1. Introduction

Since the earliest days of aeronautics, icing was found to be a crucial problem for aircraft flight. In-flight ice accretion occurs on the leading edge of an aircraft wing and usually covers only 2% of the wing chord, with the thickness of the ice layer being about a few centimeters. However, even an ice layer of a few centimeters thickness at the key parts of the aircraft is enough to cause flow separation and destroy lift, increase drag and reduce the maximum lifting capability, affect the control surface effectiveness, and in some cases decrease engine performance and stability [

1,

2,

3]. Therefore, people have been working on aircraft anti-icing methods for many years [

4,

5,

6]. The present ice protection methods are hot bleed air, freezing point depressants, and electro-thermal resistance heating. However, they all have potential limitations, for example, pneumatic boots bonded to the ice prone surface are subject to corrosion and damage by external objects, therefore, they need to be replaced every two or three years. The freezing-point depressant systems achieve the purpose of aircraft anti-icing by releasing ethylene glycol through many orifices in the leading edge of an aircraft. There are two main hazards: on the one hand, it increases the weight of the aircraft; on the other hand, since ethylene glycol is a toxic substance, release of this substance into the air can cause environmental pollution. The principle of electro-thermal systems is to use resistance pads to heat the aircraft to above the melting temperature of ice, and in general it requires dedicated generators, which results in significant cost.

The aforementioned methods cannot meet the performance requirements for new aircraft. Therefore, it is imperative to develop a safe and reliable de-icing system. A new method for electro-impulse de-icing has emerged.

Electro-impulse de-icing (EIDI) is one of the mechanical de-icing systems, and it assures the safety of aircrafts in an icing condition. It has major advantages, such as low energy, minimal maintenance, great reliability, and low cost and weight [

7,

8].

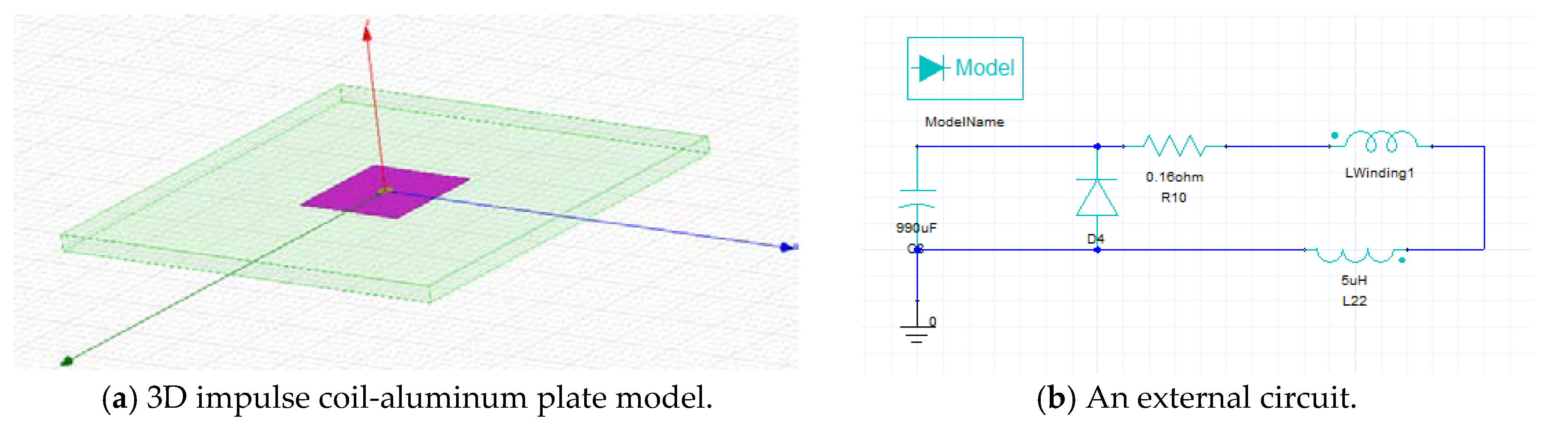

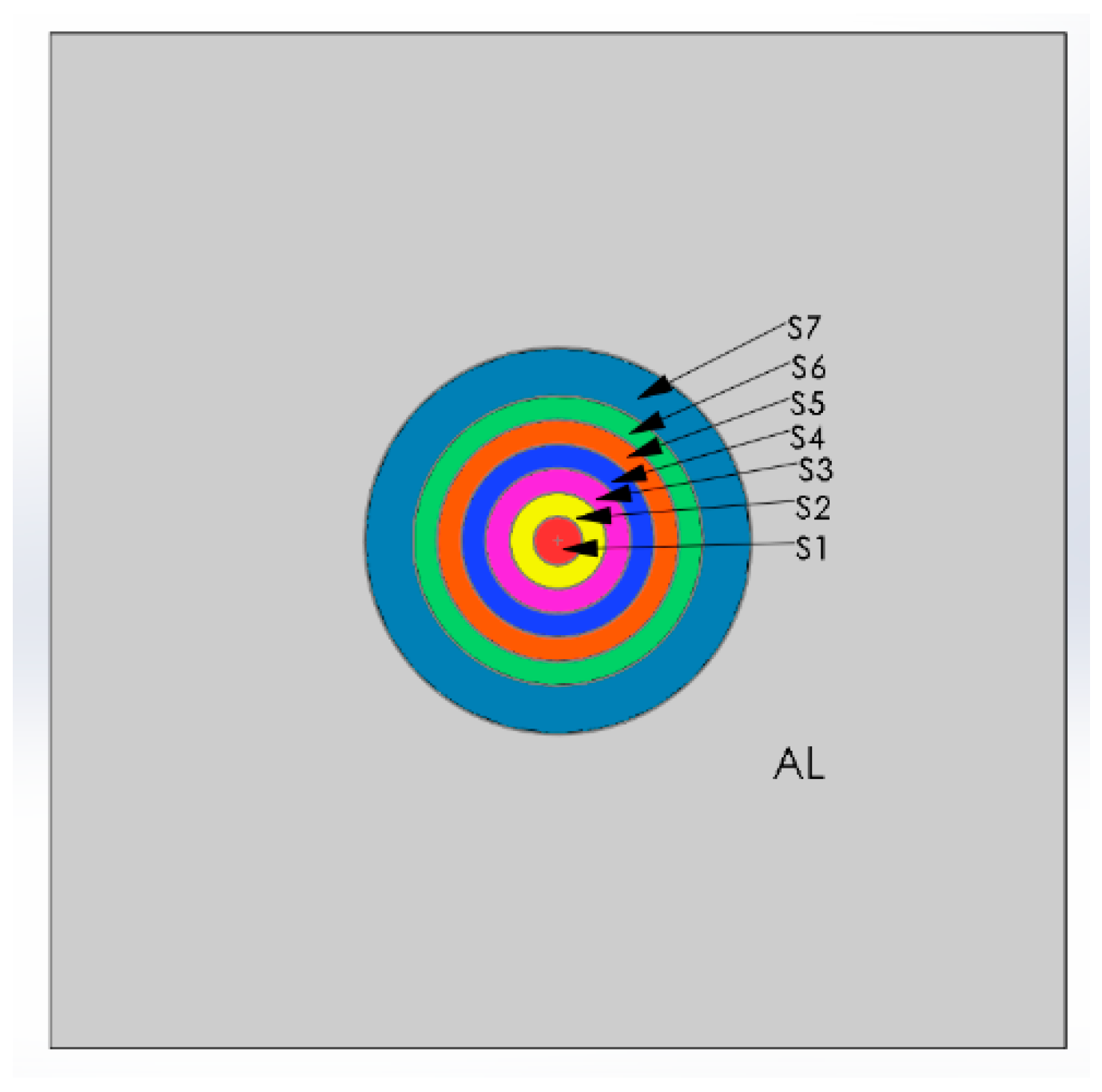

The basic circuit of the electro-impulse de-icing system is shown in

Figure 1. The working principle is the pulse coils are connected to a high voltage capacitor by low resistance, low inductance cables. When the switch is turned on, the discharge of the capacitor through the impulse coils creates a rapidly forming and collapsing electro-magnetic field. According to Maxwell’s law, we know that the time-dependent magnetic field induces eddy currents in the metal skin. Therefore, the instantaneous impulse force of several hundred pounds magnitude is obtained by the Lorentz force formula, but the duration is only a few hundred microseconds. A small amplitude, high acceleration movement of the skin acts to shatter, de-bond, and expel the ice.

Researchers [

9,

10,

11] have studied the phenomenon of ice layer peeling on the surface of the skin under the action of a single coil system. The number of coils is greater than one when a real EIDI system is installed on the aircraft [

12,

13,

14], so the position arrangement and start-up time of the multiple coils may affect the vibration condition to the effect of the ice removing effect. The de-icing criteria used in previous studies [

15,

16,

17] are from the literature [

18]. The adhesion between the ice layer and the skin is different under different icing conditions. Therefore, the conclusions of [

18] are not suitable for all icing environments. Ice tensile strength and ice/aluminum adhesive shear strength used in [

19] are 1.5 Mpa and 0.5 Mpa, respectively. However, this does not explain how the values are obtained. Therefore, the study of de-icing criteria is very important for the electro-impulse de-icing system.

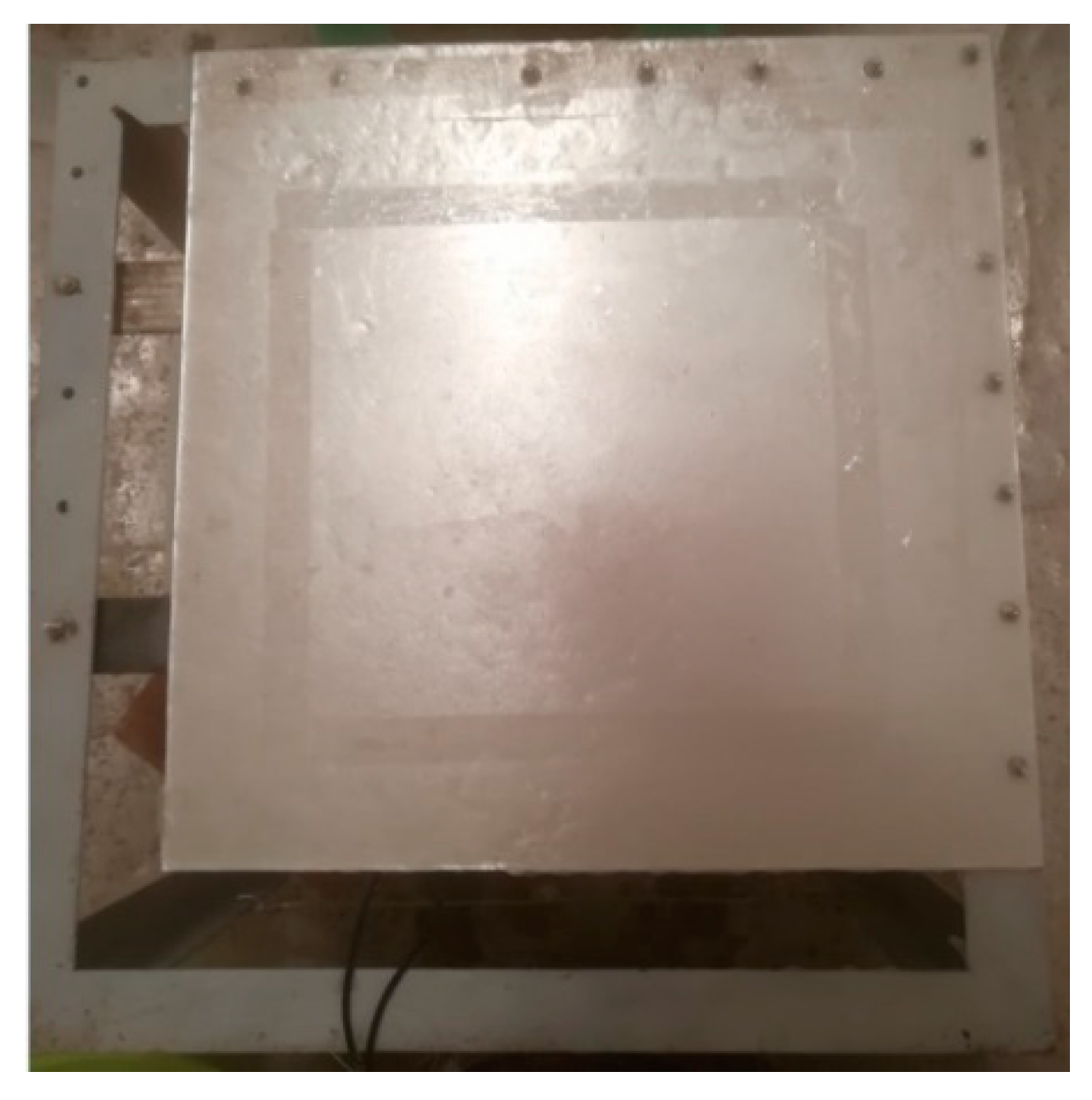

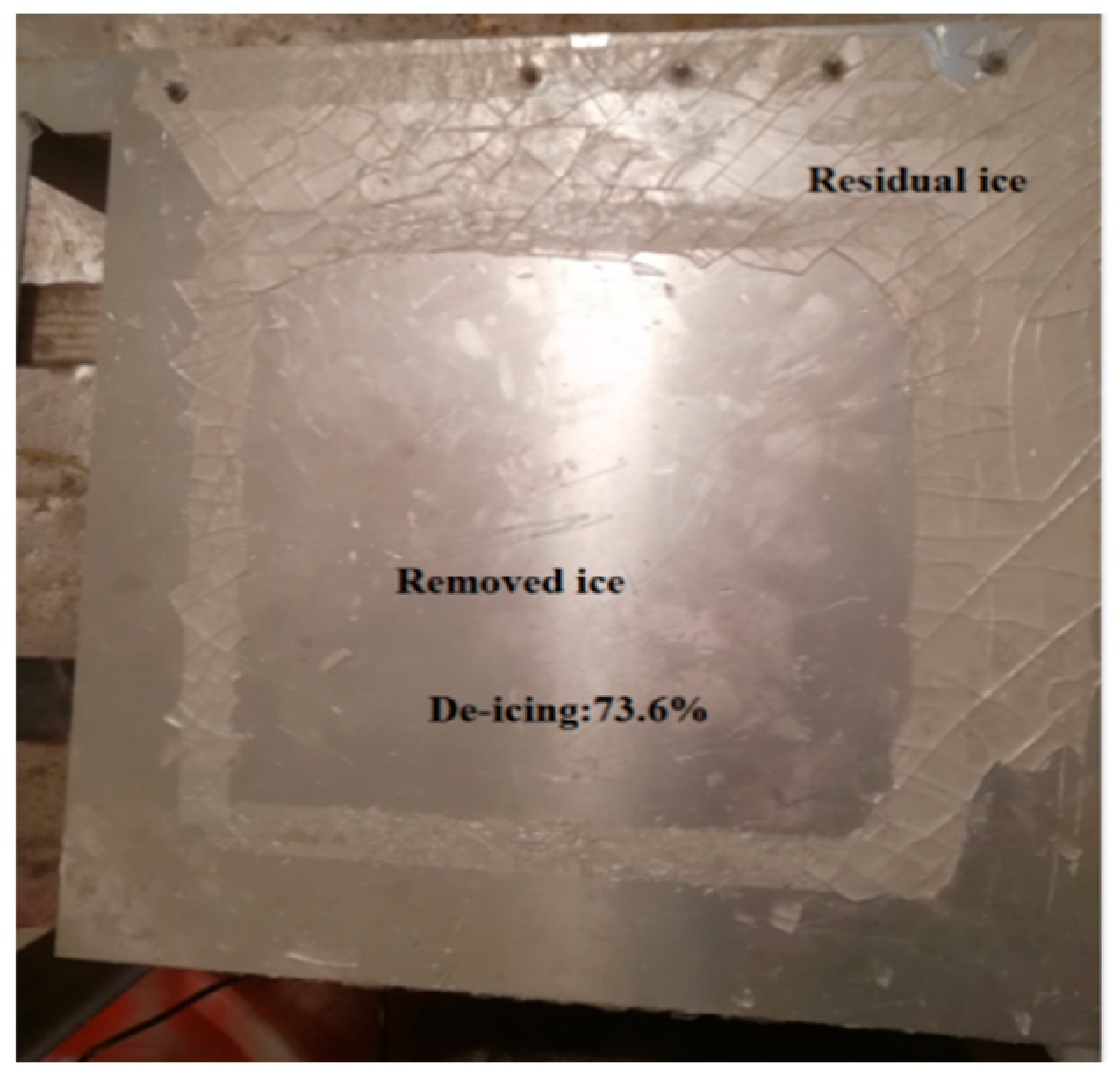

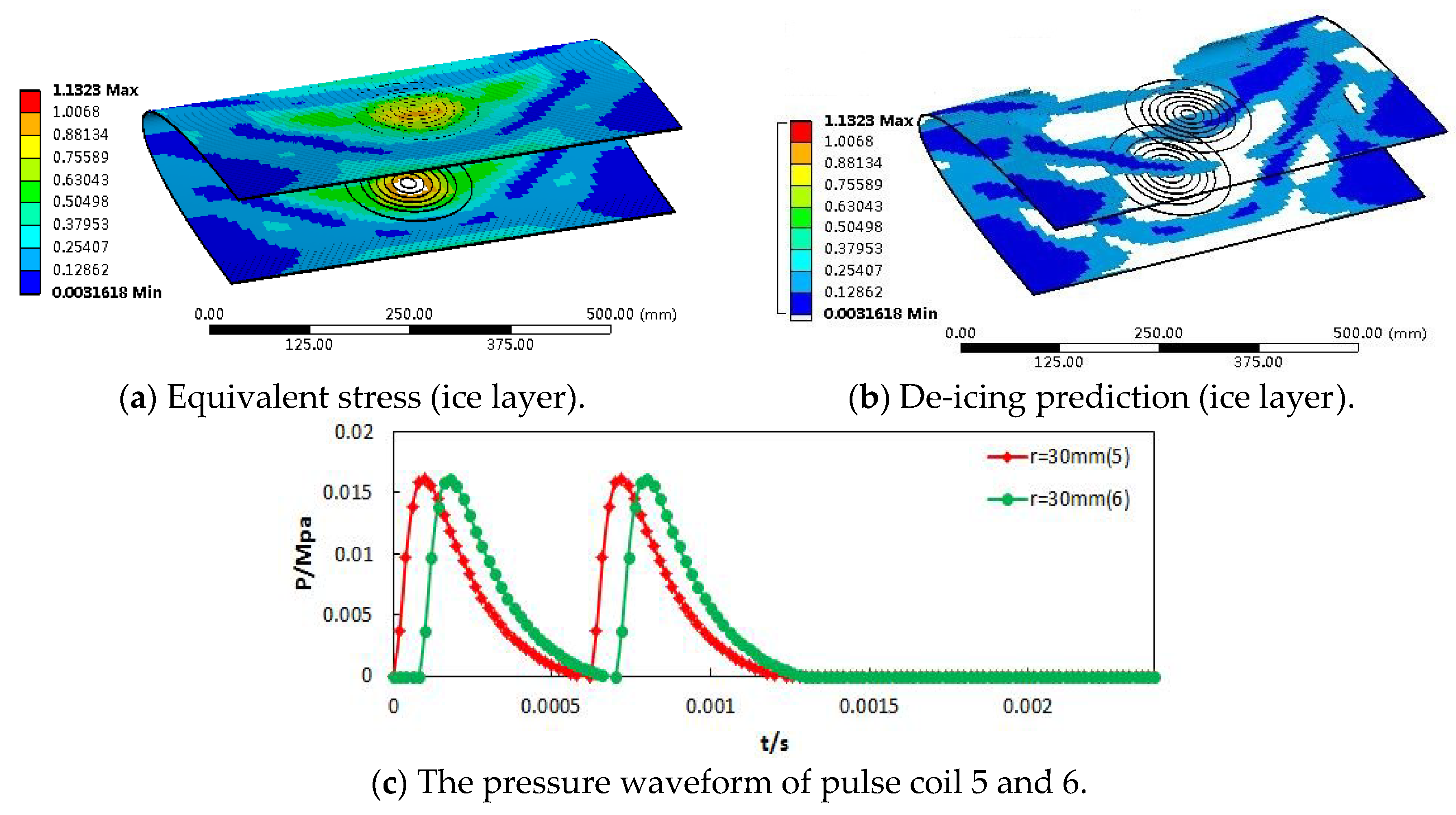

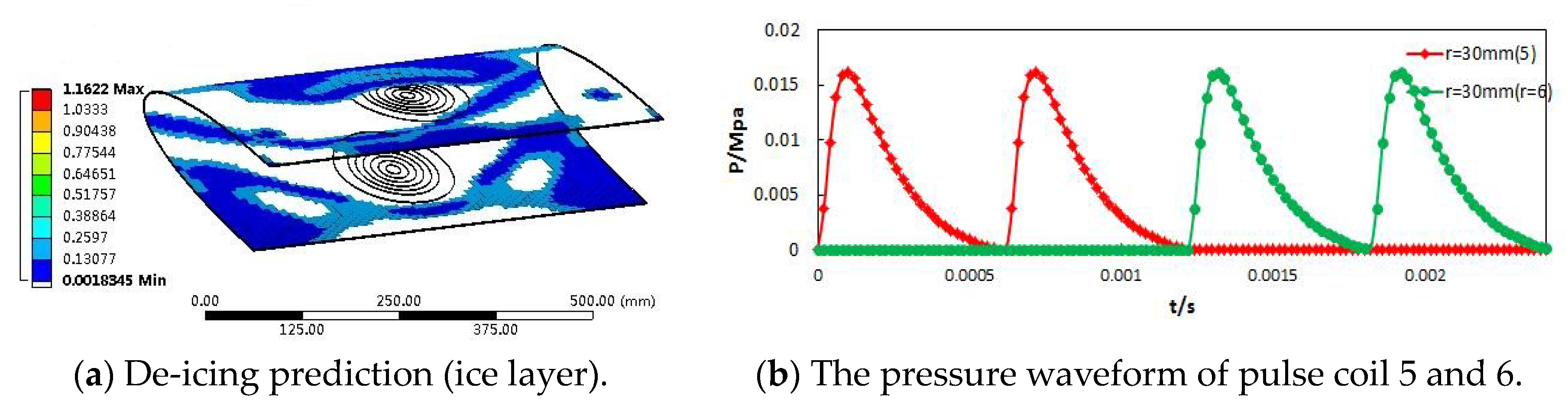

All the experiments in this paper were obtained in an artificial climate chamber. Replacing the skin with an aluminum plate, the electro-impulse de-icing system with a single coil was used. The de-icing range obtained by experiments after each pulse was compared with the calculated result, and it was proven that the calculation process for de-icing prediction was correct. In addition, in the same icing environment, the adhesion between the ice layer and the skin was measured by a tensile test, and the new de-icing criteria was obtained. Finally, a three-dimensional NACA0012 wing-ice layer model was established; the effect of the number, placement arrangement, and the start-up time of pulse coils on the de-icing ratio was analyzed, which provided a reference for the design and installation of the subsequent electro-impulse de-icing system.

2. System Composition and Structural Dynamic Studies

The structural dynamics equation is expressed as [

20]

where [M] is the overall quality matrix, [C] is the overall damping matrix, [K] is the overall stiffness matrix, F is the impulse force, and U is the node displacement,

is the node accelerated velocity,

is the node velocity.

In the continuous linear elastic body vibration, the relationship between normal stress, shear stress and displacement and external force is described. The expression for the stress can be written as

Substituting the node displacement into Equation (2), for each node can be obtained.

The characteristic equation for the stress state is solved by the theory of one-dimensional cubic equation. Therefore, the practical calculation formulae for the principal stress can be written as

where

;

;

.

From the formulae above,

can be obtained. Substituting

into Equation (3), the equivalent stress can be written as