1. Introduction

With the development of computer science, some advanced techniques, such as model predictive control [

1], performance seeking control [

2], direct thrust control [

3], and model-based fault diagnosis [

4], are emerging in the field of engine control in recent years. These techniques all require an onboard model to provide either measurable or unmeasurable parameters of the engine for control, monitoring, and diagnostics [

5,

6]. However, the engine inevitably suffers various physical faults (e.g., foreign object damage, blade erosion and corrosion, worn seals, excess clearances) during its service life. These faults lead to performance deterioration and, thus, mismatch between the onboard model and the engine [

7,

8]. Maintenance and installation would also cause a slight performance difference between individual engines of the same type [

9,

10]. These facts press the onboard model to have the self-tuning capability to eliminate the deviation. In addition, when the degradation degree or the operating state of the engine varies, a new self-tuning process is necessary to accommodate the changed deviation [

11]. A slow estimation process can lead to a longtime mismatch and, thus, degrade the quality of control, monitoring, and diagnosis, even causing engine failures in severe scenarios. Therefore, establishing an onboard model with self-tuning and fast estimation capability is a key task in these above techniques.

To acquire the self-tuning capability, Luppold firstly employed a Kalman filter, which is implemented with a recursive algorithm and can estimate both system states and unmeasurable parameters in real-time, to provide a set of tuners that would adapt a piecewise state variable model to output a better match with the actual performance [

12]. The tuners are derived by the residuals between the model and the measurements and consist of health parameters such as efficiencies and flow parameters [

13,

14]. Besides that, Panov proposed a Kalman-based performance tracking tool, in which the tuners generated by the filter were fed to a dynamic real-time model to match the degraded measurements [

15]. Since the Kalman filter is an estimator applied to linear systems, the modeling error of the onboard model has a corruptive effect on the estimation results [

16]. To address this problem, Volponi added an empirical neural network module, and Pang proposed an improved incremental linearized Kalman filter [

17,

18]. On the other hand, non-linear Kalman filters, such as the extended Kalman filter [

19,

20] and unscented Kalman filter [

21,

22], were introduced to construct a nonlinear onboard adaptive model due to a better estimation accuracy than the linear one. Burnell utilized the extended Kalman filter to establish an adaptive component level model and realized the nonlinear model predictive control based on the model [

23]. Dewallef applied the unscented Kalman filter to monitor performance by estimating health parameters [

24]. Yang compared the estimation results of these Kalman filters and concluded that the constant gain extended Kalman filter can achieve a better balance in accuracy and computation time [

25].

However, the usage of nonlinear Kalman filters brings a heavy computation burden. To improve the real-time property, data-driven methods were proposed [

26]. By establishing the mapping relationship between measurable output parameters and unmeasurable parameters offline, these methods can finish parameter estimation in a short period of computing time. Wang adopted a BP neural network to train the mapping relationship between the measured output biases and unmeasured ones so that the outputs of the onboard model were adapted to those of the real engine [

27]. Wang constructed the mapping relationship between some measurable parameters and three deterioration condition parameters, based on a multi-input and multi-output recursive reduced least squares support vector regression algorithm, to realize the self-tuning capability of a turbo-shaft engine onboard model under the degraded condition [

28]. Nevertheless, the drawback of the data-driven methods is that ensuring the model’s accuracy needs a lot of effective data [

29]. In addition, the generalization ability of the algorithms used should be considered [

30].

Although the Kalman-based methods and the data-driven methods have achieved satisfactory results in adaptive estimation, the capability of fast estimation is still an aspect that needs attention and a solution. In fact, the Kalman-based methods employ a multi-step iterative process to obtain optimal estimation results. The iterative process often spends several seconds to complete it. And the data-driven methods are influenced by the dynamic response of measurable output parameters, especially those measured by temperature sensors, which makes the results also have a dynamic response process of about 9 s [

28]. As a consequence, the applications of the Kalman-based methods and the data-driven methods to model-based control and diagnosis are somewhat restricted.

Aiming at the defect of existing methods in fast estimation capability, a novel onboard adaptive model is proposed in this paper. The main contributions are as follows: (1) To speed up performance estimation, a novel modeling method is developed, which can eliminate the repetitive and long-time model mismatch. (2) A model tuner with quick availability is adopted in the model, which helps to assess the characteristic deviations of components rapidly. (3) An algorithm with memory function is employed to predict the tuners and, thus, shorten the time of self-tuning.

The remainder of this paper is organized as follows:

Section 2 details the methodology of the proposed onboard adaptive model.

Section 3 shows and discusses the simulation results to demonstrate the effectiveness of the model. Finally,

Section 4 concludes this paper.

2. Methodology

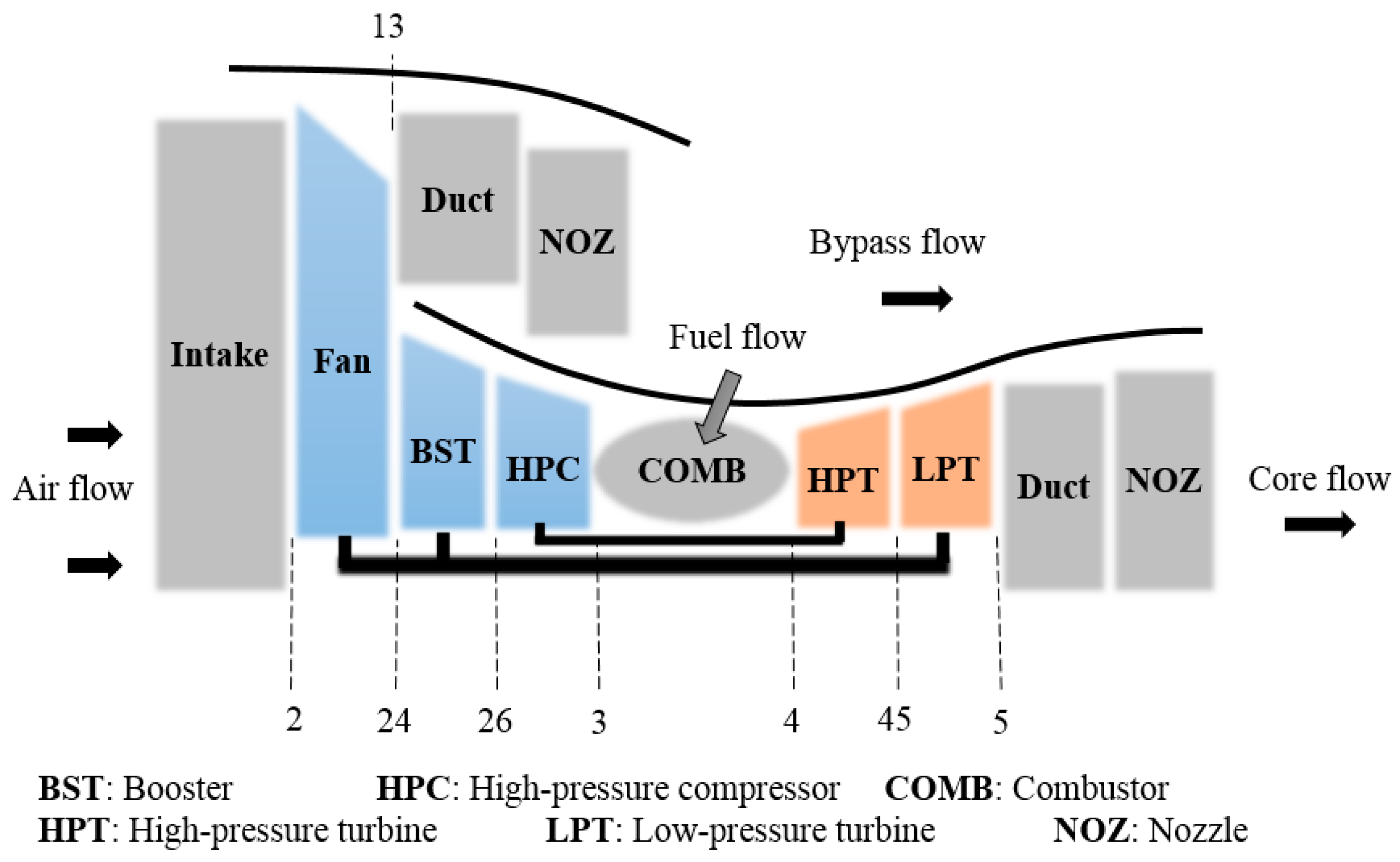

Without loss of generality, a typical civil high-bypass twin-shaft turbofan engine, which belongs to the General Electric CF6 series, is selected as the research object. The construction of this engine is shown in

Figure 1, with components of intake, fan, booster, high-pressure compressor (HPC), combustor, high-pressure turbine (HPT), low-pressure turbine (LPT), duct and nozzle of bypass, and core. In addition, the engine has the following performance parameters at the design point: the thrust is 254.6 kN, the pressure ratio is 29.6, the fuel mass flow rate is 2.5236 kg/s, the high-pressure rotor speed is 10,270 rpm, and the low-pressure rotor speed is 3390 rpm.

The component level model of this turbofan engine is implemented using the Simulink Toolbox for the Modeling and Analysis of Thermodynamics Systems (T-MATS), which is an open-source modeling package on behalf of NASA [

31]. The modeling procedures are summarized as follows: firstly, each component is modeled based on aero-thermodynamics principles. Then, considering the cooperation equations, which include the flow continuity equations, pressure balance equations, and power balance equations or rotor dynamics equations, the cooperation relationship among the component models is established. Finally, using the Newton–Raphson method to solve the formulated nonlinear equations, the measurable performance parameters, such as the rotor speeds, pressures, and temperatures in the flow path, and the unmeasurable parameters, such as thrust, can be derived. All the engine performance maps and relevant data are acquired from the gas turbine simulation program (GSP) [

32].

The constructed model can be expressed with a system of non-linear differential equations in state space:

where

is the state vector,

is the input vector,

is the flight condition vector,

is the characteristic vector, and

is the output vector. All the vectors are column vectors, and the same are below, unless otherwise specified.

The state vector contains the low-pressure rotor speed and the high-pressure rotor speed : . The flight condition vector is composed of altitude H and Mach number Ma: . The output vector comprises measurable parameters and unmeasurable parameters : .

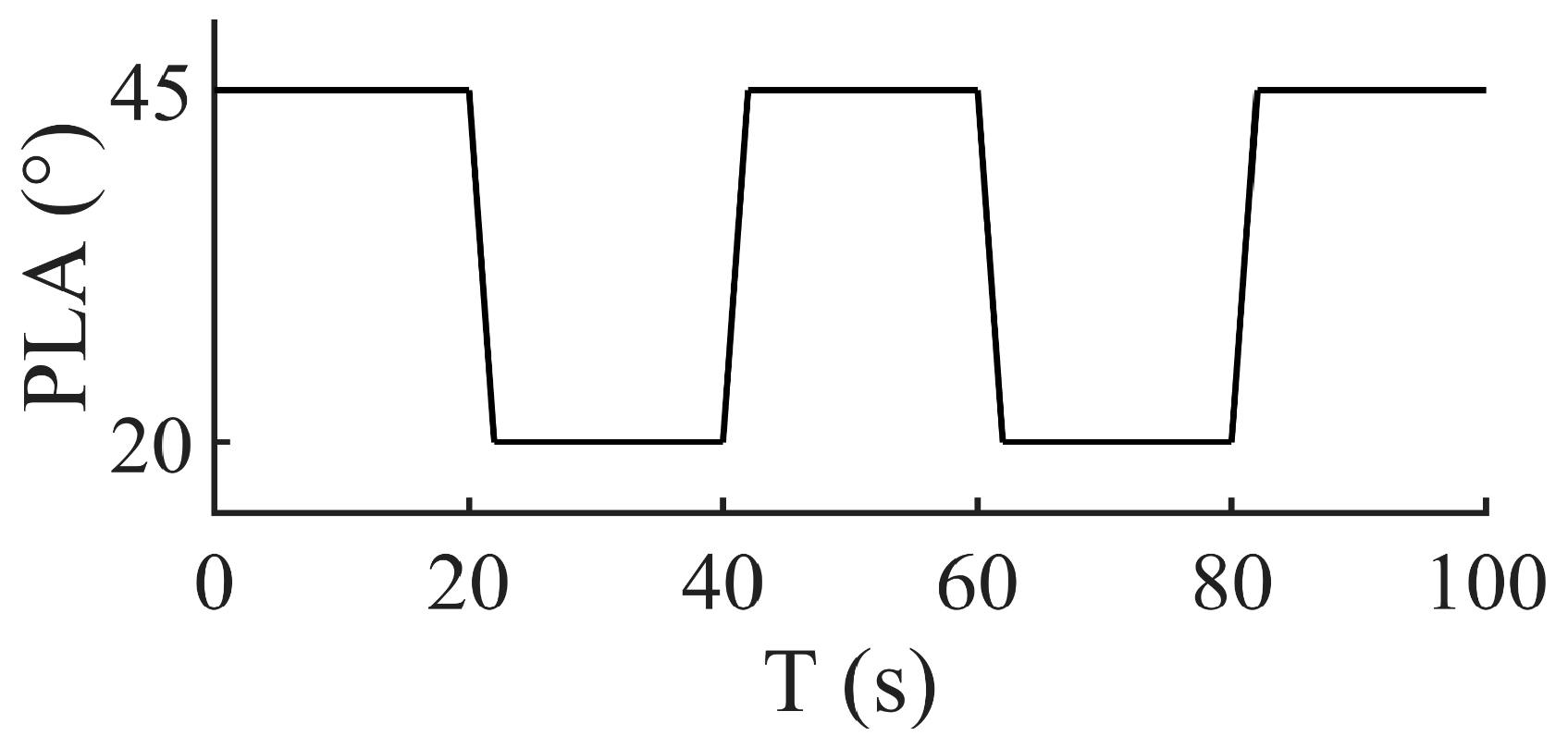

The input vector consists of the following control variables: —fuel flow, —variable guide vane angle, and —bleed/blow-off valve angle. Together with the flight condition vector, it constitutes the engine’s operating condition. In fact, the engine’s operation is inseparable from the control system. For a closed-loop system containing the engine and the control system, the input vector is selected as the command of power level angle (PLA) for convenience: . Correspondingly, Equation (1) describes the equations of the closed-loop system. It is worth mentioning that, in the closed-loop system, the PLA can still be translated to the engine’s control variables through the control system.

The characteristic vector contains the characteristics of each component. Taking the HPC as an example, its characteristics include corrected mass flow, efficiency, pressure ratio, and corrected speed. When the components’ characteristics are at their nominal value, the component level model is a benchmark model. However, the characteristics would deviate from their nominal value and, thus, cause a mismatch between the benchmark model and the actual engine, when the engine is in deterioration. Therefore, for the component level model, obtaining the actual characteristics accurately and quickly is the key to its performance estimation capability.

2.1. Actual Characteristics Calculation

It seems like an inverse mathematical problem of Equation (1) to calculate the components’ actual characteristics according to the measurements. The known information is the operating condition and the measurable parameters, which contain the input vector

, the flight condition vector

, the state vector

, and the pressure and temperature of some stations, whereas the actual characteristics are unknown. To compute the characteristics of all components, a single point adaptation method is developed from existing approaches [

33,

34,

35,

36] and described as follows. It should be noted that data handling is required to eliminate the abnormal data before applying the method.

Let the known information be defined as the known parameters

and the unknown components’ characteristics defined as the to-be-adapted parameters

. It should be noted that some characteristics can be obtained directly from

, such as the corrected speed of the fan. In the engine, the thermodynamic relationship between the known parameters and the unknown characteristics can be represented with Equation (2):

where

and

is the number of the known parameters,

and

is the number of the to-be-adapted parameters, and

are nonlinear functions.

Given a guess of the to-be-adapted parameters, which is denoted by subscript “0”,

can be obtained by substituting

into Equation (2). If

deviates far from

, it is obvious that

is not appropriate to be the solution. Using Taylor expansion at point (

), a linearized relationship between the deviation of the known parameters

and the deviation of the to-be-adapted parameters

can be expressed as:

where

is the influence coefficient matrix, and it can be calculated by differential or difference. By properly selecting the known parameters in

, the rank of

is guaranteed to be min (

).

If

is reversible, i.e.,

, then a

can be calculated and used to modify

to

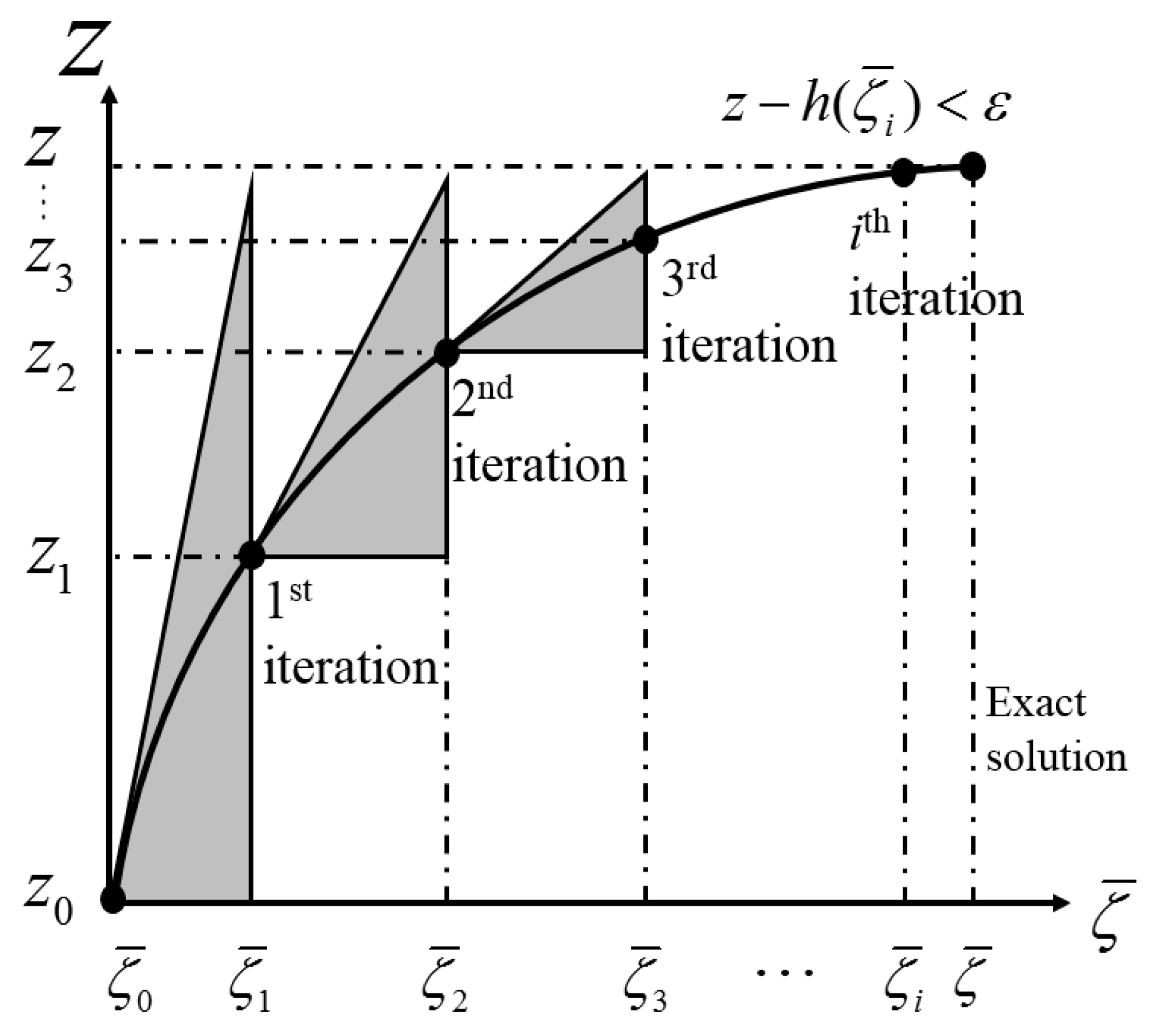

. The first iteration is described above, and the iterative process using the Newton–Raphson method is illustrated in

Figure 2.

After the ith iteration, a converged solution is obtained if the deviation between and is smaller than a threshold set . It is not difficult to find that the closer the guess of the to-be-adapted parameters to the exact solution is, the faster the calculation of the components’ actual characteristics is. Within the range of operating conditions, several pre-determined results are used to interpolate an appropriate guess. Thus, the converged solution can be obtained by no more than 50 iterations in practice.

In addition, the number of the known parameters

may not be equal to the number of the to-be-adapted parameters

. If

, Equation (3) is under-determined, which leads to an infinite number of solutions. While if

, Equation (3) is over-determined and there are redundant equations. In a least-squares sense, pseudoinverses can be defined as Equations (4) and (5), separately, to derive the best solution of these two cases.

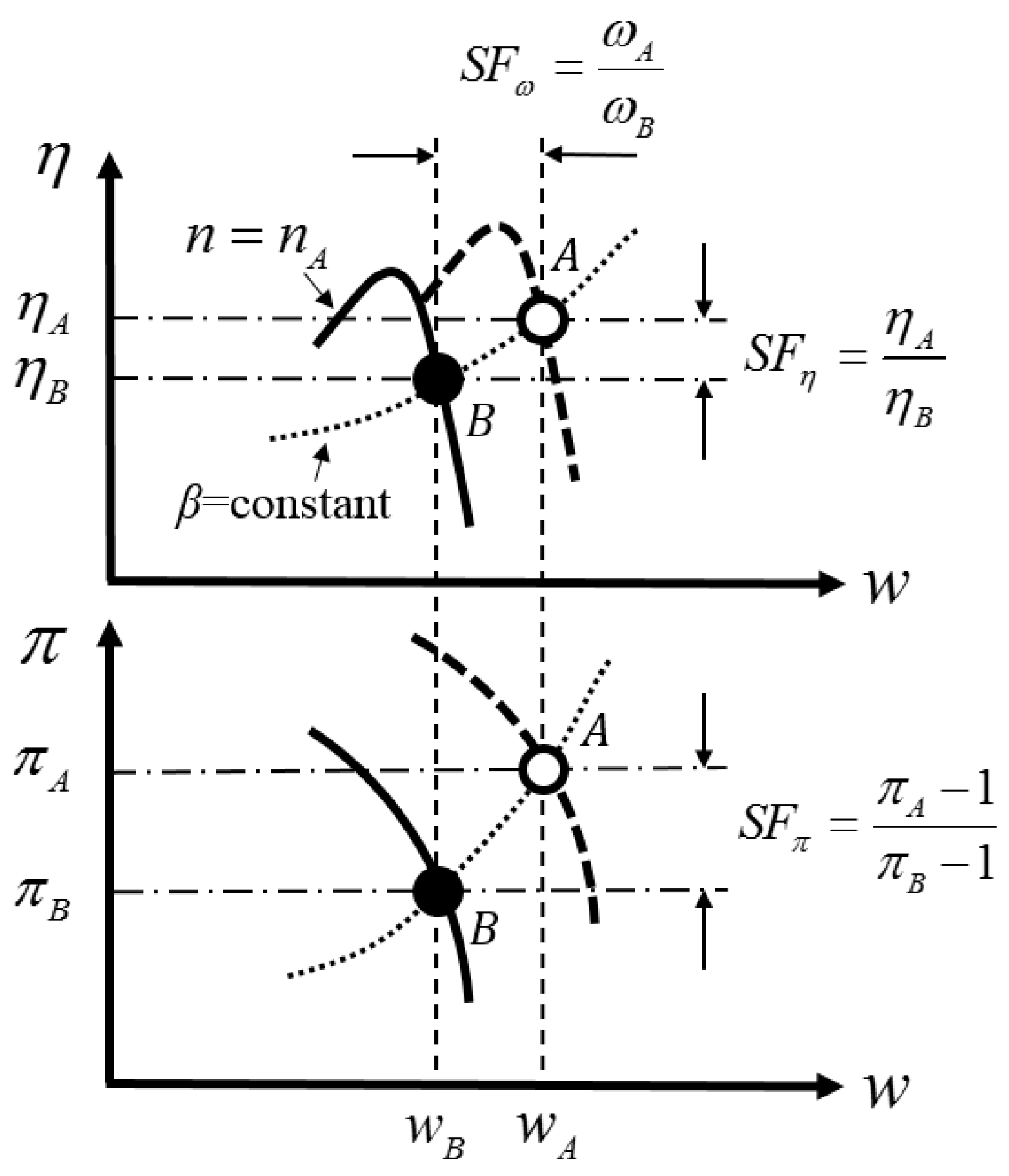

2.2. Scaling Factor Definition

Normally, the components’ actual characteristics do not comply with their nominal values. Taking a compressor characteristic map, for example, a hollow point A (

) that represents the calculated characteristics is not on the corresponding speed line where

, as shown in

Figure 3. To find the matching point on the map, a reasonable assumption, that the speed line

is shifted along a scaling line where the auxiliary map coordinate

is constant to pass through point A, is introduced [

37]. Under this assumption, a solid point B can be located at the intersection of the speed line and the scaling line.

A scaling factor (

) is defined to quantify the deviations between the actual characteristics and their nominal values [

38,

39,

40]. By comparing point A with point B, the

of compressors can be calculated:

The of turbines is similar to that of compressors and can also be determined by Equation (6). However, there is a slight difference: that the scaling line with constant is exactly the same line with constant pressure ratio, i.e., always holds in the turbines.

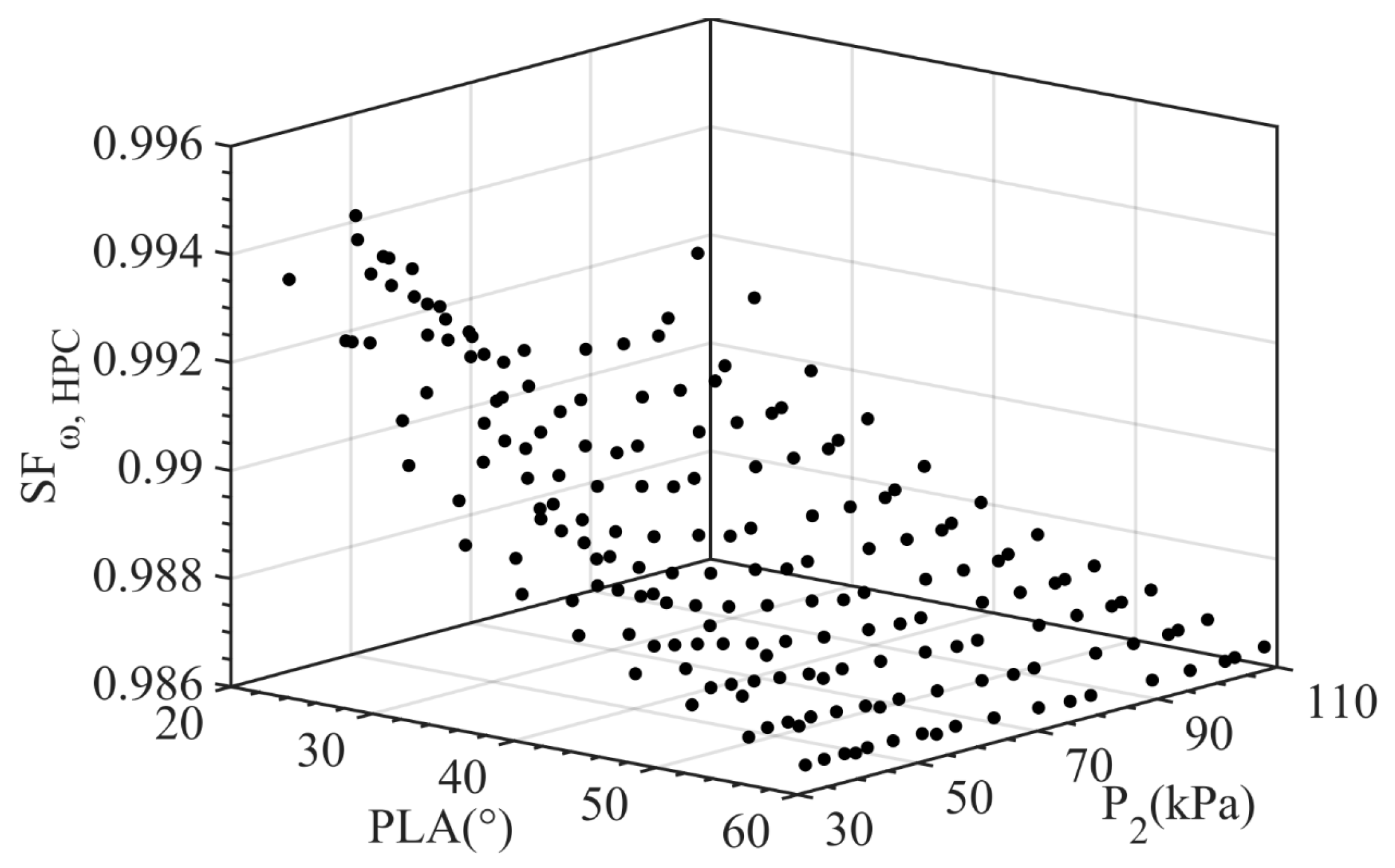

From its definition and calculation process, it is obviously revealed that the

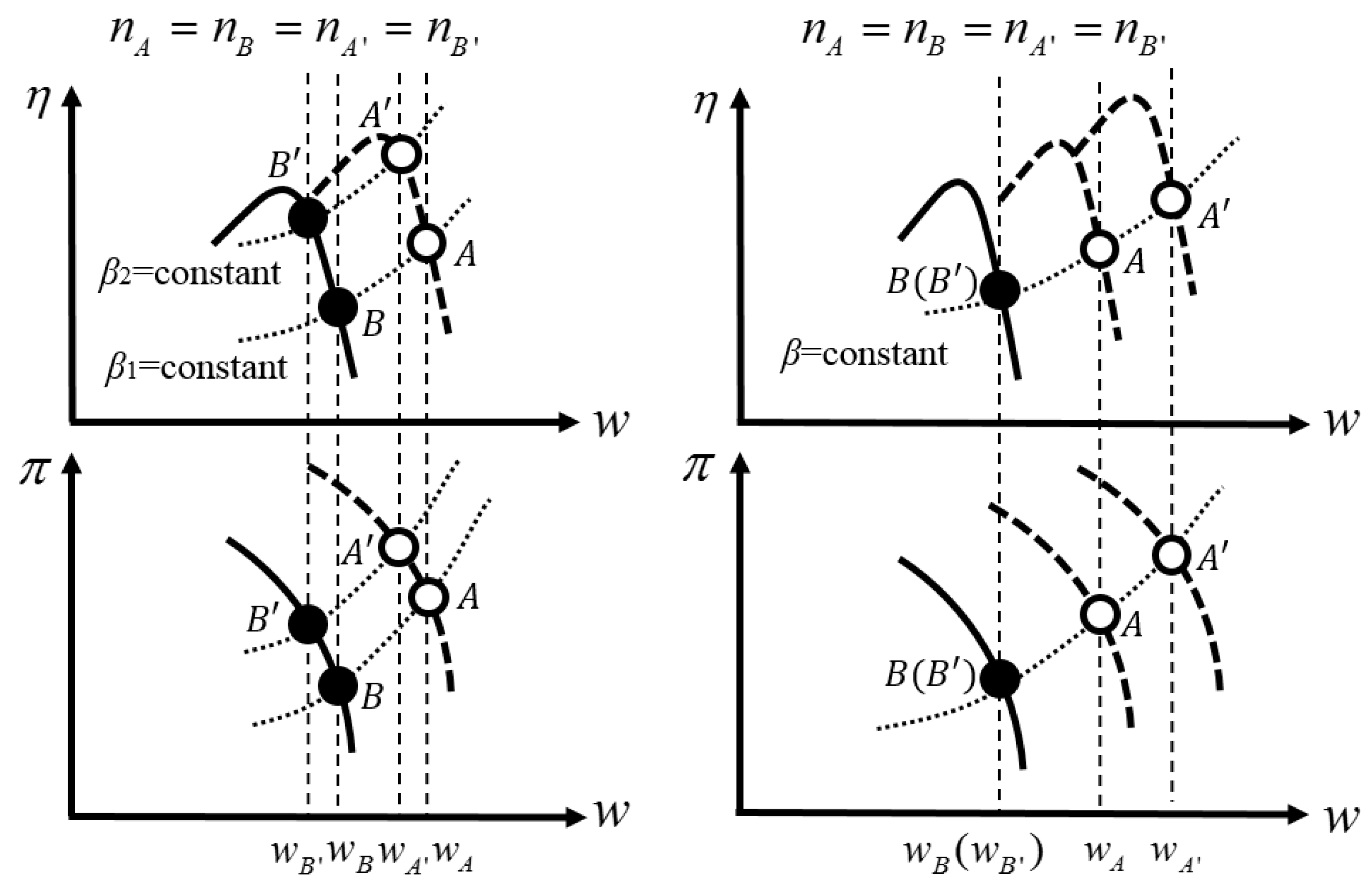

is related to the operating condition and degradation degree of the engine.

Figure 4 depicts the variation of the

caused by the variation of either the operating condition or the degradation degree on a compressor map. The left figure represents an example of the

changing with the operation condition when the degradation degree remains constant, while the right one is opposite. Therefore, the defined

represents the characteristic deviations at a certain operating condition and degradation degree.

Usually, engines degrade very slowly during a small temporal scale, such as a day or an hour, in its early life stage. It can be considered that the degradation degree keeps the same attribute. However, the engine’s operating condition varies significantly with the aircraft flight mission. Thus, the influence of the operating condition on the exceeds that of the degradation degree and becomes the focus of this paper below.

2.3. Scaling Factor Prediction

By introducing the

, Equation (1) can be rewritten as Equation (7):

where vector

contains the nominal values of each component’s characteristics, and vector

comprises the

of concerned components.

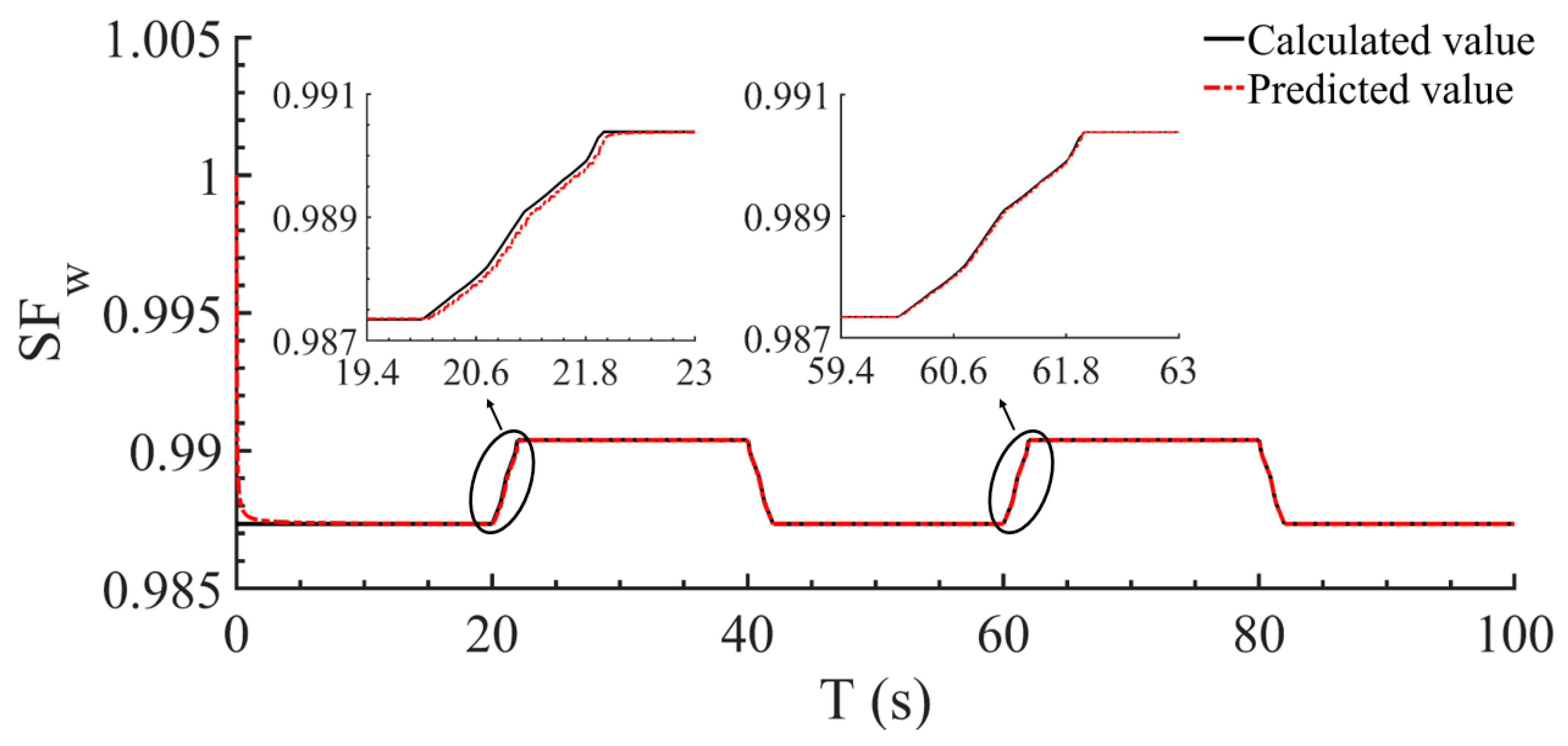

Undoubtedly, the can be seen as model tuners. When the engine is in deterioration, the actual components’ characteristics can be obtained by using the to modify ; thus, the degraded performance of the real engine can be estimated accurately.

However, the engine inevitably will vary its operating condition. When the operating condition changes, the calculation often corresponds to the operating condition several seconds prior due to the dynamic response of the measurable parameters. Then, employing the directly in Equation (7) would also cause hysteretic estimation results. For performance fast estimation, the at present operating condition should be acquired quickly.

Since the

relate to the operating condition, a mapping relationship for each

with the operating condition is constructed as Equation (8):

With the aid of the mapping relationship established, an algorithm with memory function is designed to predict the

at present operating condition. And the prediction problem of each

can be formulated as:

where

,

, and

mean the operating conditions and their corresponding

at the past time;

,

, and

are those at the present time.

The designed algorithm can be divided into two parts: the first is to store the historical data, i.e., , , and , and the second is to predict the at the present time.

During the engine’s operation, measurements are continuously generated. Thus, each can be calculated from the measurements continuously. The calculated together with its corresponding operating condition forms the mapping relationship as Equation (8) and is regarded as the historical data.

To store the historical data, a grid of is generated, where is the number of parameters in the operating condition, and is the intervals of each parameter divided in equal proportion. After normalization, the intervals of each parameter are expressed as , , …, . Then, each section of the grid can be characterized by the interval of parameters. For each group of , , and , which section of the grid it belongs to can be judged according to the parameters in and , and the value of the can be stored in this section. Each section has a storage space to record values and adopts a first-in–first-out principle.

To predict the at the present time, firstly the corresponding section according to the parameters in and are found, which is the operating condition at the present time. Then, the values in the section are read and the average as the at the present time is taken. When the section has no value, the value of the at the previous time is maintained. Then, the initial value of is set to 1. The prediction result will be transmitted to Equation (7).

By applying the algorithm in parallel multiple times, all the at present operating condition can be acquired. Thus, the in Equation (7) can be modified to the actual characteristics, and the engine performance can be estimated rapidly.

In terms of memory consumption, a double type number takes up 8 bytes. So, the max memory consumption of the algorithm is about kB. It is not difficult to find that the number of parameters has the greatest impact on the memory consumption.

Eliminating irrelevant variables can help to save memory and curtail the computational complexity [

41]. To reveal a concise relationship between the

and the operating condition, four cases are considered and summarized in

Table 1.

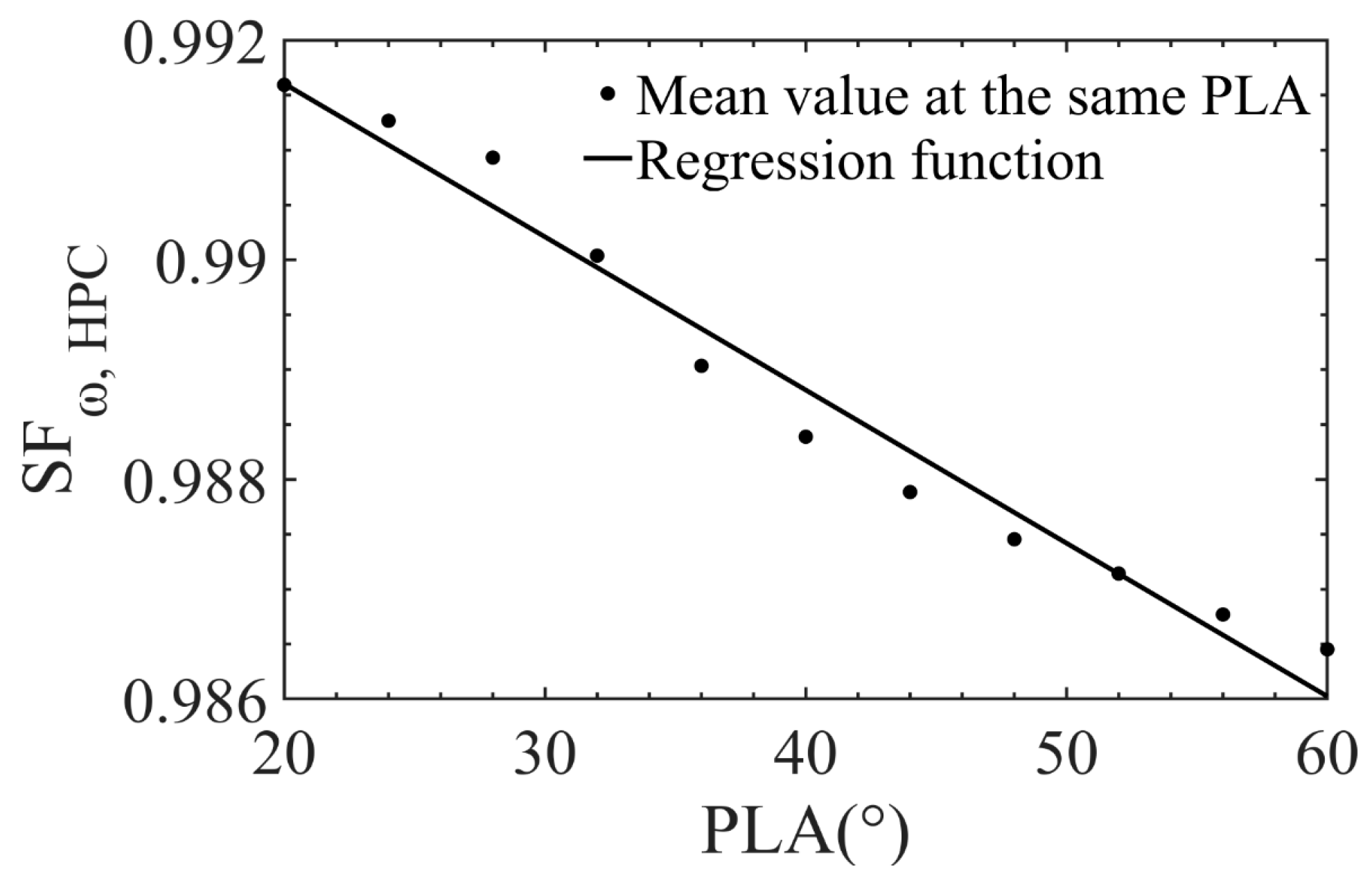

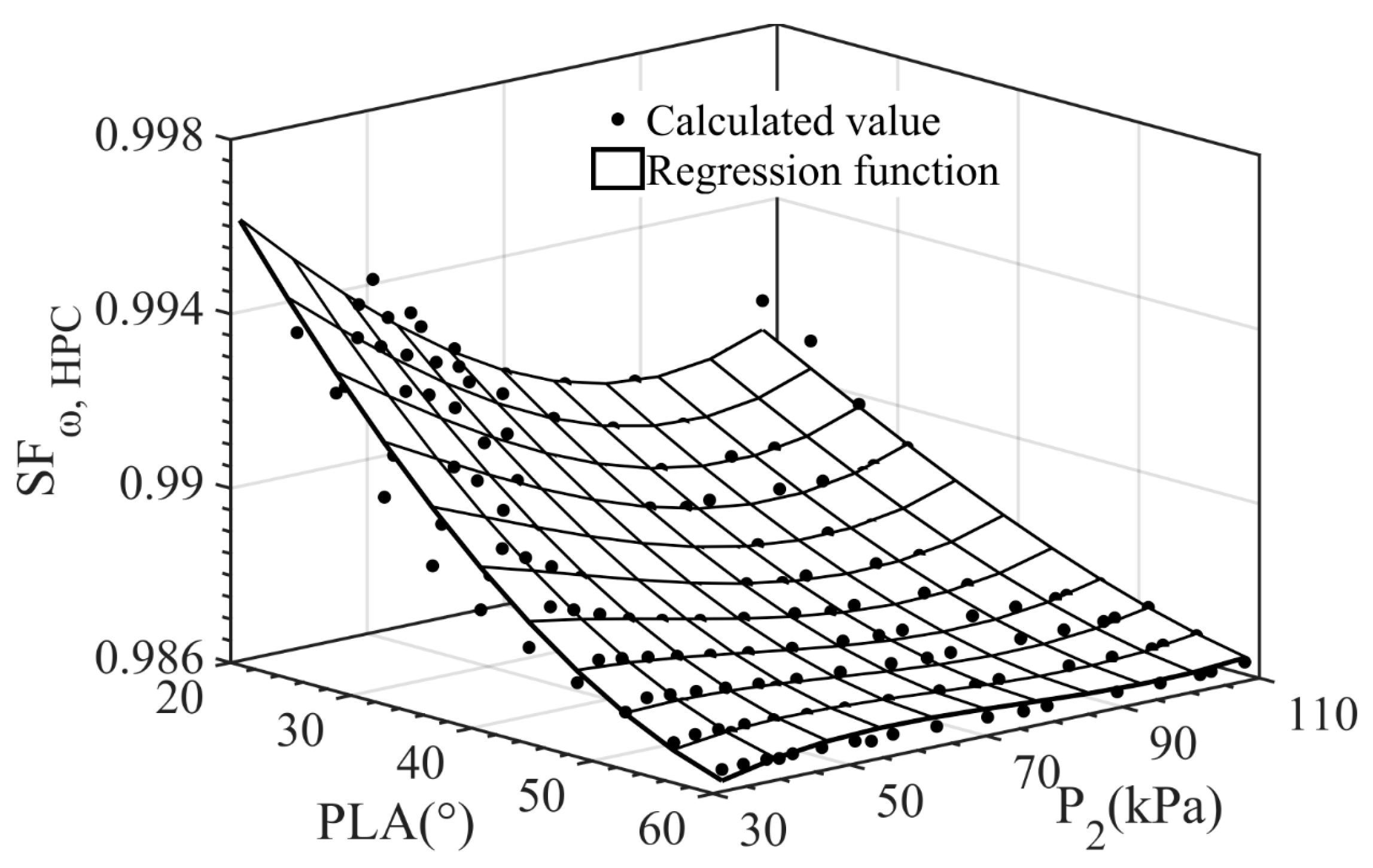

From Case 1 to Case 4, the operating condition in the mapping relationship is considered gradually comprehensive. In Case 1, neither nor is included, and the is regarded as a constant. Case 2 and Case 3, separately, select and of the operating condition to form the mapping relationship. With no simplification, both and are involved in the last case.

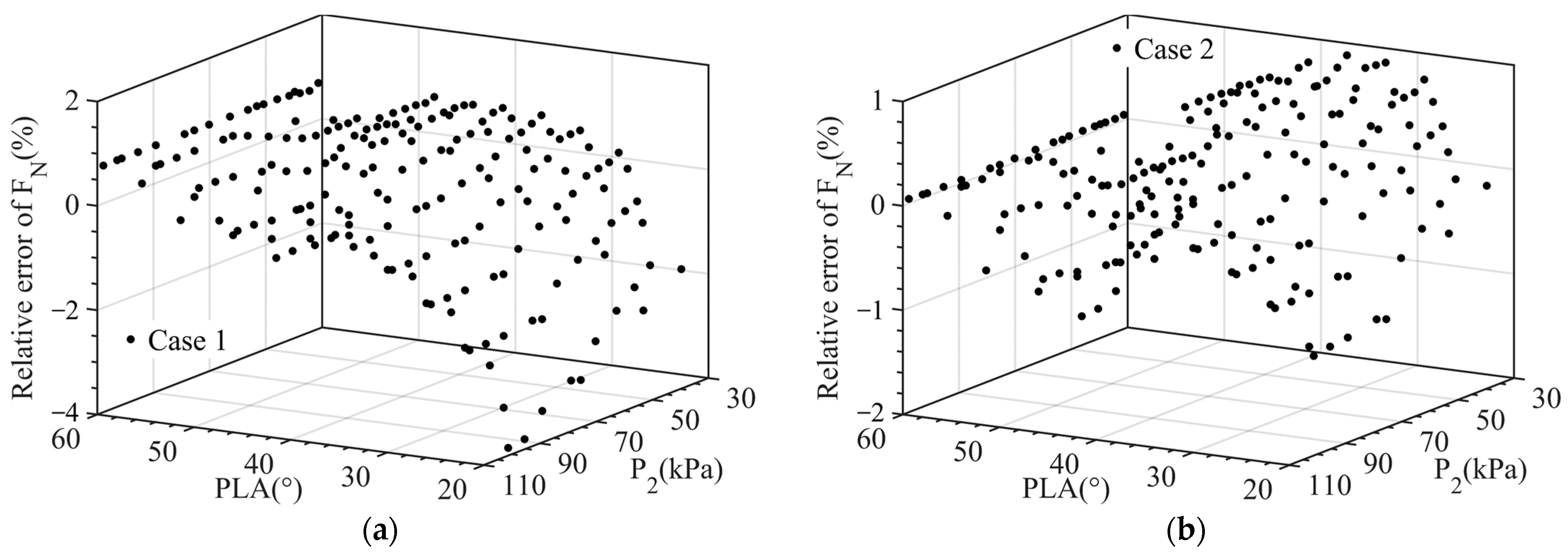

The case can be determined by comparing the estimation accuracy of multiple operating conditions. Specifically, each operating condition and corresponding calculated are reckoned as one sample, and these samples can form a dataset. In the dataset, revealing the mapping relationship of each case is a regression problem. Multivariate polynomial is adopted to solve it. The coefficient and order of the polynomial can be determined based on the least squares principle. All the polynomials will be used to calculate the again at these operating conditions, and, thus, the estimation results will be obtained for comparison.

2.4. Onboard Adaptive Model Framework

In combination with the contents of the above subsection, an aeroengine onboard adaptive model for performance fast estimation is established, the framework of which is shown in

Figure 5.

4. Conclusions

In this paper, an onboard adaptive model with fast estimation capability is proposed. Considering that a benchmark model can be adapted to the actual engine by employing some tuners, a component level model is constructed, and some scaling factors are introduced. The scaling factors can be derived from the measurements and are represented as mapping relationships with the operating condition. An algorithm with memory function is designed to rapidly obtain the scaling factors at the present operating condition. Finally, feeding the scaling factors to the benchmark model, the engine performance can be estimated accurately and quickly. Simulation scenarios are implemented to illustrate the effectiveness of the proposed model. The results are as follows:

(1) By employing the as the model tuners, the proposed model has high estimation accuracy at both single points and multiple points when the engine is in deterioration. The relative errors of the model are almost 0 at single points and no more than 0.66% at multiple points.

(2) The correlation between the and the operating condition is thoroughly considered. Representing the as a function of and can achieve a better estimation accuracy compared with other cases.

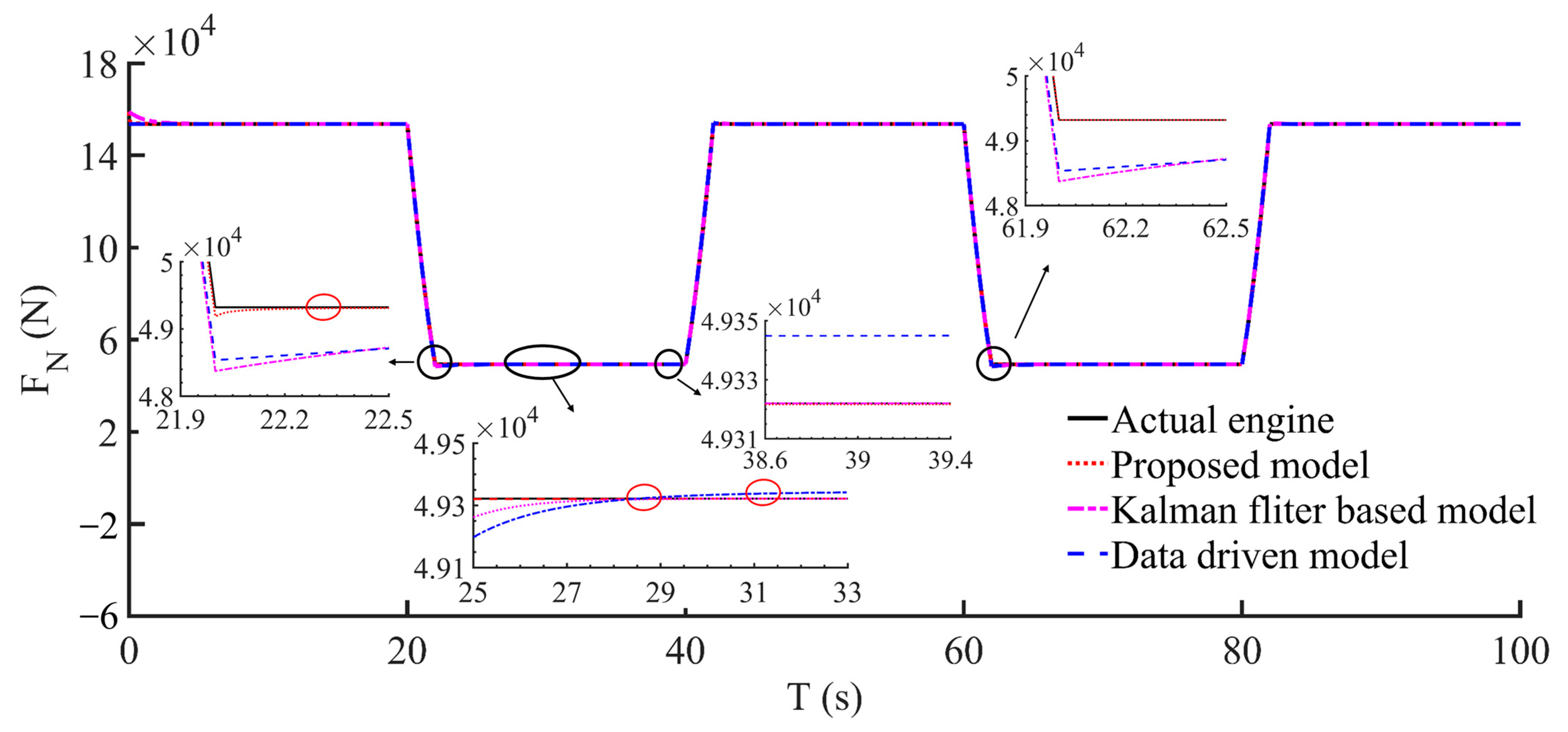

(3) Compared with the Kalman-based and the data-driven methods, the proposed model has smaller relative errors and shorter dynamic response time when the engine varies the operating state. With the aid of an algorithm with memory function, the proposed model can avoid repeated self-tuning processes.

Overall, all the results demonstrate that the proposed model has self-tuning and fast estimation capability and is a potential for application in engine control, monitoring, and diagnostics.