Increasing the Efficiency of Aircraft Ground Handling—A Case Study

Abstract

1. Introduction

2. Methodology

2.1. Acquisition of Input Data

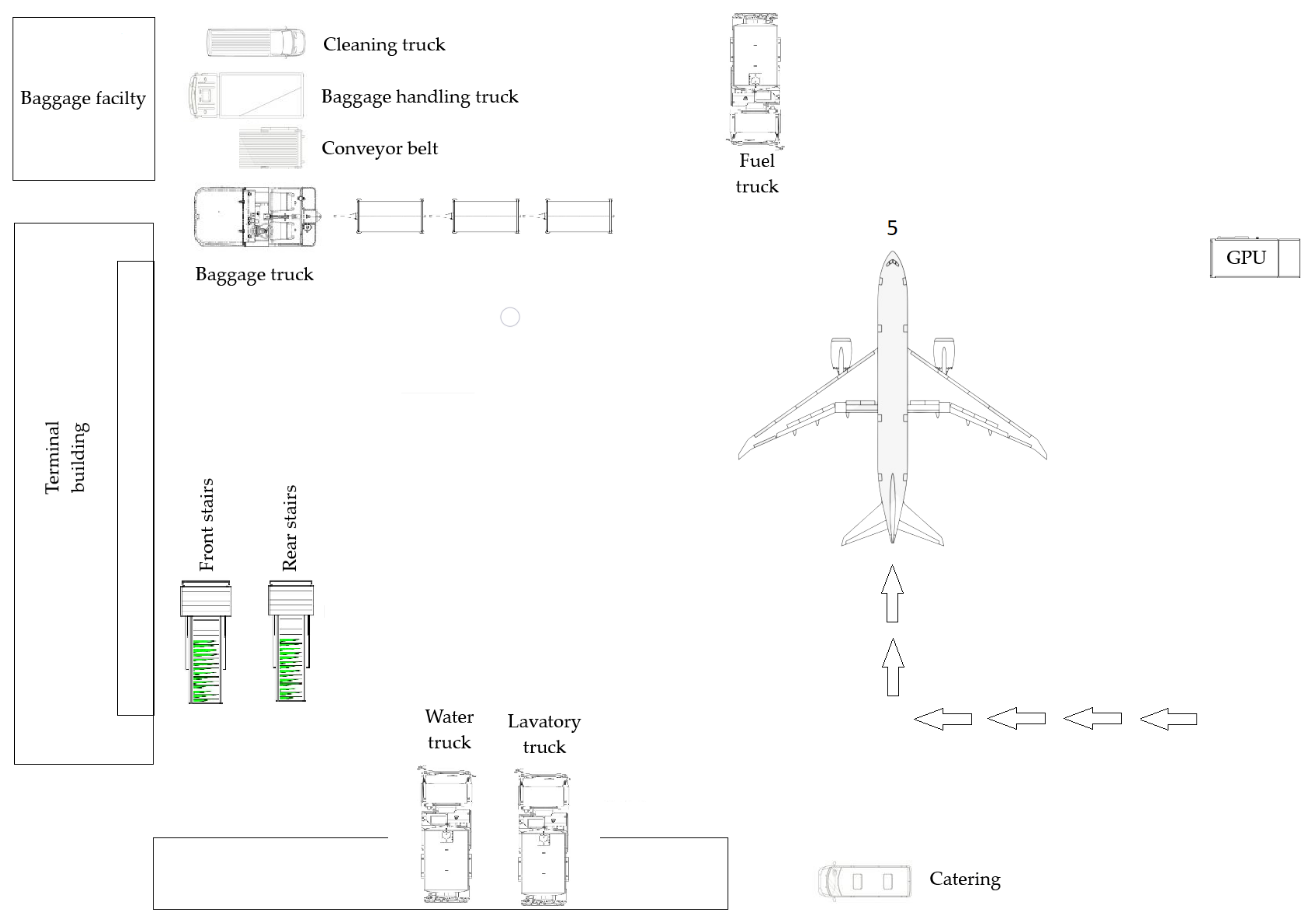

2.2. Number of Employees and Ground Handling Equipment

- 1x Tractor with GPU,

- 2x Mobile stairs for boarding and alighting of passengers,

- 1x Fuel truck with JET-A1,

- 1x Water truck,

- 1x Lavatory truck,

- 1x Special baggage unloading vehicle with built-in belt conveyor,

- 1x Belt conveyor for baggage loading,

- 1x Tractor with trolleys for departure baggage,

- 1x Catering vehicle.

3. Results and Discussion

3.1. Initial Measurement Process

3.2. Measurement Process after Changes Were Applied

3.3. Statistical Evaluation of Measured Data

- A1—aircraft guidance to stand,

- A2—aircraft wedging,

- A3—GPU delivery and connection,

- A4—approach of the front steps to the aircraft,

- A5—approach of the rear steps to the aircraft.

- A6—passenger disembarking,

- A7—delivery of the fuel truck,

- A8—refueling of the aircraft,

- A9—arrival of aircraft cleaning staff,

- A10—aircraft cleaning.

- A11—delivery of lavatory truck,

- A12—emptying of the waste tank,

- A13—delivery of the water truck,

- A14—filing the aircraft with drinking water,

- A15—delivery of baggage truck.

- A16—delivery of baggage trolley and belt conveyor,

- A17—baggage unloading,

- A18—baggage loading,

- A19—parking of belt conveyor,

- A20—parking of special luggage vehicle.

- A21—delivery of catering truck,

- A22—catering loading,

- A23—passenger boarding,

- A24—preparation of documentation,

- A25—checking the departure documentation.

- A26—front steps apposition,

- A27—rear steps apposition,

- A28—disconnection and parking of GPU,

- A29—unwedging of the aircraft,

- A30—engine start and roll-off.

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Litvaj, I.; Poniščiaková, O.; Stančeková, D.; Drbúl, M. Knowledge processes and their implementation in small transport companies. In Proceedings of the 17th International Conference Transport Means, Kaunas, Lithuania, 24–25 October 2013; pp. 153–156, ISSN 1822296X. [Google Scholar]

- Ju, Y.; Wang, A.; Shi, X.; Che, H. Simulation of emergency material transport process. In Proceedings of the 4th International Conference on Wireless Communications, Networking and Mobile Computing, Dalian, China, 12–14 October 2008. [Google Scholar] [CrossRef]

- Chovanec, A. Optimization of mainteinance production link. In Transport Means; Publishing House Technologija: Kaunas, Lithuania, 2007; pp. 118–121. ISSN 1822296X. [Google Scholar]

- Teplická, K.; Čulková, K.; Manová, E. Using of operation analysis models in selected industrial firm. Acta Montan. Slovaca 2012, 17, 151–157, ISSN 13351788. [Google Scholar]

- Nedeliakova, E.; Stefancova, V. Innovative methodology for quality and risk management in logistics processes of transport undertakings. In Proceedings of the 18th International Scientific Conference Business Logistics in Modern Management, Osijek, Croatia, 11–12 October 2018; pp. 41–53. [Google Scholar]

- Olszanska, S.; Prokopiuk, I. Balanced scorecard as an effective method for process management in a transport company. Sci. J. Sil. Univ. Technol. Ser. Transp. 2021, 111, 119–128. [Google Scholar] [CrossRef]

- Hu, C.; Zhu, W.F. Material handling sequence planning for parallel process. In Proceedings of the 2014 Sixth International Conference on Measuring Technology and Mechatronics Automation, Zhangjiajie, China, 10–11 January 2014; pp. 387–390. [Google Scholar] [CrossRef]

- Peceny, L.; Meško, P.; Kampf, R.; Gašparík, J. Optimisation in transport and logistic processes. Transp. Res. Procedia 2020, 44, 15–22. [Google Scholar] [CrossRef]

- Poliakova, B.; Semanova, S. The use of transport processes modelling in the freight transport company. In Proceedings of the 21st International Scientific Conference Transport Means, Juodkrantė, Lithuania, 20–22 September 2017; pp. 913–918, ISSN 1822296X. [Google Scholar]

- Martin, I.; Alessandra, G. Double-criterion optimalization of distributive system structure. In Proceedings of the International Scientific Conference on Quantitative Methods in Economics (Multiple Criteria Decision Making XVI), Bratislava, Slovakia, 30 May–1 June 2012; pp. 85–91. [Google Scholar]

- Szabo, S. Optimization of the parameters of aircraft ground handling by cost function. In Proceedings of the Central European Conference in Finance and Economics (CEFE2017), Herľany, Slovakia, 20–21 September 2017; pp. 733–739, ISBN 978-80-553-2906-2. [Google Scholar]

- Mikes, P. Behavioral aspects in optimalization of transport-system. Int. J. Syst. Sci. 1975, 6, 57–66. [Google Scholar] [CrossRef]

- Nyulasziova, M.; Palova, D. Implementing a decision support system in the transport process management of a small Slovak transport company. J. Entrep. Manag. Innov. 2020, 16, 75–106. [Google Scholar] [CrossRef]

- Koščák, P.; Berežný, Š.; Vajdová, I.; Koblen, I.; Ojciec, M.; Matisková, D.; Puškáš, T. Reducing the negative environmental impact of winter airport maintenance through its model design and simulation. Int. J. Environ. Res. Public Health 2020, 17, 1296. [Google Scholar] [CrossRef] [PubMed]

- Abramovic, B.; Nedeliakova, E.; Panak, M.; Šipuš, D. Synergies in logistics processes for railway transport. In Proceedings of the 17th International Scientific Conference Business Logistics in Modern Management, Osijek, Croatia, 12–13 October 2017; pp. 15–28. [Google Scholar] [CrossRef]

- Baublys, A. Principles for modelling technological processes in transport terminal. Transport 2009, 24, 5–13. [Google Scholar] [CrossRef]

- Pacaiova, H.; Korba, P.; Hovanec, M.; Galanda, J.; Šváb, P.; Lukáč, J. Use of simulation tools for optimization of the time duration of winter maintenance activities at airports. Sustainability 2021, 13, 1095. [Google Scholar] [CrossRef]

- Šváb, P.; Korba, P.; Albert, M.; Kolesár, J. Information system to support the management of winter airport maintenance. In Proceedings of the 2019 New Trends in Aviation Development (NTAD) Conference, Chlumec nad Cidlinou, Czech Republic, 26–27 September 2019. [Google Scholar] [CrossRef]

- Šváb, P.; Pilát, M.; Kešeľová, M.; Tomanová, K.; Machalová, B. Improving safety with progressive methods to decrease risks during ground handling at the airports. J. Glob. Sci. 2021, 6, 1–12, ISSN 2453-756X. [Google Scholar]

- Brezina, D.; Šimák, L.; Hudáková, M.; Masár, M. Comparison of transport problems in process of evacuation. Transp. Res. Procedia 2019, 40, 970–977. [Google Scholar] [CrossRef]

- Klyde, D.H.; Magdaleno, R.E.; Reinsberg, J.G. Effect of tire pressure on aircraft ground handling. J. Guid. Control. Dyn. 2003, 26, 558–564. [Google Scholar] [CrossRef]

- Camaj, J.; Mašek, J.; Kendra, M. Simulation of the transport centre process by using special tools. Procedia Eng. 2016, 134, 224–230. [Google Scholar] [CrossRef]

- Bolek, K.; Kazimierz, L. Development of transport by telematics. In Proceedings of the 19th International Conference on Transport System Telematics, TST 2019, Jaworze, Poland, 27 February–2 March 2019. [Google Scholar] [CrossRef]

- Prochazka, P.; Zaskodny, P.; Tarabek, P. Optimalization of the systemic evidence of returnable packaging transport—Analyticalsynthetic model. In Proceedings of the 2007 IEEE International Conference on Service Operations and Logistics, and Informatics, Philadelphia, PA, USA, 27–29 August 2007. [Google Scholar] [CrossRef]

- Marasová, D.; Ml, D.M.; Tobisová, A.; Jenčová, E. Baggage Transport Safety System at the Airport. In Proceedings of the 20th International Conference VVaPOL, Vysoké Tatry, Slovakia, 18–21 September 2018; pp. 88–95, ISBN 978-80-553-2742-6. [Google Scholar]

- Lawrence, B.; Theodore, C.R.; Johnson, W.; Berger, T. A handling qualities analysis tool for rotorcraft conceptual designs. Aeronaut. J. 2018, 122, 960–987. [Google Scholar] [CrossRef]

- Sznajderman, L.; Ramírez-Díaz, G.; Di Bernardi, C.A. Influence of the apron parking stand management policy on aircraft and ground support equipment (gse) gaseous emissions at airports. Aerospace 2021, 8, 87. [Google Scholar] [CrossRef]

- Hejtmanek, P. Elementary vehicle handling models. In Proceedings of the 20th International Conference Transport Means, Juodkrantė, Lithuania, 5–7 October 2016; pp. 505–508, ISSN 1822-296X. [Google Scholar]

- Authier, M.; Lortie, M.; Gagnon, M. Manual handling techniques: Comparing novices and experts. Int. J. Ind. Ergon. 1996, 17, 419–429. [Google Scholar] [CrossRef]

- Horstmeier, T.; de Haan, F. Influence of ground handling on turn round time of new large aircraft. Aircr. Eng. Aerosp. Technol. 2001, 73, 266–271. [Google Scholar] [CrossRef]

- Lizbetin, J. Draft of handling equipment for material elements transportation. In Proceedings of the International Conference on Traffic and Transport Engineering, Belgrade, Serbia, 27–28 September 2018; pp. 441–448. [Google Scholar]

- Hraskova, D.; Bartošová, V. Process based management in a profile and objectives of the transport company. Adv. Educ. Res. 2014, 61, 109–115, ISSN 04696255. [Google Scholar]

- Krzyzewska, I. Problems in the organisation of the transport process on the international market. Sci. J. Sil. Univ. Technol. Ser. Transp. 2021, 112, 113–123. [Google Scholar] [CrossRef]

- Drljaca, M.; Sesar, V. Quality factors of transport process. Transp. Res. Procedia 2019, 40, 1030–1036. [Google Scholar] [CrossRef]

- Balážiková, M.; Balážiková, M.; Hovanec, M.; Švab, P.; Wysoczańská, B. Estimation of human factor reliability in air operation. In Proceedings of the 2019 New Trends in Aviation Development (NTAD), Chlumec nad Cidlinou, Czech Republic, 26–27 September 2019; pp. 209–213. [Google Scholar] [CrossRef]

- Rodchenko, V.V.; Zaichik, L.E.; Yashin, Y.P. Handling qualities criteria for roll control of highly augmented aircraft. J. Guid. Control Dyn. 2003, 26, 928–933. [Google Scholar] [CrossRef]

- Tabares, D.A.; Mora-Camino, F.; Drouin, A. A multi-time scale management structure for airport ground handling automation. J. Air Transp. Manag. 2021, 90, 101959. [Google Scholar] [CrossRef]

- Schultz, M. Fast aircraft turnaround enabled by reliable passenger boarding. Aerospace 2018, 5, 8. [Google Scholar] [CrossRef]

| Procedure | Time |

|---|---|

| Guide the aircraft to the stand | |

| The wedge of the aircraft | |

| Setting up and connecting a GPU | |

| Apposition of stairs | |

| Exit of passengers | |

| Delivery of fuel vehicles | |

| Refueling JET—A1 | |

| Arrival of aircraft cleaning staff | |

| Cleaning the interior of the aircraft | |

| Delivery of lavatory truck | |

| Dropping of pallets | |

| Delivery of water truck | |

| Filling the aircraft with drinking water | |

| Delivery of a belt conveyor and a tractor with trolleys for checked baggage | |

| Unloading baggage | |

| Baggage loading | |

| Parking of a belt conveyor and a special baggagevehicle | |

| Catering vehicle delivery | |

| Loading catering | |

| Boarding of passengers | |

| Preparation of departure documentation | |

| Transport and inspection of documents stoving + crew | |

| Parking of stairs | |

| Disconnect and park the GPU | |

| Clearance of the aircraft | |

| Rolling out of the stand |

| Procedure | Number of Employees |

|---|---|

| Guide the aircraft to the stand and wedge the aircraft (also during the departure procedure) | 1 employee |

| Setting up and connecting a GPU | 1 employee |

| Apposition of stairs | 2 employees |

| Exit of passengers and boarding of passengers | 1 employee |

| Delivery of fuel vehicle + refueling | 1 employee |

| Cleaning the interior of the aircraft | 4 employees |

| Parking of lavatory truck + draining of toilets | 1 employee |

| Delivery of a drinking water vehicle + filling of the vehicle with drinking water | 1 employee |

| Delivery of a belt conveyor and a tractor with trolleys for checked baggage | 1 employee |

| Unloading + loading baggage | 4 employees |

| Vehicle delivery catering + loading catering | 2 employees |

| Preparation of departure documentation | 2 employees |

| Procedure | Time |

|---|---|

| Guide the aircraft to the stand | 0:42 |

| The wedge of the aircraft | 0:23 |

| Setting up and connecting a GPU | 1:52 |

| Apposition of stairs | P: 1:25, Z: 1:20 |

| Exit of passengers | 3:56 |

| Delivery of fuel vehicles | 1:42 |

| Refueling JET—A1 | 5:53—4253t |

| Arrival of aircraft cleaning staff | 1:40 |

| Cleaning the interior of the aircraft | 13:15 |

| Delivery of toilet vehicles | 2:30 |

| Dropping of pallets | 1:52 |

| Delivery of drinking water vehicle | 2:41 |

| Filling the aircraft with drinking water | 1:15 |

| Delivery of a belt conveyor and a tractor with trolleys for checked baggage and a special baggage vehicle | V = 2:23, PD = 2:15 |

| Unloading baggage | 9:52 |

| Baggage loading | 10:21 |

| Parking of a belt conveyor and a special baggage vehicle | PD = 0:40, V = 0:48 |

| Catering vehicle delivery | 8:12 |

| Loading catering | 12:45 |

| Boarding of passengers | 12:15 |

| Preparation of departure documentation | 3:35 |

| Transport and inspection of documents stoving + crew | 3:24 |

| Parking of stairs | P: 0:51, Z 1:25 |

| Disconnect and park the GPU | 0:53 |

| Clearance of the aircraft | 0:40 |

| Rolling off the stand + throwing the aircraft engines | 4:25 |

| Procedure | Time |

|---|---|

| Guide the aircraft to the stand | 0:52 |

| The wedge of the aircraft | 0:36 |

| Setting up and connecting a GPU | 1:15 |

| Apposition of stairs | P: 0:25, Z: 0:58 |

| Exit of passengers | 7:14 |

| Delivery of fuel vehicles | 0:17 |

| Refueling JET—A1 | 8:16—6436t |

| Arrival of aircraft cleaning staff | 0:41 |

| Cleaning the interior of the aircraft | 19:36 |

| Delivery of toilet vehicles | 0:35 |

| Dropping of pallets | 4:46 |

| Delivery of drinking water vehicle | 0:29 |

| Filling the aircraft with drinking water | 1:12 |

| Delivery of a belt conveyor and a tractor with trolleys for checked baggage and a special baggage vehicle | V = 0:28, PD = 0:41 |

| Unloading baggage | 13:48 |

| baggage loading | 21:23 |

| Parking of a belt conveyor and a special baggage vehicle | PD = 0:32, V = 0:41 |

| Catering vehicle delivery | 3:22 |

| Loading catering | 18:36 |

| Boarding of passengers | 15:36 |

| Preparation of departure documentation | 4:18 |

| Transport and inspection of documents stoving + crew | 5:20 |

| Parking of stairs | P: 0:54, Z: 0:52 |

| Disconnect and park the GPU | 1:12 |

| Clearance of the aircraft | 0:46 |

| Rolling off the stand + throwing the aircraft engines | 3:20 |

| Operation | N | Mean Value ± Measurement Deviation | Measurement Deviation | Min | Max | P |

|---|---|---|---|---|---|---|

| A1 Before | 78 | 0.490000 ± 0.082664 | 0.087831 | 0.36 | 0.59 | 0.742392 |

| A1 After | 78 | 0.501429 ± 0.076687 | 0.36 | 0.59 | ||

| A2 Before | 78 | 0.322857 ± 0.097248 | 0.069213 | 0.23 | 0.51 | 0.536572 |

| A2 After | 78 | 0.340000 ± 0.088318 | 0.25 | 0.51 | ||

| A3 Before | 78 | 1.330000 ± 0.163401 | 0.204893 | 1.15 | 1.52 | 0.147937 |

| A3 After | 78 | 1.201429 ± 0.073808 | 1.15 | 1.36 | ||

| A4 Before | 78 | 1.244286 ± 0.101136 | 0.073030 | 1.15 | 1.46 | 0.000000 |

| A4 After | 78 | 0.274286 ± 0.092890 | 0.18 | 0.41 | ||

| A5 Before | 78 | 1.211429 ± 0.089709 | 0.150539 | 1.08 | 1.36 | 0.000007 |

| A5 After | 78 | 0.395714 ± 0.099139 | 0.25 | 0.58 |

| Operation | N | Mean Value ± Measurement Deviation | Measurement Deviation | Min | Max | P |

|---|---|---|---|---|---|---|

| A6 Before | 78 | 5.457143 ± 1.422740 | 1.581231 | 3.46 | 7.14 | 0.716990 |

| A6 After | 78 | 5.684286 ± 1.174675 | 3.46 | 7.14 | ||

| A7 Before | 78 | 1.345714 ± 0.149427 | 0.124690 | 1.15 | 1.56 | 0.000000 |

| A7 After | 78 | 0.204286 ± 0.053497 | 0.10 | 0.26 | ||

| A8 Before | 78 | 8.255714 ± 2.235359 | 1.375714 | 5.53 | 11.54 | 0.059329 |

| A8 After | 78 | 6.880000 ± 0.944157 | 5.20 | 8.16 | ||

| A9 Before | 78 | 1.567143 ± 0.480961 | 0.498522 | 1.12 | 2.35 | 0.000653 |

| A9 After | 78 | 0.350000 ± 0.087750 | 0.26 | 0.51 | ||

| A10 Before | 78 | 15.29286 ± 2.839071 | 3.171726 | 12.18 | 19.36 | 0.570825 |

| A10 After | 78 | 16.01143 ± 2.842865 | 12.18 | 19.36 |

| Operation | N | Mean Value ± Measurement Deviation | Measurement Deviation | Min | Max | P |

|---|---|---|---|---|---|---|

| A11 Before | 78 | 2.298571 ± 0.094944 | 0.136835 | 2.16 | 2.46 | 0.000000 |

| A11 After | 78 | 0.375714 ± 0.084628 | 0.30 | 0.51 | ||

| A12 Before | 78 | 2.331429 ± 1.025840 | 1.597868 | 1.36 | 4.46 | 0.680234 |

| A12 After | 78 | 2.592857 ± 1.017738 | 1.36 | 4.46 | ||

| A13 Before | 78 | 2.475714 ± 0.315164 | 0.564383 | 2.26 | 3.16 | 0.000071 |

| A13 After | 78 | 0.420000 ± 0.363822 | 0.19 | 1.23 | ||

| A14 Before | 78 | 0.877143 ± 0.342380 | 0.363816 | 0.48 | 1.18 | 0.976147 |

| A14 After | 78 | 0.872857 ± 0.338561 | 0.48 | 1.18 | ||

| A15 Before | 78 | 2.258571 ± 0.130949 | 0.155349 | 2.10 | 2.46 | 0.000000 |

| A15 After | 78 | 0.288571 ± 0.065683 | 0.20 | 0.37 |

| Operation | N | Mean Value ± Measurement Deviation | Measurement Deviation | Min | Max | P |

|---|---|---|---|---|---|---|

| A16 Before | 78 | 2.478571 ± 0.443074 | 0.386695 | 2.06 | 3.15 | 0.000008 |

| A16 After | 78 | 0.398571 ± 0.081328 | 0.28 | 0.52 | ||

| A17 Before | 78 | 12.00143 ± 1.793306 | 1.890841 | 9.36 | 13.48 | 0.697587 |

| A17 After | 78 | 12.29286 ± 1.457083 | 9.36 | 13.48 | ||

| A18 Before | 78 | 16.43000 ± 4.603115 | 4.722167 | 9.56 | 21.23 | 0.578797 |

| A18 After | 78 | 17.47714 ± 3.696849 | 9.56 | 21.23 | ||

| A19 Before | 78 | 0.374286 ± 0.056231 | 0.069727 | 0.30 | 0.46 | 0.366890 |

| A19 After | 78 | 0.348571 ± 0.064402 | 0.25 | 0.43 | ||

| A20 Before | 78 | 0.498571 ± 0.063095 | 0.042857 | 0.42 | 0.59 | 0.042732 |

| A20 After | 78 | 0.455714 ± 0.072309 | 0.36 | 0.56 |

| Operation | N | Mean Value ± Measurement Deviation | Measurement Deviation | Min | Max | P |

|---|---|---|---|---|---|---|

| A21 Before | 78 | 7.850000 ± 1.679305 | 1.595968 | 5.23 | 10.26 | 0.000187 |

| A21 After | 78 | 2.951429 ± 0.460848 | 2.40 | 3.53 | ||

| A22 Before | 78 | 15.76286 ± 2.552076 | 2.596459 | 12.26 | 18.36 | 0.777567 |

| A22 After | 78 | 16.05286 ± 2.204561 | 12.26 | 18.36 | ||

| A23 Before | 78 | 13.56857 ± 1.481288 | 3.380212 | 12.06 | 15.51 | 0.273432 |

| A23 After | 78 | 12.02857 ± 3.185631 | 6.36 | 15.36 | ||

| A24 Before | 78 | 3.957143 ± 0.697823 | 0.757109 | 3.20 | 5.15 | 0.977076 |

| A24 After | 78 | 3.948571 ± 0.706834 | 3.20 | 5.15 | ||

| A25 Before | 78 | 3.748571 ± 0.720079 | 1.138694 | 2.58 | 4.58 | 0.359293 |

| A25 After | 78 | 4.175714 ± 0.972349 | 2.58 | 5.23 |

| Operation | N | Mean Value ± Measurement Deviation | Measurement Deviation | Min | Max | P |

|---|---|---|---|---|---|---|

| A26 Before | 78 | 0.602857 ± 0.311165 | 0.352299 | 0.43 | 1.30 | 0.487083 |

| A26 After | 78 | 0.504286 ± 0.061606 | 0.43 | 0.58 | ||

| A27 Before | 78 | 0.742857 ± 0.409175 | 0.514342 | 0.26 | 1.25 | 0.248252 |

| A27 After | 78 | 0.494286 ± 0.290623 | 0.24 | 1.12 | ||

| A28 Before | 78 | 0.774286 ± 0.306858 | 0.501892 | 0.49 | 1.13 | 0.667253 |

| A28 After | 78 | 0.860000 ± 0.311020 | 0.49 | 1.13 | ||

| A29 Before | 78 | 0.358571 ± 0.099403 | 0.102377 | 0.15 | 0.46 | 0.599740 |

| A29 After | 78 | 0.337143 ± 0.104994 | 0.15 | 0.46 | ||

| A30 Before | 78 | 4.075714 ± 0.986017 | 1.026538 | 2.46 | 5.20 | 0.977457 |

| A30 After | 78 | 4.064286 ± 0.948698 | 2.59 | 5.20 |

| Measurements | Group 1 | Group 2 | Group 3 | Group 4 | Group 5 | Group 6 | Group 7 | ∑ |

|---|---|---|---|---|---|---|---|---|

| Before (t/min) | 108.3 | 107.53 | 148.83 | 136.8 | 133.47 | 140.06 | 134.89 | 909.88 |

| After (t/min) | 80.12 | 132.61 | 117.46 | 109.99 | 119.02 | 112.39 | 117.89 | 789.48 |

| Time saved (t/min) | 28.18 | −25.08 | 31.37 | 26.81 | 14.45 | 27.67 | 17.00 | 120.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szabo, S.; Pilát, M.; Makó, S.; Korba, P.; Čičváková, M.; Kmec, Ľ. Increasing the Efficiency of Aircraft Ground Handling—A Case Study. Aerospace 2022, 9, 2. https://doi.org/10.3390/aerospace9010002

Szabo S, Pilát M, Makó S, Korba P, Čičváková M, Kmec Ľ. Increasing the Efficiency of Aircraft Ground Handling—A Case Study. Aerospace. 2022; 9(1):2. https://doi.org/10.3390/aerospace9010002

Chicago/Turabian StyleSzabo, Stanislav, Marek Pilát, Sebastián Makó, Peter Korba, Miroslava Čičváková, and Ľubomír Kmec. 2022. "Increasing the Efficiency of Aircraft Ground Handling—A Case Study" Aerospace 9, no. 1: 2. https://doi.org/10.3390/aerospace9010002

APA StyleSzabo, S., Pilát, M., Makó, S., Korba, P., Čičváková, M., & Kmec, Ľ. (2022). Increasing the Efficiency of Aircraft Ground Handling—A Case Study. Aerospace, 9(1), 2. https://doi.org/10.3390/aerospace9010002