Study of Brake Disc Friction Characteristics Effect on Low Frequency Brake Induced Vibration of Aircraft Landing Gear

Abstract

1. Introduction

2. The Model of Gear Walk System

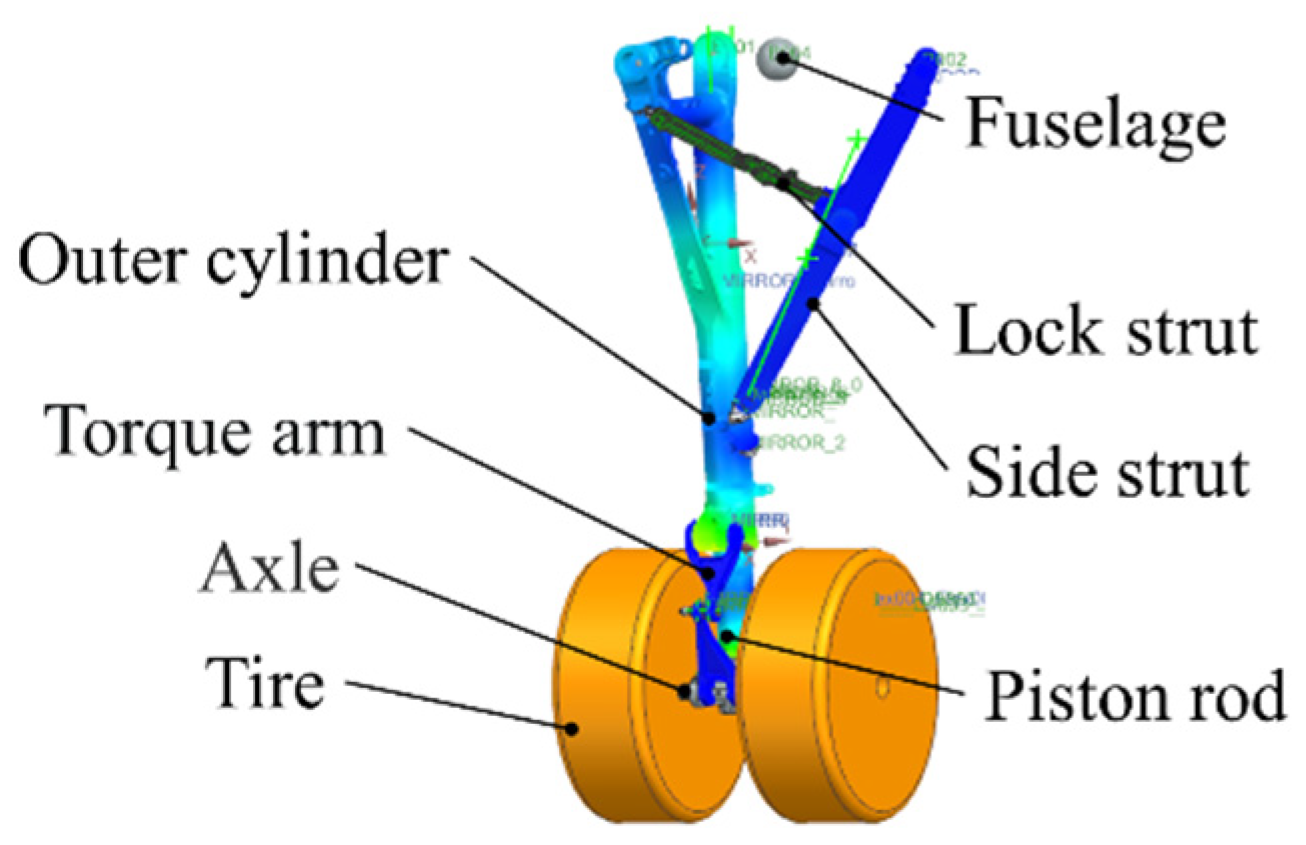

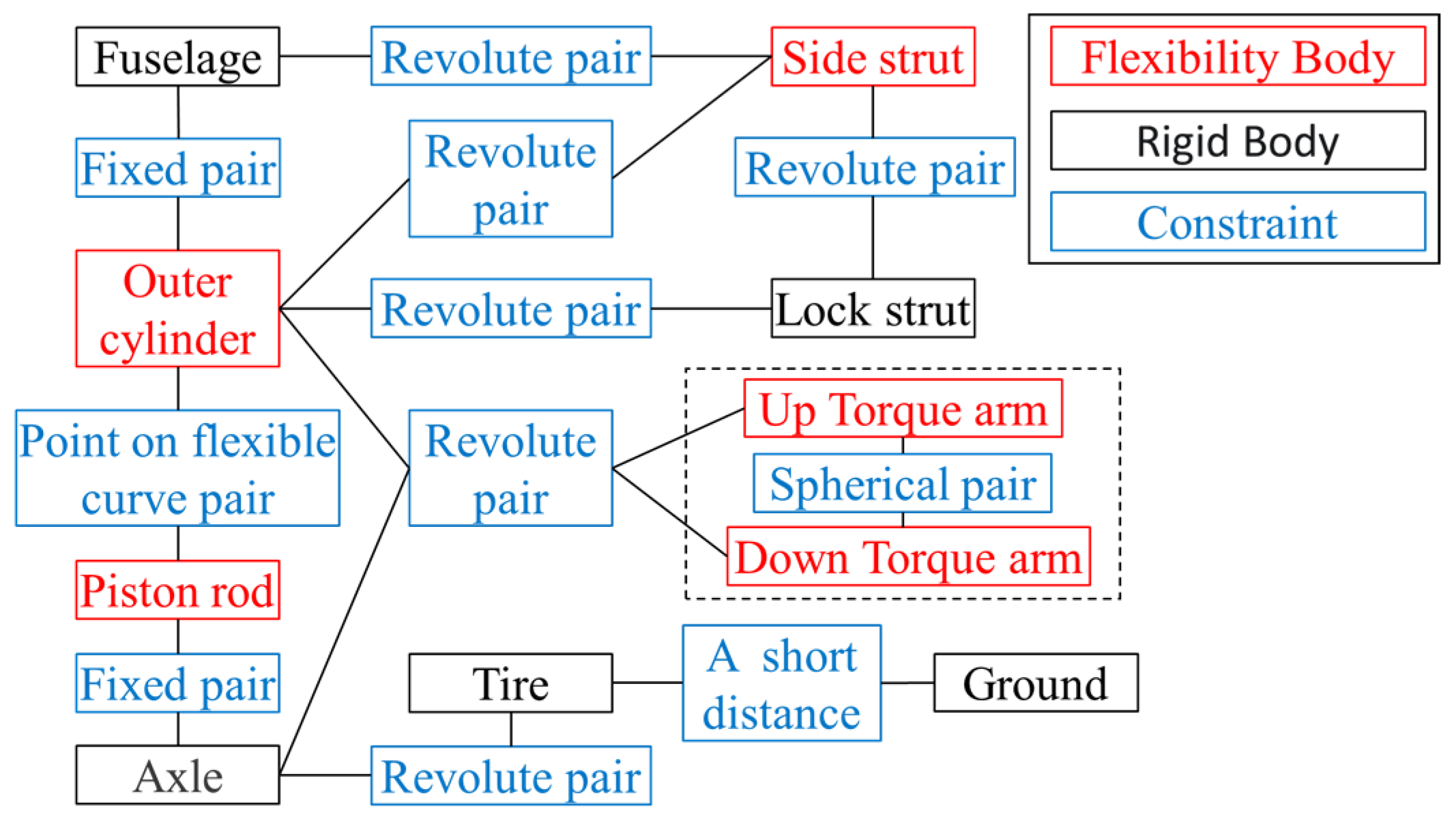

2.1. The Rigid–Flexible Coupling Dynamics Model of Landing Gear

2.1.1. Model of Buffer

2.1.2. Flexible Processing and Constraint Relations

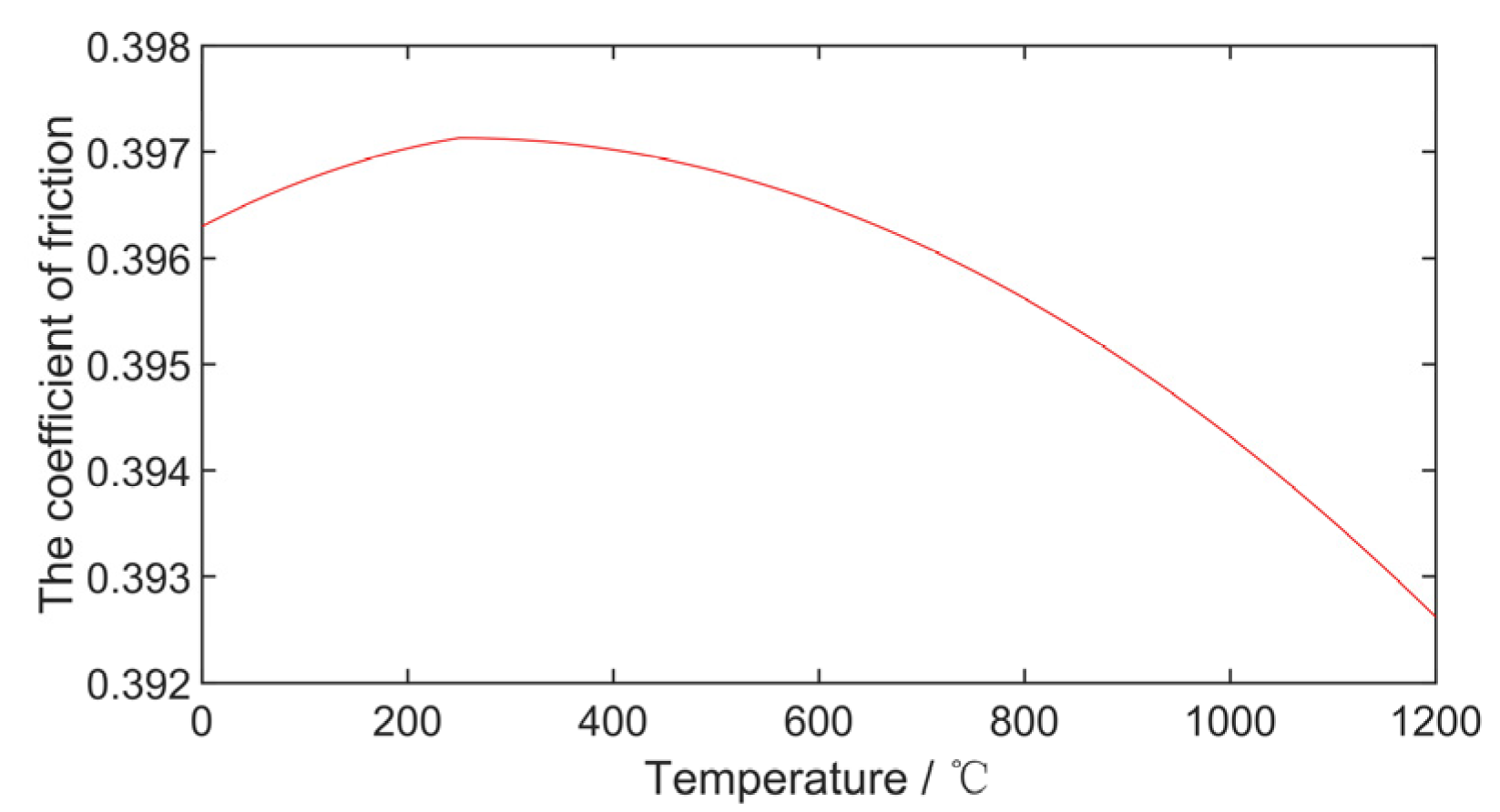

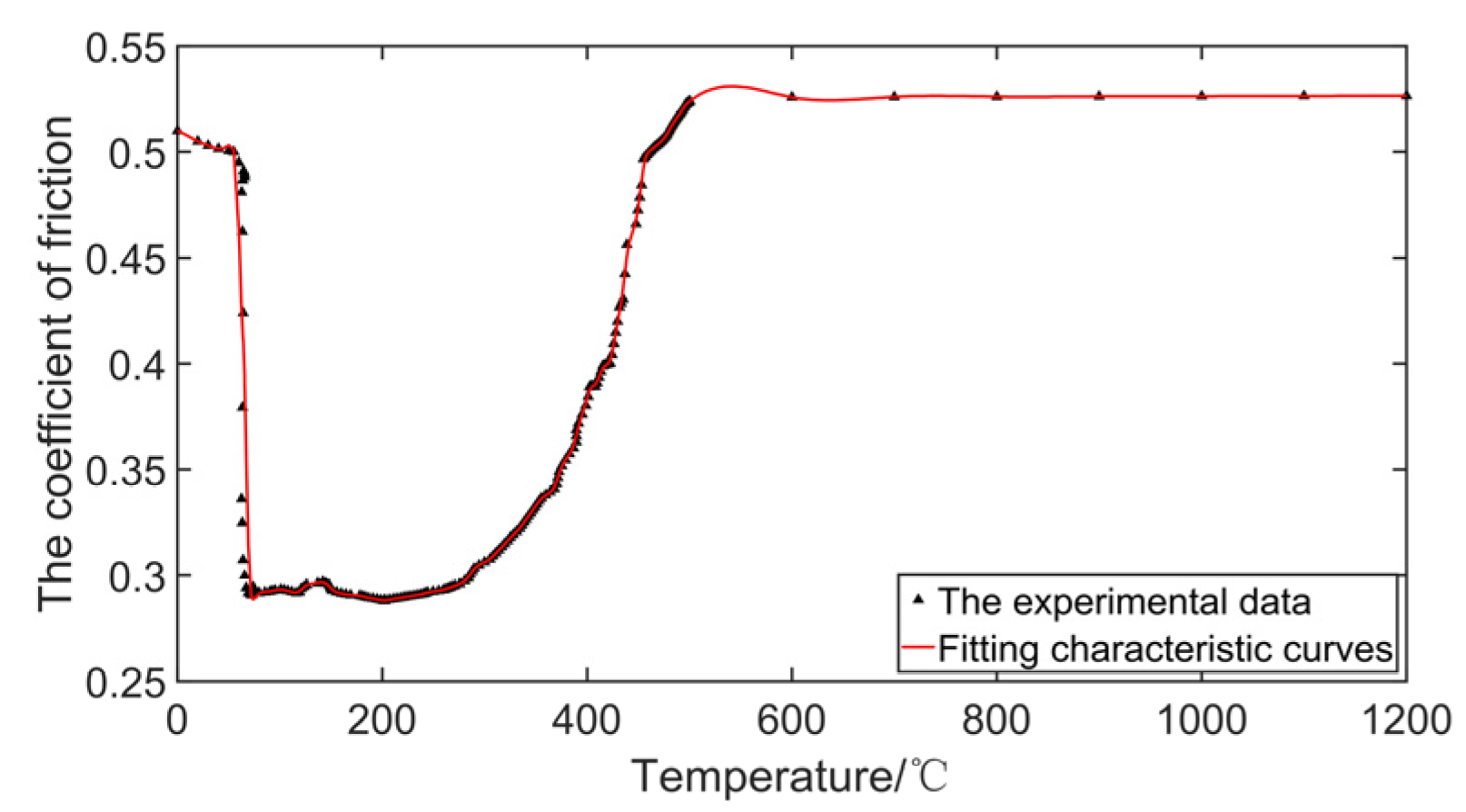

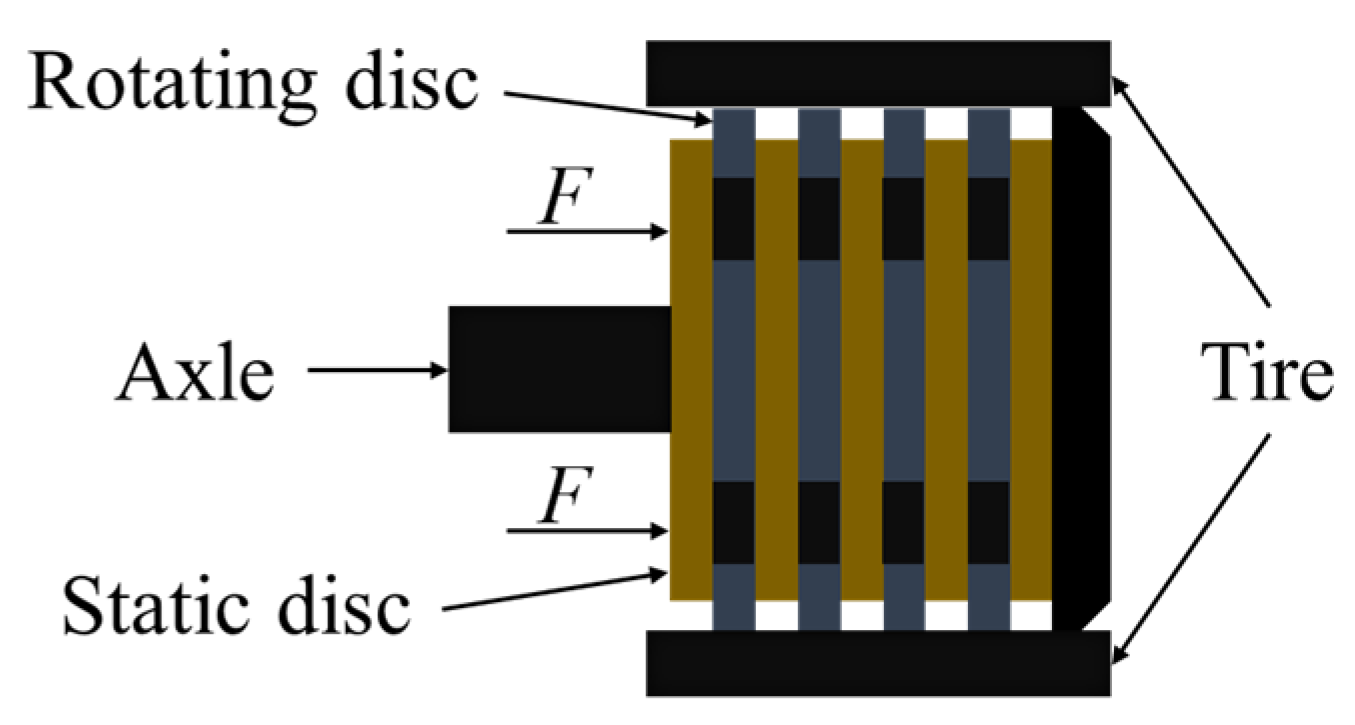

2.2. Variable Friction Model of the Brake Disc

2.2.1. Temperature Variation Model

2.2.2. Temperature–Friction Coefficient Model

2.3. Hydraulic Brake System Model

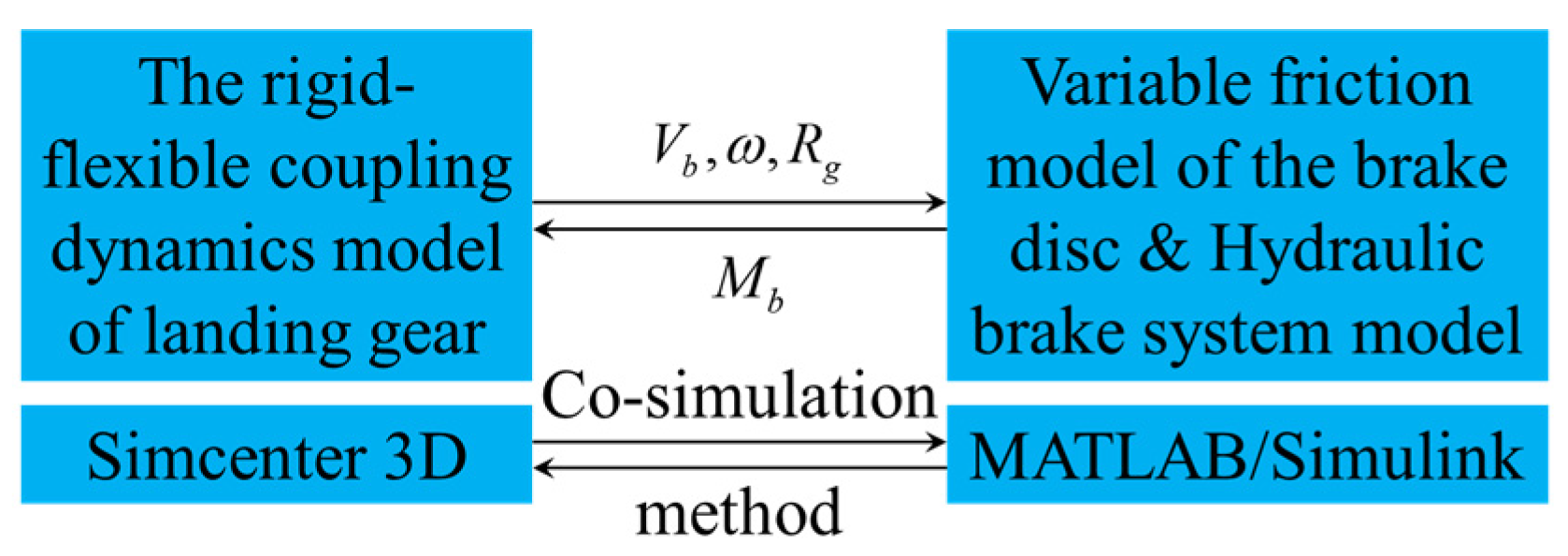

2.4. Co-Simulation Method

3. Analysis of the Brake Disc Friction Characteristics Effect on Gear Walk

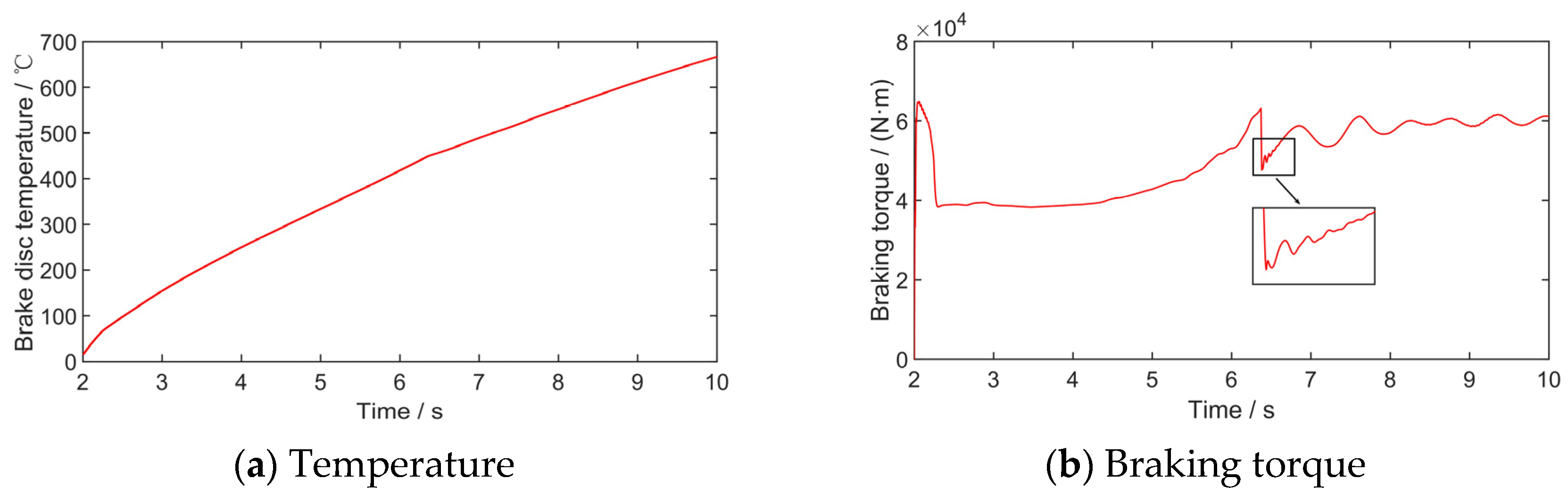

3.1. C/SiC Brake Disc Variable Friction Characteristics Effect on Gear Walk

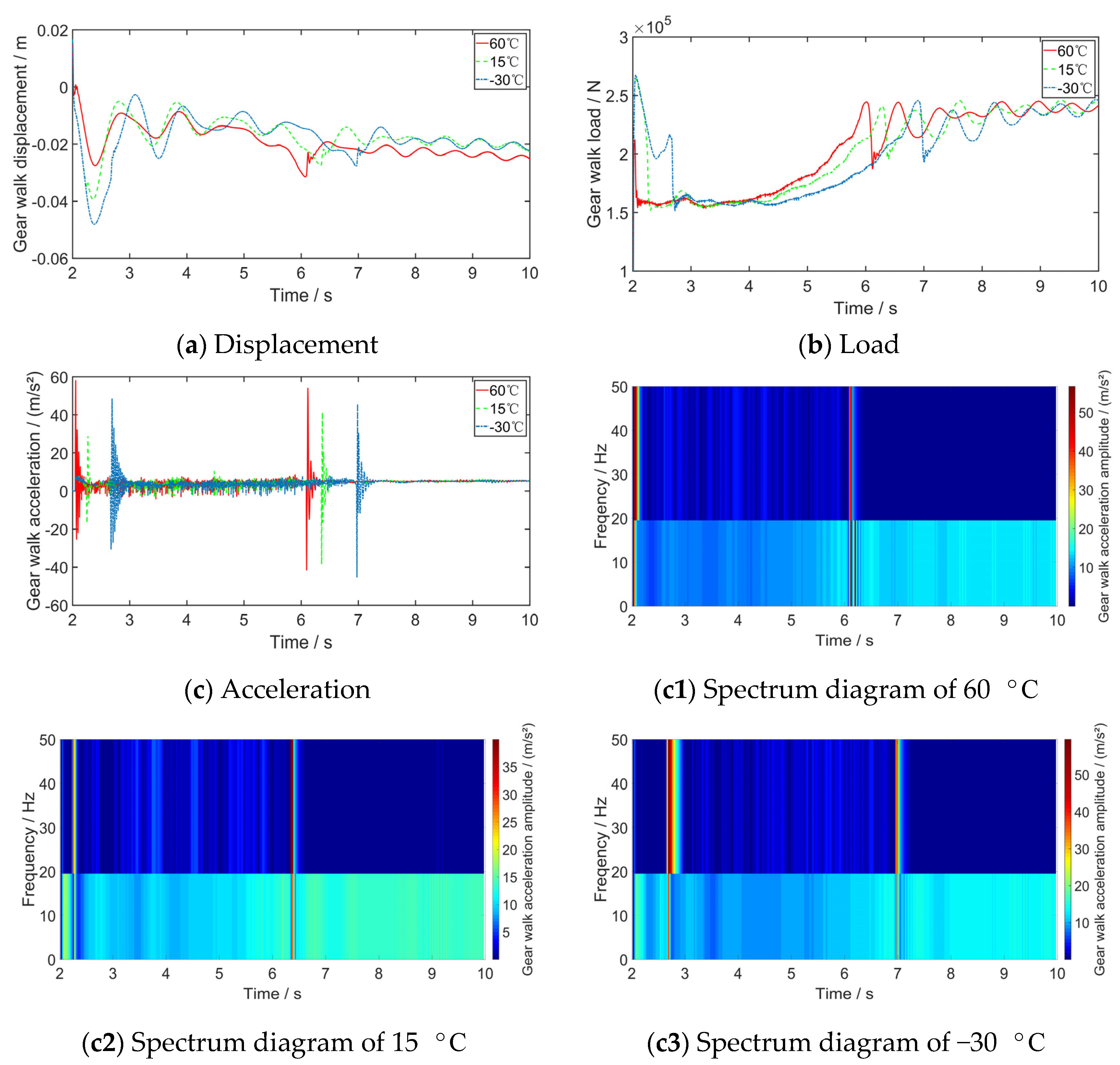

3.2. Brake Disc Friction Characteristics Effect on Gear Walk under Different Ambient Temperatures

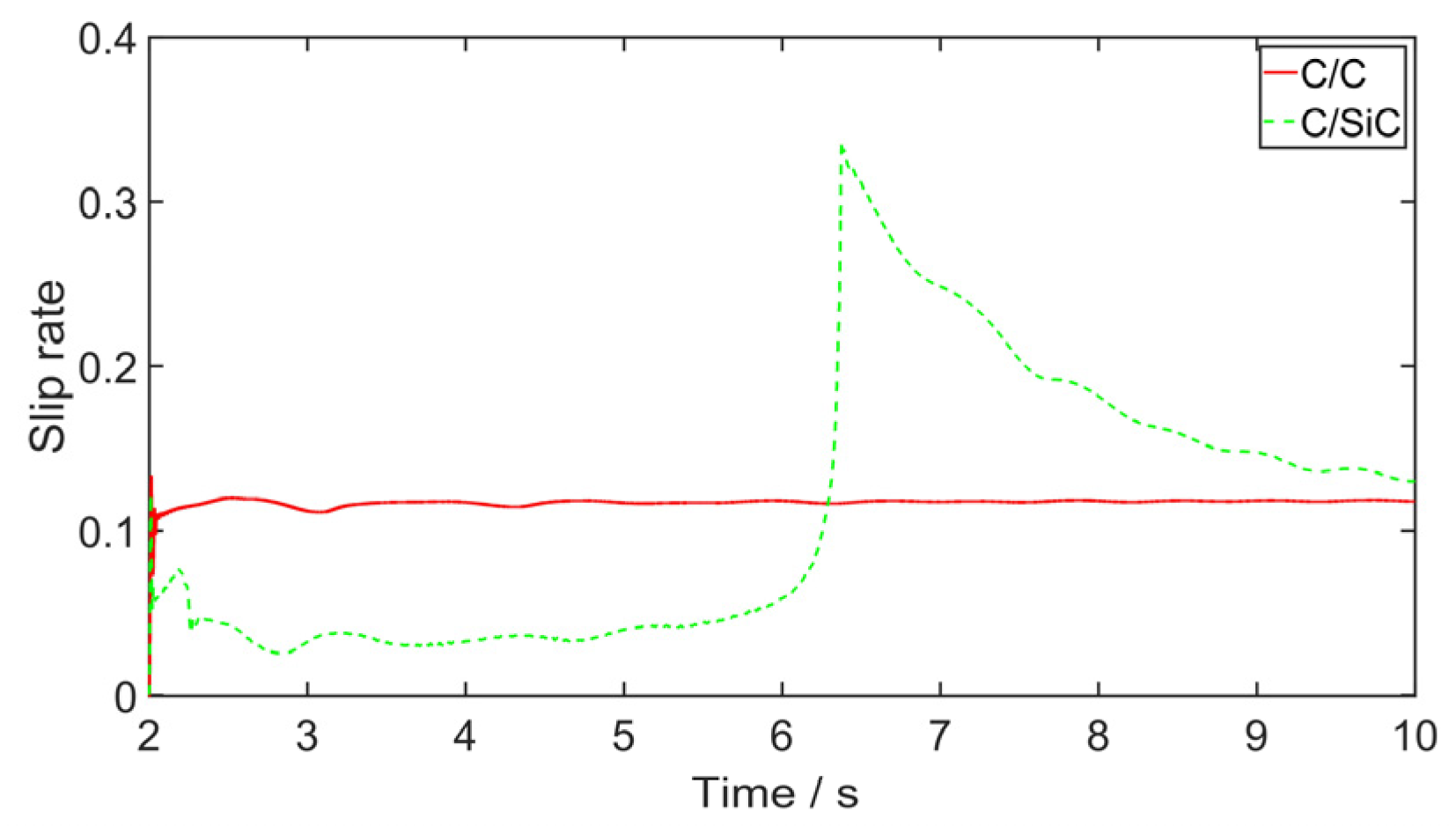

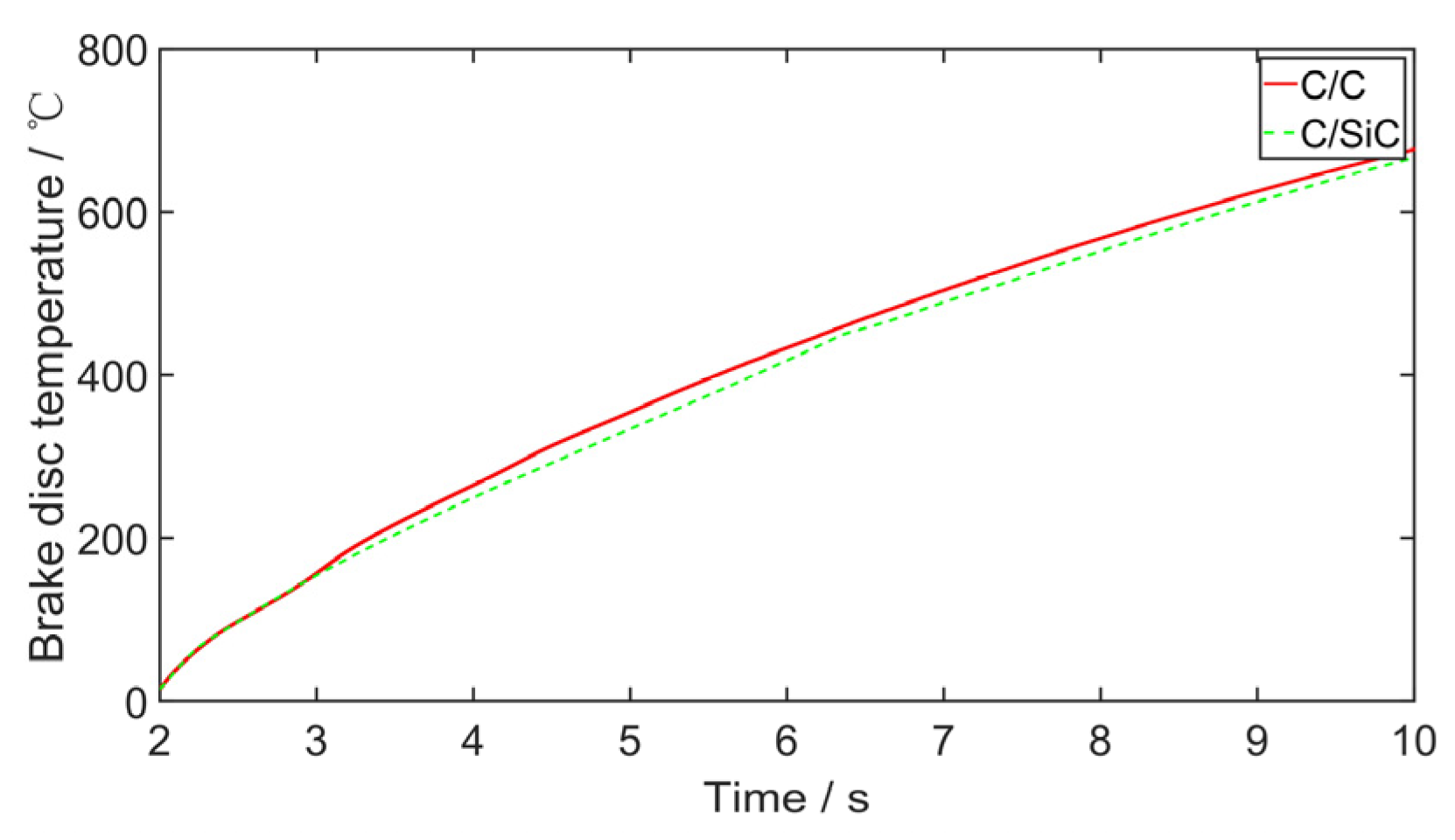

3.3. Brake Disc Material Effect on Gear Walk

4. Conclusions

- 1.

- In the time domain simulation analysis of gear walk, there is a “negative slope” phenomenon between the C/SiC brake disc friction coefficient and the wheel speed. The friction coefficient changes greatly when the temperature is below 600 °C. This phenomenon has a great effect on the gear walk characteristics and the control effect of the slip rate PID brake control law. The friction coefficient of the C/C disc has little change, and the variable friction characteristic is stable. Attention should be paid to the effect of the friction characteristics of the brake disc on the accuracy of simulation results;

- 2.

- The variable friction characteristics of C/SiC are easily affected by ambient temperature. The occurrence time of the “negative slope” phenomenon will be affected by different ambient temperatures. The change of ambient temperature has a great influence on the displacement and load of gear walk;

- 3.

- A C/SiC brake disc can solve the defect of a C/C brake disc’s low friction coefficient to a certain extent, which requires less brake pressure to be provided by the hydraulic system in the braking process and saves on energy consumption. However, the problem of large braking torque fluctuation caused by the “negative slope” phenomenon will also exacerbate gear walk and affect the braking efficiency of aircraft.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Enright, J.J. Laboratory Simulation of Landing Gear Pitch-Plane Dynamics. SAE Trans. 1985, 94, 857–866. [Google Scholar]

- Jiao, Z.; Wang, Z.; Sun, D.; Liu, X.; Shang, Y.; Wu, S. A novel aircraft anti-skid brake control method based on runway maximum friction tracking algorithm. Aerosp. Sci. Technol. 2021, 110, 106482. [Google Scholar] [CrossRef]

- Jiao, Z.; Bai, N.; Liu, J.; LI, Y.; Wang, Z.; Sun, D.; Qi, P.; Shang, Y. Aircraft anti-skid braking control technology: A review. Acta Aeronaut. et Astronaut. Sin. 2022, 43, 1–27. [Google Scholar] [CrossRef]

- Yang, X. Problem of Landing Gear Vibration Arisen from Wheel and Brake. China Civ. Aviat. 1995, 09, 27–28. [Google Scholar]

- Gualdi, S.; Morandini, M.; Ghiringhelli, G.L. Anti-skid induced aircraft landing gear instability. Aerosp. Sci. Technol. 2008, 12, 627–637. [Google Scholar] [CrossRef]

- D’Avico, L.; Tanelli, M.; Savaresi, S.M.; Airoldi, M.; Rapicano, G. A deceleration-based algorithm for anti-skid control of aircraft. IFAC-PapersOnLine 2017, 50, 14168–14173. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Farhang, K. Gear Walk Instability Studies Using a Vibration Model of a Reduced Scale Landing Gear System. In Proceedings of the ASME 2002 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Montreal, QC, Canada, 29 September–2 October 2002. [Google Scholar]

- Yin, Q.; Jiang, J.Z.; Neild, S.A.; Nie, H. Investigation of gear walk suppression while maintaining braking performance in a main landing gear. Aerosp. Sci. Technol. 2019, 91, 122–135. [Google Scholar] [CrossRef]

- Liao, D.; Jiao, Z.; Wang, Z.; Qi, P.; Liu, X. Vibration Analysis on Six-wheel Landing Gear Induced by Anti-skid Brake. In Proceedings of the 2021 IEEE International Conference on Electrical Engineering and Mechatronics Technology (ICEEMT), Qingdao, China, 2–4 July 2021. [Google Scholar]

- Khapane, P.D. Gear walk instability studies using flexible multibody dynamics simulation methods in SIMPACK. Aerosp. Sci. Technol. 2006, 10, 19–25. [Google Scholar] [CrossRef]

- Rovira, A.; Roda, A.; Lewis, R.; Marshall, M. Application of Fastsim with variable coefficient of friction using twin disc experimental measurements. Wear 2012, 274, 109–126. [Google Scholar] [CrossRef]

- Lee, N.-J.; Kang, C.-G. The effect of a variable disc pad friction coefficient for the mechanical brake system of a railway vehicle. PLoS ONE 2015, 10, e0135459. [Google Scholar] [CrossRef] [PubMed]

- Ehret, M. Identification of a dynamic friction model for railway disc brakes. Proc. Inst. Mech.Eng. Part F J. Rail Rapid Transit 2021, 235, 1214–1224. [Google Scholar] [CrossRef]

- Liu, Z.; Xie, Y. Simulation study of aircraft brake system based on variable friction coefficient. Aeronaut. Sci. Technol. 2015, 26, 33–38. [Google Scholar]

- Krenkel, W.; Heidenreich, B.; Renz, R. C/C-SiC composites for advanced friction systems. Adv. Eng. Mater. 2002, 4, 427–436. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Y.; Lou, J.; Zhang, L.; Cheng, L.; Chen, Z. Analysis of friction and wear properties of C/SiC composites. J. Aeronaut. Mater. 2005, 25, 49–54. [Google Scholar]

- Li, Z.; Xiao, P.; Zhang, B.-g.; Li, Y.; Lu, Y.-h. Preparation and tribological properties of C/C–SiC brake composites modified by in situ grown carbon nanofibers. Ceram. Int. 2015, 41, 11733–11740. [Google Scholar] [CrossRef]

- Fan, S.; Yang, C.; He, L.; Du, Y.; Krenkel, W.; Greil, P.; Travitzky, N. Progress of ceramic matrix composites brake materials for aircraft application. Rev. Adv. Mater. Sci. 2016, 44, 313–325. [Google Scholar]

- Ribbens, W.B.; Fredricks, R. A Sliding Mode Observer Based ABS for Aircraft and Land Vehicles. SAE Trans. 2003, 112, 223–230. [Google Scholar]

- Ryder, F.L.; Zaid, M. Landing-Gear Vibration Instability. J. Aerosp. Sci. 1959, 26, 303–309. [Google Scholar] [CrossRef]

- Lei, B.; Yi, M.; Xu, H. 3-D temperature field for C/C composite braking discs. Acta Mater. Compos. Sin. 2009, 26, 113–117. [Google Scholar] [CrossRef]

- Wu, Z. Study on Optimal Wear Control of Aircraft Landing Brake Based on Extended Life. Master’s Thesis, Civil Aviation University of China, Tianjin, China, 2018. [Google Scholar]

- Wang, J.; He, C. Determination of tire-runway friction coefficient. J.-Northwestern Polytech. Univ. 2000, 18, 569–571. [Google Scholar]

- Flugge, W.; Coale, C. The Influence of Wheel Spin-up on Landing-Gear Impact; National Advisory Committee for Aeronautics, NACA: Washington, DC, USA, 1954. [Google Scholar]

| Model | Parameter | Value |

|---|---|---|

| The rigid–flexible coupling dynamics model of landing gear | Vertical stiffness of tire | 3.4 × 106 |

| Vertical damping of tire | 5.5 × 105 | |

| Cornering stiffness of tire | 3000 | |

| Radius of tire | 0.625 | |

| Inertia of tire | 10.473 | |

| Mass of fuselage | 77,600 | |

| Inertia of fuselage roll | 1.493 × 106 | |

| Inertia of fuselage yaw | 4.68 × 106 | |

| Inertia of fuselage pitch | 3.317 × 106 | |

| Density | 7.83 × 103 | |

| Elastic Modulus | 2 × 105 | |

| Poisson’s ratio | 0.3 | |

| Variable friction model of the brake disc | Reference viscosity of air | 17.5 × 10-6 |

| Volume expansion coefficient | 0.0033 | |

| Mass of the brake disc | 36 | |

| Radius of rotating disc | 0.141 | |

| Radius of static disc | 0.209 | |

| Density of air | 1.225 | |

| Thickness of the interlayer | 0.05 | |

| Hydraulic brake system model | Anti-skid current amplification factor | 50 |

| Proportional coefficient | 200 | |

| Integral coefficient | 150 | |

| Derivative coefficient | 60 |

| Brake Disc Material | ||||

|---|---|---|---|---|

| C/C | 676.62 | 1.36 × 10-3 | 8.96 × 103 | 0.25 |

| C/SiC | 666.70 | 2.77 × 10-3 | 21.91 × 103 | 39.98 |

| Effect comparison of brake discs of different materials | −1.49% | +51.08% | +59.11% | +99.37% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Yin, Q.; Wei, X.; Song, J.; Nie, H. Study of Brake Disc Friction Characteristics Effect on Low Frequency Brake Induced Vibration of Aircraft Landing Gear. Aerospace 2022, 9, 809. https://doi.org/10.3390/aerospace9120809

Zhang S, Yin Q, Wei X, Song J, Nie H. Study of Brake Disc Friction Characteristics Effect on Low Frequency Brake Induced Vibration of Aircraft Landing Gear. Aerospace. 2022; 9(12):809. https://doi.org/10.3390/aerospace9120809

Chicago/Turabian StyleZhang, Songyang, Qiaozhi Yin, Xiaohui Wei, Jiayi Song, and Hong Nie. 2022. "Study of Brake Disc Friction Characteristics Effect on Low Frequency Brake Induced Vibration of Aircraft Landing Gear" Aerospace 9, no. 12: 809. https://doi.org/10.3390/aerospace9120809

APA StyleZhang, S., Yin, Q., Wei, X., Song, J., & Nie, H. (2022). Study of Brake Disc Friction Characteristics Effect on Low Frequency Brake Induced Vibration of Aircraft Landing Gear. Aerospace, 9(12), 809. https://doi.org/10.3390/aerospace9120809