR Effects in Limestone Reservoir Cores Containing Anhydrite: A Discussion of the Chemical Mechanism. Energy Fuels 2015, 29, 6903–6911. [Google Scholar] [CrossRef]

- Nasralla, R.A.; Nasr-El-Din, H.A. Impact of Cation Type and Concentration in Injected Brine on Oil Recovery in Sandstone Reservoirs. J. Pet. Sci. Eng. 2014, 122, 384–395. [Google Scholar] [CrossRef]

- Sharma, H.; Mohanty, K.K. An Experimental and Modeling Study to Investigate Brine-Rock Interactions during Low Salinity Water Flooding in Carbonates. J. Pet. Sci. Eng. 2018, 165, 1021–1039. [Google Scholar] [CrossRef]

- Hassenkam, T.; Pedersen, C.S.; Dalby, K.; Austad, T.; Stipp, S.L.S. Pore Scale Observation of Low Salinity Effects on Outcrop and Oil Reservoir Sandstone. Colloids Surf. A Physicochem. Eng. Asp. 2011, 390, 179–188. [Google Scholar] [CrossRef]

- Song, J.; Zeng, Y.; Wang, L.; Duan, X.; Puerto, M.; Chapman, W.G.; Biswal, S.L.; Hirasaki, G.J. Surface Complexation Modeling of Calcite Zeta Potential Measurements in Brines with Mixed Potential Determining Ions (Ca2+, CO32−, Mg2+, SO42−) for Characterizing Carbonate Wettability. J. Colloid Interface Sci. 2017, 506, 169–179. [Google Scholar] [CrossRef] [PubMed]

- Skrettingland, K.; Holt, T.; Tweheyo, M.T.; Skjevrak, I. Snorre Low-Salinity-Water Injection—Coreflooding Experiments and Single-Well Field Pilot. SPE Reserv. Eval. Eng. 2011, 14, 182–192. [Google Scholar] [CrossRef]

- Brady, P.V.; Krumhansl, J.L. A Surface Complexation Model of Oil–Brine–Sandstone Interfaces at 100 °C: Low Salinity Waterflooding. J. Pet. Sci. Eng. 2012, 81, 171–176. [Google Scholar] [CrossRef]

- Behera, U.S.; Sangwai, J.S.; Baskaran, D.; Byun, H.-S. A Comprehensive Review on Low Salinity Water Injection for Enhanced Oil Recovery: Fundamental Insights, Laboratory and Field Studies, and Economic Aspects. Energy Fuels 2025, 39, 72–103. [Google Scholar] [CrossRef]

- Lyu, C.; Zhong, L.; Ning, Z.; Chen, M.; Cole, D.R. Review on Underlying Mechanisms of Low Salinity Waterflooding: Comparisons between Sandstone and Carbonate. Energy Fuels 2022, 36, 2407–2423. [Google Scholar] [CrossRef]

- Mumbere, W.; Sagala, F.; Gupta, U.; Bbosa, D. Reservoir Potential Unlocked: Synergies Between Low-Salinity Water Flooding, Nanoparticles and Surfactants in Enhanced Oil Recovery—A Review. ACS Omega 2025, 10, 31216–31261. [Google Scholar] [CrossRef]

- Marquez, R.; Ding, H.; Barrios, N.; Vera, R.E.; Salager, J.-L.; Al-Shalabi, E.W.; Mettu, S. Recent Advances in Enhanced Oil Recovery with Low-Salinity Waterflooding and Its Hybrid Methods in Carbonate Reservoirs. Energy Fuels 2025, 39, 8769–8799. [Google Scholar] [CrossRef]

- Haghighi, O.; Zargar, G.; Khaksar Manshad, A.; Ali, M.; Takassi, M.; Ali, J.; Keshavarz, A. Effect of Environment-Friendly Non-Ionic Surfactant on Interfacial Tension Reduction and Wettability Alteration; Implications for Enhanced Oil Recovery. Energies 2020, 13, 3988. [Google Scholar] [CrossRef]

- Saxena, N.; Saxena, A.; Mandal, A. Synthesis, Characterization and Enhanced Oil Recovery Potential Analysis through Simulation of a Natural Anionic Surfactant. J. Mol. Liq. 2019, 282, 545–556. [Google Scholar] [CrossRef]

- Khorram Ghahfarokhi, A.; Dadashi, A.; Daryasafar, A.; Moghadasi, J. Feasibility Study of New Natural Leaf-Derived Surfactants on the IFT in an Oil–Aqueous System: Experimental Investigation. J. Pet. Explor. Prod. Technol. 2015, 5, 375–382. [Google Scholar] [CrossRef]

- Dashtaki, S.R.M.; Ali, J.A.; Majeed, B.; Manshad, A.K.; Nowrouzi, I.; Iglauer, S.; Keshavarz, A. Evaluation the Role of Natural Surfactants from Tanacetum and Tarragon Plants in EOR Applications. J. Mol. Liq. 2022, 361, 119576. [Google Scholar] [CrossRef]

- Norouzpour, M.; Azdarpour, A.; Nabipour, M.; Santos, R.M.; Khaksar Manshad, A.; Iglauer, S.; Akhondzadeh, H.; Keshavarz, A. Red Beet Plant as a Novel Source of Natural Surfactant Combined with ‘Smart Water’ for EOR Purposes in Carbonate Reservoirs. J. Mol. Liq. 2023, 370, 121051. [Google Scholar] [CrossRef]

- Kalam, S.; Kamal, M.S.; Patil, S.; Hussain, S.M.S. Impact of Spacer Nature and Counter Ions on Rheological Behavior of Novel Polymer-Cationic Gemini Surfactant Systems at High Temperature. Polymers 2020, 12, 1027. [Google Scholar] [CrossRef]

- Gbadamosi, A.; Hussai, S.M.S.; Kamal, M.S.; Patil, S.; Solling, T.; Hassan, S.F.; Wang, J. Evaluating the Potential of Zwitterionic Surfactants for Enhanced Oil Recovery: Effect of Headgroups and Unsaturation. Energy Fuels 2023, 37, 5078–5086. [Google Scholar] [CrossRef]

- Quintella, C.M.; Rodrigues, P.D.; Hanna, S.A.; Nicoleti, J.L.; Carvalho, E.B.; de Medeiros, A.C.G.; Ramos-de-Souza, E.; dos Santos, E.S.; Vasconcelos, A.C.; de Moura, J.D. Sustainable Enhanced Oil Recovery Fluid Based on Synergic Effects of Cationic, Anionic, and Nonionic Surfactants in Low Salinity: SLS.; QA; and SDBS. ACS Omega 2025, 10, 8408–8419. [Google Scholar] [CrossRef]

- Qin, Z.; Arshadi, M.; Piri, M. Carbonated Water Injection and In Situ CO2 Exsolution in Oil-Wet Carbonate: A Micro-Scale Experimental Investigation. Energy Fuels 2021, 35, 6615–6632. [Google Scholar] [CrossRef]

- Moghadasi, R.; Kord, S.; Moghadasi, J.; Dashti, H. Mechanistic Understanding of Asphaltenes Surface Behavior at Oil/Water Interface: An Experimental Study. J. Mol. Liq. 2019, 285, 562–571. [Google Scholar] [CrossRef]

- Lele, P.; Syed, A.H.; Riordon, J.; Mosavat, N.; Guerrero, A.; Fadaei, H.; Sinton, D. Deformation of Microdroplets in Crude Oil for Rapid Screening of Enhanced Oil Recovery Additives. J. Pet. Sci. Eng. 2018, 165, 298–304. [Google Scholar] [CrossRef]

- Quintella, C.M.; Nascimento dos Santos, L.; Cruz Serra de Araújo, V.; Reis Gonçalves da Silva, H.; Ramos-de-Souza, E.; Bacic de Carvalho, E.; Hanna, S.A. Scientific and Technological Assessment of Xanthan and HPAM in the Low Environmental Impact Fluids for Advanced Oil Recovery (EOR). Rev. Indicação Geogr. Inov. INGI 2023, 7, 2255–2270. [Google Scholar] [CrossRef]

- Ramos de Souza, E.; Rodrigues, P.D.; Sampaio, I.C.F.; Bacic, E.; Crugeira, P.J.L.; Vasconcelos, A.C.; dos Santos Silva, M.; dos Santos, J.N.; Quintella, C.M.; Pinheiro, A.L.B.; et al. Xanthan Gum Produced by Xanthomonas Campestris Using Produced Water and Crude Glycerin as an Environmentally Friendlier Agent to Enhance Oil Recovery. Fuel 2022, 310, 122421. [Google Scholar] [CrossRef]

- Hanna, S.A.; Oliveira, P.C.C.A.; Santos, A.C.C.; Souza, E.R.; Carvalho, E.B.; Quintella, C.M. Enhanced Oil Recovery with Low Environmental Impact: Mapping Science (Articles) and Technology (Patents). Rev. Indicação Geogr. Inov. INGI 2023, 7, 2052–2068. [Google Scholar] [CrossRef]

- Wang, D.; Sun, S.; Cui, K.; Li, H.; Gong, Y.; Hou, J.; Zhang, Z. Wettability Alteration in Low-Permeability Sandstone Reservoirs by “SiO2–Rhamnolipid” Nanofluid. Energy Fuels 2019, 33, 12170–12181. [Google Scholar] [CrossRef]

- Li, X.; Yue, X.; Zou, J.; Yan, R. Effect of In-Situ Emulsification of Surfactant on the Enhanced Oil Recovery in Low-Permeability Reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2022, 634, 127991. [Google Scholar] [CrossRef]

- Liu, D.; Xu, J.; Zhao, H.; Zhang, X.; Zhou, H.; Wu, D.; Liu, Y.; Yu, P.; Xu, Z.; Kang, W.; et al. Nanoemulsions Stabilized by Anionic and Non-Ionic Surfactants for Enhanced Oil Recovery in Ultra-Low Permeability Reservoirs: Performance Evaluation and Mechanism Study. Colloids Surf. A Physicochem. Eng. Asp. 2022, 637, 128235. [Google Scholar] [CrossRef]

- Zhao, M.; Cheng, Y.; Wu, Y.; Dai, C.; Gao, M.; Yan, R.; Guo, X. Enhanced Oil Recovery Mechanism by Surfactant-Silica Nanoparticles Imbibition in Ultra-Low Permeability Reservoirs. J. Mol. Liq. 2022, 348, 118010. [Google Scholar] [CrossRef]

- Bai, Y.; Pu, C.; Liu, S.; Li, X.; Liang, L.; Liu, J. A Novel Amphiphilic Janus Nano-Silica for Enhanced Oil Recovery in Low-Permeability Reservoirs: An Experimental Study. Colloids Surf. A Physicochem. Eng. Asp. 2022, 637, 128279. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, P.; Huang, S.; Hao, H.; Zhang, M.; Lu, G. Performance and Applicable Limits of Multi-Stage Gas Channeling Control System for CO2 Flooding in Ultra-Low Permeability Reservoirs. J. Pet. Sci. Eng. 2020, 192, 107336. [Google Scholar] [CrossRef]

- Cui, G.; Yang, L.; Fang, J.; Qiu, Z.; Wang, Y.; Ren, S. Geochemical Reactions and Their Influence on Petrophysical Properties of Ultra-Low Permeability Oil Reservoirs during Water and CO2 Flooding. J. Pet. Sci. Eng. 2021, 203, 108672. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, M.; You, Q.; Fan, H.; Li, W.; Liu, Y.; Fang, J.; Zhao, G.; Jin, Z.; Dai, C. Smart Mobility Control Agent for Enhanced Oil Recovery during CO2 Flooding in Ultra-Low Permeability Reservoirs. Fuel 2019, 241, 442–450. [Google Scholar] [CrossRef]

- Ahmadi, M.A. Developing a Robust Surrogate Model of Chemical Flooding Based on the Artificial Neural Network for Enhanced Oil Recovery Implications. Math. Probl. Eng. 2015, 2015, 706897. [Google Scholar] [CrossRef]

- Le Van, S.; Chon, B.H. Evaluating the Critical Performances of a CO2–Enhanced Oil Recovery Process Using Artificial Neural Network Models. J. Pet. Sci. Eng. 2017, 157, 207–222. [Google Scholar] [CrossRef]

- Van, S.L.; Chon, B.H. Effective Prediction and Management of a CO2 Flooding Process for Enhancing Oil Recovery Using Artificial Neural Networks. J. Energy Resour. Technol. 2018, 140, 032906. [Google Scholar] [CrossRef]

- Bisweswar, G.; Al-Hamairi, A.; Jin, S. Carbonated Water Injection: An Efficient EOR Approach. A Review of Fundamentals and Prospects. J. Pet. Explor. Prod. Technol. 2020, 10, 673–685. [Google Scholar] [CrossRef]

- Lashkarbolooki, M.; Riazi, M.; Ayatollahi, S. Experimental Investigation of Dynamic Swelling and Bond Number of Crude Oil during Carbonated Water Flooding; Effect of Temperature and Pressure. Fuel 2018, 214, 135–143. [Google Scholar] [CrossRef]

- Cobos, J.E.; Kissami, Y.; Alkutaini, I.A.; Søgaard, E.G. Microcalorimetric Study of Carbonating Produced Water as a Promising CO2 Storage and Enhanced Oil Recovery Method. Energies 2022, 15, 2888. [Google Scholar] [CrossRef]

- Li, S.; Zhang, K.; Jia, N.; Liu, L. Evaluation of Four CO2 Injection Schemes for Unlocking Oils from Low-Permeability Formations under Immiscible Conditions. Fuel 2018, 234, 814–823. [Google Scholar] [CrossRef]

- Hao, H.; Hou, J.; Zhao, F.; Song, Z.; Hou, L.; Wang, Z. Gas Channeling Control during CO2 Immiscible Flooding in 3D Radial Flow Model with Complex Fractures and Heterogeneity. J. Pet. Sci. Eng. 2016, 146, 890–901. [Google Scholar] [CrossRef]

- Tan, Y.; Li, Q.; Xu, L.; Ghaffar, A.; Zhou, X.; Li, P. A Critical Review of Carbon Dioxide Enhanced Oil Recovery in Carbonate Reservoirs. Fuel 2022, 328, 125256. [Google Scholar] [CrossRef]

- Koleini, M.M.; Mehraban, M.F.; Ayatollahi, S. Effects of Low Salinity Water on Calcite/Brine Interface: A Molecular Dynamics Simulation Study. Colloids Surf. A Physicochem. Eng. Asp. 2018, 537, 61–68. [Google Scholar] [CrossRef]

- Prabhakar, S.; Melnik, R. Influence of Mg2+, (SO4)2− and Na+ Ions of Sea Water in Crude Oil Recovery: DFT and Ab Initio Molecular Dynamics Simulations. Colloids Surf. A Physicochem. Eng. Asp. 2018, 539, 53–58. [Google Scholar] [CrossRef]

- Abdolahi, S.; Rashidi, F.; Miri, R. Effects of Temperature on the Interaction of Water and Oil Components on the Carbonated Pore Wall: Molecular Dynamics Simulation Study. J. Porous Media 2022, 25, 83–107. [Google Scholar] [CrossRef]

- Zhao, J.; Yao, G.; Ramisetti, S.B.; Hammond, R.B.; Wen, D. Molecular Dynamics Simulation of the Salinity Effect on the n -Decane/Water/Vapor Interfacial Equilibrium. Energy Fuels 2018, 32, 11080–11092. [Google Scholar] [CrossRef]

- Zeitler, T.R.; Greathouse, J.A.; Cygan, R.T.; Fredrich, J.T.; Jerauld, G.R. Molecular Dynamics Simulation of Resin Adsorption at Kaolinite Edge Sites: Effect of Surface Deprotonation on Interfacial Structure. J. Phys. Chem. C 2017, 121, 22787–22796. [Google Scholar] [CrossRef]

- Tetteh, J.; Bai, S.; Kubelka, J.; Piri, M. Surfactant-Induced Wettability Reversal on Oil-Wet Calcite Surfaces: Experimentation and Molecular Dynamics Simulations with Scaled-Charges. J Colloid Interface Sci 2022, 609, 890–900. [Google Scholar] [CrossRef]

- Hou, J.; Lin, S.; Du, J.; Sui, H. Study of the Adsorption Behavior of Surfactants on Carbonate Surface by Experiment and Molecular Dynamics Simulation. Front Chem 2022, 10, 847986. [Google Scholar] [CrossRef] [PubMed]

- Ramos de Souza, E.; Vasconcelos, A.C.; Melo, W.G.L.; Quintella, C.M.; de Carvalho, E.B.; dos Santos, E.S. The Stabilization of Oil-Bound Thin Brine Films over a Fixed Substrate with Electrically Charged Surfactants Subject to van Der Waals and Electrostatic Forces. Geoenergy Sci. Eng. 2023, 227, 211805. [Google Scholar] [CrossRef]

- Pu, W.-F.; Liu, R.; Li, B.; Jin, F.-Y.; Peng, Q.; Sun, L.; Du, D.-J.; Yao, F.-S. Amphoteric Hyperbranched Polymers with Multistimuli-Responsive Behavior in the Application of Polymer Flooding. RSC Adv. 2015, 5, 88002–88013. [Google Scholar] [CrossRef]

- Mahmoud, M.; Elkatatny, S.; Abdelgawad, K.Z. Using High- and Low-Salinity Seawater Injection to Maintain the Oil Reservoir Pressure without Damage. J. Pet. Explor. Prod. Technol. 2017, 7, 589–596. [Google Scholar] [CrossRef]

- Rahimi, A.; Honarvar, B.; Safari, M. The Role of Salinity and Aging Time on Carbonate Reservoir in Low Salinity Seawater and Smart Seawater Flooding. J. Pet. Sci. Eng. 2020, 187, 106739. [Google Scholar] [CrossRef]

- Velusamy, S.; Sakthivel, S.; Sangwai, J.S. Effect of Imidazolium-Based Ionic Liquids on the Interfacial Tension of the Alkane–Water System and Its Influence on the Wettability Alteration of Quartz under Saline Conditions through Contact Angle Measurements. Ind. Eng. Chem. Res. 2017, 56, 13521–13534. [Google Scholar] [CrossRef]