Discrete-Time Model Predictive Controller Using Laguerre Functions for Active Flutter Suppression of a 2D wing with a Flap

Abstract

:1. Introduction

2. Theory and Methods

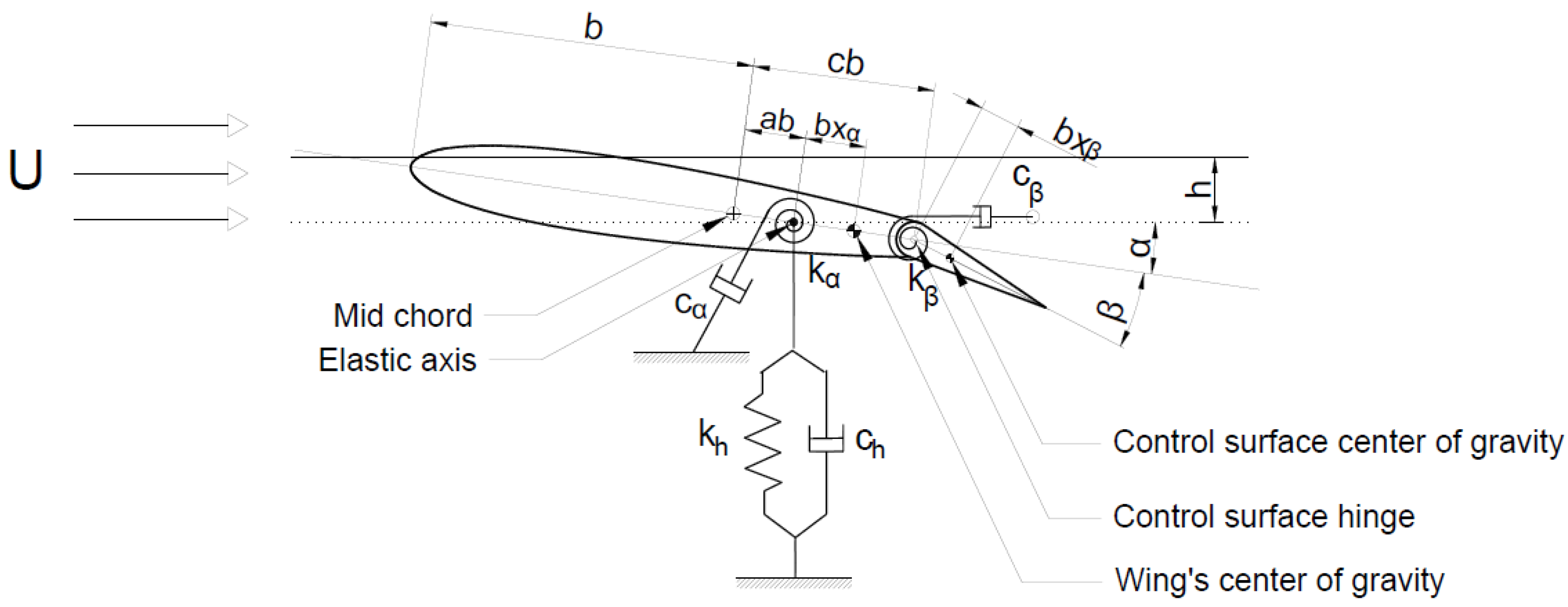

2.1. The Aeroelastic Model

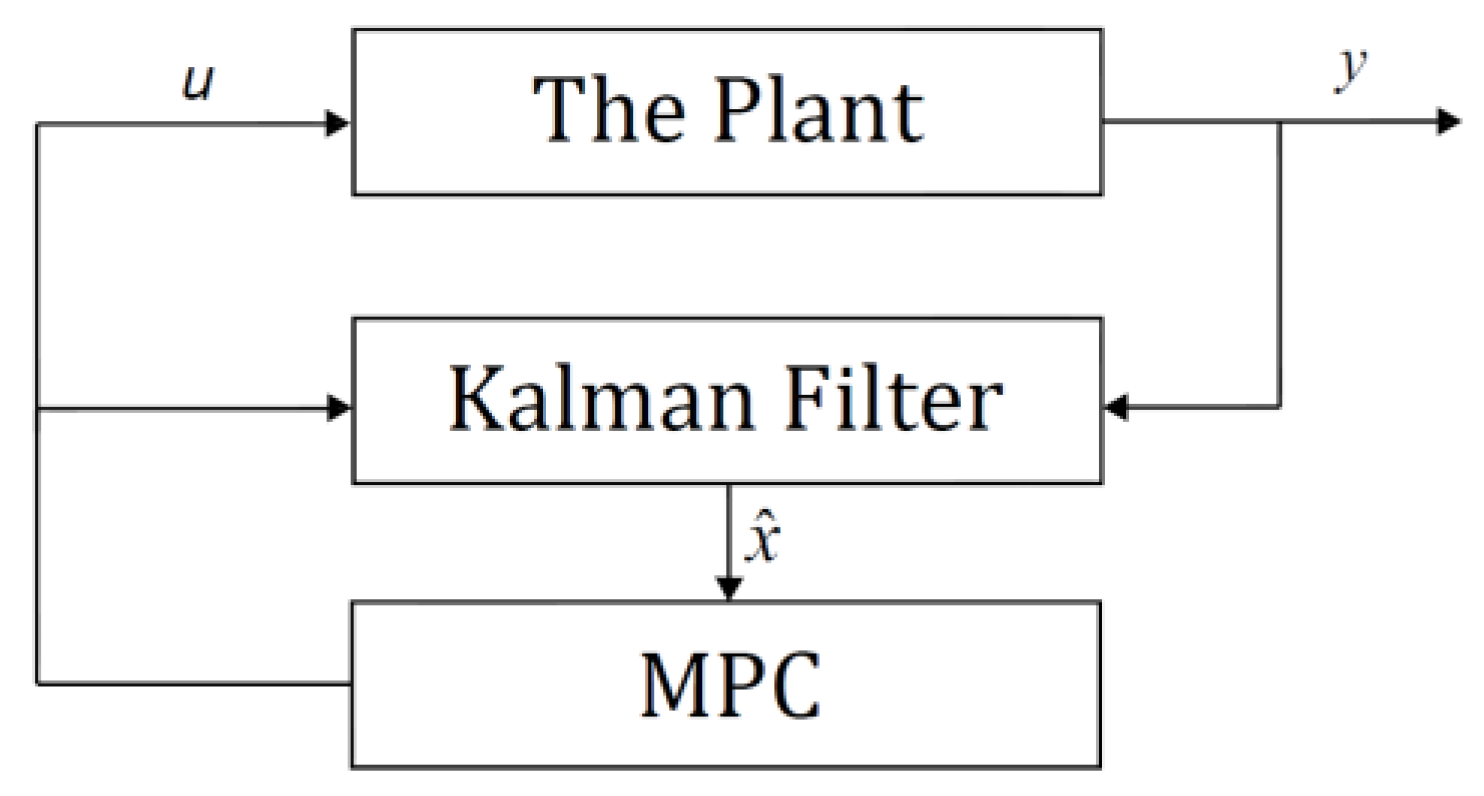

2.2. Discrete Time MPC Using Laguerre Fnctions

2.3. Discrete Time Kalman Filter

2.4. Simulation Results Analysis

- The 10–90% rise time to give an indication of the speed of the response.

- The present overshoot, , which measures the similarity with which the actual response matches the step input.

- The settling time, , which indicates how quickly the system settles within 2% of the input amplitude.

3. Results and Discussion

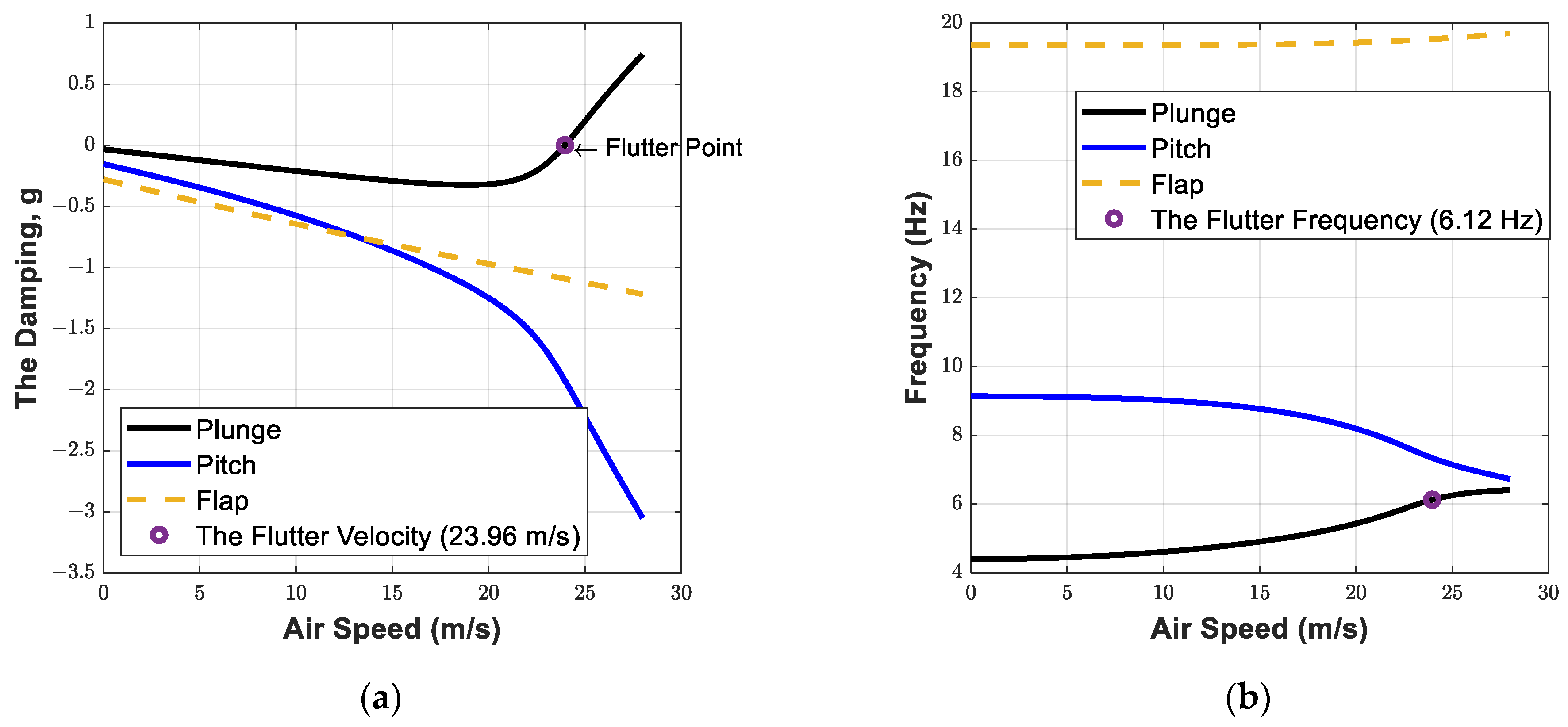

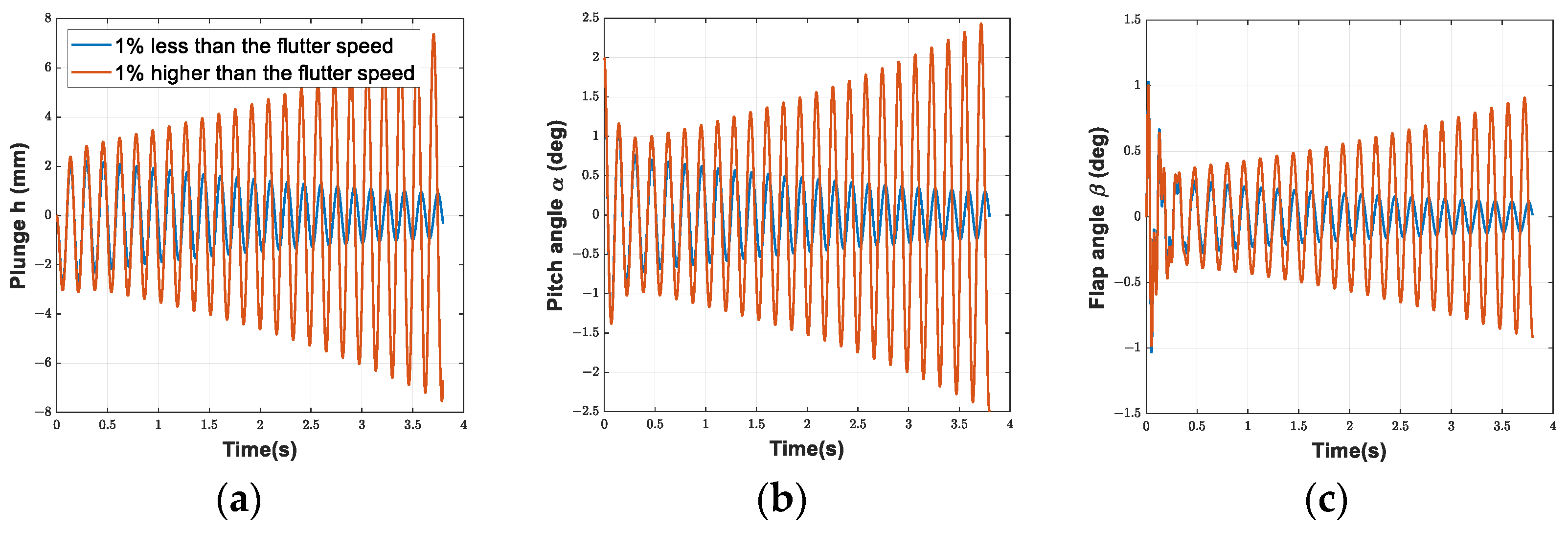

3.1. The Open Loop System Analysis

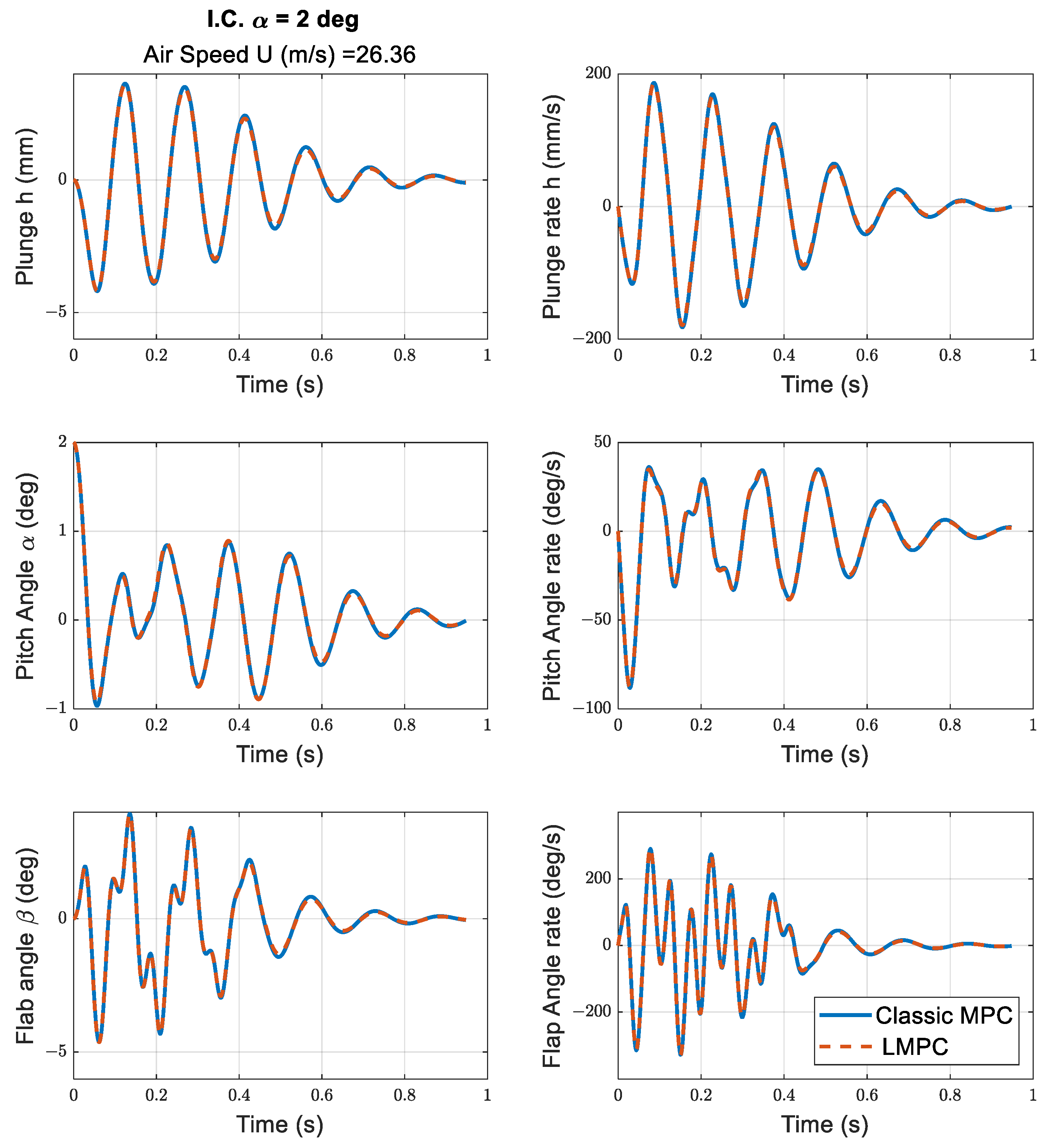

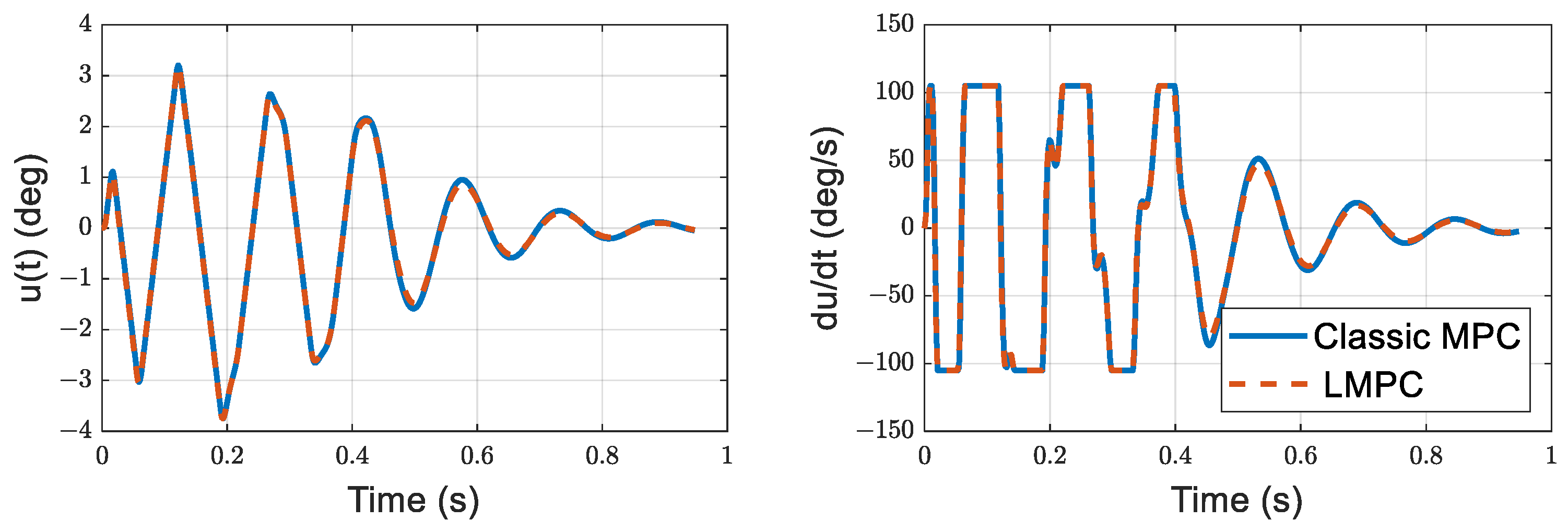

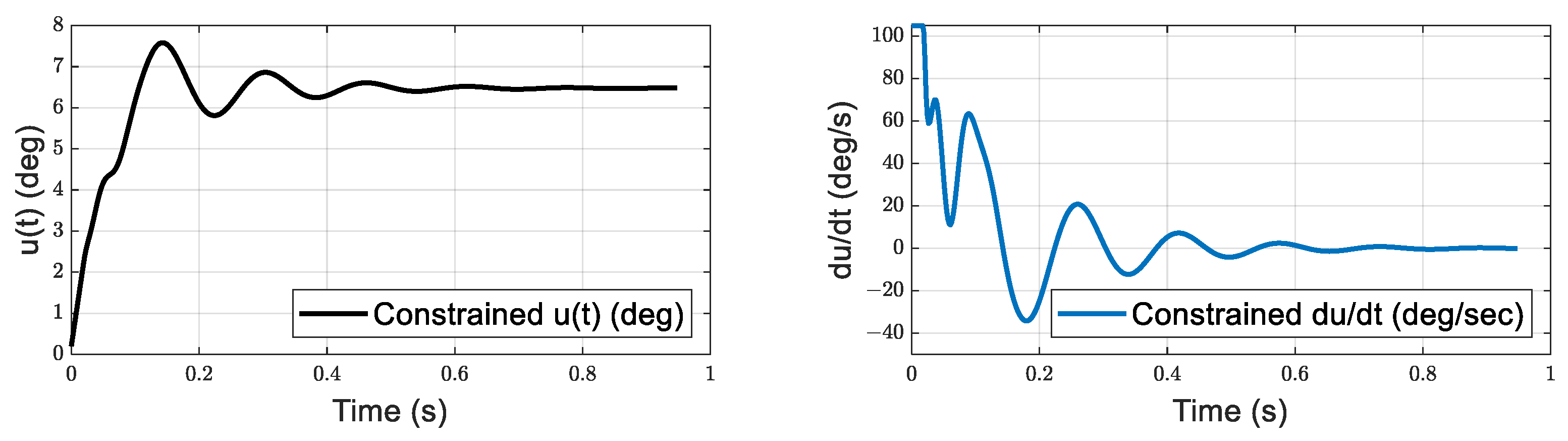

3.2. Closed Loop MPC Using Laguerre Functions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

| ; | The ratio of the total wing’s mass to the mass of the air affected by the wing |

| ; | The dimensionless radius of gyration of the wing about the elastic axis |

| ; | The dimensionless radius of gyration of the control surface about its hinge |

| ; | The plunge structural stiffness, where is uncoupled plunge fre-quency |

| ; | The pitch structural stiffness, where is uncoupled pitch fre-quency |

| ; | The control surface structural stiffness, where is uncoupled control surface frequency |

| ; | The ratio of uncoupled plunge and pitch natural frequencies |

| ; | The reduced velocity, or the dimensionless free stream speed of air |

| ; | The plunge structural damping, where is the plunge damping ratio |

| ; | The pitch structural damping, where is the pitch damping ratio |

| ; | The control surface structural damping, where is the control sur-face damping ratio |

| ; | The dimensionless time |

Appendix C

| Geometric Parameters | |

| Chord | 0.254 m |

| Span | 0.52 m |

| Semi-chord, b | 0.127 m |

| Elastic axis, a with respect to b | −0.5 |

| Hinge line, c with respect to b | 0.5 |

| Mass Parameters | |

| Mass of the wing | 0.62868 kg |

| Mass of the aileron | 0.18597 kg |

| Mass/length of the wing-aileron | 0.1558 kg/m |

| Mass of support blocks | 0.47485 × 2 kg |

| Inertial Parameters | |

| Sα (per span) | 0.08587 kg m |

| Sβ (per span) | 0.00395 kg m |

| xα | 0.434 |

| xβ | 0.01996 |

| Iα (per span) | 0.01347 kg m2 |

| Iβ (per span) | 0.0003264 kg m2 |

| rα | 0.7321 |

| rβ | 0.11397 |

| κ | 0.03984 |

| Stiffness Parameters | |

| Kα (per span) | 14,861 1/s2 |

| Kβ (per span) | 155 1/s2 |

| Kh (per span) | 1809 1/s2 |

| Damping Parameters | |

| ζα (log-dec) | 0.01626 |

| ζβ (log-dec) | 0.0115 |

| ζh (log-dec) | 0.0113 |

| W.P. Jones’ Approximation | |

| λ1 | 0.014 |

| δ1 | 0.165 |

| λ2 | 0.320 |

| δ2 | 0.335 |

References

- Hodges, D.H.; Pierce, G.A. Introduction to Structural Dynamics and Aeroelasticity, 2nd ed.; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar] [CrossRef]

- De Marqui, C.; Belo, E.M.; Marques, F.D. A flutter suppression active controller. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2005, 219, 19–33. [Google Scholar] [CrossRef]

- Junior, C.D.M.; Rebolho, D.C.; Belo, E.M.; Marques, F.D. Identification of flutter parameters for a wing model. J. Braz. Soc. Mech. Sci. Eng. 2006, 28, 339–346. [Google Scholar] [CrossRef]

- Kehoe, M.W. A Historical Overview of Flight Flutter Testing. In AGARD Structural and Materials Panel Meeting; NASA-TM-4720; NASA: Washington, DC, USA, 1995. [Google Scholar]

- Alizadeh, A.; Ebrahimi, Z.; Mazidi, A.; Fazelzadeh, S.A. Experimental nonlinear flutter analysis of a cantilever wing/store. Int. J. Struct. Stab. Dyn. 2020, 20, 2050082. [Google Scholar] [CrossRef]

- Chen, X.; Hu, R.; Tang, H.; Li, Y.; Yu, E.; Wang, L. Flutter stability of a long-span suspension bridge during erection in mountainous areas. Int. J. Struct. Stab. Dyn. 2020, 20, 2050102. [Google Scholar] [CrossRef]

- Borglund, D.; Kuttenkeuler, J. Active wing flutter suppression using a trailing edge flap. J. Fluids Struct. 2002, 16, 271–294. [Google Scholar] [CrossRef]

- Theis, J.; Pfifer, H.; Seiler, P.J. Robust Control Design for Active Flutter Suppression. In Proceedings of the AIAA Atmospheric Flight Mechanics Conference, San Diego, CA, USA, 4–8 January 2016. [Google Scholar]

- Cunha-Filho, A.; de Lima, A.; Donadon, M.; Leão, L. Flutter suppression of plates using passive constrained viscoelastic layers. Mech. Syst. Signal Process. 2016, 79, 99–111. [Google Scholar] [CrossRef]

- York, D.L. Analysis of Flutter and Flutter Suppression via an Energy Method. Master’s Thesis, Virginia Tech, Blacksburg, VA, USA, 1980. Available online: https://vtechworks.lib.vt.edu/handle/10919/43300 (accessed on 7 August 2020).

- Yuan, Y.; Yu, P.; Librescu, L.; Marzocca, P. Aeroelasticity of time-delayed feedback control of two-dimensional supersonic lifting surfaces. J. Guid. Control. Dyn. 2004, 27, 795–803. [Google Scholar] [CrossRef]

- Marzocca, P.; Silva, W.; Librescu, L. Open/Closed-Loop Nonlinear Aeroelasticity for Airfoils via Volterra Series Approach. In Proceedings of the 43rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Denver, CO, USA, 22–25 April 2002. [Google Scholar]

- Barker, J.M.; Balas, G.J.; Blue, P.A. Gain-Scheduled Linear Fractional Control for Active Flutter Suppression. J. Guid. Control. Dyn. 1999, 22, 507–512. [Google Scholar] [CrossRef]

- Horikawa, H.; Dowell, E.H. An Elementary Explanation of the Flutter Mechanism with Active Feedback Controls. J. Aircr. 1979, 16, 225–232. [Google Scholar] [CrossRef]

- Marretta, R.A.; Marino, F. Wing flutter suppression enhancement using a well-suited active control model. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2007, 221, 441–452. [Google Scholar] [CrossRef]

- Ashish, T. Modern Control Design with Matlab and Simulink; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- Karpel, M. Design for active flutter suppression and gust alleviation using state-space aeroelastic modeling. J. Aircr. 1982, 19, 221–227. [Google Scholar] [CrossRef]

- Garrard, W.L.; Liebst, B.S. Active flutter suppression using eigenspace and linear quadratic design techniques. J. Guid. Control. Dyn. 1985, 8, 304–311. [Google Scholar] [CrossRef]

- Block, J.; Gilliatt, H.; Block, J.; Gilliatt, H. Active Control of an Aeroelastic Structure. In Proceedings of the 35th Aerospace Sciences Meeting and Exhibit, Reston, NV, USA, 6–9 January 1997. [Google Scholar] [CrossRef]

- Olds, S.D. Modeling and LQR control of a two-dimensional airfoil. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 1997. Available online: http://hdl.handle.net/10919/36668 (accessed on 7 August 2020).

- Hopwood, J.W.; Ruskin, B.; Broderick, D.J.; Wei, F.-S. Aeroservoelastic Design and Wind Tunnel Testing using Parameter-Varying Optimal Control and Inertial-Based Sensing. In Proceedings of the AIAA Scitech 2019 Forum, San Diego, CA, USA, 7–11 January 2019. [Google Scholar] [CrossRef]

- Darabseh, T.T.; Tarabulsi, A.M.; Mourad, A.-H.I. Active Flutter Suppression of a Two-Dimensional Wing using Linear Quadratic Gaussian Optimal Control. Int. J. Struct. Stab. Dyn. 2022. [Google Scholar] [CrossRef]

- Bhoir, N.; Singh, S.N. Output feedback nonlinear control of an aeroelastic system with unsteady aerodynamics. Aerosp. Sci. Technol. 2004, 8, 195–205. [Google Scholar] [CrossRef]

- Sutherland, A.N. A Demonstration of Pitch-Plunge Flutter Suppression Using LQG Control. In Proceedings of the 27th International Congress of The Aeronautical Sciences Conference, Nice, France, 19–24 September 2010. [Google Scholar]

- Boscariol, P.; Gasparetto, A.; Zanotto, V. Active position and vibration control of a flexible links mechanism using model-based predictive control. J. Dyn. Syst. Meas. Control 2010, 132, 014506. [Google Scholar] [CrossRef]

- Na, M.G. A model predictive controller for the water level of nuclear steam generators. J. Korean Nucl. Soc. 2001, 33, 102–110. [Google Scholar]

- Pinheiro, T.C.F.; Silveira, A.S. Constrained discrete model predictive control of an arm-manipulator using Laguerre function. Optim. Control Appl. Methods 2020, 42, 160–179. [Google Scholar] [CrossRef]

- Mayne, D.Q.; Rawlings, J.B.; Rao, C.V.; Scokaert, P.O.M. Constrained model predictive control: Stability and optimality. Automatica 2000, 36, 789–814. [Google Scholar] [CrossRef]

- Wang, L. Model Predictive Control System Design and Implementation Using MATLAB®; Springer: London, UK, 2009. [Google Scholar] [CrossRef]

- Chipofya, M.; Lee, D.J.; Chong, K.T. Trajectory Tracking and Stabilization of a Quadrotor Using Model Predictive Control of Laguerre Functions. In Abstract and Applied Analysis; Hindawi Publishing Corporation: London, UK, 2015; Volume 2015, p. 12. [Google Scholar] [CrossRef]

- Tewari, A. Aeroservoelasticity: Modeling and Control; Springer: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Fung, Y.C. An Introduction to the Theory of Aeroelasticity; Dover Publications: Mineola, NY, USA, 2002. [Google Scholar]

- Dimitriadis, G. Introduction to Nonlinear Aeroelasticity; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Sutherland, A.N. A Small Scale Pitch-Plunge Flutter Model for Active Flutter Control Research. In Proceedings of the 26th International Congress of the Aeronautical Sciences including the 8th AIAA Aviation Technology, Integration, and Operations (ATIO) Conference, Anchorage, AK, USA, 14–19 September 2008. [Google Scholar]

- Theodorsen, T. Report No. 496, general theory of aerodynamic instability and the mechanism of flutter. J. Frankl. Inst. 1935, 219, 766–767. [Google Scholar] [CrossRef]

- Rossiter, J.A. Model-Based Predictive Control: A Practical Approach; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Wang, L. Discrete Time Model Predictive Control Design Using Laguerre Functions. In Proceedings of the 2001 American Control Conference, Arlington, VA, USA, 25–27 June 2001. [Google Scholar]

- Hovland, G. Introduction to Kalman Filtering; METR4200—Advanced Control. 2004. Available online: https://www.scribd.com/document/500629483/METR4200-8 (accessed on 10 August 2020).

- Outanoute, M.; Selmani, A.; Guerbaoui, M.; Ed-dahhak, A.; Lachhab, A.; Bouchikhi, B. Predictive control algorithm using laguerre functions for greenhouse temperature control. Int. J. Control Autom. 2018, 11, 11–20. [Google Scholar]

- Dorf, R.C.; Bishop, R.H. Modern Control Systems; Pearson Prentice Hall: Hoboken, NJ, USA, 2008. [Google Scholar]

- Conner, M.; Tang, D.; Dowell, E.; Virgin, L. Nonlinear Behavior of a Typical Airfoil Section with Control Surface Freeplay: A Numerical and Experimental Study. J. Fluids Struct. 1997, 11, 89–109. [Google Scholar] [CrossRef]

- Prazenica, R.J. Model Predictive Control of a Nonlinear Aeroelastic System Using Reduced-Order Volterra Models. In Proceedings of the AIAA Atmospheric Flight Mechanics Conference, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar]

- Wright, J.R.; Cooper, J.E. Introduction to Aircraft Aeroelasticity and Loads; John Wiley & Sons: Hoboken, NJ, USA, 2008; Volume 20. [Google Scholar]

| Trial No. | R | u(deg) Input Const. | du/dt Input Const. | Ts for h | ISE for h | Ts for α | ISE for α | Ts for β | ISE for β | ISU | u(deg) max. | du/dt max. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 25 | No | No | 0.6 | 0.02 | 0.7 | 0.02 | 0.5 | 0.16 | 0.14 | 11.8 | 2000 |

| 2 | 50 | No | No | 0.8 | 0.03 | 0.8 | 0.02 | 0.6 | 0.17 | 0.15 | 7.9 | 1194 |

| 3 | 25 | 10 | 105 | 0.8 | 0.03 | 0.8 | 0.02 | 0.7 | 0.13 | 0.16 | 3.9 | 105 |

| 4 | 50 | 10 | 105 | 0.8 | 0.03 | 0.8 | 0.02 | 0.8 | 0.14 | 0.16 | 3.7 | 105 |

| Trial No. | R | u(deg) Input Const. | du/dt Input Const. | ISE for β | Tr | P.O. % | Ts | ISU | u(deg) max. | du/dt max. |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 25 | No | No | 0.04 | 0.08 | 21 | 0.46 | 0.17 | 7.6 | 332 |

| 2 | 50 | No | No | 0.04 | 0.08 | 19 | 0.47 | 0.17 | 7.5 | 263 |

| 3 | 25 | 10 | 105 | 0.05 | 0.09 | 20 | 0.47 | 0.18 | 7.6 | 105 |

| 4 | 50 | 10 | 105 | 0.06 | 0.09 | 18 | 0.48 | 0.18 | 7.5 | 105 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darabseh, T.; Tarabulsi, A.; Mourad, A.-H.I. Discrete-Time Model Predictive Controller Using Laguerre Functions for Active Flutter Suppression of a 2D wing with a Flap. Aerospace 2022, 9, 475. https://doi.org/10.3390/aerospace9090475

Darabseh T, Tarabulsi A, Mourad A-HI. Discrete-Time Model Predictive Controller Using Laguerre Functions for Active Flutter Suppression of a 2D wing with a Flap. Aerospace. 2022; 9(9):475. https://doi.org/10.3390/aerospace9090475

Chicago/Turabian StyleDarabseh, Tariq, Abdallah Tarabulsi, and Abdel-Hamid I. Mourad. 2022. "Discrete-Time Model Predictive Controller Using Laguerre Functions for Active Flutter Suppression of a 2D wing with a Flap" Aerospace 9, no. 9: 475. https://doi.org/10.3390/aerospace9090475

APA StyleDarabseh, T., Tarabulsi, A., & Mourad, A.-H. I. (2022). Discrete-Time Model Predictive Controller Using Laguerre Functions for Active Flutter Suppression of a 2D wing with a Flap. Aerospace, 9(9), 475. https://doi.org/10.3390/aerospace9090475