Life-Cycle Analysis and Evaluation of Mechanical Properties of a Bio-Based Structural Adhesive

Abstract

:1. Introduction

2. Materials

3. Methodologies

3.1. Overview of Mechanical Testing

3.2. LCA

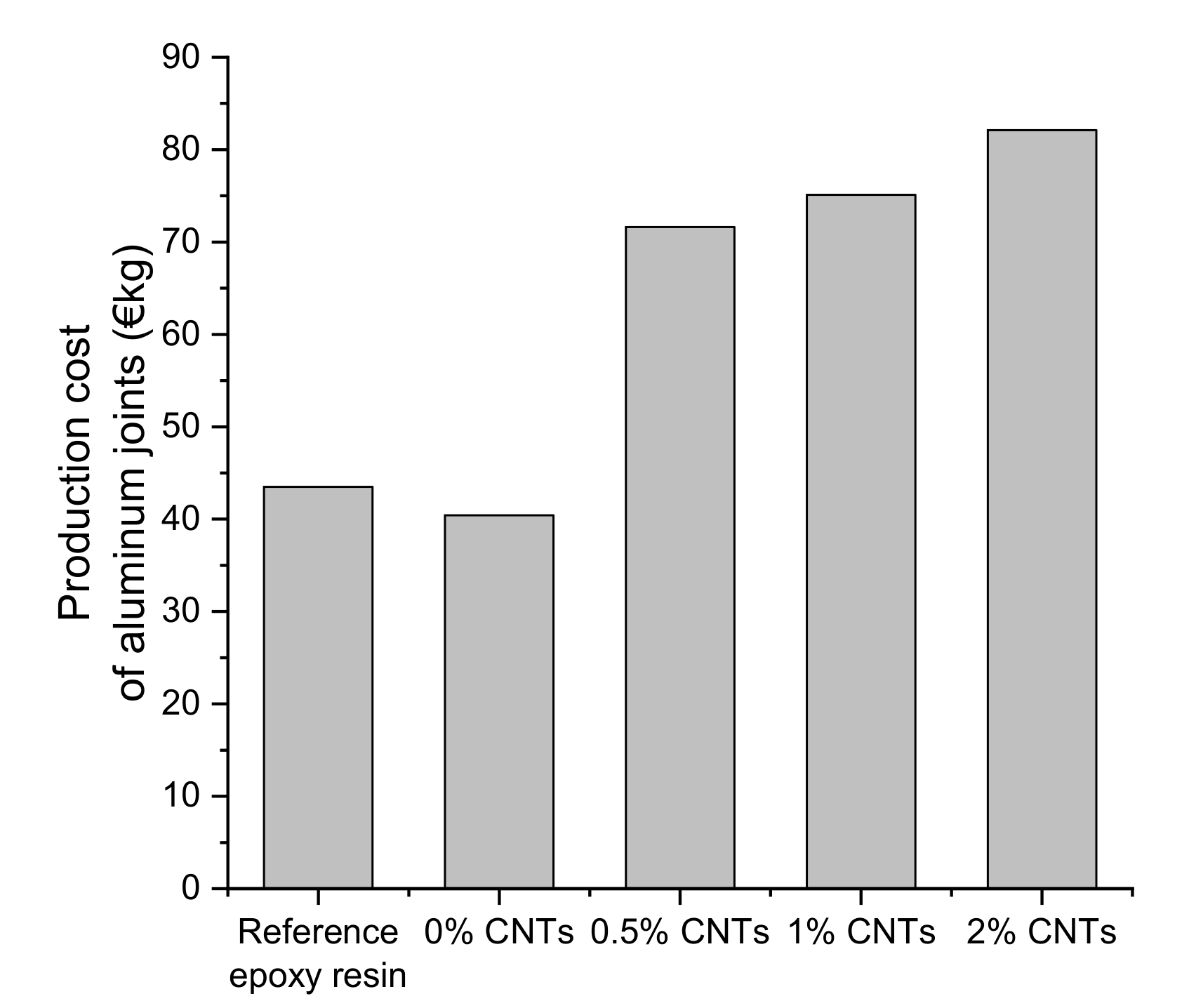

3.3. Production Cost

3.4. Evaluation of Mechanical Properties

4. Results

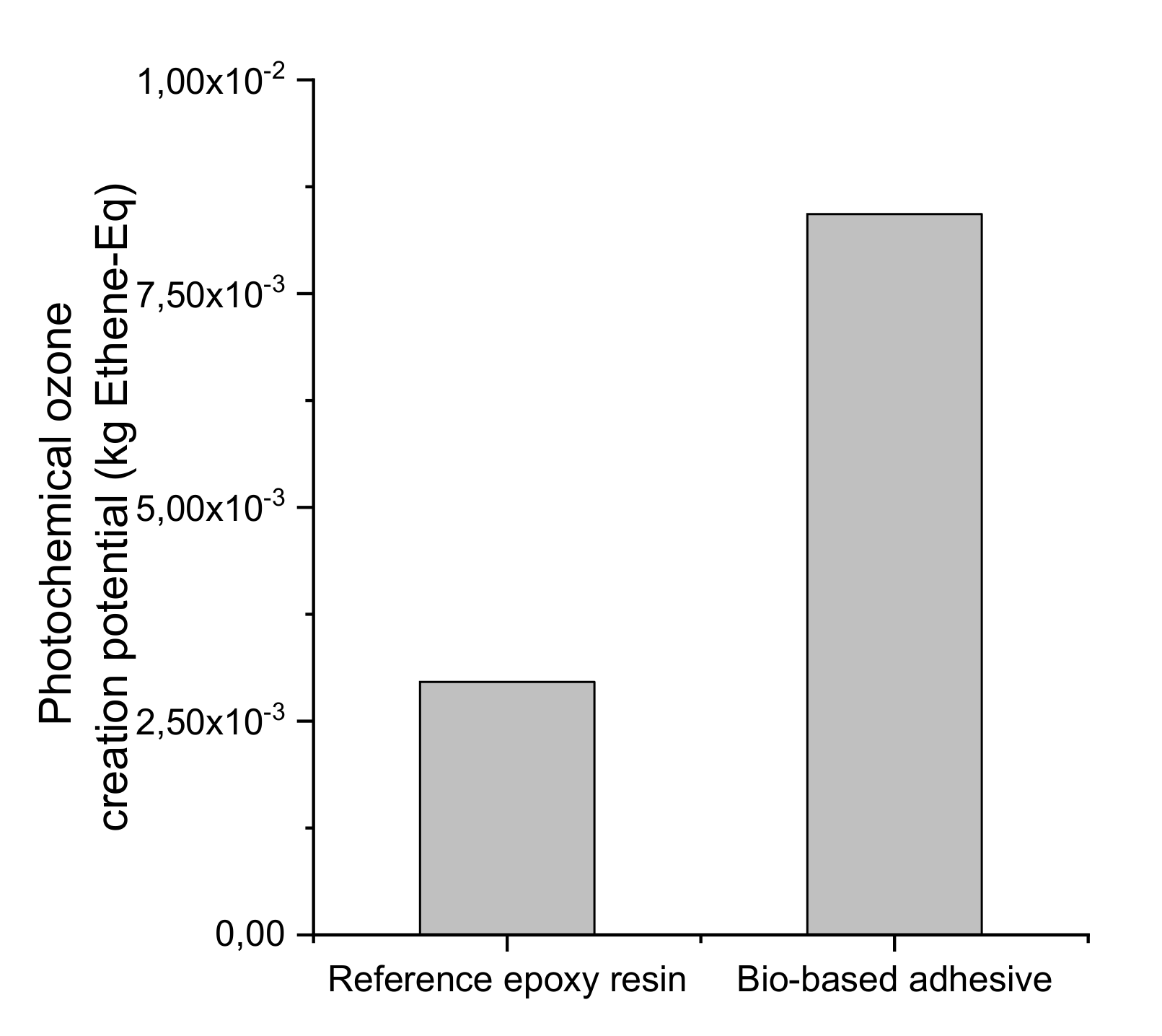

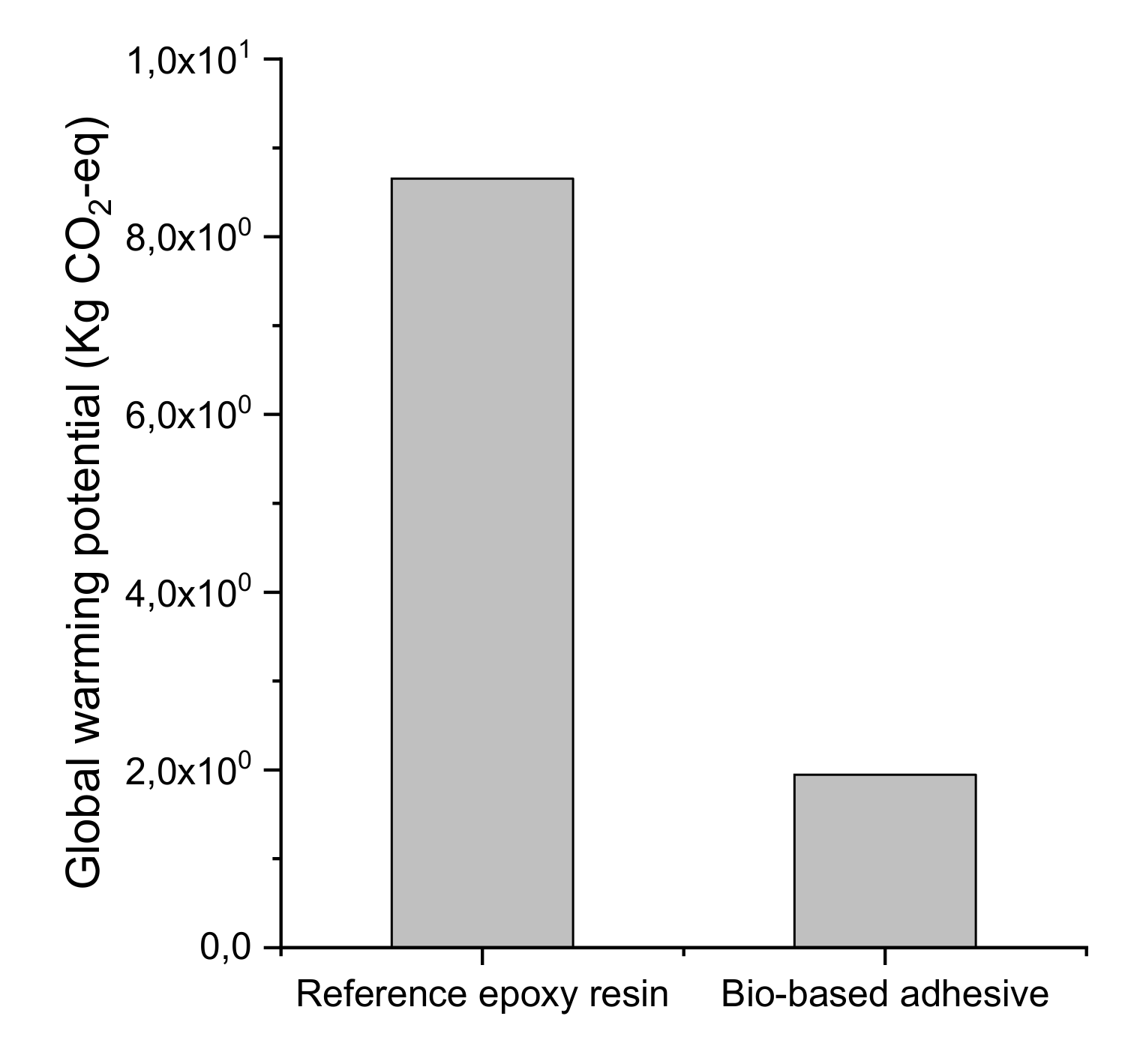

4.1. Results of the LCA

4.2. Results of the Mechanical Evaluation of the Bio Adhesive

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Cavalcanti, W.; Brune, K.; Noeske, M.; Tserpes, K.; Ostachowicz, W.; Schlag, M. (Eds.) Adhesive Bonding of Aircraft Composite Structures: Non-Destructive Testing and Quality Assurance Concepts; Springer Nature: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Pantelakis, S.; Tserpes, K. (Eds.) Revolutionizing Aircraft Materials and Processes; Springer Nature: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Bachmann, J.; Yi, X.; Tserpes, K.; Sguazzo, C.; Barbu, L.; Tse, B.; Soutis, C.; Ramón, E.; Linuesa, H.; Bechtel, S. Towards a Circular Economy in the Aviation Sector Using Eco-Composites for Interior and Secondary Structures. Results and Recommendations from the EU/China Project ECO-COMPASS. Aerospace 2021, 8, 131. [Google Scholar] [CrossRef]

- Kreibich, U.T.; Marcantonio, A.F. New Developments in Structural Adhesives for the Automotive Industry. J. Adhes. 1987, 22, 153–165. [Google Scholar] [CrossRef]

- Kocí, V.; Loubal, T. LCA of liquid epoxy resin produced based on propylene and on glycerin. Acta Environ. Univ. Comen. 2012, 20, 62–67. [Google Scholar]

- Kočí, V.; Picková, E. Life cycle perspective of liquid epoxy resin use in the automotive industry. Pol. J. Environ. Stud. 2019, 29, 653–667. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Vijayan, D. Life Cycle Assessment (LCA) of Epoxy-Based Materials. In Micro and Nanostructured Epoxy/Rubber Blends; Sabu, T., Sinturel, C., Raju, T., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Francis, R. (Ed.) Recycling of Polymers: Methods, Characterization and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Feih, S.; Boiocchi, E.; Mathys, G.; Mathys, Z.; Gibson, A.; Mouritz, A. Mechanical properties of thermally-treated and recycled glass fibres. Compos. Part B Eng. 2011, 42, 350–358. [Google Scholar] [CrossRef] [Green Version]

- Hyde, J.R.; Lester, E.; Kingman, S.; Pickering, S.; Wong, K.H. Supercritical propanol, a possible route to composite carbon fibre recovery: A viability study. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2171–2175. [Google Scholar] [CrossRef]

- Pérez, R.L.; Ayala, C.E.; Opiri, M.M.; Ezzir, A.; Li, G.; Warner, I.M. Recycling Thermoset Epoxy Resin Using Alkyl-Methyl-Imidazolium Ionic Liquids as Green Solvents. ACS Appl. Polym. Mater. 2021, 3, 5588–5595. [Google Scholar] [CrossRef]

- Sukanto, H.; Raharjo, W.W.; Ariawan, D.; Triyono, J.; Kaavesina, M. Epoxy resins thermosetting for mechanical engineering. Open Eng. 2021, 11, 797–814. [Google Scholar] [CrossRef]

- Elghazzaoui, H. Contribution à L’étude de la Dégradation des Composites Carbone/Époxy par Solvolyse Dans l’eau Subcritique et Supercritique en Vue de Leur Recyclage. Ph.D. Thesis, Université de Nantes, Nantes, France, 2012. [Google Scholar]

- Onwudili, J.A.; Yildirir, E.; Williams, P.T. Catalytic Hydrothermal Degradation of Carbon Reinforced Plastic Wastes for Carbon Fibre and Chemical Feedstock Recovery. Waste Biomass Valorization 2013, 4, 87–93. [Google Scholar] [CrossRef]

- Chen, N.; Zeng, Q.; Lin, Q.; Rao, J. Development of defatted soy flour based bio-adhesives using Viscozyme L. Ind. Crop. Prod. 2015, 76, 198–203. [Google Scholar] [CrossRef]

- Gu, K.; Huang, J.; Li, K. Preparation and evaluation of particleboard bonded with a soy flour-based adhesive with a new curing agent. J. Adhes. Sci. Technol. 2013, 27, 2053–2064. [Google Scholar] [CrossRef]

- Luo, J.; Luo, J.; Li, X.; Li, K.; Gao, Q.; Li, J. Toughening improvement to a soybean meal-based bio-adhesive using an interpenetrating acrylic emulsion network. J. Mater. Sci. 2016, 51, 9330–9341. [Google Scholar] [CrossRef]

- Lei, H.; Du, G.; Wu, Z.; Xi, X.; Dong, Z. Cross-linked soy-based wood adhesives for plywood. Int. J. Adhes. Adhes. 2014, 50, 199–203. [Google Scholar] [CrossRef]

- Ceseracciu, L.; Heredia-Guerrero, J.; Dante, S.; Athanassiou, A.; Bayer, S. Robust and biodegradable elastomers based on corn starch and polydimethylsiloxane (PDMS). ACS Appl. Mater. Interfaces 2015, 18, 3742–3753. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Pinkl, S.; Gindl-Altmutter, W. Application of surface chemical functionalized cellulose nanocrystals to improve the performance of UF adhesives used in wood based composites-MDF type. Carbohydr. Polym. 2019, 206, 11–20. [Google Scholar] [CrossRef]

- Scarica, C.; Suriano, R.; Levi, M.; Turri, S.; Griffini, G. Lignin Functionalized with Succinic Anhydride as Building Block for Biobased Thermosetting Polyester Coatings. ACS Sustain. Chem. Eng. 2018, 6, 3392–3401. [Google Scholar] [CrossRef]

- Rathi, S.; Saka, R.; Domb, A.J.; Khan, W. Protein-based bioadhesives and bioglues. Polym. Adv. Technol. 2019, 30, 217–234. [Google Scholar] [CrossRef]

- Clark, R.A. Fibrin sealant in wound repair: A systematic survey of the literature. Expert Opin. Investig. Drugs 2000, 9, 2371–2392. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Yu, X.; Li, Y.; Su, Z.; Jandt, K.D.; Wei, G. Protein-mimetic peptide nanofibers: Motif design, self-assembly synthesis, and sequence-specific biomedical applications. Prog. Polym. Sci. 2018, 80, 94–124. [Google Scholar] [CrossRef]

- Tzatzadakis, V.; Tserpes, K. Production of a novel bio-based structural adhesive and characterization of mechanical properties. J. Adhes. 2021, 97, 936–951. [Google Scholar] [CrossRef]

- Tzatzadakis, V.; Tserpes, K. Experimental characterization of the hygrothermal ageing effects on the bulk mechanical properties and lap-shear strength of the novel bio-based epichlorohydrin/cardanol adhesive. J. Adhes. 2020, 97, 1–19. [Google Scholar] [CrossRef]

- Tserpes, K.; Tzatzadakis, V. Synthesis and Experimental Characterization of a MWCNT-Filled Bio-Based Adhesive. Aerospace 2021, 8, 26. [Google Scholar] [CrossRef]

- Spolchemie.cz. [Internet]. 2020. Available online: https://www.spolchemie.cz/media/c2786f0c-de6f-4393-b1cc-e01520878fd3/Jy_j6w/4distributors/EPD%20LER%20A%20certification%20websites.pdf (accessed on 3 November 2020).

- Environmental Labels and Declarations–Type III Environmental Declarations–Principles and Procedures; EN ISO 14025; International Standard Organisation (ISO): Geneva, Switzerland, 2006.

- ISO 14040. Environmental Management-Life Cycle Assessment-Principles and Framework (ISO 14040: 2006); CEN (European Committee for Standardisation): Brussels, Belgium, 2006. [Google Scholar]

- Matanza, A.; Vargas, G.; Leon, I.; Pousse, M.; Salmon, N.; Marieta, C. Life cycle analysis of standard and high-performance cements based on carbon nanotubes composites for construction applications. World SB 2014, 4, 28–30. [Google Scholar]

- Upadhyayula, V.K.; Meyer, D.E.; Curran, M.A.; Gonzalez, M. Life cycle assessment as a tool to enhance the environmental performance of carbon nanotube products: A review. J. Clean. Prod. 2012, 26, 37–47. [Google Scholar] [CrossRef]

- Singh, A.; Agboola, A.; Yaws, C.L.; Lou, H.H.; Pike, R.W.; Li, X.; Hopper, J.R. Environmental Impact Assessment for Potential Continuous Processes for the Production of Carbon Nanotubes. Am. J. Environ. Sci. 2008, 4, 522–534. [Google Scholar] [CrossRef]

- Khanna, V.; Bakshi, B.; Lee, L. Carbon nanofiber production: Life cycle energy consumption and environmental impact. J. Ind. Ecol. 2008, 12, 394–410. [Google Scholar] [CrossRef]

- Katsiropoulos, C.V.; Loukopoulos, A.; Pantelakis, S.G. Comparative Environmental and Cost Analysis of Alternative Production Scenarios Associated with a Helicopter’s Canopy. Aerospace 2019, 6, 3. [Google Scholar] [CrossRef] [Green Version]

- electricityMap. Live CO2 Emissions of Electricity Consumption. [Internet]. Available online: https://app.electricitymap.org/map (accessed on 3 November 2020).

- Burchardt, B. Advances in polyurethane structural adhesives. In Advances in Structural Adhesive Bonding; Elsevier: Amsterdam, The Netherlands, 2010; pp. 35–65. [Google Scholar]

- Hollaway, L. Key issues in the use of fibre reinforced polymer (FRP) composites in the rehabilitation and retrofitting of concrete structures. In Service Life Estimation and Extension of Civil Engineering Structures; Elsevier: Amsterdam, The Netherlands, 2011; pp. 3–74. [Google Scholar]

- Araldite Industrial Adhesives–Home [Internet]. Aralditeadhesives.com. 2020. Available online: http://aralditeadhesives.com/index.php?option=com_content&view=article&id=48&Itemid=142&lang=en (accessed on 14 November 2020).

- LOCTITE Solutions [Internet]. Henkel-adhesives.com. 2020. Available online: https://www.henkel-adhesives.com/us/en/about/our-brands/loctite.html (accessed on 14 November 2020).

- Overview of Materials for Epoxy Adhesive [Internet]. Matweb.com. 2020. Available online: http://www.matweb.com/search/datasheettext.aspx?matguid=c1ec1ad603c74f628578663aaf44f261 (accessed on 14 November 2020).

- McDevitt, J.E.; Grigsby, W.J. Life Cycle Assessment of Bio- and Petro-Chemical Adhesives Used in Fiberboard Production. J. Polym. Environ. 2014, 22, 537–544. [Google Scholar] [CrossRef]

- Arias, A.; González-García, S.; González-Rodríguez, S.; Feijoo, G.; Moreira, M.T. Cradle-to-gate Life Cycle Assessment of bio-adhesives for the wood panel industry. A comparison with petrochemical alternatives. Sci. Total Environ. 2020, 738, 140357. [Google Scholar] [CrossRef]

- Yang, M.; Rosentrater, K.A. Life Cycle Assessment and Techno-Economic Analysis of Pressure Sensitive Bio-Adhesive Production. Energies 2019, 12, 4502. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Value 1 | |

|---|---|---|

| K | 0.55 | |

| P1 | 1.02 × 10−5 kg Sb-Eq | 87.7 MJ |

| R | 0.31 | |

| Σ1 | 1.47 × 10−7 kg Sb-Eq | 7.24 kg Sb-Eq |

| d | 0.13 | |

| E1 | 3.85 × 10−7 kg Sb-Eq | 19.5 kg Sb-Eq |

| Parameter | Value 2 |

|---|---|

| k | 0.55 |

| P2 | 2.08 × 10−2 kg SO2-eq |

| r | 0.31 |

| Σ2 | 3.53 × 10−3 kg SO2-eq |

| d | 0.13 |

| E2 | 8.94 × 10−4 kg SO2-eq |

| Parameter | Value 3 |

|---|---|

| k | 0.55 |

| P3 | 1.29 × 10−2 kg Phosphate-eq |

| r | 0.31 |

| Σ3 | 1.47 × 10−3 kg Phosphate-eq |

| d | 0.13 |

| E3 | 2.84 × 10−3 kg Phosphate-eq |

| Parameter | Value 4 |

|---|---|

| k | 0.55 |

| P4 | 1.93 × 10−7 kg CFC11-eq |

| r | 0.31 |

| Σ4 | 4.12 × 10−8 kg CFC11-eq |

| d | 0.13 |

| E4 | 1.05 × 10−7 kg CFC11-eq |

| Parameter | Value 5 |

|---|---|

| k | 0.55 |

| P5 | 1.52 × 10−2 kg ethene-Eq |

| r | 0.31 |

| Σ5 | 1.38 × 10−4 kg ethene-Eq |

| d | 0.13 |

| E5 | 1.05 × 10−4 kg ethene-Eq |

| Parameter | Value 6 | ||

|---|---|---|---|

| k | 0.55 | ||

| P6 | 5.14 | ||

| r | 0.31 | ||

| Σ6 | −2.31 | ||

| d | 0.13 | ||

| E6 | −1.11 | ||

| ν | 0.5% | 1% | 2% |

| N | 6.80E+02 | ||

| Materials | Cost (€/kg) |

|---|---|

| NaOH | 30 |

| Phosphoric acid | 50 |

| Deionized water | 2 |

| CNTs | 700 |

| Structural Adhesive | Tensile Strength (MPa) | Glass Transition Temperature (C°) |

|---|---|---|

| AV 8504 | 50.33 | 130.0 |

| EPI 200 | 51.71 | 55.30 |

| EPI 300 | 53.78 | 70.00 |

| EA 9309 | 32.20 | 61.00 |

| EA9330 | 38.60 | 57.00 |

| EA 9330.3 | 42.00 | 54.00 |

| EA 9395 | 55.60 | 73.00 |

| EA960F | 15.20 | 66.00 |

| EA 9309NA | 31.00 | 53.00 |

| EA 9394S | 46.00 | 78.00 |

| EA 9309.2 | 37.20 | 79.00 |

| Mean Value: | 41.24 | 70.57 |

| Structural Adhesive | KIC (MPa·m1/2) |

|---|---|

| MY750 | 1.254 |

| CY 230/HY 951 | 1.028 |

| Epon828/Dicyandiamide | 1.220 |

| W635/EC57 | 1.190 |

| EC57 Elantas® Camattini | 1.200 |

| Epon828 | 2.170 |

| Mean Value: | 1.34 |

| Structural Adhesive | Lap Shear Strength (MPa) |

|---|---|

| AV 8504 | 12.76 |

| EPI 100 | 34.47 |

| EPI 1210/9615 | 17.24 |

| EPI 1210/9861 | 19.31 |

| EPI 1217 | 17.24 |

| EPI 1534 | 20.68 |

| EPI 1544 | 17.93 |

| EPI 1559 | 18.62 |

| EPI 1565 | 6.89 |

| EPI 200 | 19.10 |

| EPI 300 | 28.96 |

| EPI 8000 | 26.89 |

| EPI 8543 | 13.79 |

| FAST 10 | 19.31 |

| EA 9309,3 | 38.00 |

| EA9330 | 34.50 |

| EA 9330,3 | 39.30 |

| EA 9395 | 29.70 |

| EA960F | 15.20 |

| EA 9359,3 | 31.00 |

| EA 9394 | 28.90 |

| Mean Value: | 23.32 |

| Nonstructural Adhesive | Young’s Modulus (GPa) |

|---|---|

| AW 136H/HY991 | 2.1 |

| E-05CL HYSOL | 1.9 |

| Araldite® LY 564 | 2.1 |

| Mean Value: | 2.0 |

| Nonstructural Adhesive | Tensile Strength (MPa) |

|---|---|

| AW 136H/HY991 | 42 |

| E-00NS HYSOL | 12 |

| E-90FL HYSOL | 13 |

| Mean Value: | 22 |

| Nonstructural Adhesive | Glass Transition Temperature (C°) |

|---|---|

| AW 136H/HY991 | 55 |

| E-00NS HYSOL | 35 |

| E-90FL HYSOL | 30 |

| Mean Value: | 40 |

| Nonstructural Adhesive | KIC (MPa·m1/2) | Reference |

|---|---|---|

| DER 661 | 0.57 | 30 |

| RTM6 | 0.61 | 31 |

| Araldite® LY 564 | 0.68 | 32 |

| Epikote 828/HD-Acc43 | 1.52 | 33 |

| Epikote 828/HN-2200R | 2.77 | 33 |

| Mean Value: | 1.23 |

| Nonstructural Adhesive | Lap Shear Strength (MPa) |

|---|---|

| AW 136H/HY991 | 13 |

| AY105-1/HY998 | 14 |

| E-00NS HYSOL | 11 |

| 3035 | 2.5 |

| E-90FL HYSOL | 5.5 |

| Mean Value: | 9.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tserpes, K.; Tzatzadakis, V. Life-Cycle Analysis and Evaluation of Mechanical Properties of a Bio-Based Structural Adhesive. Aerospace 2022, 9, 64. https://doi.org/10.3390/aerospace9020064

Tserpes K, Tzatzadakis V. Life-Cycle Analysis and Evaluation of Mechanical Properties of a Bio-Based Structural Adhesive. Aerospace. 2022; 9(2):64. https://doi.org/10.3390/aerospace9020064

Chicago/Turabian StyleTserpes, Konstantinos, and Vasileios Tzatzadakis. 2022. "Life-Cycle Analysis and Evaluation of Mechanical Properties of a Bio-Based Structural Adhesive" Aerospace 9, no. 2: 64. https://doi.org/10.3390/aerospace9020064

APA StyleTserpes, K., & Tzatzadakis, V. (2022). Life-Cycle Analysis and Evaluation of Mechanical Properties of a Bio-Based Structural Adhesive. Aerospace, 9(2), 64. https://doi.org/10.3390/aerospace9020064