Multidisciplinary Optimization of Thermal Insulation Layer for Stratospheric Airship with a Solar Array

Abstract

:1. Introduction

2. Theoretical Method

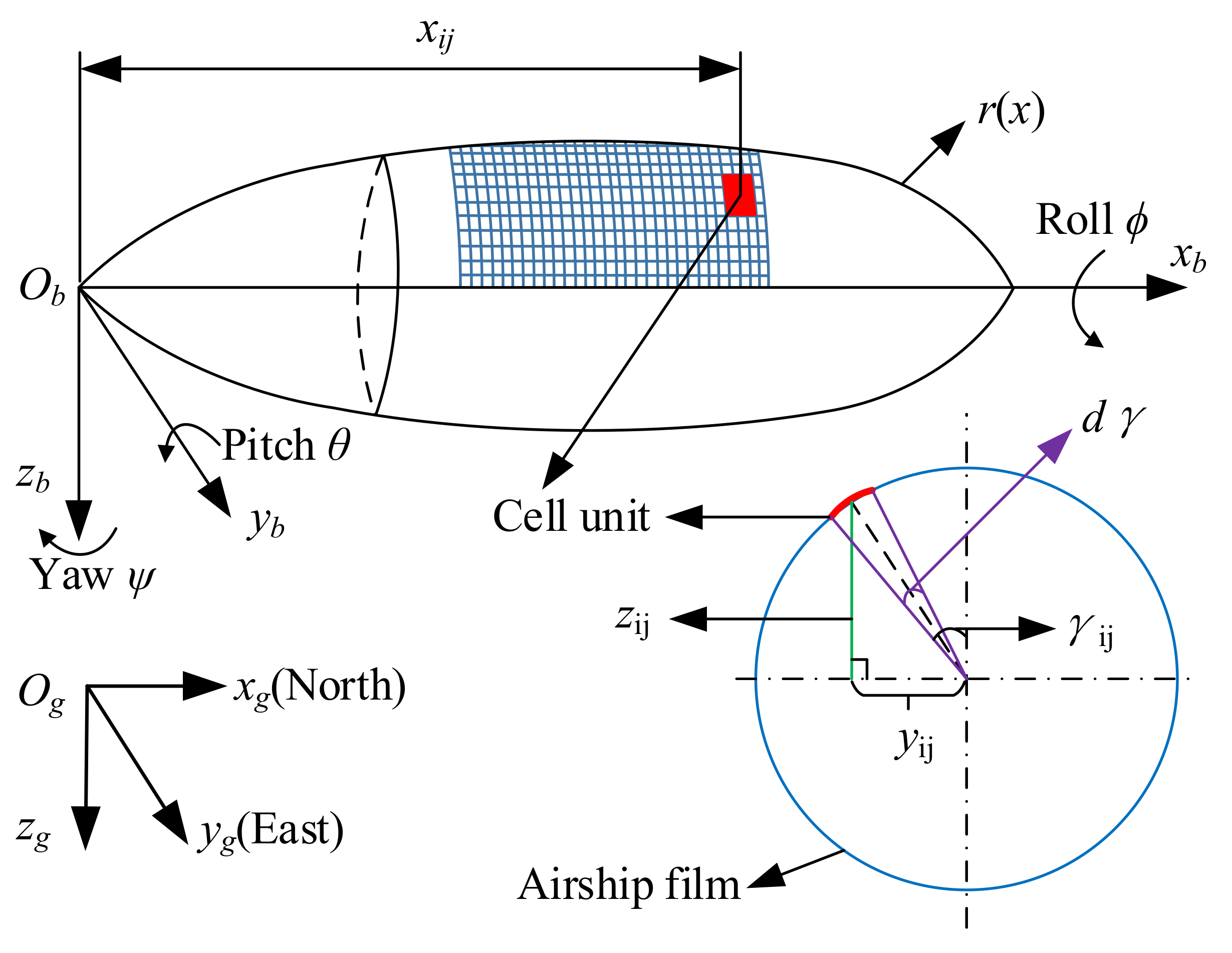

2.1. Spatial Geometry Model

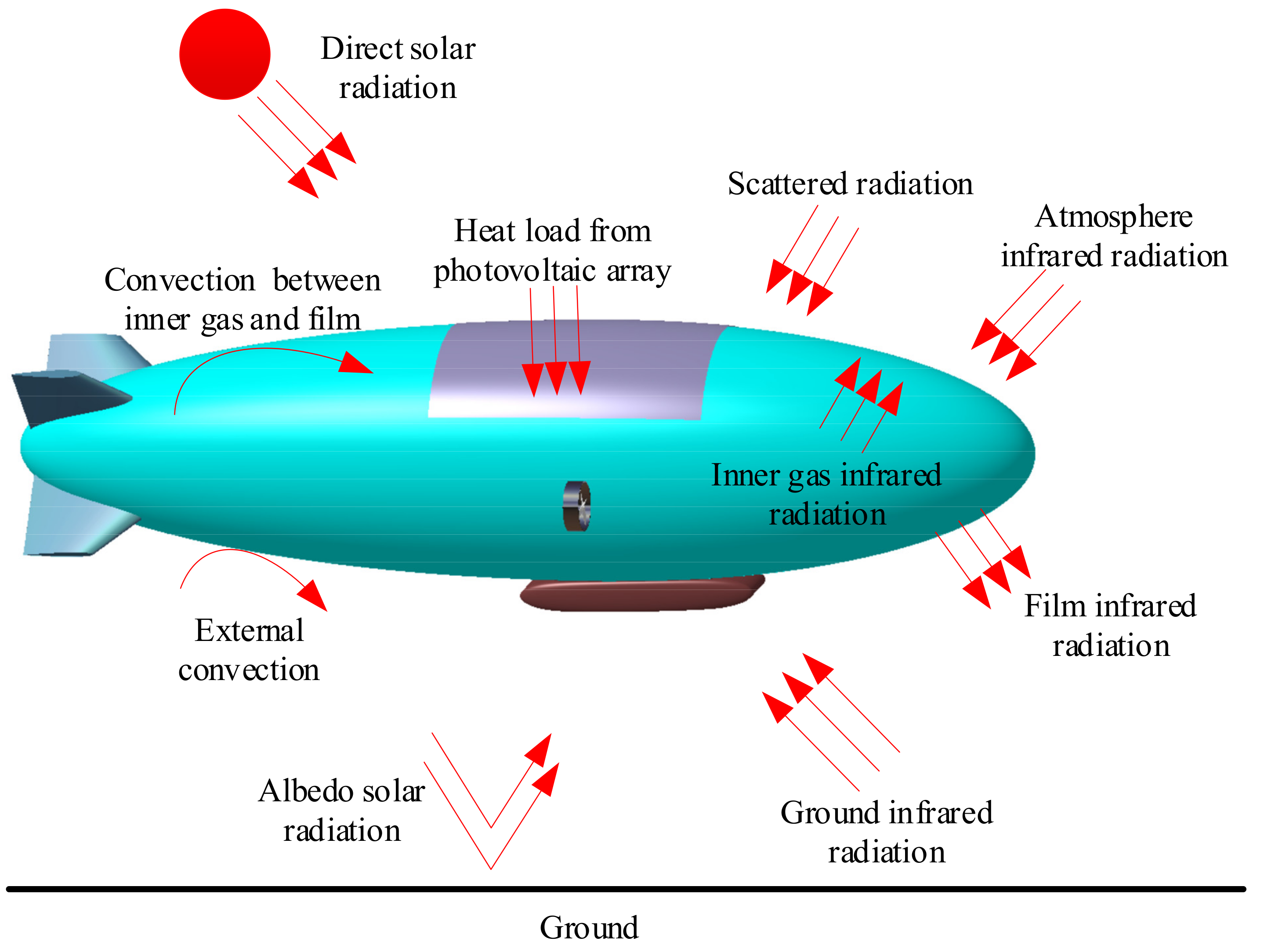

2.2. Thermal Environment

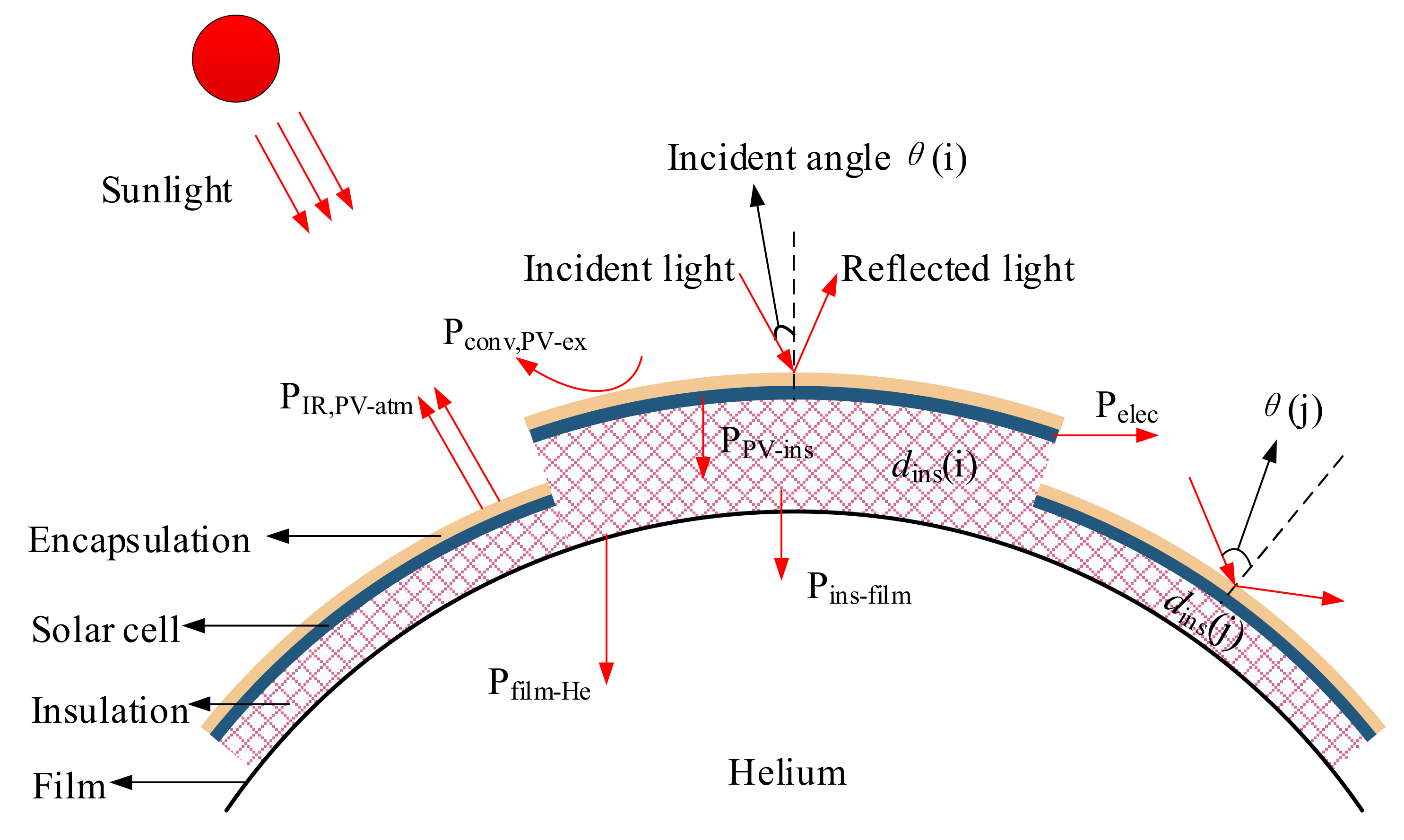

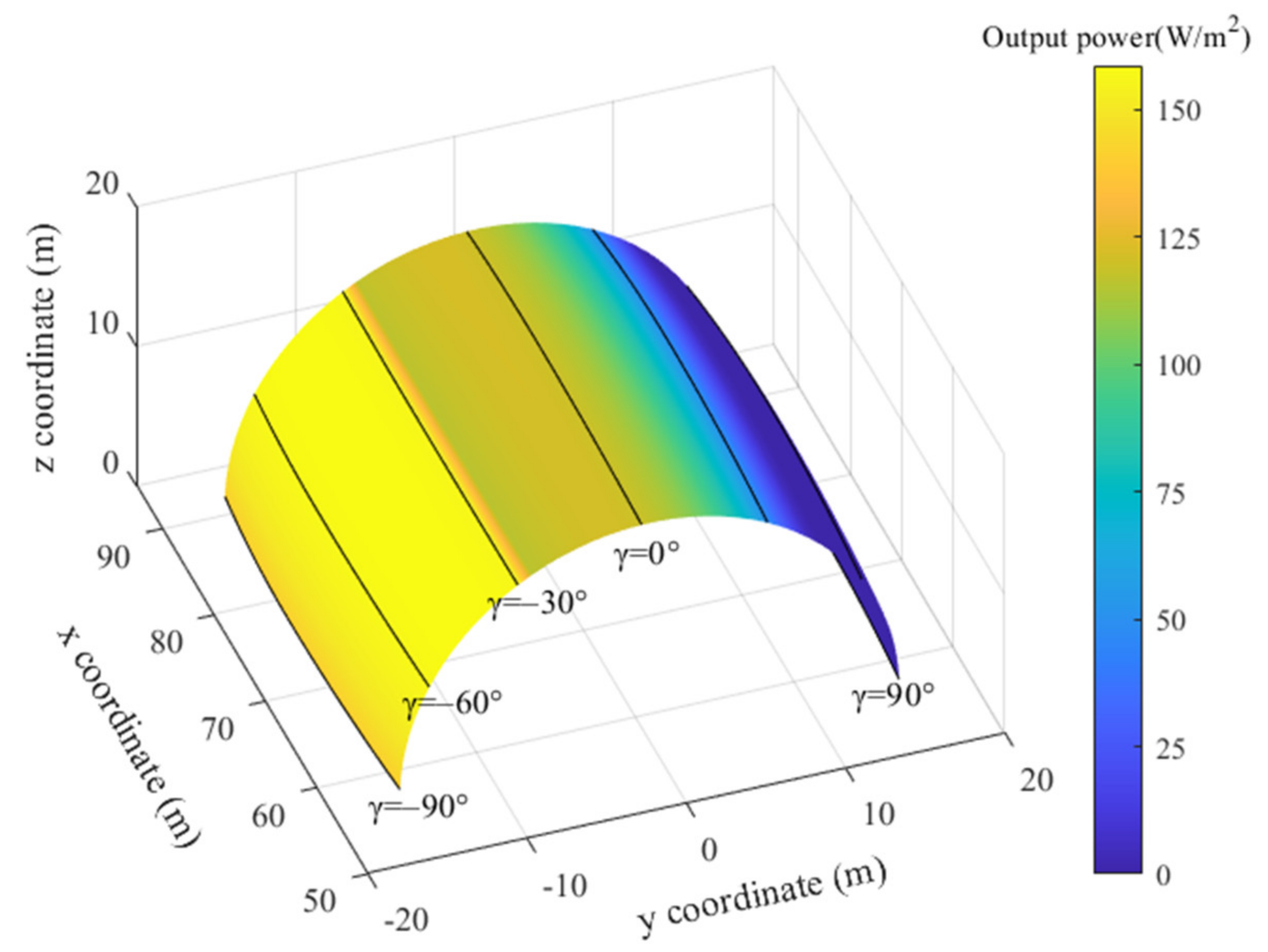

2.3. Power Model

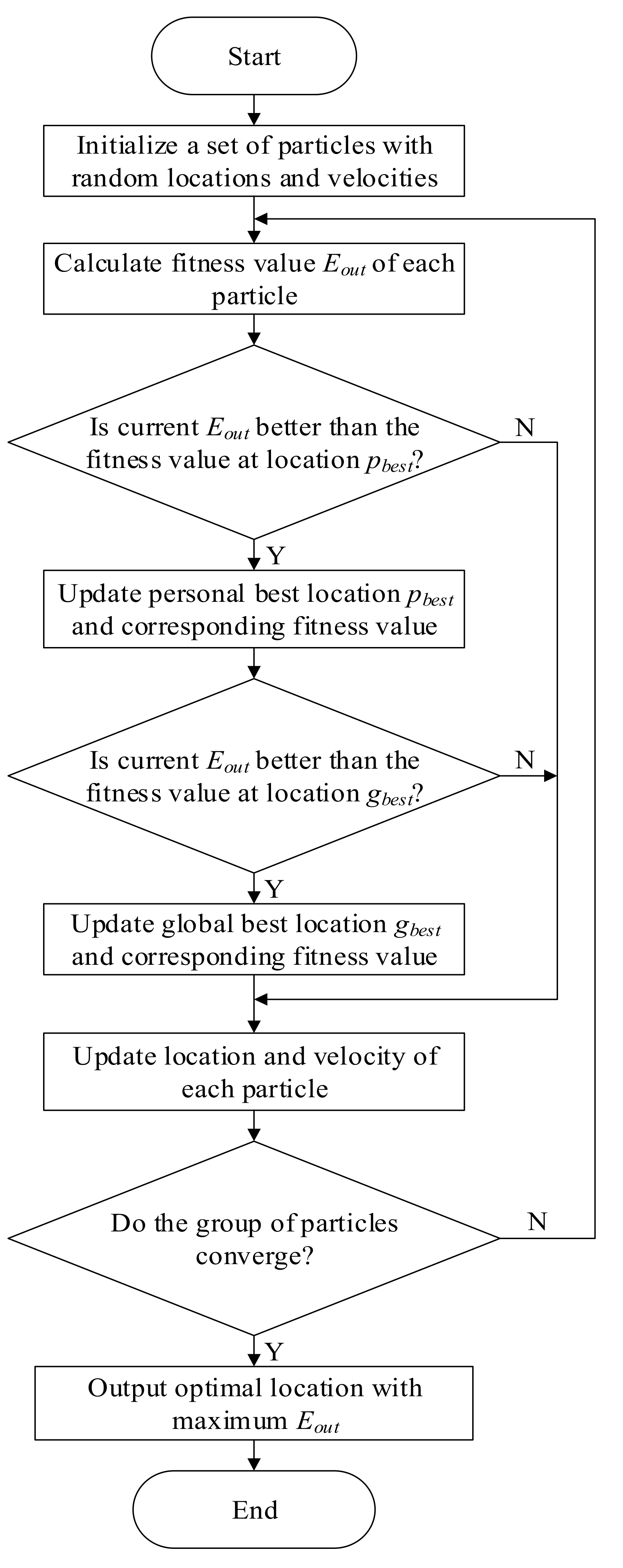

2.4. Optimization Method of Insulation Layer Configuration

3. Results and Discussion

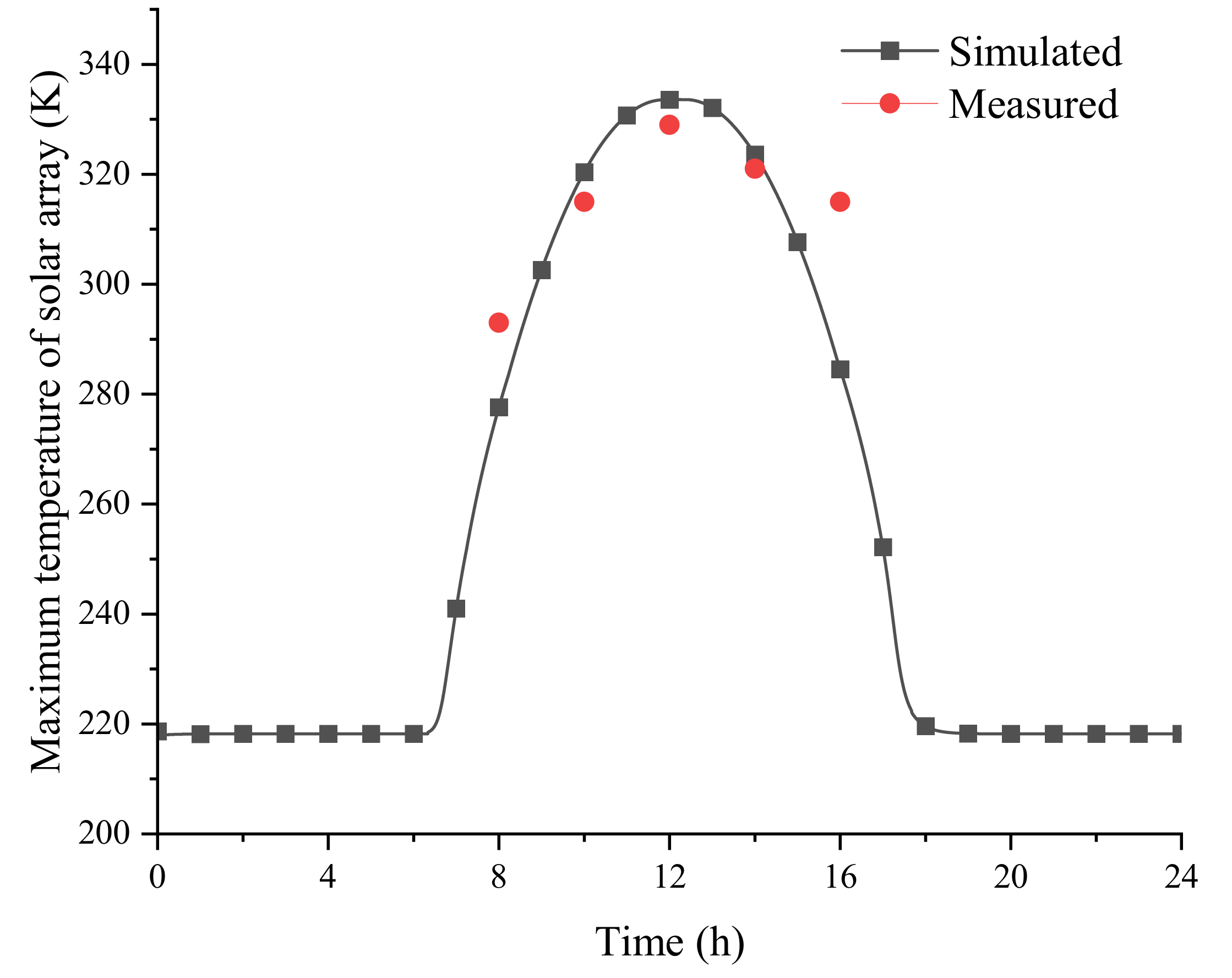

3.1. Model Validation

3.2. Simulation Condition

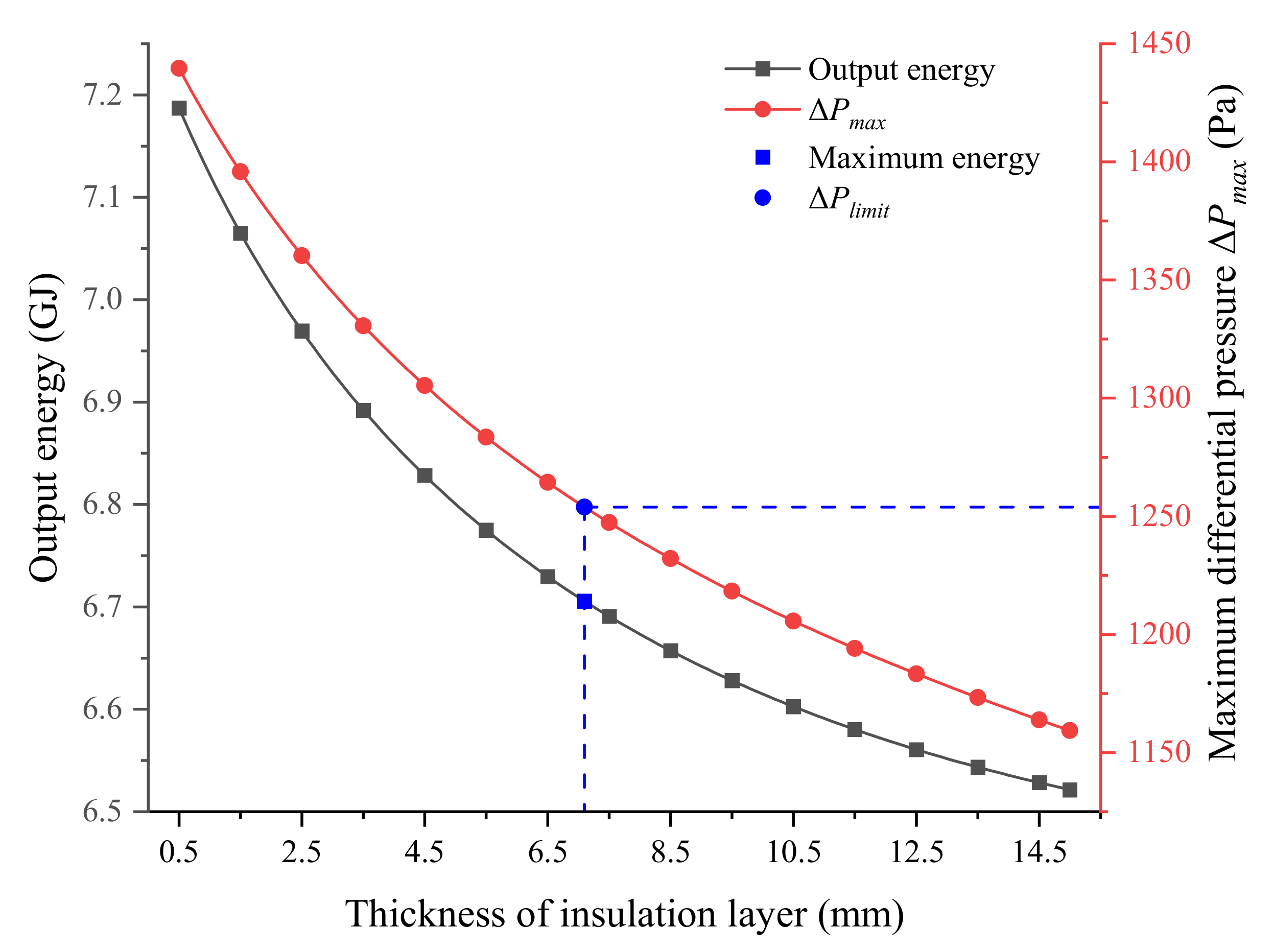

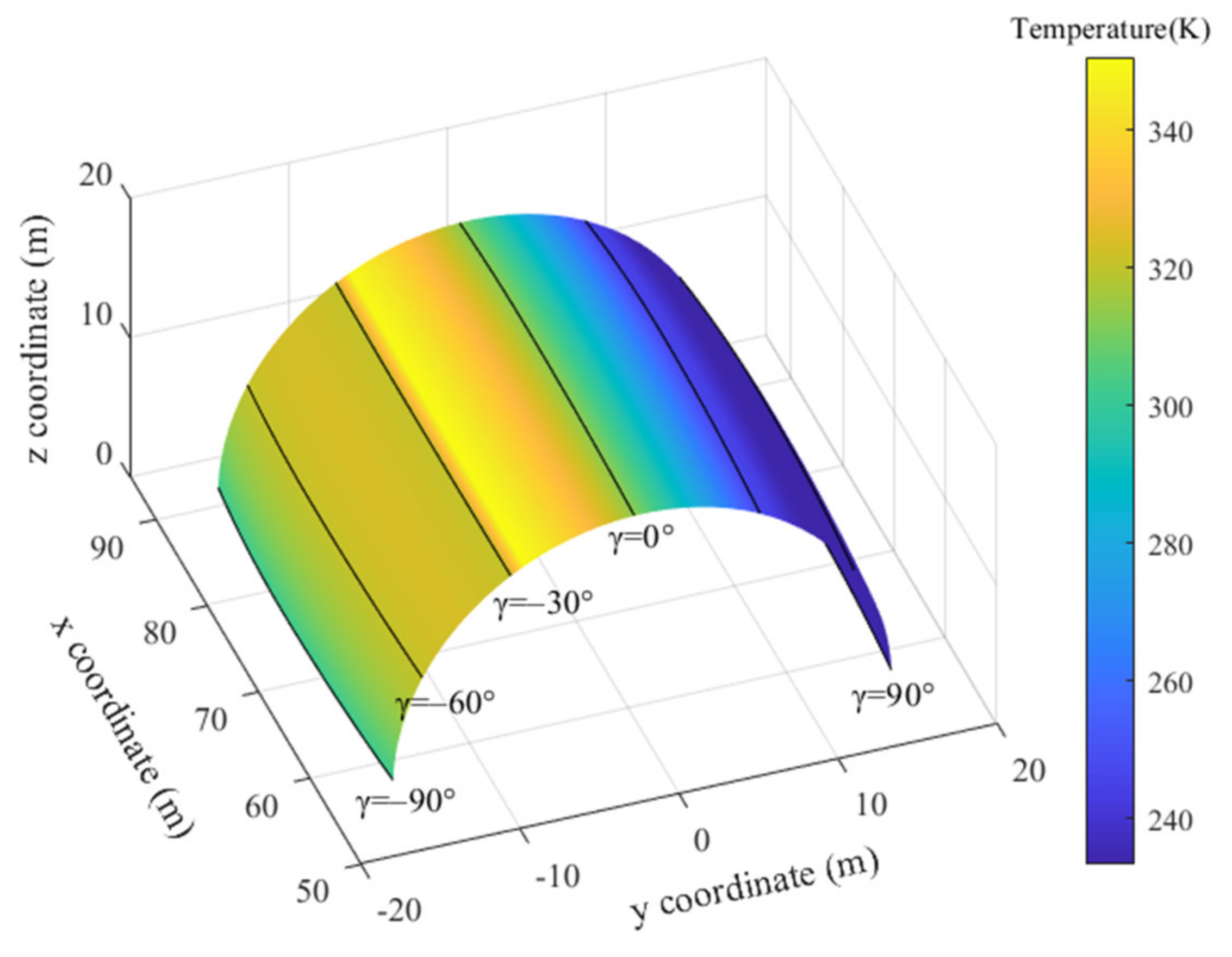

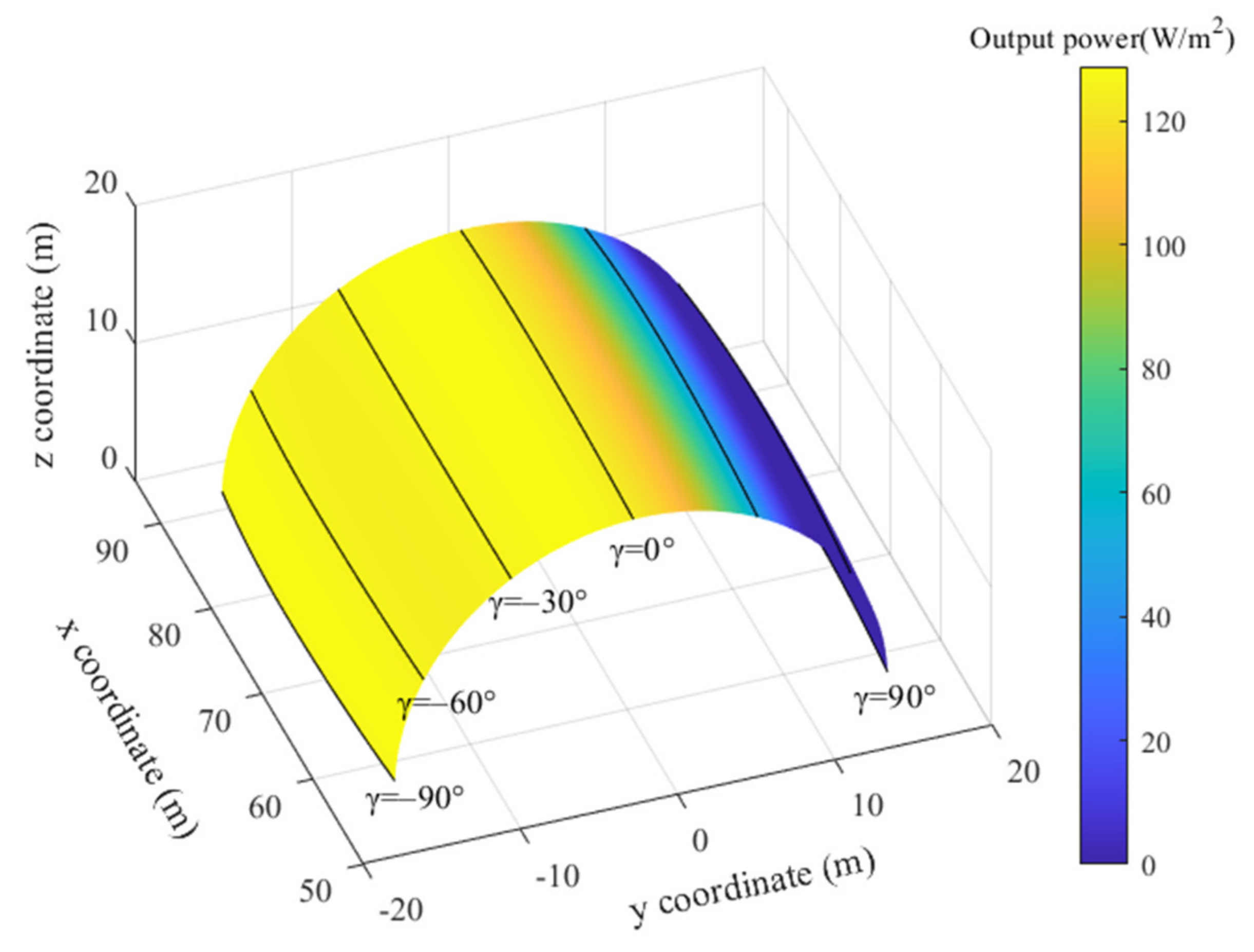

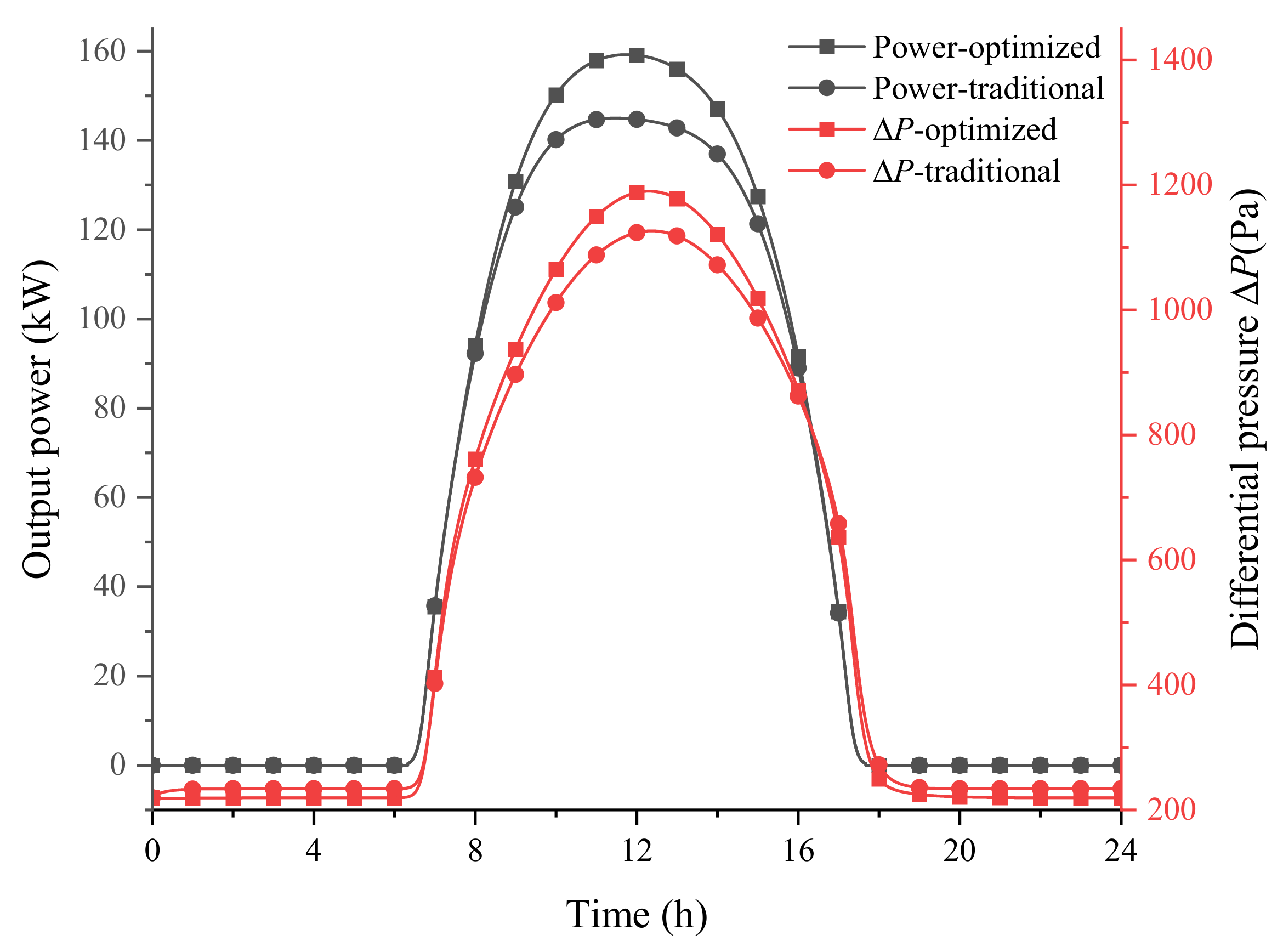

3.3. Effect of Insulation Configuration

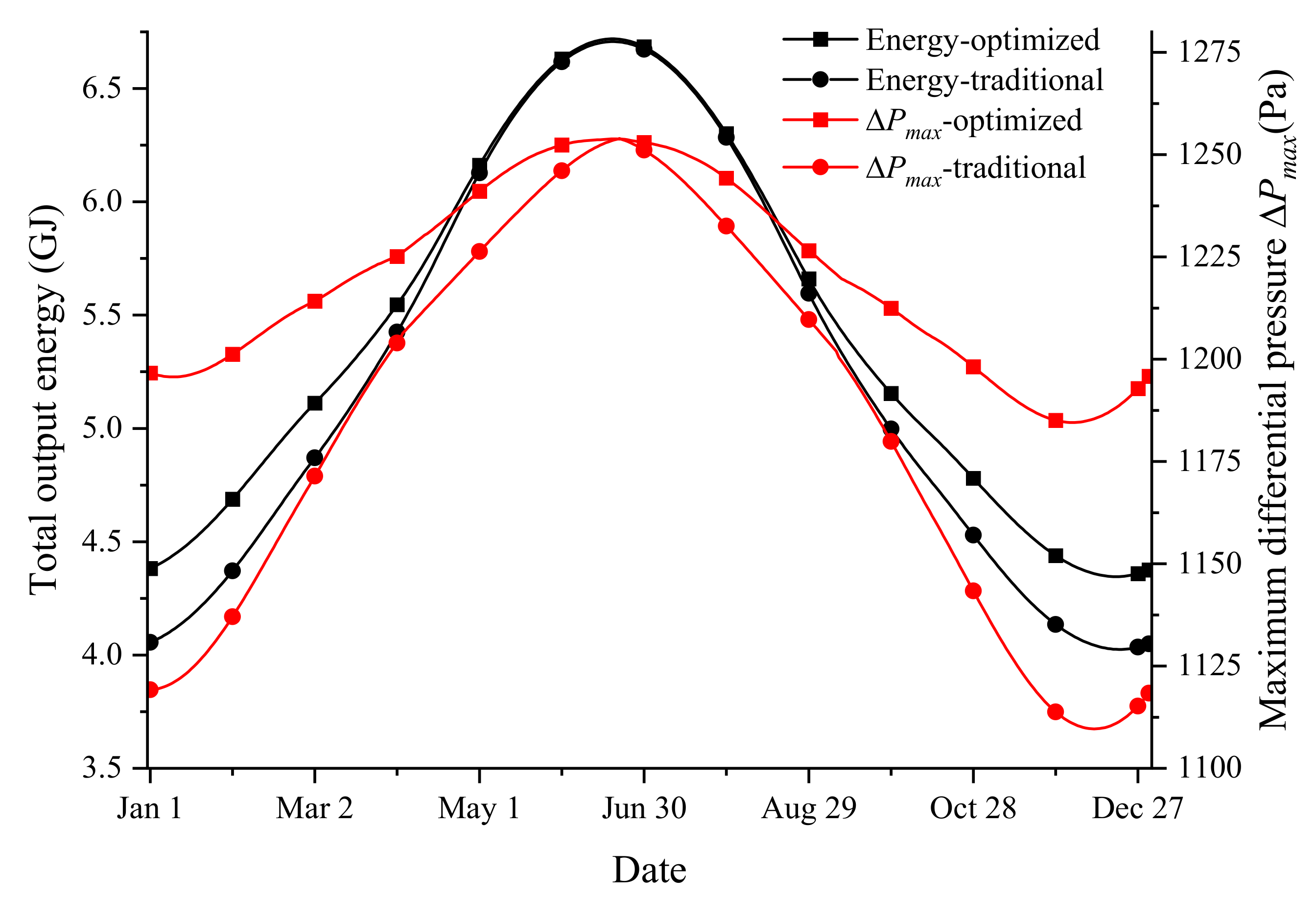

3.4. Comparative Analysis

4. Conclusions

- 1.

- The thickness of the insulation layer has a significant influence on the output power of the solar array and maximum differential pressure of the airship. Decreasing thickness is beneficial for reducing the average temperatures of the solar cells, hence increasing energy acquisition. However, a thin thermal insulation layer results in the temperature rise of the inner gas of the airship, causing an increase of differential pressure, which could lead to structural failure of the airship film.

- 2.

- The optimized configuration significantly reduces the total weight of the thermal insulation layers. Meanwhile, the limit of the maximum differential pressure is not exceeded. The thicknesses of the optimized insulation layers vary with the central angles. For the investigated airship, the thicknesses of the insulation layers with a central angle from 0° to ±30° are thickened, and the others are thinned. The decreased mass of insulations can be used to increase the capacity of carrying payload.

- 3.

- The optimized layout of the insulations improves the output energy of the solar array throughout the entire year. In the long time period, the optimized arrangement functions to increase the energy acquirement and maximum differential pressure, especially on dates when the solar radiation are insufficient (before and after the winter solstice). The maximum increase of the total output energy during a day is 8.2% on the winter solstice. The proposed method plays an essential role in the long endurance mission of stratospheric airships.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gonzalo, J.; López, D.; Domínguez, D.; García, A.; Escapa, A. On the capabilities and limitations of high altitude pseudo-satellites. Prog. Aerosp. Sci. 2018, 98, 37–56. [Google Scholar] [CrossRef]

- Frezza, L.; Marzioli, P.; Santoni, F.; Piergentili, F. VHF Omnidirectional Range (VOR) Experimental Positioning for Stratospheric Vehicles. Aerospace 2021, 8, 263. [Google Scholar] [CrossRef]

- Mano, S.; Ajay Sriram, R.; Vinayagamurthy, G.; Pillai, S.N.; Pasha, A.A.; Reddy, D.S.K.; Rahman, M.M. Effect of a Circular Slot on Hybrid Airship Aerodynamic Characteristics. Aerospace 2021, 8, 166. [Google Scholar] [CrossRef]

- Pande, D.; Verstraete, D. Impact of solar cell characteristics and operating conditions on the sizing of a solar powered nonrigid airship. Aerosp. Sci. Technol. 2018, 72, 353–363. [Google Scholar] [CrossRef]

- Xu, Y.; Zhu, W.; Li, J.; Zhang, L. Improvement of endurance performance for high-altitude solar-powered airships: A review. Acta Astronaut. 2020, 167, 245–259. [Google Scholar] [CrossRef]

- Garg, A.; Burnwal, S.; Pallapothu, A.; Alawa, R.; Ghosh, A. Solar Panel Area Estimation and Optimization for Geostationary Stratospheric Airships. In Proceedings of the 11th AIAA Aviation Technology, Integration and Operations (ATIO) Conference, Virginia Beach, VA, USA, 20–22 September 2011. [Google Scholar]

- Wang, H.; Song, B.; Zuo, L. Effect of High-Altitude Airship’s Attitude on Performance of its Energy System. J. Aircr. 2007, 44, 2077–2080. [Google Scholar] [CrossRef]

- Alam, M.I.; Pant, R.S. Multidisciplinary approach for solar area optimization of high altitude airships. Energy Convers. Manag. 2018, 164, 301–310. [Google Scholar] [CrossRef]

- Li, J.; Lv, M.; Tan, D.; Zhu, W.; Sun, K.; Zhang, Y. Output performance analyses of solar array on stratospheric airship with thermal effect. Appl. Therm. Eng. 2016, 104, 743–750. [Google Scholar] [CrossRef]

- Du, H.; Zhu, W.; Wu, Y.; Zhang, L.; Li, J.; Lv, M. Effect of angular losses on the output performance of solar array on long-endurance stratospheric airship. Energy Convers. Manag. 2017, 147, 135–144. [Google Scholar] [CrossRef]

- Dai, Q.; Cao, L.; Zhang, G.; Fang, X. Thermal performance analysis of solar array for solar powered stratospheric airship. Appl. Therm. Eng. 2020, 171, 115077. [Google Scholar] [CrossRef]

- Shi, H.; Chen, J.; Hu, L.; Geng, S.; Zhang, T.; Feng, Y. Multi-parameter sensitivity analysis on thermal characteristics of stratospheric airship. Case Stud. Therm. Eng. 2021, 25, 100902. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, C. Thermal Analysis of a Stratospheric Airship in Working Process. In Proceedings of the AIAA Balloon Systems Conference; American Institute for Aeronautics and Astronautics (AIAA): Reston, VA, USA, 2009. [Google Scholar]

- Li, X.; Fang, X.; Dai, Q. Research on Thermal Characteristics of Photovoltaic Array of Stratospheric Airship. J. Aircr. 2011, 48, 1380–1386. [Google Scholar] [CrossRef]

- Sun, K.; Yang, Q.; Yang, Y.; Wang, S.; Xie, Y.; Sun, M.; Chen, X.; Xu, J. Numerical Simulation and Thermal Analysis of Stratospheric Airship. Procedia Eng. 2015, 99, 763–772. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.K.; Han, C.Y. Analytical and numerical approaches of a solar array thermal analysis in a low-earth orbit satellite. Adv. Space Res. 2010, 46, 1427–1439. [Google Scholar] [CrossRef]

- Sun, K.; Zhu, M.; Liu, Q. Membrane Material-Based Rigid Solar Array Design and Thermal Simulation for Stratospheric Airships. Adv. Mater. Sci. Eng. 2014, 2014, 192707. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Lv, M.; Sun, K.; Zhu, W. Thermal insulation performance of lightweight substrate for solar array on stratospheric airships. Appl. Therm. Eng. 2016, 107, 1158–1165. [Google Scholar] [CrossRef]

- Meng, J.; Liu, S.; Yao, Z.; Lv, M. Optimization design of a thermal protection structure for the solar array of stratospheric airships. Renew. Energy 2019, 133, 593–605. [Google Scholar] [CrossRef]

- Tang, R.; Wu, T. Optimal tilt-angles for solar collectors used in China. Appl. Energy 2004, 79, 239–248. [Google Scholar] [CrossRef]

- Atmeh, G.; Subbarao, K. Guidance, Navigation and Control of Unmanned Airships under Time-Varying Wind for Extended Surveillance. Aerospace 2016, 3, 8. [Google Scholar] [CrossRef] [Green Version]

- Khoury, G.A. Airship Technology; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Gemignani, M.; Marcuccio, S. Dynamic Characterization of a High-Altitude Balloon during a Flight Campaign for the Detection of ISM Radio Background in the Stratosphere. Aerospace 2021, 8, 21. [Google Scholar] [CrossRef]

- Yang, X.; Liu, D. Renewable power system simulation and endurance analysis for stratospheric airships. Renew. Energy 2017, 113, 1070–1076. [Google Scholar] [CrossRef]

- Despotovic, M.; Nedic, V. Comparison of optimum tilt angles of solar collectors determined at yearly, seasonal and monthly levels. Energy Convers. Manage. 2015, 97, 121–131. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, W.; Hou, Z. Improved Thermal and Vertical Trajectory Model for Performance Prediction of Stratospheric Balloons. J. Aerosp. Eng. 2013, 28, 04014075. [Google Scholar] [CrossRef]

- Gao, X.-Z.; Hou, Z.-X.; Guo, Z.; Liu, J.-X.; Chen, X.-Q. Energy management strategy for solar-powered high-altitude long-endurance aircraft. Energy Convers. Manag. 2013, 70, 20–30. [Google Scholar] [CrossRef]

- Yang, X. Prediction of thermal behavior and trajectory of stratospheric airships during ascent based on simulation. Adv. Space Res. 2016, 57, 2326–2336. [Google Scholar] [CrossRef]

- Zhang, L.; Li, J.; Wu, Y.; Lv, M. Analysis of attitude planning and energy balance of stratospheric airship. Energy 2019, 183, 1089–1103. [Google Scholar] [CrossRef]

- Yamawaki, T.; Mizukami, S.; Masui, T.; Takahashi, H. Experimental investigation on generated power of amorphous PV module for roof azimuth. Sol. Energy Mater. Sol. Cells 2001, 67, 369–377. [Google Scholar] [CrossRef]

- Martin, N.; Ruiz, J.M. Calculation of the PV modules angular losses under field conditions by means of an analytical model. Sol. Energy Mater. Sol. Cells 2001, 70, 25–38. [Google Scholar] [CrossRef]

- Khan, F.; Baek, S.-H.; Kim, J.H. Wide range temperature dependence of analytical photovoltaic cell parameters for silicon solar cells under high illumination conditions. Appl. Energy 2016, 183, 715–724. [Google Scholar] [CrossRef]

- Dai, Q.; Fang, X.; Li, X.; Tian, L. Performance simulation of high altitude scientific balloons. Adv. Space Res. 2012, 49, 1045–1052. [Google Scholar] [CrossRef]

- Anoop, S.; Velamati, R.K.; Oruganti, V. Aerodynamic characteristics of an aerostat under unsteady wind gust conditions. Aerosp. Sci. Technol. 2021, 113, 106684. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the Icnn95-international Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995. [Google Scholar]

- Gangadhar, A.; Manikandan, M.; Rajaram, D.; Mavris, D. Conceptual Design and Feasibility Study of Winged Hybrid Airship. Aerospace 2021, 9, 8. [Google Scholar] [CrossRef]

- Harada, K.; Eguchi, K.; Sano, M.; Sasa, S. Experimental Study of Thermal Modeling for Stratospheric Platform Airship. In Proceedings of the AIAA’s 3rd Annual Aviation Technology, Integration, and Operations (ATIO) Forum, Denver, CO, USA, 17–19 November 2003. [Google Scholar]

- Hersbach, H.; Bell, B.; Berrisford, P.; Biavati, G.; Horány, A.; Muñoz Sabater, J.; Nicolas, J.; Peubey, C.; Radu, R.; Rozum, I.; et al. ERA5 Hourly Data on Single Levels from 1979 to Present. Copernicus Climate Change Service (C3S) Climate Data Store (CDS). 2018. Available online: https://cds.climate.copernicus.eu/cdsapp#!/dataset/reanalysis-era5-single-levels?tab=overview (accessed on 1 December 2021).

| Requirements | Value | Design Parameters | Value |

|---|---|---|---|

| Flight altitude, km | 20 | Volume of airship, m3 | 71,897 |

| Location | Jiujiang (30° N, 116° E) | , m | 53.8 |

| Working date | 1 January~31 December | , m | 76.2 |

| Flight direction | East–west | , m | 16.3 |

| Airspeed, m/s | 15 | Total mass, kg | 6392 |

| Payload capacity, kg | 650 | Film mass, kg | 2140 |

| Thickness range of insulation layers, mm | 0.5~15 | Helium mass, kg | 882 |

| Central angle range, ° | −90~90 | Propulsion system mass, kg | 957 |

| Allowable stress of skin, MPa | 52.5 | Storage battery mass, kg | 1130 |

| Limit of differential pressure, Pa | 1254 | Solar array mass, kg | 398 |

| Parameters | Traditional Layout | Optimized Layout |

|---|---|---|

| Insulation layer mass, kg | 235 | 176.5 |

| Limit of differential pressure, Pa | 1254 | 1254 |

| Maximum differential pressure, Pa | 1253.9 | 1253.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Xu, Z.; Du, H.; Lv, M. Multidisciplinary Optimization of Thermal Insulation Layer for Stratospheric Airship with a Solar Array. Aerospace 2022, 9, 83. https://doi.org/10.3390/aerospace9020083

Liu Y, Xu Z, Du H, Lv M. Multidisciplinary Optimization of Thermal Insulation Layer for Stratospheric Airship with a Solar Array. Aerospace. 2022; 9(2):83. https://doi.org/10.3390/aerospace9020083

Chicago/Turabian StyleLiu, Yang, Ziyuan Xu, Huafei Du, and Mingyun Lv. 2022. "Multidisciplinary Optimization of Thermal Insulation Layer for Stratospheric Airship with a Solar Array" Aerospace 9, no. 2: 83. https://doi.org/10.3390/aerospace9020083

APA StyleLiu, Y., Xu, Z., Du, H., & Lv, M. (2022). Multidisciplinary Optimization of Thermal Insulation Layer for Stratospheric Airship with a Solar Array. Aerospace, 9(2), 83. https://doi.org/10.3390/aerospace9020083