Abstract

Can a hybrid composite made of recycled carbon fibres and natural fibres improve the flexural mechanical properties of epoxy composites compared to pure natural fibre reinforced polymers (NFRP)? Growing environmental concerns have led to an increased interest in the application of bio-based materials such as natural fibres in composites. Despite their good specific properties based on their low fibre density, the application of NFRP in load bearing applications such as aviation secondary structures is still limited. Low strength NFRP, compared to composites such as carbon fibre reinforced polymers (CFRP), have significant drawbacks. At the same time, the constantly growing demand for CFRP in aviation and other transport sectors inevitably leads to an increasing amount of waste from manufacturing processes and end-of-life products. Recovering valuable carbon fibres by means of recycling and their corresponding re-application is an important task. However, such recycled carbon fibres (rCF) are usually available in a deteriorated (downcycled) form compared to virgin carbon fibres (vCF), which is limiting their use for high performance applications. Therefore, in this study the combination of natural fibres and rCF in a hybrid composite was assessed for the effect on flexural mechanical properties. Monolithic laminates made of hybrid nonwoven containing flax fibres and recycled carbon fibres were manufactured with a fibre volume fraction of 30% and compared to references with pure flax and rCF reinforcement. Three-point bending tests show a potential increase in flexural mechanical properties by combining rCF and flax fibre in a hybrid nonwoven.

1. Introduction

Fibre reinforced polymers (FRP) have gained importance in aviation and other transportation sectors due to their excellent mechanical properties combined with relatively low weight. High performance composites like carbon fibre reinforced polymers (CFRP) and also glass fibre reinforced polymers (GFRP) are used in primary and secondary structures of modern aircrafts. They enable the construction of lighter and more efficient aircraft resulting in the reduction of fuel consumption and increased payloads Carbon fibres consume high amounts of energy during the production phase. Therefore, it is of high interest to reduce the consumption of synthetic materials in favour of bio-based materials in certain applications. Bio-based (renewable) materials like natural fibres have been under investigation for a long time for their use in composites but they have not yet been introduced into modern aircraft in a noticeable way. Lack of experience and confidence in the long-term performance and mechanical properties of composites containing natural fibres are still an obstacle for their usage in safety relevant applications like primary structures (e.g., fuselage). However, secondary structures and interior composites, which are not stressed on such high levels offer possible areas of application in aviation [1].

In contrast to synthetic fibres, natural fibres are characterised by a complex multiscale structure, leading to a large variability in mechanical properties for different natural fibres [2]. Compared to glass fibres, natural fibres usually offer good specific stiffness due to their low density. However, their tensile strength cannot compete even when taking into account the fibre density. Furthermore, the length of natural fibres is limited to the maximum of the plant length. Single flax fibres reach a maximum length in the two-digit millimetre range. This is a major difference compared to synthetic fibres which are available as filaments in theoretically unrestricted length. A comprehensive review of natural fibres and their properties can be found in the literature [3,4,5,6,7].

The mechanical properties of natural fibre reinforced polymers (NFRP) are typically lower when compared to GFRP and especially CFRP. In order to broaden the application of NFRP, it is important to increase their mechanical properties. Several ways to improve the mechanical properties of NFRP have been investigated [8]. Most of them use chemical treatments to improve the fibre-matrix adhesion. For example, the effect of silane coupling agents on NFRP has been reviewed by Xie et al. [9]. As another example, the positive effects of the grafting of flax fibres with nanoparticles and incorporation of carbon nanotubes on natural fibres was recently reviewed by Li et al. [10].

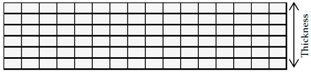

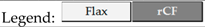

Another way to increase the mechanical properties of NFRP is the hybridization with synthetic fibres such as glass or carbon fibres. There is a differentiation between interlayer (interply) and intralayer (intraply) hybrid composites [11,12]. A common configuration of hybrid composites is the interlayer (Figure 1a) because it is simple to produce by stacking commercially available reinforcement layers with different types of fibres, such as carbon fibre and glass fibre woven fabrics. A mix of different fibre types in one layer characterises intralayer hybrid composites, resulting in a higher dispersion of fibres but also a more complex production process (Figure 1b). Swolfs et al. [11] reported the limited availability of investigations in the comparison of interlayer and intralayer hybrid composites. Smaller delamination areas have been found by Park et al. [13] after impact tests in intralayer compared to interlayer hybrids aramid/polypropylene fibre composites. An increased resistance to crack propagation has been found by Pegoretti et al. [14] for E-glass and polyvinyl alcohol woven fabrics.

Figure 1.

Hybrid configurations: interlayer (a) and intralayer (b). Dark and light grey fields indicate different types of fibres in the hybrid laminate. Based on [11].

In the literature, a multitude of hybrid combinations of all kind of natural fibres with glass, aramid and carbon fibres can be found. Manders and Bader [15] evaluated the tensile mechanical properties of glass/carbon fibre hybrid composites with epoxy resin. They found that the dispersion and localisation of the fibres had a strong effect on the results. An increase in toughness and failure strain was observed with a finer dispersion (“hybrid effect”). Reddy et al. [16] found a gradual increase in tensile and flexural modulus by stacking layers of jute, pineapple leaf and glass fibres. Lützkendorf et al. [17] assessed the combination of recycled carbon fibres (rCF) and natural fibres in a hybrid nonwoven and thermoplastic polypropylene matrix. With bonding agent, the flexural stiffness could be increased by more than 100% with an rCF-content of 20%. Using rCF/PP only in the top-layers with pure NF/PP in between (interlayer hybrid) led to a minor increase in flexural stiffness. Flynn et al. [18] tested the effects of hybridization with flax and carbon fibre fabrics in different stacking configurations. A gain in tensile strength of 252% compared to a purely flax fibre reinforced composite was found for the hybrid variant. Adekunle et al. [19] tested different hybrid combinations of woven and nonwoven flax fibres with glass fibres using a soybean oil derived bio-resin. They found a considerable increase in tensile strength by integration of a glass fibre mat. Cicala et al. [20] combined flax and carbon fibres in different stacking sequences and found up to three times higher tensile strength compared to the pure flax composite. Murdani et al. [21] found that the damping ratio decreased while flexural properties were improved by adding glass and carbon fibres to a jute fibre reinforced composite.

Summarizing the available literature on hybrid natural fibre/synthetic fibre composites, an improvement in mechanical properties was usually observed. A majority of studies are based on reinforcements using usual (commercial) delivery forms of reinforcement, such as woven fabric. However, the increasing use of CFRP in aviation and other high performance applications leads to a further rise in carbon fibre production. Double-digit growth for the demand of carbon fibre is expected in the next decade [22]. From an ecological perspective, composites like CFRP consume high amounts of energy during the production phase. The high value of carbon fibres makes them very interesting for recycling. Recycled carbon fibres can be obtained from production waste (dry fibres from cutting and trimming as well as uncured prepreg) and cured end-of-life CFRP products. Close-loop recycling, as with metals is currently not available for end-of-life CFRP because of their intrinsic heterogenic structure. Especially in combination with cross-linked thermoset polymer systems, this impedes efficient recycling at the end of life [23].

Potential cost savings and reduced energy consumption through carbon fibre recycling were predicted by Carberry [24]. However, recycling processes can be even more expensive compared to the production of vCF [25]. A comprehensive overview of composite recycling processes can be found in the review papers of Oliveux et al. [26] and Naqvi et al. [27]. Currently, the CFRP recycling process with the highest technology readiness level is pyrolysis [28]. CFRP waste is fed into the pyrolysis chamber at temperatures up to 600 °C. Pyrolysis has already found its way into commercial applications in the UK and Germany [29]. Typically, the quality of the recycled carbon fibres (rCF) is lower compared to virgin carbon fibres (vCF). A main reason is the discontinuous length due to the preceding shredding process to reduce the size of end-of-life parts. The removal of fibre sizing and thus a possible reduction of fibre-matrix adhesion is another drawback. Information on the influence of the fibre-matrix interface and interphase on the composite properties can be found in the work of Jesson et al. [30]. The mechanical properties of rCF can still be considered as very good. Tensile fibre tests have shown comparable results for rCF and vCF [31]. Because of the reduced length, the application of rCF is currently restricted to alternative use-cases with lower quality requirements [28]. The usual delivery forms are chopped, milled and pelletized rCF [29]. Another way to obtain recycled fibres is the recycling of waste of carbon fibre fabrics generated during the production of composites. Waste from fabric cutting is the main source for this material. The short and variable length of rCF is a challenge for converting them into continuous yarns used in woven reinforcements. Nonwovens made of chopped rCF are already available on the market [32,33].

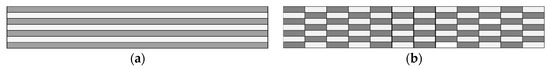

Chopped rCF (Figure 2b) shows some apparent similarities to natural fibres (Figure 2a), for example, randomness, restricted length and curvature. Therefore, a possible way of using rCF is in combination with natural fibres in a hybrid nonwoven as reinforcement for FRP, combining the very good mechanical properties of the rCF with the low density and good damping properties of natural fibres. Nonwoven processes are capable of combining different types of fibres of variable length in a single web structure. Nonwovens are also less expensive and potentially more eco efficient compared to classic woven fabrics from bio-fibres due to their simple production process [34]. The question is, do the added steps in the production of a hybrid nonwoven add benefits compared to a more common reinforcement, which uses just one fibre type in woven or nonwoven fabrics? The aim of this study is to make a preliminary assessment of the impact of flexural mechanical properties. An overview of typical manufacturing processes for nonwoven fabric in relation to fibre length and degree of isotropic behaviour is given in Figure 3. A distinction can be made between four processes, and the two dry-laying processes are capable of processing fibre lengths of more than 30 mm. Aerodynamic airlay processes usually utilize an airstream to feed the fibres on a moving belt. Carding is a process of separating individual fibres, using a series of dividing and re-dividing steps. This results in a parallelisation of the fibres. Carding is possible by using hand cards or drum cards in which fibres are fed through one or more pinned drums. The nonwoven web can be parallel or random laid. Parallel laid carded nonwoven usually results in good tensile strength and low elongation in the machine direction (MD) compared to the cross direction (CD) [34].

Figure 2.

The delivery form of the fibres used for the assessment of hybrid nonwoven in this study. Flax fibres (a) and recycled carbon fibres (b).

Figure 3.

Manufacturing processes for nonwoven in relation to fibre length and degree of isotropic material properties. Figure based on [35].

The manufacturing processes of nonwoven fabrics are very efficient and it is possible to use different fibre length fractions. For woven fabrics, the fibres are normally processed into yarns, which leads to strong twists and thus to areas of potentially poor wettability by liquid resin systems. A possible advantage of the use of nonwoven for FRP lies in the better availability of the fibres to be embedded in the resin system. Nonwoven is an obvious choice because of the fibre characteristics of the flax and rCF. However, fibres can be damaged because of the mechanical stress during the carding process [35].

The hybrid combination of recycled carbon fibres with natural fibres and their different distribution in thermoset composites has not been assessed in detail so far. This study aimed to provide a preliminary assessment of the potential of hybrid rCF/flax nonwoven as reinforcement in combination with a thermoset resin. Two references, pure flax and pure rCF nonwoven reinforced composite, were produced as a base line. Two hybrid variants contained fibres in the same total volumetric mixing ratio of flax to rCF (3:1). The difference was the distribution of the rCF over the laminate thickness. The effect on flexural mechanical properties was studied by three-point bending (3PB). This test was chosen because of the simple specimen preparation and the small size of the samples.

2. Materials and Methods

2.1. Materials

The four variants of laminates tested in this paper were based on recycled carbon fibres from production waste (e.g., dry fibre cut-off) and staple flax fibres. Flax fibres were obtained from the company Intercot in Barcelona, Spain. The flax fibres had no length restriction due to chopping. To avoid the potentially weak fibre-matrix adhesion of pyrolysed rCF because of their removed sizing, recycled fibres from dry cut-off waste were chosen for this preliminary study. Those rCF usually have an intact sizing. However, the exact type of sizing was unknown. These rCF, chopped to maximum length of 25 mm, were obtained from CarboNXT GmbH (Wischhafen, Germany). The delivery form of the fibres is shown in Figure 2. A thermoset matrix system, the two-component liquid epoxy infusion resin Epikote™ RIMR135 with curing agent RIMH1366 (Hexion B.V., Rotterdam, The Netherlands) was used to produce the laminates.

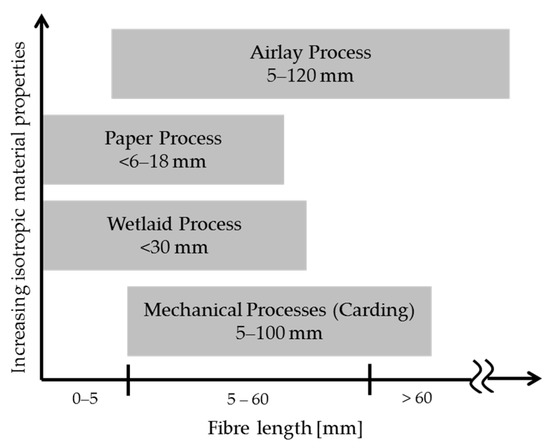

2.2. Manufacturing of the Nonwoven

Sensitivity of electrical equipment to short circuits caused by conductive rCF led to the decision to perform the whole nonwoven manufacturing process in a closed exhaust hood. Therefore, a simple two-stage laboratory process was used to manufacture the nonwoven from flax and recycled carbon fibres. The first step in the process was opening of the fibres. The resulting increased volume of the fibre batches led to better control of the fibre feed into the card. The fibre opening process used in this study was based on the principle of a gas jet mixer. A container with a volume of approximately seven litres was modified for fibre opening and mixing, as shown in Figure 4a. Compressed air (2–3 bars) was introduced to the fibre filled container through a funnel attached the bottom. A manually controlled pistol was used to control the release of the compressed air in a pulsating manner. Circular distributed air outlets with cotton wool filter elements were installed in the upper part to the capsule. The outflowing compressed air took up the fibres and whirled them around in the capsule, resulting in a fibre opening (separation). This is schematically shown in Figure 4a. Opening and mixing processes also removed shives (wooden residues of the bast fibre stem) and dust which was gathered in the cotton wool filters. A transparent screw cap was used to visually observe the opening process. The fibre mixing was carried out in the same modified container that was used for the fibre opening. After opening, fibre batches were mixed according to the mixing ratio given in Table 1.

Figure 4.

Reinforcement manufacturing process with fibre opening and mixing in a capsule with turbulent air (a) and nonwoven web formation on a small-scale electric card with two rotating drums (b).

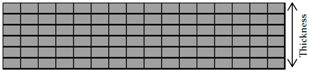

Table 1.

Nomenclature, composition and schematic drawings of the volumetric distribution of flax (light grey) and rCF (dark grey). Total fibre volume content for each composite was approximately 30%. The volumetric rCF to flax ratio in the outer layers of the Gr-22.5Flax-7.5rCF laminate was rCF/flax = 3:1 (intralayer). The four inner layers contained 100% flax fibres, resulting in a combination of intralayer and interlayer hybrid. The same total amount of flax and rCF was used for the 22.5Flax-7.5rCF laminate (pure intralayer).

For the nonwoven web formation, an electric drum card with a simple two drum design was purchased from the company Holzwurmwolle in Alfdorf, Germany) (Figure 4b). Both drums had a width of 190 mm. The diameter of the small drum was 45 mm. The big drum had a diameter of 160 mm, resulting in a circumferential length of approximately 500 mm. Both drums could be individually activated and adjusted for rotating direction and rotating speed. Carding cloths with buckled needles of 17 mm length were attached to the drums. Needle density was 52 ppsi for the small intake drum and 72 ppsi for the big drum. Nonwoven webs with an area of approximately 500 mm length to 190 mm width were produced.

The opened fibres were fed manually to the electric drum carding device. A possible result of the manual feeding process was the increased risk of uneven fibre distribution (areal weight) in the nonwoven. This effect was reduced by quality control and the stacking process of several nonwoven layers to even out the distribution of fibres in the laminate. The fibres fed manually to the carding device were taken up by the small entrance roll and fed to the counter rotating big drum. This process step was carried out until all fibres were taken up from the big drum. Compression of the fibres on the big drum was carried out with a fixed brush. A flat card with a needle felt of 52 ppsi pressed manually on the big drum during the fibre take-up process led to a further increased fibre density of the nonwoven web. The last step was cutting and manual removal of the nonwoven from the big roll followed by quality control. No further compaction was applied to the nonwoven webs before laminate manufacturing. The quality control included the measurement of areal weight and checking the distribution of fibres with the help of a transmission light desk.

2.3. Composition and Nomenclature of the Composites

The stacking sequence and number of nonwovens used for the composite manufacturing is shown in Table 1. Four variations of laminates with a total of six nonwoven layers were produced. All layers were stacked symmetrically to the neutral axis and oriented in the same direction. The machine direction (MD) of the nonwoven was always oriented in 0° laminate direction. As the carding process led to a clear orientation of fibres in MD compared to the cross direction (CD), the laminates had no in-plane isotropic characteristics.

The nomenclature used for the laminates in this paper is a combination of fibre volume fraction in percent and the used fibre, e.g., 30Flax = 30% fibre volume fraction of flax fibres. Two non-hybrid reference laminates contain nonwoven with pure flax (30Flax) and pure rCF (30rC) reinforcements. Furthermore, two hybrid variants with an rCF to flax ratio of 1:3 but differing fibre distribution were manufactured. Of these, the intralayer hybrid variant contained 22.5 vol.-% flax fibres and 7.5 vol.-% rCF (=22.5Flax-7.5rCF) which were mixed with the aim of achieving a homogeneous distribution. The gradient or sandwich like variant was a combination of interlayer and intralayer hybrid nonwoven (Gr-22.5Flax-7.5rCF). Here, the rCF were distributed only in each outer layer mixed with a smaller amount of flax fibres added (intralayer). In these outer layers, the nonwoven had a flax rCF to flax ratio of 3:1. The four layers in between were purely made of flax fibres. The gradient variant was chosen in order to assess the effect of the concentration of rCF on the flexural mechanical properties. Placing stiffer plies (i.e., layers with higher rCF content) away from the neutral axis should result in increased flexural mechanical properties [12]. For both hybrid variants the same total mixing ratio of rCF and flax fibres was applied.

2.4. Manufacturing of the Composites

The two-component epoxy resin RIMR135 and hardener RIMH1366 were mixed in a weight ratio of 100:35, followed by a degassing step in a desiccator to remove air bubbles. The nonwoven layers have been stacked in order to achieve the desired fibre volume fraction and fibre distribution at an intended thickness of 3 mm. The stacking sequence, number of layers and nomenclature of the laminates is shown in Table 1. The monolithic laminates were produced with the single line infusion (SLI) method in a Lauffer hydraulic press (500 mm × 500 mm pressing area). The SLI process is characterised by using the same line for vacuum generation followed by the liquid resin infusion. Curing time in the heated hydraulic press was 120 min at 85 °C followed by deforming and post-curing at 100 °C for 60 min in a Memmert UFP500 convection oven (Memmert GmbH + Co. KG, Schwabach, Germany). After cutting, ultrasonic testing in water were carried out to assess the laminate quality regarding pore distribution and delamination. The cured and trimmed laminates were stored at 23 °C and 50% relative humidity. The physical properties of the laminates are summarized in Table 2.

Table 2.

Measured and calculated physical properties of the cured monolithic composites.

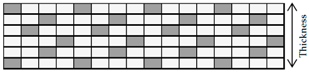

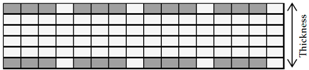

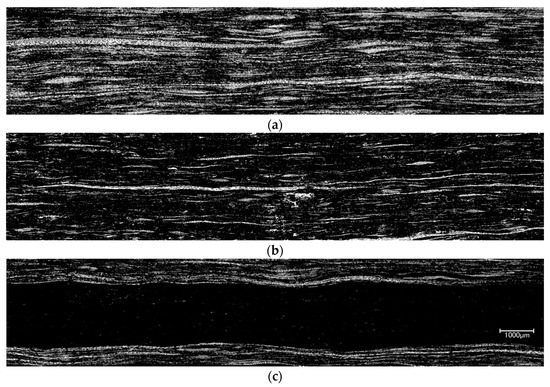

Figure 5 gives an overview of the obtained distribution of the rCF in the laminates 30rCF (a), 22.5Flax-7.5rCF (b) and Gr-22.5Flax-7.5rCF (c). The microscopic images were processed in such a way that the rCF appear as white pixels while all other constituents (epoxy resin, flax fibres) and voids appear as pure black pixels. However, the exact fibre volume content could not be calculated by measuring the total area of white pixels. The rCF were located in a different angle to the image plain, resulting in ellipses instead of circles. This indicates the randomness of the fibre orientation typically seen in nonwoven fabric. In Figure 5a, the higher amount 30 vol.-% rCF compared to 7.5 vol.-% rCF in Figure 5b,c is obvious. For all laminates, the distribution of rCF and flax fibres was not homogeneous. This can be seen in the areal concentration of white pixels. Furthermore, Figure 5c shows the concentration of rCF in both outer layers of the laminate. Undulations and varying thicknesses of the rCF rich layers can be observed and are typical for all produced samples.

Figure 5.

Visualisation of the typical rCF distribution shown as white areas. For the laminates 30rCF (a) and 22.5Flax-7.5rCF (b), the rCF should have been evenly distributed all over the composite. As not all fibres where fully opened, fibre rich areas as well as resin rich areas occurred. The laminate Gr-22.5Flax-7.5rCF (c) contains the same volumetric amount of rCF compared to (b), but is concentrated in both outer nonwoven layers. Micrographs were taken with Keyence VFX1000 and VH-Z100UR lens (×200) and stitched to a horizontal panorama. The image plane is the 90° laminate direction. All images were converted to black (flax, epoxy resin, voids) and white pixels (rCF) with the colour threshold tool in ImageJ software.

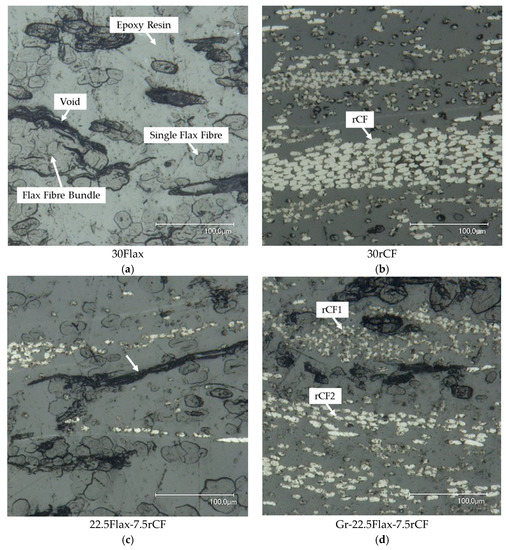

More detailed microscopic images of all four tested variants are shown in Figure 6. Here, the flax fibres and rCF are clearly visible. Flax fibres occur both as single fibres as well as in accumulations of single flax fibres (technical fibres). Voids can be observed especially around these flax fibre accumulations (Figure 6a). Flax fibres oriented perpendicular or in an angle between 0° and 90° appear as elongated dark voids (Figure 6c), most likely resulting from the removal of flax fibre segments during the polishing process. Filaments of rCF are visible as bright areas in Figure 6b, 6c and 6d. Similarly to the flax fibres, the rCF are arranged as single fibres as well as accumulations from the original tows. The fibre orientation can roughly be calculated using the minimum and maximum diameter of the ellipse. For example, in Figure 6d the group of carbon fibre marked as rCF1 has an angle of approximately 0° and is therefore oriented in the machine direction (MD = 0° laminate direction). The rCF2 in Figure 6d has a major axis length of about 40 µm and a minor axis length of about 7 µm (i.e., the diameter of the carbon fibre). Using the cosine function this results in an approximately 75° fibre angle. However, the curvature (Figure 2) of the fibres makes clear statements on fibre orientation difficult.

Figure 6.

The micrographs show exemplary images of the fibres and their distribution in a 0° laminate direction, corresponding to the nonwoven machine direction. Reference composites of flax and rCF are shown in (a) respectively (b). All images show areas near the upper or lower surface of the composites in order to give a better distinction of the amount of rCF relative to flax fibres in the homogeneous hybrid composite (c) compared to the concentration of rCF in the outer layers (d). Voids between fibre and matrix are visible as dark areas. The elongated dark areas, as indicated by the arrow in (c) are probably flax fibres oriented near 90° laminate direction that were removed during the polishing process of the microscopy specimens.

The micrographs in Figure 6 indicate the relatively low fibre volume content of approximately 30% for all tested laminates, visible by major areas of epoxy resin. The calculated void content was highest for the pure flax fibre reinforced sample 30Flax (7.7%, see Table 2), while the two hybrid laminates had an even lower void content compared to the pure rCF reinforced laminate 30rCF. For the laminates containing flax fibre, the void content can partly be explained by water in the natural fibres. Generally, also the processing parameters during the laminate manufacturing have an impact on the void content [36].

2.5. Characterisation Methods

Micrographs were prepared with VFX1000 digital microscope (Keyence, Osaka, Japan) and VH-Z100UR lens (Keyence, Osaka, Japan). For this, samples in the 0° and 90° direction measuring 15 mm width were cut and embedded in a room temperature curing acrylic resin ClaroCit (Struers GmbH, Willich, Germany) followed by a three-stage polishing process. ImageJ software (version 1.50e) was used to analyse the micrograph images.

Three-point flexural tests were carried out according to the standard DIN EN ISO 14125 (class II, l/h ≅ 20) on a Zwick Roell universal testing machine Z005. A strain rate of 2 mm/min was used with a load cell of 5 kN (type KAF-Z, Zwick Roell GmbH & Co KG, Ulm, Germany). Strain was measured by cross-head displacement. Test samples were sawed to 60 mm length and 15 mm width in the 0° and 90° laminate direction on a KKS 1300 C (MAIKO Engineering GmbH). A span-to-depth ratio of 20:1 at a laminate thickness of 3 mm was chosen in this study because of the limited available number of specimens. The relatively low span-to-depth ratio can cause shear stresses resulting in additional displacements, and therefore, a potentially lower modulus [12]. Six samples were tested in the 0° direction. Because of limited composite space, a minimum of just two samples were tested in the 90° direction. The flexural modulus was calculated with the secant method between 0.05% and 0.25% strain.

3. Results and Discussion

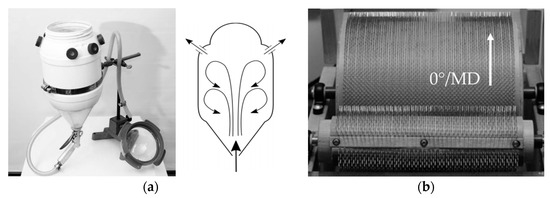

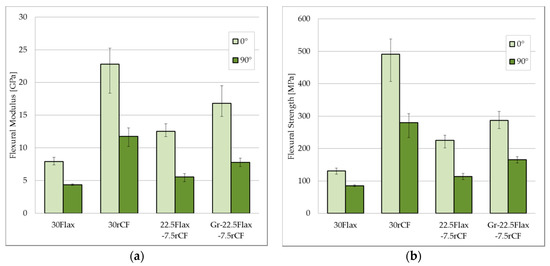

The mean results and standard deviations on flexural strength, modulus and strain at failure obtained from the flexural test are summarized in Table 3. Figure 7 provides a graphical overview of the test results for flexural strength and modulus. It can be observed that the fibre type and distribution in hybrid laminates has a strong impact on the flexural mechanical properties.

Table 3.

Data for flexural strength (σ), flexural modulus (E) and strain at break (ε) testing in 0° and 90° laminate directions with standard deviations. All layers of the laminates are pointing in the same direction. 0° corresponds to the machine direction (MD) in nonwoven. 90° corresponds to the cross direction (CD) in nonwoven.

Figure 7.

Flexural modulus (a) and flexural strength (b) in the 0° and 90° composite direction in accordance with DIN EN ISO 14125. The error bars show the minimum and maximum values measured for each set of specimens.

As a reference, the pure flax fibre reinforced laminate 30Flax achieved the lowest flexural mechanical properties of all tested laminates. Mean flexural strength was 131.2 MPa in the 0° laminate direction, while the mean flexural stiffness was 7.9 GPa. A decrease of 35% for flexural strength and 45% for flexural modulus was found in the transverse (90°) direction compared to the 0° laminate direction. The lower flexural properties in 90° can be explained by the stronger alignment of the fibres in the machine direction (MD) compared to the cross direction (CD) for the nonwoven produced with the electrical carding machine (see Section 2.2).

The laminate with the highest flexural modulus and strength was reinforced purely with rCF nonwoven (30rCF). In the 0° laminate direction, 30rCF reached a mean flexural strength of 491.5 MPa and a modulus of 22.8 GPa. Flexural strength and modulus dropped by 43% and 49%, respectively, in the 90° laminate direction. Compared to the pure flax fibre reinforced variant (30Flax), a strong increase of 274% for flexural strength and 188% for flexural modulus was observed for 30rCF.

The intralayer hybrid laminate 22.5F-7.5rC, with an rCF to flax ratio of 3:1 distributed evenly in the laminate, reached a flexural strength of 225.3 MPa and a flexural modulus of 12.5 GPa in the 0° direction. Similar to the other laminates, flexural strength and modulus decreased by 49% and 56%, respectively, in the 90° laminate test direction. Compared to the pure flax reinforced laminate 30F, the substitution of 7.5 vol.-% flax fibres by rCF led to an increase of 72% strength and 59% stiffness in the 0° direction. The increase in flexural modulus and flexural strength was considerably lower in the 90° laminate test direction compared to the 0° direction. This corresponds to the stronger alignment of fibres in the machine direction (MD) during manufacturing of the nonwoven and led to a stronger influence of the matrix in the 90° direction.

In contrast to 22.5Flax-7.5rCF, the second hybrid laminate Gr-22.5Flax-7.5rCF contained the same total volumetric flax to rCF ratio of 3:1. However, here all rCF fibres were concentrated in the outer layers with flax to rCF ratio of 1:3. All remaining flax fibres were located as non-hybrid layers in the four middle layers (see Table 1). This resulted in a combined intralayer and interlayer hybrid configuration. Concentrating the rCF in the outer layers resulted in a flexural strength of 286.7 MPa and a flexural modulus of 16.8 GPa in the 0° laminate direction. Compared to the evenly distributed rCF/flax mix in the laminate 22.5Flax-7.5rCF, the flexural strength and modulus were further increased by 27% and 34%, respectively. Compared to the pure flax fibre reinforced variant (30Flax), an increase of 118% flexural strength and 113% modulus was found. The flexural properties of the pure rCF laminate (30rCF) were still out of reach with a reduction of flexural strength of −71% for Gr-22.5Flax-7.5rCF. However, the flexural modulus of the Gr-22.5Flax-7.5rCF laminate approaches the stiffness of the 30rCF laminate with a loss of −36%. A reduction in flexural strength (−42%) and modulus (−54%) in the 90° laminate direction compared to 0° was found for Gr-22.5Flax-7.5rCF.

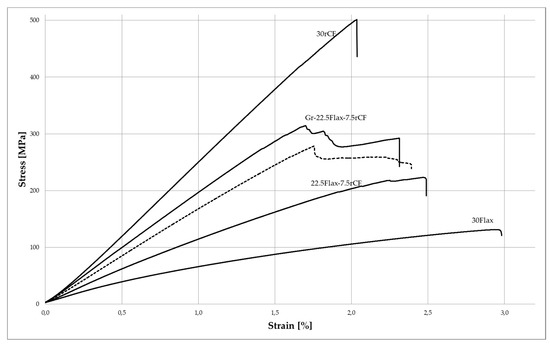

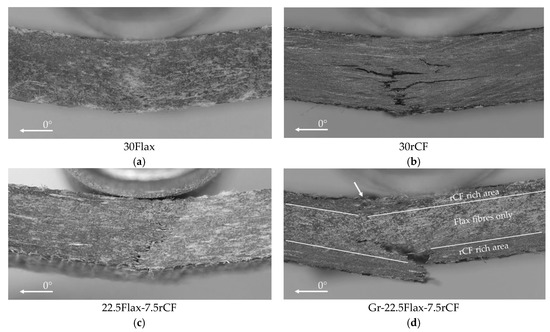

Typical stress-strain curves for each set of specimens in the 0° laminate direction (=machine direction of nonwoven) can be seen in Figure 8, while Figure 9 gives an overview of the fracture pattern after completion of the three-point bending tests. All measurement curves show an almost linear, slightly degressive behavior. Major differences in the stress-strain curves can be observed in stiffness, stress and strain at failure. While the 30rCF laminate obtained the highest flexural stress at failure, it also had the steepest rise, resulting in the highest stiffness. The fracture pattern of 30rCF is shown in Figure 9b. Fracture occurred abruptly on the tension side (lower side in the specimen), with clearly visible delamination effects and branched crack patterns. The reference laminate 30Flax, made purely of flax fibres, had the lowest mechanical properties of approximately 125 MPa flexural strength and 8 GPa flexural modulus. A more degressive behaviour compared to 30rCF is visible for the test curve in Figure 8. The strain at failure of about 3% is considerably higher compared to the laminates containing rCF with a strain at failure of up to 2.5%. Just as in laminate 30rCF, the fracture of 30Flax occurred on the tension side of the laminate, without observation of compression damage (Figure 9a).

Figure 8.

Stress-strain curves of three-point bending test samples in the 0° laminate test direction (similar to the machine direction of the nonwoven). For the sake of clarity, only one typical curve, with results comparable to the average values per set of specimens, is shown here. For Gr-22.5Flax-7.5rCF, a second dashed curve is indicating the considerable deviations between the test specimens because of the manual nonwoven production.

Figure 9.

Fracture patterns after completion of the three-point bending tests in the 0° laminate test direction. The arrow in (d) marks the first area of compressive failure in the laminate with rCF concentration in the outer layers while the final failure occurred on the tensile side. The rCF rich areas in the laminate Gr-22.5Flax-7.5rCF (d) are marked. All other samples (a–c) failed on the tensile side without any visible compression damage. All images were extracted from video footage taken during testing with Panasonic GH-5 and Sigma 105 mm/2.8 DG Macro HSM lens mounted on a tripod. The loading pin of the flexural test is the blurred object in the upper part of the images.

The hybridisation of flax and rCF introduced further variables, which resulted in a more complex behaviour of the stress-strain curves in the form of several drops of load (primary and final failure). The hybrid laminate 22.5Flax-7.5rCF (with evenly distributed rCF) shows several minor drops, starting at a strain of approximately 1.9%. Each drop is followed by a further increasing stress level as can be seen in the exemplary measurement curve in Figure 8. Similar to the purely flax and rCF reinforced laminates, the fracture pattern was predominantly visible on the tension side (Figure 9c).

A stronger distinction between primary and final flexural failure was observed for the gradient laminate Gr-22.5Flax-7.5rCF. Kretzis et al. [12] described the flexural behaviour of hybrid fibre reinforced composites. They found that for some hybrid configurations, the stress at primary failure was about half of the stress at final failure. In the case of the laminate Gr-22.5Flax-7.5rCF, the first failure occurred on the compression side. The location of the compression failure (buckling) is indicated with an arrow in Figure 9d and can also be attributed to a slight drop visible in the exemplary stress-strain curve at a strain of approximately 1.4% (Figure 8). This first compressive failure had no significant effect on the further development of the stress-strain curve. Final failure started on the tension side, comparable to the other tested laminates. However, the final failure did not occur as a single catastrophic failure. Instead, after the first visible tensile failure, the stress level dropped slightly at a strain of approximately 1.7%, until the specimen failed completely at a strain of approximately 2.3%.

In the 90° laminate test direction the flexural mechanical properties were considerably lower than the 0° test direction because of the main fibre alignment in the machine direction of the composite. The failure in the 90° laminate test direction always occurred on the tension side without visible compression failure. Typically, the crack pattern was less branched compared to the 0° laminate test direction, with the exception of the 30rCF laminate, which showed a similar crack pattern in the 0° and 90° test direction.

Deviations in flexural mechanical properties measured for the hybrid nonwoven specimens were observed. The highest standard deviation in the 0° laminate test direction was found in the Gr-22.5Flax-7.5rCF variant. In principle, the standard deviation varies between 4.5% and 11.8% in the 0° laminate test direction. Two curves measured during the flexural test for the Gr-22.5Flax-rCF samples are shown in Figure 8 as an example. The dashed line shows a low performing sample of Gr-22.5Flax-7.5rCF for comparison. Different reasons for the standard deviation can be considered and will be discussed in the following paragraph.

The distribution of fibres (rCF and flax) in the nonwoven was not fully homogeneous and led to variance in the fibre volume content in the laminate. For example, relative accumulations of rCF lead to higher mechanical properties in these specific areas compared to areas with low fibre content. An example can be observed in Figure 5c, which shows a deviation in the thickness of the rCF rich outer layers. The random distribution of fibres in the nonwoven also has an effect on the fibre orientation in different areas of the laminate. This can lead to fibres oriented anywhere between the 0° and 90° laminate direction. The laboratory nonwoven produced in this study also showed a strong curvature of fibres which resulted in reduced mechanical performance compared to perfectly aligned fibres. Another aspect, generally applicable for natural fibre reinforced polymers, is the embedding of shives into the composite and a considerable void content. Shives are wooden particles that can be left over from the manufacturing process of the flax fibres. With a possible shive diameter in the millimetre range, compared to approximately 20 µm for flax fibres, these shives can act as a weak point in the composite. Voids and unwanted constituents like shives can increase stresses locally, leading to earlier failure [37].

4. Conclusions and Outlook

Growing environmental concerns have led to an increased interest in the application of bio-based materials such as flax fibres in composites. In parallel, increasing amounts of CFRP waste raise questions on the utilisation of valuable recycled carbon fibres (rCF). Recycling only makes sense when the regained materials are used again in new applications. As NFRP usually have low mechanical properties compared to GFRP and CFRP, a possible solution for the improvement could be the addition of rCF in a hybrid composite. This study gives a preliminary insight into the potential of mixing flax fibres with rCF in a hybrid nonwoven and the effect on the flexural properties of epoxy composites.

The nonwoven, containing flax and rCF was manufactured manually with a two-drum card. While obtaining the typical overall randomness of fibre distribution, the nonwoven had a fibre orientation in the machine direction. Epoxy laminates with 30% fibre volume content were manufactured. The results presented in this study show that mixing natural bast fibres such as flax with a small amount of recycled carbon fibres (7.5 volume percent of the laminate) can lead to a significant increase in flexural mechanical properties compared to a composite only reinforced with flax fibres. The concentration of rCF in the outer layers of the laminate, away from the neutral axis, further increased the flexural mechanical properties, compared to the same mixing ratio of rCF to flax distributed evenly in the laminate. However, the flexural mechanical properties of composites purely reinforced with rCF were not obtained with the hybrid variants.

The hybrid combination of flax and rCF makes it possible to modify the material characteristics. The mixing ratio and distribution of the different fibres can be fully adapted to the requirements of the desired application. While such hybrid composites lose their fully bio-based nature, they may gain enough multifunctional characteristics to compete with fully synthetic materials. Usually, a high degree of freedom for the choice of fibre orientation, ranging from a strong fibre orientation up to a more isotropic material behaviour, can be obtained by standard nonwoven manufacturing processes. Therefore, a hybrid combination of natural fibres and recycled carbon fibres can be considered as a possible alternative to state-of-the-art materials such as GFRP for application in semi-structural applications. However, a more detailed characterisation of the hybrid nonwoven from rCF and flax is required. Tensile, compressive, damping and fatigue behaviour need to be characterised for a better understanding of the potential of natural fibres combined with recycled carbon fibres. An assessment of the damping properties is important to highlight the multifunctional advantages of the multiscale structure of natural fibres. Furthermore, recycled carbon fibres from a pyrolysis process should also be considered. Such rCF are decreased in size by the pyrolysis step, usually leading to reduced fibre-matrix adhesion. Chemical and physical treatments of the rCF could help to improve this interface.

Finally, it must be stressed that the environmental impacts need to be assessed. For example, a reduction in environmental impacts is not generally possible by just substituting synthetic fibres with natural fibres. The use-phase in transportation applications usually has a strong impact on the environmental properties. Another important aspect is the end-of-life treatment. NFRP can be incinerated but the addition of rCF would make another process necessary. Further recycling of the rCF in the hybrid laminates is theoretically possible. Such “re-recycled” rCF could be recovered in an even more deteriorated quality and used to produce milled rCF in the form that is already available today [38]. It is important to calculate the environmental impacts of all life phases of composites with a life cycle assessment (LCA); from raw material extraction, production, and the use-phase to the end-of-life treatments, and to compare them with competing materials.

Author Contributions

J.B. conceived and designed the experiments; J.B. performed the experiments; J.B., P.W. and M.W. analysed the data; J.B. wrote the paper.

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 690638 and the Special Research Plan on Civil Aircraft of Ministry for Industry and Information of the People’s Republic of China (MIIT) under Grant No MJ-2015-H-G-103.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bachmann, J.; Yi, X.; Gong, H.; Martinez, X.; Tserpes, K.; Ramon, E.; Paris, C.; Moreira, P.; Fang, Z.; Li, Y.; et al. Outlook on ecologically improved composites for aviation interior and secondary structures. CEAS Aeronaut. J. 2018, 9, 533–543. [Google Scholar] [CrossRef]

- Li, Y.; Hi, Y.; Hu, C.; Yu, Y. Microstructures and mechanical properties of natural fibers. Adv. Mater. Res. 2008, 33–37, 553–558. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. A 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibres and its composites—A review. Compos. B 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Summerscales, J.; Dissanayake, N.; Virk, A.; Hall, W. A review of bast fibres and their composites. Part 2—Composites. Compos. B 2010, 41, 1336–1344. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Tech. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypch, F. Biodegradable composites based on lignocellulosic fibers —An overview. J. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A. review. Egypt. J. Pet. 2017. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. A 2010, 806–819. [Google Scholar] [CrossRef]

- Li, Y.; Yi, X.; Xian, G. An overview of structural-functional-integrated composites based on the hierarchical microstructures of plant fibers. Adv. Compos. Hybrid. Mater. 2018, 1, 232–246. [Google Scholar] [CrossRef]

- Swolfs, Y.; Crauwels, L.; Van Breda, E. Tensile behaviour of intralayer hybrid composites of carbon fibre and self-reinforced polypropylene. Compos. A 2014, 59, 78–84. [Google Scholar] [CrossRef]

- Kretzis, G. A review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastics. Comoposites 1987, 18, 13–23. [Google Scholar] [CrossRef]

- Park, R.; Jang, J. Effect of laminate geometry on impact performance of aramid fiber/polyethylene fiber hybrid composites. J. Appl. Polym. Sci. 2000, 75, 952–959. [Google Scholar] [CrossRef]

- Pegoretti, A.; Fabbri, E.; Migliaresi, P.F. Intraply and interplay hybrid composites based on E-glass and poly(vinyl alcohol) woven fabrics: Tensile and impact properties. Polym. Int. 2004, 53, 1920–1927. [Google Scholar] [CrossRef]

- Manders, P.W.; Bader, M.G. The strength of hybrid glass/carbon fibre composites. J. Mater. Sci. 1981, 16, 2233–2245. [Google Scholar] [CrossRef]

- Indra Reddy, M.; Anil Kumar, M.; Rama Bhadri Raju, C. Tensile and Flexural properties of Jute, Pineapple leaf and Glass Fiber Reinforced Polymer Matrix Hybrid Composites. Mater. Today 2018, 5, 458–462. [Google Scholar] [CrossRef]

- Lützkendorf, R.; Reussmann, T.; Danzer, M. Hybride Verbundwerkstoffe mit recycelten Carbonfasern. Lightweightdesign 2017, 2, 22–26. [Google Scholar] [CrossRef]

- Flynn, J.; Amiri, A.; Ulven, C. Hybridized carbon and flax fiber composites for tailored performance. J. Mat. Des. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Adekunle, K.; Cho, S.W.; Ketzscher, R.; Skrifvars, M. Mechanical Properties of Natural Fiber Hybrid Composites Based on Renewable Thermoset Resins Derived from Soybean Oil, for use in technical applications. J. Appl. Polym. Sci. 2012, 124, 4530–4541. [Google Scholar] [CrossRef]

- Cicala, G.; Pergolizzi, E.; Piscopo, F.; Carbone, D.; Recca, G. Hybrid composites manufactured by resin infusion with a fully recyclable bioepoxy resin. Compos. B 2018, 132, 69–79. [Google Scholar] [CrossRef]

- Murdani, A.; Hadi, A.; Amrullah, U.S. Flexural Properties and Vibration Behavior of JuteGlassCarbon Fiber Reinforced Unsaturated Polyester Hybrid Composites for Wind Turbine Blade. Key Eng. Mater. 2017, 748, 62–68. [Google Scholar] [CrossRef]

- Witten, E.; Kraus, T.; Kühnel, M. Composites-Marktbericht 2015: Marktentwicklungen, Trends, Ausblicke und Herausforderungen. CCeV and AVK, 21 September 2015. Available online: http://www.avk-tv.de/files/20151214_20150923_composites_marktbericht_gesamt.pdf (accessed on 25 June 2018).

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P. Recycling of composite materials. Chem. Eng. Process. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Carberry, W. Airplane Recycling Efforts Benefit Boeing Operators. Available online: http://www.boeingvideo.com/commercial/aeromagazine/articles/qtr_4_08/pdfs/AERO_Q408_article02.pdf (accessed on 30 June 2018).

- Verma, S.; Balasubramamaniam, B.; Gupta, R.K. Recycling, reclamation and re-manufacturing of carbon fibres. Curr. Option Green Sus. Chem. 2018, 13, 86–90. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Mysore Prabhakara, H.; Bramer, E.A.; Dierkes, W. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Rybicka, J.; Tiwari, A.; Leeke, G.A. Technology readiness level assessment of composites recycling technologies. J. Clean. Prod. 2016, 112, 1001–1012. [Google Scholar] [CrossRef]

- Gardiner, G. Recycled Carbon Fiber Update: Closing the CFRP Lifecycle Loop. Compos. Tech. 2014. Available online: https://www.compositesworld.com/articles/recycled-carbon-fiber-update-closing-the-cfrp-lifecycle-loop (accessed on 25 June 2018).

- Jesson, D.A.; Watts, J.F. The Interface and Interphase in Polymer Matrix Composites: Effect on Mechanical Properties and Methods for Identfication. Polym. Rev. 2012, 52, 321–354. [Google Scholar] [CrossRef]

- Fischer, H.; Schmid, H.G. Quality Control for Recycled Carbon Fibres. Kunststoffe Intern. 2013, 11, 68–71. [Google Scholar]

- Illing-Günther, H.; Hofmann, M.; Gulich, B. Nonwovens made of recycled carbon fibres as basic material for composites. In Proceedings of the 7th International CFK-Valley Stade Convention “Latest Innovations ins CFPR Technology”, Stade, Germany, 11–12 June 2013. [Google Scholar]

- Recycling Today. ELG Carbon Fibre Ltd. to Highlight Role of Recycled Carbon Fibre. 2016. Available online: http://www.recyclingtoday.com/article/elg-carbon-fibre-jec-world-2016-exhibit (accessed on 31 August 2018).

- Albrecht, W.; Fuchs, H.; Kittelmann, W. Nonwoven Fabrics: Raw Materials, Manufacture, Applications, Characteristics, Testing Processes; Wiley-VCH Verlag GmbH & Co. KGkA: Germany, 2015; Available online: https://onlinelibrary.wiley.com/doi/book/10.1002/3527603344 (accessed on 30 June 2018).

- Lütke, C.; Rübsam, U.; Schlüter, T.; Schröter, A.; Gloy, Y.S. Sustainability in Luxury Textile Applications: A Contradiction or a New Business Opportunity. In Handbook of Sustainable Luxury Textiles and Fashion; Gardetti, M.A., Muthu, S.S., Eds.; Springer: Singapore, 2015; pp. 121–143. ISBN 978-981-287-632-4. [Google Scholar]

- Li, Y.; Ma, H.; Shen, Y.; Li, Q.; Zheng, Z. Effects of resin inside fiber lumen on the mechanical properties of sisal fiber reinforced composites. Compos. Sci. Technol. 2015, 108, 32–40. [Google Scholar] [CrossRef]

- Pupure, L.; Varna, J.; Joffe, R.; Berthold, F.; Miettinen, A. Mechanical properties of natural fiber composites produced using dynamic sheet former. Wood Mater Sci. Eng. 2018. [Google Scholar] [CrossRef]

- Composites World 2016. Recycled Carbon Fiber: Its Time Has Come. Available online: https://www.compositesworld.com/columns/recycled-carbon-fiber-its-time-has-come (accessed on 8 September 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).