Advancements in 3D Printing: Directed Energy Deposition Techniques, Defect Analysis, and Quality Monitoring

Abstract

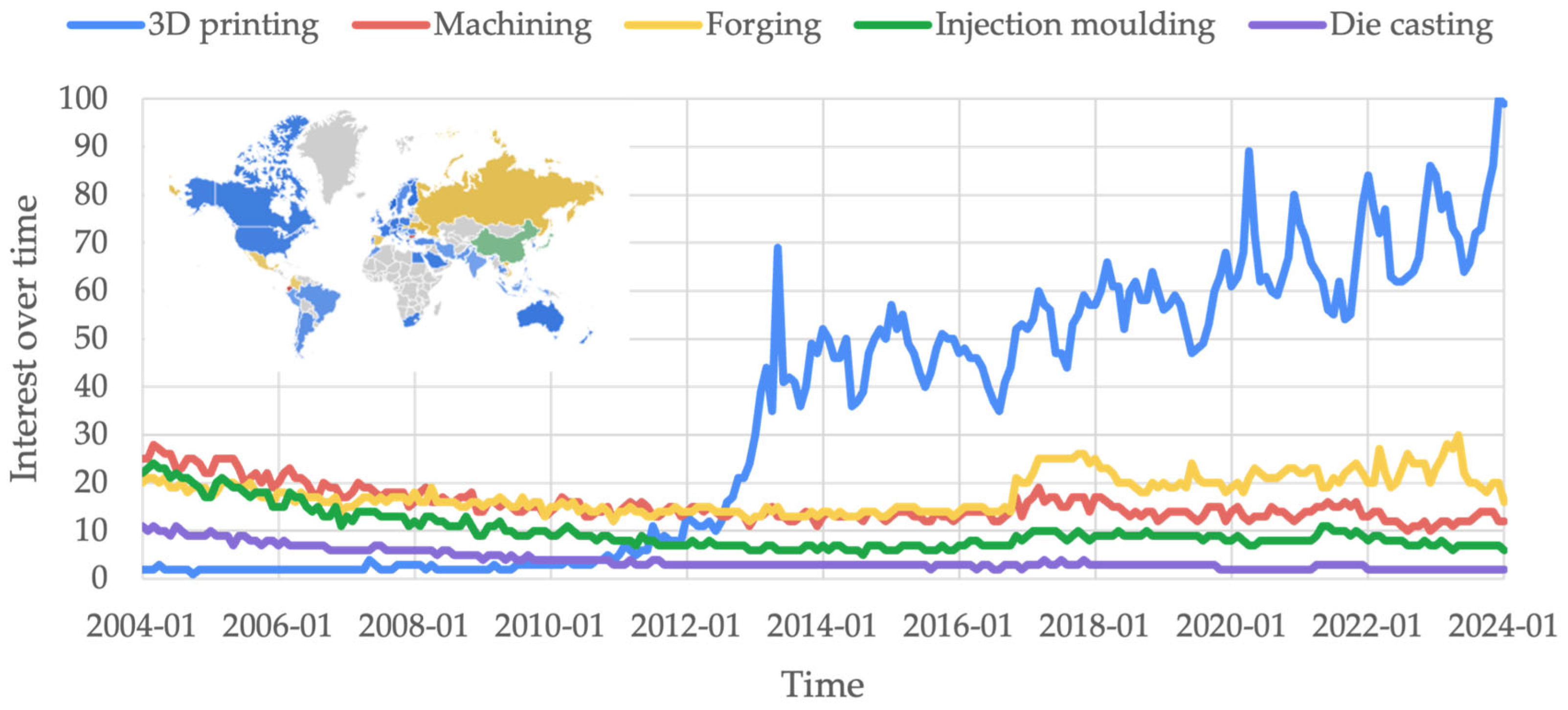

1. Introduction

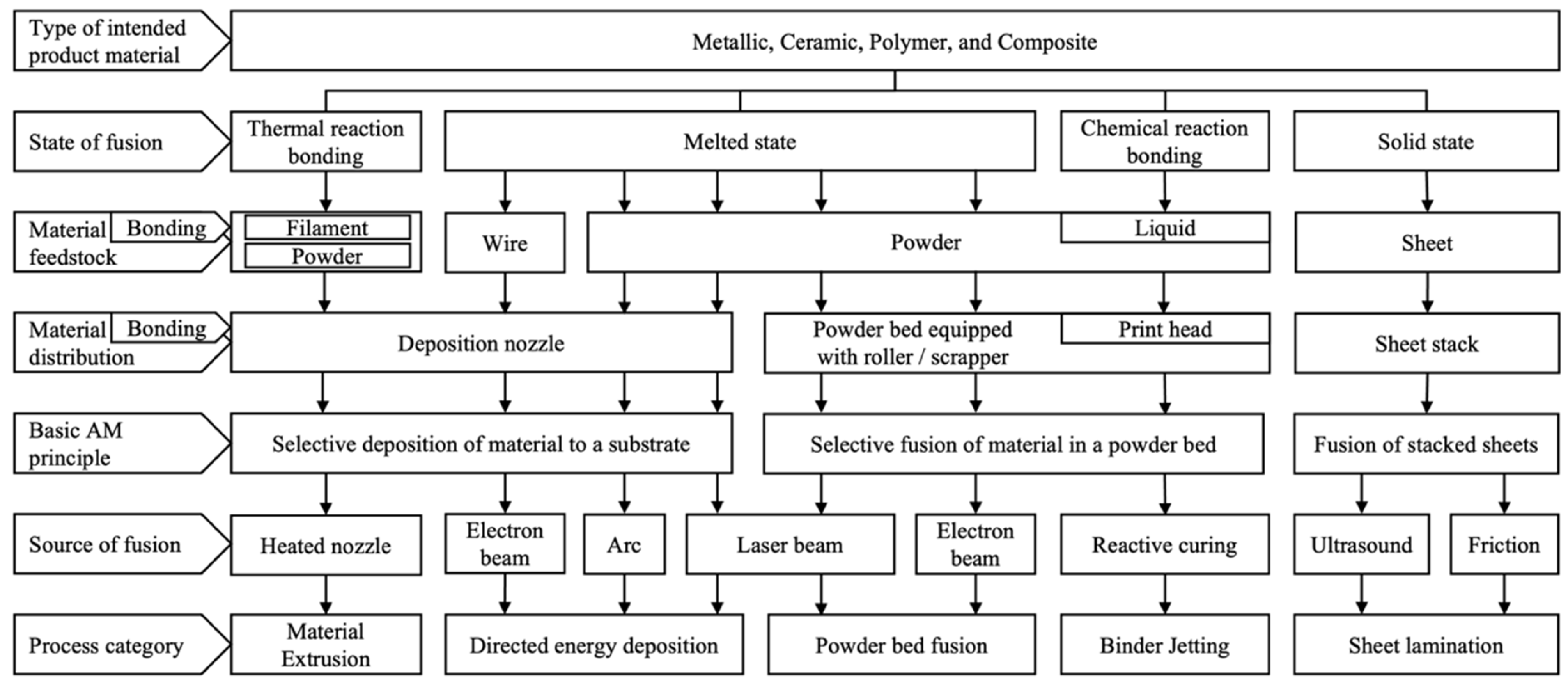

2. Metal Additive Manufacturing

3. Directed Energy Deposition

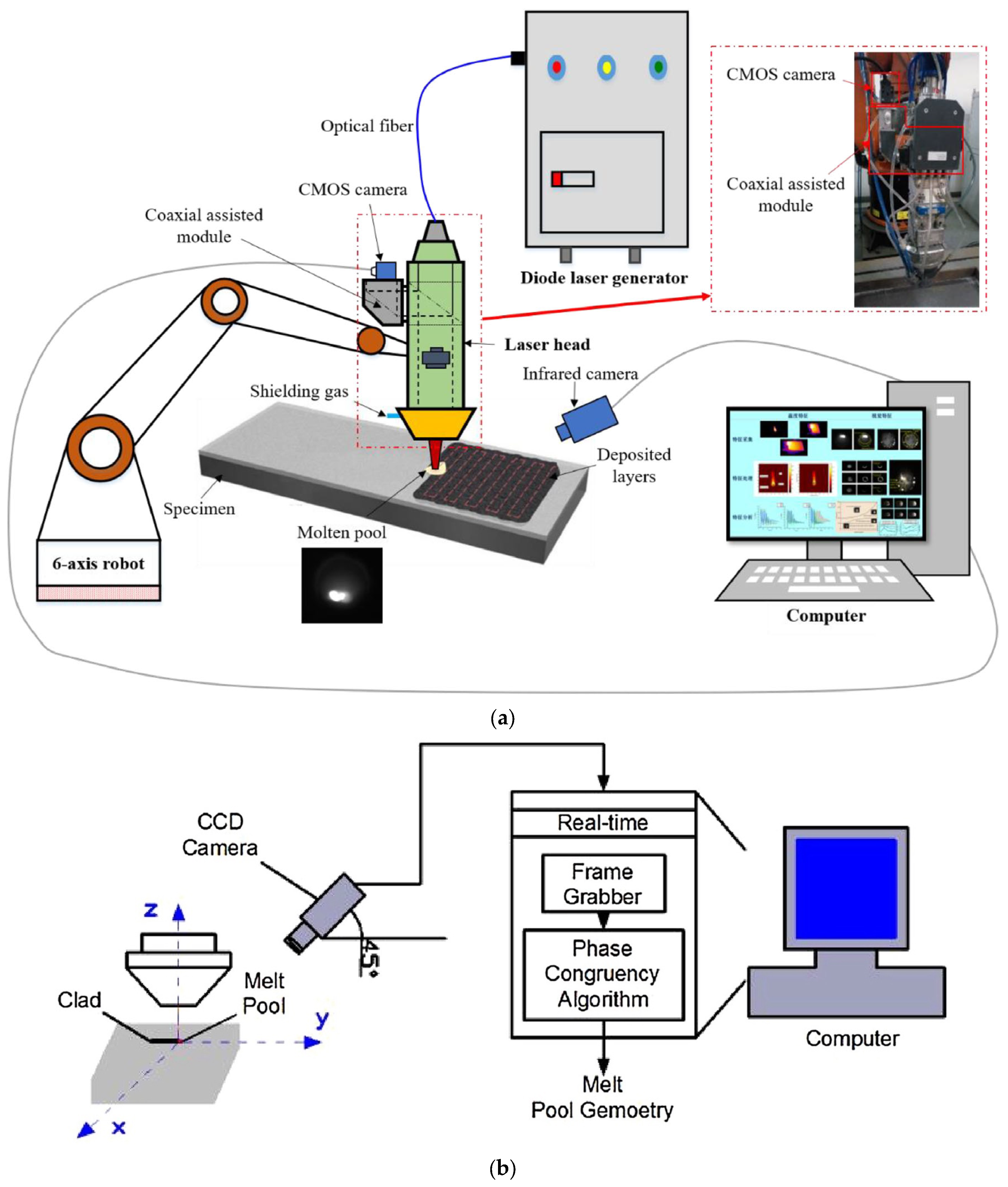

3.1. The Melt Pool Morphology

3.2. Process Parameters and Their Relation to the Melt Pool Morphology

3.2.1. Laser Power

| Ref. | Analysis | Structure | Material | Melt Pool Size | For an Increase in Each Input Variable the Output Effect Is Shown by Symbol 1 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Substrate | Powder | Laser Power | Scanning Speed 2 | Powder Feed Rate | Standoff Distance | Hatch Spacing | Beam Size | |||||

| [103] | Linear Regression | Single-track | Annealed Inconel 718 | Inconel 718 | Height | ↑ | ↓ | ↑ | ||||

| Width | ↑ | ↓ | — | |||||||||

| Depth | ||||||||||||

| Dilution | ||||||||||||

| [104] | 2D Visualization | Thin-wall | TA6V alloy | TA6V alloy | Height | — | ↑ | |||||

| Width | ↑ | — | ||||||||||

| Depth | ||||||||||||

| Dilution | ||||||||||||

| [105] | 2D plot | Thin-wall | EN43A (AISI 1050) mild steel | AISI 316 Stainless Steel (50–150 μm) | Height | — | ↓ | ↑ | ||||

| Width | ↑ | ↓ | — | |||||||||

| Depth | ||||||||||||

| Dilution | ||||||||||||

| [96] | 2D plot | Single-track | Stainless-steel 316L | Steel alloy EN25 | Height | |||||||

| Width | ↑ | ↓ | ↑ | |||||||||

| Depth | ||||||||||||

| Dilution | ||||||||||||

| [114] | ANN | Single-track | Mild Steel | SS316L (D90: 50–150 μm) | Height | ↑ | ↓ | ↑ | ↑ | |||

| Width | ↑ | ↓ | — | ↑ | ||||||||

| Depth | ↑ | ↓ | ↓ | ↓ | ||||||||

| Dilution | ↑ | — | ↓ | ↓ | ||||||||

| Inconel 625 (D90: 50–150 μm) | Height | — | ↓ | ↑ | ↑ | |||||||

| Width | ↑ | ↓ | — | ↑ | ||||||||

| Depth | ↑ | — | ↓ | ↓ | ||||||||

| Dilution | ↑ | ↑ | ↓ | ↓ | ||||||||

| Hastelloy X (D90: 50–150 μm) | Height | ↑ | ↓ | ↑ | ↑ | |||||||

| Width | ↑ | ↓ | — | ↑ | ||||||||

| Depth | ↑ | — | ↓ | ↓ | ||||||||

| Dilution | ↑ | ↑ | ↓ | ↓ | ||||||||

| [87] | Image analysis | Single-track | 316L stainless-steel | AISI 316L (80 µm) | Height | ↑ | ↓ | |||||

| Width | ↑ | ↓ | ||||||||||

| Depth | ↑ | ↓ | ||||||||||

| Dilution | ||||||||||||

| [113] | Response Surface Methodology | Double-tracks | Al6061 | Al5083 | Height | ↑ | ↓ | ↑ | ↓ | |||

| Width | ||||||||||||

| Depth | ||||||||||||

| Dilution | — | ↑ | ↓ | ↑ | ||||||||

| [112] | Linear Regression (Empirical–Statistical analysis) | Single-track | A-286 Stainless Steel | Inconel 718 (45–90 µm) | Height | ↑ | ↑ | |||||

| Width | ↓ | ↓ | ||||||||||

| Depth | ||||||||||||

| Dilution | ↓ | ↓ | ||||||||||

| [111] | Linear Regression | Single-track | Inconel 738 | NiCrAlY (50–100 µm) | Height | ↑ | ↓ | ↑ | ||||

| Width | ↑ | ↓ | — | |||||||||

| Depth | ||||||||||||

| Dilution | — | ↑ | ↓ | |||||||||

| [110] | Linear Regression | Single-track | Ti-6Al-4V | Ti-6Al-4V (90–125 µm) | Height | ↑ | ↓ | ↑ | ||||

| Width | ↑ | ↓ | — | |||||||||

| Depth | ↑ | ↑ | ↓ | |||||||||

| Dilution | — | ↑ | ↓ | |||||||||

| [109] | 2D plot and image analysis | Single-track | Martensitic stainless-steel AISI 420 | Commercial powder of NiCr 80/20 (purity of 98%) and TiC | Height | ↑ | ↑ | ↑ | ||||

| Width | ↑ | — | ↑↓ | |||||||||

| Depth | ↑ | ↓ | ↓ | |||||||||

| Dilution | ↑ | ↓ | ↓ | |||||||||

| [108] | ANOVA | Single-track | SS316 | Inconel 718 (45–100 µm) | Height | ↓ | ↓ | ↑ | ||||

| Width | ↑ | ↓ | ↓ | |||||||||

| Depth | ↑ | ↓ | ↓ | |||||||||

| Dilution | ↑ | ↓ | ↓ | |||||||||

| [97] | Linear Regression, Image Analysis, Process maps | Single-track | Mild steel (S235JR) | Inconel 718 (45–105 µm) | Height | — | ↑ | |||||

| Width | ↑ | — | ||||||||||

| Depth | ↑ | ↓ | ↓ | |||||||||

| Dilution | ↑ | — | ↓ | |||||||||

| [107] | Response Surface Methodology, Linear Regression, ANOVA | Singe-track | Copper | CuCrZr alloy (D90: 59.91 μm) | Height | ↑ | ↓ | ↑ | ||||

| Width | ↑ | ↓ | ↑ | |||||||||

| Depth | ↑ | ↓ | ↓ | |||||||||

| Dilution | ↑ | ↓ | ↓ | |||||||||

| [115] | Response Surface Methodology, ANOVA, 2D plot | Single-track | Ti6Al4V | Ti6Al4V | Height | ↑↓ | ↓ | ↑ | ||||

| Width | ↑↓ | ↓ | ↓ | |||||||||

| Depth | ↑↓ | ↓ | ↓ | |||||||||

| Dilution | ↑↓ | ↓ | ↓ | |||||||||

| [116] | 2D visualisation and compare their microstructural properties | Single-track | Wrought Alloy 718 | Alloy 718 (40–105 μm) | Height | ↑↓ | ↓ | — | ||||

| Width | ↑ | ↓ | ↑ | |||||||||

| Depth | ↑ | ↑↓ | ↑↓ | |||||||||

| Dilution | ↑ | ↑ | ↓ | |||||||||

| [121] | Response Surface Methodology | Single-track | 316L Stainless steel | 316L Stainless steel (45–53 μm) | Height | ↓ | ↑↓ | ↑↓ | ↑↓ | |||

| Width | ↓ | ↑↓ | ↑↓ | ↑↓ | ||||||||

| Depth | ||||||||||||

| Dilution | ||||||||||||

| [85] | Linear Regression, ANOVA, Analytical Model | Single-track | AISI 304 Stainless steel | Nickel-based superalloy (15–45 µm) | Height | ↑↓ | ||||||

| Width | ↑↓ | |||||||||||

| Depth | ↓ | |||||||||||

| Dilution | ↓ | |||||||||||

| [86] | 2D visualisation | Single-track | Ti-6Al-4V | Ti-6Al-4V | Height | ↑ | ||||||

| Width | ↑↓ | |||||||||||

| Depth | ↑↓ | |||||||||||

| Dilution | ↑ | |||||||||||

| [106] | Response Surface Methodology, ANOVA | Single-track | AISI 1045 | AISI M4 (53–150 µm) | Height | ↑ | ↑ | |||||

| Width | ↑ | ↑ | ||||||||||

| Depth | ||||||||||||

| Dilution | ↑ | ↑ | ||||||||||

| [99] | ANOVA | Single-track | S355 low alloyed steel | AISI 316L stainless steel (53–150 μm) | Height | |||||||

| Width | ||||||||||||

| Depth | ↑ | ↓ | ||||||||||

| Dilution | ||||||||||||

3.2.2. Scan Speed

3.2.3. Powder Feed Rate

4. Defects in DED and Their Formation Mechanism

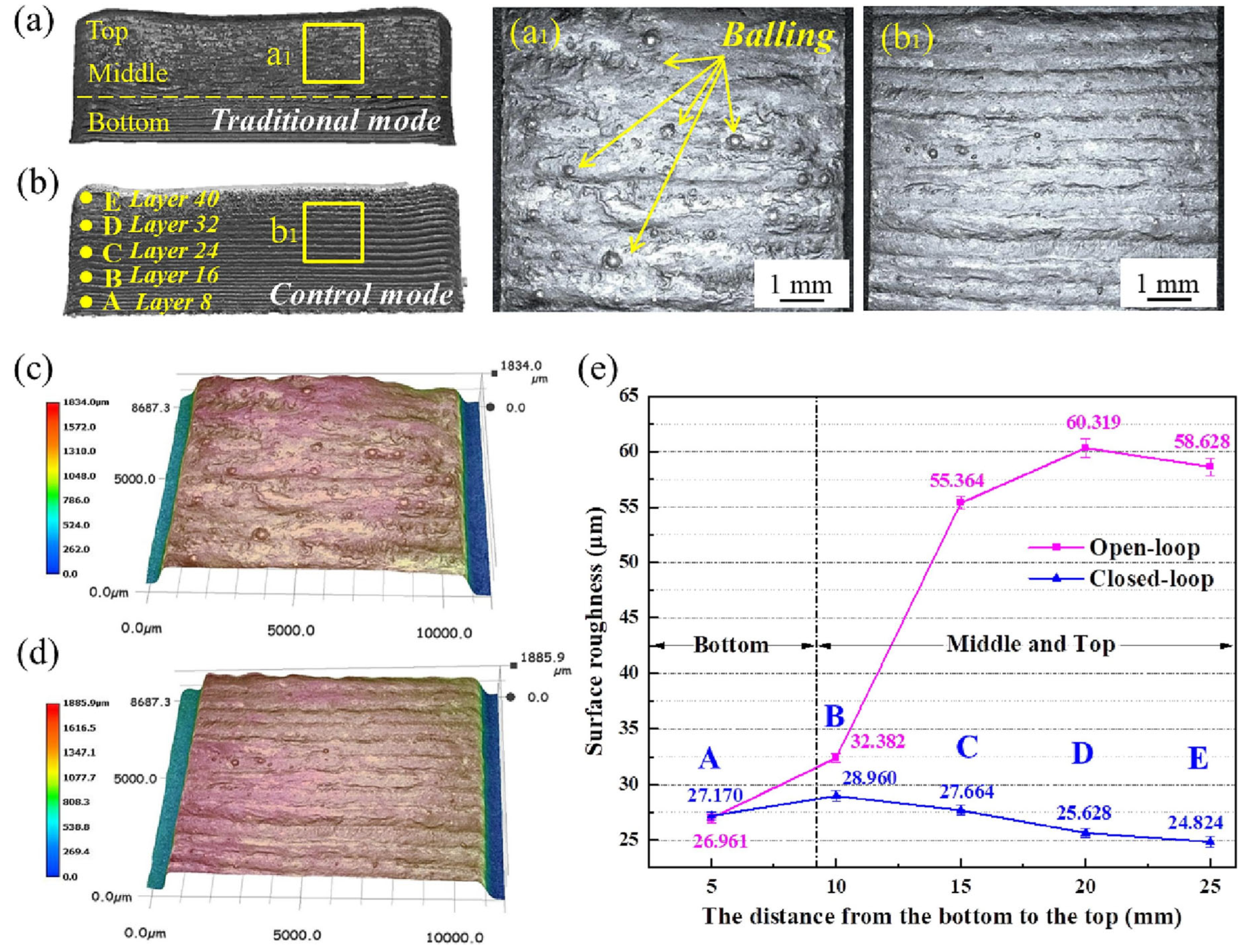

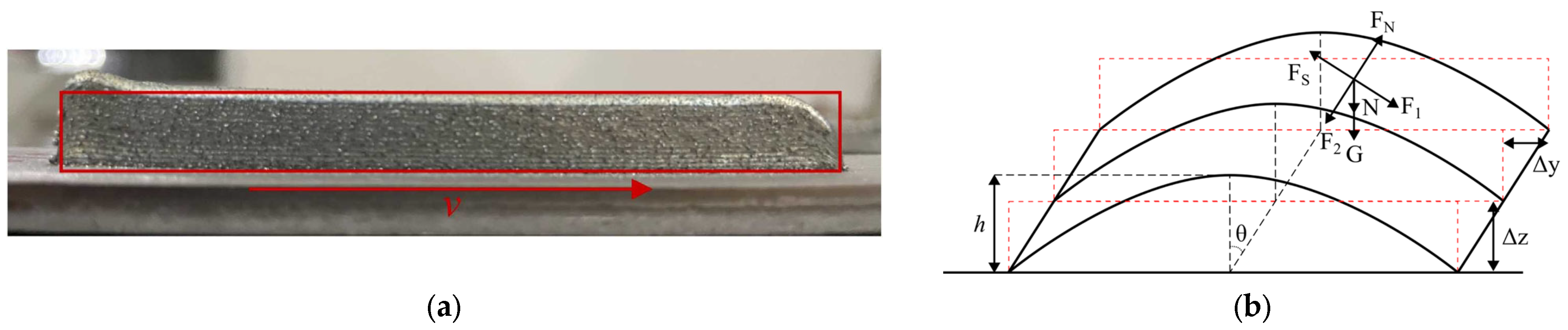

4.1. Geometrical Defects

4.1.1. Non-Uniform Layer Thickness

4.1.2. Edge Collapse

4.2. Morphological Defects

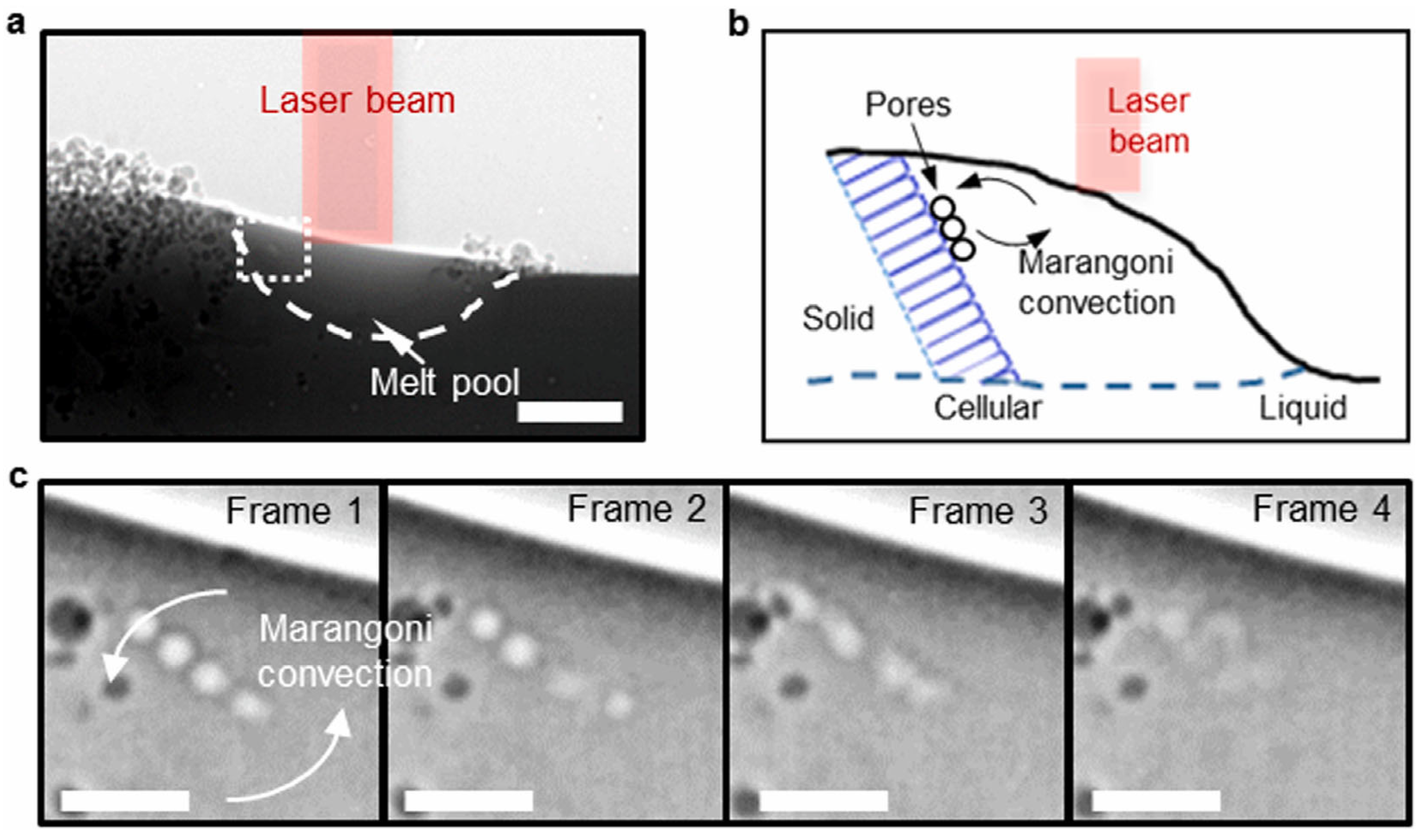

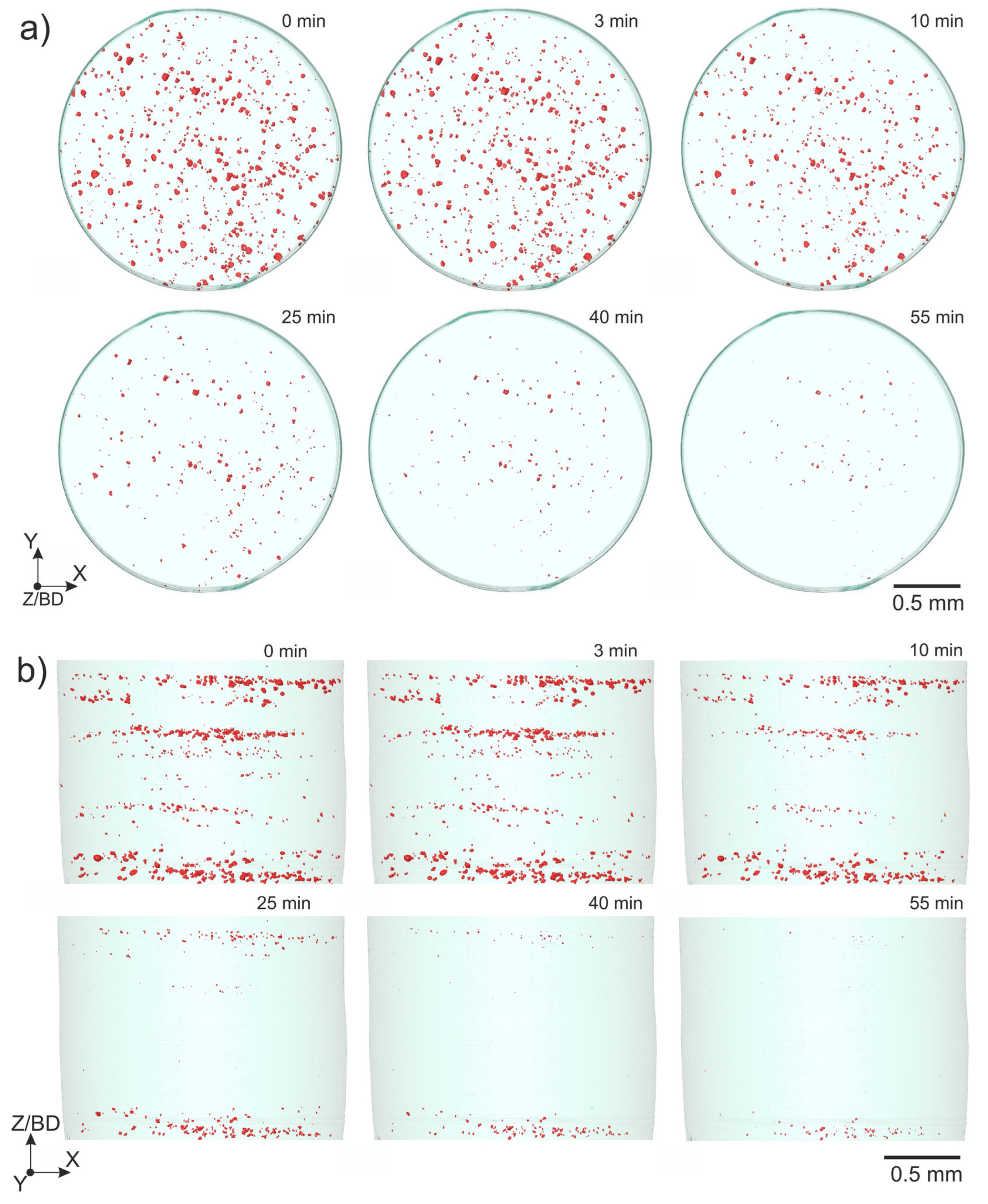

4.2.1. Porosity

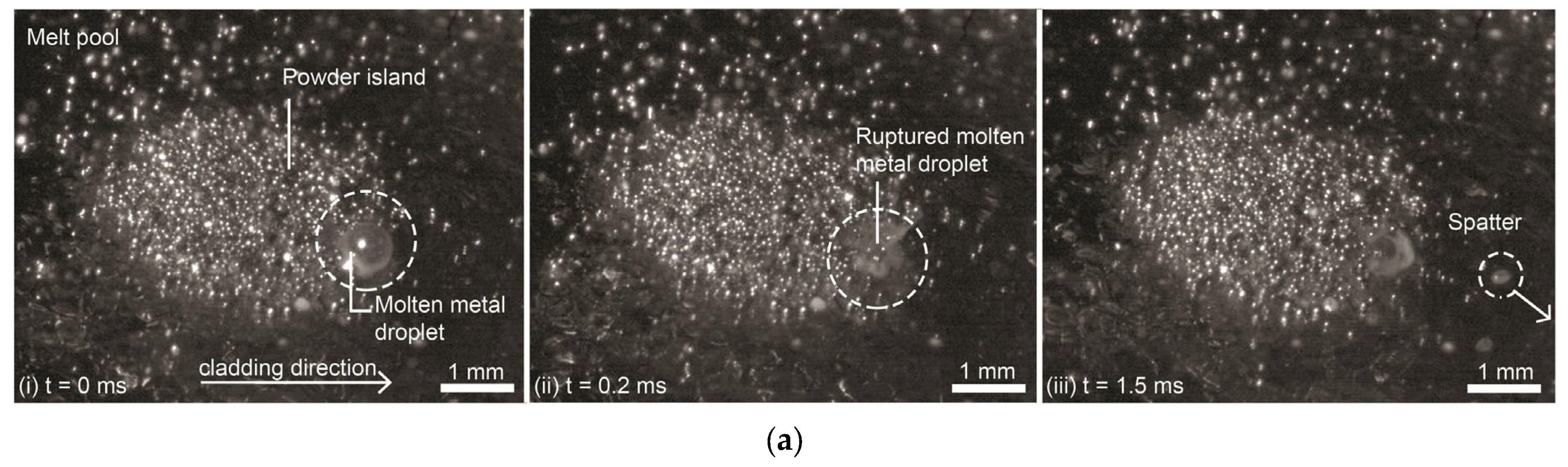

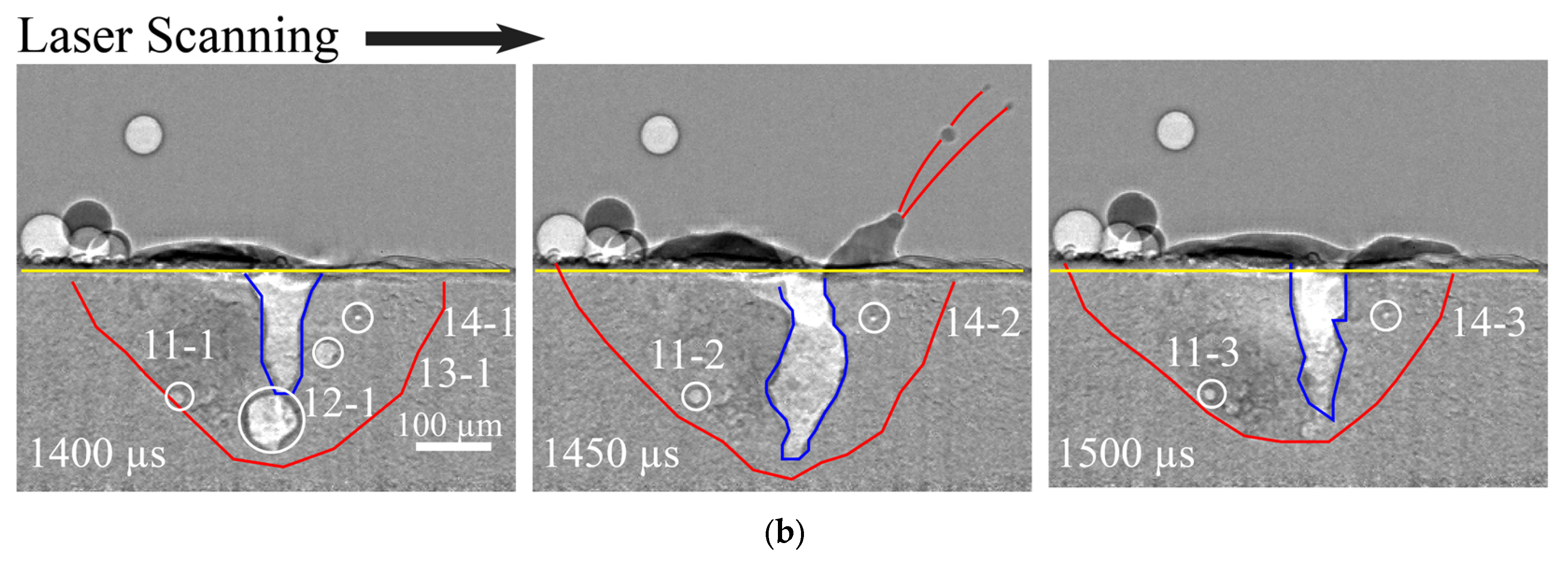

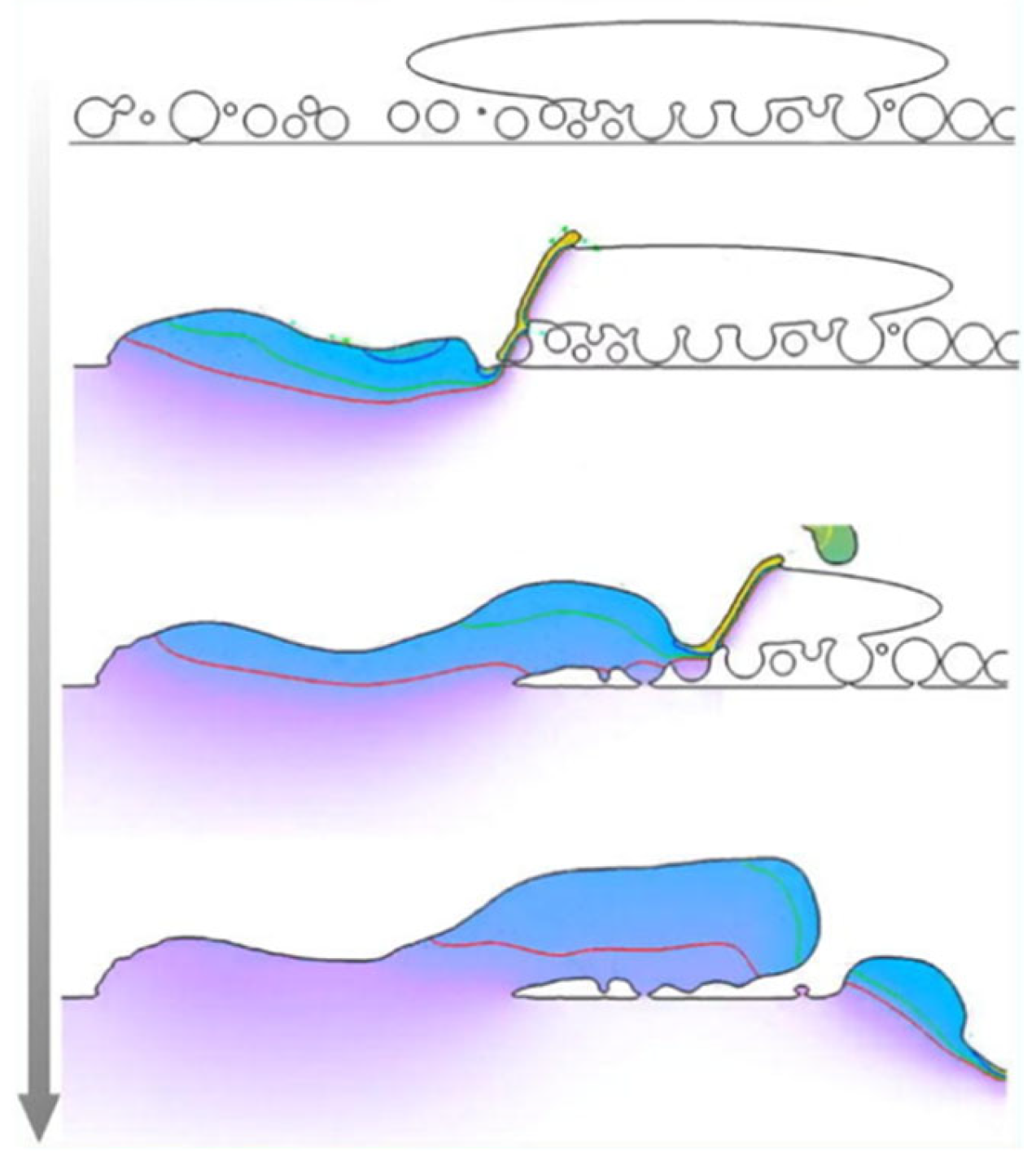

4.2.2. Spatters

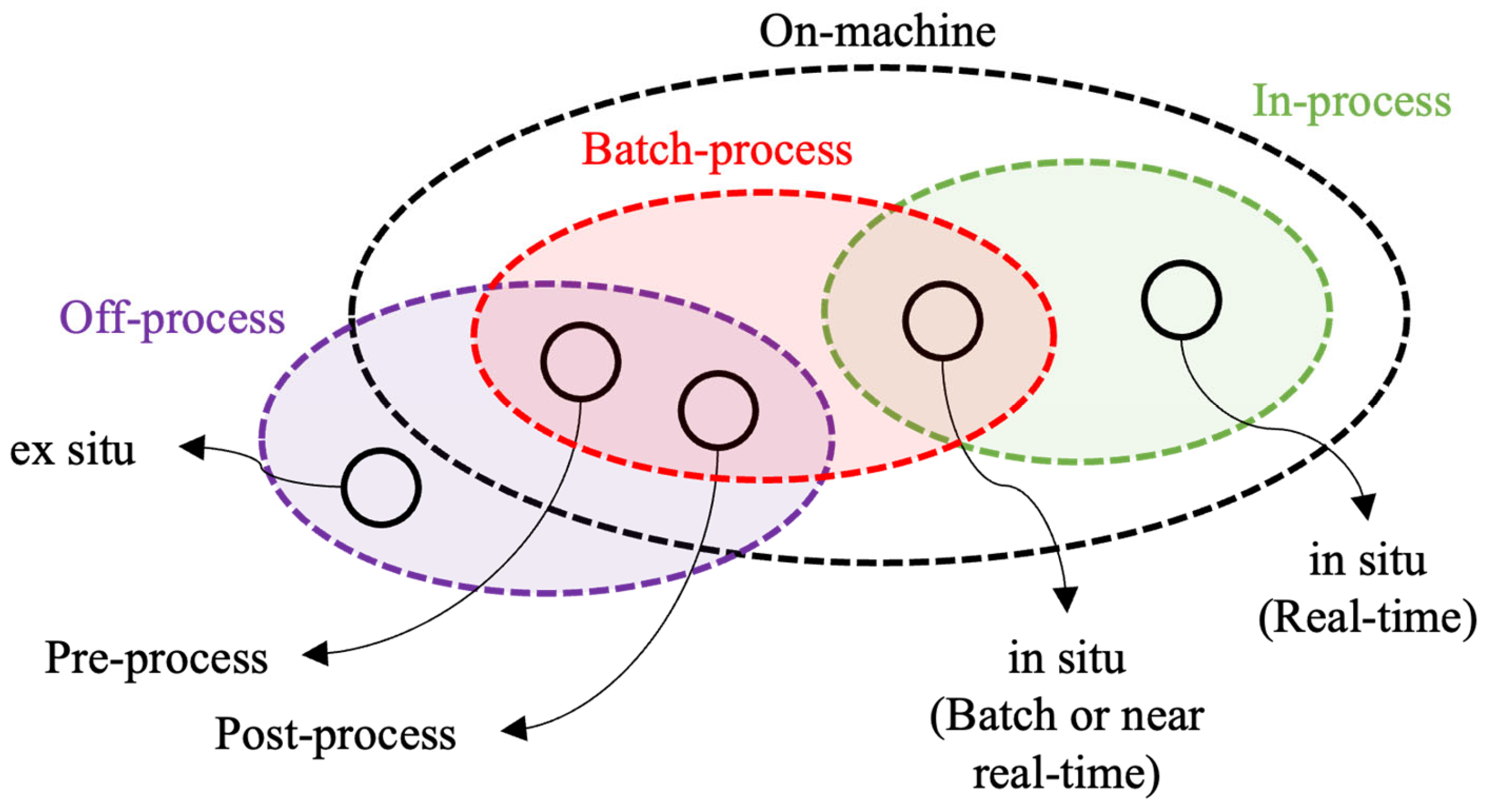

5. Inspection and Verification Approaches for Quality Assurance in DED Process

5.1. Terminology and Definitions Related to Measurement and Monitoring Techniques

5.2. In-Process Measurement Technologies and Its Process Signatures in Metal AM

5.2.1. Optical Inspection Techniques

Vision-Based Signals

Laser-Based Scanning

Thermal Signals

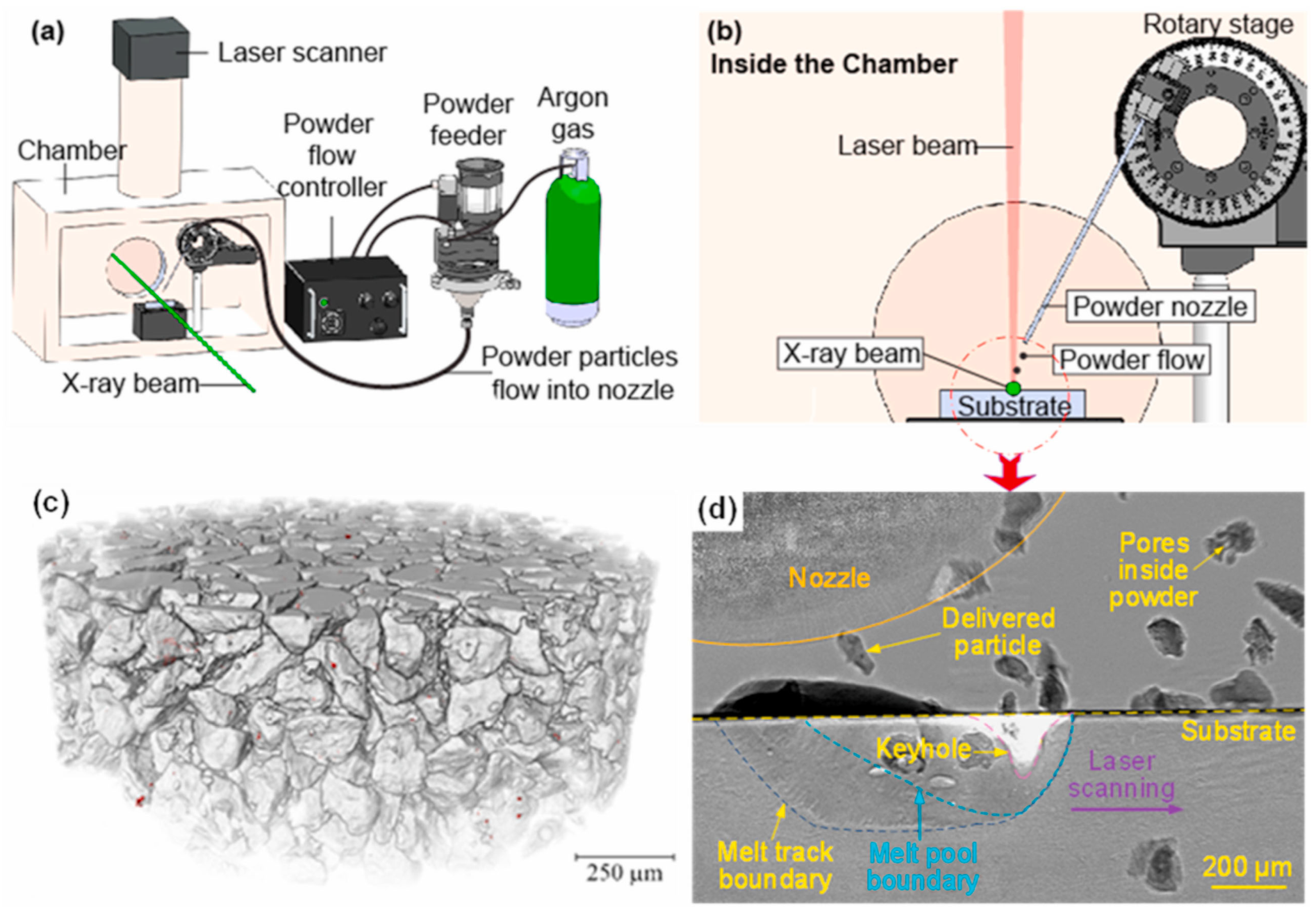

X-ray Imaging

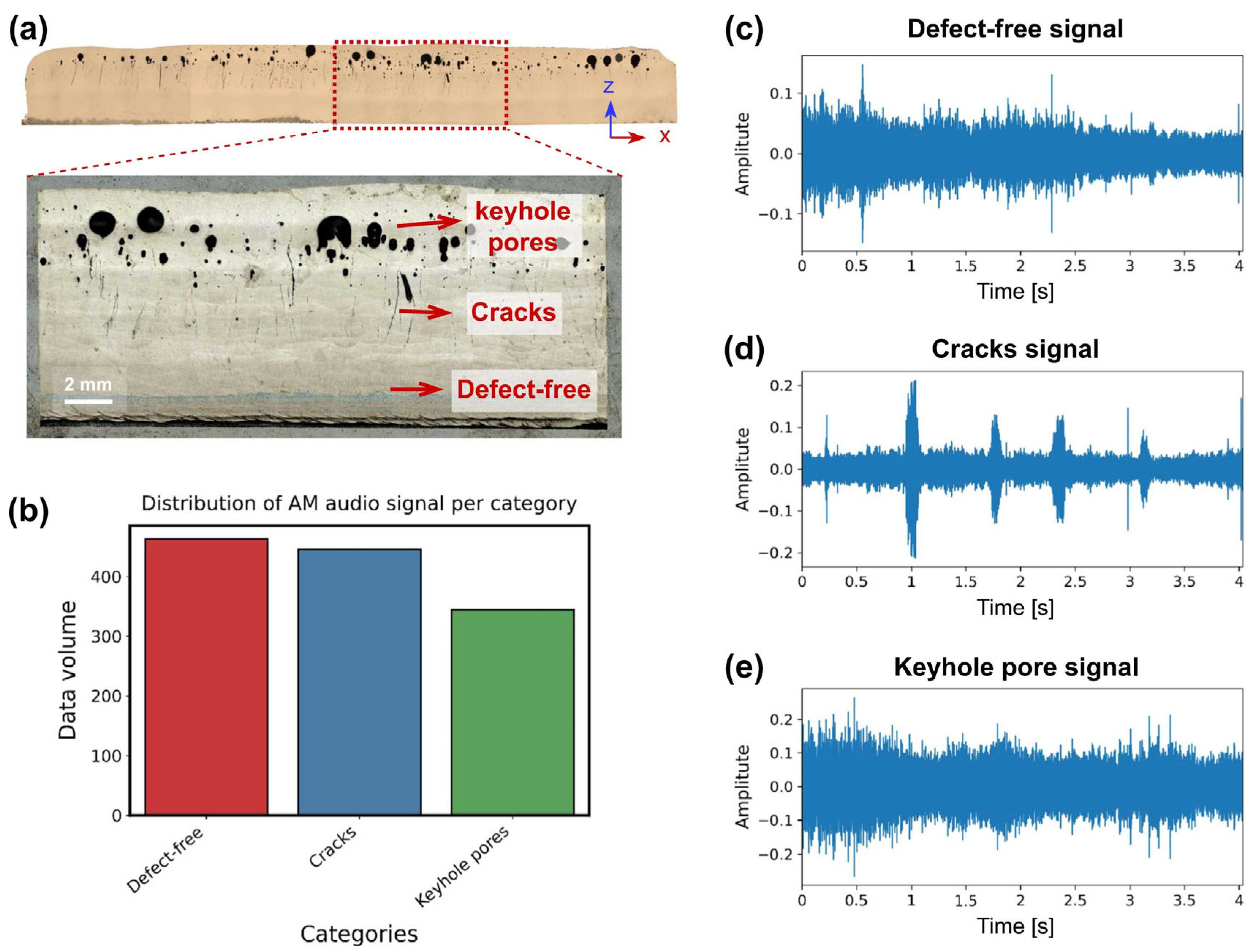

5.2.2. Acoustic Signals

5.2.3. Spectral and Other Signals

5.3. Challenges in Real-Time Data Acquisition

5.3.1. Spatter-Induced Disturbances

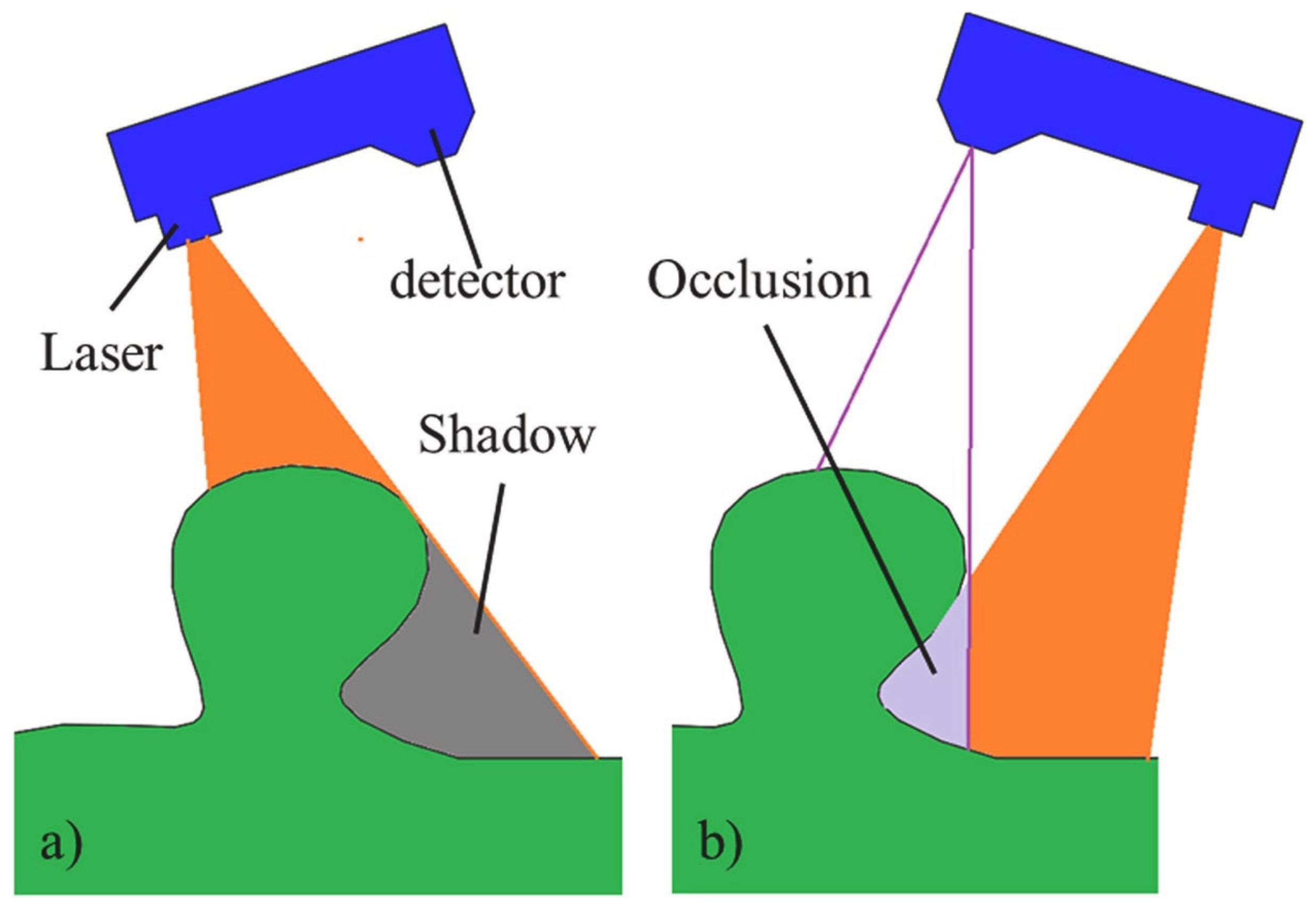

5.3.2. Shadow and Occlusion Effect

5.3.3. Hot-Red-Glowing Surfaces

6. Data Analytics and Statistical Approaches for In Situ Defect Detection

6.1. Outliers and Concept Drift Detection

6.2. Point Cloud Data Structure

6.3. Spatiotemporal Analysis

6.4. Performance Evaluation and Defects Identification

6.5. Melt Pool Geometrical Modelling

6.5.1. Physics-Based Approach

6.5.2. Data-Driven Approach

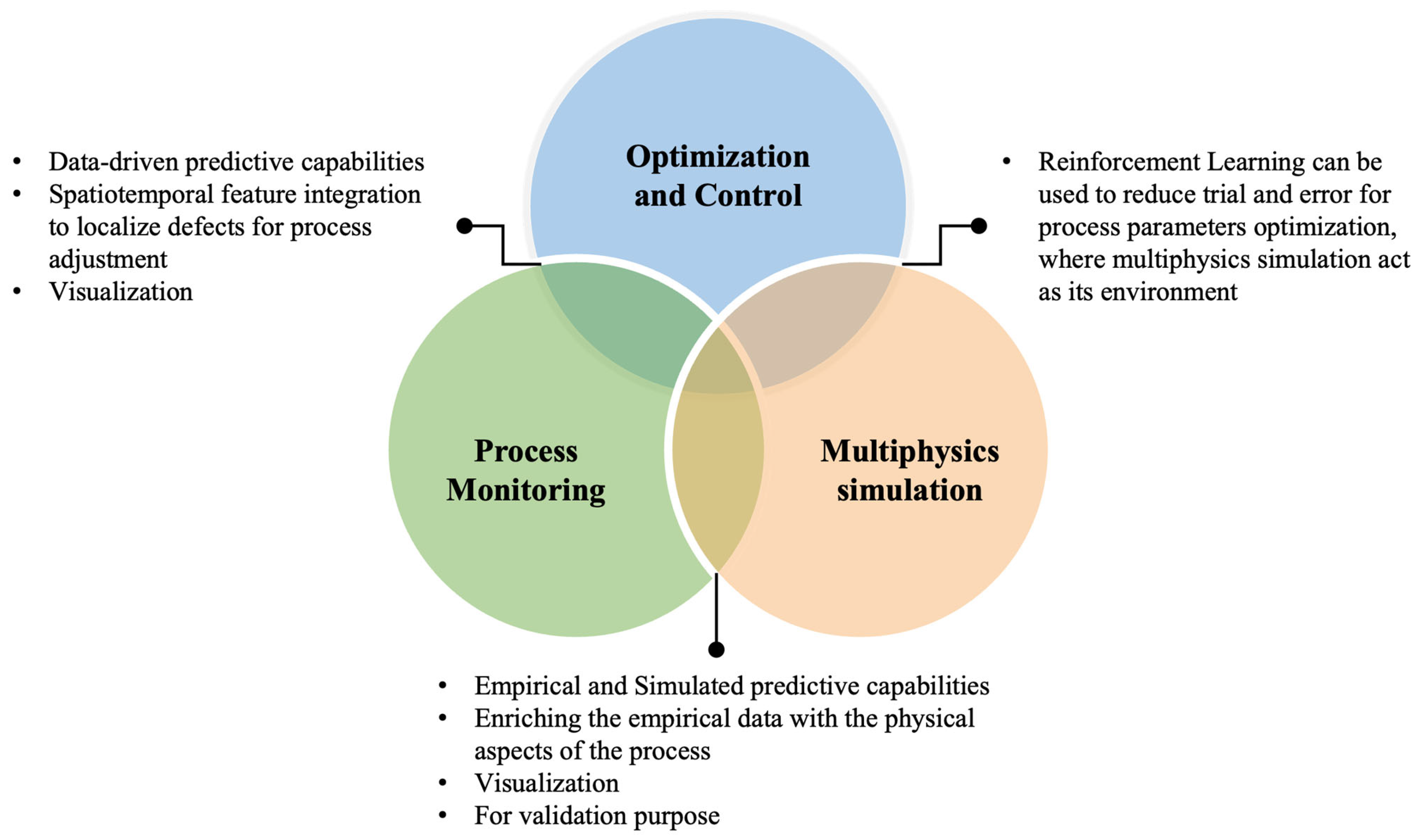

7. Research Gap Analysis and Future Outlooks

7.1. Research Gap Analysis

7.2. Future Outlooks

8. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| AE | Acoustic Emission |

| AM | Additive Manufacturing |

| ANN | Artificial Neural Network |

| AISI | American Iron and Steel Institute |

| ASTM | American Society for Testing and Materials |

| BJT | Binder Jetting |

| CAD | Computer-Aided Design |

| CAGR | Compounded Annual Growth Rate |

| CCD | Charge-Coupled Device |

| CMOS | Complementary Metal Oxide Semiconductor |

| CNC | Computer Numerical Control |

| CNN | Convolutional Neural Network |

| CO2 | Carbon Dioxide |

| CT | Computed Tomography |

| DAOSE | Deviation Along the Overhanging Surface Edge |

| DBSCAN | Density-Based Spatial Clustering of Applications with Noise |

| DDM | Drift Detection Method |

| DED | Directed Energy Deposition |

| DMD | Direct Metal Deposition |

| DFAM | Design For Additive Manufacturing |

| DFMA | Design For Manufacture and Assembly |

| DSPOT | Drift Streaming Peak-Over-Threshold |

| DT | Digital Twin |

| EBAM | Electron Beam Additive Manufacturing |

| FBG | Fiber Bragg Grating |

| FEA | Finite Element Analysis |

| FGM | Functionally Graded Material |

| G-CODE | Geometric Code |

| GPD | Generalized Pareto Distribution |

| GRU | Gated Recurrent Unit |

| HAZ | Heat-Affected Zone |

| H/D | Height-over-Depth |

| HIP | Hot Isostatic Pressing |

| ICI | Inline Coherent Imaging |

| INGAAS | Indium Gallium Arsenide |

| IR | Infrared |

| ISO | International Organization of Standardization |

| KNN | K-Nearest Neighbours |

| LENS™ | Laser Engineered Net Shaping |

| LMD | Laser Metal Deposition |

| LoF | Lack-of-Fusion |

| LP-DED | Laser–Powder-based Directed Energy Deposition |

| LSTM | Long Short-Term Memory |

| ME | Material Extrusion |

| MRO | Maintenance, Repair, and Overhaul |

| NASA | National Aeronautics and Space Administration |

| NCC | Numerical Control Code |

| ND:YAG | Neodymium-Doped Yttrium Aluminium Garnet |

| NDT | Non-Destructive Testing |

| NIR | Near-Infrared |

| NiCr | Nickel–Chromium |

| OD | Orthogonal Deviation |

| OES | Optical Emission Spectroscopy |

| PBF | Powder Bed Fusion |

| PCA | Principal Component Analysis |

| PCAST | President’s Council of Advisors on Science and Technology |

| POT | Peaks-Over-Threshold |

| RANSAC | Random Sample Consensus |

| R&D | Research and Development |

| RE | Relative Error |

| RL | Reinforcement Learning |

| RMSE | Root Mean Squared Error |

| SDAM | Secondary Dendrite Arm Spacing |

| SoD | Standoff Distance |

| SL | Sheet Lamination |

| SLA | Stereolithography |

| SLM | Selective Laser Melting |

| SPC | Statistical Process Control |

| STL | Standard Tessellation Language |

| TiC | Titanium Carbide |

| TVP | Tensor-to-Vector Projection |

| UV | Ultraviolet |

| USD | United States Dollar |

| WAAM | Wire Arc Additive Manufacturing |

| XCT | X-Ray Computed Tomography |

| XGBOOST | Extreme Gradient Boosting |

| X-Ray | X-radiation |

| Yb | Ytterbium |

References

- ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO/ASTM: Geneva, Switzerland, 2021.

- Executive Office of the US President. Capturing a Domestic Competitive Advantage in Advanced Manufacturing. 2012. Available online: https://www.energy.gov/sites/prod/files/2013/11/f4/pcast_annex1_july2012.pdf (accessed on 12 January 2024).

- Scott, C. United Nations Encourages More Countries to Invest in 3D Printing. 2015. Available online: https://3dprint.com/105046/united-nations-wipo-report/ (accessed on 12 January 2024).

- World Intellectual Property Organization. Getting Rid of Bulky Plasters with 3-D Printed Technology. 2022. Available online: https://www.wipo.int/wipo_magazine/en/ip-at-work/2022/3d-printed-technology.html (accessed on 12 January 2024).

- Research and Markets. Additive Manufacturing Global Market Report 2024. 5807051. 2024. Available online: https://www.researchandmarkets.com/reports/5807051/additive-manufacturing-global-market-report# (accessed on 12 January 2024).

- Toyserkani, E.; Sarker, D.; Ibhadode, O.O.; Liravi, F.; Russo, P.; Taherkhani, K. Metal Additive Manufacturing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2021; p. 624. [Google Scholar]

- Baumers, M.; Dickens, P.; Tuck, C.; Hague, R. The cost of additive manufacturing: Machine productivity, economies of scale and technology-push. Technol. Forecast. Soc. Chang. 2016, 102, 193–201. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Economics of additive manufacturing for end-usable metal parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- Thomas, D.S.; Gilbert, S.W. Costs and cost effectiveness of additive manufacturing. NIST Spec. Publ. 2014, 1176, 12. [Google Scholar]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for additive manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B.; Khorasani, M.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in metal additive manufacturing: A review of common processes, industrial applications, and current challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Bhatia, A.; Sehgal, A.K. Additive manufacturing materials, methods and applications: A review. Mater. Today Proc. 2023, 81, 1060–1067. [Google Scholar] [CrossRef]

- Gradl, P.R.; Mireles, O.R.; Protz, C.S.; Garcia, C.P. Metal Additive Manufacturing for Propulsion Applications; AIAA Progress in Astronautics and Aeronautics Book Series; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2022. [Google Scholar]

- Mazzucato, F.; Avram, O.; Valente, A.; Carpanzano, E. Recent advances toward the industrialization of metal additive manufacturing. Syst. Eng. Fourth Ind. Revolut. 2019, 273–319. [Google Scholar] [CrossRef]

- Praveena, B.; Lokesh, N.; Buradi, A.; Santhosh, N.; Praveena, B.; Vignesh, R. A comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential. Mater. Today Proc. 2022, 52, 1309–1313. [Google Scholar]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S. Additive manufacturing: Recent trends, applications and future outlooks. Prog. Addit. Manuf. 2022, 7, 261–287. [Google Scholar] [CrossRef]

- Lettori, J.; Raffaeli, R.; Peruzzini, M.; Schmidt, J.; Pellicciari, M. Additive manufacturing adoption in product design: An overview from literature and industry. Procedia Manuf. 2020, 51, 655–662. [Google Scholar] [CrossRef]

- Tuvayanond, W.; Prasittisopin, L. Design for Manufacture and Assembly of Digital Fabrication and Additive Manufacturing in Construction: A Review. Buildings 2023, 13, 429. [Google Scholar] [CrossRef]

- Schmelzle, J.; Kline, E.V.; Dickman, C.J.; Reutzel, E.W.; Jones, G.; Simpson, T.W. (Re) Designing for part consolidation: Understanding the challenges of metal additive manufacturing. J. Mech. Des. 2015, 137, 111404. [Google Scholar] [CrossRef]

- Nayyeri, P.; Zareinia, K.; Bougherara, H. Planar and nonplanar slicing algorithms for fused deposition modeling technology: A critical review. Int. J. Adv. Manuf. Technol. 2022, 119, 2785–2810. [Google Scholar] [CrossRef]

- Feldhausen, T.; Heinrich, L.; Saleeby, K.; Burl, A.; Post, B.; MacDonald, E.; Saldana, C.; Love, L. Review of Computer-Aided Manufacturing (CAM) strategies for hybrid directed energy deposition. Addit. Manuf. 2022, 56, 102900. [Google Scholar] [CrossRef]

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.; Wang, C.C.L.; et al. Current and future trends in topology optimization for additive manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Carrozza, A.; Aversa, A.; Mazzucato, F.; Lombardi, M.; Biamino, S.; Valente, A.; Fino, P. An innovative approach on directed energy deposition optimization: A study of the process environment’s influence on the quality of Ti-6Al-4V samples. Appl. Sci. 2020, 10, 4212. [Google Scholar] [CrossRef]

- Gaikwad, A.; Yavari, R.; Montazeri, M.; Cole, K.; Bian, L.; Rao, P. Toward the digital twin of additive manufacturing: Integrating thermal simulations, sensing, and analytics to detect process faults. IISE Trans. 2020, 52, 1204–1217. [Google Scholar] [CrossRef]

- Hu, K.; Wang, Y.; Li, W.; Wang, L. CNN-BiLSTM enabled prediction on molten pool width for thin-walled part fabrication using Laser Directed Energy Deposition. J. Manuf. Process. 2022, 78, 32–45. [Google Scholar] [CrossRef]

- Gao, X.; Yao, X.X.; Niu, F.Y.; Zhang, Z. The influence of nozzle geometry on powder flow behaviors in directed energy deposition additive manufacturing. Adv. Powder Technol. 2022, 33, 103487. [Google Scholar] [CrossRef]

- Tan, H.; Zhang, F.; Wen, R.; Chen, J.; Huang, W. Experiment study of powder flow feed behavior of laser solid forming. Opt. Lasers Eng. 2012, 50, 391–398. [Google Scholar] [CrossRef]

- Saboori, A.; Biamino, S.; Lombardi, M.; Tusacciu, S.; Busatto, M.; Lai, M.; Fino, P. How the nozzle position affects the geometry of the melt pool in directed energy deposition process. Powder Metall. 2019, 62, 213–217. [Google Scholar] [CrossRef]

- Zhang, Y.; Jing, H.; Xu, L.; Han, Y.; Zhao, L. Effects of different scanning patterns on nickel alloy-directed energy deposition based on thermal analysis. Virtual Phys. Prototyp. 2021, 16 (Suppl. S1), S98–S115. [Google Scholar] [CrossRef]

- Moradi, M.; Hasani, A.; Beiranvand, Z.M.; Ashoori, A. Additive manufacturing of stellite 6 superalloy by direct laser metal deposition—Part 2: Effects of scanning pattern and laser power reduction in differrent layers. Opt. Laser Technol. 2020, 131, 106455. [Google Scholar] [CrossRef]

- Chua, Z.Y.; Ahn, I.H.; Moon, S.K. Process monitoring and inspection systems in metal additive manufacturing: Status and applications. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 235–245. [Google Scholar] [CrossRef]

- Zhu, K.; Fuh, J.Y.H.; Lin, X. Metal-based additive manufacturing condition monitoring: A review on machine learning based approaches. IEEE/ASME Trans. Mechatron. 2021, 27, 2495–2510. [Google Scholar] [CrossRef]

- Cai, Y.; Xiong, J.; Chen, H.; Zhang, G. A review of in-situ monitoring and process control system in metal-based laser additive manufacturing. J. Manuf. Syst. 2023, 70, 309–326. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Bandini, M.; Guagliano, M. Surface post-treatments for metal additive manufacturing: Progress, challenges, and opportunities. Addit. Manuf. 2021, 37, 101619. [Google Scholar] [CrossRef]

- Laleh, M.; Sadeghi, E.; Revilla, R.I.; Chao, Q.; Haghdadi, N.; Hughes, A.E.; Xu, W.; De Graeve, I.; Qian, M.; Gibson, I.; et al. Heat treatment for metal additive manufacturing. Prog. Mater. Sci. 2023, 133, 101051. [Google Scholar]

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J.J. Overview of materials qualification needs for metal additive manufacturing. JOM 2016, 68, 747–764. [Google Scholar] [CrossRef]

- Seifi, M.; Gorelik, M.; Waller, J.; Hrabe, N.; Shamsaei, N.; Daniewicz, S.; Lewandowski, J.J. Progress towards metal additive manufacturing standardization to support qualification and certification. JOM 2017, 69, 439–455. [Google Scholar] [CrossRef]

- Chen, Z.; Han, C.; Gao, M.; Kandukuri, S.Y.; Zhou, K. A review on qualification and certification for metal additive manufacturing. Virtual Phys. Prototyp. 2022, 17, 382–405. [Google Scholar] [CrossRef]

- Jamroz, W.; Szafraniec, J.; Kurek, M.; Jachowicz, R. 3D printing in pharmaceutical and medical applications–recent achievements and challenges. Pharm. Res. 2018, 35, 176. [Google Scholar] [CrossRef] [PubMed]

- Gradl, P.R.; Teasley, T.W.; Protz, C.S.; Katsarelis, C.; Chen, P. Process development and hot-fire testing of additively manufactured NASA HR-1 for liquid rocket engine applications. In AIAA Propulsion and Energy 2021 Forum; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2021; p. 3236. [Google Scholar]

- Gardner, L.; Kyvelou, P.; Herbert, G.; Buchanan, C. Testing and initial verification of the world’s first metal 3D printed bridge. J. Constr. Steel Res. 2020, 172, 106233. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Mahale, R.S.; Shamanth, V.; Hemanth, K.; Nithin, S.; Sharath, P.; Shashanka, R.; Patil, A.; Shetty, D. Processes and applications of metal additive manufacturing. Mater. Today Proc. 2022, 54, 228–233. [Google Scholar] [CrossRef]

- Murugan, P.D.; Vijayananth, S.; Natarajan, M.; Jayabalakrishnan, D.; Arul, K.; Jayaseelan, V.; Elanchezhian, J. A current state of metal additive manufacturing methods: A review. Mater. Today Proc. 2022, 59, 1277–1283. [Google Scholar] [CrossRef]

- Brennan, M.; Keist, J.; Palmer, T. Defects in Metal Additive Manufacturing Processes; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Mohd Yusuf, S.; Cutler, S.; Gao, N. The impact of metal additive manufacturing on the aerospace industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Cooke, S.; Ahmadi, K.; Willerth, S.; Herring, R. Metal additive manufacturing: Technology, metallurgy and modelling. J. Manuf. Process. 2020, 57, 978–1003. [Google Scholar] [CrossRef]

- Megahed, M.; Mindt, H.-W.; N’dri, N.; Duan, H.; Desmaison, O. Metal additive-manufacturing process and residual stress modeling. Integr. Mater. Manuf. Innov. 2016, 5, 61–93. [Google Scholar] [CrossRef]

- Vayre, B.; Vignat, F.; Villeneuve, F. Metallic additive manufacturing: State-of-the-art review and prospects. Mech. Ind. 2012, 13, 89–96. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Armstrong, M.; Mehrabi, H.; Naveed, N. An overview of modern metal additive manufacturing technology. J. Manuf. Process. 2022, 84, 1001–1029. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Zhang, Y.; Bose, S. Recent developments in metal additive manufacturing. Curr. Opin. Chem. Eng. 2020, 28, 96–104. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M.; Veldhuis, S.C. A review of metal additive manufacturing technologies. Solid State Phenom. 2018, 278, 1–14. [Google Scholar] [CrossRef]

- Market.Us. Additive Manufacturing with Metal Powders Market. 22861. 2024. Available online: https://market.us/report/additive-manufacturing-with-metal-powders-market/#overview (accessed on 12 January 2024).

- Singh, A.; Kapil, S.; Das, M. A comprehensive review of the methods and mechanisms for powder feedstock handling in directed energy deposition. Addit. Manuf. 2020, 35, 101388. [Google Scholar] [CrossRef]

- Özel, T.; Shokri, H.; Loizeau, R. A review on wire-fed directed energy deposition based metal additive manufacturing. J. Manuf. Mater. Process. 2023, 7, 45. [Google Scholar] [CrossRef]

- Gradl, P.; Tinker, D.C.; Park, A.; Mireles, O.R.; Garcia, M.; Wilkerson, R.; Mckinney, C. Robust metal additive manufacturing process selection and development for aerospace components. J. Mater. Eng. Perform. 2022, 31, 6013–6044. [Google Scholar] [CrossRef]

- Babuska, T.F.; Krick, B.A.; Susan, D.F.; Kustas, A.B. Comparison of powder bed fusion and directed energy deposition for tailoring mechanical properties of traditionally brittle alloys. Manuf. Lett. 2021, 28, 30–34. [Google Scholar] [CrossRef]

- Chechik, L.; Todd, I. Inconel 718 two ways: Powder bed fusion vs. directed energy deposition. Addit. Manuf. Lett. 2023, 6, 100145. [Google Scholar] [CrossRef]

- Ansari, M.; Jabari, E.; Toyserkani, E. Opportunities and challenges in additive manufacturing of functionally graded metallic materials via powder-fed laser directed energy deposition: A review. J. Mater. Process. Technol. 2021, 294, 117117. [Google Scholar] [CrossRef]

- Yi, H.; Wang, Q.; Cao, H. Wire-arc directed energy deposition of magnesium alloys: Microstructure, properties and quality optimization strategies. J. Mater. Res. Technol. 2022, 20, 627–649. [Google Scholar] [CrossRef]

- Gonzalez, L.C.; Tuominen, J.; Ahmed, S.; Patnamsetty, M.; Peura, P. Directed energy deposition of AA7075-Effect of TiC nanoparticles on microstructure. Results Mater. 2022, 16, 100341. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zuback, J.S.; De, A.; DebRoy, T. Printability of alloys for additive manufacturing. Sci. Rep. 2016, 6, 19717. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace applications of laser additive manufacturing. In Laser Additive Manufacturing: Materials, Design, Technologies, and Applications; Woodhead Publishing: Cambridge, UK, 2017; pp. 351–371. [Google Scholar] [CrossRef]

- Vartanian, K.; Brewer, L.; Manley, K.; Cobbs, T. Powder bed fusion vs. directed energy deposition benchmark study: Mid-size part with simple geometry. Optomec Tech. Rep. 2016, 1, 1–4. [Google Scholar]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.D.; De, A.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Mazzucato, F.; Menerini, M.; Valente, A. Laser-based Hybrid System for Inconel 718 part repairing. Procedia CIRP 2020, 95, 29–34. [Google Scholar] [CrossRef]

- Mazzucato, F.; Forni, D.; Valente, A.; Cadoni, E. Laser metal deposition of Inconel 718 alloy and as-built mechanical properties compared to casting. Materials 2021, 14, 437. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Gibson, I.; Rosen, D.; Stucker, B. Directed energy deposition processes. In Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: New York, NY, USA, 2015; pp. 245–268. [Google Scholar]

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, eabg1487. [Google Scholar] [CrossRef] [PubMed]

- Yilmaz, O.; Ugla, A.A. Shaped metal deposition technique in additive manufacturing: A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1781–1798. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, J.; Wang, G. Fundamental study on plasma deposition manufacturing. Surf. Coat. Technol. 2003, 171, 112–118. [Google Scholar] [CrossRef]

- Kumar, S.P.; Elangovan, S.; Mohanraj, R.; Narayanan, V.S. Significance of continuous wave and pulsed wave laser in direct metal deposition. Mater. Today Proc. 2021, 46, 8086–8096. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the art in directed energy deposition: From additive manufacturing to materials design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Mazzarisi, M.; Errico, V.; Angelastro, A.; Campanelli, S.L. Influence of standoff distance and laser defocusing distance on direct laser metal deposition of a nickel-based superalloy. Int. J. Adv. Manuf. Technol. 2022, 120, 2407–2428. [Google Scholar] [CrossRef]

- Carrozza, A.; Mazzucato, F.; Aversa, A.; Lombardi, M.; Bondioli, F.; Biamino, S.; Valente, A.; Fino, P. Single scans of Ti-6Al-4V by directed energy deposition: A cost and time effective methodology to assess the proper process window. Met. Mater. Int. 2021, 27, 3590–3602. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Bassini, E. Directed energy deposition of aisi 316l stainless steel powder: Effect of process parameters. Metals 2021, 11, 932. [Google Scholar] [CrossRef]

- Liu, M.; Kumar, A.; Bukkapatnam, S.; Kuttolamadom, M. A review of the anomalies in directed energy deposition (DED) processes & potential solutions-Part quality & defects. Procedia Manuf. 2021, 53, 507–518. [Google Scholar]

- Haley, J.C.; Schoenung, J.M.; Lavernia, E.J. Observations of particle-melt pool impact events in directed energy deposition. Addit. Manuf. 2018, 22, 368–374. [Google Scholar] [CrossRef]

- Wei, H.; Mukherjee, T.; Zhang, W.; Zuback, J.; Knapp, G.; De, A.; DebRoy, T. Mechanistic models for additive manufacturing of metallic components. Prog. Mater. Sci. 2021, 116, 100703. [Google Scholar] [CrossRef]

- Bayat, M.; Nadimpalli, V.K.; Biondani, F.G.; Jafarzadeh, S.; Thorborg, J.; Tiedje, N.S.; Bissacco, G.; Pedersen, D.B.; Hattel, J.H. On the role of the powder stream on the heat and fluid flow conditions during directed energy deposition of maraging steel—Multiphysics modeling and experimental validation. Addit. Manuf. 2021, 43, 102021. [Google Scholar] [CrossRef]

- Volkov, A.N.; Zhigilei, L.V. Melt dynamics and melt-through time in continuous wave laser heating of metal films: Contributions of the recoil vapor pressure and Marangoni effects. Int. J. Heat Mass Transf. 2017, 112, 300–317. [Google Scholar] [CrossRef]

- Leung, C.L.A.; Marussi, S.; Atwood, R.C.; Towrie, M.; Withers, P.J.; Lee, P.D. In situ X-ray imaging of defect and molten pool dynamics in laser additive manufacturing. Nat. Commun. 2018, 9, 1355. [Google Scholar] [CrossRef]

- Ki, H.; Mazumder, J.; Mohanty, P.S. Modeling of laser keyhole welding: Part I. Mathematical modeling, numerical methodology, role of recoil pressure, multiple reflections, and free surface evolution. Metall. Mater. Trans. A 2002, 33, 1817–1830. [Google Scholar] [CrossRef]

- Sreekanth, S. Laser-Directed Energy Deposition: Influence of Process Parameters and Heat-Treatments. Ph.D. Dissertation, University West, Trollhättan, Sweden, 2020. [Google Scholar]

- Sampson, R.; Lancaster, R.; Sutcliffe, M.; Carswell, D.; Hauser, C.; Barras, J. The influence of key process parameters on melt pool geometry in direct energy deposition additive manufacturing systems. Opt. Laser Technol. 2021, 134, 106609. [Google Scholar] [CrossRef]

- Bax, B.; Rajput, R.; Kellet, R.; Reisacher, M. Systematic evaluation of process parameter maps for laser cladding and directed energy deposition. Addit. Manuf. 2018, 21, 487–494. [Google Scholar] [CrossRef]

- Pinkerton, A.J. Advances in the modeling of laser direct metal deposition. J. Laser Appl. 2015, 27, S15001. [Google Scholar] [CrossRef]

- Goodarzi, D.M.; Pekkarinen, J.; Salminen, A. Effect of process parameters in laser cladding on substrate melted areas and the substrate melted shape. J. Laser Appl. 2015, 27, S29201. [Google Scholar] [CrossRef]

- Shim, D.-S.; Baek, G.-Y.; Seo, J.-S.; Shin, G.-Y.; Kim, K.-P.; Lee, K.-Y. Effect of layer thickness setting on deposition characteristics in direct energy deposition (DED) process. Opt. Laser Technol. 2016, 86, 69–78. [Google Scholar] [CrossRef]

- Ocylok, S.; Alexeev, E.; Mann, S.; Weisheit, A.; Wissenbach, K.; Kelbassa, I. Correlations of melt pool geometry and process parameters during laser metal deposition by coaxial process monitoring. Phys. Procedia 2014, 56, 228–238. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, W.; Shang, X. Research on the processing experiments of laser metal deposition shaping. Opt. Laser Technol. 2007, 39, 549–557. [Google Scholar] [CrossRef]

- Corbin, D.J.; Nassar, A.R.; Reutzel, E.W.; Beese, A.M.; Kistler, N.A.; Zhong, C.; Biermann, T.; Gasser, A.; Poprawe, R.; Kujanpää, V.P.; et al. Effect of directed energy deposition processing parameters on laser deposited Inconel® 718: External morphology. J. Laser Appl. 2017, 29, 022001. [Google Scholar] [CrossRef]

- Peyre, P.; Aubry, P.; Fabbro, R.; Neveu, R.; Longuet, A. Analytical and numerical modelling of the direct metal deposition laser process. J. Phys. D Appl. Phys. 2008, 41, 025403. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Li, L. Multiple-layer cladding of stainless steel using a high-powered diode laser: An experimental investigation of the process characteristics and material properties. Thin Solid Film. 2004, 453, 471–476. [Google Scholar] [CrossRef]

- Lee, E.M.; Shin, G.Y.; Yoon, H.S.; Shim, D.S. Study of the effects of process parameters on deposited single track of M4 powder based direct energy deposition. J. Mech. Sci. Technol. 2017, 31, 3411–3418. [Google Scholar] [CrossRef]

- Zardoshtian, A.; Ansari, M.; Esmaeilzadeh, R.; Keshavarzkermani, A.; Jahed, H.; Toyserkani, E. Laser-directed energy deposition of CuCrZr alloy: From statistical process parameter optimization to microstructural analysis. Int. J. Adv. Manuf. Technol. 2023, 126, 4407–4418. [Google Scholar] [CrossRef]

- Gullipalli, C.; Thawari, N.; Chandak, A.; Gupta, T. Statistical analysis of clad geometry in direct energy deposition of inconel 718 single tracks. J. Mater. Eng. Perform. 2022, 31, 6922–6932. [Google Scholar] [CrossRef]

- Saeedi, R.; Razavi, R.S.; Bakhshi, S.R.; Erfanmanesh, M.; Bani, A.A. Optimization and characterization of laser cladding of NiCr and NiCr–TiC composite coatings on AISI 420 stainless steel. Ceram. Int. 2021, 47, 4097–4110. [Google Scholar] [CrossRef]

- Nabhani, M.; Razavi, R.S.; Barekat, M. An empirical-statistical model for laser cladding of Ti-6Al-4V powder on Ti-6Al-4V substrate. Opt. Laser Technol. 2018, 100, 265–271. [Google Scholar] [CrossRef]

- Ansari, M.; Razavi, R.S.; Barekat, M. An empirical-statistical model for coaxial laser cladding of NiCrAlY powder on Inconel 738 superalloy. Opt. Laser Technol. 2016, 86, 136–144. [Google Scholar] [CrossRef]

- Alizadeh-Sh, M.; Marashi, S.P.H.; Ranjbarnodeh, E.; Shoja-Razavi, R.; Oliveira, J.P. Prediction of solidification cracking by an empirical-statistical analysis for laser cladding of Inconel 718 powder on a non-weldable substrate. Opt. Laser Technol. 2020, 128, 106244. [Google Scholar] [CrossRef]

- Svetlizky, D.; Zheng, B.; Steinberg, D.M.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. The influence of laser directed energy deposition (DED) processing parameters for Al5083 studied by central composite design. J. Mater. Res. Technol. 2022, 17, 3157–3171. [Google Scholar] [CrossRef]

- Feenstra, D.; Molotnikov, A.; Birbilis, N. Utilisation of artificial neural networks to rationalise processing windows in directed energy deposition applications. Mater. Des. 2021, 198, 109342. [Google Scholar] [CrossRef]

- Sun, Y.; Hao, M. Statistical analysis and optimization of process parameters in Ti6Al4V laser cladding using Nd: YAG laser. Opt. Lasers Eng. 2012, 50, 985–995. [Google Scholar] [CrossRef]

- Sreekanth, S.; Ghassemali, E.; Hurtig, K.; Joshi, S.; Andersson, J. Effect of direct energy deposition process parameters on single-track deposits of alloy 718. Metals 2020, 10, 96. [Google Scholar] [CrossRef]

- Lee, Y.; Nordin, M.; Babu, S.; Farson, D. Influence of fluid convection on weld pool formation in laser cladding. Weld. J. 2014, 93, 292–300. [Google Scholar]

- Srivastava, D.; Chang, I.; Loretto, M. The optimisation of processing parameters and characterisation of microstructure of direct laser fabricated TiAl alloy components. Mater. Des. 2000, 21, 425–433. [Google Scholar] [CrossRef]

- Kono, D.; Yamaguchi, H.; Oda, Y.; Sakai, T. Stabilization of standoff distance by efficient and adaptive updating of layer height command in directed energy deposition. CIRP J. Manuf. Sci. Technol. 2020, 31, 244–250. [Google Scholar] [CrossRef]

- Lin, P.-Y.; Shen, F.-C.; Wu, K.-T.; Hwang, S.-J.; Lee, H.-H. Process optimization for directed energy deposition of SS316L components. Int. J. Adv. Manuf. Technol. 2020, 111, 1387–1400. [Google Scholar] [CrossRef]

- Ermurat, M.; Arslan, M.A.; Erzincanli, F.; Uzman, I. Process parameters investigation of a laser-generated single clad for minimum size using design of experiments. Rapid Prototyp. J. 2013, 19, 452–462. [Google Scholar] [CrossRef]

- Odermatt, A.E.; Dorn, F.; Ventzke, V.; Kashaev, N. Coaxial laser directed energy deposition with wire of thin-walled duplex stainless steel parts: Process discontinuities and their impact on the mechanical properties. CIRP J. Manuf. Sci. Technol. 2022, 37, 443–453. [Google Scholar] [CrossRef]

- Bremer, J.; Walderich, P.; Pirch, N.; Schleifenbaum, J.H.; Gasser, A.; Schopphoven, T. Effects of path accuracy on additively manufactured specimens by laser material deposition using six-axis robots. J. Laser Appl. 2021, 33, 012045. [Google Scholar] [CrossRef]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Pinkerton, A. Laser direct metal deposition: Theory and applications in manufacturing and maintenance. In Advances in Laser Materials Processing; Elsevier: Amsterdam, The Netherlands, 2010; pp. 461–491. [Google Scholar]

- Amine, T.; Newkirk, J.W.; Liou, F. Investigation of effect of process parameters on multilayer builds by direct metal deposition. Appl. Therm. Eng. 2014, 73, 500–511. [Google Scholar] [CrossRef]

- Elkington, H. Laser Direct Energy Deposition—The Effect of Process Parameters on Inconel 718; Sheffield Hallam University: Sheffield, UK, 2021. [Google Scholar]

- Thanumoorthy, R.S.; Sekar, P.; Bontha, S.; Balan, A. A study on the effect of process parameters and scan strategies on microstructure and mechanical properties of laser directed energy deposited IN718. J. Mater. Process. Technol. 2023, 319, 118096. [Google Scholar] [CrossRef]

- He, B.; Li, D.; Zhang, A.; Ge, J.; Yang, X.; Hu, X. Influence of scanning pattern on the edge collapse of solid parts in laser metal direct forming. Opt. Laser Technol. 2013, 48, 171–177. [Google Scholar] [CrossRef]

- de Oliveira, U.; Ocelík, V.; De Hosson, J. Analysis of coaxial laser cladding processing conditions. Surf. Coat. Technol. 2005, 197, 127–136. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, Y.; Yang, L.; Zhao, X.; Qu, W.; Yu, T. Effect of shielding gas flow rate on cladding quality of direct laser fabrication AISI 316L stainless steel. J. Manuf. Process. 2019, 48, 51–65. [Google Scholar] [CrossRef]

- Traxel, K.D.; Malihi, D.; Starkey, K.; Bandyopadhyay, A. Model-driven directed-energy-deposition process workflow incorporating powder flowrate as key parameter. Manuf. Lett. 2020, 25, 88–92. [Google Scholar] [CrossRef]

- Mazzarisi, M.; Campanelli, S.L.; Angelastro, A.; Dassisti, M. Phenomenological modelling of direct laser metal deposition for single tracks. Int. J. Adv. Manuf. Technol. 2020, 111, 1955–1970. [Google Scholar] [CrossRef]

- AbouelNour, Y.; Gupta, N. In-situ monitoring of sub-surface and internal defects in additive manufacturing: A review. Mater. Des. 2022, 222, 111063. [Google Scholar] [CrossRef]

- Qin, L.; Wang, K.; Li, X.; Zhou, S.; Yang, G. Review of the formation mechanisms and control methods of geometrical defects in laser deposition manufacturing. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100052. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Kiani, P.; Dupuy, A.D.; Ma, K.; Schoenung, J.M. Directed energy deposition of AlSi10Mg: Single track nonscalability and bulk properties. Mater. Des. 2020, 194, 108847. [Google Scholar] [CrossRef]

- Craig, O.; Bois-Brochu, A.; Plucknett, K. Geometry and surface characteristics of H13 hot-work tool steel manufactured using laser-directed energy deposition. Int. J. Adv. Manuf. Technol. 2021, 116, 699–718. [Google Scholar] [CrossRef]

- Ponche, R.; Kerbrat, O.; Mognol, P.; Hascoet, J.-Y. A novel methodology of design for Additive Manufacturing applied to Additive Laser Manufacturing process. Robot. Comput.-Integr. Manuf. 2014, 30, 389–398. [Google Scholar] [CrossRef]

- Su, Y.; Wang, C.; Xu, X.; Luo, K.; Lu, J. Pore defects and corrosion behavior of AISI 316L stainless steel fabricated by laser directed energy deposition under closed-loop control. Surf. Coat. Technol. 2023, 463, 129527. [Google Scholar] [CrossRef]

- Donadello, S.; Motta, M.; Demir, A.G.; Previtali, B. Monitoring of laser metal deposition height by means of coaxial laser triangulation. Opt. Lasers Eng. 2019, 112, 136–144. [Google Scholar] [CrossRef]

- Ščetinec, A.; Klobčar, D.; Bračun, D. In-process path replanning and online layer height control through deposition arc current for gas metal arc based additive manufacturing. J. Manuf. Process. 2021, 64, 1169–1179. [Google Scholar] [CrossRef]

- Pi, G.; Zhang, A.; Zhu, G.; Li, D.; Lu, B. Research on the forming process of three-dimensional metal parts fabricated by laser direct metal forming. Int. J. Adv. Manuf. Technol. 2011, 57, 841–847. [Google Scholar] [CrossRef]

- Wang, X.; Deng, D.; Hu, Y.; Ning, F.; Wang, H.; Cong, W.; Zhang, H. Overhang structure and accuracy in laser engineered net shaping of Fe-Cr steel. Opt. Laser Technol. 2018, 106, 357–365. [Google Scholar] [CrossRef]

- Yu, R.; Yu, S.; Yu, Z.; Zheng, B. Directed energy deposition-arc of thin-walled aerobat shell with structures of internal ribs and overhanging gaps. Int. J. Adv. Manuf. Technol. 2023, 127, 305–321. [Google Scholar] [CrossRef]

- Jiang, J.; Stringer, J.; Xu, X.; Zhong, R.Y. Investigation of printable threshold overhang angle in extrusion-based additive manufacturing for reducing support waste. Int. J. Comput. Integr. Manuf. 2018, 31, 961–969. [Google Scholar] [CrossRef]

- Kaji, F.; Jinoop, A.N.; Zimny, M.; Frikel, G.; Tam, K.; Toyserkani, E. Process planning for additive manufacturing of geometries with variable overhang angles using a robotic laser directed energy deposition system. Addit. Manuf. Lett. 2022, 2, 100035. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current status and perspectives on wire and arc additive manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef] [PubMed]

- Gruber, S.; Grunert, C.; Riede, M.; Lopez, E.; Marquardt, A.; Brueckner, F.; Leyens, C. Comparison of dimensional accuracy and tolerances of powder bed based and nozzle based additive manufacturing processes. J. Laser Appl. 2020, 32, 032016. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, K.; Li, W.; Wang, L. Prediction of melt pool width and layer height for Laser Directed Energy Deposition enabled by physics-driven temporal convolutional network. J. Manuf. Syst. 2023, 69, 1–17. [Google Scholar] [CrossRef]

- Wang, P.; Tan, X.; He, C.; Nai, M.L.S.; Huang, R.; Tor, S.B.; Wei, J. Scanning optical microscopy for porosity quantification of additively manufactured components. Addit. Manuf. 2018, 21, 350–358. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, D.; Zhao, D.; Niu, F.; Zhang, H.; Yan, S.; Ma, G. Process optimization of melt growth alumina/aluminum titanate composites directed energy deposition: Effects of scanning speed. Addit. Manuf. 2020, 35, 101210. [Google Scholar] [CrossRef]

- Chen, Y.; Clark, S.J.; Sinclair, L.; Leung, C.L.A.; Marussi, S.; Connolley, T.; Atwood, R.C.; Baxter, G.J.; Jones, M.A.; Todd, I.; et al. Synchrotron X-ray imaging of directed energy deposition additive manufacturing of titanium alloy Ti-6242. Addit. Manuf. 2021, 41, 101969. [Google Scholar] [CrossRef]

- Sohn, H.; Liu, P.; Yoon, H.; Yi, K.; Yang, L.; Kim, S. Real-time porosity reduction during metal directed energy deposition using a pulse laser. J. Mater. Sci. Technol. 2022, 116, 214–223. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Chia, H.Y.; Yan, W. Mechanism of keyhole pore formation in metal additive manufacturing. npj Comput. Mater. 2022, 8, 22. [Google Scholar] [CrossRef]

- Young, Z.A.; Guo, Q.; Parab, N.D.; Zhao, C.; Qu, M.; Escano, L.; Fezzaa, K.; Everhart, W.; Sun, T.; Chen, L. Types of spatter and their features and formation mechanisms in laser powder bed fusion additive manufacturing process. Addit. Manuf. 2020, 36, 101438. [Google Scholar] [CrossRef]

- Stair, A.J.; Webler, B.A.; Beuth, J.L.; de Boer, M.P. Demonstration and Analysis of Conditions to Obtain a High Strength Inconel 625 to Stainless Steel 304L Interface by Directed Energy Deposition. Metall. Mater. Trans. A 2024, 1–14. [Google Scholar] [CrossRef]

- Mishurova, T.; Evsevleev, S.; Piault, P.; King, A.; Henry, L.; Bruno, G. Understanding the hot isostatic pressing effectiveness of laser powder bed fusion Ti-6Al-4V by in-situ X-ray imaging and diffraction experiments. Sci. Rep. 2023, 13, 18433. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Yang, Y.; Liu, Y.; Bai, Y.; Tan, C. Formation Mechanism of Spatter and Its Influence on Mechanical Properties in Process of Laser Powder Bed Fusion. In Laser Powder Bed Fusion of Additive Manufacturing Technology; Springer: Berlin/Heidelberg, Germany, 2023; pp. 135–177. [Google Scholar]

- Wu, D.; Hua, X.; Li, F.; Huang, L. Understanding of spatter formation in fiber laser welding of 5083 aluminum alloy. Int. J. Heat Mass Transf. 2017, 113, 730–740. [Google Scholar] [CrossRef]

- Zhao, C.; Guo, Q.; Li, X.; Parab, N.; Fezzaa, K.; Tan, W.; Chen, L.; Sun, T. Bulk-explosion-induced metal spattering during laser processing. Phys. Rev. X 2019, 9, 021052. [Google Scholar] [CrossRef]

- Qu, M.; Guo, Q.; Escano, L.I.; Nabaa, A.; Hojjatzadeh, S.M.H.; Young, Z.A.; Chen, L. Controlling process instability for defect lean metal additive manufacturing. Nat. Commun. 2022, 13, 1079. [Google Scholar] [CrossRef] [PubMed]

- Prasad, H.S.; Brueckner, F.; Kaplan, A.F. Powder incorporation and spatter formation in high deposition rate blown powder directed energy deposition. Addit. Manuf. 2020, 35, 101413. [Google Scholar] [CrossRef]

- Wolff, S.J.; Wu, H.; Parab, N.; Zhao, C.; Ehmann, K.F.; Sun, T.; Cao, J. In-situ high-speed X-ray imaging of piezo-driven directed energy deposition additive manufacturing. Sci. Rep. 2019, 9, 962. [Google Scholar] [CrossRef]

- Iquebal, A.S.; Yadav, A.; Botcha, B.; Gorthi, R.K.; Bukkapatnam, S. Tracking and quantifying spatter characteristics in a laser directed energy deposition process using Kalman filter. Manuf. Lett. 2022, 33, 692–700. [Google Scholar] [CrossRef]

- Wang, S.; Ning, J.; Zhu, L.; Yang, Z.; Yan, W.; Dun, Y.; Xue, P.; Xu, P.; Bose, S.; Bandyopadhyay, A. Role of porosity defects in metal 3D printing: Formation mechanisms, impacts on properties and mitigation strategies. Mater. Today 2022, 59, 133–160. [Google Scholar] [CrossRef]

- Li, S.; Chen, G.; Katayama, S.; Zhang, Y. Relationship between spatter formation and dynamic molten pool during high-power deep-penetration laser welding. Appl. Surf. Sci. 2014, 303, 481–488. [Google Scholar] [CrossRef]

- Zheng, H.; Li, H.; Lang, L.; Gong, S.; Ge, Y. Effects of scan speed on vapor plume behavior and spatter generation in laser powder bed fusion additive manufacturing. J. Manuf. Process. 2018, 36, 60–67. [Google Scholar] [CrossRef]

- Ly, S.; Rubenchik, A.M.; Khairallah, S.A.; Guss, G.; Matthews, M.J. Metal vapor micro-jet controls material redistribution in laser powder bed fusion additive manufacturing. Sci. Rep. 2017, 7, 4085. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yang, Y.; Mai, S.; Wang, D.; Song, C. Investigation into spatter behavior during selective laser melting of AISI 316L stainless steel powder. Mater. Des. 2015, 87, 797–806. [Google Scholar] [CrossRef]

- Li, Z.; Li, H.; Yin, J.; Li, Y.; Nie, Z.; Li, X.; You, D.; Guan, K.; Duan, W.; Cao, L.; et al. A review of spatter in laser powder bed fusion additive manufacturing: In situ detection, generation, effects, and countermeasures. Micromachines 2022, 13, 1366. [Google Scholar] [CrossRef] [PubMed]

- Ikeshoji, T.-T.; Yonehara, M.; Kato, C.; Yanaga, Y.; Takeshita, K.; Kyogoku, H. Spattering mechanism of laser powder bed fusion additive manufacturing on heterogeneous surfaces. Sci. Rep. 2022, 12, 20384. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, H.; Kawahito, Y.; Nishimoto, K.; Katayama, S. Elucidation of melt flows and spatter formation mechanisms during high power laser welding of pure titanium. J. Laser Appl. 2015, 27, 032012. [Google Scholar] [CrossRef]

- Repossini, G.; Laguzza, V.; Grasso, M.; Colosimo, B.M. On the use of spatter signature for in-situ monitoring of Laser Powder Bed Fusion. Addit. Manuf. 2017, 16, 35–48. [Google Scholar] [CrossRef]

- Taatali, A.; Sadaoui, S.E.; Louar, M.A.; Mahiddini, B. On-machine dimensional inspection: Machine vision-based approach. Int. J. Adv. Manuf. Technol. 2024, 131, 393–407. [Google Scholar] [CrossRef]

- Leach, R.; Bourell, D.; Carmignato, S.; Donmez, A.; Senin, N.; Dewulf, W. Geometrical metrology for metal additive manufacturing. CIRP Ann. 2019, 68, 677–700. [Google Scholar] [CrossRef]

- Dickins, A.; Widjanarko, T.; Lawes, S.; Leach, R. Design of a multi-sensor in-situ inspection system for additive manufacturing. In ASPE and EUSPEN Summer Topical Meeting on Advancing Precision in Additive Manufacturing; 2018; pp. 152–248. [Google Scholar]

- Leach, R. Integrated metrology 10-year roadmap for advanced manufacturing. In HVM Catapult Coventry; High Value Manufacturing Catapult: Birmingham, UK, 2020; pp. 4–7. [Google Scholar]

- Leach, R.; Carmignato, S. Precision Metal Additive Manufacturing; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Lin, X.; Zhu, K.; Fuh, J.Y.H.; Duan, X. Metal-based additive manufacturing condition monitoring methods: From measurement to control. ISA Trans. 2022, 120, 147–166. [Google Scholar] [CrossRef]

- Tang, Z.-J.; Liu, W.-W.; Wang, Y.-W.; Saleheen, K.M.; Liu, Z.-C.; Peng, S.-T.; Zhang, Z.; Zhang, H.-C. A review on in situ monitoring technology for directed energy deposition of metals. Int. J. Adv. Manuf. Technol. 2020, 108, 3437–3463. [Google Scholar] [CrossRef]

- Zhang, P.; Zhou, X.; Ma, H.; Hu, J.; He, Y.; Wang, X.; Duan, Y. Anomaly detection in laser metal deposition with photodiode-based melt pool monitoring system. Opt. Laser Technol. 2021, 144, 107454. [Google Scholar] [CrossRef]

- Park, H.; Rhee, S.; Kim, D. A fuzzy pattern recognition based system for monitoring laser weld quality. Meas. Sci. Technol. 2001, 12, 1318. [Google Scholar] [CrossRef]

- Kanko, J.A.; Sibley, A.P.; Fraser, J.M. In situ morphology-based defect detection of selective laser melting through inline coherent imaging. J. Mater. Process. Technol. 2016, 231, 488–500. [Google Scholar] [CrossRef]

- Souflas, T.; Bikas, H.; Ghassempouri, M.; Salmi, A.; Atzeni, E.; Saboori, A.; Brugnetti, I.; Valente, A.; Mazzucato, F.; Stavropoulos, P. A comparative study of dry and cryogenic milling for Directed Energy Deposited IN718 components: Effect on process and part quality. Int. J. Adv. Manuf. Technol. 2022, 119, 745–758. [Google Scholar] [CrossRef]

- He, W.; Shi, W.; Li, J.; Xie, H. In-situ monitoring and deformation characterization by optical techniques; part I: Laser-aided direct metal deposition for additive manufacturing. Opt. Lasers Eng. 2019, 122, 74–88. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, S.; Li, H.; Hu, Y. Review of in situ and real-time monitoring of metal additive manufacturing based on image processing. Int. J. Adv. Manuf. Technol. 2022, 123, 1–20. [Google Scholar] [CrossRef]

- Ding, Y.; Dwivedi, R.; Kovacevic, R. Process planning for 8-axis robotized laser-based direct metal deposition system: A case on building revolved part. Robot. Comput.-Integr. Manuf. 2017, 44, 67–76. [Google Scholar] [CrossRef]

- Iravani-Tabrizipour, M.; Toyserkani, E. An image-based feature tracking algorithm for real-time measurement of clad height. Mach. Vis. Appl. 2007, 18, 343–354. [Google Scholar] [CrossRef]

- Naiel, M.A.; Ertay, D.S.; Vlasea, M.; Fieguth, P. Adaptive vision-based detection of laser-material interaction for directed energy deposition. Addit. Manuf. 2020, 36, 101468. [Google Scholar] [CrossRef]

- Perani, M.; Baraldo, S.; Decker, M.; Vandone, A.; Valente, A.; Paoli, B. Track geometry prediction for Laser Metal Deposition based on on-line artificial vision and deep neural networks. Robot. Comput.-Integr. Manuf. 2023, 79, 102445. [Google Scholar] [CrossRef]

- Yang, L.; Sohn, H.; Ma, Z.; Jeon, I.; Liu, P.; Cheng, J.C. Real-time layer height estimation during multi-layer directed energy deposition using domain adaptive neural networks. Comput. Ind. 2023, 148, 103882. [Google Scholar] [CrossRef]

- Hsu, H.-W.; Lo, Y.-L.; Lee, M.-H. Vision-based inspection system for cladding height measurement in Direct Energy Deposition (DED). Addit. Manuf. 2019, 27, 372–378. [Google Scholar] [CrossRef]

- Song, L.; Mazumder, J. Feedback control of melt pool temperature during laser cladding process. IEEE Trans. Control. Syst. Technol. 2010, 19, 1349–1356. [Google Scholar] [CrossRef]

- Farshidianfar, M.H.; Khajepour, A.; Zeinali, M.; Gelrich, A. System identification and height control of laser cladding using adaptive neuro-fuzzy inference systems. In International Congress on Applications of Lasers & Electro-Optics; Laser Institute of America: Orlando, FL, USA, 2013; Volume 2013, pp. 615–623. [Google Scholar]

- Zeinali, M.; Khajepour, A. Height control in laser cladding using adaptive sliding mode technique: Theory and experiment. J. Manuf. Sci. Eng. 2010, 132, 041016. [Google Scholar] [CrossRef]

- Borovkov, H.; de la Yedra, A.G.; Zurutuza, X.; Angulo, X.; Alvarez, P.; Pereira, J.C.; Cortes, F. In-line height measurement technique for directed energy deposition processes. J. Manuf. Mater. Process. 2021, 5, 85. [Google Scholar] [CrossRef]

- Pandiyan, V.; Cui, D.; Le-Quang, T.; Deshpande, P.; Wasmer, K.; Shevchik, S. In situ quality monitoring in direct energy deposition process using co-axial process zone imaging and deep contrastive learning. J. Manuf. Process. 2022, 81, 1064–1075. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, W.; Li, L. In-process measurement of melt pool cross-sectional geometry and grain orientation in a laser directed energy deposition additive manufacturing process. Opt. Laser Technol. 2020, 129, 106280. [Google Scholar] [CrossRef]

- Tang, Z.-J.; Liu, W.-W.; Zhang, N.; Wang, Y.-W.; Zhang, H.-C. Real–time prediction of penetration depths of laser surface melting based on coaxial visual monitoring. Opt. Lasers Eng. 2020, 128, 106034. [Google Scholar] [CrossRef]

- Song, L.; Wang, F.; Li, S.; Han, X. Phase congruency melt pool edge extraction for laser additive manufacturing. J. Mater. Process. Technol. 2017, 250, 261–269. [Google Scholar] [CrossRef]

- Lin, W.; Shen, H.; Fu, J.; Wu, S. Online quality monitoring in material extrusion additive manufacturing processes based on laser scanning technology. Precis. Eng. 2019, 60, 76–84. [Google Scholar] [CrossRef]

- Bacciaglia, A.; Ceruti, A.; Liverani, A. Photogrammetry and additive manufacturing based methodology for decentralized spare Part Production in automotive industry. In Proceedings of the Intelligent Human Systems Integration 2020: Proceedings of the 3rd International Conference on Intelligent Human Systems Integration (IHSI 2020): Integrating People and Intelligent Systems, Modena, Italy, 19–21 February 2020; Springer: Berlin/Heidelberg, Germany, 2020; pp. 796–802. [Google Scholar]

- Ye, Z.; Liu, C.; Kan, C. Stereo vision enabled flexible in-situ process authentication of additive manufacturing. Manuf. Lett. 2023, 35, 1155–1162. [Google Scholar] [CrossRef]

- Li, Z.; Liu, X.; Wen, S.; He, P.; Zhong, K.; Wei, Q.; Shi, Y.; Liu, S. In situ 3D monitoring of geometric signatures in the powder-bed-fusion additive manufacturing process via vision sensing methods. Sensors 2018, 18, 1180. [Google Scholar] [CrossRef]

- Chen, L.; Yao, X.; Xu, P.; Moon, S.K.; Bi, G. Rapid surface defect identification for additive manufacturing with in-situ point cloud processing and machine learning. Virtual Phys. Prototyp. 2021, 16, 50–67. [Google Scholar] [CrossRef]

- Chen, L.; Yao, X.; Xu, P.; Moon, S.K.; Bi, G. Surface monitoring for additive manufacturing with in-situ point cloud processing. In Proceedings of the 2020 6th International Conference on Control, Automation and Robotics (ICCAR), Singapore, 20–23 April 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 196–201. [Google Scholar]

- Heralić, A.; Christiansson, A.-K.; Lennartson, B. Height control of laser metal-wire deposition based on iterative learning control and 3D scanning. Opt. Lasers Eng. 2012, 50, 1230–1241. [Google Scholar] [CrossRef]

- Donadello, S.; Motta, M.; Demir, A.G.; Previtali, B. Coaxial laser triangulation for height monitoring in laser metal deposition. Procedia Cirp 2018, 74, 144–148. [Google Scholar] [CrossRef]

- Ye, Z.; Liu, C.; Tian, W.; Kan, C. In-situ point cloud fusion for layer-wise monitoring of additive manufacturing. J. Manuf. Syst. 2021, 61, 210–222. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, W.; Suresh, V.; Hamilton, J.; Yeh, L.-H.; Jiang, X.; Zhang, Z.; Li, Q.; Li, B.; Rivero, I.V.; et al. In situ monitoring of direct energy deposition via structured light system and its application in remanufacturing industry. Int. J. Adv. Manuf. Technol. 2021, 116, 959–974. [Google Scholar] [CrossRef]

- Wang, R.; Law, A.C.; Garcia, D.; Yang, S.; Kong, Z. Development of structured light 3D-scanner with high spatial resolution and its applications for additive manufacturing quality assurance. Int. J. Adv. Manuf. Technol. 2021, 117, 845–862. [Google Scholar] [CrossRef]

- Stavroulakis, P.I.; Leach, R.K. Invited review article: Review of post-process optical form metrology for industrial-grade metal additive manufactured parts. Rev. Sci. Instrum. 2016, 87, 041101. [Google Scholar] [CrossRef]

- Tootooni, M.S.; Dsouza, A.; Donovan, R.; Rao, P.K.; Kong, Z.; Borgesen, P. Classifying the dimensional variation in additive manufactured parts from laser-scanned three-dimensional point cloud data using machine learning approaches. J. Manuf. Sci. Eng. 2017, 139, 091005. [Google Scholar] [CrossRef]

- Tang, S.; Wang, G.; Zhang, H. In situ 3D monitoring and control of geometric signatures in wire and arc additive manufacturing. Surf. Topogr. Metrol. Prop. 2019, 7, 025013. [Google Scholar] [CrossRef]

- Vavilov, V.; Burleigh, D. Infrared Thermography and Thermal Nondestructive Testing; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Nuñez, L.; Sabharwall, P.; van Rooyen, I.J. In situ embedment of type K sheathed thermocouples with directed energy deposition. Int. J. Adv. Manuf. Technol. 2023, 127, 3611–3623. [Google Scholar] [CrossRef]

- De Baere, D.; Devesse, W.; De Pauw, B.; Smeesters, L.; Thienpont, H.; Guillaume, P. Spectroscopic monitoring and melt pool temperature estimation during the laser metal deposition process. J. Laser Appl. 2016, 28, 022303. [Google Scholar] [CrossRef]

- Hooper, P.A. Melt pool temperature and cooling rates in laser powder bed fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Z.; Wu, D. Prediction of melt pool temperature in directed energy deposition using machine learning. Addit. Manuf. 2021, 37, 101692. [Google Scholar] [CrossRef]

- Mazzarisi, M.; Angelastro, A.; Latte, M.; Colucci, T.; Palano, F.; Campanelli, S.L. Thermal monitoring of laser metal deposition strategies using infrared thermography. J. Manuf. Process. 2023, 85, 594–611. [Google Scholar] [CrossRef]

- Nair, A.M.; Muvvala, G.; Sarkar, S.; Nath, A.K. Real-time detection of cooling rate using pyrometers in tandem in laser material processing and directed energy deposition. Mater. Lett. 2020, 277, 128330. [Google Scholar] [CrossRef]

- Miyagi, M.; Tsukamoto, T.; Kawanaka, H. Adaptive shape control of laser-deposited metal structures by adjusting weld pool size. J. Laser Appl. 2014, 26, 032003. [Google Scholar] [CrossRef]

- Zanini, F.; Sbettega, E.; Carmignato, S. X-ray computed tomography for metal additive manufacturing: Challenges and solutions for accuracy enhancement. Procedia Cirp 2018, 75, 114–118. [Google Scholar] [CrossRef]

- du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Effects of defects on mechanical properties in metal additive manufacturing: A review focusing on X-ray tomography insights. Mater. Des. 2020, 187, 108385. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. On the use of X-ray computed tomography in assessment of 3D-printed components. J. Nondestruct. Eval. 2020, 39, 75. [Google Scholar] [CrossRef]

- Gobert, C.; Reutzel, E.W.; Petrich, J.; Nassar, A.R.; Phoha, S. Application of supervised machine learning for defect detection during metallic powder bed fusion additive manufacturing using high resolution imaging. Addit. Manuf. 2018, 21, 517–528. [Google Scholar] [CrossRef]

- Snow, Z.; Diehl, B.; Reutzel, E.W.; Nassar, A. Toward in-situ flaw detection in laser powder bed fusion additive manufacturing through layerwise imagery and machine learning. J. Manuf. Syst. 2021, 59, 12–26. [Google Scholar] [CrossRef]

- Forien, J.-B.; Calta, N.P.; DePond, P.J.; Guss, G.M.; Roehling, T.T.; Matthews, M.J. Detecting keyhole pore defects and monitoring process signatures during laser powder bed fusion: A correlation between in situ pyrometry and ex situ X-ray radiography. Addit. Manuf. 2020, 35, 101336. [Google Scholar] [CrossRef]

- Oliveira, J.P.; LaLonde, A.D.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 108762. [Google Scholar] [CrossRef]

- du Plessis, A.; Yadroitsev, I.; Yadroitsava, I.; Le Roux, S.G. X-ray microcomputed tomography in additive manufacturing: A review of the current technology and applications. 3D Print. Addit. Manuf. 2018, 5, 227–247. [Google Scholar] [CrossRef]

- Warnett, J.M.; Titarenko, V.; Kiraci, E.; Attridge, A.; Lionheart, W.R.B.; Withers, P.J.; A Williams, M. Towards in-process x-ray CT for dimensional metrology. Meas. Sci. Technol. 2016, 27, 035401. [Google Scholar] [CrossRef]

- Davies, S. Nikon Metrology Inspection Technology and Additive Manufacturing Advance Patient-Specific Implants. TCT Magazine 3D Printing & Additive Manufacturing Intelligence. Available online: https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/nikon-metrology-inspection-technology-patient-specific-implants/ (accessed on 12 January 2024).

- Wolff, S.J.; Wang, H.; Gould, B.; Parab, N.; Wu, Z.; Zhao, C.; Greco, A.; Sun, T. In situ X-ray imaging of pore formation mechanisms and dynamics in laser powder-blown directed energy deposition additive manufacturing. Int. J. Mach. Tools Manuf. 2021, 166, 103743. [Google Scholar] [CrossRef]

- Chen, L.; Yao, X.; Tan, C.; He, W.; Su, J.; Weng, F.; Chew, Y.; Ng, N.P.H.; Moon, S.K. In-situ crack and keyhole pore detection in laser directed energy deposition through acoustic signal and deep learning. Addit. Manuf. 2023, 69, 103547. [Google Scholar] [CrossRef]

- Tempelman, J.R.; Wachtor, A.J.; Flynn, E.B.; Depond, P.J.; Forien, J.-B.; Guss, G.M.; Calta, N.P.; Matthews, M.J. Sensor fusion of pyrometry and acoustic measurements for localized keyhole pore identification in laser powder bed fusion. J. Mater. Process. Technol. 2022, 308, 117656. [Google Scholar] [CrossRef]

- Tempelman, J.R.; Wachtor, A.J.; Flynn, E.B.; Depond, P.J.; Forien, J.-B.; Guss, G.M.; Calta, N.P.; Matthews, M.J. Detection of keyhole pore formations in laser powder-bed fusion using acoustic process monitoring measurements. Addit. Manuf. 2022, 55, 102735. [Google Scholar] [CrossRef]

- Plotnikov, Y.; Henkel, D.; Burdick, J.; French, A.; Sions, J.; Bourne, K. Infrared-assisted acoustic emission process monitoring for additive manufacturing. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2019; Volume 2102. [Google Scholar]

- Hauser, T.; Reisch, R.T.; Kamps, T.; Kaplan, A.F.; Volpp, J. Acoustic emissions in directed energy deposition processes. Int. J. Adv. Manuf. Technol. 2022, 119, 3517–3532. [Google Scholar] [CrossRef]

- Hossain, M.S.; Taheri, H. In situ process monitoring for additive manufacturing through acoustic techniques. J. Mater. Eng. Perform. 2020, 29, 6249–6262. [Google Scholar] [CrossRef]

- Ito, K.; Kusano, M.; Demura, M.; Watanabe, M. Detection and location of microdefects during selective laser melting by wireless acoustic emission measurement. Addit. Manuf. 2021, 40, 101915. [Google Scholar] [CrossRef]

- Ye, D.; Zhang, Y.; Zhu, K.; Hong, G.; YingHsi, J. Characterization of acoustic signals during a direct metal laser sintering process. In Proceedings of the International Conference on Energy Equipment Science and Engineering II, (ICEESE 2016), Guangzhou, China, 12–14 November 2016; CRC Press: Boca Raton, FL, USA, 2017; pp. 1315–1320. [Google Scholar]

- Whiting, J.; Springer, A.; Sciammarella, F. Real-time acoustic emission monitoring of powder mass flow rate for directed energy deposition. Addit. Manuf. 2018, 23, 312–318. [Google Scholar] [CrossRef] [PubMed]

- Shevchik, S.A.; Kenel, C.; Leinenbach, C.; Wasmer, K. Acoustic emission for in situ quality monitoring in additive manufacturing using spectral convolutional neural networks. Addit. Manuf. 2018, 21, 598–604. [Google Scholar] [CrossRef]

- Dryburgh, P.; Pieris, D.; Martina, F.; Patel, R.; Sharples, S.; Li, W.; Clare, A.T.; Williams, S.; Smith, R.J. Spatially resolved acoustic spectroscopy for integrity assessment in wire–arc additive manufacturing. Addit. Manuf. 2019, 28, 236–251. [Google Scholar] [CrossRef]

- Li, S.; Chen, B.; Tan, C.; Song, X. In situ identification of laser directed energy deposition condition based on acoustic emission. Opt. Laser Technol. 2024, 169, 110152. [Google Scholar] [CrossRef]

- Shi, Y.; Zhao, N.; Chen, Y.; Liu, J.; Li, J.; Hou, Z.; Zhou, G. Spectroscopic analysis of Nd/Al co-doped silica glass fabricated by laser additive manufacturing. J. Non-Cryst. Solids 2023, 604, 122139. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, F.; Yuan, J.; Jia, C.; Ren, X.; Yang, L. Investigation on surface morphology and microstructure of double-wire+ arc additive manufactured aluminum alloys based on spectral analysis. J. Manuf. Process. 2022, 84, 639–651. [Google Scholar] [CrossRef]

- Lough, C.S.; Escano, L.; Qu, M.; Smith, C.C.; Landers, R.G.; Bristow, D.A.; Chen, L.; Kinzel, E.C. In-situ optical emission spectroscopy of selective laser melting. J. Manuf. Process. 2020, 53, 336–341. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W.; Harooni, M.; Ma, J.; Kovacevic, R. Real-time monitoring of laser hot-wire cladding of Inconel 625. Opt. Laser Technol. 2014, 62, 124–134. [Google Scholar] [CrossRef]

- Montazeri, M.; Nassar, A.R.; Dunbar, A.J.; Rao, P. In-process monitoring of porosity in additive manufacturing using optical emission spectroscopy. IISE Trans. 2020, 52, 500–515. [Google Scholar] [CrossRef]

- Lison, M.; Devesse, W.; de Baere, D.; Hinderdael, M.; Guillaume, P. Hyperspectral and thermal temperature estimation during laser cladding. J. Laser Appl. 2019, 31, 022313. [Google Scholar] [CrossRef]

- Gerdes, N.; Hoff, C.; Hermsdorf, J.; Kaierle, S.; Overmeyer, L. Hyperspectral imaging for prediction of surface roughness in laser powder bed fusion. Int. J. Adv. Manuf. Technol. 2021, 115, 1249–1258. [Google Scholar] [CrossRef]

- Gao, X.; Chen, Y. Detection of micro gap weld using magneto-optical imaging during laser welding. Int. J. Adv. Manuf. Technol. 2014, 73, 23–33. [Google Scholar] [CrossRef]

- Ning, J.; Zhao, Y.; Zhu, L.; Yang, C.; Yu, M.; Yang, Z.; Qin, S.; Jiang, Z.; Xu, L.; Li, J.; et al. Height consistency compensation in laser-directed energy deposition of thin-walled parts. Int. J. Mech. Sci. 2024, 266, 108963. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Y.; Lei, Y.; Wei, H.; Chen, C.; Liu, F.; Zhao, P.; Wang, K. A single-sensor multi-scale quality monitoring methodology for laser-directed energy deposition: Example with height instability and porosity monitoring in additive manufacturing of ceramic thin-walled parts. Addit. Manuf. 2024, 79, 103923. [Google Scholar] [CrossRef]

- Slodczyk, M.; Ilin, A.; Kiedrowski, T.; Bareth, T.; Ploshikhin, V. Spatter reduction by multi-beam illumination in laser powder-bed fusion. Mater. Des. 2021, 212, 110206. [Google Scholar] [CrossRef]

- Rezaeifar, H.; Elbestawi, M. Minimizing the surface roughness in L-PBF additive manufacturing process using a combined feedforward plus feedback control system. Int. J. Adv. Manuf. Technol. 2022, 121, 7811–7831. [Google Scholar] [CrossRef]

- Zhang, Y.; Fuh, J.Y.; Ye, D.; Hong, G.S. In-situ monitoring of laser-based PBF via off-axis vision and image processing approaches. Addit. Manuf. 2019, 25, 263–274. [Google Scholar] [CrossRef]

- Feng, W.; Mao, Z.; Yang, Y.; Ma, H.; Zhao, K.; Qi, C.; Hao, C.; Liu, Z.; Xie, H.; Liu, S. Online defect detection method and system based on similarity of the temperature field in the melt pool. Addit. Manuf. 2022, 54, 102760. [Google Scholar] [CrossRef]

- Yan, H.; Grasso, M.; Paynabar, K.; Colosimo, B.M. Real-time detection of clustered events in video-imaging data with applications to additive manufacturing. IISE Trans. 2022, 54, 464–480. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, Z.; Fan, W. Online detection of powder spatters in the additive manufacturing process. Measurement 2022, 194, 111040. [Google Scholar] [CrossRef]

- Cannizzaro, D.; Varrella, A.G.; Paradiso, S.; Sampieri, R.; Macii, E.; Patti, E.; Di Cataldo, S. Image analytics and machine learning for in-situ defects detection in Additive Manufacturing. In Proceedings of the 2021 Design, Automation & Test in Europe Conference & Exhibition (DATE), Grenoble, France, 1–5 February 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 603–608. [Google Scholar]

- Kalami, H.; Urbanic, J. Exploration of surface roughness measurement solutions for additive manufactured components built by multi-axis tool paths. Addit. Manuf. 2021, 38, 101822. [Google Scholar] [CrossRef]

- Lyu, J.; Manoochehri, S. Online convolutional neural network-based anomaly detection and quality control for fused filament fabrication process. Virtual Phys. Prototyp. 2021, 16, 160–177. [Google Scholar] [CrossRef]

- Akhavan, J.; Lyu, J.; Manoochehri, S. A deep learning solution for real-time quality assessment and control in additive manufacturing using point cloud data. J. Intell. Manuf. 2023, 35, 1389–1406. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Q.; Li, Q.; Wu, Z.; Chen, C.; Xu, J.; Xue, J. Research on morphology detection of metal additive manufacturing process based on fringe projection and binocular vision. Appl. Sci. 2022, 12, 9232. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, L.; Peng, Y.; Wang, M.; Xue, Z.; Wu, J.; Yang, Y.; Zhang, J. Ultra-fast laser ultrasonic imaging method for online inspection of metal additive manufacturing. Opt. Lasers Eng. 2023, 160, 107244. [Google Scholar] [CrossRef]

- Binega, E.; Yang, L.; Sohn, H.; Cheng, J.C. Online geometry monitoring during directed energy deposition additive manufacturing using laser line scanning. Precis. Eng. 2022, 73, 104–114. [Google Scholar] [CrossRef]

- Agrahari, S.; Singh, A.K. Concept drift detection in data stream mining: A literature review. J. King Saud Univ.-Comput. Inf. Sci. 2022, 34, 9523–9540. [Google Scholar] [CrossRef]

- Baena-Garcıa, M.; del Campo-Ávila, J.; Fidalgo, R.; Bifet, A.; Gavalda, R.; Morales-Bueno, R. Early drift detection method. In Fourth International Workshop on Knowledge Discovery from Data Streams; Citeseer: Princeton, NJ, USA, 2006; Volume 6, pp. 77–86. [Google Scholar]

- Mouss, H.; Mouss, D.; Mouss, N.; Sefouhi, L. Test of page-hinckley, an approach for fault detection in an agro-alimentary production system. In Proceedings of the 2004 5th Asian Control Conference (IEEE Cat. No. 04EX904), Melbourne, Australia, 20–23 July 2004; IEEE: Piscataway, NJ, USA, 2004; Volume 2, pp. 815–818. [Google Scholar]

- Vallim, R.M.; De Mello, R.F. Proposal of a new stability concept to detect changes in unsupervised data streams. Expert Syst. Appl. 2014, 41, 7350–7360. [Google Scholar] [CrossRef]

- Siffer, A.; Fouque, P.-A.; Termier, A.; Largouet, C. Anomaly detection in streams with extreme value theory. In Proceedings of the 23rd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Halifax, NS, Canada, 13–17 August 2017; pp. 1067–1075. [Google Scholar]

- Imran, M.M.; Jung, G.; Kim, Y.; Abas, P.E.; De Silva, L.C.; Kim, Y.B. A computational method for improving the data acquisition process in the Laser Metal Deposition. In Proceedings of the 2023 57th Annual Conference on Information Sciences and Systems (CISS), Baltimore, MD, USA, 22–24 March 2023; IEEE: Piscataway, NJ, USA; pp. 1–6. [Google Scholar]

- Mu’az Imran, M.; Jung, G.; Kim, Y.; Chandratilak De Silva, L.; Che Idris, A.; Abas, P.E.; Kim, Y.B. Detection of spatter signature for streaming data in the laser metal deposition process. Int. J. Comput. Digit. Syst. 2023, 14, 1–15. [Google Scholar]

- Lee, E.T.; Fan, Z.; Sencer, B. A new approach to detect surface defects from 3D point cloud data with surface normal Gabor filter (SNGF). J. Manuf. Process. 2023, 92, 196–205. [Google Scholar] [CrossRef]

- Rusu, R.B.; Cousins, S. 3d is here: Point cloud library (pcl). In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; IEEE: Piscataway, NJ, USA; pp. 1–4. [Google Scholar]

- Schnabel, R.; Wahl, R.; Klein, R. Efficient RANSAC for point-cloud shape detection. In Computer Graphics Forum; Wiley Online Library: Hoboken, NJ, USA, 2007; Volume 26, pp. 214–226. [Google Scholar]

- Ye, Z.; Liu, C.; Tian, W.; Kan, C. A deep learning approach for the identification of small process shifts in additive manufacturing using 3D point clouds. Procedia Manuf. 2020, 48, 770–775. [Google Scholar] [CrossRef]

- Petrich, J.; Snow, Z.; Corbin, D.; Reutzel, E.W. Multi-modal sensor fusion with machine learning for data-driven process monitoring for additive manufacturing. Addit. Manuf. 2021, 48, 102364. [Google Scholar] [CrossRef]

- Gronle, M.; Grasso, M.; Granito, E.; Schaal, F.; Colosimo, B.M. Open data for open science in Industry 4.0: In-situ monitoring of quality in additive manufacturing. J. Qual. Technol. 2023, 55, 253–265. [Google Scholar] [CrossRef]

- Garmendia, I.; Leunda, J.; Pujana, J.; Lamikiz, A. In-process height control during laser metal deposition based on structured light 3D scanning. Procedia Cirp 2018, 68, 375–380. [Google Scholar] [CrossRef]

- Bernhard, R.; Neef, P.; Wiche, H.; Hoff, C.; Hermsdorf, J.; Kaierle, S.; Wesling, V. Defect detection in additive manufacturing via a toolpath overlaid melt-pool-temperature tomography. J. Laser Appl. 2020, 32, 022055. [Google Scholar] [CrossRef]

- Kahl, M.; Schramm, S.; Neumann, M.; Kroll, A. Identification of a spatio-temporal temperature model for laser metal deposition. Metals 2021, 11, 2050. [Google Scholar] [CrossRef]

- Seifi, S.H.; Tian, W.; Doude, H.; Tschopp, M.A.; Bian, L. Layer-wise modeling and anomaly detection for laser-based additive manufacturing. J. Manuf. Sci. Eng. 2019, 141, 081013. [Google Scholar] [CrossRef]

- Colosimo, B.M.; Grasso, M. Spatially weighted PCA for monitoring video image data with application to additive manufacturing. J. Qual. Technol. 2018, 50, 391–417. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, Y.; Yeung, H.; Krishnamurty, S. From scan strategy to melt pool prediction: A neighboring-effect modeling method. J. Comput. Inf. Sci. Eng. 2020, 20, 051001. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, S.; Lu, Y.; Witherell, P.; Kumara, S. Spatiotemporal monitoring of melt-pool variations in metal-based additive manufacturing. IEEE Robot. Autom. Lett. 2022, 7, 8249–8256. [Google Scholar] [CrossRef]

- Imran, M.M.; Kim, Y.; Jung, G.; De Silva, L.C.; Suh, J.-H.; Abas, P.E.; Kim, Y.B. In-Situ Process Monitoring and Defects Detection Based on Geometrical Topography With Streaming Point Cloud Processing in Directed Energy Deposition. IEEE Access 2023, 11, 131319–131337. [Google Scholar] [CrossRef]

- Khanzadeh, M.; Tian, W.; Yadollahi, A.; Doude, H.R.; Tschopp, M.A.; Bian, L. Dual process monitoring of metal-based additive manufacturing using tensor decomposition of thermal image streams. Addit. Manuf. 2018, 23, 443–456. [Google Scholar] [CrossRef]

- Guerra, M.G.; Errico, V.; Fusco, A.; Lavecchia, F.; Campanelli, S.L.; Galantucci, L.M. High resolution-optical tomography for in-process layerwise monitoring of a laser-powder bed fusion technology. Addit. Manuf. 2022, 55, 102850. [Google Scholar] [CrossRef]

- Yang, L.; Lo, L.; Ding, S.; Ozel, T. Monitoring and detection of meltpool and spatter regions in laser powder bed fusion of super alloy Inconel 625. Prog. Addit. Manuf. 2020, 5, 367–378. [Google Scholar] [CrossRef]