Additive Manufacturing of Novel Hybrid Monolithic Ceramic Substrates

Abstract

:1. Introduction

2. Materials and Methods

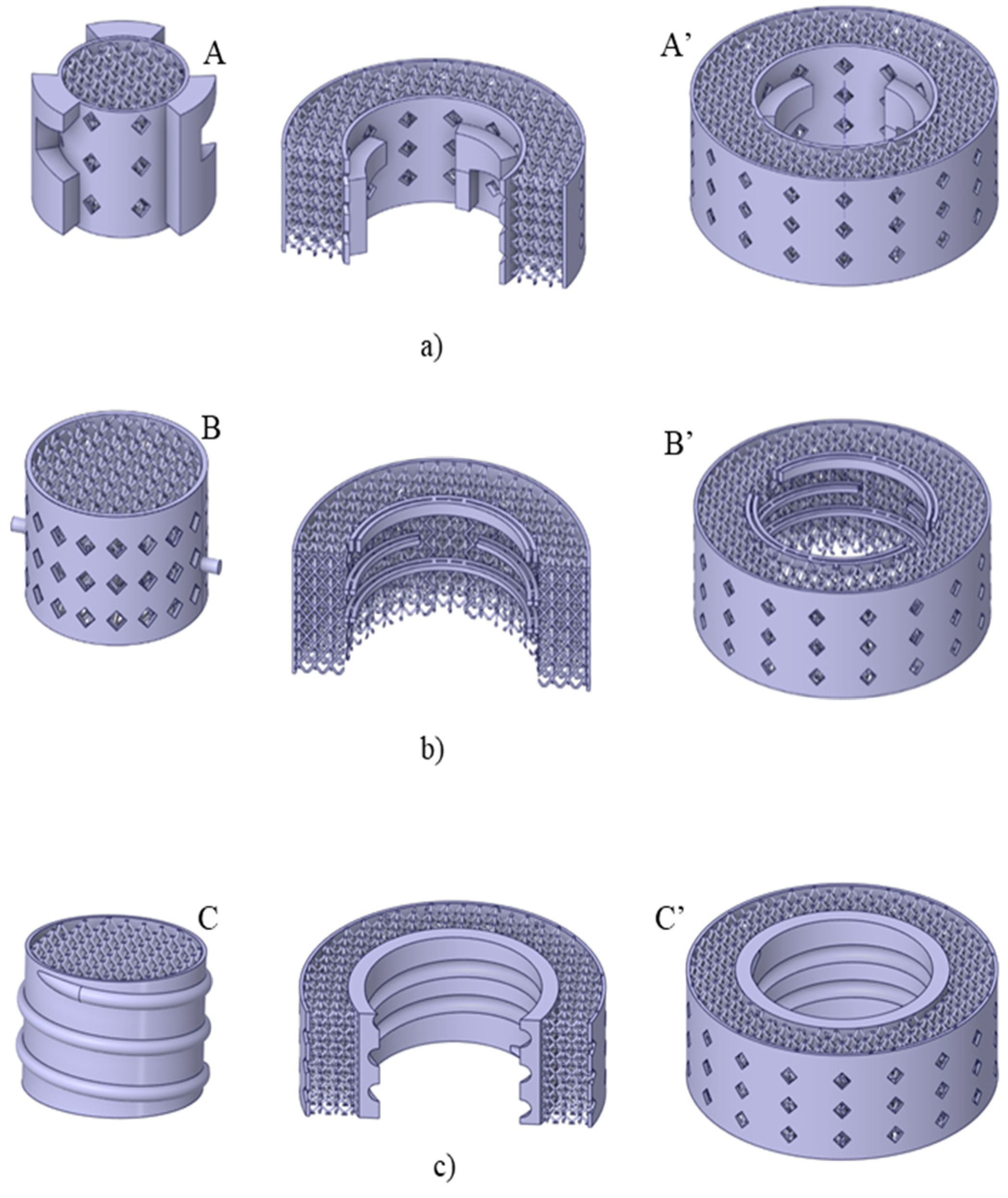

2.1. Interlock Designs

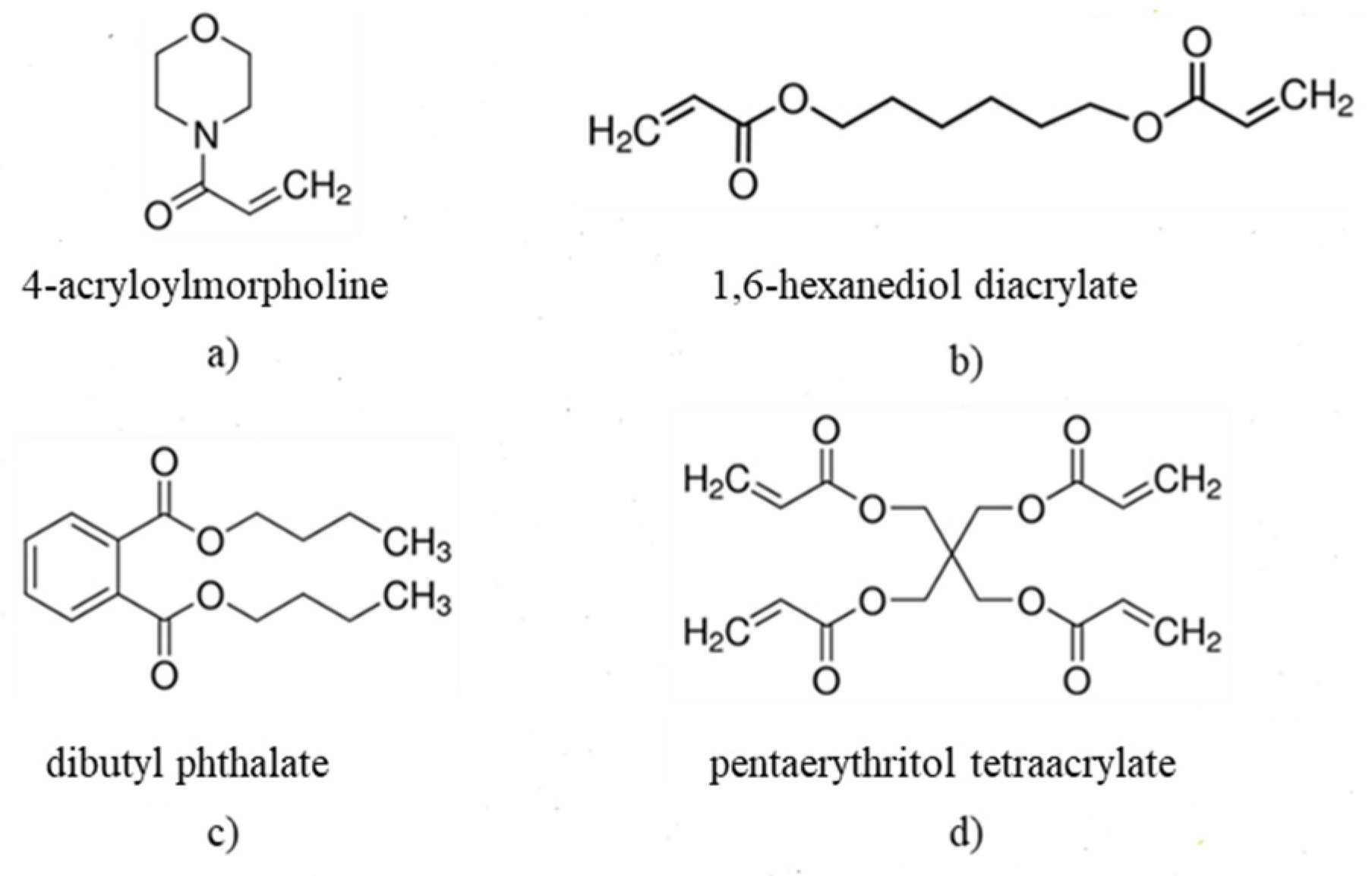

2.2. Ceramic Slurry Preparation and Characterisation

2.3. Green Body Shaping via DLP

2.4. Thermal Post-Processing of the Green Bodies

2.5. Part Characterisation

3. Results and Discussion

3.1. Slurry Characterisation

3.2. Thermal Debinding Analysis

3.3. Characterisation of the Printed and Sintered Samples

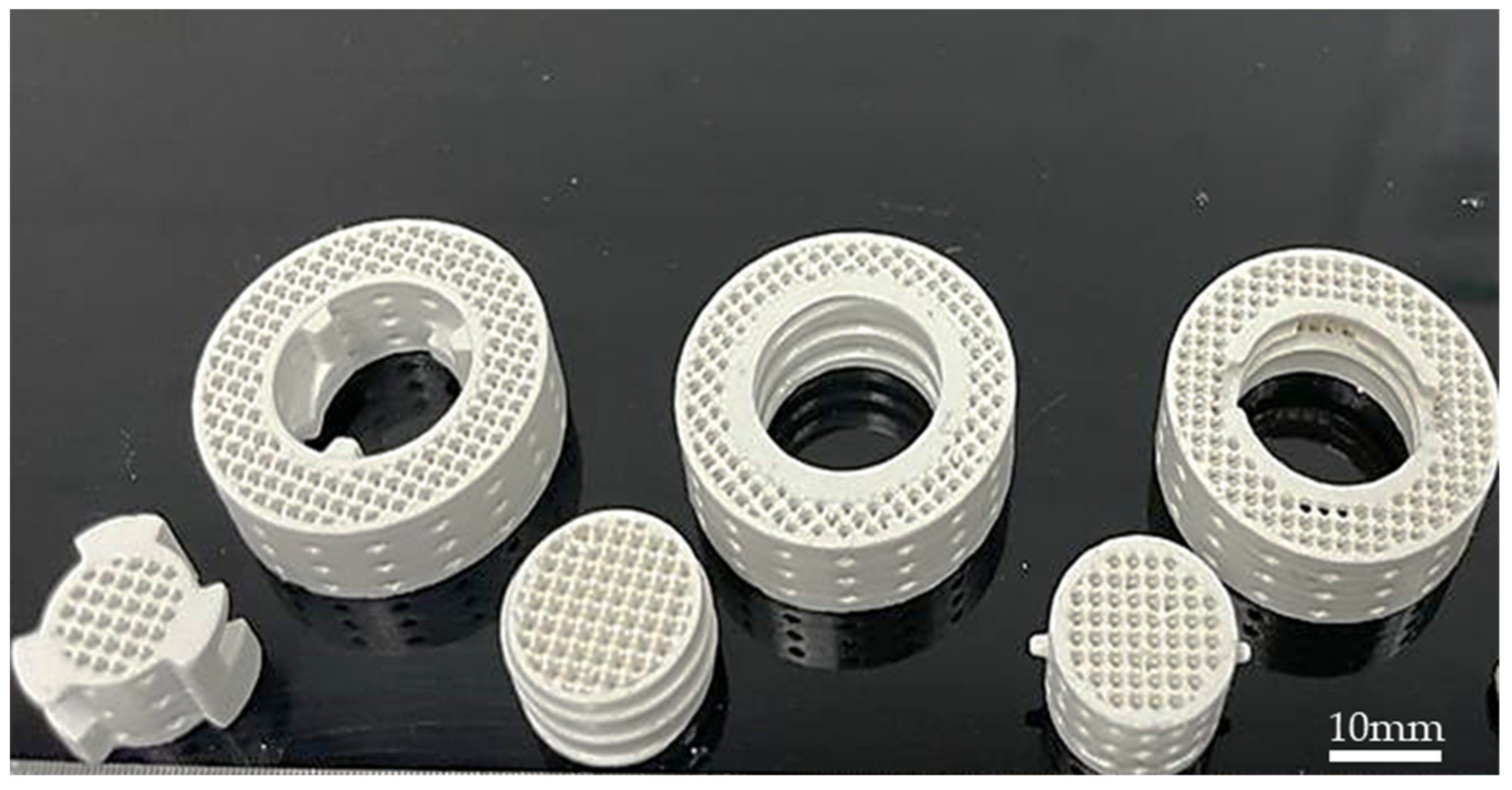

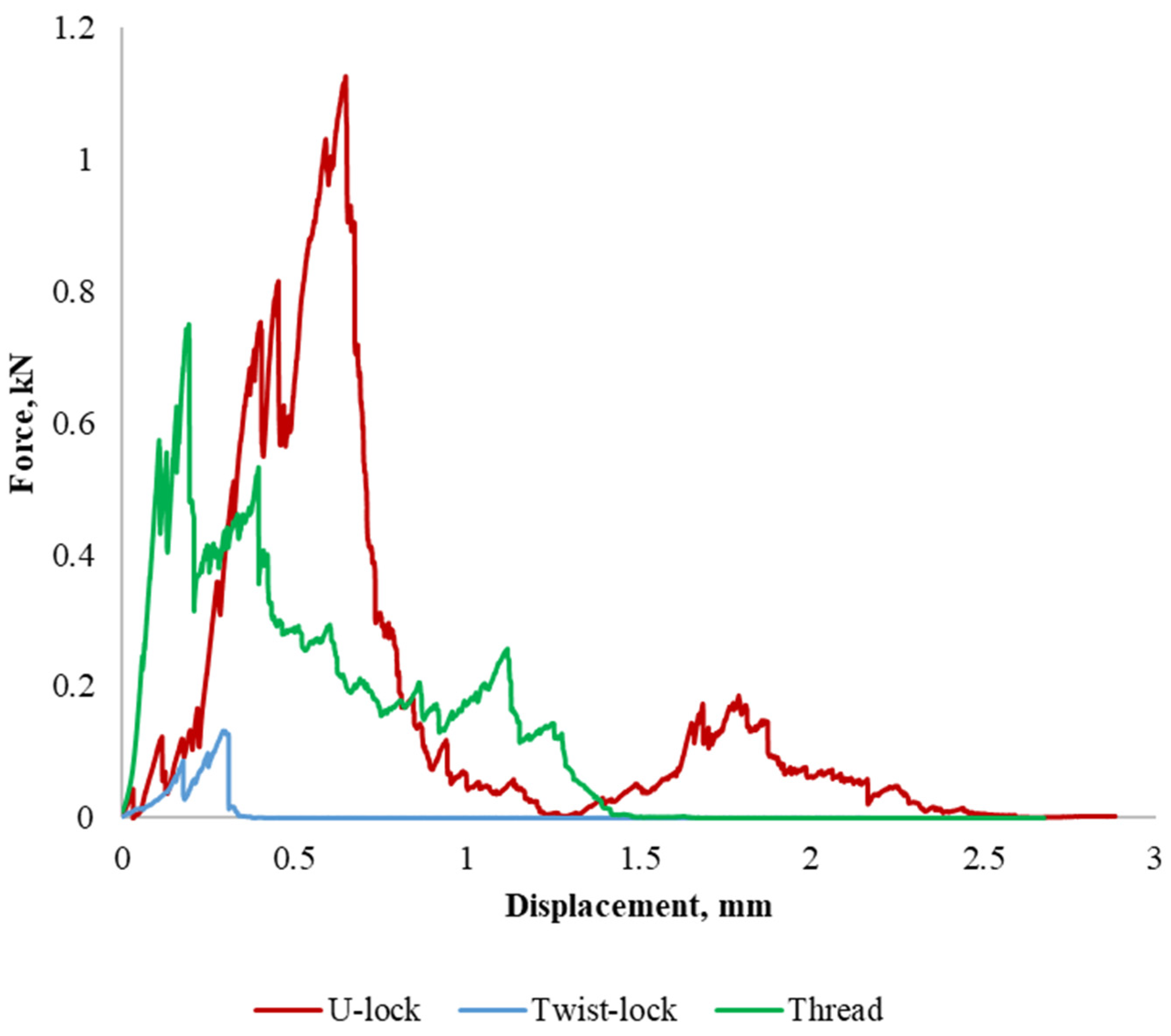

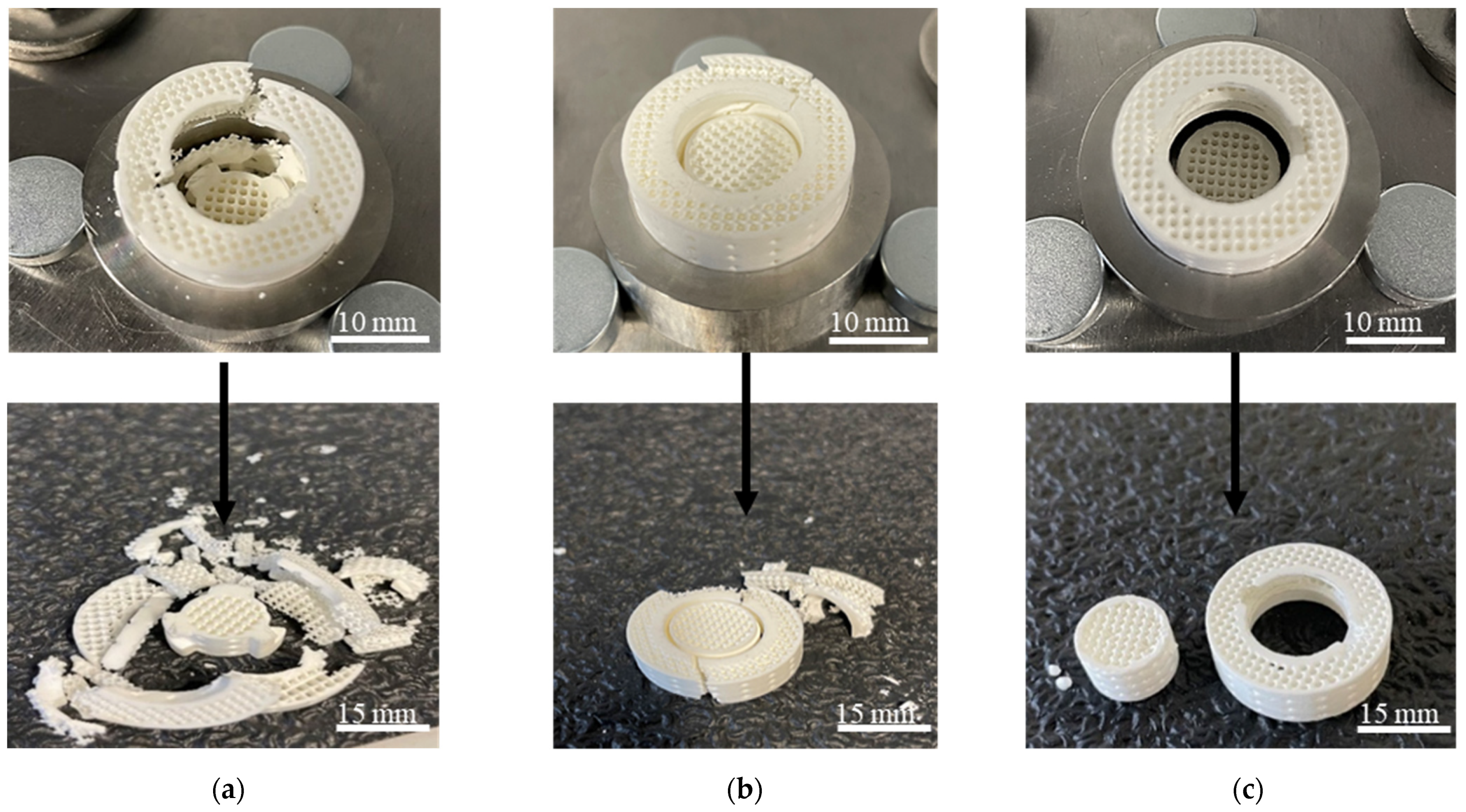

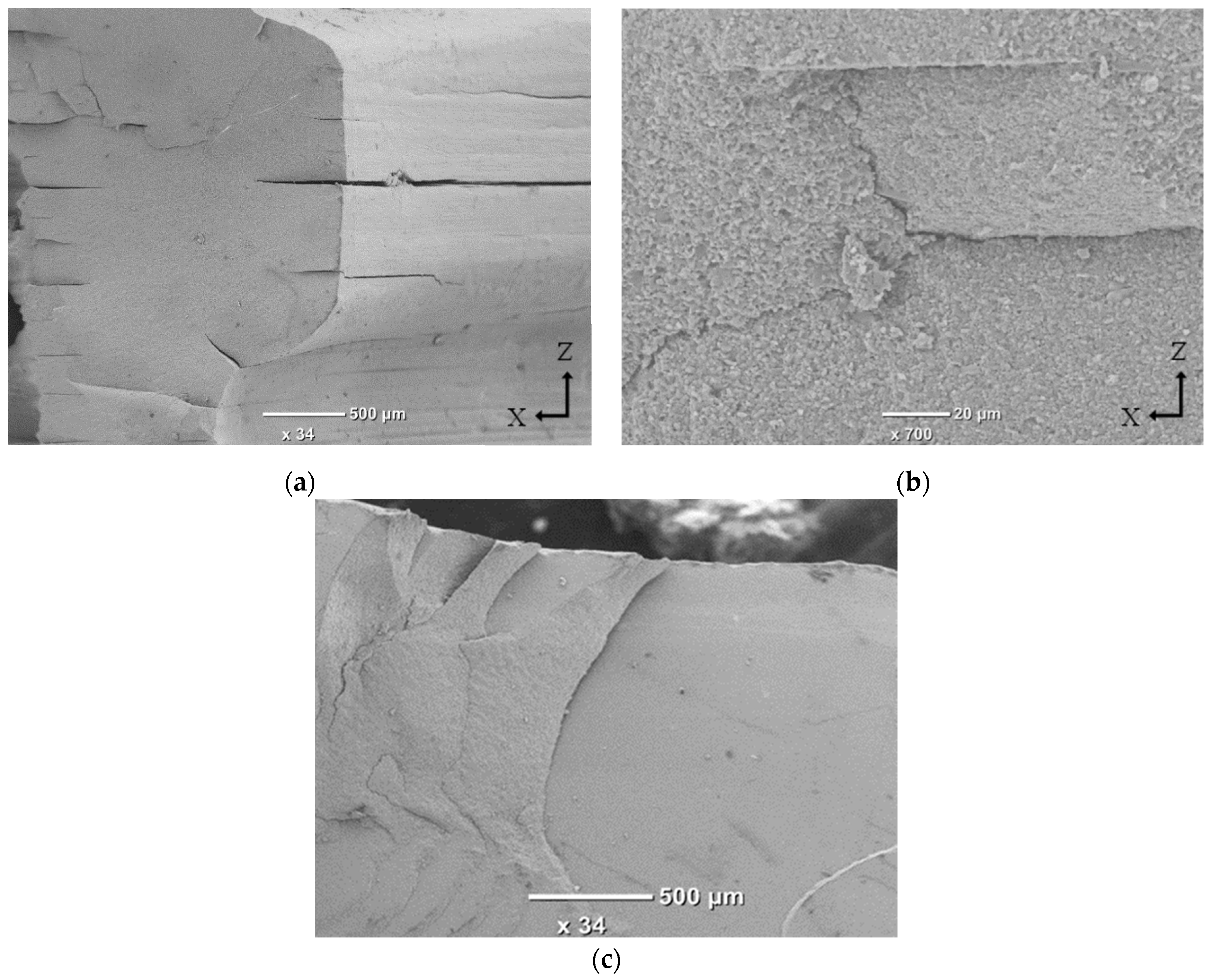

3.4. Mechanical Integrity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baharudin, L.; Watson, M.J. Monolithic Substrate Support Catalyst Design Considerations for Steam Methane Reforming Operation. Rev. Chem. Eng. 2018, 34, 481–501. [Google Scholar] [CrossRef]

- Ayodhya, A.S.; Narayanappa, K.G. An Overview of After-Treatment Systems for Diesel Engines. Environ. Sci. Pollut. Res. 2018, 25, 35034–35047. [Google Scholar] [CrossRef] [PubMed]

- Lefort, I.; Tsolakis, A. A Thermally Efficient DOC Configuration to Improve CO and THC Conversion Efficiency. SAE Tech. Pap. 2013. [Google Scholar] [CrossRef]

- Hazlett, M.J.; Epling, W.S. Heterogeneous Catalyst Design: Zoned and Layered Catalysts in Diesel Vehicle Aftertreatment Monolith Reactors. Can. J. Chem. Eng. 2019, 97, 188–206. [Google Scholar] [CrossRef]

- Megaritis, A.; Wyszynski, M.L.; Tsolakis, A.; Cracknell, R.; Peucheret, S.M.; Xu, H.M.; Abu-Jrai, A.; Golunski, S.E.; Theinnoi, K. Exhaust Gas Fuel Reforming for IC Engines Using Diesel Type Fuels. SAE Tech. Pap. Ser. 2010, 1, 1289–1294. [Google Scholar] [CrossRef]

- Herreros, J.M.; Gill, S.S.; Lefort, I.; Tsolakis, A.; Millington, P.; Moss, E. Enhancing the Low Temperature Oxidation Performance over a Pt and a Pt-Pd Diesel Oxidation Catalyst. Appl. Catal. B Environ. 2014, 147, 835–841. [Google Scholar] [CrossRef] [Green Version]

- Umar, M.; Nozari, H.; Menezes, M.R.; Herreros, J.M.; Lau, C.S.; Tsolakis, A. Hydrogen Production from Bioethanol Fuel Mixtures via Exhaust Heat Recovery in Diesel Engines: A Promising Route towards More Energy Efficient Road Vehicles. Int. J. Hydrog. Energy 2021, 46, 23603–23614. [Google Scholar] [CrossRef]

- Azis, M.M.; Auvray, X.; Olsson, L.; Creaser, D. Evaluation of H2 Effect on NO Oxidation over a Diesel Oxidation Catalyst. Appl. Catal. B Environ. 2015, 179, 542–550. [Google Scholar] [CrossRef]

- Theinnoi, K.; Temwutthikun, W.; Wongchang, T.; Sawatmongkhon, B. Application of Exhaust Gas Fuel Reforming in Diesel Engines towards the Improvement Urban Air Qualities. Energy Procedia 2018, 152, 875–882. [Google Scholar] [CrossRef]

- Negri, M. Technology Development for ADN-Based Green Monopropellant Thrusters—An Overview of the Rheform Project. In Proceedings of the 7th European Conference for Aeronautics and Space Sciences, Milan, Italy, 3–6 July 2017; pp. 1–13. [Google Scholar]

- Koopmans, R.; Schuh, S.; Bartok, T.; Forschungs-, F.; Gmbh, T.; Kaplan-straße, V.; Neustadt, W.; Schwentenwein, M.; Spitzbart, M. Performance Comparison between Extruded and Printed Ceramic Monoliths for Catalysts. In Proceedings of the 7th European Conference for Aeronautic and Space Sciences (EUCASS), Milan, Italy, 3–6 July 2017; p. 2700. [Google Scholar]

- Essa, K.; Hassanin, H.; Attallah, M.M.; Adkins, N.J.; Musker, A.J.; Roberts, G.T.; Tenev, N.; Smith, M. Development and Testing of an Additively Manufactured Monolithic Catalyst Bed for HTP Thruster Applications. Appl. Catal. A Gen. 2017, 542, 125–135. [Google Scholar] [CrossRef] [Green Version]

- Hassanin, H.; Alkendi, Y.; Elsayed, M.; Essa, K.; Zweiri, Y. Controlling the Properties of Additively Manufactured Cellular Structures Using Machine Learning Approaches. Adv. Eng. Mater. 2020, 22, 1901338. [Google Scholar] [CrossRef]

- Hassanin, H.; El-Sayed, M.A.; Elshaer, A.; Essa, K.; Jiang, K. Microfabrication of Net Shape Zirconia/Alumina Nanocomposite Micro Parts. Nanomaterials 2018, 8, 593. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sabouri, A.; Yetisen, A.K.; Sadigzade, R.; Hassanin, H.; Essa, K.; Butt, H. Three-Dimensional Microstructured Lattices for Oil Sensing. Energy Fuels 2017, 31, 2524–2529. [Google Scholar] [CrossRef] [Green Version]

- El-Sayed, M.A.; Essa, K.; Ghazy, M.; Hassanin, H. Design Optimization of Additively Manufactured Titanium Lattice Structures for Biomedical Implants. Int. J. Adv. Manuf. Technol. 2020, 110, 2257–2268. [Google Scholar] [CrossRef]

- Hassanin, H.; Essa, K.; Elshaer, A.; Imbaby, M.; El-Mongy, H.H.; El-Sayed, T.A. Micro-Fabrication of Ceramics: Additive Manufacturing and Conventional Technologies. J. Adv. Ceram. 2021, 10, 1–27. [Google Scholar] [CrossRef]

- Kovacev, N.; Li, S.; Zeraati-Rezaei, S.; Hemida, H.; Tsolakis, A.; Essa, K. Effects of the Internal Structures of Monolith Ceramic Substrates on Thermal and Hydraulic Properties: Additive Manufacturing, Numerical Modelling and Experimental Testing. Int. J. Adv. Manuf. Technol. 2020, 112, 1115–1132. [Google Scholar] [CrossRef]

- Papetti, V.; Eggenschwiler, P.D.; Della Torre, A.; Lucci, F.; Ortona, A.; Montenegro, G. Additive Manufactured Open Cell Polyhedral Structures as Substrates for Automotive Catalysts. Int. J. Heat Mass Transf. 2018, 126, 1035–1047. [Google Scholar] [CrossRef]

- Ferrizz, R.M.; Stuecker, J.N.; Cesarano, J.; Miller, J.E. Monolithic Supports with Unique Geometries and Enhanced Mass Transfer. Ind. Eng. Chem. Res. 2005, 44, 302–308. [Google Scholar] [CrossRef] [Green Version]

- Hajimirzaee, S.; Doyle, A.M. 3D Printed Catalytic Converters with Enhanced Activity for Low-Temperature Methane Oxidation in Dual-Fuel Engines. Fuel 2020, 274, 117848. [Google Scholar] [CrossRef]

- Kovacev, N.; Li, S.; Essa, K. Effect of the Preparation Techniques of Photopolymerizable Ceramic Slurry and Printing Parameters on the Accuracy of 3D Printed Lattice Structures. J. Eur. Ceram. Soc. 2021, 41, 7734–7743. [Google Scholar] [CrossRef]

- Schweiger, J.; Bomze, D.; Schwentenwein, M. 3D Printing of Zirconia–What Is the Future? Curr. Oral Health Rep. 2019, 6, 339–343. [Google Scholar] [CrossRef]

- Johansson, E.; Lidström, O.; Johansson, J.; Lyckfeldt, O.; Adolfsson, E. Influence of Resin Composition on the Defect Formation in Alumina Manufactured by Stereolithography. Materials 2017, 10, 138. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gonzalez, P.; Schwarzer, E.; Scheithauer, U.; Kooijmans, N.; Moritz, T. Additive Manufacturing of Functionally Graded Ceramic Materials by Stereolithography. J. Vis. Exp. 2019, 2019, e57943. [Google Scholar] [CrossRef] [PubMed]

- Pfaffinger, M.; Mitteramskogler, G.; Gmeiner, R.; Stampfl, J. Thermal Debinding of Ceramic-Filled Photopolymers. Mater. Sci. Forum 2015, 825–826, 75–81. [Google Scholar] [CrossRef]

- Sun, J.; Binner, J.; Bai, J. Effect of Surface Treatment on the Dispersion of Nano Zirconia Particles in Non-Aqueous Suspensions for Stereolithography. J. Eur. Ceram. Soc. 2019, 39, 1660–1667. [Google Scholar] [CrossRef]

- Zakeri, S.; Vippola, M.; Levänen, E. A Comprehensive Review of the Photopolymerization of Ceramic Resins Used in Stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- He, R.; Liu, W.; Wu, Z.; An, D.; Huang, M.; Wu, H.; Jiang, Q.; Ji, X.; Wu, S.; Xie, Z. Fabrication of Complex-Shaped Zirconia Ceramic Parts via a DLP-Stereolithography-Based 3D Printing Method. Ceram. Int. 2018, 44, 3412–3416. [Google Scholar] [CrossRef]

- Borlaf, M.; Serra-Capdevila, A.; Colominas, C.; Graule, T. Development of UV-Curable ZrO2 Slurries for Additive Manufacturing (LCM-DLP) Technology. J. Eur. Ceram. Soc. 2019, 39, 3797–3803. [Google Scholar] [CrossRef]

- Wang, L.; Liu, X.; Wang, G.; Tang, W.; Li, S.; Duan, W.; Dou, R. Partially Stabilized Zirconia Moulds Fabricated by Stereolithographic Additive Manufacturing via Digital Light Processing. Mater. Sci. Eng. A 2020, 770, 138537. [Google Scholar] [CrossRef]

- Kowsari, K.; Zhang, B.; Panjwani, S.; Chen, Z.; Hingorani, H.; Akbari, S.; Fang, N.X.; Ge, Q. Photopolymer Formulation to Minimize Feature Size, Surface Roughness, and Stair-Stepping in Digital Light Processing-Based Three-Dimensional Printing. Addit. Manuf. 2018, 24, 627–638. [Google Scholar] [CrossRef]

- Li, X.; Zhong, H.; Zhang, J.; Duan, Y.; Bai, H.; Li, J.; Jiang, D. Dispersion and Properties of Zirconia Suspensions for Stereolithography. Int. J. Appl. Ceram. Technol. 2019, 17, 239–247. [Google Scholar] [CrossRef] [Green Version]

- De Camargo, I.L.; Erbereli, R.; Taylor, H.; Fortulan, C.A. 3Y-TZP DLP Additive Manufacturing: Solvent-Free Slurry Development and Characterization. Mater. Res. 2021, 24. [Google Scholar] [CrossRef]

- Santoliquido, O.; Bianchi, G.; Dimopoulos Eggenschwiler, P.; Ortona, A. Additive Manufacturing of Periodic Ceramic Substrates for Automotive Catalyst Supports. Int. J. Appl. Ceram. Technol. 2017, 14, 1164–1173. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Pelanconi, M.; Ortona, A.; Abu Al-Rub, R.K. Additive Manufacturing of Architected Catalytic Ceramic Substrates Based on Triply Periodic Minimal Surfaces. J. Am. Ceram. Soc. 2019, 102, 6176–6193. [Google Scholar] [CrossRef]

- Osman, R.B.; van der Veen, A.J.; Huiberts, D.; Wismeijer, D.; Alharbi, N. 3D-Printing Zirconia Implants; a Dream or a Reality? An in-Vitro Study Evaluating the Dimensional Accuracy, Surface Topography and Mechanical Properties of Printed Zirconia Implant and Discs. J. Mech. Behav. Biomed. Mater. 2017, 75, 521–528. [Google Scholar] [CrossRef]

| Technology | Layer Thickness, µm | Printing Build Volume (X,Y,Z), mm | Individual Pixel Size, µm | Wavelength, nm |

|---|---|---|---|---|

| DLP | 10–200 | 96 × 54 × 110 | 40 | 405 |

| CAD, mm | Green Body, mm | Sintered Body, mm | Sintering Shrinkage, % | |||||

|---|---|---|---|---|---|---|---|---|

| Part | X–Y | Z | X–Y | Z | X–Y | Z | X–Y | Z |

| A | 14.53 | 10.77 | 15.02 ± 0.17 | 10.50 ± 0.23 | 13.01 ± 0.09 | 8.52 ± 0.06 | 13.38 | 18.86 |

| A’ | 29.03 | 10.77 | 29.16 ± 0.20 | 10.46 ± 0.18 | 24.87 ± 0.07 | 8.40 ± 0.02 | 14.71 | 19.69 |

| B | 14.53 | 10.77 | 14.78 ± 0.08 | 10.46 ± 0.02 | 12.78 ± 0.06 | 8.57 ± 0.21 | 13.52 | 18.07 |

| B’ | 29.03 | 10.77 | 29.08 ± 0.14 | 10.44 ± 0.04 | 24.81 ± 0.49 | 8.49 ± 0.11 | 14.68 | 18.68 |

| C | 14.53 | 10.77 | 14.93 ± 0.23 | 10.44 ± 0.12 | 12.89 ± 0.10 | 8.50 ± 0.06 | 13.66 | 18.58 |

| C’ | 29.03 | 10.77 | 29.22 ± 0.11 | 10.58 ± 0.17 | 24.86 ± 0.07 | 8.58 ± 0.12 | 14.92 | 18.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kovacev, N.; Li, S.; Li, W.; Zeraati-Rezaei, S.; Tsolakis, A.; Essa, K. Additive Manufacturing of Novel Hybrid Monolithic Ceramic Substrates. Aerospace 2022, 9, 255. https://doi.org/10.3390/aerospace9050255

Kovacev N, Li S, Li W, Zeraati-Rezaei S, Tsolakis A, Essa K. Additive Manufacturing of Novel Hybrid Monolithic Ceramic Substrates. Aerospace. 2022; 9(5):255. https://doi.org/10.3390/aerospace9050255

Chicago/Turabian StyleKovacev, Nikolina, Sheng Li, Weining Li, Soheil Zeraati-Rezaei, Athanasios Tsolakis, and Khamis Essa. 2022. "Additive Manufacturing of Novel Hybrid Monolithic Ceramic Substrates" Aerospace 9, no. 5: 255. https://doi.org/10.3390/aerospace9050255

APA StyleKovacev, N., Li, S., Li, W., Zeraati-Rezaei, S., Tsolakis, A., & Essa, K. (2022). Additive Manufacturing of Novel Hybrid Monolithic Ceramic Substrates. Aerospace, 9(5), 255. https://doi.org/10.3390/aerospace9050255