Electrical Discharge Machining of Alumina Using Cu-Ag and Cu Mono- and Multi-Layer Coatings and ZnO Powder-Mixed Water Medium

Abstract

1. Introduction

- -

- It is commercially available;

- -

- Stable under fire exposure conditions and is not reactive to water;

- -

- Refers to the materials that require considerable preheating, under all ambient temperature conditions, before ignition and combustion can occur;

- -

- Is a widely used n-type semiconductor;

- -

- -

- Code 2: Intense or continued but not chronic exposure could cause temporary incapacitation or possible residual injury, for health;

- Code 1: Materials that require considerable preheating, under all ambient temperature conditions, before ignition and combustion can occur, for flammability;

- Code 0: Normally stable, even under fire exposure conditions, and is not reactive with water, for instability–reactivity.

2. Materials and Methods

2.1. Sintering of the Samples

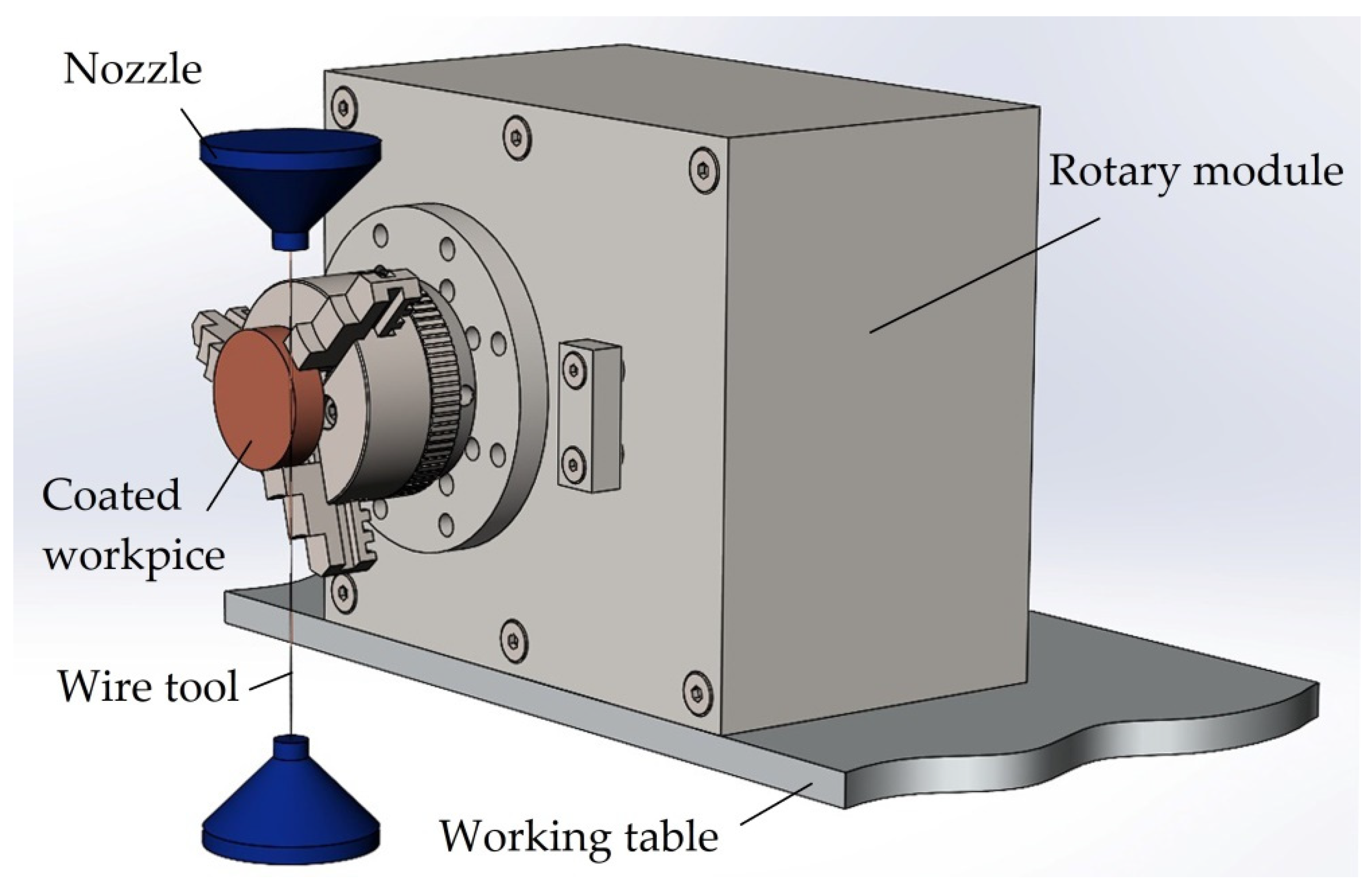

2.2. Electrical Discharge Machining

2.3. Assisting ZnO-Powder-Mixed Deionized Water Medium

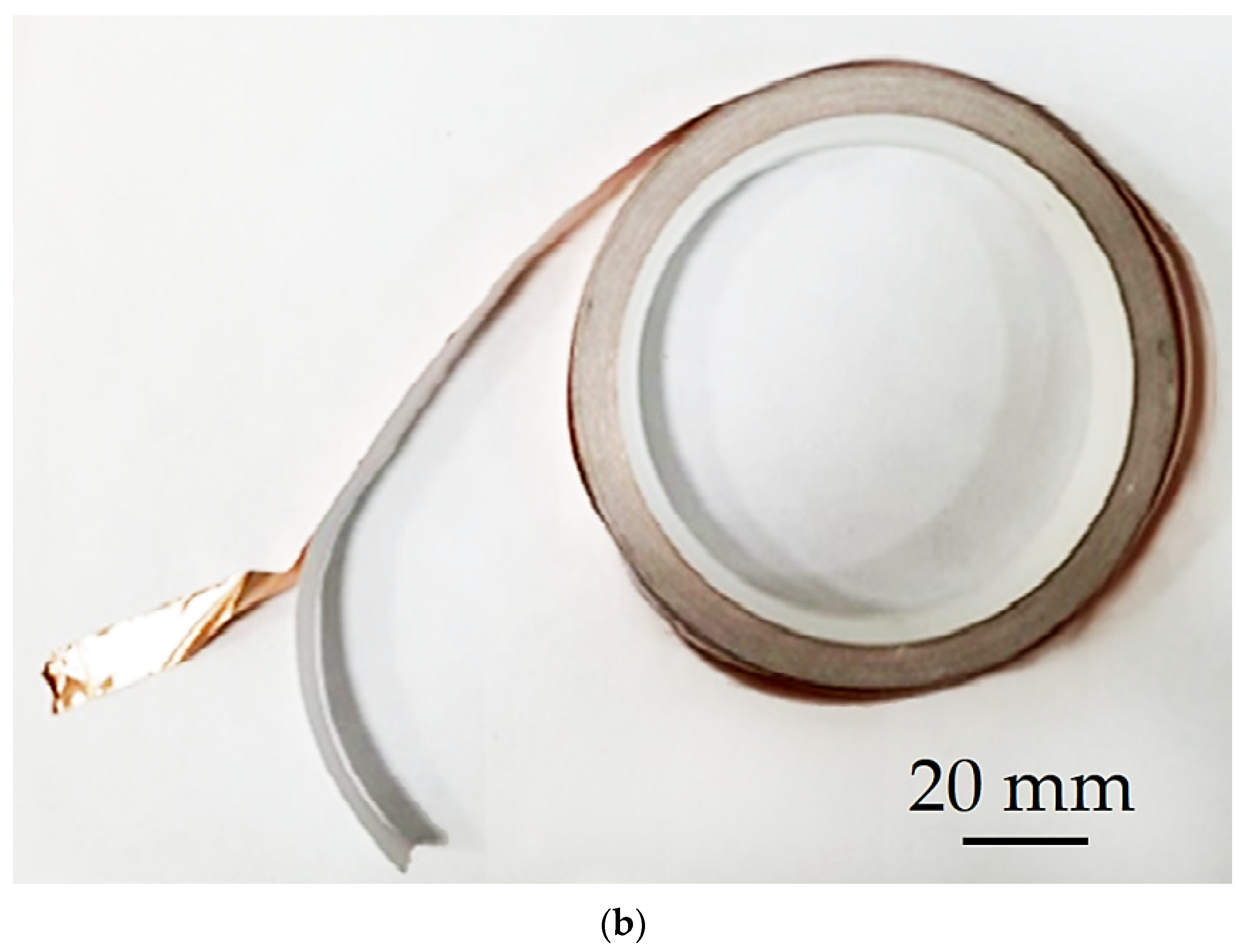

2.4. Assisting Electrode

3. Results

3.1. Characterization of ZnO Powder

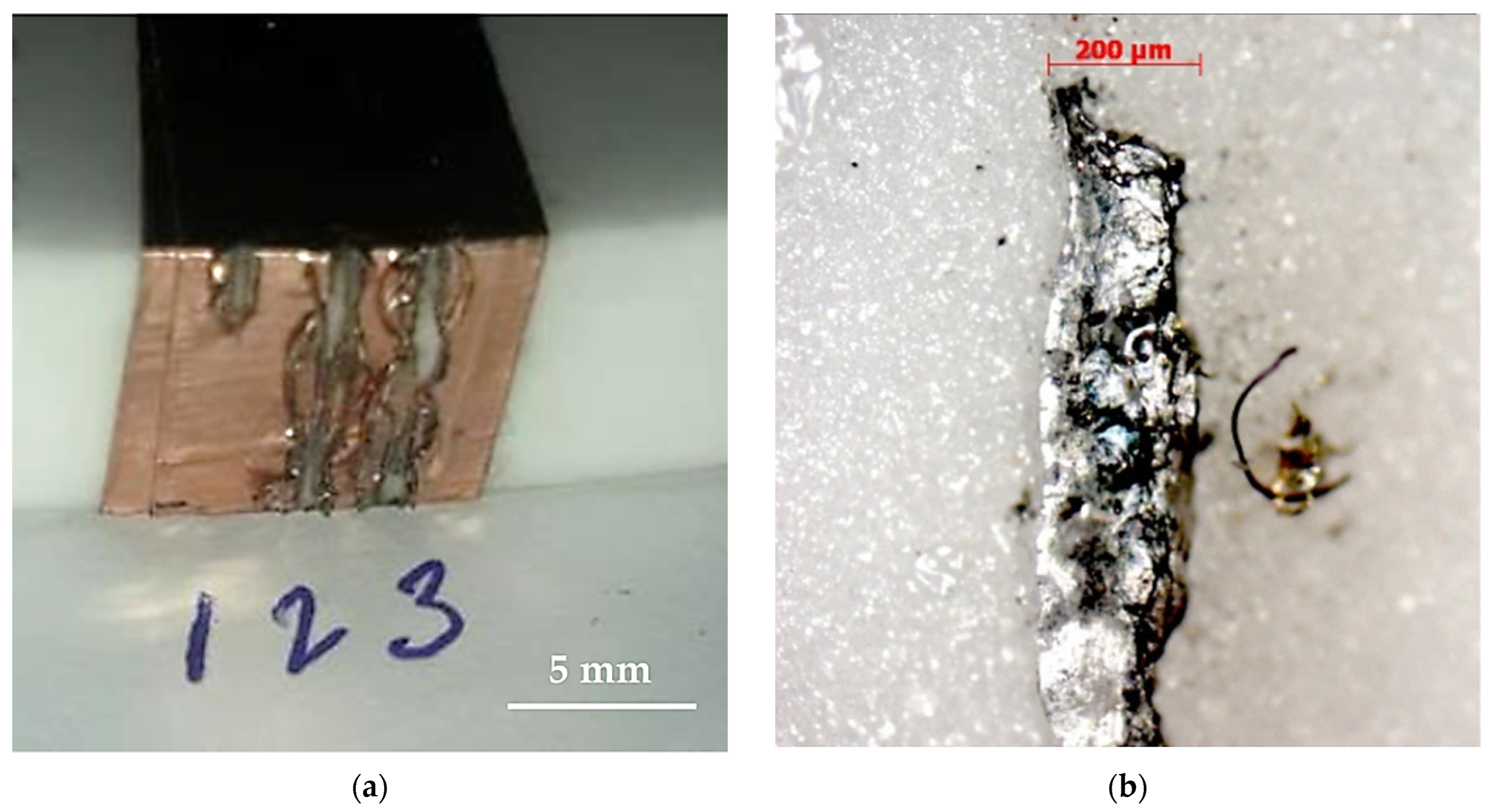

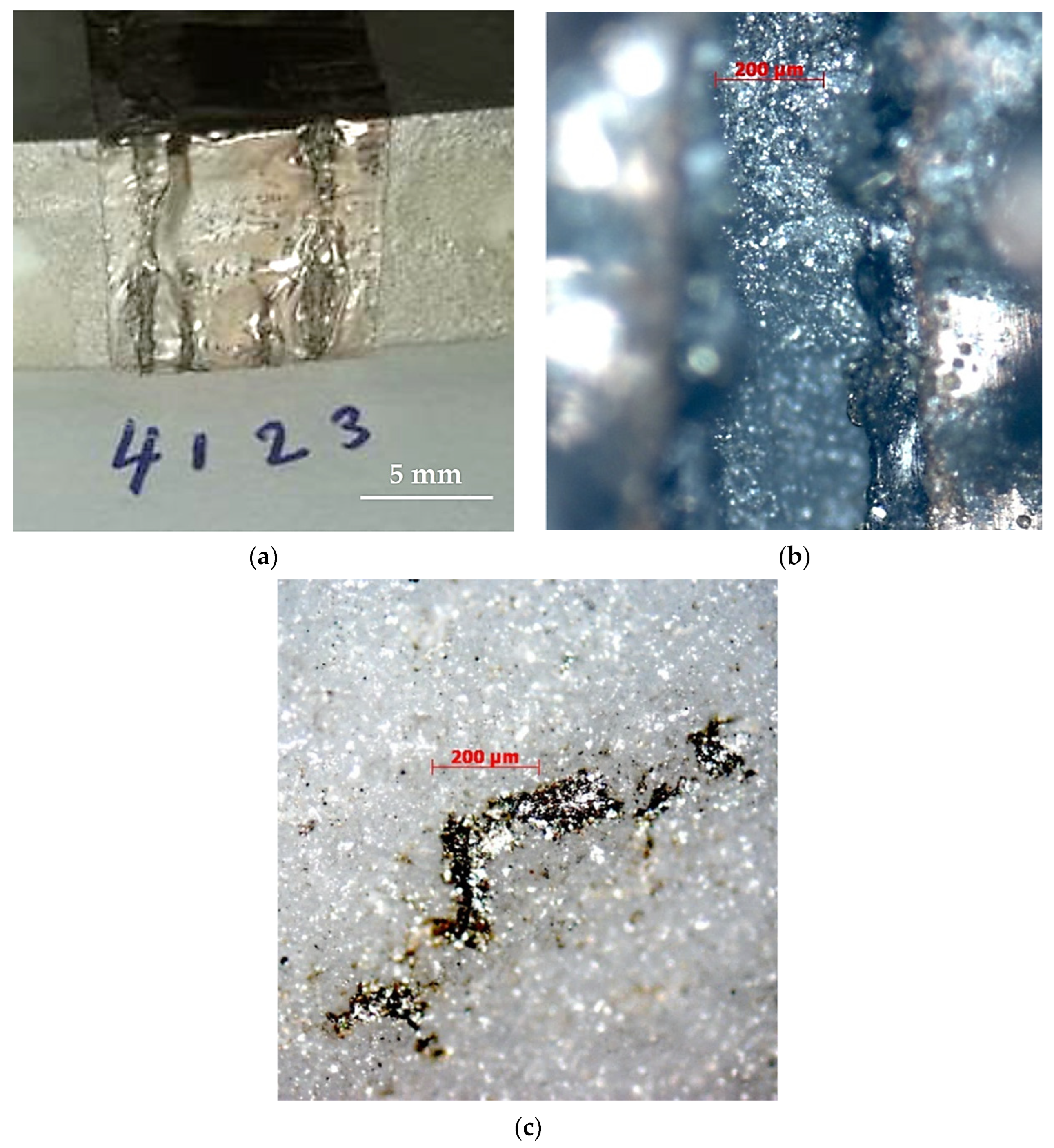

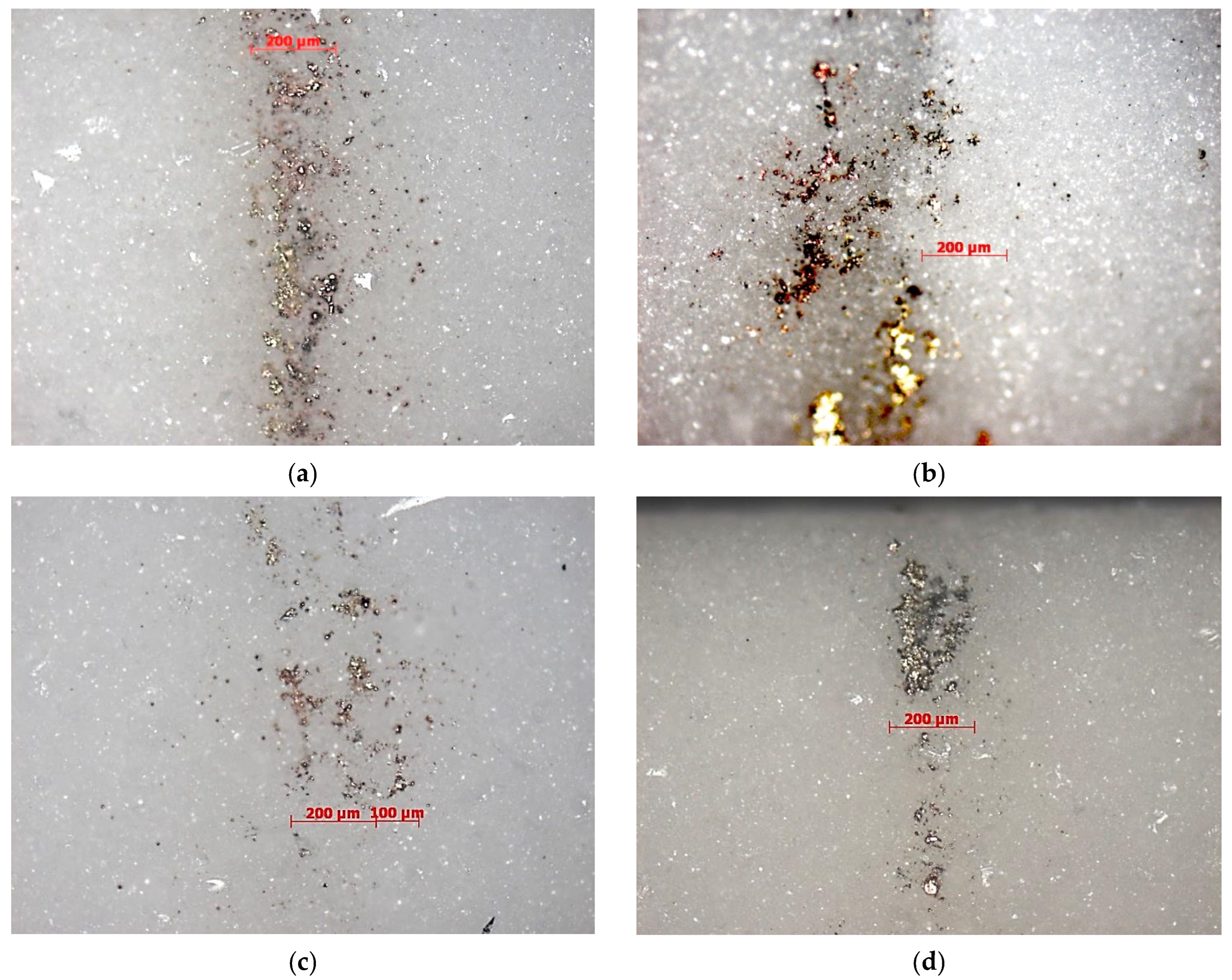

3.2. Preliminary Testing of the Developed Coatings in Deionized Water Medium

3.3. Electrical Discharge Machining in ZnO Powder-Mixed Deionized Water Medium

- A pulse frequency of 7 and 10 kHz and a pulse duration of 0.5 µs;

- A pulse frequency of 5 and 10 kHz and a pulse duration of 1.0 µs.

3.4. Scanning Electron Microscopy and Chemical Analyses

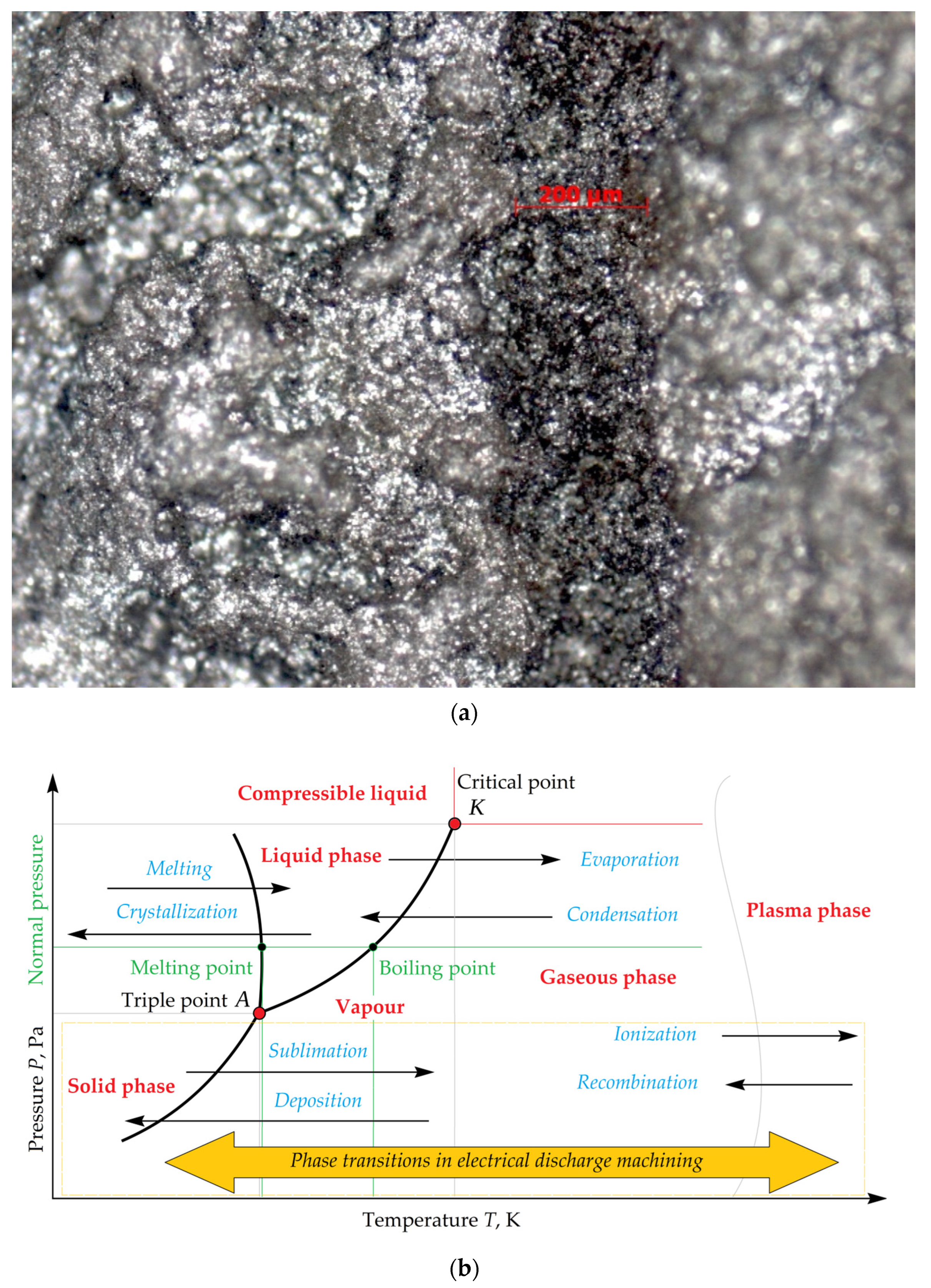

4. Discussion

- Even with the lower concentration of the suspension powder, it is possible to achieve higher values of material removal rate (7 g/L for ZnO in the current study comparing 150 g/L for TiO₂ [50]) in combination with a copper coating that can be related to the electrical properties of the assisting powder such as band gap more than to specific electrical resistance of the coating;

- Complex multi-layer complex coating can reduce performance due to a decrease in the electrical conductivity: there is a noticeable difference between mono- and multi-layer Cu-Ag and Cu sandwich coatings and a mono- and double-layer coatings, but no effect was observed between double and triple copper coating;

- Temperature and holding time during coating tempering do not demonstrate any noticeable effect. However, a slight improvement was observed between tempered and not tempered samples that do not have a principle character but significantly enlarge the labor intensity of the work.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oppong Boakye, G.; Geambazu, L.E.; Ormsdottir, A.M.; Gunnarsson, B.G.; Csaki, I.; Fanicchia, F.; Kovalov, D.; Karlsdottir, S.N. Microstructural Properties and Wear Resistance of Fe-Cr-Co-Ni-Mo-Based High Entropy Alloy Coatings Deposited with Different Coating Techniques. Appl. Sci. 2022, 12, 3156. [Google Scholar] [CrossRef]

- Mahesh, K.; Philip, J.T.; Joshi, S.N.; Kuriachen, B. Machinability of Inconel 718: A critical review on the impact of cutting temperatures. Mater. Manuf. Process. 2021, 36, 753–791. [Google Scholar] [CrossRef]

- Padalko, A.G.; Ellert, O.G.; Efimov, N.N.; Novotortsev, V.M.; Talanova, G.V.; Zubarev, G.I.; Fedotov, V.T.; Suchkov, A.N.; Solntsev, K.A. High-pressure phase transformations, microstructure, and magnetic properties of the hypereutectic alloy 10Ni-90Al. Inorg. Mater. 2013, 49, 1098–1105. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Shaysultanov, D.G.; Tikhonovsky, M.A.; Zherebtsov, S.V. Structure and high temperature mechanical properties of novel non-equiatomic Fe-(Co, Mn)-Cr-Ni-Al-(Ti) high entropy alloys. Intermetallics 2018, 102, 140–151. [Google Scholar] [CrossRef]

- Zhong, Q.; Wei, K.; Yue, X.; Zhou, R.; Zeng, X. Powder densification behavior and microstructure formation mechanism of W-Ni alloy processed by selective laser melting. J. Alloys Compd. 2022, 908, 164609. [Google Scholar] [CrossRef]

- Pingale, A.D.; Belgamwar, S.U.; Rathore, J.S. A novel approach for facile synthesis of Cu-Ni/GNPs composites with excellent mechanical and tribological properties. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2020, 260, 114643. [Google Scholar] [CrossRef]

- Grigoriev, S.; Peretyagin, P.; Smirnov, A.; Solis, W.; Diaz, L.A.; Fernandez, A.; Torrecillas, R. Effect of graphene addition on the mechanical and electrical properties of Al2O3-SiCw ceramics. J. Eur. Ceram. Soc. 2017, 37, 2473–2479. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Peretyagin, P.Y.; Seleznev, A.E.; Okunkova, A.A.; Smirnov, A. The Effect of TiC Additive on Mechanical and Electrical Properties of Al2O3 Ceramic. Appl. Sci. 2018, 8, 2385. [Google Scholar] [CrossRef]

- Díaz, L.A.; Montes-Morán, M.A.; Peretyagin, P.Y.; Vladimirov, Y.G.; Okunkova, A.; Moya, J.S.; Torrecillas, R. Zirconia-alumina-nanodiamond composites with gemological properties. J. Nanoparticle Res. 2014, 16, 2257. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Fedorov, S.V.; Okunkova, A.A.; Pivkin, P.M.; Peretyagin, P.Y.; Ershov, A. Development of DLC-Coated Solid SiAlON/TiN Ceramic End Mills for Nickel Alloy Machining: Problems and Prospects. Coatings 2021, 11, 532. [Google Scholar] [CrossRef]

- Rashid, A.; Bilal, A.; Liu, C.; Jahan, M.P.; Talamona, D.; Perveen, A. Effect of Conductive Coatings on Micro-Electro-Discharge Machinability of Aluminum Nitride Ceramic Using on-Machine-Fabricated Microelectrodes. Materials 2019, 12, 3316. [Google Scholar] [CrossRef] [PubMed]

- Zawada-Michałowska, M.; Pieśko, P.; Józwik, J. Tribological Aspects of Cutting Tool Wear during the Turning of Stainless Steels. Materials 2020, 13, 123. [Google Scholar] [CrossRef] [PubMed]

- Shabani, M.; Sacramento, J.; Oliveira, F.J.; Silva, R.F. Multilayer CVD Diamond Coatings in the Machining of an Al6061-15 Vol % Al2O3 Composite. Coatings 2017, 7, 165. [Google Scholar] [CrossRef]

- Staszuk, M.; Pakuła, D.; Pancielejko, M.; Tański, T.; Dobrzański, L.A. Investigations on wear mechanisms of PVD coatings on carbides and sialons. Arch. Metall. Mater. 2017, 62, 2095–2100. [Google Scholar] [CrossRef]

- Yang, Q.; Wu, T.; Wang, L.; Chen, Y.; Chen, L.; Lou, D.; Cheng, J.; Liu, D. Laser-induced gradient microstrcutres on Si3N4 ceramics and their wettability analysis. Mater. Chem. Phys. 2021, 270, 124749. [Google Scholar] [CrossRef]

- Kang, Z.; Fu, Y.; Ji, J.; Tian, L. Numerical Investigation of Microtexture Cutting Tool on Hydrodynamic Lubrication. J. Tribol. 2017, 139, 054502. [Google Scholar] [CrossRef]

- Kuzin, V.; Grigoriev, S.N.; Volosova, M.A. The role of the thermal factor in the wear mechanism of ceramic tools: Part 1. Macrolevel. J. Frict. Wear 2014, 35, 505–510. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Shaysultanov, D.G.; Chernichenko, R.S.; Tikhonovsky, M.A.; Zherebtsov, S.V. Effect of Al on structure and mechanical properties of Fe-Mn-Cr-Ni-Al non-equiatomic high entropy alloys with high Fe content. J. Alloys Compd. 2019, 770, 194–203. [Google Scholar] [CrossRef]

- Mohsan, A.U.H.; Liu, Z.; Padhy, G.K. A review on the progress towards improvement in surface integrity of Inconel 718 under high pressure and flood cooling conditions. Int. J. Adv. Manuf. Technol. 2017, 91, 107–125. [Google Scholar] [CrossRef]

- Filippov, A.V.; Tarasov, S.Y.; Podgornyh, O.A.; Shamarin, N.N.; Filippova, E.O. Oriented microtexturing on the surface of high-speed steel cutting tool. AIP Conf. Proc. 2016, 1783, 020057. [Google Scholar]

- Wu, Z.; Deng, J.; Su, C.; Luo, C.; Xia, D. Performance of the micro-texture self-lubricating and pulsating heat pipe self-cooling tools in dry cutting process. Int. J. Refract. Met. Hard Mater. 2014, 45, 238–248. [Google Scholar] [CrossRef]

- Pakuła, D.; Staszuk, M.; Dziekońska, M.; Kožmín, P.; Čermák, A. Laser Micro-Texturing of Sintered Tool Materials Surface. Materials 2019, 12, 3152. [Google Scholar] [CrossRef] [PubMed]

- Niketh, S.; Samuel, G.L. Surface textured drill tools-an effective approach for minimizing chip evacuation force and burr formation during high aspect ratio machining of titanium alloy. J. Manuf. Sci. Eng. Trans. ASME 2021, 143, 041005. [Google Scholar] [CrossRef]

- Lazarenko, B.R.; Lazarenko, N.I. Electric spark machining of metals in water and electrolytes. Surf. Eng. Appl. Electrochem. 1980, 1, 5–8. [Google Scholar]

- Lazarenko, B.R.; Duradzhi, V.N.; Bryantsev, I.V. Effect of Incorporating an additional inductance on the characteristics of anode and cathode processes. Surf. Eng. Appl. Electrochem. 1979, 5, 8–13. [Google Scholar]

- Lukashenko, S.V.; Kovtun, A.V.; Dashuk, P.N.; Sokolov, B.N. The Method of Electrical Discharge Machining of Dielectrics. Patent 1,542,715, 10 December 1986. [Google Scholar]

- Kumar, M.; Vaishya, R.O.; Suri, N.M.; Manna, A. An Experimental Investigation of Surface Characterization for Zirconia Ceramic Using Electrochemical Discharge Machining Process. Arab. J. Sci. Eng. 2021, 46, 2269–2281. [Google Scholar] [CrossRef]

- Raju, P.; Babasaheb, S. Study on analysis of plasma resistance variation in WEDM of insulating zirconia. Mater. Manuf. Process. 2021, 36, 59–72. [Google Scholar] [CrossRef]

- Guo, Y.; Hou, P.; Shao, D.; Li, Z.; Wang, L.; Tang, L. High-Speed Wire Electrical Discharge Machining of Insulating Zirconia with a Novel Assisting Electrode. Mater. Manuf. Process. 2014, 29, 526–531. [Google Scholar] [CrossRef]

- Shinde, B.; Pawade, R. Study on analysis of kerf width variation in WEDM of insulating zirconia. Mater. Manuf. Process. 2021, 36, 1010–1018. [Google Scholar] [CrossRef]

- Hou, P.; Guo, Y.; Shao, D.; Li, Z.; Wureli, Y.; Tang, L. Influence of open-circuit voltage on high-speed wire electrical discharge machining of insulating Zirconia. Int. J. Adv. Manuf. Technol. 2014, 73, 229–239. [Google Scholar] [CrossRef]

- Ji, R.; Liu, Y.; Zhang, Y.; Wang, F.; Cai, B.; Fu, X. Single discharge machining insulating Al2O3 stantaneous pulse energy in kerosene. Mater. Manuf. Process. 2012, 27, 676–682. [Google Scholar] [CrossRef]

- Moudood, M.A.; Sabur, A.; Ali, M.Y.; Jaafar, I.H. Effect of Peak Current on Material Removal Rate for Electrical Discharge Machining of Non-Conductive Al2O3 Ceramic. Adv. Mater. Res. 2014, 845, 730–734. [Google Scholar] [CrossRef]

- Liu, Y.H.; Li, X.P.; Ji, R.J.; Yu, L.L.; Zhang, H.F.; Li, Q.Y. Effect of technological parameter on the process performance for electric discharge milling of insulating Al2O3 ceramic. J. Mater. Process. Technol. 2008, 208, 245–250. [Google Scholar] [CrossRef]

- Lin, Y.-J.; Lin, Y.-C.; Wang, A.-C.; Wang, D.A.; Chow, H.M. Machining characteristics of EDM for non-conductive ceramics using adherent copper foils. In Advanced Materials Research, Materials Processing Technologies, Proceedings of the International Conference on Advances in Materials and Manufacturing Processes, Shenzhen, China, 6–8 November 2010; Jiang, Z.Y., Liu, X.H., Bu, J.L., Eds.; Trans Tech Publications Ltd.: Durnten-Zurich, Switzerland, 2010. [Google Scholar] [CrossRef]

- Panova, T.V.; Kovivchak, V.S. Formation of Oxide Layers on the Surface of Copper and its Alloys Modified by a High-Power Ion Beam. J. Surf. Investig. 2019, 13, 1098–1102. [Google Scholar] [CrossRef]

- Murzin, S.P.; Kryuchkov, A.N. Formation of ZnO/CuO heterostructure caused by laser-induced vibration action. Procedia Eng. 2017, 176, 546–551. [Google Scholar] [CrossRef]

- Silva, N.; Ramírez, S.; Díaz, I.; Garcia, A.; Hassan, N. Easy, Quick, and Reproducible Sonochemical Synthesis of CuO Nanoparticles. Materials 2019, 12, 804. [Google Scholar] [CrossRef] [PubMed]

- Zheng, W.; Chen, Y.; Peng, X.; Zhong, K.; Lin, Y.; Huang, Z. The Phase Evolution and Physical Properties of Binary Copper Oxide Thin Films Prepared by Reactive Magnetron Sputtering. Materials 2018, 11, 1253. [Google Scholar] [CrossRef] [PubMed]

- Ikim, M.I.; Spiridonova, E.Y.; Belysheva, T.V.; Gromov, V.F.; Gerasimov, G.N.; Trakhtenberg, L.I. Structural properties of metal oxide nanocomposites: Effect of preparation method. Russ. J. Phys. Chem. B 2016, 10, 543–546. [Google Scholar] [CrossRef]

- Ming, F. Effects of low melting point oxides addition on sintering characteristics of ZnO-glass varistors. Rare Met. Mater. Eng. 2002, 31, 221–224. [Google Scholar]

- Brzezińska, M.; García-Muñoz, P.; Ruppert, A.M.; Keller, N. Photoactive ZnO Materials for Solar Light-Induced CuxO-ZnO Catalyst Preparation. Materials 2018, 11, 2260. [Google Scholar] [CrossRef]

- Lee, H.; Zhang, X.; Hwang, J.; Park, J. Morphological Influence of Solution-Processed Zinc Oxide Films on Electrical Characteristics of Thin-Film Transistors. Materials 2016, 9, 851. [Google Scholar] [CrossRef]

- Sahu, A.K.; Chatterjee, S.; Nayak, P.K.; Mahapatra, S.S. Study on effect of tool electrodes on surface finish during electrical discharge machining of Nitinol. IOP Conf. Ser. Mate. Sci. Eng. 2018, 338, 012033. [Google Scholar] [CrossRef]

- Movchan, B.A.; Grechanyuk, N.I. Microhardness and microbrittleness of condensates of the TiC-Al2O3 system. Inorg. Mater. 1981, 17, 972–973. [Google Scholar]

- Zhikhareva, I.G.; Zhikharev, A.I. Modeling of Electrodeposited Precipitation Structure. Izv. Vyss. Uchebnykh Zaved. Khimiya Khimicheskaya Tekhnologiya 1993, 36, 52–58. [Google Scholar]

- Kubaschewski, O. Experimental Thermochemistry of Alloys. Thermochim. Acta 1988, 129, 11–27. [Google Scholar] [CrossRef]

- Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V.; Hamdy, K.; Mikhailova, M.A. Electrical Discharge Machining Non-Conductive Ceramics: Combination of Materials. Technologies 2020, 8, 32. [Google Scholar] [CrossRef]

- Okunkova, A.A.; Volosova, M.A.; Kropotkina, E.Y.; Hamdy, K.; Grigoriev, S.N. Electrical Discharge Machining of Alumina Using Ni-Cr Coating and SnO Powder-Mixed Dielectric Medium. Metals 2022, 12, 1749. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Okunkova, A.A.; Volosova, M.A.; Hamdy, K.; Metel, A.S. Electrical Discharge Machining of Al2O3 Using Copper Tape and TiO2 Powder-Mixed Water Medium. Technologies 2022, 10, 116. [Google Scholar] [CrossRef]

- Grigoriev, S.; Volosova, M.; Fyodorov, S.; Lyakhovetskiy, M.; Seleznev, A. DLC-coating application to improve the durability of ceramic tools. J. Mater. Eng. Perform. 2019, 28, 4415–4426. [Google Scholar] [CrossRef]

- Grigor’ev, S.N.; Fedorov, S.V.; Pavlov, M.D.; Okun’kova, A.A.; So, Y.M. Complex surface modification of carbide tool by Nb + Hf + Ti alloying followed by hardfacing (Ti + Al)N. J. Frict. Wear 2013, 34, 14–18. [Google Scholar] [CrossRef]

- Volosova, M.; Grigoriev, S.; Metel, A.; Shein, A. The role of thin-film vacuum-plasma coatings and their influence on the efficiency of ceramic cutting inserts. Coatings 2018, 8, 287. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Gurin, V.D.; Volosova, M.A.; Cherkasova, N.Y. Development of residual cutting tool life prediction algorithm by processing on CNC machine tool. Mater. Werkst. 2013, 44, 790–796. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Kozochkin, M.P.; Sabirov, F.S.; Kutin, A.A. Diagnostic systems as basis for technological improvement. Proc. CIRP 2012, 1, 599–604. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Sinopalnikov, V.A.; Tereshin, M.V.; Gurin, V.D. Control of parameters of the cutting process on the basis of diagnostics of the machine tool and workpiece. Meas. Tech. 2012, 55, 555–558. [Google Scholar] [CrossRef]

- Viswanathan, V.; Laha, T.; Balani, K.; Agarwal, A.; Seal, S. Challenges and advances in nanocomposite processing techniques. Mater. Sci. Eng. R 2006, 54, 121–285. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, J.; Jiang, W. Recent development in reactive synthesis of nanostructured bulk materials by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2013, 39, 103–112. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Wang, L.J.; Jiang, W.; Chen, L.-D. Microstructure and properties of Al2O3-TiC composites fabricated by combination of high-energy ball milling and spark plasma sintering (SPS). J. Inorg. Mater. 2005, 20, 1445. [Google Scholar]

- Grigoriev, S.N.; Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V.; Hamdy, K.; Podrabinnik, P.A.; Pivkin, P.M.; Kozochkin, M.P.; Porvatov, A.N. Electrical Discharge Machining of Oxide Nanocomposite: Nanomodification of Surface and Subsurface Layers. J. Manuf. Mater. Process. 2020, 4, 96. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V.; Hamdy, K.; Podrabinnik, P.A.; Pivkin, P.M.; Kozochkin, M.P.; Porvatov, A.N. Wire Tool Electrode Behavior and Wear under Discharge Pulses. Technologies 2020, 8, 49. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Kozochkin, M.P.; Porvatov, A.N.; Volosova, M.A.; Okunkova, A.A. Electrical discharge machining of ceramic nanocomposites: Sublimation phenomena and adaptive control. Heliyon 2019, 5, e02629. [Google Scholar] [CrossRef]

- Ay, M.; Etyemez, A. Optimization of the effects of wire EDM parameters on tolerances. Emerg. Mater. Res. 2020, 9, 527–531. [Google Scholar] [CrossRef]

- Markopoulos, A.P.; Papazoglou, E.-L.; Karmiris-Obratański, P. Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052. Machines 2020, 8, 12. [Google Scholar] [CrossRef]

- Moghaddam, M.A.; Kolahan, F. An optimised back propagation neural network approach and simulated annealing algorithm towards optimisation of EDM process parameters. Int. J. Manuf. Res. 2015, 10, 215–236. [Google Scholar] [CrossRef]

- Melnik, Y.A.; Kozochkin, M.P.; Porvatov, A.N.; Okunkova, A.A. On adaptive control for electrical discharge machining using vibroacoustic emission. Technologies 2018, 6, 96. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Kozochkin, M.P.; Kropotkina, E.Y.; Okunkova, A.A. Study of wire tool-electrode behavior during electrical discharge machining by vibroacoustic monitoring. Mech. Ind. 2016, 17, 717. [Google Scholar] [CrossRef]

- Grigor’ev, S.N.; Kozochkin, M.P.; Fedorov, S.V.; Porvatov, A.N.; Okun’kova, A.A. Study of Electroerosion Processing by Vibroacoustic Diagnostic Methods. Meas. Tech. 2015, 58, 878–884. [Google Scholar] [CrossRef]

- Kucukturk, G.; Cogun, C. A New Method for Machining of Electrically Nonconductive Workpieces Using Electric Discharge Machining Technique. Mach. Sci. Technol. 2010, 14, 189–207. [Google Scholar] [CrossRef]

- Kumar, A.; Mandal, A.; Dixit, A.R.; Das, A.K. Performance evaluation of Al2O3 nano powder mixed dielectric for electric discharge machining of Inconel 825. Mater. Manuf. Process. 2018, 33, 986–995. [Google Scholar] [CrossRef]

- Tzeng, Y.F.; Lee, C.Y. Effects of powder characteristics on electrodischarge machining efficiency. Int. J. Adv. Manuf. Technol. 2001, 17, 586–592. [Google Scholar] [CrossRef]

- Fukuzawa, Y.; Tani, T.; Mohri, N. Machining characteristics of insulated Si3N4 ceramics by electrical discharge method—Use of powder-mixed machining fluid. J. Ceram. Soc. Jpn. 2000, 108, 184–190. [Google Scholar] [CrossRef][Green Version]

- Zhang, W.; Li, L.; Wang, N.; Teng, Y.L. Machining of 7Cr13Mo steel by US-PMEDM process. Mater. Manuf. Process. 2021, 9, 1060–1066. [Google Scholar] [CrossRef]

- Gavrin, V.N.; Kozlova, Y.P.; Veretenkin, E.P.; Logachev, A.V.; Logacheva, A.I.; Lednev, I.S.; Okunkova, A.A. Reactor target from metal chromium for “pure” high-intensive artificial neutrino source. Phys. Part. Nucl. Lett. 2016, 13, 267–273. [Google Scholar] [CrossRef]

- Volosova, M.A.; Okunkova, A.A.; Povolotskiy, D.; Podrabinnik, P.A. Study of electrical discharge machining for the parts of nuclear industry usage. Mech. Ind. 2015, 7, 706. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V.; Hamdy, K.; Podrabinnik, P.A. Elemental and Thermochemical Analyses of Materials after Electrical Discharge Machining in Water: Focus on Ni and Zn. Materials 2021, 14, 3189. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Teleshevskii, V.I. Measurement Problems in Technological Shaping Processes. Meas. Tech. 2011, 54, 744–749. [Google Scholar] [CrossRef]

- Li, Y.; Zheng, G.; Cheng, X.; Yang, X.; Xu, R.; Zhang, H. Cutting performance evaluation of the coated tools in high-speed milling of AISI 4340 steel. Materials 2019, 12, 3266. [Google Scholar] [CrossRef]

- Zakharov, O.V.; Brzhozovskii, B.M. Accuracy of centering during measurement by roundness gauges. Meas. Tech. 2006, 49, 1094–1097. [Google Scholar] [CrossRef]

- Rezchikov, A.F.; Kochetkov, A.V.; Zakharov, O.V. Mathematical models for estimating the degree of influence of major factors on performance and accuracy of coordinate measuring machines. MATEC Web Conf. 2017, 129, 01054. [Google Scholar] [CrossRef][Green Version]

- Zakharov, O.V.; Balaev, A.F.; Kochetkov, A.V. Modeling Optimal Path of Touch Sensor of Coordinate Measuring Machine Based on Traveling Salesman Problem Solution. Procedia Eng. 2017, 206, 1458–1463. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V.; Hamdy, K.; Podrabinnik, P.A. Sub-Microstructure of Surface and Subsurface Layers after Electrical Discharge Machining Structural Materials in Water. Metals 2021, 11, 1040. [Google Scholar] [CrossRef]

- Vozniakovskii, A.A.; Kidalov, S.V.; Kol’tsova, T.S. Development of composite material aluminum-carbon nanotubes with high hardness and controlled thermal conductivity. J. Compos. Mater. 2019, 53, 2959–2965. [Google Scholar] [CrossRef]

- Yuan, H.; Zhu, F.; Yang, B.; Xu, B.; Dai, Y. Latest progress in aluminum production by alumina carbothermic reduction in vacuum. J. Vac. Sci. Technol. 2011, 31, 765–774. [Google Scholar]

- Slepchenkov, M.M.; Kolosov, D.A.; Glukhova, O.E. Novel Van Der Waals Heterostructures Based on Borophene, Graphene-like GaN and ZnO for Nanoelectronics: A First Principles Study. Materials 2022, 15, 4084. [Google Scholar] [CrossRef]

- Xin, M. Crystal Structure and Optical Properties of ZnO:Ce Nano Film. Molecules 2022, 27, 5308. [Google Scholar] [CrossRef] [PubMed]

- Platonov, V.; Nasriddinov, A.; Rumyantseva, M. Electrospun ZnO/Pd Nanofibers as Extremely Sensitive Material for Hydrogen Detection in Oxygen Free Gas Phase. Polymers 2022, 14, 3481. [Google Scholar] [CrossRef]

- Li, J.; Mushtaq, N.; Arshad, N.; Shah, M.A.K.Y.; Irshad, M.S.; Yan, R.; Yan, S.; Lu, Y. Proton-Ion Conductivity in Hexagonal Wurtzite-Nanostructured ZnO Particles When Exposed to a Reducing Atmosphere. Crystals 2022, 12, 1519. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Tarasova, T.V.; Filatova, A.A.; Sundukov, S.K.; Volosova, M.A.; Okunkova, A.A.; Melnik, Y.A.; Podrabinnik, P.A. Influence of Postprocessing on Wear Resistance of Aerospace Steel Parts Produced by Laser Powder Bed Fusion. Technologies 2020, 8, 73. [Google Scholar] [CrossRef]

- Vereschaka, A.S.; Grigoriev, S.N.; Sotova, E.S.; Vereschaka, A.A. Improving the efficiency of the cutting tools made of mixed ceramics by applying modifying nano-scale multilayered coatings. Adv. Mater. Res. 2013, 712–715, 391–394. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Volosova, M.A.; Batako, A.; Vereschaka, A.S.; Sitnikov, N.N.; Seleznev, A.E. Nano-scale multi-layered coatings for improved efficiency of ceramic cutting tools. Int. J. Adv. Manuf. Technol. 2017, 90, 27–43. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Vereschaka, A.A.; Fyodorov, S.V.; Sitnikov, N.N.; Batako, A.D. Comparative analysis of cutting properties and nature of wear of carbide cutting tools with multi-layered nano-structured and gradient coatings produced by using of various deposition methods. Int. J. Adv. Manuf. Technol. 2017, 90, 3421–3435. [Google Scholar] [CrossRef]

- Grigoriev, S.; Volosova, M.; Vereschaka, A.; Sitnikov, N.; Milovich, F.; Bublikov, J.; Fyodorov, S.; Seleznev, A. Properties of (Cr, Al, Si)N-(DLC-Si) composite coatings deposited on a cutting ceramic substrate. Ceram. Int. 2020, 46, 18241–18255. [Google Scholar] [CrossRef]

- Grigoriev, S.; Pristinskiy, Y.; Volosova, M.; Fedorov, S.; Okunkova, A.; Peretyagin, P.; Smirnov, A. Wire electrical discharge machining, mechanical and tribological performance of TiN reinforced multiscale SiAlON ceramic composites fabricated by spark plasma sintering. Appl. Sci. 2021, 11, 657. [Google Scholar] [CrossRef]

- Fedorov, S.V.; Pavlov, M.D.; Okunkova, A.A. Effect of structural and phase transformations in alloyed subsurface layer of hard-alloy tools on their wear resistance during cutting of high-temperature alloys. J. Frict. Wear 2013, 34, 190–198. [Google Scholar] [CrossRef]

- Kondratev, V.V.; Ershov, V.A.; Shakhray, S.G.; Ivanov, N.A. Preliminary heating of calcined anode. Tsvetnye Met. 2015, 1, 54–56. [Google Scholar]

- Hill, J.D. Basic Principles of EDM. Cut. Tool Eng. 1978, 30, 8–10. [Google Scholar]

- Pamfilov, E.A. Features of wear and ways to improve the wear resistance of dies and wood-cutting tools. Trenie I Iznos 1997, 18, 321–330. [Google Scholar]

- Reibakh, S.Y.; Segida, A.P. Thermal deformation of electrical-discharge blanking machines. Sov. Eng. Res. 1989, 9, 113–114. [Google Scholar]

- Derevyanko, M.S.; Kondrat’ev, A.V. Phase transformations and thermodynamic properties of oxide systems. Izv. Ferr. Metall. 2022, 65, 188–189. [Google Scholar] [CrossRef]

| Parameters | Value and Description |

|---|---|

| Max axis motions X × Y × Z, mm | 125 × 200 × 80 |

| Tool positioning accuracy, µm | ±1 |

| Average surface roughness parameter Ra, µm | 0.6 |

| Dielectric medium | Any |

| Max power consumption, kW | <6 |

| Factor | Measuring Units | Value |

|---|---|---|

| Operational voltage, Uo | V | 108; 72; 60; 48; 36 |

| Pulse frequency, f | kHz | 2; 5; 8; 11; 15; 17; 20; 25; 30 |

| Pulse duration, D | µs | 0.5; 1; 1.5; 1.75; 2; 2.35; 2.5; 2.68; 2.7 |

| Rewinding speed, vW | m/min | 3; 3.4; 7; 10 |

| Feed rate, vF | mm/min | 0.1; 0.3; 0.4; 0.5; 1 |

| Wire tension FT | N | 0.05; 0.1; 0.25; 0.3; 0.4 |

| Chemical Substances | Chemical Formula | wt.% |

|---|---|---|

| Zinc oxide | ZnO | Balance |

| Manganese | Mn | ≤0.0005 |

| Arsenic | As | ≤0.0002 |

| Cadmium | Cd | not standardized |

| Potassium permanganate | KMnO₄ | ≤0.01 |

| Potassium | K | ≤0.005 |

| Calcium | Ca | ≤0.01 |

| Substances insoluble in hydrochloric acid | - | ≤0.01 |

| Sulfates | SO₄ | ≤0.01 |

| Phosphates | PO₄RR′R″ | not standardized |

| Chlorides | ClxR (x = 1–5) | ≤0.004 |

| Iron | Fe | ≤0.001 |

| Sodium | Na | not standardized |

| Copper | Cu | ≤0.001 |

| Lead | Pb | ≤0.01 |

| Assisting Coating | Adhesive Type | Thickness, mm | Electrical Conductivity γ 1, S∙cm−1 | Specific Electrical Resistivity 2, Ω∙mm2∙m−1 |

|---|---|---|---|---|

| Silver Adhesive | Polymer-based + Silver powder | 0.100–0.110 | 0.009486 ± 0.00001 | 1.0542 × 10−6 |

| Copper tape, 1 layer | Resin-based | 0.040 | 0.580046 ± 0.00001 | 0.01724 × 10−6 |

| Copper tape, 2 layers | Resin-based | 2 × 0.040 | ||

| Copper tape, 3 layers | Resin-based | 3 × 0.040 | ||

| Sandwich “Copper tape + Silver Adhesive”, 1 layer | Polymer-based + Silver powder | 0.150 | 0.584112 ± 0.00001 | 0.01712 × 10−6 |

| Sandwich “Copper tape + Silver Adhesive”, 2 layers | Polymer-based + Silver powder | 2 × 0.150 | ||

| Sandwich “Copper tape + Silver Adhesive”, 3 layers | Polymer-based + Silver powder | 3 × 0.150 | ||

| Graphite 3 | - | - | - | 8.00 |

| Distilled water 3 | - | - | - | 103–104 |

| Parameter | Value |

|---|---|

| Thickness of copper basis, mm | 0.035 ± 0.0002 |

| Tensile strength, N/cm | 115 |

| Elongation (Extension ratio), % | <2 |

| Specific electrical resistivity, Ω∙mm2∙m−1 | 0.016–0.017 |

| Operating temperature, °C | From −40 to +110 ± 5 |

| Tape width, mm | 10 |

| Factor | Measuring Units | Value |

|---|---|---|

| Operational voltage, Uo | V | 108 |

| Pulse frequency, f | kHz | 2; 5; 7; 10; 15; 20; 25; 30 |

| Pulse duration, D | µs | 0.5; 1.0; 1.5; 2.0; 2.5; 2.64 |

| Rewinding speed, vW | m/min | 7 |

| Feed rate, vF | mm/min | 0.3 |

| Wire tension FT | N | 0.25 |

| Powder Concentration, g/L | Pulse Frequency, kHz | Pulse Duration, µs | |||||

|---|---|---|---|---|---|---|---|

| 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 2.64 | ||

| 7 | 2 | x | x | x | x | x | x |

| 5 | x | 1 | 1 | 1 | 0 | x | |

| 7 | x | 1 | 1 | 1 | 1 | x | |

| 10 | x | 1 | 1 | 1 | 0 | x | |

| 15 | x | 1 | 1 | 1 | 0 | x | |

| 20 | x | 1 | 1 | 1 | x | x | |

| 25 | x | 1 | 1 | 1 | 1 | x | |

| 30 | x | x | x | x | 0 | x | |

| 14 | 2 | x | x | x | x | x | x |

| 5 | x | 1 | 1 | x | x | x | |

| 7 | x | 2 | 1 | 0 | 0 | x | |

| 10 | x | 1 | 0 | 0 | 0 | x | |

| 15 | x | x | x | x | x | x | |

| 20 | x | x | x | x | x | x | |

| 25 | x | x | x | x | x | x | |

| 30 | x | x | x | x | x | x | |

| 21 | 2 | x | x | x | x | x | x |

| 5 | 2 | 1 | 0 | x | x | x | |

| 7 | 1 | 2 | x | x | x | x | |

| 10 | 1 | 1 | 0 | x | x | x | |

| 15 | x | x | x | x | x | x | |

| 20 | x | x | x | x | x | x | |

| 25 | x | x | x | x | x | x | |

| 30 | x | x | x | x | x | x | |

| 35 | 2 | x | 0 | x | x | x | x |

| 5 | 0 | 2 | 0 | x | x | x | |

| 7 | x | 1 | x | x | x | x | |

| 10 | 0 | 2 | 0 | x | x | x | |

| 15 | x | x | x | x | x | x | |

| 20 | x | x | x | x | x | x | |

| 25 | x | x | x | x | x | x | |

| 30 | x | x | x | x | x | x | |

| 50 | 2 | 0 | 2 | 0 | x | x | x |

| 5 | x | 1 | x | x | x | x | |

| 7 | x | 1 | x | x | x | x | |

| 10 | 0 | 2 | 0 | x | x | x | |

| 15 | x | 1 | x | x | x | x | |

| 20 | x | x | x | x | x | x | |

| 25 | x | x | x | x | x | x | |

| 30 | x | x | x | x | x | x | |

| 100 | 2 | x | 2 | 0 | x | x | x |

| 5 | x | 1 | 0 | x | x | x | |

| 7 | 0 | 2 | 0 | x | x | x | |

| 10 | 0 | 2 | x | x | x | x | |

| 15 | x | 0 | x | x | x | x | |

| 20 | x | x | x | x | x | x | |

| 25 | x | x | x | x | x | x | |

| 30 | x | x | x | x | x | x | |

| Spectrum | Weight Ratio of O, wt.% | Weight Ratio of Al, wt.% | Weight Ratio of Cu, wt.% | Weight Ratio of C, wt.% |

|---|---|---|---|---|

| 1 | 54.19 | 45.81 | - | - |

| 2 | 54.95 | 45.05 | - | - |

| 3 | 2.43 | - | 86.68 | 10.88 |

| 4 | 3.41 | 1.48 | 84.08 | 11.03 |

| 5 | 4.64 | 0.3 | 88.37 | 6.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okunkova, A.A.; Volosova, M.A.; Hamdy, K.; Gkhashim, K.I. Electrical Discharge Machining of Alumina Using Cu-Ag and Cu Mono- and Multi-Layer Coatings and ZnO Powder-Mixed Water Medium. Technologies 2023, 11, 6. https://doi.org/10.3390/technologies11010006

Okunkova AA, Volosova MA, Hamdy K, Gkhashim KI. Electrical Discharge Machining of Alumina Using Cu-Ag and Cu Mono- and Multi-Layer Coatings and ZnO Powder-Mixed Water Medium. Technologies. 2023; 11(1):6. https://doi.org/10.3390/technologies11010006

Chicago/Turabian StyleOkunkova, Anna A., Marina A. Volosova, Khaled Hamdy, and Khasan I. Gkhashim. 2023. "Electrical Discharge Machining of Alumina Using Cu-Ag and Cu Mono- and Multi-Layer Coatings and ZnO Powder-Mixed Water Medium" Technologies 11, no. 1: 6. https://doi.org/10.3390/technologies11010006

APA StyleOkunkova, A. A., Volosova, M. A., Hamdy, K., & Gkhashim, K. I. (2023). Electrical Discharge Machining of Alumina Using Cu-Ag and Cu Mono- and Multi-Layer Coatings and ZnO Powder-Mixed Water Medium. Technologies, 11(1), 6. https://doi.org/10.3390/technologies11010006