Preparation and Characterization of Fluorine-Containing Polyimide Films with Enhanced Output Performance for Potential Applications as Negative Friction Layers for Triboelectric Nanogenerators

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization Methods

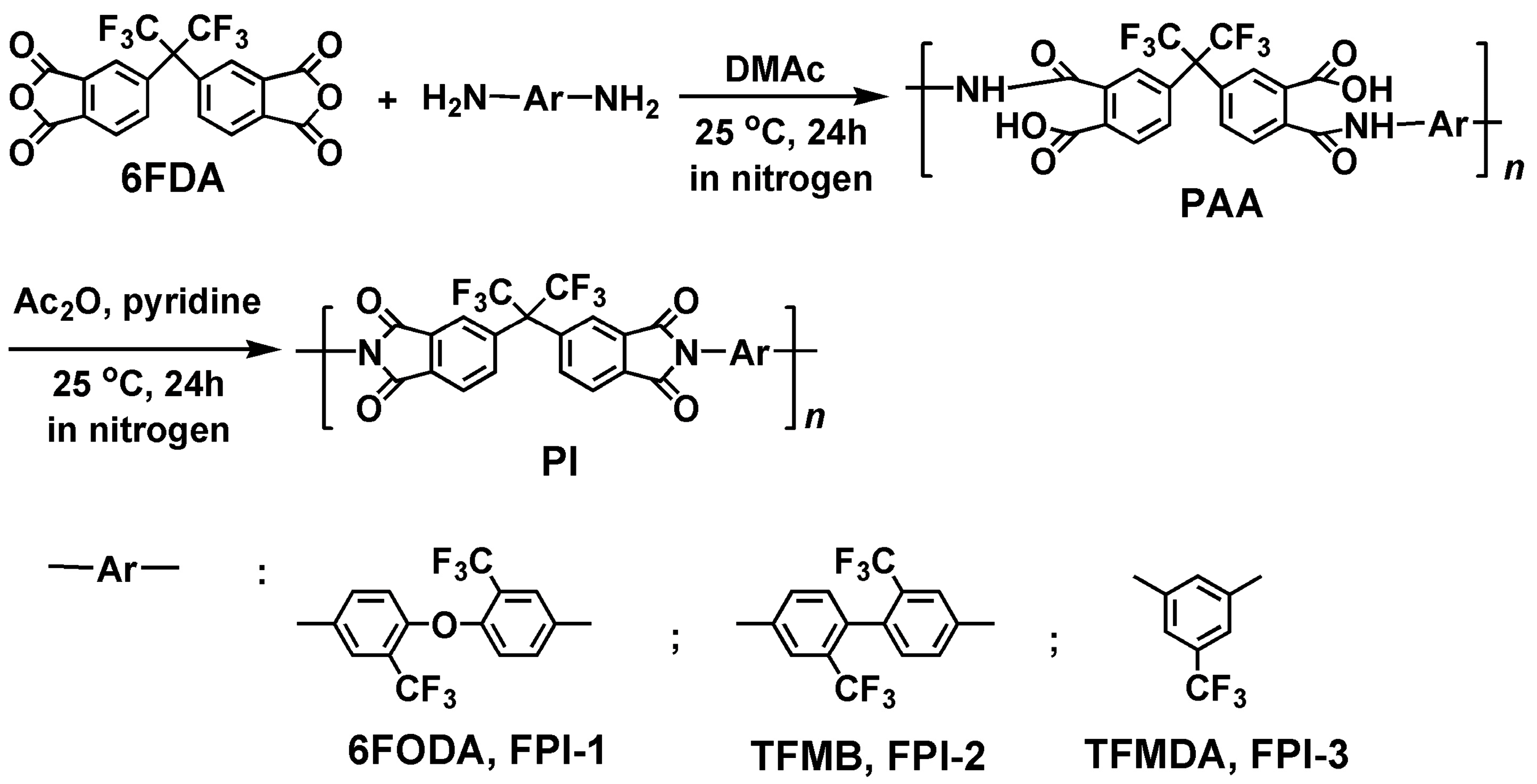

2.3. PI Resins Synthesis and Films Preparation

2.4. TENG Devices Fabrication

3. Results and Discussion

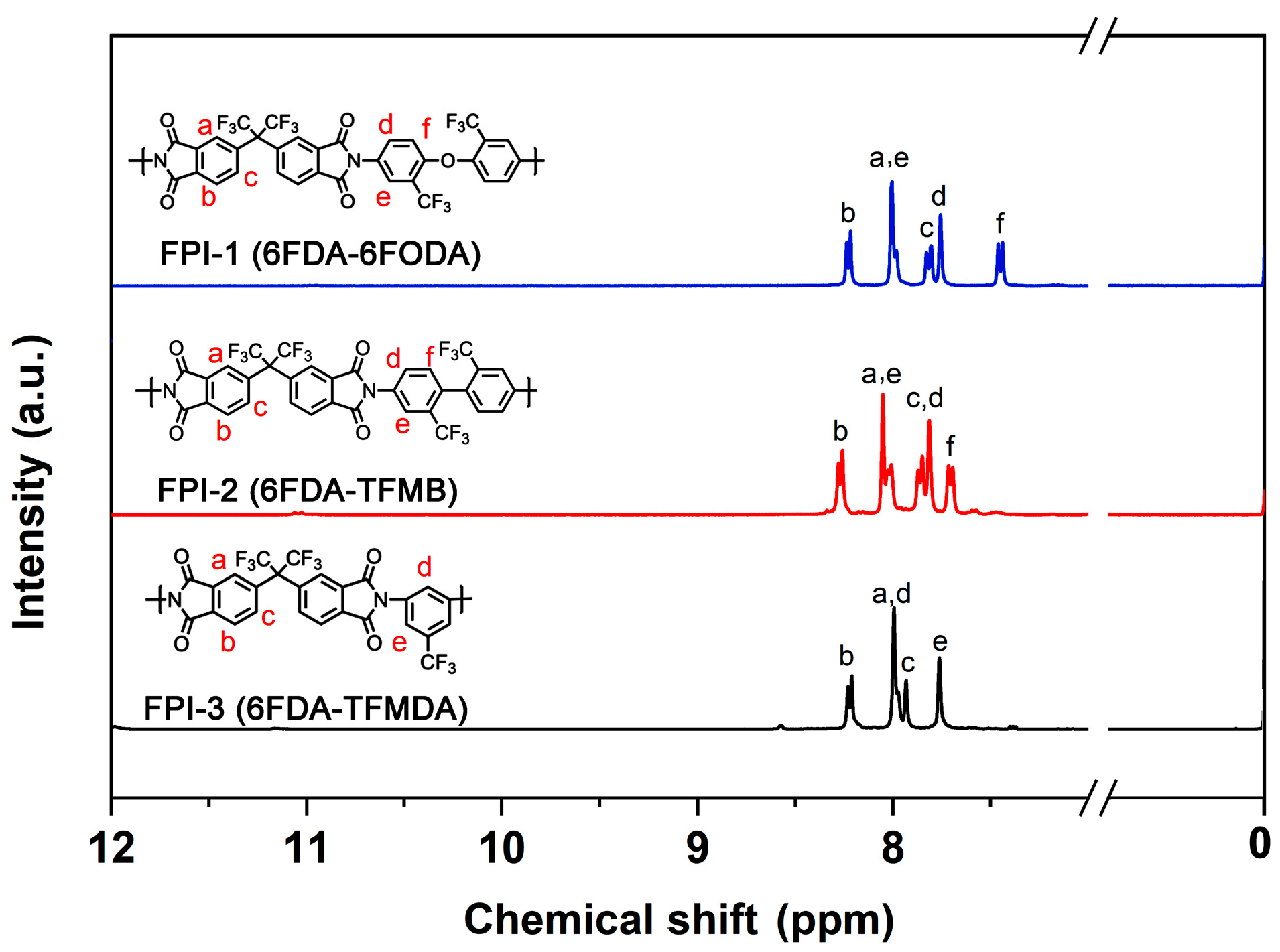

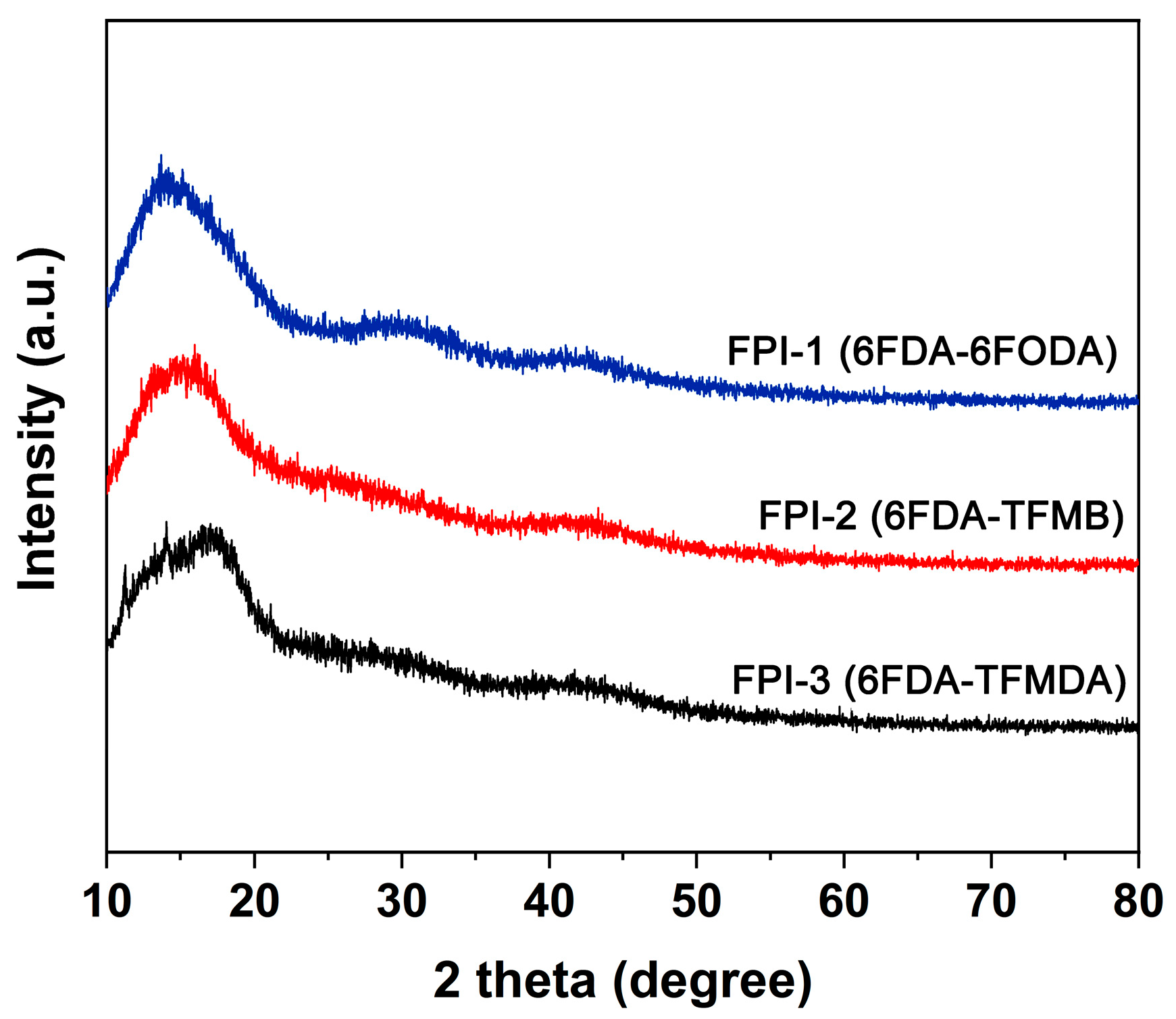

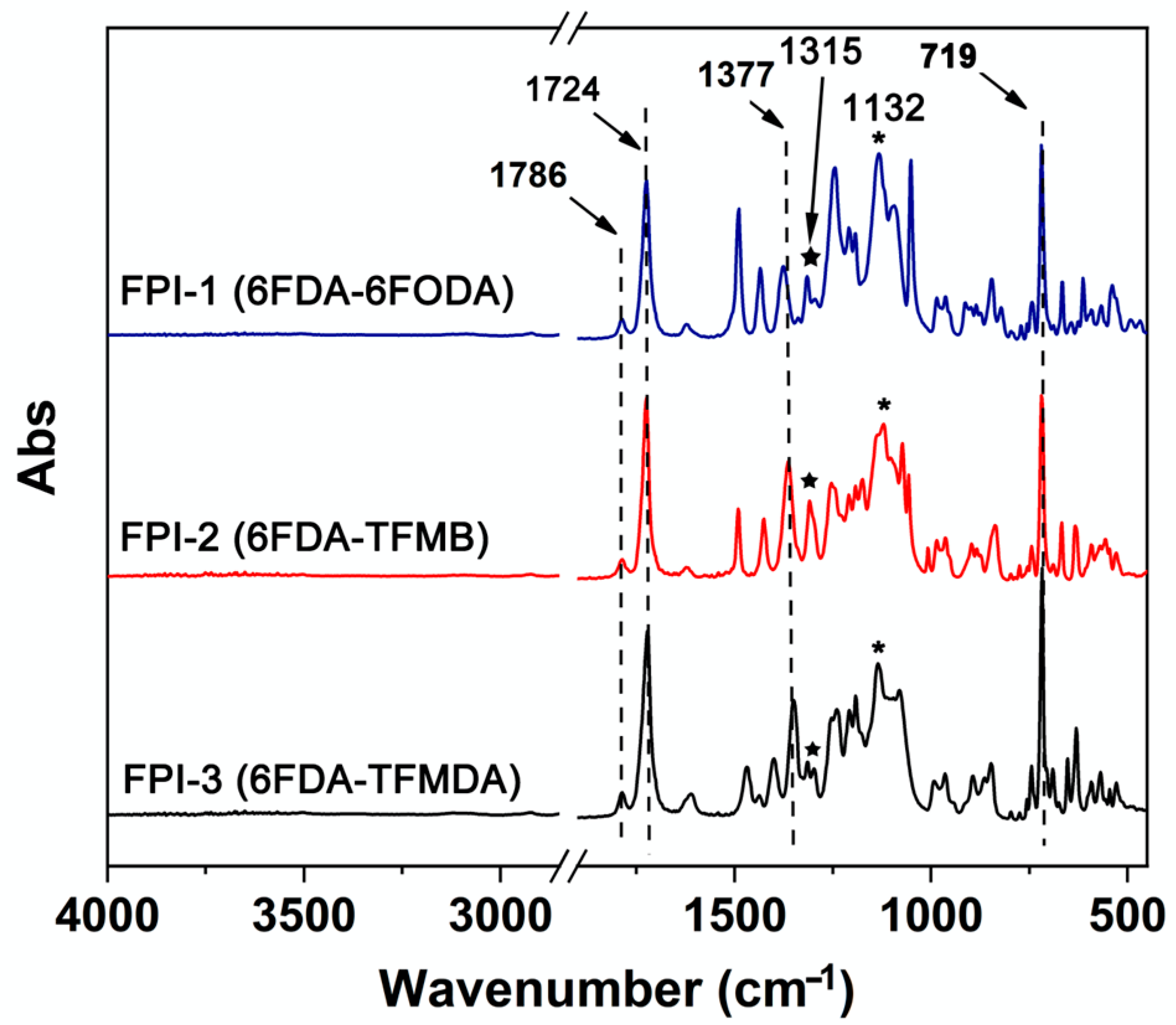

3.1. PI Resins Synthesis and Films Preparation

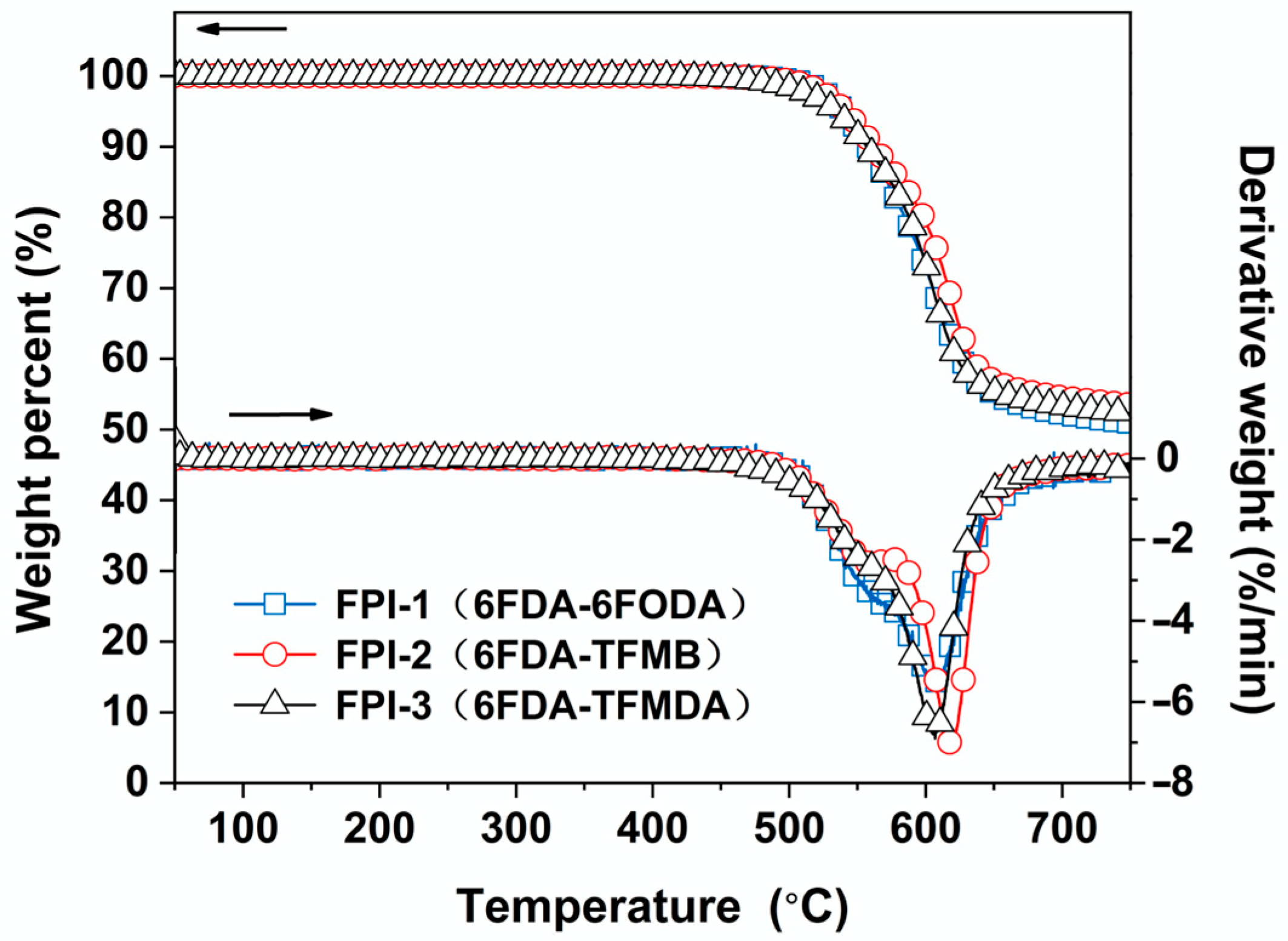

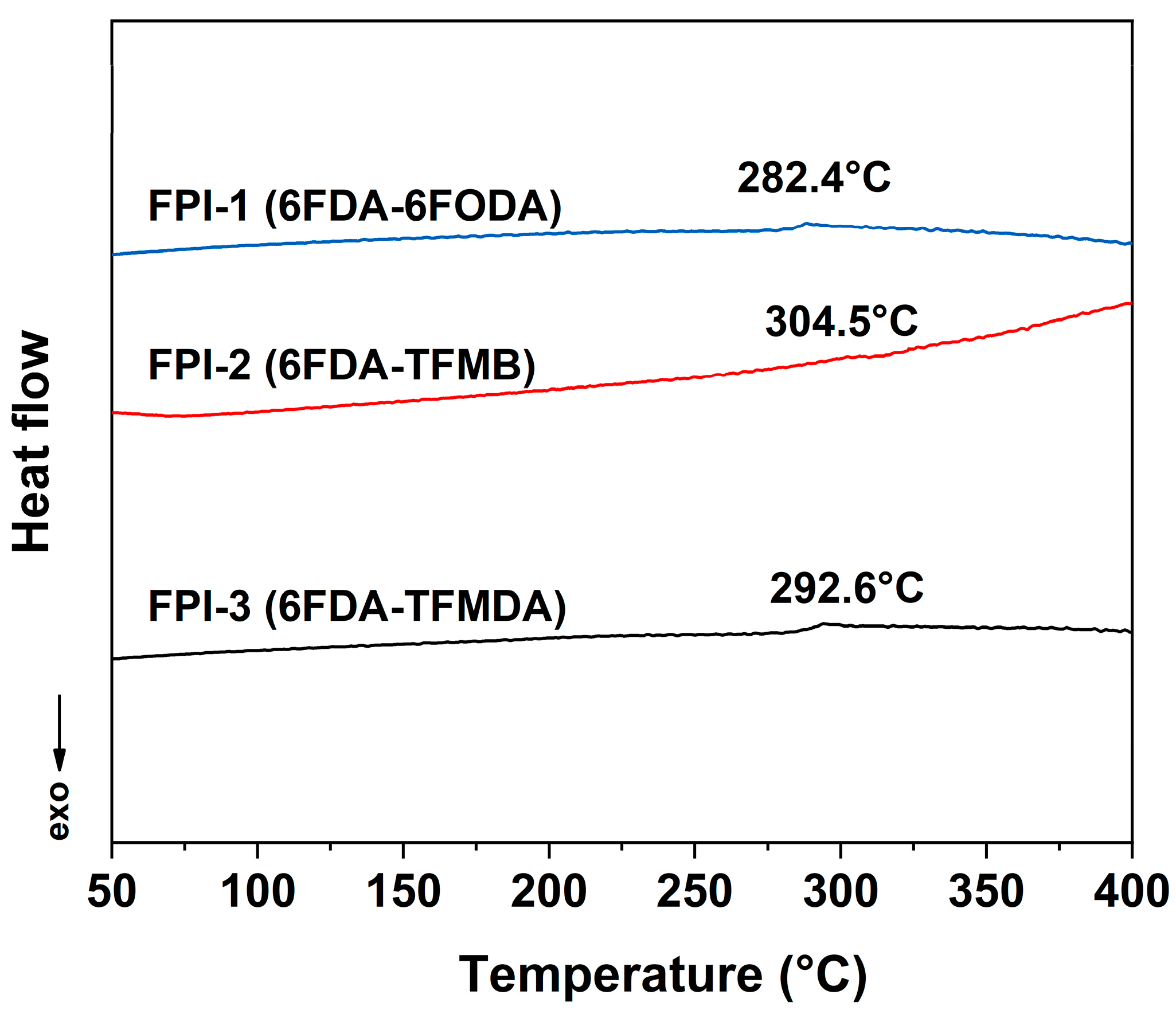

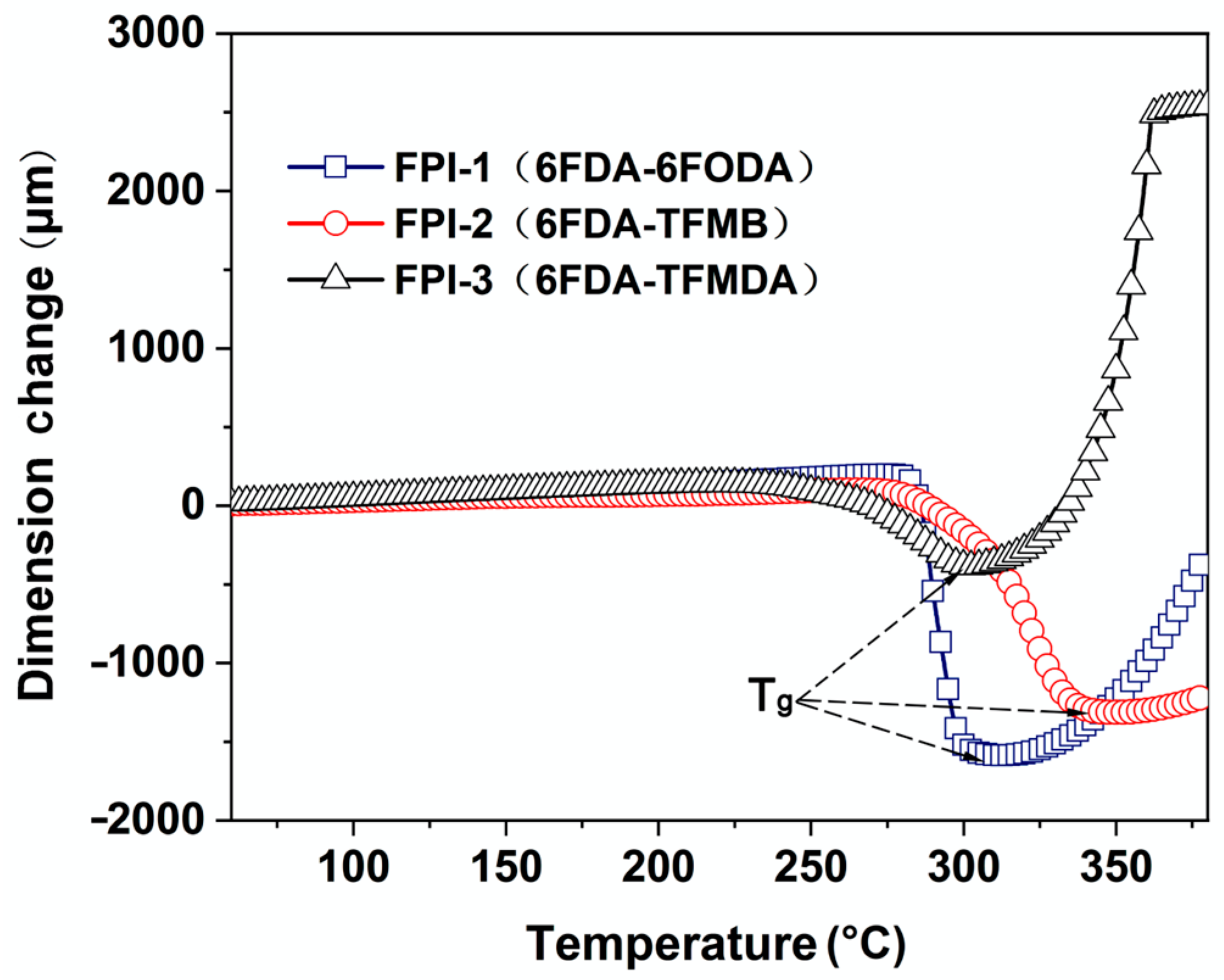

3.2. Thermal Properties

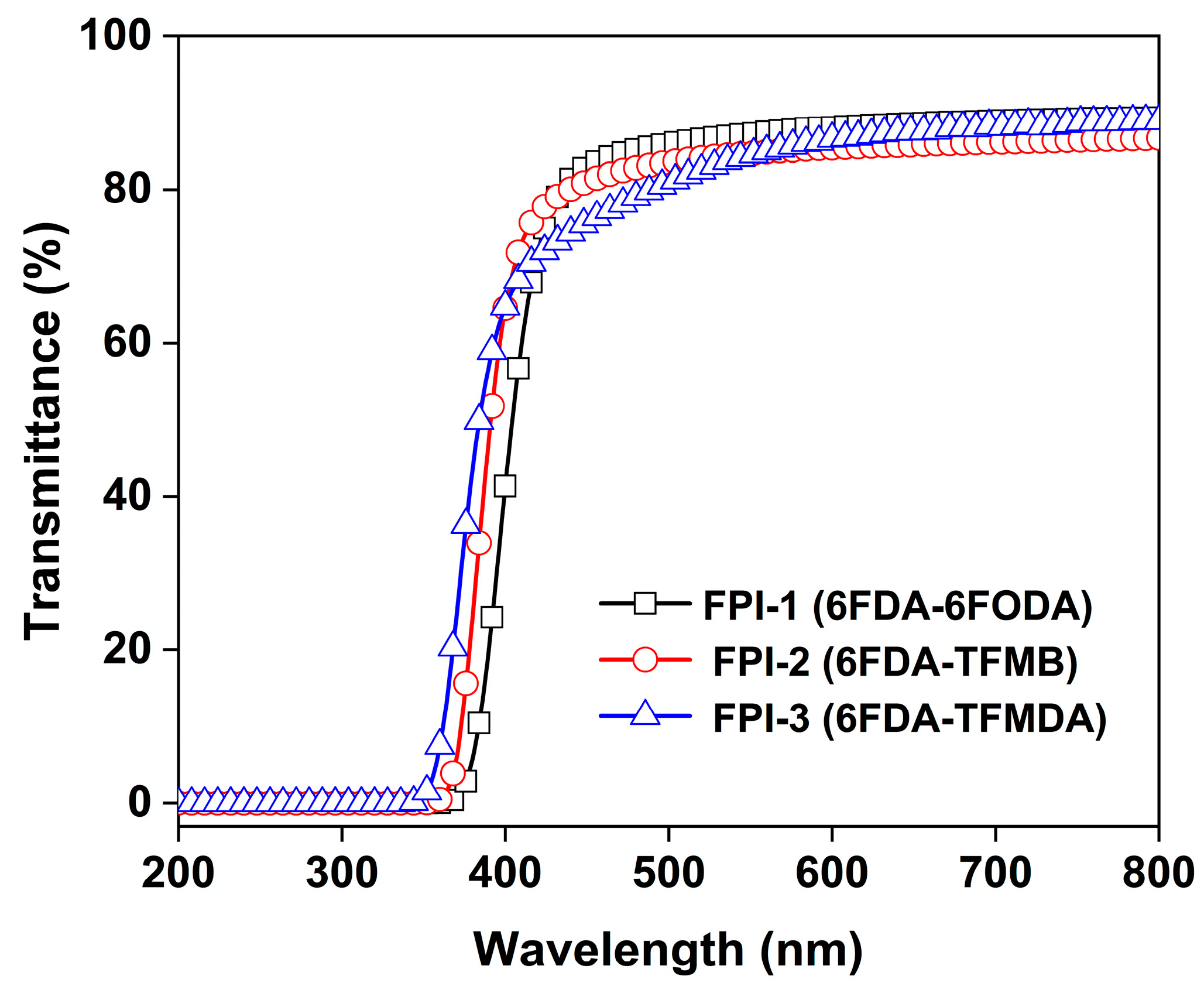

3.3. Optical Properties

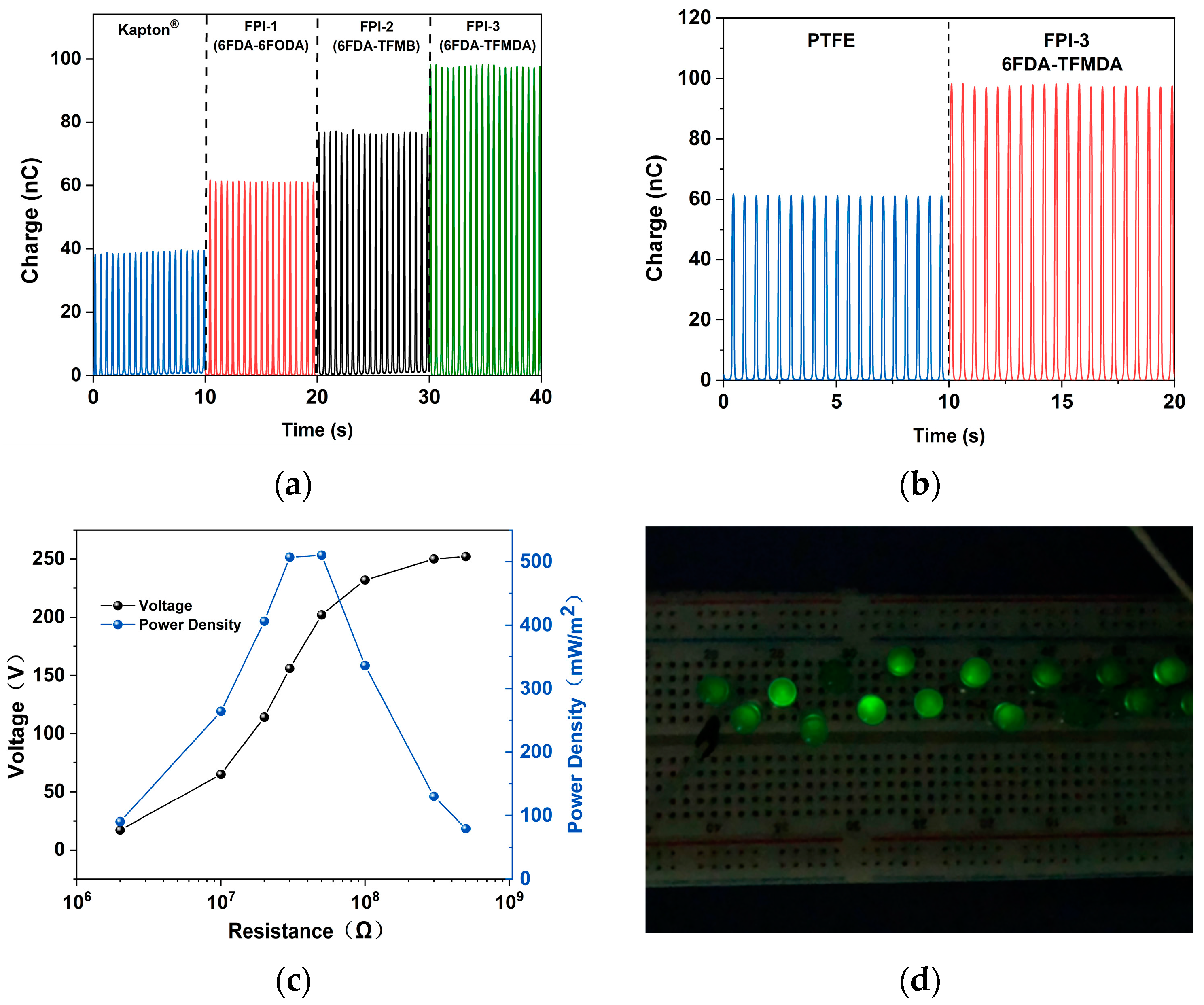

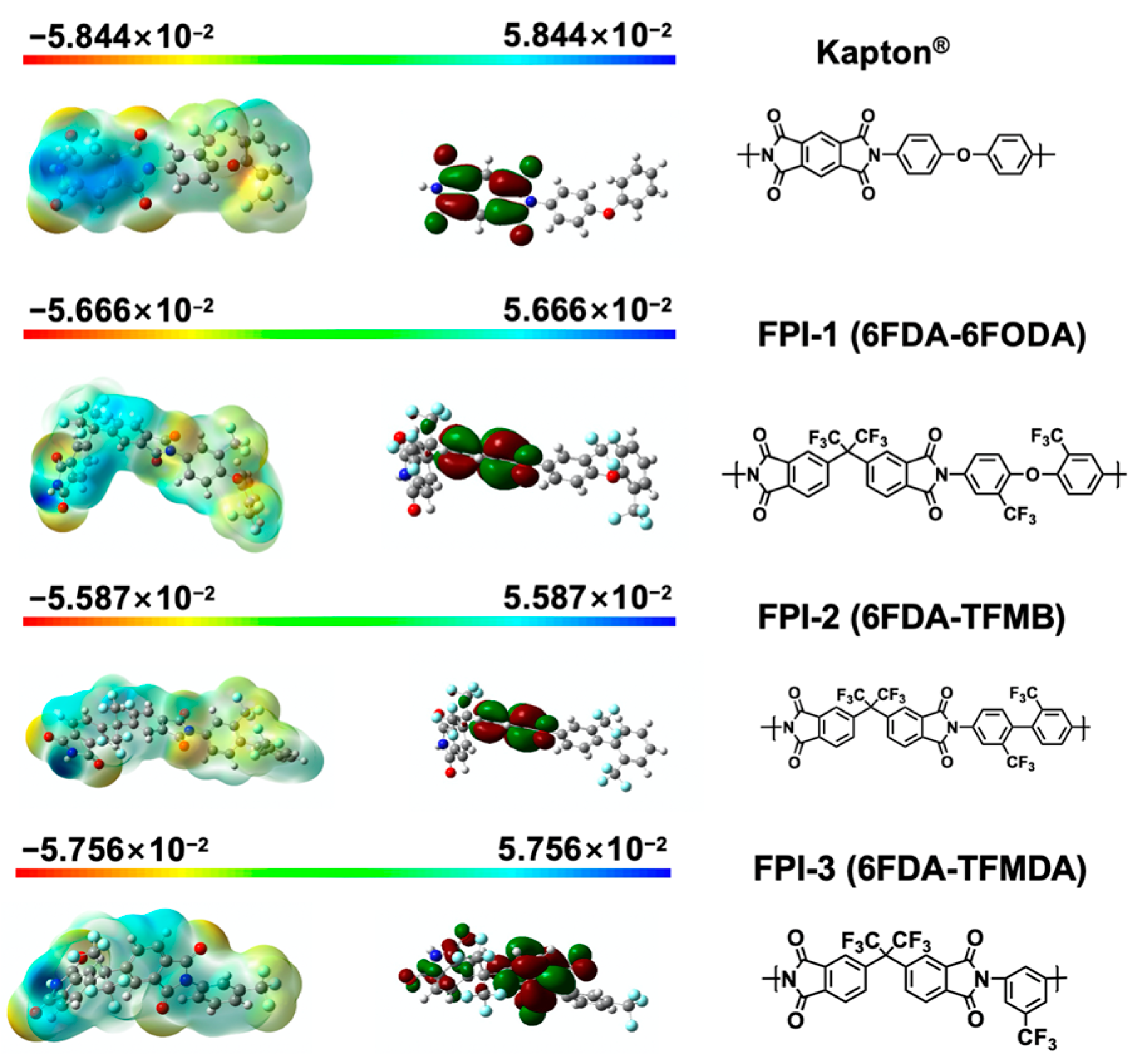

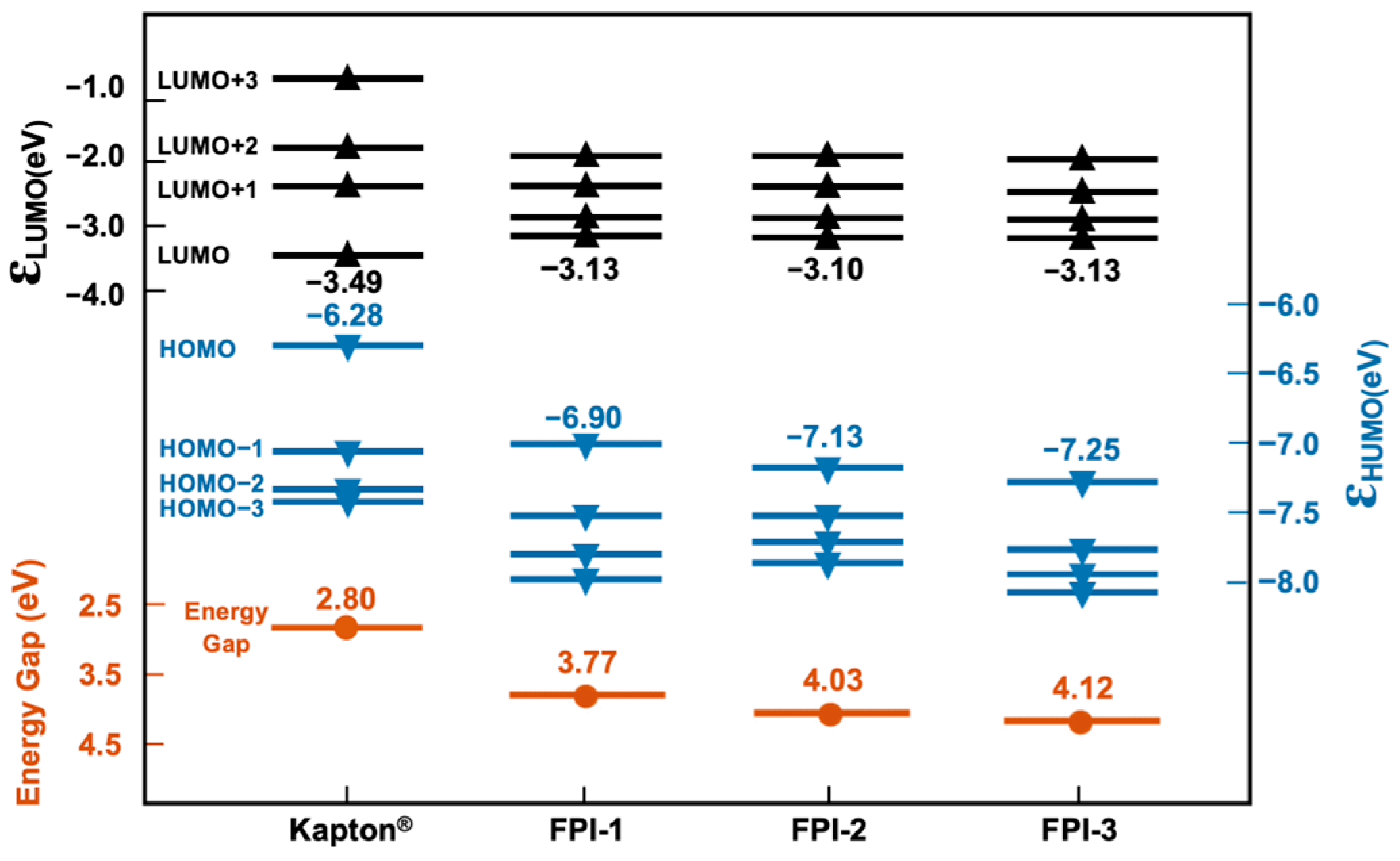

3.4. Triboelectric Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Atzori, L.; Iera, A.; Morabito, G. The internet of things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Invernizzi, F.; Dulio, S.; Patrini, M.; Guizzetti, G.; Mustarelli, P. Energy harvesting from human motion: Materials and techniques. Chem. Soc. Rev. 2016, 45, 5455–5473. [Google Scholar] [CrossRef] [PubMed]

- Chung, J.; Yong, H.; Moon, H.; Duong, Q.V.; Choi, S.T.; Kim, D.; Lee, S. Hand-driven gyroscopic hybrid nanogenerator for recharging portable devices. Adv. Sci. 2018, 5, 1801054. [Google Scholar] [CrossRef]

- Wang, Z.L. Entropy theory of distributed energy for internet of things. Nano Energy 2019, 58, 669–672. [Google Scholar] [CrossRef]

- Dong, K.; Peng, X.; Wang, Z.L. Fiber/fabric-based piezoelectric and triboelectric nanogenerators for flexible/stretchable and wearable electronics and artificial intelligence. Adv. Energy Mater. 2020, 32, 1902549. [Google Scholar] [CrossRef] [PubMed]

- Jie, Y.; Jia, X.; Zou, J.; Chen, Y.; Wang, N.; Wang, Z.L.; Cao, X. Natural leaf made triboelectric nanogenerator for harvesting environmental mechanical energy. Adv. Energy Mater. 2018, 8, 1703133. [Google Scholar] [CrossRef]

- Zhao, J.; Zhen, G.; Liu, G.; Bu, T.; Liu, W.; Fu, X.; Zhang, P.; Zhang, C.; Wang, Z.L. Remarkable merits of triboelectric nanogenerator than electromagnetic generator for harvesting small-amplitude mechanical energy. Nano Energy 2019, 61, 111–118. [Google Scholar] [CrossRef]

- Kim, W.G.; Kim, D.W.; Tcho, I.W.; Kim, J.K.; Kim, M.S.; Choi, Y.K. Triboelectric nanogenerator: Structure, mechanism, and applications. ACS Nano 2021, 15, 258–287. [Google Scholar] [CrossRef]

- Ghosh, K.; Iffelsberger, C.; Konečný, M.; Vyskočil, J.; Michalička, J.; Pumera, M. Nanoarchitectonics of triboelectric nanogenerator for conversion of abundant mechanical energy to green hydrogen. Adv. Energy Mater. 2023, 13, 2203476. [Google Scholar] [CrossRef]

- Fan, F.R.; Tian, Z.Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, K.; Yang, Y. A one-structure-based multieffects coupled nanogenerator for simultaneously scavenging thermal, solar, and mechanical energies. Adv. Sci. 2018, 5, 1700622. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Yang, Y.; Wang, Z.L. Scavenging wind energy by triboelectric nanogenerators. Adv. Energy Mater. 2018, 8, 1702649. [Google Scholar] [CrossRef]

- Liang, X.; Zhao, T.; Jiang, W.; Yu, X.; Hu, Y.; Zhu, P.; Zheng, H.; Sun, R.; Wong, C.P. Highly transparent triboelectric nanogenerator utilizing in-situ chemically welded silver nanowire network as electrode for mechanical energy harvesting and body motion monitoring. Nano Energy 2019, 59, 508–516. [Google Scholar] [CrossRef]

- Qu, Z.; Huang, M.; Chen, C.; An, Y.; Liu, H.; Zhang, Q.; Wang, X.; Liu, Y.; Yin, W.; Li, X. Spherical triboelectric nanogenerator based on eccentric structure for omnidirectional low frequency water wave energy harvesting. Adv. Funct. Mater. 2022, 32, 2202048. [Google Scholar] [CrossRef]

- Wang, J.; Ma, L.; He, J.; Yao, Y.; Zhu, X.; Peng, L.; Yang, J.; Li, K.; Qu, M. Superwettable hybrid dielectric based multimodal triboelectric nanogenerator with superior durability and efficiency for biomechanical energy and hydropower harvesting. Chem. Eng. J. 2022, 431, 134002. [Google Scholar] [CrossRef]

- Rani, G.M.; Wu, C.M.; Motora, K.G.; Umapathi, R.; Jose, C.R.M. Acoustic-electric conversion and triboelectric properties of nature-driven CF-CNT based triboelectric nanogenerator for mechanical and sound energy harvesting. Nano Energy 2023, 108, 108211. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric nanogenerator: A foundation of the energy for the new era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Zhang, Q.; Barri, K.; Kari, S.R.; Wang, Z.L.; Alavi, A.H. Multifunctional triboelectric nanogenerator-enabled structural elements for next generation civil infrastructure monitoring systems. Adv. Funct. Mater. 2021, 31, 2105825. [Google Scholar] [CrossRef]

- Meena, K.K.; Arief, I.; Ghosh, A.K.; Liebscher, H.; Hait, S.; Nagel, J.; Heinrich, G.; Fery, A.; Das, A. 3D-printed stretchable hybrid piezoelectric-triboelectric nanogenerator for smart tire: Onboard real-time tread wear monitoring system. Nano Energy 2023, 115, 108707. [Google Scholar] [CrossRef]

- Khandelwal, G.; Maria Joseph Raj, N.P.; Kim, S.J. Materials beyond conventional triboelectric series for fabrication and appli-cations of triboelectric nanogenerators. Adv. Energy Mater. 2021, 11, 2101170. [Google Scholar] [CrossRef]

- Liu, Z.; Huang, Y.; Shi, Y.; Tao, X.; He, H.; Chen, F.; Huang, Z.X.; Wang, Z.L.; Chen, X.Y.; Qu, J.P. Fabrication of triboelectric polymer films via repeated rheological forging for ultrahigh surface charge density. Nat. Commun. 2022, 13, 4083. [Google Scholar] [CrossRef] [PubMed]

- Arief, I.; Zimmermann, P.; Hait, S.; Park, H.; Ghosh, A.K.; Janke, A.; Chattopadhyay, S.; Nagel, J.; Heinrich, G.; Das, A.; et al. Elastomeric microwell-based triboelectric nanogenerators by in situ simultaneous transfer-printing. Mater Horiz. 2022, 9, 1468–1478. [Google Scholar] [CrossRef] [PubMed]

- Suresh, J.N.; Arief, I.; Naskar, K.; Heinrich, G.; Tahir, M.; Wießner, S.; Das, A. The role of chemical microstructures and compositions on the actuation performance of dielectric elastomers: A materials research perspective. Nano Sel. 2023, 4, 289–315. [Google Scholar] [CrossRef]

- Yu, Y.; Li, H.; Zhao, D.; Gao, Q.; Li, X.; Wang, J.; Wang, Z.L.; Cheng, T. Material’s selection rules for high performance triboelectric nanogenerators. Mater. Today 2023, 64, 61–71. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, Y.; Guo, L.; Wang, P.; He, X.; Dai, G.; Zheng, H.; Chen, C.; Wang, A.C.; Xu, C.; et al. Quantifying the triboelectric series. Nat. Commun. 2019, 10, 1427. [Google Scholar] [CrossRef] [PubMed]

- Chen, A.; Zhang, C.; Zhu, G.; Wang, Z.L. Polymer materials for high-performance triboelectric Nanogenerators. Adv. Sci. 2020, 7, 2000186. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Olin, H. Material choices for triboelectric nanogenerators: A critical review. EcoMat 2020, 2, e12062. [Google Scholar] [CrossRef]

- Lee, J.W.; Jung, S.; Lee, T.W.; Jo, J.; Chae, H.Y.; Choi, K.; Kim, J.J.; Lee, H.J.; Yang, C.; Baik, J.M. High-output triboelectric nanogenerator based on dual inductive and resonance effects-controlled highly transparent polyimide for self-powered sensor network systems. Adv. Energy Mater. 2019, 9, 1901987. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.; He, J.; Li, Z.; Li, L. Synthesis of fluorinated polyimide towards a transparent triboelectric nanogenerator applied on screen surface. J. Mater. Chem. A 2021, 9, 6583–6590. [Google Scholar] [CrossRef]

- Guo, Y.; Qiu, H.; Ruan, K.; Zhang, Y.; Gu, J. Hierarchically multifunctional polyimide composite films with strongly enhanced thermal conductivity. Nano-Micro Lett. 2022, 14, 26. [Google Scholar] [CrossRef]

- Kim, M.; Choi, C.; Lee, J.P.; Kim, J.; Cha, C. Multiscale engineering of nanofiber-aerogel composite nanogenerator with tunable triboelectric performance based on multifunctional polysuccinimide. Small 2022, 18, 2107316. [Google Scholar] [CrossRef] [PubMed]

- Tao, X.; Li, S.; Shi, Y.; Wang, X.; Tian, J.; Liu, Z.; Yang, P.; Chen, X.; Wang, Z.L. Triboelectric polymer with high thermal charge stability for harvesting energy from 200 °C flowing air. Adv. Funct. Mater. 2021, 31, 2106082. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, C.; Li, X.; Yao, Y.; Lan, L.; Zhao, F.; Ye, Z.; Ying, Y.; Ping, J. All-electrospun flexible triboelectric nanogenerator based on metallic MXene nanosheets. Nano Energy 2019, 59, 268–276. [Google Scholar] [CrossRef]

- Shi, L.; Jin, H.; Dong, S.; Huang, S.; Kuang, H.; Xu, H.; Zhang, S.; Li, S.; Wang, X.; Luo, J. High-performance triboelectric nanogenerator based on electrospun PVDF-graphene nanosheet composite nanofibers for energy harvesting. Nano Energy 2021, 80, 105599. [Google Scholar] [CrossRef]

- Zhang, R.; Ortegren, J.; Hummelgård, M.; Olsen, M.; Andersson, H.; Olin, H. A review of the advances in composites/nanocomposites for triboelectric nano-generators. Nanotechnology 2022, 33, 212003. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Kim, T.W.; Choi, H.Y. Reduced graphene-oxide acting as electron-trapping sites in the friction layer for giant triboelectric enhancement. Nano Energy 2017, 32, 542–550. [Google Scholar] [CrossRef]

- Niu, S.; Wang, Z.L. Theoretical systems of triboelectric nanogenerators. Nano Energy 2015, 14, 161–192. [Google Scholar] [CrossRef]

- Li, X.; Lau, T.H.; Guan, D.; Zi, Y. A universal method for quantitative analysis of triboelectric nanogenerators. J. Mater. Chem. A 2019, 7, 19485–19494. [Google Scholar] [CrossRef]

- Kim, M.P.; Um, D.S.; Shin, Y.E.; Ko, H. High-performance triboelectric devices via dielectric polarization: A review. Nanoscale Res. Lett. 2021, 16, 1–14. [Google Scholar] [CrossRef]

- Lai, J.; Ke, Y.; Cao, Z.; Xu, W.; Pan, J.; Dong, Y.; Zhou, Q.; Meng, G.; Pan, C.; Xia, F. Bimetallic strip based triboelectric nanogenerator for self-powered high temperature alarm system. Nano Today 2022, 43, 101437. [Google Scholar] [CrossRef]

- Bui, V.T.; Huynh, N.D.; Chau, N.M.; Kim, W.; Kim, H.; Oh, I.K.; Choi, D. High-temperature operatable triboelectric nanogenerator using microdome-patterned polyimide for self-powered sensors. Nano Energy 2022, 101, 107612. [Google Scholar] [CrossRef]

- Xing, F.; Ou, Z.; Gao, X.; Chen, B.; Wang, Z.L. Harvesting Electrical Energy from High Temperature Environment by Aerogel Nano-Covered Triboelectric Yarns. Adv. Funct. Mater. 2022, 32, 2205275. [Google Scholar] [CrossRef]

- Ouyang, R.; Huang, Y.; Ye, H.; Zhang, Z.; Xue, H. Copper particles-PTFE tube based triboelectric nanogenerator for wave energy harvesting. Nano Energy 2022, 102, 107749. [Google Scholar] [CrossRef]

- Lei, H.; Li, X.; Wang, J.; Song, Y.; Tian, G.; Huang, M.; Wu, D. DFT and molecular dynamic simulation for the dielectric property analysis of polyimides. Chem. Phys. Lett. 2022, 786, 139131. [Google Scholar] [CrossRef]

- Peng, W.F.; Lei, H.Y.; Zhang, X.X.; Qiu, L.H.; Huang, M.J. Fluorine substitution effect on the material properties in transparent aromatic polyimides. Chin. J. Polym. Sci. 2022, 40, 781–788. [Google Scholar] [CrossRef]

- Kotov, B.V.; Gordina, T.A.; Voishchev, V.S.; Kolninov, O.V.; Pravednikov, A.N. Aromatic polyimides as charge transfer complexes. Polym. Sci. USSR 1977, 19, 711–716. [Google Scholar] [CrossRef]

- San Sebastian, M.; Martínez-Martínez, V.; Maceiras, A.; Vilas, J.L.; Lopez-Arbeloa, I.; León, L.M. Enhanced charge-transfer emission in polyimides by cyano-groups doping. J. Phys. Chem. B 2015, 119, 5685–5692. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Wang, X.; Li, H.; Wang, F.; Hu, Y. First-principles investigations on the contact electrification mechanism between metal and amorphous polymers for triboelectric nanogenerators. Nano Energy 2019, 63, 103864. [Google Scholar] [CrossRef]

| PI | 6FDA (g, mol) | 6FODA (g, mol) | TFMB (g, mol) | TFMDA (g, mol) | DMAc (g) |

|---|---|---|---|---|---|

| FPI-1 | 22.2120, 0.05 | 16.8115, 0.05 | NA a | NA | 117.8 |

| FPI-2 | 22.2120, 0.05 | NA | 16.0115, 0.05 | NA | 152.9 |

| FPI-3 | 22.2120, 0.05 | NA | NA | 8.8070, 0.05 | 72.4 |

| FPI | [η]inh a (dL/g) | Molecular Weight b | Solubility c | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mn (×104 g/mol) | Mw (×104 g/mol) | PDI | NMP | DMAc | GBL | CPA | THF | ||

| FPI-1 | 1.22 | 25.21 | 32.21 | 1.26 | ++ | ++ | ++ | ++ | ++ |

| FPI-2 | 0.96 | 10.87 | 18.22 | 1.68 | ++ | ++ | ++ | ++ | ++ |

| FPI-3 | 0.73 | 5.37 | 10.56 | 1.65 | ++ | ++ | ++ | ++ | ++ |

| Samples | T5% a (°C) | Tmax a (°C) | Rw750 a (%) | Tg,DSC a (°C) | Tg,TMA a (°C) | CTE a (×10−6/K) |

|---|---|---|---|---|---|---|

| FPI-1 | 540 | 608 | 50.9 | 282.4 | 300.4 | 51.3 |

| FPI-2 | 541 | 619 | 53.5 | 304.5 | 336.5 | 54.0 |

| FPI-3 | 534 | 606 | 52.3 | 292.6 | 302.3 | 42.5 |

| Samples | λcut a (nm) | T400 b (%) | T450 b (%) | L* c | a* c | b* c | Haze (%) |

|---|---|---|---|---|---|---|---|

| FPI-1 | 343 | 41.3 | 83.0 | 96.04 | −0.55 | 1.76 | 1.93 |

| FPI-2 | 347 | 64.5 | 81.0 | 95.86 | −0.20 | 1.37 | 2.08 |

| FPI-3 | 332 | 64.8 | 75.7 | 94.87 | −0.74 | 4.37 | 2.10 |

| Samples | Voc (V) a | Isc (μA) b | Qsc (nc) c |

|---|---|---|---|

| Kapton® | 63.4 | 2.05 | 36 |

| FPI-1 | 204.6 | 5.45 | 61 |

| FPI-2 | 258.9 | 6.56 | 76 |

| FPI-3 | 277.8 | 9.54 | 98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Z.; Yuan, S.; Ren, X.; He, Z.; Wang, Z.; Han, S.; Qi, Y.; Yu, H.; Liu, J. Preparation and Characterization of Fluorine-Containing Polyimide Films with Enhanced Output Performance for Potential Applications as Negative Friction Layers for Triboelectric Nanogenerators. Technologies 2023, 11, 136. https://doi.org/10.3390/technologies11050136

Pan Z, Yuan S, Ren X, He Z, Wang Z, Han S, Qi Y, Yu H, Liu J. Preparation and Characterization of Fluorine-Containing Polyimide Films with Enhanced Output Performance for Potential Applications as Negative Friction Layers for Triboelectric Nanogenerators. Technologies. 2023; 11(5):136. https://doi.org/10.3390/technologies11050136

Chicago/Turabian StylePan, Zhen, Shunqi Yuan, Xi Ren, Zhibin He, Zhenzhong Wang, Shujun Han, Yuexin Qi, Haifeng Yu, and Jingang Liu. 2023. "Preparation and Characterization of Fluorine-Containing Polyimide Films with Enhanced Output Performance for Potential Applications as Negative Friction Layers for Triboelectric Nanogenerators" Technologies 11, no. 5: 136. https://doi.org/10.3390/technologies11050136

APA StylePan, Z., Yuan, S., Ren, X., He, Z., Wang, Z., Han, S., Qi, Y., Yu, H., & Liu, J. (2023). Preparation and Characterization of Fluorine-Containing Polyimide Films with Enhanced Output Performance for Potential Applications as Negative Friction Layers for Triboelectric Nanogenerators. Technologies, 11(5), 136. https://doi.org/10.3390/technologies11050136