Abstract

An inductive pulsed plasma thruster (IPPT) operates by pulsing high current through an inductor, typically a coil of some type, producing an electromagnetic field that drives current in a plasma, accelerating it to high speed. The IPPT is electrodeless, with no direct electrical connection between the externally applied pulsed high-current circuit and the current conducted in the plasma. Several different configurations were proposed and tested, including those that produce a plasma consisting of an accelerating current sheet and those that use closed magnetic flux lines to help confine the plasma during acceleration. Specific impulses up to 7000 s and thrust efficiencies over 50% have been measured. The present state-of-the-art for IPPTs is reviewed, focusing on the operation, modeling techniques, and major subsystems found in various configurations. Following that review is documentation of IPPT technology advancement paths that were proposed or considered.

1. Introduction

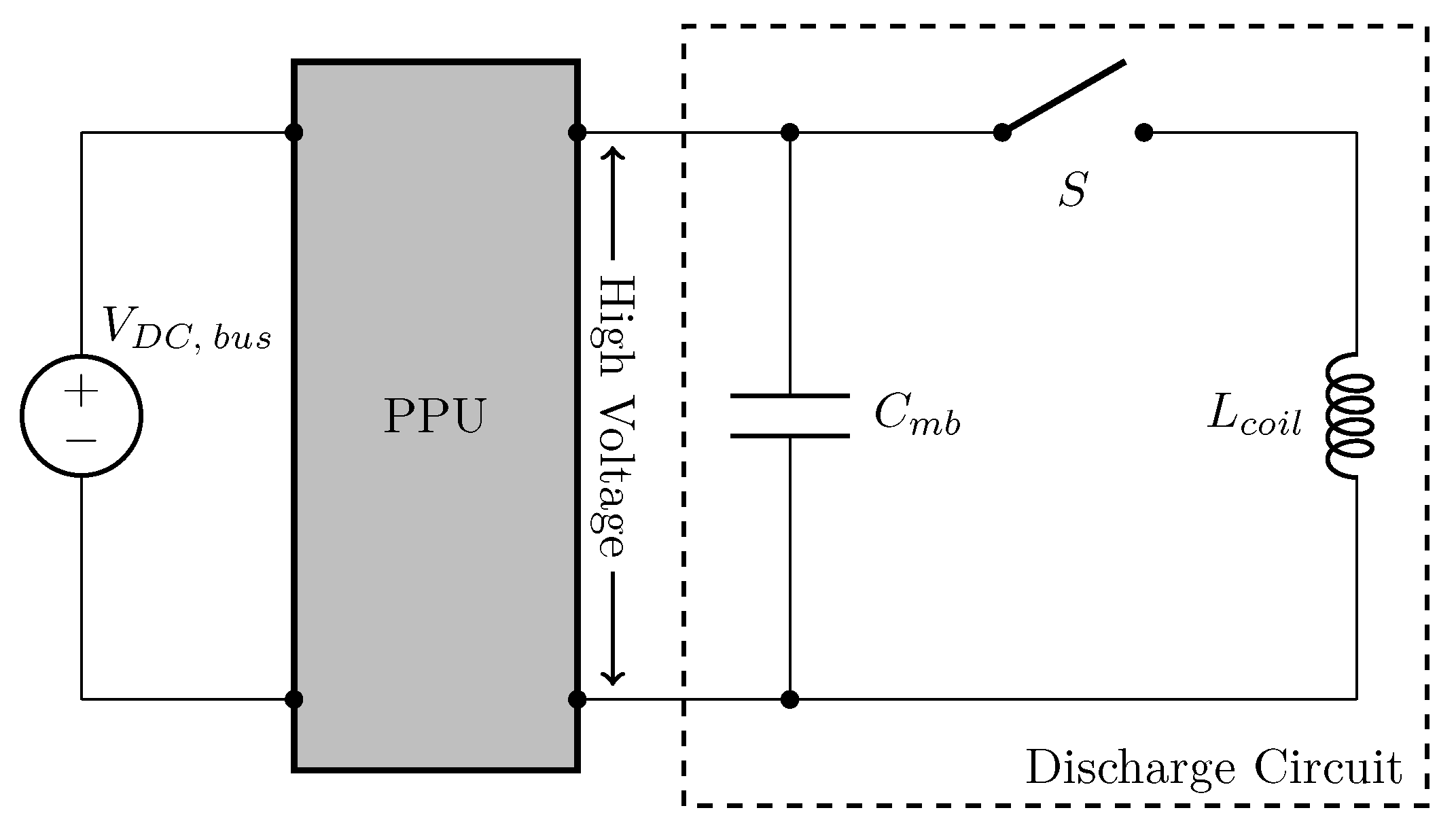

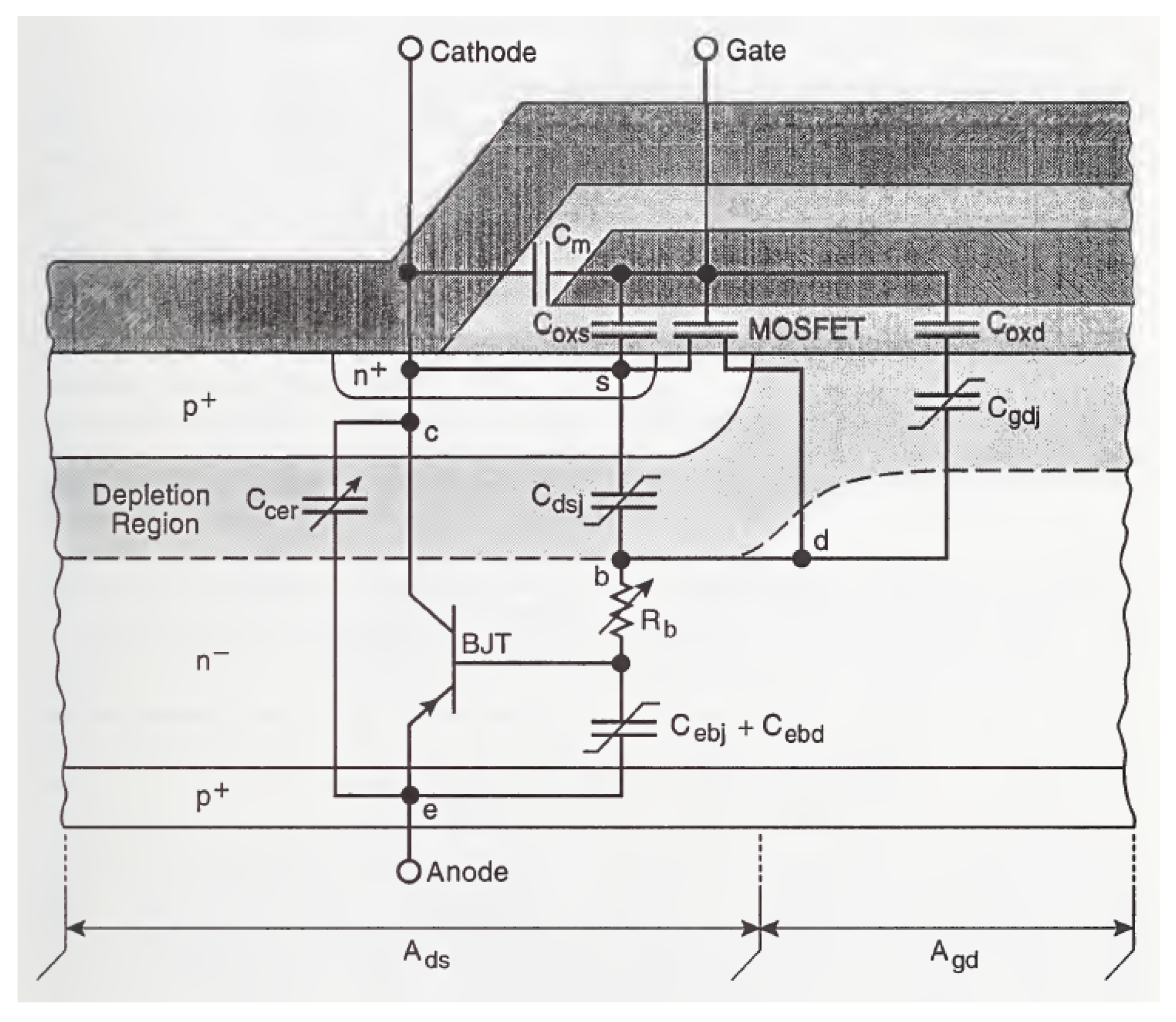

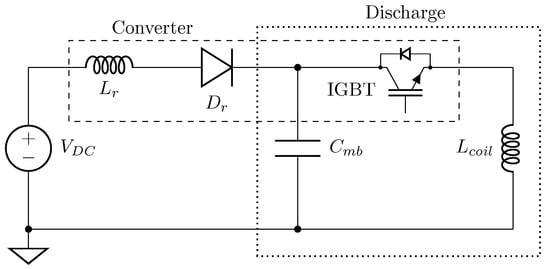

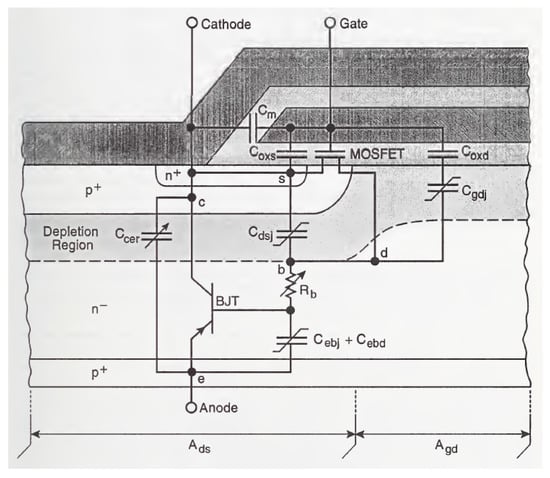

An inductive pulsed plasma thruster (IPPT) is a spacecraft propulsion system that uses short, high current electrical pulses flowing through an inductive coil or set of coils to drive currents in a plasma and expel it at high speed. While there are multiple implementations that can operate in the manner described, they all share some common features. The electrical energy is typically stored at high voltage in capacitors before being discharged rapidly through the inductive coil. Switches for the pulsed circuit are required to hold off voltages of multiple kV during the capacitor charging phase and then often conduct 10 s of kA of current when discharging. The switches must allow for a very high current rise rate during pulses that last on the order of 1–10 s. Coupling between the coils and the propellant is all accomplished inductively, making these devices electrodeless. This electrodeless nature eliminates electrode erosion caused by high-rate charge transfer across the material-vacuum interface found in thrusters with electrodes, where the propellant is in contact with electrodes and completes the electrical circuit. As such, IPPTs are capable of operation on propellants that could be corrosive to electrodes in other plasma thrusters.

While the thruster types described in this paper have unique aspects to their operation, at a high level IPPTs operate through a combination of Ampère’s and Faraday’s laws, given respectively as:

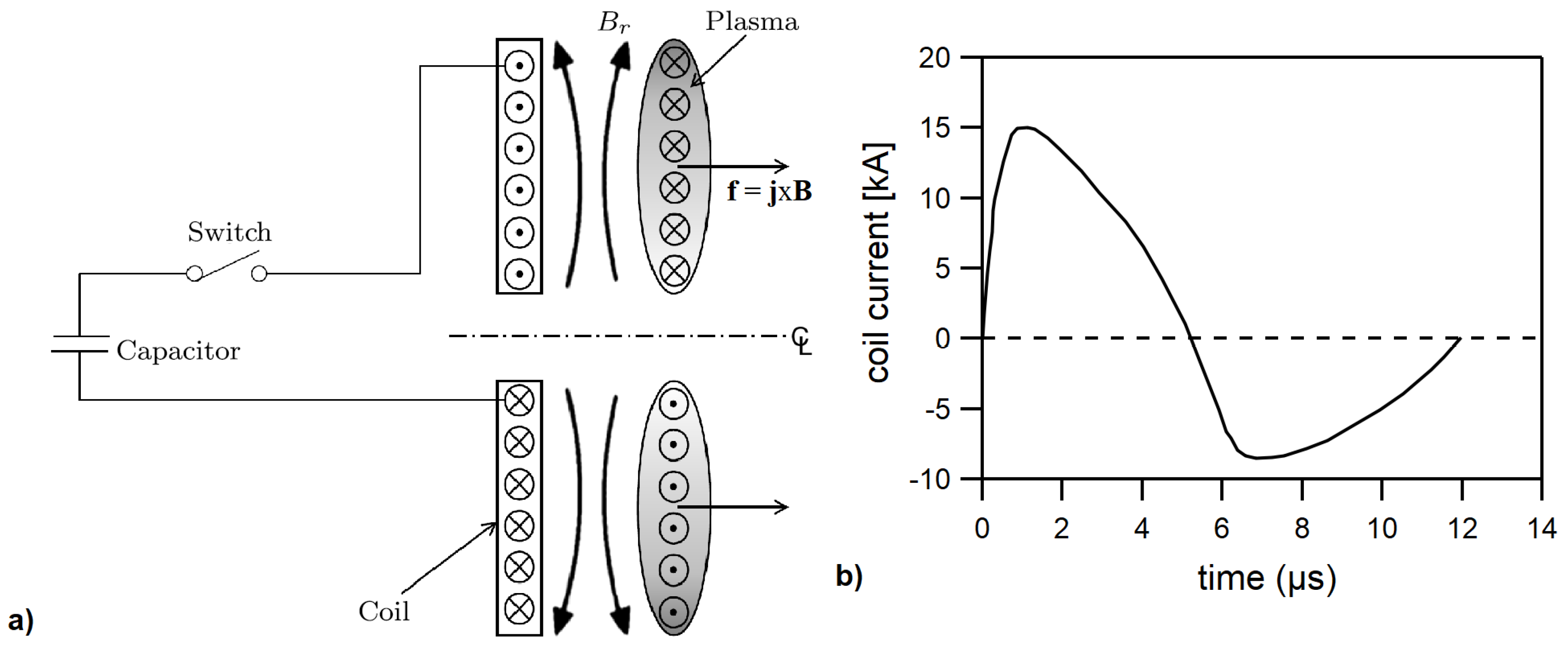

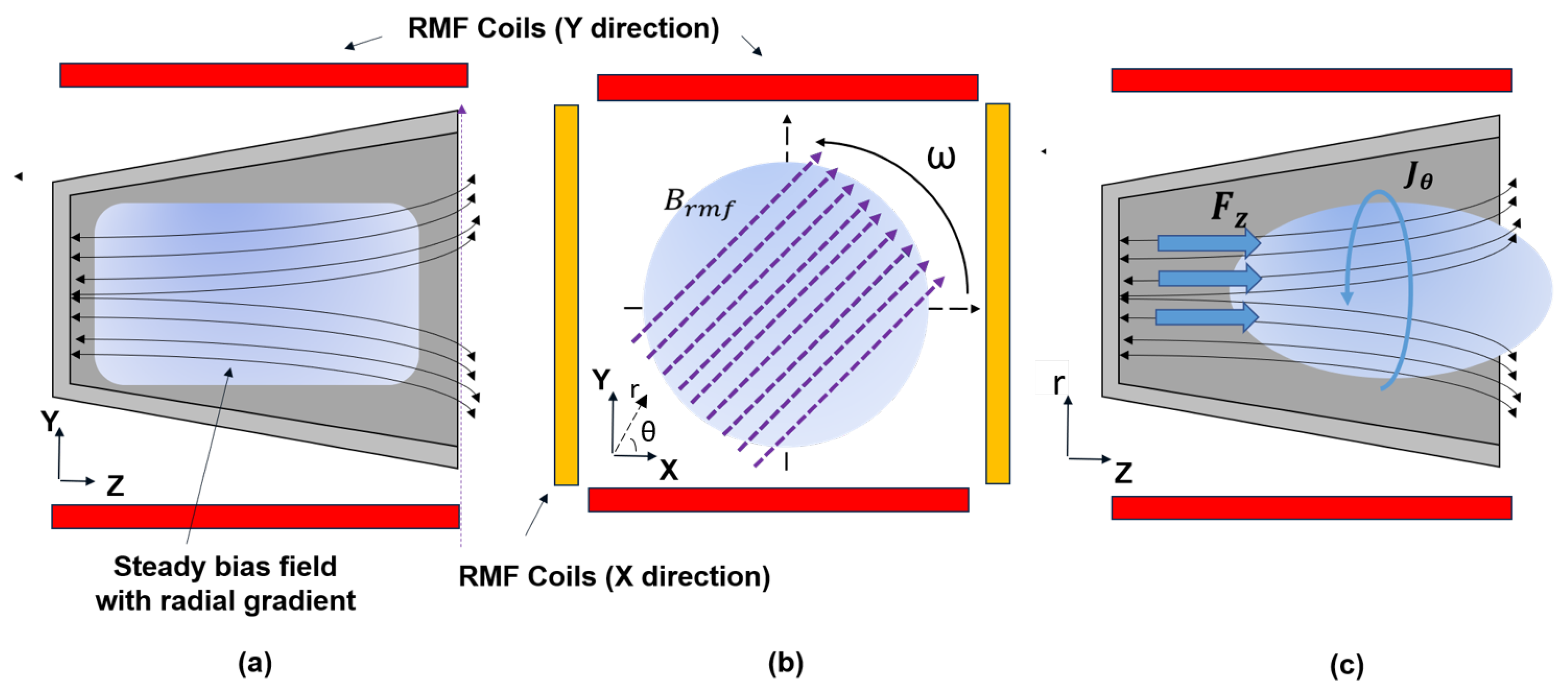

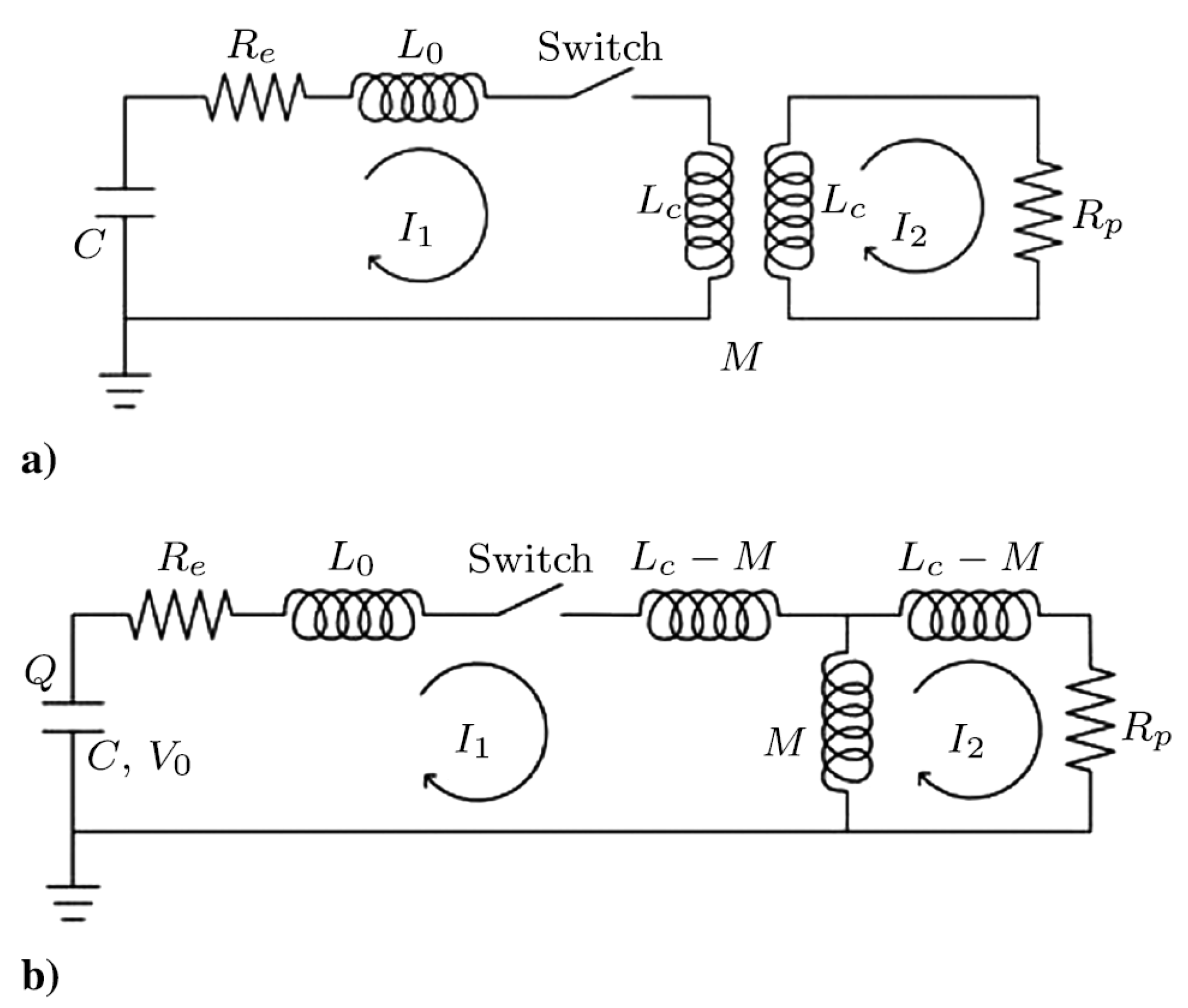

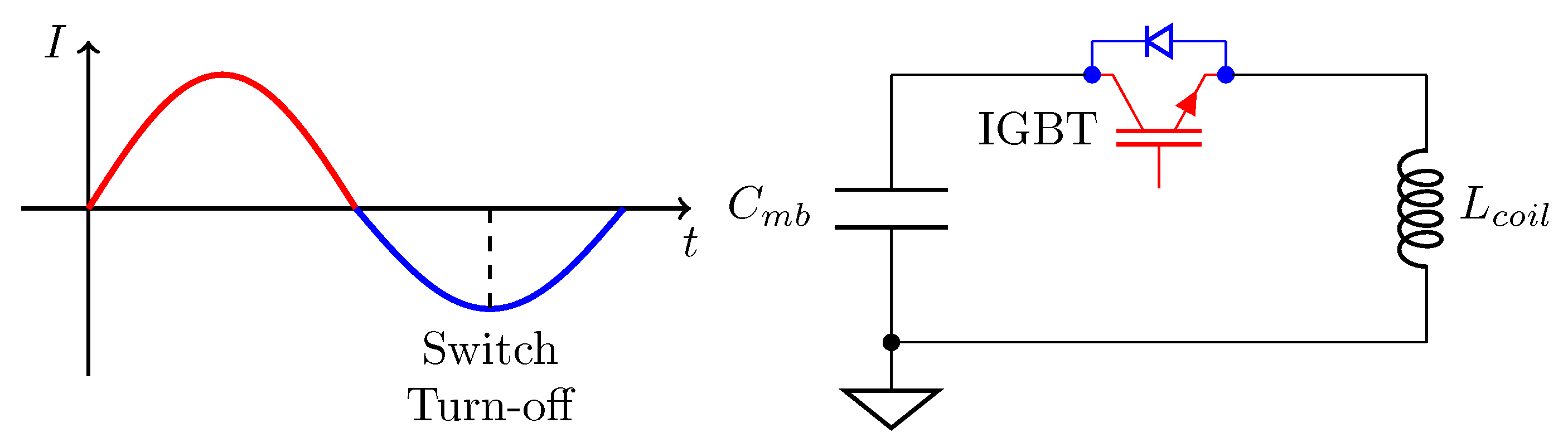

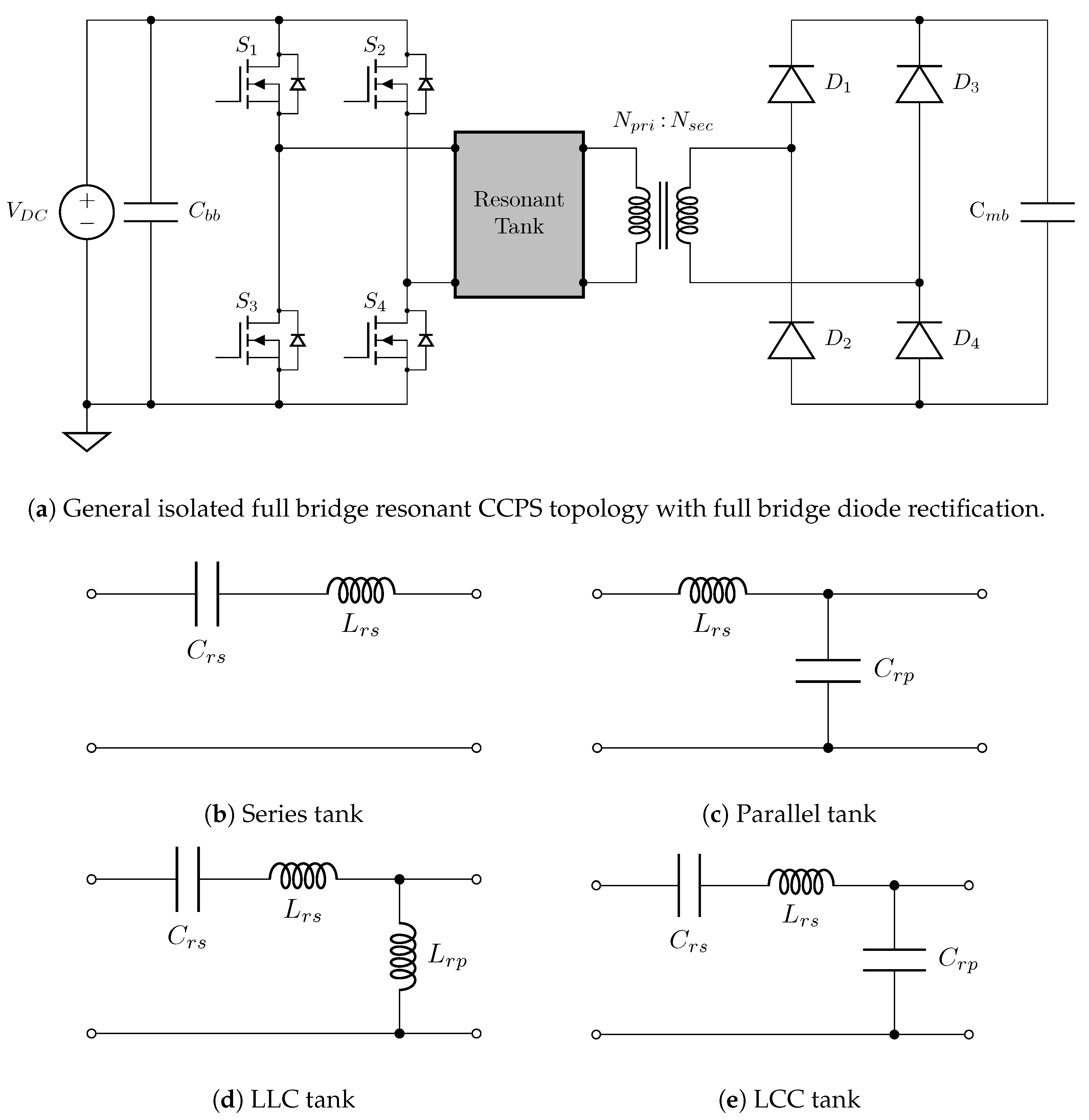

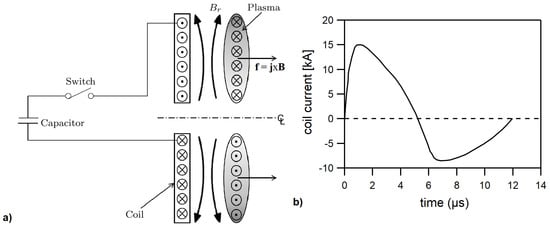

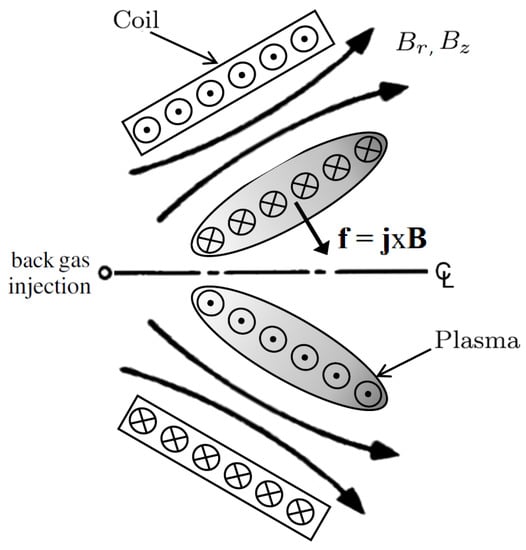

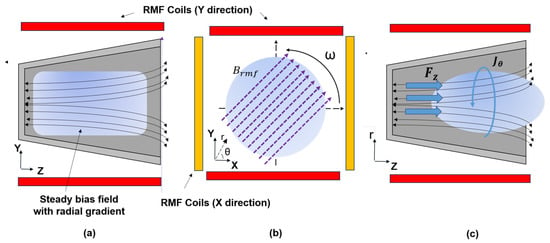

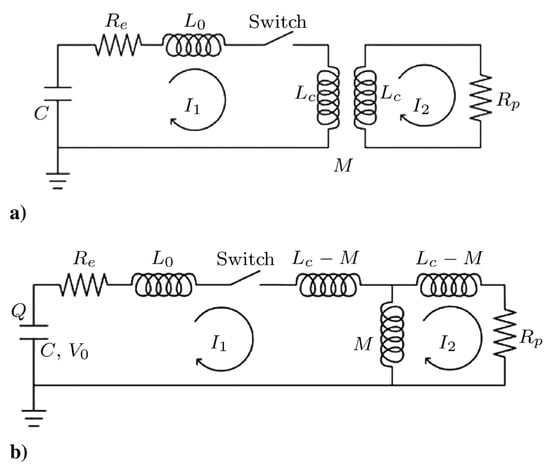

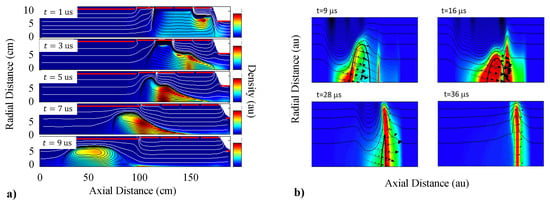

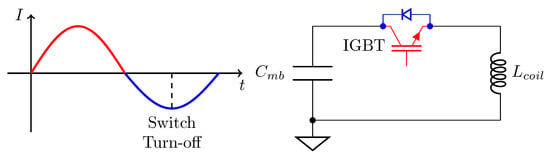

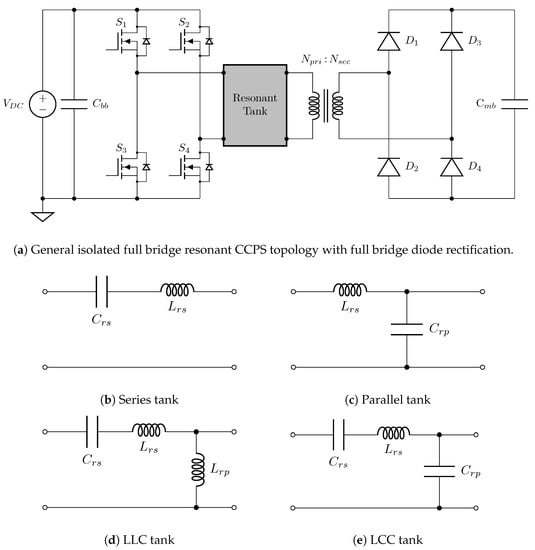

In these equations the electric and magnetic field vectors are and , the current density vector is , and the permeability of free space is . Using the schematic of Figure 1a for illustrative purposes, current flowing azimuthally in the coil produces a radial magnetic field through the relationship in Ampère’s law. A fast time-variation in the current produces an equally rapidly varying magnetic field that, through Faraday’s law, induces a strong azimuthal electric field. The direction of the electric field is opposite to the current in the coil, giving rise to a counter-rotating azimuthal plasma current. The currents in the coil and plasma electromagnetically repel each other, axially accelerating the current-carrying plasma to yield thrust.

Figure 1.

(a) Schematic showing the basic operation of a planar IPPT, where the Lorentz body force in the axial direction arises from the interaction between the azimuthal plasma current density and the radial magnetic field . (b) Sample discharge current from the PIT MK Va for one of the nine parallel coils (from [9]).

IPPTs must overcome inherent difficulties related to both ionization and acceleration to achieve high efficiencies [1]. Since the primary (external) circuit is completed without the presence of an induced (secondary circuit) plasma current, a delay between current initiation in the primary circuit and ionization of the gas will result in increased resistive energy dissipation in the primary circuit. In addition, once the secondary plasma current exists, electrodynamic coupling between the two current loops is a function of the mutual inductance between the two circuits, which decreases quickly as the separation between the plasma and the external circuit increases. Efficient operation can only be achieved if a significant fraction of energy transfer to the secondary circuit can be accomplished rapidly, before the plasma is too distant to effectively couple with the primary circuit. Finally, in addition to transferring energy to the plasma quickly, an efficient pulse circuit must be capable of performing significant electromagnetic work on the propellant. The inductance of the circuit increases as a function of time, and this increase is representative of the amount of electromagnetic work the circuit is capable of performing. For efficient acceleration the ratio of the coil inductance , which is the amount by which the circuit inductance increases during the pulse, to the initial (also called stray or parasitic) inductance , which is fixed and performs no electromagnetic work on the propellant, must be much larger than unity [2].

For the purposes of classification, we subdivide IPPTs into two general categories. Inherent in these categories is the nature of the magnetic flux surfaces in the thruster. One category consists of thrusters in which a current sheet is formed and accelerated in the direction perpendicular to the electromagnetic coil. These thrusters are characterized by open magnetic flux surfaces in the gap between the coil and the plasma current loops, with the flux surfaces exiting the gap at the extents of the coil and current sheet. The main thruster of this type in the literature is the Pulsed Inductive Thruster (PIT) [3], though theta-pinch and conical theta-pinch devices can also be operated in this mode [4]. The other category is comprised of thrusters in which closed magnetic flux surfaces are embedded within and aid in confinement of the plasma. Plasmas in this configuration are generally known as compact toroids, with those under development for spacecraft propulsion known as field-reversed configuration (FRC) thrusters [5] or plasmoid thrusters [6].

It is a goal of the present paper to provide a review of the state-of-the-art for all IPPT research and development. There is a comprehensive review of the open magnetic flux surface planar thrusters [7] and a review of FRC plasma devices as they relate to fusion [8], but to the authors’ knowledge there has never before been a single publication that presented a technological review of all open and closed magnetic flux surface IPPT types. We discuss the major thruster variants, describing their modes of operation and presenting any available experimental measurements that aid in quantifying propulsive performance. The modeling techniques that have been applied to IPPTs are also reviewed, with emphasis placed on the insights that have been gained by these efforts. Finally, we discuss the major subsystems needed to operate an IPPT, describing the current state-of-the-art and present limitations of these subsystems and their constituent components.

The other purpose of this paper is to describe possible paths to advance IPPTs beyond the current state-of-the-art. Included in this description is a listing of the present gaps in technological capabilities or basic understanding of physical processes in these thrusters or their constituent subsystems. Following the same structure as the review of the present state-of-the-art, we provide a discussion of various potential means to improve different thruster variant designs by enhancements to current modeling capabilities and through advancement in the capabilities of specific subsystems and components.

2. Review of Inductive Pulsed Plasma Thrusters

We proceed with a description of the different IPPT variants and their inherent properties and operating characteristics. The results of key test campaigns are summarized and, when available, the measured performance for each thruster variant is presented. The specific impulse (thrust per unit weight flow of propellant) in any pulsed thruster is:

where is the average exhaust velocity of all the propellant injected into the thruster for a pulse, is Earth’s gravitational acceleration constant, is the impulse bit or impulse per pulse of the thruster, and is the mass bit or injected propellant mass per pulse. Likewise, the thrust efficiency in a pulsed thruster is the ratio of directed kinetic energy in the expelled plasma jet to the initial stored electrical energy , and is given as:

2.1. Open Magnetic Flux Thrusters

Open magnetic flux IPPTs have an inductive coil configured such that when a capacitor bank is discharged by closing a switch, an azimuthal current is driven in the coil. If there is an ionized gas over the face of the coil, the time-varying current in the coil will induce a counter-rotating azimuthal current sheet in the plasma that mirrors the geometry of the driving coil, as illustrated in Figure 1a for a planar thruster variant. The coil and plasma currents produce a concentrated axisymmetric magnetic field in the r-z plane that is sandwiched between the two current rings. The plasma is accelerated to high exhaust velocities in the direction perpendicular to the coil face by the Lorentz body force arising from the interactions of the plasma current and magnetic field. Any gas that is encountered by the accelerating current sheet may be entrained in the sheet. The representative discharge current waveform in Figure 1b shows the relative timescale and magnitude of the current in an IPPT.

2.1.1. Planar Thrusters

The IPPT variant that has seen the most sustained development work as a propulsion system is the planar thruster known as the Pulsed Inductive Thruster (PIT), researched by Dailey and Lovberg [3]. This thruster type has been the subject of many past experimental studies and was discussed in detail in a comprehensive review by Polzin [7]. What follows is a summary of the major experimental results described in that review, as these results represent the current state-of-the-art for planar IPPTs.

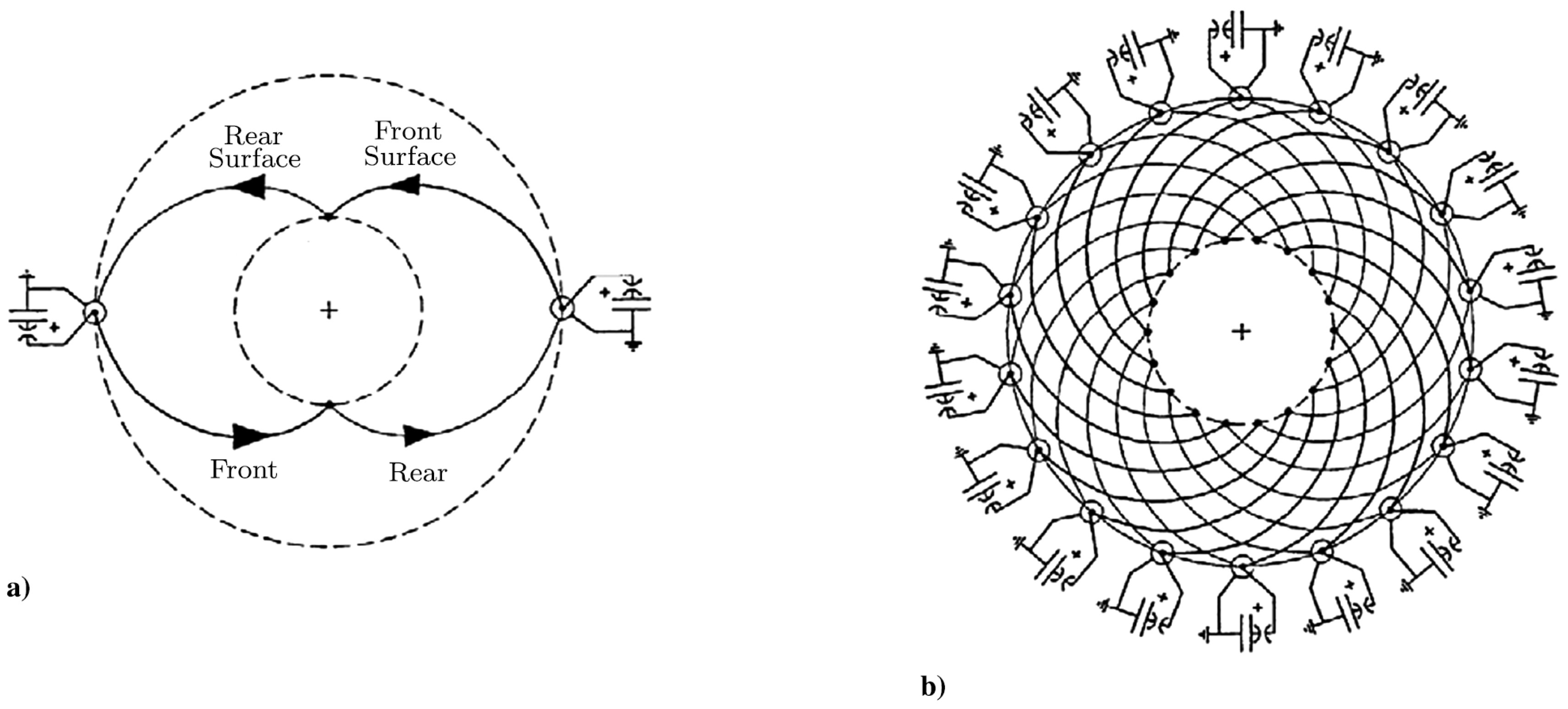

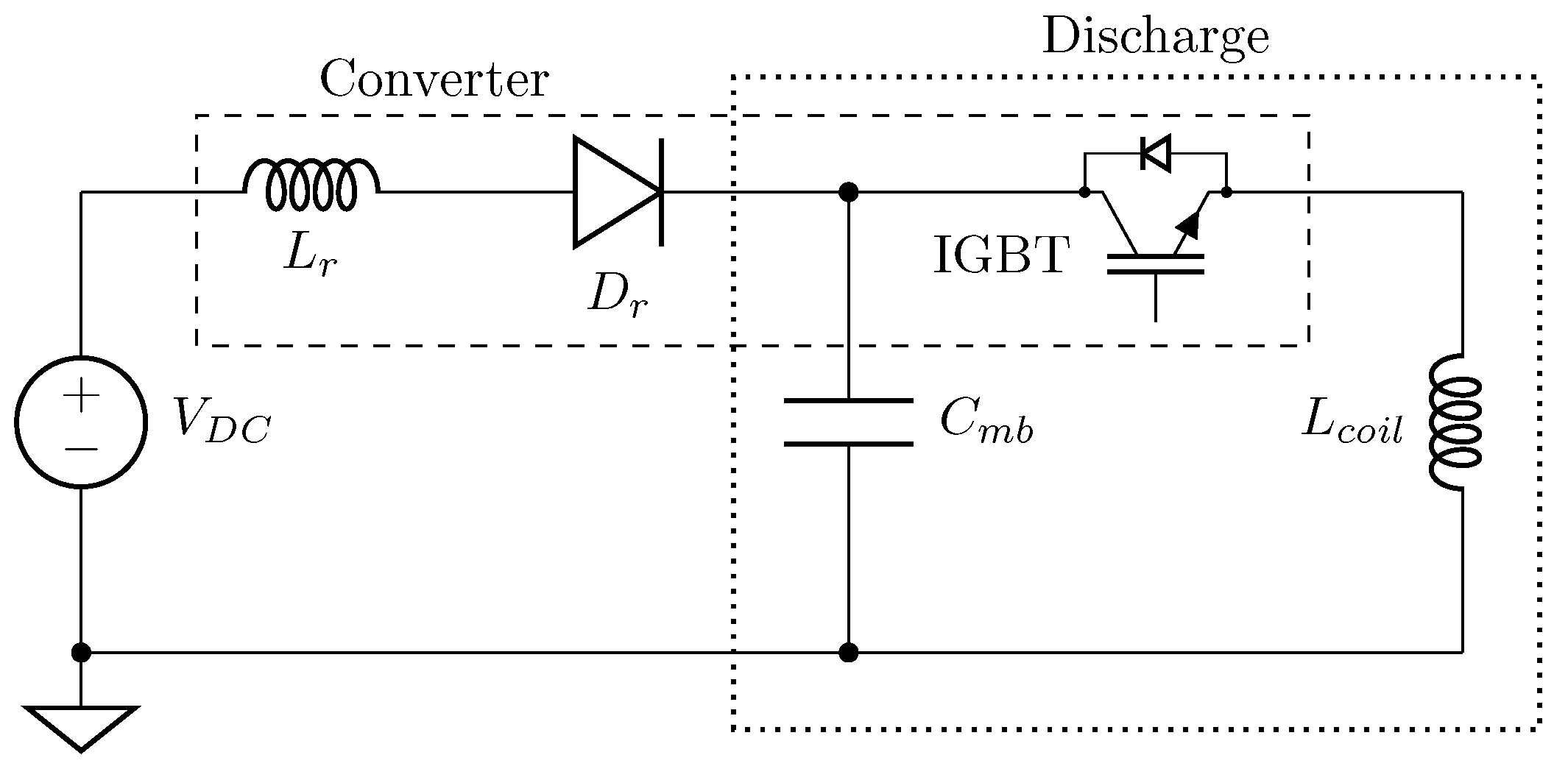

Significant work on the PIT was aimed at minimizing the delay time between the initiation of the external current pulse and the breakdown of the gas over the face of the coil. This was accomplished by increasing the current rise rate in the coil, as this generates stronger fields in the gas and serves to more rapidly ionize the propellant. The current rise rate can be raised by increasing the initial charge voltage on the capacitor bank or by decreasing the parasitic or stray inductance in the circuit. Many tests over a number of years were conducted in the 15–24 kV range. However, the biggest improvement was realized in the PIT MK V and MK Va where the coil was reconfigured from a number of parallel Archimedes spirals connected to a single capacitor bank to the Marx-bank configuration shown in Figure 2 [3]. In this configuration, the azimuthal voltage initially applied to the coil is double that of any individual capacitor, so the nominal 15–16 kV of capacitor charge appears as a net 30–32 kV initial azimuthal voltage. The Marx-bank configuration also has the advantage of adding the stray inductance for each leg of the circuit in parallel, yielding a much lower net stray inductance for an overall lumped-element circuit. The combination of greater net azimuthal voltage and lower stray inductance resulted in a much greater current rise rate in the thruster, reducing the delay in the breakdown of the propellant and also producing a far more uniform current sheet over the coil face [7].

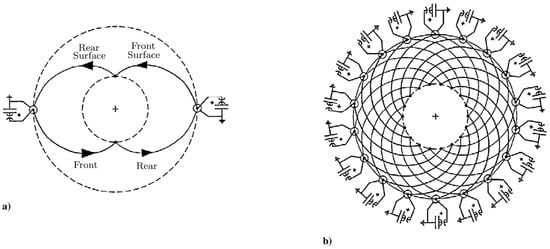

Figure 2.

PIT MK V and MK Va Marx-generator coil configuration: (a) one complete Marx-generator loop and (b) the nine complete loops comprising the entire coil (from [3]).

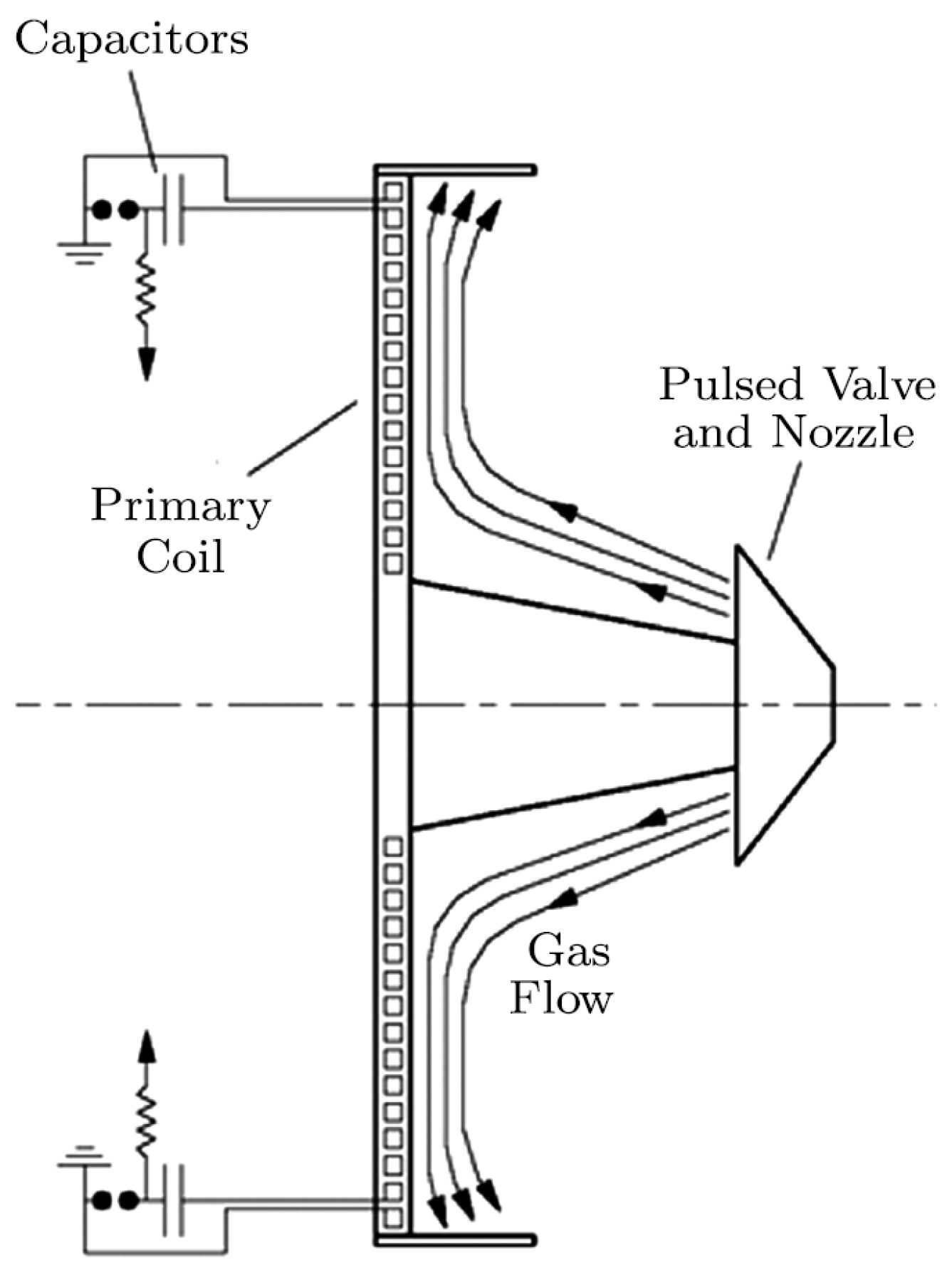

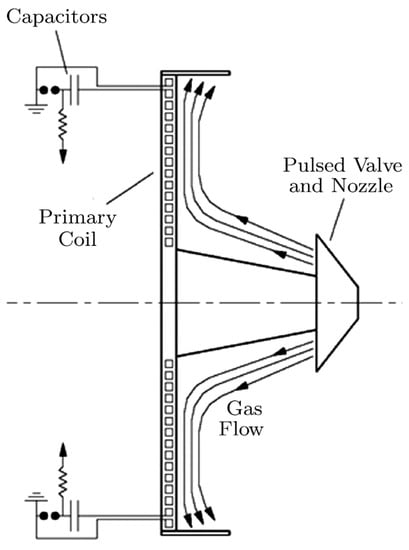

The injection of gas in the PIT is also a major issue that was addressed over a number of experimental campaigns. The primary problem is that injected gas can readily escape to the vacuum of space before it has been electromagnetically accelerated. This escaping gas moves slowly compared to the portion of the gas that is electromagnetically accelerated, reducing the average of the injected gas. To address this issue, a tall conical structure was located along the centerline of the thruster with nozzles that injected gas towards the thruster face as depicted in Figure 3. It was shown that the gas stagnated and had to first spread radially along the coil face before it could escape to vacuum, yielding a somewhat uniform propellant distribution over the coil [3,10]. After the gas had moved radially outward but before too much had the opportunity to escape, the current pulse was initiated, ionizing and accelerating the gas.

Figure 3.

Schematic showing a typical propellant injection scheme employed on the PIT (from [3]).

Initial work on the PIT involved coils with outer diameters of 20 and 30 cm [11,12], but most later iterations had coil diameters of 1 m [3,13,14]. The distance over which the coil electromagnetically interacts or couples with the gas is, to first order, a fixed fraction of the overall coil diameter. Consequently, increasing the coil diameter increases the overall interaction distance. All other things being equal, increasing the interaction distance will increase the overall amount of injected gas that is within the coupling region when the thruster circuit is discharged. The nature of the reduction in the electromagnetic interaction as a function of distance is such that the closer the gas is to the coil, as a fraction of the overall interaction distance, the greater the potential electromagnetic interaction.

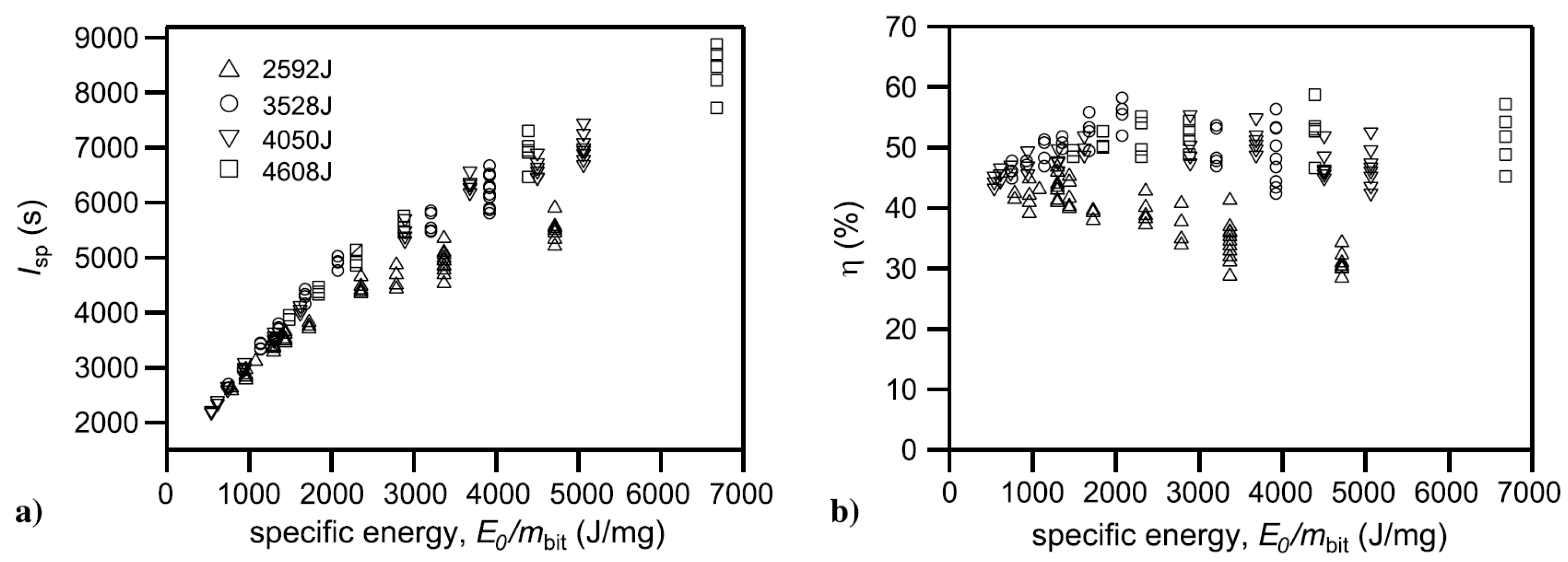

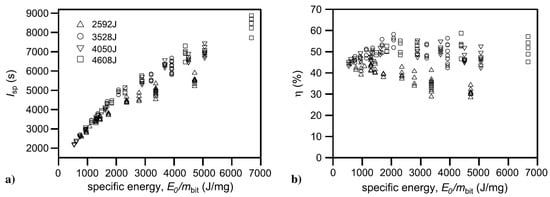

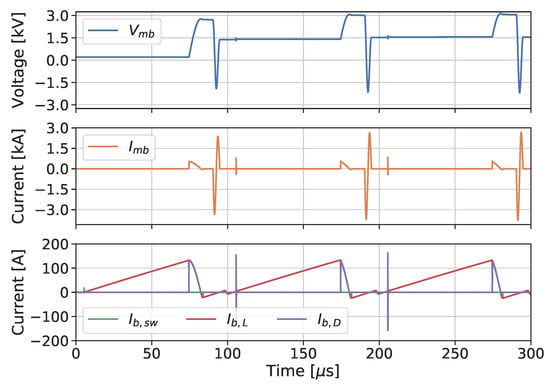

The PIT MK V (4.5 F bank capacitance) and MK Va (9 F bank capacitance)—both configurations are sometimes collectively referred to in the literature as the MK V—represent the current IPPT state-of-the-art in terms of thruster performance. Of all IPPTs, there are more direct thrust measurements for these variants than for all other thruster concepts in the literature [7]. These thrusters have published thrust measurements for single-pulse operation on a number of different propellants, specifically helium (He), carbon dioxide (CO), argon (Ar), ammonia (NH), and simulated hydrazine (N + 4NH). Of all these propellants, the highest performance was achieved on ammonia, with efficiencies of over 50% in the MK Va [3] as illustrated in Figure 4. Notably, this high efficiency was demonstrated over a broad range of , which is very interesting from a mission planning perspective because it shows a range over which the can be throttled without a significant reduction in performance. In the same way that any electric motor exhibits a peak in efficiency as a function of motor speed, this constant high efficiency regime was understood as operation in the regime where there is a match between the external circuit and gas acceleration timescales such that the transfer of electrical energy into kinetic energy of the plasma is maximized. Finally, it was shown that the efficiency was reduced and the did not rise as quickly as a function of increasing specific energy () when the discharge energy per pulse was ∼2600 J. This observed trend is presently not well understood.

Figure 4.

(a) Specific impulse and (b) thrust efficiency as a function of specific energy for the PIT MK Va thruster operating on ammonia propellant (data from [3]).

There were attempts to use preionization to increase the primary discharge ionization rate in planar IPPTs, though the results of such experiments were decidedly mixed. In the 30 cm planar IPPT a low energy fast current pulse was driven through the acceleration coil prior to the main discharge [12]. This did preionize the gas, but the fields produced by the current in the coil have the same orientation as those that accelerate the propellant, resulting in the preionized gas being electromagnetically pushed a finite distance away from the coil face before the main discharge pulse. Energy coupled into the propellant at the location of the now-displaced preionized gas, but as this location was further from the coil, there was less potential for electromagnetic work.

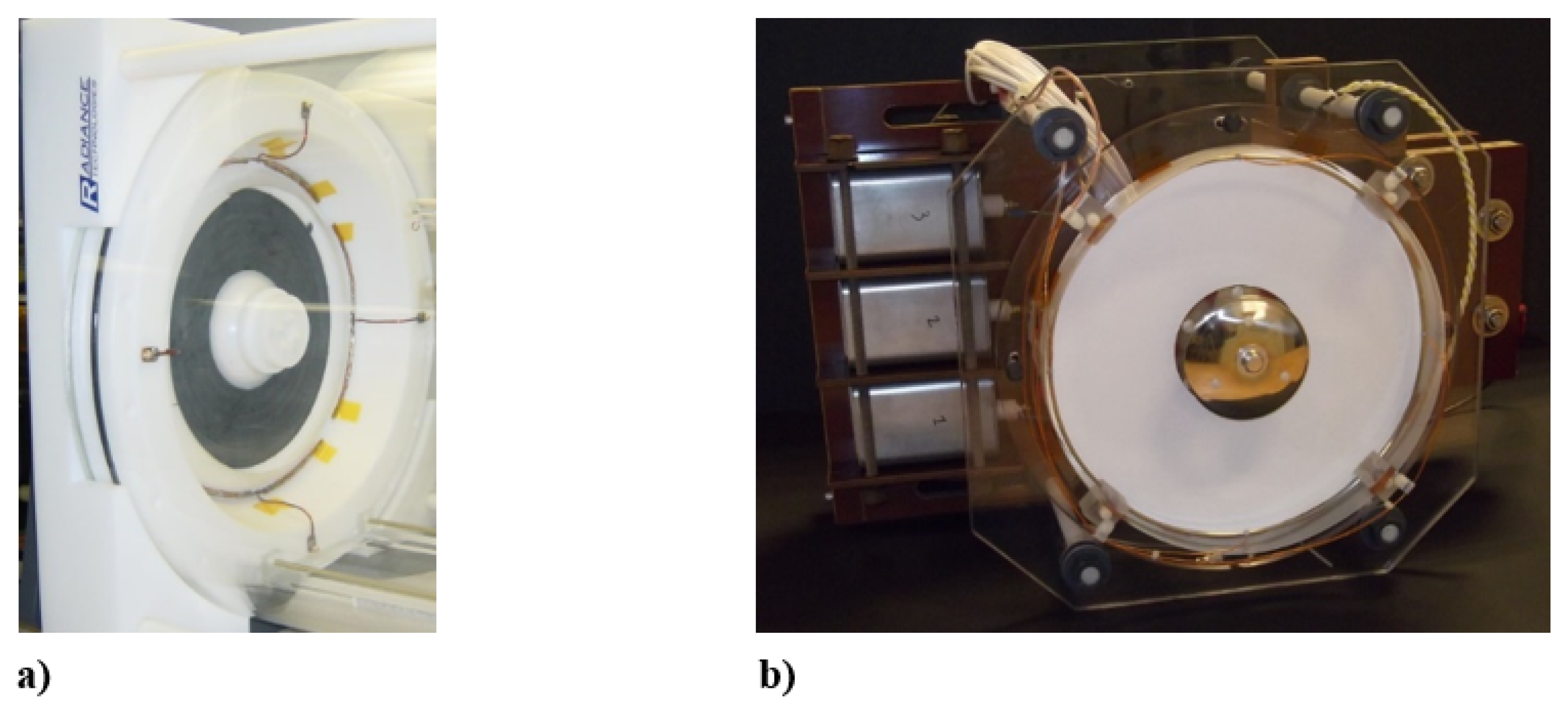

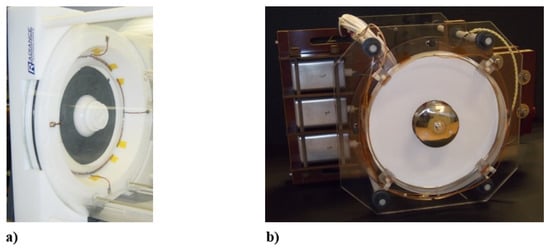

In the Faraday accelerator with radio-frequency assisted discharge (FARAD) device a planar coil was used in conjunction with a gas that was ionized in an RF discharge and directed to the coil face by an applied radial magnetic field [15,16]. The discharge energy was much lower in FARAD compared to the PIT (<100 J compared to 4 kJ), so the plasma current would not form without the presence of the preionization. Testing of the initial FARAD proof-of-concept device demonstrated that preionization could be used to lower the main discharge requirements on propellant breakdown, but further study is required to more properly quantify this effect. In a later higher-energy 100 J/pulse implementation of the FARAD concept, shown in Figure 5a, a pulsed RF vector inversion generator (VIG) discharge [17] preionization scheme was employed. In this thruster at the discharge energy levels tested, the main discharge was sufficient to ionize the neutral gas without preionization and no attempt was made to more thoroughly quantify the effects of preionization on reducing the breakdown voltage or improving thruster performance.

Figure 5.

(a) The FARAD thruster (from [17]), (b) The 27 cm diameter planar IPPT (from [18]).

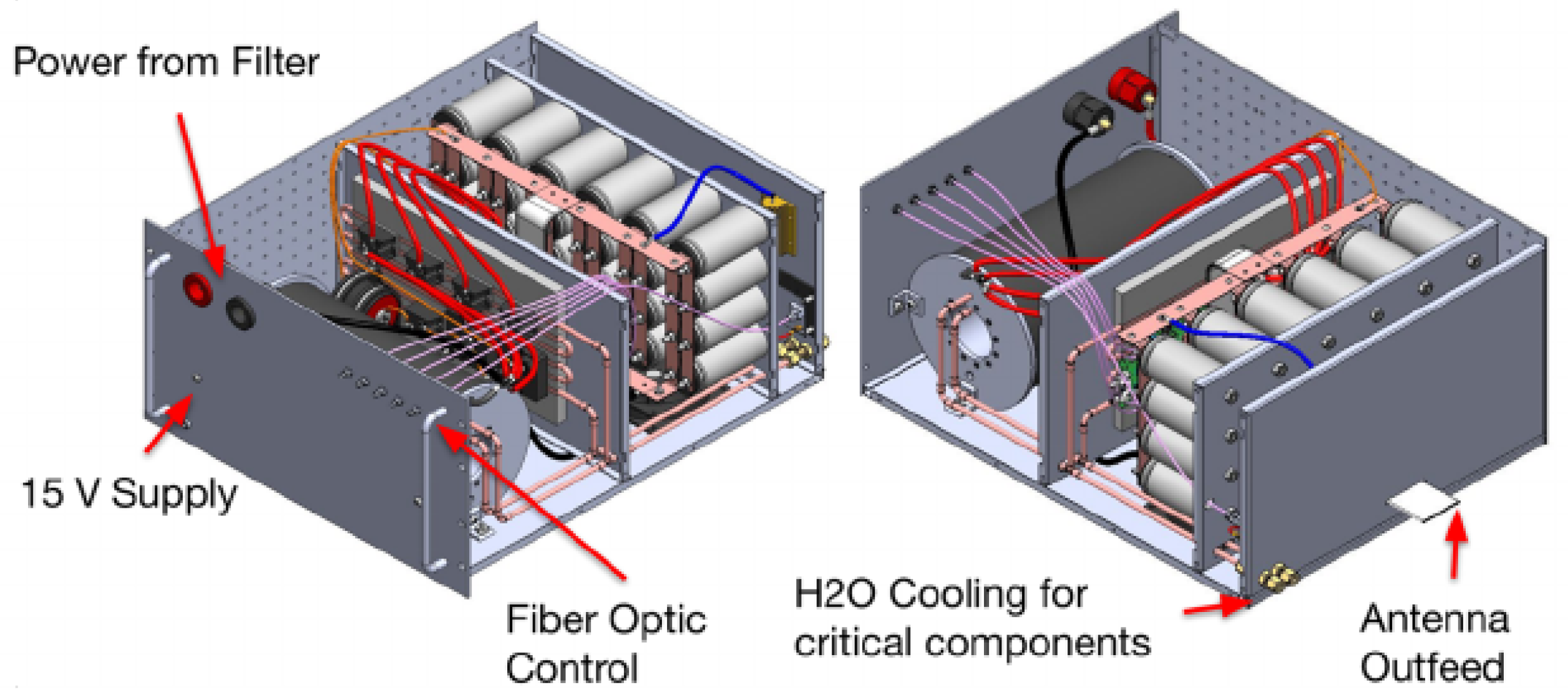

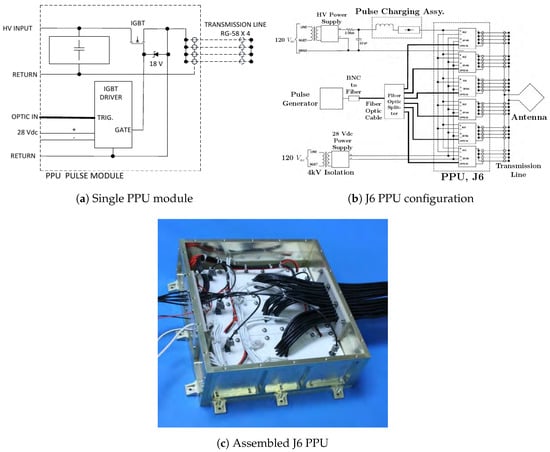

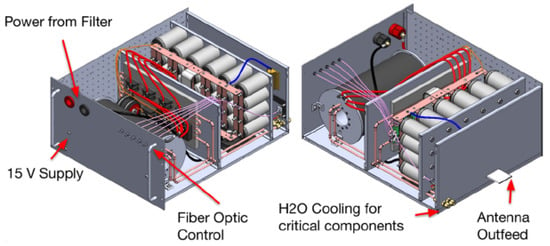

The NASA-Marshall 27 cm diameter planar IPPT, shown in Figure 5b, was assembled to test cyclic operation with all the major subsystems of an IPPT, including a solid-state switching system, a pulsed gas valve, and preionization [18]. The thruster was designed to operate at cyclic rates up to 30 Hz and average powers in the range of 1–5 kW. The acceleration coil consisted of six two-turn spiral-wound leads in parallel, driven by a 10 F capacitor. The switch used was a hockey-puck type thyristor rated for a maximum hold-off voltage of 4.5 kV, a peak current of 30 kA, and a maximum of 22 kA/s. A fast pulsed gas valve, with an opening time of 300 s, was used to inject propellant gas (argon) over the coil face. The device had a DC glow discharge preionizer. As with FARAD, the main bank discharge was able to ionize the gas by itself, and there was no systematic study of the effect of the preionizer. The thruster was tested in vacuum, however to-date there have been no thrust measurements on the device.

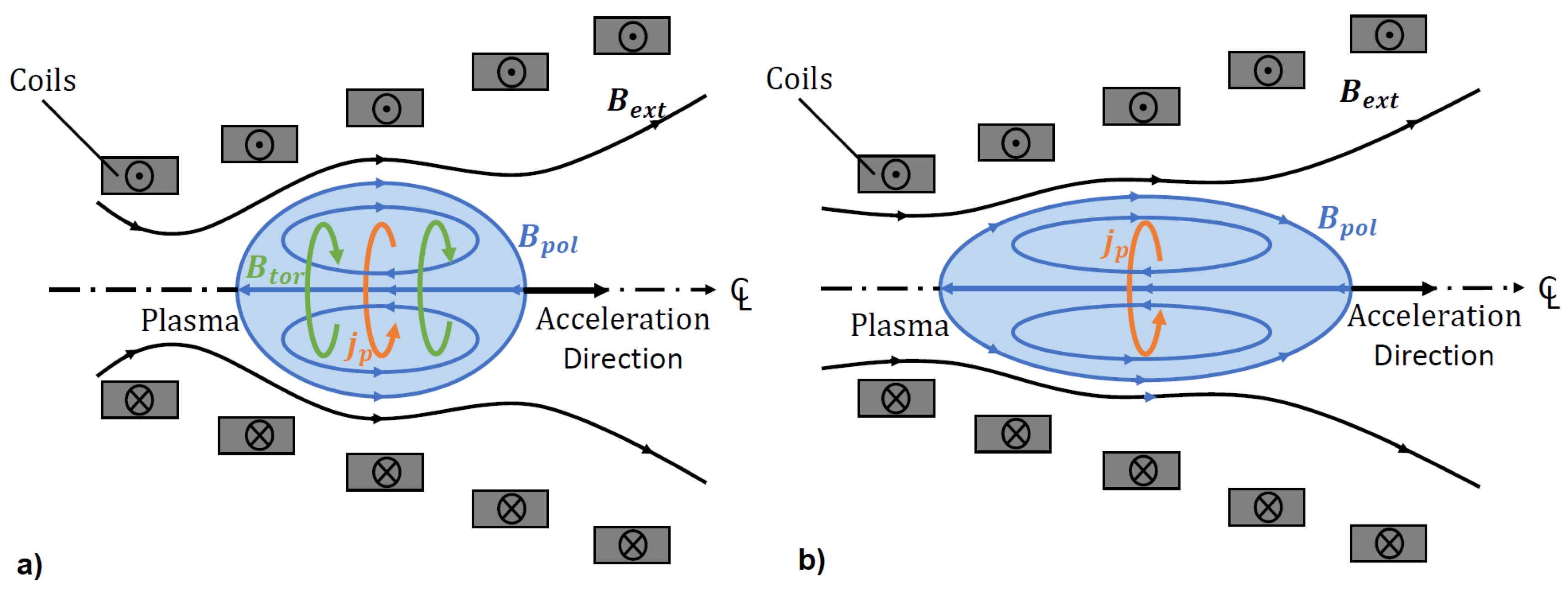

2.1.2. Conical Theta-Pinch Thrusters

In a conical theta-pinch (CTP) IPPT operating in the open magnetic flux mode, a current sheet forms on the interior surface of a conical coil and is accelerated in both the axial direction and radially-inward as illustrated in Figure 6. There has been significantly less research performed on open magnetic flux CTP devices relative to the planar IPPTs. It was hypothesized that the CTP geometry may have an advantage over planar thrusters because the propellant would be better contained within the volume defined by the conical coil. This geometry was not without potential issues, however. Specifically, since the accelerating force is in the direction perpendicular to the coil face, radially-inward motion will be imparted to the gas that must be converted by some means to axial motion if it is to produce thrust.

Figure 6.

Schematic showing the basic operation of an open magnetic flux conical theta-pinch inductive pulsed plasma thruster. The Lorentz body force , with components in the radial axial directions, arises from the interaction between the azimuthal plasma current density and the radial and axial magnetic field components .

Hallock et al. [4,19] performed testing on CTP-IPPTs proof-of-concept devices fabricated with cone angles of 20°, 38°, and 60°, measured from the centerline of the thruster. The exit diameters for these three coils were approximately 15, 23, and 25 cm, respectively. Tests were conducted in both the single pulse mode and at repetition rates up to 5 Hz and discharge energies up to 500 J/pulse. While other pulsed thrusters have operated at much faster pulse rates and greater average power throughput, their discharge energies per pulse were more than two orders of magnitude lower than the CTP testing. Also, like the PIT series of thrusters, the performance was directly measured on a thrust stand for single pulse and repetition rate operation.

Two different gas injection schemes were employed in the CTP testing. In the first scheme, gas was injected from the back of the thruster at the location illustrated in Figure 6 labeled ‘back gas injection’. This resulted in exceptionally low impulse bit measurements, implying that only a small amount of the injected gas was reaching the coil face while most of the gas remained nearer to the centerline and too far from the coil to be effectively accelerated. To test that hypothesis, a scheme was implemented to inject gas directly against the coil with a swirl imparted to the propellant to hold it against the face longer. This appeared to partially remedy the problem as the impulse bit of the thruster did indeed increase by almost a factor of 4–5 relative to when gas was injected from the back of the thruster [19].

Even when the gas was injected against the coil face, the efficiencies based on thrust measurements were below 6% on argon [4]. These data compare unfavorably with the ∼15–30% efficiencies measured with argon in the PIT MK I and MK V planar thrusters [7]. Interestingly, the impulse bits and efficiencies were greatest for the 38° cone angle, with markedly lower values measured for the 20° and 60° cone angles. One conclusion from the experimental data was that the radial velocity imparted to the gas was simply not being effectively converted to axial motion, which can result in significant efficiency losses. However, that would imply that the largest cone angle should have the best performance, which was not the case. It was noted that the smaller, lower power planar IPPTs were less efficient than larger, higher power PITs. The results of that work point to additional loss mechanisms in the CTP-IPPTs tested, specifically incomplete current sheet formation and excessive dissipation of energy in the entrainment of gas encountered farther from the the coil face where the electromagnetic acceleration force is reduced.

Preionization techniques were tested in the CTP geometry [19]. Application of a DC voltage to ionize the gas before the pulse was implemented, and for gas injection from the back of the thruster this preionization was necessary in ionizing the gas over the coil face during the main discharge. It was found for the discharge energies tested that when the gas was injected directly against the coil preionization was not required and, in fact, had no observable effect on the discharge current waveform or the measured performance. Consequently, it was not employed for the CTP performance measurements previously discussed. A second technique used a microwave-driven electron cyclotron resonance (ECR) discharge where permanent magnets oriented along the outside of the coil would form regions of cyclotron resonance along the inner face of the acceleration coil. While this technique succeeded in producing a luminescent plasma at microwave power levels up to 3 kW, it was discarded because it presented logistical challenges in terms of transferring the power onto the thrust stand. In addition, the high frequency waves were driving currents in the thruster coils that were causing damage to the thruster and insulation.

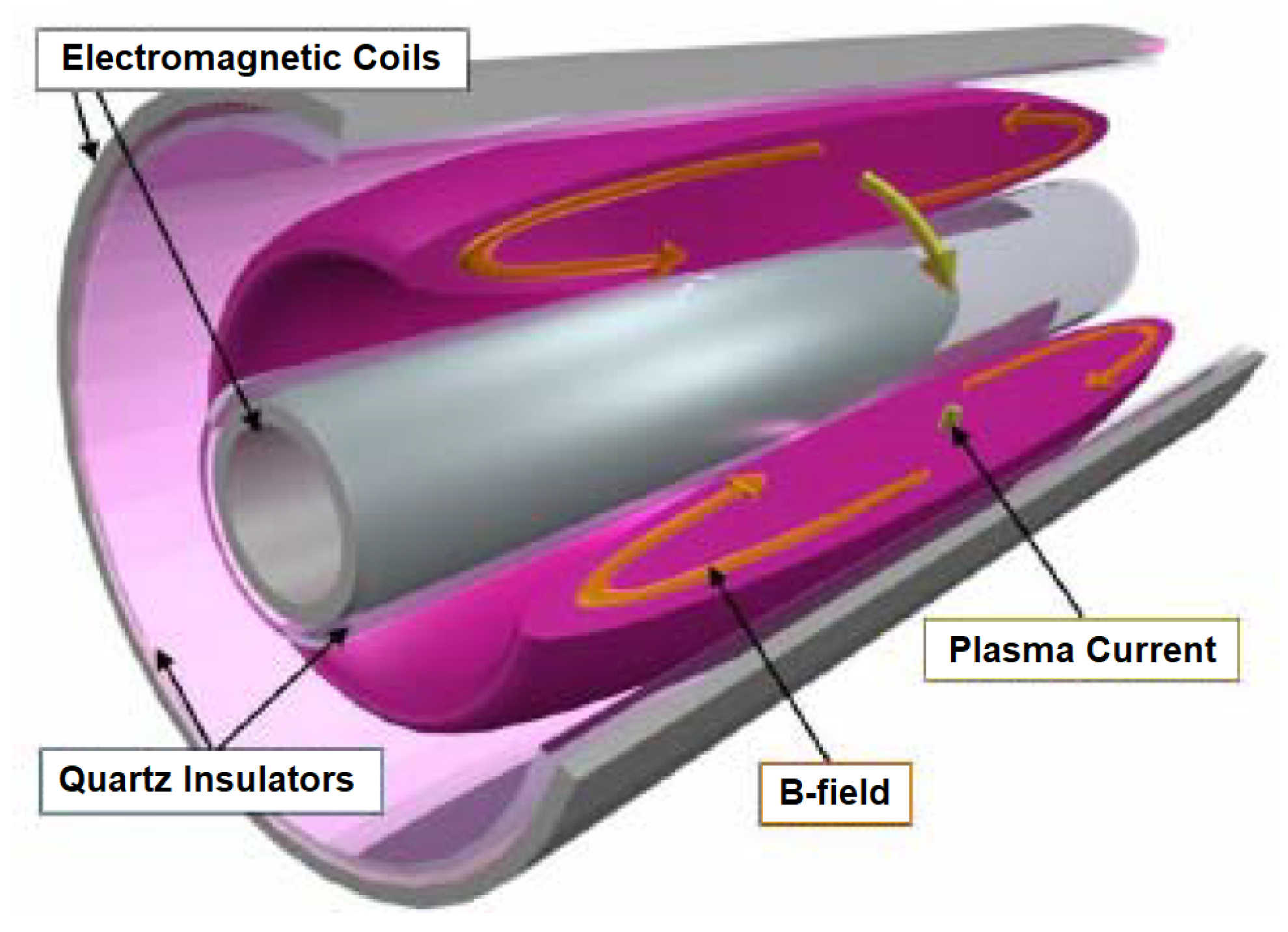

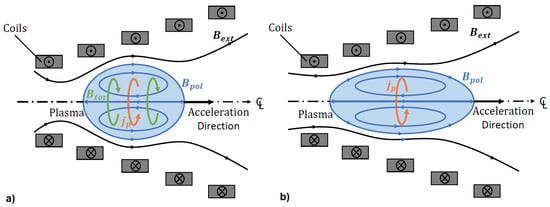

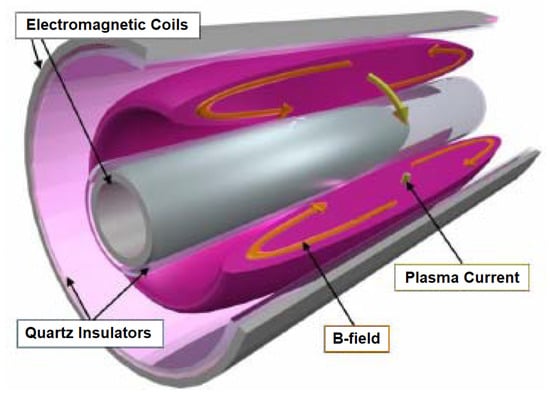

2.2. Closed Magnetic Flux Thrusters

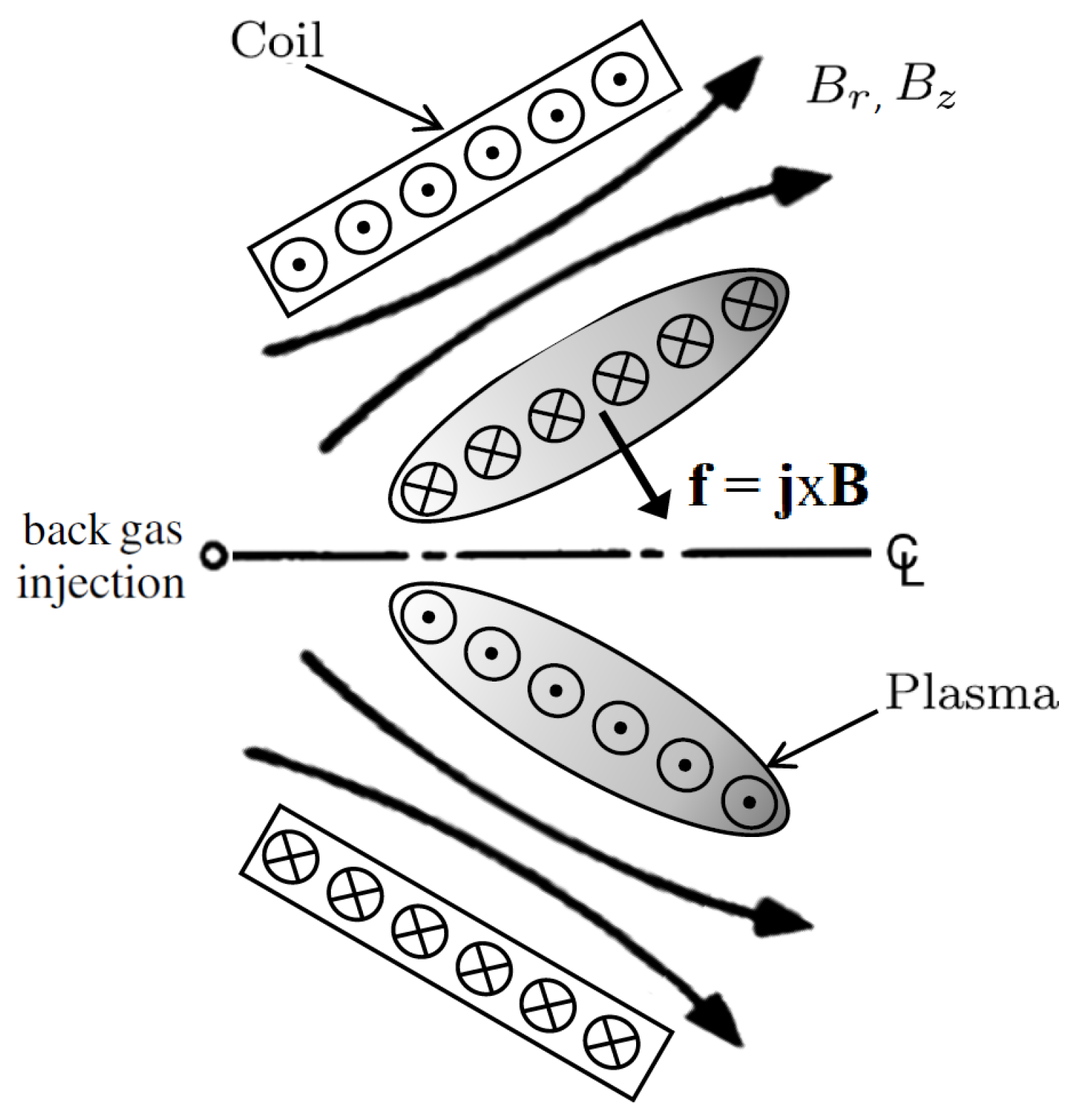

Closed magnetic flux IPPTs are similar to open magnetic flux IPPTs from a circuit standpoint: on closing a switch, energy stored in a capacitor is discharged as current through an inductive coil. Under certain circumstances the current induced in the ionized propellant gas can produce a closed internal magnetic field topology. Plasmas embedded within such a closed magnetic field structure are referred to as plasmoids or compact toroids. The closed magnetic flux isolates the plasmoid from its surroundings and enables both passive (thermal) and active (electromagnetic) acceleration. Compact toroids fall into two broad categories: spheromaks, which have both poloidal and toroidal magnetic fields, and field-reversed configurations (FRC), which have poloidal fields only [8]. Each of these categories is illustrated schematically in Figure 7.

Figure 7.

Schematic illustrations of conical coil sets containing (a) a spheromak plasma and (b) a field-reversed configuration (FRC) plasma, showing the directional sense of the current in the coils, the azimuthal plasma current , and poloidal magnetic field , the magnetic field external to the plasma , and the toroidal magnetic field in the spheromak configuration.

Closed magnetic flux IPPT research has mainly focused on the formation and acceleration of FRCs [20]. The FRC plasma is characterized by an azimuthal current density and no azimuthal magnetic field. The magnetic field vector instead lies primarily in the meridional (r-z) plane. A high plasma beta, wherein the thermal energy density of the plasma is comparable to the magnetic energy density, is required to achieve the closed flux configuration. We note here that the plasma beta (typically defined as the ratio of the plasma pressure to the external magnetic pressure) is a local quantity and is not necessarily all that useful when discussing these types of thrusters. In fact, this value can exhibit a wide variation within the plasma and greatly exceed unity at certain points (at the O-point of an FRC, where the magnetic field vanishes, beta approaches infinity). When discussing beta in an FRC context, what is often meant is the volume-averaged beta () [8,21,22]. This term is derived based on an axial balance of the tension of the field line and the plasma pressure in the FRC. The derivation of assumes a prolate, axisymmetric FRC inside a cylindrical coil that is “sufficiently” long such that the field lines are straight at the mid-plane and at the ends of the coil. A result of this analysis is

where and are the separatrix and coil radii respectively. Typically, the ratio of radii is approximately equal to 0.5, which makes roughly equal to unity. An FRC that extended to radially fill the volume inside the coil would only have a minimum of 0.5 (i.e., 0.5 is the lower theoretical limit of in these devices), so in practice, 0.5≤<1.0, with some fusion FRC experiments achieving of ∼0.9 [23].

The ability to achieve a high motivated intense FRC plasma research for compact fusion energy reactor applications. The fusion energy research community pioneered the idea of inductively accelerating two FRC plasmas to high velocities (∼100 km/s) and colliding them to produce a single plasmoid within a confinement chamber [24,25]. In this case, the main motivations for accelerating FRCs were to provide kinetic stability during formation and repurpose plasma kinetic energy for heating and compression during confinement. While we do not wish to provide an in depth discussion of instabilities here (the discussion of FRC stability being the subject of numerous papers), we note that what was long considered to be the most dangerous instability was the m = 1/n = 1 internal tilt mode [23,26], which is not driven by . In most cases, the 1–10 s timescales for plasma thruster applications is too short for instabilities to greatly impact the plasma before it is expelled.

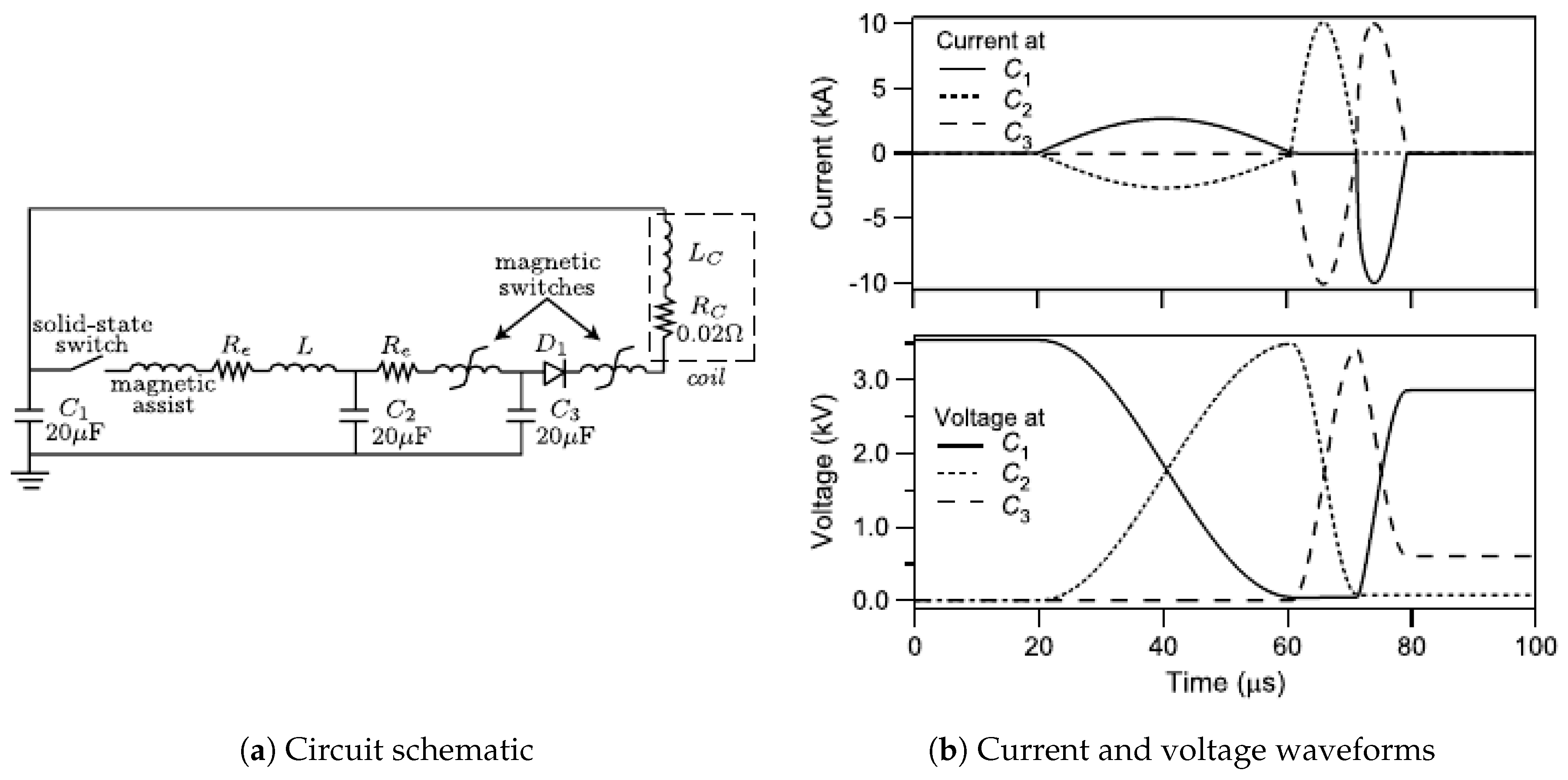

FRC plasmas can be formed through a variety of different processes. In this section we will classify concepts according to their formation method and review different test articles that have applied these techniques to develop accelerators for in-space propulsion.

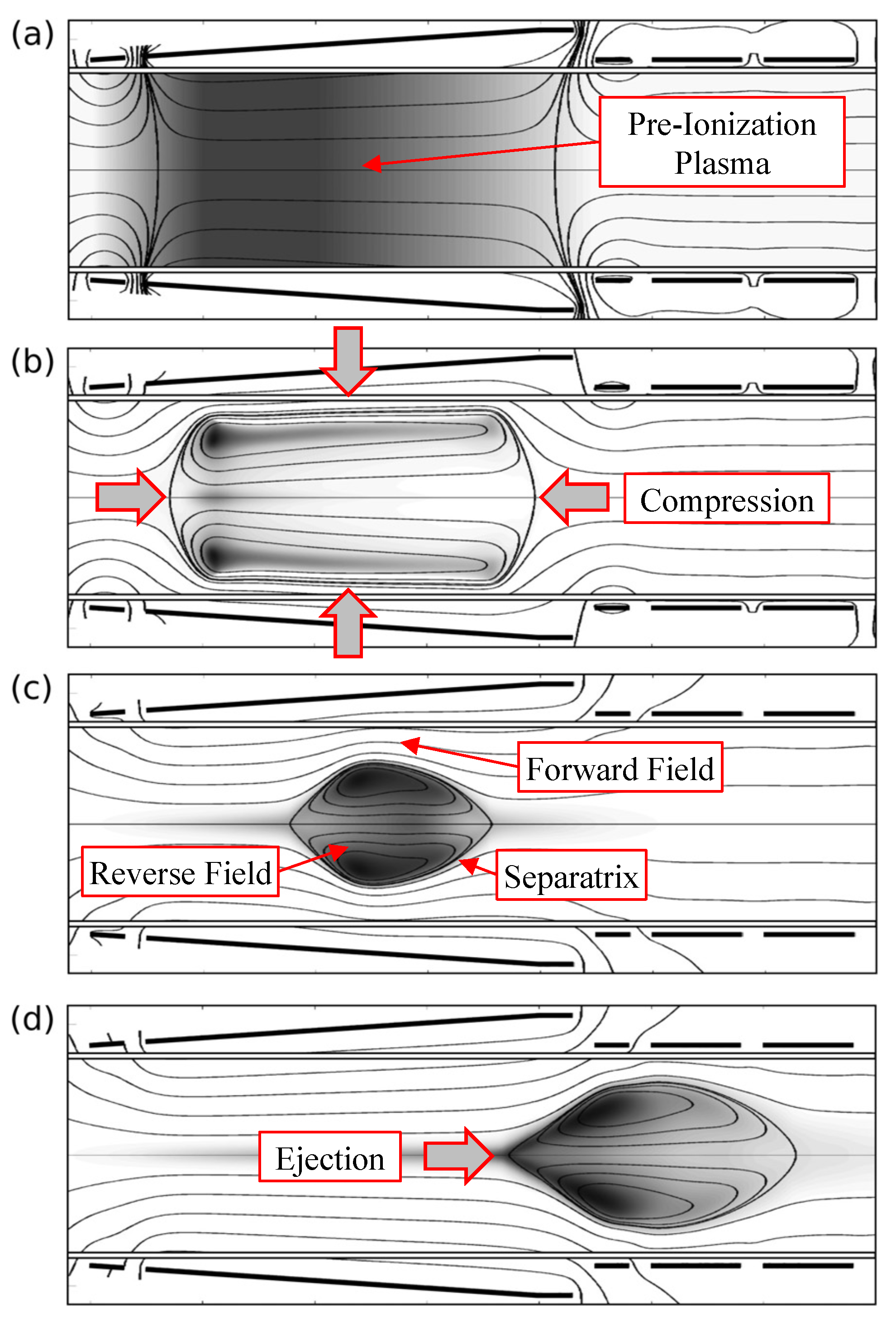

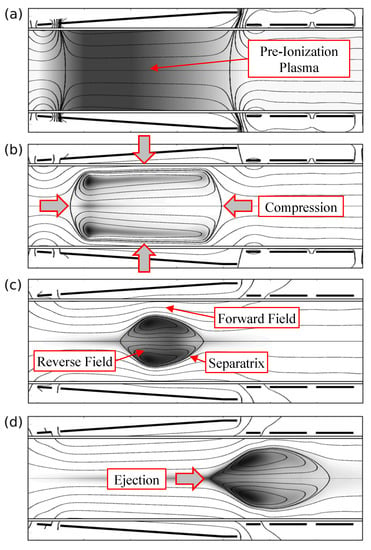

2.2.1. Field-Reversed Theta-Pinch FRCs

The first FRCs were created using a method referred to as field-reversed theta-pinch (FRTP) formation [27]. FRTP formation (illustrated in Figure 8) begins with a background applied axial magnetic field embedded within a partially ionized plasma (often referred to as the preionization plasma). A strong pulse of current is generated in a coil or coils placed on the outside of the plasma chamber and aligned concentric with the plasma. The coils are designed to create a magnetic field (forward field) that opposes the magnetic field initially embedded in the plasma (reverse field). If the current rise time is faster than the inductive decay time of the plasma, the reverse field is unable to diffuse from the plasma and a closed magnetic flux topology is formed. A well-defined flux surface (separatrix) separates the reverse and forward fields, and provides stability to the plasma during acceleration and translation [28]. Radial compression of the FRC increases the magnetic field strength, which simultaneously increases the field-line tension and causes the FRC to contract axially. Radial and axial compression of the plasma occurs during this process prior to reaching an equilibrium state wherein the external magnetic pressure is balanced by the plasma pressure. Controlling magnetic field reconnection through programmed formation of the FRC proved to be crucial in creating stable, long-lived FRC plasmas [8]. For IPPT applications using conical theta-pinch geometries, research suggests it is possible to achieve this closed-flux equilibrium state on timescales faster than the ejection time of the plasmoid [29]. However, uncertainties exist regarding the scalability of FRTP to energy levels useful for electric propulsion, the sensitivity to preionization, the recovery of thermal energy obtained during compression, and the quantification of potentially significant plasma-wall interactions during field-reversal.

Figure 8.

Schematic showing field-reversed theta pinch formation for closed magnetic flux thrusters: (a) preionization plasma is introduced into a background magnetic field; (b) a strong pulse of current generates a time-dependent magnetic field with polarity opposing the initial background magnetic field that compresses the plasma both radially and axially; (c) a closed magnetic field structure confines the plasma within a separatrix that divides the forward and reverse fields; and (d) magnetic field gradients in the axial direction accelerate and eject the resulting plasmoid (Reproduced/modified from [29]; with the permission of AIP Publishing.).

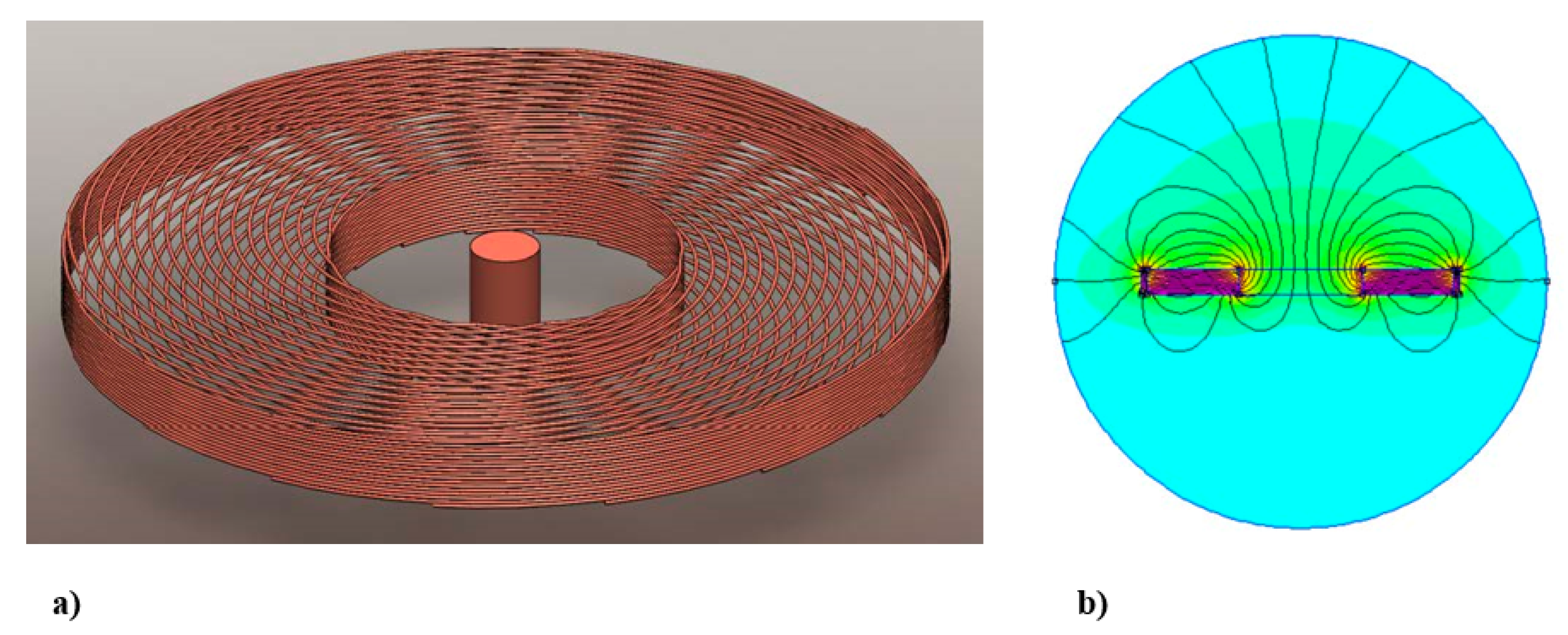

The Plasmoid Thruster Experiment (PTX) [6,30,31] used a conical theta-pinch coil to both form and accelerate plasmoids. The primary acceleration mechanism is the Lorentz body force caused by the interaction of the azimuthal plasma current and the applied field generated by the coil. Some acceleration may also be due to the conversion of thermal energy to directed kinetic energy when the plasma expands in the magnetic nozzle formed by the coil, however this contribution has to-date not been quantified. In PTX, plasmoids were formed by discharging a capacitor charged to 35 kV (energy of ∼350 J) through a single-turn conical theta-pinch coil with a 17.5° half-angle. The resulting discharge had a peak current of 50 kA with a ringing frequency of 500 kHz. The plasma was formed in a Pyrex tube connected to the rest of the vacuum chamber while the coil was located outside the vessel. PTX used the first/second half-cycle formation technique first used in FRTPs [8]. In the first half-cycle the plasma is formed (pre-ionized) and seeded with the reversed (bias) field. The subsequent half-cycle applies the forward field causing the magnetic field lines to reconnect into a closed field-line structure. A separate Blumlein preionizer (frequency of ∼4.5 MHz) was attached to the coil, but only used a few times before it failed due to an interaction with the main bank. Propellant gas was injected using a fast pulsed gas valve (PGV) with a plenum isolated from the gas supply by a limiting orifice. Owing to the characteristics of the circuit and the switch (in this case, a Perkin-Elmer GP-32B spark-gap) PTX could only be operated over a narrow range in voltage; in practice it was almost always set to 35 kV. Experimental conditions were varied by changing the gas pressure in the plenum and the delay time between the valve opening and the capacitor discharge.

A wide array of diagnostics was used with PTX. A three-channel excluded flux-array under the theta-pinch coil (later expanded to six channels) was used to determine the location and shape of the separatrix. Quadruple Langmuir probe measurements were performed to determine the evolution of the electron temperature, plasma density, and ion Mach number. Line integrated plasma density was measured with a quadrature heterodyne HeNe interferometer, similar to the system used in Refs. [32,33,34]. Additional measurements were performed using internal magnetic field probes, a 0.3 m spectrometer, and a 100 Mframe/s framing camera. End-on imaging of the coil showed that the preionization occurred during the second half-cycle (after the first zero-crossing in current) [6]. The interferometry data show that, for long valve delay times, the plasma pushes and accelerates neutral gas ahead of the plasmoid [31]. Electron temperatures measured downstream with the quadruple Langmuir probe were up to 20 eV for hydrogen and lower than that (∼8 eV) for argon [30], although there were indications that the temperatures were much higher closer to the coil. Magnetic probe data exhibited a double-peak structure suggesting the formation of two distinct plasmoids—a hypothesis that was consistent with the high-speed imaging. Optical velocimety measurements indicated argon velocities of ∼22–28 km/s, providing order of magnitude agreement with the quadruple Langmuir probe measurements. Excluded flux array measurements indicated that a closed field-line plasmoid was created with argon but not with hydrogen [35]. No evidence of closed flux surfaces was observed downstream of the coil. It was surmised that with hydrogen, the plasma was rapidly expelled out of the coil before reconnection could occur.

The PT-1 plasmoid thruster shown in Figure 9 was fabricated as a brass-board device based on experience derived from PTX [36]. It had separate drive and bias coils, each consisting of four parallel three-turn leads wound on an alumina form, and each driven by its own capacitor bank. In series with the bias coil, fore and aft of it, were two reverse-wound field-shaping coils. The purpose of these were to create a cusp-field on either end of the coil to promote faster and better controlled reconnection. PT-1 could be operated in two modes: a plasmoid thruster mode with the bias coil driven in the opposite sense to the drive coil, or a conical theta-pinch mode with the bias and drive coils driven in the same sense. Both drive and bias circuits were switched with spark-gap switches, later replaced with thryristors. Glow discharge and VIG preionizers were attempted, but owing to programmatic considerations, no extensive testing was done with PT-1.

Figure 9.

The PT-1 plasmoid thruster test article.

The Magnetically Accelerated Plasmoid (MAP) experiment [37] also employed a conical theta-pinch coil to form and accelerate FRC plasmoids. In addition to the main theta-pinch coil, MAP possessed a series of downstream magnetic coils that were sequentially pulsed to provide additional acceleration by establishing a traveling magnetic wave that could electromagnetically push the plasmoid. Experiments successfully demonstrated the power supply and switching technologies required to form the magnetic wave. Preliminary results on a deuterium-helium gas mixture measured plasmoid velocities up to ∼180 km/s. By combining density measurements from a HeNe interferometer with FRC equilibrium measurements from magnetic probes, the MAP experiments were the first to provide a technique for estimating the mass contained within the plasmoid.

The Missouri Plasmoid Experiment (MPX) [38,39] was designed to study the physics of FRTP plasma formation with heavy gases when operating at discharge energy levels of relevance to electric propulsion. Experiments focused primarily on the preionization phase of FRC formation. Early results demonstrated a strong dependence of preionization energy efficiency on gas pressure for both air and argon over a pressure range from 0 to 60 mtorr [38]. Argon demonstrated greater shot-to-shot repeatability and higher energy transfer efficiency at lower pressures, where the energy transfer efficiency was defined as the energy absorbed into the plasma as a fraction of total pulse energy. The maximum energy transfer efficiency for argon was measured to be 25% and occured nearly 10 s (roughly four discharge periods) after pulse initiation. Notably, it was not determined how energy transferred from the coil was distributed among various plasma energy channels such as ionization, heating, and acceleration. Application of a low-power DC plasma discharge during preionization was later found to improve energy transfer at low pressures [39]. Results from MPX highlight significant concerns regarding the ability of FRTP to form FRC plasmas at pressures and timescales consistent with the energy, circuit, and plasma dynamics constraints of IPPTs.

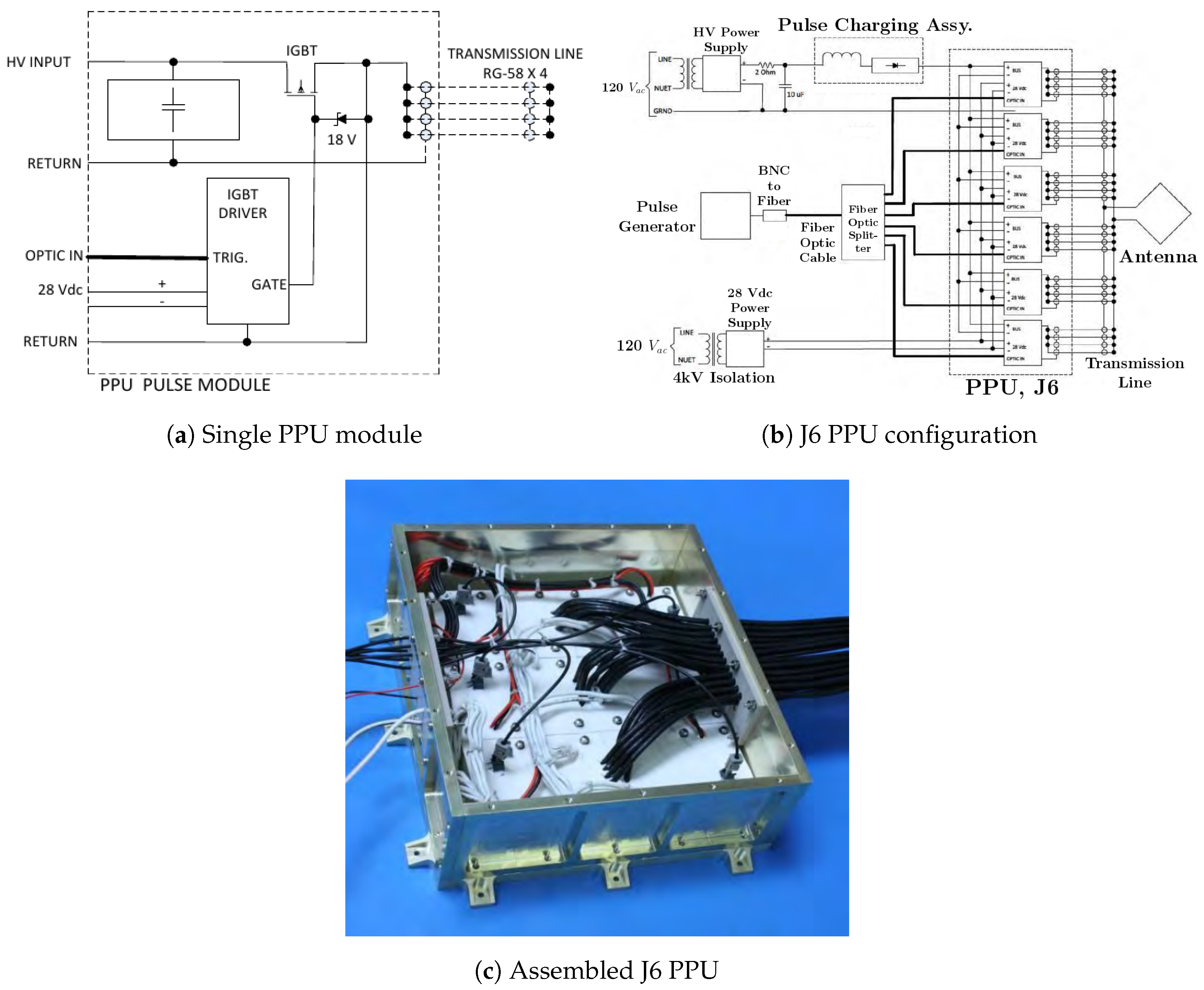

2.2.2. Rotating Magnetic Field FRC Thrusters

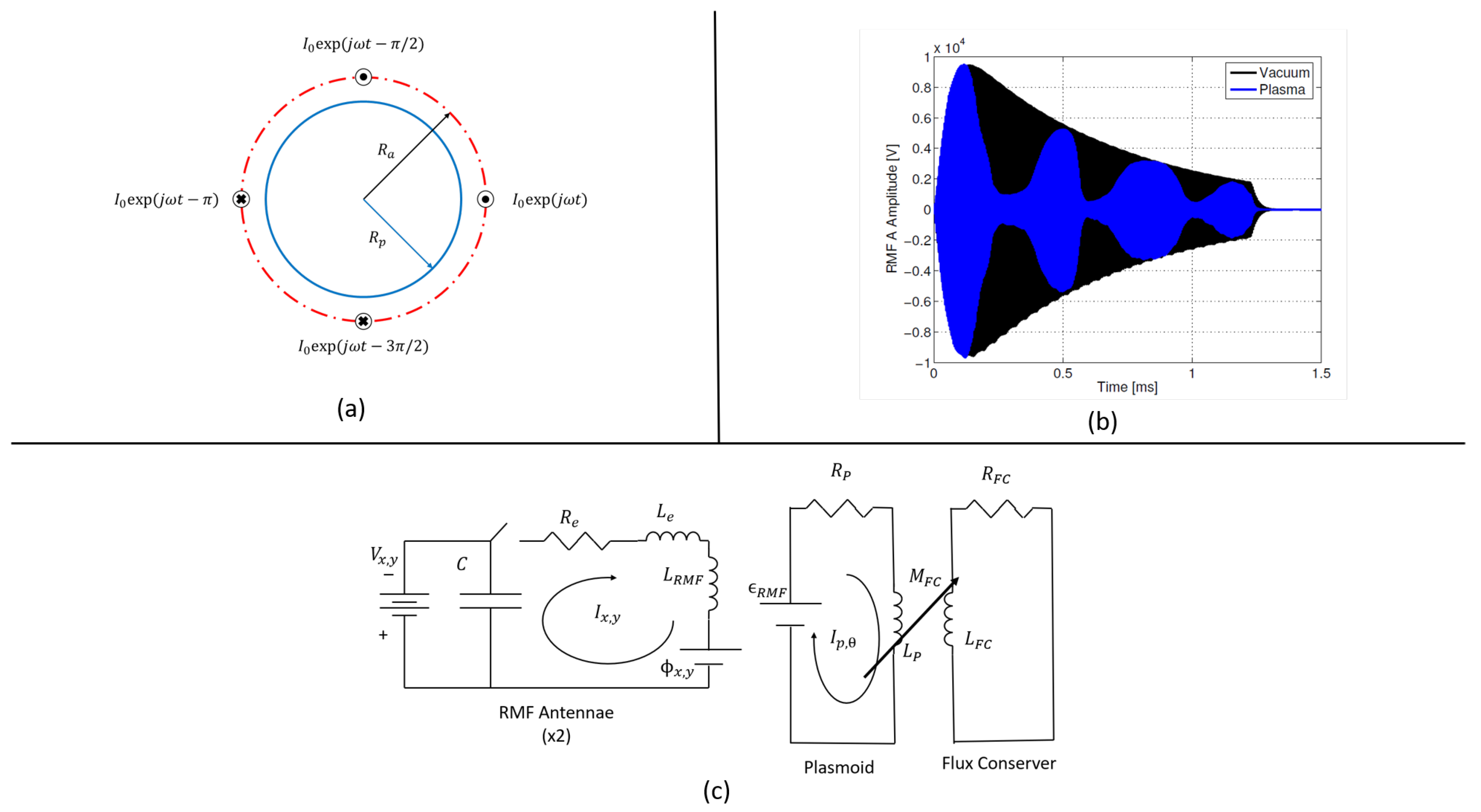

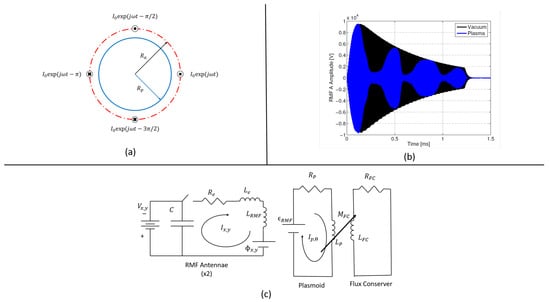

The Rotating Magnetic Field (RMF)-FRC thruster differs from theta-pinch devices in the mechanism employed to drive the azimuthal current that forms the plasmoid. In the RMF-FRC, this current results from a azimuthaly-rotating transverse magnetic field applied to the plasma. Once the gas is ionized, the current both aides in sustaining the plasma discharge and gives rise to an axial Lorentz body force resulting from interactions with the radial components of an applied, background magnetic field. The RMF-FRC has in principle a few advantages over other methods for generating FRC plasmoids. For example, in contrast to purely pulsed based methods such as theta-pinches, the RMF can operate in a pulsed or a continuous wave mode where the rotating magnetic field continuously drives a plasma current. The RMF-FRC requires substantially lower currents to drive the plasmoid since the necessary azimuthal current depends on the frequency of the RMF rather than the amplitude. Thus, the voltage necessary to drive the currents for the RMF field can be significantly lower than in pulsed FRC-generation methods [40].

The RMF current drive mechanism was first proposed for the purpose of plasma confinement by Blevin and Thonemanan [41]. Over the following decades, several institutions researched RMF plasmoids for fusion applications. Formation, sustainment, and translation were key aspects studied by the groups [40]. Researchers at the University of Washington and Mathematical Sciences Northwest (MSNW) built on the initial translation work, exploring a thruster concept based on the RMF-formation of an FRC which is then expelled using an applied magnetic field with an axial gradient [42]. A number of research groups continue to investigate the feasibility of RMF-FRC thrusters for propulsion with averaged power levels ranging from 1 kW to 100 s of kW. Open challenges associated with testing these devices include thermal loading of the circuit components, potential arcing between high-voltage antennae and the surrounding plasma environment, and operation of the thruster and power processing unit (PPU) for appreciable lengths of time (minutes or greater) to properly resolve thrust measurements at steady state. In large part due to these technical obstacles, the full capabilities of RMF-FRCs have yet to be demonstrated. It remains unclear as to whether this particular implementation can achieve performance levels that are competitive with other concepts.

Principle of Operation

We review a simplified model for RMF-FRC operation. This model is based on the derivation first presented by Blevin and Thonemann [41]. The key elements in the formation process are illustrated in Figure 10. Neutral gas with a small amount of seed plasma from a preionizer fills the discharge chamber. This plasma is confined by a steady background magnetic field with a radial gradient, given in cylindrical coordinates as

Figure 10.

RMF-FRC Operation—(a) Side view cross-section in the r-z plane of the thruster illustrating how ionized gas is injected into the discharge chamber. A steady bias magnetic field with radial gradient is present. (b) End-on view of the thruster in the r- plane depicting two sets of coils oriented in the x- and y-directions that generate a rotating magnetic field (RMF) by using sinusoidal currents at frequency applied 90° out of phase. The RMF induces axial and azimuthal currents. (c) Side view of the r-z plane illustrating FRC formation. Large azimuthal currents form the plasmoid and interact with the external radial magnetic field component to axially accelerate the plasmoid via a Lorentz body force.

Two sets of saddle coils are oriented perpendicular to each other and phase-shifted currents with frequency are driven through these coils generating alternating magnetic fields that are 90° out of phase. The combined effect of these coils creates a RMF of the form

where is the amplitude of the magnetic field. While a real RMF would have spatial variation, this idealization of the field does not. The RMF frequency should be much greater than the ion cyclotron frequency but much less than the electron cyclotron frequency to ensure that the induced ion currents are much smaller than the electron currents. The combination of Faraday’s law of induction and the generalized Ohm’s law for an infinitely long plasma column show that the time varying RMF magnetic field produces an electric field that in turn drives an azimuthal plasma current. The electron Hall parameter is defined as , where is the plasma resistivity, is the electron density, and e is the elementary charge. In the limit of low plasma resistivity, will be much greater than one and the electrons will rotate in sync with the RMF. In this case, the plasma current density as a function of radial position is:

where is assumed constant.

The azimuthal current drives field-reversal in these devices. The current gives rise to a diamagnetic field that opposes the applied magnetic field of Equation (5), reversing it close to centerline and forming a plasma body that is magnetically isolated. The above formulation, specifically Equation (7), illustrates a key advantage of RMF-FRC thrusters. In principle, if the resistivity is sufficiently low, the current that is driven in the azimuthal direction is independent of the current in the driving coils. This is in contrast to theta pinch methods or other pulsed methods that require current levels of kA or greater to generate a reversed field configuration.

There are multiple mechanisms that have been proposed to date by which RMF-FRCs may be axially accelerated to generate thrust. These include a Lorentz body force that results from interaction with the applied field [42], a self-field-derived Lorentz body force [43], and thermal-to-kinetic energy conversion [44]. We proceed with a brief discussion of each mechanism.

Lorentz body force via applied field: Slough et al. [42] proposed that the azimuthal plasma current driven by the RMF in Equation (7) interacts with the radial component of an the applied external magnetic field in Equation (5) to give rise to a Lorentz body force:

where the volumetric integral is performed over the plasma volume to yield the total force. This result suggests that the force on the plasmoid scales linearly with the RMF-driven current.

Self-field acceleration: A self-field acceleration mechanism may comprise part of the total thrust mechanism. In many RMF-FRC’s, there is a component called the flux conserver that acts to sustain a constant flux on the short timescales of FRC formation and ejection. The flux conservers consist of either metallic straps concentrically placed along the thruster cone or actually comprise the cone itself. As the plasmoid forms, the rapidly changing plasma currents produce a magnetic field that couples to the conductive material in the flux conservers. This process will in turn drive a mirror current which can act on the plasmoid. It has been proposed that the resulting force will scale as , similar to other pulsed inductive devices where J is the RMF plasma current (c.f. [43]).

Thermal-to-kinetic energy conversion: Slough et al. [42] posited that acceleration in the RMF-FRC also may stem from the conversion of thermal energy, introduced by Ohmic heating of the plasma through the RMF current, to directed kinetic energy via adiabatic expansion. In this case, the flux conservers combined with the self-contained nature of the RMF-FRC both work to prevent thermal losses to the walls of the chamber and instead redirect this energy into directed thrust. The kinetic energy of the propellant (and by extension the force) is related to the change in the enthalpy of the plasmoid as it is accelerated.

Although it is likely that all three mechanisms may contribute to thrust generation in FRC-RMF devices, to date, it is not known if one is dominant or indeed how the total thrust is distributed between these three mechanisms. This ambiguity largely stems from the lack of experimental performance measurements that would permit evaluation of the predicted scalings for each mechanism.

Review of RMF-FRC Test Articles

The potential for high performance of RMF-FRC thrusters has served as motivation for the fabrication and testing of a number of test articles. The Air Force Research Laboratory, Tokyo University, University of Washington, MSNW, and University of Michigan have all developed systems of varying capabilities. The thrusters share common design elements, namely that each has a preionizer, RMF antennae system, and a steady bias field. Additional components and capabilities may be present to suit the institutions specific experimental goals. Although these test articles have different geometries and operate at power levels (ranging from 500 W to 100s of kWs), the work on these devices shares the common goal of improving understanding of thrust generation and ultimately demonstrating performance. Unfortunately, direct thrust measurements have not been performed for these thrusters and test articles.

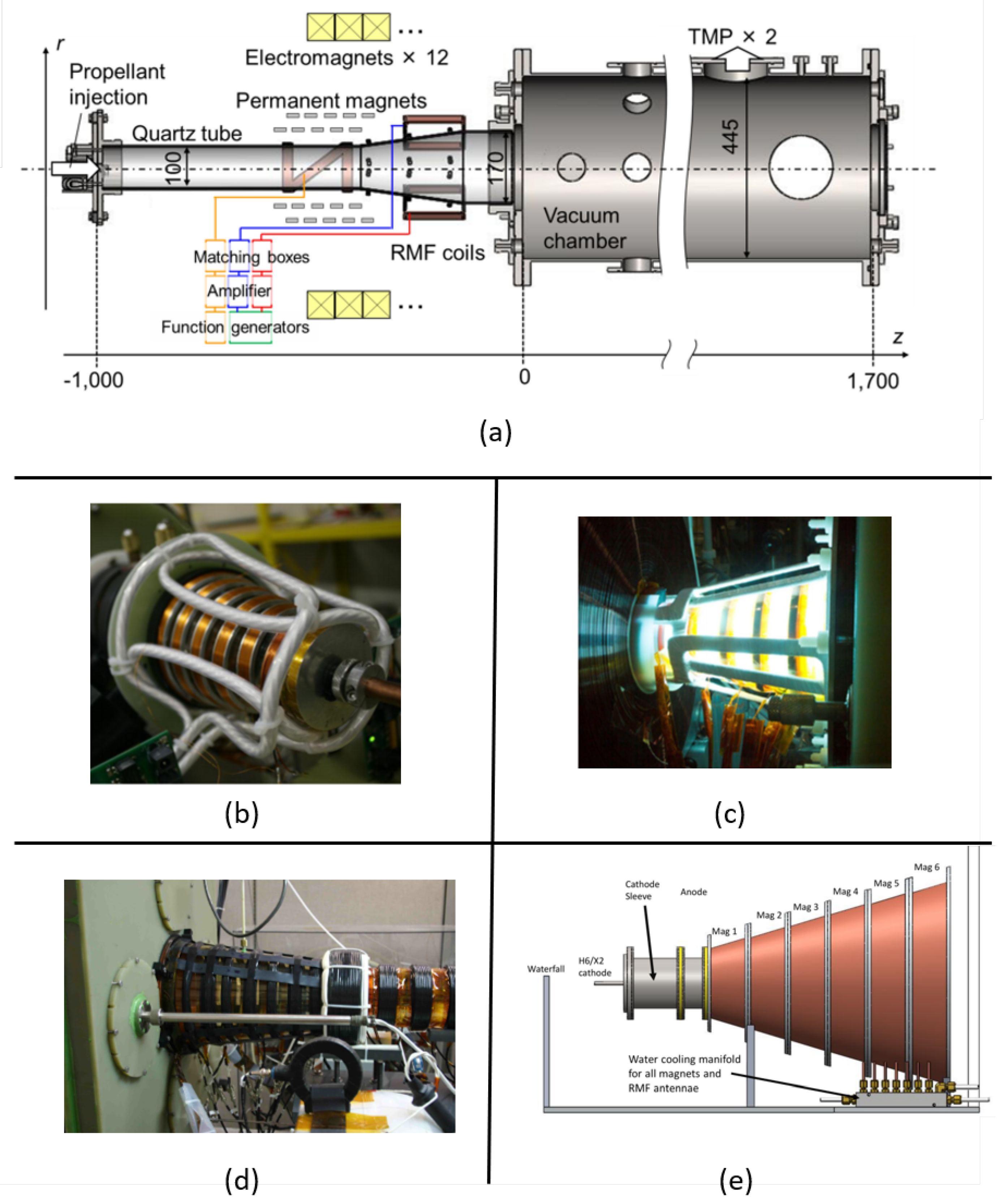

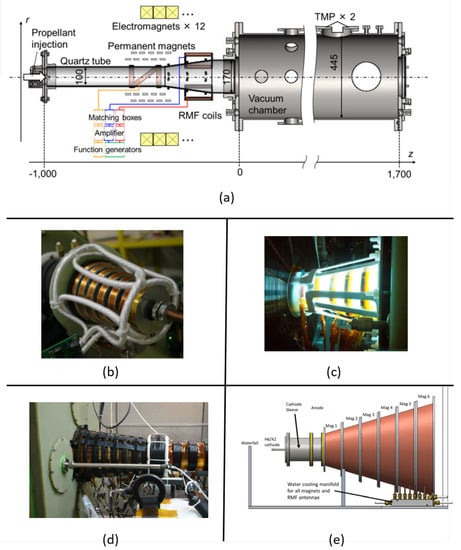

The electrodeless helicon plasma thruster (Figure 11a) leveraged the Large Mirror Device (LMD) configuration to study the acceleration of high density helicon plasmas [45]. It consists of a quartz tube that gradually expands as it enters a drift vacuum chamber. Permanent magnets placed along the tube act as a magnetic nozzle, and an RMF acceleration stage was added to the design. The helicon plasma source was typically operated at 1 kW and the RMF coil were driven at 1 MHz with a peak-to-peak current of up to 100 A. Operation of the RMF stage produced an observed increase in the axial ion velocities, which was attributed to three possible factors. The first is that the azimuthal induced current by the RMF leads to acceleration through the Lorentz body force arising through the interaction of the current and applied radial magnetic field component. Second, it was hypothesized that a strong radial density gradient forms, producing a diamagnetic current that interacts with the applied field to yield a force. Finally, an axial pressure gradient in the gas could be contributing to the thrust. Interestingly, the growth in all three possible acceleration mechanisms scales with increasing plasma density, which the RMF-driven azimuthal current promotes quite effectively [46].

Figure 11.

RMF-FRC test articles: (a) Schematic of Tokyo University electrodeless helicon plasma thruster (from [45]; licensed under a Creative Commons Attribution (CC BY) license), (b) MSNW electromagnetic plasma thruster (from [47]; reproduced with permission of the author), (c) Air Force Research Laboratory RP3-X thruster (from [49]), (d) MSNW electrodeless Lorentz force thruster (from [51]; reproduced with permission of the author), (e) CAD model of the University of Michigan RMF thruster (from [43]; reproduced with permission of Electric Rocket Propulsion Society).

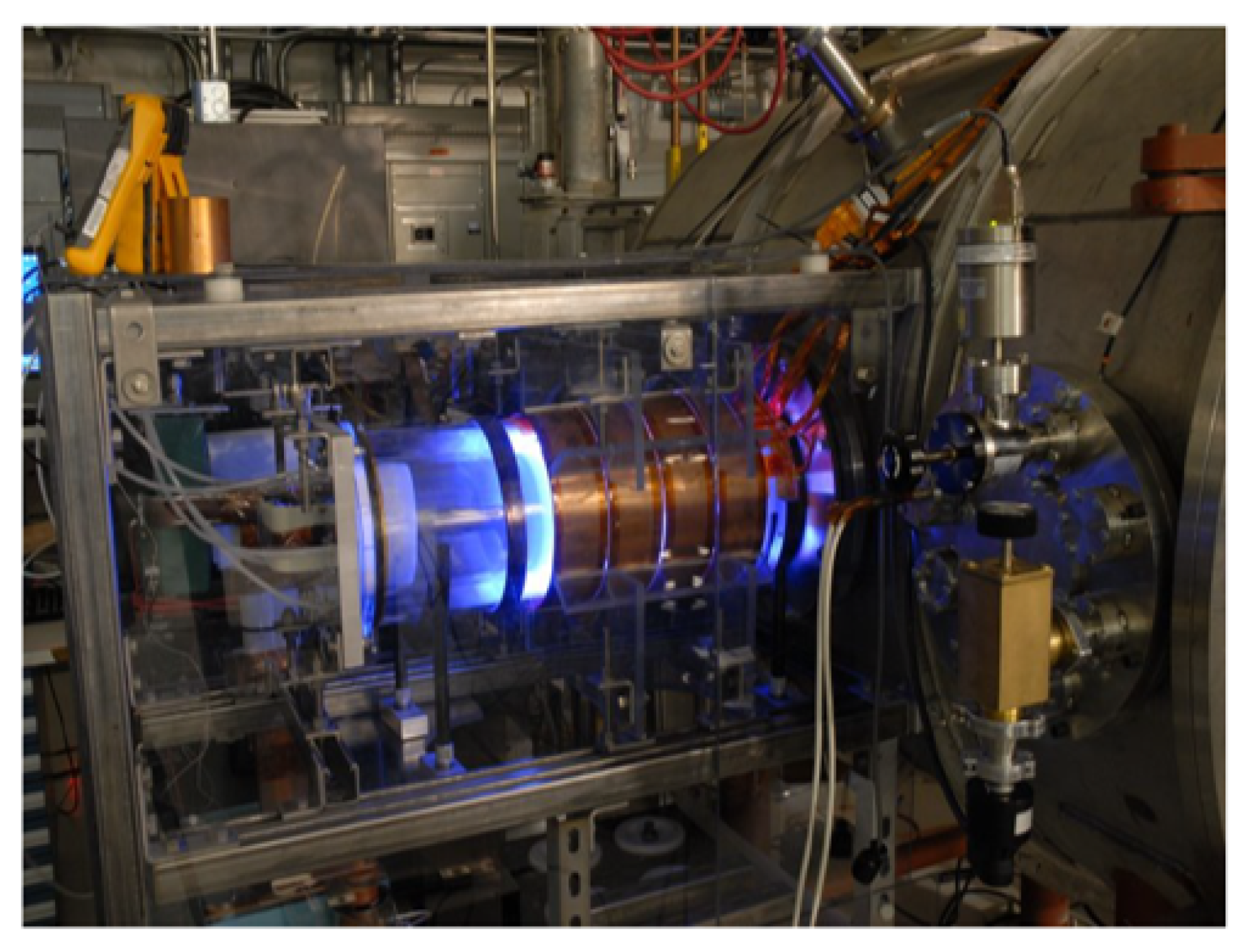

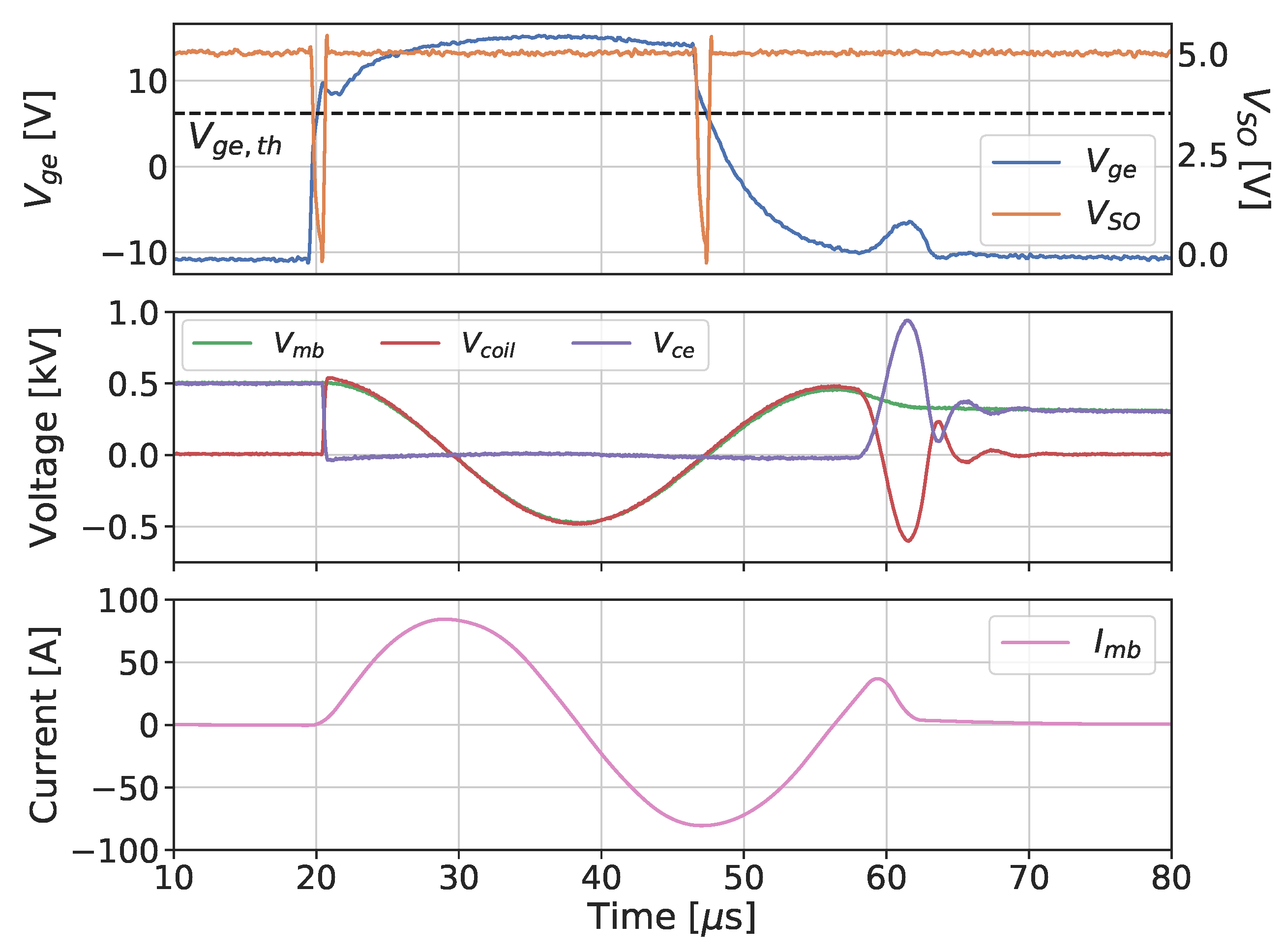

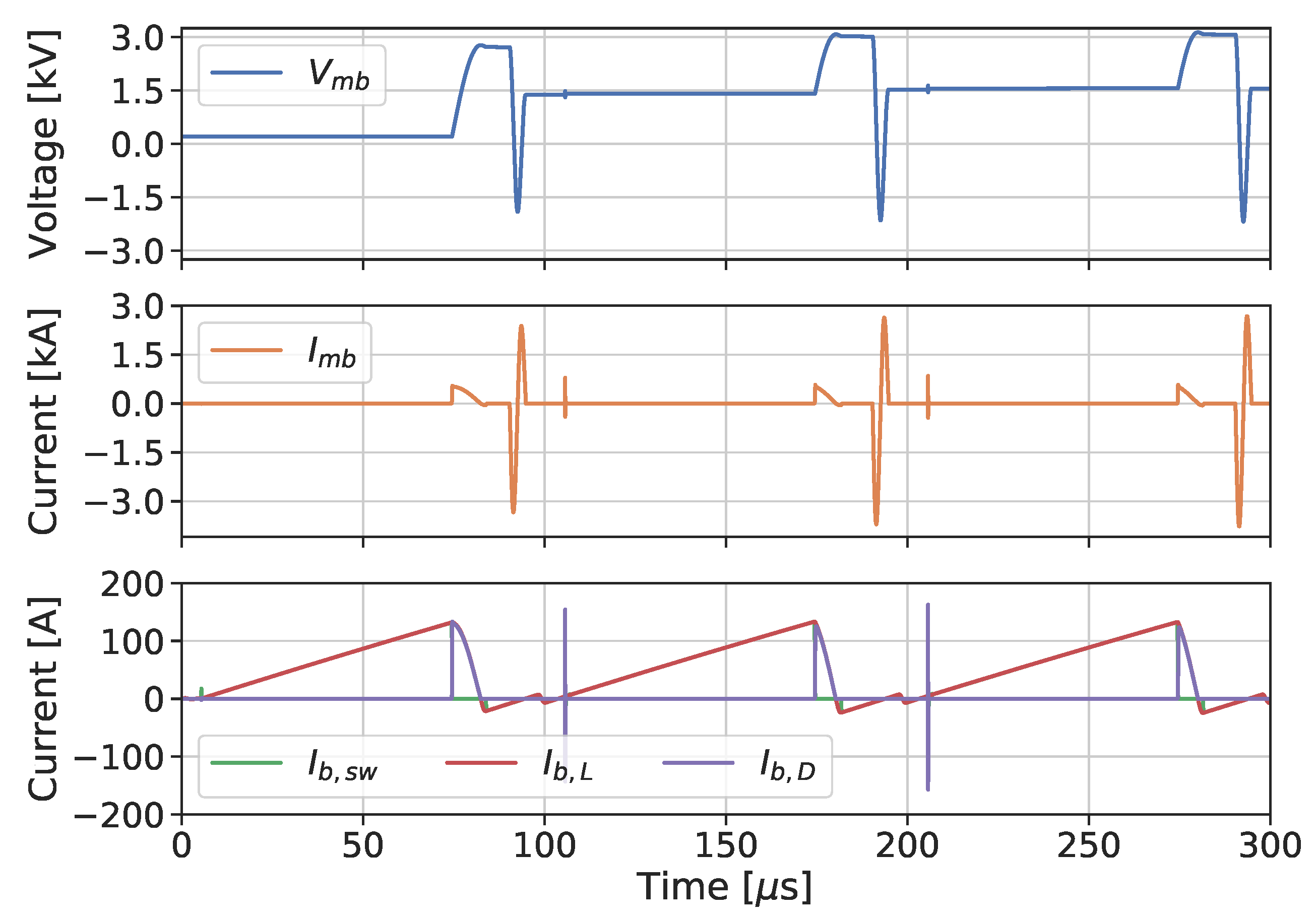

The electromagnetic plasmoid thruster (EMPT) (Figure 11b) was a low power 500–5000 W pulsed RMF device [47]. The goal of the development effort was to demonstrate continuous wave (CW) operation (up to 50 pulses) of a plasmoid thruster and its PPU. It was the first IPPT configuration to demonstrate CW operation with a steady-state propellant flow, operating at average power levels up to 1 kW. The pulse rate was 2800 Hz at pulse energies of 2 J for single pulse and 12.7 J for multi-pulse operation. The thruster consisted of a conical quartz tube with bias field magnets and RMF antennae placed along the length of the tube. It used a small electrode at the base of the thruster as a preionizer. Performance was estimated using a ballistic pendulum thrust measurement in conjunction with Langmuir probes to obtain time of flight data. Operation of the RMF at increased repetition rates resulted in greater mass entrainment and use of the propellant relative to single pulse operation. Impulses of up to 0.12 mN-s were observed for 6 ms gas puffs which generated nine plasmoids.

The RP3-X (Figure 11c) is an RMF-FRC test article with four coils that line the thruster cone and are arranged in such a way as to create the necessary rotating magnetic field [48]. The thruster itself is vacuum sealed with the exit plane attaching to a larger vacuum chamber. It can operate at a pulse frequency of 10 kHz and an energy of 5 J per pulse. It has operated on xenon propellant with an applied 300 G magnetic field [49].

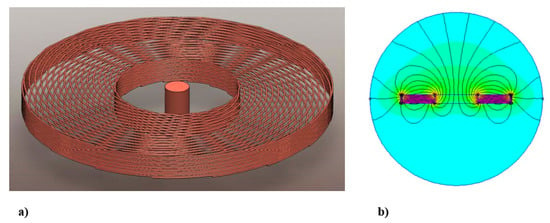

The electrodeless Lorentz force thruster (ELF) (Figure 11d) was a prototype device fabricated to demonstrate high power RMF-FRC operation. It was envisioned to be scalable to 10–100 kW to compete with other high power state-of-the-art electric thrusters, specifically Hall thrusters. The inductive nature of the thruster makes it possible to operate on chemically active propellants that would damage the electrodes in other thruster options. The thruster performance is affected by the choice of propellant, but for any selected propellant the thruster is throttleable to higher power densities without any additional alterations to the overall thruster configuration [50].

The ELF preionizer consists of an electrode connected to a puff valve, which serves to partially ionize the neutral gas as it is injected. The thrust chamber consists of a 42 cm long conical quartz cavity with a 16° half-angle. The thruster is wrapped with flux conservers, which are sections of copper strap that act to conserve the total axial flux on the timescales of FRC formation and translation. Outside of the flux conservers are a series of coils that produce the magnetic bias field necessary for field reversal and plasmoid acceleration. Finally, the two pairs of RMF coils are located outside the bias coils. These are copper straps run the length of the thruster cone and are responsible for producing the large rotating magnetic fields that induces the azimuthal current. The thruster exhausts into a small vacuum chamber, which serves as a drift area permitting the study of plasmoid translation physics [44].

Although it was fabricated to operate in a CW mode at a pulse rate of multiple kHz, PPU constraints limited the number of possible pulses in a given time period. Published data center on a “standard” shot with a discharge energy of 46 J at a 300 kHz RMF frequency. Operating at this condition on nitrogen, it was estimated that 16% of the total input energy was deposited into the plasma as thermal and magnetic energy. Of that, it was further estimated that half was converted into kinetic energy, resulting in an efficiency of 8%. Radiated energy was the dominant estimated energy loss mechanism, at 78% of the total input energy [51].

The University of Michigan (UM) RMF-FRC thruster (Figure 11e) is based on the ELF design and includes lessons learned from past RMF test campaigns. The thruster is designed to operate at a pulse rate of 1 kHz, which is much faster than the characteristic response of standard thrust stands and should permit performance measurements using conventional electric propulsion thrust stands [52]. If successful, this would represent the first direct thrust measurements on an RMF-FRC test article.

The UM-RMF thruster preionizer is based on a cylindrical, lanthanum hexaboride (LaB) hollow cathode. Preionized propellant is injected through the central bore of the cathode, with additional neutral propellant injected in a ring-pattern surrounding the cathode. The bias field is generated by six conically arranged aluminum bobbins wrapped in magnet wire which also act as the thruster cone. The cone half angle is 16°. Each bobbin measures 7 cm in length and is electrically isolated from the other bobbins to prevent eddy currents from developing along the length of the cone. Embedded between the magnet wire and bobbins is a cooling loop to mitigate thermal loading when operating the magnets at high currents (∼10 A each). The bias coils are designed to provide a peak centerline axial field of 300 G. Lining the inside of the thruster cone are two RMF antennae, each consisting of two current loops arranged in an orthogonal orientation with respect to each other. The antennae consist of 0.25-in diameter copper tubing. Cooling water can be flowed through the antennae when operating at higher power levels. The system baseline is to operate with a peak current of 4.5 kA, which was selected to ensure full penetration of the RMF field into the plasma [43].

At a 1 kHz pulse rate, the average input power to the UM-RMF thruster is approximately 30 kW per antenna. The capacitor banks in the PPU can be changed to produce different RMF frequencies. A set of 24 F and 660 nF capacitor banks have been constructed to provide RMF frequencies of 20 kHz and 300 kHz respectively. The antenna, PPU circuit elements, magnetic field strength and shape, and amount of seed plasma can all be varied, permitting the exploration of a wide parameter space. This test article has yet to be operated. The current status of the UM thruster as of the writing of this article is that it has been assembled but has not been operated.

Technical Obstacles to Testing

There are a number of technical challenges in implementation and operation of RMF-FRCs. The high voltages necessary to drive the RMF currents in the antennae can result in electrical arcing to the surrounding conducting material. The large currents can give rise to excessive heating of the circuit and thruster components. Many thrusters are attached to a flange on a vacuum chamber and eject the plasmoids into a weaker bias field, making it difficult to confirm detachment of the plasma from the applied field. It is also challenging to operate the various circuit components at high power levels (10 kW and greater). Coupling the power into the thruster is hampered by losses to the surrounding structure and resistive losses in the the circuit components. Losses can be mitigated by placing the PPU near the thruster in the vacuum facility, but this introduces issues related to high-voltage arcing and thermal loading in the PPU itself. Finally, operation at high power requires sufficiently high pumping speeds to maintain low background pressures for extended periods of time.

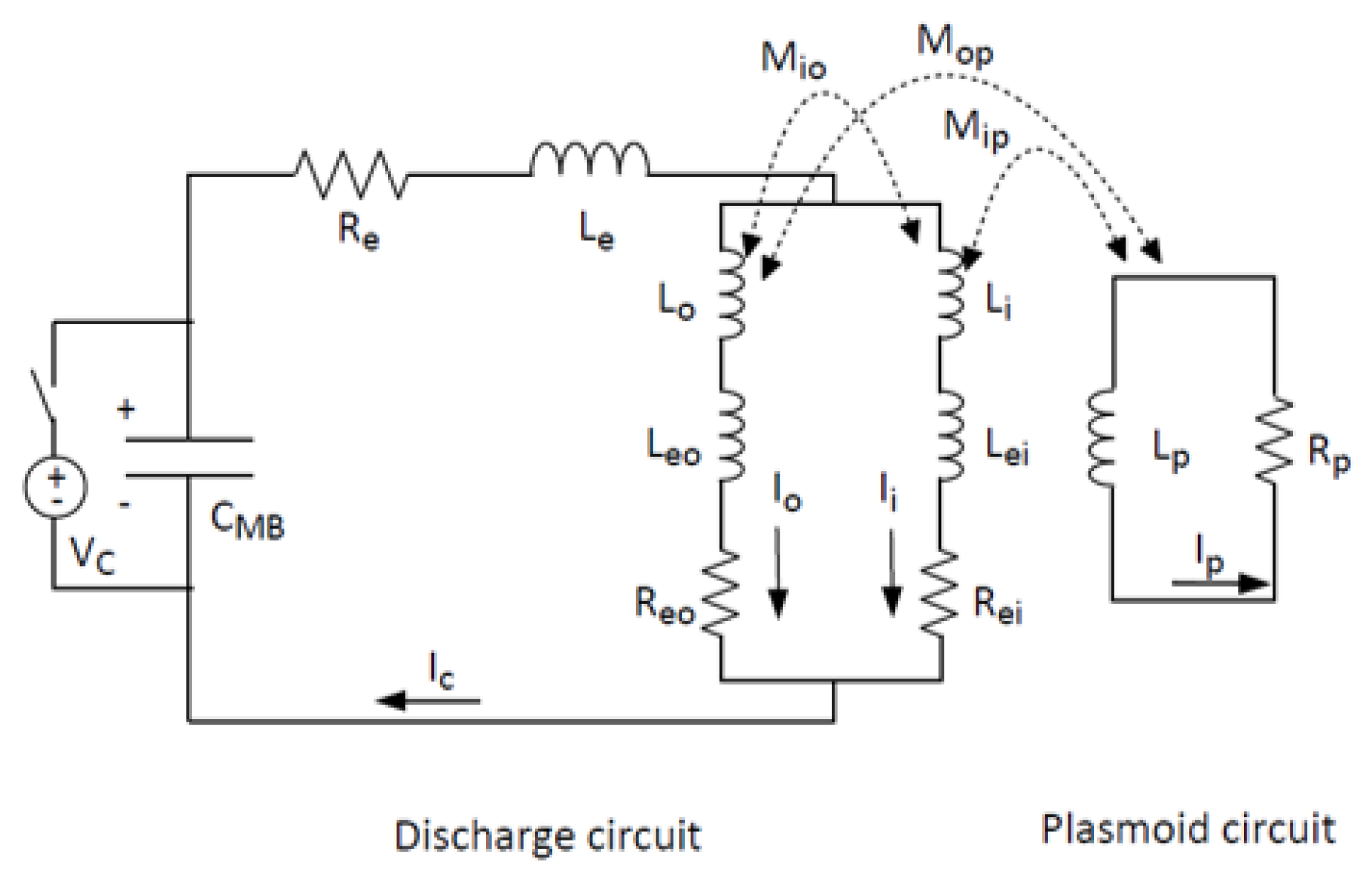

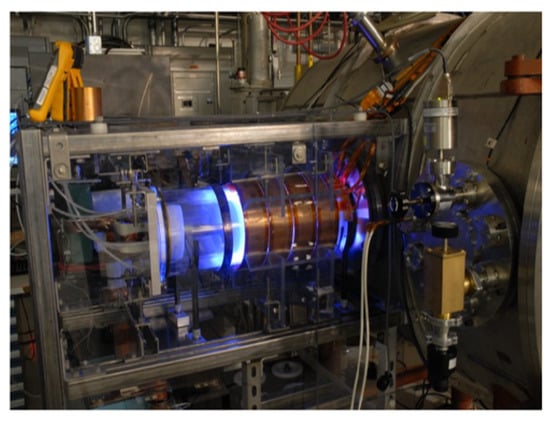

2.2.3. Annular FRC Thrusters

The annular FRC thruster (AFRC) is a variation on the theta-pinch FRC that uses two sets of coils to drive an azimuthal current in the plasma [53], as illustrated in Figure 12. In this implementation, the plasmoid forms in the annulus between the two coils. The AFRC was proposed as an alternative to theta-pinch FRCs as the former can operate at lower voltages (1 kV compared to 10 s of kV) and the addition of the second coil permits the formation of the plasmoid on much shorter time scales relative to the standard theta-pinch FRC. If the outer coil is angled, the magnetic field has an axial gradient and the radial magnetic field component couples with the azimuthal current to yield a Lorentz body force that accelerates the plasmoid. The use of two coils also introduces more flexibility and control of the acceleration process. The inner coil is primarily used to add flux to the plasmoid while the outer coil provides a counter pressure to confine the plasma. The coils can be operated synchronously or independently, although the latter requires the addition of a second power supply [54].

Figure 12.

Diagram of an AFRC thruster (from [53]).

The first AFRC device was developed in 1963 by Phillips et al. [55] to study the formation physics of plasmoids for fusion experiments. Several other groups implemented similar configurations, and in 1967 Alidieres et al. [56] demonstrated the first translation of an AFRC plasmoid. To accomplish this, a radial magnetic field created by an iron circuit was introduced. While translation speeds of up to 200 km/s were observed, energy conservation analyses indicated that only a small fraction of the plasma was accelerated.

The use of the AFRC for high power electric propulsion was first realized in the experimental coaxial field reversed configuration thruster (XOCOT) [57]. The first stage of the experiment, dubbed XOCOT-S, was a study of AFRC plasmoid formation on argon and xenon. The device operated at discharge voltages of less than 1 kV with peak discharge energies of 1.1 kJ. The experiments explored the production of high density plasmas, although it was noted that insufficient preionization resulted in poor formation during the first half cycle of the discharge.

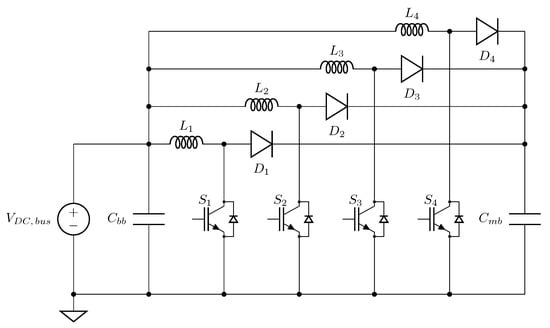

Knowledge gained from the XOCOT-S experiment was used to inform the second stage of the study, the XOCOT-T3, shown in Figure 13. The experiments performed by Hill [54] aimed to study the translation of AFRC-generated plasmoids. The outer coil was angled to introduce the radial magnetic field component necessary to yield the Lorentz body force that would accelerate the plasma. The coils were operated in a parallel mode powered by a single pulsed supply at frequencies of 10 kHz and 20 kHz and discharge energies of 0.1, 0.5, and 1 kJ/pulse. Magnetic field probes observed plasmoid formation between the coils, but for all conditions tested there was no evidence of plasmoid translation and no downstream observations of coherent plasmoid structures. Plasmas that did appear downstream were attributed to a thermal jet escaping from the AFRC.

Figure 13.

XOCOT-T3 experiment (from [54]; reproduced with permission of the author).

Three hypotheses were put forth to explain the failure of the plasmoid to translate. The first is that there was an inherent induction limit for the system which limited the current driven in the plasma to levels insufficient to form a plasmoid. The second is that the plasma had low electrical conductivity, owing to low electron temperatures, resulting in rapid magnetic field diffusion that short-circuited the FRC formation process. It was determined that temperatures greater than 20 eV could reduce the rate of magnetic field diffusion to the level that would permit plasmoid formation. Finally, a plasma instability of some type could have resulted in the destruction of the plasmoid before it was able to translate downstream. As of this writing, measurements have yet to validate any of these hypotheses.

2.3. Summary of Experimental Data

Presented in Table 1 is a summary of operating parameters and test data measured for various IPPTs. In this table we have only listed the thrusters for which there exists at least a partial record of data in the literature. Most telling is the lack of data to quantify the performance of most of these thrusters. To develop greater understanding of IPPTs and facilitate future modeling efforts, future test campaigns must focus on gathering more complete sets of data on the performance and operating conditions of different thruster concepts.

Table 1.

Summary of operating parameters and test data for various IPPTs. (* data not available, ** equivalent circuit voltage, *** equivalent circuit current, estimated value, not applicable).

3. Review of Modeling Techniques

Multiple modeling techniques have been applied to IPPTs over the years, from simple one-dimensional models to full two- and three-dimensional magnetohydrodynamic (MHD) approaches. In the following section, we review the various models employed to develop an understanding of IPPTs and note the major insights gained with each model.

3.1. Open Magnetic Flux Thrusters

The modeling of open flux thrusters has primarily focused on modeling the acceleration process and capturing the electromagnetic coupling between the external primary circuit and the accelerating plasma circuit. Most models for these types of thrusters assume that the gas is already ionized to a sufficient degree to conduct current, and while some of the models do permit additional ionization during the discharge, they do not account for the initial breakdown process.

3.1.1. Planar Thruster Modeling

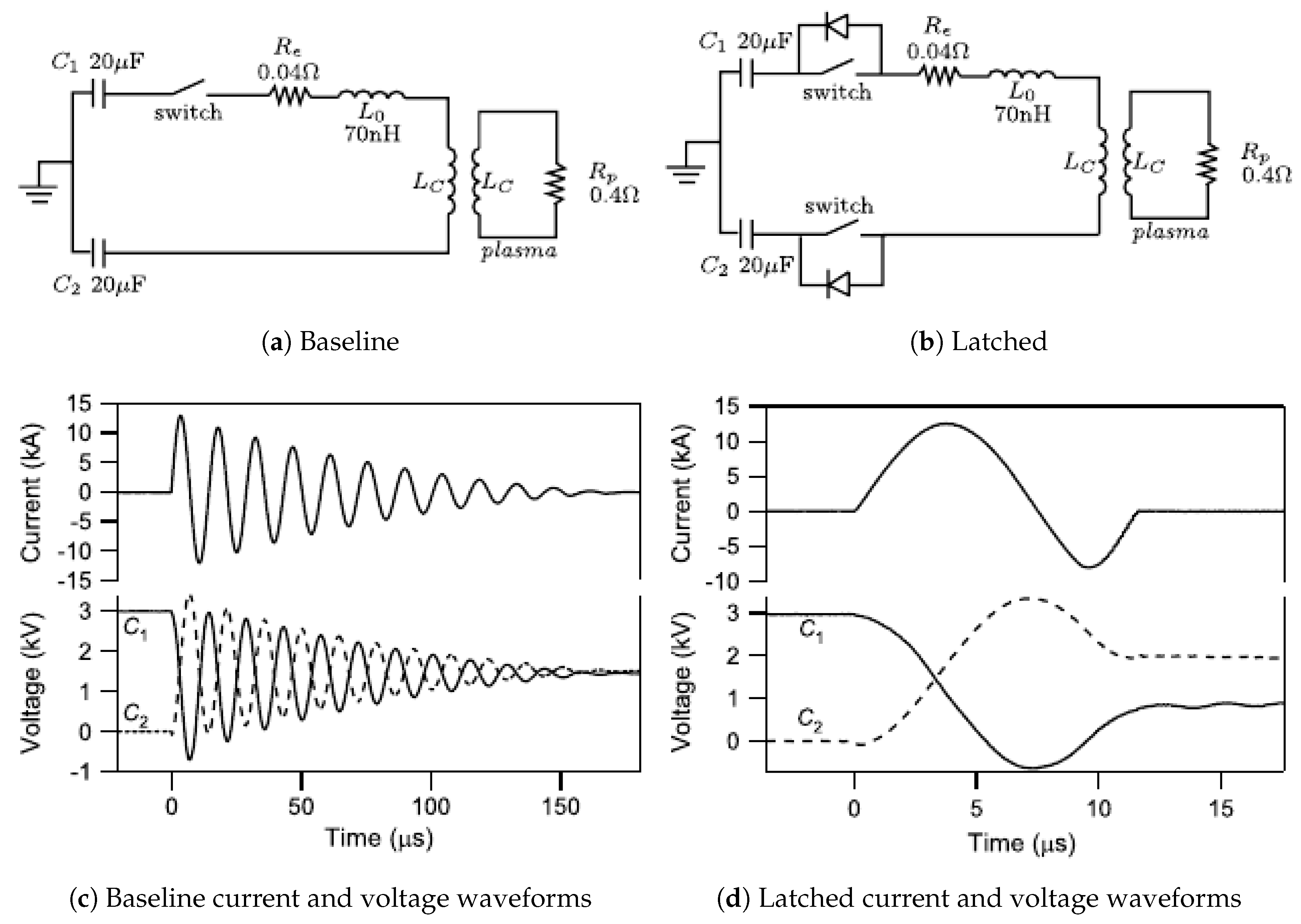

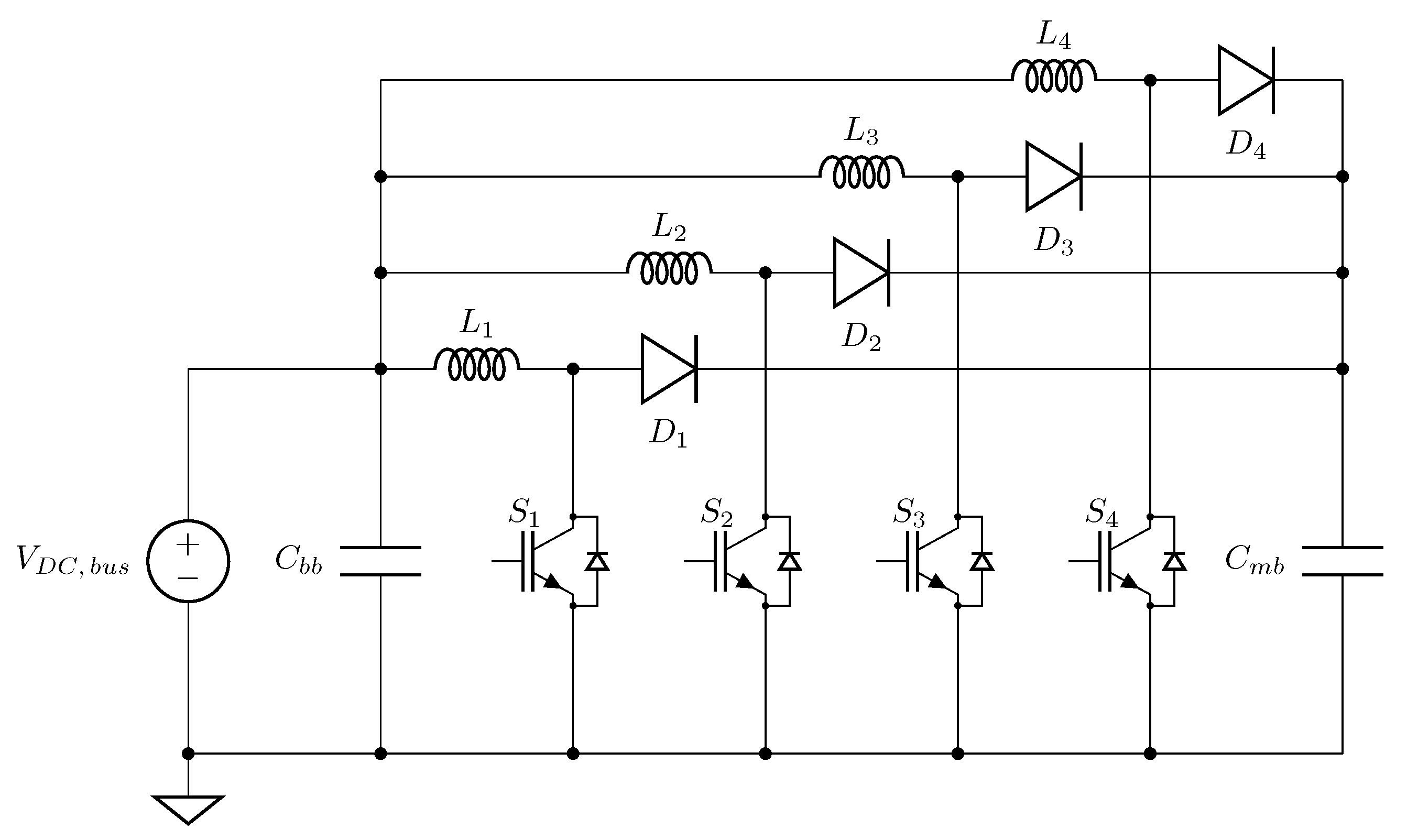

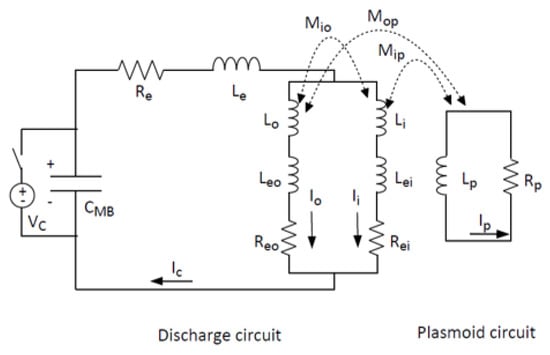

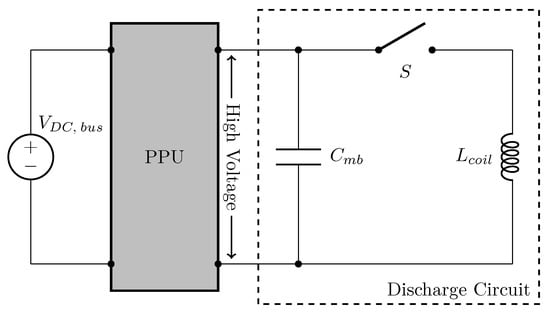

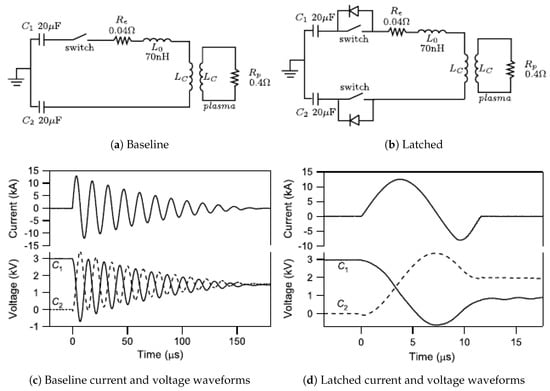

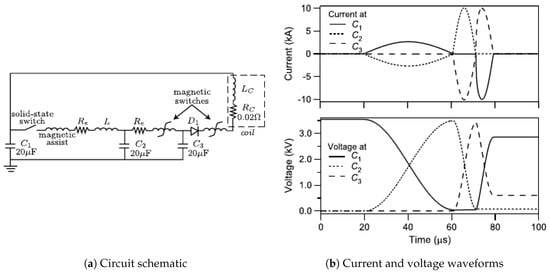

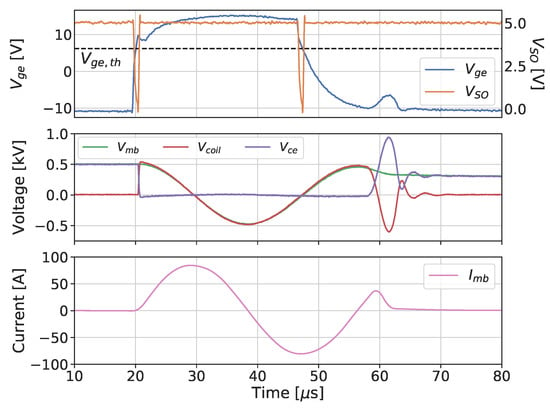

The primary model used for planar IPPTs in the literature for several years is a lumped-element circuit model coupled to a one-dimensional momentum equation [3,7,13,59,60]. The circuit can be drawn in the manner shown in Figure 14a. In the figure, the initial charge voltage on the capacitor C drives current in the primary circuit, through circuit elements with external resistance , stray or parasitic inductance , and coil inductance . The primary circuit couples to the plasma like a transformer with mutual inductance M between the circuits. An induced secondary plasma current is driven through an inductance and a plasma resistance . It is straightforward to rearrange the circuit into the equivalent configuration shown in Figure 14b, and this permits the writing of first-order ordinary differential circuit equations that can be used to numerically solve the electrical problem.

Figure 14.

Circuit models: (a) general lumped-element representation of an IPPT and (b) equivalent circuit (after [16]).

The key to coupling the circuit equations and the motion of the plasma lies in the mutual inductance term, which is a function of the separation distance between the primary and secondary circuits. This dependence can be found experimentally using a conducting metal disk to simulate the plasma at different downstream positions [13], or it can be found numerically using a solver to simulate the magnetic field as a function of plasma position [19,59,61,62]. Since the acceleration problem has no closed form solution and must be calculated numerically, it is straightforward to use a table lookup for the mutual inductance function. However, it has been found and validated in several studies that the mutual inductance for a planar IPPT can be curve fitted using a function of the form

where z is the axial direction of motion of the plasma and the curve fit parameter is the decoupling length, which represents the characteristic length scale of electromagnetic interaction between the two circuits.

The axial linear propellant density distribution in front of the coil is and it can assume several potential configurations. The plasma sheet is assumed to possess an initial mass of propellant and to entrain and accelerate to the sheet speed all propellant encountered as the sheet moves. The overall mass in the sheet is

where is the time-dependent velocity of the plasma. Finally, the momentum of the plasma is governed by the equation

where the term on the left side of the equation represents the electromagnetic force on the plasma, the first term on the right side represents the momentum invested in accelerating the already-entrained propellant, and the second term on the right side represents the momentum that must be expended to entrain propellant encountered by the plasma, ‘instantaneously’ accelerating it to the current sheet speed.

While the model is relatively straightforward to solve, a simple examination of the governing equations reveals much about the nature of these thrusters and their operation. The mutual inductance in Equation (9) and the corresponding electromagnetic force in Equation (11) both decrease exponentially as a function of separation distance, showing the importance of accelerating the propellant while it is near to the coil face. In addition, the last term in Equation (11), which involves the entrainment of propellant encountered by the moving plasma, reduces the useful additional acceleration that can be performed for a given level of electromagnetic force, implying that neutral propellant should be entrained early in the discharge cycle when the plasma velocity is still low so as to reduce entrainment losses.

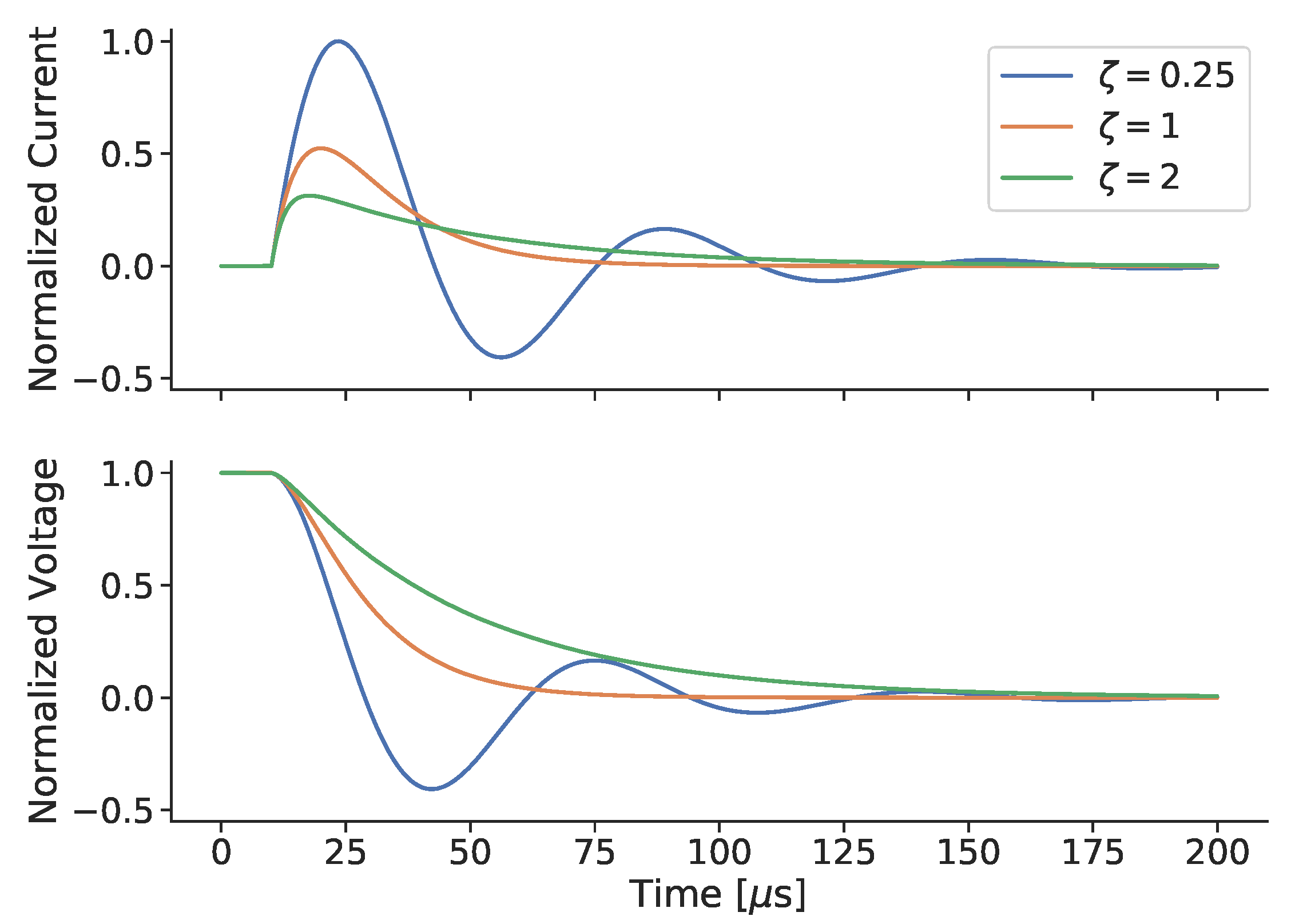

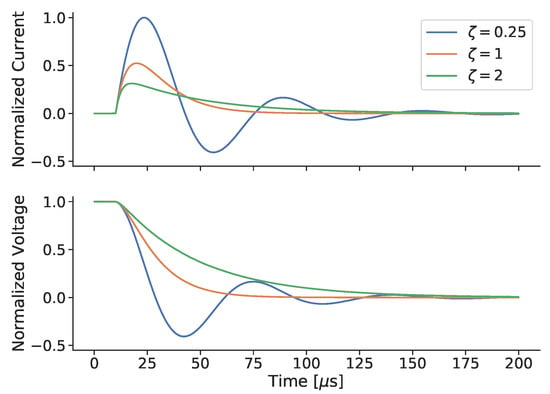

Polzin et al. [16,60,63] nondimensionalized the one-dimensional coupled equation set and generated solutions over the parameter space represented by the remaining nondimensional parameters to gain insight into the performance scaling trends in planar IPPTs. This work provided a mathematical foundation to understand findings in the PIT MK V and MK Va data that had previously been explained through less rigorous experimental intuition. The most important new finding was the derivation of a dynamic impedance parameter

where is the initial charge voltage on the capacitor bank. It was shown that this term can be decomposed into several dimensionless ratios, with the most insightful being a ratio of the natural period of the external circuit to the time interval over which the motion of the plasma will increase the inductance of the external circuit by one unit of . Another independent circuit model study found substantially similar results [59]. A broad maximum in efficiency as a function of was discovered, and it was further shown that the operating parameters of the MK Va spanned a range of that included the maximum efficiency from the modeling, with a reduction in efficiency of only a few percent at the extremes of the experimental data range. The values of computed for the MK V, on the other hand, were more removed from the values that yielded maximum efficiency, explaining the lower performance relative to the MK Va. The work also rigorously showed that greater acceleration occurred for highly underdamped circuits and for propellant distributions where most of the injected mass was close to the acceleration coil. This combination of conditions results in high peak currents and correspondingly high accelerating forces while the plasma and coil are still near enough for appreciable acceleration to be imparted to the former.

The one-dimensional acceleration model was upgraded to include the time-evolution of energy in the plasma and to more realistically represent the plasma state properties [64]. Simulations were useful in calculating the partitioning of energy between different energy sinks in the plasma as a function of time and the controllable parameters of the discharge. An examination of the relative magnitudes of these different sinks highlighted the less-useful dissipative modes that could increase at the expense of useful plasma acceleration.

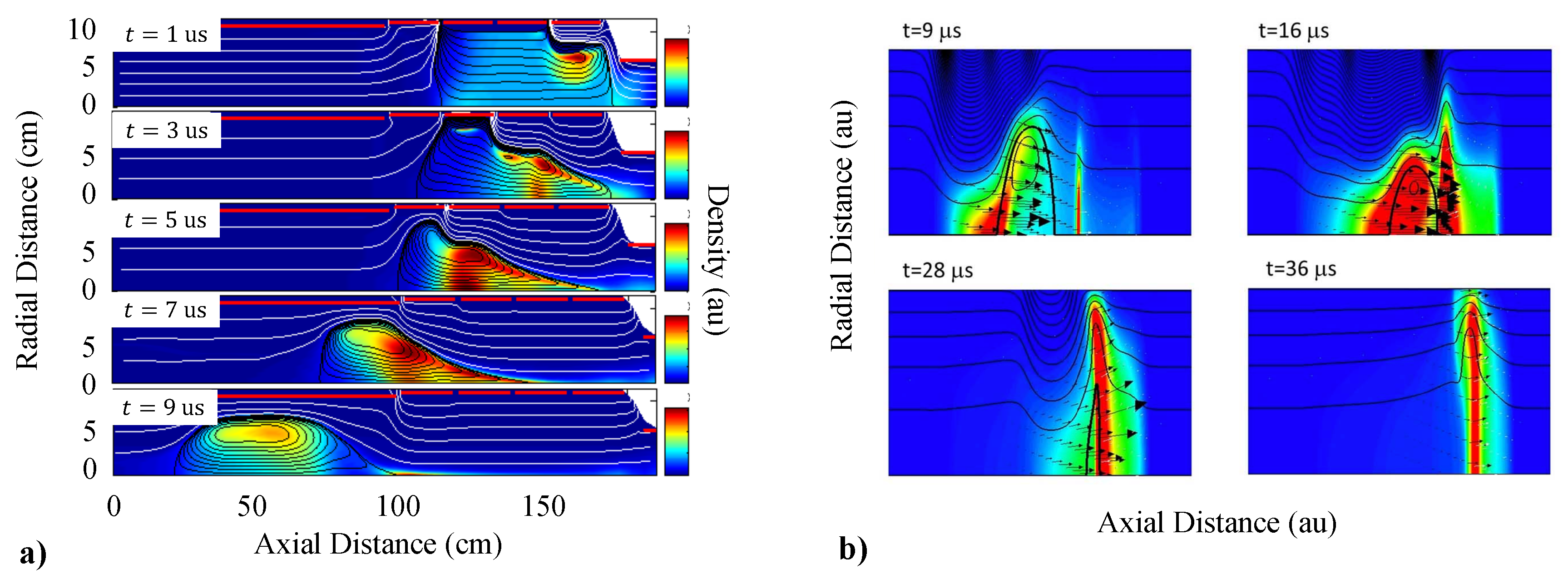

Mikellides et al. [65,66,67] performed 2-D axisymmetric modeling using the multiblock arbitrary coordinate hydromagnetic (MACH) code. This was the first major time-dependent simulation of the plasma evolution using an MHD solver, though a pair of upgrades had to be implemented during the course of the research to improve the results. In the most recent simulations, at each timestep the computed magnetic field and plasma resistivity were integrated over the solution domain and used to insert the effects of time-varying resistive and inductive plasma circuit voltage losses into the model governing the solution for the time-dependent external circuit current [67]. Also, a new non-equilibrium equation of state model for ammonia was developed and included to more accurately model the MK Va data [68].

The MHD modeling provided some interesting insights into planar IPPT operation [7,66,67]. A good match was obtained for the first half-cycle of the external circuit current and the computed thruster performance mostly exhibited good quantitative agreement with the MK V and MK Va experimental data for multiple propellants. The time-evolution of the plasma in two dimensions was insightful in showing first that the plasma maintained remarkable radial uniformity and also in demonstrating the amount of accelerated plasma that impacted the central cone located downstream from the acceleration coil face that was used to inject gas into the thruster. A critical specific energy beyond which efficiency declined was identified in these results and in computations on a lower discharge energy variant [69]. The specific energy beyond which efficiency declines exhibits good quantitative agreement with experimental data. The modeling of performance on ammonia also exhibited very good quantitative agreement with the far more simple and less computationally intensive one-dimensional coupled performance model. As the latter did not contain radiation energy losses, this agreement supported the conclusion that radiation losses in the PIT operating on ammonia were small or negligible.

Che et al. [70] presented a two-dimensional axisymmetric MHD model of an IPPT using a formulation that coupled the external circuit with the plasma circuit electrical response. In this work, a separate domain for the drive coil was used to calculate the plasma voltage component presented to the external circuit. This was found by integrating the azimuthal electric field along the path of one of the spiral wires comprising the acceleration coil. While a planar coil was studied in this work, this approach allows for the calculation of the plasma voltage presented to non-planar external coil geometries as well. Computational domains outside the thruster body were also added to help determine the effects of nearby conductive structures, namely the walls of a conductive vacuum chamber and a coaxial capacitor mounting plate located behind the drive coil. It is worth noting the plasma was assumed to be in local thermodynamic equilibrium (LTE) and electrons, ions, and neutral particles as having the same temperature. This is in contrast to the model of Mikellides et al. [65], where thermal non-equilibrium between ions and electrons was allowed with each with their own energy equation.

Using their model, Che et al. [70] simulated the PIT MK I and obtained several interesting results. A secondary current sheet was observed to form when the current in the drive coil reversed sign during the second half period of the discharge cycle. This secondary sheet was found to contribute up to ≈20% of the total impulse and did not “short-circuit” the primary current sheet. It was also observed that and could be kept relatively constant over a range of discharge energies so long as was adjusted to maintain a constant specific energy (). A critical specific energy beyond which efficiency declined was not observed within the simulated range of parameters. This may be due to the fact that the design parameters of the MK I place it well outside of the range of optimized efficiency achieved in the MK Va thruster. Third, compression of the initial propellant in the direction of the coil face was found to noticeably improve thruster performance. Reducing radial non-uniformities was also found to positively affect propulsive performance to a lesser extent. Finally, conductive structures located within the decoupling distance of the drive coil were found to adversely impact thruster performance. The effect was most severe for the interaction with the coaxial grounding plate located slightly behind the drive coil. Structures located beyond the decoupling distance were found to have minimal impact, which is in agreement with previous results obtained using the one-dimensional coupled performance model [62].

3.1.2. Conical Theta-Pinch Thruster Modeling

Hallock et al. [19,71] attempted to expand the one-dimensional plasma acceleration model coupled to the lumped-element circuit model by modifying it to include the inherent two-dimensional plasma motion found in CTP-IPPTs. The keys to this work were magnetic field modeling results and experimental measurements used to determine the functional variation in mutual inductance between the conical acceleration coil and the plasma moving in either the axial or radial direction. Putting this into the equation of motion yielded accelerating electromagnetic forces in both the axial and radially-inward directions, corresponding to the directions of negative gradient in the mutual inductance. This work did not address the problem of mass entrainment, instead assuming all propellant mass was initially in the plasma at the start of the discharge. The biggest shortcoming of the model was the lack of a mechanism to convert radial motion of the plasma into axial momentum. Finally, while computations were performed for certain cone-angles, the resulting computational model could not be readily applied to a cone of arbitrary angle.

There were some interesting insights from this effort, despite some gross assumptions incorporated into the model. With a second degree-of-freedom in the equations of motion, the plasma can electromagnetically decouple from the coil moving radially as well as axially, and rapid radial displacement results in a significant reduction in axial acceleration of the propellant. It is tempting to think that this radial motion could be converted into axial motion, but that conversion will certainly incur some additional losses due to increased entropy of the gas. This strongly favors the planar IPPT configuration over the CTP-IPPT, where in the former energy is coupled from the circuit directly into motion of the plasma in the preferred, axial direction without the need for additional processes to turn the flow and generate thrust.

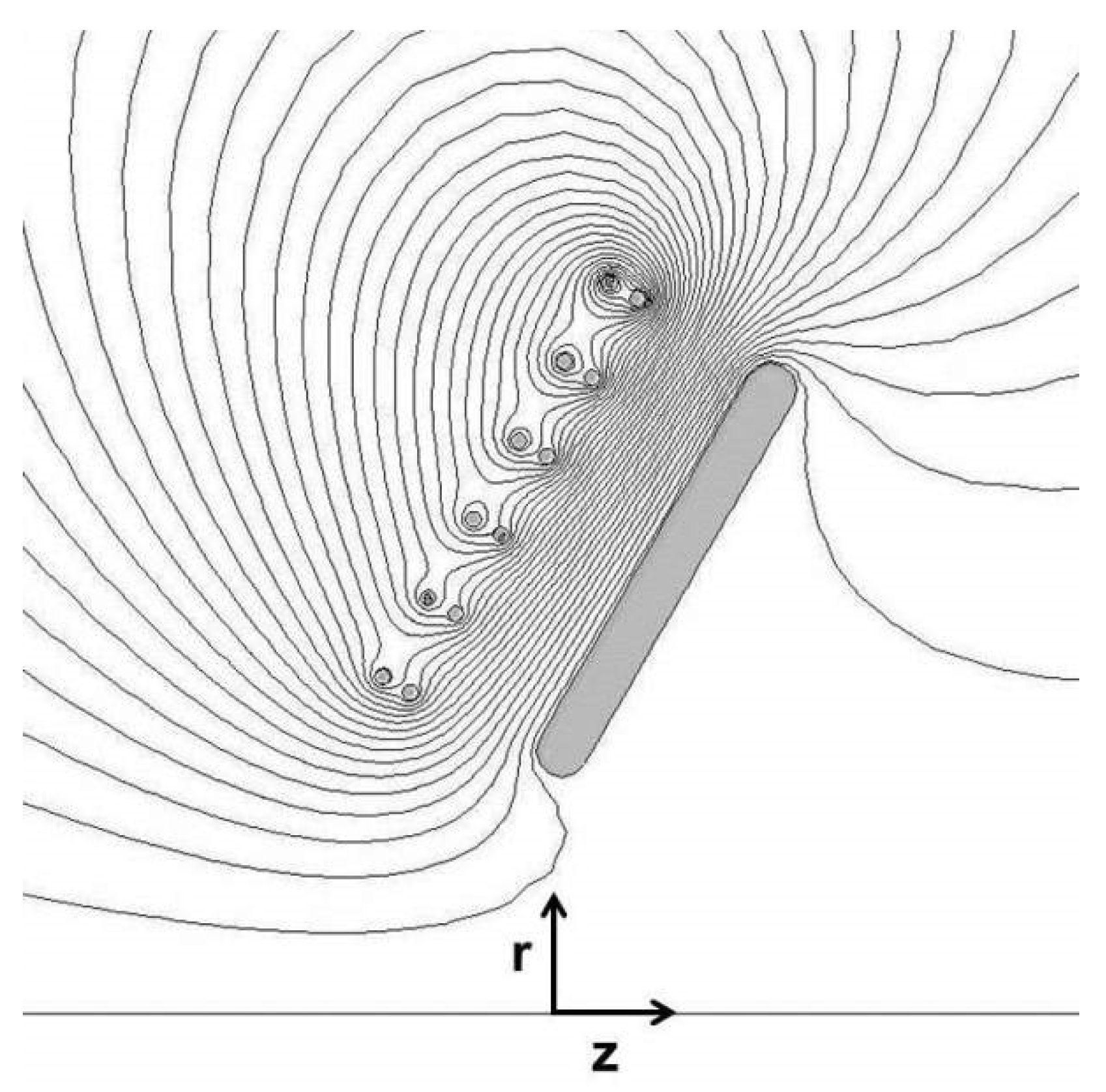

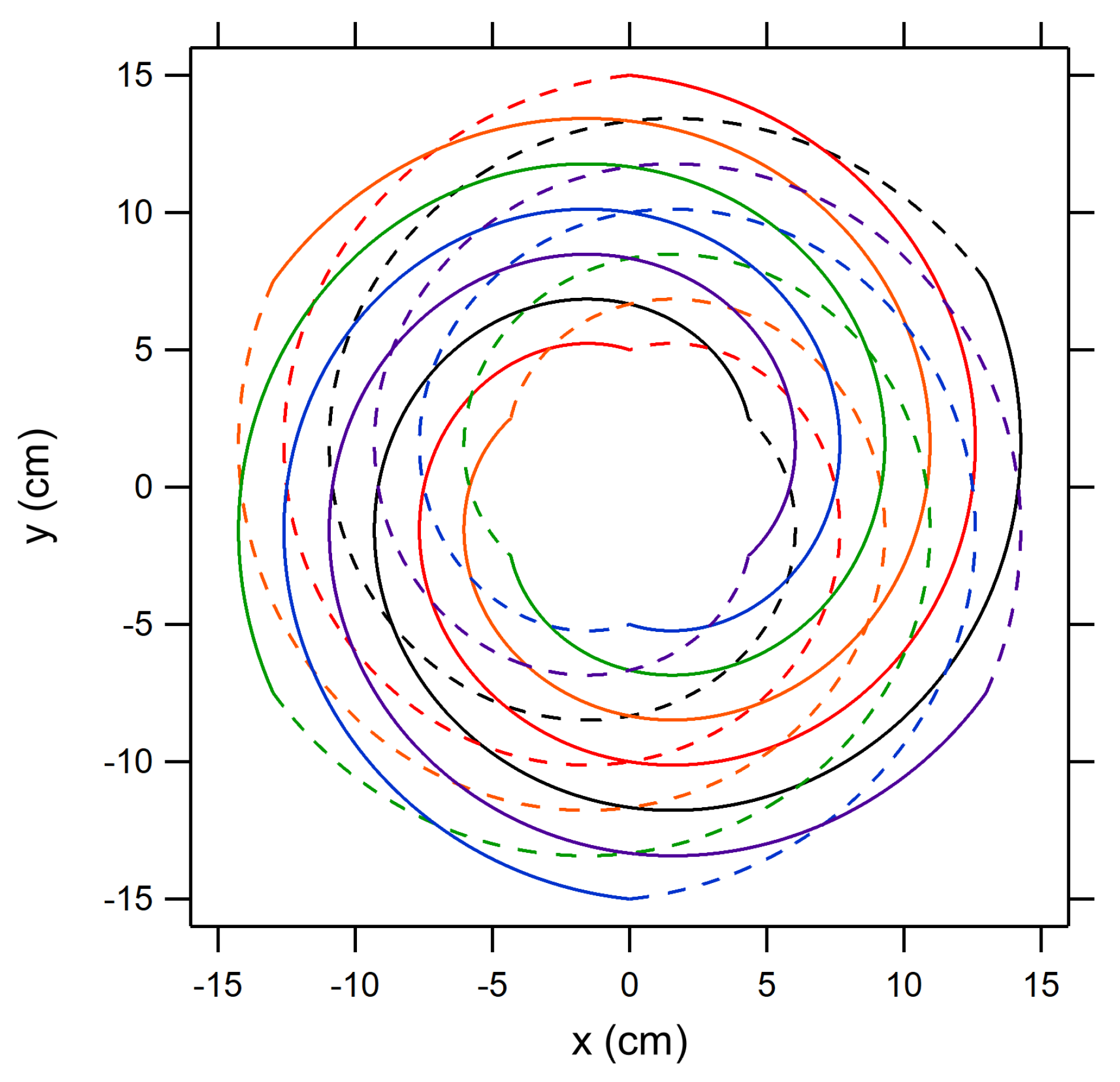

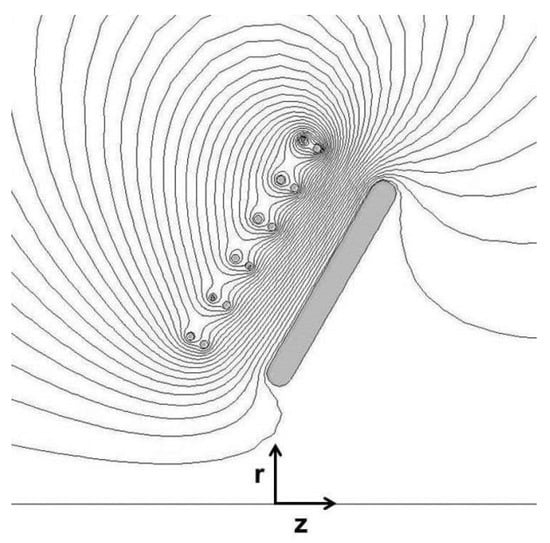

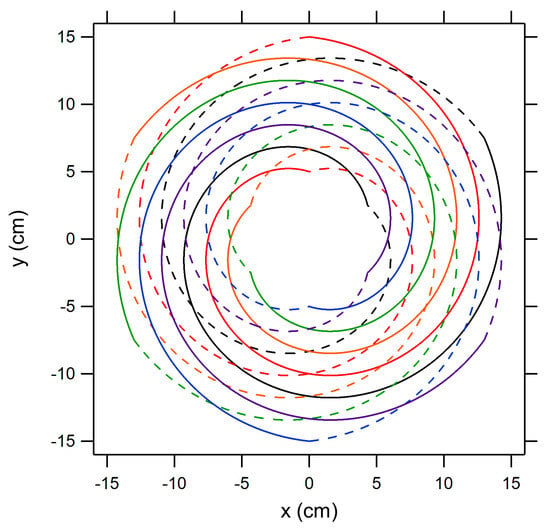

Martin [72] also developed a circuit model coupled to radial and axial equations of motion to investigate the performance of conical IPPTs with cone angles from 10° to 90° (i.e., planar), treating the plasma as a radially compressible slug conformal to the coil. The mutual inductance was calculated using the magnetic field solver QuickField for a variety of plasma locations, with the plasma modeled as a slug with finite dimensions and a large conductivity. Flux contours for one such calculation, with a six-fold parallel 2 turn coil with cone angle of 60° is shown in Figure 15; this coil is equivalent to the FARAD coil from Ref. [73] if it were folded in to the specified cone angle. From these results, the total magnetic energy in the configuration is calculated, and from those are derived the plasma position dependent mutual inductance values, which are stored in a look-up table and used for interpolation during solution of the coupled circuit/dynamic equations. The radial equation of motion included a restoring force due to the plasma pressure which was computed with a simplified equation of state. The results of this model agreed with those of Hallock et al. [19,71] described above; in particular it predicted that the maximum efficiency will be attained by a planar coil. These calculations also found a local maximum in the efficiency (though not an absolute maximum) for a cone angle less than 90°, as was observed experimentally in Ref. [4].

Figure 15.

Magnetic flux contours calculated with QuickField for a coil with six two-turn leads in parallel and a cone angle of 60°. The plasma thickness is 1 cm. The overall dimensions of the coil are similar to the FARAD coil of Ref. [73].

3.2. Closed Magnetic Flux Thrusters

Modeling of closed magnetic flux thrusters has focused mainly on understanding FRC formation and plasmoid acceleration and the impact these processes have on thruster performance. We review here in increasing order of complexity the modeling approaches that have been applied to date for FRC thrusters. These include simple scaling laws, equivalent circuit models, and high fidelity full plasma simulations. In each case, we discuss the model predictions for the key performance metrics such as specific impulse, efficiency, and thrust.

3.2.1. Thruster Scaling Laws

Scaling laws are simple analytical expressions that relate thruster operating conditions and geometry to performance metrics. IPPTs are inherently complex devices. High fidelity models are required to fully capture the physics involved in thrust generation. However, those codes require significant computational time and complexity, and it may be difficult to determine physical scaling relations from the simulation results. To circumvent this issue, scaling laws can sometimes be found by applying numerous assumptions to a model to arrive at first order expressions that capture, to an extent, the effects key physical processes have on performance.

Efficiency from Energy Conservation

The model introduced by Slough et al. [42] is predicated on the assumption that acceleration of the RMF-FRC is a two stage process. First, the plasmoid is accelerated by a Lorentz body force that arises from the interaction of the azimuthal plasma currents and the external magnetic field. Second, any thermal energy introduced into the plasmoid through Ohmic heating during FRC formation is recovered through adiabatic expansion. To arrive at a tractable analytical expression for the work performed by the Lorentz body force, this model employs the assumption of constant FRC plasma properties in a conical geometry with fully magnetized electrons (see Figure 10c). The kinetic energy delivered to the plasma by the Lorentz body force can be written as

where is the average radius of the plasmoid, is the length of the thruster cone, is the magnitude of the externally applied magnetic field, and the cone half angle of the thruster is given by . Physically, this result shows that the energy of the propellant will increase with the size of the thruster, the plasma density of the plasmoid, the RMF drive frequency, and the strength of the external magnetic field [42]. The conversion of thermal to kinetic energy is found by balancing the plasma and magnetic pressures to yield

where . Here, is the initial plasma temperature before expansion and T is the temperature after the plasmoid is ejected. Equation (14) indicates that the thermal energy converted to kinetic energy scales as the square of the externally applied magnetic field. The total efficiency is found by summing Equations (13) and (14) over the total energy expended in the system. Weber [51] identified each of the relevant energy loss modes to further deconstruct the energy flow in the system to find an overall scaling law for efficiency:

The energy sinks in the denominator are: kinetic (), thermal and magnetic (), ionization (), resistance in the flux conservers (), screened RMF (), convection (), and radiation () energy losses. Not included are the losses in the driver circuit, so Equation (15) only accounts for the energy imparted to the plasma by the RMF.