Energy Efficiency in Additive Manufacturing: Condensed Review

Abstract

1. Introduction

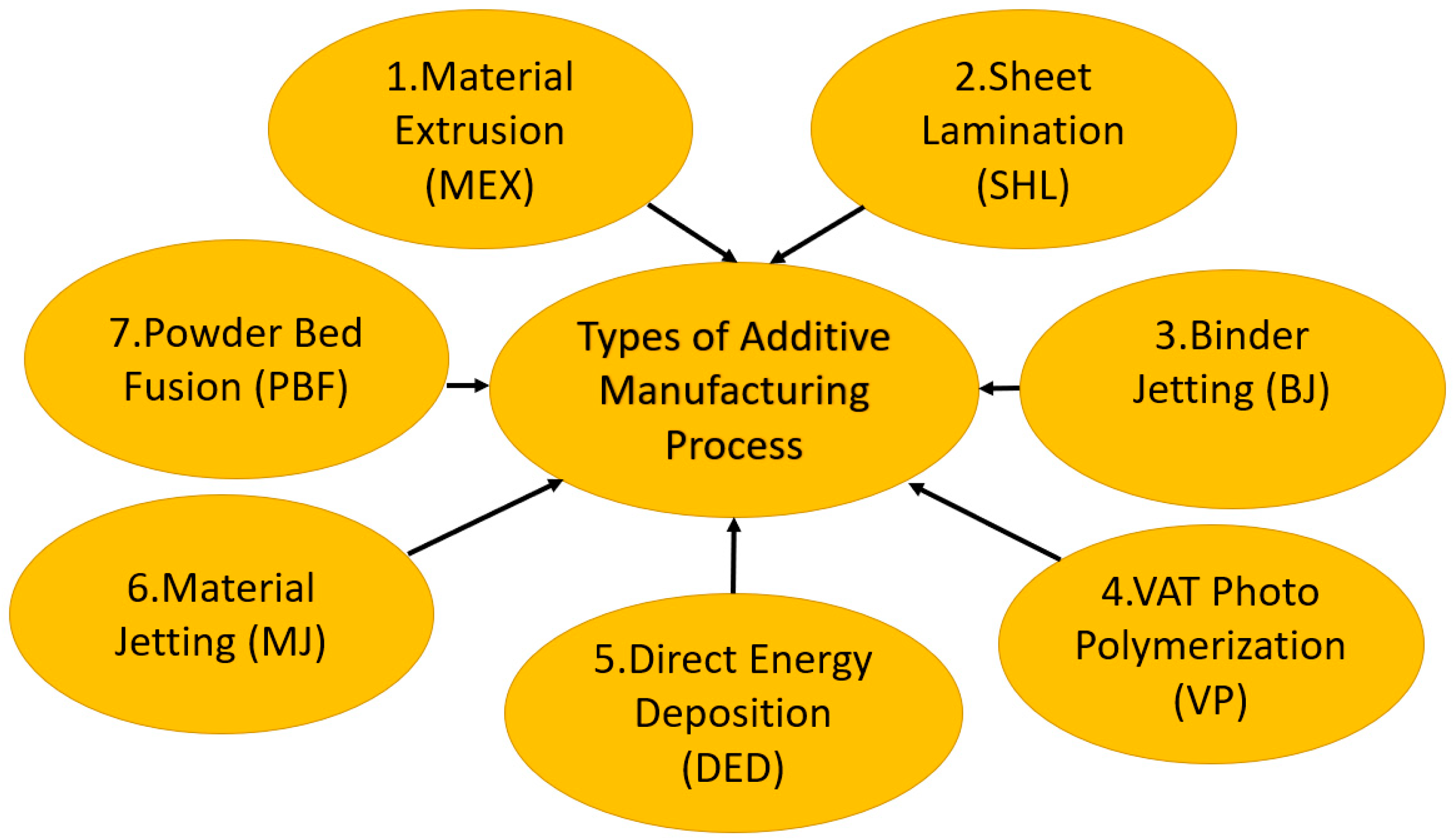

2. AM Processes

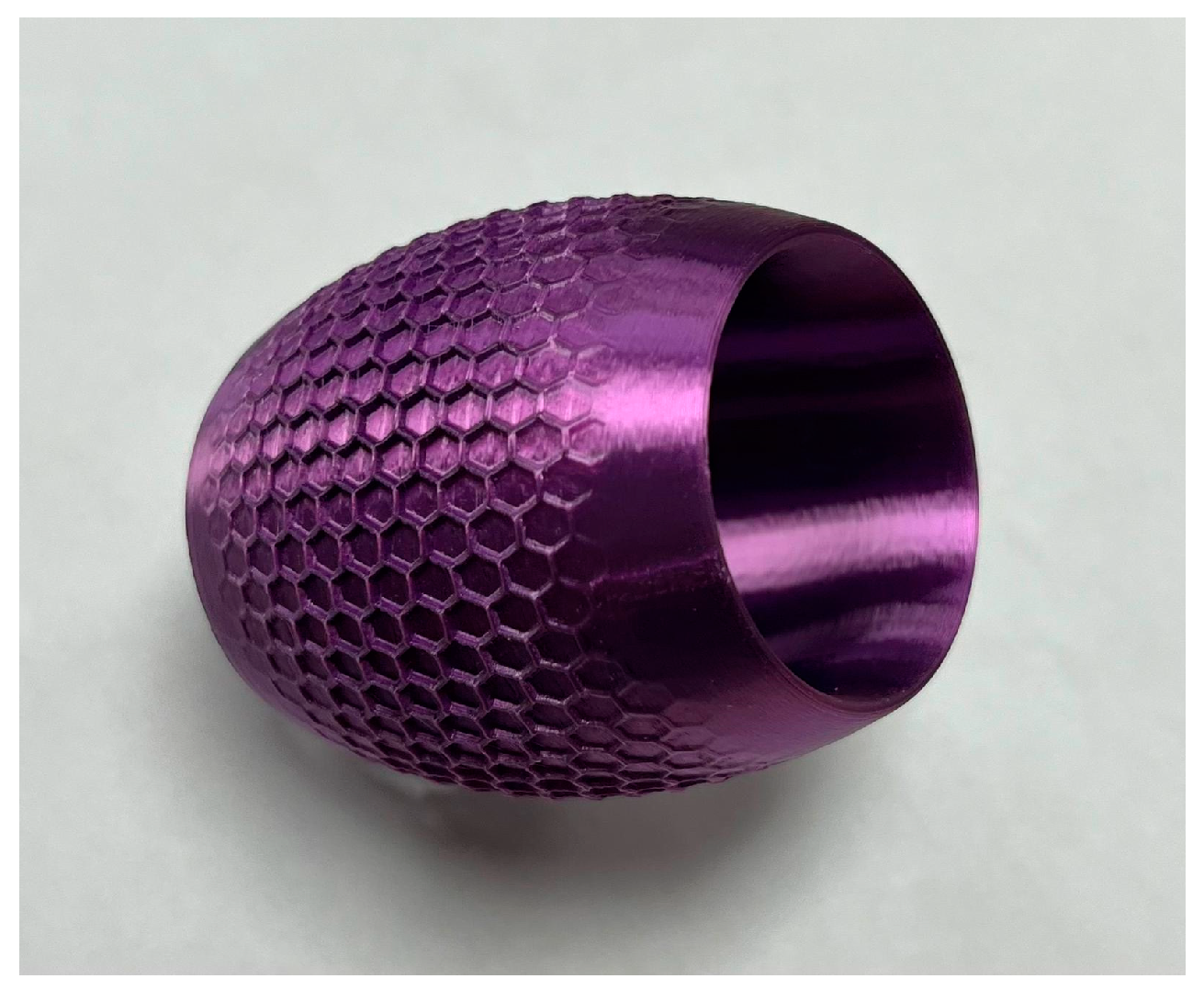

2.1. Material Extrusion (MEX)

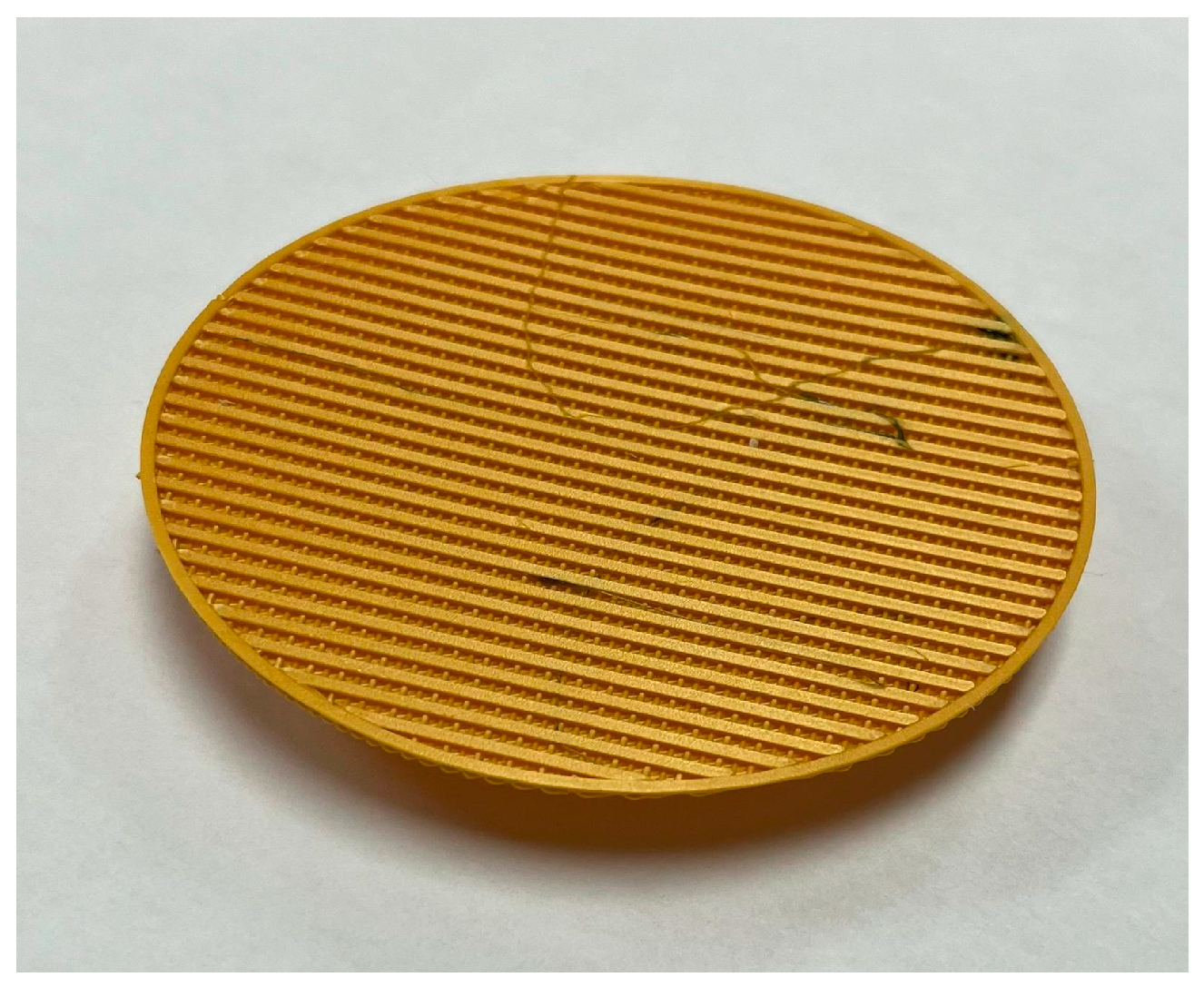

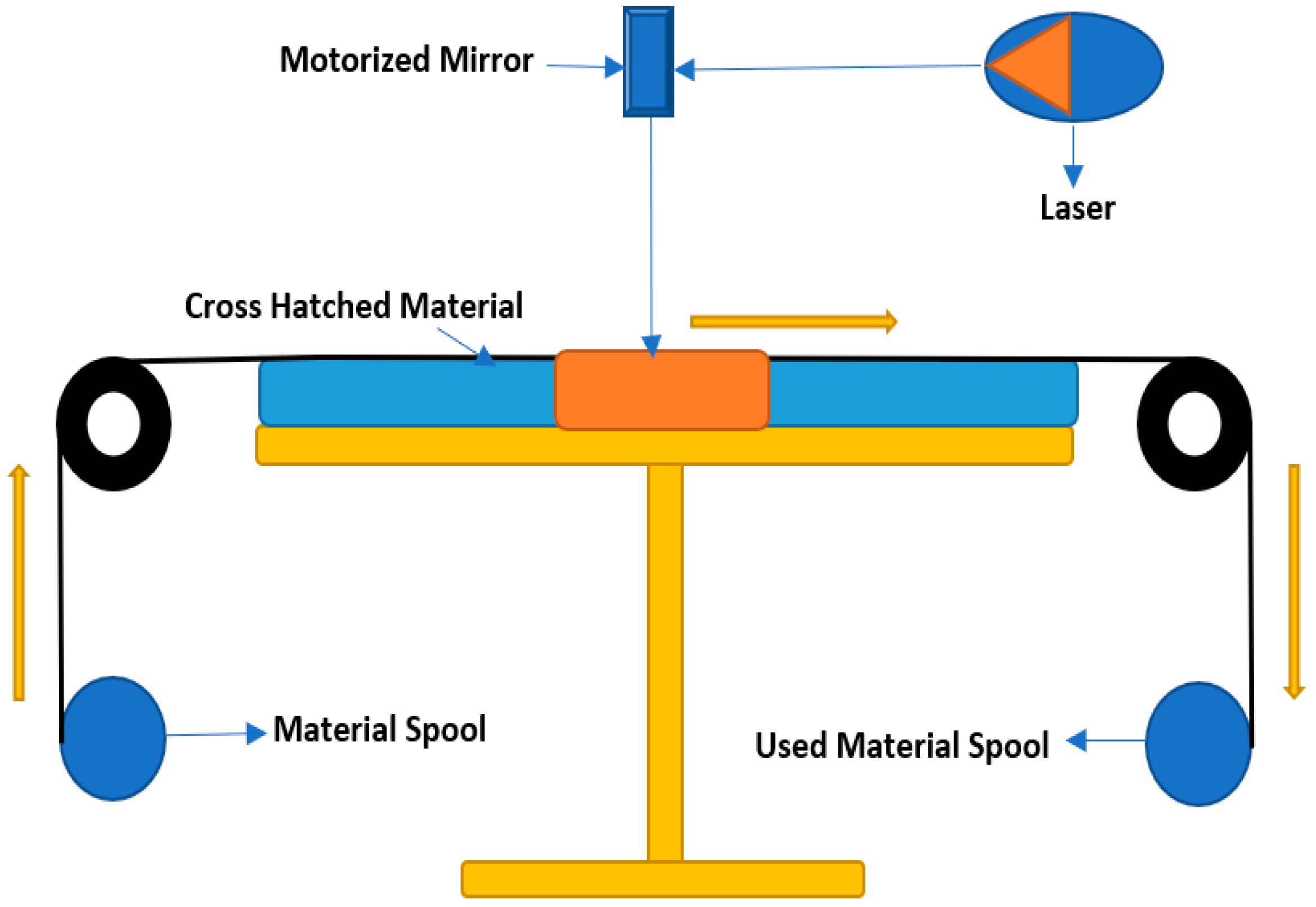

2.2. Sheet Lamination (SHL)

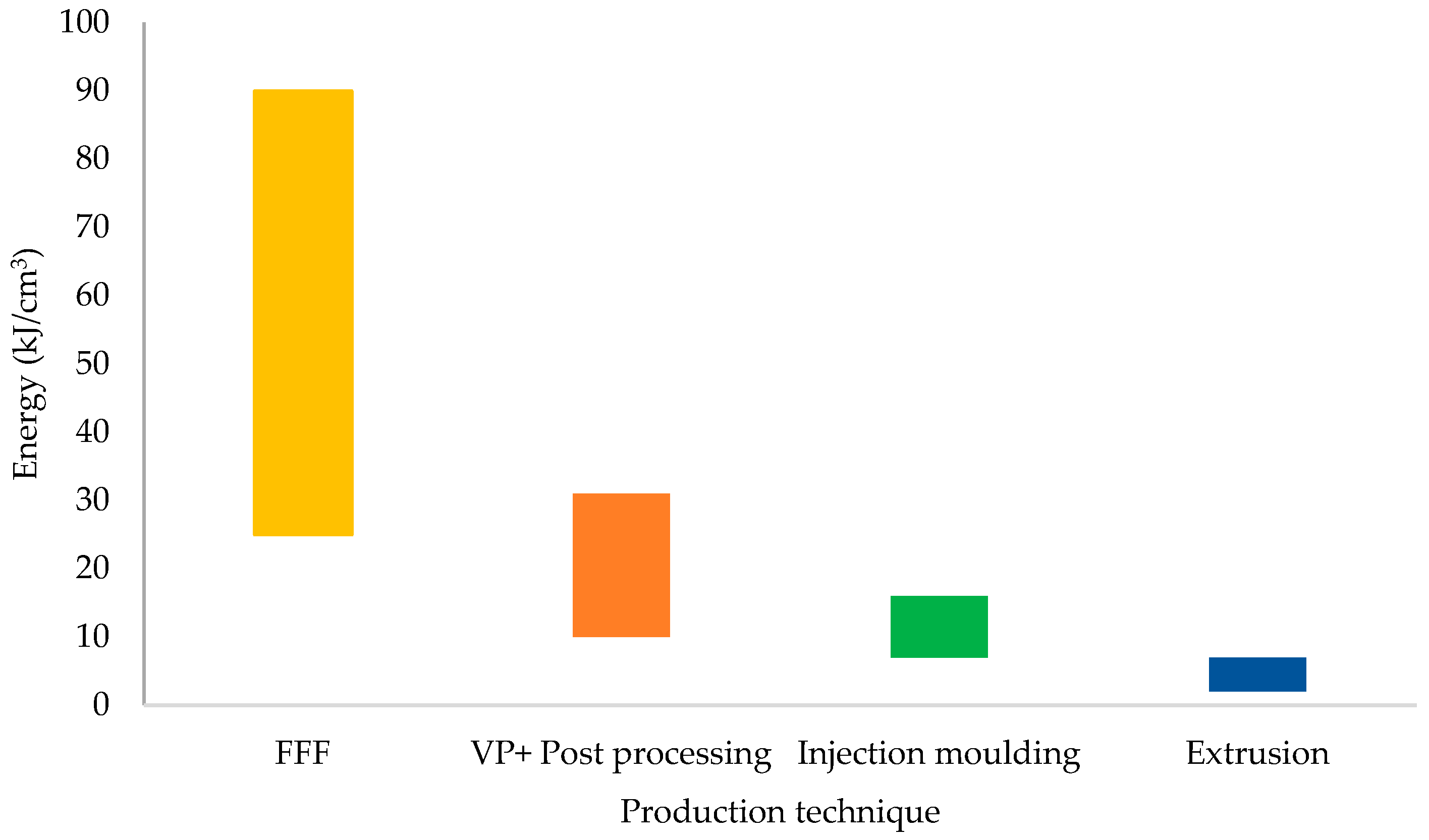

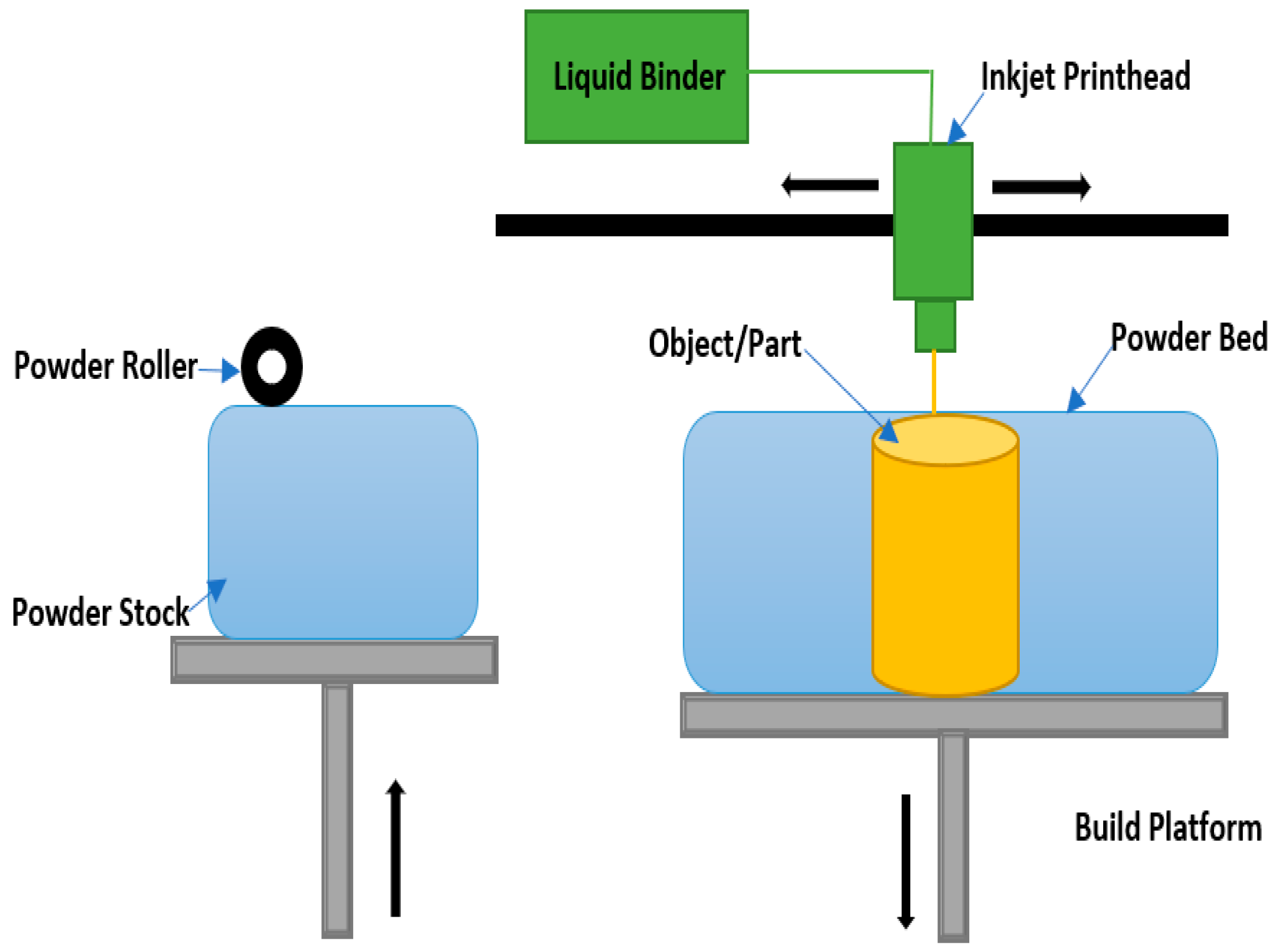

2.3. Binder Jetting (BJ)

2.4. VAT Photo Polymerization (VP)

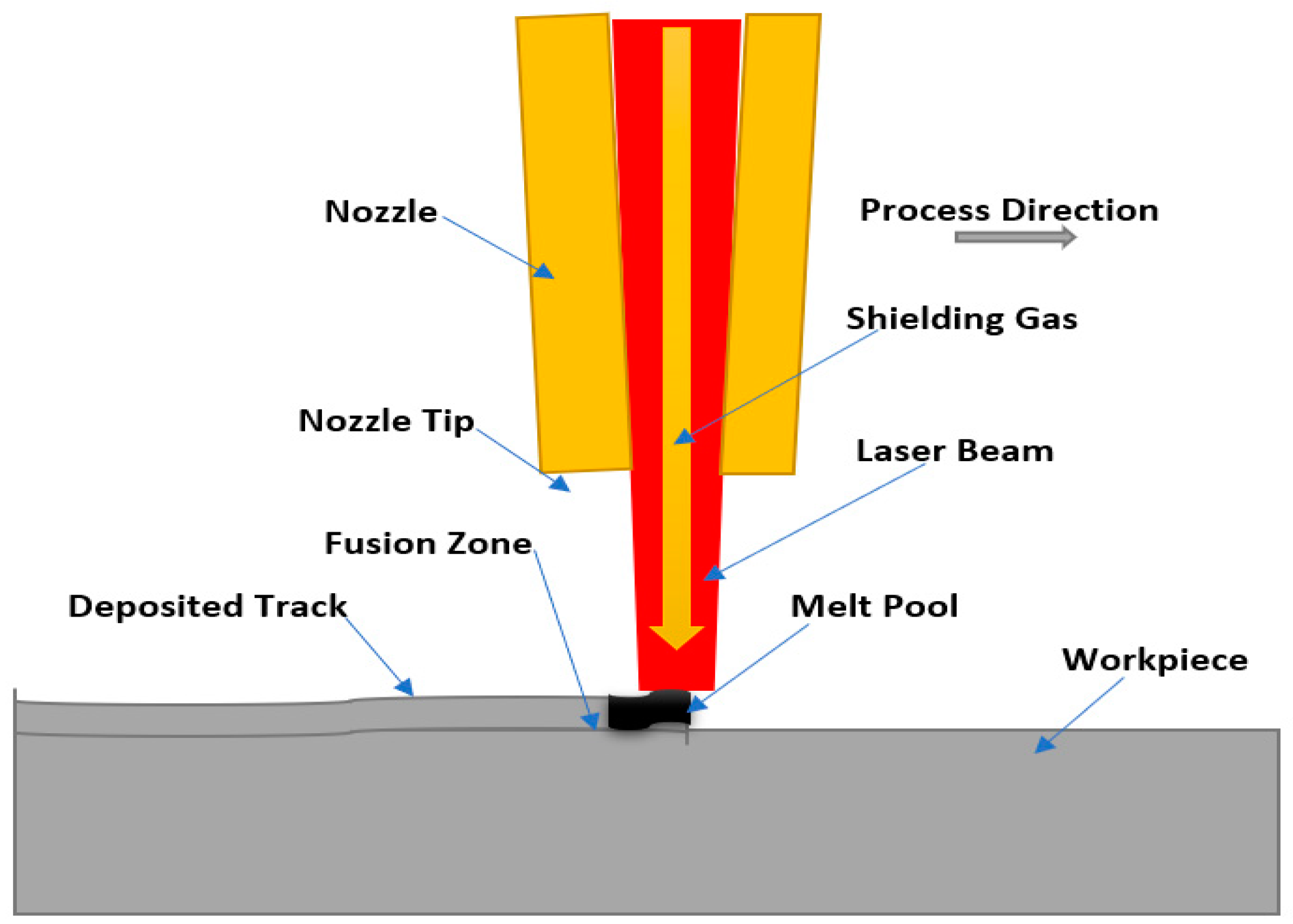

2.5. Direct Energy Deposition (DED)

2.6. Material Jetting (MJ)

2.7. Powder Bed Fusion (PBF)

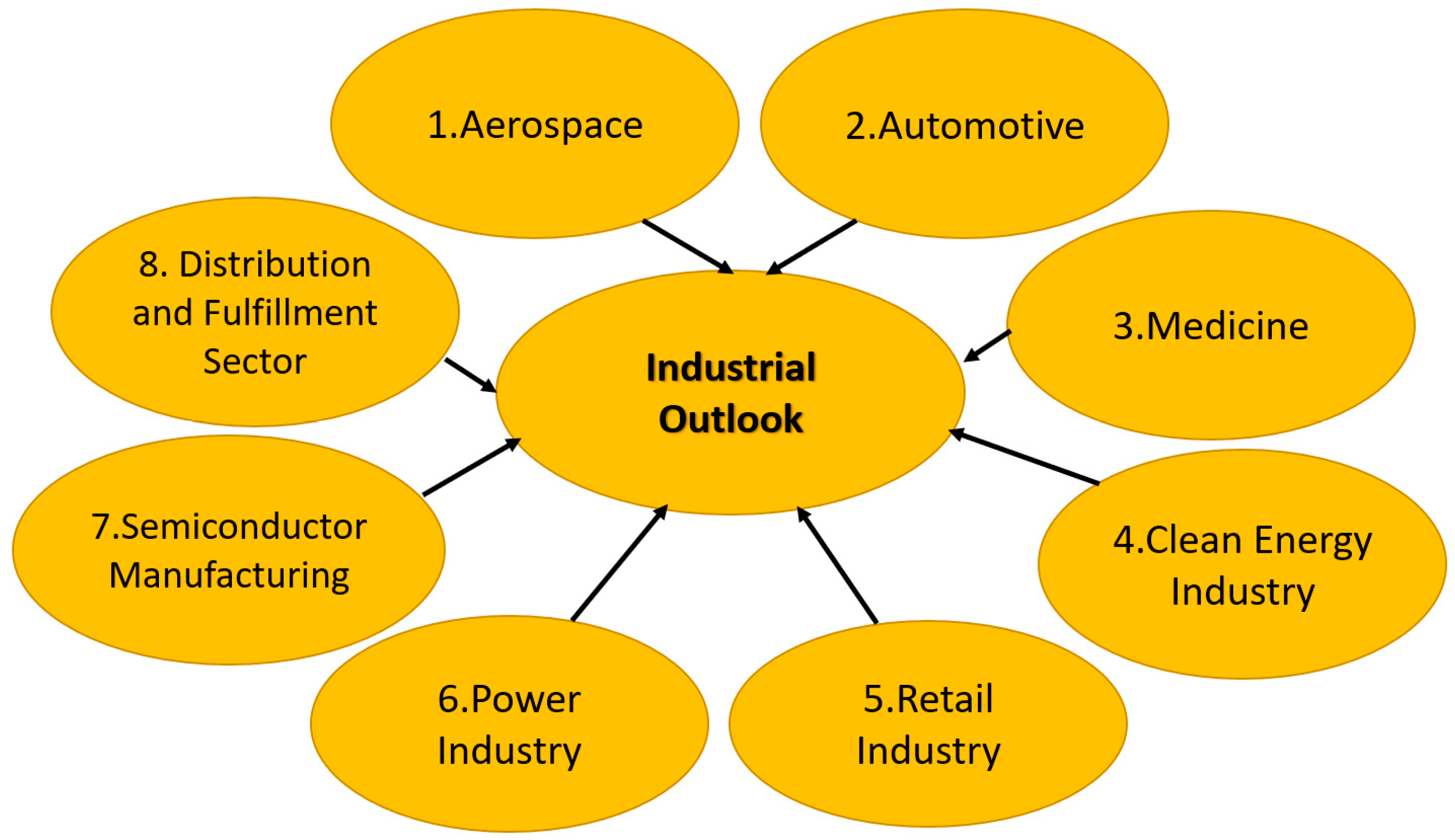

3. Industrial Outlook

3.1. Aerospace

3.2. Automotive

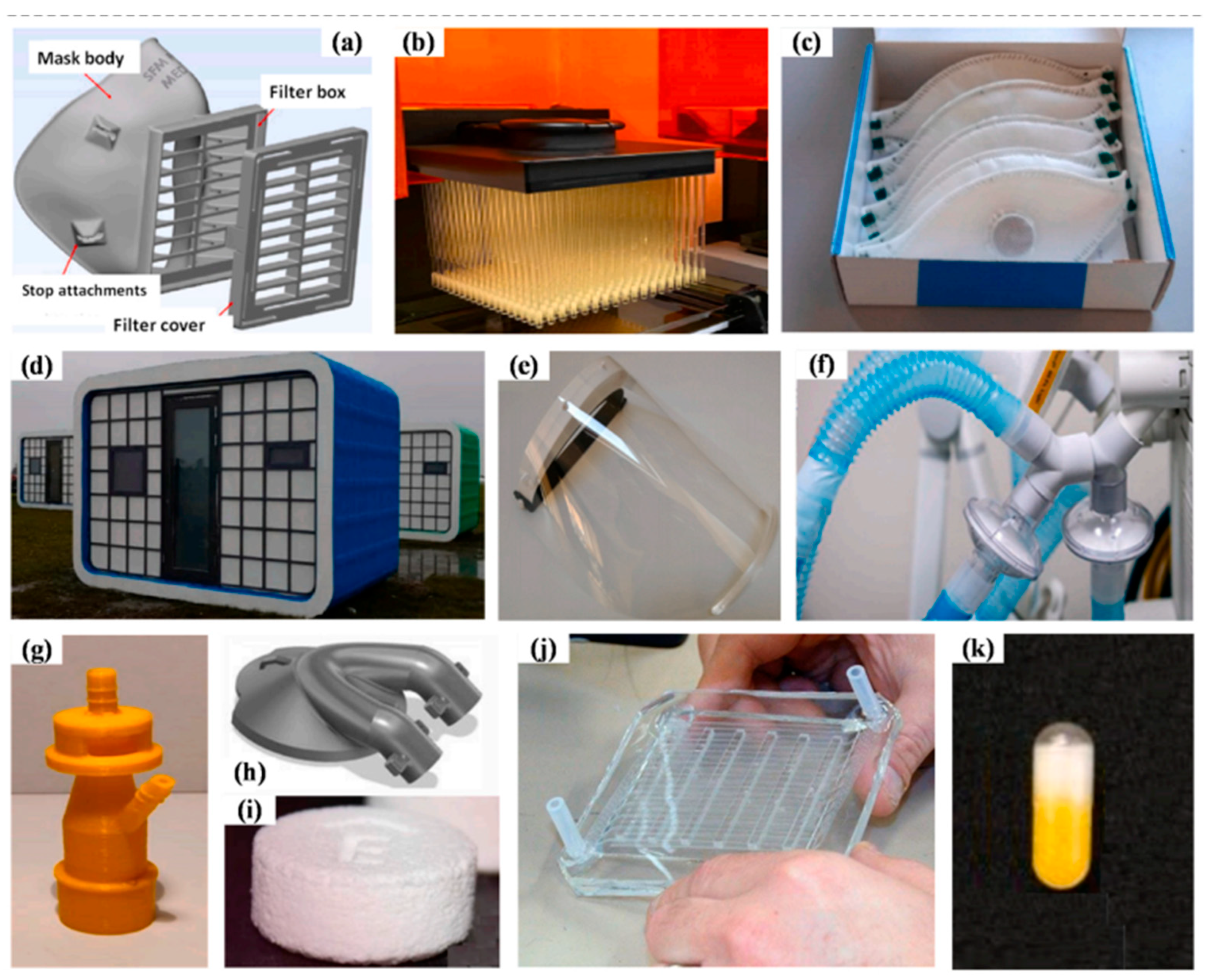

3.3. Medicine

3.4. Clean Energy Industry

3.5. Retail Industry

3.6. Power Industry

3.7. Semiconductor Manufacturing

3.8. Distribution and Fulfillment Sector

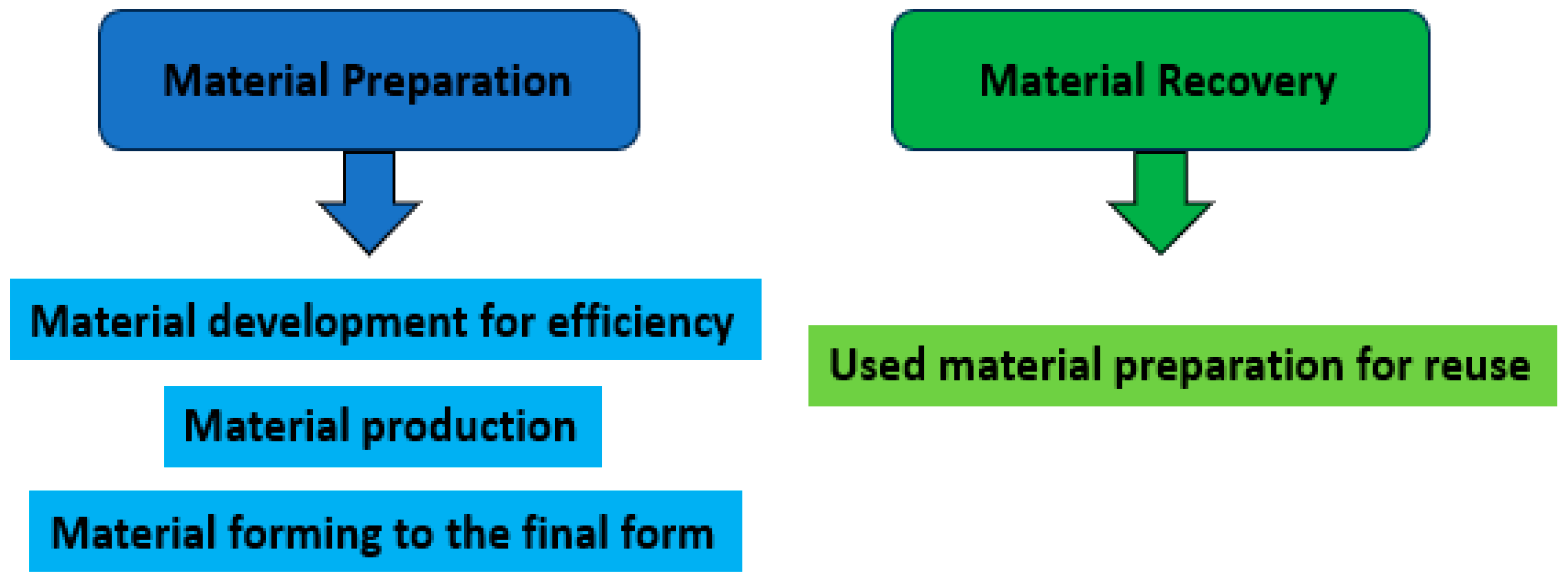

4. Material Discoveries

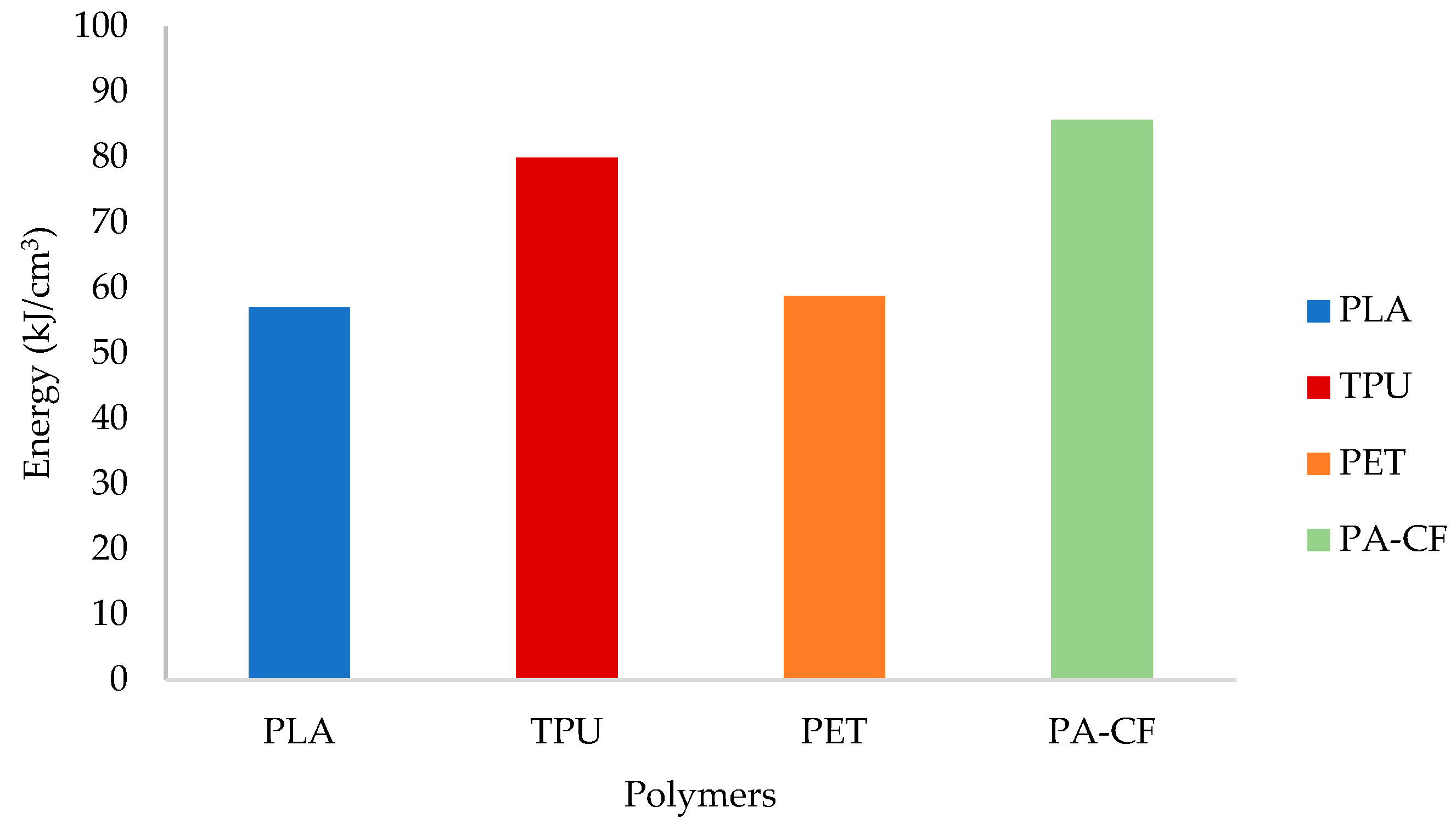

4.1. Polymers

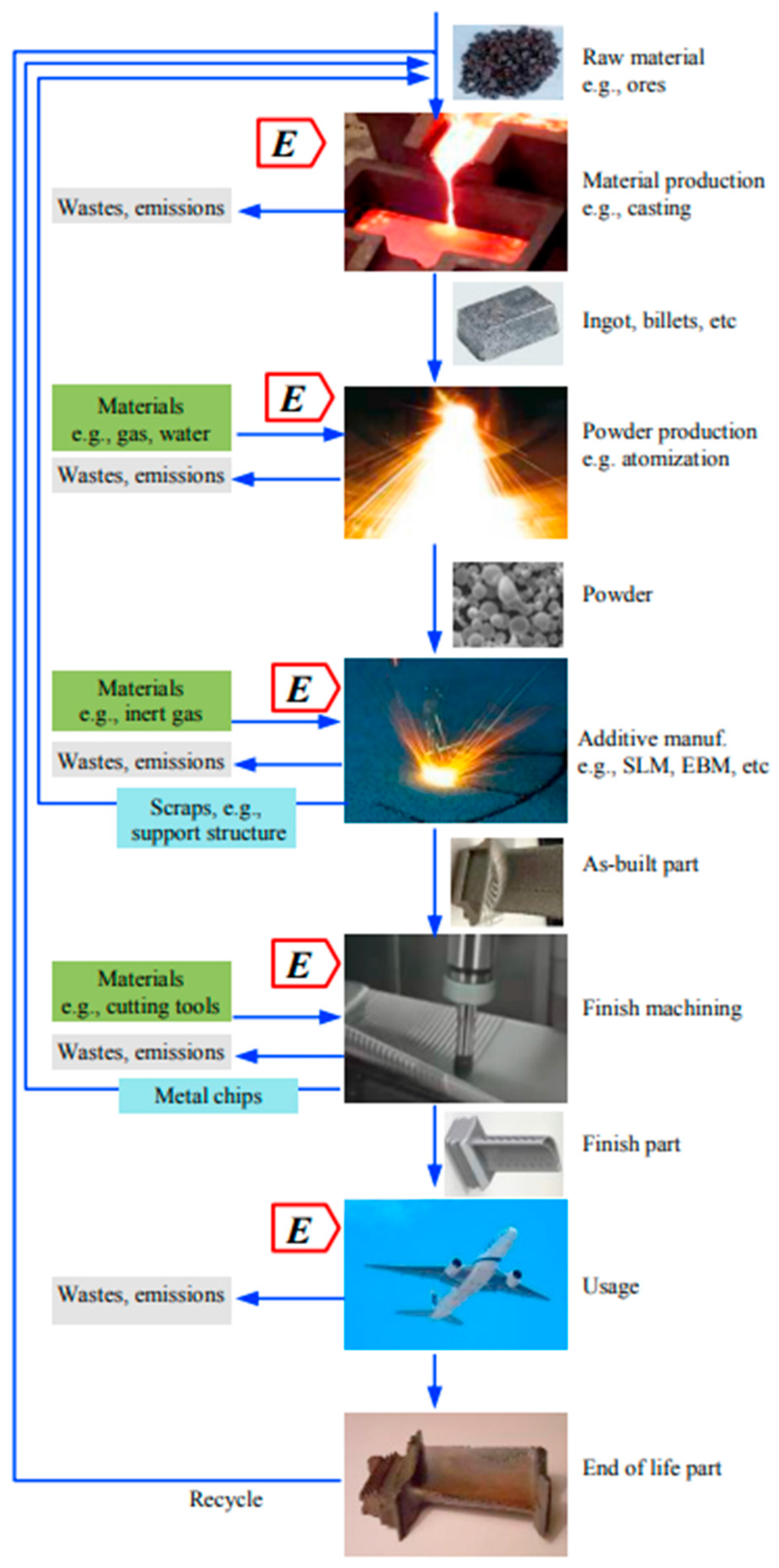

4.2. Metals

4.3. Ceramics

4.4. Future Prospects and Challenges in AM Materials

5. Initiatives and Standards

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jemghili, R.; Ait Taleb, A.; Mansouri, K. Additive Manufacturing Progress as a New Industrial Revolution. In Proceedings of the 2020 IEEE 2nd International Conference on Electronics, Control, Optimization and Computer Science, ICECOCS 2020, Kenitra, Morocco, 2–3 December 2020. [Google Scholar] [CrossRef]

- Alifui-Segbaya, F.; Ituarte, I.F.; Hasanov, S.; Gupta, A.; Fidan, I. Opportunities and Limitations of Additive Manufacturing. In Springer Handbooks; Springer: Cham, Switzerland, 2023; Part F1592; pp. 125–143. [Google Scholar] [CrossRef]

- Bermeo-Ayerbe, M.A.; Ocampo-Martinez, C.; Diaz-Rozo, J. Data-Driven Energy Prediction Modeling for Both Energy Efficiency and Maintenance in Smart Manufacturing Systems. Energy 2022, 238, 121691. [Google Scholar] [CrossRef]

- Hinshaw, H.J.; Terry, S.; Fidan, I. Power Consumption Investigation for Fused Filament Fabricated Specimen. Int. J. Rapid Manuf. 2020, 9, 268. [Google Scholar] [CrossRef]

- Terry, S.; Lu, H.; Fidan, I.; Zhang, Y.; Tantawi, K.; Guo, T.; Asiabanpour, B. The Influence of Smart Manufacturing towards Energy Conservation: A Review. Technologies 2020, 8, 31. [Google Scholar] [CrossRef]

- Sun, C.; Wang, Y.; McMurtrey, M.D.; Jerred, N.D.; Liou, F.; Li, J. Additive Manufacturing for Energy: A Review. Appl. Energy 2021, 282, 116041. [Google Scholar] [CrossRef]

- Dudek, P.; Zagórski, K. Cost, Resources, and Energy Efficiency of Additive Manufacturing. In Proceedings of the E3S Web of Conferences, Krakow, Poland, 21–23 September 2017; Volume 14, p. 01040. [Google Scholar] [CrossRef]

- Monteiro, H.; Carmona-Aparicio, G.; Lei, I.; Despeisse, M. Energy and Material Efficiency Strategies Enabled by Metal Additive Manufacturing—A Review for the Aeronautic and Aerospace Sectors. Energy Rep. 2022, 8, 298–305. [Google Scholar] [CrossRef]

- Gao, C.; Wolff, S.; Wang, S. Eco-Friendly Additive Manufacturing of Metals: Energy Efficiency and Life Cycle Analysis. J. Manuf. Syst. 2021, 60, 459–472. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Li, C.; Fang, X.Y.; Guo, Y.B. Energy Consumption in Additive Manufacturing of Metal Parts. Procedia Manuf. 2018, 26, 834–845. [Google Scholar] [CrossRef]

- Hu, L.; Wang, Y.; Shu, L.; Cai, W.; Lv, J.; Xu, K. Energy Benchmark for Evaluating the Energy Efficiency of Selective Laser Melting Processes. Appl. Therm. Eng. 2023, 221, 119870. [Google Scholar] [CrossRef]

- Rouf, S.; Malik, A.; Singh, N.; Raina, A.; Naveed, N.; Siddiqui, M.I.H.; Haq, M.I.U. Additive Manufacturing Technologies: Industrial and Medical Applications. Sustain. Oper. Comput. 2022, 3, 258–274. [Google Scholar] [CrossRef]

- Ali, M.A.; Fidan, I.; Tantawi, K. Investigation of the Impact of Power Consumption, Surface Roughness, and Part Complexity in Stereolithography and Fused Filament Fabrication. Int. J. Adv. Manuf. Technol. 2023, 126, 2665–2676. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021(En); Additive Manufacturing—General Principles—Fundamentals and Vocabulary. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-2:v1:en (accessed on 17 January 2024).

- Abeykoon, C.; McMillan, A.; Nguyen, B.K. Energy Efficiency in Extrusion-Related Polymer Processing: A Review of State of the Art and Potential Efficiency Improvements. Renew. Sustain. Energy Rev. 2021, 147, 111219. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Moutsopoulou, A.; Karapidakis, E. Energy Consumption vs. Tensile Strength of Poly[Methyl Methacrylate] in Material Extrusion 3D Printing: The Impact of Six Control Settings. Polymers 2023, 15, 845. [Google Scholar] [CrossRef] [PubMed]

- Quarto, M. An Empirical Method for Forecasting Energy Consumption in Material Extrusion. Int. J. Adv. Manuf. Technol. 2023, 127, 2911–2920. [Google Scholar] [CrossRef]

- Ender-3 3D Printer. Available online: https://www.creality.com/products/ender-3-3d-printer (accessed on 16 January 2024).

- Hopkins, N.; Jiang, L.; Brooks, H. Energy Consumption of Common Desktop Additive Manufacturing Technologies. Clean. Eng. Technol. 2021, 2, 100068. [Google Scholar] [CrossRef]

- Alghamdi, S.S.; John, S.; Choudhury, N.R.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef] [PubMed]

- Dermeik, B.; Travitzky, N. Laminated Object Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2020, 22, 2000256. [Google Scholar] [CrossRef]

- Meteyer, S.; Xu, X.; Perry, N.; Zhao, Y.F. Energy and Material Flow Analysis of Binder-Jetting Additive Manufacturing Processes. Procedia CIRP 2014, 15, 19–25. [Google Scholar] [CrossRef]

- Du, W.; Ren, X.; Pei, Z.; Ma, C. Ceramic Binder Jetting Additive Manufacturing: A Literature Review on Density. J. Manuf. Sci. Eng. Trans. ASME 2020, 142, 040801. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Yang, M.; Kowsari, K.; Myrie, N.O.; Espinosa-Hoyos, D.; Jagielska, A.; Kim, S.; Fang, N.X.; Van Vliet, K.J. Additive Manufacturing of High Aspect-Ratio Structures with Self-Focusing Photopolymerization. Light Adv. Manuf. 2022, 3, 542–571. [Google Scholar] [CrossRef]

- Ahn, D.G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Alya, S.; Singh, R. Discrete Phase Modeling of the Powder Flow Dynamics and the Catchment Efficiency in Laser Directed Energy Deposition with Inclined Coaxial Nozzles. J. Manuf. Sci. Eng. Trans. ASME 2021, 143, 081004. [Google Scholar] [CrossRef]

- Krimpenis, A.A.; Noeas, G.D. Application of Hybrid Manufacturing Processes in Microfabrication. J. Manuf. Process. 2022, 80, 328–346. [Google Scholar] [CrossRef]

- Baumers, M.; Wildman, R.; Tuck, C.; Dickens, P.; Hague, R.; Wildman, R.; Tuck, C.; Dickens, P.; Hague, R. Modeling Build Time, Process Energy Consumption and Cost of Material Jetting-Based Additive Manufacturing. NIP Digit. Fabr. Conf. 2015, 31, 311–316. [Google Scholar] [CrossRef] [PubMed]

- Jayavelu, J. Advancements in Three-Dimensional Printing for the Medical Device Industry. Trends Dev. Med. Devices 2020, 3–16. [Google Scholar] [CrossRef]

- Singh, R.; Gupta, A.; Tripathi, O.; Srivastava, S.; Singh, B.; Awasthi, A.; Rajput, S.K.; Sonia, P.; Singhal, P.; Saxena, K.K. Powder Bed Fusion Process in Additive Manufacturing: An Overview. Mater. Today Proc. 2020, 26, 3058–3070. [Google Scholar] [CrossRef]

- Afazov, S.; Roberts, A.; Wright, L.; Jadhav, P.; Holloway, A.; Basoalto, H.; Milne, K.; Brierley, N. Metal Powder Bed Fusion Process Chains: An Overview of Modelling Techniques. Prog. Addit. Manuf. 2021, 7, 289–314. [Google Scholar] [CrossRef]

- Munir, Q.; Kärki, T. Cost Analysis of Various Factors for Geopolymer 3D Printing of Construction Products in Factories and on Construction Sites. Recycling 2021, 6, 60. [Google Scholar] [CrossRef]

- Fidan, I.; Huseynov, O.; Ali, M.A.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Hasanov, S.; Tantawi, K.; Yasa, E.; Yilmaz, O.; et al. Recent Inventions in Additive Manufacturing: Holistic Review. Inventions 2023, 8, 103. [Google Scholar] [CrossRef]

- Rajeshirke, M.; Alkunte, S.; Huseynov, O.; Fidan, I. Fatigue Analysis of Additively Manufactured Short Carbon Fiber-Reinforced PETG Components. Int. J. Adv. Manuf. Technol. 2023, 128, 2377–2394. [Google Scholar] [CrossRef]

- Fidan, I.; Norris, M.; Rajeshirke, M.; Huseynov, O.; Alkunte, S.; Dasari, J.K.; Zhang, Z. Non-Traditional Delivery of Hands-on Manufacturing Courses. In Proceedings of the ASEE2022, Minneapolis, MN, USA, 26–29 June 2022; Available online: https://peer.asee.org/40950 (accessed on 17 January 2024).

- Alkunte, S.; Fidan, I.; Hasanov, S. Experimental Analysis of Functionally Graded Materials Produced by Fused Filament Fab-Rication. In Proceedings of the 2022 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 25–27 July 2022. [Google Scholar] [CrossRef]

- Nyamekye, P.; Rahimpour Golroudbary, S.; Piili, H.; Luukka, P.; Kraslawski, A. Impact of Additive Manufacturing on Titanium Supply Chain: Case of Titanium Alloys in Automotive and Aerospace Industries. Adv. Ind. Manuf. Eng. 2023, 6, 100112. [Google Scholar] [CrossRef]

- Alkunte, S.; Rajeshirke, M.; Fidan, I.; Hasanov, S. Performance Evaluation of Fatigue Behavior in Extrusion-Based Functionally Graded Materials. Int. J. Adv. Manuf. Technol. 2023, 128, 863–875. [Google Scholar] [CrossRef]

- Alkunte, S.; Fidan, I. Machine Learning-Based Fatigue Life Prediction of Functionally Graded Materials Using Material Extrusion Technology. J. Compos. Sci. 2023, 7, 420. [Google Scholar] [CrossRef]

- Korniejenko, K.; Pławecka, K.; Kozub, B. An Overview for Modern Energy-Efficient Solutions for Lunar and Martian Habitats Made Based on Geopolymers Composites and 3D Printing Technology. Energies 2022, 15, 9322. [Google Scholar] [CrossRef]

- Waddell, T.; Toombs, J.; Reilly, A.; Schwab, T.; Castaneda, C.; Shan, I.; Lewis, T.; Mohnot, P.; Potter, D.; Taylor, H. Use of Volumetric Additive Manufacturing as an In-Space Manufacturing Technology. Acta Astronaut. 2023, 211, 474–482. [Google Scholar] [CrossRef]

- Omiyale, B.O.; Olugbade, T.O.; Abioye, T.E.; Farayibi, P.K. Wire Arc Additive Manufacturing of Aluminium Alloys for Aerospace and Automotive Applications: A Review. Mater. Sci. Technol. 2022, 38, 391–408. [Google Scholar] [CrossRef]

- Suryakant, A.S.; Gajjal, S.Y.; Mahajan, D.A. Contact Stress Analysis for ‘Gear’ to Optimize Mass Using CAE Techniques. Int. J. Sci. Eng. Technol. Res. 2014, 3, 3491–3495. [Google Scholar]

- Asiri, S. Modeling and Analysis of Automotive Engine Crankshaft Made of Composite and Functionally Graded Materials. Adv. Mater. Sci. Eng. 2022, 2022, 4005368. [Google Scholar] [CrossRef]

- Salmi, M. Additive Manufacturing Processes in Medical Applications. Materials 2021, 14, 191. [Google Scholar] [CrossRef]

- Velu, R.; Calais, T.; Jayakumar, A.; Raspall, F. A Comprehensive Review on Bio-Nanomaterials for Medical Implants and Feasibility Studies on Fabrication of Such Implants by Additive Manufacturing Technique. Materials 2019, 13, 92. [Google Scholar] [CrossRef]

- Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennie, A. Review on Additive Manufacturing of Multi-Material Parts: Progress and Challenges. J. Manuf. Mater. Process. 2021, 6, 4. [Google Scholar] [CrossRef]

- Wang, Y.; Ahmed, A.; Azam, A.; Bing, D.; Shan, Z.; Zhang, Z.; Tariq, M.K.; Sultana, J.; Mushtaq, R.T.; Mehboob, A.; et al. Applications of Additive Manufacturing (AM) in Sustainable Energy Generation and Battle against COVID-19 Pandemic: The Knowledge Evolution of 3D Printing. J. Manuf. Syst. 2021, 60, 709–733. [Google Scholar] [CrossRef] [PubMed]

- Mehrpouya, M.; Vosooghnia, A.; Dehghanghadikolaei, A.; Fotovvati, B. The Benefits of Additive Manufacturing for Sustainable Design and Production. In Sustainable Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 29–59. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kazancoglu, Y.; Sezer, M.D.; Top, N.; Sahin, I. Optimizing Fused Deposition Modelling Parameters Based on the Design for Additive Manufacturing to Enhance Product Sustainability. Comput. Ind. 2023, 145, 103833. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H.; Bhuddhi, D. Additive Manufacturing: Expanding 3D Printing Horizon in Industry 4.0. Int. J. Interact. Des. Manuf. 2023, 17, 2221–2235. [Google Scholar] [CrossRef]

- Chyr, G.; DeSimone, J.M. Review of High-Performance Sustainable Polymers in Additive Manufacturing. Green Chem. 2023, 25, 453–466. [Google Scholar] [CrossRef]

- Hawes, G.F.; Rehman, S.; Rangom, Y.; Pope, M.A. Advanced Manufacturing Approaches for Electrochemical Energy Storage Devices. Int. Mater. Rev. 2023, 68, 323–364. [Google Scholar] [CrossRef]

- Bassyouni, Z.; Allagui, A.; Abou Ziki, J.D. Microsized Electrochemical Energy Storage Devices and Their Fabrication Techniques For Portable Applications. Adv. Mater. Technol. 2023, 8, 2200459. [Google Scholar] [CrossRef]

- Wuamprakhon, P.; Crapnell, R.D.; Sigley, E.; Hurst, N.J.; Williams, R.J.; Sawangphruk, M.; Keefe, E.M.; Banks, C.E. Recycled Additive Manufacturing Feedstocks for Fabricating High Voltage, Low-Cost Aqueous Supercapacitors. Adv. Sustain. Syst. 2023, 7, 2200407. [Google Scholar] [CrossRef]

- Lunetto, V.; Galati, M.; Settineri, L.; Iuliano, L. Sustainability in the Manufacturing of Composite Materials: A Literature Review and Directions for Future Research. J. Manuf. Process. 2023, 85, 858–874. [Google Scholar] [CrossRef]

- Osipovich, K.; Kalashnikov, K.; Chumaevskii, A.; Gurianov, D.; Kalashnikova, T.; Vorontsov, A.; Zykova, A.; Utyaganova, V.; Panfilov, A.; Nikolaeva, A.; et al. Wire-Feed Electron Beam Additive Manufacturing: A Review. Metals 2023, 13, 279. [Google Scholar] [CrossRef]

- Kaood, A.; Elhagali, I.O.; Hassan, M.A. Investigation of High-Efficiency Compact Jet Impingement Cooling Modules for High-Power Applications. Int. J. Therm. Sci. 2023, 184, 108006. [Google Scholar] [CrossRef]

- Calignano, F.; Mercurio, V. An Overview of the Impact of Additive Manufacturing on Supply Chain, Reshoring, and Sustainability. Clean. Logist. Supply Chain. 2023, 7, 100103. [Google Scholar] [CrossRef]

- Ekren, B.Y.; Stylos, N.; Zwiegelaar, J.; Turhanlar, E.E.; Kumar, V. Additive Manufacturing Integration in E-Commerce Supply Chain Network to Improve Resilience and Competitiveness. Simul. Model. Pr. Theory 2023, 122, 102676. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Patel, V.; Kumar, A.; Koppad, P.G. A Review of Various Materials for Additive Manufacturing: Recent Trends and Processing Issues. J. Mater. Res. Technol. 2022, 21, 2612–2641. [Google Scholar] [CrossRef]

- Zindani, D.; Kumar, K. An Insight into Additive Manufacturing of Fiber Reinforced Polymer Composite. Int. J. Lightweight Mater. Manuf. 2019, 2, 267–278. [Google Scholar] [CrossRef]

- Bánhegyi, G. Polymer Compatibility and Interfaces in Extrusion-Based Multicomponent Additive Manufacturing—A Mini-Review. Adv. Ind. Eng. Polym. Res. 2023. [Google Scholar] [CrossRef]

- Huseynov, O.; Hasanov, S.; Fidan, I. Influence of the Matrix Material on the Thermal Properties of the Short Carbon Fiber Reinforced Polymer Composites Manufactured by Material Extrusion. J. Manuf. Process. 2023, 92, 521–533. [Google Scholar] [CrossRef]

- Diniță, A.; Ripeanu, R.G.; Ilincă, C.N.; Cursaru, D.; Matei, D.; Naim, R.I.; Tănase, M.; Portoacă, A.I. Advancements in Fiber-Reinforced Polymer Composites: A Comprehensive Analysis. Polymers 2023, 16, 2. [Google Scholar] [CrossRef]

- Le Gentil, T.; Langot, J.; Therriault, D.; Kerbrat, O. Identifying Efficient Solutions for Additive Manufacturing of Short Carbon-Fiber Reinforced Polyamide 6 from Energy and Mechanical Perspectives. Procedia CIRP 2023, 116, 540–545. [Google Scholar] [CrossRef]

- Gupta, A.; Hasanov, S.; Alifui-Segbaya, F.; Fidan, I. Composites (Fiber-Reinforced Plastic Matrix Composites). In Springer Handbooks; Springer: Cham, Switzerland, 2023; Part F1592; pp. 627–637. [Google Scholar] [CrossRef]

- Chaudhary, R.P.; Parameswaran, C.; Idrees, M.; Rasaki, A.S.; Liu, C.; Chen, Z.; Colombo, P. Additive Manufacturing of Polymer-Derived Ceramics: Materials, Technologies, Properties and Potential Applications. Prog. Mater. Sci. 2022, 128, 100969. [Google Scholar] [CrossRef]

- Singh, M.K.; Mohanty, A.K.; Misra, M. Upcycling of Waste Polyolefins in Natural Fiber and Sustainable Filler-Based Biocomposites: A Study on Recent Developments and Future Perspectives. Compos. Part B Eng. 2023, 263, 110852. [Google Scholar] [CrossRef]

- Armstrong, M.; Mehrabi, H.; Naveed, N. An Overview of Modern Metal Additive Manufacturing Technology. J. Manuf. Process. 2022, 84, 1001–1029. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Amato, K.N.; Gaytan, S.M.; Hernandez, J.; Ramirez, D.A.; Shindo, P.W.; Medina, F.; Wicker, R.B. Fabrication of Metal and Alloy Components by Additive Manufacturing: Examples of 3D Materials Science. J. Mater. Res. Technol. 2012, 1, 42–54. [Google Scholar] [CrossRef]

- Rashid, A.; Gopaluni, A. A Review of Residual Stress and Deformation Modeling for Metal Additive Manufacturing Processes. Chin. J. Mech. Eng. Addit. Manuf. Front. 2023, 2, 100102. [Google Scholar] [CrossRef]

- Chen, S.; Gao, H.; Zhang, Y.; Wu, Q.; Gao, Z.; Zhou, X. Review on Residual Stresses in Metal Additive Manufacturing: Formation Mechanisms, Parameter Dependencies, Prediction and Control Approaches. J. Mater. Res. Technol. 2022, 17, 2950–2974. [Google Scholar] [CrossRef]

- du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Effects of Defects on Mechanical Properties in Metal Additive Manufacturing: A Review Focusing on X-Ray Tomography Insights. Mater. Des. 2020, 187, 108385. [Google Scholar] [CrossRef]

- Johnson, N.S.; Vulimiri, P.S.; To, A.C.; Zhang, X.; Brice, C.A.; Kappes, B.B.; Stebner, A.P. Invited Review: Machine Learning for Materials Developments in Metals Additive Manufacturing. Addit. Manuf. 2020, 36, 101641. [Google Scholar] [CrossRef]

- Nyamekye, P.; Lakshmanan, R.; Tepponen, V.; Westman, S. Sustainability Aspects of Additive Manufacturing: Leveraging Resource Efficiency via Product Design Optimization and Laser Powder Bed Fusion. Heliyon 2024, 10, e23152. [Google Scholar] [CrossRef]

- Mecheter, A.; Tarlochan, F.; Kucukvar, M. A Review of Conventional versus Additive Manufacturing for Metals: Life-Cycle Environmental and Economic Analysis. Sustainability 2023, 15, 12299. [Google Scholar] [CrossRef]

- Fidan, I. Bench Marking Studies for 3D Printing Process. In Proceedings of the 1st Annual Manufacturing Technology Summit, Dearborn, MI, USA, 10 August 2004; pp. 1–7. [Google Scholar]

- Hegab, H.; Khanna, N.; Monib, N.; Salem, A. Design for Sustainable Additive Manufacturing: A Review. Sustain. Mater. Technol. 2023, 35, e00576. [Google Scholar] [CrossRef]

- Majeed, A.; Ahmed, A.; Lv, J.; Peng, T.; Muzamil, M. A State-of-the-Art Review on Energy Consumption and Quality Characteristics in Metal Additive Manufacturing Processes. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 249. [Google Scholar] [CrossRef]

- Products—The Virtual Foundry, Inc. Available online: https://thevirtualfoundry.com/products/ (accessed on 18 January 2024).

- Plastic and Metal Filaments by Ultrafuse®|BASF FORWARD AM. Available online: https://forward-am.com/material-portfolio/ultrafuse-filaments-for-fused-filaments-fabrication-fff/ (accessed on 18 January 2024).

- Gong, H.; Snelling, D.; Kardel, K.; Carrano, A. Comparison of Stainless Steel 316L Parts Made by FDM- and SLM-Based Additive Manufacturing Processes. JOM 2019, 71, 880–885. [Google Scholar] [CrossRef]

- Buchanan, R.; Kumar Dasari, J.; Fidan, I.; Allen, M.; Bhattacharya, I. Knowledge Base Development for Mechanical Properties and Energy Consumption of Iron-PLA Composite Filaments in Additive Manufacturing. Int. Solid Free. Fabr. Symp. 2022. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive Manufacturing of Advanced Ceramic Materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Diener, S.; Zocca, A.; Günster, J. Literature Review: Methods for Achieving High Powder Bed Densities in Ceramic Powder Bed Based Additive Manufacturing. Open Ceram. 2021, 8, 100191. [Google Scholar] [CrossRef]

- Heim, T.; Kern, F. Influence of the Feedstock Preparation on the Properties of Highly Filled Alumina Green-Body and Sintered Parts Produced by Fused Deposition of Ceramic. Ceramics 2023, 6, 241–254. [Google Scholar] [CrossRef]

- Dadkhah, M.; Tulliani, J.M.; Saboori, A.; Iuliano, L. Additive Manufacturing of Ceramics: Advances, Challenges, and Outlook. J. Eur. Ceram. Soc. 2023, 43, 6635–6664. [Google Scholar] [CrossRef]

- Mobarak, M.H.; Islam, M.A.; Hossain, N.; Al Mahmud, M.Z.; Rayhan, M.T.; Nishi, N.J.; Chowdhury, M.A. Recent Advances of Additive Manufacturing in Implant Fabrication—A Review. Appl. Surf. Sci. Adv. 2023, 18, 100462. [Google Scholar] [CrossRef]

- Fan, D.; Li, Y.; Wang, X.; Zhu, T.; Wang, Q.; Cai, H.; Li, W.; Tian, Y.; Liu, Z. Progressive 3D Printing Technology and Its Application in Medical Materials. Front. Pharmacol. 2020, 11, 122. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Perše, L.S.; Nanni, F. Advancements in Metal Additive Manufacturing: A Comprehensive Review of Material Extrusion with Highly Filled Polymers. J. Manuf. Mater. Process. 2024, 8, 14. [Google Scholar] [CrossRef]

- Wang, W.; Gao, X.; Li, Z.; Shen, C.; Wang, G.; He, R. Fiber-laying-assisted material extrusion additive manufacturing of continuous carbon fiber reinforced SiC ceramic matrix composites. In Materials Science and Engineering: A; Elsevier: Amsterdam, The Netherlands, 2024; Volume 890, p. 145944. ISSN 0921-5093. [Google Scholar] [CrossRef]

- May, G.; Psarommatis, F. Maximizing Energy Efficiency in Additive Manufacturing: A Review and Framework for Future Research. Energies 2023, 16, 4179. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Recycling in Additive Manufacturing: A Systematic Literature Review and Opportunities for the Circular Economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Günther, J.; Brenne, F.; Droste, M.; Wendler, M.; Volkova, O.; Biermann, H.; Niendorf, T. Design of Novel Materials for Additive Manufacturing—Isotropic Microstructure and High Defect Tolerance. Sci. Rep. 2018, 8, 1298. [Google Scholar] [CrossRef]

- Daraban, A.E.O.; Negrea, C.S.; Artimon, F.G.P.; Angelescu, D.; Popan, G.; Gheorghe, S.I.; Gheorghe, M. A Deep Look at Metal Additive Manufacturing Recycling and Use Tools for Sustainability Performance. Sustainability 2019, 11, 5494. [Google Scholar] [CrossRef]

- Tantawi, K.H.; Fidan, I.; Tantawy, A. Status of Smart Manufacturing in the United States. In Proceedings of the 2019 IEEE 9th Annual Computing and Communication Workshop and Conference, CCWC 2019, Las Vegas, NV, USA, 7–9 January 2019; pp. 281–283. [Google Scholar] [CrossRef]

- Tantawi, K.H.; Fidan, I.; Musa, Y.; Tantawy, A. Smart Manufacturing: Post-Pandemic and Future Trends; IGI Global: Hershey, PA, USA; pp. 278–300. [CrossRef]

- Attaran, M. Additive Manufacturing: The Most Promising Technology to Alter the Supply Chain and Logistics. J. Serv. Sci. Manag. 2017, 10, 189–206. [Google Scholar] [CrossRef]

- Mohammadizadeh, M.; Lu, H.; Fidan, I.; Tantawi, K.; Gupta, A.; Hasanov, S.; Zhang, Z.; Alifui-Segbaya, F.; Rennie, A. Mechanical and Thermal Analyses of Metal-PLA Components Fabricated by Metal Material Extrusion. Inventions 2020, 5, 44. [Google Scholar] [CrossRef]

- Tantawi, K.H.; Ashcroft, J.; Cossette, M.; Kepner, G.; Friedman, J. Investigation of the Post-Pandemic STEM Education (STEM 3.0). J. Adv. Technol. Educ. 2022, 1, 1. [Google Scholar] [CrossRef]

- Butler, D.; Woolliams, P. Standards in Additive Manufacturing. Precis. Met. Addit. Manuf. 2020, 133–156. [Google Scholar] [CrossRef]

- Kawalkar, R.; Dubey, H.K.; Lokhande, S.P. A Review for Advancements in Standardization for Additive Manufacturing. Mater. Today Proc. 2022, 50, 1983–1990. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, E. Metal Additive Manufacturing in Aircraft: Current Application, Opportunities and Challenges. IOP Conf. Series: Mater. Sci. Eng. 2019, 493, 012032. [Google Scholar] [CrossRef]

- Continuous Lower Energy, Emissions, and Noise (CLEEN) Program|Federal Aviation Administration. Available online: https://www.faa.gov/about/office_org/headquarters_offices/apl/eee/technology_saf_operations/cleen (accessed on 27 December 2023).

- Gardner, L. Metal Additive Manufacturing in Structural Engineering—Review, Advances, Opportunities and Outlook. Structures 2023, 47, 2178–2193. [Google Scholar] [CrossRef]

- Kent, R. Energy Management in Plastics Processing—Framework for Measurement, Assessment and Prediction. Plast. Rubber Compos. 2008, 37, 96–104. [Google Scholar] [CrossRef]

- Tan, C.; Li, R.; Su, J.; Du, D.; Du, Y.; Attard, B.; Chew, Y.; Zhang, H.; Lavernia, E.J.; Fautrelle, Y.; et al. Review on Field Assisted Metal Additive Manufacturing. Int. J. Mach. Tools Manuf. 2023, 189, 104032. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, Y.; Song, Y.; Xu, J.; Zhang, S.; Tan, J. Deep Pattern Matching for Energy Consumption Prediction of Complex Structures in Ecological Additive Manufacturing. IEEE Trans. Ind. Inform. 2023, 1–12. [Google Scholar] [CrossRef]

- Li, C.; Zheng, P.; Yin, Y.; Wang, B.; Wang, L. Deep Reinforcement Learning in Smart Manufacturing: A Review and Prospects. CIRP J. Manuf. Sci. Technol. 2023, 40, 75–101. [Google Scholar] [CrossRef]

- Xian, W.; Yu, K.; Han, F.; Fang, L.; He, D.; Han, Q.L. Advanced Manufacturing in Industry 5.0: A Survey of Key Enabling Technologies and Future Trends. IEEE Trans. Ind. Inform. 2023, 20, 1055–1068. [Google Scholar] [CrossRef]

| Layer Height (µm) | Print Time (min) | Mean Power (W) | Energy per Print (kJ) | Volume Extruded (cm3) |

|---|---|---|---|---|

| 100 | 350 | 118 | 2488 | 26.1 |

| 200 | 226 | 120 | 1631 | 28.6 |

| 300 | 195 | 110 | 1296 | 31.8 |

| Standard/Guideline and Issuing Organization, Date | Name | Energy Efficiency Contribution |

|---|---|---|

| ISO/ASTM 52910:2018 | Additive manufacturing—Design—Requirements, guidelines and recommendations | Optimizes material use, weight, and stress concentrations in designs. |

| ISO/ASTM 52901:2017 | Additive manufacturing General principles Requirements for purchased AM parts | Encourages using recycled and eco-friendly materials, thus more sustainability, and less energy consumption in material processing |

| ISO/ASTM PWI 52920-1 | Additive manufacturing—Qualification principles—Part 1: Conformity assessment for AM System in industrial use | Provides quality guidelines for the AM production sites such as Optimized building parameters, support structures, and machine operation practices. |

| ISO/ASTM PWI 52920-2 | Additive manufacturing—Qualification principles—Part 2: Conformity assessment at Industrial additive manufacturing centers | Provides quality guidelines for the AM production sites such as Optimized building parameters, support structures, and machine operation practices. |

| AMS7011 by SAE (2022) | Electron Beam-Powder Bed Fusion (EB-PBF) Produced Preforms and Parts Titanium Alloy, 6Al-4V Hot Isostatically Pressed | Defines particular powder characteristics and heat treatment procedures, consequently improving energy efficiency during processing. |

| ARP7042 by SAE | Development Planning for Design of Additive Manufactured Components in an Aircraft System | Through emphasizing optimized designs that contribute to reducing weight, and materials and therefore lower fuel consumption in aircraft. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fidan, I.; Naikwadi, V.; Alkunte, S.; Mishra, R.; Tantawi, K. Energy Efficiency in Additive Manufacturing: Condensed Review. Technologies 2024, 12, 21. https://doi.org/10.3390/technologies12020021

Fidan I, Naikwadi V, Alkunte S, Mishra R, Tantawi K. Energy Efficiency in Additive Manufacturing: Condensed Review. Technologies. 2024; 12(2):21. https://doi.org/10.3390/technologies12020021

Chicago/Turabian StyleFidan, Ismail, Vivekanand Naikwadi, Suhas Alkunte, Roshan Mishra, and Khalid Tantawi. 2024. "Energy Efficiency in Additive Manufacturing: Condensed Review" Technologies 12, no. 2: 21. https://doi.org/10.3390/technologies12020021

APA StyleFidan, I., Naikwadi, V., Alkunte, S., Mishra, R., & Tantawi, K. (2024). Energy Efficiency in Additive Manufacturing: Condensed Review. Technologies, 12(2), 21. https://doi.org/10.3390/technologies12020021