An Insight on the Crashworthiness Behavior of a Full-Scale Composite Fuselage Section at Different Impact Angles

Abstract

1. Introduction

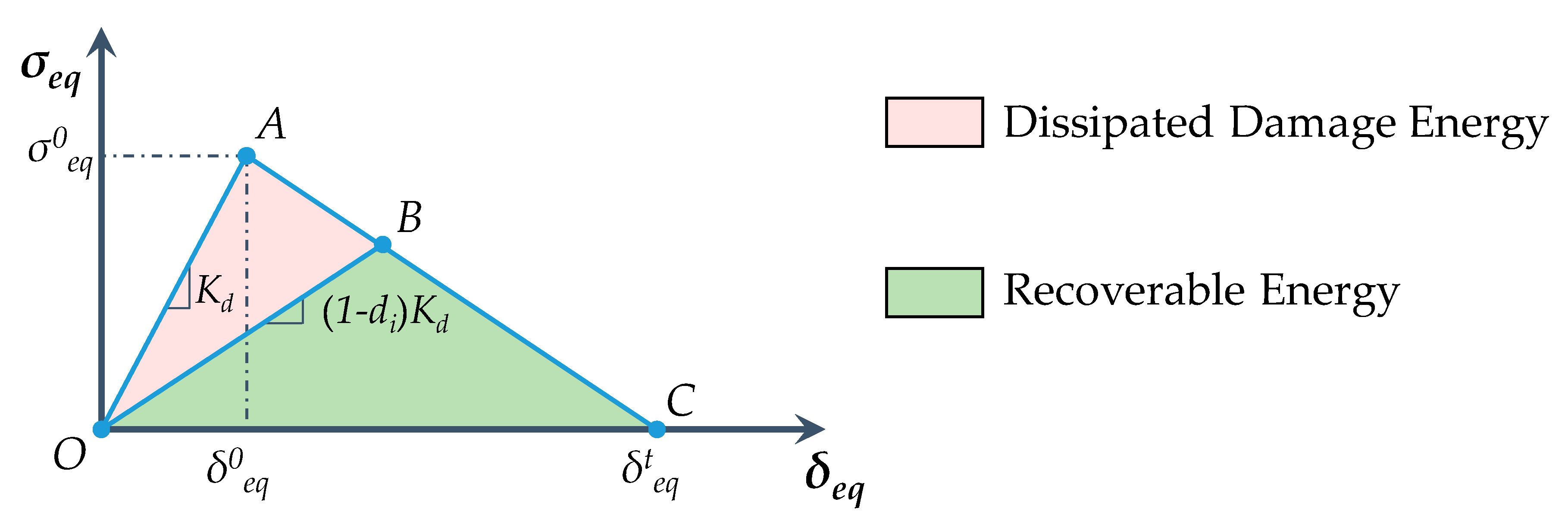

2. Theoretical Background

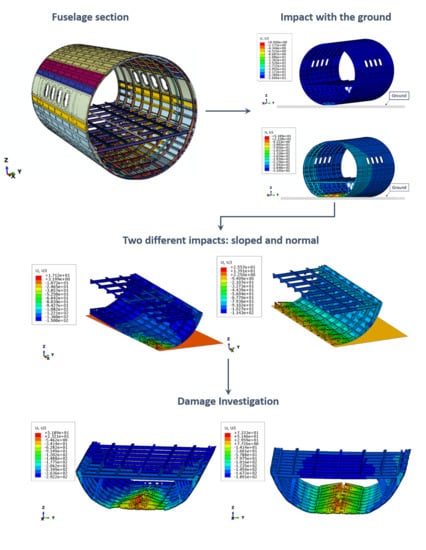

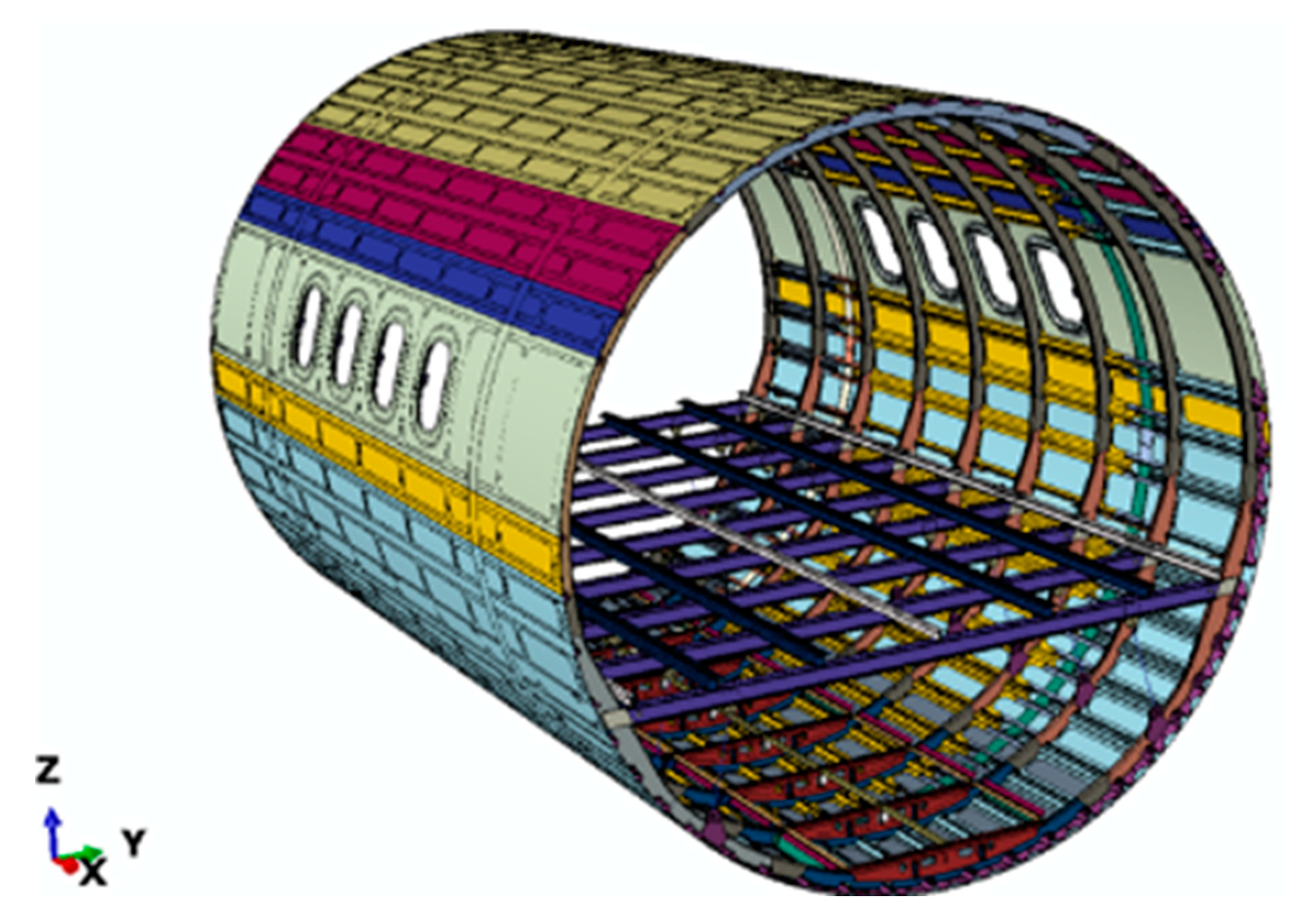

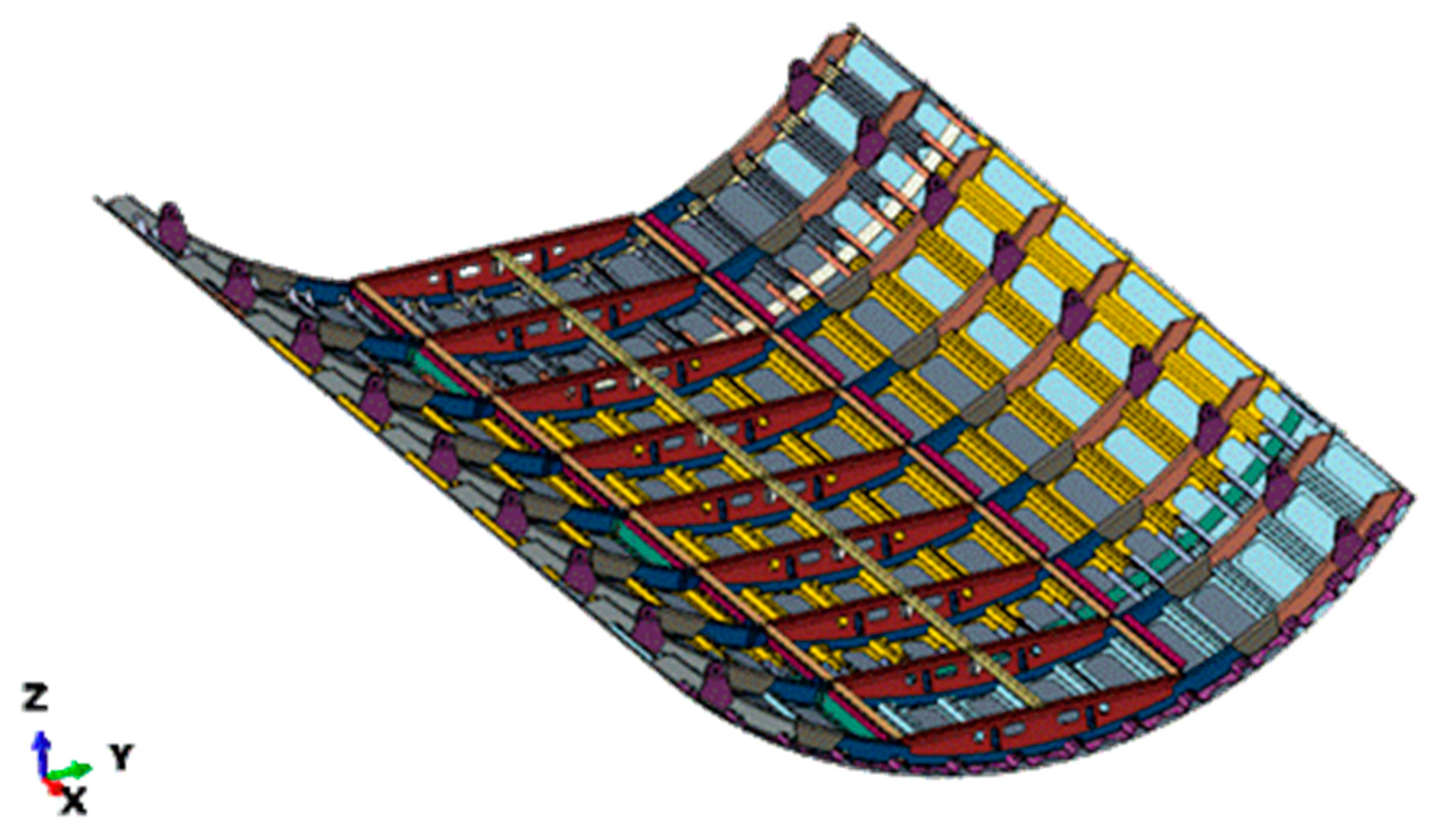

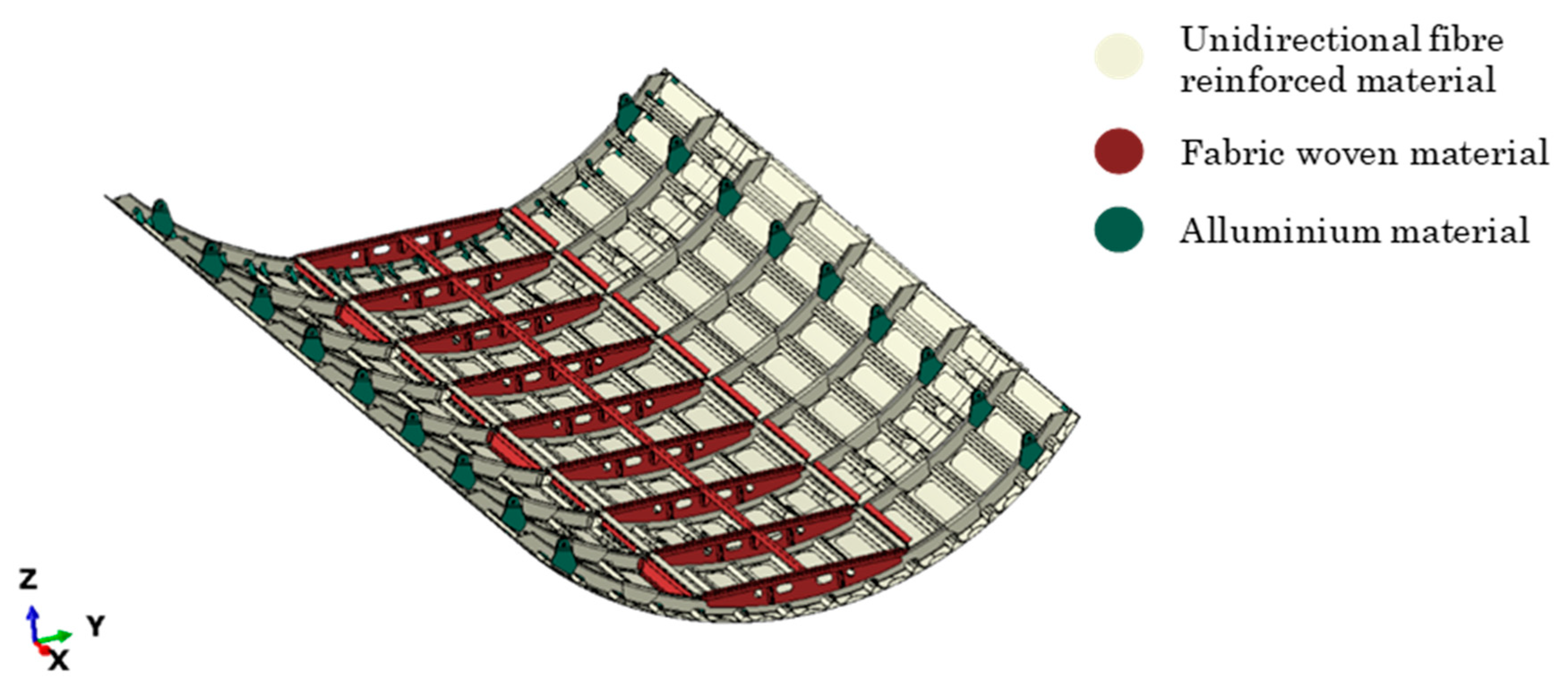

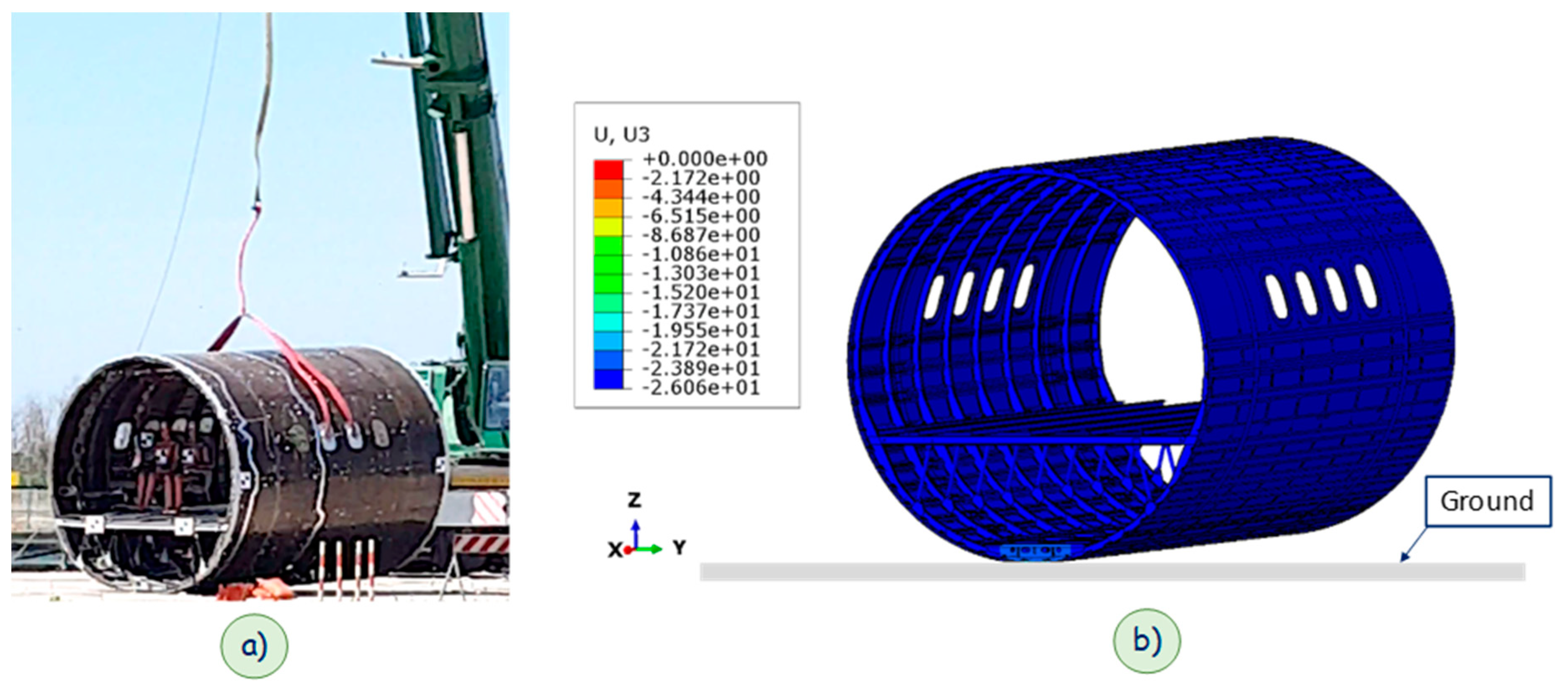

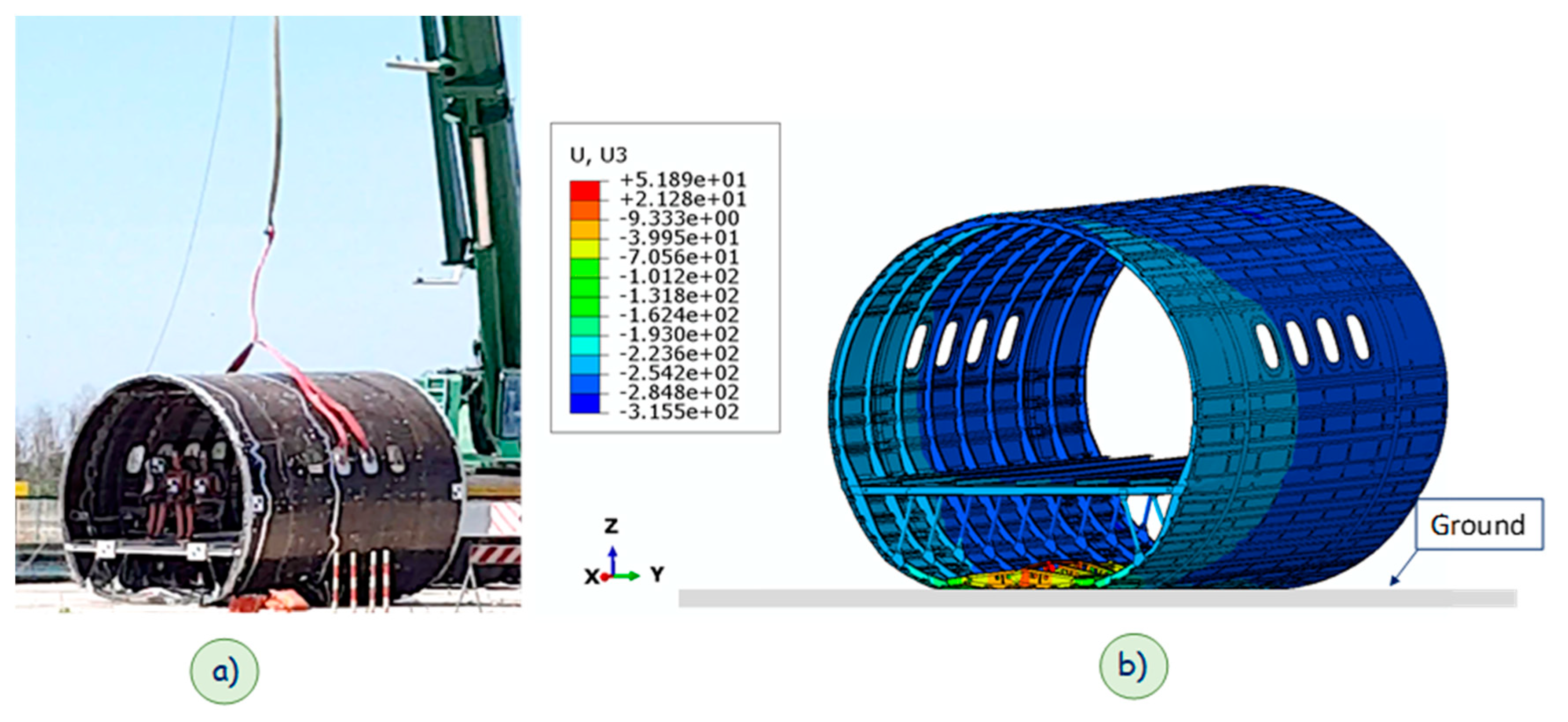

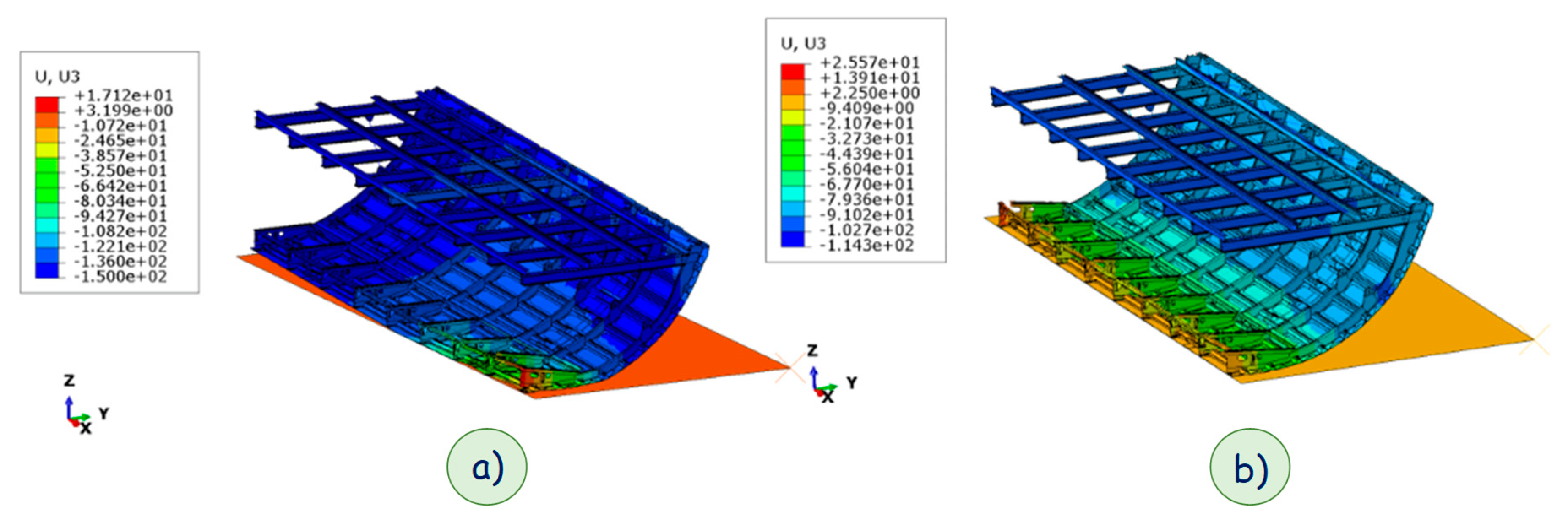

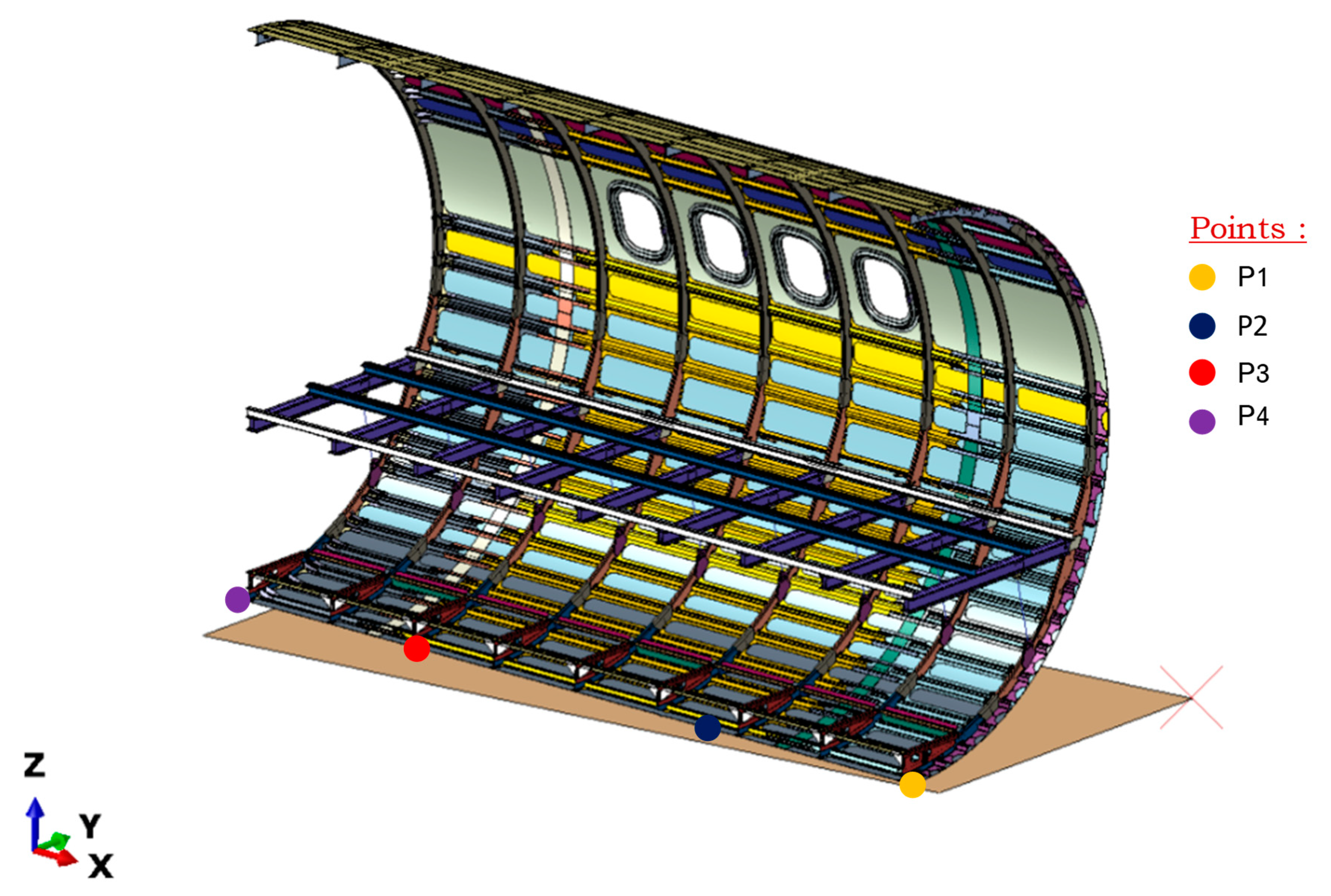

3. Geometrical Model and Numerical FEM Model Description

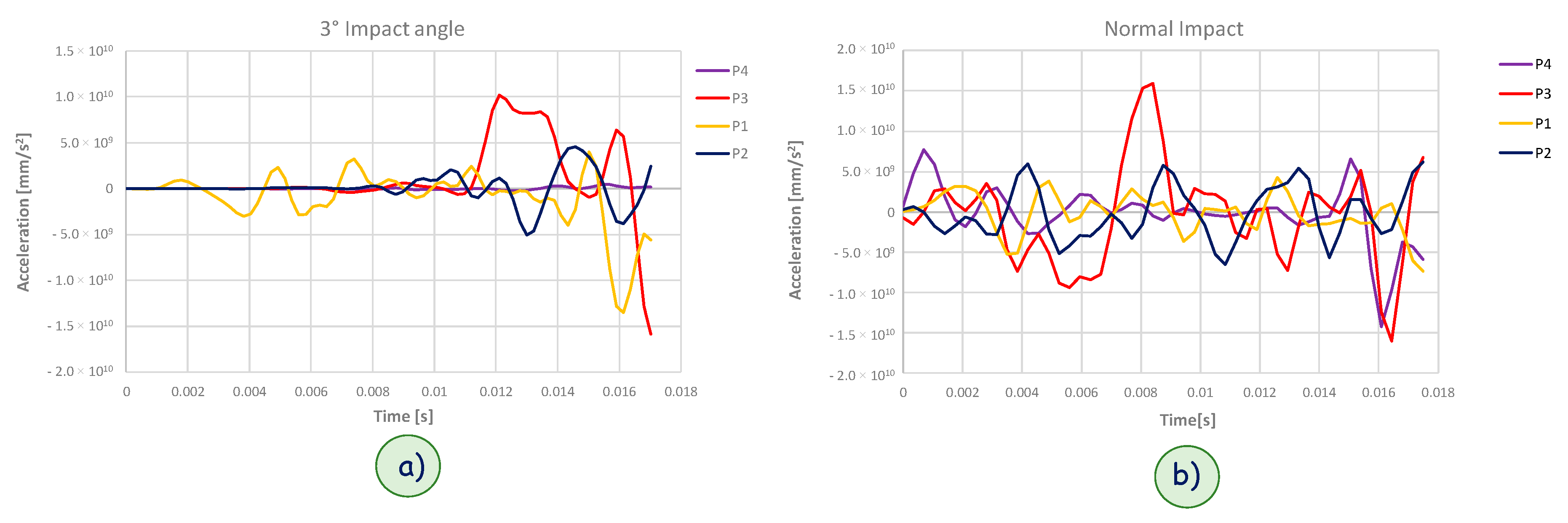

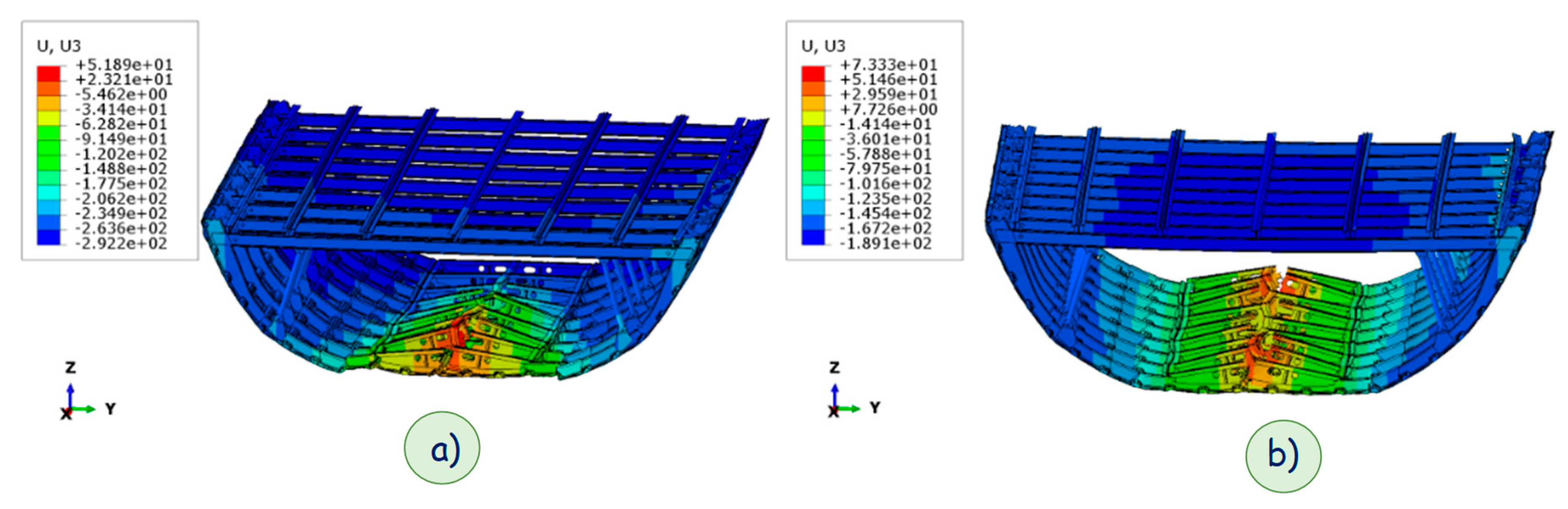

4. Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Federal Aviation Regulations. Part 25—Aircrashworthiness Standards: Transport Category Airplanes; Federal Aviation Adminstration, Department of Transportation: Washington, DC, USA, 2003.

- Cronkhite, J.D.; Berry, V.L. Crashworthy Airframe Design Concepts—Fabrication and Testing; NASA Contractor, Report 3603; NASA: Washington, DC, USA, 1982.

- Guida, M.; Manzoni, A.; Zuppardi, A.; Caputo, F.; Marulo, F.; De Luca, A. Development of a multibody system for crashworthiness certification of aircraft seat. Multibody Syst. Dyn. 2018, 44, 191–221. [Google Scholar] [CrossRef]

- Caputo, F.; De Luca, A.; Marulo, F.; Guida, M.; Vitolo, B. Numerical-experimental assessment of a hybrid FE-MB model of an aircraft seat sled test. Int. J. Aerospace Eng. 2018, 8943826. [Google Scholar] [CrossRef]

- Riccio, A.; Caputo, F.; Di Felice, G.; Saputo, S.; Toscano, C.; Lopresto, V. A Joint Numerical-Experimental Study on Impact Induced Intra-laminar and Inter-laminar Damage in Laminated Composites. Appl. Compos. Mater. 2016, 23, 219–237. [Google Scholar] [CrossRef]

- Riccio, A.; Ricchiuto, R.; Saputo, S.; Raimondo, A.; Caputo, F.; Antonucci, V.; Lopresto, V. Impact behaviour of omega stiffened composite panels. Prog. Aerosp. Sci. 2016, 81, 41–48. [Google Scholar] [CrossRef]

- Ren, Y.R.; Xiang, J.W. Crashworthiness uncentainty analysis of typical civil aircraft based on Box-Behnken method. Chin. J. Aeronaut. 2014, 27, 253–262. [Google Scholar] [CrossRef]

- Caputo, F.; De Luca, A.; Greco, A.; Maietta, S.; Marro, A.; Apicella, A. Investigation on the static and dynamic structural behaviours of a regional aircraft main landing gear by a new numerical methodology. Frattura ed Integrità Strutturale 2018, 12, 191–204. [Google Scholar] [CrossRef]

- Riccio, A.; Cristiano, R.; Saputo, S.; Sellitto, A. Numerical methodologies for simulating bird-strike on composite wings. Compos. Struct. 2018, 202, 590–602. [Google Scholar] [CrossRef]

- Perfetto, D.; De Luca, A.; Lamanna, G.; Chiariello, A.; Di Caprio, F.; Di Palma, L.; Caputo, F. Drop test simulation and validation of a full composite fuselage section of a regional aircraft. Procedia Struct. Integr. 2018, 12, 380–391. [Google Scholar] [CrossRef]

- Jackson, K.E.; Fasanella, E.L. NASA Langley Research Center impact dynamics research facility research survey. J. Aircraft 2004, 41, 511–522. [Google Scholar] [CrossRef]

- Bisagni, C. Crashworthiness of helicopter subfloor structures. Int. J. Impact Eng. 2002, 27, 1067–1082. [Google Scholar] [CrossRef]

- Adams, A.; Lankarani, H.M. A modern aerospace modelling approach for evaluation of aircraft fuselage crashworthiness. Int. J. Crashworthiness 2003, 8, 401–413. [Google Scholar] [CrossRef]

- Sellitto, A.; Riccio, A.; Russo, A.; Zarrelli, M.; Toscano, C.; Lopresto, V. Compressive behaviour of a damaged omega stiffened panel: Damage detection and numerical analysis. Compos. Struct. 2019, 209, 300–316. [Google Scholar] [CrossRef]

- McGuire, R.J.; Nissley, W.J.; Newcomb, J.E. Vertical Drop Test of a Fairchild Metro III; FAA Report DOT/FAA/CT-93/1; U.S. G.P.O.: Washington, DC, USA, 1993.

- Abramowitz, A.; Ingraham, P.A.; McGuire, R. Vertical Drop Test of a Shorts 3-30 Airplane; FAA Report DOT/FAA/AR-99/87; U.S. G.P.O.: Washington, DC, USA, 1999.

- Federal Aviation Administration. Special Conditions: Boeing Model 787-8 Airplane; Crashworthiness, Docket No. NM368 Special Conditions No. 25-362-SC, US Federal Register 72; U.S. G.P.O.: Washington, DC, USA, 2007.

- Federal Aviation Administration. Special Conditions: Airbus A350-900 Airplane; Crashworthiness, Emergency Landing Conditions, Docket No. FAA-2013-0892 Special Conditions No. 25-537-SC, US Federal Register 79; U.S. G.P.O.: Washington, DC, USA, 2014.

- Maia, L.G.; de Oliveira, P.H.I.A. Crashworthy Composite Fuselage Section Concept for Next Generation General Aviation; SAE Technical Paper 2005-01-4011; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Riccio, A.; Raimondo, A.; Di Caprio, F.; Fusco, M.; Sanità, P. Experimental and numerical investigation on the crashworthiness of a composite fuselage subfloor support system. Compos. Part B Eng. 2018, 150, 93–103. [Google Scholar] [CrossRef]

- Kumakura, I.; Minegishi, M.; Iwasaki, K. Impact Simulation of Simplified Structural Models of Aircraft Fuselage; SAE Technical Paper 2000-01-5586; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Zheng, J.; Xiang, J.; Luo, Z.; Ren, Y. Crashworthiness design of transport aircraft subfloor using polymer foams. Int. J. Crashworthiness 2011, 16, 375–383. [Google Scholar] [CrossRef]

- Shoji, H.; Miyaki, H.; Iwasaki, K.; Minegishi, M. Crashworthiness research on cabin structure at JAXA. In Proceedings of the 5th Triennial International Aircraft Fire and Cabin Safety Research Conference, Atlantic City, NJ, USA, 30 October 2007. [Google Scholar]

- Ren, Y.; Xiang, J. A comparative study of the crashworthiness of civil aircraft with different strut configurations. Int. J. Crashworthiness 2010, 15, 321–330. [Google Scholar] [CrossRef]

- Hu, D.Y.; Meng, K.P.; Yang, Z.Y. Numerical investigation of the energy absorption characteristics of a fan shaped deployable energy absorber. Int. J. Crashworthiness 2014, 19, 126–138. [Google Scholar] [CrossRef]

- Huculak, R.D.; Lankarani, H.M. Methods of evaluating ES-2 leg flail in dynamic evaluation and certification tests of side-facing aircraft seats. Int. J. Crashworthiness 2015, 20, 613–628. [Google Scholar] [CrossRef]

- Liu, X.C.; Guo, J.; Bai, C.Y.; Sun, X.S.; Mou, R.K. Droptest and crash simulation of a civil airplane fuselage section. Chin. J. Aeronaut. 2015, 28, 447–456. [Google Scholar] [CrossRef]

- Paz, J.; Diaz, J.; Romera, L.; Costas, M. Size and shape optimization of aluminum tubes with GFRP honeycomb reinforcements for crashworthy aircraft structures. Compos. Struct. 2015, 133, 499–507. [Google Scholar] [CrossRef]

- Ren, Y.R.; Xiang, J.W. The crashworthiness of civil air Craft using different quadrangular tubes as cabin-floor struts. Int. J. Crashworthiness 2011, 16, 253–262. [Google Scholar] [CrossRef]

- Ren, Y.R.; Xiang, J.W. Energy absorption structures design of civil aircraft to improve crashworthiness. Aeronaut. J. 2014, 118, 383–398. [Google Scholar] [CrossRef]

- Ren, Y.R.; Xiang, J.W.; Zheng, J.Q.; Luo, Z.P. Crashworthiness analysis of aircraft fuselage with sine-wave beamstructure. Chin. J. Aeronaut. 2016, 29, 403–410. [Google Scholar] [CrossRef]

- Schatrow, P.; Waimer, M. Crash concept for composite transport aircraft using mainly tensile and compressive absorption mechanisms. CEAS Aeronaut. J. 2016, 7, 471–482. [Google Scholar] [CrossRef]

- Shi, Q.H.; Dai, D.; Cao, Z.H. Tensile failure strength analysis and Experimental confirmation of stitch reinforced composite of T-stiffened structure. Polym. Compos. 2012, 20, 307–311. [Google Scholar] [CrossRef]

- Sturma, R.; Klett, Y.; Kindervater, C.; Voggenreiter, H. Failure of CFRP airframe sandwich panels under crash relevant loading conditions. Compos. Struct. 2014, 112, 11–21. [Google Scholar] [CrossRef]

- Riccio, A.; Raimondo, A.; Saputo, S.; Sellitto, A.; Battaglia, M.; Petrone, G. A numerical study on the impact behaviour of natural fibres made honeycomb cores. Compos. Struct. 2018, 202, 909–916. [Google Scholar] [CrossRef]

- Khalili, S.M.R.; Soroush, M.; Davar, A.; Rahmani, O. Finite element modeling of low-velocity impact on laminated composite plates and cylindrical shells. Compos. Struct. 2011, 93, 1363–1375. [Google Scholar] [CrossRef]

- Chattopadhyay, S. Response of elastic plates to impact including the effects of shear deformation. In Recent Advances in Engineering Science; Springer: Berlin, Germany, 1977; pp. 127–138. [Google Scholar]

- Shivakumar, K.N.; Elber, W.; Illg, W. Prediction of impact force and duration due to low-velocity impact on circular composite laminates. J. Appl. Mech. Trans. ASME 1985, 52, 674–680. [Google Scholar] [CrossRef]

- Dassault System Abaqus 2016 User’s Manual; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2016.

| Failure | Equivalent Stress | Equivalent Displacement |

|---|---|---|

| Fiber tension | ||

| Fiber compression | ||

| Matrix tension | ||

| Matrix compression |

| Unidirectional CFRP | |

|---|---|

| Young’s Modulus, E11 [MPa] | 137,500 |

| Young’s Modulus, E22 [MPa] | 8200 |

| Shear Modulus, G12 [MPa] | 3950 |

| Shear Modulus, G13 [MPa] | 3950 |

| Shear Modulus, G23 [MPa] | 3950 |

| Poisson’s ratio, ν12 = ν13 = ν23 [-] | 0.35 |

| Fiber Tensile Strength, F1t [MPa] | 1890 |

| Fiber Compressive Strength, F1c [MPa] | 1008 |

| Matrix Tensile Strength, F2t [MPa] | 86.5 |

| Matrix Compressive Strength, F2c [MPa] | 112 |

| In-Plane Shear Strength, S12 [MPa] | 95 |

| Out-Plane Shear Strength, S23 [MPa] | 100 |

| Density, ρ [ton/mm3] | 1.9 × 10−9 |

| Ply thickness, tp [mm] | 0.129 |

| Woven Fabric | |

|---|---|

| Young’s Modulus, E11 [MPa] | 55,000 |

| Young’s Modulus, E22 [MPa] | 55,000 |

| Shear Modulus, G12 [MPa] | 3363 |

| Shear Modulus, G13 [MPa] | 3363 |

| Shear Modulus, G23 [MPa] | 3363 |

| Poisson’s ratio, ν12 = ν13 = ν23 [-] | 0.30 |

| Fiber Tensile Strength, F1t [MPa] | 650 |

| Fiber Compressive Strength, F1c [MPa] | 650 |

| Matrix Tensile Strength, F2t [MPa] | 650 |

| Matrix Compressive Strength, F2c [MPa] | 650 |

| In-Plane Shear Strength, S12 [MPa] | 150 |

| Out-Plane Shear Strength, S23 [MPa] | 150 |

| Density, ρ [ton/mm3] | 1.97 × 10−9 |

| Ply thickness, tp [mm] | 0.25 mm |

| Al2024 | |

|---|---|

| Young’s Modulus, E [MPa] | 70,000 |

| Poisson’s ratio, ν [-] | 0.33 |

| Yield stress, σy [MPa] | 369 |

| Ultimate Tensile stress, σf [MPa] | 469 |

| Density, ρ [ton/mm3] | 2.7 × 10−9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riccio, A.; Saputo, S.; Sellitto, A.; Russo, A.; Di Caprio, F.; Di Palma, L. An Insight on the Crashworthiness Behavior of a Full-Scale Composite Fuselage Section at Different Impact Angles. Aerospace 2019, 6, 72. https://doi.org/10.3390/aerospace6060072

Riccio A, Saputo S, Sellitto A, Russo A, Di Caprio F, Di Palma L. An Insight on the Crashworthiness Behavior of a Full-Scale Composite Fuselage Section at Different Impact Angles. Aerospace. 2019; 6(6):72. https://doi.org/10.3390/aerospace6060072

Chicago/Turabian StyleRiccio, Aniello, Salvatore Saputo, Andrea Sellitto, Angela Russo, Francesco Di Caprio, and Luigi Di Palma. 2019. "An Insight on the Crashworthiness Behavior of a Full-Scale Composite Fuselage Section at Different Impact Angles" Aerospace 6, no. 6: 72. https://doi.org/10.3390/aerospace6060072

APA StyleRiccio, A., Saputo, S., Sellitto, A., Russo, A., Di Caprio, F., & Di Palma, L. (2019). An Insight on the Crashworthiness Behavior of a Full-Scale Composite Fuselage Section at Different Impact Angles. Aerospace, 6(6), 72. https://doi.org/10.3390/aerospace6060072