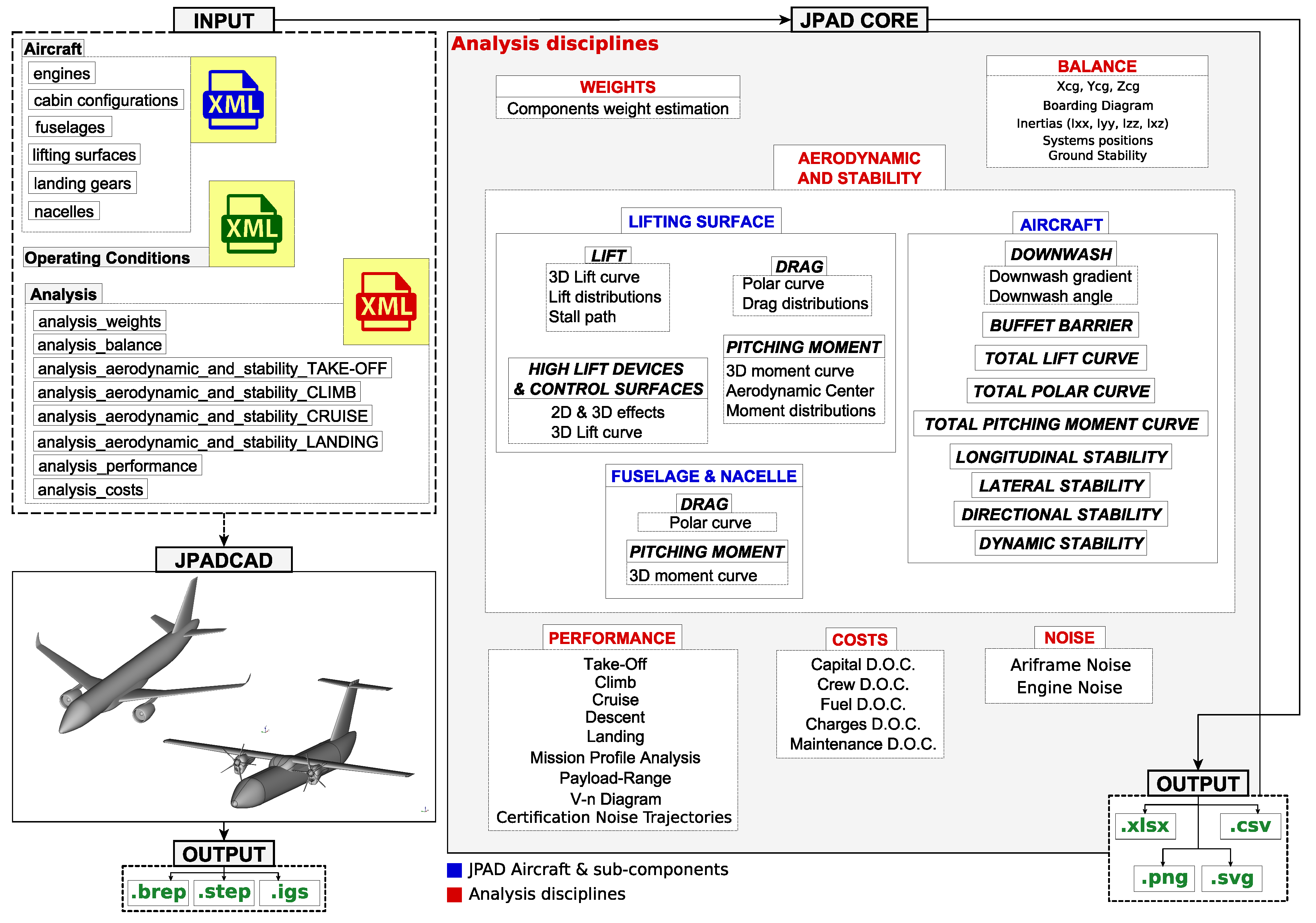

The performance analysis module in JPAD has been completely designed using a simulation-based approach to carry out both flight and ground performance studies with a high level of fidelity. This feature is usually not implemented inside most of the currently available preliminary aircraft design software, which relies on semi-empirical approaches, especially for the take-off and the landing phases.

In the overall JPAD core dependency map, the performance module requires some aircraft weight data as well as trimmed aerodynamic data concerning polar drag curves and lift curves in every standard flight condition (take-off, climb, cruise, and landing). The inputs can be assigned by the user manually—if the analysis is carried out in standalone mode, i.e., when a single focused performance study is required—or they can be fetched from a higher level aircraft analysis manager instance—e.g., when a full-blown design loop is executed. In the first case, two approaches are possible: working with parametrically defined parabolic drag polar curves, or using external drag polar curves if the user has higher fidelity data. In any case, lift curve data must be given using only the following parameters in clean, take-off, and landing configurations: lift curve slope, lift coefficient at zero angle of attack, and maximum lift coefficient. In addition, also the rudder effectiveness coefficient must be specified, in case of a standalone take-off study, to allow the estimation of the minimum control speed (). That is the minimum speed for which a sudden, single engine failure (with the remaining engines at take-off power) does not result in loss of primary flight control.

All performance assessment procedures use an engine database for each installed engine (multiple types of engine are possible in order to model hybrid propulsion aircraft). The user also has the possibility to define a wide set of calibration factors (all set to 1.0 by default) to trim all engine related quantities (thrusts, SFC, and emission indexes) for each engine rating (maximum take-off, APR, maximum climb, maximum continuous, maximum cruise, flight idle, and ground idle).

Among them, this section focuses on take-off, landing, and certification noise trajectories analysis modules. A detailed description of the implemented simulation methodologies is provided, which highlights important features usually not considered by classical semi-empirical approaches used for typical preliminary design activities.

3.1. Take-Off Simulation Model

The take-off analysis module computes conventional aircraft take-off performance using a simulation model first proposed in [

28]. However, due to major modifications that have been recently implemented, a review of the methodology is presented here.

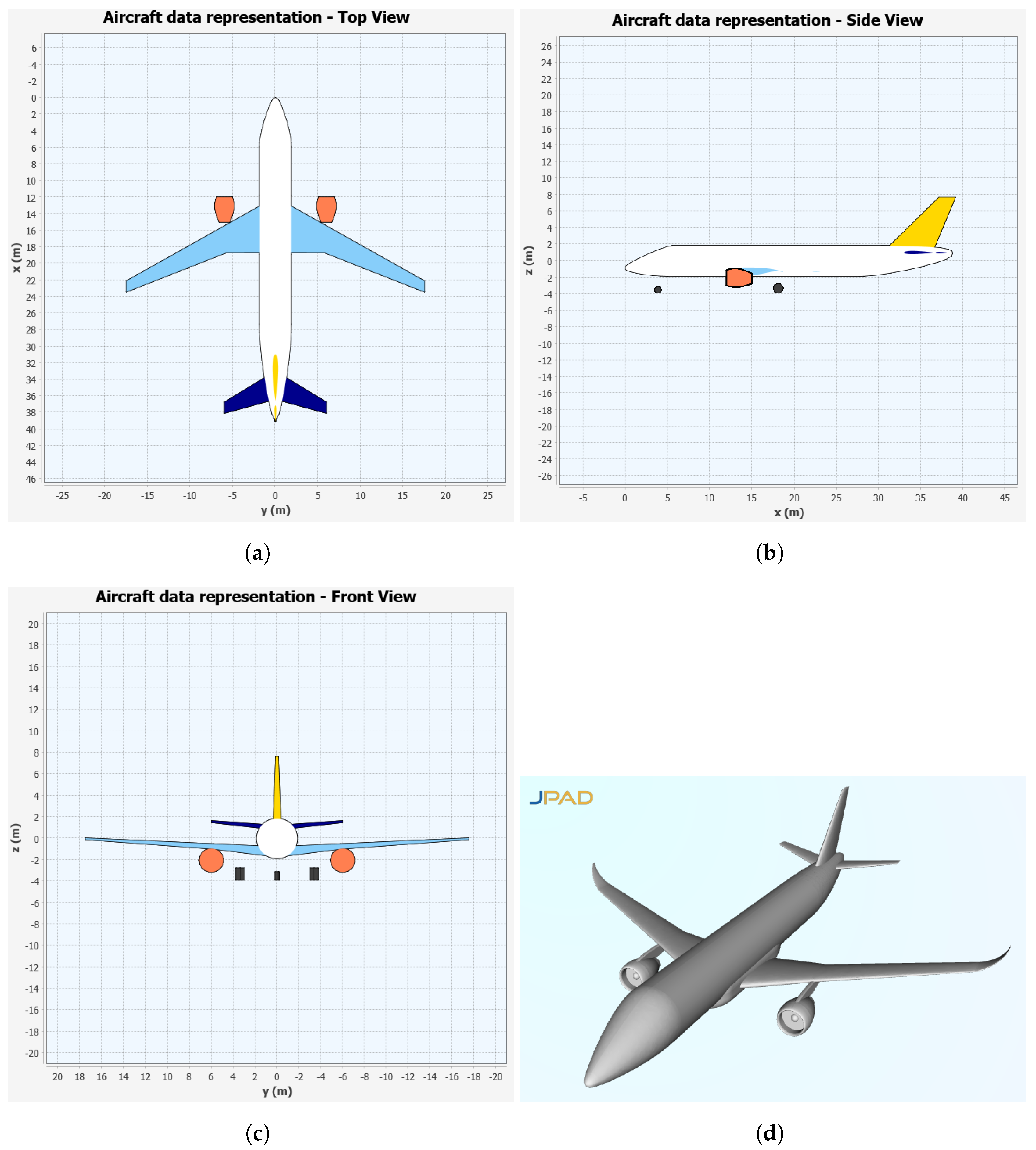

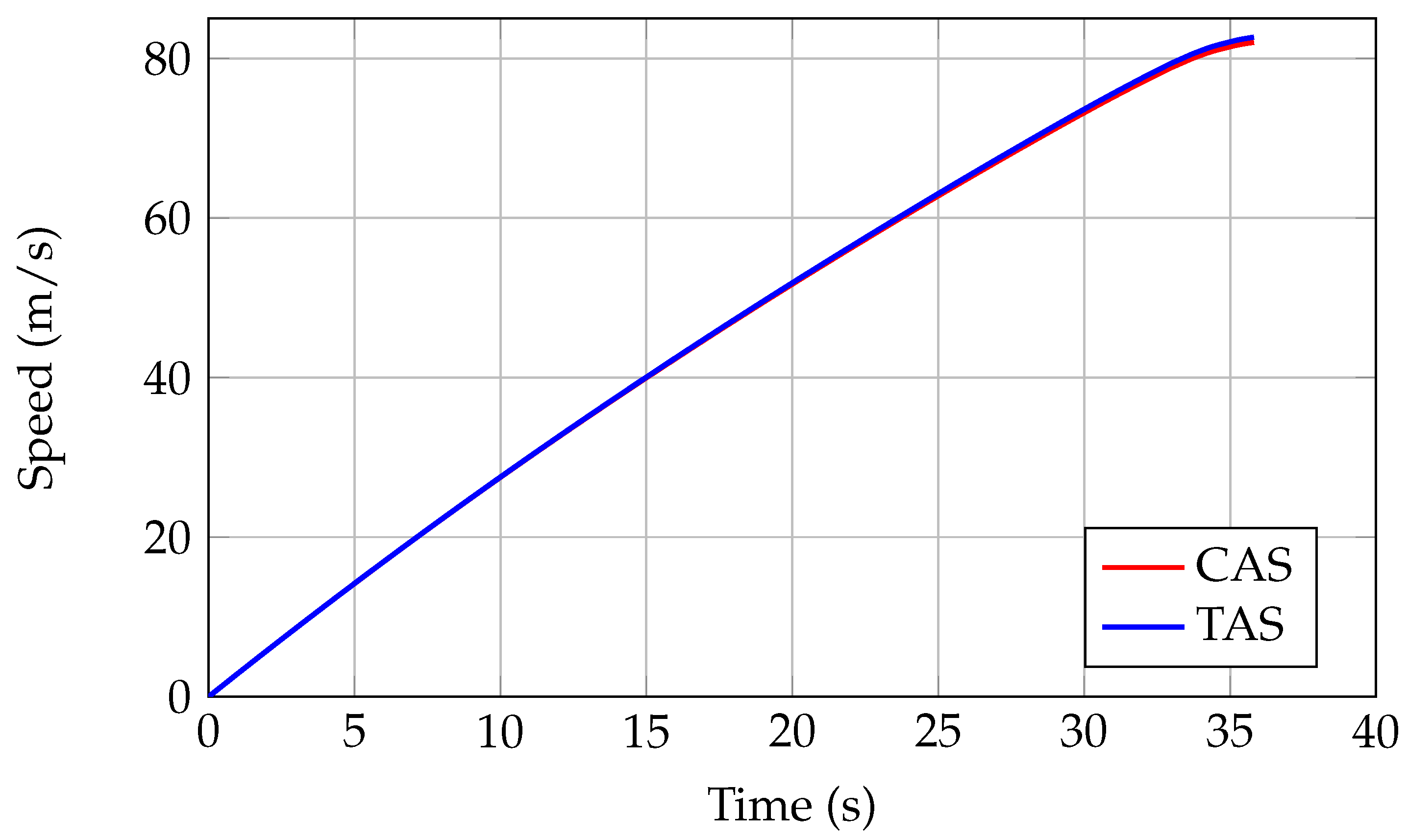

The analysis procedure solves a set of ODEs that model the aircraft equations of motion during the whole take-off phase, including the ground roll, the transition to the airborne phase, and the initial climb, up to (and beyond) the conventional standard established by regulations. The aircraft is modeled as a point mass constrained to move in a vertical plane under the action of propulsive, aerodynamic ground contact forces and weight, and hence is treated as a dynamic system in its state-space representation. The unknowns are the following fundamental variables of motion that describe completely the aircraft’s state during the whole maneuver:

Position s, i.e., center of gravity projected vertically on ground;

Ground speed V;

Flight path angle ;

Center of gravity altitude above the ground h;

Mass m.

The take-off state equations are then written in the following compact form

that can be expressed as [

28]:

where the unknown

are the vector of state variables, and the input

is a given function of time that corresponds to an assumed angle of attack time history during take-off. The right-hand side of system (

1) is defined by the following functions:

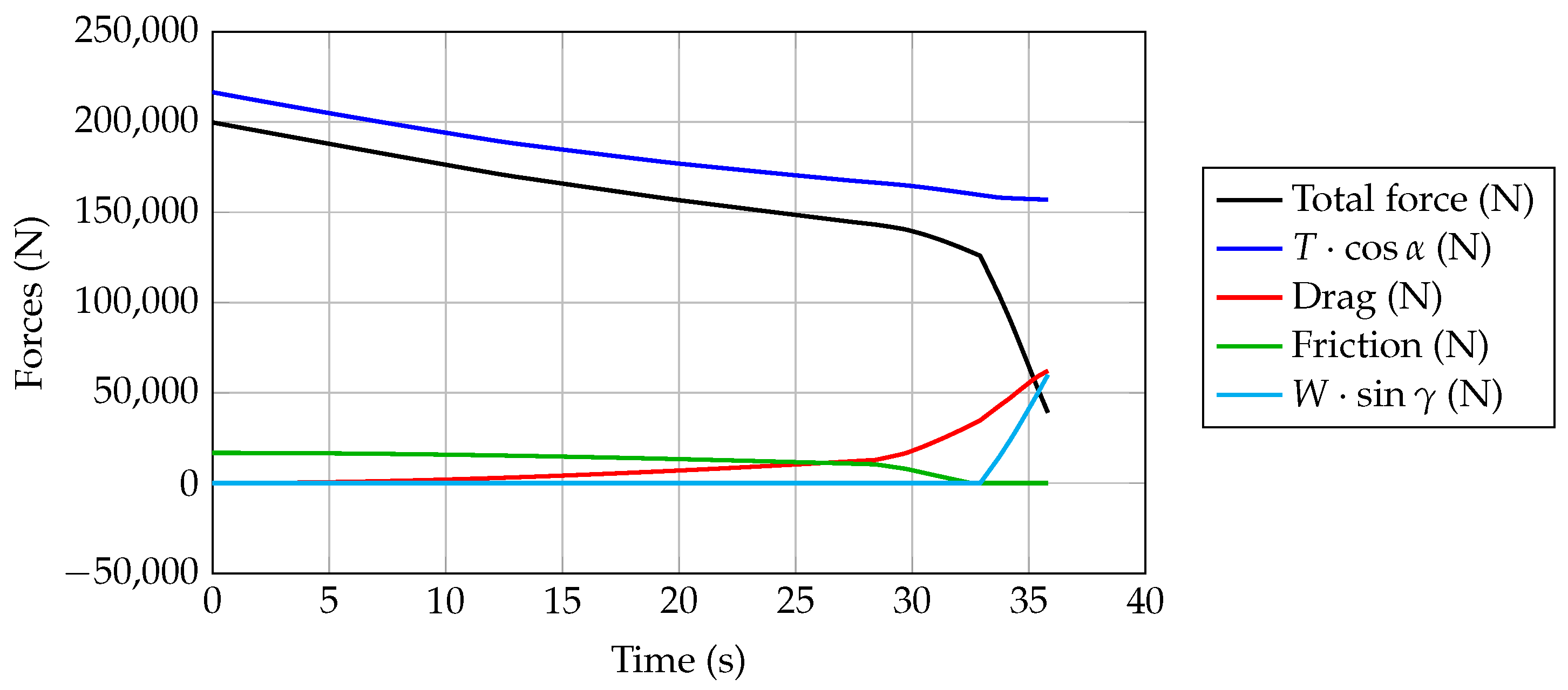

where

T is the total thrust (for all engines set to maximum Take-off rating),

D is the aerodynamic drag,

L is the aerodynamic lift,

W is the weight, and

is the tangential force proportional to the rolling friction coefficient

.

Thrust calculations are performed for each engine separately and then summed together to have the total value

T. Each thrust vector intensity is calculated by means of a known interpolating function

based on a table lookup algorithm, where

is the instantaneous airspeed and

is an assigned constant wind speed (horizontal component, negative in case of headwind). Consequently, the total thrust becomes a function

of the ground speed

V. The total thrust vector is projected on the aircraft body-fixed reference frame and its components are used appropriately. The mass state function

is given by the the fuel flow

, which is calculated by a table lookup interpolating function included in the engine datapack. The drag

D and lift

L, as functions of airspeed, altitude, flight path angle, aircraft mass, and angle of attack, are given by the following conventional formulas:

The switching function

of aircraft velocity and angle of attack is defined as follows:

The lift coefficient

is taken from the aircraft trimmed lift curve with high-lift devices (flaps, and slats if present) deflected in take-off positions. The same applies for the drag coefficient

. This justifies the dependency of these two aerodynamic coefficients on aircraft mass. Both these coefficients are then scaled to take into account the ground effect on the induced drag, as proposed in [

49].

The set of formulas (2) makes (

1) a closed system of ODEs. When the function

is assigned and the system is associated with a set of initial conditions, in this particular case equal to

, a well-posed IVP is formed, which can be solved numerically.

The function of time

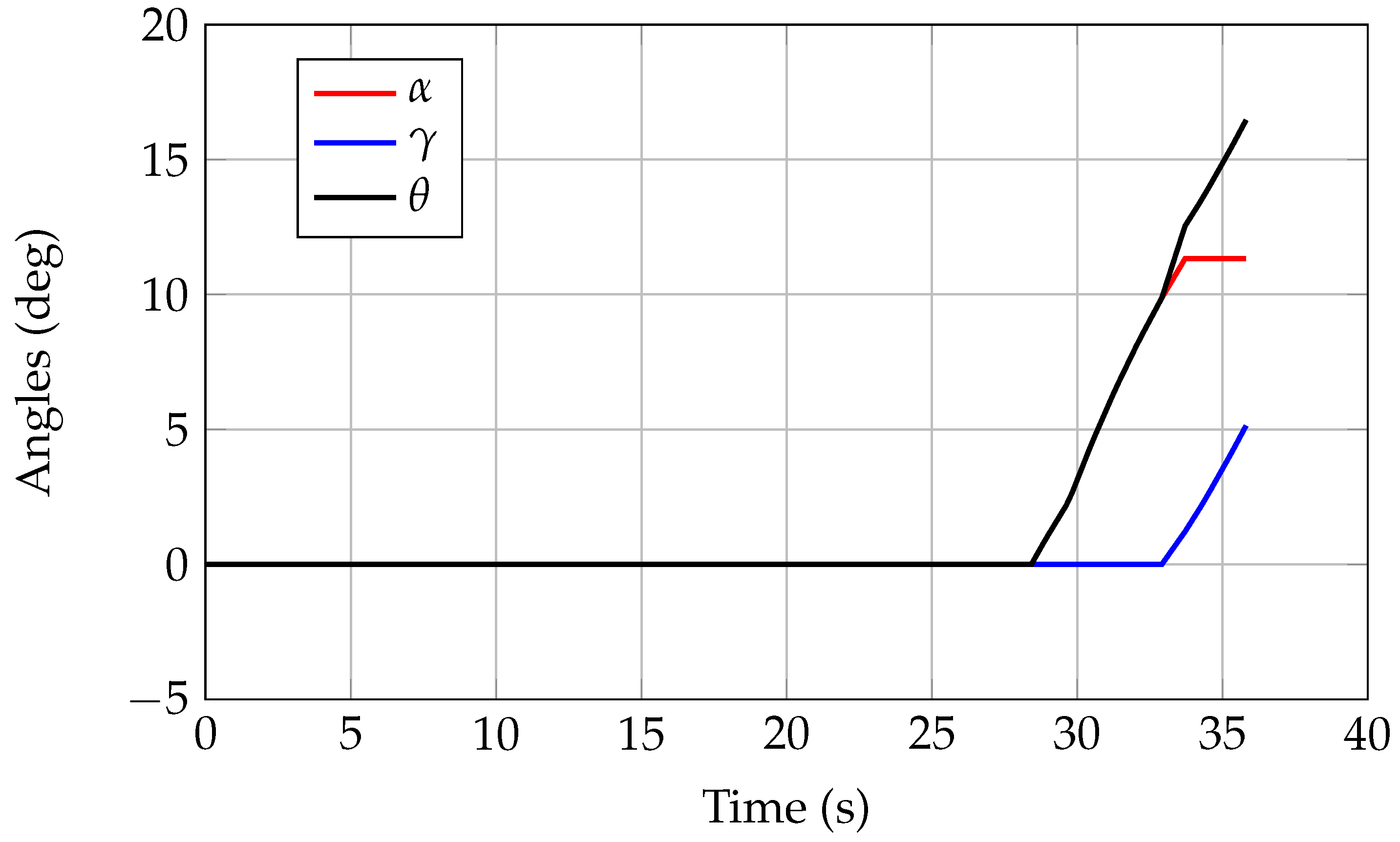

represents the input law of the angle of attack and is defined as follows:

where

is the time during the ground roll at which the aircraft rotation starts, that is, when

V reaches a given value

called rotation speed. The function

is represented in

Figure 3. In Equation (

3), the methodology assumes a constant angle of attack

during the ground roll phase up to the rotation speed, and a given non-zero law

for the post-rotation angle of attack time history. After the rotation, the angle of attack changes according to an assigned initial value of its time derivative

, which decreases with time according to the following law:

that is, as a function of the instantaneous angle of attack, until the time

is reached. In this particular instant the aircraft achieves the maximum admissible lift coefficient in take-off configuration, which is set by default at 90% of the maximum achievable take-off lift coefficient. In Equation (

4), the slope

and the initial angle of attack time derivative

are assigned as inputs. From time

onward, the pilot keeps the angle of attack constant for an assigned time interval

, during which the airplane decelerates due to a higher induced drag. After this short time interval, the pilot must reduce the angle of attack in order to contain the deceleration. Hence, a negative time derivative

is considered after time

, assumed constant for simplicity. Finally, since the decrease in angle of attack provides also for a reduction in lift coefficient, the time

will be reached when the load factor is reduced to a value of 1. This means that a balance of forces perpendicular to the flight path has been achieved and

returns to a value of 0. The model assumes a steady climbing flight after time

.

During the simulation, the fuselage attitude angle is constantly monitored to ensure the absence of tail strike. If the tail touches the ground a visual warning is launched by the calculation module.

The calculation of take-off distance in OEI condition is quite the same as the nominal AEO case, with the difference being that when one engine becomes inoperative during the maneuver there is a discontinuity in thrust, and a drag increment due to the failed engine [

50]. In the event of an engine failure during the take-off ground run, the pilot must decide whether to continue the take-off, or instead, abort the maneuver and decelerate to a stop. Obviously, if the engine failure occurs when the aircraft is traveling very slowly, the aircraft should be kept on the ground and brought to a stop at some safe location off the runway. Conversely, if the engine failure occurs when the aircraft is faster than the decision speed, the take-off should be continued. The designer must provide a means for deciding whether it is safer to reject the take-off or continue the maneuver.

The critical velocity, denoted as , is the velocity at which action is done. The time between the recognition of an engine failure, which occurs at , and the critical velocity , when action is performed, is required to be more than one second. Generally, this time period, which is set by the reaction time of the average pilot, is taken to be about . If the pilot’s decision is to continue the take-off with one engine inoperative, the distance to the point where lift-off speed is achieved, and to the subsequent climb-out to 35 height above the runway, will obviously be longer than the case with all engines operating. The calculation of the take-off distance in this situation is quite the same as the one that determines the nominal take-off length, with the difference being that now there is an abrupt change in total thrust time history. In particular, individual contributions to are still read from the database but considering a number of engines reduced by one from the time at which the engine failure occurred.

On the other hand, in case of rejected take-off, the pilot will apply the necessary braking procedures in order to get the maximum allowed deceleration while maintaining adequate control of the airplane’s motion. From time

when the engine failure occurs, i.e., when velocity assumes a value

, until the pilot reacts by activating brakes, there is only a discontinuity in thrust. After an assigned time interval in which the pilot decides to abort the take-off, the thrust is set to minimum (ground idle engine rating), brakes are activated, and a higher friction coefficient is set. During this phase, the Equation (

2b) changes in the following way:

where

is bigger than

and it is usually about 0.3 or 0.4.

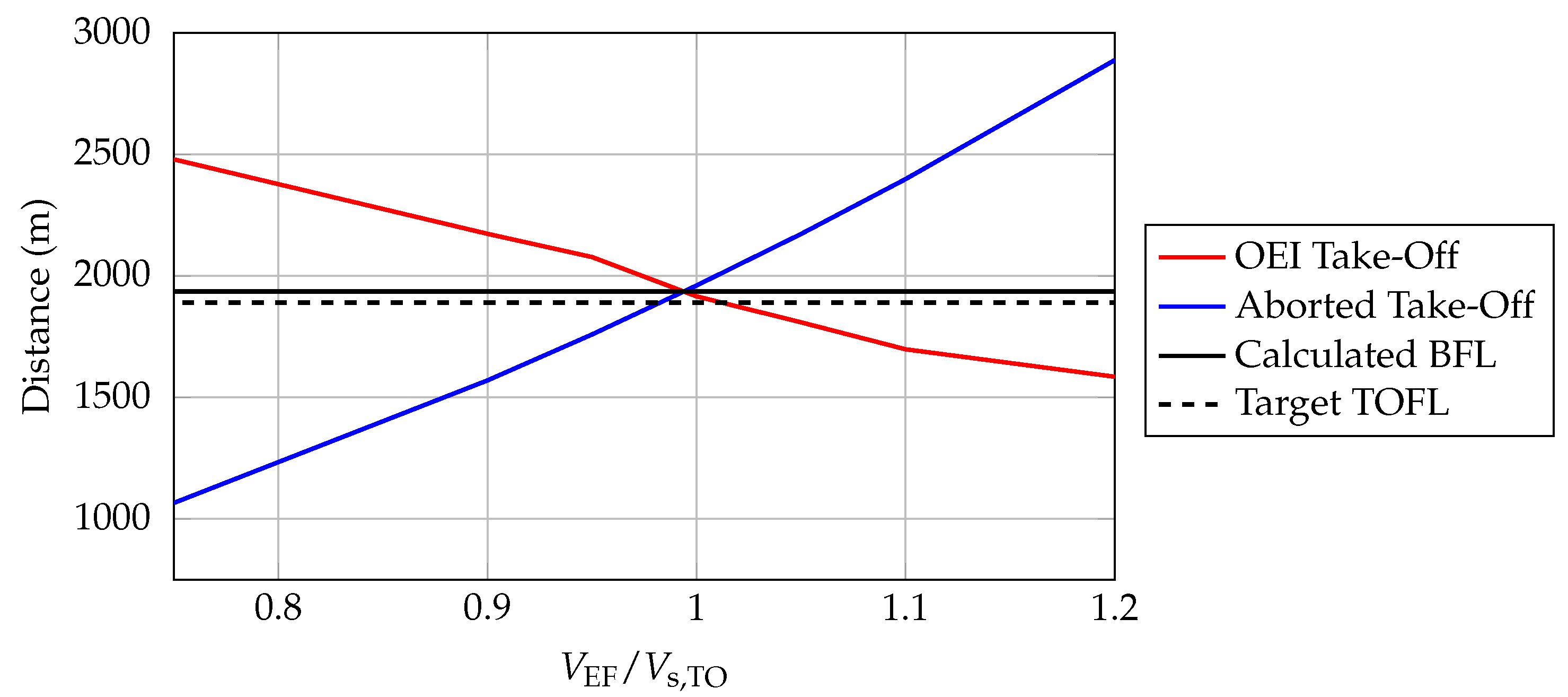

Instead of considering the limiting cases of an aborted take-off at low

and a OEI take-off at high

, it is useful to determine the critical velocity at which the distance required to continue the take-off with one engine inoperative equals the distance required to safely abort it. This velocity is the decision speed named

by regulations, while the related distance is the balanced field length, BFL. To calculate this distance and the related velocity, both the OEI take-off distance and the aborted take-off distance are estimated at different

. These two distances are then plotted against the corresponding engine failure speeds, and the intersection of the two curves, at which the two distances are the same, defines the BFL and the

(see

Figure 4).

Although JPAD provides for default values for most of the inputs necessary to perform take-off simulations, the user has the possibility to manually assign each of them. The list of inputs to the take-off analysis module is reported in

Table 1. The user can define the desired percentage of the take-off stall speed required to calculate the rotation speed. However, according to FAR regulations [

51] (part 25, subpart B, paragraph 25.107), the rotation speed may not be less than

nor less than 1.05 times the minimum control speed. Furthermore, regulations define a minimum safety speed

(both in AEO and OEI conditions) equal to at least 1.13 times the take-off stall speed, in cases of airplanes with two or three engines, and 1.08 times the take-off stall speed, in cases of aircraft with more than three engines. To ensure that those conditions are satisfied, the take-off calculation module of JPAD firstly calculates

and BFL, along with the rotation speed necessary to fly over the obstacle at 1.13 times the take-off stall speed in OEI condition; successively, using those velocities, the software verifies whether or not the desired rotation speed may be feasible. In case of an unfeasible user-defined rotation speed, the most limiting one will be chosen.

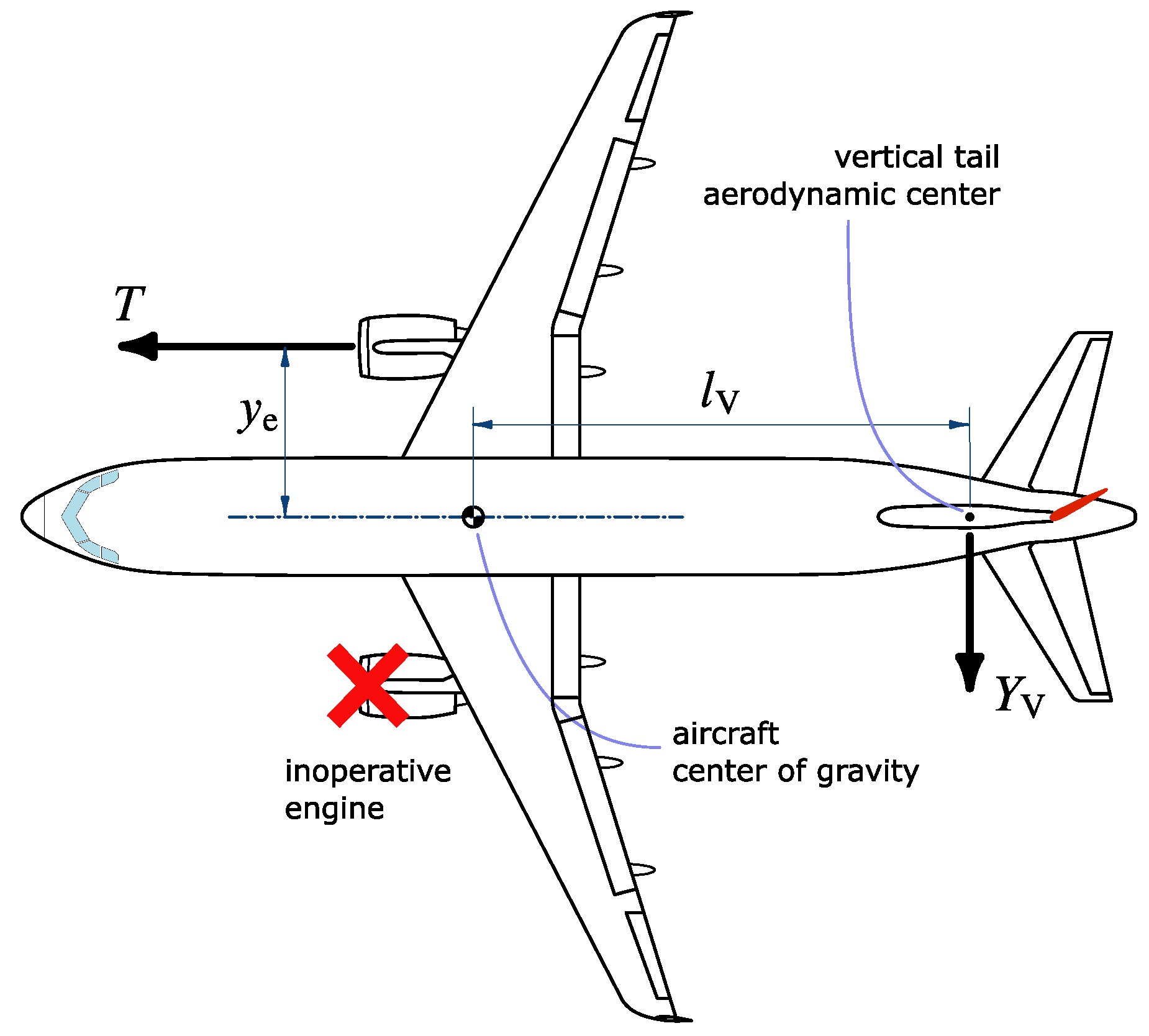

Take-off simulations are hence reliable when the

is correctly evaluated. This speed is the calibrated airspeed below which the airplane’s directional or lateral control, on the ground or airborne, can no longer be maintained by the pilot after the failure of the most critical wing-mounted engine, as long as the thrust of the opposite engine on the other wing is at the maximum take-off setting (see

Figure 5). Regulations define several different types of

, but the most important one for multi-engine airplanes is the minimum control speed in air,

. This airspeed dictates a strong sizing criterion for vertical tails and for the aerodynamic flight control surfaces, especially for the rudder which is used to compensate the yawing moment caused by thrust asymmetry. The quantity

is the minimum speed at which a full rudder will be necessary to fly with a constant heading and with leveled wings (with gears retracted). In particular, engineers have to make sure that their design complies with requirements in terms of

in the following operating conditions:

One engine inoperative;

Thrust at take-off setting (maximum continuous thrust or APR setting);

Maximum rudder angle deflections;

Most unfavorable center of gravity position.

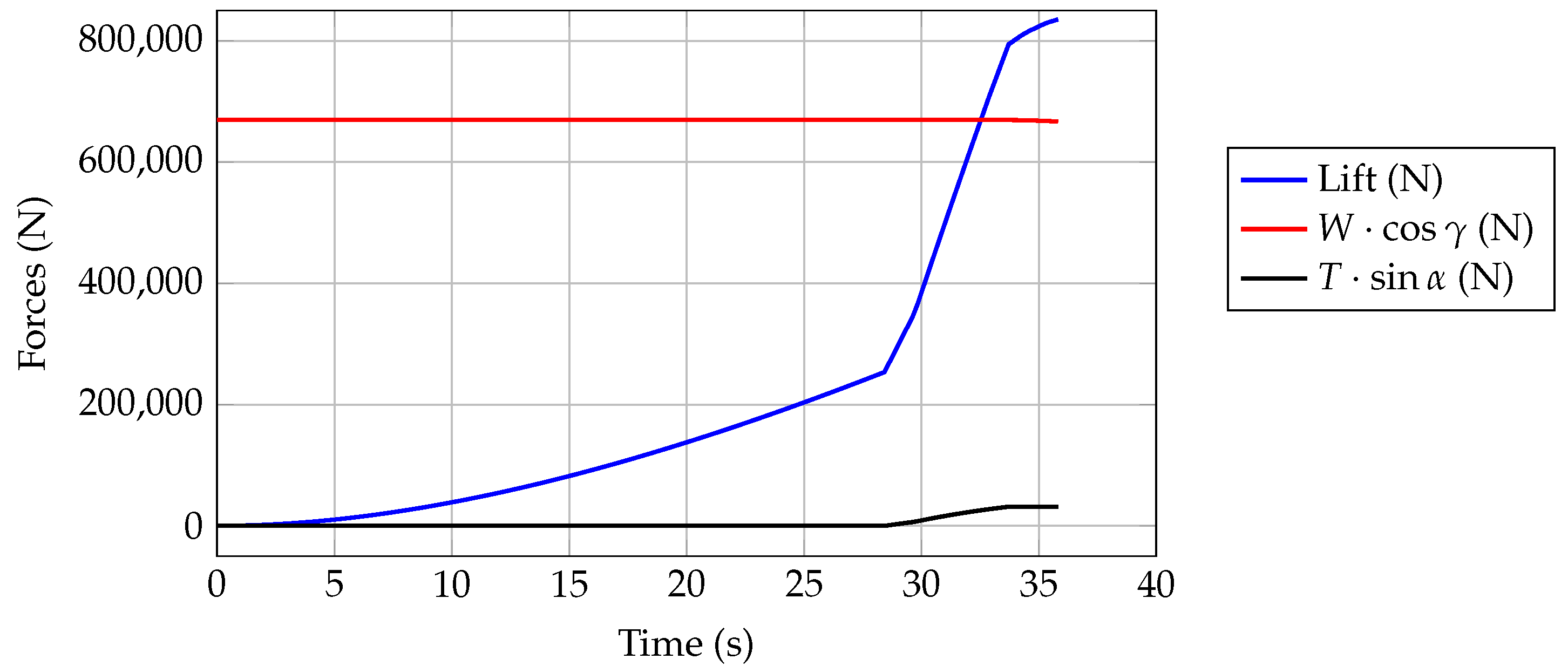

A visual representation of the forces

T and

determining the airplane equilibrium in yaw at speed

is provided by

Figure 5. The critical engine, which is the most distant from the center of gravity, generates a thrust that decreases with airspeed, while the yawing moment

of the vertical tail may be expressed as:

The most important parameters that characterize the aerodynamics of directional control are:

The vertical tail aspect ratio;

The ratio between the vertical tail span and the fuselage diameter at vertical tail aerodynamic center;

The horizontal tail position.

The wing has a negligible effect, because of its distance from the asymmetric flow field induced by the rudder. The rudder control power

is calculated as follows [

52]:

Here

is the isolated vertical tail lift curve slope,

is the interference factor due to rudder deflection,

is a rudder span effectiveness factor,

is the rudder effectiveness,

is the vertical tail dynamic pressure ratio, and

is the vertical tail volumetric coefficient (

is the distance from the aerodynamic center of the vertical tail to the center of gravity of the airplane, as shown in

Figure 5). The

factor is a function of the rudder span-wise extension, as proposed in [

53], while the rudder effectiveness

can be assigned as a constant or as a function of the rudder deflection according to well known classical semi-empirical approaches found in the literature [

54,

55]. Finally, the factor

is expressed as

where

is the vertical tail aspect ratio and

is defined as the ratio between the yawing moment coefficient of the fuselage-vertical tail combination and the yawing moment coefficient of the isolated vertical tail. The value of

is obtained from a surrogate model named VeDSC [

52] that takes into account the interference effects due to mutual positions of the fin, fuselage, and horizontal empennage.

3.2. Landing Simulation Model

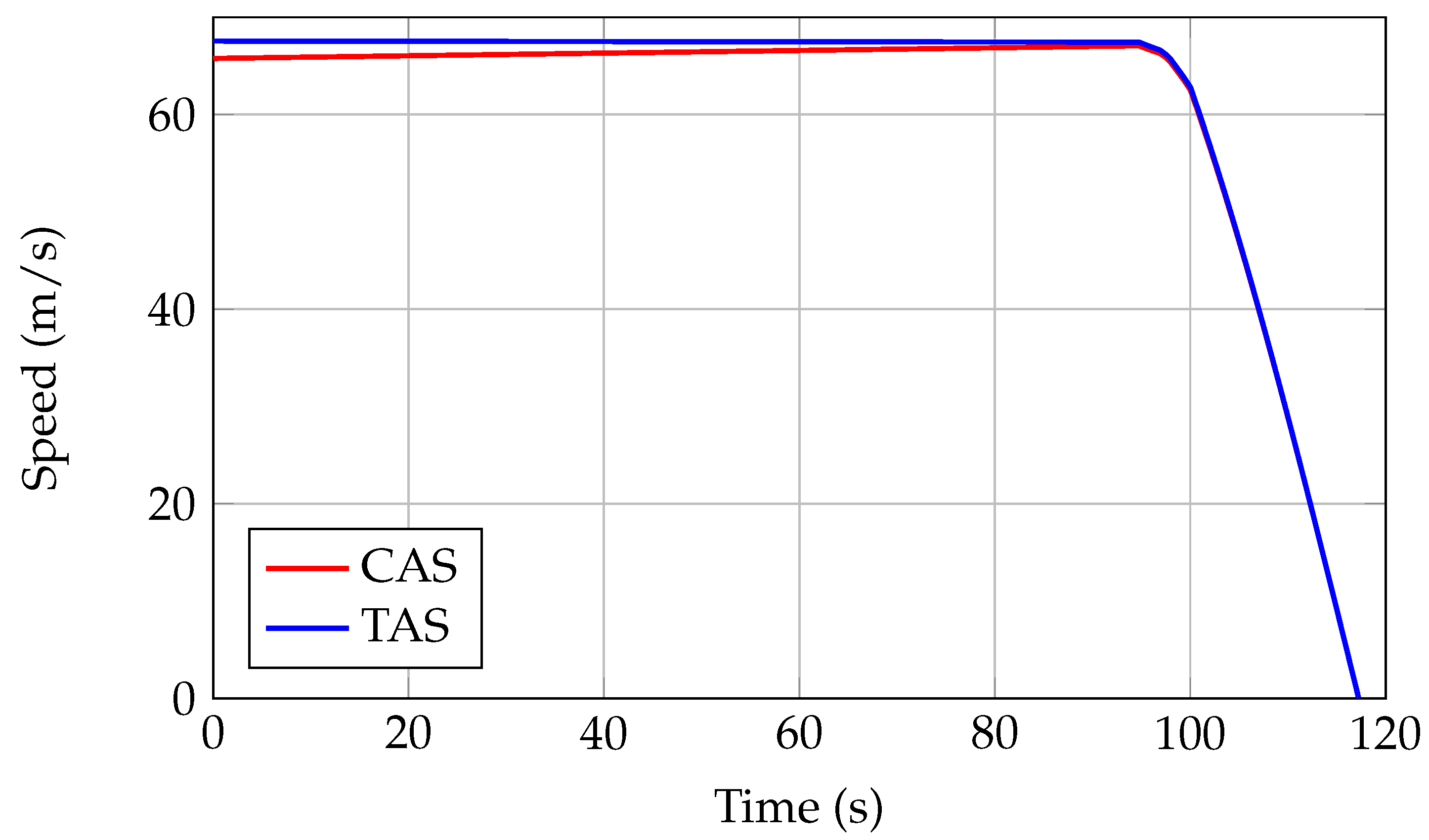

For the landing characteristics, JPAD also provides a simulation-based design approach involving the resolution of an ODE system. Landing simulations start at with the airplane at 1500 ft above the runway; the approach phase begins in steady flight conditions. The overall maneuver is the sequence of

A stabilized approach descending down to the conventional obstacle height of 50 ft;

A final approach down to 20 ft—that is, a smooth rotation in pitch with negligible initial variation of flight path angle;

A flare, with a smooth reduction of flight path angle evolving progressively into an almost horizontal trajectory;

A touch down and transition to ground roll;

A ground roll decelerating to a stop on the runway.

According to FAR regulations [

56] (part 25, subpart B, paragraph 25.125), during the stabilized approach the aircraft must maintain a calibrated airspeed of not less than 1.23 times the 1-g stall speed in landing configuration; this speed must be kept all the way down to the altitude of 50 ft. Furthermore, the simulation model assumes a constant flight path angle

for the approach, which can be assigned by the user (a typical value is

). This angle determines the amount of thrust necessary in the simulation to keep a stabilized glide path.

At the landing obstacle altitude of 50 ft the aircraft begins the final approach down to the initial flare rotation altitude assumed to be at 20 ft above the ground, a height suggested in [

57] as an averaged value for transport aircraft. In this phase, the aircraft speed must be kept almost constant and the overall thrust is changed to the flight idle setting for each engine. As a consequence, the angle of attack begins to rise during the final approach to provide for the amount of lift necessary to keep the flight path angle constant.

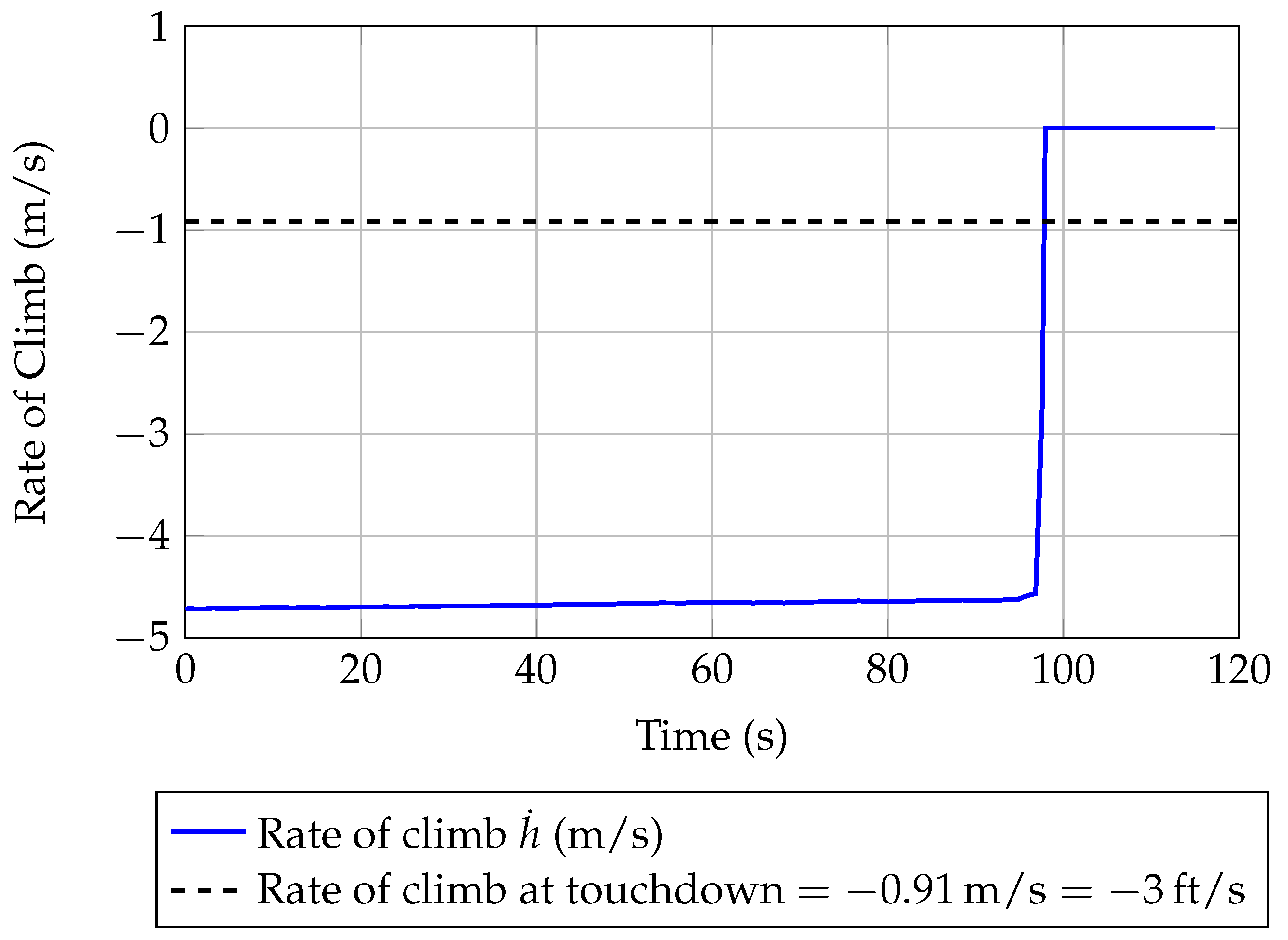

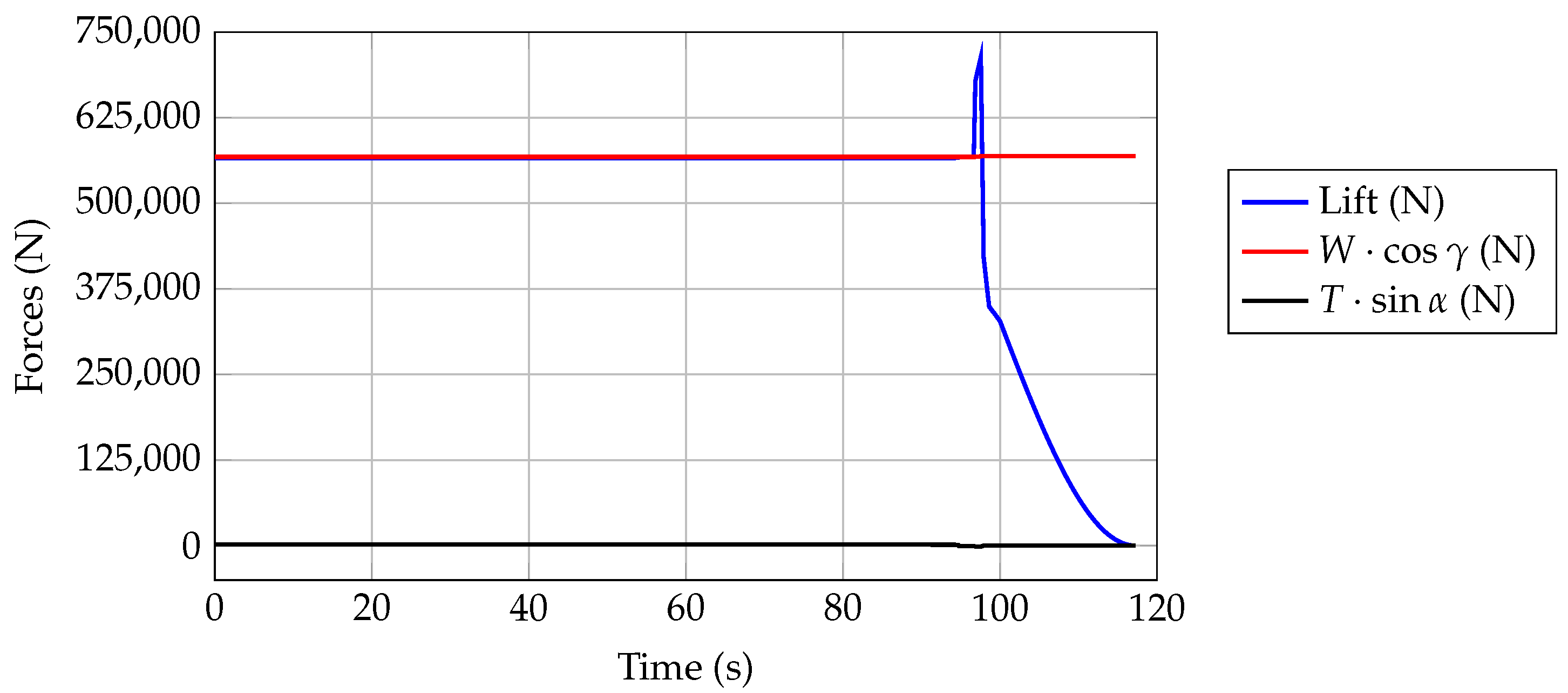

During the flare rotation a smooth transition from a normal approach attitude to a landing attitude must be accomplished by gradually rounding out the flight path to one that is parallel with the ground, and within a few inches above the runway. During this rotation the angle of attack increases, providing for higher lift and a higher induced drag resulting in a deceleration of the aircraft. At the end of the flare the airplane must touch the ground with its main landing gears and a with a reasonably low value of the vertical speed. A typical value of the descent speed at touchdown is between 2 and 3 ft/s [

58]. However, as found in [

58], service experience on various families of Boeing aircraft indicates that most flight crews report a hard landing when the sink rate exceeds approximately 4 ft/s. In addition, FAR regulations [

59] (part 25, subpart C, paragraph 25.473) specify a limit descent velocity of 10 ft/s at the design landing weight or a limit descent velocity of 6 ft/s at the design take-off weight. To allow the user to investigate different landing scenarios, the target rate of descent at touchdown can be selected as input parameter among the ones in

Table 2.

Finally, after the touchdown, and after few seconds of wheel free-roll, the pilot must apply breaking to all wheels, deflect all spoilers and adjust each engine setting to ground idle. The simulation ends when the aircraft speed reaches a value of zero.

The equations of motion in case of landing are the following, where

is the touchdown time:

The aircraft drag coefficient, calculated from the input drag polar curve in landing configuration taking into account also the ground effect, is incremented during the ground roll phase to model the effect of spoiler deflection. This additive contribution is calculated as proposed in [

60], using each spoiler’s maximum deflection angle specified in the JPAD aircraft data model. Similarly, spoiler deflection also affects the lift coefficient, which is reduced by an amount dependent on each spoiler span ratio [

60]. This effect provides for an increased wheel friction force, and so more effective deceleration. The increase in braking effectiveness due to spoilers may also be configured in JPAD by the user through the performance input file.

To take into account for thrust reverse during the landing simulation, the ground idle engine rating used for the ground roll phase can be modified by means of a dedicated calibration factor provided in the performance analysis input file. Otherwise, the ground idle rating of the JPAD engine database can be manually edited, including negative thrust ratios.

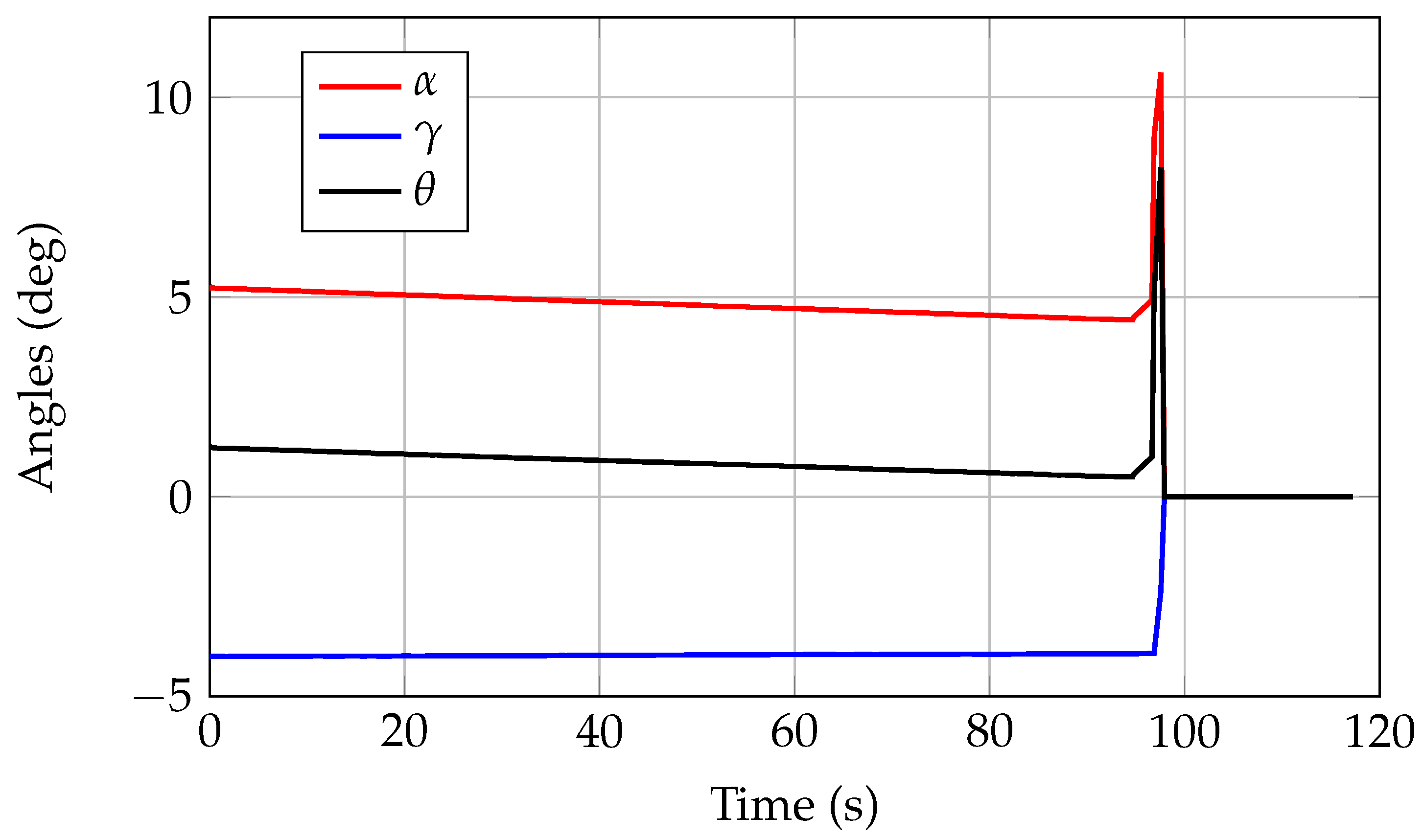

The function in system (9), still represents the input law of the angle of attack as a function of time and is constructed as follows:

At the beginning of the initial approach the angle of attack is calculated from the equilibrium lifting coefficient in landing configuration associated with the initial aircraft weight and with the prescribed approach speed of 1.23 times the stall speed at landing.

During both initial and final approach phases, the model implements a proportional control that senses the flight path angle and regulates to keep equal to zero.

From the height of 20 ft to touchdown a special algorithm calculates for the flare segment; this procedure is explained below in more detail.

Once the aircraft has touched the ground, a user-defined, constant value of the angle of attack is considered (this latter is set to zero degrees by default).

The flare rotation plays a very important role in the landing simulation since it must provide for a reasonable value of the vertical speed at touchdown and at the same time it has to ensure that the aircraft effectively touches the ground with a flight path angle very close to zero. The key parameter is the angle of attack time derivative, which is unknown. Thus, the following iterative process is applied to find a constant

during flare that makes the overall landing maneuver compliant with all the required conditions (see also s

Figure 6 and

Figure 7):

Two initial attempts are made assuming the impossible case of a null angle of attack time derivative and the case of during the flare rotation. These attempts are used to make a forecast of the required pitching angular velocity to match the target value of the rate of descent. The forecast is made by using linear interpolations or extrapolations.

In case the simulation step should overshoot the user-defined limitation on the allowed maximum achievable lifting coefficient during landing rotation (by default set to 90% of the landing maximum lift coefficient), a warning is launched and the last calculated lift coefficient is considered.

In case the aircraft should touch the ground with an angle of attack bigger than the fuselage upsweep angle, a tail strike warning is launched. At the same time, if the required angle of attack time derivative should provide for an angle of attack at touchdown lower than 0 deg, a nose strike warning is launched. This feature provides for an important aircraft design check, monitoring whether the aircraft has been designed with an adequate value of the aerodynamic efficiency in landing (higher lift capabilities lead to lower angles of attack at touchdown, while poor lift capabilities provide for higher angles of attack).

If the aircraft reaches the required altitude and at the same time provides for a touchdown vertical speed below or equal to the threshold, the flare simulation ends, and the ground roll phase can start.

If flare rotation simulation fails, the JPAD performance manager switches the air distance calculation to the simpler circular arc approach proposed in [

58] before then moving on to the integration of the ODE set for the final ground segment.

As for take-off simulations, JPAD provides default values of most of the simulation inputs for the landing simulation as well. However, the user has the ability to manually assign each of them. The list of inputs necessary to accomplish a landing analysis is reported in

Table 3.

Starting from both take-off and landing simulations, a specific performance module has been completely dedicated to the calculation of certification take-off and landing noise trajectories. In both cases, part 36, appendix A, of the FAR [

61] specifies all conditions under which aircraft noise certification tests must be conducted.

3.3. Take-Off and Landing Simulation Model for Noise Certification

The procedure for take-off noise trajectory analysis is almost the same as the AEO normal take-off, with the important difference that all simulations must be carried out considering an ISA temperature deviation of . In addition to the normal take-off simulation, once the aircraft passes the obstacle at 35 ft, landing gear must be retracted. This is simulated by linearly reducing the current drag coefficient, from the trimmed drag polar in take-off configuration, of a quantity equal to the overall landing gear’s drag coefficient. The time interval assumed to perform this reduction is set by default to 12 s; however, the user can change this value in the performance analysis configuration file.

The time history of the angle of attack defined in

Figure 3 is used to model the input variable

up to the obstacle altitude. From there, the instant at which the acceleration reaches a value near to zero is monitored to estimate the aircraft speed to be maintained during the rest of the simulation. This velocity must be in the interval

. To ensure this condition in simulation, an iterative process is carried out by varying the rotation speed

appropriately, while making sure that in all cases the speed profile complies with all the limitations described for a normal take-off. Thus, if the calculated climb speed is less than the lower bound of the prescribed interval, the aircraft’s rotation speed is increased to allow for a higher lift-off speed. The rotation speed is reduced in the opposite case.

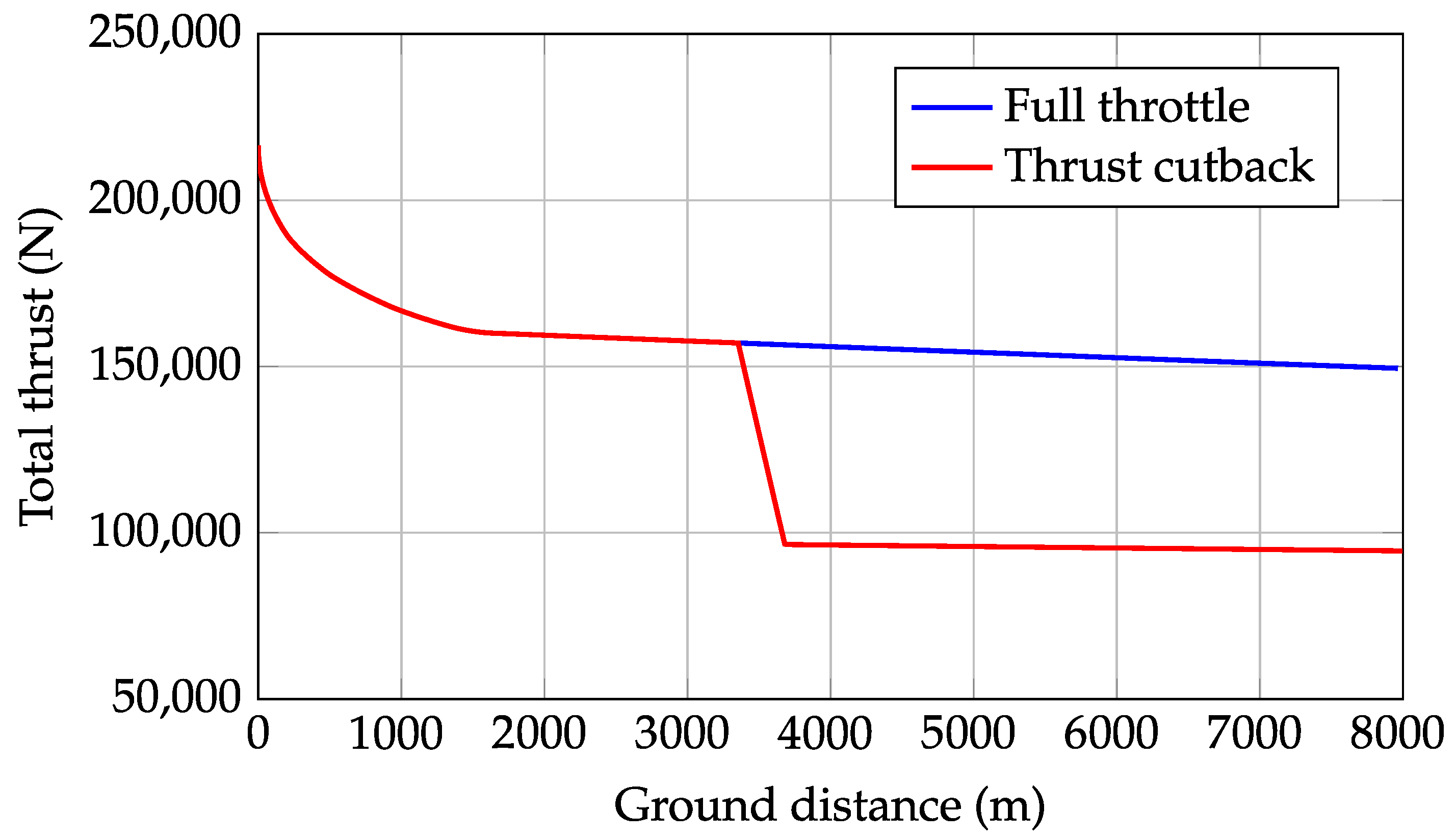

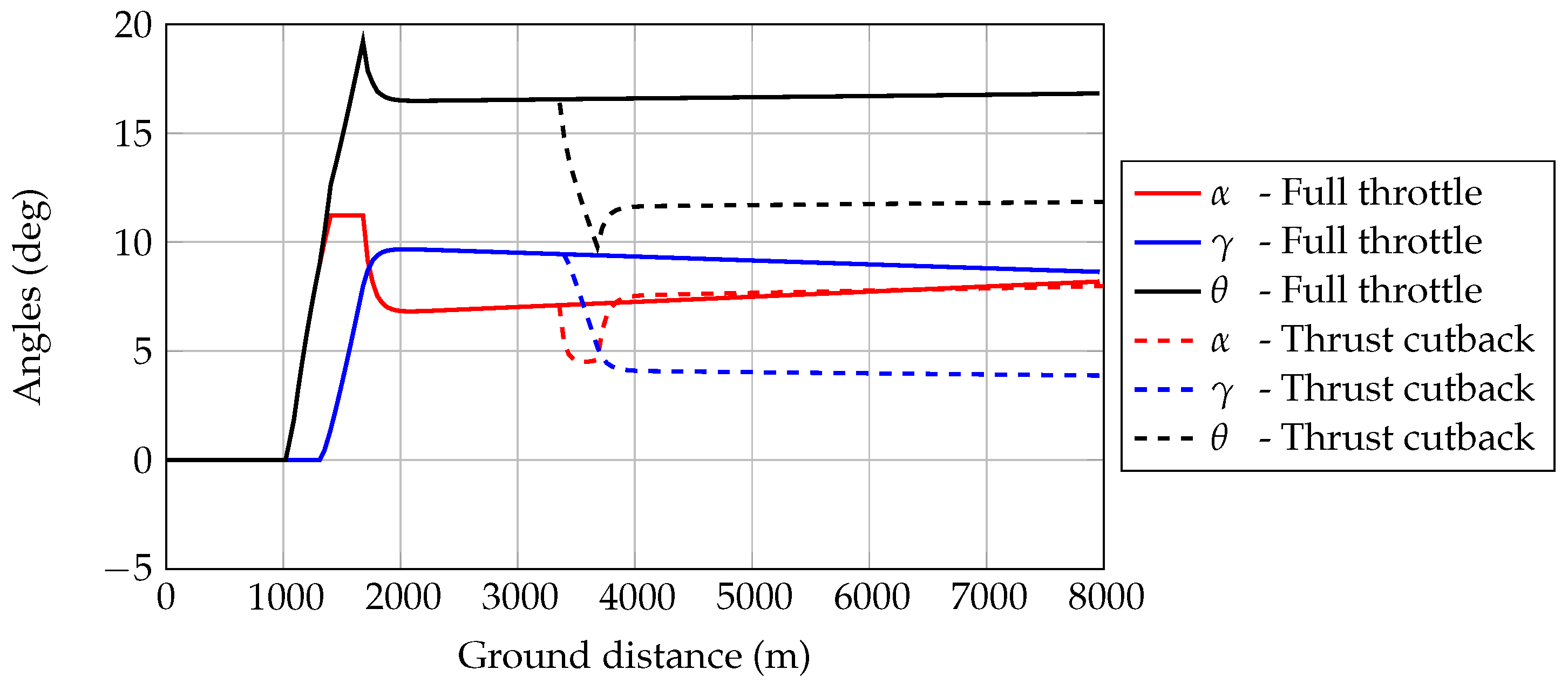

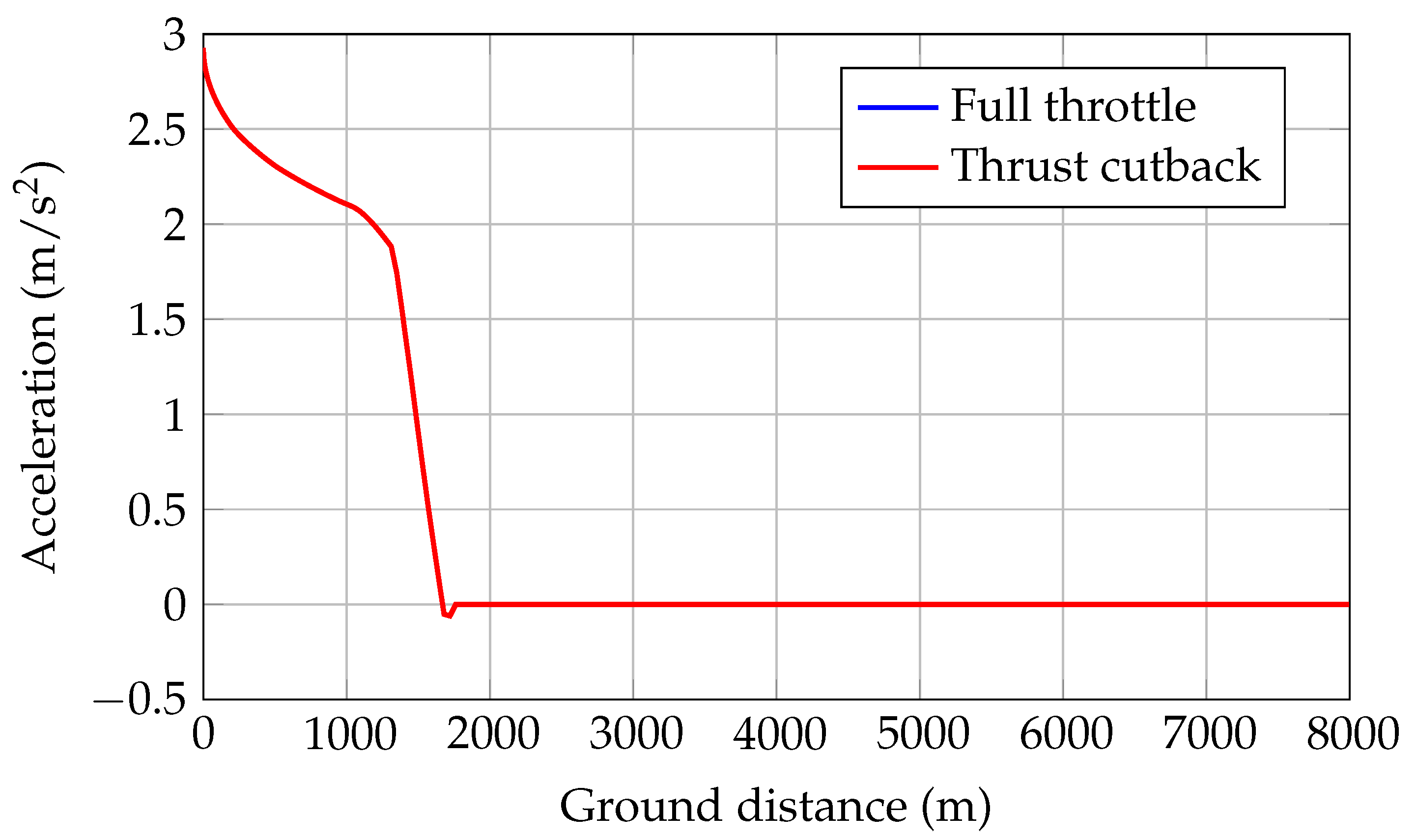

To maintain a steady climb after the obstacle, a proper law

has to be established in order to get a constant climb speed. To ensure such behavior, the model implements a proportional control that senses the flight speed

V and the rate of climb

and regulates

to keep their variations close to zero. Two scenarios are considered at this point: a 100% take-off thrust simulation and another one with a thrust cutback occurring at a specific altitude prescribed by regulations. The cutback altitude is selected as follows: 689 ft (210 m) for airplanes with more than three engines; 853 ft (260 m) for airplanes with three engines; and 984 ft (300 m) for airplanes with fewer than three engines. The cutback thrust setting must be selected according to the FAR [

62] (Appendix B, Part 36, Section B36.7). Upon reaching the cutback altitude, the aircraft thrust is reduced, but the total amount

T must not be less than the thrust required to maintain either of the following (whichever is greater): a climb gradient of 4%, and in the case of multi-engine airplanes, level flight with one engine inoperative.

In both scenarios, 100% thrust and cutback, the simulation continues until the aircraft reaches a user-defined horizontal distance from the starting point, set by default at 8000 m. The 100% thrust case is related to the definition of a lateral noise certification point, which is that location on ground where the highest noise level is measured among all the possible measuring stations located on a line parallel to the runway center line (at a side distance of 450 m). The cutback thrust case is related to the flyover noise certification point which is set by the FAR at 6500 m from the brake-release point along the runway’s center line. Ending the simulation further than 6500 m ensures that the aircraft passes above the flyover certification point. A representation of all noise certification measurement points is provided in

Figure 8, while a complete overview of the input data needed to perform both take-off noise trajectories simulation is reported in

Table 4.

Landing noise trajectory simulations are practically the same as for normal landings. However, the need to only model the trajectory up to the end of the final approach allows one to completely ignore the flare and ground roll segments. According to FAR (appendix A, part 36) the approach noise certification point is defined as the location at 2300 m from the brake release (or 2000 m from the runway start) which corresponds to an aircraft altitude above the ground of

m (see

Figure 8).

Both take-off and landing noise trajectories calculated using the proposed approach can be used as starting points for complete aircraft noise assessments. Thus, JPAD has been provided with an interface to an external tool named ATTILA, developed at the University of Naples Federico II, dedicated to this specific type of analysis. The noise topic lies outside the scope of this paper; however, a description of the prediction methodology implemented in this software can be found in [

63], both in terms of airframe and engine noise.