Thermal Management System Optimization for a Parallel Hybrid Aircraft Considering Mission Fuel Burn

Abstract

:1. Introduction

1.1. Review of Thermal Management Architectures and Modeling Approaches

1.2. Efficient Thermal Management for a Parallel Hybrid Transport Aircraft

1.3. Objectives

2. System Description and Methods

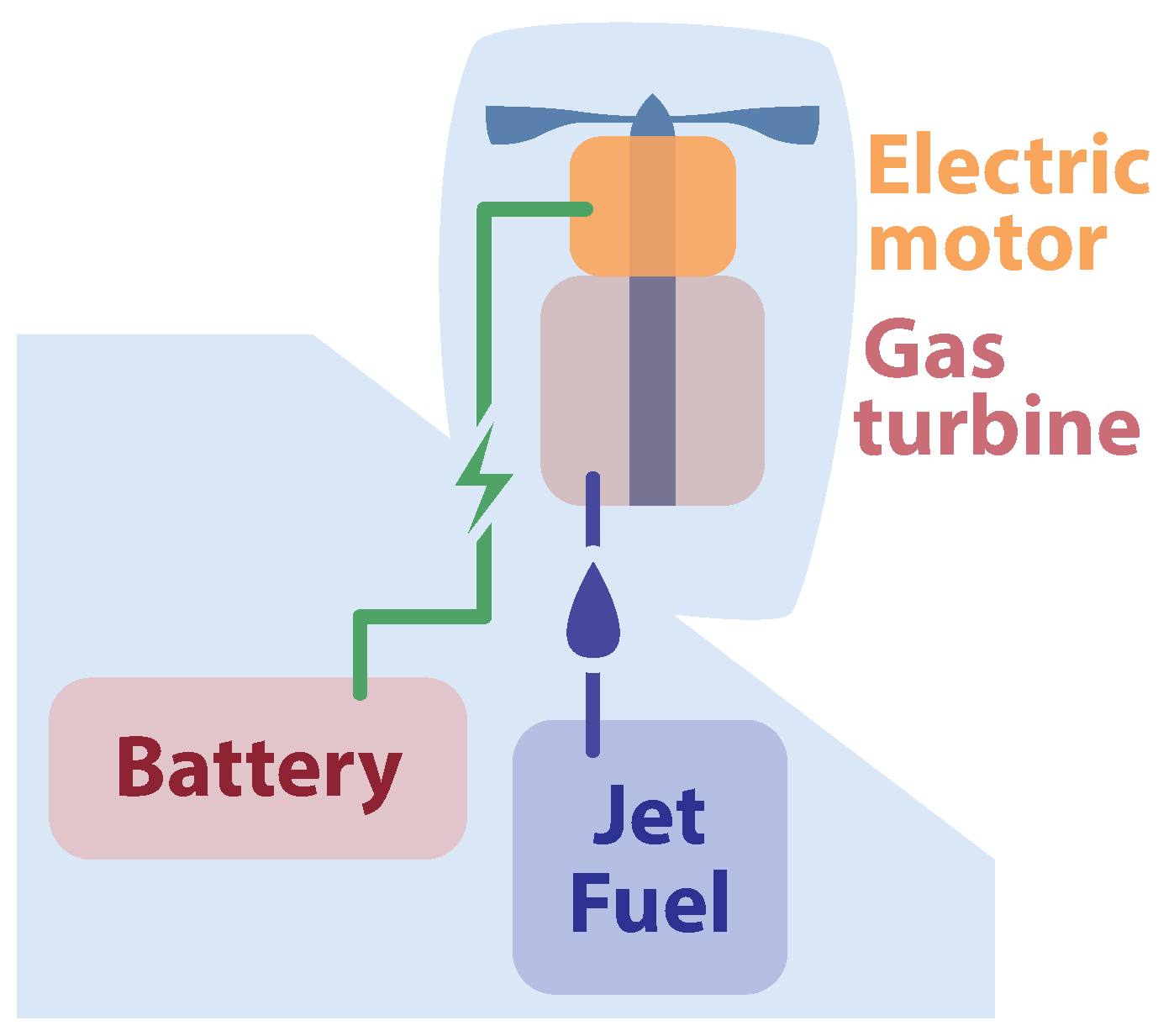

- 1.

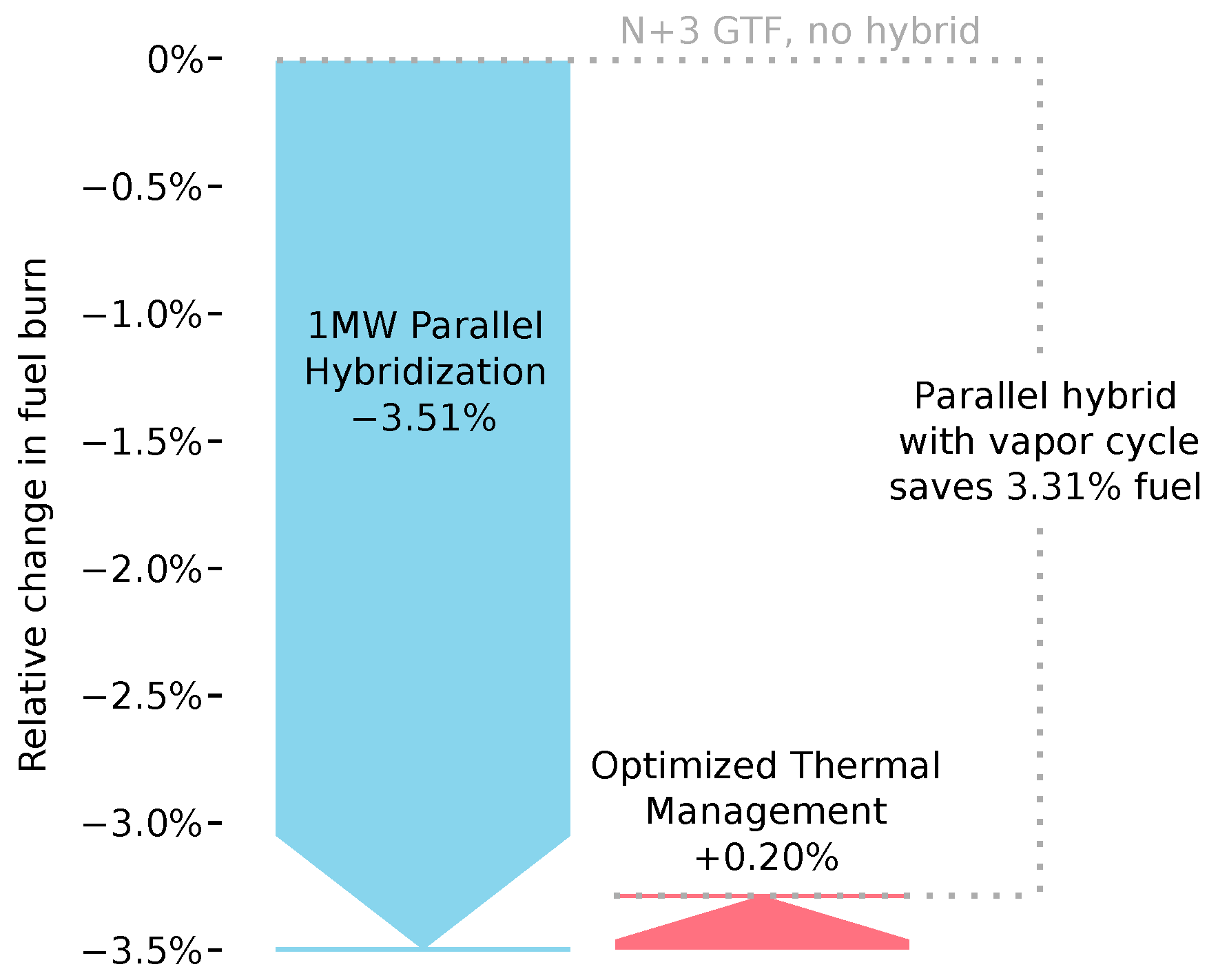

- N+3 Conventional: single-aisle airframe with advanced technology GTFs and no hybrid propulsion system. This represents the baseline N+3 aircraft attained by continuing to refine existing technology.

- 2.

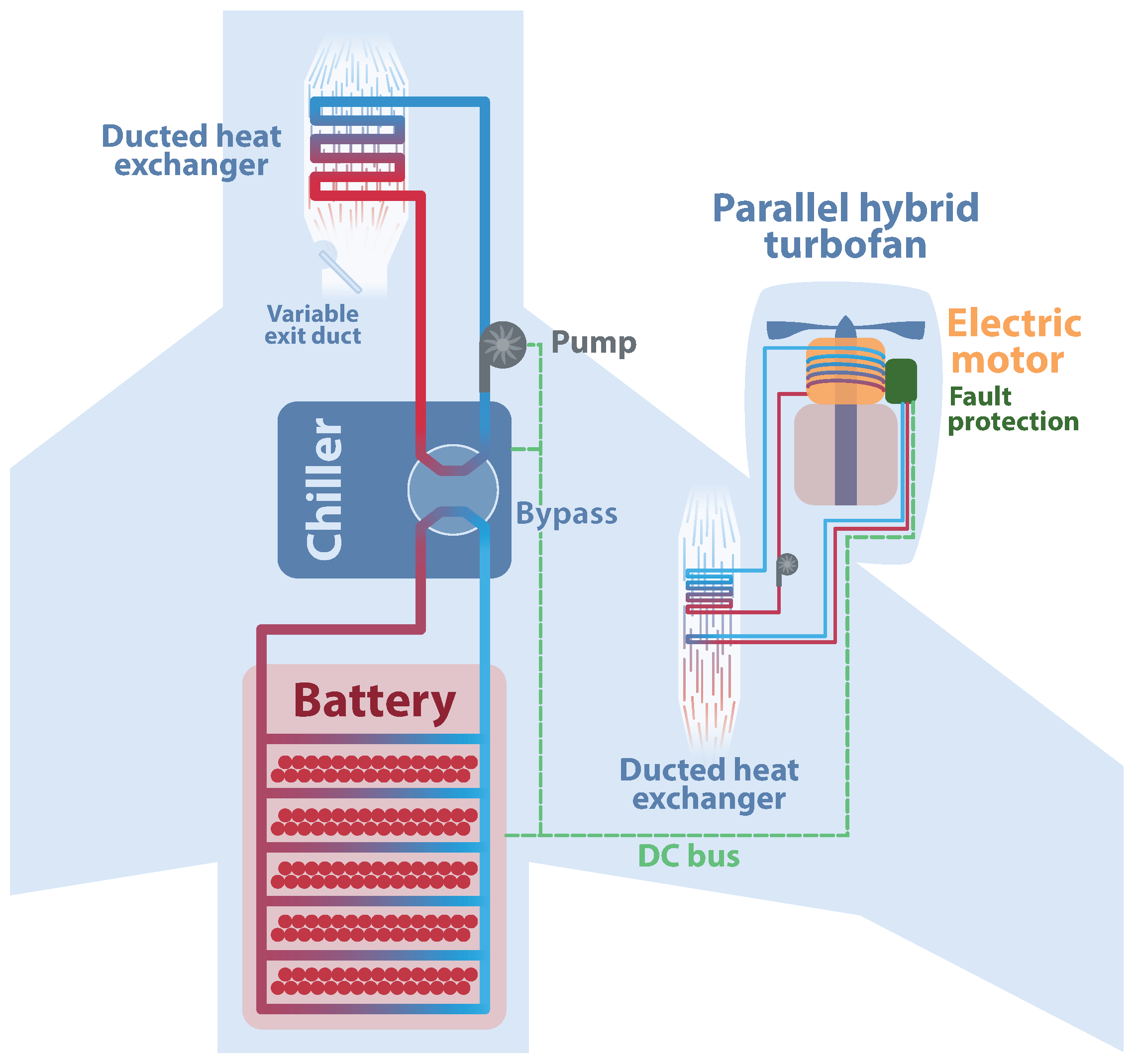

- Vapor cycle hybrid: single-aisle airframe with advanced technology GTFs, each with 1 MW hybrid-electric boost and a vapor cycle chiller. This is a representative parallel hybrid aircraft with a conventional thermal management system against which we can compare the TREES architecture.

- 3.

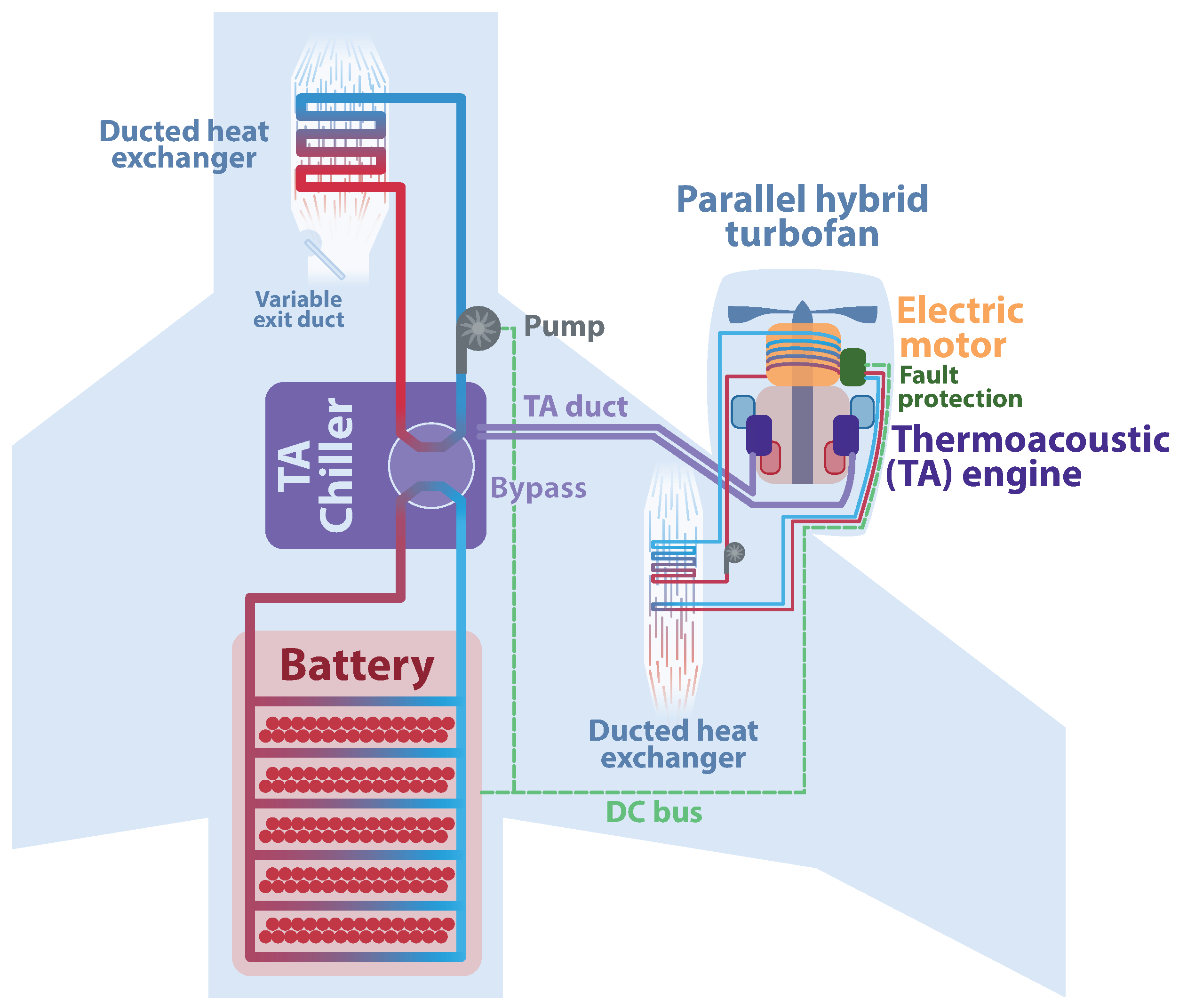

- TREES hybrid: single-aisle airframe with advanced technology GTFs, each with 1 MW hybrid-electric boost and the TREES thermoacoustic chiller system driven by engine waste heat recovery.

2.1. Concept of Operations

Airframe and Weights

2.2. Propulsion

2.2.1. Optimization Problem

2.2.2. Optimized Engine Designs

- 1.

- An electric motor provides up to 1 MW power to the fan shaft.

- 2.

- 10 kW thermoacoustic power is generated by extracting heat from the core exhaust and transferring it to the bypass duct (thus slightly recuperating the cycle).

- 3.

- Heat exchangers in the core exhaust and fan bypass ducts incur total pressure losses.

2.2.3. Integration into Aircraft Model

2.3. Thermal Management System

2.3.1. VCS Aircraft

2.3.2. TREES Aircraft

2.4. Optimization Problem Formulation

3. Relative Performance of Architectures

3.1. Sensitivity Analysis

- 1.

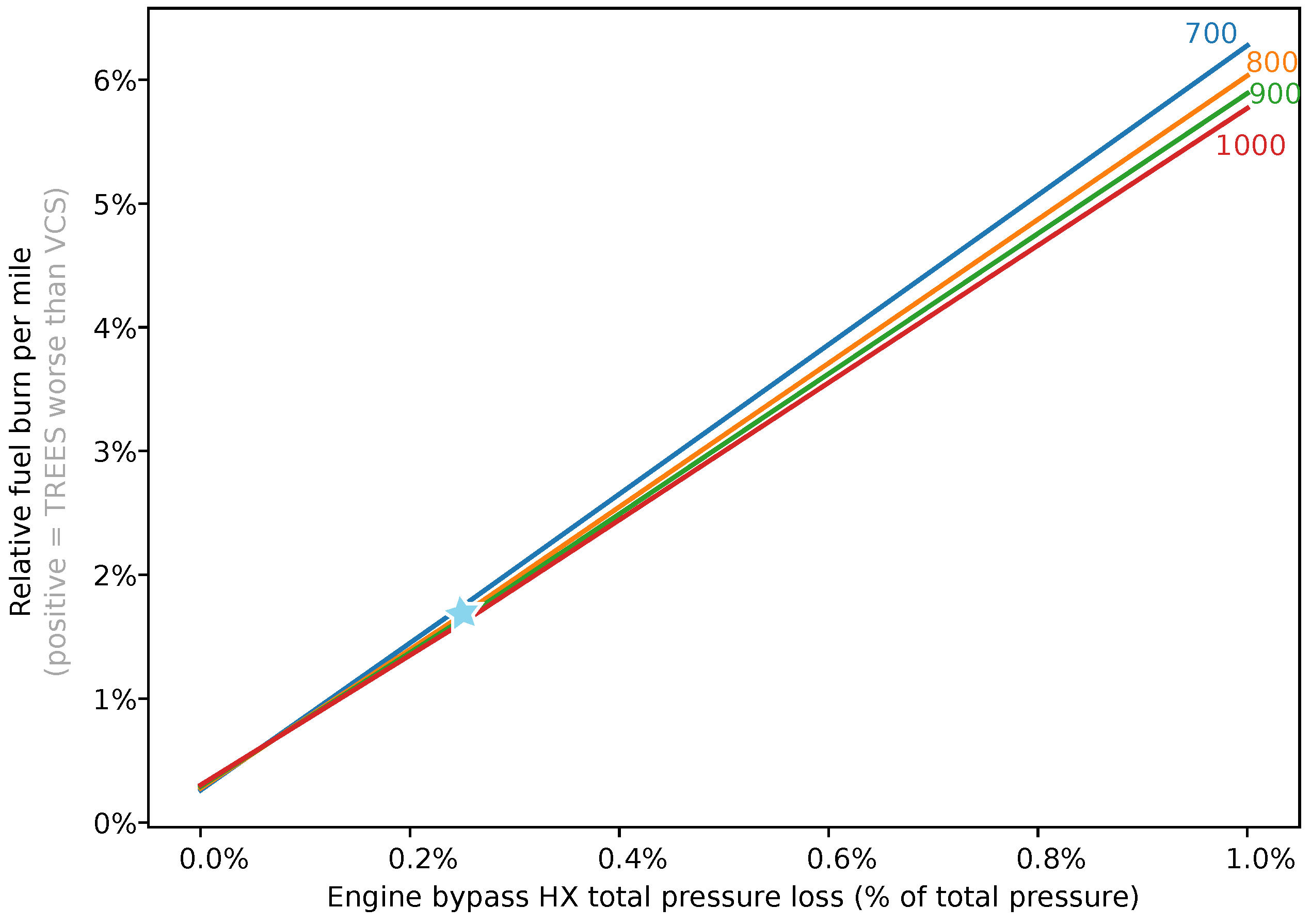

- Engine bypass heat exchanger total pressure loss.

- 2.

- Thermoacoustic tube weight.

- 3.

- Battery-specific energy.

- 4.

- Design range.

- 5.

- Thermoacoustic chiller efficiency.

- 6.

- Vapor cycle chiller-specific power.

- 7.

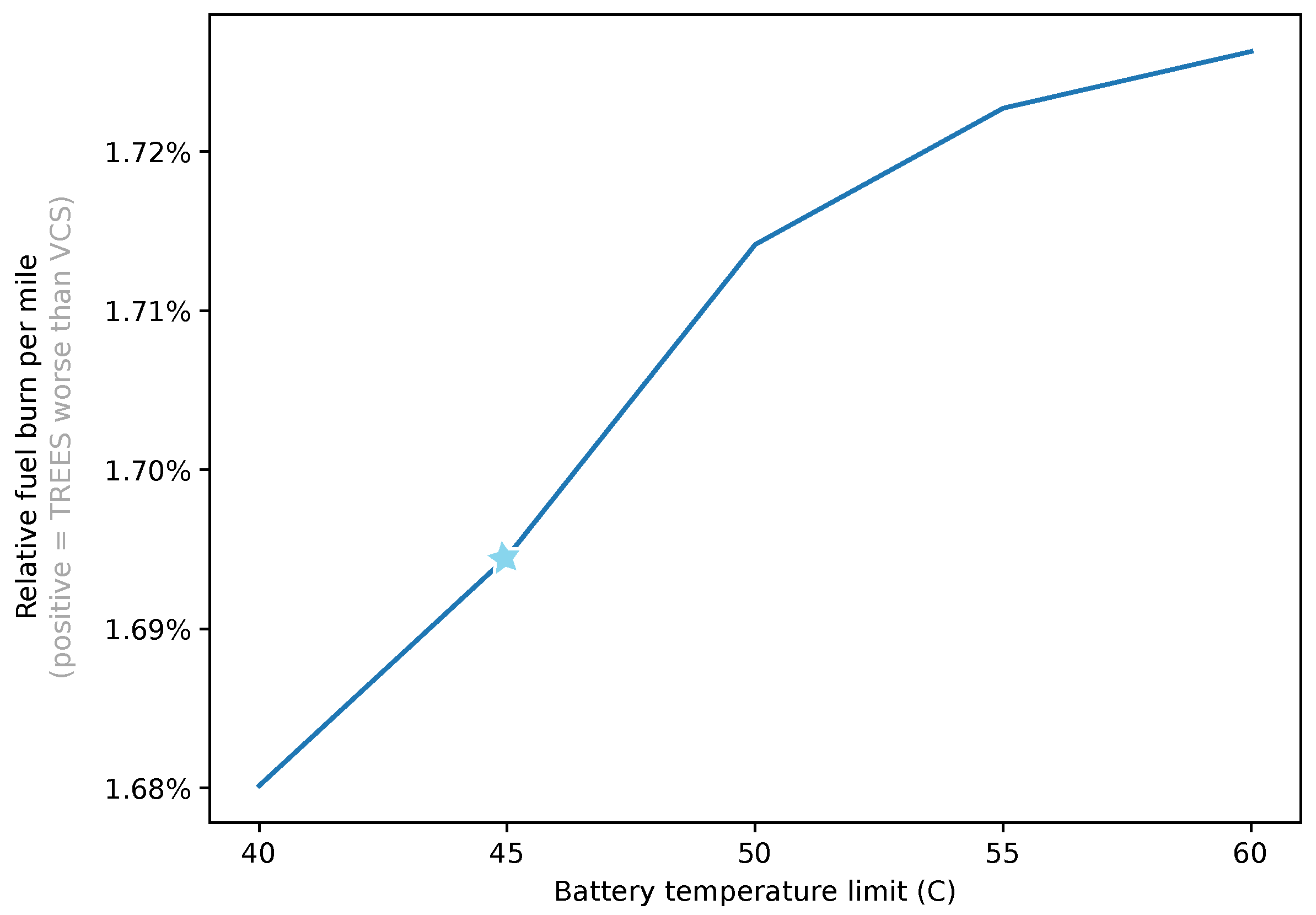

- Battery temperature limit.

3.1.1. Engine Bypass Heat Exchanger Total Pressure Loss

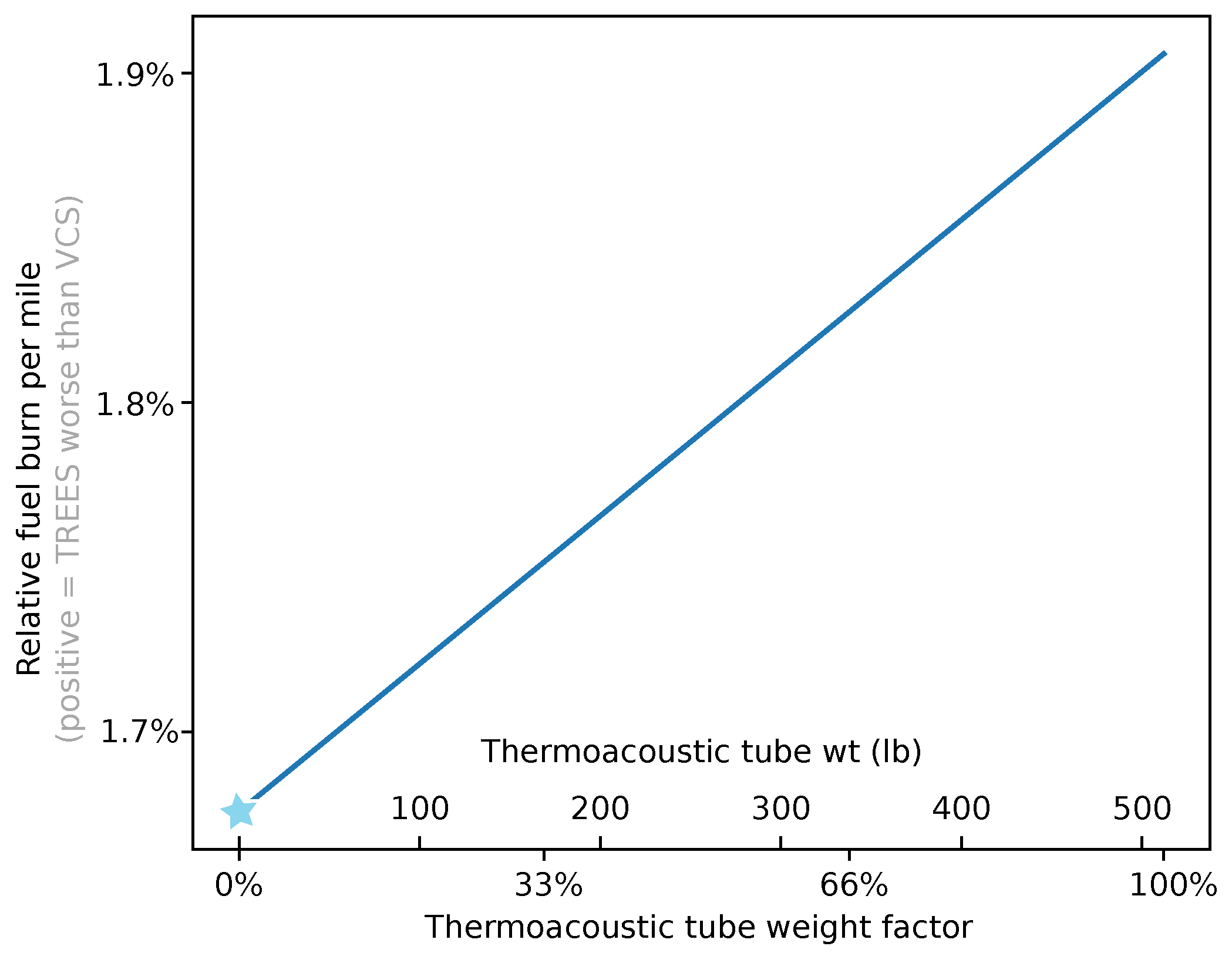

3.1.2. Thermoacoustic Tube Weight

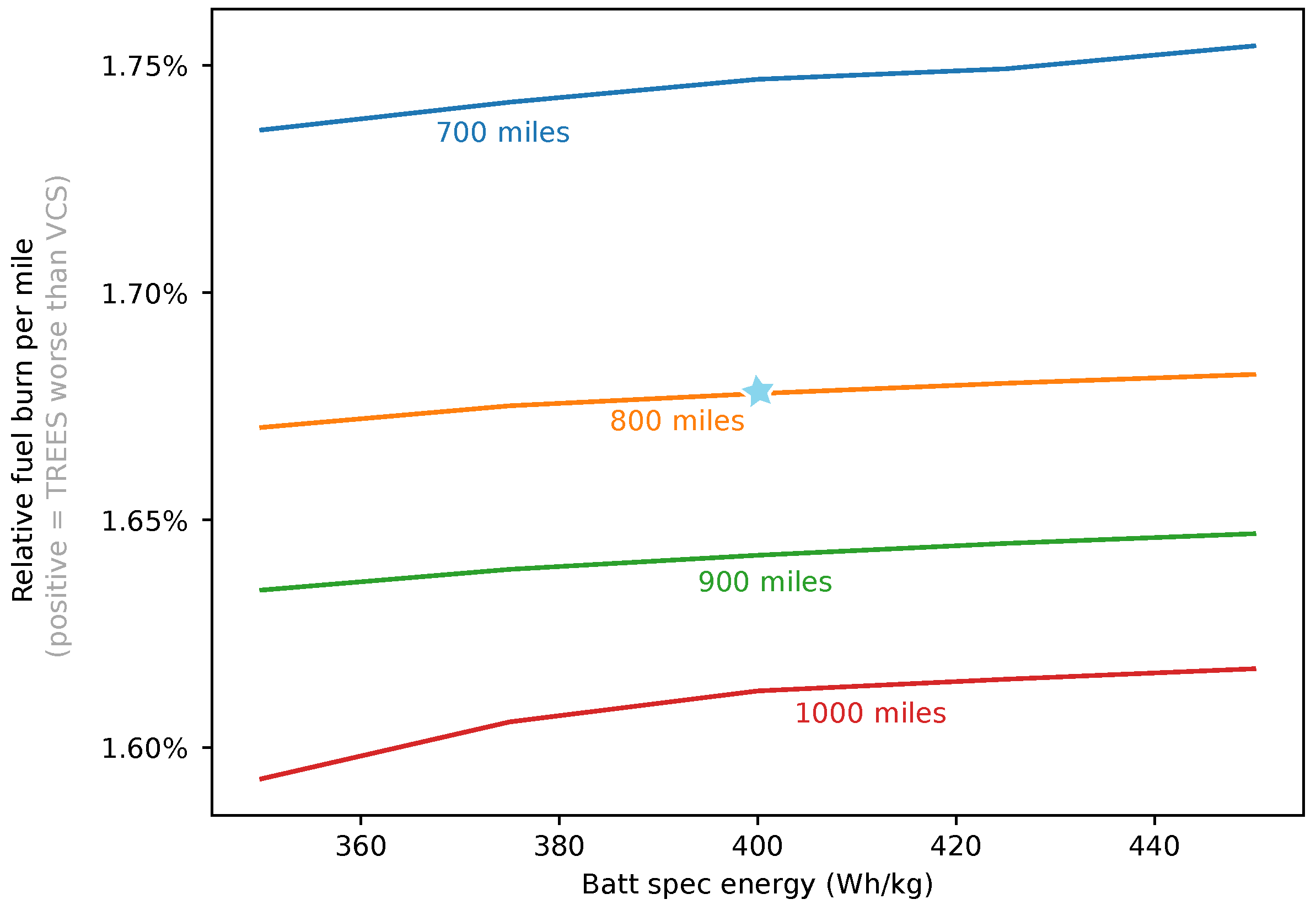

3.1.3. Battery-Specific Energy and Design Range

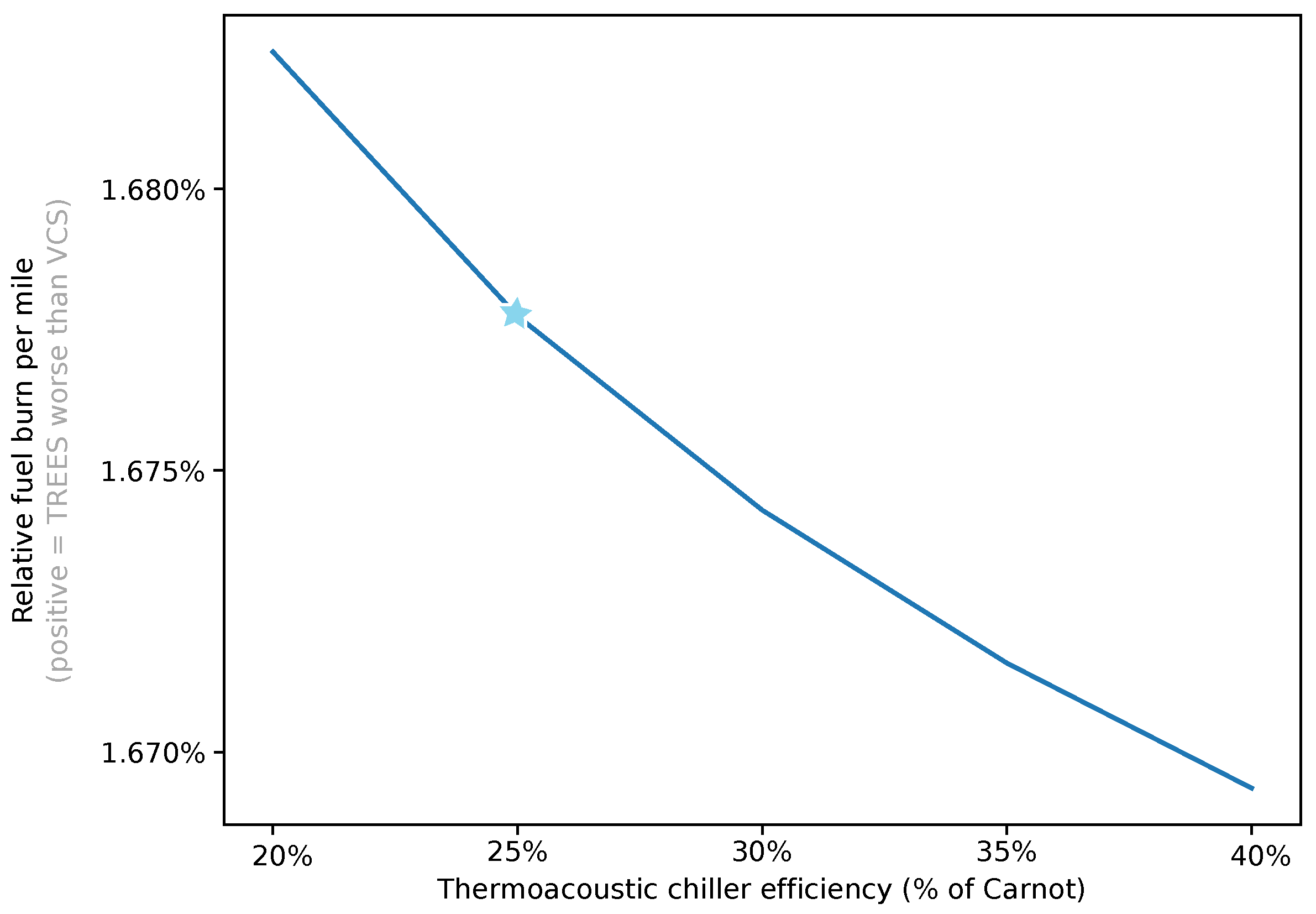

3.1.4. Thermoacoustic Chiller Efficiency

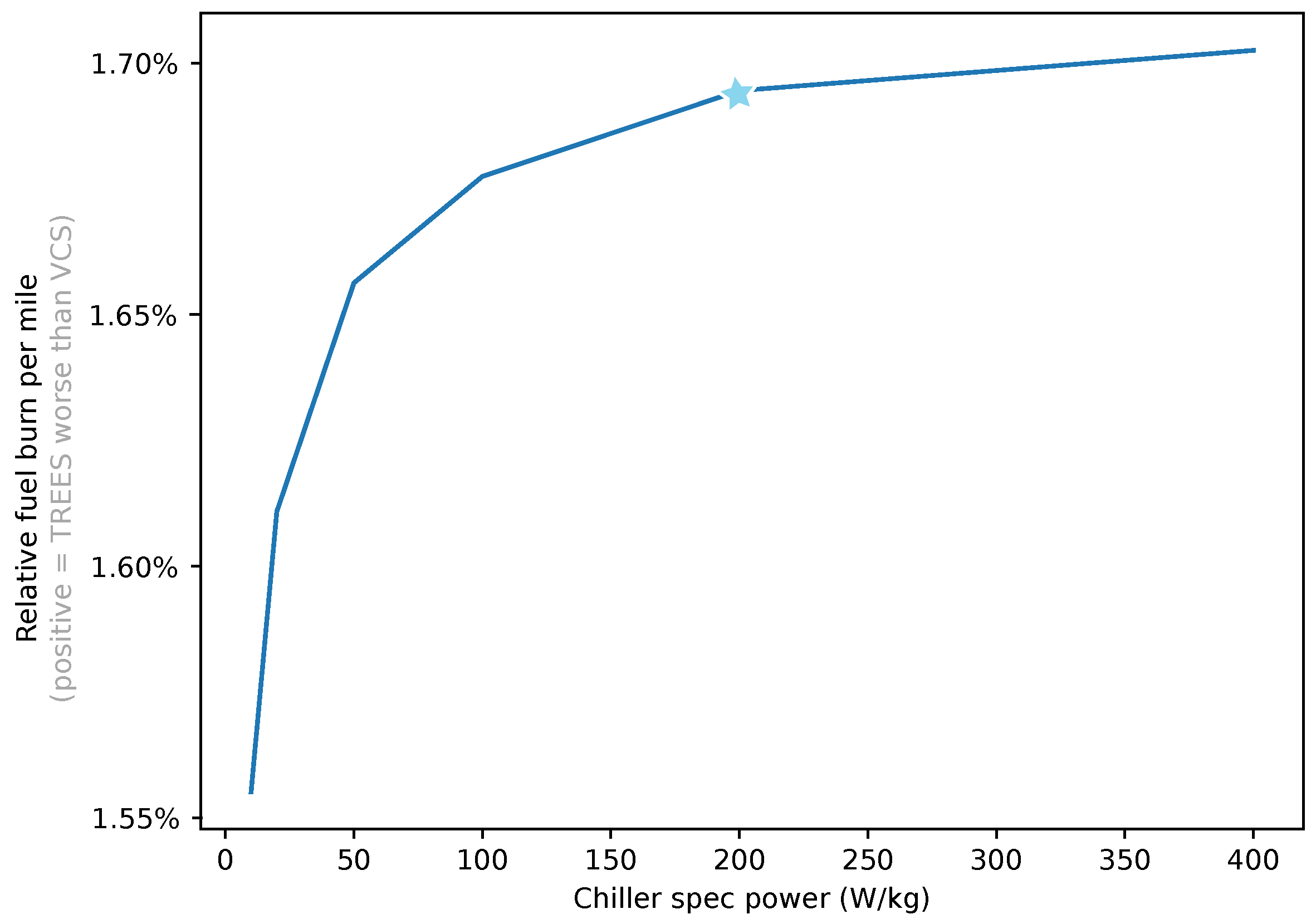

3.1.5. Vapor Cycle Chiller-Specific Power

3.1.6. Battery Temperature Limit

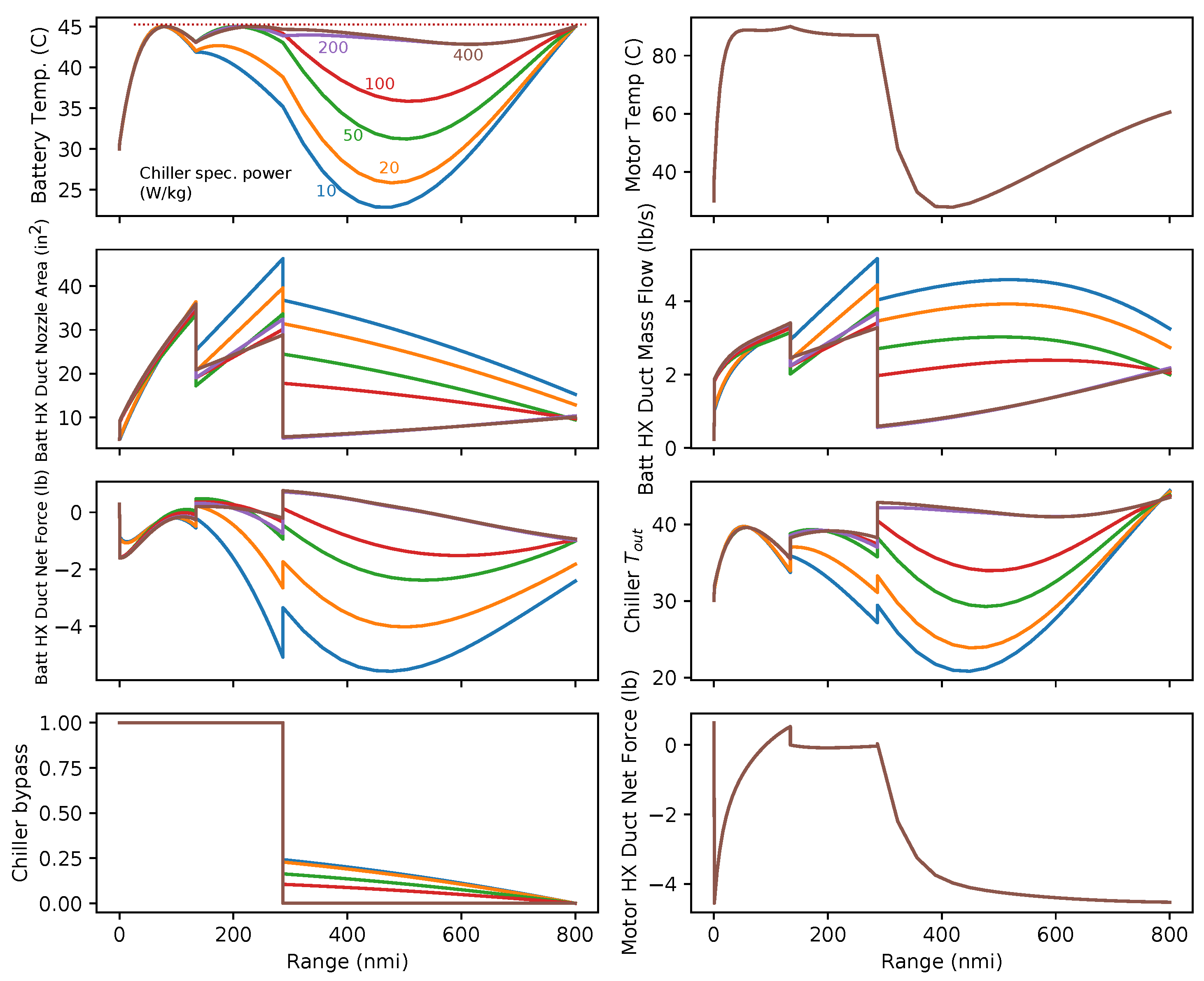

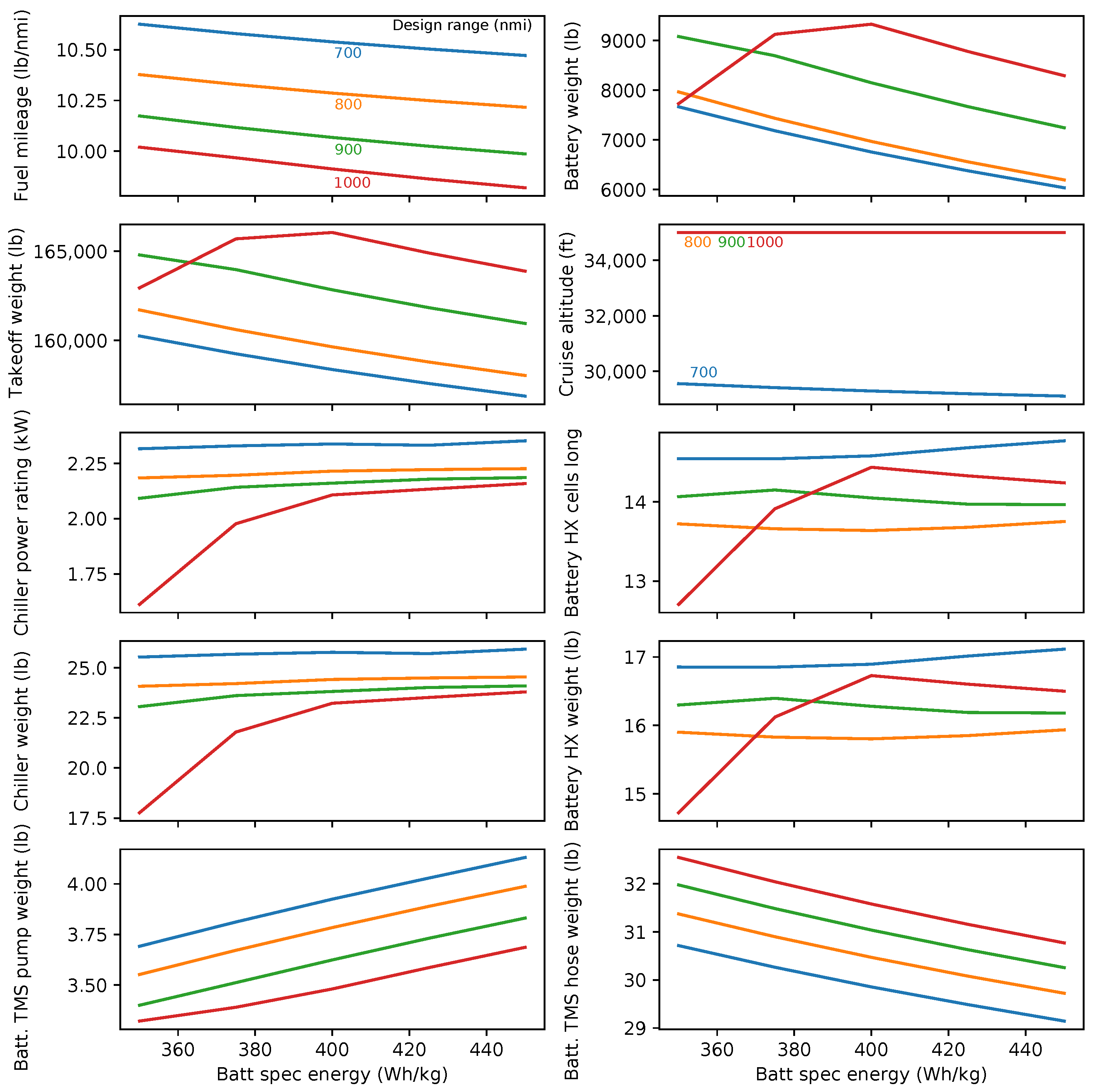

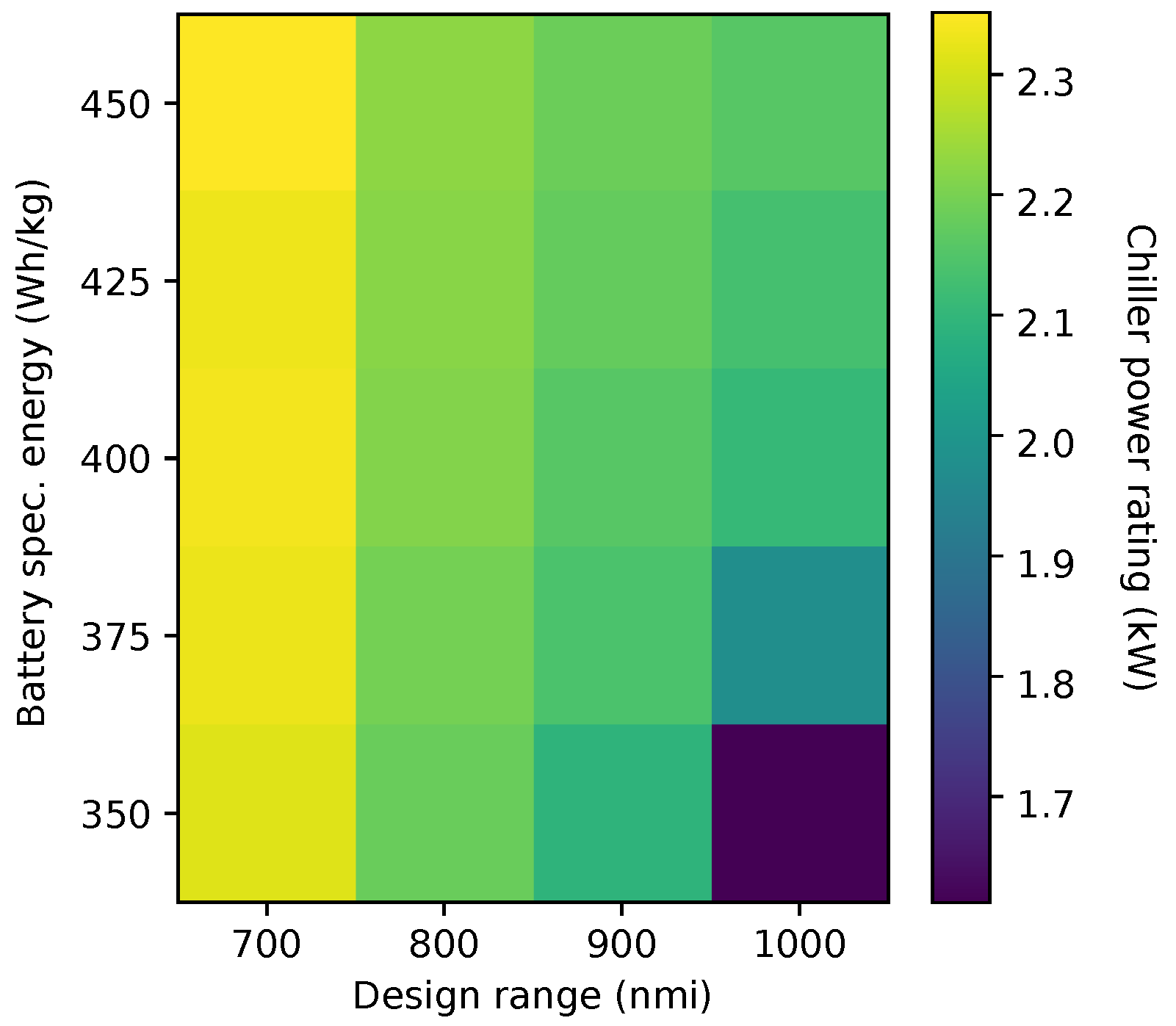

4. Vapor Cycle TMS Design Sensitivities

- 1.

- Range.

- 2.

- Specific power of the chiller.

- 3.

- Specific energy of the battery.

- 4.

- Temperature limits of the battery.

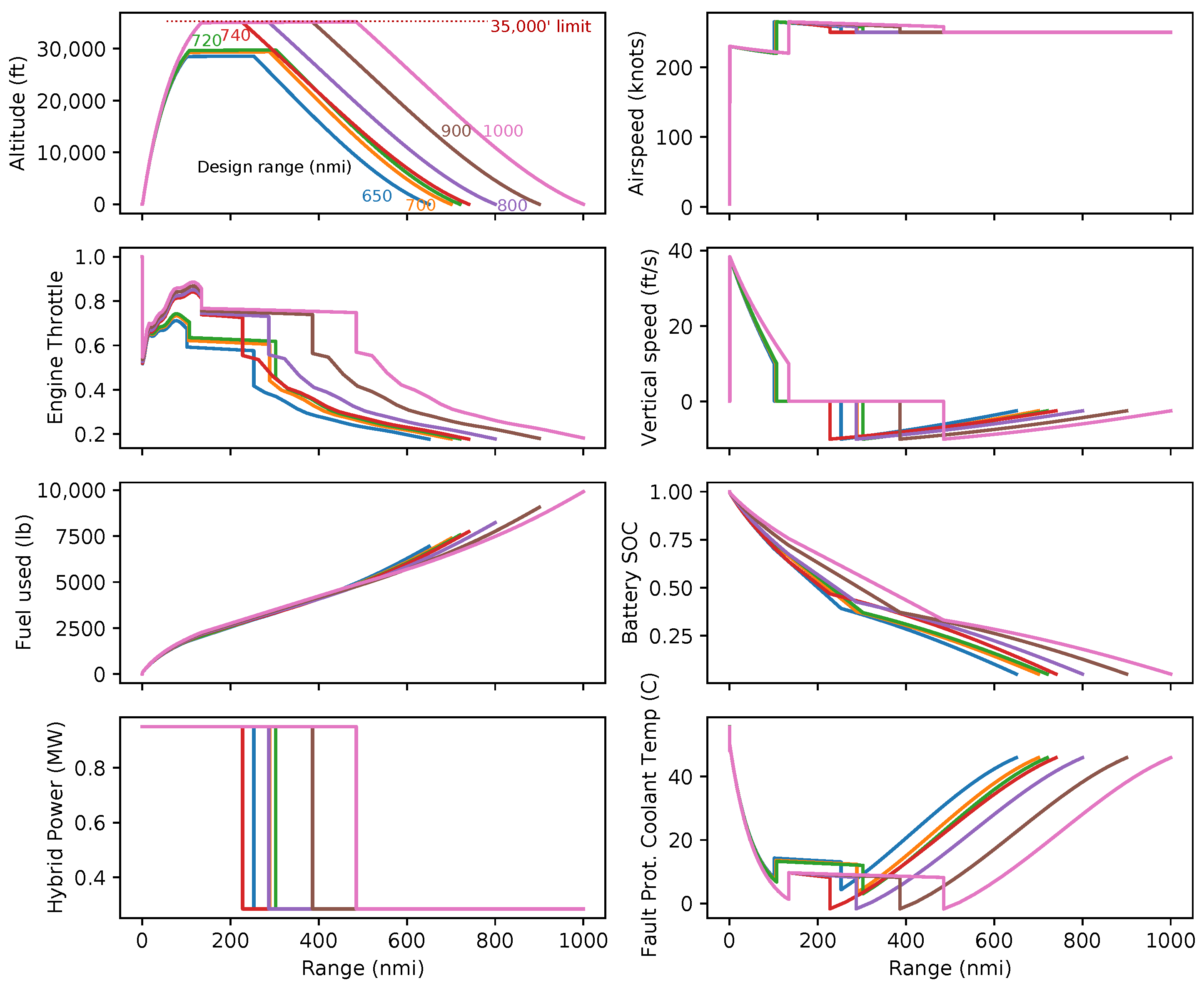

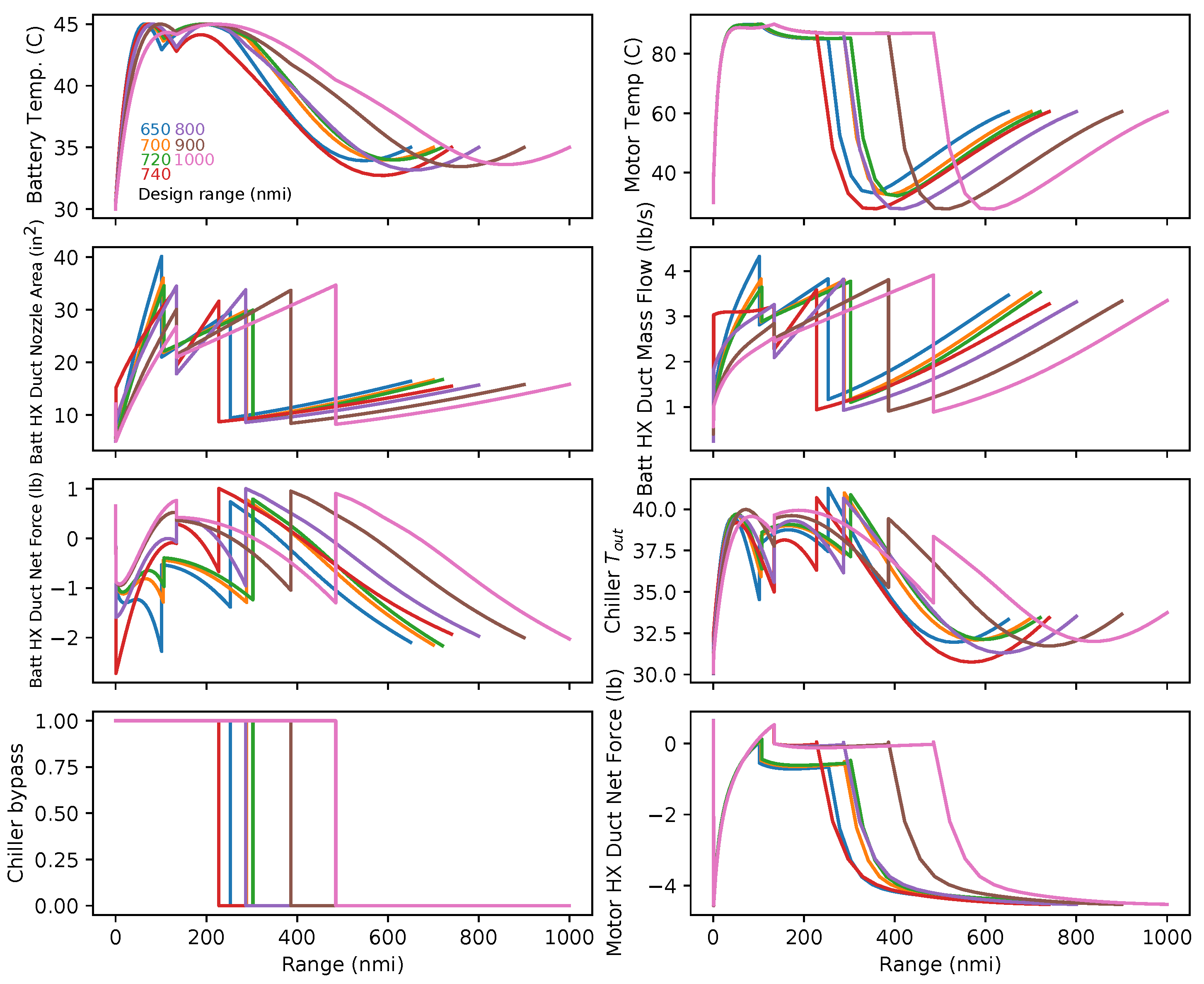

4.1. Effect of Range

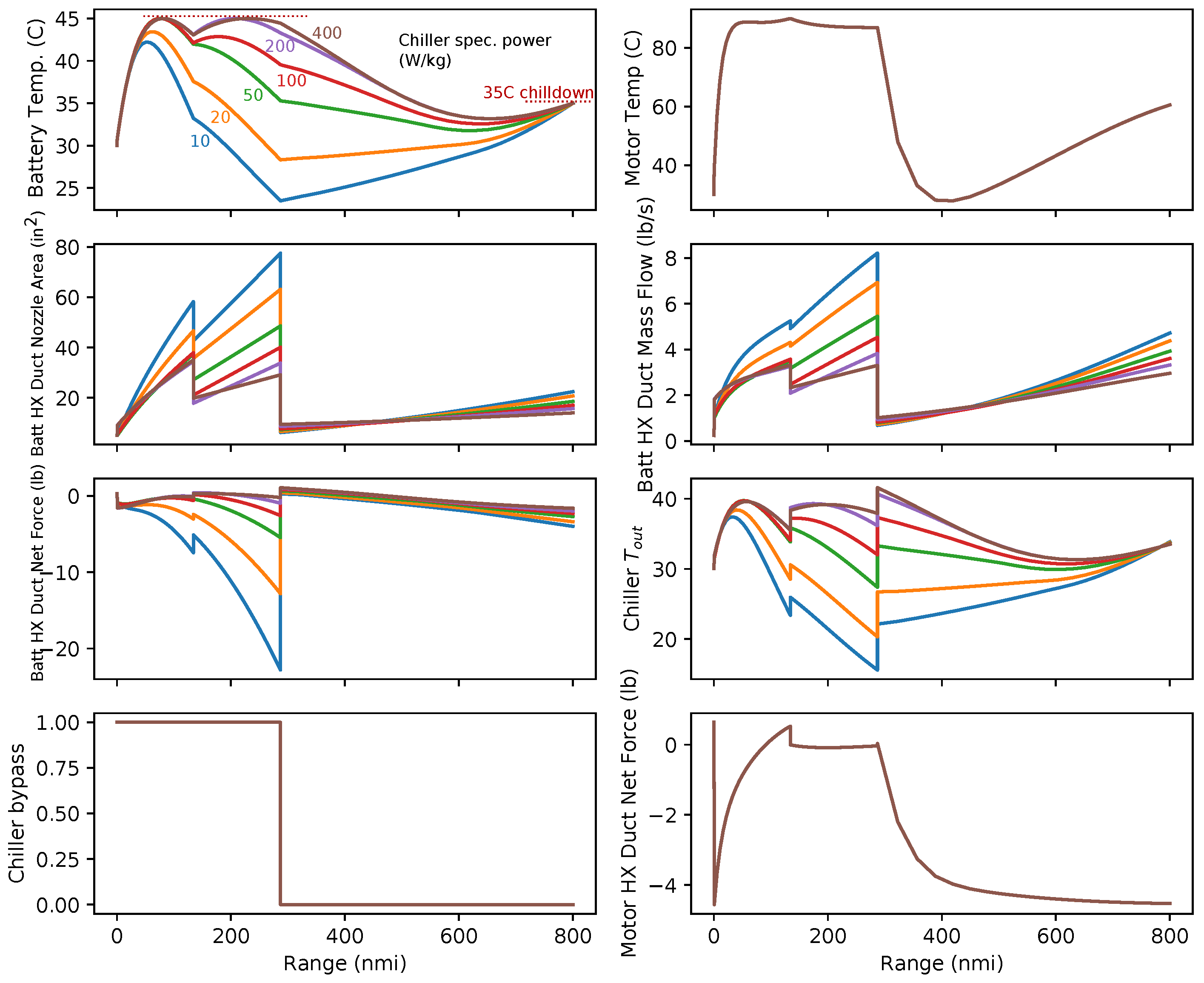

4.2. Effect of Chiller-Specific Power

4.3. Effect of Battery-Specific Energy

4.4. Effect of Battery Thermal Limitations

5. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BPR | Bypass ratio |

| CFD | Computational fluid dynamics |

| CRZ | Cruise |

| GTF | Geared turbofan |

| HX | Heat exchanger |

| LPC | Low pressure compressor |

| MDP | Multi-design point |

| ODE | Ordinary differential equation |

| OEW | Operating empty weight |

| OPR | Overall pressure ratio |

| PR | Pressure ratio |

| RTO | Rejected takeoff |

| SLS | Sea level static |

| SOC | State of charge |

| TA | Thermoacoustic |

| TMS | Thermal management system |

| TOC | Top of climb |

| TREES | Thermal Recovery Energy Efficient System |

| TSFC | Thrust-specific fuel consumption |

| VCS | Vapor cycle system |

| XS | Cross sectional |

Appendix A. Optimized VCS TMS Design Data

| Range | nmi | 650 | 700 | 720 | 800 | 900 | 1000 |

|---|---|---|---|---|---|---|---|

| Battery-specific energy | Wh/kg | 400 | 400 | 400 | 400 | 400 | 400 |

| Chiller-specific power | W/kg | 200 | 200 | 200 | 200 | 200 | 200 |

| Design Variables | |||||||

| Cruise altitude | ft | 28,479 | 29,293 | 29,649 | 35,000 | 35,000 | 35,000 |

| Takeoff weight | lbm | 156,906 | 158,371 | 158,937 | 159,643 | 162,834 | 166,043 |

| Battery weight | lbm | 6242.8 | 6756.3 | 6951.5 | 6968.8 | 8148.2 | 9326.4 |

| Battery TMS | |||||||

| Chiller power rating | kW | 2.38 | 2.34 | 2.32 | 2.21 | 2.16 | 2.11 |

| Battery HX cells wide | 204.81 | 204.81 | 204.81 | 204.81 | 204.81 | 204.81 | |

| Battery HX cells long | 14.66 | 14.58 | 14.55 | 13.64 | 14.05 | 14.44 | |

| Coolant pump power | kW | 0.82 | 0.80 | 0.79 | 0.77 | 0.74 | 0.71 |

| Hose diameter | inch | 1.27 | 1.27 | 1.28 | 1.29 | 1.30 | 1.31 |

| Motor TMS | |||||||

| Motor HX cells wide | 413.22 | 413.22 | 413.22 | 413.22 | 413.22 | 413.22 | |

| Motor HX cells long | 17.27 | 17.14 | 17.08 | 16.32 | 16.34 | 16.35 | |

| Motor HX cells tall | 17.04 | 17.04 | 17.04 | 17.04 | 17.04 | 17.04 | |

| Fault prot. HX cells long | 3.78 | 3.78 | 3.78 | 3.72 | 3.72 | 3.72 | |

| Nozzle area | inch2 | 15.21 | 15.24 | 15.26 | 15.61 | 15.61 | 15.61 |

| Coolant pump power | kW | 0.14 | 0.14 | 0.14 | 0.13 | 0.13 | 0.12 |

| Hose diameter | inch | 0.72 | 0.72 | 0.73 | 0.73 | 0.74 | 0.74 |

| Objective | |||||||

| Fuel burn | lbm | 6938.18 | 7377.20 | 7553.04 | 8229.13 | 9061.01 | 9912.62 |

| Constraints | |||||||

| Final SOC | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | |

| Battery HX width | inch | 11.71 | 11.71 | 11.71 | 11.71 | 11.71 | 11.71 |

| Battery HX XS area | inch2 | 300.00 | 300.00 | 300.00 | 300.00 | 300.00 | 300.00 |

| Motor HX width | inch | 23.62 | 23.62 | 23.62 | 23.62 | 23.62 | 23.62 |

| Motor HX height | inch | 11.81 | 11.81 | 11.81 | 11.81 | 11.81 | 11.81 |

| Motor HX XS area | inch2 | 206.30 | 206.30 | 206.30 | 206.30 | 206.30 | 206.30 |

| Payload | lbm | 44,092.45 | 44,092.45 | 44,092.45 | 44,092.45 | 44,092.45 | 44,092.45 |

| Outputs | |||||||

| Chiller weight | lbm | 26.22 | 25.77 | 25.59 | 24.41 | 23.81 | 23.23 |

| Battery HX weight | lbm | 16.99 | 16.89 | 16.86 | 15.80 | 16.28 | 16.73 |

| Batt. TMS pump weight | lbm | 4.02 | 3.92 | 3.89 | 3.78 | 3.62 | 3.48 |

| Batt. TMS hose weight | lbm | 29.51 | 29.85 | 29.99 | 30.47 | 31.04 | 31.58 |

| Motor HX weight | lbm | 13.98 | 13.88 | 13.83 | 13.21 | 13.23 | 13.24 |

| Motor TMS pump weight | lbm | 0.69 | 0.67 | 0.67 | 0.65 | 0.63 | 0.61 |

| Motor TMS hose weight | lbm | 4.77 | 4.82 | 4.85 | 4.92 | 5.02 | 5.10 |

| Chiller-Specific Power | W/kg | 10 | 20 | 50 | 100 | 200 | 400 |

|---|---|---|---|---|---|---|---|

| Range | nmi | 800 | 800 | 800 | 800 | 800 | 800 |

| Battery-specific energy | Wh/kg | 400 | 400 | 400 | 400 | 400 | 400 |

| Design Variables | |||||||

| Cruise altitude | ft | 35,000 | 35,000 | 35,000 | 35,000 | 35,000 | 35,000 |

| Takeoff weight | lbm | 160,149 | 159,913 | 159,748 | 159,681 | 159,643 | 159,621 |

| Battery weight | lbm | 6958.5 | 6960.6 | 6964.0 | 6966.5 | 6968.8 | 6970.3 |

| Battery TMS | |||||||

| Chiller power rating | kW | 1.21 | 1.41 | 1.74 | 1.98 | 2.21 | 2.37 |

| Battery HX cells wide | 204.81 | 204.81 | 204.81 | 204.81 | 204.81 | 204.81 | |

| Battery HX cells long | 21.86 | 19.02 | 16.04 | 14.57 | 13.64 | 13.24 | |

| Coolant pump power | kW | 0.71 | 0.73 | 0.75 | 0.76 | 0.77 | 0.78 |

| Hose diameter | inch | 1.30 | 1.29 | 1.29 | 1.29 | 1.29 | 1.29 |

| Motor TMS | |||||||

| Motor HX cells wide | 413.22 | 413.22 | 413.22 | 413.22 | 413.22 | 413.22 | |

| Motor HX cells long | 16.31 | 16.32 | 16.32 | 16.32 | 16.32 | 16.32 | |

| Motor HX cells tall | 17.04 | 17.04 | 17.04 | 17.04 | 17.04 | 17.04 | |

| Fault prot. HX cells long | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | |

| Nozzle area | inch2 | 15.62 | 15.61 | 15.61 | 15.61 | 15.61 | 15.61 |

| Coolant pump power | kW | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 |

| Hose diameter | inch | 0.74 | 0.73 | 0.73 | 0.73 | 0.73 | 0.73 |

| Objective | |||||||

| Fuel burn | lbm | 8251.63 | 8241.23 | 8233.77 | 8230.81 | 8229.13 | 8228.22 |

| Constraints | |||||||

| Final SOC | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | |

| Battery HX width | inch | 11.71 | 11.71 | 11.71 | 11.71 | 11.71 | 11.71 |

| Battery HX XS area | inch2 | 300.00 | 300.00 | 300.00 | 300.00 | 300.00 | 300.00 |

| Motor HX width | inch | 23.62 | 23.62 | 23.62 | 23.62 | 23.62 | 23.62 |

| Motor HX height | inch | 11.81 | 11.81 | 11.81 | 11.81 | 11.81 | 11.81 |

| Motor HX XS area | inch2 | 206.30 | 206.30 | 206.30 | 206.30 | 206.30 | 206.30 |

| Payload | lbm | 44,092.45 | 44,092.45 | 44,092.45 | 44,092.45 | 44,092.45 | 44,092.45 |

| Outputs | |||||||

| Chiller weight | lbm | 266.64 | 155.41 | 76.52 | 43.73 | 24.41 | 13.05 |

| Battery HX weight | lbm | 25.33 | 22.04 | 18.59 | 16.88 | 15.80 | 15.34 |

| Batt. TMS pump weight | lbm | 3.47 | 3.58 | 3.69 | 3.74 | 3.78 | 3.80 |

| Batt. TMS hose weight | lbm | 31.05 | 30.77 | 30.58 | 30.51 | 30.47 | 30.45 |

| Motor HX weight | lbm | 13.21 | 13.21 | 13.21 | 13.21 | 13.21 | 13.21 |

| Motor TMS pump weight | lbm | 0.63 | 0.64 | 0.65 | 0.65 | 0.65 | 0.65 |

| Motor TMS hose weight | lbm | 5.02 | 4.97 | 4.94 | 4.93 | 4.92 | 4.92 |

| Chiller-Specific Power | W/kg | 10 | 20 | 50 | 100 | 200 | 400 |

|---|---|---|---|---|---|---|---|

| Range | nmi | 800 | 800 | 800 | 800 | 800 | 800 |

| Battery-specific energy | Wh/kg | 400 | 400 | 400 | 400 | 400 | 400 |

| Design Variables | |||||||

| Cruise altitude | ft | 35,000 | 35,000 | 35,000 | 35,000 | 35,000 | 35,000 |

| Takeoff weight | lbm | 159,804 | 159,718 | 159,657 | 159,627 | 159,614 | 159,596 |

| Battery weight | lbm | 6951.2 | 6952.7 | 6955.9 | 6958.6 | 6963.0 | 6963.4 |

| Battery TMS | |||||||

| Chiller power rating | kW | 0.50 | 0.65 | 0.95 | 1.21 | 1.59 | 1.63 |

| Battery HX cells wide | 204.81 | 204.81 | 204.81 | 204.81 | 204.81 | 204.81 | |

| Battery HX cells long | 18.87 | 17.10 | 14.88 | 13.69 | 12.61 | 12.41 | |

| Coolant pump power | kW | 0.72 | 0.74 | 0.76 | 0.77 | 0.78 | 0.78 |

| Hose diameter | inch | 1.30 | 1.29 | 1.29 | 1.29 | 1.29 | 1.28 |

| Motor TMS | |||||||

| Motor HX cells wide | 413.22 | 413.22 | 413.22 | 413.22 | 413.22 | 413.22 | |

| Motor HX cells long | 16.32 | 16.32 | 16.32 | 16.32 | 16.32 | 16.32 | |

| Motor HX cells tall | 17.04 | 17.04 | 17.04 | 17.04 | 17.04 | 17.04 | |

| Fault prot. HX cells long | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | |

| Nozzle area | inch2 | 15.61 | 15.61 | 15.61 | 15.61 | 15.61 | 15.61 |

| Coolant pump power | kW | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 |

| Hose diameter | inch | 0.74 | 0.73 | 0.73 | 0.73 | 0.73 | 0.73 |

| Objective | |||||||

| Fuel burn | lbm | 8238.95 | 8234.43 | 8230.75 | 8229.04 | 8227.66 | 8227.01 |

| Constraints | |||||||

| Final SOC | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | |

| Battery HX width | inch | 11.71 | 11.71 | 11.71 | 11.71 | 11.71 | 11.71 |

| Battery HX XS area | inch2 | 300.00 | 300.00 | 300.00 | 300.00 | 300.00 | 300.00 |

| Motor HX width | inch | 23.62 | 23.62 | 23.62 | 23.62 | 23.62 | 23.62 |

| Motor HX height | inch | 11.81 | 11.81 | 11.81 | 11.81 | 11.81 | 11.81 |

| Motor HX XS area | inch2 | 206.30 | 206.30 | 206.30 | 206.30 | 206.30 | 206.30 |

| Payload | lbm | 44,092.45 | 44,092.45 | 44,092.45 | 44,092.45 | 44,092.45 | 44,092.45 |

| Outputs | |||||||

| Chiller weight | lbm | 111.14 | 71.36 | 41.99 | 26.71 | 17.52 | 9.01 |

| Battery HX weight | lbm | 21.86 | 19.82 | 17.24 | 15.86 | 14.62 | 14.38 |

| Batt. TMS pump weight | lbm | 3.52 | 3.62 | 3.72 | 3.78 | 3.83 | 3.84 |

| Batt. TMS hose weight | lbm | 31.02 | 30.75 | 30.55 | 30.48 | 30.43 | 30.41 |

| Motor HX weight | lbm | 13.21 | 13.21 | 13.21 | 13.21 | 13.21 | 13.21 |

| Motor TMS pump weight | lbm | 0.63 | 0.64 | 0.65 | 0.65 | 0.65 | 0.65 |

| Motor TMS hose weight | lbm | 5.01 | 4.97 | 4.94 | 4.93 | 4.92 | 4.91 |

| Battery-Specific Energy | Wh/kg | 350 | 375 | 400 | 425 | 450 |

|---|---|---|---|---|---|---|

| Range | nmi | 800 | 800 | 800 | 800 | 800 |

| Chiller-specific power | W/kg | 200 | 200 | 200 | 200 | 200 |

| Design Variables | ||||||

| Cruise altitude | ft | 35,000 | 35,000 | 35,000 | 35,000 | 35,000 |

| Takeoff weight | lbm | 161,707 | 160,606 | 159,643 | 158,793 | 158,038 |

| Battery weight | lbm | 7963.9 | 7433.1 | 6968.8 | 6559.0 | 6194.7 |

| Battery TMS | ||||||

| Chiller power rating | kW | 2.18 | 2.20 | 2.21 | 2.22 | 2.23 |

| Battery HX cells wide | 204.81 | 204.81 | 204.81 | 204.81 | 204.81 | |

| Battery HX cells long | 13.72 | 13.66 | 13.64 | 13.68 | 13.75 | |

| Coolant pump power | kW | 0.72 | 0.75 | 0.77 | 0.79 | 0.81 |

| Hose diameter | inch | 1.30 | 1.30 | 1.29 | 1.28 | 1.27 |

| Motor TMS | ||||||

| Motor HX cells wide | 413.22 | 413.22 | 413.22 | 413.22 | 413.22 | |

| Motor HX cells long | 16.29 | 16.30 | 16.32 | 16.33 | 16.34 | |

| Motor HX cells tall | 17.04 | 17.04 | 17.04 | 17.04 | 17.04 | |

| Fault prot. HX cells long | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | |

| Nozzle area | inch2 | 15.62 | 15.62 | 15.61 | 15.61 | 15.61 |

| Coolant pump power | kW | 0.13 | 0.13 | 0.13 | 0.14 | 0.14 |

| Hose diameter | inch | 0.74 | 0.74 | 0.73 | 0.73 | 0.72 |

| Objective | ||||||

| Fuel burn | lbm | 8302.01 | 8262.99 | 8229.13 | 8199.47 | 8173.27 |

| Constraints | ||||||

| Final SOC | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | |

| Battery HX width | inch | 11.71 | 11.71 | 11.71 | 11.71 | 11.71 |

| Battery HX XS area | inch2 | 300.00 | 300.00 | 300.00 | 300.00 | 300.00 |

| Motor HX width | inch | 23.62 | 23.62 | 23.62 | 23.62 | 23.62 |

| Motor HX height | inch | 11.81 | 11.81 | 11.81 | 11.81 | 11.81 |

| Motor HX XS area | inch2 | 206.30 | 206.30 | 206.30 | 206.30 | 206.30 |

| Payload | lbm | 44,092.45 | 44,092.45 | 44,092.45 | 44,092.45 | 44,092.45 |

| Outputs | ||||||

| Chiller weight | lbm | 24.07 | 24.21 | 24.41 | 24.49 | 24.53 |

| Battery HX weight | lbm | 15.90 | 15.83 | 15.80 | 15.85 | 15.93 |

| Batt. TMS pump weight | lbm | 3.55 | 3.67 | 3.78 | 3.89 | 3.99 |

| Batt. TMS hose weight | lbm | 31.37 | 30.90 | 30.47 | 30.08 | 29.72 |

| Motor HX weight | lbm | 13.19 | 13.20 | 13.21 | 13.22 | 13.23 |

| Motor TMS pump weight | lbm | 0.61 | 0.63 | 0.65 | 0.67 | 0.68 |

| Motor TMS hose weight | lbm | 5.07 | 4.99 | 4.92 | 4.86 | 4.80 |

| Battery Temperature Limit | C | 40 | 45 | 50 | 55 | 60 |

|---|---|---|---|---|---|---|

| Range | nmi | 800 | 800 | 800 | 800 | 800 |

| Battery-specific energy | Wh/kg | 400 | 400 | 400 | 400 | 400 |

| Chiller-specific power | W/kg | 200 | 200 | 200 | 200 | 200 |

| Design Variables | ||||||

| Cruise altitude | ft | 35,000 | 35,000 | 35,000 | 35,000 | 35,000 |

| Takeoff weight | lbm | 159,626 | 159,614 | 159,549 | 159,543 | 159,538 |

| Battery weight | lbm | 6963.6 | 6963.0 | 6947.8 | 6948.0 | 6947.8 |

| Battery TMS | ||||||

| Chiller power rating | kW | 1.68 | 1.59 | 0.10 | 0.10 | 0.10 |

| Battery HX cells wide | 204.81 | 204.81 | 204.81 | 192.46 | 162.75 | |

| Battery HX cells long | 15.96 | 12.61 | 12.63 | 11.12 | 10.86 | |

| Coolant pump power | kW | 0.76 | 0.78 | 0.78 | 0.79 | 0.78 |

| Hose diameter | inch | 1.29 | 1.29 | 1.28 | 1.28 | 1.28 |

| Motor TMS | ||||||

| Motor HX cells wide | 413.22 | 413.22 | 413.22 | 413.22 | 413.22 | |

| Motor HX cells long | 16.32 | 16.32 | 16.32 | 16.32 | 16.32 | |

| Motor HX cells tall | 17.04 | 17.04 | 17.04 | 17.04 | 17.04 | |

| Fault prot. HX cells long | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | |

| Nozzle area | inch2 | 15.61 | 15.61 | 15.61 | 15.61 | 15.61 |

| Coolant pump power | kW | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 |

| Hose diameter | inch | 0.73 | 0.73 | 0.73 | 0.73 | 0.73 |

| Objective | ||||||

| Fuel burn | lbm | 8229.26 | 8227.66 | 8225.79 | 8224.89 | 8224.44 |

| Constraints | ||||||

| Final SOC | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | |

| Battery HX width | inch | 11.71 | 11.71 | 11.71 | 11.00 | 9.30 |

| Battery HX XS area | inch2 | 300.00 | 300.00 | 300.00 | 281.91 | 238.39 |

| Motor HX width | inch | 23.62 | 23.62 | 23.62 | 23.62 | 23.62 |

| Motor HX height | inch | 11.81 | 11.81 | 11.81 | 11.81 | 11.81 |

| Motor HX XS area | inch2 | 206.30 | 206.30 | 206.30 | 206.30 | 206.30 |

| Payload | lbm | 44092.45 | 44092.45 | 44092.45 | 44092.45 | 44092.45 |

| Outputs | ||||||

| Chiller weight | lbm | 18.54 | 17.52 | 1.10 | 1.10 | 1.10 |

| Battery HX weight | lbm | 18.49 | 14.62 | 14.64 | 12.19 | 10.28 |

| Batt. TMS pump weight | lbm | 3.73 | 3.83 | 3.83 | 3.88 | 3.83 |

| Batt. TMS hose weight | lbm | 30.44 | 30.43 | 30.42 | 30.38 | 30.37 |

| Motor HX weight | lbm | 13.21 | 13.21 | 13.21 | 13.21 | 13.21 |

| Motor TMS pump weight | lbm | 0.65 | 0.65 | 0.65 | 0.65 | 0.66 |

| Motor TMS hose weight | lbm | 4.92 | 4.92 | 4.91 | 4.91 | 4.91 |

References

- Bradley, M.K.; Droney, C.K. Subsonic Ultra Green Aircraft Research: Phase II—Volume II—Hybrid Electric Design Exploration; Contractor Report NASA/CR—2015-218704/VOL2; NASA Langley Research Center: Hampton, VA, USA, 2015. [Google Scholar]

- NASA Glenn Research Center. Electrified Aircraft Propulsion (EAP)—Hybrid Electric. Available online: https://www1.grc.nasa.gov/aeronautics/eap/airplane-concepts/hybrid-electric/ (accessed on 21 June 2021).

- GE Aviation Press Release. GE Aviation and Safran Launch Advanced Technology Demonstration Program for Sustainable Engines; Extend CFM Partnership to 2050. 2021. Available online: https://www.geaviation.com/press-release/other-news-information/ge-aviation-and-safran-launch-advanced-technology (accessed on 14 February 2022).

- GE Aviation Press Release. GE Aviation Selected by NASA for Hybrid Electric Technology Demonstrator. 2021. Available online: https://www.geaviation.com/press-release/other-news-information/ge-aviation-selected-nasa-hybrid-electric-technology (accessed on 14 February 2022).

- GE Aviation Press Release. GE Aviation to Partner with Boeing on Hybrid Electric Flight Test Demonstration Program. 2022. Available online: https://www.geaviation.com/press-release/other-news-information/ge-aviation-partner-boeing-hybrid-electric-flight-test (accessed on 14 February 2022).

- Electra.aero Press Release. Electra Charts the Course for Hybrid-Electric eSTOL Certification. 2021. Available online: https://www.prnewswire.com/news-releases/electra-charts-the-course-for-hybrid-electric-estol-certification-301357070.html?tc=eml_cleartime (accessed on 14 February 2022).

- Brelje, B.; Martins, J.R.R.A. Electric, Hybrid, and Turboelectric Fixed-Wing Aircraft: A Review of Concepts, Models, and Design Approaches. Prog. Aerosp. Sci. 2019, 104, 1–19. [Google Scholar] [CrossRef]

- Falck, R.D.; Chin, J.; Schnulo, S.L.; Burt, J.M.; Gray, J.S. Trajectory Optimization of Electric Aircraft Subject to Subsystem Thermal Constraints. In Proceedings of the 18th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar] [CrossRef] [Green Version]

- Schnulo, S.L.; Chin, J.; Smith, A.D.; Dubois, A. Steady State Thermal Analyses of SCEPTOR X-57 Wingtip Propulsion. In Proceedings of the 17th AIAA Aviation Technology, Integration, and Operations Conference, Denver, CO, USA, 5–9 June 2017; pp. 1–14. [Google Scholar] [CrossRef]

- Edwards, R.; Smith, A. Design and Test of a Structurally-Integrated Heat Sink for the Maxwell X-57 High Lift Motor Controller. 2019. Available online: https://ntrs.nasa.gov/citations/20190033145 (accessed on 25 April 2022).

- Lents, C.E.; Hardin, L.W.; Rheaume, J.; Kohlman, L. Parallel Hybrid Gas-Electric Geared Turbofan Engine Conceptual Design and Benefits Analysis. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016. [Google Scholar] [CrossRef] [Green Version]

- Nöst, M.; Doppler, C.; Klell, M.; Trattner, A. Thermal Management of PEM Fuel Cells in Electric Vehicles. In Comprehensive Energy Management—Safe Adaptation, Predictive Control and Thermal Management; SpringerBriefs in Applied Sciences and Technology; Springer International Publishing: Cham, Switzerland, 2017; pp. 93–112. [Google Scholar] [CrossRef]

- Bower, G. Tesla Model 3 Battery Cooling Much-Improved...Track Mode? 2018. Available online: https://insideevs.com/news/338711/tesla-model-3-battery-cooling-much-improved-track-mode/ (accessed on 25 April 2022).

- Clarke, S.; Redifer, M.; Papathakis, K.V.; Samuel, A.; Foster, T. X-57 power and command system design. In Proceedings of the 2017 IEEE Transportation and Electrification Conference and Expo (ITEC 2017), Chicago, IL, USA, 22–24 June 2017; pp. 393–400. [Google Scholar] [CrossRef] [Green Version]

- Freeman, J.; Osterkamp, P.; Green, M.W.; Gibson, A.R.; Schiltgen, B.T. Challenges and opportunities for electric aircraft thermal management. Aircr. Eng. Aerosp. Technol. 2014, 86, 519–524. [Google Scholar] [CrossRef]

- Schiltgen, B.T.; Freeman, J. Aeropropulsive Interaction and Thermal System Integration within the ECO-150: A Turboelectric Distributed Propulsion Airliner with Conventional Electric Machines. In Proceedings of the 16th AIAA Aviation Technology, Integration, and Operations Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar] [CrossRef]

- Trawick, D.; Perullo, C.A.; Armstrong, M.J.; Snyder, D.; Tai, J.C.; Mavris, D.N. Development and Application of GT-HEAT for the Electrically Variable Engine Design. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar] [CrossRef]

- Vratny, P.C.; Kuhn, H.; Hornung, M. Influences of voltage variations on electric power architectures for hybrid electric aircraft. CEAS Aeronaut. J. 2017, 8, 31–43. [Google Scholar] [CrossRef]

- Chapman, J.W.; Schnulo, S.L.; Nitzsche, M.P. Development of a Thermal Management System for Electrified Aircraft. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar] [CrossRef]

- Bell, M.E.; Litt, J.S. An Electrical Modeling and Thermal Analysis Toolbox for Electrified Aircraft Propulsion Simulation. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Virtual Event, 24–28 August 2020. [Google Scholar] [CrossRef]

- Byahut, S.; Uranga, A. Power Distribution and Thermal Management Modeling for Electrified Aircraft. In Proceedings of the 2020 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), New Orleans, LA, USA, 26–28 August 2020; pp. 1–15. [Google Scholar] [CrossRef]

- Dyson, R.W. Novel Thermal Energy Conversion Technologies for Advanced Electric Air Vehicles. In Proceedings of the 2018 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), Cincinnati, OH, USA, 12–14 July 2018; pp. 1–14. [Google Scholar]

- Dyson, R.W.; Rodriguez, L.; Roth, M.E.; Raitano, P. Solid-State Exergy Optimized Electric Aircraft Thermal and Fault Management. In Proceedings of the 2020 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), New Orleans, LA, USA, 26–28 August 2020; pp. 1–16. [Google Scholar]

- Dyson, R.W. Electric Aircraft Cryogenic Cooling with Thermo-acoustic Exergy Management. In Proceedings of the 2019 Cryogenic Engineering Conference and International Cryogenic Materials Conference, Hartford, CT, USA, 21–25 July 2019. [Google Scholar]

- Durand, D.; Adachi, D.; Harvey, D.; Jaco, C.; Michaelian, M.; Nguyen, T.; Petach, M.; Raab, J. Mid InfraRed Instrument (MIRI) cooler subsystem design. Cryocoolers 2009, 15, 7–12. [Google Scholar]

- Ross, R., Jr.; Johnson, D. NASA’s advanced cryocooler technology development program (ACTDP). AIP Conf. Proc. Am. Inst. Phys. 2006, 823, 607–614. [Google Scholar]

- Brelje, B.J.; Martins, J.R.R.A. Development of a Conceptual Design Model for Aircraft Electric Propulsion with Efficient Gradients. In Proceedings of the AIAA/IEEE Electric Aircraft Technologies Symposium, Cincinnati, OH, USA, 12–14 July 2018. [Google Scholar] [CrossRef]

- Brelje, B.J.; Jasa, J.P.; Martins, J.R.R.A.; Gray, J.S. Development of a Conceptual-Level Thermal Management System Design Capability in OpenConcept. In Proceedings of the NATO Research Symposium on Hybrid/Electric Aero-Propulsion Systems for Military Applications (AVT-RSY-323), Trondheim, Norway, 7–9 October 2019. [Google Scholar] [CrossRef]

- Nita, M.; Scholz, D. Estimating the Oswald Factor from Basic Aircraft Geometrical Parameters. In Proceedings of the Deutscher Luft- und Raumfahrtkongress, Berlin, Germany, 10–12 September 2012. [Google Scholar]

- 737 Technical Site. Technical Specifications. 2021. Available online: http://www.b737.org.uk/techspecsdetailed.htm (accessed on 25 April 2022).

- Raymer, D.P. Aircraft Design: A Conceptual Approach, 5th ed.; AIAA: Reston, VA, USA, 2012. [Google Scholar]

- Hendricks, E.S.; Gray, J.S. pyCycle: A Tool for Efficient Optimization of Gas Turbine Engine Cycles. Aerospace 2019, 6, 87. [Google Scholar] [CrossRef] [Green Version]

- Jones, S.M.; Haller, W.J.; Tong, M.T. An N+3 Technology Level Reference Propulsion System; Technical Report NASA/TM—2017-219501; NASA Glenn Research Center: Cleveland, OH, USA, 2017. [Google Scholar]

- Gray, J.S.; Hwang, J.T.; Martins, J.R.R.A.; Moore, K.T.; Naylor, B.A. OpenMDAO: An open-source framework for multidisciplinary design, analysis, and optimization. Struct. Multidiscip. Optim. 2019, 59, 1075–1104. [Google Scholar] [CrossRef]

- Gill, P.E.; Murray, W.; Saunders, M.A. SNOPT: An SQP Algorithm for Large-Scale Constrained Optimization. SIAM Rev. 2005, 47, 99–131. [Google Scholar] [CrossRef]

- Wu, N.; Kenway, G.; Mader, C.A.; Jasa, J.; Martins, J.R.R.A. pyOptSparse: A Python framework for large-scale constrained nonlinear optimization of sparse systems. J. Open Source Softw. 2020, 5, 2564. [Google Scholar] [CrossRef]

- Brelje, B. Multidisciplinary Design Optimization of Electric Aircraft Considering Systems Modeling and Packaging. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2021. [Google Scholar]

- Rheaume, J.M.; Macdonald, M.; Lents, C.E. Commercial Hybrid Electric Aircraft Thermal Management System Design, Simulation, and Operation Improvements. In Proceedings of the 2019 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), Indianapolis, IN, USA, 22–24 August 2019. [Google Scholar] [CrossRef]

- Rheaume, J.; Lents, C. Energy Storage for Commercial Hybrid Electric Aircraft; SAE Technical Paper 2016-01-2014, SAE 2016 Aerospace Systems and Technology Conference; SAE Technical Paper: Hartford, CT, USA, 2016. [Google Scholar] [CrossRef]

- Lents, C.; Hardin, L. Fuel Burn and Energy Consumption Reductions of a Single-Aisle Class Parallel Hybrid Propulsion System. In Proceedings of the 2019 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), Indianapolis, IN, USA, 22–24 August 2019; pp. 1–8. [Google Scholar]

- Rheaume, J.; Lents, C.E. Design and simulation of a commercial hybrid electric aircraft thermal management system. In Proceedings of the 2018 AIAA/IEEE Electric Aircraft Technologies Symposium, Cincinnati, OH, USA, 9–11 July 2018. [Google Scholar] [CrossRef]

- Kellermann, H.; Lüdemann, M.; Pohl, M.; Hornung, M. Design and Optimization of Ram Air–Based Thermal Management Systems for Hybrid-Electric Aircraft. Aerospace 2021, 8, 3. [Google Scholar] [CrossRef]

- Hendricks, T.J.; Tarau, C.; Dyson, R.W. Hybrid Electric Aircraft Thermal Management: Now, New Visions and Future Concepts and Formulation. In Proceedings of the 2021 20th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm), San Diego, CA, USA, 1–4 June 2021; pp. 467–476. [Google Scholar]

- Weisstein, E.W. Simpson’s Rule, from MathWorld—A Wolfram Web Resource. 2003. Available online: http://mathworld.wolfram.com/SimpsonsRule.html (accessed on 25 April 2022).

- Eaton Aeroquip. Rubber Hose, Fittings and Assemblies for Aerospace Applications. 2013. Available online: https://shop.boeing.com/medias/TF100-16E-Rubber-Hose-Fittings-Assys.pdf (accessed on 25 April 2022).

- Dyson, R.W.; NASA Glenn Research Center. Personal communication, 2020.

| Quantity | Value |

|---|---|

| Oswald efficiency | 0.801 |

| Zero lift drag coefficient (takeoff) | 0.03 |

| Zero lift drag coefficient (cruise) | 0.01925 |

| Maximum lift coefficient (takeoff) | 2.0 |

| Operating empty weight | 92,310 lbs |

| Maximum takeoff weight | 174,170 lbs |

| Maximum landing weight | 146,275 lbs |

| Maximum fuel weight | 46,329 lbs |

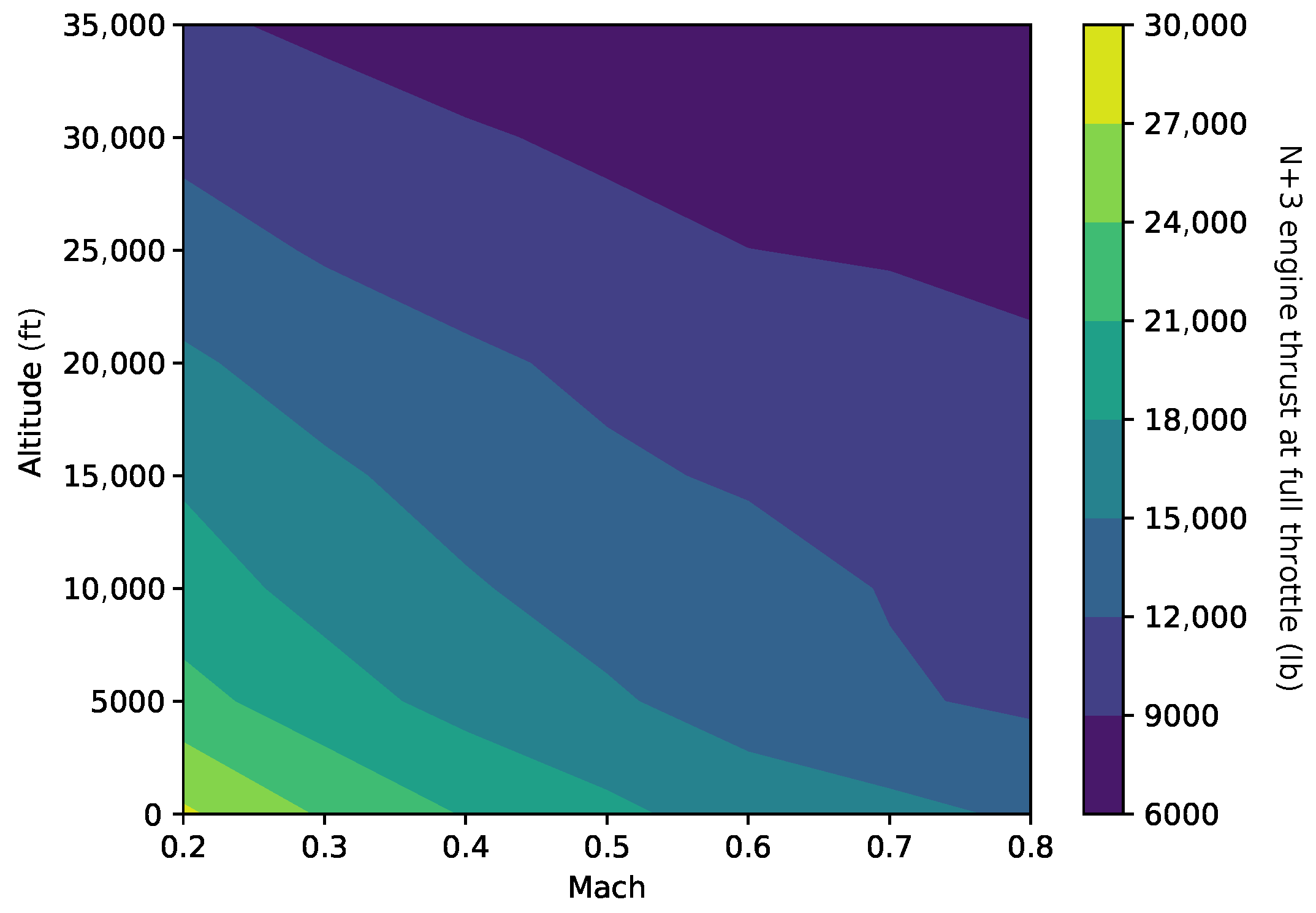

| Condition | Mach | Altitude (ft) | Thrust Required (lb) |

|---|---|---|---|

| RTO | 0.25 | 0 | 22,800 |

| SLS | 0.0 | 0 | 28,621 |

| Cruise | 0.8 | 35,000 | 5510 |

| TOC (design) | 0.8 | 35,000 | 6200 |

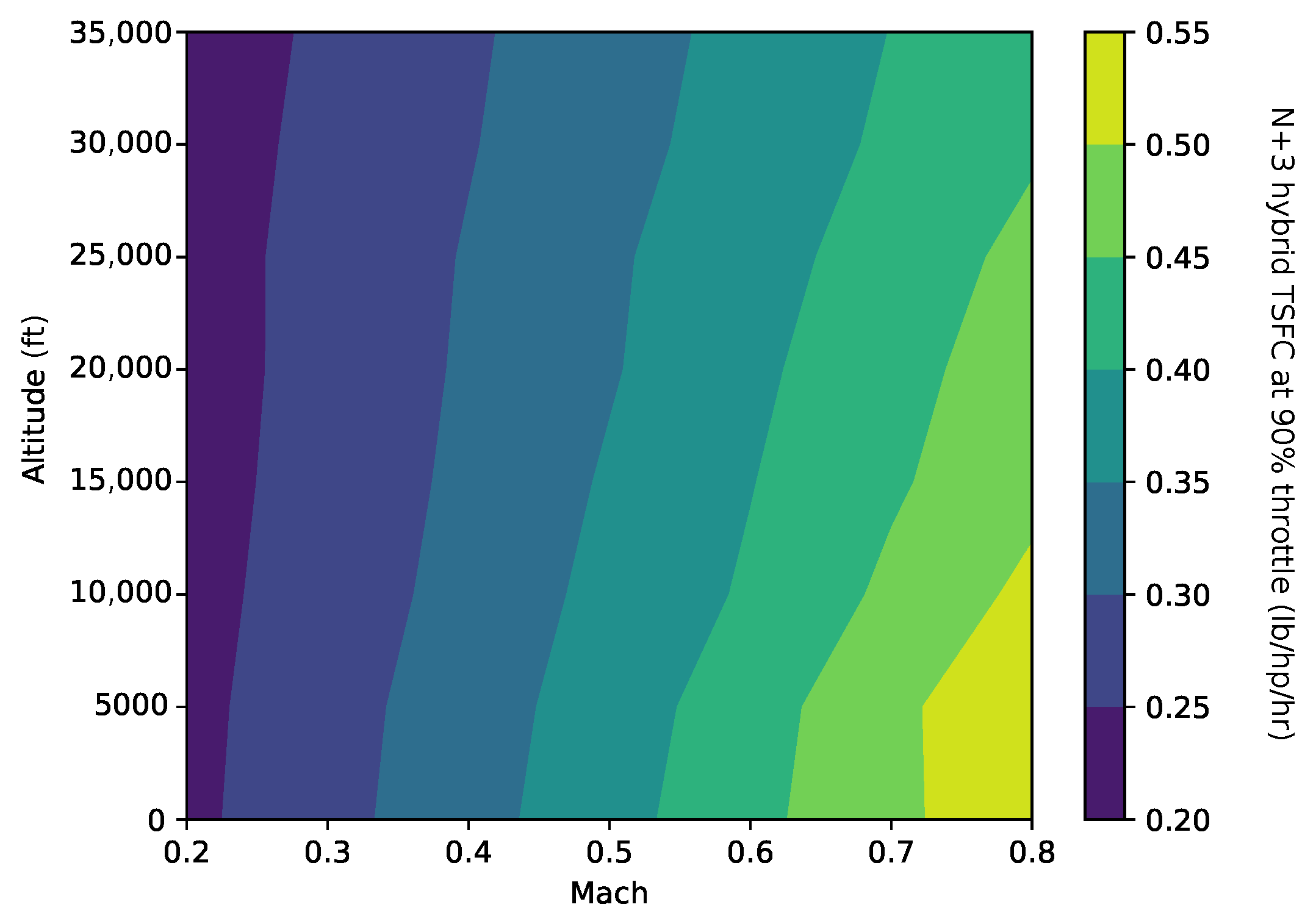

| Units | Lower | Upper | Optimum (Conventional) | Optimum (Hybrid VCS) | Optimum (Hybrid TREES) | ||

|---|---|---|---|---|---|---|---|

| minimize | CRZ fuel burn | lb/s | 0.6652 | 0.6627 | 0.6711 | ||

| with respect to | fan | 1.2 | 1.4 | 1.307 | 1.308 | 1.310 | |

| LPC | 2.5 | 4.0 | 4.0 | 4.0 | 4.0 | ||

| OPR | 40 | 70 | 64.54 | 65.71 | 65.77 | ||

| 1.35 | 1.45 | 1.35 | 1.35 | 1.35 | |||

| BPR at TOC | 17.0 | 24.5 | 19.53 | 19.66 | 19.65 | ||

| at TOC | lb/s | 780 | 850 | 810.92 | 810.92 | 810.92 | |

| at RTO | kW | 0 | 1000 | — | 1000 | 1000 | |

| at SLS | kW | 0 | 1000 | — | 1000 | 1000 | |

| at TOC | kW | 0 | 1000 | — | 0 | 0 | |

| subject to | at RTO | R | 3400 | 3176 | 3097 | 3116 | |

| at TOC | R | 3230 | 2932 | 2927 | 2945 | ||

| inch | 100 | 100 | 100 | 100 |

| Component | Weight Metric |

|---|---|

| Battery | 400 Wh/kg |

| Electric motor and power electronics | 5 kW/kg |

| Chiller | 200 W/kg |

| Coolant pump | 450 W/kg |

| Coolant hose | 1356 kg/m3, sized for 300 psi hoop stress [45] |

| Heat exchanger | Weight from aluminum case, plates, and fins |

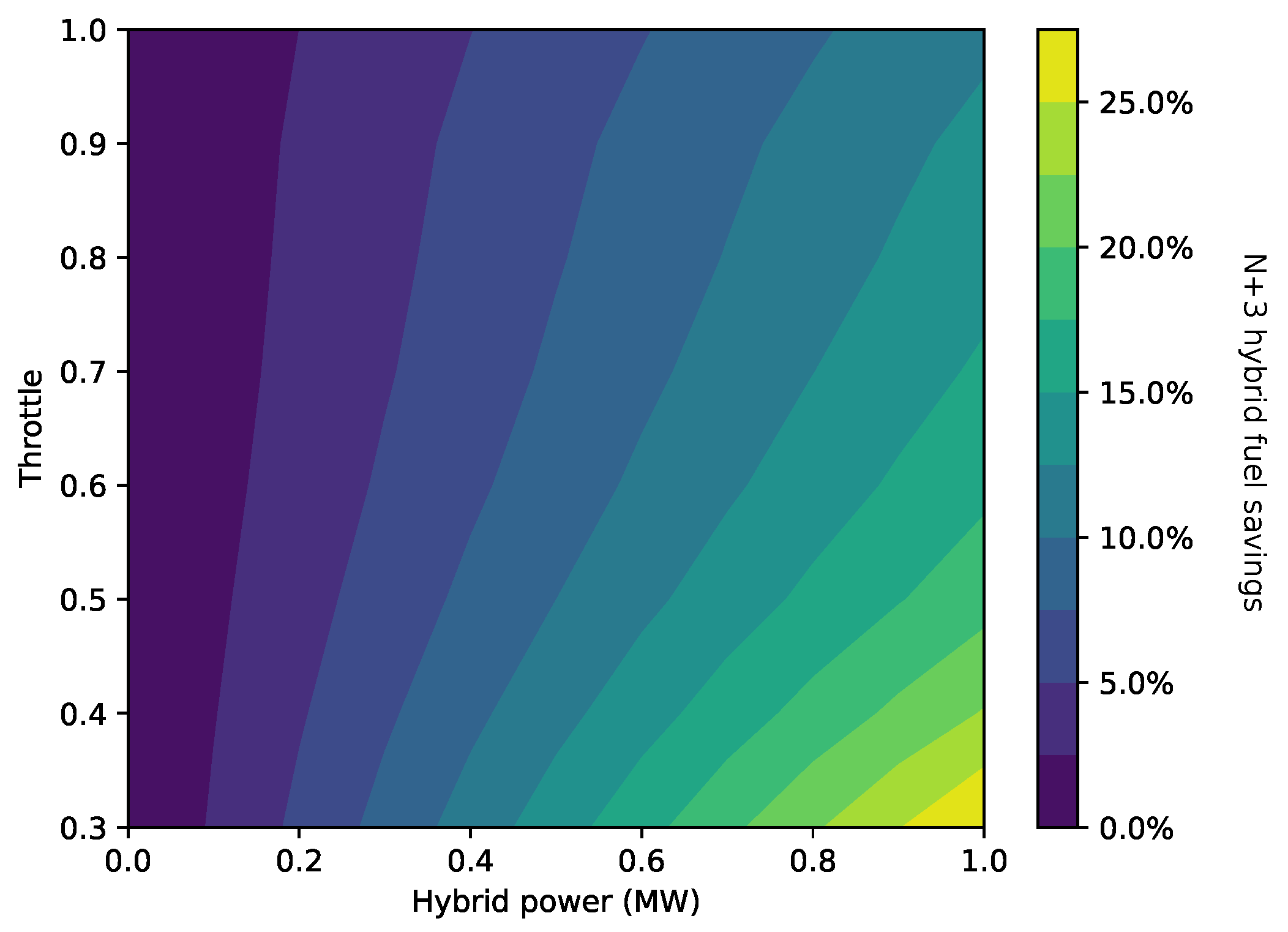

| Unit | Lower | Upper | Optimum VCS | Optimum TREES | |||

|---|---|---|---|---|---|---|---|

| minimize | Mission fuel burn | kg | 3732.7 | 3795.2 | |||

| with respect to | Cruise altitude | ft | 29,000 | 35,000 | 35,000 | 35,000 | |

| Takeoff weight | kg | 50,000 | 79,002 | 72,413 | 72,432 | ||

| Battery system | Battery weight | kg | 3000 | 12,500 | 3160.0 | 3151.6 | |

| HX channels wide (cold side) | 2 | 1500 | 204.8 | 204.8 | |||

| HX fins long (cold side) | 3 | 75 | 13.60 | 10.76 | |||

| Motor system | HX channels wide (cold side) | 50 | 1500 | 413.2 | 413.2 | ||

| HX fins long (cold side) | 3 | 75 | 16.32 | 16.32 | |||

| Duct nozzle area | inch2 | 5 | 60 | 15.61 | 15.61 | ||

| HX number of stacks | 10 | 25 | 17.04 | 17.04 | |||

| Fault protection HX fins long | 1 | 4 | 3.72 | 3.72 | |||

| Coolant loops | Chiller power rating | kW | 0.1 | 7 | 2.214 | — | |

| Battery coolant pump power | kW | 0.1 | 5 | 0.77 | 0.80 | ||

| Motor coolant pump power | kW | 0.1 | 5 | 0.13 | 0.13 | ||

| Battery hose diameter | inch | 0.5 | 2 | 1.285 | 1.284 | ||

| Motor hose diameter | inch | 0.5 | 2 | 0.73 | 0.73 | ||

| Hybrid throttle | Climb start | 0.02 | 1 | 1 | 1 | ||

| Climb end | 0.02 | 1 | 1 | 1 | |||

| Cruise start | 0.02 | 1 | 1 | 1 | |||

| Cruise end | 0.02 | 1 | 1 | 1 | |||

| Descent start | 0.02 | 0.3 | 0.3 | 0.3 | |||

| Descent end | 0.02 | 0.3 | 0.3 | 0.3 | |||

| Chiller bypass | Climb start | 0 (chill) | 1 (bypass) | 1 | 0 | ||

| Climb end | 0 | 1 | 1 | 0 | |||

| Cruise start | 0 | 1 | 1 | 0 | |||

| Cruise end | 0 | 1 | 1 | 0 | |||

| Descent start | 0 | 1 | 0 | 0 | |||

| Descent end | 0 | 1 | 0 | 0 | |||

| Battery duct nozzle area | Ground roll start | inch2 | 5 | 150 | 5 | 10.5 | |

| Ground roll end | inch2 | 5 | 150 | 5 | 5 | ||

| Climb start | inch2 | 5 | 150 | 9.4 | 5 | ||

| Climb end | inch2 | 5 | 150 | 34.5 | 27.9 | ||

| Cruise start | inch2 | 5 | 150 | 17.8 | 24.9 | ||

| Cruise end | inch2 | 5 | 150 | 34.8 | 26.1 | ||

| Descent start | inch2 | 5 | 150 | 8.6 | 5.3 | ||

| Descent end | inch2 | 5 | 150 | 15.7 | 5 | ||

| subject to | Payload | kg | 20,000 | 20,000 | 20,000 | ||

| Battery final state of charge | 0.05 | 0.05 | 0.05 | ||||

| Temp limits | Battery | C | 45 | max = 45 | max = 45 | ||

| Motor | C | 90 | max = 90 | max = 90 | |||

| Fault protection | C | 50 | max = 50 | max = 50 | |||

| TMS | Battery HX width | m | 1.2 | 0.297 | 0.297 | ||

| Battery HX cross-section area | inch2 | 70 | 300 | 300 | 300 | ||

| Motor HX width | m | 0.6 | 0.6 | 0.6 | |||

| Motor HX height | m | 0.3 | 0.3 | 0.3 | |||

| Motor HX cross-section area | inch2 | 70 | 300 | 206.3 | 206.3 | ||

| Battery pump sizing margin | 1 | 1 | 1 | ||||

| Motor pump sizing margin | 1 | 1 | 1 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adler, E.J.; Brelje, B.J.; Martins, J.R.R.A. Thermal Management System Optimization for a Parallel Hybrid Aircraft Considering Mission Fuel Burn. Aerospace 2022, 9, 243. https://doi.org/10.3390/aerospace9050243

Adler EJ, Brelje BJ, Martins JRRA. Thermal Management System Optimization for a Parallel Hybrid Aircraft Considering Mission Fuel Burn. Aerospace. 2022; 9(5):243. https://doi.org/10.3390/aerospace9050243

Chicago/Turabian StyleAdler, Eytan J., Benjamin J. Brelje, and Joaquim R. R. A. Martins. 2022. "Thermal Management System Optimization for a Parallel Hybrid Aircraft Considering Mission Fuel Burn" Aerospace 9, no. 5: 243. https://doi.org/10.3390/aerospace9050243

APA StyleAdler, E. J., Brelje, B. J., & Martins, J. R. R. A. (2022). Thermal Management System Optimization for a Parallel Hybrid Aircraft Considering Mission Fuel Burn. Aerospace, 9(5), 243. https://doi.org/10.3390/aerospace9050243