RFID Tags for On-Metal Applications: A Brief Survey

Abstract

1. Introduction

- What problem was solved by the publication or patent?

- In what country was the research carried out or the patent published?

- What was the RFID operating frequency used in the application?

- What was the flexibility of the tag used in the application?

2. Materials and Methods

3. Results

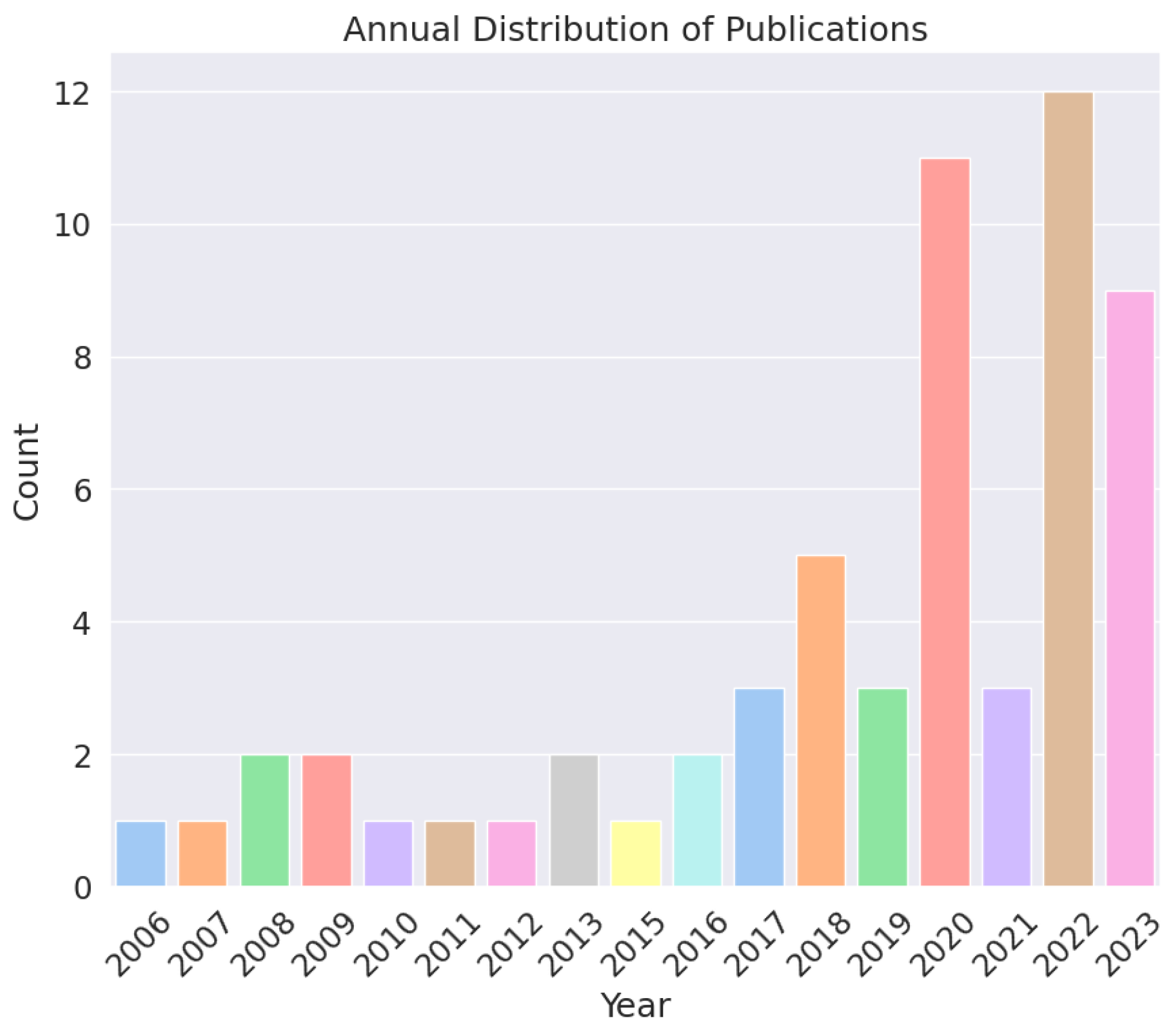

3.1. Articles

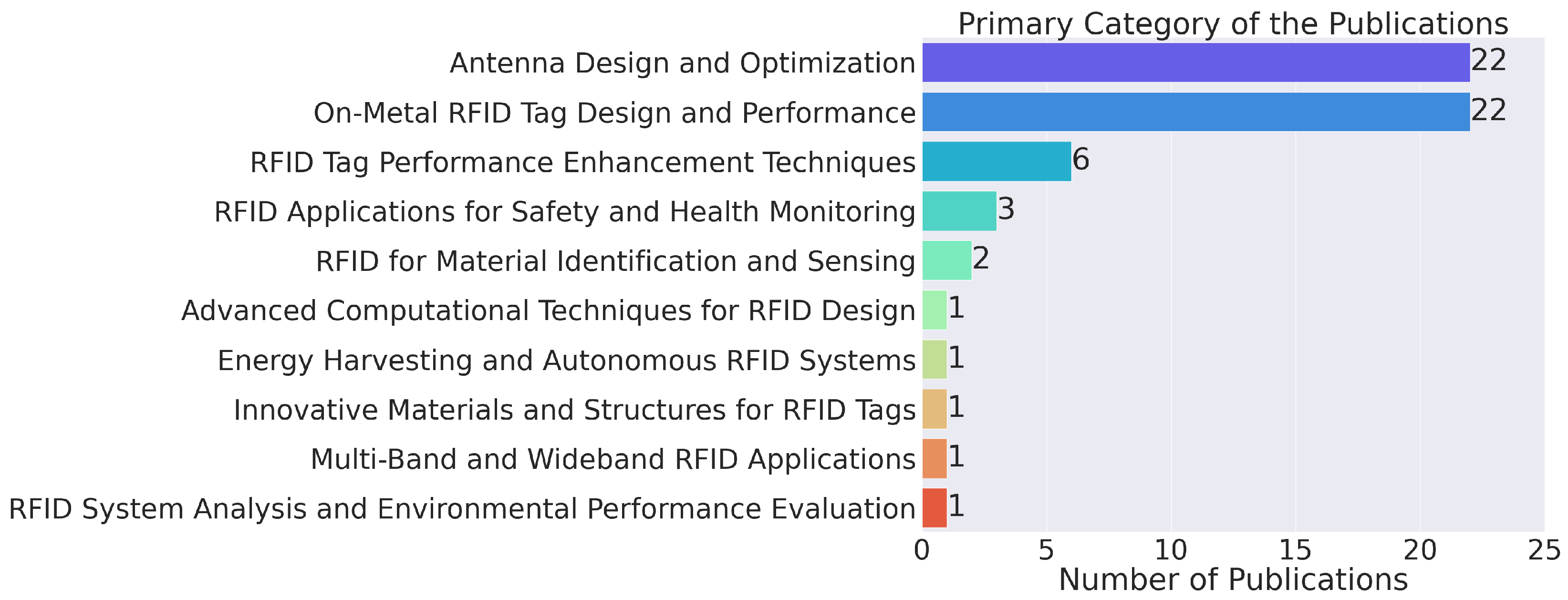

- On-Metal RFID Tag Design and Performance: This category encompasses research focused on the development and optimization of RFID tags specifically designed to function effectively on metal surfaces. These studies address unique challenges posed by metal environments, such as signal reflection and interference, proposing solutions to maintain high performance in terms of read range, data accuracy, and durability of RFID tags when attached to metallic objects.

- Antenna Design and Optimization: Articles classified under this category explore the intricacies of RFID antenna design, including the development of novel antenna structures, the optimization of existing designs for better performance, and the application of advanced optimization techniques. The focus is on enhancing the efficiency, read range, and adaptability of RFID antennas to various operational conditions and frequencies.

- RFID Tag Performance Enhancement Techniques: This category captures studies that propose methods and technologies to improve the overall performance of RFID tags. This includes enhancing the read range, sensitivity, and reliability of tags through material innovation, electromagnetic band-gap materials, and other performance enhancing techniques, especially in challenging environments.

- Multi-Band and Wideband RFID Applications: Research articles in this category explore the development and application of RFID systems that operate across multiple frequency bands or utilize wideband technology. These studies aim to improve the versatility and adaptability of RFID systems, enabling them to cater to a wider range of applications and standards in different regions.

- RFID Applications for Safety and Health Monitoring: This category includes studies that apply RFID technology to monitor safety and health, such as tracking worker locations in hazardous environments, monitoring structural health, and detecting changes in environmental conditions. The focus is on leveraging RFID for real-time data collection and analysis to enhance safety and preventive measures.

- Innovative Materials and Structures for RFID Tags: The articles in this category focus on the exploration and application of innovative materials and structural designs in the creation of RFID tags. This includes the use of high-conductivity graphene, flexible substrates, and novel antenna structures to improve tag performance and enable new applications, particularly in challenging or unconventional environments.

- RFID System Analysis and Environmental Performance Evaluation: This category covers comprehensive studies on the analysis of RFID systems’ performance in various environmental conditions. It includes the evaluation of factors that affect system efficiency, such as interference, materials, and operational scenarios, to understand and mitigate potential performance problems.

- Energy Harvesting and Autonomous RFID Systems: Research in this category is dedicated to the development of RFID systems that can harvest energy from their surroundings to power themselves. This includes innovations in energy harvesting techniques and the design of autonomous RFID sensors and tags for applications where battery replacement is impractical.

- RFID for Material Identification and Sensing: Articles classified here discuss the use of RFID technology for identifying materials and sensing environmental or structural changes. This includes methods for passive material identification, crack sensing, and integrating RFID with sensor technology to expand its application beyond traditional tracking and identification.

- Advanced Computational Techniques for RFID Design: This category highlights studies employing advanced computational methods, such as deep learning and particle swarm optimization, in the design and optimization of RFID systems. The focus is on using these techniques to predict electromagnetic responses, optimize antenna designs, and improve the overall performance and efficiency of RFID tags and systems.

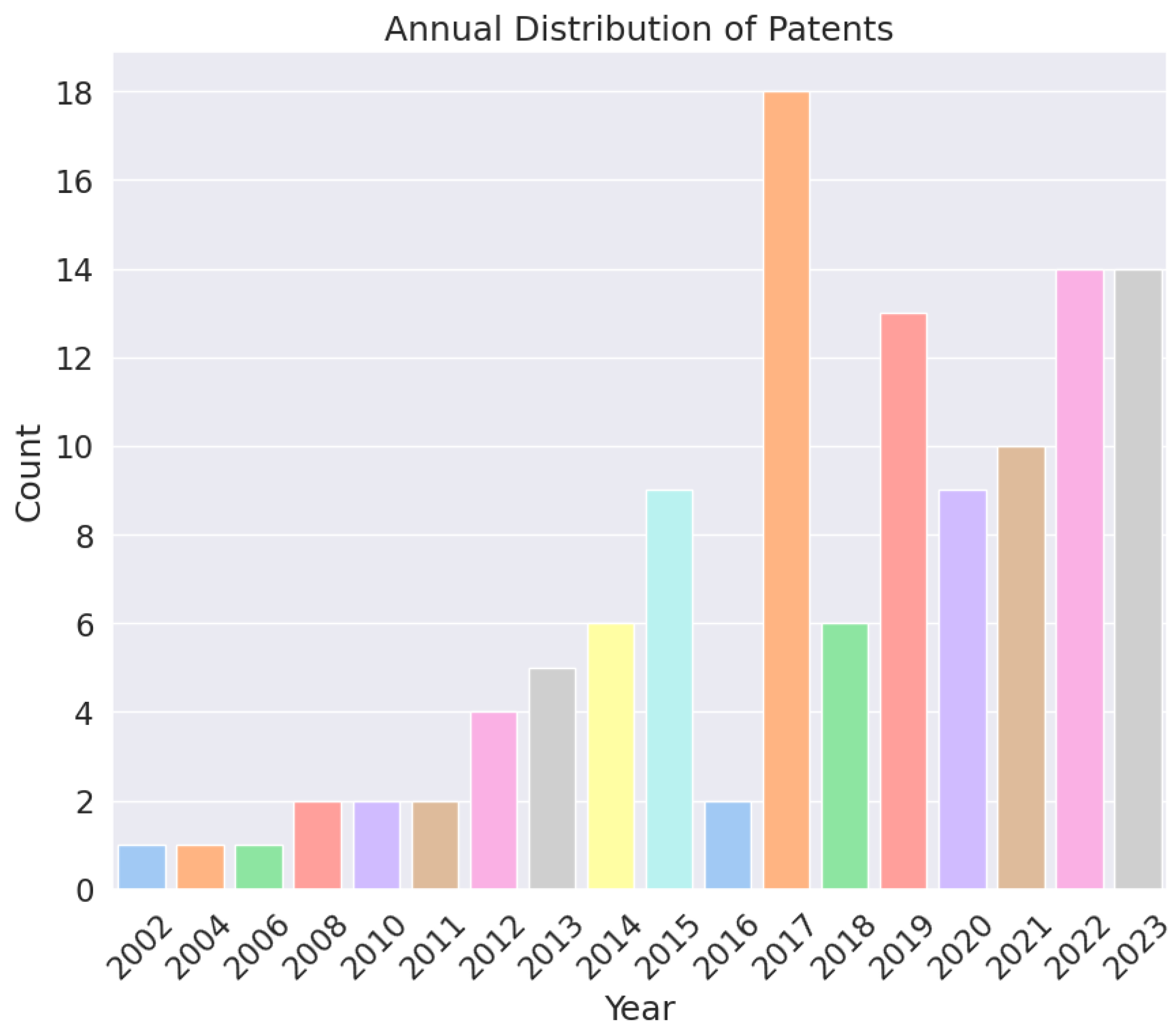

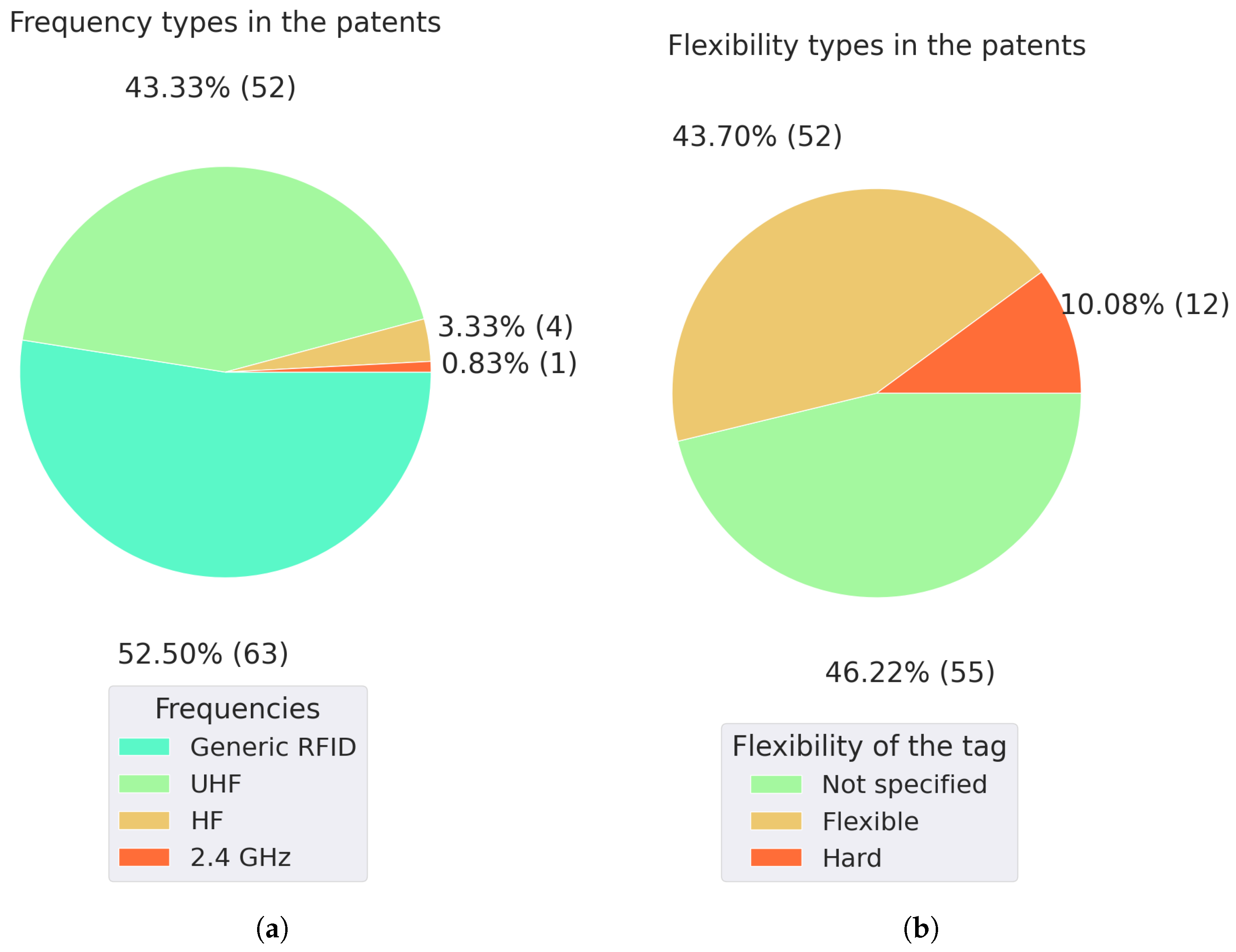

3.2. Patents

- RFID Tag Design for Metal Surfaces: Focuses on innovations to overcome challenges associated with RFID tagging on metal surfaces. Includes tags optimized for metal, anti-metal RFID tags, and designs utilizing ferromagnetic flakes or metal fasteners as antennas.

- RFID in Healthcare and Medical Instrument Tracking: Covers RFID applications to track medical instruments, produce surgical trays, and identify medical vials. Includes encapsulated devices in surgical instruments and RFID memory tags with metal components.

- Advanced RFID Tag Structures and Materials: Include items detailing structural innovations in RFID tags, such as 3D structures, dual-resonance tags, and tags with composite layers for improved performance and environmental resistance.

- RFID Systems for Authentication and Security: The focus is on the use of RFID to authenticate precious metals, jewelry, and other valuable items. Includes tamper-proof and tamper-resistant designs, anti-dismounting structures, and tags with integrated security features.

- Smart RFID Tag Assemblies and Integration: Covers smart tag assemblies that integrate RFID technology with microchips and antennas, including designs for embedded systems, encapsulated electronic devices, and integrated circuits for tracking and data transmission.

- RFID Applications in Industrial Settings and Logistics: Includes RFID solutions for inventory management, asset tracking, and enhancing operational efficiency in industrial settings. Covers tags for railcar wheelsets, gas turbine engines, and automated spray painting lines.

- RFID for Environmental and Material Adaptation: Focuses on RFID tags designed to function in challenging environments or on difficult substrates. Includes heat-resistant tags, flexible tags for uneven surfaces, and designs optimized for liquid monitoring.

- Innovative RFID Interfaces and Systems: Encompasses novel RFID-based interfaces and systems, such as mixed reality interfaces for Computer Numerical Control (CNC) production, RFID for retail attention, and intelligent inventory systems with RFID electronic labels.

- RFID Tag Manufacturing and Assembly Techniques: Details methods and processes for producing and assembling RFID tags and components, including sequential introduction of structural modules, “flip chip” assembly on fabric substrates, and production of microstrip patch antennas.

- Specialized RFID Features and Applications: Covers RFID tags and systems with specialized features or for specific applications, such as temperature sensing, liquid monitoring, flexible anti-metal labels, and RFID tags with light-emitting capabilities.

4. Discussion

5. Research Gaps and Future Extensions

- Future expansions of this study could include using a broader array of databases to explore articles and patents, aiming to cover as many relevant publications as possible. Expanding the temporal range further back could also provide insights into the evolution of RFID technology.

- Further investigation could also consider aspects like the cost of tag production and its performance, which were not covered in this work. An economic analysis could provide valuable insights into the cost-effectiveness and ROI of implementing RFID systems on metallic surfaces across different industries.

- Search for studies that use other technologies in conjunction with RFID tags on metal surfaces, such as integrations with the Internet of Things (IoT) and machine learning systems, and verify their advantages and limitations when compared to traditional use in this context.

- A comparative study between the use of RFID tags and other tracking technologies, such as Bluetooth, on a metal surface could provide some insights into the advantages and limitations of each.

- An important aspect that could be explored in the future is how extreme usage conditions, such as high temperatures, which are commonly associated with the use of RFID tags on metal, affect the reliability and durability of these tags.

- Future studies could also focus on materials science and how they impact the performance of RFID tags on metal surfaces, covering the latest advancements in this field.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RFID | Radio-frequency identification |

| RF | Radio-frequency |

| UHF | Ultra-High Frequency |

| HF | High Frequency |

| UWB | Ultra-Wide Band |

Appendix A

| Reference | Title | Year | Publisher |

|---|---|---|---|

| [12] | Miniature Long-Range Ceramic On-Metal RFID Tag | 2022 | IEEE |

| [13] | A Novel Antenna Design for Passive RFID Transponders on Metal Surfaces | 2006 | IEEE |

| [14] | Small Wideband Antenna for On-Metal UHF RFID Tag Design | 2021 | IEEE |

| [15] | Characteristics of passive UHF RFID tags on metal slabs | 2009 | IEEE |

| [16] | UHF RFID Tags for On-/Off-Metal Applications Fabricated Using Additive Manufacturing | 2017 | IEEE |

| [17] | Coupled-PILAs for Miniature On-metal RFID Tag Design | 2020 | IEEE |

| [18] | RFID tag antenna for use on metal | 2010 | IEEE |

| [19] | Low-profile, high-permeability antennaless RFID tags for use on metal objects | 2012 | IEEE |

| [20] | Compact ceramic on-metal RFID tag | 2022 | IEEE |

| [21] | M-Shaped Folded-patch Antenna for On-Metal UHF RFID Tag Design | 2022 | IEEE |

| [22] | Loop-Coupled Small Antenna With Enhanced Bandwidth for On-Metal UHF RFID Tag Design | 2023 | IEEE |

| [23] | Flexible Low-Profile On-Metal Tag Antenna for Asset Tracking and Identification | 2022 | IEEE |

| [24] | Complementarily Coupled C-Shaped Microstrip Patches With Wide-Range Frequency Tuning Capability for Metal-Applicable UHF RFID Tag Design | 2022 | IEEE |

| [25] | UHF RFID Tag Design Using Theory of Characteristics Modes for Platform-Tolerant and Harsh Metallic Environments | 2022 | IEEE |

| [26] | Bio-Inspired Circular-Polarized UHF RFID Tag Design Using Characteristic Mode Analysis | 2023 | IEEE |

| [27] | Circularly Polarized RFID Tag Antenna Design for Metallic Poles Using Characteristic Mode Analysis | 2019 | IEEE |

| [28] | A Compact UHF-RFID Tag Antenna Based on PIFA Structure for Two-Side Anti-Metal Application | 2023 | IEEE |

| [29] | Investigation of Low-Profile RFID Antenna Using AMC Substrate for Anti-Metallic Application | 2018 | IEEE |

| [30] | Low Cost Passive UHF RFID Packaging with Electromagnetic Band Gap (EBG) Substrate for Metal Objects | 2007 | IEEE |

| [31] | Passive UHF RFID with ferrite electromagnetic band gap (EBG) material for metal objects tracking | 2008 | IEEE |

| [32] | Passive UHF RFID Packaging With Electromagnetic Band Gap (EBG) Material for Metallic Objects Tracking | 2011 | IEEE |

| [33] | Multi-system, multi-band RFID antenna: Bridging the gap between HF- and UHF-based RFID applications | 2008 | IEEE |

| [34] | Flexible Folded-Patch Antenna with Tapered Edges for Metal-Mountable UHF RFID Tag Design | 2020 | IEEE |

| [35] | Metal-mountable microstrip RFID tag antenna for high impedance microchip | 2009 | IEEE |

| [36] | A new UHF anti-metal RFID tag antenna design with open-circuited stub feed | 2013 | IEEE |

| [5] | Design of UHF RFID broadband anti-metal tag antenna applied on surface of metallic objects | 2013 | IEEE |

| [37] | A Compact UHF RFID Tag Antenna for Anti-Metal Used on Both Sides | 2020 | IEEE |

| [38] | Compact long-range ceramic RFID tag for on-metal and non-metal applications | 2022 | IEEE |

| [39] | Research on Response Characteristics of Antenna Sensor for Metal Structure Defect Detection | 2020 | IEEE |

| [40] | Bendable Folded-Patch Antenna With Resonant Ring Manufactured Based on Foam Support and PET Substrate for On-Metal UHF RFID | 2023 | IEEE |

| [41] | A Novel Multiresonant Chipless RFID Tag for Directional Strain Measurement on Metal Surface | 2023 | IEEE |

| [42] | High-Efficient Compact Folded-Patch Antenna Fed by T-Shaped L-Probe for On-Metal UHF RFID Tag Design | 2020 | IEEE |

| [43] | A small flexible anti-metal RFID tag antenna | 2016 | IEEE |

| [44] | A Miniaturized Tag Antenna for UHF RFID Metallic Objects | 2023 | IEEE |

| [45] | Small UHF RFID tag antenna for metallic objects | 2015 | IEEE |

| [46] | Microstrip Dipole UHF-RFID Tag Antenna for Metal Object Tagging | 2016 | IEEE |

| [47] | A UHF RFID Tag Embeddable in Small Metal Cavities | 2018 | IEEE |

| [48] | Detection of Strain Magnitude and Direction Based on an RFID Sensor Array | 2022 | IEEE |

| [49] | Compact Magnetic Loop Antenna for Omnidirectional On-Metal UHF Tag Design | 2020 | IEEE |

| [50] | Slotted Folded Patch Antenna With Double-T-slots for Platform-Insensitive UHF Tag Design | 2019 | IEEE |

| [51] | Miniaturized Dipolar Patch Antenna With Narrow Meandered Slotline for UHF Tag | 2017 | IEEE |

| [52] | Folded Patch Antenna With Tunable Inductive Slots and Stubs for UHF Tag Design | 2018 | IEEE |

| [53] | Compact Orientation Insensitive Dipolar Patch for Metal-Mountable UHF RFID Tag Design | 2018 | IEEE |

| [54] | Compact Folded Dipole With Embedded Matching Loop for Universal Tag Applications | 2017 | IEEE |

| [55] | Platform Tolerant RFID Tag Antenna Design for Safety and Real-Time Tracking of On-site Workers at Riskier Workplaces | 2023 | Hindawi |

| [56] | Flexible Anti-Metal RFID Tag Antenna Based on High-Conductivity Graphene Assembly Film | 2021 | MDPI |

| [57] | Analysis of Electromagnetic Interference for Anti-Medal UHF RFID Temperature Tag in High Power Electronic Equipment | 2023 | MDPI |

| [58] | Frequency Switchable Global RFID Tag Antennae with Metal Compatibility for Worldwide Vehicle Transportation | 2023 | MDPI |

| [59] | Machine Learning-Based Structural Health Monitoring Using RFID for Harsh Environmental Conditions | 2022 | MDPI |

| [60] | Design of a new anti-metal RFID temperature tag antenna based on short-circuit stub structure | 2022 | Science Direct |

| [61] | Ultra slim and small UHF RFID tag design for mounting on curved surfaces | 2021 | Science Direct |

| [62] | Stretchable chipless RFID multi-strain sensors using direct printing of aerosolized nanocomposite | 2020 | Science Direct |

| [63] | Research on Performance of Anti-metal RFID in Field Test of Type and 500 kV Substation | 2020 | IOP Science |

| [64] | Development of RFID Tag Antenna With Graphene Material Using Deep Learning | 2022 | IOP Science |

| [65] | Design of UHF Tag Antenna Based on Internet of Things | 2020 | IOP Science |

| [66] | A Compact Folded RFID Tag Antenna with Nested Deformable Rings for Two-Side Anti-Metal Application | 2022 | Progress In Electromagnetics Research (PIER) |

| [67] | A Novel Ultra High Frequency Flexible Anti-Metal Tag Antenna Design | 2019 | World Scientific Research Journal (WSRJ) |

| [68] | Wireless and autonomous sensor for Integrated Engine Health Management | 2018 | PHM Society European Conference |

| [69] | Surface crack detection and monitoring in metal structure using RFID tag | 2020 | Emerald |

| [70] | Design of an UHF RFID Anti-metal Tag Antenna | 2020 | International Core Journal of Engineering |

| Category | References |

|---|---|

| On-Metal RFID Tag Design and Performance | [5,12,14,17,19,21,23,28,35,37,38,40,42,43,44,51,52,53,54,66,67,70] |

| Antenna Design and Optimization | [13,18,20,22,24,25,26,27,29,33,34,36,41,45,46,47,49,50,56,60,61,65] |

| RFID Tag Performance Enhancement Techniques | [15,16,30,31,32,57] |

| Multi-Band and Wideband RFID Applications | [58] |

| RFID Applications for Safety and Health Monitoring | [39,55,69] |

| Innovative Materials and Structures for RFID Tags | [62] |

| RFID System Analysis and Environmental Performance Evaluation | [63] |

| Energy Harvesting and Autonomous RFID Systems | [68] |

| RFID for Material Identification and Sensing | [48,59] |

| Advanced Computational Techniques for RFID Design | [64] |

References

- Rao, K.; Nikitin, P.; Lam, S. Antenna design for UHF RFID tags: A review and a practical application. IEEE Trans. Antennas Propag. 2005, 53, 3870–3876. [Google Scholar] [CrossRef]

- Baashirah, R.; Abuzneid, A. Survey on Prominent RFID Authentication Protocols for Passive Tags. Sensors 2018, 18, 3584. [Google Scholar] [CrossRef] [PubMed]

- Björninen, T.; Sydänheimo, L.; Ukkonen, L.; Rahmat-Samii, Y. Advances in antenna designs for UHF RFID tags mountable on conductive items. IEEE Antennas Propag. Mag. 2014, 56, 79–103. [Google Scholar] [CrossRef]

- RFID: Desvantagens e Dificuldades na Implantação. Available online: https://www.afixgraf.com.br/blog/rfid-vantagens-desvantagens/ (accessed on 13 February 2024).

- He, Y.; Pan, Z. Design of UHF RFID broadband anti-metal tag antenna applied on surface of metallic objects. In Proceedings of the 2013 IEEE Wireless Communications and Networking Conference (WCNC), Shanghai, China, 7–10 April 2013; pp. 4352–4357. [Google Scholar] [CrossRef]

- Yiyang, F.; Yikun, W.; Kaiqiang, Z. The design of anti-metal RFID antenna used in deep well completion system. In Proceedings of the 2016 2nd IEEE International Conference on Computer and Communications (ICCC), Chengdu, China, 14–17 October 2016; pp. 1719–1722. [Google Scholar] [CrossRef]

- Unhelkar, B.; Joshi, S.; Sharma, M.; Prakash, S.; Mani, A.K.; Prasad, M. Enhancing supply chain performance using RFID technology and decision support systems in the industry 4.0—A systematic literature review. Int. J. Inf. Manag. Data Insights 2022, 2, 100084. [Google Scholar] [CrossRef]

- Sarkar, B.; Takeyeva, D.; Guchhait, R.; Sarkar, M. Optimized radio-frequency identification system for different warehouse shapes. Knowl.-Based Syst. 2022, 258, 109811. [Google Scholar] [CrossRef]

- Erman, F.; Koziel, S.; Leifsson, L. Broadband/Dual-Band Metal-Mountable UHF RFID Tag Antennas: A Systematic Review, Taxonomy Analysis, Standards of Seamless RFID System Operation, Supporting IoT Implementations, Recommendations, and Future Directions. IEEE Internet Things J. 2023, 10, 14780–14797. [Google Scholar] [CrossRef]

- OpenAI. ChatGPT: Optimizing Language Models for Dialogue. 2024. Available online: https://openai.com/ (accessed on 10 April 2024).

- World Intellectual Property Organization-WIPO. PCT-The International Patent System. Available online: https://www.wipo.int/pct/en/index.html (accessed on 5 February 2024).

- Yusupov, I.; Dobrykh, D.; Filonov, D.; Slobozhanyuk, A.; Ginzburg, P. Miniature Long-Range Ceramic On-Metal RFID Tag. IEEE Trans. Antennas Propag. 2022, 70, 10226–10232. [Google Scholar] [CrossRef]

- Bovelli, S.; Neubauer, F.; Heller, C. A Novel Antenna Design for Passive RFID Transponders on Metal Surfaces. In Proceedings of the 2006 European Microwave Conference, Manchester, UK, 10–15 September 2006; pp. 580–582. [Google Scholar] [CrossRef]

- Lee, S.R.; Lim, E.H.; Rahim, S.K.A. Small Wideband Antenna for On-Metal UHF RFID Tag Design. IEEE J. Radio Freq. Identif. 2022, 6, 121–127. [Google Scholar] [CrossRef]

- Arumugam, D.D.; Engels, D.W. Characteristics of passive UHF RFID tags on metal slabs. In Proceedings of the 2009 IEEE Antennas and Propagation Society International Symposium, North Charleston, SC, USA, 1–5 June 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Ramirez, R.A.; Rojas-Nastrucci, E.A.; Weller, T.M. UHF RFID Tags for On-/Off-Metal Applications Fabricated Using Additive Manufacturing. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 1635–1638. [Google Scholar] [CrossRef]

- Lee, Y.H.; Chee, P.S.; Lim, E.H.; Bong, F.L. Coupled-PILAs for Miniature On-metal RFID Tag Design. In Proceedings of the 2020 IEEE Asia-Pacific Microwave Conference (APMC), Hong Kong, China, 8–11 December 2020; pp. 878–880. [Google Scholar] [CrossRef]

- Tao, X.; Geng, J.; Jin, R.; Liang, X.; Wu, H. RFID tag antenna for use on metal. In Proceedings of the 2010 International Workshop on Antenna Technology (iWAT), Lisbon, Portugal, 1–3 March 2010; pp. 1–4. [Google Scholar] [CrossRef]

- Bauer-Reich, C.; Berge, L.; Reich, M. Low-profile, high-permeability antennaless RFID tags for use on metal objects. In Proceedings of the 2012 IEEE International Workshop on Antenna Technology (iWAT), Tucson, AZ, USA, 5–7 March 2012; pp. 32–35. [Google Scholar] [CrossRef]

- Yusupov, I.; Dobrykh, D.; Filonov, D.; Slobozhanyuk, A.; Ginzburg, P. Compact ceramic on-metal RFID tag. In Proceedings of the 2022 IEEE-APS Topical Conference on Antennas and Propagation in Wireless Communications (APWC), Cagliari, Italy, 12–14 September 2022; p. 084. [Google Scholar] [CrossRef]

- Zhao, L.; Ma, Y.; Meng, W. M-Shaped Folded-patch Antenna for On-Metal UHF RFID Tag Design. In Proceedings of the 2022 IEEE International Conference on RFID (RFID), Cagliari, Italy, 12–14 September 2022; pp. 81–86. [Google Scholar] [CrossRef]

- Lee, S.R.; Ng, W.H.; Lim, E.H.; Rahim, S.K.A. Loop-Coupled Small Antenna with Enhanced Bandwidth for On-Metal UHF RFID Tag Design. IEEE Trans. Antennas Propag. 2023, 71, 3660–3664. [Google Scholar] [CrossRef]

- Miswadi, N.; Rahman, N.H.A.; Subahir, S.; Lim, E.H.; Aris, M.A.; Mun, C.K. Flexible Low-Profile On-Metal Tag Antenna for Asset Tracking and Identification. In Proceedings of the 2022 International Symposium on Antennas and Propagation (ISAP), Sydney, Australia, 31 October–3 November 2022; pp. 399–400. [Google Scholar] [CrossRef]

- Murugesh, M.; Lim, E.H.; Chee, P.S.; Bong, F.L. Complementarily Coupled C-Shaped Microstrip Patches with Wide-Range Frequency Tuning Capability for Metal-Applicable UHF RFID Tag Design. IEEE Trans. Antennas Propag. 2022, 70, 11548–11558. [Google Scholar] [CrossRef]

- Sharif, A.; Ouyang, J.; Raza, A.; Hussain, S.; Nasir, M.; Arshad, K.; Assaleh, K.; Ramzan, N.; Imran, M.A.; Abbasi, Q.H. UHF RFID Tag Design Using Theory of Characteristics Modes for Platform-Tolerant and Harsh Metallic Environments. IEEE J. Radio Freq. Identif. 2022, 6, 524–533. [Google Scholar] [CrossRef]

- Sharif, A.; Kumar, R.; Althobaiti, T.; Alotaibi, A.A.; Safi, L.; Ramzan, N.; Imran, M.A.; Abbasi, Q.H. Bio-Inspired Circular-Polarized UHF RFID Tag Design Using Characteristic Mode Analysis. IEEE Sens. J. 2023, 23, 10847–10855. [Google Scholar] [CrossRef]

- Yan, Y.; Ouyang, J.; Ma, X.; Wang, R.; Sharif, A. Circularly Polarized RFID Tag Antenna Design for Metallic Poles Using Characteristic Mode Analysis. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 1327–1331. [Google Scholar] [CrossRef]

- Lai, W.; Yuan, J.; Niu, C. A Compact UHF-RFID Tag Antenna Based on PIFA Structure for Two-Side Anti-Metal Application. In Proceedings of the 2023 IEEE 6th International Conference on Electronic Information and Communication Technology (ICEICT), Qingdao, China, 21–24 July 2023; pp. 1180–1183. [Google Scholar] [CrossRef]

- He, W.; Xu, B. Investigation of Low-Profile RFID Antenna Using AMC Substrate for Anti-Metallic Application. In Proceedings of the 2018 Progress in Electromagnetics Research Symposium (PIERS-Toyama), Toyama, Japan, 1–4 August 2018; pp. 2187–2191. [Google Scholar] [CrossRef]

- Gao, B.; Cheng, C.H.; Yuen, M.M.; Murch, R.D. Low Cost Passive UHF RFID Packaging with Electromagnetic Band Gap (EBG) Substrate for Metal Objects. In Proceedings of the 2007 Proceedings 57th Electronic Components and Technology Conference, Sparks, NV, USA, 29 May–1 June 2007; pp. 974–978. [Google Scholar] [CrossRef]

- Gao, B.; Yuen, M.M. Passive UHF RFID with ferrite electromagnetic band gap (EBG) material for metal objects tracking. In Proceedings of the 2008 58th Electronic Components and Technology Conference, Lake Buena Vista, FL, USA, 27–30 May 2008; pp. 1990–1994. [Google Scholar] [CrossRef]

- Gao, B.; Yuen, M.M.F. Passive UHF RFID Packaging with Electromagnetic Band Gap (EBG) Material for Metallic Objects Tracking. IEEE Trans. Components, Packag. Manuf. Technol. 2011, 1, 1140–1146. [Google Scholar] [CrossRef]

- Hirvonen, M.; Pesonen, N.; Vermesan, O.; Rusu, C.; Enoksson, P. Multi-system, multi-band RFID antenna: Bridging the gap between HF- and UHF-based RFID applications. In Proceedings of the 2008 European Conference on Wireless Technology, Amsterdam, The Netherlands, 27–28 October 2008; pp. 346–349. [Google Scholar] [CrossRef]

- Murugesh, M.; Lee, Y.H.; Chee, P.S.; Lim, E.H. Flexible Folded-Patch Antenna with Tapered Edges for Metal-Mountable UHF RFID Tag Design. In Proceedings of the 2020 IEEE International RF and Microwave Conference (RFM), Kuala Lumpur, Malaysia, 14–16 December 2020; pp. 1–3. [Google Scholar] [CrossRef]

- Koskinen, T.; Rahmat-Samii, Y. Metal-mountable microstrip RFID tag antenna for high impedance microchip. In Proceedings of the 2009 3rd European Conference on Antennas and Propagation, Berlin, Germany, 23–27 March 2009; pp. 2791–2795. [Google Scholar]

- He, Y.; Zhang, H. A new UHF anti-metal RFID tag antenna design with open-circuited stub feed. In Proceedings of the 2013 IEEE International Conference on Communications (ICC), Budapest, Hungary, 9–13 June 2013; pp. 5809–5813. [Google Scholar] [CrossRef]

- Zheng, J.; Yuan, J.; Chen, Z. A Compact UHF RFID Tag Antenna for Anti-Metal Used on Both Sides. In Proceedings of the 2020 Cross Strait Radio Science & Wireless Technology Conference (CSRSWTC), Fuzhou, China, 13–16 December 2020; pp. 1–3. [Google Scholar] [CrossRef]

- Dobrykh, D.; Yusupov, I.; Slobozhanyuk, A.; Filonov, D.; Ginzburg, P. Compact long-range ceramic RFID tag for on-metal and non-metal applications. In Proceedings of the 2022 IEEE 12th International Conference on RFID Technology and Applications (RFID-TA), Cagliari, Italy, 12–14 September 2022; pp. 94–97. [Google Scholar] [CrossRef]

- Jianbin, C.; Qiang, L.; Hao, W.; Xiang, L.; Wei, Q. Research on Response Characteristics of Antenna Sensor for Metal Structure Defect Detection. In Proceedings of the 2020 Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020; pp. 1944–1948. [Google Scholar] [CrossRef]

- Zhao, L.; Ma, Y.; Meng, W.; Peng, K.; Liu, K. Bendable Folded-Patch Antenna with Resonant Ring Manufactured Based on Foam Support and PET Substrate for On-Metal UHF RFID. IEEE J. Radio Freq. Identif. 2023, 7, 591–600. [Google Scholar] [CrossRef]

- Cheng, X.; Yu, Y.; Wang, F.; Tian, G. A Novel Multiresonant Chipless RFID Tag for Directional Strain Measurement on Metal Surface. IEEE Trans. Microw. Theory Tech. 2023, 71, 916–925. [Google Scholar] [CrossRef]

- Lee, S.R.; Lim, E.H.; Bong, F.L.; Chung, B.K. High-Efficient Compact Folded-Patch Antenna Fed by T-Shaped L-Probe for On-Metal UHF RFID Tag Design. IEEE Trans. Antennas Propag. 2020, 68, 152–160. [Google Scholar] [CrossRef]

- Wu, G.; Ouyang, J.; Chen, B.; Jin, L.; Long, R. A small flexible anti-metal RFID tag antenna. In Proceedings of the 2016 IEEE 5th Asia-Pacific Conference on Antennas and Propagation (APCAP), Kaohsiung, Taiwan, 26–29 July 2016; pp. 289–290. [Google Scholar] [CrossRef]

- Xu, R.; Shen, Z. A Miniaturized Tag Antenna for UHF RFID Metallic Objects. In Proceedings of the 2023 International Microwave and Antenna Symposium (IMAS), Cairo, Egypt, 7–9 February 2023; pp. 170–171. [Google Scholar] [CrossRef]

- López-Soriano, S.; Parrón, J. Small UHF RFID tag antenna for metallic objects. In Proceedings of the 2015 9th European Conference on Antennas and Propagation (EuCAP), Lisbon, Portugal, 13–17 April 2015; pp. 1–5. [Google Scholar]

- Faudzi, N.; Rashid, A.; Ibrahim, A.; Khyasudeen, M.; Ali, M. Microstrip Dipole UHF-RFID Tag Antenna for Metal Object Tagging. In Proceedings of the 2016 International Conference on Computer and Communication Engineering (ICCCE), Kuala Lumpur, Malaysia, 26–27 July 2016; pp. 36–41. [Google Scholar] [CrossRef]

- Michel, A.; Franchina, V.; Nepa, P.; Salvatore, A. A UHF RFID Tag Embeddable in Small Metal Cavities. IEEE Trans. Antennas Propag. 2019, 67, 1374–1379. [Google Scholar] [CrossRef]

- Zhang, M.; Qiu, J.; Lan, Y.; Wu, J.; Yu, J.; Xu, Z.; Li, E. Detection of Strain Magnitude and Direction Based on an RFID Sensor Array. IEEE Trans. Instrum. Meas. 2022, 71, 1–13. [Google Scholar] [CrossRef]

- Lee, S.R.; Ng, W.H.; Lim, E.H.; Bong, F.L.; Chung, B.K. Compact Magnetic Loop Antenna for Omnidirectional On-Metal UHF Tag Design. IEEE Trans. Antennas Propag. 2020, 68, 765–772. [Google Scholar] [CrossRef]

- Lee, S.R.; Lim, E.H.; Bong, F.L.; Chung, B.K. Slotted Folded Patch Antenna with Double-T-slots for Platform-Insensitive UHF Tag Design. IEEE Trans. Antennas Propag. 2019, 67, 670–675. [Google Scholar] [CrossRef]

- Bong, F.L.; Lim, E.H.; Lo, F.L. Miniaturized Dipolar Patch Antenna with Narrow Meandered Slotline for UHF Tag. IEEE Trans. Antennas Propag. 2017, 65, 4435–4442. [Google Scholar] [CrossRef]

- Ng, W.H.; Lim, E.H.; Bong, F.L.; Chung, B.K. Folded Patch Antenna with Tunable Inductive Slots and Stubs for UHF Tag Design. IEEE Trans. Antennas Propagation 2018, 66, 2799–2806. [Google Scholar] [CrossRef]

- Bong, F.L.; Lim, E.H.; Lo, F.L. Compact Orientation Insensitive Dipolar Patch for Metal-Mountable UHF RFID Tag Design. IEEE Trans. Antennas Propag. 2018, 66, 1788–1795. [Google Scholar] [CrossRef]

- Bong, F.L.; Lim, E.H.; Lo, F.L. Compact Folded Dipole with Embedded Matching Loop for Universal Tag Applications. IEEE Trans. Antennas Propag. 2017, 65, 2173–2181. [Google Scholar] [CrossRef]

- Bansal, A.; Khanna, R.; Sharma, S. Platform Tolerant RFID Tag Antenna Design for Safety and Real-Time Tracking of On-site Workers at Riskier Workplaces. Int. J. Antennas Propag. 2023, 2023, 2038899. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, C.; Wang, Y.; Wang, Z.; Liu, C.; He, D.; Wu, Z.P. Flexible Anti-Metal RFID Tag Antenna Based on High-Conductivity Graphene Assembly Film. Sensors 2021, 21, 1513. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Zhou, Z.; Xiao, Z.; Liu, H.; Lu, Z.; Su, L.; Guo, W.; Deng, X. Analysis of Electromagnetic Interference for Anti-Medal UHF RFID Temperature Tag in High Power Electronic Equipment. Electronics 2023, 12, 3577. [Google Scholar] [CrossRef]

- Mazumder, K.; Ghosh, A.; Bhattacharya, A.; Ahmad, S.; Ghaffar, A.; Hussein, M. Frequency Switchable Global RFID Tag Antennae with Metal Compatibility for Worldwide Vehicle Transportation. Sensors 2023, 23, 3854. [Google Scholar] [CrossRef] [PubMed]

- Zhao, A.; Sunny, A.I.; Li, L.; Wang, T. Machine Learning-Based Structural Health Monitoring Using RFID for Harsh Environmental Conditions. Electronics 2022, 11, 1740. [Google Scholar] [CrossRef]

- Zhang, G.; Luo, B.; Wang, Q.; Deng, X. Design of a new anti-metal RFID temperature tag antenna based on short-circuit stub structure. Procedia Comput. Sci. 2022, 203, 367–374. [Google Scholar] [CrossRef]

- Morales Peña, C.D.; de Oliveira, D.B.; da Silva, E.J.; Benjó da Silva, M.W. Ultra slim and small UHF RFID tag design for mounting on curved surfaces. AEU-Int. J. Electron. Commun. 2021, 128, 153502. [Google Scholar] [CrossRef]

- Min, S.H.; Kim, H.J.; Quan, Y.J.; Kim, H.S.; Lyu, J.H.; Lee, G.Y.; Ahn, S.H. Stretchable chipless RFID multi-strain sensors using direct printing of aerosolised nanocomposite. Sens. Actuators A Phys. 2020, 313, 112224. [Google Scholar] [CrossRef]

- Yang, M.; Tan, H.; Liu, M.; Chen, X.; Huang, R.; Liu, Q. Research on Performance of Anti-metal RFID in Field Test of Type and 500kV Substation. IOP Conf. Ser. Mater. Sci. Eng. 2020, 740, 012080. [Google Scholar] [CrossRef]

- Rajalakshmi, S.; Jagan, G.C.; Padmapriya; Asha, S.; Rao, N.K.K.; Shrivastava, R. Development of RFID Tag Antenna with Graphene Material Using Deep Learning. J. Phys. Conf. Ser. 2022, 2272, 012012. [Google Scholar] [CrossRef]

- Huajuan, C. Design of UHF Tag Antenna Based on Internet of Things. J. Phys. Conf. Ser. 2020, 1486, 022042. [Google Scholar] [CrossRef]

- Niu, C.; Yuan, J.; Xu, Z. A Compact Folded RFID Tag Antenna with Nested Deformable Rings for Two-side Anti-metal Application. Prog. Electromagn. Res. C 2022, 125, 191–200. [Google Scholar] [CrossRef]

- Zhao, W. A Novel Ultra High Frequency Flexible Anti-Metal Tag Antenna Design. World Sci. Res. J. 2019, 5, 69–74. [Google Scholar]

- Hebrard, Y.; Bastard, G.; Lhommeau, T. A Wireless and autonomous sensor for Integrated Engine Health Management. In Proceedings of the PHM Society European Conference, Utrecht, The Netherlands, 3–6 July 2018; Volume 4. [Google Scholar]

- Xu, Y.; Dong, L.; Wang, H.; Xie, X.; Wang, P. Surface crack detection and monitoring in metal structure using RFID tag. Sens. Rev. 2020, 40, 81–88. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, K. Design of an UHF RFID anti-metal tag antenna. Int. Core J. Eng. 2020, 6, 309–317. [Google Scholar]

| Criteria | Type |

|---|---|

| The document is not related to an application of a RFID tag in a metallic surface | Exclusion |

| The document is duplicated | Exclusion |

| The document is not in the selected year range (2006–2023 for articles and 2002–2023 for patents). | Exclusion |

| The document is not available online | Exclusion |

| The document is related to an application of a RFID tag on a metallic surface | Inclusion |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, E.; Júnior, S.; Silva, L.F.V.; Batista, M.; Santos, E.; Araújo, Í.; Araújo, J.; Barboza, E.; Gomes, F.; Fraga, I.T.; et al. RFID Tags for On-Metal Applications: A Brief Survey. Technologies 2024, 12, 58. https://doi.org/10.3390/technologies12050058

Pereira E, Júnior S, Silva LFV, Batista M, Santos E, Araújo Í, Araújo J, Barboza E, Gomes F, Fraga IT, et al. RFID Tags for On-Metal Applications: A Brief Survey. Technologies. 2024; 12(5):58. https://doi.org/10.3390/technologies12050058

Chicago/Turabian StylePereira, Emanuel, Sandoval Júnior, Luís Felipe Vieira Silva, Mateus Batista, Eliel Santos, Ícaro Araújo, Jobson Araújo, Erick Barboza, Francisco Gomes, Ismael Trindade Fraga, and et al. 2024. "RFID Tags for On-Metal Applications: A Brief Survey" Technologies 12, no. 5: 58. https://doi.org/10.3390/technologies12050058

APA StylePereira, E., Júnior, S., Silva, L. F. V., Batista, M., Santos, E., Araújo, Í., Araújo, J., Barboza, E., Gomes, F., Fraga, I. T., Dos Santos, D. O., & Davanso, R. (2024). RFID Tags for On-Metal Applications: A Brief Survey. Technologies, 12(5), 58. https://doi.org/10.3390/technologies12050058