Abstract

This paper presents original research on the identification and modeling of quality requirements for structural products in aircraft structures. As the main objective of this research, the authors focused on identifying the relationship between the previously mentioned requirements and the technical knowledge necessary to improve the quality of the processes involved. This scientific paper presents research in terms of defining a global engineering process addressing, as a starting point, the requirements necessary to be met in the manufacture of structural products for the structure of aircraft. The authors have identified directions for improvement in the global engineering process which will certainly lead to the creation of a sustainable, competitive advantage for the organization where the research was conducted. Based on the concept of intellectual capital and its components, the authors developed a model of knowledge analysis related to the requirements in order to later develop knowledge matrices at the subprocess level. This research presents a pragmatic evaluation based on the experience of those involved, but also on a study focused on pre-modeling the knowledge necessary to be considered and involved in the global engineering process. After this desideratum, the relationship between knowledge–requirements, but also the relationship between requirements–knowledge, was achieved, establishing a direct connection with the global quality of the analyzed products from the perspective of streamlining the global engineering process. This research is based on an entire procedure of analysis and modeling of the processes and subprocesses considered that could lead to favorable results from an economic point of view, but also from a technical point of view, the recommendation being to implement those presented to increase the competitive advantage in the profiled market.

1. Introduction

Correlating product quality requirements with awareness in the global process is an original approach to quality management in an aerospace organization so that compliance with product requirements can lead to the efficiency of the aforementioned process and also to the effectiveness of the relationship between requirements and knowledge [1,2,3,4].

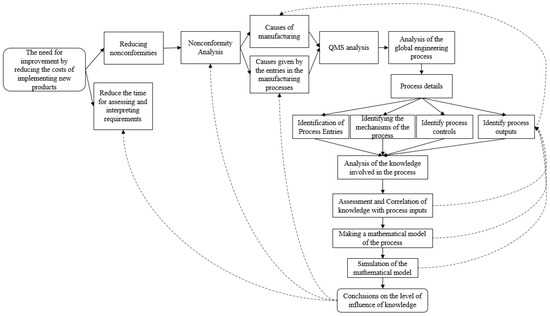

Figure 1 shows the approach of the relationship between product requirements in the context of the global engineering process, generated by the need to improve process quality in the organization where the research was conducted by reducing the costs of implementing new structural products. Regarding the structural products, reference works are mentioned [5,6,7,8,9,10,11,12].

Figure 1.

Plan to address the relationship between product requirements in the engineering process within an aerospace industry organization.

Following the financial analysis of the organization, in terms of production costs, two areas of improvement were identified related to engineering processes, namely reducing the number of nonconformities, and reducing the time of evaluation and interpretation of product quality requirements. The first direction, namely the reduction of nonconformities, is a direction that is supported by methods of the quality management system such as analysis of nonconformities, corrective actions, and continuous improvement; on the other hand, the second direction is not supported by such methods but rather depends on the way in which the management of knowledge and product quality requirements is carried out.

The specialized bibliography approaches knowledge management from a theoretical point of view and refers to the field of activity of the organization without going into the details within it. In this sense, the authors mentioned [13,14,15] produced work that deals with such matters.

This paper presents, in a detailed way, the place and role of the global engineering process but also all the technical and managerial aspects related to this subject, with an application within an industrial organization in the aerospace field.

This study originated from the need for quality improvements in an aerospace manufacturing organization which had to manage a large amount of product requirements during a transfer of work and industrialization process.

In the specific domain literature, there could not be identified a similar approach on the direct relationship between knowledge and product quality requirements. These subjects bring in the discussion from a general perspective.

The research can be considered as starting with the approach method on a product quality requirement breakdown and a direct connection to the engineering process deliverables. This approach provides a baseline for the engineering knowledge gap analysis for any industrial organization which intends to industrialize new products, as well as a starting point to develop the training plans to cover new requirements.

The main goal of this research is to provide a method, together with first versions of different analysis tools, that any engineering organization can use to scan its level of knowledge in relation to the products realized. In addition to applying these methods and tools, this study validates the method, at least in the research condition. Finally, this research opens new research directions.

The current manuscript is structured as follows. In Section 2, the theoretical framework is presented. In Section 3, the research methodology is described. In Section 4, the authors present the knowledge analysis in an aerospace industrial organization, and in Section 5 is presented the assessment of knowledge involved in the global engineering process and its relationship with product quality requirements. Finally, to conclude the paper, the principal conclusions of the study are made known, followed by the study limitations and future research.

2. Theoretical Framework

Developed countries are emerging economies, and they produce a lot of thanks to technological innovations, especially in the current era (i.e., in the era of Industrial Revolution 4.0, which means that all economic activities must develop technological innovations to increase the productivity of all activities) from economics [16]. The concept of open innovation and its sub-attribute of ecological innovation should be viewed through the lens of corporate governance and how managers make decisions about the application of research, development, and innovation [17].

Open innovation can lead to the elimination of shortcomings arising from inadequate knowledge [18,19]. Experience is a particularly important parameter of open innovation, as the relevant literature demonstrates. In fact, in experience-based companies, where innovation processes are based on technical knowledge, there is a positive correlation between the level of openness and the effectiveness of innovation [20].

The need for open innovation becomes more apparent when companies must address issues of environmental compliance, the need for modern technologies, the needs of customers, the need for effective communication with external stakeholders, and the need for new knowledge [21]. One of the main reasons companies adopt open innovation is that they find it hard to afford to innovate on their own [22].

Article [23] states that open innovation in companies through sustainable development includes business development, co-creation, knowledge management, mitigation of climate change and environmental impacts, ecosystems, decision-making, the economy, the cycle of life, and energy efficiency, which in turn are promising topics for future research and the achievement of industry goals. In an article [24] on the dynamics of open innovation, the authors identified a consumer behavior decision-making process that will help marketing managers create a marketing strategy that will make the consumer want to buy. In [25], the authors emphasize the fact that economic development measures that affect only the leading industries may have no other effect than the impact on the acceleration of economic growth. It is mentioned in [26] that the development of a dynamic culture of open innovation is important to achieve truly open innovation in public organizations, because in addition to legal and institutional barriers, cultural barriers must be overcome. If open innovation is implemented effectively, its momentum can lead to significant company growth [27].

According to the theory of open innovation [28], a holistic cognitive approach should allow a company to effectively explore internal knowledge and assimilate external knowledge about a dynamic environment [29,30,31]. On the other hand, innovation has been defined as a tool that “combines existing knowledge in new ways” [32,33], highlighting the limits and potential of the organization’s cognitive substratum to promote sustainability and innovation.

Until recently, knowledge was primarily perceived as something positive that organizations must deal with to get the most out of it. The development of the field of knowledge management has evolved into practices, processes, activities and other potential knowledge management tools and measures to support organizations in achieving this goal. So, organizations have focused on finding and developing the right knowledge and using it to their advantage.

Economics, organization, and management based on knowledge are commonly used concepts when we talk about new economic trends. This fact is mainly related to the knowledge revolution of the 21st century, which drew attention to knowledge, considered as the main element in ensuring the functionality and efficiency of organizations.

The availability of information and knowledge management guide corporate innovation processes towards greater competitive advantage.

Process management is recognized as a set of methods and techniques for discovering a business process, developing designs for this process, monitoring it through data measurement, and optimizing and automating the process using human, technological, and financial resources [34].

The entire process management life cycle requires innovation at every step to accelerate workflows [35]. Such innovations must also be closely aligned with organizational goals, namely exploration and exploitation, to meet the needs of ambidexterity in the digital knowledge economy. Knowledge-sharing among process teams, from the most experienced to the newcomers, is critical to the success of process management [36]. Article [37] also identified four project-based factors, including (1) task specialization, (2) knowledge transfer, (3) knowledge transformation, and (4) uncertainty and change management, which help to embrace ambidexterity.

Previous research has shown that some of the core elements of process management (e.g., strategic alignment, people, culture, and governance) play a vital role in the successful implementation of a business process [38]. For example, the organizational structure should support the organization’s adoption of process control at different hierarchical levels (e.g., board of directors, managers, and assembly-line workers) [39]. Similarly, an organization’s external environment (e.g., stakeholders, customers, and competitors) can influence the performance of process management when a new technology enters the market. Consequently, [40] summarized these contextual factors into four groups, namely goal-related, process-related, organizational factors, and environmental process management context factors. Repetition is also seen in studies of process management maturity models and their recommendations for achieving wider adoption of process management [41].

One of the most important aspects to consider is the current tendency of companies to focus on intensive knowledge and the capitalization of new ideas that lead to innovation. At the current stage of economic life, businesses can be built more on models of thinking than on models of their products and services offered. For an organization to be effective, it is equally important that the problem be questioned in terms of the effective distribution of products as well as the transformation of intangible assets in economic value. Finally, when products and services are postponed, competition in the market is measured from the point of view of intangible assets.

Intellectual capital becomes the main factor in the management of production and reproduction processes in the economic system. Of all the factors of production, the greatest added value was brought by the knowledge that was created. This knowledge, in the economic interpretation of a key factor, allows for the generation of benefits over a lengthy period, guaranteeing the competitive advantage of the company, and forms the basis of intellectual capital. This knowledge, combined with the potential of human skills, competencies, ideas, intuition, professional experience, working methods, and customer relations, is called intellectual capital [42,43].

Knowledge-based thinking provides a systematic and engaging direction for creative problem solving by integrating human, business, and technical factors with a focus on creating innovative solutions based on a user-centric perspective. An increasing number of companies and institutions is adopting this method of user-centric innovation, along with mindsets and toolkits [43,44].

3. Research Methodology

The research methodology used is a qualitative one, since the main objective of this research is to identify the factors which have the most impact on the relationship between knowledge, product requirements, and product quality. This research is based on case studies in an organization where the author faces engineering challenges with product requirements in daily activities. The study was planned in a longitudinal time horizon considering the distinct types of products that have been implemented in the manufacturing process. In addition, the data related to the products’ quality impacted by the engineering deliverables could be collected due to the traceability process implemented in the organizational study. Also, for every deliverable produced and for every product, information was collected from each engineering process, such as product number and revision, employee name, and creation and release dates. Knowing the name of the employee who realized the deliverables, periodic evaluation results for them, and results of nonconformity analysis, the matrix method was used to identify any areas where gaps of knowledge exist.

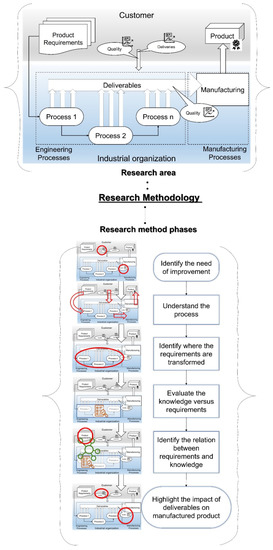

Figure 2 presents the scheme of research design which describes the processes and techniques for data collection and data analysis.

Figure 2.

Research design.

This paper’s objective is to highlight the importance of knowledge-level in the engineering process and the impact it has on the quality of manufactured products. All this is possible because the main manufacturing process input, next to materials, is engineering deliverables. Every misinterpreted product requirement is implemented in the manufacturing process, i.e., on products considered as requirements. Even if there is a quality control process in place, there are nonconform products realized that generate unnecessary cost.

4. Knowledge Analysis in an Aerospace Industrial Organization

The approach to intellectual capital within some industrial organizations is an extremely complex subject, and most studies in this field mention the need to establish the particularities of the study in making a relevant analysis of intellectual capital. The approach of intellectual capital in the context of research is focused on the analysis of this desideratum used in the global engineering process within an industrial organization in the field of aerospace. Without considering the concept of global intellectual capital and process management by correctly identifying which knowledge is needed, a pertinent analysis of the global engineering process and the mapping of this global process proposed in the research is not possible [45,46]. The aim was to follow a path of information in a global context and, at the same time, analyze each stage as a component part of the previously mentioned process.

The global engineering process we are referring to can be integrated into a quality management system that can bring about improvement in all requirements in the context in which we propose the application of continuous improvement.

The process we are referring to, being a functional process in a real industrial organization, is integrated in a quality management system, it being a “frozen” process, i.e., a process that can only be modified through a process of improvement according to the requirements of the quality management system. In the study we present, we considered that any process can be continuously improved by improving the capital of the intellect used in the process.

The engineering processes within industrial organizations in the analyzed industry have, as a mechanism, intellectual capital oriented towards the technical and managerial fields. Complementary to these areas, knowledge of the processes within the quality management system and communication knowledge were paramount due to the impact they can have on the development of processes.

It has been established what knowledge is to be evaluated in the global engineering process, and we propose an analysis model aimed at identifying all the knowledge that is involved in transforming product quality requirements.

The large volume of information generated by the multitude of activities throughout the process, being quite difficult to manage, motivated us, at this point in the research, to approach it in a structured and logical way.

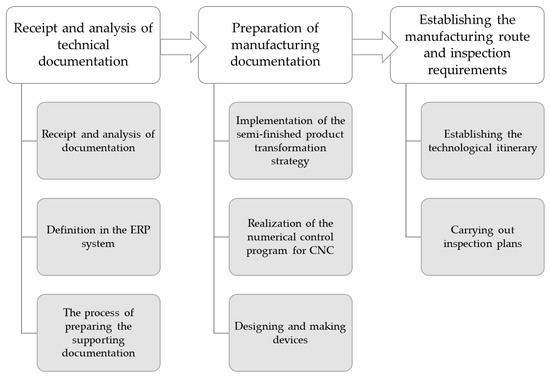

The global engineering process consists of eight main processes, structured in three groups. These groups have been designed based on the types of deliverables that these processes generate. Figure 3 shows how these processes were distributed.

Figure 3.

Grouping the component processes within the global engineering process.

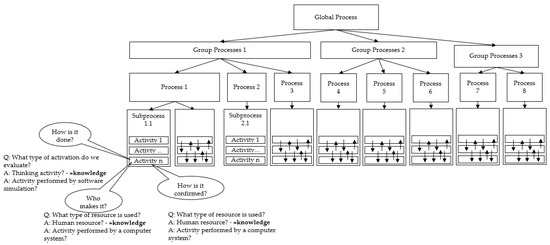

As shown in Figure 4, each process consists of subprocesses, which are performed by a sequence of activities. Identification of the knowledge used in these activities was achieved by asking three basic questions for each activity, namely:

Figure 4.

Model designed to detail the global engineering process.

- -

- How is the activity done?

- -

- Who performs the activity?

- -

- How is the deliverable confirmed, or how is the activity completed?

The model presented in Figure 4 is limited to the actual study context, considering a management perspective over the process. The grouping of the process is based on this specific study in one manufacturing organization. Of course, this can be adapted to any manufacturing organization based on its processes structure.

For a better understanding of the approach, presented below are the expectations of what is to be achieved after completing the questionnaire for the process.

The first question regarding how the activity is performed leads to obtaining the details of the activity from the point of view of the execution process of the activity, namely, a human-resource thinking activity or an activity of simulation and calculation of an application or equipment.

The second question regarding who performs the activity is complementary to the first question and obtains specific information on the type of resource that is involved in the execution of the activity.

The last question regarding how the deliverable is confirmed, or the completion of the activity, aims to identify how to control the activity, the type of resource needed to complete the deliverables, and the completion of the respective activities and processes.

The studied process, being an engineering process, is mainly oriented towards the use of human resources, i.e., the technical knowledge specific to the industrial field. The issue of human resources has been addressed in works such as [47,48].

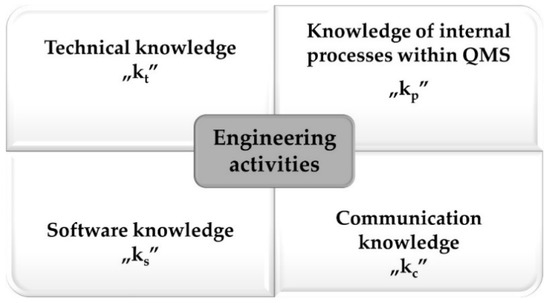

Following the application of the analysis model of the global engineering process, the knowledge necessary to carry out the activities within the engineering process can be identified according to Figure 5.

Figure 5.

Types of knowledge involved in engineering activities.

The four types of knowledge were considered because of how engineering activities can be executed. If any engineering activity is to be realized, the person who executes it must have technical knowledge to understand the product requirements as well as the organization’s capabilities. To transform the requirements into the deliverable required in the manufacturing process, software skills become necessary. Without knowing how the internal quality management systems work, knowing which procedure and traceability process is required to be followed in order to realize the deliverables can be considered nonconforming output to internal processes. All this knowledge is used to prepare the deliverable required for an organization; in addition, communication knowledge is required to assure that internal project planning is respected, and that any other organizational employee receives the correct and complete product requirements.

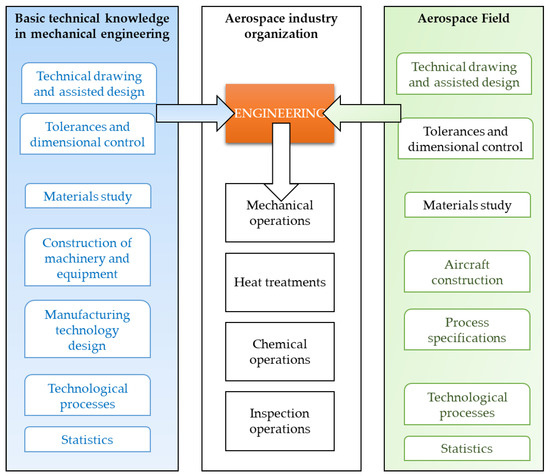

Technical knowledge (kt), in the industrial organization approached, is represented by knowledge of basic mechanical engineering and general knowledge of engineering.

In an organization with the field of activity aimed at the manufacture of structural components of aircraft, mechanical engineering knowledge is considered basic knowledge. The vast field of technical knowledge has been reduced to the manufacture of metal structural components in the aerospace field. Manufacturing issues are addressed in different research by [47,48,49,50,51]. According to Figure 6, in addition to the basic technical knowledge of mechanical engineering, for the realization of metal structural components, specific knowledge in the field of aerospace is also required. Some of this is complementary to general knowledge, bringing only the specificity of the field, such as:

Figure 6.

Types of knowledge used in aerospace industry organizations with a focus on the manufacture of mechanical structural components.

- Technical design, tolerances, and dimensional control—which bring particularities to the aerospace field;

- Study of materials—which only complements the basic knowledge with that on specific materials used in this field;

- Basic knowledge of technological manufacturing processes—which is also supplemented with knowledge of aerospace-specific technological processes, which is distributed in this field through so-called process specifications.

All this technical knowledge is used and developed in organizations through engineering processes, which is why this scientific paper is aimed at this area. Aspects regarding technical documentation are approached in different research by [52,53,54].

Knowledge of internal processes within the QMS (kp) manages activities in accordance with internal procedures and instructions. This is especially important because it concerns the management of product quality requirements from the point of view of the quality management system, as well as certain product quality requirements integrated into these procedures. Therefore, the proper conduct of processes and activities of organizations depends on compliance with these procedures. However, without this knowledge, the risk of making non-compliant products is higher. Ensuring knowledge at the level of all resources is achieved through:

- Regular training of resources followed by evaluations;

- Implementation of automation in applications used in organizational processes;

- Periodic auditing of processes, both internal and external.

Within all internal organizations, the quality management system provides, according to the standard AS9100D [55], guidance related to how the knowledge shall be gained and from which resources. Thus, the research in this study is intended to be a complement to these requirements with the aim of improving the approach to internal processes from the perspective of the necessary knowledge.

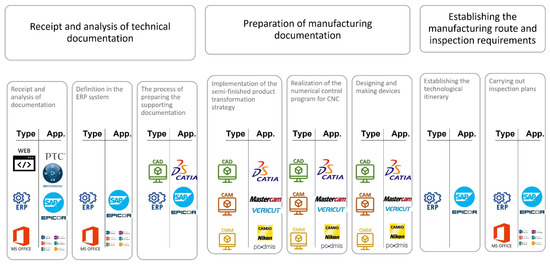

Software knowledge (ks) is needed to use and develop IT solutions to support the activities of the global engineering process. Nowadays, IT applications have taken over a large part of certain engineering activities, especially those of design, programming of numerically controlled mechanical processing machines, programming of measuring equipment, heat-treatment equipment, plastic deformation, automatic painting lines, etc. Aspects regarding the global engineering process in this context have also been identified in the literature, in works such as [56,57,58].

The software knowledge used in the global engineering process within industrial organizations in the field of aerospace is directly correlated with the IT applications used in this process. In this context, it is about:

- Knowledge of using PLM applications (Product Lifecycle Management), WEB (web platforms of PLM applications), and MS OFFICE (general communication applications and general information management);

- Knowledge of using ERP applications (Enterprise Resource Planning);

- Knowledge of using CAD applications (Computer Aided Design);

- Knowledge of using CAM applications (Computer Aided Manufacturing);

- Knowledge of using CMM applications (Coordinate Measuring Machine).

Similar aspects are presented regarding the aerospace field by [59,60,61].

For a better understanding of how to use applications in the global engineering process, Figure 7 presents the types of applications used in each individual process, as well as some examples of these applications.

Figure 7.

Distribution of the types of IT applications used in the global engineering process.

The level of knowledge regarding the use of these applications has a direct impact on the productivity and efficiency of activities within the processes. The higher the level, the shorter the time required for the activity, resulting in higher productivity. At the same time, a higher level of application knowledge builds on the ability of resources. In this way, the efficiency of the activity is ensured through the control and execution of the activity in relation to its entrances and exits.

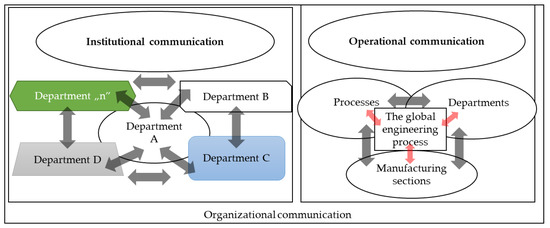

Through communication knowledge (kc), resources communicate within an organization and externally in relation to product quality requirements. In the analyzed bibliographical references, the subject is approached by [62]. This knowledge is important in this study because it is an important part of intellectual capital. At the same time, any activity within the engineering process that is performed by human resources also needs communication skills to streamline the entire process. Therefore, good communication regarding product quality requirements ensures a good transfer of information, i.e., a better interpretation of it.

The communication of information related to communication knowledge connected to product quality requirements refers to operational communication consisting of the messages within the organization that are transmitted for the realization of the operational plan.

Figure 8 represents graphically the area where communication applied in the global engineering process is found in relation to organizational communication.

Figure 8.

Locating the type of communication within the global engineering process related to organizational communication.

This communication, as mentioned above, is related to the requirements of the products within the process, but also outside it, in the context of operational communication.

The importance of this type of communication is evidenced by the impact it has on product quality requirements throughout the management process, from receiving the requirements from the customer, to interpreting them, to carrying out the manufacturing process, to controlling the requirements and certifying products in relation to customer requirements.

The communication skills used in the global engineering process in aerospace industry organizations are:

- Knowledge of the official language of the field used in the transmission of product requirements, namely, English;

- Knowledge of the formulation of internal requirements always using references to documented and authorized information;

- Knowledge of the level of detail that must be contained in a message, depending on the recipient of the message.

An example is presented of communication to senior management regarding the stage of implementation of some products for which an implementation delay is due to interpretation of the requirements regarding the achievement of the mechanical properties of the materials and the way in which they are verified. This communication is not appropriate since the message does not transmit information about the stage and also includes certain details that are not required. This example can have an impact on product quality requirements for on-time delivery through the ability of the message to generate product de-planning because of the lack of information on the real stage of the product implementation process within the organization.

Communication skills are a difficult topic for industry organizations to address because they are acquired with professional experience. Therefore, organizations that are at the beginning of the road most often encounter this lack of knowledge [63,64,65,66]. Of course, in addition to these types of communication skills, there are many others that have an impact on the organization but are not the subject of this study.

In this phase, we established the types of knowledge generally used in the global engineering process. Next, we analyzed the activities that generate the process deliverables with the greatest impact on the whole process and on the product quality requirements.

The proposed model for the analysis, evaluation, and relation of the knowledge involved in the global engineering process, aims to:

- Identify the distribution of types of knowledge in the process;

- Highlight that knowledge with the greatest impact on the process;

- Highlight that knowledge with the greatest impact on the quality requirements of the products managed by the process.

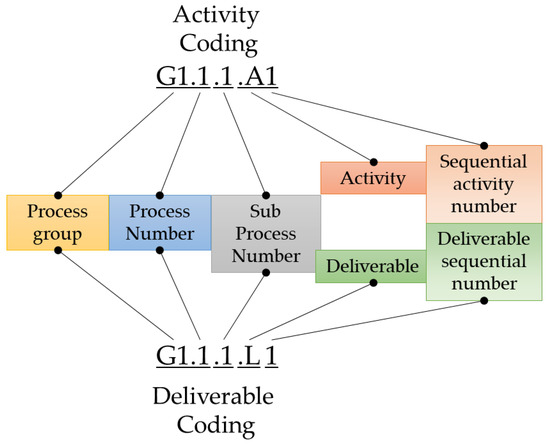

The structuring of the information and its coding have the role of facilitating identification of those activities and deliverables that are of interest from the total activities that are carried out within the organization. The code of each activity is performed according to Figure 9.

Figure 9.

Activities and deliverables codification.

Table 1, Table 2, Table 3 and Table 4 show the activities of the subprocesses involved in the global engineering process, as they are carried out in an industrial organization in the field of aerospace. Among the bibliographical references in which the subject of process modeling is touched, this work is mentioned [67,68,69,70].

Table 1.

Description of the activities of process groups G1.1 and G1.2.

Table 2.

Description of the activities of process groups G1.3 and G2.4.

Table 3.

Description of process group activities G2.5 and G2.6.

Table 4.

Description of the activities of process groups G3.7 and G3.8.

For each activity, the types of knowledge necessary to carry it out were identified. A code has been assigned to each category of knowledge, which will be used later in the mathematical model of the global engineering process.

Following the analysis of the data presented (Table 1, Table 2, Table 3 and Table 4), it was found that the overall engineering process consists of a considerable number of corresponding subprocesses and activities (Table 5).

Table 5.

The content of the global engineering process in terms of the number of processes, subprocesses, activities, and deliverables.

Identification of the types of knowledge was accomplished through analysis of the procedures and work instructions within the global engineering process. The functioning of the global engineering process in industrial organizations with a field of activity in the processing of structural components in the aerospace field is based on the knowledge of the resources involved in this process. The level of knowledge available regarding the process at a given time has a direct impact on the products, which are the result of the implementation of the knowledge-based thinking process.

Thirty-six categories of technical knowledge used in the global engineering process were identified. This technical knowledge is grouped into three different categories:

- General technical knowledge of the manufacture of metal products;

- Technical knowledge of aerospace structural products;

- Technical knowledge of aerospace-specific manufacturing processes.

The general technical knowledge of the manufacture of metal products involves the aspects presented in Table 6.

Table 6.

List of general technical knowledge required for the global engineering process.

The technical knowledge of structural products in the field of aerospace involves the aspects presented in Table 7.

Table 7.

List of technical knowledge of aerospace structural products.

Technical knowledge on aerospace-specific manufacturing processes is presented in Table 8.

Table 8.

List of technical knowledge of aerospace-specific manufacturing processes.

Following the analysis of these issues, the knowledge regarding the internal processes within the quality management system was identified as being related to the component processes/subprocesses of the global engineering process.

This result is obvious, since the organization is certified from the point of view of the quality management system. In this context, the types of knowledge presented in Table 9 were identified.

Table 9.

List of QMS process knowledge.

Knowledge of IT applications plays an important role in the global engineering process since it provides the human resources involved in this process, the computing power, and the tools necessary for the design of manufacturing technologies and technical and commercial data management within organizations. In this context, the knowledge of various IT applications as presented in Table 10 was identified.

Table 10.

Software knowledge list.

Communication skills are also the subject of this study. This knowledge is a factor in influencing product quality requirements because, in industrial organizations and especially in the global engineering process, the transmission of incorrect information regarding product quality requirements between the resources involved can directly alter the deliverables of component processes. Therefore, only three categories of knowledge presented in Table 11 were identified.

Table 11.

List of communication knowledge.

Communication skills are found in all processes, subprocesses, and activities of the global engineering process. Through the analysis of the global engineering process, it was found that the industrial organization has developed its own language of communication, using very specific technical terms and references. Similar issues regarding industrial organizations are also addressed by [71,72].

For a better understanding of how knowledge is involved in the component activities of the global engineering process, the knowledge involved for each individual activity was identified following the study of this process. Thus, approaching each subprocess with the component activities, one can observe the variety of technical knowledge involved as well as the presence of each category of knowledge.

5. Assessment of Knowledge Involved in the Global Engineering Process and Its Relationship with Product Quality Requirements

Regardless of the field of activity, industrial organizations need a period during which they can gain the knowledge necessary to understand and interpret the requirements of product quality.

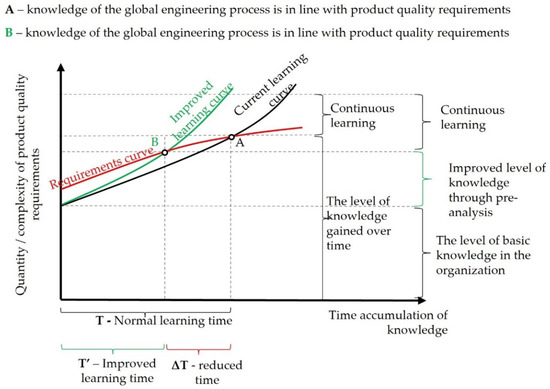

Figure 10 represents the author’s point of view about knowledge accumulation over time inside of an organization after multiple interactions with product requirements.

Figure 10.

Interaction of product quality requirements with knowledge of industrial organizations.

According to Figure 10, this time may vary depending on the level of basic knowledge and complexity, or, in other words, the level of product quality requirements.

This study raises the issue of identifying the possibility of improving knowledge within industrial organizations within a shorter period and with higher efficiency.

In Figure 10, point “A” is the point of intersection between the product quality requirements curve and the learning curve, at which point, at time interval “T”, the level of knowledge within the organization is equal (according) to the product quality requirements. Reducing the learning time ΔT to the interval T’ can be achieved only by optimizing the method of accumulating knowledge within organizations. Thus, the intersection point of the product quality requirements curve and the improved learning curve can be obtained at a shorter time interval, T’. From this, it can be deduced that the moment when the requirements are correlated with the knowledge of the organization is critical for reducing the type of assimilation. The efficiency of this relationship is directly related to the level of detail of the requirements and knowledge in the shortest possible time.

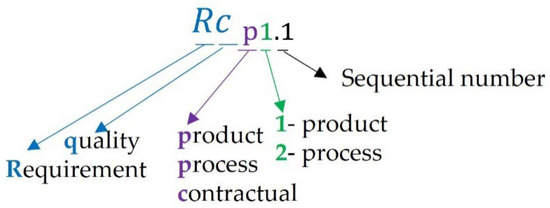

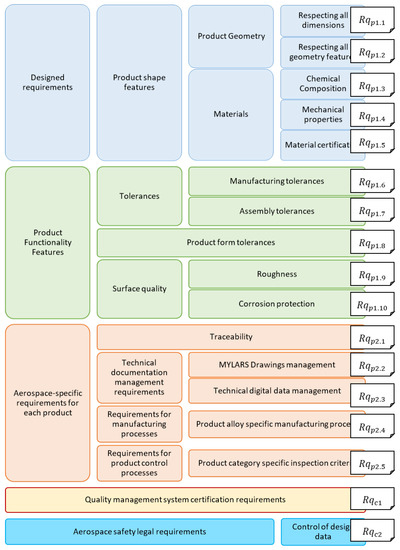

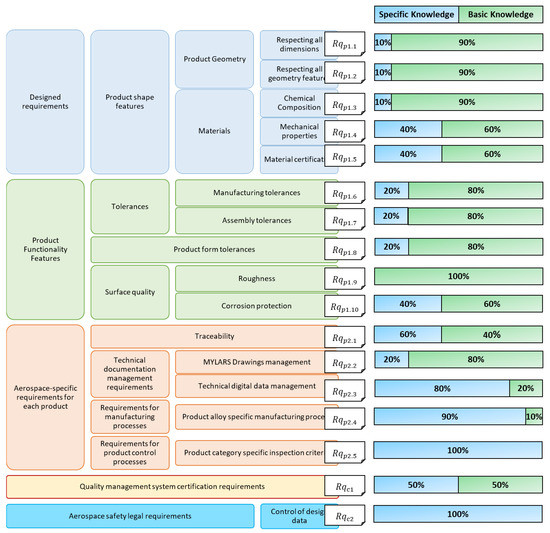

The quality requirements of aerospace structural products used in this study cover all common requirements for these types of products. Thus, starting from the four broad categories of structural product quality requirements, the use of level IV detailing was considered to correlate them with the knowledge involved in the global engineering process. Their coding was performed according to the coding scheme in Figure 11.

Figure 11.

Coding of aerospace structural product quality requirements.

To be manufactured, the quality requirements of the products must contain at least the design requirements (shape, dimensions, and material tolerances). In addition, in the aerospace industry, they are also defined as:

- Aerospace-specific product quality requirements;

- Product manufacturing requirements in an organization with a certified quality management system;

- Legal requirements for passenger safety in the field of aerospace.

The purpose of the detail in Figure 11 is to define those requirements common to all metal structural products in the field of aerospace. This grouping has been done according to how these requirements are used to prepare deliverables in the global engineering process within industrial organizations in the field of aerospace.

The relationship between product quality requirements and the knowledge involved in this process is based on the following criteria:

- The requirement is used in the subprocess to achieve deliverability.

- The requirement is used in the activity to be evaluated and transferred to the next activity or subprocess.

- The requirement is used in the manufacturing process for the physical realization of the product.

- The requirement is used in quality-control processes.

After identifying the interaction between the quality requirements and the knowledge involved, it is much easier to assess the knowledge.

This knowledge consists of two components:

- Basic knowledge;

- Knowledge specific to the products being made.

Basic knowledge is acquired through learning in educational institutions. In this study, we limit ourselves to technical institutions—engineering. Thus, it is considered that most of the quality requirements of metal structural products in the aerospace field are covered by approximately 62% of the knowledge acquired through learning in the profile institutions. This assessment is based on a comparison of knowledge of aerospace-specific requirements with those generally applicable in the industrial field of metal products.

The distribution of the two types of knowledge within the requirements of the quality of structural products creates the possibility to verify the degree of influence of the knowledge on the requirements in the global engineering process when the deliverables are created. It also gives organizations the opportunity to analyze new product requirements in relation to the capabilities of the global engineering process.

Global engineering process capability represents the ability to transfer product quality requirements into process deliverables for the realization of products through manufacturing processes within the limits of all quality requirements received from customers. This capability is related to the knowledge available at some point in the process. Therefore, the more the knowledge in the processes covers the requirements of the product quality, the better the process capability.

Approaching the relationship between product quality requirements and the knowledge available within organizations either creates directions for improving knowledge or demonstrates the ability of the process to transfer the requirements communicated by customers in the manufacturing process to make the products (Figure 12).

Figure 12.

Levels of aerospace structural product quality requirements and their coding.

In Figure 13, the split of basic knowledge was made by taking into consideration the technical requirement characteristics, such as the general knowledge learned in a technical high school or college. There is an approximation considered as a point of reference, which was reviewed in the study during the knowledge evaluation directly related to product requirements. Of course, the values can be considered only in the study case presented in this research. Still, there are a few research directions on this subject which were developed in future research.

Figure 13.

Estimation of the proportions of knowledge in the global engineering process on the quality requirements of structural metal products.

This approach also greatly helps the process of analyzing product nonconformities, providing a direct channel from noncompliance with a requirement to the process or the processes that have had a direct influence on these requirements.

To be able to analyze the level of influence of the global engineering process on product manufacturing processes or, in other words, on product quality, the mathematical determination of the influence of knowledge on deliverables is the first step and will be the subject of further research.

6. Conclusions

As a theoretical contribution to this scientific work, the authors highlighted the relationship between knowledge and product quality, which is well-known, and all of us are trying to improve the quality by accumulating increased knowledge.

Still, a practical implication of the research shows one of the shortest paths in the improvement process—improvement of knowledge in relation to product requirements which are interacting within a noticeably brief time.

This paper represents an important part of the author’s doctoral thesis. Experience in the author’s structural parts manufacturing process organization supports a pragmatic view of how knowledge is managed to be developed to achieve high-quality products in today’s large, competitive aerospace industry market.

Another practical implication of the research addresses the relationship between product quality requirements and global engineering process knowledge through an ordinal approach to product requirement management from the perspective of engineering processes within aerospace industry organizations. In this context, directions for improvement related to engineering processes have been identified.

In this scientific paper, the efficiency of manufacturing processes has been practically approached from the perspective of engineering processes within organizations by achieving high-quality deliverables used in manufacturing processes.

Theoretically, the knowledge involved in the overall engineering process has been identified, for each individual activity, to practically create opportunities to evaluate and improve the process from different perspectives and is analyzed in this important study.

The entire study highlights the risk of misinterpreting the product requirements due to organizational knowledge being misaligned with them. The goal of this study was to make obvious that all requirements together must be understood and linked to organizational knowledge. The approach of the study, as explained in Figure 2, was to capture the logical research approach, guiding the researcher and filed engineers/managers whenever there were needs for improvements.

In the field of aerospace, due to the magnitude of both the volume and the complexity of the product requirements, the deliverables required for the manufacturing process require additional effort in terms of knowledge and methods by which they are made.

The identification of the deliverables of the manufacturing process was made by analyzing practically the quality management system and identifying the global engineering process.

Practically, the global engineering process of an industrial aerospace organization was detailed and analyzed using classical methods of analysis. Starting from the approach of intellectual capital, a model of knowledge analysis in the industrial organization was developed, the diversity of knowledge at the level of the organization’s processes was analyzed, and the knowledge matrices at the level of subprocesses were drawn up.

Three large groups of processes were identified, each consisting of eight processes. All eight processes consist of 19 subprocesses and 70 activities each. All this together generates a total of 23 deliverables needed for manufacturing processes, and more. In this context, the challenge was to determine which deliverables can streamline manufacturing processes the fastest and at the lowest cost.

To this end, a tool has been practically developed to analyze the influence of quality requirements on the deliverables required for manufacturing processes when making products.

The analysis of the interdependencies of deliverables at the time of their realization in the global engineering process led to the practical identification of deliverables with the greatest influence on the quality of the final product. The deliverable with the greatest influence has been identified as the 3D model of the finished part. Once the deliverables of the global engineering process were identified, their relationship with product quality requirements favored localization of the interactions between the processes, subprocesses, and, respectively, the activities of the global engineering process, with the product quality requirements.

This analysis ultimately led to the identification of the types of knowledge required in the global engineering process directly related to product quality requirements.

One aspect worth considering was the assessment of the knowledge involved in the overall engineering process and its relationship with product quality requirements.

This assessment is the preamble to the analysis of the level of influence of the global engineering process on product manufacturing processes or, in other words, on product quality, which may lead to the mathematical determination of the influence of knowledge on deliverables to be made in subsequent research.

This paper is part of a case study on real manufacturing organizations which face real issues in managing product quality requirements and how these are converted into deliverables and respectively into physical products. The issue being generated thereby is the level of knowledge.

Therefore, the conclusions drawn after the completion of this scientific research highlight the fact that the subject is a topical one among organizations with activity in the aerospace industry and, at the same time, opens new fields of research that can bring competitive and strategic advantages to companies.

Author Contributions

Conceptualization, G.I.P. and A.M.T.; methodology, A.M.T.; software, G.I.P. and A.M.T.; validation, A.M.T.; formal analysis, A.B.P.; investigation, G.I.P. and A.M.T.; resources, G.I.P.; data curation, G.I.P. and A.M.T.; writing—original draft preparation, G.I.P. and A.M.T.; writing—review and editing, A.B.P.; visualization, A.M.T. and A.B.P.; supervision, A.M.T.; project administration, G.I.P. and A.M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Luna, J.; Addepalli, S.; Salonitis, K.; Makatsoris, H. Assessment of an emerging aerospace manufacturing cluster and its dependence on the mature global clusters. Procedia Manuf. 2018, 19, 26–33. [Google Scholar] [CrossRef]

- López Pascual, J.; Rodríguez, M.; Juan, C.; Rambaud, S.C. The Enhanced-Earned Value Management (E-EVM) Model: A Proposal for the Aerospace Industry. Symmetry 2021, 13, 232. [Google Scholar] [CrossRef]

- Liang, K. A global-local finite element analysis of hybrid composite-to-metal bolted connections used in aerospace engineering. J. Cent. South Univ. 2017, 24, 1225–1232. [Google Scholar] [CrossRef]

- Mary, R. Think Global, Lead Local: A Case Study on the Global Leadership Knowledge, Skills, and Abilities Implemented in an Aerospace Organization. Ph.D. Thesis, City University of Seattle, Seattle, WA, USA, 2020. [Google Scholar]

- Andriy, V.G. Aeronautical and Aerospace Material and Structural Damages to Failures: Theoretical Concepts. Int. J. Aerosp. Eng. 2018, 7, 4126085. [Google Scholar]

- Boeing. Boeing: 787 Dreamliner. 20 04. 2021. Available online: http://www.boeing.com/commercial/787/#/design-highlights/visionary-design/composites/advanced-composite-use (accessed on 1 August 2021).

- Airbus. AIRBUS Passenger Aircraft—A350 XWB. 20 04. 2021. Available online: http://www.airbus.com/aircraftfamilies/passengeraircraft/a350xwbfamily/ (accessed on 1 August 2021).

- Quintiere, J.G.; Walters, R.N.; Crowley, S. Flammability Properties of Aircraft Carbon-Fiber Structural Composite; Technical Report, Report no. DOT/FAA/AR-07/57; Office of Aviation Research and Development, Federal Aviation Administration: Washington, DC, USA, 2007.

- Sengupta, P.; Manna, I. Advanced High-Temperature Structural Materials for Aerospace and Power Sectors: A Critical Review. Trans. Indian Inst. Met. 2019, 72, 2043–2059. [Google Scholar] [CrossRef]

- Iliopoulos, A.; Jones, R.; Michopoulos, J.; Phan, N.; Singh Raman, R.K.S. Crack Growth in a Range of Additively Manufactured Aerospace Structural Materials. Aerospace 2018, 5, 118. [Google Scholar] [CrossRef]

- Exarchos, D.A.; Dalla, P.T.; Tragazikis, I.K.; Dassios, K.G.; Zafeiropoulos, N.E.; Karabela, M.M.; De Crescenzo, C.; Karatza, D.; Musmarra, D.; Chianese, S.; et al. Development and Characterization of High Performance Shape Memory Alloy Coatings for Structural Aerospace Applications. Materials 2018, 11, 832. [Google Scholar] [CrossRef]

- Mansour, A. Investigating the Compressive Strength of CFRP Pre-Preg Scrap from Aerospace Industries: Compression Molding. In Proceedings of the Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 26 March–10 April 2019; pp. 1–6. [Google Scholar]

- El Souri, M.; Gao, J.; Owodunni, O.; Simmonds, C.; Martin, N. Improving Design for Manufacturing implementation in knowledge intensive collaborative environments: An analysis of organisational factors in aerospace manufacturing. In Proceedings of the 2017 IEEE Technology & Engineering Management Conference (TEMSCON), Santa Clara, CA, USA, 8–10 June 2017; pp. 448–454. [Google Scholar]

- Garre, P.; Nikhil Bharadwaj, V.V.S.; Shashank, P.S.; Harish, M.; Dheeraj, M.S. Applying lean in aerospace manufacturing. Mater. Today Proc. 2017, 4, 8439–8446. [Google Scholar] [CrossRef]

- Gao, J.; Bernard, A. Product development. Int. J. Adv. Manuf. Technol. 2018, 94, 1545–1550. [Google Scholar] [CrossRef]

- Saleh, H.; Surya, B.; Ahmad, D.A.; Manda, D. The Role of Natural and Human Resources on Economic Growth and Regional Development: With Discussion of Open Innovation Dynamics. J. Open Innov. Technol. Mark. Complex. 2020, 6, 103. [Google Scholar] [CrossRef]

- Asensio-López, D.; Cabeza-García, L.; González-Álvarez, N. Corporate governance and innovation: A theoretical review. Eur. J. Manag. Bus. Econ. 2019, 28, 266–284. [Google Scholar] [CrossRef]

- Aguilera-Caracuel, J.; Ortiz-de-Mandojana, N. Green Innovation and Financial Performance: An Institutional Approach. Organ. Environ. 2013, 26, 365–385. [Google Scholar] [CrossRef]

- Hung, K.-P.; Chou, C. The impact of open innovation on firm performance: The moderating effects of internal R&D and environmental turbulence. Technovation 2013, 33, 368–380. [Google Scholar] [CrossRef]

- Zhao, S.; Sun, Y.; Xu, X. Research on open innovation performance: A review. Inf. Technol. Manag. 2016, 17, 279–287. [Google Scholar] [CrossRef]

- Yang, D.; Wang, A.X.; Zhou, K.Z.; Jiang, W. Environmental Strategy, Institutional Force, and Innovation Capability: A Managerial Cognition Perspective. J. Bus. Ethics 2019, 159, 1147–1161. [Google Scholar] [CrossRef]

- van de Vrande, V.; de Jong, J.P.; Vanhaverbeke, W.; de Rochemont, M. Open innovation in SMEs: Trends, motives and management challenges. Technovation 2009, 29, 423–437. [Google Scholar] [CrossRef]

- Cano, J.; Londoño-Pineda, A. Scientific Literature Analysis on Sustainability with the Implication of Open Innovation. J. Open Innov. Technol. Mark. Complex. 2020, 6, 162. [Google Scholar] [CrossRef]

- Amladi, P. HR’s guide to the digital transformation: Ten digital economy use cases for transforming human resources in manufacturing. Strateg. HR Rev. 2017, 16, 66–70. [Google Scholar] [CrossRef]

- Yun, J.J.; Won, D.; Park, K. Entrepreneurial cyclical dynamics of open innovation. J. Evol. Econ. 2018, 28, 1151–1174. [Google Scholar] [CrossRef]

- Yun, J.H.J.; Zhao, X.; Jung, K.H.; Yigitcanlar, T. The Culture for Open Innovation Dynamics. Sustainability 2020, 12, 5076. [Google Scholar] [CrossRef]

- Skordoulis, M.; Ntanos, S.; Kyriakopoulos, G.; Arabatzis, G.; Galatsidas, S.; Chalikias, M. Environmental Innovation, Open Innovation Dynamics and Competitive Advantage of Medium and Large-Sized Firms. J. Open Innov. Technol. Mark. Complex. 2020, 6, 195. [Google Scholar] [CrossRef]

- Alexy, O.; Bascavusoglu-Moreau, E.; Salter, A.J. Toward an aspiration-level theory of open innovation. Ind. Corp. Chang. 2016, 25, 289–306. [Google Scholar] [CrossRef]

- DEL Giudice, M.; Maggioni, V. Managerial practices and operative directions of knowledge management within inter-firm networks: A global view. J. Knowl. Manag. 2014, 18, 841–846. [Google Scholar] [CrossRef]

- Ferraris, A.; Santoro, G.; Dezi, L. How MNC’s subsidiaries may improve their innovative performance? The role of external sources and knowledge management capabilities. J. Knowl. Manag. 2017, 21, 540–552. [Google Scholar] [CrossRef]

- Santoro, G.; Vrontis, D.; Thrassou, A.; Dezi, L. The Internet of Things: Building a knowledge management system for open innovation and knowledge management capacity. Technol. Forecast. Soc. Chang. 2018, 136, 347–354. [Google Scholar] [CrossRef]

- du Plessis, M. The role of knowledge management in innovation. J. Knowl. Manag. 2007, 11, 20–29. [Google Scholar] [CrossRef]

- Paschek, D.; Luminosu, C.T.; Draghici, A. Automated business process management–in times of digital transformation using machine learning or artificial intelligence. MATEC Web Conf. 2017, 121, 04007. [Google Scholar] [CrossRef]

- Marrella, A. What Automated Planning Can Do for Business Process Management. In Business Process Management Workshops; Springer: Barcelona, Spain, 2017; pp. 7–19. [Google Scholar]

- Koopman, A.; Seymour, L.F. Factors impacting successful BPMS adoption and use: A South African financial services case study. In Enterprise, Business-Process and Information Systems Modeling; Springer: Cham, Switzerland, 2020; Volume 387, pp. 55–69. [Google Scholar]

- Binci, D.; Belisari, S.; Appolloni, A. BPM and change management: An ambidextrous perspective. Bus. Process Manag. J. 2019, 26, 1–23. [Google Scholar] [CrossRef]

- Rosemann, M.; Brocke, J. The Six Core Elements of Business Process Management; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-642-00415-5. [Google Scholar]

- Guadalupe, M.; Li, H.; Wulf, J.; Brynjolfsson, E.; Collis, D.; Dessein, W.; Gibbons, B.; Greenstein, S.; Hambrick, D.; Helfat, C.; et al. Who Lives in the C-Suite? Organizational Structure and the Division of Labor in Top Management. Manag. Decis. 2014, 60, 824–844. [Google Scholar] [CrossRef]

- Brocke, J.V.; Zelt, S.; Schmiedel, T. On the role of context in business process management. Int. J. Inf. Manag. 2015, 36, 486–495. [Google Scholar] [CrossRef]

- Ahmad, T.; Van Looy, A. Business Process Management and Digital Innovations: A Systematic Literature Review. Sustainability 2020, 12, 6827. [Google Scholar] [CrossRef]

- Nikolova, I. Manifestation of Intellectual Capital in Trade During Period 2008–2018. Econ. Altern. 2019, 3, 370–384. [Google Scholar]

- Park, H.; McKilligan, S. A Systematic Literature Review for Human-Computer Interaction and Design Thinking Process Integration. In Design, User Experience, and Usability: Theory and Practice; Marcus, A., Wang, W., Eds.; DUXU 2018. Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2018; Volume 10918. [Google Scholar] [CrossRef]

- Flick, U. Qualitative Research-State of the Art. Soc. Sci. Inf. 2002, 41, 5–24. [Google Scholar] [CrossRef]

- Saunders, M.N.; Lewis, P.; Thornhill, A.; Bristow, A. Understanding research philosophy and approaches to theory development. In Research Methods for Business Students; Pearson Education: London, UK, 2015. [Google Scholar]

- Volkova, V.N.; Vasiliev, A.Y.; Efremov, A.A.; Loginova, A.V. Information technologies to support decision-making in the engineering and control. In Proceedings of the 2017 XX IEEE International Conference on Soft Computing and Measurements (SCM), St. Petersburg, Russia, 24–26 May 2017; pp. 727–730. [Google Scholar]

- Fu, M.; Wang, D.; Wang, J.; Li, M. Modeling Method of Operational Task Combined with IDEF and UML. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 October 2018; pp. 1443–1447. [Google Scholar]

- Fernando, M.; Jesus, R.; Manuel, O.; Morales-Palma, D. Preliminary ontology definition for aerospace assembly lines in Airbus using Models for Manufacturing methodology. Procedia Manuf. 2019, 28, 207–213. [Google Scholar]

- Proulx, M.; Gardoni, M. Methodology for Designing a Collaborative Business Model–Case Study Aerospace Cluster. In IFIP Advances in Information and Communication Technology; Nyffenegger, F., Ríos, J., Rivest, L., Bouras, A., Eds.; Springer: Cham, Switzerland, 2020; p. 594. [Google Scholar]

- Shanmugam, R.; Ramoni, M.; Thangamani, G.; Thangaraj, M. Influence of Additive Manufactured Stainless Steel Tool Electrode on Machinability of Beta Titanium Alloy. Metals 2021, 11, 778. [Google Scholar] [CrossRef]

- Alonso, U.; Veiga, F.; Suárez, A.; Artaza, T. Experimental Investigation of the Influence of Wire Arc Additive Manufacturing on the Machinability of Titanium Parts. Metals 2020, 10, 24. [Google Scholar] [CrossRef]

- Shunmugavel, M.; Polishetty, A.; Goldberg, M.; Singh, R.; Littlefair, G. A comparative study of mechanical properties and machinability of wrought and additive manufactured (selective laser melting) titanium alloy-Ti-6Al-4V. Rapid Prototyp. J. 2017, 23, 1051–1056. [Google Scholar] [CrossRef]

- Zhou, W.; Shao, Z.; Yu, J.; Lin, J. Advances and Trends in Forming Curved Extrusion Profiles. Materials 2021, 14, 1603. [Google Scholar] [CrossRef]

- Pham, T.; Kwon, P.; Foster, S. Additive Manufacturing and Topology Optimization of Magnetic Materials for Electrical Machines—A Review. Energies 2021, 14, 283. [Google Scholar] [CrossRef]

- Kim, H.; Jo, Y.; Lee, D. R&D, Marketing, Strategic Planning, or Human Resources? Which CEO Career Is Most Helpful for the Economic Sustainability of ICT Startups in South Korea? Sustainability 2021, 13, 2729. [Google Scholar]

- AS9100D: Quality Management Systems-Requirements for Aviation, Space and Defense Organizations; SAE International: Warrendale, PA, USA, 2016.

- Wu, T.-H.; Wu, F.; Liang, C.-J.; Li, Y.-F.; Tseng, C.-M.; Kang, S.-C. A virtual reality tool for training in global engineering collaboration. Univers. Access Inf. Soc. 2019, 18, 243–255. [Google Scholar] [CrossRef]

- Alblawi, A.; Nawab, M.; Alsyaari, A. Application of systems engineering approach in senior design projects. In Proceedings of the 2018 IEEE Global Engineering Education Conference (EDUCON), Santa Cruz de Tenerife, Spain, 17–20 April 2018; pp. 1151–1160. [Google Scholar]

- Queiruga-Dios, A. Evaluating engineering competencies: A new paradigm. In Proceedings of the IEEE Global Engineering Education Conference (EDUCON), Santa Cruz de Tenerife, Spain, 17–20 April 2018; pp. 2052–2055. [Google Scholar]

- Alsaqaf, W.; Maya, D.; Roel, W. Quality requirements challenges in the context of large-scale distributed agile: An empirical study. Inf. Softw. Technol. 2019, 110, 39–55. [Google Scholar] [CrossRef]

- Li, B.; Feng, P.; Zeng, L.; Xu, C.; Zhang, J. Path planning method for on-machine inspection of aerospace structures based on adjacent feature graph. Robot. Comput. Manuf. 2018, 54, 17–34. [Google Scholar] [CrossRef]

- Rao, D.B.; Rao, K.V.; Krishna, A.G. A hybrid approach to multi response optimization of micro milling process parameters using Taguchi method based graph theory and matrix approach (GTMA) and utility concept. Measurement 2018, 120, 43–51. [Google Scholar] [CrossRef]

- Tanaka, Y.; Eldar, Y.C.; Ortega, A.; Cheung, G. Sampling Signals on Graphs: From Theory to Applications. IEEE Signal Process. Mag. 2020, 37, 14–30. [Google Scholar] [CrossRef]

- Liu, S.; Bao, J.; Lu, Y.; Li, J.; Lu, S.; Sun, X. Digital twin modeling method based on biomimicry for machining aerospace components. J. Manuf. Syst. 2021, 58, 180–195. [Google Scholar] [CrossRef]

- Li, W.; Zhao, C.; Gao, F. Linearity Evaluation and Variable Subset Partition Based Hierarchical Process Modeling and Monitoring. IEEE Trans. Ind. Electron. 2018, 65, 2683–2692. [Google Scholar] [CrossRef]

- Kazemzadeh, A.; Manteghi, M. Identification and Modeling of Effective factors in Designing the Process of Developing Aerospace ComplexProducts. Innov. Manag. J. 2020, 9, 37–77. [Google Scholar]

- Zhu, J.; Ge, Z.; Song, Z.; Gao, F. Review and big data perspectives on robust data mining approaches for industrial process modeling with outliers and missing data. Annu. Rev. Control. 2018, 46, 107–133. [Google Scholar] [CrossRef]

- Olga, K. Explaining ambidextrous leadership in the aerospace and defense organizations. Eur. Manag. J. 2019, 37, 552–563. [Google Scholar]

- Kovrigin, E.; Vasiliev, V. Trends in the development of a digital quality management system in the aerospace industry. IOP Conf. Series: Mater. Sci. Eng. 2020, 868, 012011. [Google Scholar] [CrossRef]

- Rajamani, M.; Punna, E. Enhancement of Design for Manufacturing and Assembly Guidelines for Effective Application in Aerospace Part and Process Design; SAE Technical Paper 2020-01-6001; SAE: Warrendale, PA, USA, 2020. [Google Scholar]

- Castro, S.S.; Suárez López, M.J.; Menéndez, D.G.; Marigorta, E.B. Decision matrix methodology for retrofitting techniques of existing buildings. J. Clean. Prod. 2019, 240, 118153. [Google Scholar] [CrossRef]

- Daube, O. Resolution of the 2D Navier-Stokes equations in velocity-vorticity form by means of an influence matrix technique. J. Comput. Phys. 1992, 103, 402–414. [Google Scholar] [CrossRef]

- Teixeira, M.T.; Barreto, L.S.; Taveira, S.F.; Gratieri, T.; Gelfuso, G.; Marreto, R.N.; Silva, I.C.; Cunha-Filho, M. The Influence of Matrix Technology on the Subdivision of Sustained Release Matrix Tablets. AAPS PharmSciTech 2020, 21, 8. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).