Detection and Prognosis of Propagating Faults in Flight Control Actuators for Helicopters

Abstract

1. Introduction

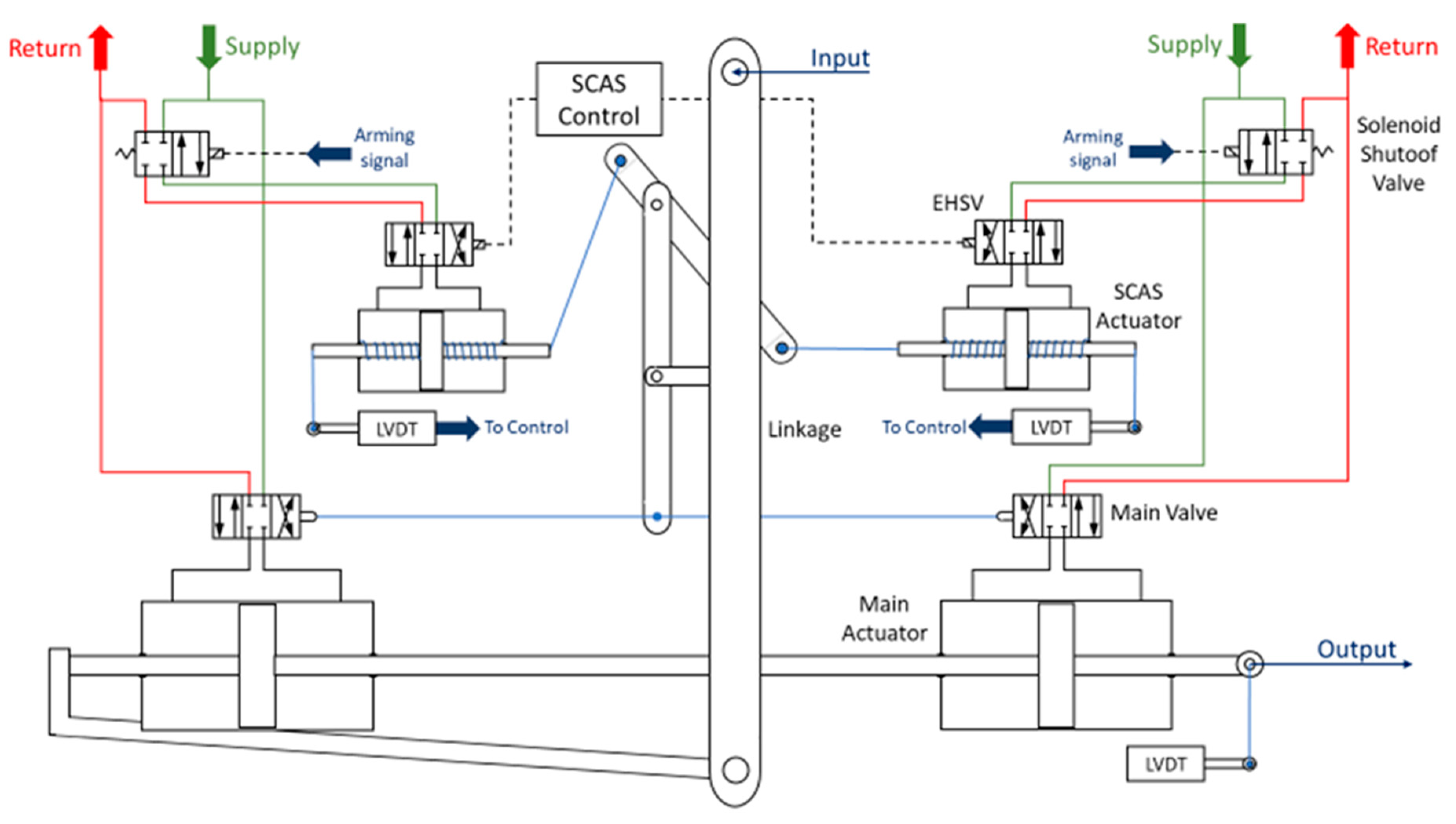

2. System Configuration and Physical Model

2.1. System Configuration

2.2. Physical Model

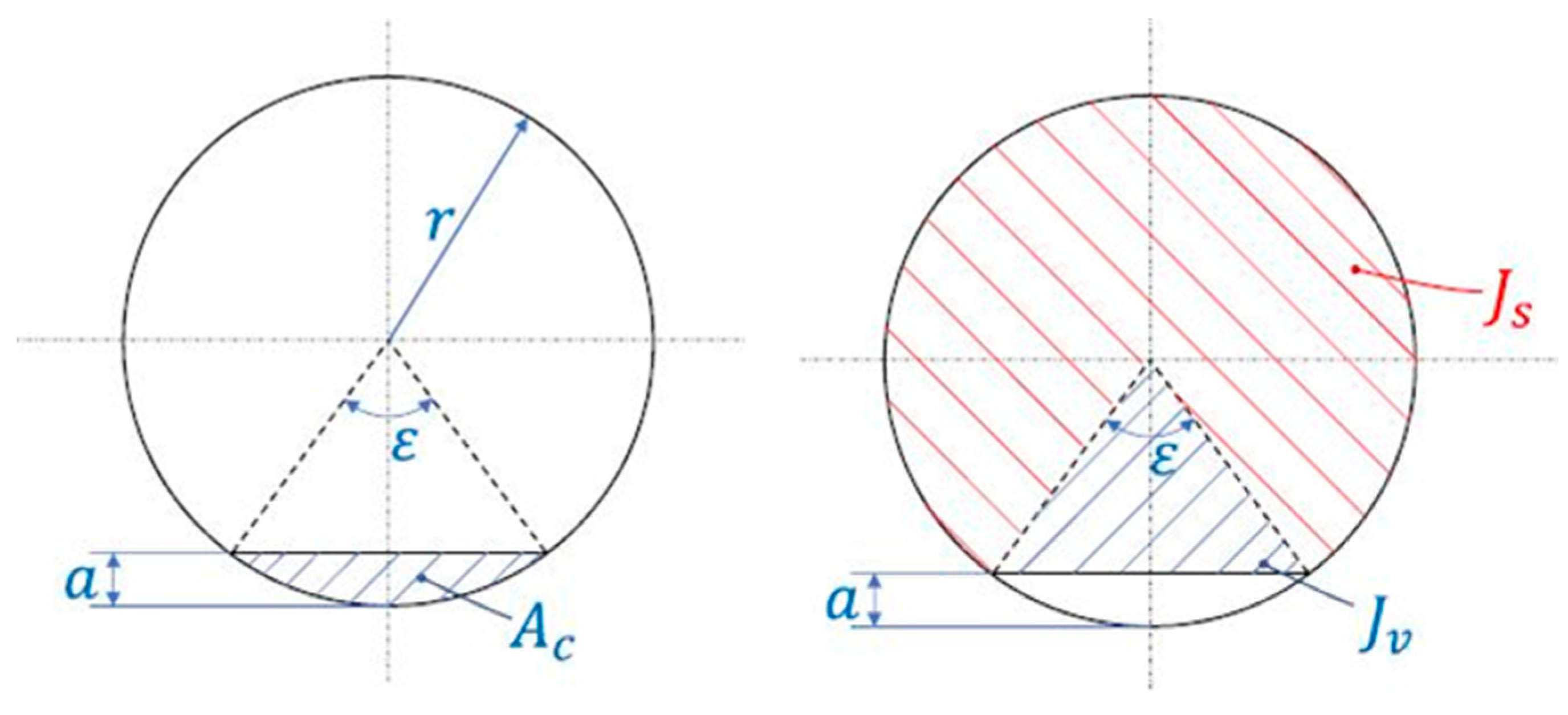

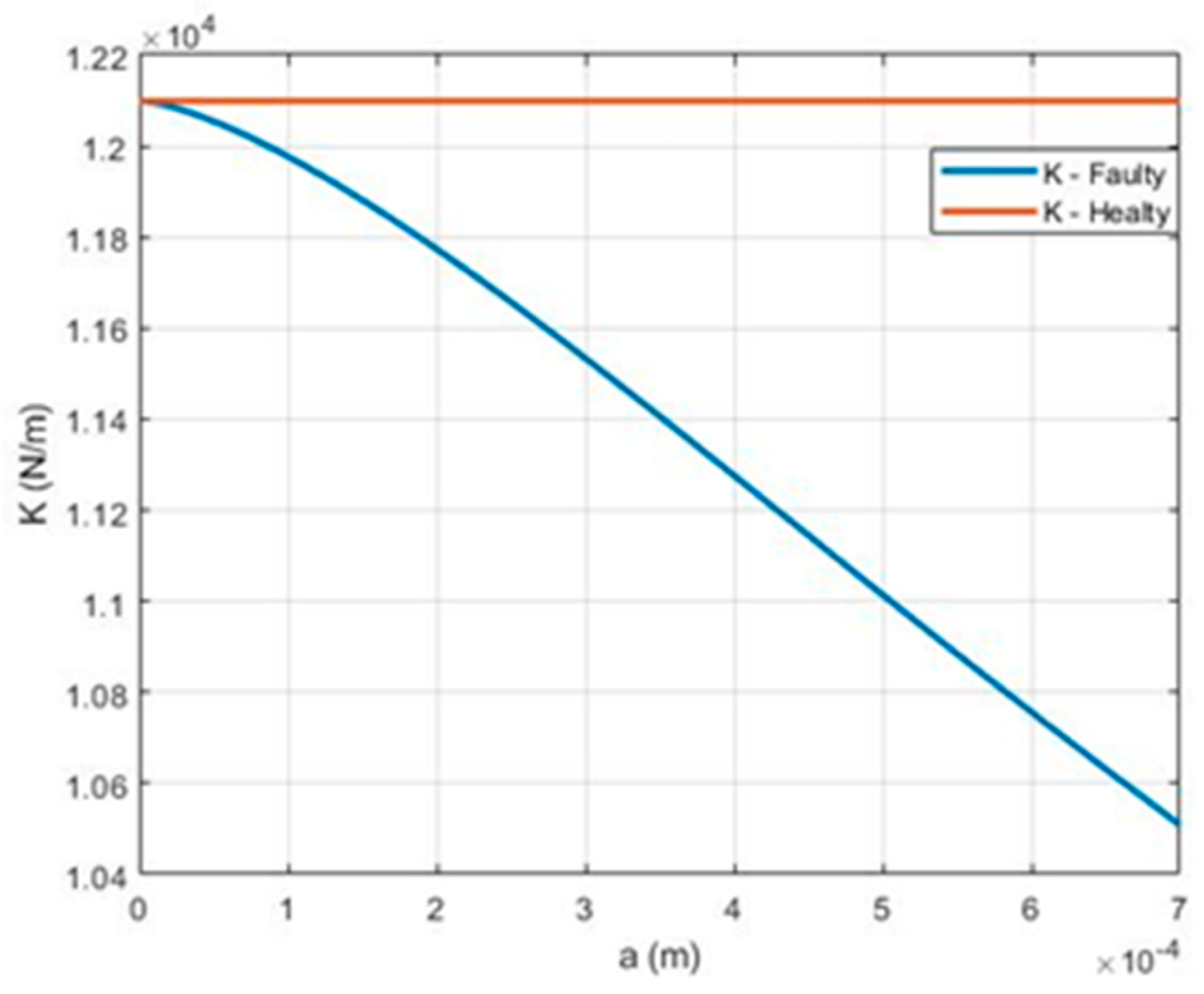

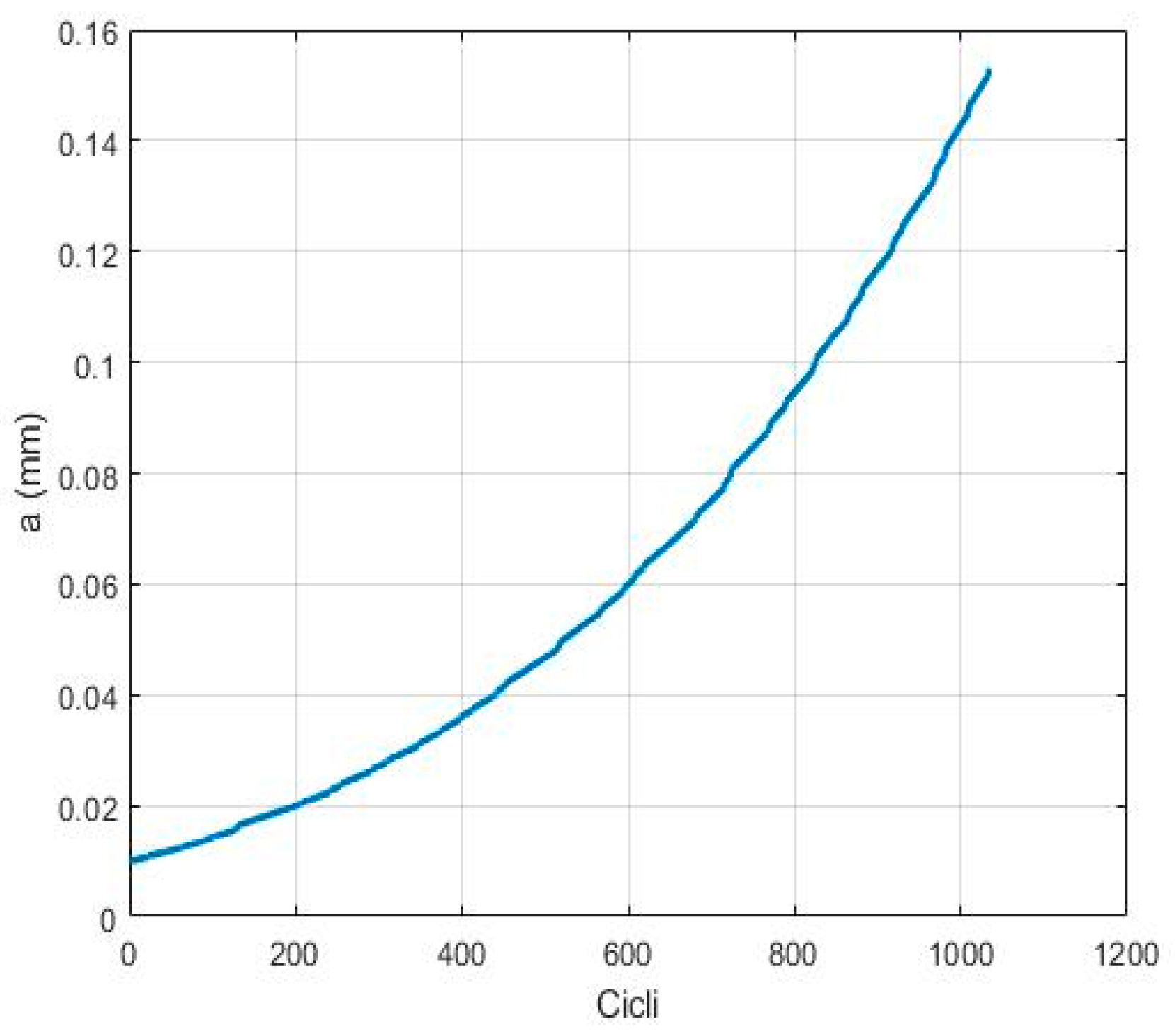

2.2.1. Spring Cracking

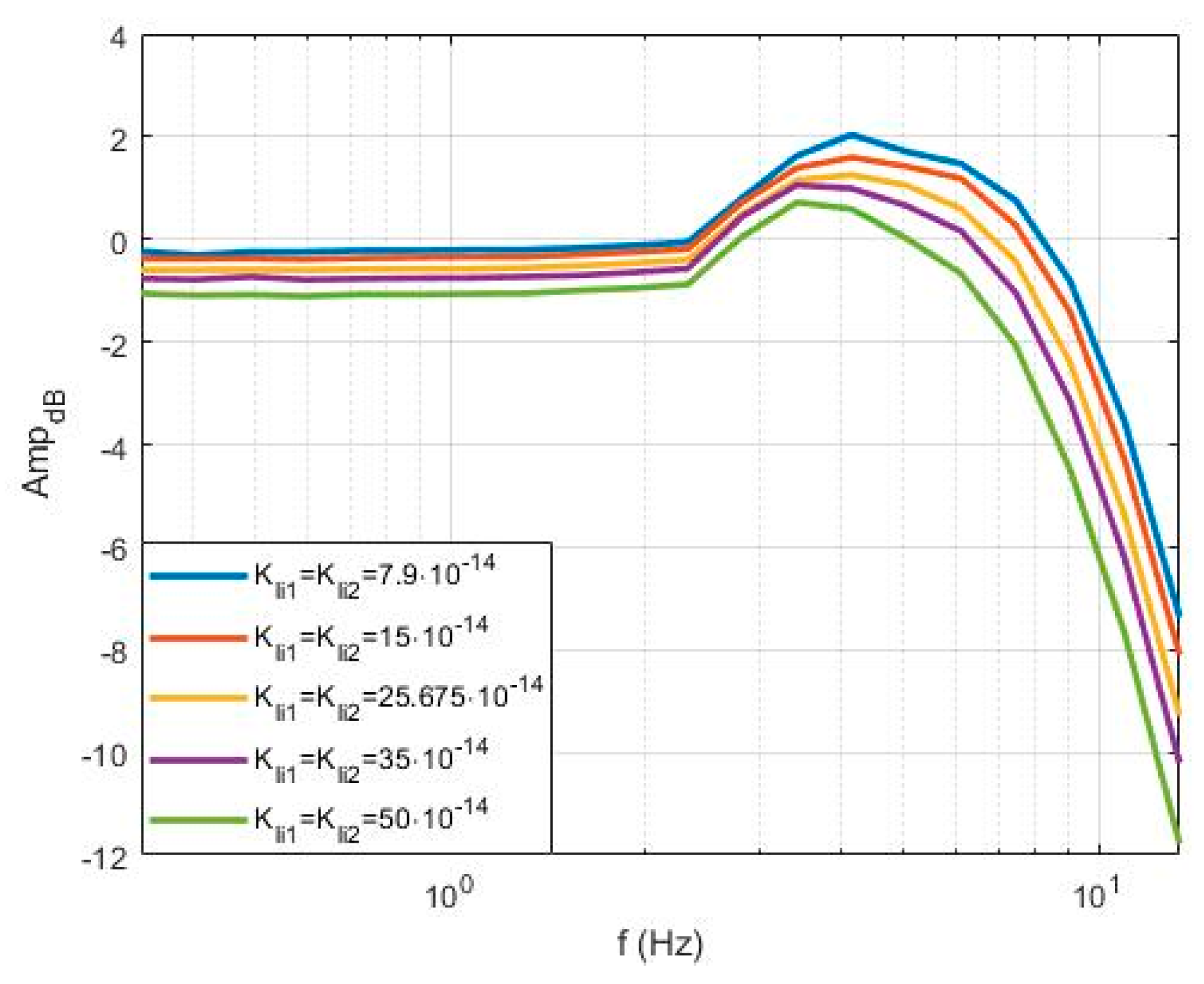

2.2.2. Seals Wear

3. Scenario Definition and Simulation

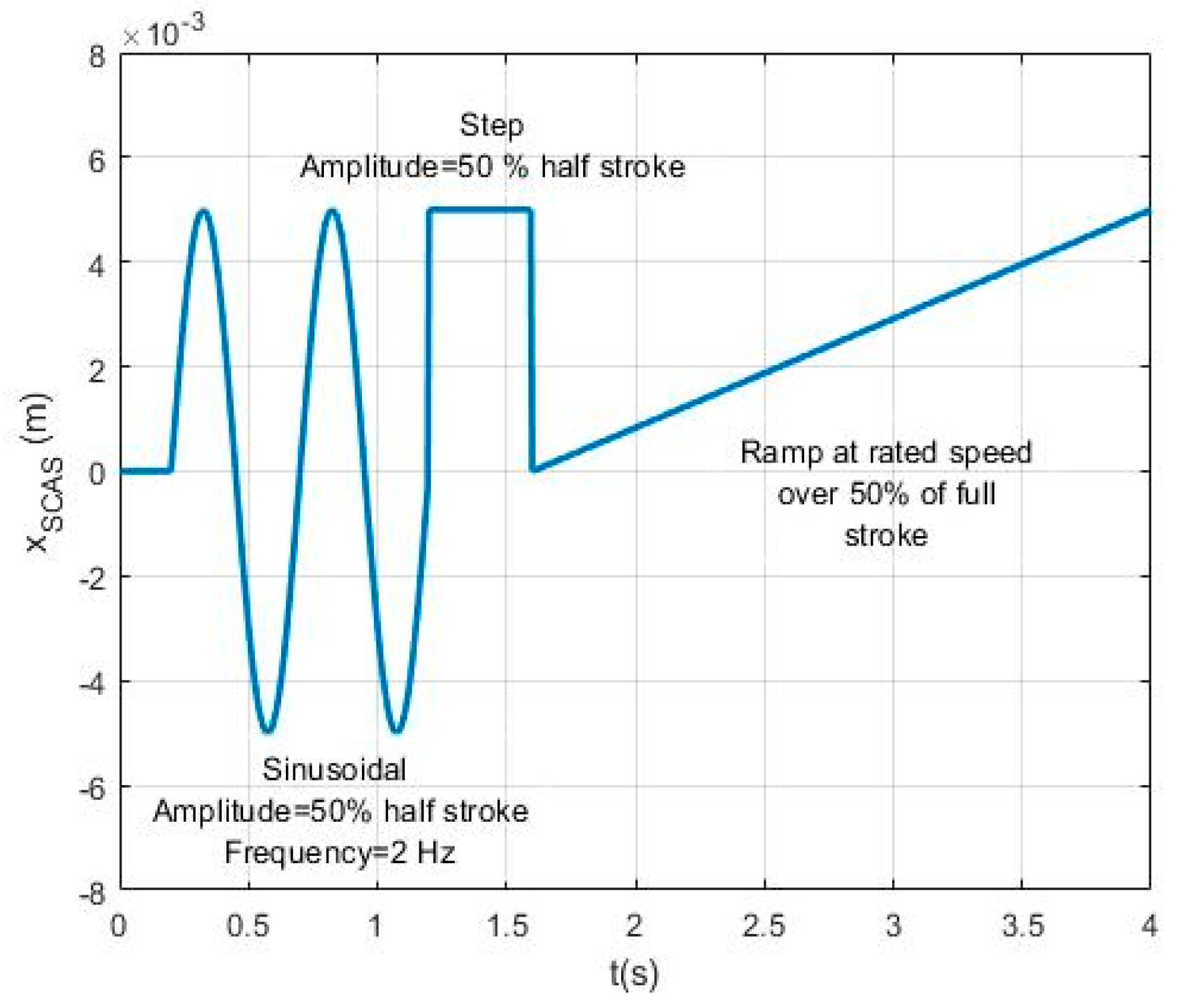

3.1. On-Ground Tests

3.2. In-Flight Conditions

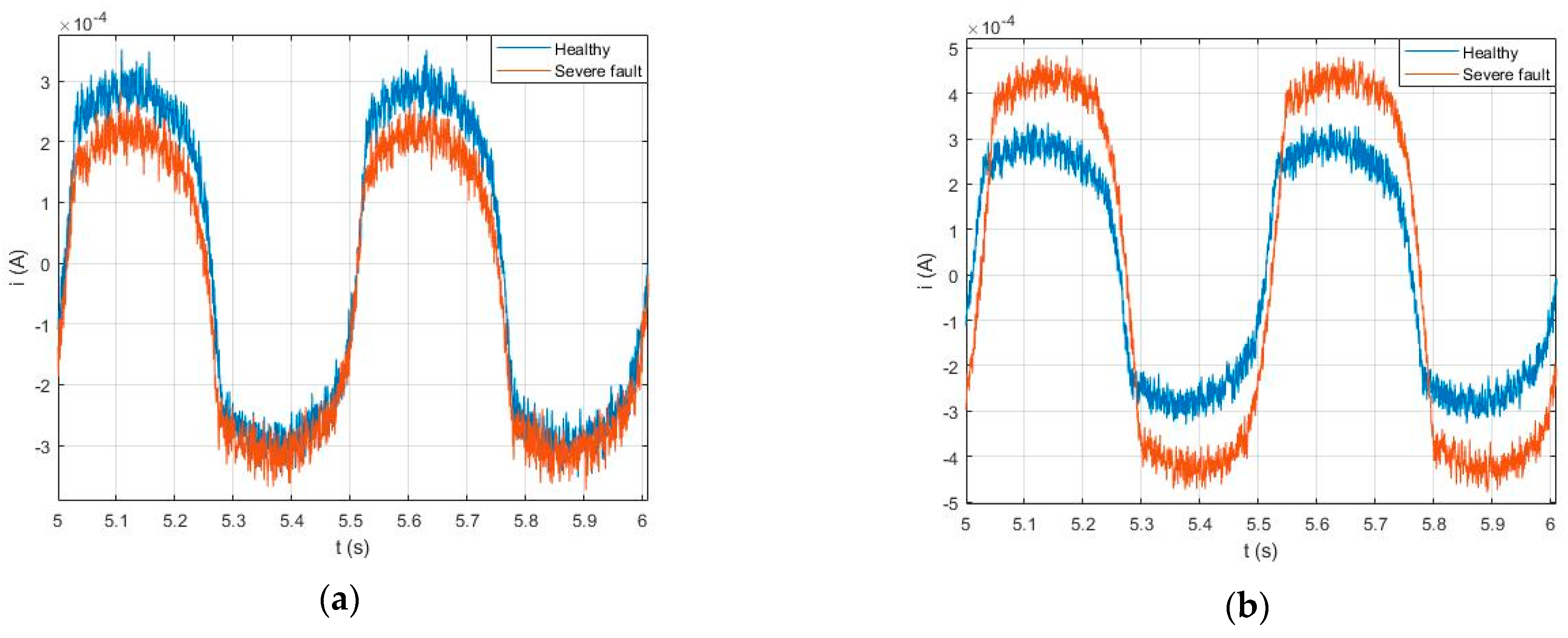

4. Feature Selection

5. PHM Algorithm

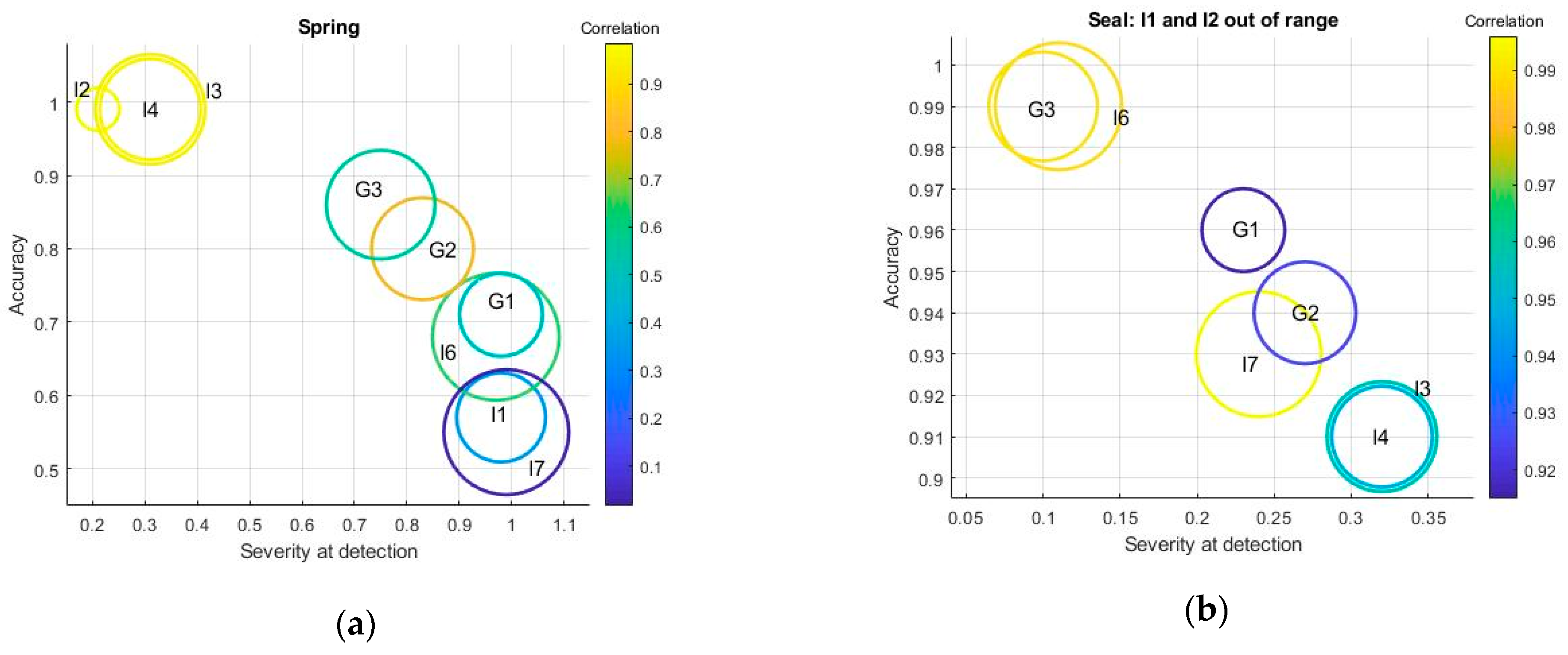

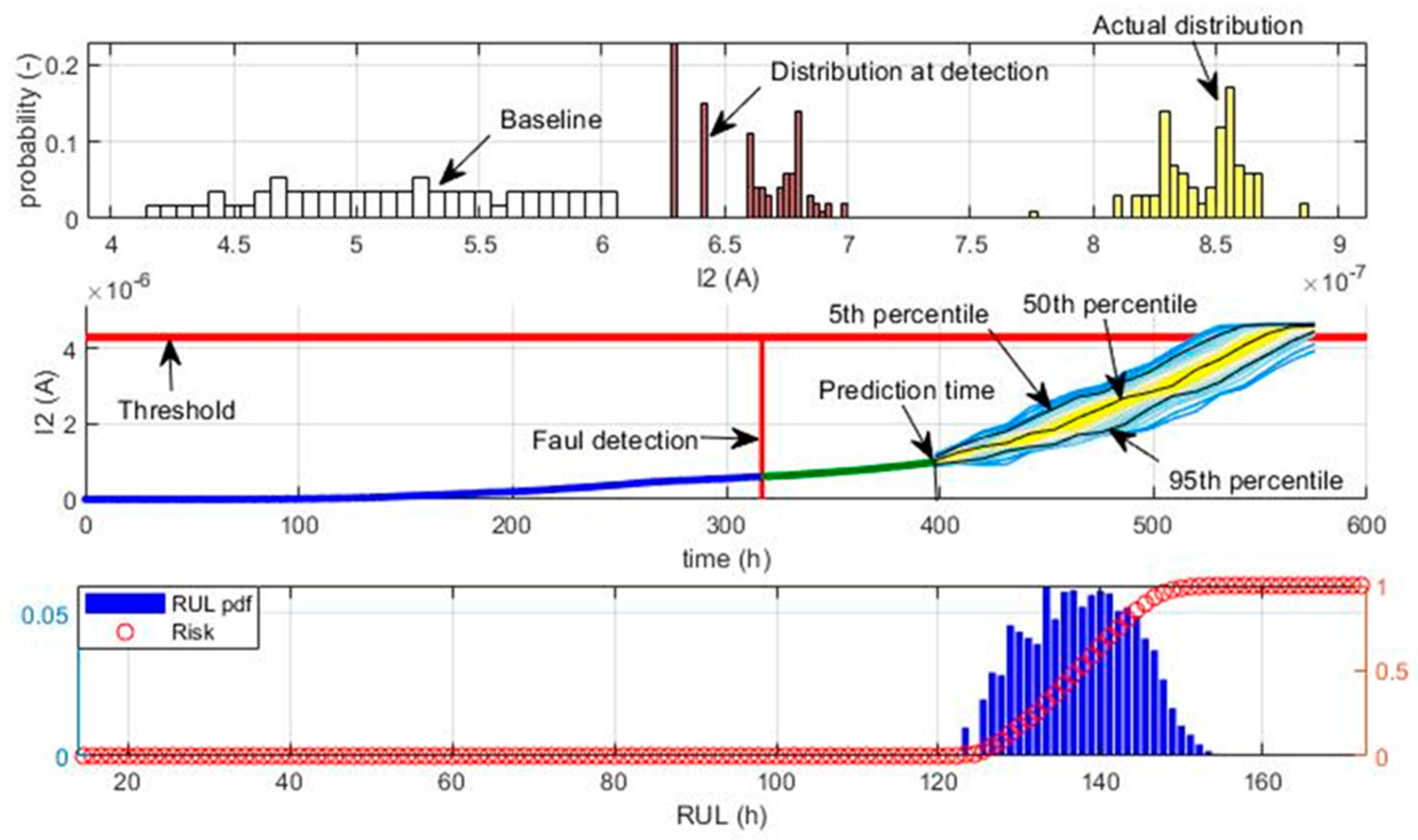

5.1. Fault Detection

5.2. Failure Prognosis

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CRA | Cumulative relative accuracy |

| FFT | Fast Fourier Transform |

| LVDT | Linear Variable Differential Transformer |

| PHM | Prognostics and health management |

| Probability density function | |

| RA | Relative accuracy |

| RMS | Root Mean Square |

| RUL | Remaining useful life |

| SCAS | Stability and command augmentation system |

Symbols

| a | Depth of crack, m |

| A | Area, m2 |

| C | Spring index R/r, dimensionless |

| D | Diameter of the spring coil, m |

| F | Axial force action on the spring, N |

| FT(η) | Geometrical factor, dimensionless |

| G | Shear modulus, Pa |

| i | Current, A |

| J | Polar second moment of area, m4 |

| K | Spring stiffness, N/m |

| Ki1 | First leakage parameter, m3/s/Pa |

| Ki2 | Second leakage parameter, m3/s/ |

| KIII | Stress intensity factor, Pa |

| La | Friction work, J |

| N | Number of spring turns, dimensionless |

| Ql | Volumetric flow rate, m3/s |

| R | Radius of the spring coil, m |

| r | Radius of the spring wire, m |

| x | Displacement, m |

| β | Experimental material parameter, N/m |

| γ | Shear strain, dimensionless |

| Δp | Differential pressure, Pa |

| δ | Spring displacement, m |

| ε | Opening angle of the crack, rad |

| η | Dimensionless crack depth a/(2r) |

| λ | Thickness of removed material, m |

| τ | Shear stress, Pa |

References

- Keller, J.; Carr, D.; Love, F.; Grabill, P.; Ngo, H.; Shanthakumaran, P. AH-64D Main Transmission Accessory Drive Spur Gear Installation Fault Detections. J. Intell. Manuf. 2012, 23, 205–211. [Google Scholar] [CrossRef]

- Blunt, D.M.; Keller, J.A. Detection of a fatigue crack in a UH-60A planet gear carrier using vibration analysis. Mech. Syst. Sig. Process. 2006, 20, 2095–2111. [Google Scholar] [CrossRef]

- Pawar, P.M.; Ganguli, R. Helicopter rotor health monitoring-A review. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2007, 221, 631–647. [Google Scholar] [CrossRef]

- Brown, D.; Georgoulas, G.; Bole, B.; Pei, H.L.; Orchard, M.; Tang, L.; Saha, B.; Saxena, A.; Goebel, K.; Vachtsevanos, G. Prognostics Enhanced Reconfigurable Control of Electro-Mechanical Actuators. In Proceedings of the Annual Conference of the Prognostics and Health Management Society PHM09, San Diego, CA, USA, 27 September–1 October 2009. [Google Scholar]

- Dalla Vedova, M.D.L.; Germanà, A.; Berri, P.C.; Maggiore, P. Model-Based Fault Detection and Identification for Prognostics of Electromechanical Actuators Using Genetic Algorithms. Aerospace 2019, 6, 94. [Google Scholar] [CrossRef]

- Byington, C.S.; Watson, M.; Edwards, D. Data-Driven Neural Network Methodology to Remaining Life Predictions for Aircraft Actuator Components. In Proceedings of the 2004 IEEE Aerospace Conference, Big Sky, MT, USA, 6–13 March 2004. [Google Scholar]

- Autin, S.; Socheleau, J.; Dellacasa, A.; De Martin, A.; Jacazio, G.; Vachtsevanos, G. Feasibility Study of a PHM System for Electro-Hydraulic Servo- Actuators for Primary Flight Controls. In Proceedings of the Annual Conference of the Prognostic and Health Management Society, Philadelphia, PA, USA, 1 September 2018. [Google Scholar]

- Jacazio, G.; Mornacchi, A.; Sorli, M. Development of a prognostics and health management system for electrohydraulic servoactuators of primary flight controls. In Proceedings of the 5th International Workshop on Aircraft System Technologies AST2015, Hamburg, Germany, 24–25 February 2015. [Google Scholar]

- Roemer, M.; Byington, C.; Kacprszynski, G.; Vachtsevanos, G.; Goebel, K. Prognostics. In Systems Health Management with Aerospace Applications; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Vachtsevanos, G.; Lewis, F.; Roemer, M.; Hess, A.; Wu, B. Intelligent Fault Diagnosis and Prognosis for Engineering Systems, 1st ed.; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- De Martin, A.; Dellacasa, A.; Jacazio, G.; Sorli, M. High-Fidelity Model of Electro-Hydraulic Actuators for Primary Flight Control Systems. In Proceedings of the BATH/ASME 2018 Symposium on Fluid Power and Motion Control, Bath, UK, 12–14 September 2018. [Google Scholar]

- Shiwaku, K.; Yamada, Y.; Koarai, J.; Kawaguchi, Y. Improvement of Fatigue Life of Valve Spring Wire by Reducing Non-Metallic Inclusions. SAE Trans. 1985. [Google Scholar] [CrossRef]

- Shigley, J.E.; Mischke, C.R.; Budynas, R.G. Shigle’s Mechanical Engineering Design, 9th ed.; Tata McGraw-Hill Education: Pennsylvania Plaza, NY, USA, 2011. [Google Scholar]

- Viola, E.; Li, Y.; Fantuzzi, N. On the Stress Intensity Factors of Cracked Beams for Structural Analysis. Key Eng. Mater. 2012, 488, 379–382. [Google Scholar] [CrossRef]

- Paris, P.; Erdogan, F.A. Critical Analysis of Crack Propagation Laws. J. Fluids Eng. Trans. ASME. 1963, 85, 528–533. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Mornacchi, A.; Vachtsevanos, G.; Jacazio, G. Prognostics and Health Management of an Electro-Hydraulic Servo Actuator. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, PHM, Coronado, CA, USA, 18–24 October 2015. [Google Scholar]

- Kullback, S.; Leibler, R.A. On Information and Sufficiency. Ann. Math. Stat. 1951, 22, 79–86. [Google Scholar] [CrossRef]

- Bradley, A.P. The Use of the Area under the ROC Curve in the Evaluation of Machine Learning Algorithms. Pattern Recognit. 1997, 30, 1145–1159. [Google Scholar] [CrossRef]

- De Martin, A.; Jacazio, G.; Sorli, M. Enhanced Particle Filter Framework for Improved Prognosis of Electro-Mechanical Flight Controls Actuators. In Proceedings of the Fourth European Conference of the Prognostic and Health Management Society, Utrecht, The Netherlands, 3–6 July 2018. [Google Scholar]

- Doucet, A.; Johansen, A.M. A Tutorial on Particle Filtering and Smoothing: Fifteen Years Later. Handb. Nonlinear Filter. 2009, 12, 656–704. [Google Scholar]

- Arulampalam, M.S.; Maskell, S.; Gordon, N.; Clapp, T. A Tutorial on Particle Filters for Online Nonlinear/Non-Gaussian Bayesian Tracking. IEEE Trans. Signal Process. 2002, 50, 174–188. [Google Scholar] [CrossRef]

- Orchard, M.E.; Vachtsevanos, G.J. A Particle-Filtering Approach for on-Line Fault Diagnosis and Failure Prognosis. Trans. Inst. Meas. Control 2009, 31, 221–246. [Google Scholar] [CrossRef]

- Acuña, D.E.; Orchard, M.E. A Theoretically Rigorous Approach to Failure Prognosis. In Proceedings of the 10th Annual Conference of the Prognostics and Health Management Society 2018 (PHM18), Philadelphia, PA, USA, 24–27 September 2018. [Google Scholar]

- Saxena, A.; Celaya, J.; Balaban, E.; Goebel, K.; Saha, B.; Saha, S.; Schwabacher, M. Metrics for Evaluating Performance of Prognostic Techniques. In Proceedings of the 2008 International Conference on Prognostics and Health Management, PHM 2008, Denver, CO, USA, 6–9 October 2008. [Google Scholar]

| Occurrence | Command | Amplitude (mm) | Frequency (Hz) |

|---|---|---|---|

| 2% | XSCAS | 0 | 0 |

| Xi | 50 | 0.05 | |

| 60% | XSCAS | 0.3 | 2 |

| Xi | 0.5 | 1.5 | |

| 30% | XSCAS | 0.3 | 1.5 |

| Xi | 0.8 | 1 | |

| 8% | XSCAS | 2 | 0.8 |

| Xi | 10 | 0.8 |

| Feature | Description | |

|---|---|---|

| G1 | mean(i) | Current mean value |

| G2 | (max(x)-set)/set | % displacement overshoot |

| G3 | i/x | Current/displacement |

| I1 | abs(fft(x))(2Hz) | Displacement FFT amplitude at 2 Hz |

| I2 | mean(xcorr(i,ih)) | Mean value cross-correlation with respect to baseline (current) |

| I3 | mean(xcorr(x,xh)) | Mean value cross-correlation with respect to baseline (displacement) |

| I4 | mean(xcorr(x)) | Displacement auto-correlation |

| I5 | rms(abs(fft(x))) | RMS displacement FFT amplitude |

| I6 | rms(x) | Displacement RMS |

| I7 | rms(i)/rms(x) | RMS current/RMS displacement |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nesci, A.; De Martin, A.; Jacazio, G.; Sorli, M. Detection and Prognosis of Propagating Faults in Flight Control Actuators for Helicopters. Aerospace 2020, 7, 20. https://doi.org/10.3390/aerospace7030020

Nesci A, De Martin A, Jacazio G, Sorli M. Detection and Prognosis of Propagating Faults in Flight Control Actuators for Helicopters. Aerospace. 2020; 7(3):20. https://doi.org/10.3390/aerospace7030020

Chicago/Turabian StyleNesci, Andrea, Andrea De Martin, Giovanni Jacazio, and Massimo Sorli. 2020. "Detection and Prognosis of Propagating Faults in Flight Control Actuators for Helicopters" Aerospace 7, no. 3: 20. https://doi.org/10.3390/aerospace7030020

APA StyleNesci, A., De Martin, A., Jacazio, G., & Sorli, M. (2020). Detection and Prognosis of Propagating Faults in Flight Control Actuators for Helicopters. Aerospace, 7(3), 20. https://doi.org/10.3390/aerospace7030020