Wrapping Deployment Simulation Analysis of Leaf-Inspired Membrane Structures

Abstract

:1. Introduction

2. The Deployment Patterns

2.1. The One-Leaf Unit

2.2. Candidate Deployment Patterns

3. Deployment Simulation of Wrapping Membrane Structures

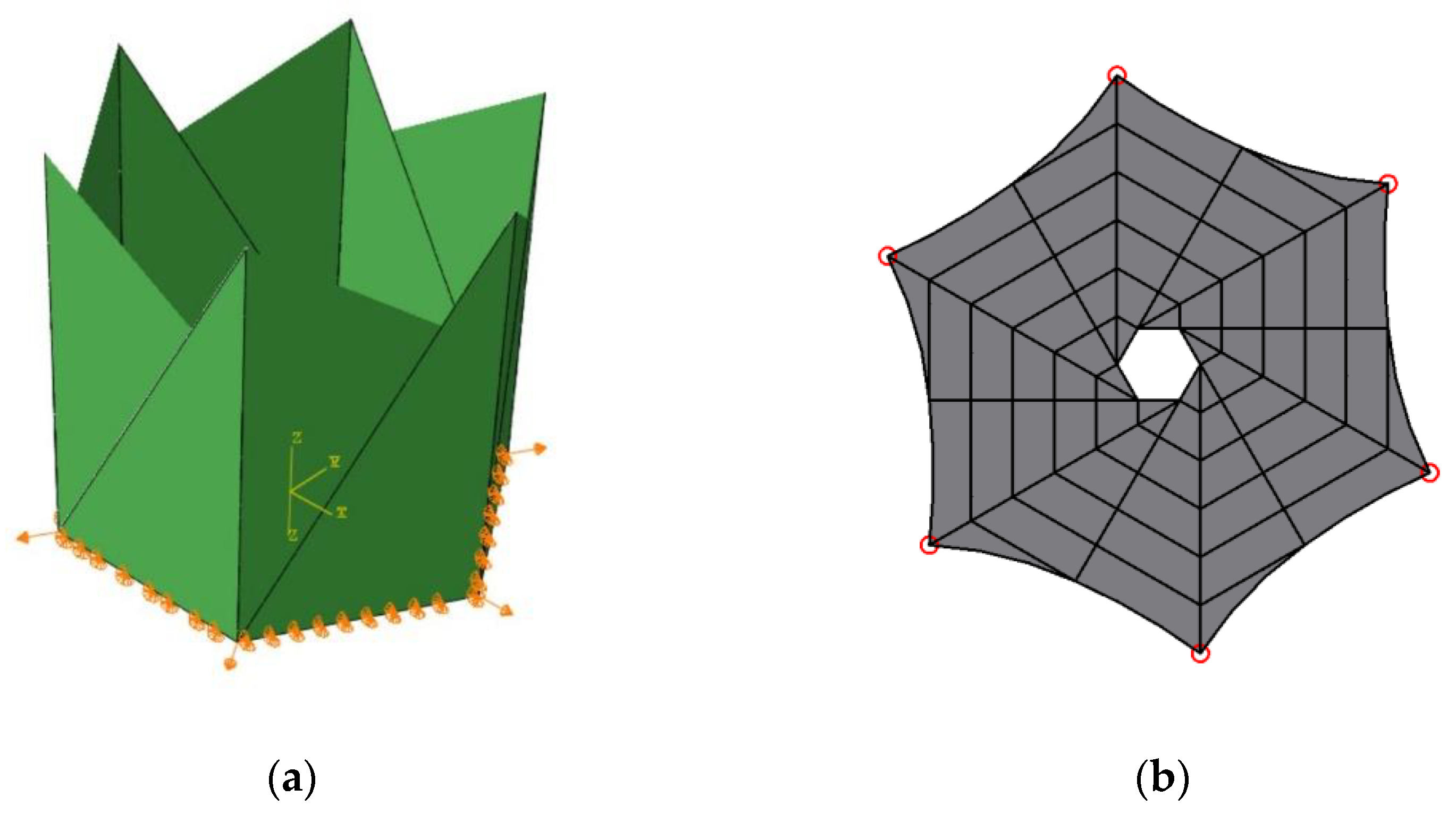

3.1. Form-Finding

3.2. Deployment Simulation

3.3. Deployment Responses

4. Crease Optimization Strategy

4.1. Creases Distribution

4.2. Deployment Performance

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Leipold, M.; Eiden, M.; Gamer, C.E.; Herbeck, L.; Kassing, D.; Niederstadt, T.; Kruger, T.; Pagel, G.; Rezazad, M.; Rozemeijer, H.; et al. Solar sail technology development and demonstration. Acta Astronaut. 2003, 52, 317–326. [Google Scholar] [CrossRef]

- Sawada, H.; Shirasawa, Y.; Mori, O.; Okuizumi, N.; Miyazaki, Y.; Matunaga, S.; Furuya, H.; Sakamoto, H.; Natori, M.; Tsuda, Y. On-orbit result and analysis of sail deployment of world’s first solar power sail IKAROS. J. Space Technol. Sci. 2013, 27, 54–68. [Google Scholar] [CrossRef]

- Seefeldt, P.; Spietz, P.; Sproewitz, T.; Grundmann, J.T.; Hillebrandt, M.; Hobbie, C.; Ruffer, M.; Straubel, M.; Toth, N.; Zander, M. Gossamer-1: Mission concept and technology for a controlled deployment of gossamer spacecraft. Adv. Space Res. 2017, 59, 434–456. [Google Scholar] [CrossRef] [Green Version]

- Johnston, J.D.; Ross, B.D.; Blandino, J.; Lawrence, J.; Perrygo, C.M. Development of sunshield structures for large space telescopes. Proc. SPIE Int. Soc. Opt. Eng. 2003, 4850, 209–220. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, R.; Yang, H. Design and deployment analysis of modular deployable structure for large antennas. J. Spacecr. Rockets 2015, 52, 1101–1111. [Google Scholar] [CrossRef]

- Liu, C.; Shi, Y.Y. Comprehensive structural analysis and optimization of the electrostatic forming membrane reflector deployable antenna. Aerosp. Sci. Technol. 2016, 53, 267–279. [Google Scholar] [CrossRef]

- Hu, J.H.; Chen, W.J.; Qu, Y.G.; Yang, D.Q. Safety and serviceability of membrane buildings: A critical review on architectural, material and structural performance. Eng. Struct. 2020, 210, 110292. [Google Scholar] [CrossRef]

- Tao, Q.; Wang, C.G.; Wang, K.; Tan, H.F. Mixed triangle lattice reinforced membrane antenna reflector: Design and analysis. AIAA J. 2020, 58, 1897–1900. [Google Scholar] [CrossRef]

- Miura, K. Method of packaging and deployment of large membranes in space. In Proceedings of the 31st Congress of International Astronautical Federation, Tokyo, Japan, 21–28 September 1980. [Google Scholar]

- Zhou, Y.; Zhang, Q.; Cai, J.G.; Zhang, Y.T.; Feng, J. Experimental study of the hysteretic behavior of energy dissipation braces based on Miura origami. Thin Walled Struct. 2021, 167, 108196. [Google Scholar] [CrossRef]

- Zhang, Q.; Pan, N.; Meloni, M.; Lu, D.; Feng, J. Reliability Analysis of Radially Retractable Roofs with Revolute Joint Clearances. Reliability Engineering. Syst. Saf. 2020, 208, 107401. [Google Scholar] [CrossRef]

- Meloni, M.; Cai, J.G.; Zhang, Q.; Sang-Hoon, D.; Li, M.; Ma, R.J.; Parashkevov, T.E.; Feng, J. Engineering Origami: A Comprehensive Review of Recent Applications, Design Methods, and Tools. Adv. Sci. 2021, 8, 2000636. [Google Scholar] [CrossRef]

- Focatiis, D.S.A.D.; Guest, S.D. Deployable membranes designed from folding tree leaves. Phil. Trans. R. Soc. A 2002, 360, 227–238. [Google Scholar] [CrossRef] [PubMed]

- Scheel, H. Space-Saving Storage of Flexible Sheets. U.S. Patent 3,848,821, 19 November 1974. [Google Scholar]

- Lee, N.; Close, S. Curved pleat folding for smooth wrapping. Proc. R. Soc. A Math. Phys. 2013, 469, 20130152. [Google Scholar] [CrossRef]

- Ishida, S.; Nojima, T.; Hagiwara, I. Design of deployable membranes using conformal mapping. J. Mech. Design. 2015, 137, 061404. [Google Scholar] [CrossRef]

- Guest, S.D.; Pellegrino, S. Inextensional wrapping of flat membranes. Structural Morphology. In Proceedings of the First International Seminar on Structural Morphology, Montpellier, France, 11 September 1992; pp. 203–215. [Google Scholar]

- Furuya, H.; Satou, Y. Deployment and retraction mechanisms for spinning solar sail membrane. In Proceedings of the 49th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Schaumburg, IL, USA, 7–10 April 2008; pp. 1–11. [Google Scholar]

- Natori, M.C.; Sakamoto, H.; Katsumata, N.; Yamakawa, H.; Kishimoto, N. Conceptual model study using origami for membrane space structures—A perspective of origami-based engineering. Mech. Eng. Rev. 2015, 2, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Satou, Y.; Furuya, H. Fold line based on mechanical properties of crease in wrapping fold membrane. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013; pp. 1–12. [Google Scholar]

- Arya, M.; Pellegrino, S. Deployment mechanics of highly compacted thin membrane structures. In Proceedings of the Spacecraft Structures Conference, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar]

- Sakamoto, H.; Natori, M.C.; Kadonishi, S.; Yasutaka, S.; Shirasawa, Y.; Okuizumi, N.; Mori, O.; Furuya, H.; Okuma, M. Folding patterns of planar gossamer space structures consisting of membranes and booms. Acta Astronaut. 2014, 94, 34–41. [Google Scholar] [CrossRef]

- Guang, C.H.; Yang, Y. Single-vertex multicrease rigid origami with nonzero thickness and its transformation into deployable mechanisms. J. Mech. Robot. 2018, 10, 011010. [Google Scholar] [CrossRef]

- Parque, V.; Suzaki, W.; Miura, S. Packaging of thick membranes using a multi-spiral folding approach: Flat and Curved Surfaces. Adv. Space Res. 2020, 67, 2589–2612. [Google Scholar] [CrossRef]

- Liu, C.J.; Deng, X.W.; Liu, J.; Peng, T.J.; Yang, S.P.; Zheng, Z.L. Dynamic response of saddle membrane structure under hail impact. Eng. Struct. 2020, 214, 110597. [Google Scholar] [CrossRef]

- Gdoutos, E.; Truong, A.; Pedivellano, A.; Royer, F.; Pellegrino, S. Ultralight deployable space structure prototype. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- Ikeya, K.; Sakamoto, H.; Nakanishi, H.; Furuya, H.; Yamazaki, M. Significance of 3U CubeSat OrigamiSat-1 for space demonstration of multifunctional deployable membrane. Acta Astronaut. 2020, 175, 363–377. [Google Scholar] [CrossRef]

- Okuizumi, N.; Yamamoto, T. Centrifugal deployment of membrane with spiral folding: Experiment and simulation. J. Space Eng. 2009, 2, 41–50. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.; Wang, X.H.; Qiu, X.M.; Zhang, X.H. Theoretical study on the parameter sensitivity over the mechanical states of inflatable membrane antenna. Aerosp. Sci. Technol. 2020, 102, 105843. [Google Scholar] [CrossRef]

- Tessler, A.; Sleight, D.W.; Wang, J.T. Effective modeling and nonlinear shell analysis of thin membranes exhibiting structural wrinkling. J. Spacecr. Rockets 2012, 42, 287–298. [Google Scholar] [CrossRef]

- Liyanage, P.M.; Mallikarachchi, H.M.Y.C. Origami based folding patterns for compact deployable structures. In Proceedings of the 4th International Conference for Structural Engineering and Construction Management, Kandy, Sri Lanka, 13–15 December 2013; pp. 1–13. [Google Scholar]

- Satou, Y.; Furuya, H. Local buckling in crease induced by wrapping fold of space membrane. J. Spacecr. Rockets 2014, 51, 595–603. [Google Scholar] [CrossRef]

- Kang, C.W.; Huang, H. FEM stress analysis of interfacial failure of multilayered thin film structures in nanoscratching. Adv. Mater. Res. 2016, 1136, 289–292. [Google Scholar] [CrossRef]

- Cai, J.G.; Ren, Z.; Ding, Y.F.; Deng, X.W.; Xu, Y.X.; Feng, J. Deployment simulation of foldable origami membrane structures. Aerosp. Sci. Technol. 2017, 67, 343–353. [Google Scholar] [CrossRef]

- Wei, J.Z.; Ma, R.Q.; Liu, Y.F.; Yu, J.X.; Eriksson, A.; Tan, H.F. Modal analysis and identification of deployable membrane structures. Acta Astronaut. 2018, 152, 811–822. [Google Scholar] [CrossRef]

- Yuan, T.T.; Liu, Z.Y.; Zhou, Y.H.; Liu, J.Y. Dynamic modeling for foldable origami space membrane structure with contact-impact during deployment. Multibody Syst. Dyn. 2020, 50, 1–24. [Google Scholar] [CrossRef]

- Furuya, H.; Inoue, Y.; Masuoka, T. Deployment characteristics of rotationally skew foldmembrane for spinning solar sail. In Proceedings of the 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference, Austin, TX, USA, 18–21 April 2006. [Google Scholar]

- Zirbel, S.A.; Lang, R.J.; Thomson, M.W.; Sigel, D.A.; Walkemeyer, P.E.; Trease, B.P.; Magleby, S.P.; Howell, L.L. Accommodating thickness in origami-based deployable arrays. J. Mech. Design. 2013, 135, 111005. [Google Scholar] [CrossRef]

| Pattern | Coordinate | A | B | C | Equation of Idea Planes |

|---|---|---|---|---|---|

| Pattern 1 | X | −59.751 | −45.048 | −41.672 | 120.86 z-2752.02 = 0 |

| Y | 146.414 | 162.394 | 157.843 | ||

| Z | 22.770 | 22.770 | 22.770 | ||

| Pattern 2 | X | −70.9675 | −40.9819 | −28.8771 | 480.35 z-21,884.55 = 0 |

| Y | 154.728 | 150.593 | 164.943 | ||

| Z | 45.5599 | 45.5599 | 45.5599 | ||

| Pattern 3 | X | 137.304 | 137.235 | 138.985 | 5.85 z-195.40 = 0 |

| Y | −210.955 | −213.832 | −225.654 | ||

| Z | 33.3995 | 33.3995 | 33.3712 |

| Pattern | Maximum Stress (MPa) | Maximum Driving Force (N) | Maximum Strain Energy (mJ) | Smoothness Index (mm) | Folding Height (cm) |

|---|---|---|---|---|---|

| Pattern 1 | 75 | 5.22 | 19.81 | 1.49 | 46.19 |

| Pattern 2 | 55 | 0.28 | 4.18 | 0.96 | 138.56 |

| Pattern 3 | 60 | 1.51 | 3.35 | 1.01 | 69.28 |

| Pattern | Coordinate | A | B | C |

|---|---|---|---|---|

| Pattern 2a | X | 94.3535 | 92.3292 | 90.1491 |

| Y | 40.4019 | 42.3878 | 46.1852 | |

| Z | 50.4973 | 50.4973 | 50.4973 | |

| Pattern 2b | X | 50.6343 | 42.6613 | 30.7569 |

| Y | 66.5513 | 80.6865 | 73.4856 | |

| Z | 31.2555 | 31.2555 | 31.2555 |

| Pattern | Maximum Stress (MPa) | Maximum Driving Force (N) | Maximum Strain Energy (mJ) | Smoothness Index (mm) | Folding Height (cm) |

|---|---|---|---|---|---|

| Pattern 2 | 55 | 0.28 | 4.18 | 0.96 | 138.56 |

| Pattern 2a | 66 | 0.30 | 5.86 | 1.20 | 69.39 |

| Pattern 2b | 78 | 0.33 | 6.38 | 1.49 | 46.19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Q.; Jia, W.; Wu, H.; Kueh, A.B.H.; Wang, Y.; Wang, K.; Cai, J. Wrapping Deployment Simulation Analysis of Leaf-Inspired Membrane Structures. Aerospace 2021, 8, 218. https://doi.org/10.3390/aerospace8080218

Lin Q, Jia W, Wu H, Kueh ABH, Wang Y, Wang K, Cai J. Wrapping Deployment Simulation Analysis of Leaf-Inspired Membrane Structures. Aerospace. 2021; 8(8):218. https://doi.org/10.3390/aerospace8080218

Chicago/Turabian StyleLin, Qiuhong, Wenwen Jia, Huiying Wu, Ahmad B. H. Kueh, Yutao Wang, Kexin Wang, and Jianguo Cai. 2021. "Wrapping Deployment Simulation Analysis of Leaf-Inspired Membrane Structures" Aerospace 8, no. 8: 218. https://doi.org/10.3390/aerospace8080218

APA StyleLin, Q., Jia, W., Wu, H., Kueh, A. B. H., Wang, Y., Wang, K., & Cai, J. (2021). Wrapping Deployment Simulation Analysis of Leaf-Inspired Membrane Structures. Aerospace, 8(8), 218. https://doi.org/10.3390/aerospace8080218