Determination of the Mechanical Tensile Characteristics of Some 3D-Printed Specimens from NYLON 12 CARBON Fiber Material

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Manufacturing and Preparation

2.2. Annealing Treatment

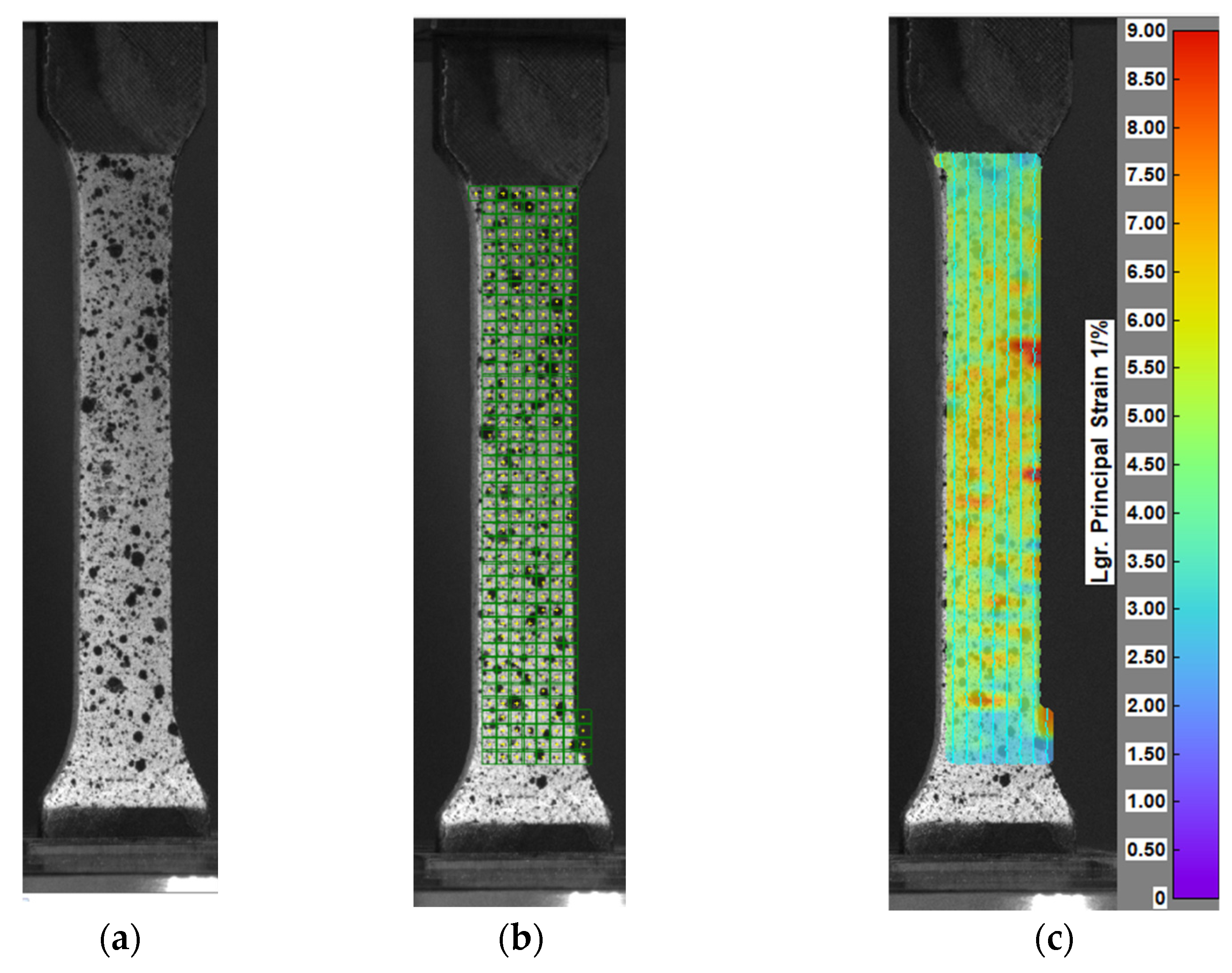

2.3. Tensile Testing

2.4. Finite Element Analysis (FEA)

3. Results

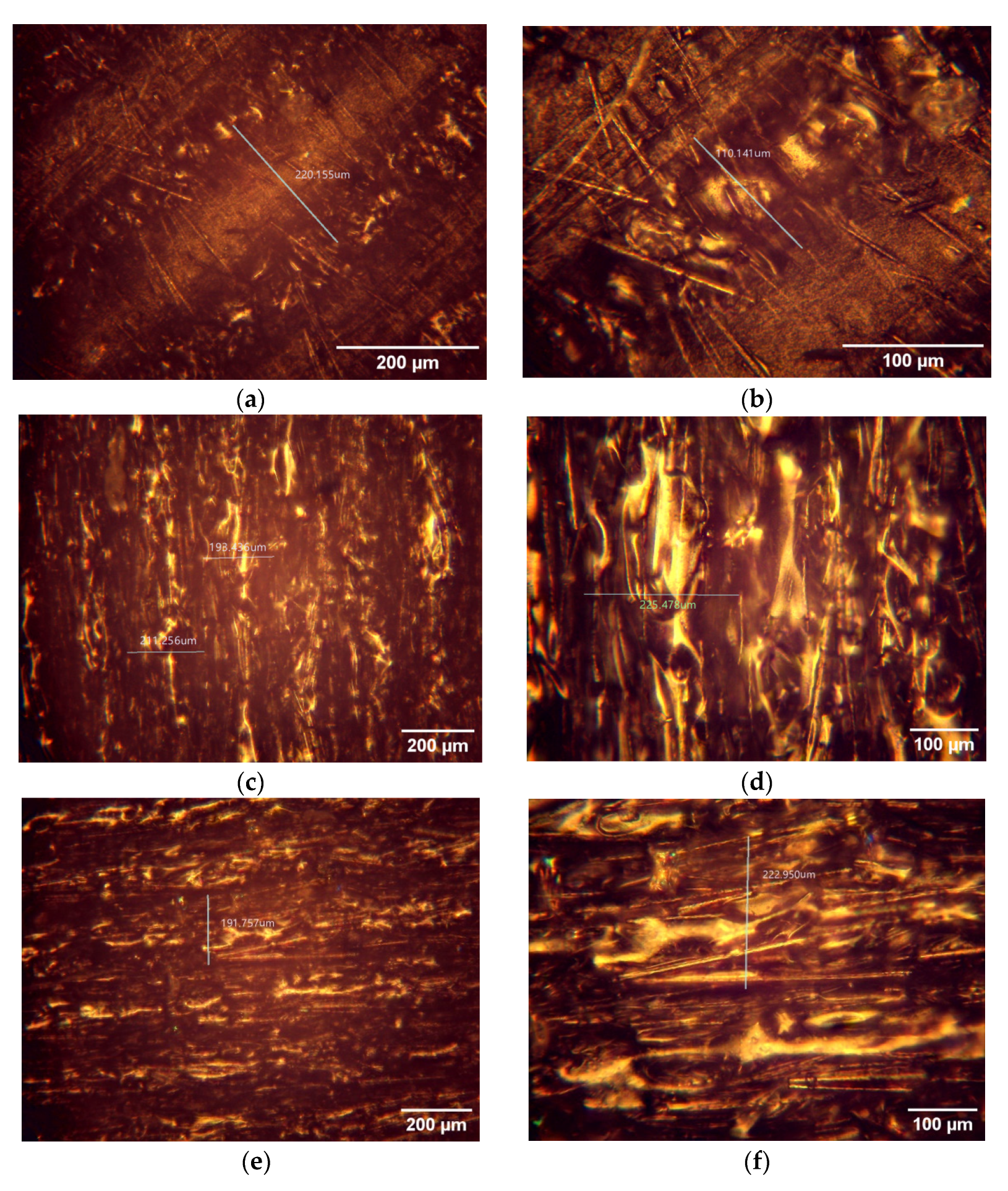

3.1. Fractured Specimens After Tensile Testing

3.2. Mechanical Properties

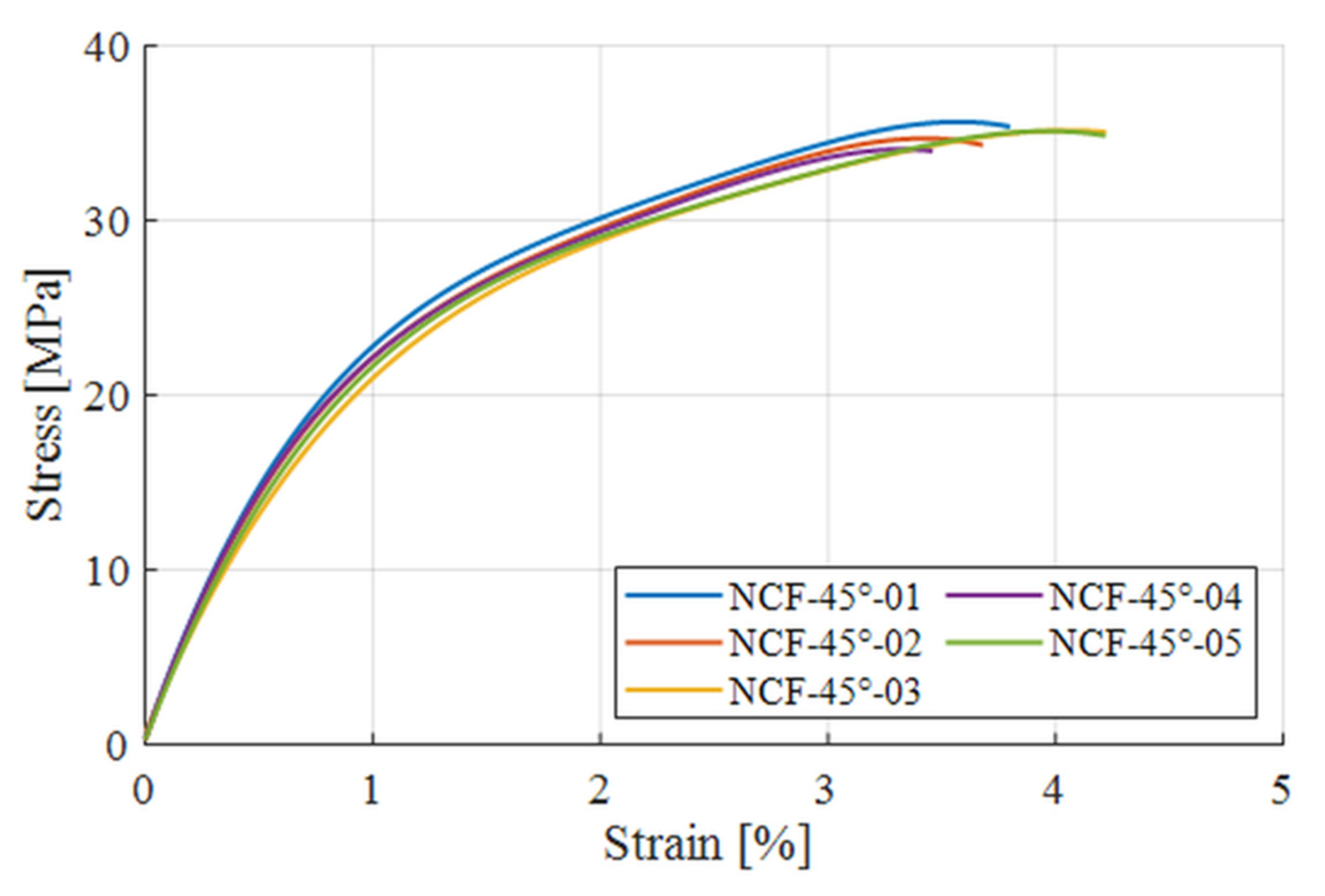

3.2.1. Horizontal Printing (Set A–45°)

3.2.2. Vertical Printing (Set B–90°)

3.2.3. Lateral Printing (Set C–0°)

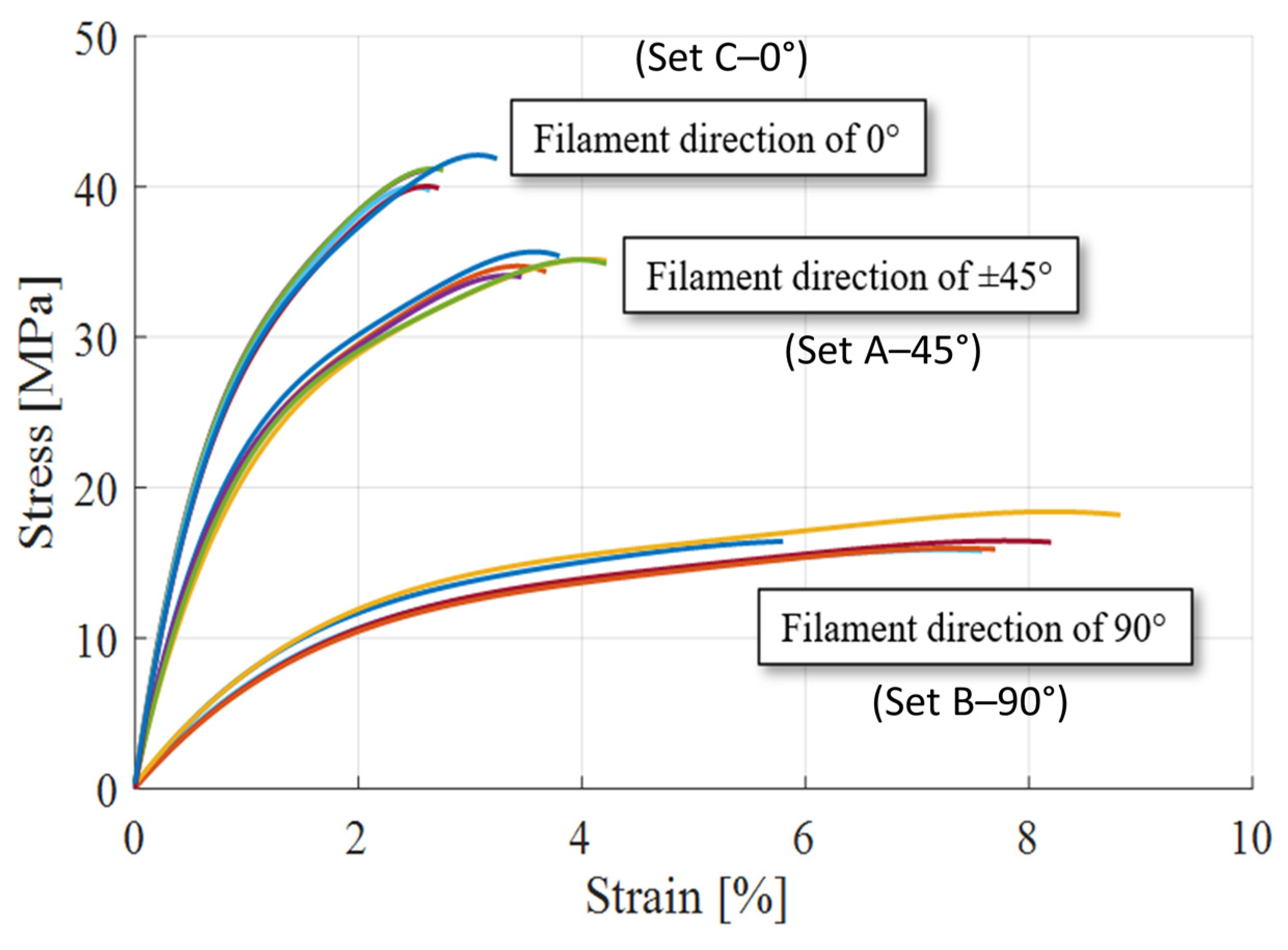

3.2.4. Comparative Analysis of Printing Orientations

3.3. Finite Element Simulation

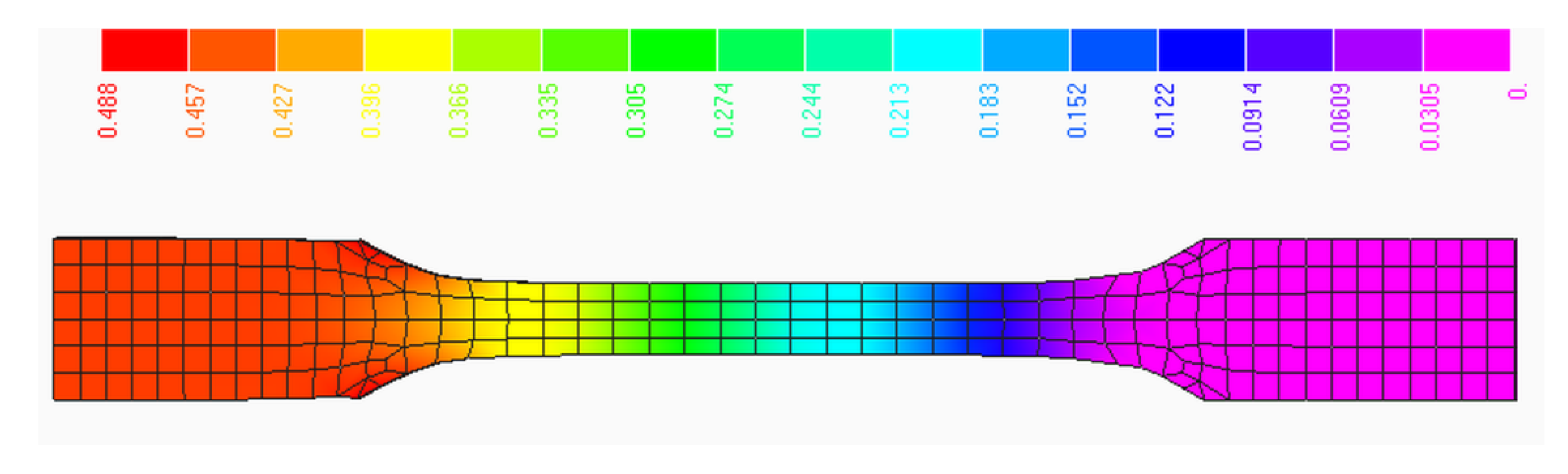

3.3.1. Finite Element Simulation for (Set A–45°)

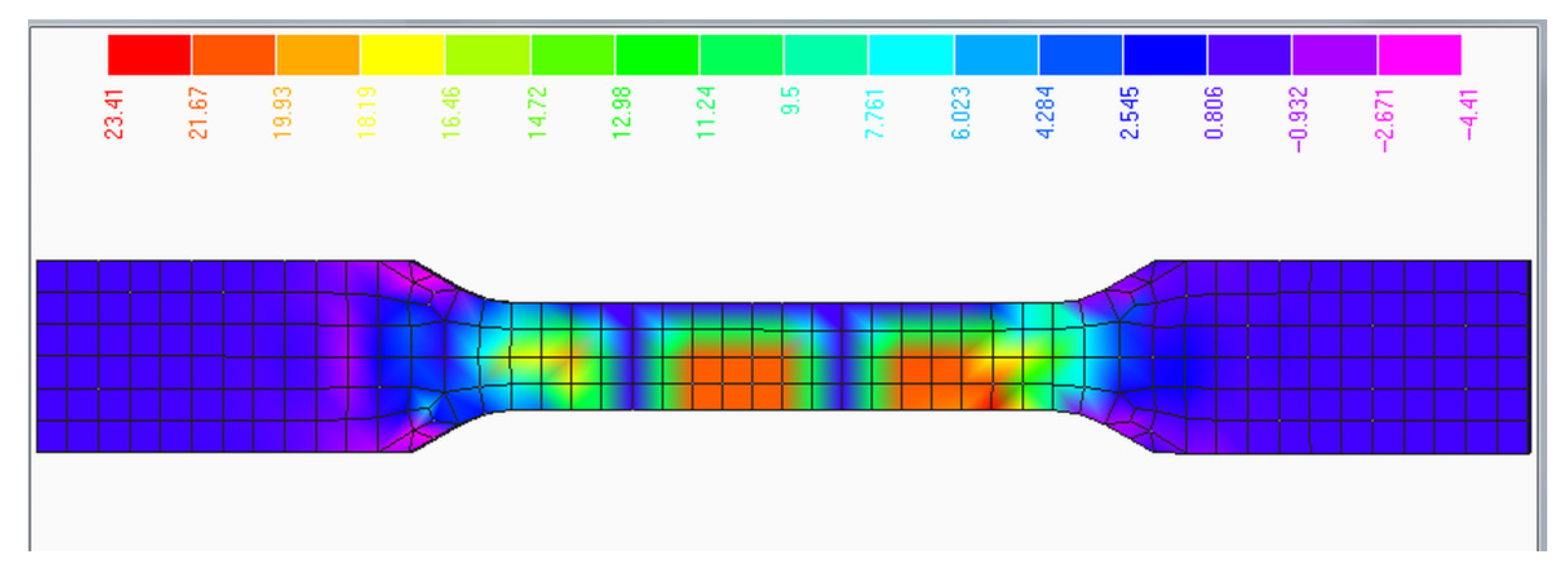

3.3.2. Finite Element Simulation for (Set B–90°)

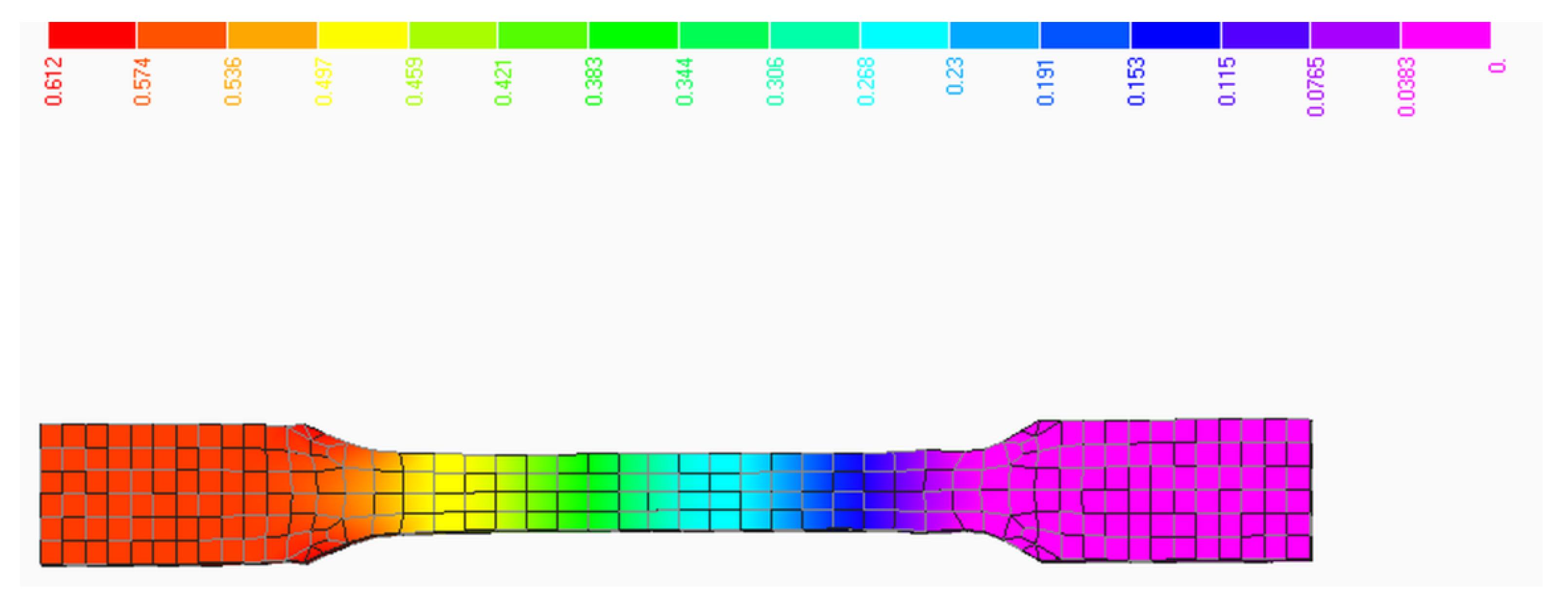

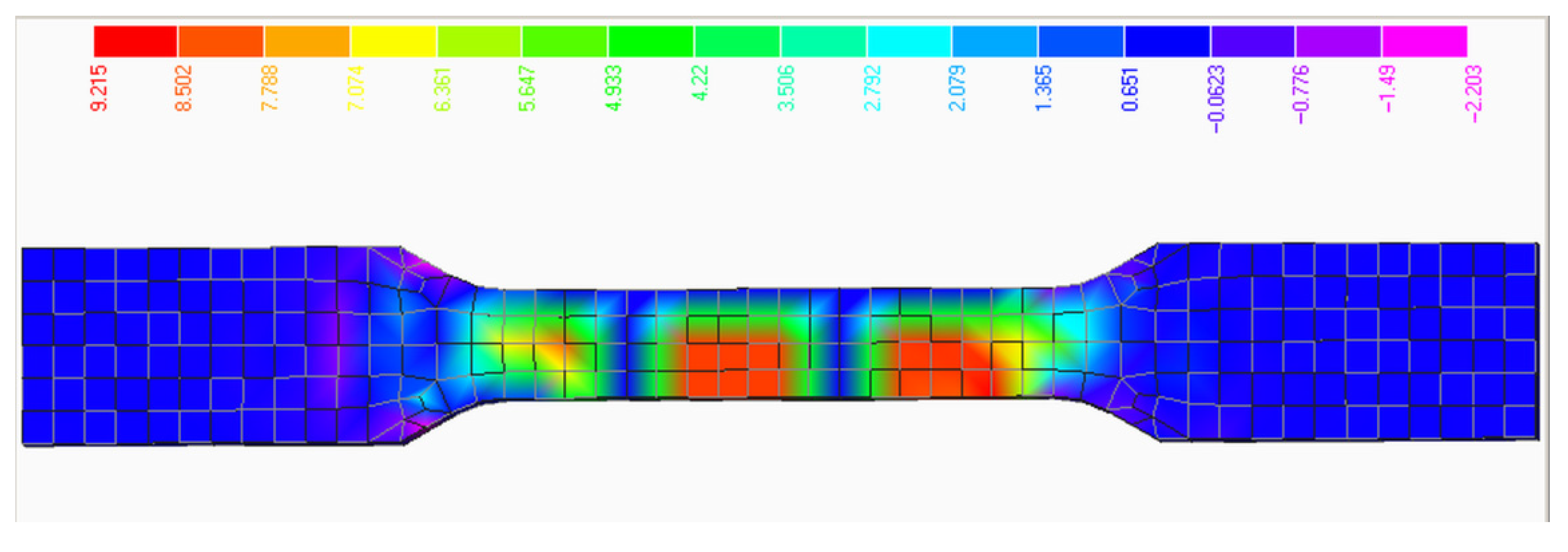

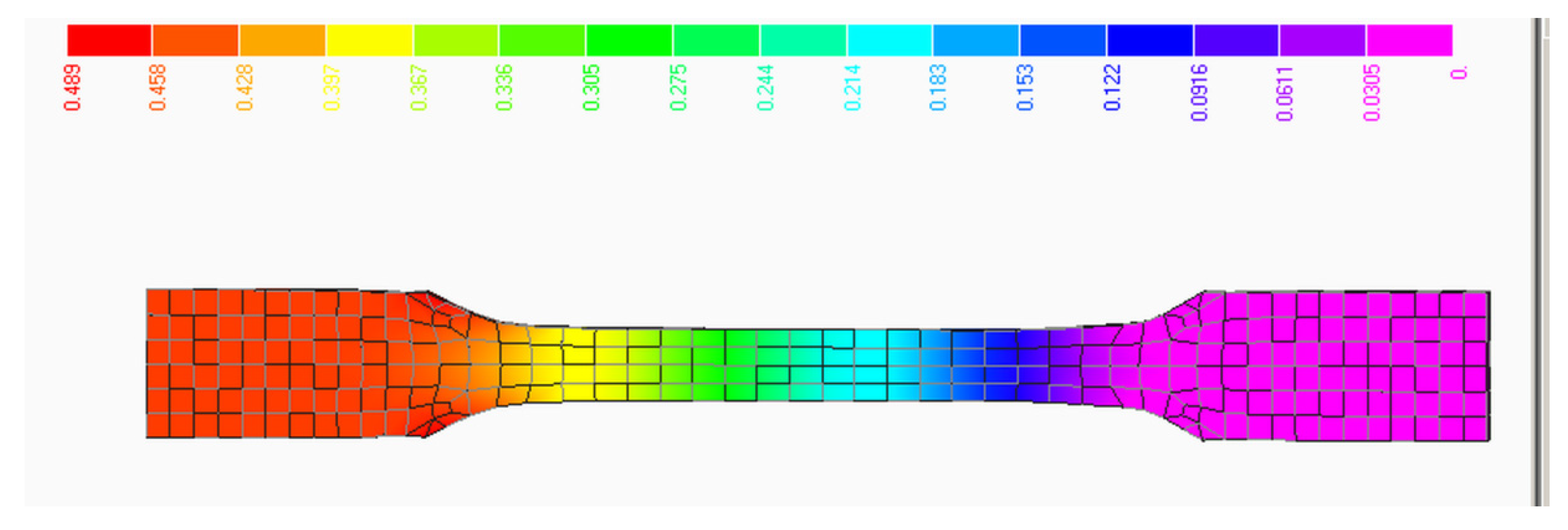

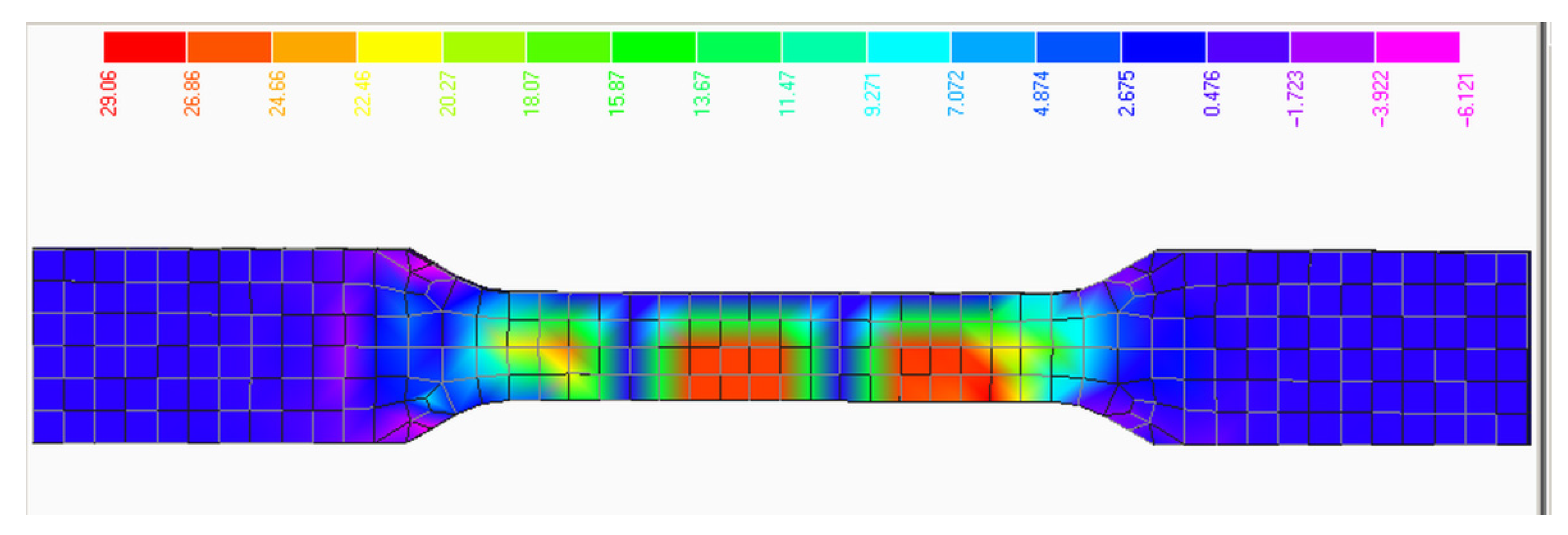

3.3.3. Finite Element Simulation for (Set C–0°)

4. Discussion

4.1. Tensile Behavior—Experimental Insights

- (Set A–45°):

- (Set B–90°):

- (Set C–0°):

4.2. Finite Element Simulations—Model Validation

- (Set A–45°): The applied load of 1089.5 N produced a maximum stress of 23.41 MPa (vs. experimental 21.79 MPa), with a maximum displacement of 0.488 mm;

- (Set B–90°): The applied load of 439 N resulted in a maximum stress of 9.21 MPa (vs. experimental 8.78 MPa), with a displacement of 0.612 mm;

- (Set C–0°): The applied load of 1385.5 N produced a maximum stress of 29.06 MPa (vs. experimental 27.71 MPa), with a displacement of 0.48 mm.

4.3. Influence of Build Orientation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| FFF | Fused Filament Fabrication |

| FDM | Fused Deposition Modeling |

| FEA | Finite Element Analysis |

| DIC | Digital Image Correlation |

| UTS | Ultimate Tensile Strength |

| E | Young’s Modulus |

| ν | Poisson’s Ratio |

| σ0.2% | Yield Strength at 0.2% Offset Strain |

| σ_UTS | Ultimate Tensile Strength |

| LC1 | Loading Case 1 |

| C1 | Constraint Case 1 |

| SR-30 | Support—material filament code |

| SCA 1200-HT | Washing station model for support removal |

| NCF | Nylon 12 Carbon Fiber |

| PLA | Polylactic Acid |

| PETG | Polyethylene Terephthalate Glycol |

| ABS | Acrylonitrile Butadiene Styrene |

| ASA | Acrylonitrile Styrene Acrylate |

| PC | Polycarbonate |

References

- Tekinalp, H.L.; Kunc, V.; Velez Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly Oriented Carbon Fiber–Polymer Composites via Additive Manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental Characterization and Micrography of 3D Printed PLA and PLA Reinforced with Short Carbon Fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Ulkir, M.; Keskin, S.; Durgun, I. Experimental Study and ANN Modeling of Tensile and Surface Quality Characteristics of PA12-CF Composites Fabricated Using FFF. Polymers 2025, 17, 1528. [Google Scholar] [CrossRef]

- Cucu, L.; Stoica, M.; Simion, I.; Cananau, S. Sustainable Component Design Using Generative Tools for Additive Manufacturing. UPB Sci. Bull. Ser. D 2021, 83, 91–104. [Google Scholar]

- Indreș, A.I.; Constantinescu, D.M.; Baciu, F.; Mocian, O.A. Low Velocity Impact Response of 3D Printed Sandwich Panels with TPU Core and PLA Faces. UPB Sci. Bull. Ser. D 2024, 86, 165–176. [Google Scholar]

- Perșinaru, Ș.; Popescu, D.; Desuraune, V. 3D-Printed Adapter for a Robot Gripper: Decisions and Failures. UPB Sci. Bull. Ser. D 2021, 83, 227–238. [Google Scholar]

- Durbacă, A.C.; Iatan, R.; Durbacă, I.; Diniță, A.; Rusănescu, C.O. Experimental Aspects of the Application of Strain Gauges on Sandwich Type Circular Plates from Polymer Composite Materials in Pressure Vessels. UPB Sci. Bull. Ser. D 2018, 80, 131–140. [Google Scholar]

- Manta (Bălaș), O.M.; Bălaș, R.; Ulmeanu, M.E.; Murzac, R.; Doicin, C. Construction and Testing of the Wave Breaking Prototype—Slosh Noise Baffle. UPB Sci. Bull. Ser. D 2022, 84, 103–116. [Google Scholar]

- Simion, I.; Arion, A.F. Dimensioning Rules for 3D Printed Parts Using Additive Technologies (FDM). UPB Sci. Bull. Ser. D 2016, 78, 79–92. [Google Scholar]

- Lupeanu, M.E.; Brooks, H.; Rennie, A.E.W.; Hill, D. Research on Deploying Technical Functional Analysis for Additive Manufacturing of a Surgical Device for Intravitreal Interventions. UPB Sci. Bull. Ser. D 2013, 75, 141–160. [Google Scholar]

- Mathe, S.; Dimonie, D. The Dependence of the Racemic Crystallization of PLLA on the Molecular Weight of the Stereo-Complexer Macromolecules. UPB Sci. Bull. Ser. B 2023, 85, 139–152. [Google Scholar]

- Iacob, M.C.; Popescu, D.; Alexandru, T.G. Printability of Thermoplastic Polyurethane with Low Shore A Hardness in the Context of Customized Insoles Production. UPB Sci. Bull. Ser. D 2024, 86, 95–106. [Google Scholar]

- Gheorghe, M.; Branzei, M.; Varzaru, G.; Ionescu, C.; Mihailescu, B.; Svasta, P.; Gheorghe, S.; Ungurelu, R.; Santos Lopez, I.; Rubio, C. Electroless Copper Deposition on Low-Temperature Silver Thick Films. UPB Sci. Bull. Ser. B 2022, 84, 131–144. [Google Scholar]

- Drăgoi, M.-V.; Hadăr, A.; Goga, N.; Grigore, L.-Ș.; Ștefan, A.; Ali, H.A. Design and Implementation of an EEG-Based BCI Prosthetic Lower Limb Using Raspberry Pi 4. UPB Sci. Bull. Ser. C 2023, 85, 353–366. [Google Scholar]

- Kiran, B.; Rajyalakshmi, G. Experimental Study on Structural Parameters of Wire Arc Additive Manufacturing on Nickel Based Alloy Using Argon Arc Welding. UPB Sci. Bull. Ser. D 2020, 82, 167–178. [Google Scholar]

- Jamil, T.; Azher, K.; Tahir, M.A.; Ali, Z.; Hameed, W.; Javed, H.H. Experimental and Numerical Dynamic Analysis of Plexiglass Acrylic for Impact Energy Using Indigenously Developed Testing Equipment. UPB Sci. Bull. Ser. D 2022, 84, 191–206. [Google Scholar]

- Zouaoui, M.; Gardan, J.; Lafon, P.; Makke, A.; Labergere, C.; Recho, N. A Finite Element Method to Predict the Mechanical Behavior of a Pre-Structured Material Manufactured by Fused Filament Fabrication in 3D Printing. Appl. Sci. 2021, 11, 5075. [Google Scholar] [CrossRef]

- Somireddy, M.; Czekanski, A.; Atre, S.V. Modelling of Failure Behaviour of 3D-Printed Composite Parts. Appl. Sci. 2022, 12, 10724. [Google Scholar] [CrossRef]

- Matúš, M. Implementation of Finite Element Method Simulation in Additive Manufacturing Control Strategies. Symmetry 2023, 15, 2036. [Google Scholar] [CrossRef]

- Minaoglou, P.; Tzotzis, A.; Efkolidis, N.; Kyratsis, P. Influence of the 3D Printing Fabrication Parameters on the Tensile Properties of Carbon-Based Composite Filament. Appl. Mech. 2024, 5, 745–761. [Google Scholar] [CrossRef]

- Oh, J.-S.; Oh, M.-J.; Han, Z.; Seo, H.-S. Effects of Fiber Orientation on the Bearing Strength of 3D-Printed Composite Materials Produced by Fused Filament Fabrication. Polymers 2024, 16, 3591. [Google Scholar] [CrossRef]

- El-Deeb, I.S.; Grabowik, C.; Esmael, E.; Nabhan, A.; Rashad, M.; Ebied, S. Investigation of Effect of Part-Build Directions and Build Orientations on Tension–Tension Mode Fatigue Behavior of Acrylonitrile Butadiene Styrene Material Printed Using Fused Filament Fabrication Technology. Materials 2024, 17, 5133. [Google Scholar] [CrossRef]

- Appalsamy, T.; Hamilton, S.L.; Kgaphola, M.J. Tensile Test Analysis of 3D Printed Specimens with Varying Print Orientation and Infill Density. J. Compos. Sci. 2024, 8, 121. [Google Scholar] [CrossRef]

- Hedjazi, L.; Belhabib, S.; Stephant, N.; Durand, S.; Guessasma, S. Effects of Microstructural Arrangement on the Mechanical Behavior of 3D Printed Polyamide. Symmetry 2023, 15, 2119. [Google Scholar] [CrossRef]

- Vanaei, S.; Shirinbayan, M.; Fattahi, A.M.; Fitoussi, J.; Tcharkhtchi, A. Orientation-Dependent Mechanical Behavior of 3D Printed PLA Parts: An Experimental–Numerical Study. Machines 2023, 11, 1086. [Google Scholar] [CrossRef]

- Yankin, D.; Popov, A.A.; Zhidkov, I.S.; Korzhenkov, A.M. Optimization of Printing Parameters to Enhance Tensile Strength and Modulus of Elasticity of 3D-Printed Nylon 12. Polymers 2023, 15, 3043. [Google Scholar] [CrossRef] [PubMed]

- Butt, J.; Khan, M.A.A.; Adnan, M.; Mohaghegh, V. Performance Analysis of FFF-Printed Carbon Fiber Composites Subjected to Different Annealing Methods. J. Manuf. Mater. Process. 2024, 8, 252. [Google Scholar] [CrossRef]

- Monkova, K.; Fabini, M.; Hribernik, A.; Chladek, M.; Kovac, J. Investigating Flexural Properties of 3D-Printed Nylon/CF Composites. Polymers 2025, 17, 788. [Google Scholar] [CrossRef]

- Song, M.; Choi, J.H.; Kim, K.W.; Park, S.J. Flowability-Dependent Anisotropic Mechanical Properties of 3D-Printed Composites. Appl. Sci. 2025, 15, 6070. [Google Scholar] [CrossRef]

- Pejkowski, Ł.; Seyda, J.; Nowicki, K.; Mrozik, D. Mechanical Performance of Non-Reinforced, Carbon Fiber Reinforced and Glass Bubbles Reinforced 3D Printed PA12 Polyamide. Polym. Test. 2022, 118, 107891. [Google Scholar] [CrossRef]

- Dong, C. Finite Element Analysis of Additively Manufactured Continuous Carbon Fiber-Reinforced Composites. JOM 2023, 75, 4150–4157. [Google Scholar] [CrossRef]

- ISO 527-2:2019; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland.

| No. | Specimen | E | Poisson | Yield Strength | Ultimate Tensile Strength |

|---|---|---|---|---|---|

| [MPa] | [−] | [MPa] | [MPa] | ||

| 1 | NCF_A_01 | 2718 | 0.49 | 21.79 | 35.90 |

| 2 | NCF_A_02 | 2778 | 0.52 | 20.91 | 34.94 |

| 3 | NCF_A_03 | 2382 | 0.36 | 21.47 | 35.17 |

| 4 | NCF_A_04 | 2699 | 0.52 | 21.36 | 34.40 |

| 5 | NCF_A_05 | 2616 | 0.51 | 21.47 | 35.17 |

| Medium | 2639 | 0.48 | 21.40 | 35.11 | |

| StDev | 154.5 | 0.07 | 0.316 | 0.540 | |

| Cv [%] | 5.857 | 13.87 | 1.48 | 1.54 | |

| No. | Specimen | E | Poisson | Yield Strength | Ultimate Tensile Strength |

|---|---|---|---|---|---|

| [MPa] | [−] | [MPa] | [MPa] | ||

| 1 | NCF_B_01 | 776.7 | 0.05 | 8.10 | 15.97 |

| 2 | NCF_B_02 | 786.1 | 0.07 | 7.89 | 16.60 |

| 3 | NCF_B_03 | 843.2 | 0.09 | 8.73 | 16.51 |

| 4 | NCF_B_04 | 759.9 | 0.06 | 7.68 | 16.09 |

| 5 | NCF_B_05 | 880.2 | 0.07 | 8.78 | 18.51 |

| Medium | 809 | 0.07 | 8.24 | 16.74 | |

| StDev | 50.55 | 0.02 | 0.493 | 1.026 | |

| Cv [%] | 6.246 | 26.04 | 5.98 | 6.13 | |

| No. | Specimen | E | Poisson | Yield Strength | Ultimate Tensile Strength |

|---|---|---|---|---|---|

| [MPa] | [-] | [MPa] | [MPa] | ||

| 1 | NCF_C_01 | 3586 | 0.34 | 27.51 | 41.24 |

| 2 | NCF_C_02 | 3532 | 0.31 | 27.47 | 41.51 |

| 3 | NCF_C_03 | 3468 | 0.34 | 27.71 | 40.67 |

| 4 | NCF_C_04 | 3395 | 0.32 | 27.10 | 40.28 |

| 5 | NCF_C_05 | 3415 | 0.31 | 26.87 | 42.19 |

| Medium | 3479 | 0.32 | 27.33 | 41.18 | |

| StDev | 79.98 | 0.02 | 0.340 | 0.744 | |

| Cv [%] | 2.299 | 4.76 | 1.25 | 1.81 | |

| Orientation | Average UTS [MPa] | Average Strain [%] | Max Displacement from FEM [mm] |

|---|---|---|---|

| (Set A–45°) | 35.11 | ~3.9 | 0.448 |

| (Set B–90°) | 16.74 | ~6.3 | 0.612 |

| (Set C–0°) | 41.18 | ~2.9 | 0.480 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babiș, C.; Dimitrescu, A.; Fica, S.A.; Antonescu, O.; Vlăsceanu, D.; Stochioiu, C. Determination of the Mechanical Tensile Characteristics of Some 3D-Printed Specimens from NYLON 12 CARBON Fiber Material. Technologies 2025, 13, 456. https://doi.org/10.3390/technologies13100456

Babiș C, Dimitrescu A, Fica SA, Antonescu O, Vlăsceanu D, Stochioiu C. Determination of the Mechanical Tensile Characteristics of Some 3D-Printed Specimens from NYLON 12 CARBON Fiber Material. Technologies. 2025; 13(10):456. https://doi.org/10.3390/technologies13100456

Chicago/Turabian StyleBabiș, Claudiu, Andrei Dimitrescu, Sorin Alexandru Fica, Ovidiu Antonescu, Daniel Vlăsceanu, and Constantin Stochioiu. 2025. "Determination of the Mechanical Tensile Characteristics of Some 3D-Printed Specimens from NYLON 12 CARBON Fiber Material" Technologies 13, no. 10: 456. https://doi.org/10.3390/technologies13100456

APA StyleBabiș, C., Dimitrescu, A., Fica, S. A., Antonescu, O., Vlăsceanu, D., & Stochioiu, C. (2025). Determination of the Mechanical Tensile Characteristics of Some 3D-Printed Specimens from NYLON 12 CARBON Fiber Material. Technologies, 13(10), 456. https://doi.org/10.3390/technologies13100456