Evaluating a Controlled Electromagnetic Launcher for Safe Remote Drug Delivery

Abstract

1. Introduction

1.1. Overview

1.2. Background

1.2.1. Prior Work Overview

1.2.2. Microneedle Delivery

1.2.3. Limitations

2. Materials and Methods

2.1. Overview

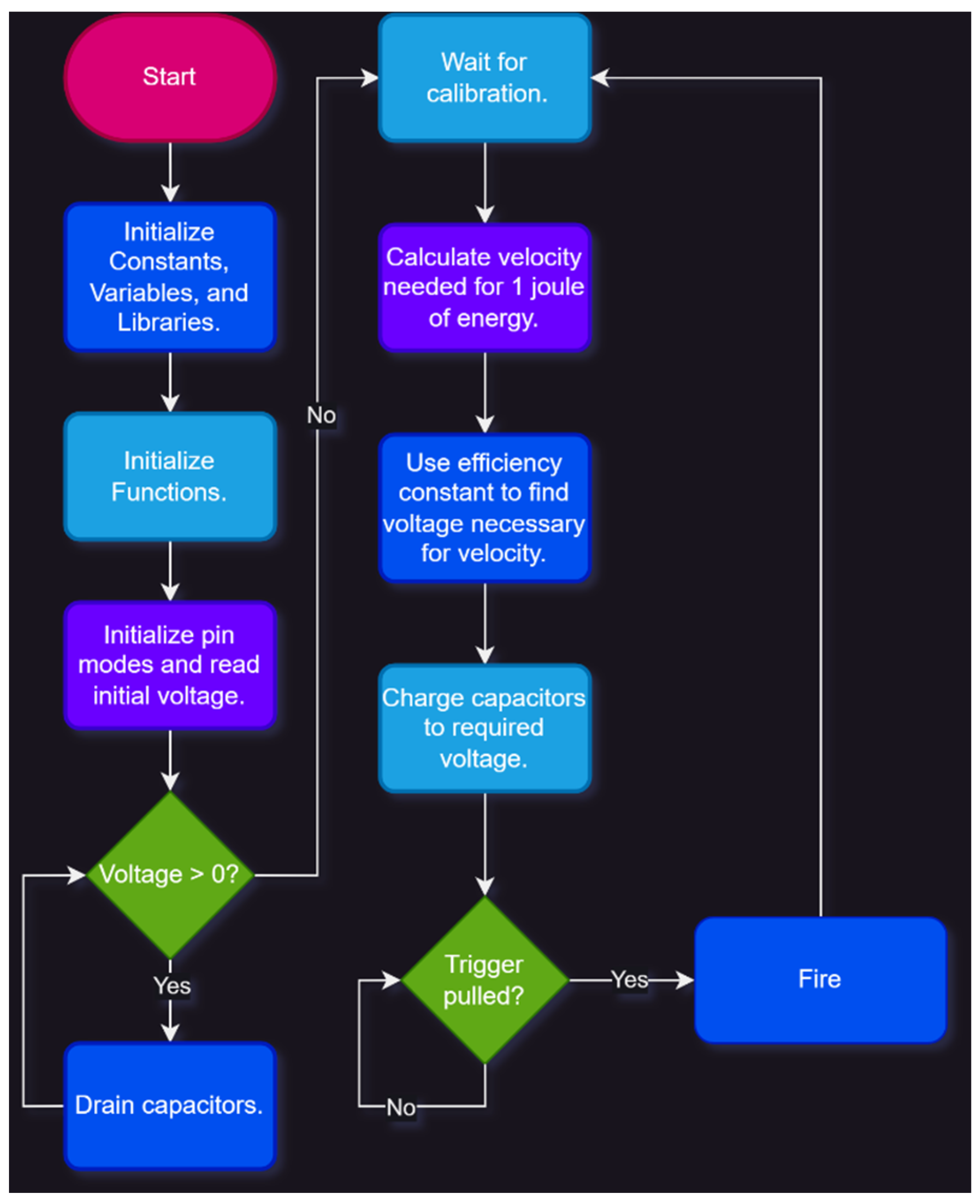

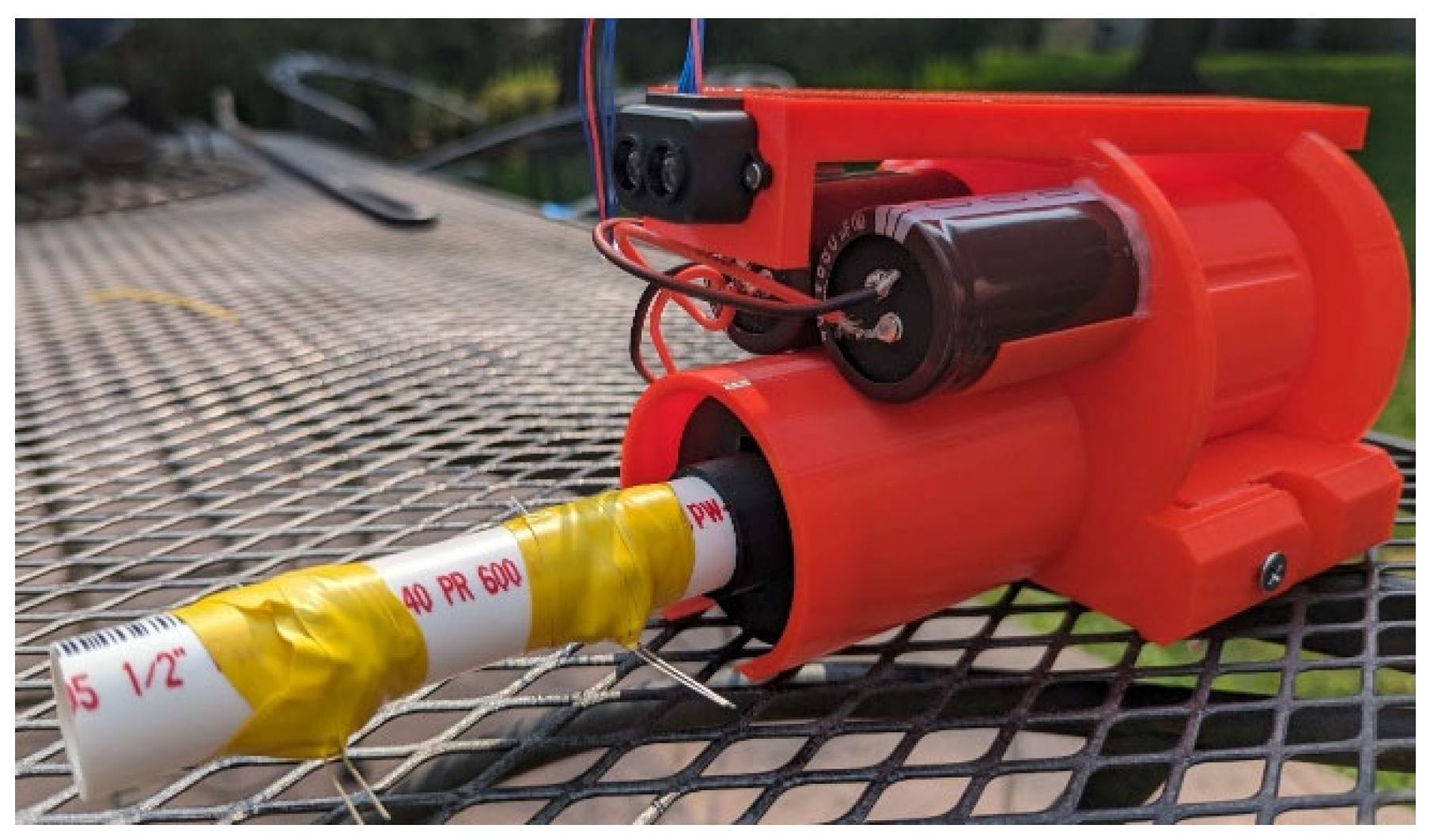

2.2. Launcher Operation

2.3. Projectile Design

2.4. Launcher Design

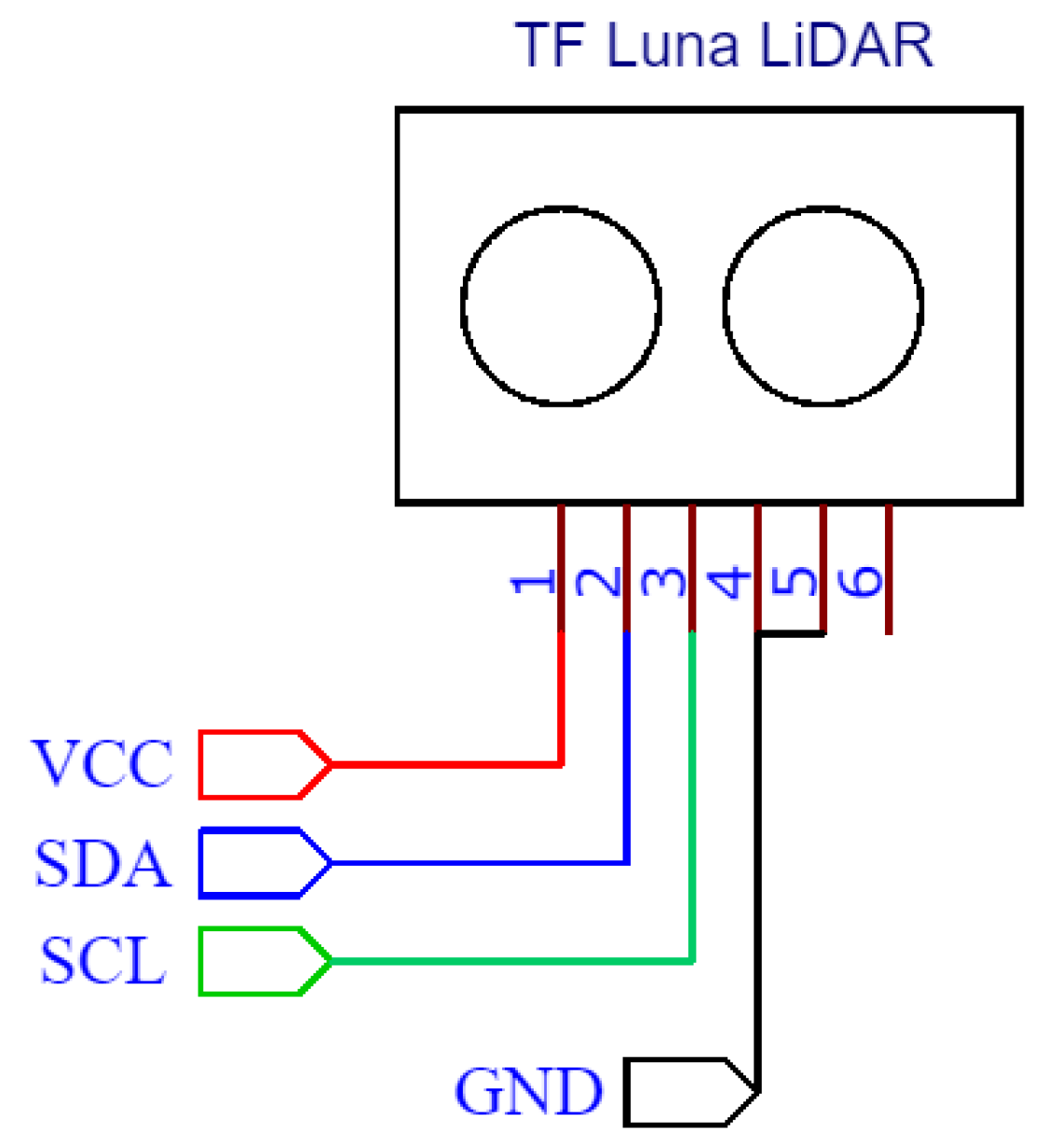

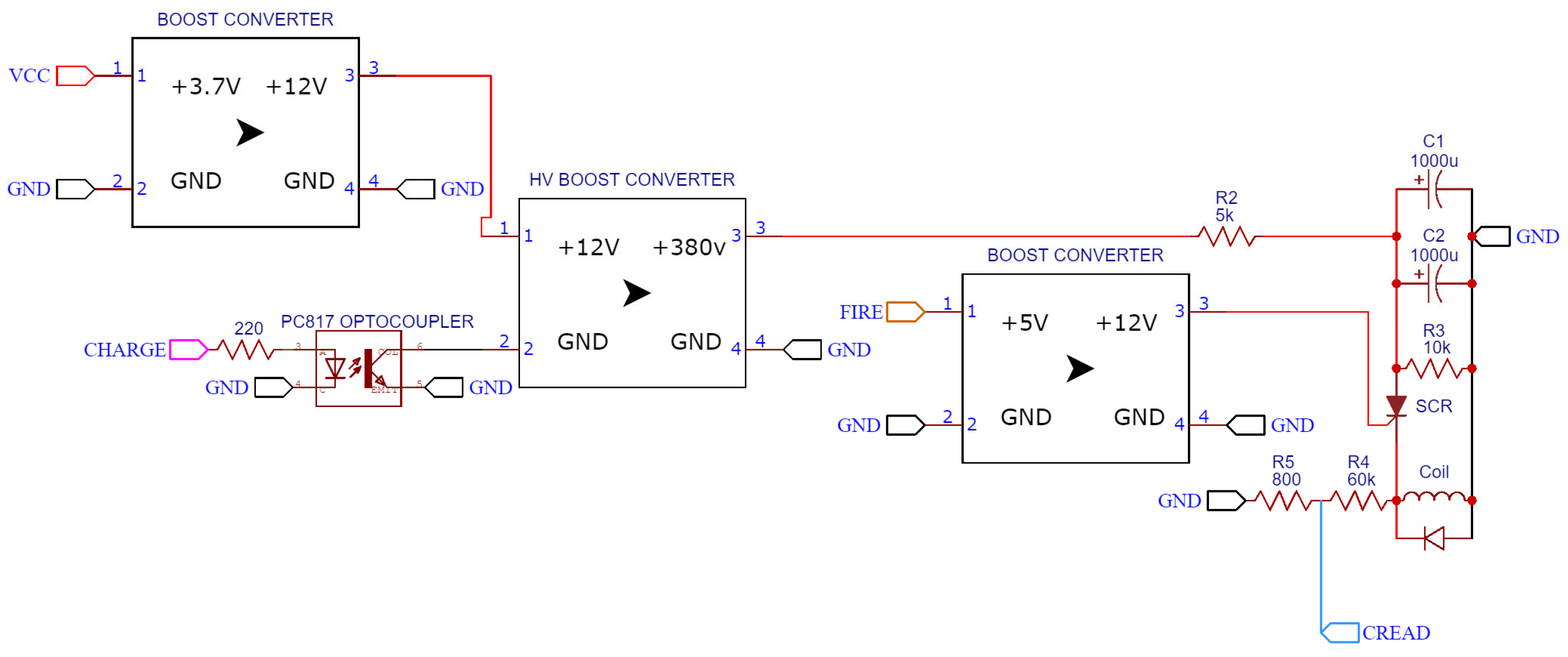

2.5. Launcher Electronics

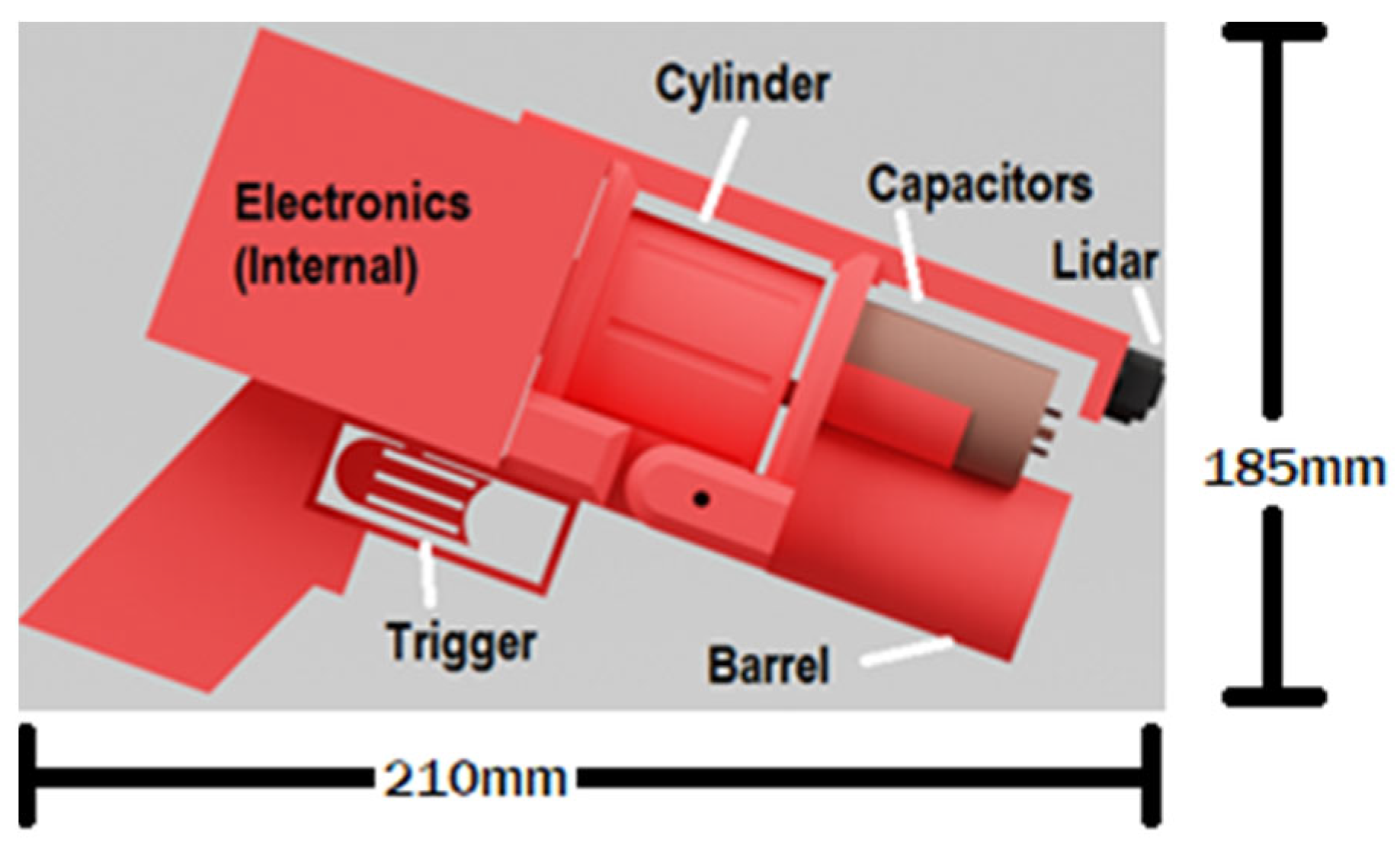

2.6. Launcher Housing

2.7. Calculations

2.8. Evaluation Criteria

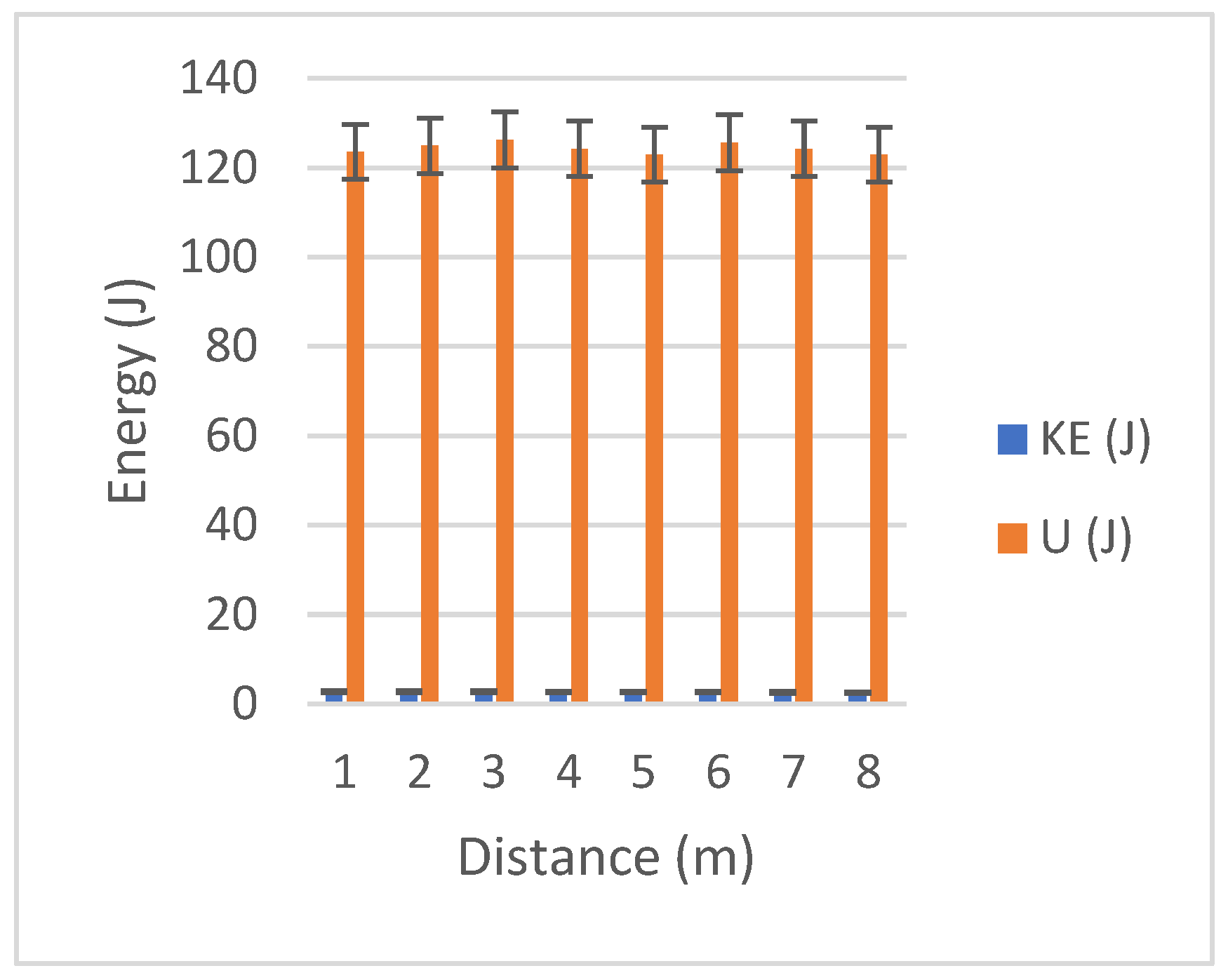

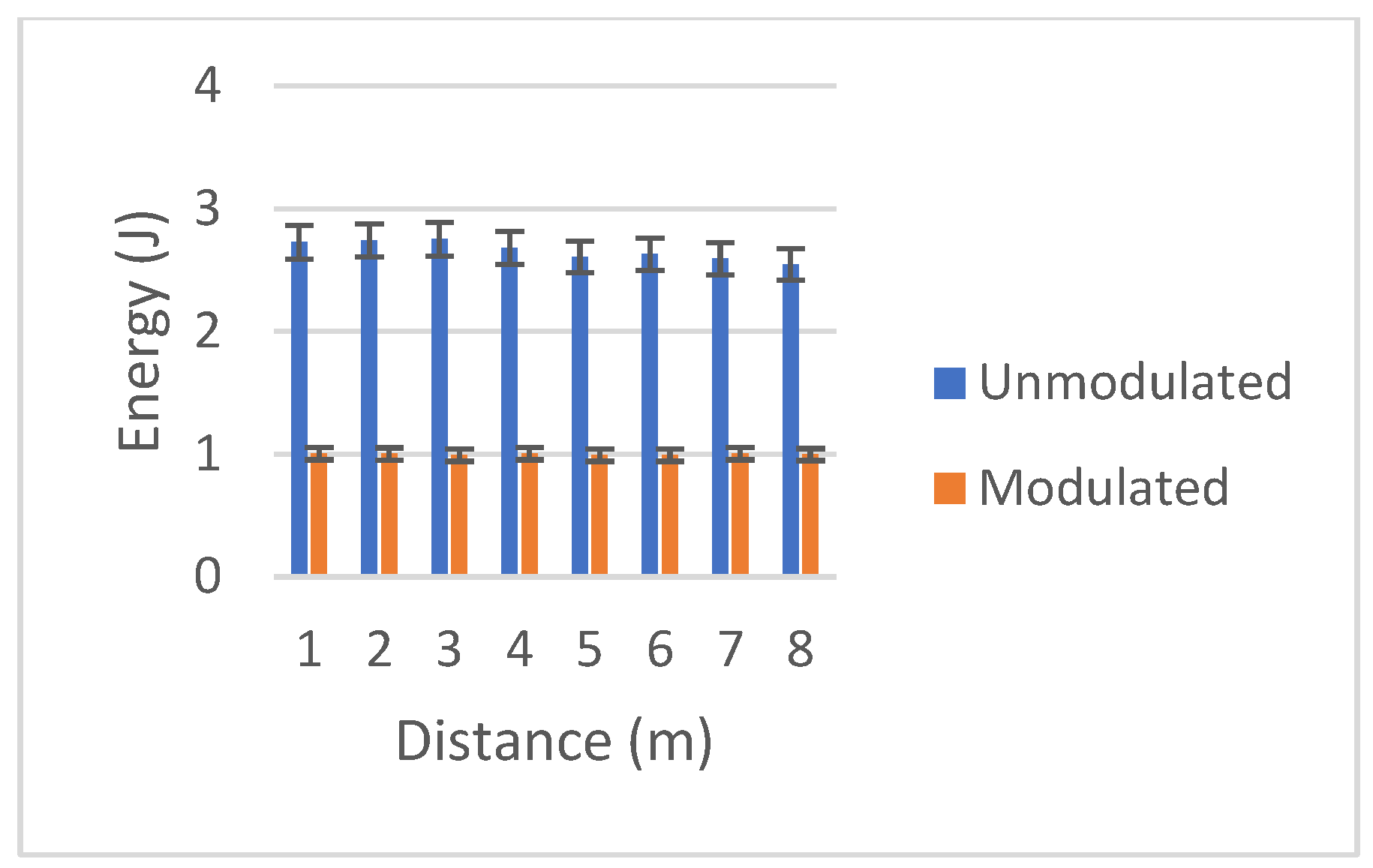

3. Results

4. Discussion

4.1. Overview

4.2. Limitations

4.3. Future Work

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barrett-Lennard, L.; Smith, T.G.; Ellis, G.M. A cetacean biopsy system using lightweight pneumatic darts, and its effect on the behavior of killer whales. Mar. Mammal Sci. 1996, 12, 14–27. [Google Scholar] [CrossRef]

- Bush, M. Remote drug delivery systems. J. Zoo Wildl. Med. 1992, 1992, 159–180. [Google Scholar]

- Vekselman, V.; Sande, L.; Kornev, K.G. Fully magnetic printing by generation of magnetic droplets on demand with a coilgun. J. Appl. Phys. 2015, 118, 224902. [Google Scholar] [CrossRef]

- Kreeger, T.J. Overview of delivery systems for the administration of contraceptives to wildlife. Contracept. Wildl. Manag. 1997, 1997, 29–48. [Google Scholar]

- Isaza, R. Remote drug delivery. Zoo Anim. Wildl. Immobil. Anesth. 2014, 2014, 155–169. [Google Scholar]

- Cattet, M.R.; Bourque, A.; Elkin, B.T.; Powley, K.D.; Dahlstrom, D.B.; Caulkett, N.A. Evaluation of the potential for injury with remote drug-delivery systems. Wildl. Soc. Bull. 2006, 34, 741–749. [Google Scholar] [CrossRef]

- Hairgrove, T.; Gill, R.; Waters, C.; Miller, R.; Mays, T.; Miller, M.; Fajt, V. Does dart gun delivery of antibiotics cause changes in drug disposition or meat quality? Am. Assoc. Bov. Pract. Conf. Proc. 2016, 2016, 167–168. [Google Scholar] [CrossRef]

- Pagano, A.M.; Peacock, E.; McKinney, M.A. Remote biopsy darting and marking of polar bears. Mar. Mammal Sci. 2014, 30, 169–183. [Google Scholar] [CrossRef]

- Noren, D.P.; Mocklin, J.A. Review of cetacean biopsy techniques: Factors contributing to successful sample collection and physiological and behavioral impacts. Mar. Mammal Sci. 2012, 28, 154–199. [Google Scholar] [CrossRef]

- Bearzi, G. First report of a common dolphin (Delphinus delphis) death following penetration of a biopsy dart. J. Cetacean Res. Manag. 2000, 2, 217–222. [Google Scholar] [CrossRef]

- Tarmizi, M.R.; Zainuddin, Z.Z. Low-cost remote drug delivery blow-dart for veterinary use. J. Wildl. Parks 2020, 35, 39–48. [Google Scholar]

- Economidou, S.; Uddin, M.; Marques, M.; Douroumis, D.; Sow, W.; Li, H.; Reid, A.; Windmill, J.; Podoleanu, A. A novel 3D printed hollow microneedle microelectromechanical system for controlled, personalized transdermal drug delivery. Addit. Manuf. 2021, 38, 101815. [Google Scholar] [CrossRef]

- Philips, B. How Accurate Is a 300fps Nerf Blaster? 30 May 2020. Available online: https://www.youtube.com/watch?v=vZtZMJEb9k4 (accessed on 1 June 2022).

- Gallagher, G.R.; Petzinger, C.; Rieger, J.A.; Dziurzynski, A.D.; Thayer, O. Development of a Safer Tranquilizer Dart. Proc. Vertebr. Pest Conf. 2010, 24, 1. [Google Scholar] [CrossRef]

- Horst, D.J. 3D printing of pharmaceutical drug delivery systems. Arch. Org. Inorg. Chem. Sci. 2018, 1, 1–5. [Google Scholar] [CrossRef]

- Jain, A.; Bansal, K.K.; Tiwari, A.; Rosling, A.; Rosenholm, J.M. Role of polymers in 3D printing technology for drug delivery-an overview. Curr. Pharm. Des. 2018, 24, 4979–4990. [Google Scholar] [CrossRef] [PubMed]

- Lui, Y.S.; Sow, W.T.; Tan, L.P.; Wu, Y.; Lai, Y.; Li, H. 4D Printing and Stimuli-responsive Materials in Biomedical Applications. Acta Biomater. 2019, 92, 19–36. [Google Scholar] [CrossRef]

- Martinez, P.R.; Goyanes, A.; Basit, A.W.; Gaisford, S. Fabrication of Drug-Loaded Hydrogels with Stereolithographic 3D Printing. Int. J. Pharm. 2017, 532, 313–317. [Google Scholar] [CrossRef] [PubMed]

- Devi, L.; Gaba, P.; Chopra, H. Tailormade Drug Delivery System: A Novel Trio Concept of 3DP+ Hydrogel+ SLA. J. Drug Deliv. Ther. 2019, 9, 861–866. [Google Scholar] [CrossRef]

- Trenfield, S.; Awad, A.; Madla, C.; Hatton, G.; Firth, J.; Goyanes, A.; Gaisford, S.; Basit, A. Shaping the future: Recent advances of 3D printing in drug delivery and healthcare. Expert Opin. Drug Deliv. 2019, 16, 1081–1094. [Google Scholar] [CrossRef]

- Massei, G.; Cowan, D. Fertility control to mitigate human–wildlife conflicts: A review. Wildl. Res. 2014, 41, 1–21. [Google Scholar] [CrossRef]

- Allen, L.; Ansel, H.C. Ansel’s Pharmaceutical Dosage Forms and Drug Delivery Systems; Lippincott Williams & Wilkins: Philadelphia, PN, USA, 2013. [Google Scholar]

- Lepowsky, E.; Tasoglu, S. 3D printing for drug manufacturing: A perspective on the future of pharmaceuticals. Int. J. Bioprinting 2018, 4, 1. [Google Scholar] [CrossRef]

- Xing, J.F.; Zheng, M.L.; Duan, X.M. Two-photon polymerization microfabrication of hydrogels: An advanced 3D printing technology for tissue engineering and drug delivery. Chem. Soc. Rev. 2015, 44, 5031–5039. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.; Jammalamadaka, U.; Tappa, K. Nanogels for pharmaceutical and biomedical applications and their fabrication using 3D printing technologies. Materials 2018, 11, 302. [Google Scholar] [CrossRef]

- Mobaraki, M.; Ghaffari, M.; Yazdanpanah, A.; Luo, Y.; Mills, D.K. Bioinks and bioprinting: A focused review. Bioprinting 2020, 18, e00080. [Google Scholar] [CrossRef]

- Rosenfield, D.A.; Acosta, A.; Tavares, D.T.; Pizzutto, C.S. Potential remote drug delivery failures due to temperature dependent viscosity and drug-loss of aqueous and emulsion-based fluids. J. Threat. Taxa 2021, 13, 17639–17645. [Google Scholar] [CrossRef]

- Walcott, H.E.; Curanovic, T.; Ghani, B.S.E.N. The Development and Testing of a Dual Function Underwater Dart Rifle. 2012. Available online: https://www.researchgate.net/profile/Horace-Walcott/publication/344179992_2012_PROCEEDINGS_AAZV_CONFERENCE_257_THE_DEVELOPMENT_AND_TESTING_OF_A_DUAL_FUNCTION_UNDERWATER_DART_RIFLE/links/5f5993e94585154dbbc3fec0/2012-PROCEEDINGS-AAZV-CONFERENCE-257-THE-DEV (accessed on 1 June 2022).

- Rosenfield, D.; Ferraro, M.; Igayara, C.; Cortopassi, S.R.G.; Pizzutto, C.S. Chemical immobilization of free-living capybaras (Hydrochoerus hydrochaeris) using ketamine-dexmedetomidine combination and a remote drug delivery system. Braz. J. Vet. Med. 2020, 42, e107220. [Google Scholar]

- Wolfe, L.L.; Miller, M.W. Using tailored tranquilizer combinations to reduce stress associated with large ungulate capture and translocation. J. Wildl. Dis. 2016, 52, S118–S124. [Google Scholar] [CrossRef]

- Milliman, K. Pressure-regulated gas gun. U.S. Patent US4616622A, 14 October 1986. Available online: https://patents.google.com/patent/US4616622A/en?oq=US4616622A (accessed on 2 July 2021).

- Bhogal, M. Controlling the Velocity of Projectiles from Gas-Powered Guns. US Patent US5265582A, 30 November 1993. [Google Scholar]

- Pneu-Dart. Available online: https://www.pneudart.com (accessed on 1 May 2019).

- Paxarms. Paxarms New Zealand LTD. Available online: http://www.paxarms.com/ (accessed on 6 May 2019).

- Kim, S.W.; Jung, H.K.; Hahn, S.Y. An optimal design of capacitor-driven coilgun. IEEE Trans. Magn. 1994, 30, 207–211. [Google Scholar]

- Schnurr, N.; Kerrisk, J.; Parker, J. Numerical predictions of railgun performance including the effects of ablation and arc drag. IEEE Trans. Magn. 1986, 22, 1733–1738. [Google Scholar] [CrossRef][Green Version]

- Koene, B.; Id-Boufker, F.; Papy, A. Kinetic non-lethal weapons. Neth. Annu. Rev. Mil. Stud. 2008, 2008, 9–24. [Google Scholar]

- Alyassi, R.; Khonji, M.; Karapetyan, A.; Chau, S.C.K.; Elbassioni, K.; Tseng, C.M. Autonomous recharging and flight mission planning for battery-operated autonomous drones. IEEE Trans. Autom. Sci. Eng. 2022, 20, 1034–1046. [Google Scholar] [CrossRef]

- LaRocco, J. Magnetar Alpha Repository. Available online: https://github.com/javeharron/magnetaralpha (accessed on 1 August 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

LaRocco, J.; Tahmina, Q.; Simonis, J. Evaluating a Controlled Electromagnetic Launcher for Safe Remote Drug Delivery. Technologies 2024, 12, 69. https://doi.org/10.3390/technologies12050069

LaRocco J, Tahmina Q, Simonis J. Evaluating a Controlled Electromagnetic Launcher for Safe Remote Drug Delivery. Technologies. 2024; 12(5):69. https://doi.org/10.3390/technologies12050069

Chicago/Turabian StyleLaRocco, John, Qudsia Tahmina, and John Simonis. 2024. "Evaluating a Controlled Electromagnetic Launcher for Safe Remote Drug Delivery" Technologies 12, no. 5: 69. https://doi.org/10.3390/technologies12050069

APA StyleLaRocco, J., Tahmina, Q., & Simonis, J. (2024). Evaluating a Controlled Electromagnetic Launcher for Safe Remote Drug Delivery. Technologies, 12(5), 69. https://doi.org/10.3390/technologies12050069