Experimental Investigation of a Cylindrical Air-Breathing Continuous Rotating Detonation Engine with Different Nozzle Throat Diameters

Abstract

:1. Introduction

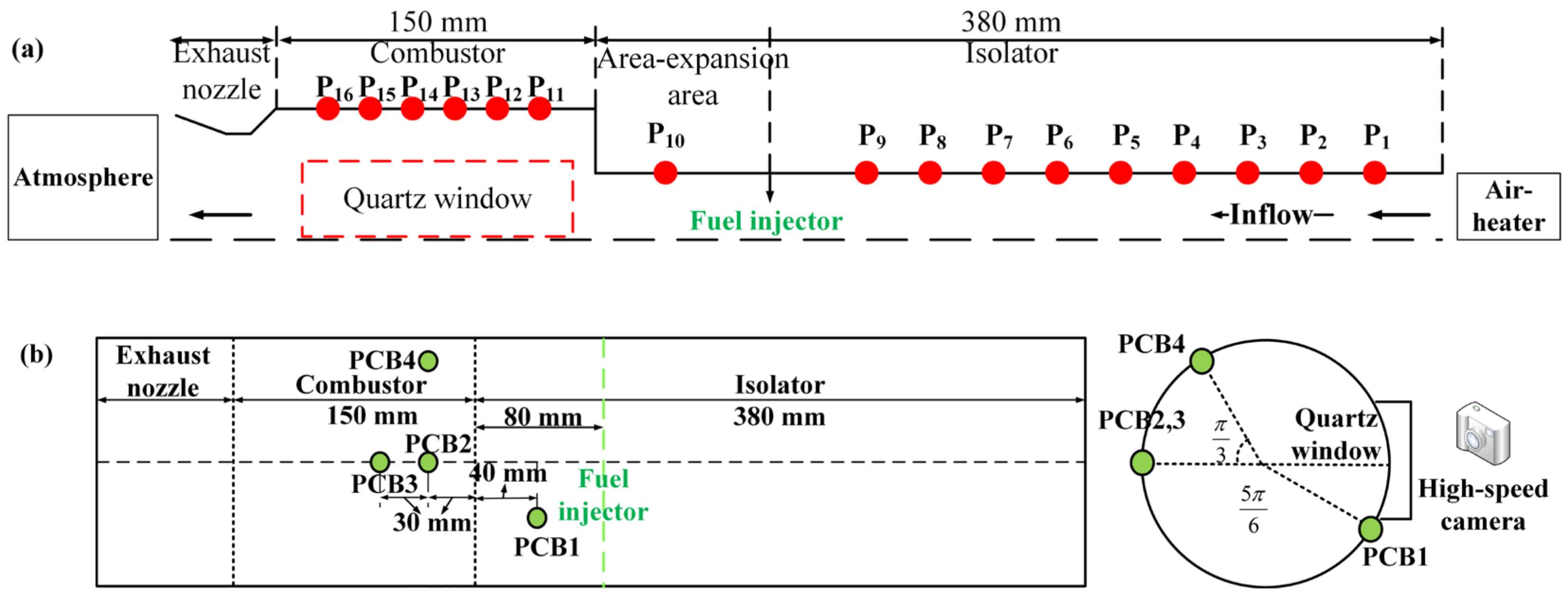

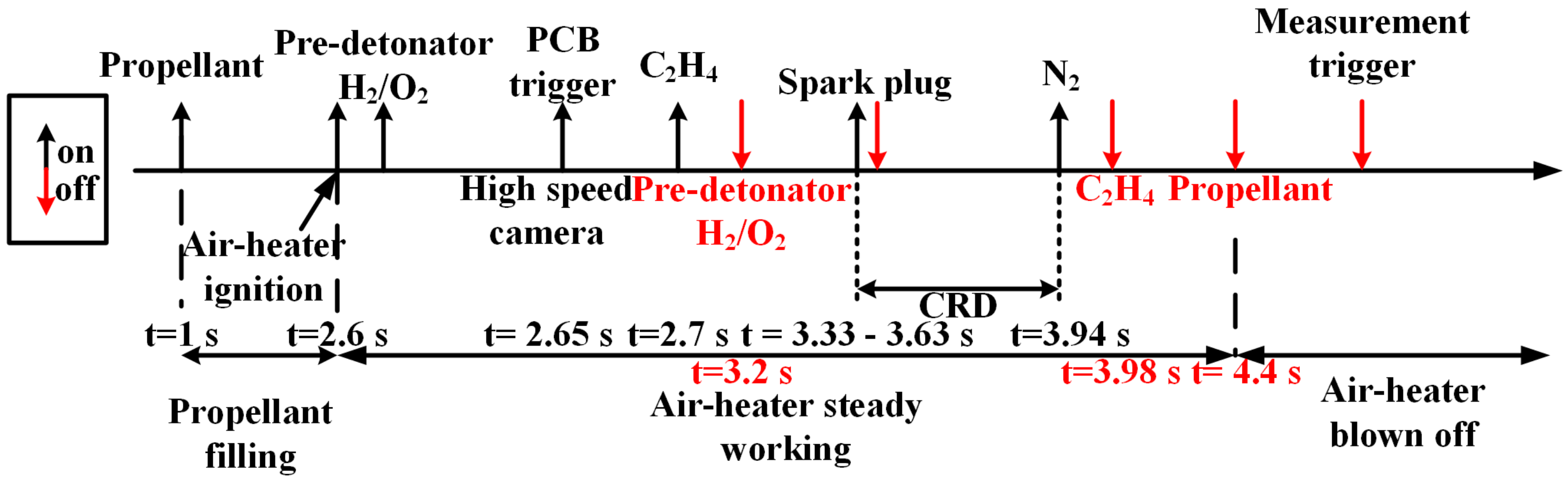

2. Experimental Section

3. Results and Discussion

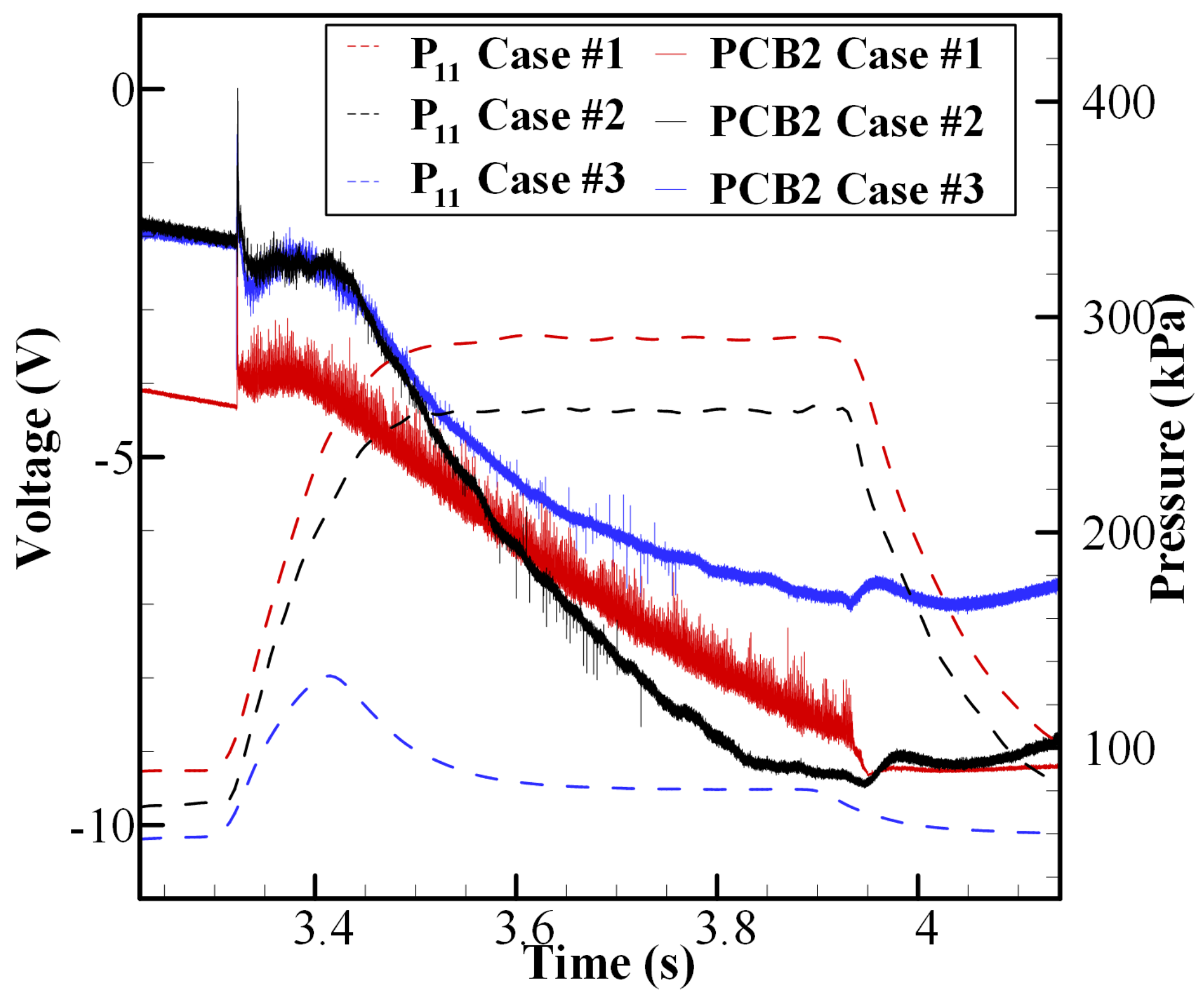

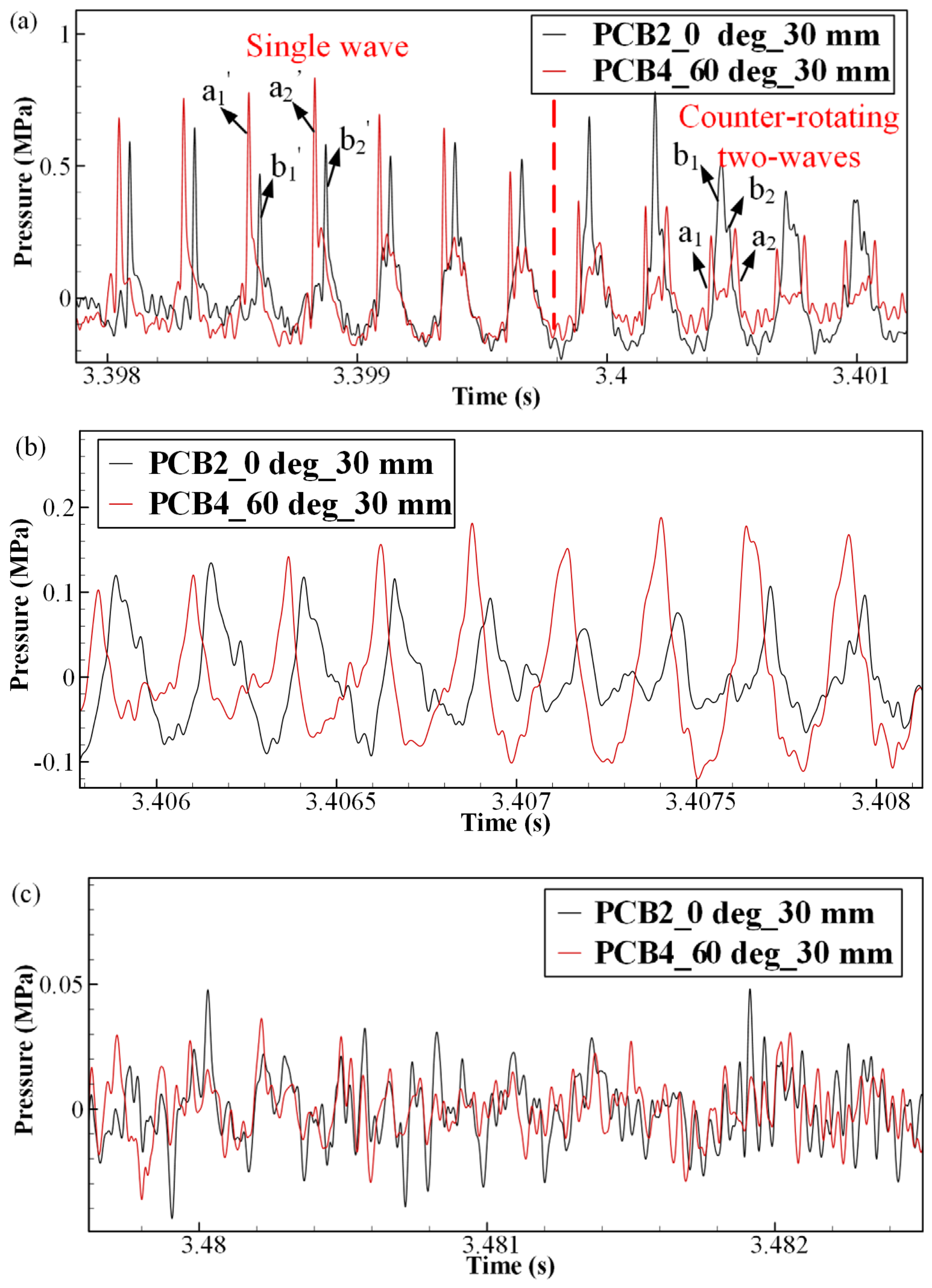

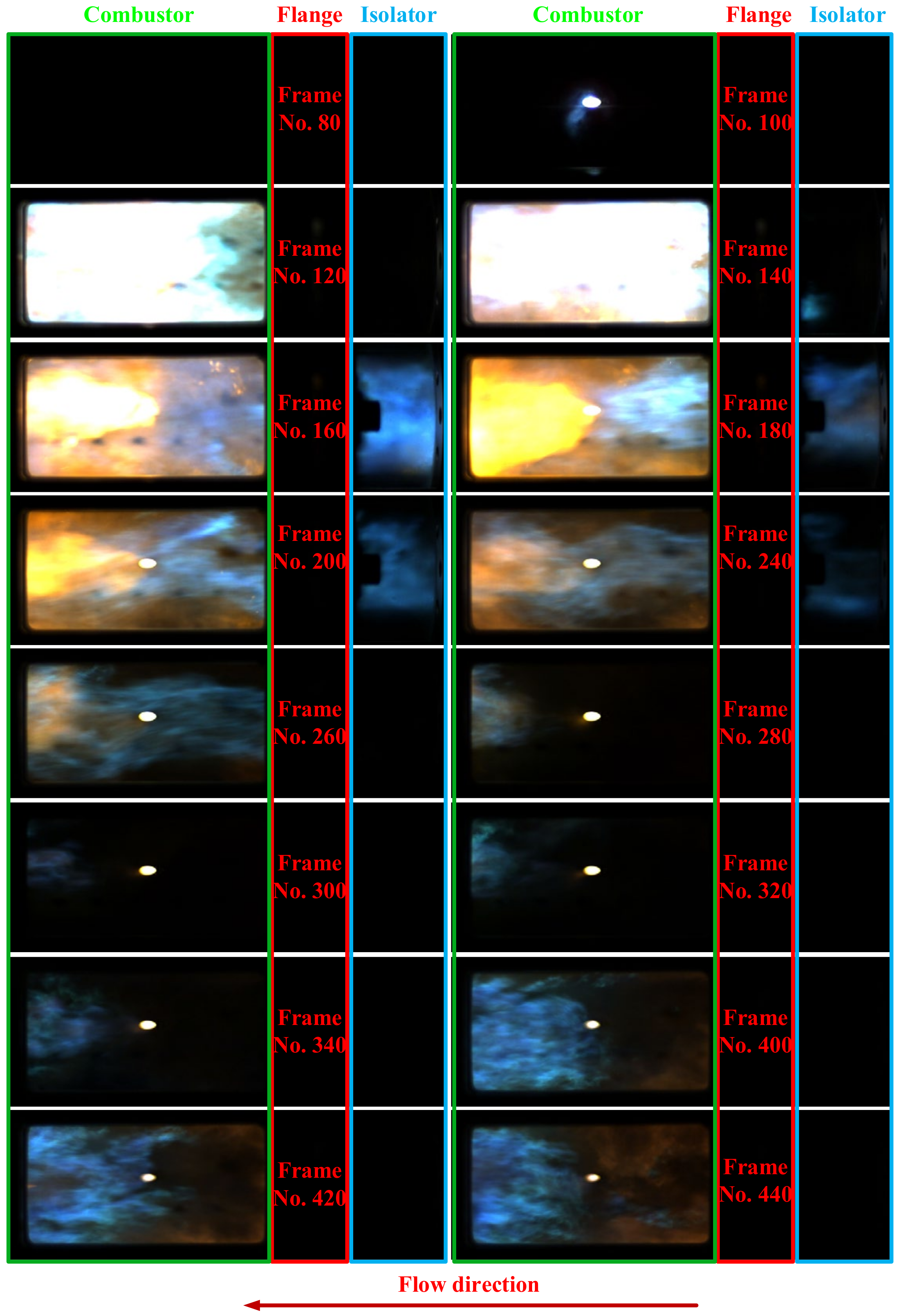

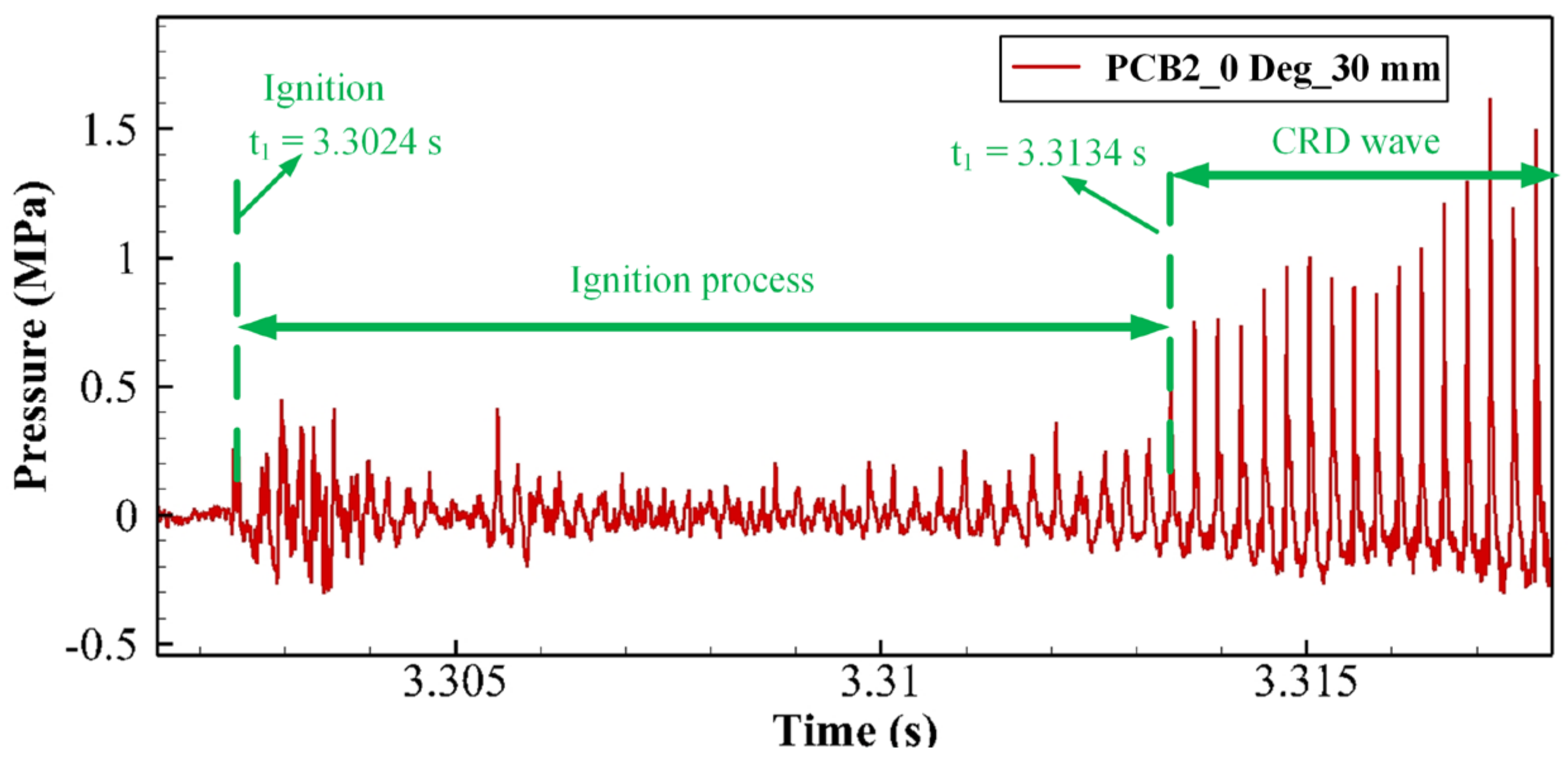

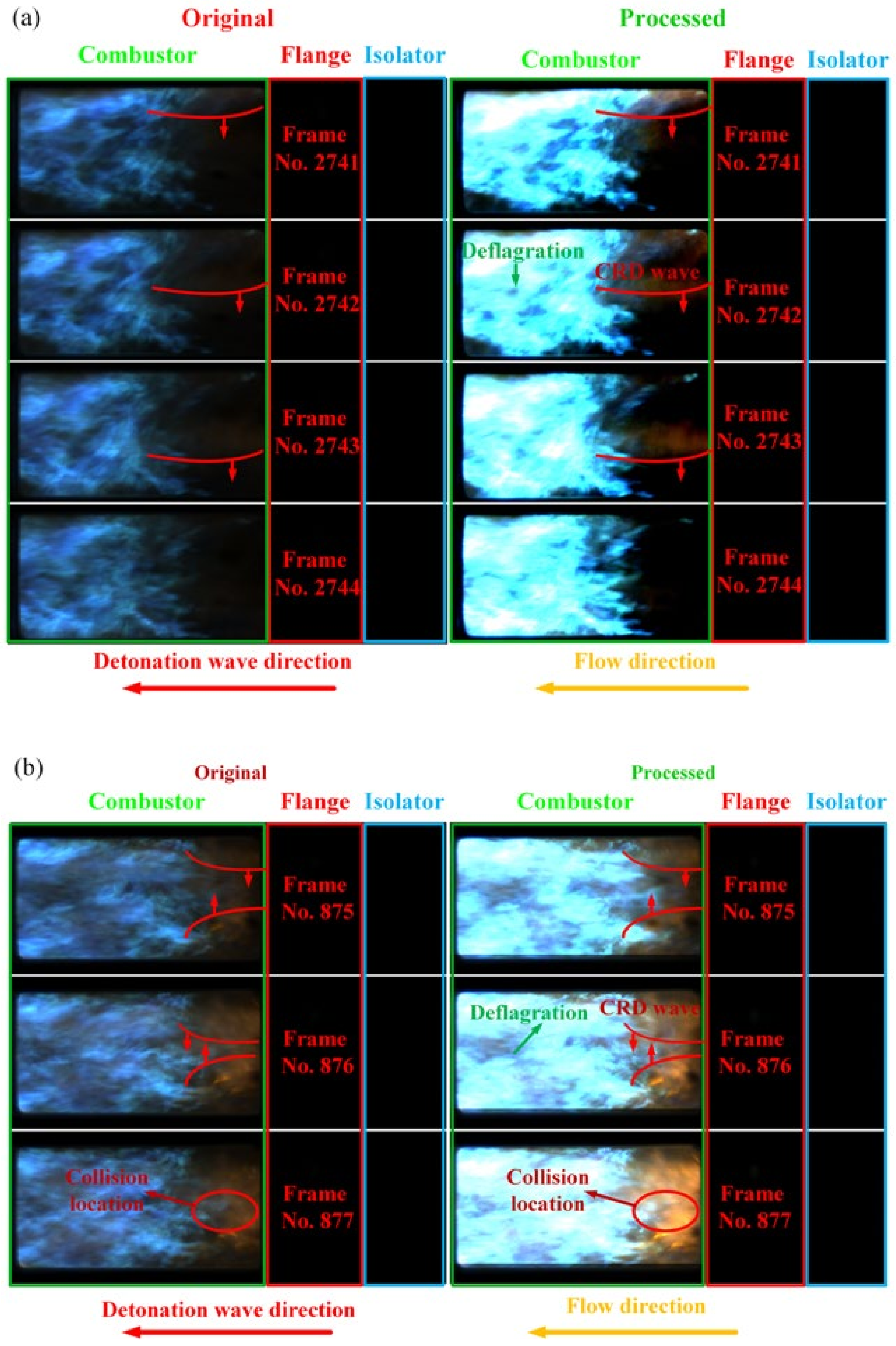

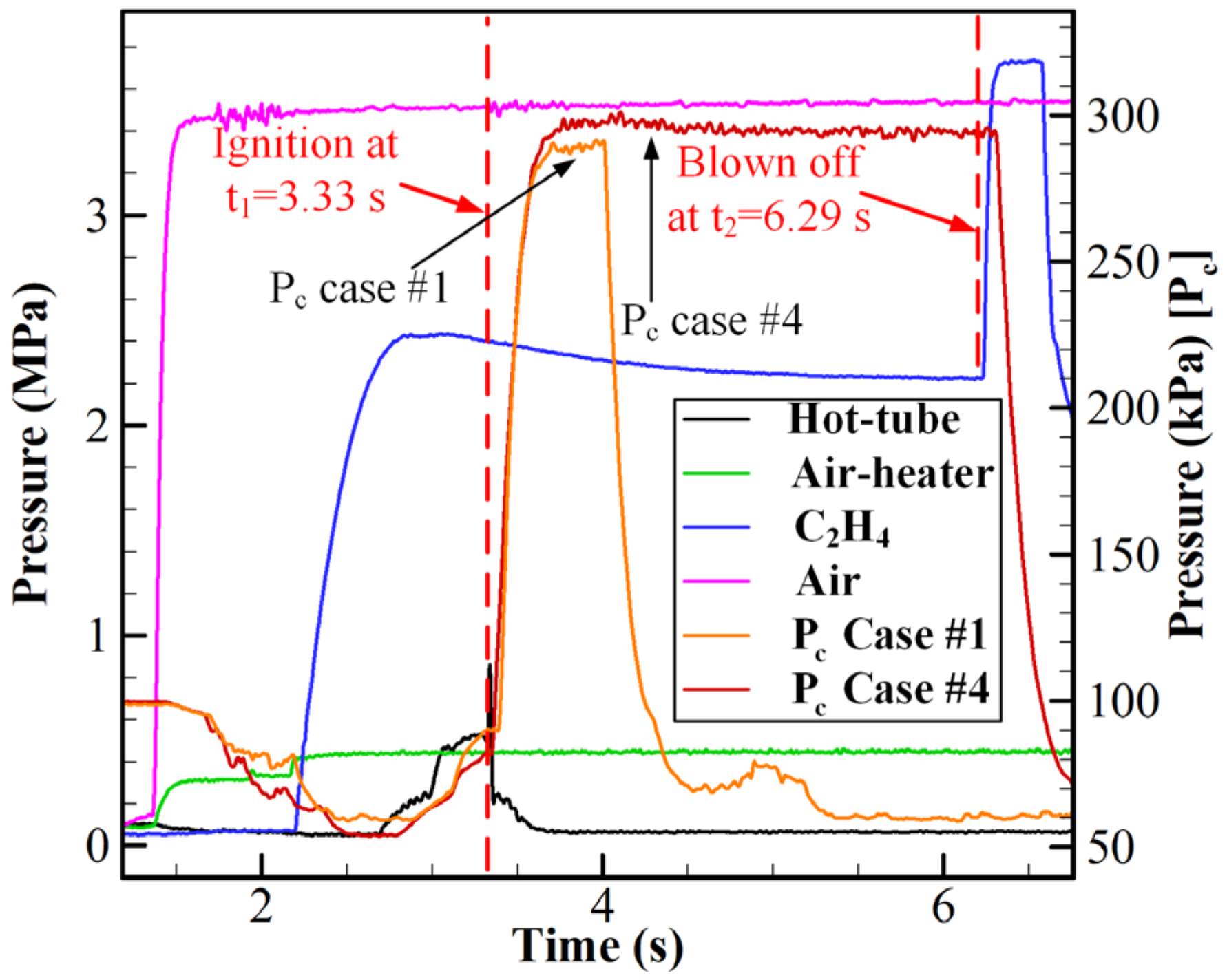

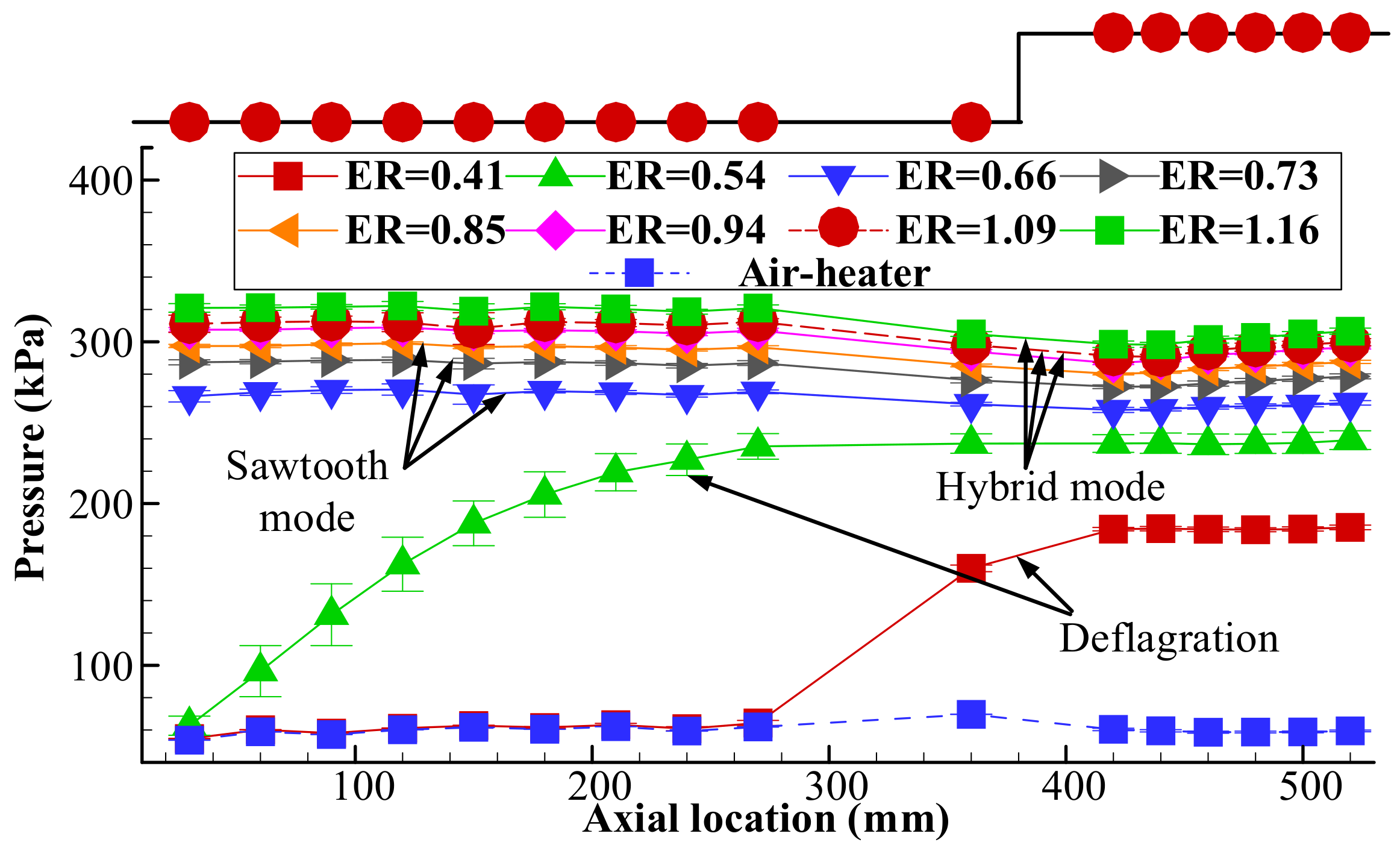

3.1. Analysis of the Detonation Wave Operation Process

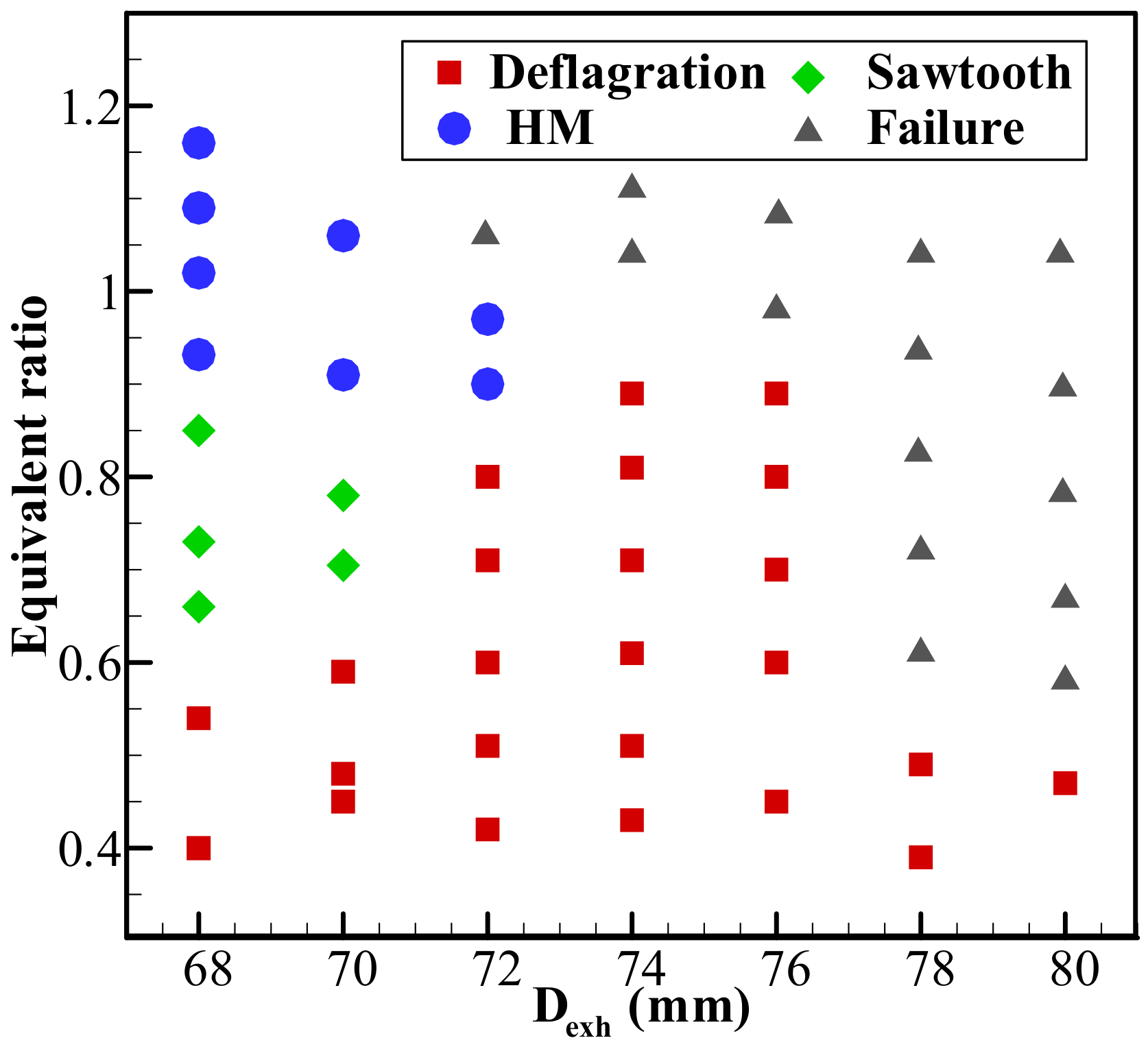

3.2. Operating Range and Combustion Modes

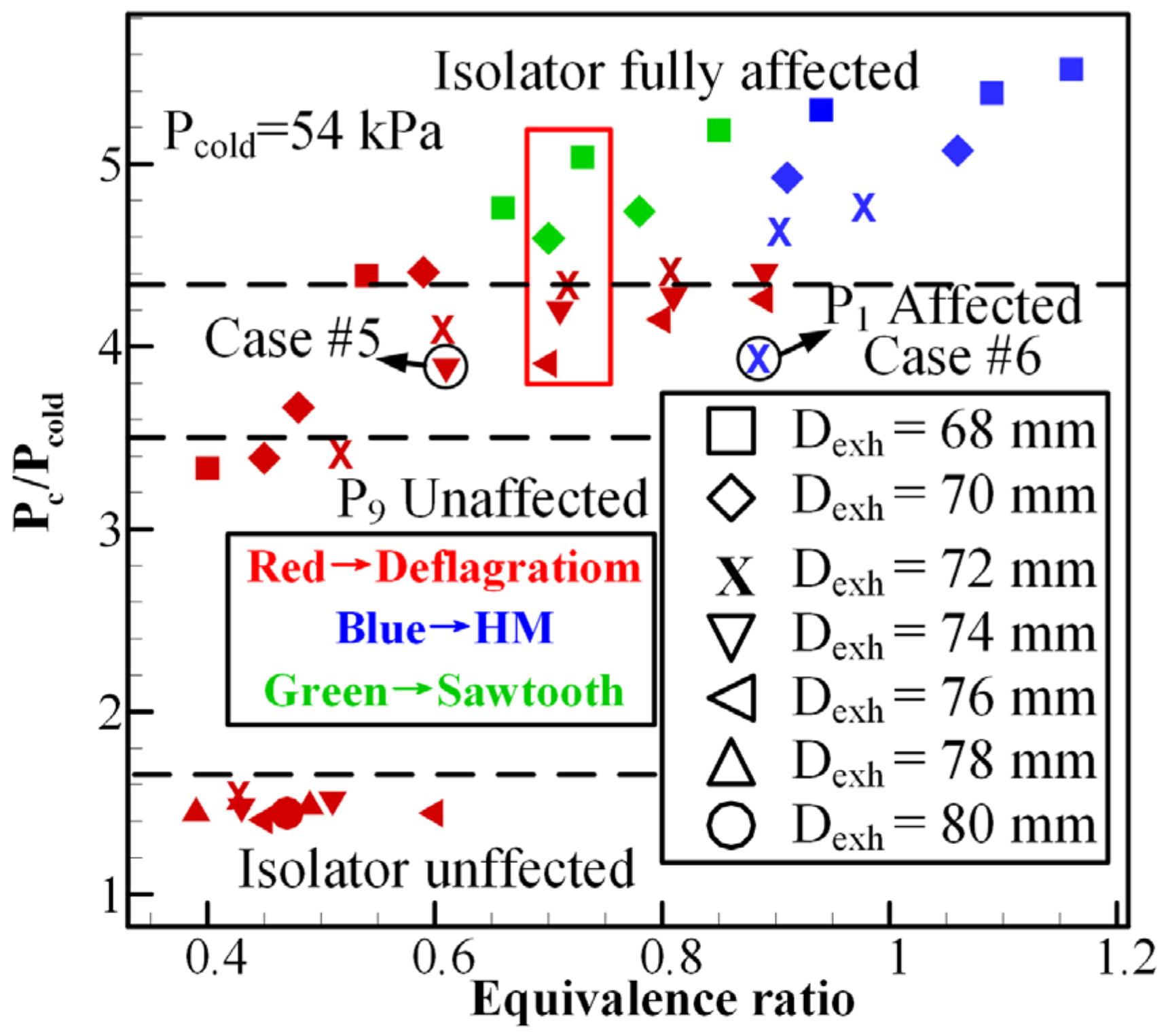

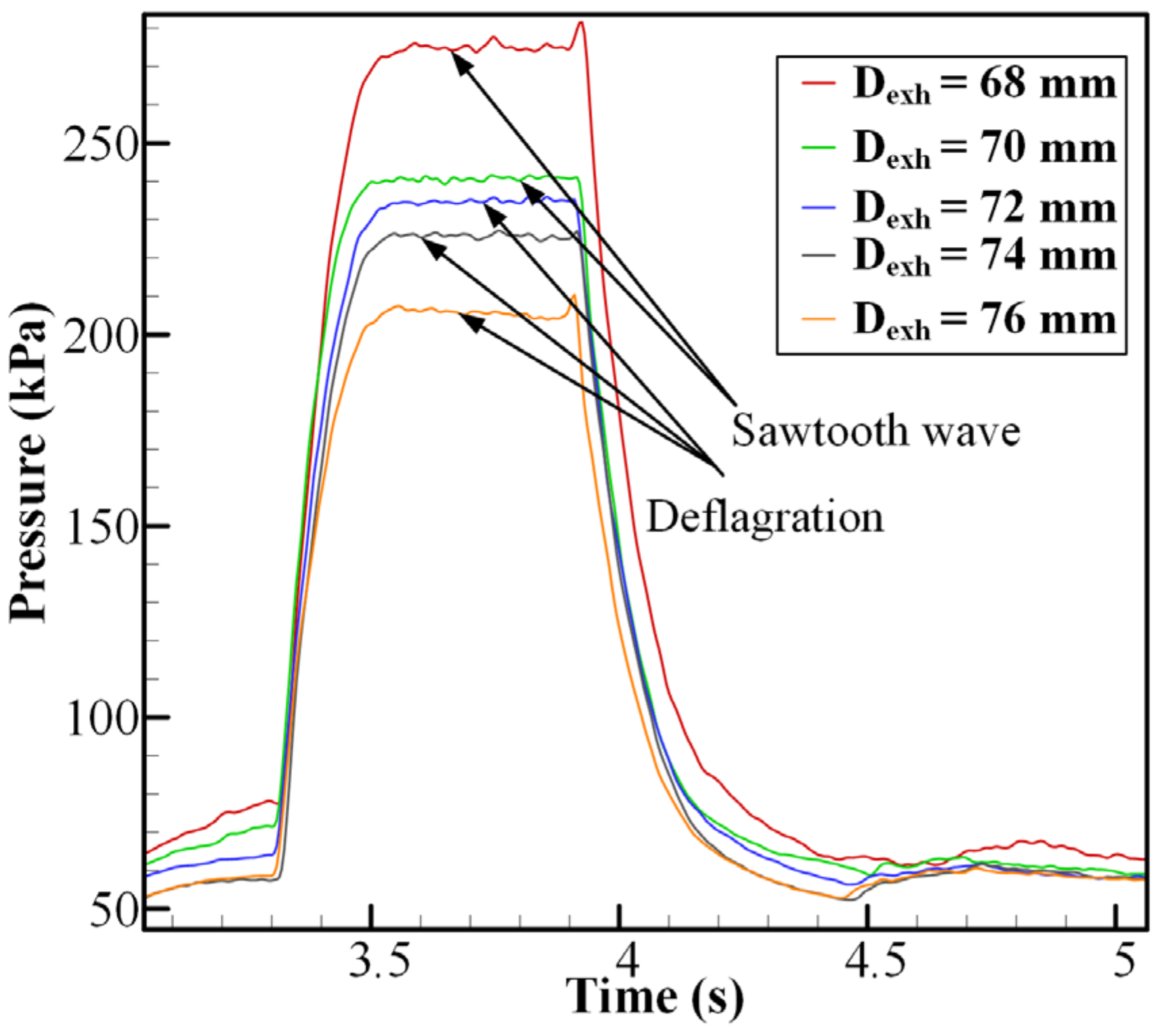

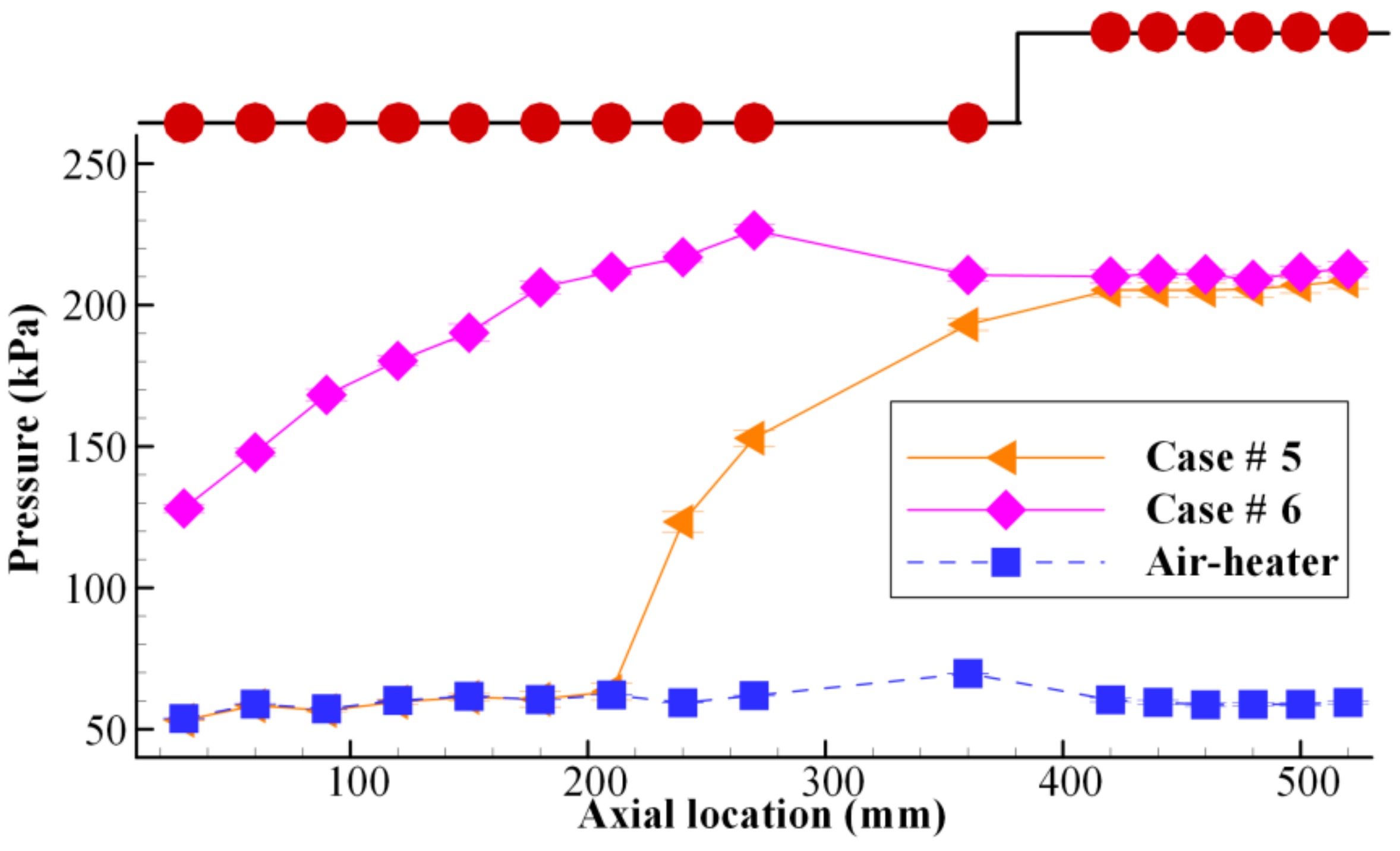

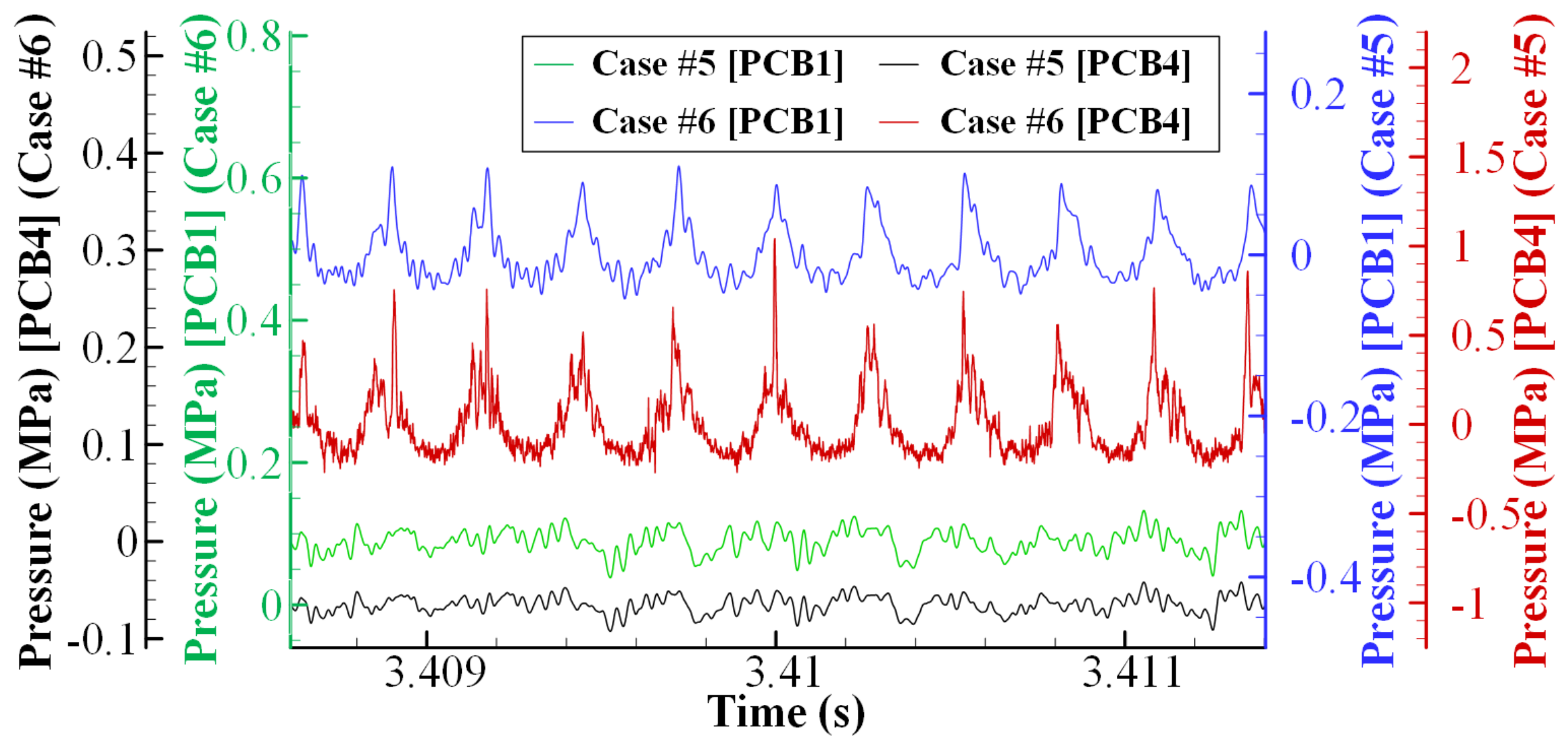

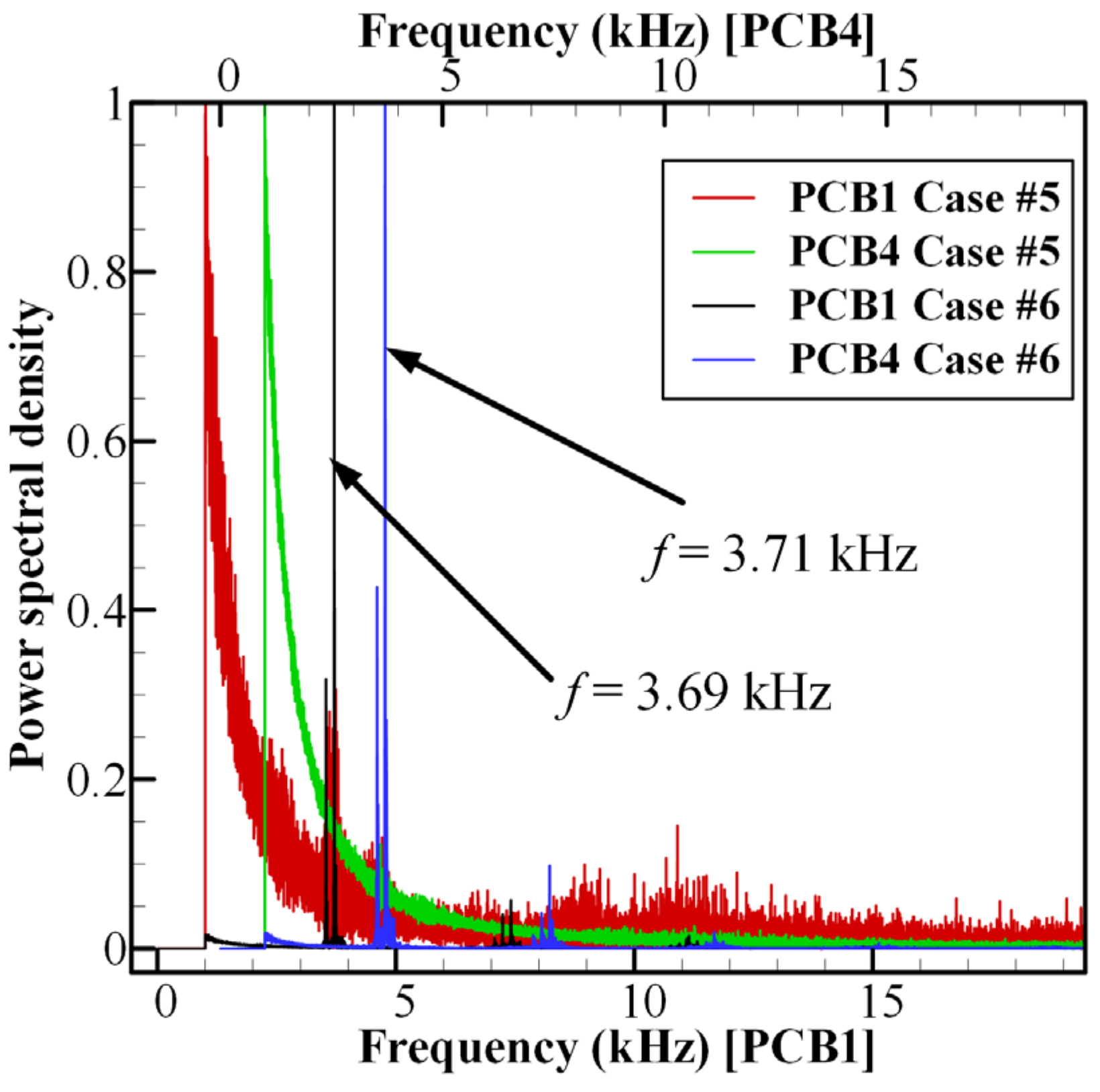

3.3. The Influence of Dynamic Backpressure on the Inflow

4. Conclusions

- (1)

- Three combustion modes were obtained under different operation conditions: deflagration, sawtooth wave, and hybrid mode. The counter-rotating two-waves and single wave alternated in the hybrid mode, which could be demonstrated in both high-frequency pressure measurements and high-speed imaging. In addition, the detonation combustion was observed to self-sustain in the combustor through the simultaneous high-speed imaging covering the combustor and isolator.

- (2)

- The detonation combustion is experimentally verified to maintain for more than three seconds in this unique engine configuration, indicating that the cylindrical isolator–combustor configuration exhibits potential for practical applications.

- (3)

- The nozzle throat diameter plays an essential role in whether the detonation wave can self-sustain. When the nozzle throat diameter was larger than the specific value, the increase in axial velocity and a reduction in fuel residence time would lead to an inappropriate accumulation of combustible mixture in the cavity forepart, resulting in neither detonation nor sawtooth wave self-sustaining. Meanwhile, the combustion modes were also sensitive to the nozzle throat diameter. The combustion mode could shift from deflagration to detonation/sawtooth wave with the same ER when the nozzle throat diameter was changed slightly.

- (4)

- The ER and nozzle throat diameter have a considerable influence on the leading edge location of the shock train. The leading edge location of the shockwave is supposed to be close to the isolator entrance in the condition of high ER and small nozzle throat diameter, which is mainly due to the detonation combustion and large blockage ratio of the nozzle. In addition, it has been verified that periodic high-frequency pressure oscillation could cause a significantly more substantial impact on the incoming flow than the steady deflagration with the close combustor pressure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Nomenclature | |

| D | diameter, mm |

| f | frequency, kHz |

| mass flow rate, g/s | |

| Ma | Mach number |

| P | pressure |

| v | velocity, m/s |

| Subscripts | |

| av | average |

| C2H4 | ethylene plenum |

| c | detonation combustor |

| exh | exhaust nozzle throat diameter |

| oxy | oxygen |

| 1–16 | pressure transducer number |

Appendix A

| Test No. | , g/s | ER | Combustion Mode | Dexh, mm |

|---|---|---|---|---|

| #1 | 994 ± 20 | 0.41 ± 0.02 | Deflagration | 68 |

| #2 | 992 ± 20 | 0.54 ± 0.02 | Deflagration | 68 |

| #3 | 997 ± 20 | 0.66 ± 0.02 | Sawtooth wave | 68 |

| #4 | 998 ± 20 | 0.73 ± 0.02 | Sawtooth wave | 68 |

| #5 | 1008 ± 20 | 0.85± 0.02 | Sawtooth wave | 68 |

| #6 | 988 ± 20 | 0.94 ± 0.02 | Hybrid mode | 68 |

| #7 | 1006 ± 20 | 1.02 ± 0.02 | Hybrid mode | 68 |

| #8 | 994 ± 20 | 1.09 ± 0.02 | Hybrid mode | 68 |

| #9 | 998 ± 20 | 1.16 ± 0.02 | Hybrid mode | 68 |

| #10 | 998 ± 20 | 0.45 ± 0.02 | Deflagration | 70 |

| #11 | 1007 ± 20 | 0.48 ± 0.02 | Deflagration | 70 |

| #12 | 996 ± 20 | 0.59 ± 0.02 | Deflagration | 70 |

| #13 | 1012 ± 20 | 0.70 ± 0.02 | Sawtooth wave | 70 |

| #14 | 1014 ± 20 | 0.78± 0.02 | Sawtooth wave | 70 |

| #15 | 1007 ± 20 | 0.91 ± 0.02 | Hybrid mode | 70 |

| #16 | 1010 ± 20 | 1.06 ± 0.02 | Hybrid mode | 70 |

| #17 | 999 ± 20 | 0.42 ± 0.02 | Deflagration | 72 |

| #18 | 1005 ± 20 | 0.51 ± 0.02 | Deflagration | 72 |

| #19 | 998 ± 20 | 0.60 ± 0.02 | Deflagration | 72 |

| #20 | 1002 ± 20 | 0.71 ± 0.02 | Deflagration | 72 |

| #21 | 1003 ± 20 | 0.80 ± 0.02 | Deflagration | 72 |

| #22 | 1001 ± 20 | 0.90 ± 0.02 | Hybrid mode | 72 |

| #23 | 1005 ± 20 | 0.97 ± 0.02 | Hybrid mode | 72 |

| #24 | 1001 ± 20 | 1.06 ± 0.02 | Failure | 72 |

| #25 | 1005 ± 20 | 0.38 ± 0.02 | Deflagration | 74 |

| #26 | 998 ± 20 | 0.51 ± 0.02 | Deflagration | 74 |

| #27 | 1002 ± 20 | 0.61 ± 0.02 | Deflagration | 74 |

| #28 | 1003 ± 20 | 0.71 ± 0.02 | Deflagration | 74 |

| #29 | 1001 ± 20 | 0.81 ± 0.02 | Deflagration | 74 |

| #30 | 1005 ± 20 | 0.89 ± 0.02 | Deflagration | 74 |

| #31 | 1001 ± 20 | 1.04 ± 0.02 | Deflagration | 74 |

| #32 | 1003 ± 20 | 1.11 ± 0.02 | Failure | 74 |

| #33 | 995 ± 20 | 0.45 ± 0.02 | Deflagration | 76 |

| #34 | 996 ± 20 | 0.60 ± 0.02 | Deflagration | 76 |

| #35 | 1005 ± 20 | 0.70 ± 0.02 | Deflagration | 76 |

| #36 | 989 ± 20 | 0.80 ± 0.02 | Deflagration | 76 |

| #37 | 1002 ± 20 | 0.89 ± 0.02 | Deflagration | 76 |

| #38 | 1003 ± 20 | 0.98 ± 0.02 | Failure | 76 |

| #39 | 1005 ± 20 | 1.09 ± 0.02 | Failure | 76 |

| #40 | 994 ± 20 | 0.39 ± 0.02 | Deflagration | 78 |

| #41 | 1005 ± 20 | 0.49 ± 0.02 | Deflagration | 78 |

| #42 | 1001 ± 20 | 0.61 ± 0.02 | Failure | 78 |

| #43 | 995 ± 20 | 0.70 ± 0.02 | Failure | 78 |

| #44 | 992 ± 20 | 0.82 ± 0.02 | Failure | 78 |

| #45 | 1003 ± 20 | 0.93 ± 0.02 | Failure | 78 |

| #46 | 1001 ± 20 | 1.04 ± 0.02 | Failure | 78 |

| #47 | 999 ± 20 | 0.48 ± 0.02 | Deflagration | 80 |

| #48 | 994 ± 20 | 0.58 ± 0.02 | Failure | 80 |

| #49 | 996 ± 20 | 0.67 ± 0.02 | Failure | 80 |

| #50 | 1004 ± 20 | 0.77 ± 0.02 | Failure | 80 |

| #51 | 1007 ± 20 | 0.91 ± 0.02 | Failure | 80 |

| #52 | 995 ± 20 | 1.04 ± 0.02 | Failure | 80 |

References

- Kailasanath, K. Recent developments in the research on pulse detonation engines. AIAA J. 2003, 41, 145–159. [Google Scholar] [CrossRef]

- Braun, E.M.; Lu, F.K.; Wilson, D.R.; Camberos, J.A. Airbreathing rotating detonation wave engine cycle analysis. Aerosp. Sci. Technol. 2013, 27, 201–208. [Google Scholar] [CrossRef] [Green Version]

- Yan, C.; Teng, H.H.; Mi, X.C.; Ng, H.D. The effect of chemical reactivity on the formation of gaseous oblique detonation waves. Aerospace 2019, 6, 62. [Google Scholar] [CrossRef] [Green Version]

- Zhdan, S.A. Mathematical model of continuous detonation in an annular combustor with a supersonic flow velocity. Combust. Explos. Shock. Waves 2008, 44, 690–697. [Google Scholar] [CrossRef]

- Dubrovskii, A.V.; Ivanov, V.S.; Zangiev, A.E.; Frolov, S.M. Three-dimensional numerical simulation of the characteristics of a ramjet power plant with a continuous detonation combustor in supersonic flight. Russ. J. Phys. Chem. B 2016, 10, 469–482. [Google Scholar] [CrossRef]

- Smirnov, N.N.; Nikitin, V.F.; Stamov, L.I.; Mikhalchenko, E.V.; Tyurenkova, V.V. Rotating detonation in a ramjet engine three-dimensional modeling. Aerosp. Sci. Technol. 2018, 81, 213–224. [Google Scholar] [CrossRef]

- Smirnov, N.N.; Nikitin, V.F.; Stamov, L.I.; Mikhalchenko, E.V.; Tyurenkova, V.V. Three-dimensional modeling of rotating detonation in a ramjet engine. Acta Astronaut. 2019, 163, 168–176. [Google Scholar] [CrossRef]

- Wu, K.; Zhang, S.; Luan, M.; Wang, J. Effects of flow-field structures on the stability of rotating detonation ramjet engine. Acta Astronaut. 2020, 168, 174–181. [Google Scholar] [CrossRef]

- Wang, C.; Liu, W.; Liu, S.; Jiang, L.; Lin, Z. Experimental verification of air-breathing continuous rotating detonation fueled by hydrogen. Int. J. Hydrog. Energy 2015, 40, 9530–9538. [Google Scholar] [CrossRef]

- Wang, C.; Liu, W.; Liu, S.; Jiang, L.; Lin, Z. Experimental investigation on detonation combustion patterns of hydrogen/vitiated air within annular combustor. Exp. Therm. Fluid Sci. 2015, 66, 269–278. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W.; Wang, Y.; Lin, Z. Free Jet Test of Continuous Rotating Detonation Ramjet Engine. In Proceedings of the 21st AIAA International Space Planes and Hypersonics Technologies Conference, Xiamen, China, 6–9 March 2017; p. 2282. [Google Scholar]

- Frolov, S.M.; Zvegintsev, V.I.; Ivanov, V.S.; Aksenov, V.S.; Shamshin, I.O.; Vnuchkov, D.A.; Nalivaichenko, D.G.; Berlin, A.A.; Fomin, V.M.; Shiplyuk, A.N.; et al. Hydrogen-fueled deto-nation ramjet model: Wind tunnel tests at approach air stream Mach number 5.7 and stagnation temperature 1500 K. Int. J. Hydrog. Energy 2018, 43, 7515–7524. [Google Scholar] [CrossRef]

- Meng, H.; Xiao, Q.; Feng, W.; Wu, M.; Han, X.; Wang, F.; Weng, C.; Zheng, Q. Air-breathing rotating detonation fueled by liquid kerosene in cavity-based annular combustor. Aerosp. Sci. Technol. 2022, 122, 107407. [Google Scholar] [CrossRef]

- Tang, X.; Wang, J.; Shao, Y.T. Three-dimensional numerical investigations of the rotating detonation engine with a hollow combustor. Combust. Flame 2004, 162, 997–1008. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, W.; Liu, S. Effects of inner cylinder length on H2/air rotating detonation. Int. J. Hydrog. Energy 2016, 41, 13281–13293. [Google Scholar] [CrossRef]

- Peng, H.; Liu, W.; Liu, S.; Zhang, H.; Jiang, L. Hydrogen-air, ethylene-air, and methane-air continuous rotating detonation in the hollow chamber. Energy 2020, 211, 118598. [Google Scholar] [CrossRef]

- Yokoo, R.; Goto, K.; Kasahara, J.; Athmanathan, V.; Braun, J.; Paniagua, G.; Meyer, T.R.; Kawasaki, A.; Matsuoka, K.; Matsuo, A.; et al. Experimental study of internal flow structures in cylindrical rotating detonation engines. Proc. Combust. Inst. 2021, 38, 3759–3768. [Google Scholar] [CrossRef]

- Gejji, R.M.; Buschhagen, T.; Slabaugh, C.D. Occurrence of Rotating Detonation Waves in a Jet-Stabilized Combustor with Premixed Injection. J. Propuls. Power 2021, 37, 645–649. [Google Scholar] [CrossRef]

- Wang, G.; Liu, W.; Liu, S.; Zhang, H.; Peng, H.; Zhou, Y. Experimental verification of cylindrical air-breathing continuous rotating detonation engine fueled by non-premixed ethylene. Acta Astronaut. 2021, 189, 722–732. [Google Scholar] [CrossRef]

- Huang, W.; Wang, Z.; Pourkashanian, M.; Ma, L.; Ingham, D.B.; Luo, S.; Lei, J.; Liu, J. Numerical investigation on the shock wave transition in a three-dimensional scramjet isolator. Acta Astronaut. 2011, 68, 1669–1675. [Google Scholar] [CrossRef]

- Su, W.; Ji, Y.; Chen, Y. Effects of dynamic backpressure on pseudoshock oscillations in scramjet inlet-isolator. J. Propuls. Power 2016, 32, 516–528. [Google Scholar] [CrossRef]

- Rankin, B.A.; Fugger, C.A.; Richardson, D.R.; Cho, K.Y.; Hoke, J.; Caswell, A.W.; Gord, J.R.; Schauer, F. Evaluation of Mixing Processes in a Non-Premixed Rotating Detonation Engine Using Acetone PLIF. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; p. 1198. [Google Scholar]

- Sun, M.; Gong, C.; Zhang, S.; Liang, J.; Liu, W.; Wang, Z. Spark ignition process in a scramjet combustor fueled by hydrogen and equipped with multi-cavities at Mach 4 flight condition. Exp. Therm. Fluid Sci. 2012, 43, 90–96. [Google Scholar] [CrossRef]

- Peng, H.; Liu, W.; Liu, S.; Zhang, H. Experimental investigations on ethylene-air Continuous Rotating Detonation wave in the hollow chamber with Laval nozzle. Acta Astronaut. 2018, 151, 137–145. [Google Scholar] [CrossRef]

- Betelin, V.B.; Nikitin, V.F.; Mikhalchenko, E.V. 3D numerical modeling of a cylindrical RDE with an inner body extending out of the nozzle. Acta Astronaut. 2020, 176, 628–646. [Google Scholar] [CrossRef]

- Wu, Y.; Weng, C.; Zheng, Q.; Wei, W.; Bai, Q. Experimental research on the performance of a rotating detonation combustor with a turbine guide vane. Energy 2021, 218, 119580. [Google Scholar] [CrossRef]

- Yang, C.; Wu, X.; Ma, H.; Peng, L.; Gao, J. Experimental research on initiation characteristics of a rotating detonation engine. Exp. Therm. Fluid Sci. 2016, 71, 154–163. [Google Scholar] [CrossRef]

- Wang, Y.; Le, J.; Wang, C.; Zheng, Y.; Huang, S. The effect of the throat width of plug nozzles on the combustion mode in rotating detonation engines. Shock. Waves 2019, 29, 471–485. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, J.; Liu, S.; Lin, Z.; Lin, W. Numerical investigation of a non-premixed hollow rotating detonation engine. Int. J. Hydrog. Energy 2019, 44, 17084–17094. [Google Scholar] [CrossRef]

- Peng, H.Y.; Liu, S.J.; Liu, W.D.; Yuan, X.Q.; Cai, X.D. Enhancement of ethylene-air continuous rotating detonation in the cavity-based annular combustor. Aerosp. Sci. Technol. 2021, 115, 106842. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Z.; Zhang, Y.; Sun, M.; Wang, H. Flame stabilization with a rear-wall-expansion cavity in a supersonic combustor. Acta Astronaut. 2018, 152, 752–756. [Google Scholar] [CrossRef]

- Manda, L.J. Spin effects on rocket nozzle performance. J. Spacecr. Rocket. 1966, 3, 1695–1696. [Google Scholar] [CrossRef]

- Wu, K.; Zhang, S.J.; She, D.W.; Wang, J.P. Analysis of flow-field characteristics and pressure gain in air-breathing rotating detonation combustor. Phys. Fluids 2022, 33, 126112. [Google Scholar] [CrossRef]

- Cai, J.; Zhou, J.; Liu, S.; Lin, Z. Effects of dynamic backpressure on shock train motions in straight isolator. Acta Astronaut. 2017, 141, 237–247. [Google Scholar] [CrossRef]

| Case No. | , g/s | ER | Combustion Mode | Dexh, mm | f, kHz | Note |

|---|---|---|---|---|---|---|

| #1 | 994 ± 20 | 1.09 ± 0.02 | Hybrid mode | 68 | 3.73 | × |

| #2 | 995 ± 20 | 0.78 ± 0.02 | Sawtooth wave | 70 | 3.82 | × |

| #3 | 997 ± 20 | 0.38 ± 0.02 | Deflagration | 74 | × | × |

| #4 | 998 ± 20 | 1.16 ± 0.02 | Hybrid mode | 68 | × | Long CRD test |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Liu, S.; Peng, H.; Liu, W. Experimental Investigation of a Cylindrical Air-Breathing Continuous Rotating Detonation Engine with Different Nozzle Throat Diameters. Aerospace 2022, 9, 267. https://doi.org/10.3390/aerospace9050267

Wang G, Liu S, Peng H, Liu W. Experimental Investigation of a Cylindrical Air-Breathing Continuous Rotating Detonation Engine with Different Nozzle Throat Diameters. Aerospace. 2022; 9(5):267. https://doi.org/10.3390/aerospace9050267

Chicago/Turabian StyleWang, Guangyu, Shijie Liu, Haoyang Peng, and Weidong Liu. 2022. "Experimental Investigation of a Cylindrical Air-Breathing Continuous Rotating Detonation Engine with Different Nozzle Throat Diameters" Aerospace 9, no. 5: 267. https://doi.org/10.3390/aerospace9050267

APA StyleWang, G., Liu, S., Peng, H., & Liu, W. (2022). Experimental Investigation of a Cylindrical Air-Breathing Continuous Rotating Detonation Engine with Different Nozzle Throat Diameters. Aerospace, 9(5), 267. https://doi.org/10.3390/aerospace9050267