1. Introduction

The lunar surface is covered by a layer of regolith several meters thick. It is formed primarily by various space weathering processes such as micrometeoroid collisions, solar wind sputtering, and cosmic ray radiation; thus, the ancient history of the Moon is recorded. The finer part of lunar regolith, several to ten microns in size, is called lunar dust, which has caused numerous difficulties in Apollo manned missions according to Apollo astronauts’ descriptions: “after several landing hours, lunar dust is the source of certain aggravating operational problems”, and “I think dust is probably one of our greatest inhibitors to a nominal operation on the Moon. I think we can overcome physiological or physical or mechanical problems except for dust” [

1,

2]. It is notable that lunar dust is a significant hazard during Apollo missions; the same can be expected for other lunar missions involving a soft landing and rocket return, or other lunar surface disturbances [

3,

4,

5,

6]. Related problems include surface obscuration, mechanism clogging, space suit pressurization leaks, and so on.

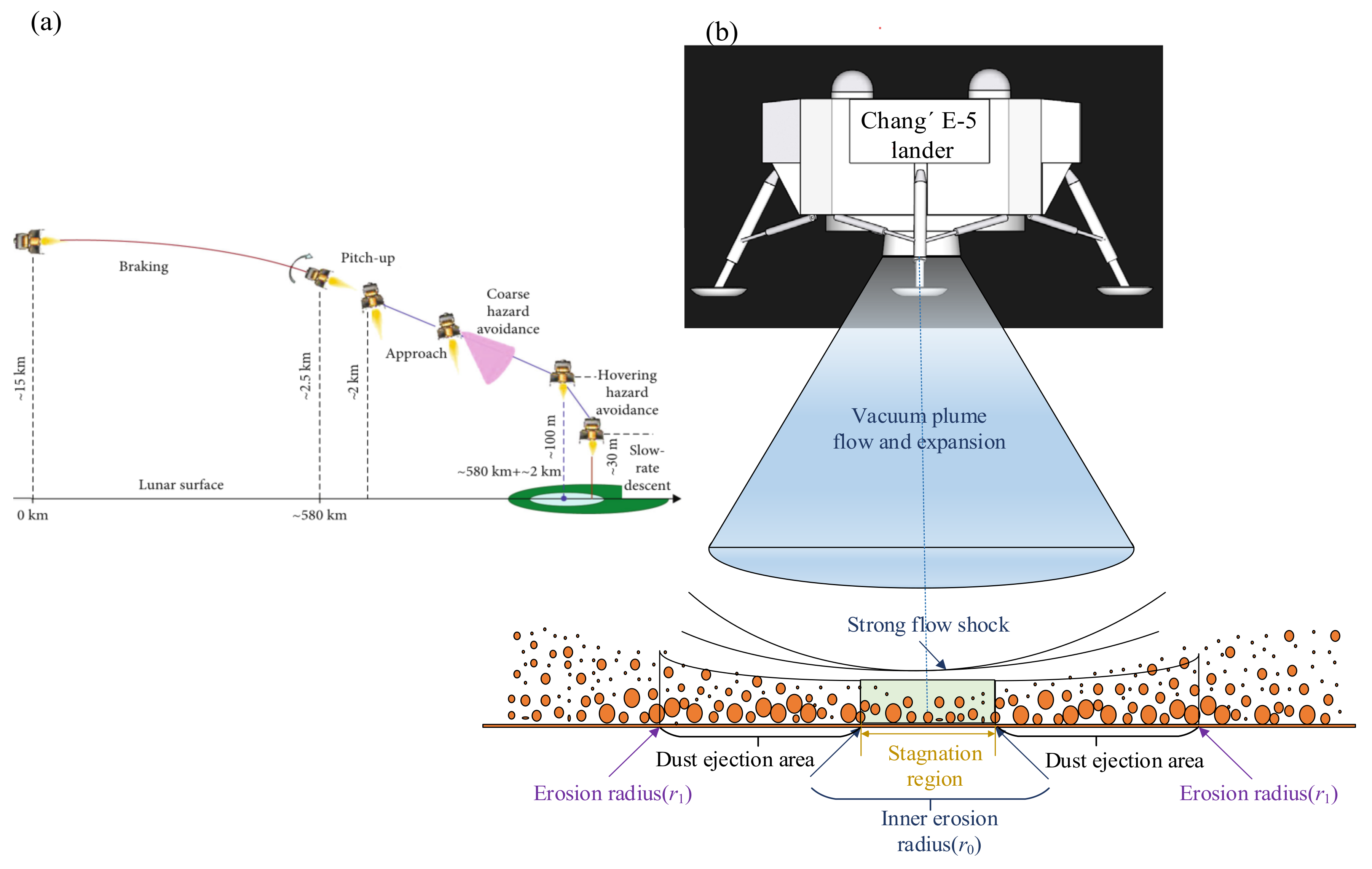

Although the lunar regolith is generally considered to be essentially static, because it is not subject to erosion induced by wind or water, it is disturbed by surface charging and levitation due to electrical force. It is also disturbed by micrometeoroids’ impact and is ejected, which is categorized as a natural mechanism disturbance [

7,

8]. In addition to natural mechanisms, human activities on the Moon also disturb uncountable lunar dust particles, resulting in serious latent hazards [

9,

10,

11]. Of all human activities that disturb the lunar regolith, landing on the Moon has the most significant impact. During this process, the engine plume can strip off surface layers of lunar regolith and eject massive quantities of high-speed lunar dust with speeds up to kilometers per second due to the Moon’s almost complete vacuum and low gravity environment. These high-speed dust particles severely threaten the safety of nearby instruments or astronauts.

To investigate engine plume erosion characteristics, an in-situ lunar dust detector is used to measure the accumulation of ejected dust particles during Apollo and Chang’E missions. On Apollo missions, the lunar dust detector comprises three solar cells acting as sensors [

12]. Such detectors on Apollo 11, Apollo 12, and Apollo 15 missions observed dust output variation during descent and ascent stages. Unfortunately, these three missions only measured the qualitative dust ejection phenomenon one hundred meters away from landing sites [

13,

14]. Lunar dust mass deposition at the landing site during the descent stage was approximately 0.83 mg/cm

2 on the Chang’E-3 mission [

15,

16]. These four missions do not provide comprehensive landing erosion information because of the limited opportunities for dust detection. In addition, allocation height, distance from the landing site, and sensor sensitive areas significantly affect dust deposition results. Therefore, different approaches are required to effectively investigate the lunar dust erosion process within such difficult boundary conditions.

Earth experimental investigation is capable of obtaining lunar erosion information, including crater shape, crater depth, and erosion parameters. Many investigations were conducted to compile information about this problem. Carly et al. established a box (measuring 12 inches by 12 inches by 7 inches) to make the plume and lunar regolith interaction a reality [

17]. In this experiment, gas velocities of 56 m/s, 40 m/s, and 37 m/s were adopted to obtain erosion crater depths over time under the influence of four different gases (Helium, Argon, Nitrogen and Carbon Dioxide), illustrating that variation in the erosion depth scale is independent of gas velocity and density, but that the time scale is dependent on gas velocity and density. Robert et al. investigated erosion properties by changing loose lunar particles’ density and mean diameter, finally finding that “crater-in-crater” geometry occurs under strong jet flow. Crater shape can be predicted in terms of an erosion parameter. In this study, the erosion parameter is extended to approximately five times that of previous laboratory experiments, which is a significant development [

18]. Current experiments conducted on Earth all rely on the Earth’s environment, as a sustained vacuum and low-gravity environment are difficult to maintain. In addition, the engine nozzle geometry and gas flow properties differ significantly on Earth when compared to the actual situation. This overly simplistic model is inadequate to produce the erosion phenomenon obtained by lunar landing; therefore, some erosion phenomenon are missed.

Benefiting from computer development, in recent years plume flow properties and corresponding erosion models began to be calculated using simulations, which is an effective method at present. As with other methods, simulation also starts with qualitative analysis, and mainly focuses on plume flow coupling from the engine nozzle to vacuum flow and expansion, and the flow field structure [

19,

20]. Next, to better understand this process, the simulation model and erosion theory are continuously optimized using researchers’ increased understanding of the lunar surface fence effect, the erosion model, relative particle trajectories, and particle velocity distribution [

19,

20,

21,

22,

23,

24,

25]. Although these investigations offer acceptable approximations of erosion characteristics to some degree, they have not been compared with actual landing erosion properties; it is therefore difficult to know if the results are reasonable. For example, He et al. and Li et al. [

22,

24] do not take actual engine thrust properties into consideration. Morries et al. [

19,

20] and Lane et al. [

23] adopt landing thrust value as vacuum flow inlet parameters, but they use water vapor as inlet gas. The actual engine outlet gas comprises several types of gas, with different physical properties, including specific temperatures, thermal conductivities, and collision properties, which result in a change in flow properties such as density, velocity, and pressure. Additionally, the erosion process is not consistent with the actual landing trajectory. The addition of the fence on the lunar surface aims to study stones’ influence on flow shape and the flow field’s physical properties, which fails to combine with landing site stone or the lunar surface’s slope gradient to reflect these factors’ effects [

21]. In addition, not only is the time spent corresponding engine altitudes during the landing process the main factor used to verify and adjust the simulation model, but it is also the basis used to calculate the mass erosion rate and total mass erosion, which has not been studied in previous works. Therefore, an accurate simulation model coupled with the actual parameters of the engine is necessary to identify accurate erosion processes and relative properties. Based on this, this study considers the actual plume properties of the Chang’E-5 mission, combining actual landing information and ground experimental results of engine plume gas properties to reveal erosion properties to their full extent. The engine-ground experimental results help to optimize flow inlet parameters, and the descent information helps offer landing trajectories and optimize simulation. In contrast with the Apollo missions, Chang’E-5’s mission designed a small thrust engine to accomplish a soft landing. With the help of the landing site dust properties’ analysis, the dust dispersal and ejection process will be obtained more accurately, making this work more comprehensive. These erosion results will help the research community better understand how the lander’s exhaust plume disturbs the regolith and its volatiles, and even guide future lunar dust protection methods.

3. Results and Discussions

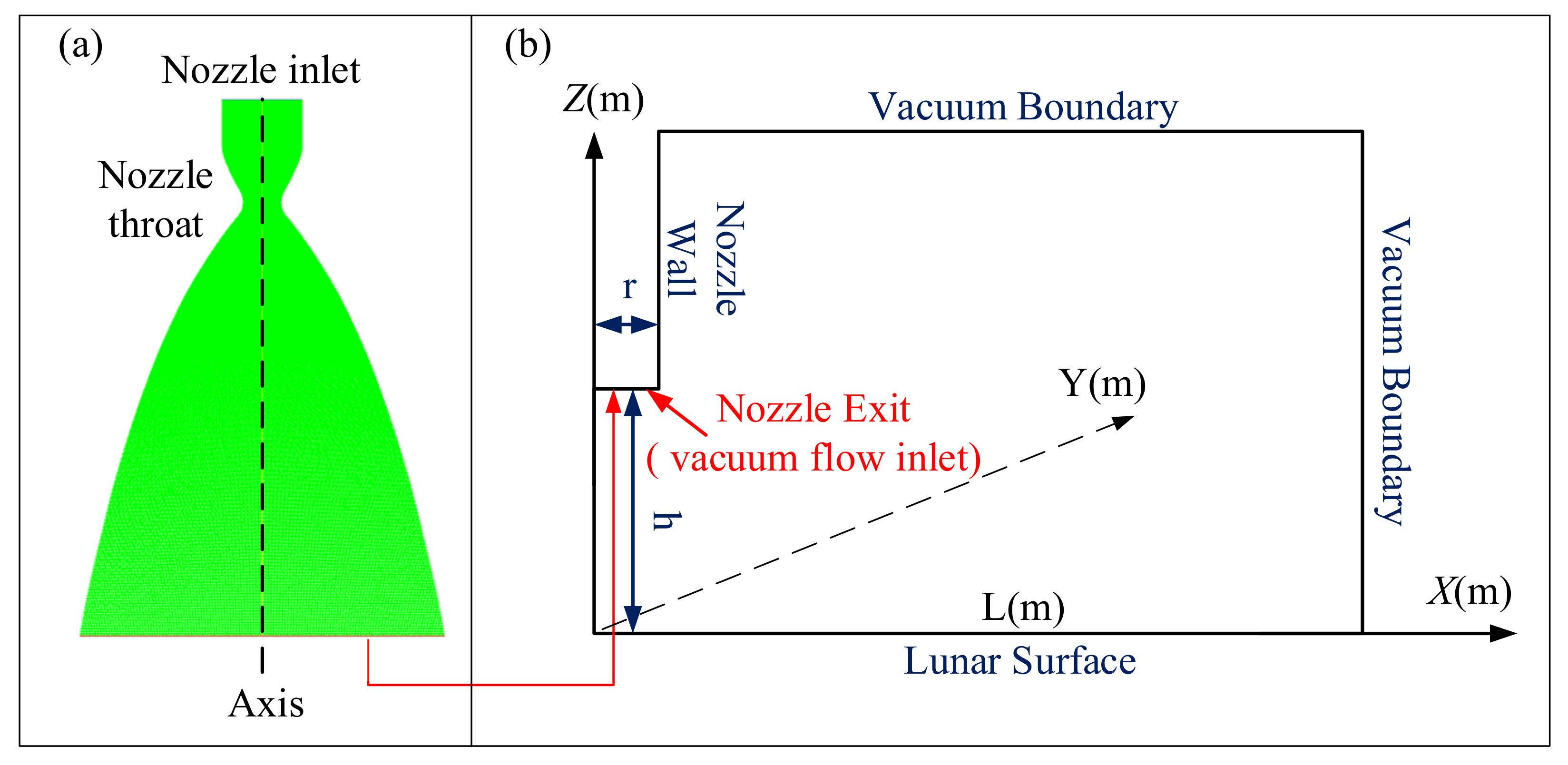

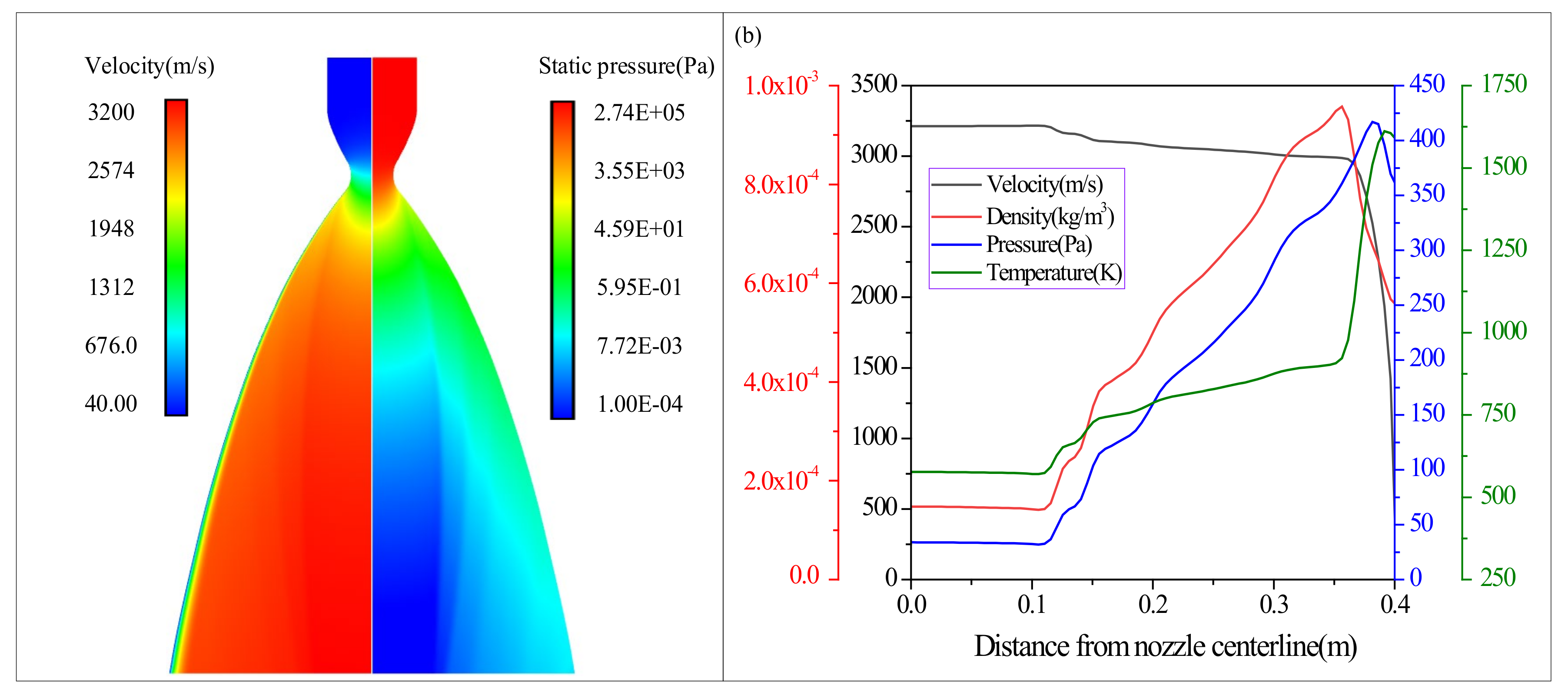

Figure 3 illustrates the nozzle internal flow properties of the Chang’E-5 mission.

Figure 3a shows the nozzle velocity and static pressure contour; the left side illustrates velocity and the right side illustrates static pressure. In

Figure 3a, one can see that the nozzle inlet velocity is low, but the static pressure is high compared to the static pressure at the outlet. Affected by the nozzle throat geometry, a compression wave occurs near the nozzle throat and spreads towards the nozzle exit, which induces a sudden change in internal gas flow properties including velocity, temperature, pressure, and density. After passing the throat, the gas gradually expands due to nozzle geometry expansion.

Figure 3a also shows that a low-speed boundary layer exists in the nozzle wall, resulting from the viscosity of the gas flow.

Figure 3b illustrates the nozzle outlet velocity, density, pressure, and temperature variation along the nozzle radial direction. The nonuniformity of nozzle outlet flow properties is induced by the compression wave at the nozzle throat. With the exception of velocity, the other flow parameters remain constant at first, then increase rapidly, and finally decrease suddenly. The position where these parameters start to increase is similar, at approximately 0.12 m from the nozzle centerline. The decrease positions are different, because decreases are led by the interplay between the compression wave and the subsequent expansion. Velocity has an inverse trend compared with the other parameters, and also has two jump points. The difference in the nozzle boundary layer results in a difference in the position of the second jump point position. Additionally, velocity, density, pressure, and temperature variation trends all agree well with those calculated during the Apollo mission, but differ in numerical values due to the thrust difference, which explains the rationality of the simulation to a certain extent [

21].

According to previous studies and present experience, the most useful method to evaluate whether the nozzle flow is precise is to compare the simulation results with the ground test.

Table 1 illustrates the nozzle exit plane flow values for the Mach number (Ma), pressure (P), temperature (T), and velocity (V) of the simulations and experiments for the Chang’E-5 and Apollo missions. The simulation results are very close to those obtained from the ground verification test results in the Chang’E-5 mission. In

Table 1, it is obvious that the thrust of the Apollo mission is much larger than that of the Chang’E-5 mission; the Apollo mission was a manned lunar exploration with a greater landing mass. In addition, the nozzle outlet radius of the Apollo mission is almost twice the size of that of the Chang’E-5 mission. Regarding nozzle outlet flow properties, the nozzle outlet velocity and Mach number are similar, but the pressure and temperature are different. The differences are mainly a result of the mass flow rates of the two missions.

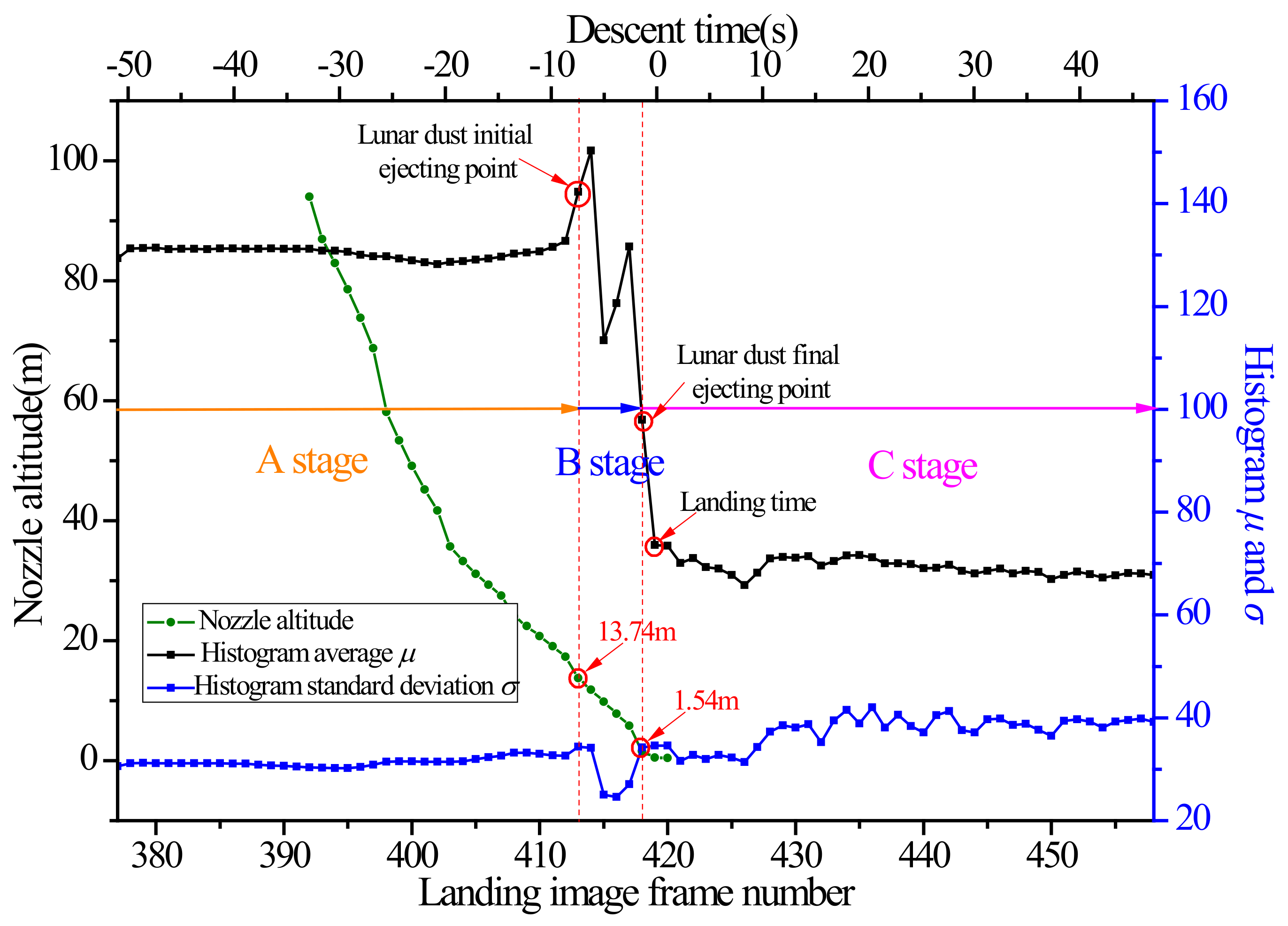

Figure 4 illustrates the variations in landing image histogram parameters and nozzle altitudes with landing time. Negative times denotes the period before landing, and positive times denotes the period after landing. The green line denotes nozzle altitude variation trends in image frame numbers 392 to 420. During this period, the nozzle altitude changes from approximately 94 m to 0.48 m. In this section, the entire histogram image of each landing photo was calculated using Matlab software to estimate if the lunar regolith was disturbed. The histogram average (

µ) indicates the brightness change in the landing photos. The histogram deviation (

σ) indicates the contrast change in the landing photos. The black line and blue line represent the

µ and

σ of landing images, respectively. These two lines remain almost constant in landing image frames 377 to 412, then fluctuate during landing image frames 413 to 418, and, finally, remain constant again. According to these changes, the process is divided into 3 stages (A stage, B stage, and C stage). In the A stage, the landing photo shows no obvious variation, indicating no ejection of lunar dust. When the nozzle altitude decreases, obvious fluctuations occur for

µ and

σ, resulting in two peaks of

µ in the B stage. For the duration of this stage, obvious brightness variation exists in the landing images, demonstrating that dust was gradually ejected by the nozzle plume, which is also demonstrated by the landing images shown in

Table 2. After that,

µ and

σ tend to be constant during the C stage, and the dust ejection phenomenon may stop when the lander engine is shut down. Photo number 412 is obviously brighter than photo number 411, which indicates that the initial ejection position of lunar dust occurs near this time point. This photo denotes 7 s before landing, when the relative height of the nozzle is 13.74 m. Therefore, this is defined as the beginning of the dust ejection point corresponding to the B stage. Next, the

µ of landing photo number 414 reaches its peak for the landing period, as does its

σ. The probable reason a decrease occurs in the histogram parameters of photo number 415 is the lander’s shadow effect. After photo number 418, the

µ and the

σ decrease slightly, indicating that only a small amount of lunar dust is ejected. As time passes, the two parameters will finally remain constant. No reverse peak point exists in

Figure 4, indicating that no large crater shadow region exists in the vicinity of the Chang’E-5 landing site which significantly affect

µ and

σ. This surface condition can also be captured using a landing photo or a panorama photo. To guarantee landing photo analysis accuracy, photos numbered 380 to 405 can be selected as references for photo brightness to illustrate the local environment.

Table 2 lists corresponding landing photos at the B stage and a detailed description of each photo during the dust ejection period. In

Table 2, the brightest region appears in the center of the photo, just below the nozzle outlet. This brightest region indicates that a thick layer of lunar regolith was blown away by the plume. As time passes, the nozzle comes closer to the landing site, and the bright region diminishes because the plume gas has a lower expansion rate before arriving at the lunar surface, resulting in a stronger collision with the lunar surface. Next, as the nozzle altitude decreases, the stronger plume dynamic pressure shapes a deeper erosion crater. At the same time, lunar dust particles are ejected with a beam shape, and fly along the radical direction. After that, a lunar surface erosion crater becomes evident. During the entire dust ejecting period, the brightest photo number is 414, which corresponds to the maximum

µ in

Figure 4. Its shutdown time and final thrust are recorded by the Chang’E-5 mission guidance navigation and control system [

27].

In

Table 2, the landing photos included at stage B are those with nozzle altitudes of 13.74 m, 11.83 m, 9.82 m, 7.83 m, 5.80 m, and 1.54 m. Hence, these six nozzle altitudes are used in the simulation to obtain lunar surface erosion process because this allows us to directly compare our simulation results with the actual Chang’E-5 landing.

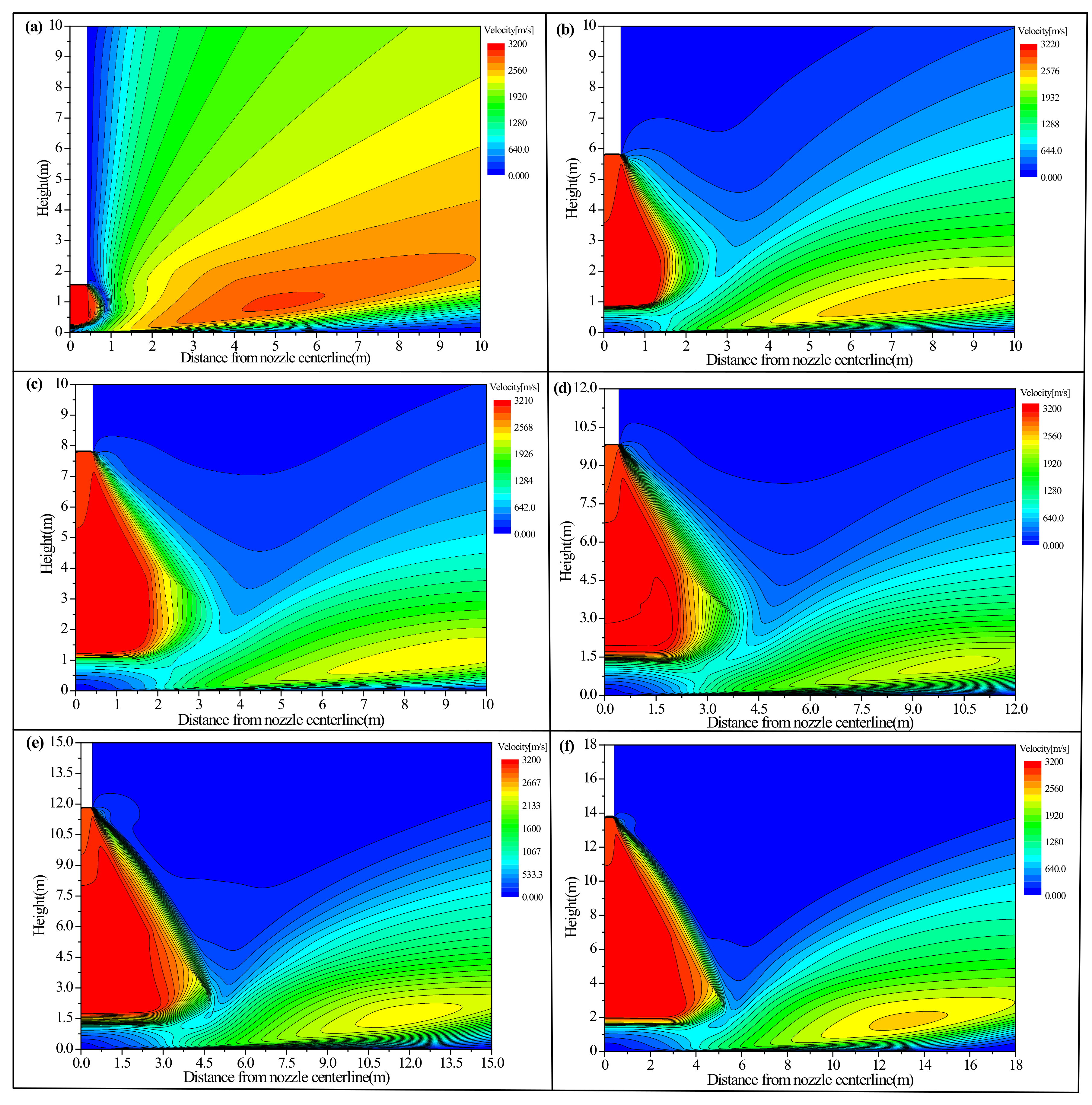

Figure 5 presents the plume velocity contours at these nozzle altitudes. Three noteworthy flow regions exist in the entire flow field. The high vacuum lunar environment condition makes the plume gas expand rapidly, forming a red flow region beneath the nozzle outlet, which is considered the first particular region. In this region, many plume gas molecules collide with each other and expand; thus, the plume gas velocity is at its maximum, and its expansion shape resembles a bowl. Comparing the six contours, it can be gathered that the area of this region decreases as the nozzle altitude decreases. For example, when the nozzle altitude is 1.54 m, this region’s boundary is approximately 0.8 m in the radical direction, but it increases to 5.1 m when the nozzle height is 13.74 m. Additionally, this region’s layer thickness also decreases with a reduction in the nozzle altitude. The probable explanation for the above phenomenon is a longer expansion time and a larger expansion space at higher altitudes. The second obvious flow region is between the first flow region and the lunar surface. Similar to the first flow region, its area also increases with nozzle height. However, when the nozzle altitude is 1.54 m, this region can scarcely be observed due to the strongest compression effect. In contrast to the first flow region, the impingement point beneath the bowl shock region occurs as a stagnation region, caused by bowl shock compression. Here, density and pressure are at their maximums, but velocity is at its slowest. After strong compression, a favorable pressure gradient takes place in the radical direction, resulting in outward plume flows in the radical direction, which define the third noteworthy flow region. This third region not only exists as a compression flow field, but also has an expansion flow field. Affected by the compression of the stagnation region, its initial flow shape is spiky; then, the plume flows in the radical direction with an expansion similar to a bow shock. What needs special attention in this region is that the center has a higher velocity, but the outer boundaries have a lower velocity, resulting in non-uniformity of velocity distribution, because the center flow has higher internal energy and less heat change, but the outer boundaries dissipate energy towards the lunar environment.

For a specific nozzle height, lunar regolith not only has an inner erosion radius (

r0), but also has an erosion radius (

r1), which was introduced in

Figure 1. The

r0 was introduced in

Table 2. In the Chang’E-4 mission, we find that the shear stress and pressure of the plume at

r0 obtained by simulation satisfy Equation (11) when the landing photos illustrate

r0 [

26]. Therefore, the same method is adopted to calculate the lunar regolith critical shear stress

τ* in this study, which can be obtained by

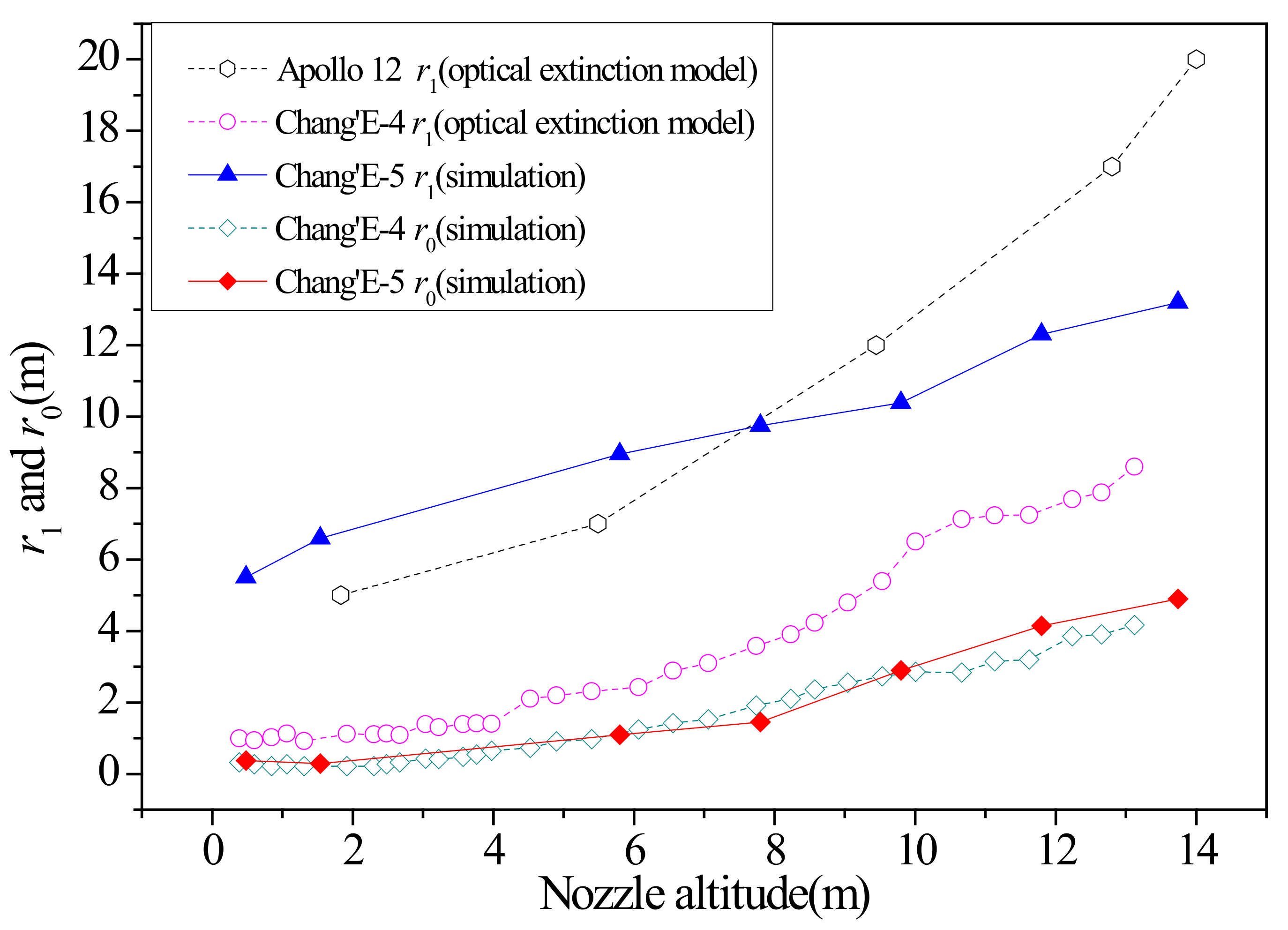

Figure 6 presents the

r0 and the

r1 at different nozzle altitudes for the Apollo 12 mission, the Chang’E-4 mission, and the Chang’E-5 mission. The

r1 of the Apollo 12 mission and the Chang’E-4 mission shown in

Figure 6 result from landing photos’ analysis (optical model), but the

r0 of the Chang’E-4 mission and the

r1 of the Chang’E-5 mission are calculated using this simulation. It can be seen that the

r0 in the Chang’E-4 and Chang’E-5 missions are similar, because the

τ* is obtained using the same Mohr–Coulomb failure criterion. In addition, the nozzle geometry is the same, and the final thrust for the two missions (Chang’E-4 = 2200 N and Chang’E-5 = 2900 N) differ only slightly, which may also be the reason for their similar

r0. In the Apollo 12 mission, the

r0 was not calculated. However, the

r1 for these three missions differ significantly. The

r1 calculated for the Chang’E-4 and Chang’E-5 missions have the same variation trends, but different values. Compared to the Apollo 12 mission, the erosion radius is bigger when the nozzle altitude is less than 8 m, but is smaller when the nozzle altitude is more than 8 m. In reality, only part of

r0 can be found via landing photo observation (only part of the nozzle altitude is visible). To obtain the

r0 at all erosion altitudes, we use the partial

r0 to find a suitable Roberts erosion model, then calculate all

r0 using simulation results. However,

r1 is not visible in the landing photos; it has to be calculated based on an optical extinction model or the Roberts erosion model. The two models lead to different results. The Roberts erosion model has a bigger

r1 because this model contains two types of erosion dust (dust particles ejecting towards lunar space and dust particles moving on the lunar surface); the optical extinction model only uses the dust particles ejecting towards lunar space.

According to Equations (12) and (13), it can be known that

a is an integrative parameter influencing the dust erosion rate. Combining plume parameters and lunar dust density (3195.2 kg/m

3) in the Chang’E-5 mission [

32], the relationship between

a and

dp at different nozzle altitudes is shown in

Figure 7a, and the relationship between

a and nozzle altitude at different

dp is shown in

Figure 7b. From

Figure 7a,b it can be seen that dust with a larger diameter has small

a, indicating that larger dust will have a smaller velocity gain for a specific nozzle altitude. However, for a specific particle diameter,

a increases as nozzle altitude increases. Using such variations, the mass erosion rate and crater depth variation with nozzle altitude of the Chang’E-5 mission are calculated based on Robert’s erosion model, which are shown in

Figure 7c,d, respectively. The lower the nozzle altitude, the bigger the mass erosion rate. For example, the maximum erosion rate is approximately 0.6 kg/m

2·s when the altitude is 1.54 m, but it is approximately 0.2 g/m

2·s when the altitude is 13.74 m. The crater depth of the Apollo mission is much bigger than that of the Chang’E-5 mission. The deepest location of the Apollo mission is approximately 1.8 m from the nozzle centerline, with a crater depth of approximately 1.3 cm; however, the deepest location is approximately 3.5 m from the nozzle centerline of the Chang’E-5 mission, with a crater depth of approximately 0.2 cm. The difference in the craters’ deepest location is mainly a result of thrust (Apollo 12 = 13.3 KN), nozzle landing trajectory, and the calculated model. A larger thrust results in less expansion of the plume’s inner region, and the plume deviates less. In the Apollo mission, the engine landing trajectory is not vertical, but inclined, making the crater center close to the nozzle centerline. In addition, the erosion model (Chang’E-5 mission) has a larger erosion range than the optical extinction model (Apollo 12 mission), because this model considers the ejected dust particles moving along the lunar surface. The difference in crater depth mainly depends on thrust and landing time. For the Apollo 12 mission, the entire erosion timespan is approximately 60 s at the three nozzle altitudes, with a final thrust of 13.3 kN. However, for the Chang’E-5 mission, the entire erosion timespan is approximately 7 s at the six nozzle altitudes, with a final thrust of 2900 N. Finally, the total erosion mass for the Apollo 12 mission and the Chang’E-5 mission is 2600 kg (optical extinction model) and 335.95 kg (simulation), respectively.

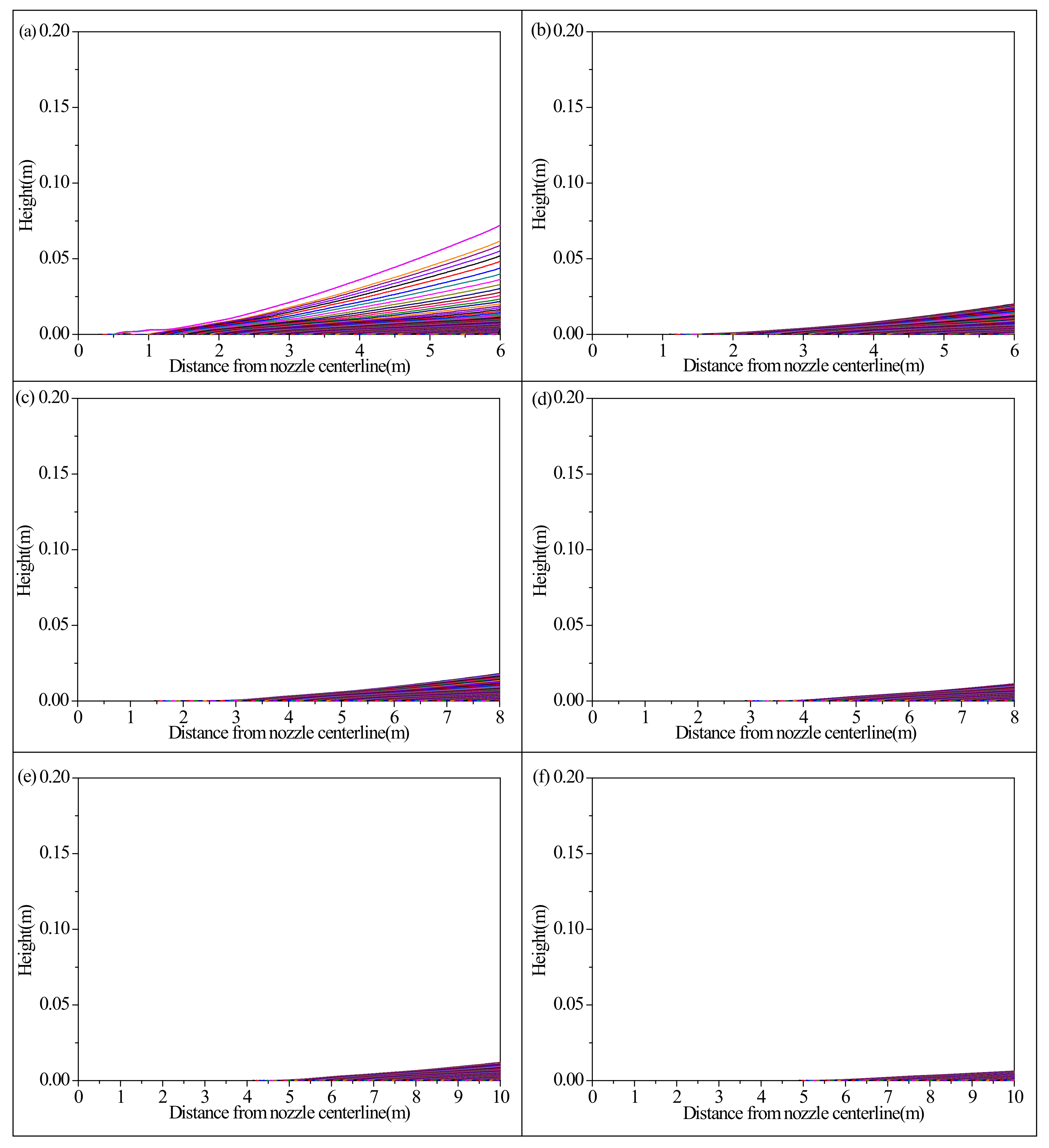

Figure 8 illustrates the 4.84 μm dust particles’ trajectories at different nozzle altitudes. The simulated particles are all injected at the six altitudes. However, the difference is that the higher the nozzle altitude, the lower the particles are, which is reasonable, due to a smaller shear stress at a higher altitude. The particles are blown away in the radical direction, and are finally no longer visible in the landing photo. The injected height for 1.54 m is much higher than for other distances, and thus the particles’ inclined angle is much larger as well.

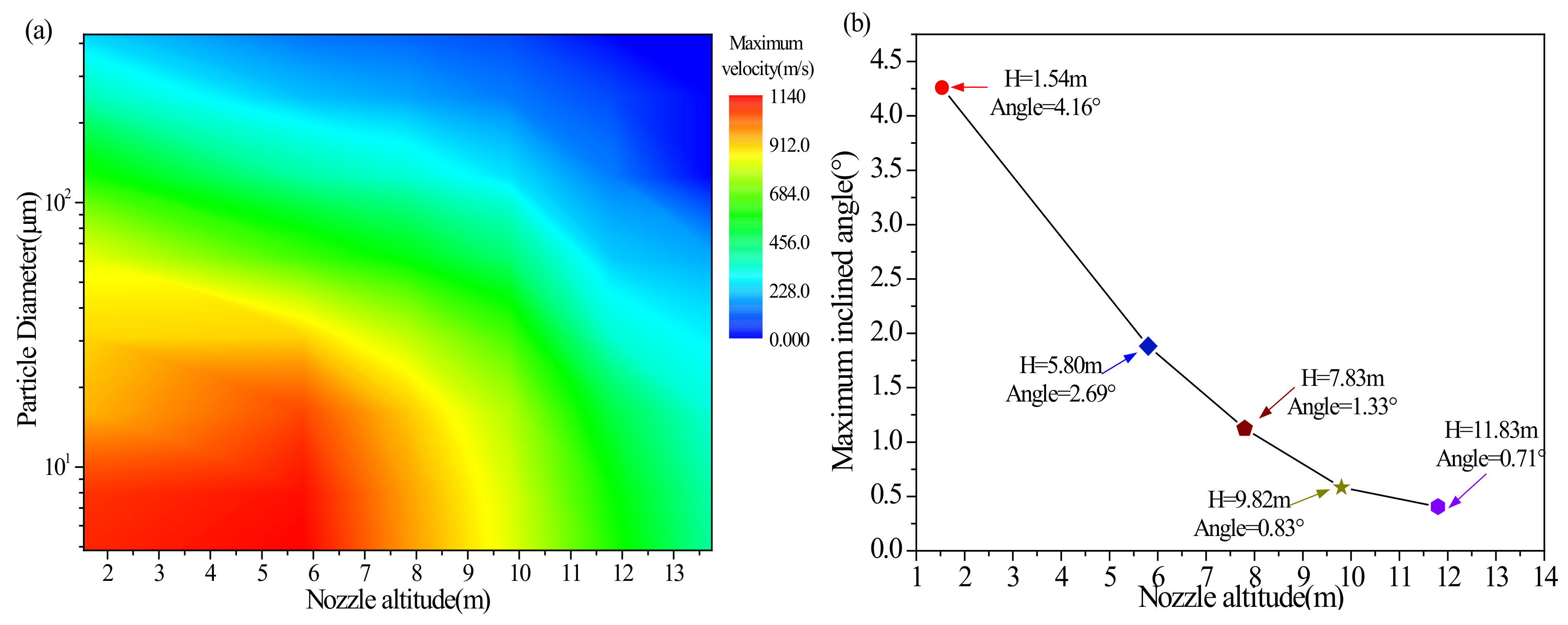

In addition to flat lunar surface erosion properties, single particle trajectory and velocity modeling (noted in

Section 2) are also key points to investigate, based on CFD simulations of the Chang’E-5 mission. The maximum velocity distribution for particles with different diameters at different nozzle altitudes is described in

Figure 9a, where the maximum velocity in the entire erosion process is 1140 m/s, which is less than the escape velocity. As predicted by previous investigations, the smaller the particle diameter is, the easier it will be to dislodge upwards and obtain a higher velocity. Therefore, as in the Apollo mission, all particles with a diameter above 1µm will not reach escape velocity. It is worth noting that the inclined angle is measured from the horizontal plane (

x-

y plane). Dust particles’ maximum inclined angles within the landing photo boundary at different nozzle altitudes are shown in

Figure 9b, indicating that the maximum inclined angle is less than 4.16° in the Chang’E-5 mission. The inclined angle rapidly decreases as nozzle altitude increases.