Open-Source Hardware Design of Modular Solar DC Nanogrid

Abstract

1. Introduction

2. Materials and Methods

2.1. System Architecture

2.2. Converter Topology for DC Nanogrid

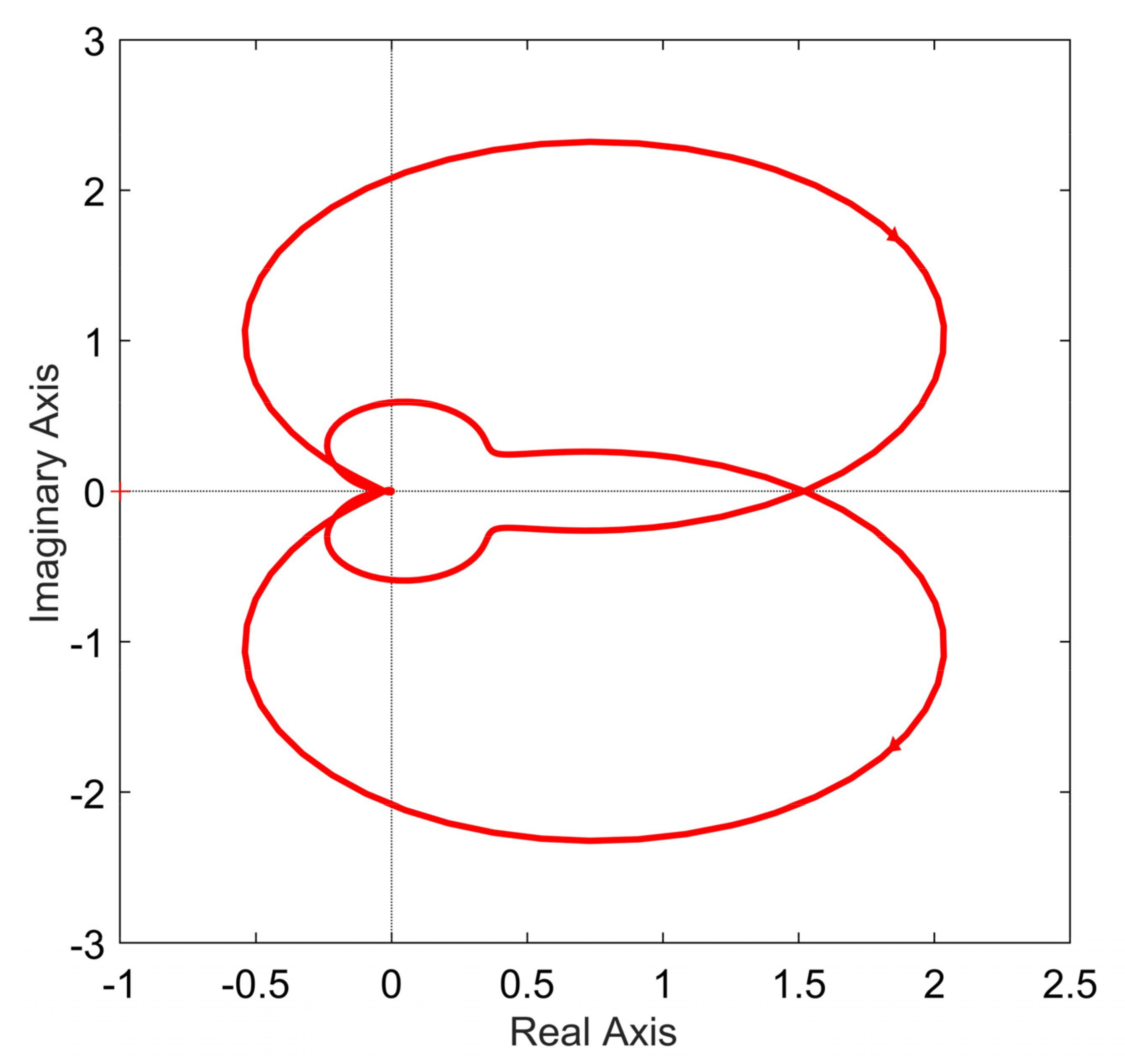

2.3. Design of Controllers

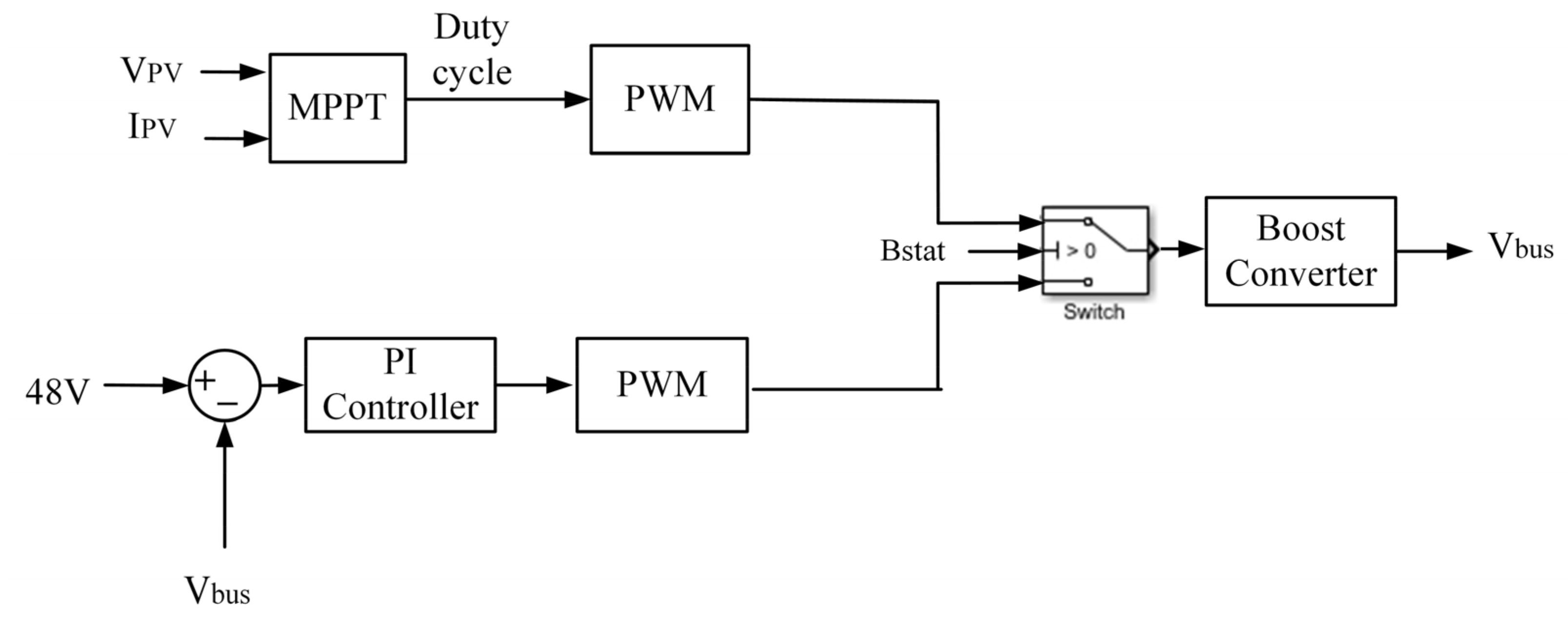

2.3.1. PV Controller Design

2.3.2. Battery Controller Design for Bidirectional Converter

2.3.3. Load Controller Design

2.4. Converter Design

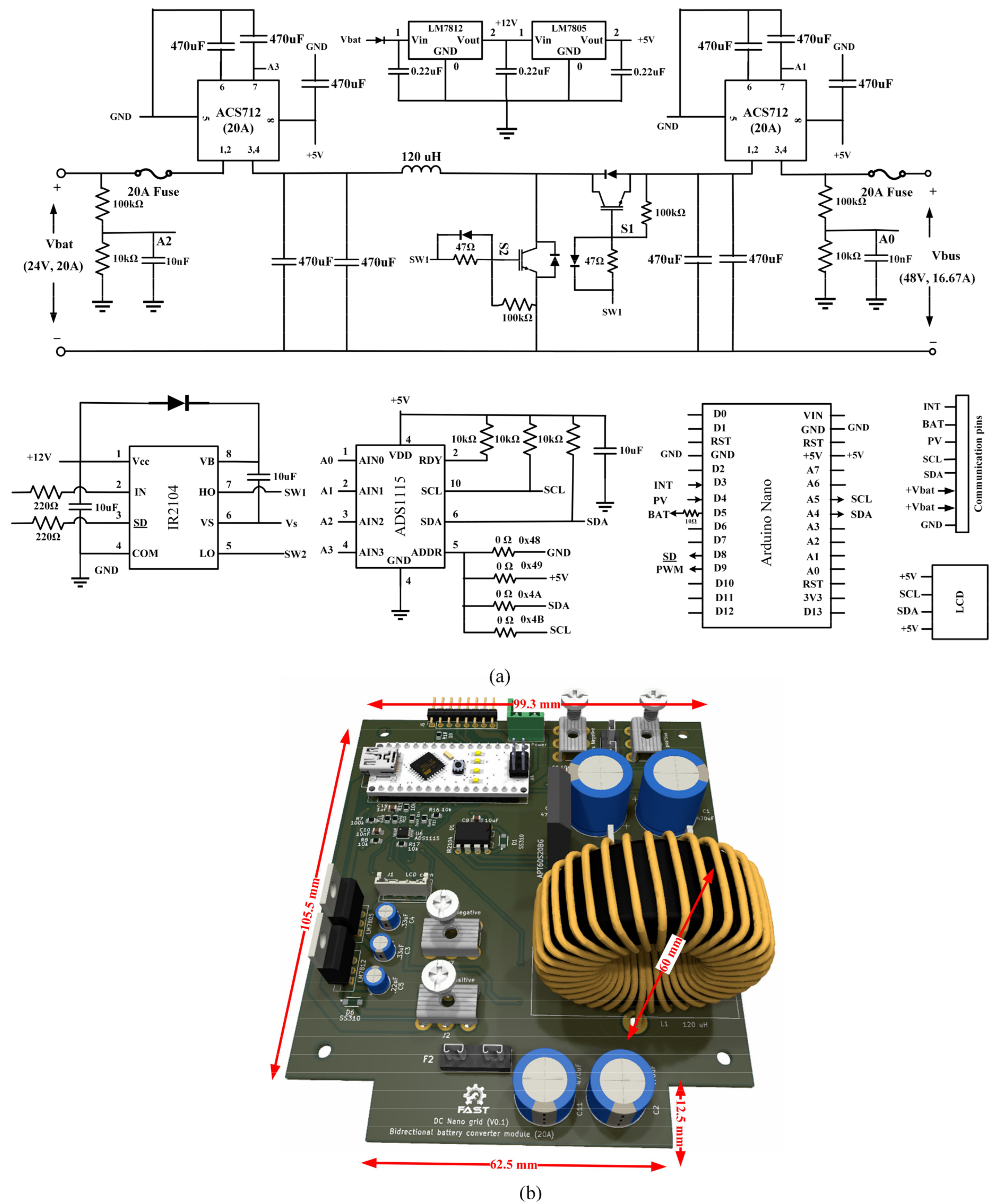

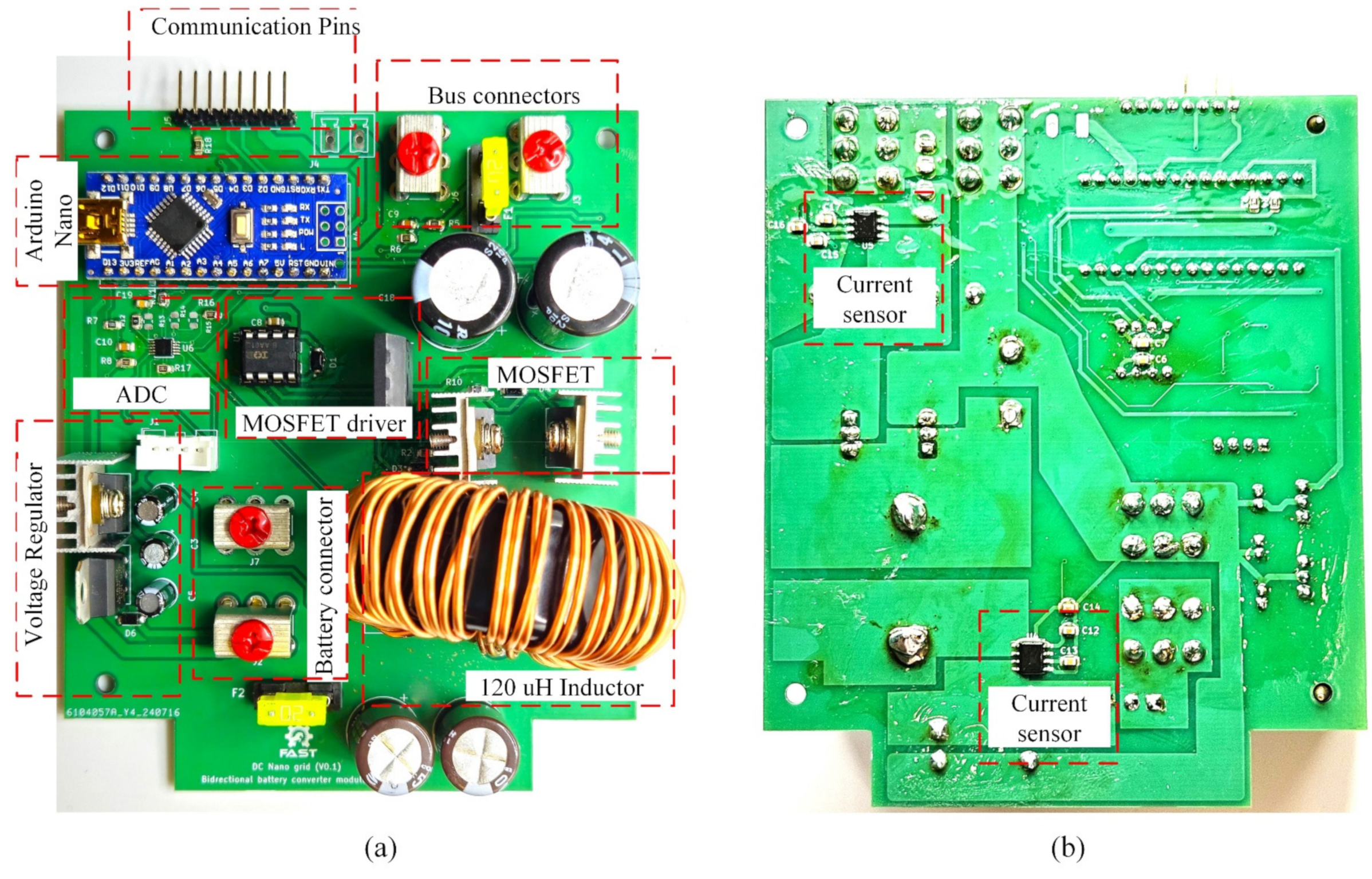

2.4.1. Bidirectional Battery Converter Design

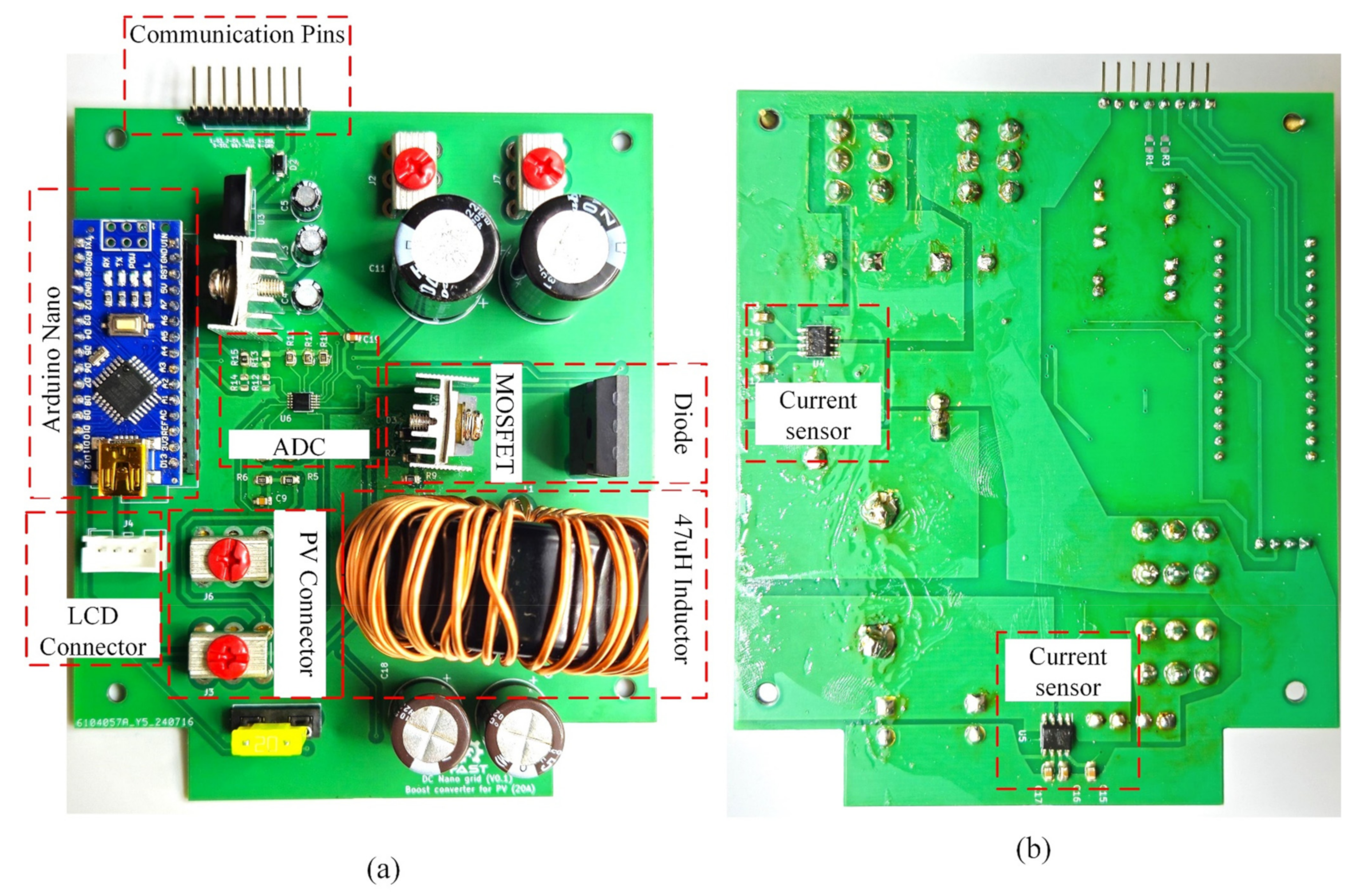

2.4.2. PV Boost Converter Design

2.4.3. Buck Converter Design

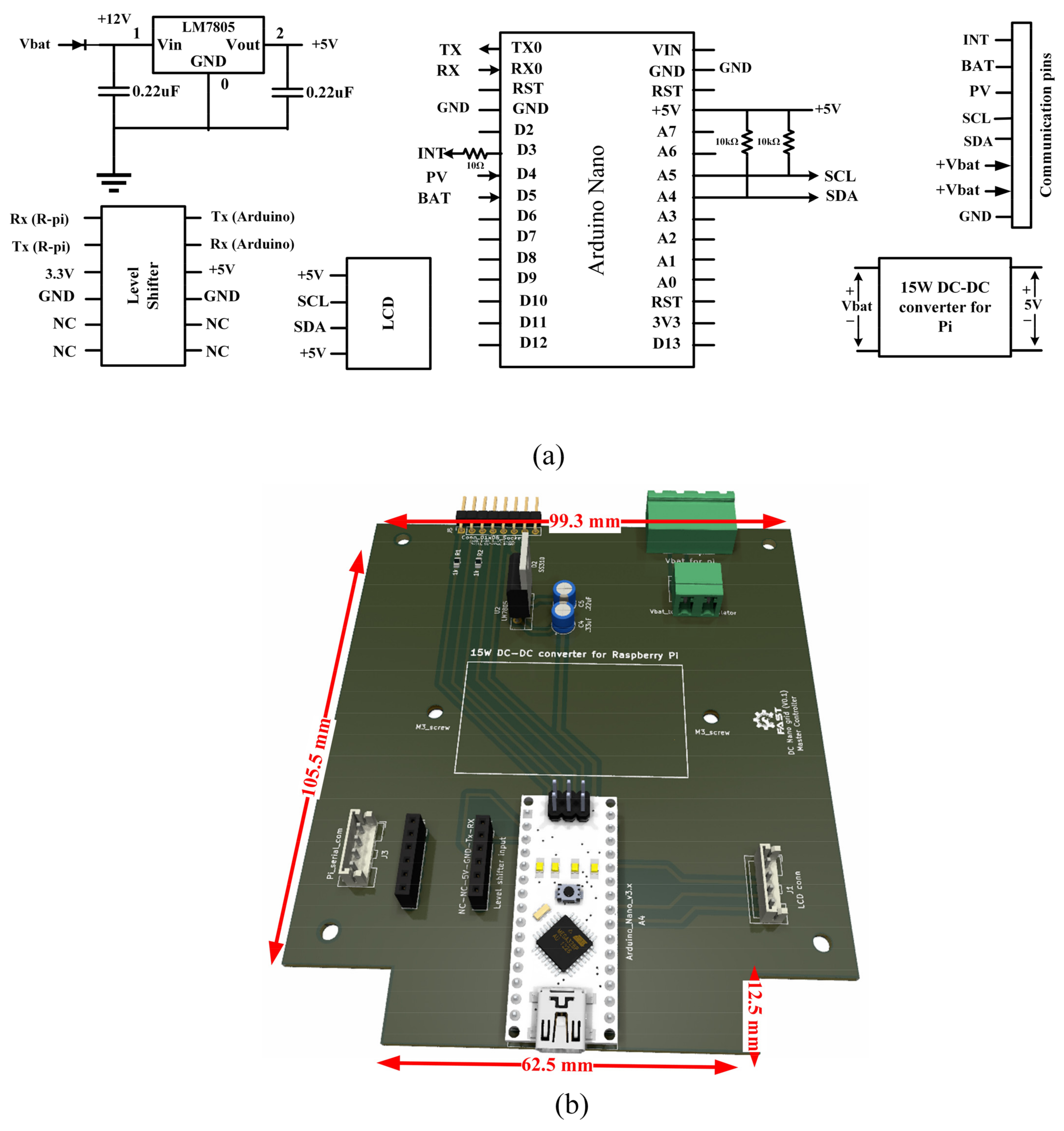

2.4.4. Master Controller Design

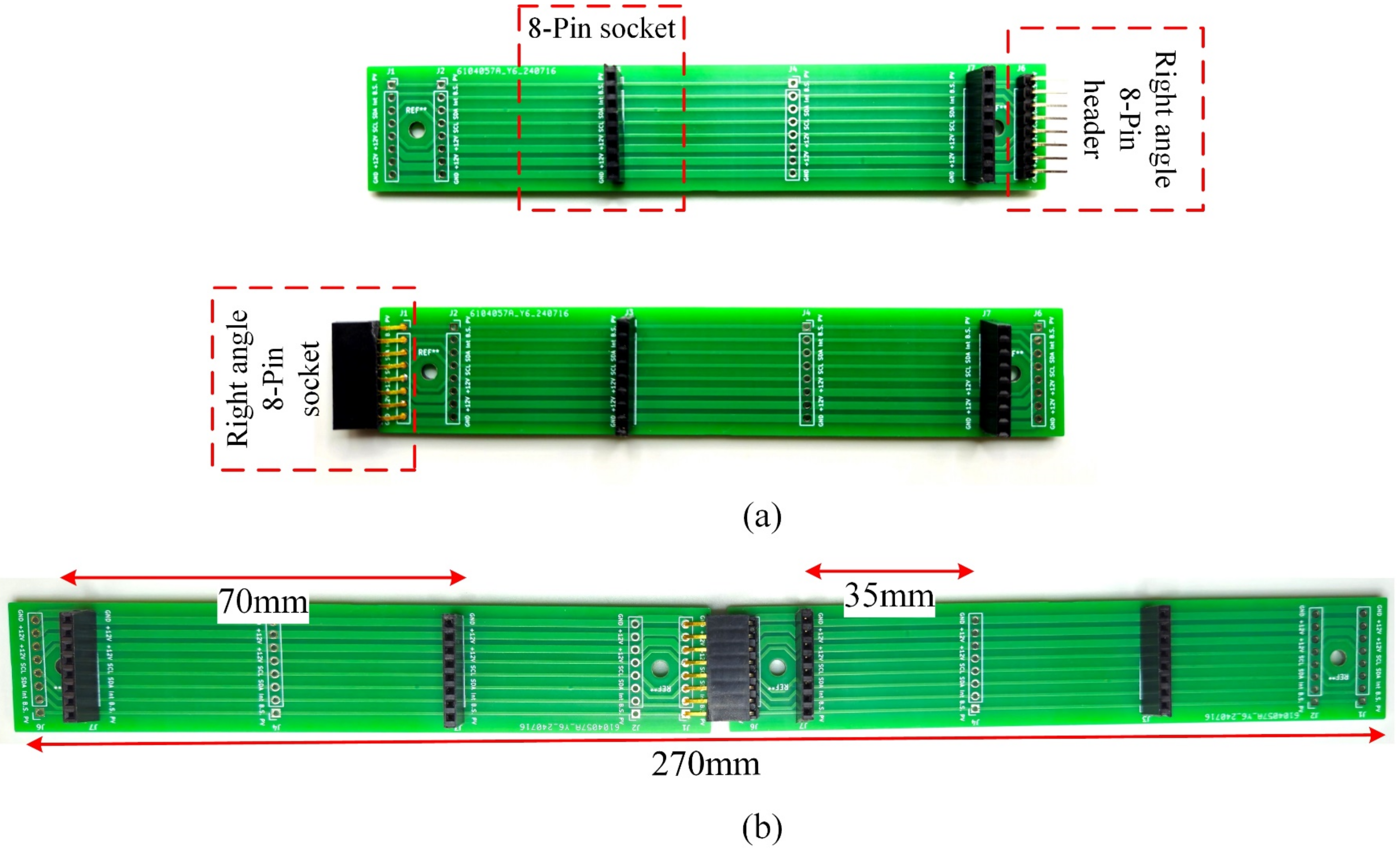

2.4.5. Communication Bus

2.4.6. Inductor Design

2.5. Bill of Materials

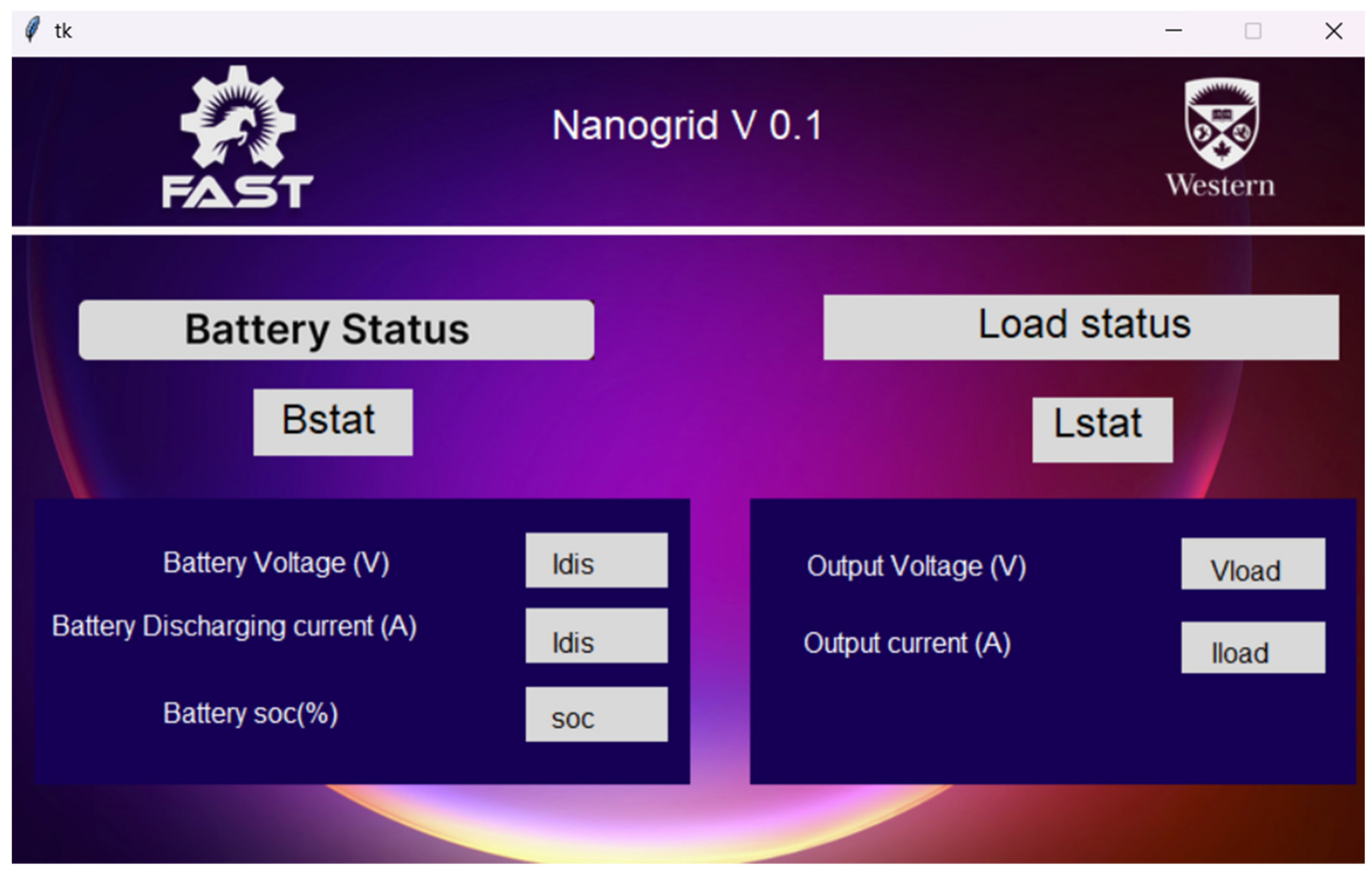

2.6. Arduino Codes and GUI

2.7. Interface and GUI

2.8. Step-by-Step Integration and Commissioning Process

- The design and assembly process of the frame and the converters encloser is given in Appendix A.

- After the converter and the frame are designed, attach the master controller to the frame. This is the only unit that does not require connections to the bus bar, and there should only be one master controller present in a DC nanogrid.

- Attach the PV and battery modules to the system one by one. For systems with multiple PV and battery modules, alternate the installation sequence between PV and battery to maintain consistent DC resistance across all modules.

- Attach the buck converter module and inverters module (if any) to the system according to the load requirements.

- Sequentially turn on all the battery switches. This action will power on the master controller and all connected modules along with the Raspberry Pi display. Next, connect the PV panels to the PV converter, and finally, connect the loads to the system.

- For shutdown, follow the reverse order of the installation process.

3. Results

3.1. MATLAB Simulink Results

- Case 1: Variation in irradiance

- Case 2: Variation of load

3.2. Final Nanogrid Hardware and Validation Tests

3.3. Supply Voltage Stability of 24 V Load

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

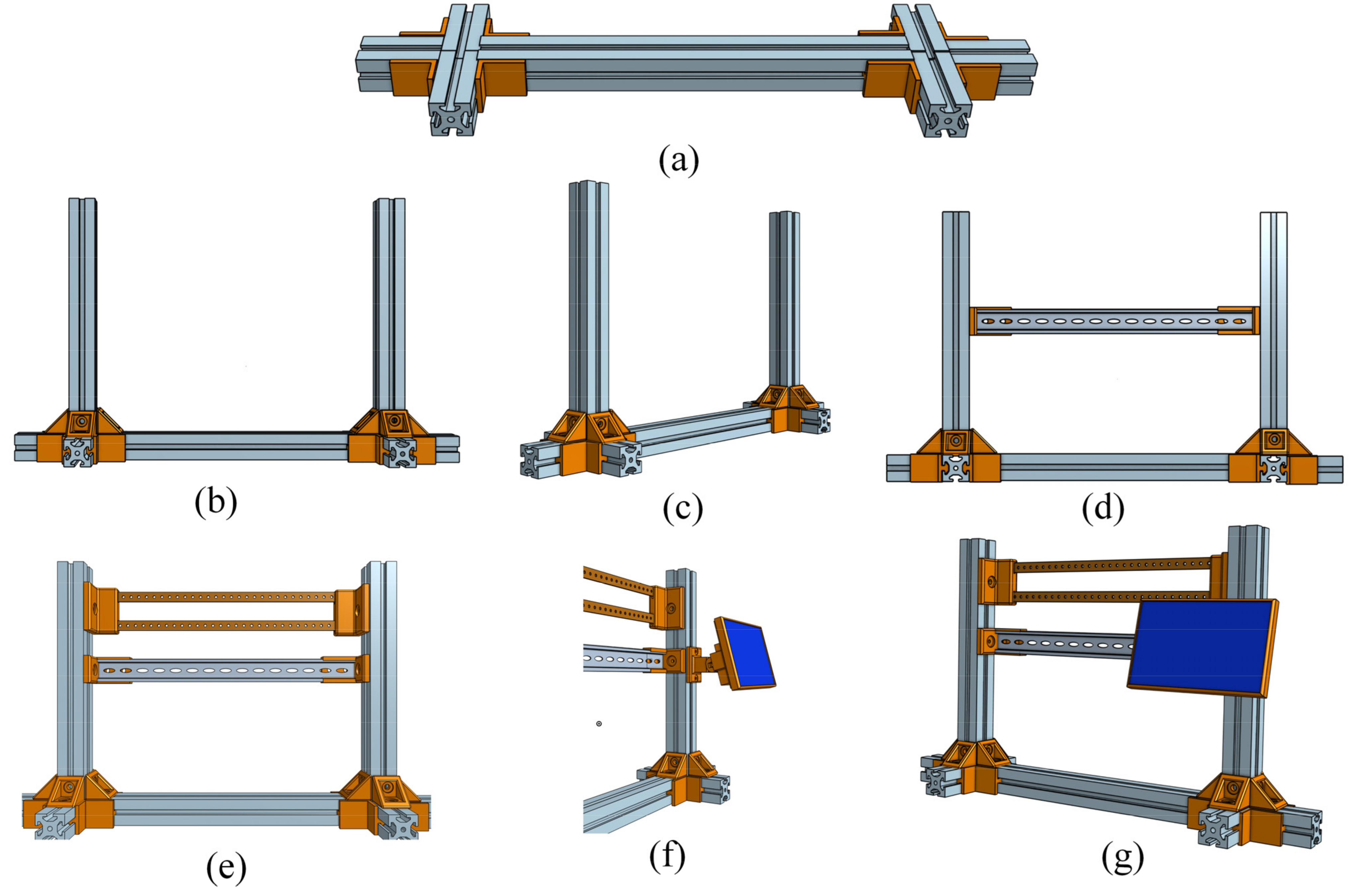

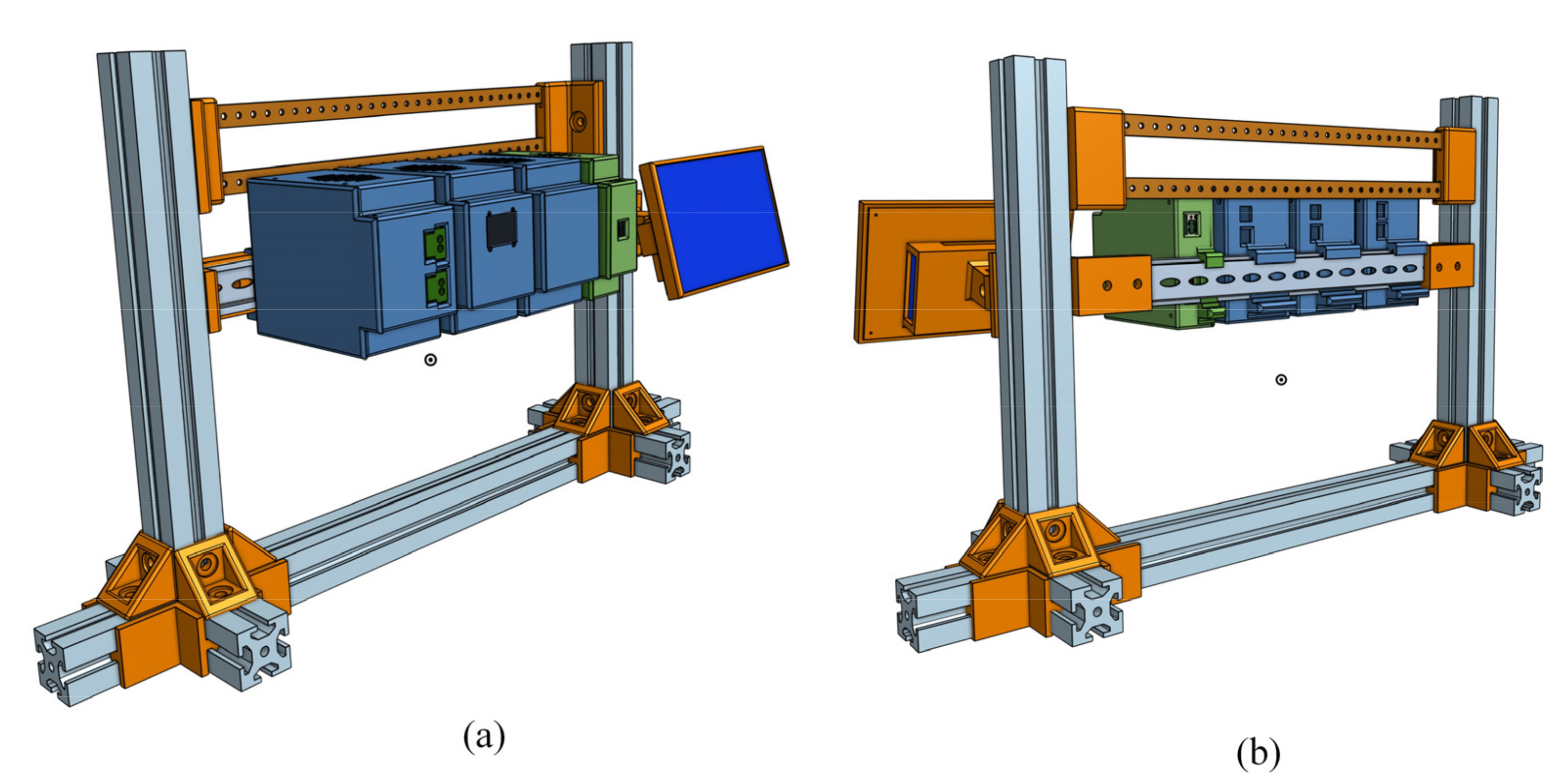

Appendix A

Appendix A.1. Integration of Converters

Appendix A.1.1. DC Nanogrid Frame Design

| Parts Name | Quantity | File Type | Location of File |

|---|---|---|---|

| Sliding corner bracket | 8 | STEP/stl | https://osf.io/73yf5/ |

| Corner bracket | 8 | STEP/stl | https://osf.io/73yf5/ |

| Holder for DIN rail | 2 | STEP/stl | https://osf.io/73yf5/ |

| Holder for bus bar | 2 | STEP/stl | https://osf.io/73yf5/ |

| Case for display | 1 | STEP/stl | https://osf.io/73yf5/ |

| Encloser for Raspberry pi | 1 | STEP/stl | https://osf.io/73yf5/ |

| Raspberry pi holder | 1 | STEP/stl | https://osf.io/73yf5/ |

| Parameter | Value |

|---|---|

| Filament | PLA |

| Layer height | 0.3 mm |

| Initial layer height | 0.2 mm |

| Infill density | 15% |

| Printing temperature | 210 °C |

| Build plate temperature | 60 °C |

| Print speed | 60 mm/s |

| Travel speed | 175 mm/s |

- The stands were assembled using the 350 mm aluminum extrusions and 80 mm support pieces first.

- The 420 mm aluminum extrusion was attached to the stands to form the frame.

- The 410 mm bus bars and DIN rail were installed within the frame.

- A case and holder for the display connected to the Raspberry Pi 4b for data monitoring were created and attached to one of the bars of the frame.

Appendix A.1.2. Converters Encloser Design

| Parts Name | Quantity | File Type | Location of File |

|---|---|---|---|

| Buck converter encloser | 1 | STEP/stl | https://osf.io/73yf5/ |

| Buck converter lid | 1 | STEP/stl | https://osf.io/73yf5/ |

| Boost converter encloser | 1 | STEP/stl | https://osf.io/73yf5/ |

| Boost converter lid | 1 | STEP/stl | https://osf.io/73yf5/ |

| Bidirectional converter encloser | 1 | STEP/stl | https://osf.io/73yf5/ |

| Bidirectional converter lid | 1 | STEP/stl | https://osf.io/73yf5/ |

| Master controller encloser | 1 | STEP/stl | https://osf.io/73yf5/ |

| Master controller lid | 1 | STEP/stl | https://osf.io/73yf5/ |

Appendix A.1.3. Final Assembly

References

- Zhou, X.; Guo, T.; Ma, Y. An Overview on Microgrid Technology. In Proceedings of the 2015 IEEE International Conference on Mechatronics and Automation (ICMA), Beijing, China, 2–5 August 2015; pp. 76–81. [Google Scholar]

- Nordman, B.; Christensen, K. DC Local Power Distribution with Microgrids and Nanogrids. In Proceedings of the 2015 IEEE 1st International Conference on DC Microgrids (ICDCM), Atlanta, GA, USA, 7–10 June 2015; pp. 199–204. [Google Scholar]

- Schonbergerschonberger, J.; Duke, R.; Round, S.D. DC-Bus Signaling: A Distributed Control Strategy for a Hybrid Renewable Nanogrid. IEEE Trans. Ind. Electron. 2006, 53, 1453–1460. [Google Scholar] [CrossRef]

- Nag, S.; Adda, R.; Ray, O.; Mishra, S. Current-Fed Switched Inverter Based Hybrid Topology for DC Nanogrid Application. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 7146–7151. [Google Scholar]

- Pearce, J.M. Photovoltaics—A Path to Sustainable Futures. Futures 2002, 34, 663–674. [Google Scholar] [CrossRef]

- Tsuma, M.; Kibaara, S. A Review of Levelized Cost of Electricity for Photovoltaic Systems Combining with Their Environmental Impacts. In Proceedings of the Sustainable Research and Innovation Conference, Juja, Kenya, 8–10 May 2019; pp. 220–225. [Google Scholar]

- Zhang, P.; Li, W.; Li, S.; Wang, Y.; Xiao, W. Reliability Assessment of Photovoltaic Power Systems: Review of Current Status and Future Perspectives. Appl. Energy 2013, 104, 822–833. [Google Scholar] [CrossRef]

- Şen, Z. Solar Energy in Progress and Future Research Trends. Prog. Energy Combust. Sci. 2004, 30, 367–416. [Google Scholar] [CrossRef]

- Vives, M.V.; Chamorro, H.R.; Ortiz-Villalba, D.; Jiménez, F.; Gonzalez-Longatt, F.M.; Jimenez-Estevez, G.; Guerrero, J.; Cadena, A.; Sood, V.K. Nanogrids: Good Practices and Challenges in the Projects in Colombia. In Microgrids for Rural Areas; Institution of Engineering and Technology: London, UK, 2020; pp. 421–446. [Google Scholar]

- Assis, F.A.; Coelho, F.C.R.; Castro, J.F.C.; Donadon, A.R.; Roncolatto, R.A.; Rosas, P.A.C.; Andrade, V.E.M.S.; Bento, R.G.; Silva, L.C.P.; Cypriano, J.G.I.; et al. Assessment of Regulatory and Market Challenges in the Economic Feasibility of a Nanogrid: A Brazilian Case. Energies 2024, 17, 341. [Google Scholar] [CrossRef]

- Breyer, C. Low-Cost Solar Power Enables a Sustainable Energy Industry System. Proc. Natl. Acad. Sci. USA 2021, 118, e2116940118. [Google Scholar] [CrossRef]

- Staff, C.B. Solar Is Now ‘Cheapest Electricity in History’, Confirms IEA. Available online: https://www.carbonbrief.org/solar-is-now-cheapest-electricity-in-history-confirms-iea/ (accessed on 28 July 2024).

- Sajeeb, M.M.H.; Rahman, A.; Arif, S. Feasibility Analysis of Solar DC Nano Grid for off Grid Rural Bangladesh. In Proceedings of the 2015 3rd International Conference on Green Energy and Technology (ICGET), Dhaka, Bangladesh, 11–12 September 2015; pp. 1–5. [Google Scholar]

- Khan, M.R.; Brown, E.D. DC Nanogrids: A Low Cost PV Based Solution for Livelihood Enhancement for Rural Bangladesh. In Proceedings of the 2014 3rd International Conference on the Developments in Renewable Energy Technology (ICDRET), Dhaka, Bangladesh, 29–31 May 2014; pp. 1–5. [Google Scholar]

- Hamatwi, E.; Davidson, I.E.; Agee, J.; Venayagamoorthy, G. Model of a Hybrid Distributed Generation System for a DC Nano-Grid. In Proceedings of the 2016 Clemson University Power Systems Conference (PSC), Clemson, SC, USA, 8–11 March 2016; pp. 1–8. [Google Scholar]

- Dahiru, A.T.; Tan, C.W. Optimal Sizing and Techno-Economic Analysis of Grid-Connected Nanogrid for Tropical Climates of the Savannah. Sustain. Cities Soc. 2020, 52, 101824. [Google Scholar] [CrossRef]

- Shwehdi, M.H.; Mohamed, S.R. Proposed Smart DC Nano-Grid for Green Buildings—A Reflective View. In Proceedings of the 2014 International Conference on Renewable Energy Research and Application (ICRERA), Milwaukee, WI, USA, 19–22 October 2014; pp. 765–769. [Google Scholar]

- Mishra, S.; Ray, O. Advances in Nanogrid Technology and Its Integration into Rural Electrification in India. In Proceedings of the 2014 International Power Electronics Conference (IPEC-Hiroshima 2014—ECCE ASIA), Hiroshima, Japan, 18–21 May 2014; pp. 2707–2713. [Google Scholar]

- Kinn, M.C. Proposed Components for the Design of a Smart Nano-Grid for a Domestic Electrical System That Operates at below 50V DC. In Proceedings of the 2011 2nd IEEE PES International Conference and Exhibition on Innovative Smart Grid Technologies, Manchester, UK, 5–7 December 2011; pp. 1–7. [Google Scholar]

- Taufik, T.; Muscarella, M. Development of DC House Prototypes as Demonstration Sites for an Alternate Solution to Rural Electrification. In Proceedings of the 2016 6th International Annual Engineering Seminar (InAES), Yogyakarta, Indonesia, 1–3 August 2016; pp. 262–265. [Google Scholar]

- Khan, S.; Rahman, M.M. Design and Simulation of Solar DC Nano Grid System from Bangladesh Perspective. In Proceedings of the 2021 International Conference on Automation, Control and Mechatronics for Industry 4.0 (ACMI), Rajshahi, Bangladesh, 8–9 July 2021; pp. 1–6. [Google Scholar]

- Joseph, S.C.; Ashok, S.; Dhanesh, P.R. Low Voltage Direct Current (LVDC) Nanogrid for Home Application. In Proceedings of the 2017 IEEE Region 10 Symposium (TENSYMP), Cochin, India, 14–16 July 2017; pp. 1–5. [Google Scholar]

- Tudu, B.; Mandal, K.K.; Chakraborty, N. Optimal Design and Development of PV-Wind-Battery Based Nano-Grid System: A Field-on-Laboratory Demonstration. Front. Energy 2019, 13, 269–283. [Google Scholar] [CrossRef]

- Almasri, A.; Al Shabrawi, B.; Sardar, A.; Al Atifi, A.; Al Harbi, A.; Ammous, A. Contribution to the Realization of DC Nano-Grid Including PV Source. In Proceedings of the 2020 Industrial & Systems Engineering Conference (ISEC), Makkah, Saudi Arabia, 9–12 April 2020; pp. 1–5. [Google Scholar]

- Cvetkovic, I.; Dong, D.; Zhang, W.; Jiang, L.; Boroyevich, D.; Lee, F.C.; Mattavelli, P. A Testbed for Experimental Validation of a Low-Voltage DC Nanogrid for Buildings. In Proceedings of the 2012 15th International Power Electronics and Motion Control Conference (EPE/PEMC), Novi Sad, Serbia, 4–6 September 2012; pp. LS7c.5-1–LS7c.5-8. [Google Scholar]

- Rahman, M.M.; Antonini, G.; Pearce, J. Open-Source DC-DC Converter Enabling Direct Integration of Solar Photovoltaics with Anion Exchange Membrane Electrolyzer for Green Hydrogen Production. Preprints 2024. [Google Scholar] [CrossRef]

- Gadzanku, S.; Kramer, A.; Smith, B. An Updated Review of the Solar PV Installation Workforce Literature; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2023. [Google Scholar] [CrossRef]

- Chagas, A.M. Haves and Have Nots Must Find a Better Way: The Case for Open Scientific Hardware. PLoS Biol. 2018, 16, e3000014. [Google Scholar] [CrossRef]

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Addison-Wesley Professional: Boston, MA, USA, 2014; ISBN 978-0-13-337390-5. [Google Scholar]

- Rahman, M.M.; Pearce, J. Modular Open Source Solar Photovoltaic-Powered DC Nanogrids with Efficient Energy Management System. Sol. Energy Sustain. Dev. J. 2024, 13, 22–42. [Google Scholar] [CrossRef]

- Dong, D.; Cvetkovic, I.; Boroyevich, D.; Zhang, W.; Wang, R.; Mattavelli, P. Grid-Interface Bidirectional Converter for Residential DC Distribution Systems—Part One: High-Density Two-Stage Topology. IEEE Trans. Power Electron. 2013, 28, 1655–1666. [Google Scholar] [CrossRef]

- Sudev, V.; Parvathy, S. Switched Boost Inverter Based Dc Nanogrid with Battery and Bi-Directional Converter. In Proceedings of the 2014 International Conference on Circuits, Power and Computing Technologies [ICCPCT-2014], Nagercoil, India, 20–21 March 2014; pp. 461–467. [Google Scholar]

- Ganesan, S.I.; Pattabiraman, D.; Govindarajan, R.K.; Rajan, M.; Nagamani, C. Control Scheme for a Bidirectional Converter in a Self-Sustaining Low-Voltage DC Nanogrid. IEEE Trans. Ind. Electron. 2015, 62, 6317–6326. [Google Scholar] [CrossRef]

- Sathler, H.H.; Sathler, L.H.; Marcelino, F.L.F.; de Oliveira, T.R.; Seleme, S.I.; Garcia, P.F.D. A Comparative Efficiency Study on Bidirectional Grid Interface Converters Applied to Low Power DC Nanogrids. In Proceedings of the 2017 Brazilian Power Electronics Conference (COBEP), Juiz de Fora, Brazil, 19–22 November 2017; pp. 1–6. [Google Scholar]

- Queiroz, F.; Praça, P.; Freitas, A.; Antunes, F. High-Gain Bidirectional DC-DC Converter for Battery Charging in DC Nanogrid of Residential Prossumer. In Proceedings of the 2019 IEEE 15th Brazilian Power Electronics Conference and 5th IEEE Southern Power Electronics Conference (COBEP/SPEC), Santos, Brazil, 1–4 December 2019; pp. 1–6. [Google Scholar]

- Goud, P.C.D.; Gupta, R. Solar PV Based Nanogrid Integrated with Battery Energy Storage to Supply Hybrid Residential Loads Using Single-Stage Hybrid Converter. IET Energy Syst. Integr. 2020, 2, 161–169. [Google Scholar] [CrossRef]

- Saxena, A.R.; Kulshreshtha, A. A Fourth-Order Bidirectional DC–DC Converter for Interfacing Battery in a Solar -Photovoltaic-Fed Low-Voltage Residential DC Nano-Grid: Design and Analysis. Int. J. Circuit Theory Appl. 2021, 49, 1932–1958. [Google Scholar] [CrossRef]

- Bodele, N.J.; Kulkarni, P.S. Modular Battery-Integrated Bidirectional Single-Stage DC–DC Converter for Solar PV Based DC Nano-Grid Application. Sol. Energy 2023, 259, 1–14. [Google Scholar] [CrossRef]

- Burmester, D.; Rayudu, R.; Seah, W.; Akinyele, D. A Review of Nanogrid Topologies and Technologies. Renew. Sustain. Energy Rev. 2017, 67, 760–775. [Google Scholar] [CrossRef]

- Cairoli, P.; Kondratiev, I.; Dougal, R.A. Controlled Power Sequencing for Fault Protection in DC Nanogrids. In Proceedings of the 2011 International Conference on Clean Electrical Power (ICCEP), Ischia, Italy, 14–16 June 2011; pp. 730–737. [Google Scholar]

- Sadabadi, M.S.; Karimi, A.; Karimi, H. Fixed-Order Decentralized/Distributed Control of Islanded Inverter-Interfaced Microgrids. Control Eng. Pract. 2015, 45, 174–193. [Google Scholar] [CrossRef]

- Uddin, M.; Mo, H.; Dong, D.; Elsawah, S.; Zhu, J.; Guerrero, J.M. Microgrids: A Review, Outstanding Issues and Future Trends. Energy Strategy Rev. 2023, 49, 101127. [Google Scholar] [CrossRef]

- Oberloier, S.; Whisman, N.G.; Hafting, F.; Pearce, J.M. Open Source Framework for a Broadly Expandable and Reconfigurable Data Acquisition and Automation Device (BREAD). HardwareX 2023, 15, e00467. [Google Scholar] [CrossRef]

- Schmid, F.; Behrendt, F. Optimal Sizing of Solar Home Systems: Charge Controller Technology and Its Influence on System Design. Sustain. Energy Technol. Assess. 2021, 45, 101198. [Google Scholar] [CrossRef]

- Pearce, J.M. Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 978-0-12-410486-0. [Google Scholar]

- Pearce, J.M. Cut Costs with Open-Source Hardware. Nature 2014, 505, 618. [Google Scholar] [CrossRef] [PubMed]

- Buitenhuis, A.J.; Pearce, J.M. Open-Source Development of Solar Photovoltaic Technology. Energy Sustain. Dev. 2012, 16, 379–388. [Google Scholar] [CrossRef]

- de Arquer Fernández, P.; Fernández Fernández, M.Á.; Carús Candás, J.L.; Arboleya Arboleya, P. An IoT Open Source Platform for Photovoltaic Plants Supervision. Int. J. Electr. Power Energy Syst. 2021, 125, 106540. [Google Scholar] [CrossRef]

- González, I.; Portalo, J.M.; Calderón, A.J. Configurable IoT Open-Source Hardware and Software I-V Curve Tracer for Photovoltaic Generators. Sensors 2021, 21, 7650. [Google Scholar] [CrossRef]

- Portalo, J.M.; González, I.; Calderón, A.J. Monitoring System for Tracking a PV Generator in an Experimental Smart Microgrid: An Open-Source Solution. Sustainability 2021, 13, 8182. [Google Scholar] [CrossRef]

- Santhosh, R.; Sabareesh, S.U.; Aswin, R.; Mahalakshmi, R. Hardware Design of PIC Microcontroller Based Charge Controller and MPPT for the Standalone PV-Battery Charging System. In Proceedings of the 2021 International Conference on Recent Trends on Electronics, Information, Communication & Technology (RTEICT), Xi’an, China, 18–20 August 2021; pp. 172–175. [Google Scholar]

- Parandhaman, M.; Annambhotla, L.T.S.; Parthiban, P. Hardware Prototype for Portable Automatic MPPT Solar Charger Using Buck Converter and PSO Technique. In Proceedings of the 2022 IEEE Delhi Section Conference (DELCON), New Delhi, India, 11–13 February 2022; pp. 1–6. [Google Scholar]

- Wirateruna, E.S.; Afroni, M.J.; Badri, F. Design of Maximum Power Point Tracking Photovoltaic System Based on Incremental Conductance Algorithm Using Arduino Uno and Boost Converter. Appl. Technol. Comput. Sci. J. 2022, 4, 101–112. [Google Scholar] [CrossRef]

- Podder, A.K.; Roy, N.K.; Pota, H.R. MPPT Methods for Solar PV Systems: A Critical Review Based on Tracking Nature. IET Renew. Power Gener. 2019, 13, 1615–1632. [Google Scholar] [CrossRef]

- Liu, F.; Duan, S.; Liu, F.; Liu, B.; Kang, Y. A Variable Step Size INC MPPT Method for PV Systems. IEEE Trans. Ind. Electron. 2008, 55, 2622–2628. [Google Scholar] [CrossRef]

- Karami, N.; Moubayed, N.; Outbib, R. General Review and Classification of Different MPPT Techniques. Renew. Sustain. Energy Rev. 2017, 68, 1–18. [Google Scholar] [CrossRef]

- Rahman, M.M.; Islam, M.S. Artificial Neural Network Based Maximum Power Point Tracking of a Photovoltaic System. In Proceedings of the 2019 3rd International Conference on Electrical, Computer & Telecommunication Engineering (ICECTE), Rajshahi, Bangladesh, 26–28 December 2019; pp. 117–120. [Google Scholar]

- Rahman, M.M.; Islam, M.S. PSO and ANN Based Hybrid MPPT Algorithm for Photovoltaic Array under Partial Shading Condition. Eng. Int. 2020, 8, 9–24. [Google Scholar] [CrossRef]

- Mohapatra, A.; Nayak, B.; Das, P.; Mohanty, K.B. A Review on MPPT Techniques of PV System under Partial Shading Condition. Renew. Sustain. Energy Rev. 2017, 80, 854–867. [Google Scholar] [CrossRef]

- Yaichi, M.; Fellah, M.-K.; Mammeri, A. A Neural Network Based MPPT Technique Controller for Photovoltaic Pumping System. Int. J. Power Electron. Drive Syst. 2014, 4, 241–255. [Google Scholar] [CrossRef]

- Yap, K.Y.; Sarimuthu, C.R.; Lim, J.M.-Y. Artificial Intelligence Based MPPT Techniques for Solar Power System: A Review. J. Mod. Power Syst. Clean Energy 2020, 8, 1043–1059. [Google Scholar] [CrossRef]

- Katche, M.L.; Makokha, A.B.; Zachary, S.O.; Adaramola, M.S. A Comprehensive Review of Maximum Power Point Tracking (MPPT) Techniques Used in Solar PV Systems. Energies 2023, 16, 2206. [Google Scholar] [CrossRef]

- Li, Y.; Li, K.; Xie, Y.; Liu, J.; Fu, C.; Liu, B. Optimized Charging of Lithium-Ion Battery for Electric Vehicles: Adaptive Multistage Constant Current–Constant Voltage Charging Strategy. Renew. Energy 2020, 146, 2688–2699. [Google Scholar] [CrossRef]

- Lawder, M.T.; Suthar, B.; Northrop, P.W.C.; De, S.; Hoff, C.M.; Leitermann, O.; Crow, M.L.; Santhanagopalan, S.; Subramanian, V.R. Battery Energy Storage System (BESS) and Battery Management System (BMS) for Grid-Scale Applications. Proc. IEEE 2014, 102, 1014–1030. [Google Scholar] [CrossRef]

- Keil, P.; Jossen, A. Charging Protocols for Lithium-Ion Batteries and Their Impact on Cycle Life—An Experimental Study with Different 18650 High-Power Cells. J. Energy Storage 2016, 6, 125–141. [Google Scholar] [CrossRef]

- Fotopoulou, M.; Pediaditis, P.; Skopetou, N.; Rakopoulos, D.; Christopoulos, S.; Kartalidis, A. A Review of the Energy Storage Systems of Non-Interconnected European Islands. Sustainability 2024, 16, 1572. [Google Scholar] [CrossRef]

- Pearce, J.M.; Rahman, M.M. Modular Open Source Solar Photovoltaic-Powered DC Nanogrids with Efficient Energy Management System. Available online: https://osf.io/sv84n/ (accessed on 26 August 2024).

- The GNU General Public License v3.0—GNU Project—Free Software Foundation. Available online: https://www.gnu.org/licenses/gpl-3.0.en.html (accessed on 26 August 2024).

- Home|CERN Open Hardware Licence. Available online: https://cern-ohl.web.cern.ch/ (accessed on 26 August 2024).

- Rahman, M.M.; Khan, S.; Pearce, J.M. Open Source Modular DC Nano Grid Hardware Designs. Available online: https://osf.io/73yf5/ (accessed on 23 July 2024).

- CSD19533KCS Data Sheet, Product Information and Support|TI.Com. Available online: https://www.ti.com/product/CSD19533KCS? (accessed on 24 July 2024).

- Iqbal, Z.; Nasir, U.; Rasheed, M.T.; Munir, K. A Comparative Analysis of Synchronous Buck, Isolated Buck and Buck Converter. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015; pp. 992–996. [Google Scholar]

- Amin, M.; Molinas, M. Non-Parametric Impedance Based Stability and Controller Bandwidth Extraction from Impedance Measurements of HVDC-Connected Wind Farms. arXiv 2017, arXiv:1704.04800. [Google Scholar]

- Amin, M.; Molinas, M. Small-Signal Stability Assessment of Power Electronics Based Power Systems: A Discussion of Impedance- and Eigenvalue-Based Methods. IEEE Trans. Ind. Appl. 2017, 53, 5014–5030. [Google Scholar] [CrossRef]

- Habibullah, M.; Nadarajah, M.; Sharma, R.; Shah, R. A Comprehensive Stability Analysis of Multi-Converter-Based DC Microgrids. In Emerging Power Converters for Renewable Energy and Electric Vehicles; CRC Press: Boca Raton, FL, USA, 2021; pp. 281–314. ISBN 978-1-00-305847-2. [Google Scholar]

- Habibullah, M.; Mithulananthan, N.; Zare, F.; Sharma, R. Impact of Control Systems on Power Quality at Common DC Bus in DC Grid. In Proceedings of the 2019 IEEE PES GTD Grand International Conference and Exposition Asia (GTD Asia), Bangkok, Thailand, 19–23 March 2019; pp. 411–416. [Google Scholar]

- Chandrasena, R.; Shahnia, F.; Ghosh, A.; Rajakaruna, S. Operation and Control of a Hybrid AC-DC Nanogrid for Future Community Houses. In Proceedings of the 2014 Australasian Universities Power Engineering Conference (AUPEC), Perth, WA, Australia, 28 September–1 October 2014. [Google Scholar]

- Justo, J.J.; Mwasilu, F.; Lee, J.; Jung, J.-W. AC-Microgrids versus DC-Microgrids with Distributed Energy Resources: A Review. Renew. Sustain. Energy Rev. 2013, 24, 387–405. [Google Scholar] [CrossRef]

- Qu, D.; Wang, M.; Sun, Z.; Chen, G. An Improved DC-Bus Signaling Control Method in a Distributed Nanogrid Interfacing Modular Converters. In Proceedings of the 2015 IEEE 11th International Conference on Power Electronics and Drive Systems, Sydney, Australia, 9–12 June 2015; pp. 214–218. [Google Scholar]

- Martin, K.; Vázquez, A.; Arias, M.; Sebastián, J. Optimization Procedure of Source/Sink Converters for DC Power Distribution Nano-Grids. In Proceedings of the 2018 IEEE 19th Workshop on Control and Modeling for Power Electronics (COMPEL), Padova, Italy, 25–28 June 2018; pp. 1–8. [Google Scholar]

- Ganguly, A.; Biswas, P.K.; Sain, C.; Ustun, T.S. Modern DC–DC Power Converter Topologies and Hybrid Control Strategies for Maximum Power Output in Sustainable Nanogrids and Picogrids—A Comprehensive Survey. Technologies 2023, 11, 102. [Google Scholar] [CrossRef]

- Nguyen, T.; Guerrero, J.; Griepentrog, G. A Self-Sustained and Flexible Control Strategy for Islanded DC Nanogrids Without Communication Links. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 8, 877–892. [Google Scholar] [CrossRef]

- Fares, A.M.; Klumpner, C.; Sumner, M. A Novel Modular Multiport Converter for Enhancing the Performance of Photovoltaic-Battery Based Power Systems. Appl. Sci. 2019, 9, 3948. [Google Scholar] [CrossRef]

- Askarian, I.; Pahlevani, M.; Knight, A.M. Three-Port Bidirectional DC/DC Converter for DC Nanogrids. IEEE Trans. Power Electron. 2021, 36, 8000–8011. [Google Scholar] [CrossRef]

- Werth, A.; Kitamura, N.; Tanaka, K. Conceptual Study for Open Energy Systems: Distributed Energy Network Using Interconnected DC Nanogrids. IEEE Trans. Smart Grid 2015, 6, 1621–1630. [Google Scholar] [CrossRef]

- Grafman, L.; Pearce, J.M.; Droz, P.; Louie, H. To Catch the Sun: Inspiring Stories of Communities Coming Together to Harness Their Own Solar Energy, and How You Can Do It Too! Humboldt State University Press: Arcata, CA, USA, 2021; ISBN 978-1-947112-62-9. [Google Scholar]

- Anker SOLIX Solar Power Generators. Available online: https://www.anker.com/ca/anker-solix/labor-day-pps (accessed on 29 August 2024).

- Victron Energy Victron Products. Available online: https://www.victronenergy.com/ (accessed on 29 August 2024).

- MEAN WELL DDR-480C-24. Available online: https://www.digikey.ca/en/products/detail/mean-well-usa-inc/DDR-480C-24/12333782 (accessed on 29 August 2024).

- Kalair, A.R.; Abas, N.; Hasan, Q.U.; Seyedmahmoudian, M.; Khan, N. Demand Side Management in Hybrid Rooftop Photovoltaic Integrated Smart Nano Grid. J. Clean. Prod. 2020, 258, 120747. [Google Scholar] [CrossRef]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The Replicating Rapid Prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. In Handbook of Research in Mass Customization and Personalization; World Scientific Publishing Company: Singapore, 2009; pp. 568–580. ISBN 978-981-4280-25-9. [Google Scholar]

| Converter | Interface | Performance | Hardware | Ref. |

|---|---|---|---|---|

| Two-stage pulse width modulation (PWM) bidirectional converter | Grid to bus | Stabilize DC bus voltage with minimum ripple and faster dynamic responses Significant reduction in DC-link capacitor | Yes | [31] |

| Switched boost inverter (SBI) | Grid to bus | Modified conventional PWM control technique and implemented in digital domain | Yes | [32] |

| Cascaded two-stage bidirectional converter | Grid to bus | Featured a dual active bridge (DAB) converter followed by a bidirectional dc-ac converter; operates in three different modes | Yes | [33] |

| Two-stage bidirectional grid interface converter (BGIC) | Grid to bus | Efficiency was greater when the first stage converter was controlled by neutral point clamped (NPC) topology and the second stage by a full bridge NPC structure | No | [34] |

| High-gain bidirectional DC–DC converter | Bus to battery storage | Ensured stability in both grid-connected and islanded modes of the nanogrid, reducing voltage ripple, eliminating the chance of improper switching between modes of operation, and establishing smooth bidirectional power flow | No | [35] |

| Boost derived hybrid converter (BDHC) | Bus to loads | Efficiency is higher than in a conventional DC nanogrid converter where dedicated converters are required for each component | Yes | [36] |

| Fourth-order bidirectional DC–DC converter (FoBiDC) | Bus to battery storage | Exhibited continuous bus side and battery side operation with minimum ripple while minimizing the effect of nonlinearity for multiple converter-based systems | Yes | [37] |

| Bidirectional modular PV battery system (BMPBS) | PV to bus | Problems associated with PV modules like module mismatch and module open circuit due to partial shading were eliminated | Yes | [38] |

| Parameters | PV Module | Battery Module | Load Module |

|---|---|---|---|

| Converter type | Boost converter | Bidirectional converter | Buck converter |

| Converter power rating (W) | 800 W | 400 W | 400 W (24 V), 200 W (12 V), and 100 W (6 V) |

| Input voltage range (V) | 15–40 V | 20–29.4 V (24 V battery) | 48 V |

| Maximum input current (A) | 20 A | 16.67 A | (8.33 A, 4.17 A, 2.08 A) |

| Output current (A) | 16.67 A | 8.33 A | 16.67 A |

| Switching frequency (kHz) | 50 kHz | 50 kHz | 50 kHz |

| Parameter | Boost Converter | Bidirectional Converter | Buck Converter (24 V) | Buck Converter (12 V) | Buck Converter (6 V) |

|---|---|---|---|---|---|

| Critical inductance | L1 = 45 μH | L2 = 115.2 μH | L3 = 57.58 μH | L4 = 43.18 μH | L5 = 25.2 μH |

| Critical capacitance | C1 = 260 μF | C2 = 217.01 μF, C3 = 173.6 μF | C4 = 43.41 μF | C5 = 86.83 μF | C6 = 173.61 μF |

| Selected inductance | L1 = 47 μH (20 A) | L2 = 120 μH (16.67 A) | L3 = 68 μH (16.67 A) | L4 = 47 μH (16.67 A) | L5 = 33 μH (16.67 A) |

| Selected capacitance | C1 = 470 μF (100 V) | C2 = 470 μF (50 V) C3 = 470 μF (100 V) | C4 = 470 μF (50 V) | C5 = 470 μF (50 V) | C6 = 470 μF (50 V) |

| Proportional gain (Kp) | 0.00021 | Charging mode: 0.0004 Discharging mode: 0.0005 | 0.000451 | 0.000722 | 0.00021 |

| Integral gain (Ki) | 2.734 | Charging mode: 4.78 Discharging mode: 6.01 | 9.52 | 11.01 | 9.35 |

| Gain margin (GM) | 15.57 dB | 17.32 dB, 15.3 dB | 14.18 dB | 20.8 dB | 13.85 dB |

| Phase margin (PM) | 90° | 90°, 90° | 90° | 90° | 90° |

| Serial | Trace Name | Function |

|---|---|---|

| 1 | PVS (D3) | PV signal from PV converter to indicate operating mode (0 = MPPT, 1 = Bus control) |

| 2 | BS (D4) | Battery status signal from battery converter (0 = current control, 1 = voltage control/isolated) |

| 3 | INT (D5) | Interrupt signal by master (normally 0) |

| 4 | SDA | Serial data line |

| 5 | SCL | Serial clock line |

| 6 | +12 V | +12 V supply for the control circuit |

| 7 | +12 V | +12 V supply for the control circuit |

| 8 | GND | Common ground |

| Parameters | Boost Converter | Bidirectional Converter | Buck Converter 1 (24 V) |

|---|---|---|---|

| Inductor | L1 = 47 μH | L2 = 120 μH | L3 = 68 μH |

| Current | 20 A | 16.67 A | 16.67 A |

| Peak current | 24 | 20 | 20 |

| Wire AWG | 16 AWG | 16 AWG | 16 AWG |

| Number of strands | 2 | 2 | 2 |

| Turns | 23 | 37 | 28 |

| Length | 3223 mm | 5266 mm | 3924 mm |

| Type | Cost (CAD) |

|---|---|

| Buck converter | CAD 55.81 |

| Boost converter | CAD 66.07 |

| Bidirectional converter | CAD 76.28 |

| Master controller | CAD 28.78 |

| Communication bus | CAD 5.03 |

| Monitoring system | CAD 147.52 |

| Total | CAD 379.49 |

| Code | File Type | Location of File |

|---|---|---|

| Boost converter code | .ino | https://osf.io/73yf5/ (accessed on 31 July 2024) |

| Buck converter code | .ino | https://osf.io/73yf5/ (accessed on 31 July 2024) |

| Bidirectional converter code | .ino | https://osf.io/73yf5/ (accessed on 31 July 2024) |

| Master controller code | .ino | https://osf.io/73yf5/ (accessed on 31 July 2024) |

| GUI for Raspberry pi | .py | https://osf.io/73yf5/ (accessed on 31 July 2024) |

| Voltage Level | Load |

|---|---|

| 24 V load | 200 W |

| 12 V load | 100 W |

| 6 V load | 80 W |

| Total | 380 W |

| Voltage Level | 0–1 | 1–2 | 2–3 |

|---|---|---|---|

| 24 V load | 200 W | 200 W | 200 W |

| 12 V load | 200 W | 200 W | 0 W |

| 6 V load | 100 W | 0 W | 0 W |

| Total | 500 W | 400 W | 200 W |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.M.; Khan, S.; Pearce, J.M. Open-Source Hardware Design of Modular Solar DC Nanogrid. Technologies 2024, 12, 167. https://doi.org/10.3390/technologies12090167

Rahman MM, Khan S, Pearce JM. Open-Source Hardware Design of Modular Solar DC Nanogrid. Technologies. 2024; 12(9):167. https://doi.org/10.3390/technologies12090167

Chicago/Turabian StyleRahman, Md Motakabbir, Sara Khan, and Joshua M. Pearce. 2024. "Open-Source Hardware Design of Modular Solar DC Nanogrid" Technologies 12, no. 9: 167. https://doi.org/10.3390/technologies12090167

APA StyleRahman, M. M., Khan, S., & Pearce, J. M. (2024). Open-Source Hardware Design of Modular Solar DC Nanogrid. Technologies, 12(9), 167. https://doi.org/10.3390/technologies12090167