A Kinetic Study of a Photo-Oxidation Reaction between α-Terpinene and Singlet Oxygen in a Novel Oscillatory Baffled Photo Reactor

Abstract

1. Introduction

2. The Reaction Scheme and Experimental Set Up

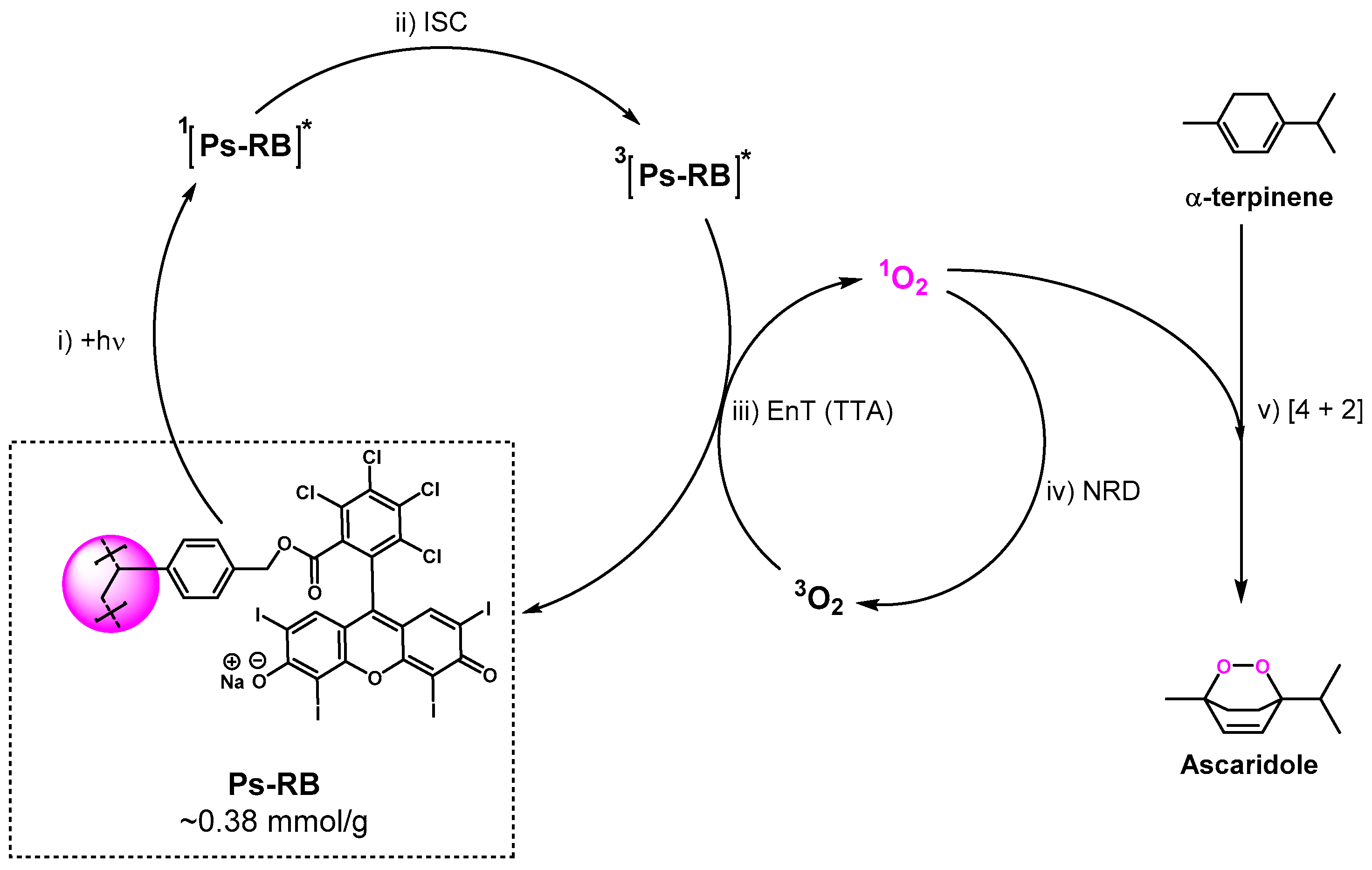

2.1. Reaction Scheme

2.2. Materials

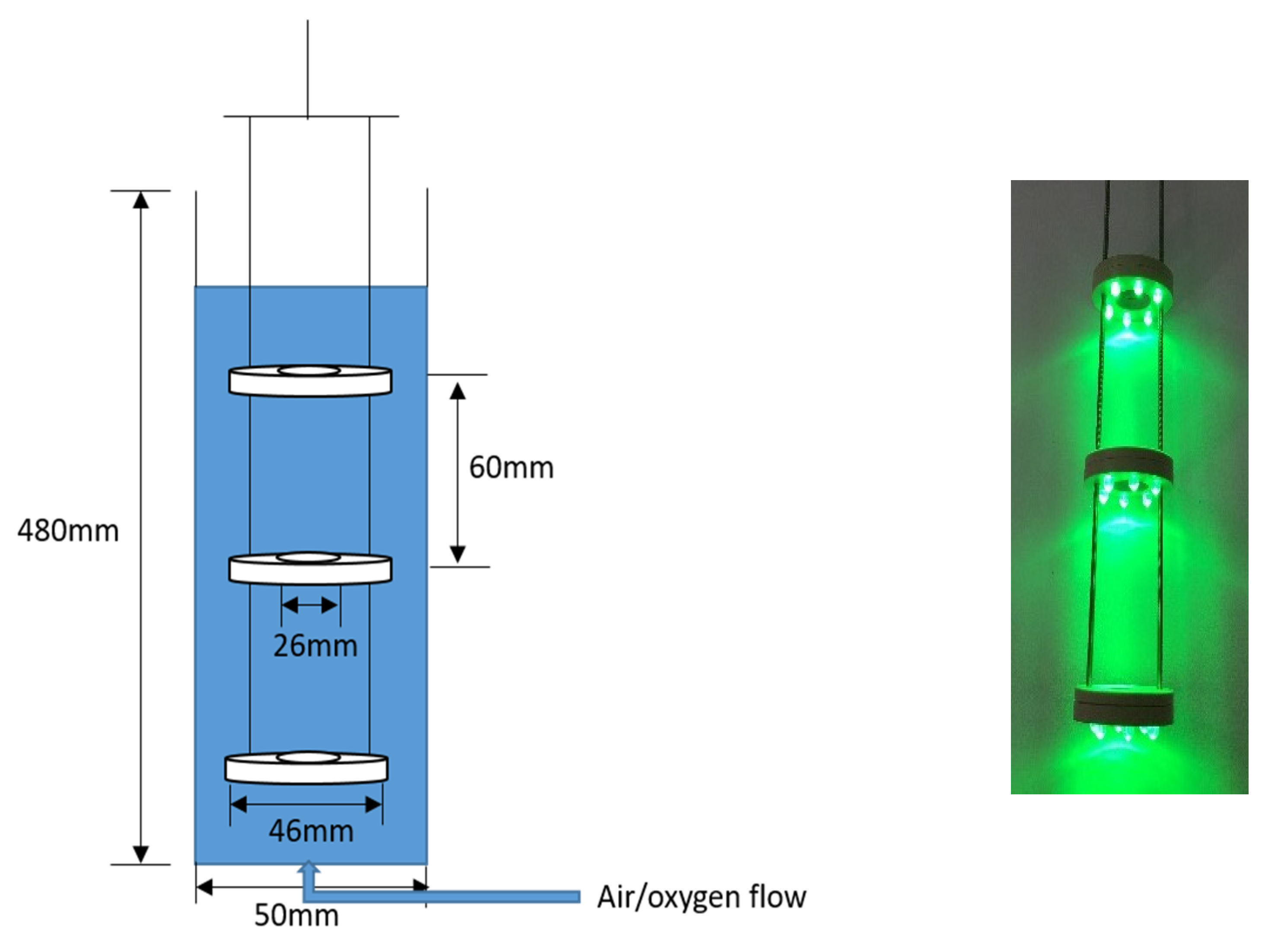

2.3. Reactor Setup

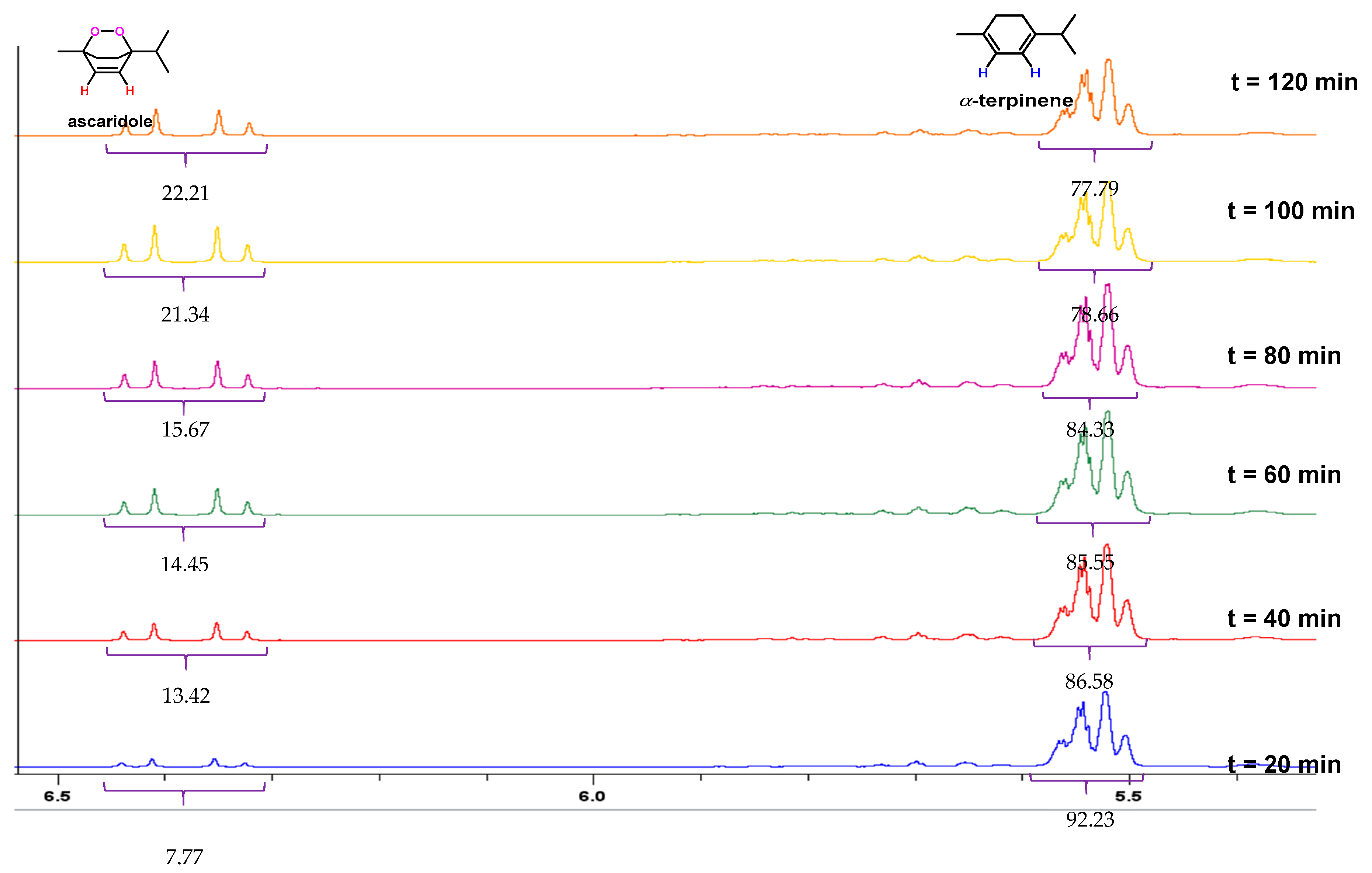

2.4. Analytic Method

- Each 2 mL sample containing CHCl3 + α-terpinene + ascaridole was injected into a dark vial to stop the reaction (reaction stops when light is off);

- The sample was placed in a round-bottom flask and the solvent (CHCl3) was removed under reduced pressure on a rotary evaporator (40 °C, 365 mbar for ~5 min);

- The oily residue was dissolved in 0.5 mL of deuterated chloroform (CDCl3) and a 1H NMR was obtained (300 MHz Bruker AVIII spectrometer);

- Peaks in the region between 6.70 and 5.40 ppm were used to determine the conversion of α-terpinene and the appearance of ascaridole.

3. Results and Discussion

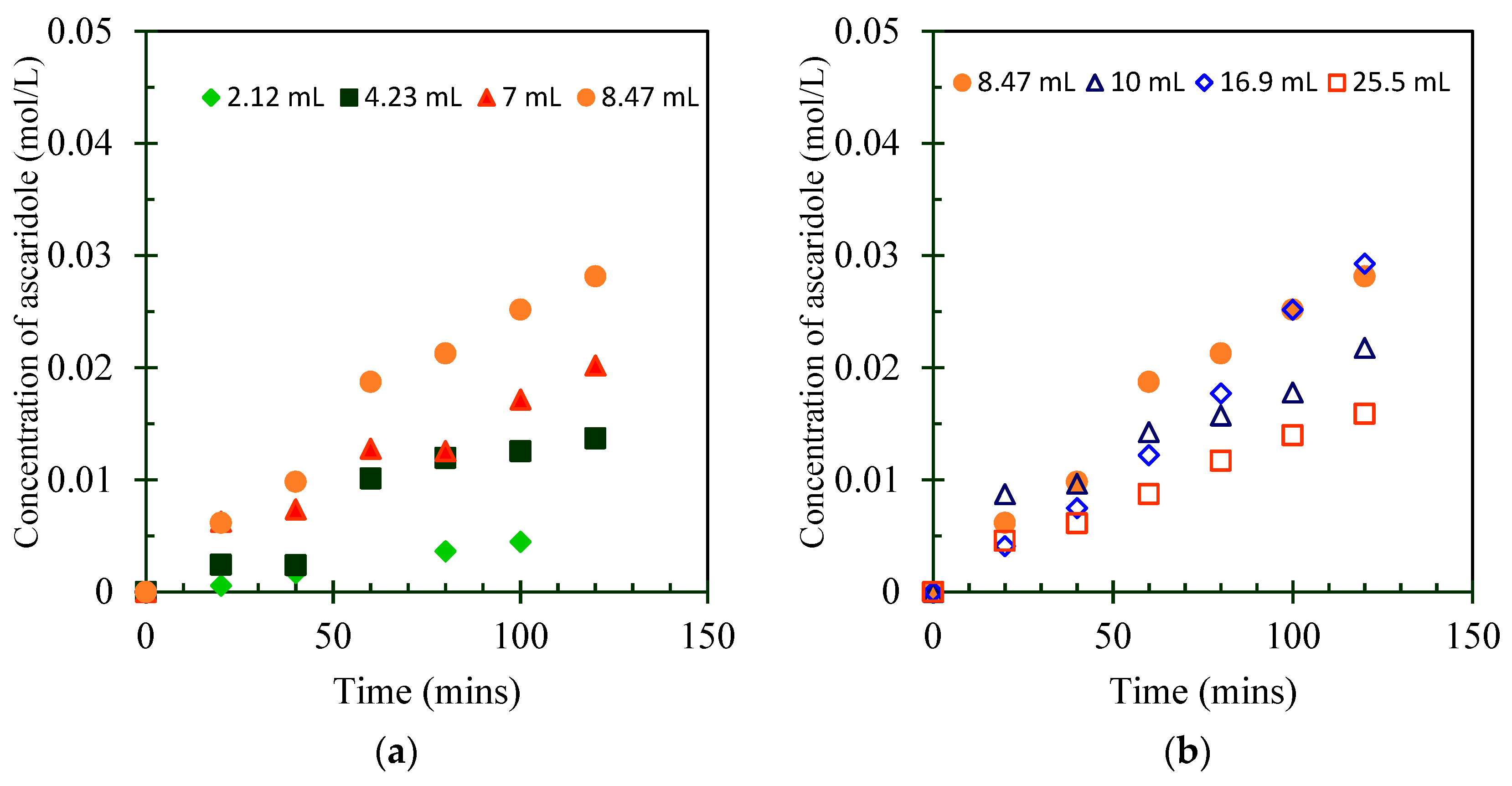

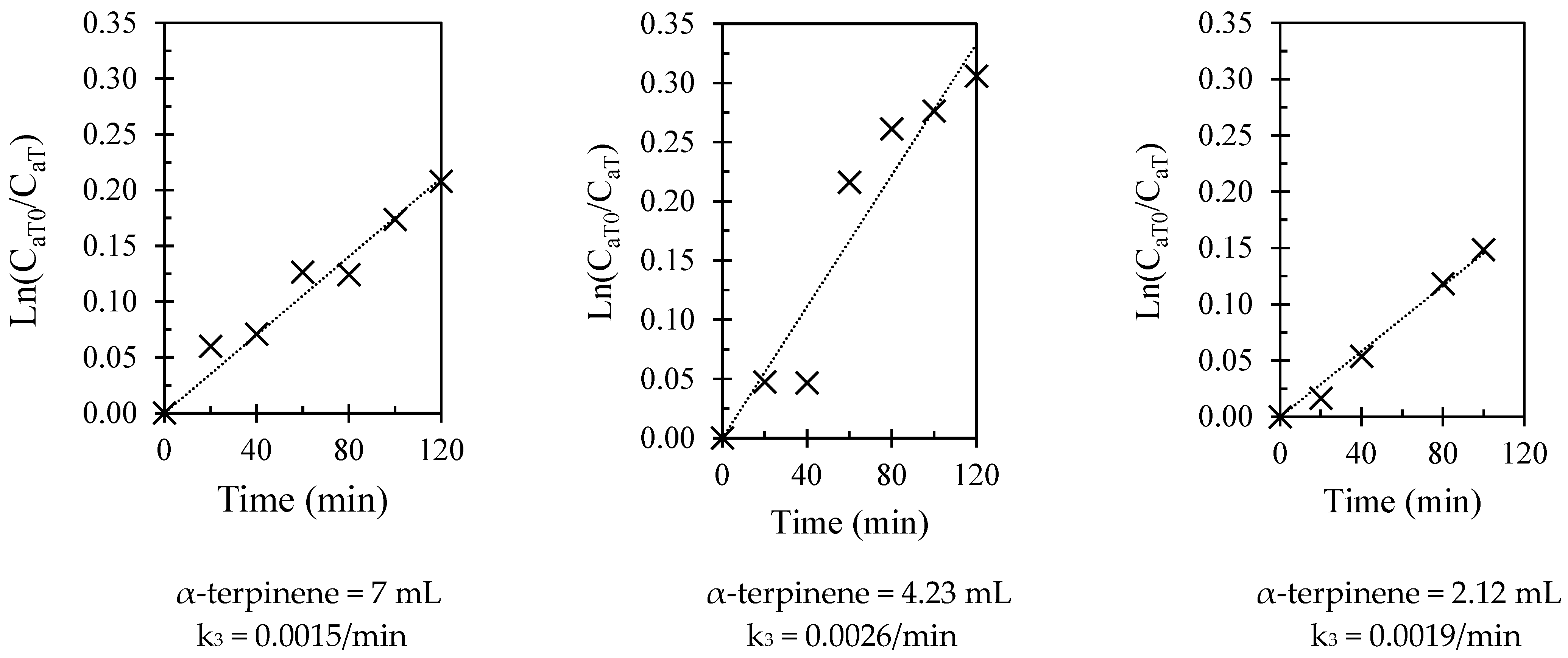

3.1. Kinetic Assessment

| α-Terpinene (mL) | Efficiency of 1O2 Utilization (%) | Efficiency of Photo Conversion (%) | Apparent Quantum Yield (%) |

|---|---|---|---|

| 7 | 10.7 | 0.10 | 87 |

| 4.23 | 14.6 | 0.07 | 57 |

| 2.12 | 4.9 | 0.06 | 19 |

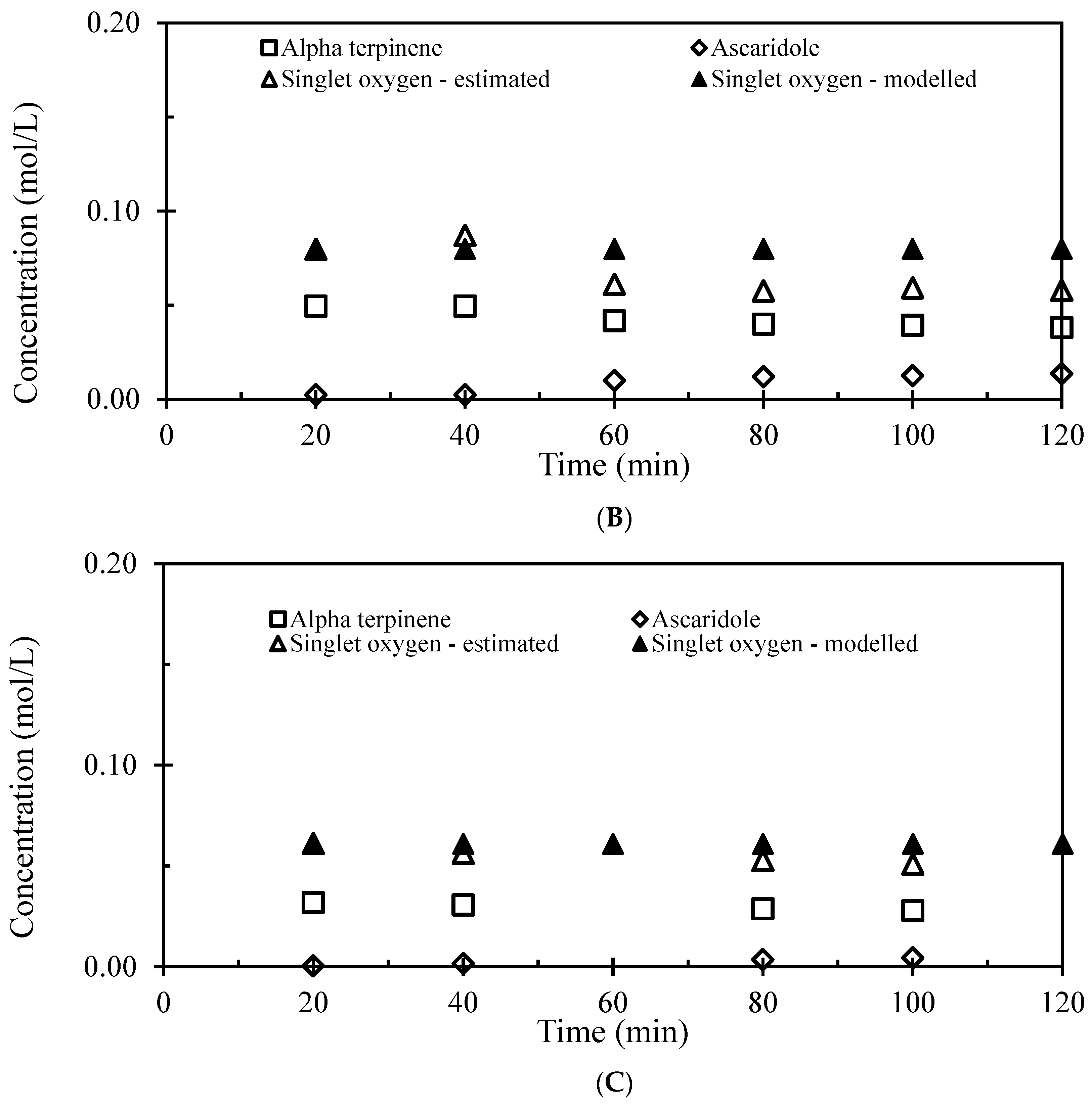

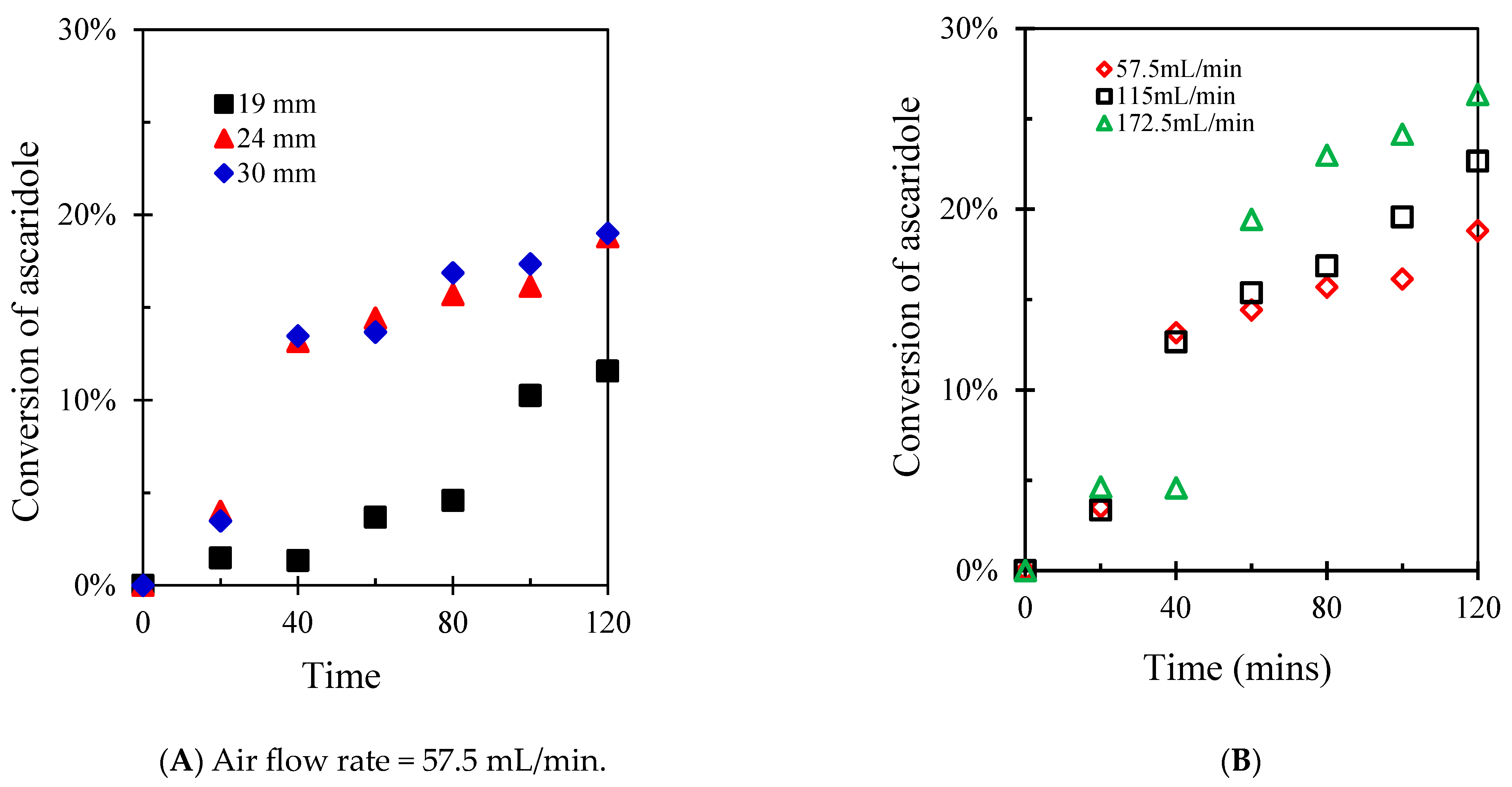

3.2. The First Step of the Reaction

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Areaas | integrated NMR area of ascaridole |

| AreaαT | integrated NMR area of α-terpinene |

| Cas | concentration of ascaridole (mol L−1) |

| CαT | concentration of α-terpinene (mol L−1) |

| D | tube diameter (m) |

| f | oscillation frequency (Hz) |

| Reo | oscillatory Reynolds number |

| St | Strouhal number |

| xo | oscillatory center-to-peak amplitude (m) |

| ρ | density (kg m−3) |

References

- Buglioni, L.; Raymenants, F.; Slattery, A.; Zondag, S.D.A.; Noël, T. Technological innovations in photochemistry for organic synthesis: Flow chemistry, high-throughput experimentation, scale-up, and photoelectrochemistry. Chem. Rev. 2021, 122, 2752–2906. [Google Scholar] [CrossRef]

- Ronzani, F.; Costarramone, N.; Blanc, S.; Benabbou, A.K.; Bechec, M.L.; Pigot, T.; Oelgemöller, M.; Lacombe, S. Visible-light photosensitized oxidation of α-terpinene using novel silica-supported sensitizers: Photooxygenation vs. photodehydrogenation. J. Catal. 2013, 303, 164–174. [Google Scholar] [CrossRef]

- Baptista, M.S.; Cadet, J.; Mascio, P.D.; Ghogare, A.A.; Greer, A.; Hamblin, M.R.; Lorente, C.; Nunez, S.C.; Ribeiro, M.S.; Thomas, A.H.; et al. Type I and type II photosensitized oxidation reactions: Guidelines and mechanistic pathways. Photochem. Photobiol. 2017, 93, 912–919. [Google Scholar] [CrossRef]

- Zondag, S.D.A.; Mazzarella, D.; Noël, T. Scale-Up of Photochemical Reactions: Transitioning from Lab Scale to Industrial Production. Annu. Rev. Chem. Biomol. Eng. 2023, 14, 283–300. [Google Scholar] [CrossRef]

- Kayahan, E.; Jacobs, M.; Braeken, L.; Thomassen, L.C.J.; Kuhn, S.; Gerven, T.V.; Leblebici, M.E. Dawn of a new era in industrial photochemistry: The scale-up of micro-and mesostructured photoreactors. Beilstein J. Org. Chem. 2020, 16, 2484–2504. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Kuijpers, K.P.L.; Hendrix, R.B.J.; Shivaprasad, P.; Hacking, J.A.; Emanuelsson, E.A.C.; Noël, T.; Schaaf, J.V.D. A kinetic study of a photo-oxidation reaction between α-terpinene and singlet oxygen in a novel oscillatory baffled photo reactor. Chem. Eng. J. 2020, 400. [Google Scholar]

- Donnelly, K.; Baumann, M. Scalability of photochemical reactions in continuous flow model. J. Flow Chem. 2021, 11, 223–241. [Google Scholar] [CrossRef]

- Lee, D.S.; Amara, Z.; Clark, C.A.; Xu, Z.; Kakimpa, B.; Morvan, H.P.; Pickering, T.J.; Poliakoff, M.; George, M.W. Continuous photo-oxidation in a vortex reactor: Efficient operations using air drawn from the laboratory. Org. Process Res. Dev. 2017, 21, 1042–1050. [Google Scholar] [CrossRef]

- Tobin, J.M.; Liu, J.; Hayes, H.; Demleitner, M.; Ellis, D.; Arrighi, V.; Xu, Z.; Vilela, F. BODIPY-based conjugated microporous polymers as reusable heterogeneous photosensitisers in a photochemical flow reactor. Polym. Chem. 2016, 7, 6662–6670. [Google Scholar] [CrossRef]

- Shvydkiv, O.; Jähnisch, K.; Steinfeldt, N.; Yavorskyy, A.; Oelgemöller, M. Visible-light photooxygenation of α-terpinene in a falling film microreactor. Catal. Today 2018, 308, 102–118. [Google Scholar] [CrossRef]

- Dong, Z.; Wen, Z.; Zhao, F.; Kuhn, S.; Noël, T. Scale-up of micro-and milli-reactors: An overview of strategies, design principles and applications. Chem. Eng. Sci. X 2021, 10, 100097. [Google Scholar] [CrossRef]

- Su, Y.; Kuijpers, K.; Hessela, V.; Noël, T. A convenient numbering-up strategy for the scale-up of gas–liquid photoredox catalysis in flow. React. Chem. Eng. 2016, 1, 73–81. [Google Scholar] [CrossRef]

- Kuijpers, K.P.L.; van Dijk, M.A.H.; Rumeur, Q.G.; Hessel, V.; Su, Y.; Noël, T. A sensitivity analysis of a numbered-up photomicroreactor system. React. Chem. Eng. 2017, 2, 109–115. [Google Scholar] [CrossRef]

- Moschetta, E.G.; Richter, S.M.; Wittenberger, S.J. Heuristics, protocol, and considerations for flow chemistry in photoredox catalysis. ChemPhotoChem 2017, 1, 539–543. [Google Scholar] [CrossRef]

- Taylor, G.I. Conditions under which dispersion of a solute in a stream of solvent can be used to measure molecular diffusion. R. Soc. 1954, 225, 473–477. [Google Scholar]

- Taylor, G.I. Dispersion of soluble matter in solvent flowing slowly through a tube. R. Soc. 1953, 219, 186–203. [Google Scholar]

- Ni, X. Photo reactor in WO2022013348A1, 2022. (Patent). Available online: https://data.epo.org/gpi/EP4182069A1-PHOTO-REACTOR (accessed on 15 January 2024).

- Mackley, M.R.; Ni, X. Mixing and dispersion in a baffled tube for steady laminar and pulsatile flow. Chem. Eng. Sci. 1991, 46, 3139–3151. [Google Scholar] [CrossRef]

- Ni, X.; Jian, H.; Fitch, A.W. Computational fluid dynamic modelling of flow patterns in an oscillatory baffled column. Chem. Eng. Sci. 2002, 57, 2849–2862. [Google Scholar] [CrossRef]

- Ni, X.; Mackley, M.R.; Harvey, A.P.; Stonestreet, P.; Baird, M.H.I.; Rao, N.V.R. Mixing through oscillations and pulsations—A guide to achieving process enhancements in the chemical and process industries. Chem. Eng. Res. Des. 2003, 81, 373–383. [Google Scholar] [CrossRef]

- Dickens, A.W.; Mackley, M.R.; Williams, H.R. Experimental residence time distribution measurements for unsteady flow in baffled tubes. Chem. Eng. Sci. 1989, 44, 1471–1479. [Google Scholar] [CrossRef]

- Jian, H.; Ni, X. A numerical study on the scale-up behaviour in oscillatory baffled columns. Chem. Eng. Res. Des. 2005, 83, 1163–1170. [Google Scholar] [CrossRef]

- Ni, X.; Gélicourt, Y.S.; Neil, J.; Howes, T. On the effect of tracer density on axial dispersion in a batch oscillatory baffled column. Chem. Eng. J. 2002, 85, 17–25. [Google Scholar] [CrossRef]

- Jimeno, G.; Lee, Y.C.; Ni, X. The effect of particle size on flow in a continuous oscillatory baffled reactor using CFD. Can. J. Chem. Eng. 2021, 100, S258–S271. [Google Scholar] [CrossRef]

- Jiang, M.; Ni, X. Reactive crystallization of paracetamol in a continuous oscillatory baffled reactor. Org. Process Res. Dev. 2019, 23, 882–890. [Google Scholar] [CrossRef]

- NiTech. Available online: www.nitechsolutions.co.uk (accessed on 15 January 2024).

- Burguete, M.I.; Galindo, F.; Gavara, R.; Luis, S.V.; Moreno, M.; Thomas, P.; Russell, D.A. Singlet oxygen generation using a porous monolithic polymer supported photosensitizer: Potential application to the photodynamic destruction of melanoma cells. Photochem. Photobiol. Sci. 2008, 8, 37–44. [Google Scholar] [CrossRef]

- Fabregat, V.; Burguete, M.I.; Galindo, F.; Luis, S.V. Singlet oxygen generation by photoactive polymeric microparticles with enhanced aqueous compatibility. Environ. Sci. Pollut. Res. 2013, 21, 11884–11892. [Google Scholar] [CrossRef]

- Aubry, J.M.; Mandard-Cazin, B.; Rougee, M.; Bensasson, R.V. Kinetic studies of singlet oxygen [4 + 2]-cycloadditions with cyclic 1, 3-dienes in 28 solvents. J. Am. Chem. Soc. 1995, 117, 9159–9164. [Google Scholar] [CrossRef]

- Adam, W.; Prein, M. Diastereoselective [4 + 2] cycloaddition of singlet oxygen in the photooxygenation of chiral naphthyl alcohols: Evidence for a hydroxy group-directing effect. J. Am. Chem. Soc. 1993, 115, 3766–3767. [Google Scholar] [CrossRef]

- Bauch, M.; Fudickar, W.; Linker, T. tereoselective [4 + 2] cycloaddition of singlet oxygen to naphthalenes controlled by carbohydrates. Molecules 2021, 26, 804. [Google Scholar] [CrossRef]

- Ghogare, A.A.; Greer, G. Using singlet oxygen to synthesize natural products and drugs. Chem. Rev. 2016, 116, 9994–10034. [Google Scholar] [CrossRef]

- Villén, L.; Manjón, F.; García-Fresnadillo, D.; Orellana, G. Solar water disinfection by photocatalytic singlet oxygen production in heterogeneous medium. Appl. Catal. B Environ. 2006, 69, 1–9. [Google Scholar] [CrossRef]

- Rodgers, M.A.J. NATO ASI Series A; Life Sciences; LENUM Publishing Corporation: New York, NY, USA, 1984; Volume 85. [Google Scholar]

- Ogilby, P.R.; Foote, C.S. Chemistry of singlet oxygen. 42. Effect of solvent, solvent isotopic substitution, and temperature on the lifetime of singlet molecular oxygen (1. DELTA. g). J. Am. Chem. Soc. 1983, 105, 3423–3430. [Google Scholar] [CrossRef]

- Gianotti, E.; Estevão, B.M.; Cucinotta, F.; Hioka, N.; Rizzi, M.; Renò, F.; Marchese, L. An Efficient Rose Bengal Based Nanoplatform for Photodynamic Therapy. Chem. Eur. J. 2014, 20, 10921–10925; [Google Scholar] [CrossRef] [PubMed]

- Whitmire, C. Photosensitizers: Types, Uses and Selected Research; Nova Science Publishers: Hauppauge, NY, USA, 2016. [Google Scholar]

- Deshpande, M.S.; Rale, V.B.; Lynch, J.M. Aureobasidium pullulans in applied microbiology: A status report. Enzym. Microb. Technol. 1992, 14, 514–527. [Google Scholar] [CrossRef]

- Wong, Y.L.; Tobin, J.M.; Xua, Z.; Vilela, F. Conjugated porous polymers for photocatalytic applications. J. Mater. Chem. A 2016, 4, 18677–18686. [Google Scholar] [CrossRef]

- Zhang, K.; Kopetzki, D.; Seeberger, P.H.; Antonietti, M.; Vilela, F. Surface area control and photocatalytic activity of conjugated microporous poly (benzothiadiazole) networks. Angew. Chem. Int. Ed. Engl. 2013, 52, 1432–1436. [Google Scholar] [CrossRef]

- Elvira, K.S.; Wootton, R.C.R.; Reis, N.M.; Mackley, M.R.; de Mello, A.J. Through-wall mass transport as a modality for safe generation of singlet oxygen in continuous flows. ACS Sustain. Chem. Eng. 2013, 1, 209–213. [Google Scholar] [CrossRef]

- Shen, J.; Steinbach, R.R.; Tobin, J.; Nakata, M.M.; Bower, M.; McCoustra, M.R.S.; Bridle, H.; Arrighi, V.; Vilela, F. Photoactive and metal-free polyamide-based polymers for water and wastewater treatment under visible light irradiation. Appl. Catal. B Environ. 2016, 193, 226–233. [Google Scholar] [CrossRef]

- Thomson, C.G.; Jones, C.M.S.; Rosair, G.; Ellis, D.D.; Hueso, J.M.; Lee, A.L.; Vilela, F. Continuous-flow synthesis and application of polymer-supported BODIPY Photosensitisers for the generation of singlet oxygen; process optimised by in-line NMR spectroscopy. J. Flow Chem. 2020, 10, 327–345. [Google Scholar] [CrossRef]

- Hoops, S.; Sahle, S.; Gauges, R.; Lee, C.; Pahle, J.; Simus, N.; Singhal, M.; Xu, L.; Mendes, P.; Kummer, U. COPASI—A complex pathway simulator. Bioinformatics 2006, 22, 3067–3074. [Google Scholar] [CrossRef]

- Alofi, S.; O’Rourke, C.; Mills, A. Kinetics of stearic acid destruction on TiO2 ‘self-cleaning’films revisited. Photochem. Photobiol. Sci. 2022, 21, 2061–2069. [Google Scholar] [CrossRef]

- Luke, L.V.; Rickenbach, S.S.; McCormick, T.M. Singlet oxygen quantum yields determined by oxygen consumption. J. Photochem. Photobiol. A Chem. 2019, 378, 131–135. [Google Scholar]

- Erickson, P.R.; Moor, K.J.; Werner, J.J.; Latch, D.E.; Arnold, W.A.; McNeill, K. Singlet oxygen phosphorescence as a probe for triplet-state dissolved organic matter reactivity. Environ. Sci. Technol. 2018, 52, 9170–9178. [Google Scholar] [CrossRef]

- Hockey, R.M.; Nouri, J.M. Turbulent flow in a baffled vessel stirred by a 60 pitched blade impeller. Chem. Eng. Sci. 1996, 51, 4405–4421. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, W.; Suna, J.; Guo, S. Triplet photosensitizers: From molecular design to applications. Chem. Soc. Rev. 2013, 42, 5323–5351. [Google Scholar] [CrossRef]

- Midden, W.R.; Wang, S.Y. Singlet oxygen generation for solution kinetics: Clean and simple. Am. Chem. Soc. 1983, 105, 4129–4135. [Google Scholar] [CrossRef]

- Sunday, M.O.; Sakugawa, H. A simple, inexpensive method for gas-phase singlet oxygen generation from sensitizer-impregnated filters: Potential application to bacteria/virus inactivation and pollutant degradation. Sci. Total Environ. 2020, 746, 141186. [Google Scholar] [CrossRef]

- Oliveira, M.S.N.; Ni, X. Characterization of a gas-liquid OBC: Bubble size and gas holdup. AIChE J. 2004, 50, 3019–3033. [Google Scholar] [CrossRef]

- Ahmed, S.M.R.; Phan, A.N.; Harvey, A.P. Scale-up of oscillatory helical baffled reactors based on residence time distribution. Chem. Eng. Technol. 2017, 40, 907–914. [Google Scholar] [CrossRef]

| Run Number | Chloroform (mL) | α-Terpinene (mL) | Number of Repeated Runs |

|---|---|---|---|

| 1 | 397.88 | 2.12 | 1 |

| 2 | 395.77 | 4.23 (default) | 2 |

| 3 | 393.00 | 7.00 | 2 |

| 4 | 391.53 | 8.47 | 3 |

| 5 | 390.00 | 10.00 | 2 |

| 6 | 383.10 | 16.90 | 2 |

| 7 | 374.50 | 25.50 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Prinsloo, R.; Ni, X. A Kinetic Study of a Photo-Oxidation Reaction between α-Terpinene and Singlet Oxygen in a Novel Oscillatory Baffled Photo Reactor. Technologies 2024, 12, 29. https://doi.org/10.3390/technologies12030029

Chen J, Prinsloo R, Ni X. A Kinetic Study of a Photo-Oxidation Reaction between α-Terpinene and Singlet Oxygen in a Novel Oscillatory Baffled Photo Reactor. Technologies. 2024; 12(3):29. https://doi.org/10.3390/technologies12030029

Chicago/Turabian StyleChen, Jianhan, Rohen Prinsloo, and Xiongwei Ni. 2024. "A Kinetic Study of a Photo-Oxidation Reaction between α-Terpinene and Singlet Oxygen in a Novel Oscillatory Baffled Photo Reactor" Technologies 12, no. 3: 29. https://doi.org/10.3390/technologies12030029

APA StyleChen, J., Prinsloo, R., & Ni, X. (2024). A Kinetic Study of a Photo-Oxidation Reaction between α-Terpinene and Singlet Oxygen in a Novel Oscillatory Baffled Photo Reactor. Technologies, 12(3), 29. https://doi.org/10.3390/technologies12030029