Numerical Investigation on Windback Seals Used in Aero Engines

Abstract

:1. Introduction

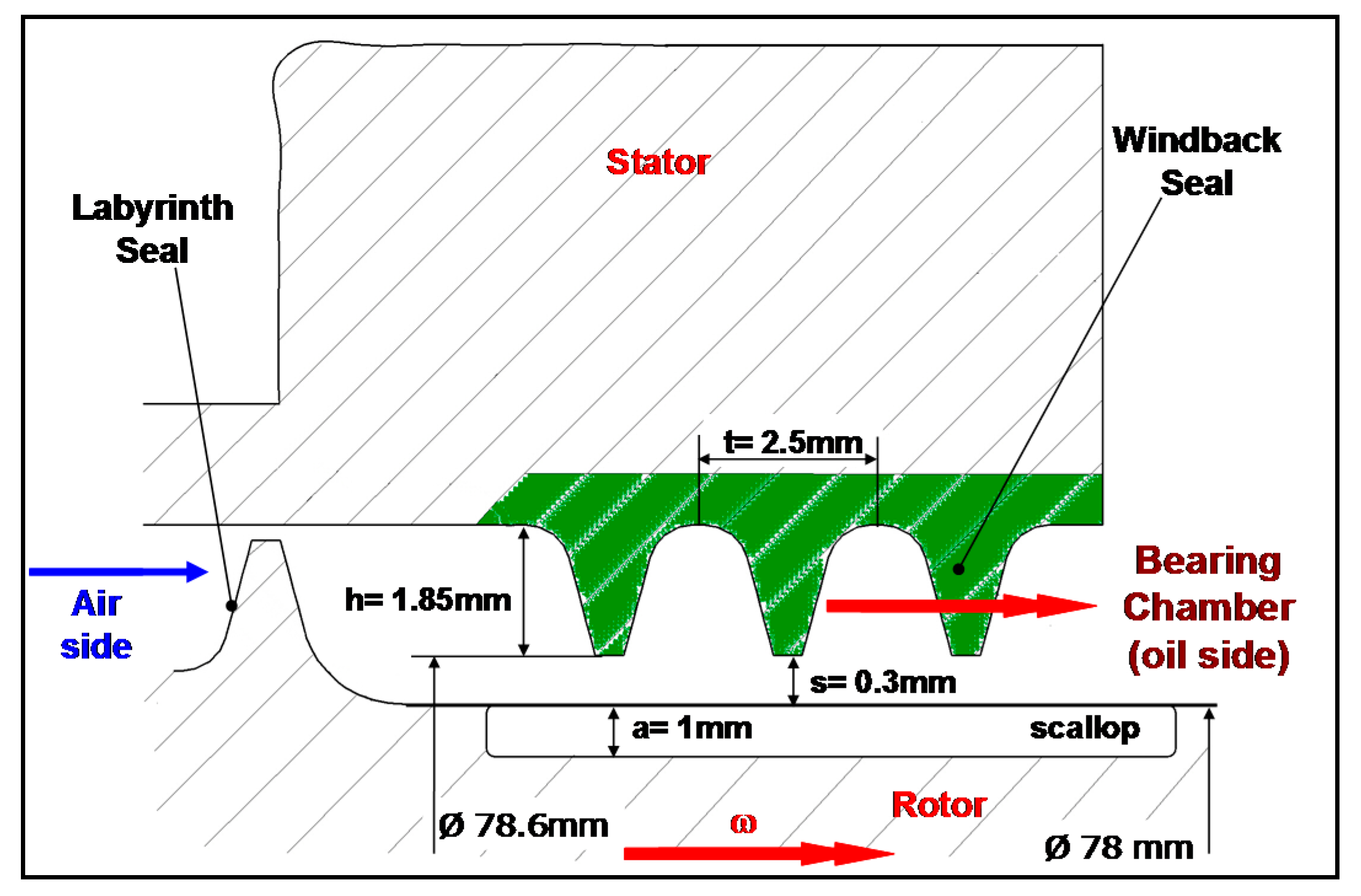

2. Seal Geometries and Operating Conditions

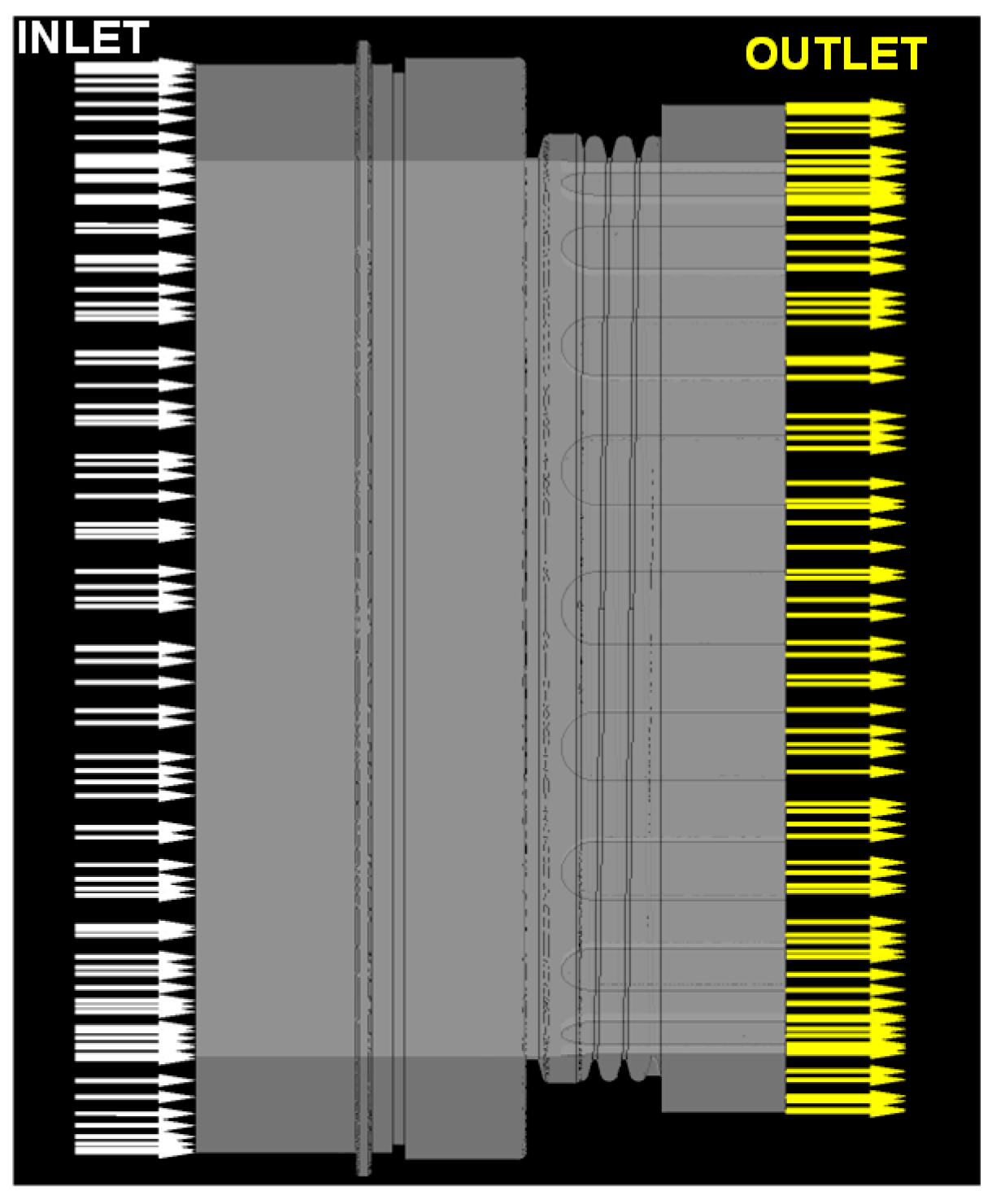

3. CFD Simulation

4. State of the Art

- C1 = 6.22819 × 10−8

- C2 = −5.82396 × 10−5

- C3 = 0.017891931

- C4 = −1.986063294

- A = 52.4 and b = −61.94

- a = (0.06946 + 34550s1.5)0.5

- b = (−9.09 × 10−4 + 3.569 × 10−11/s2)

- co = −7.475 × 10−4 − 1.372 × 10−4 × LogN(s)

5. Results

- (1)

- flow evaluation as a function of the operating conditions for different windback seal designs

- (2)

- oil particle ingestion downstream of the windback seal and particle tracing in order to evaluate the ability of the seal to repulse oil

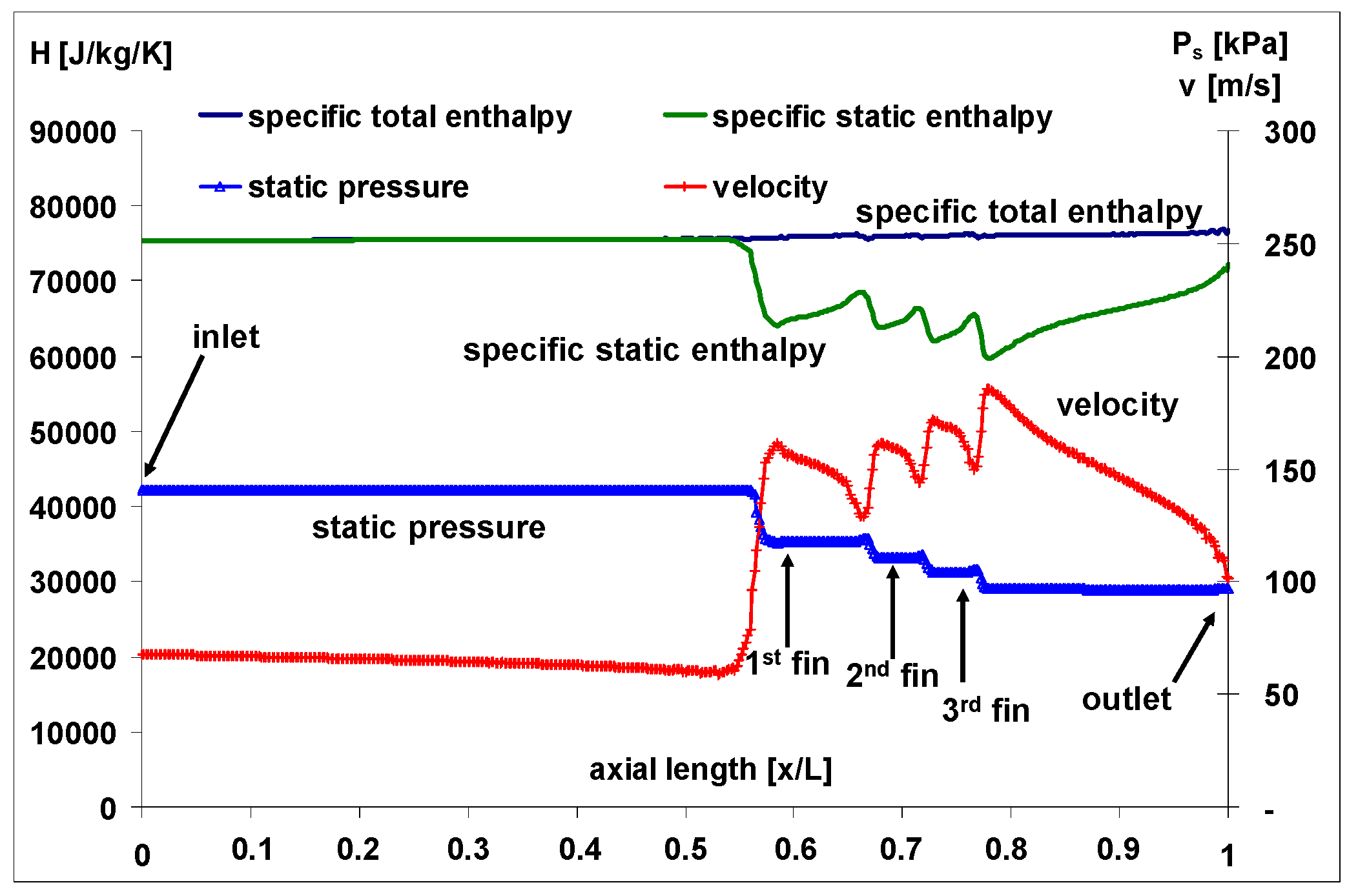

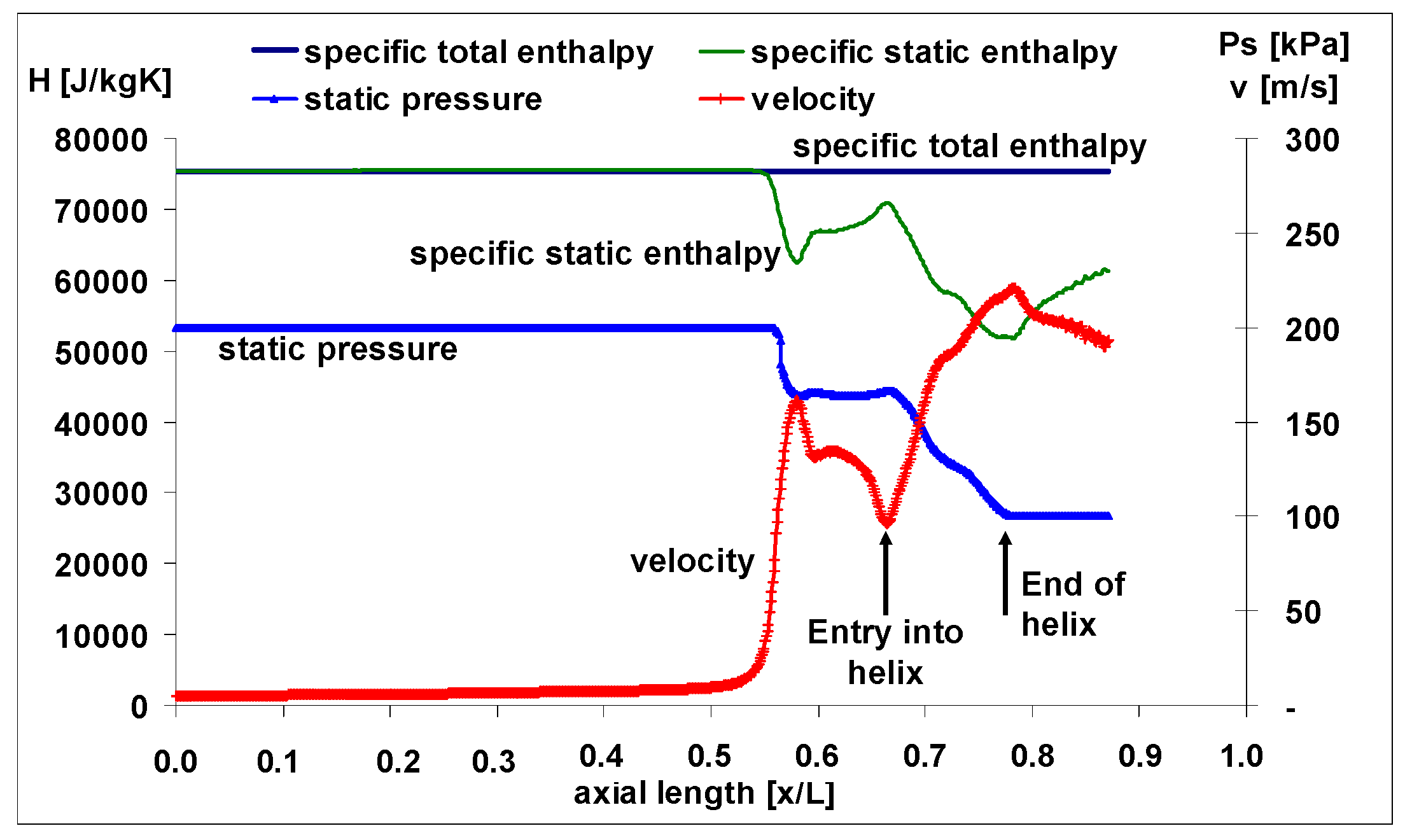

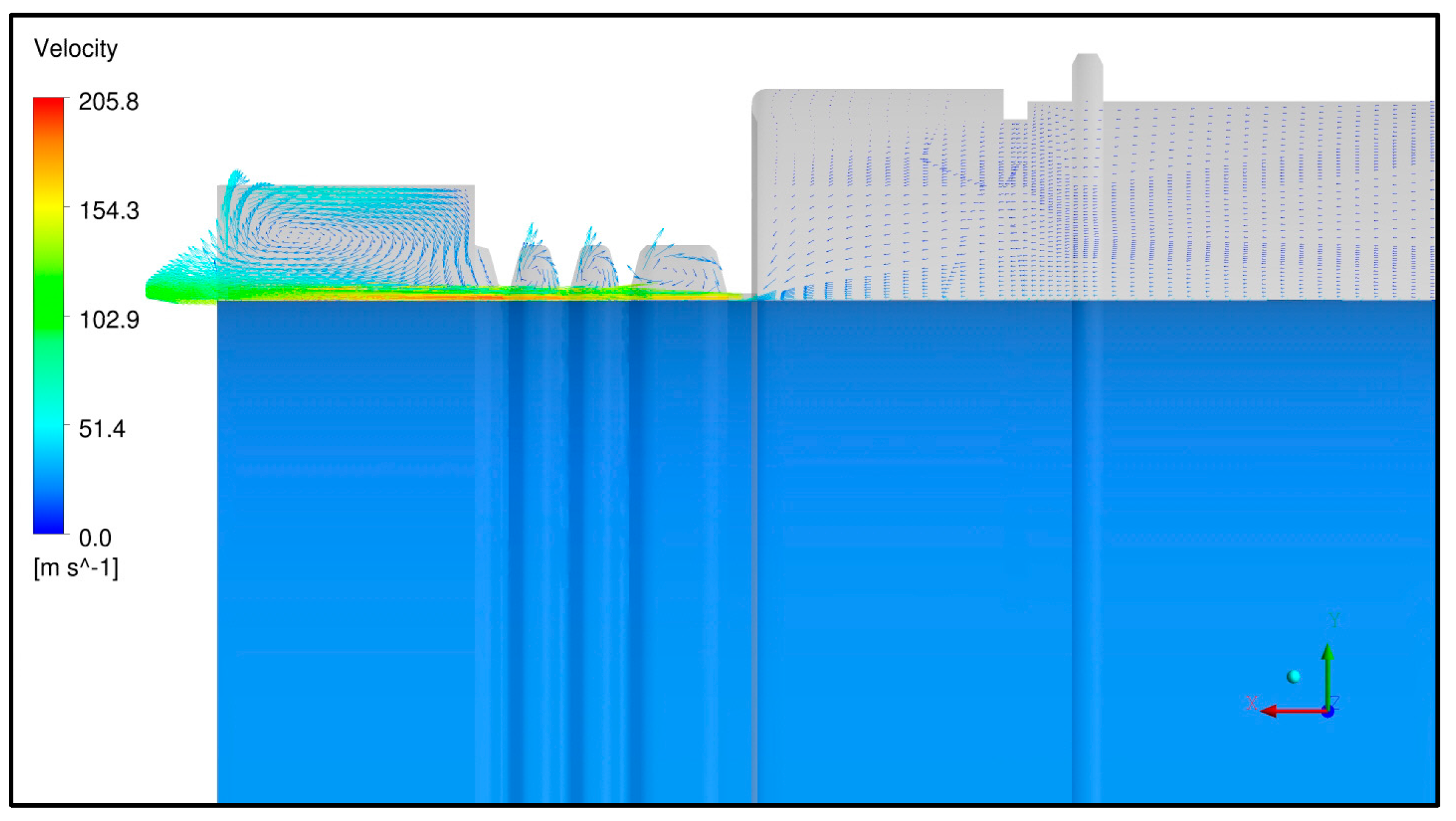

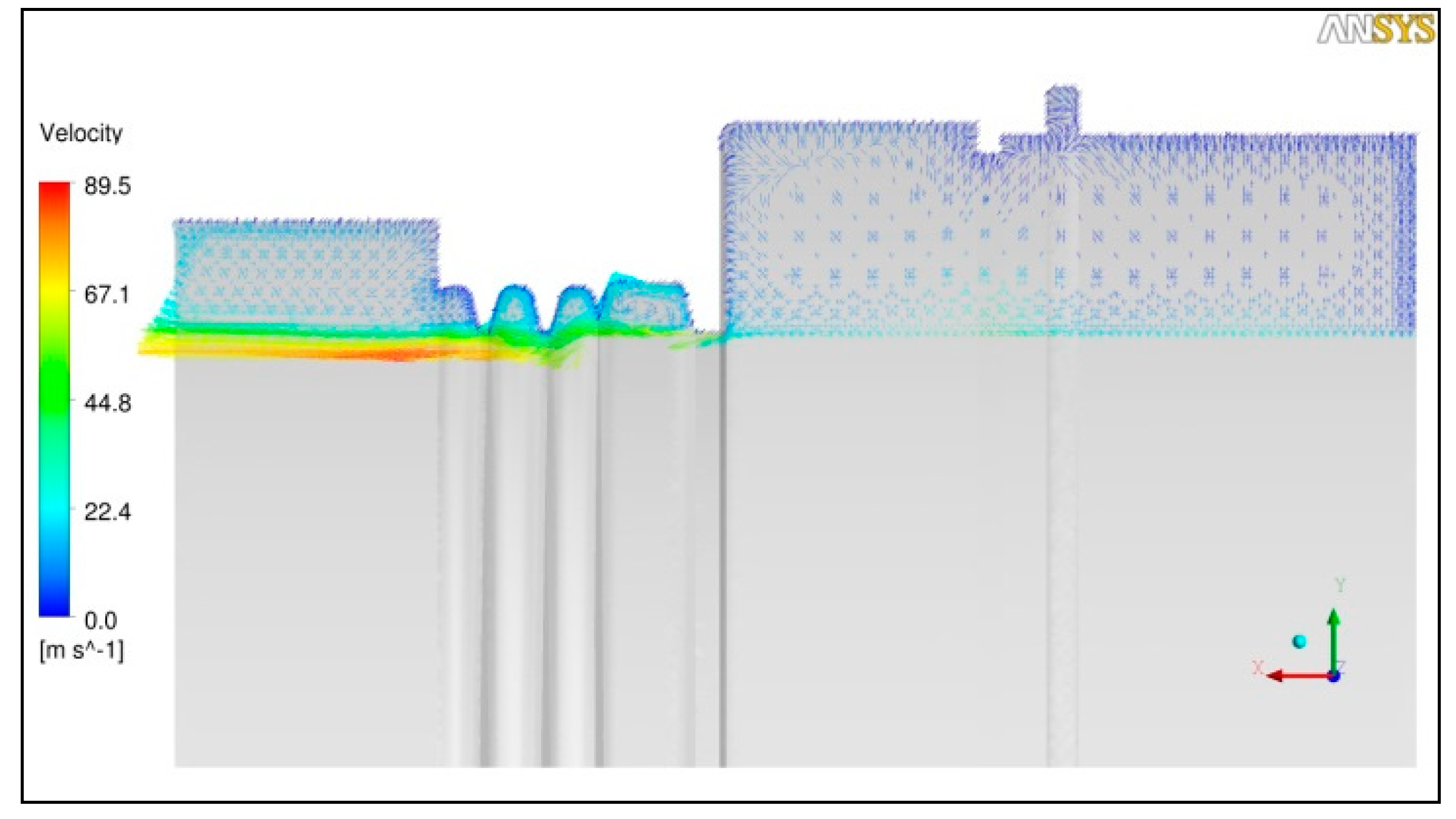

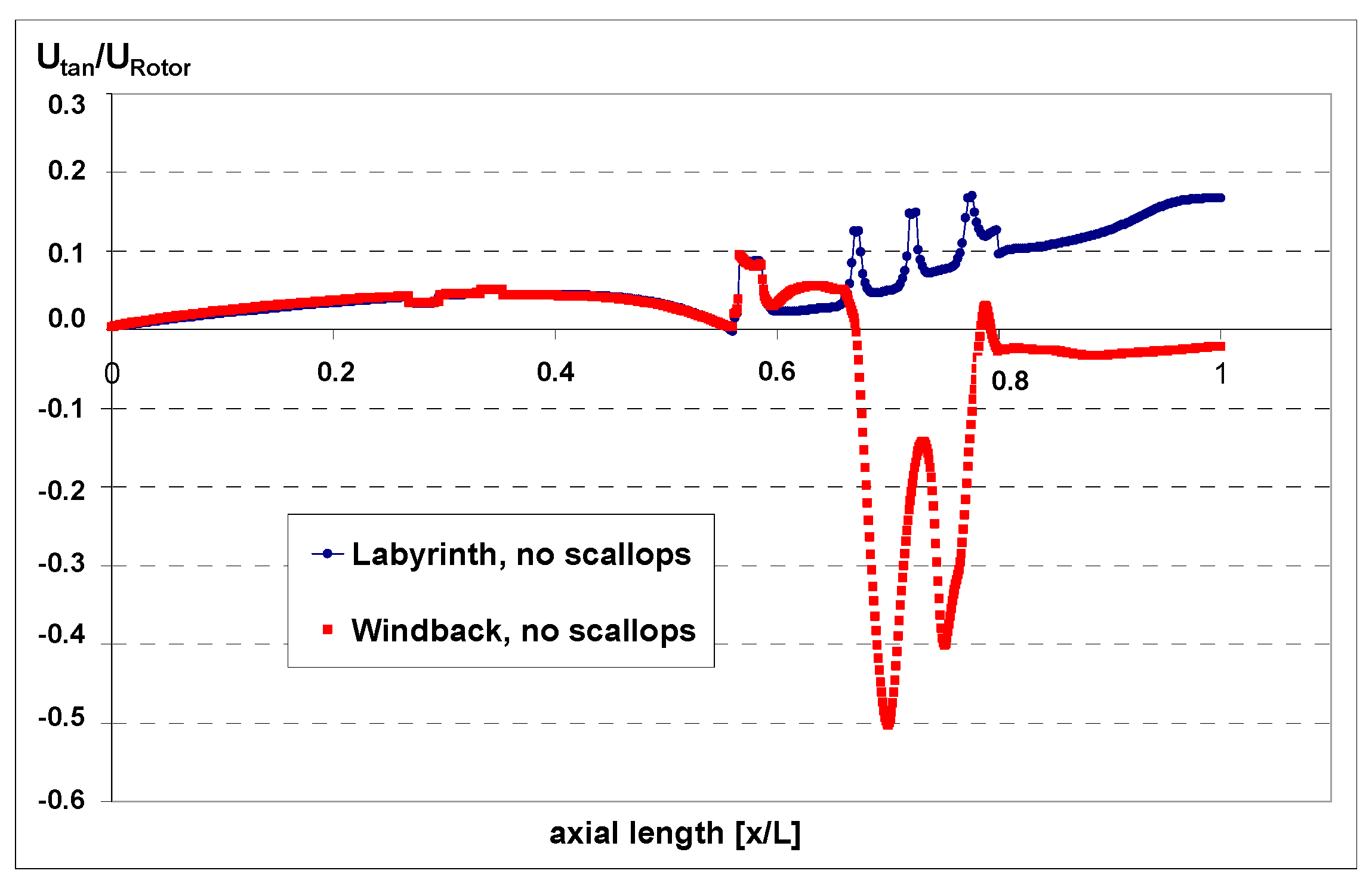

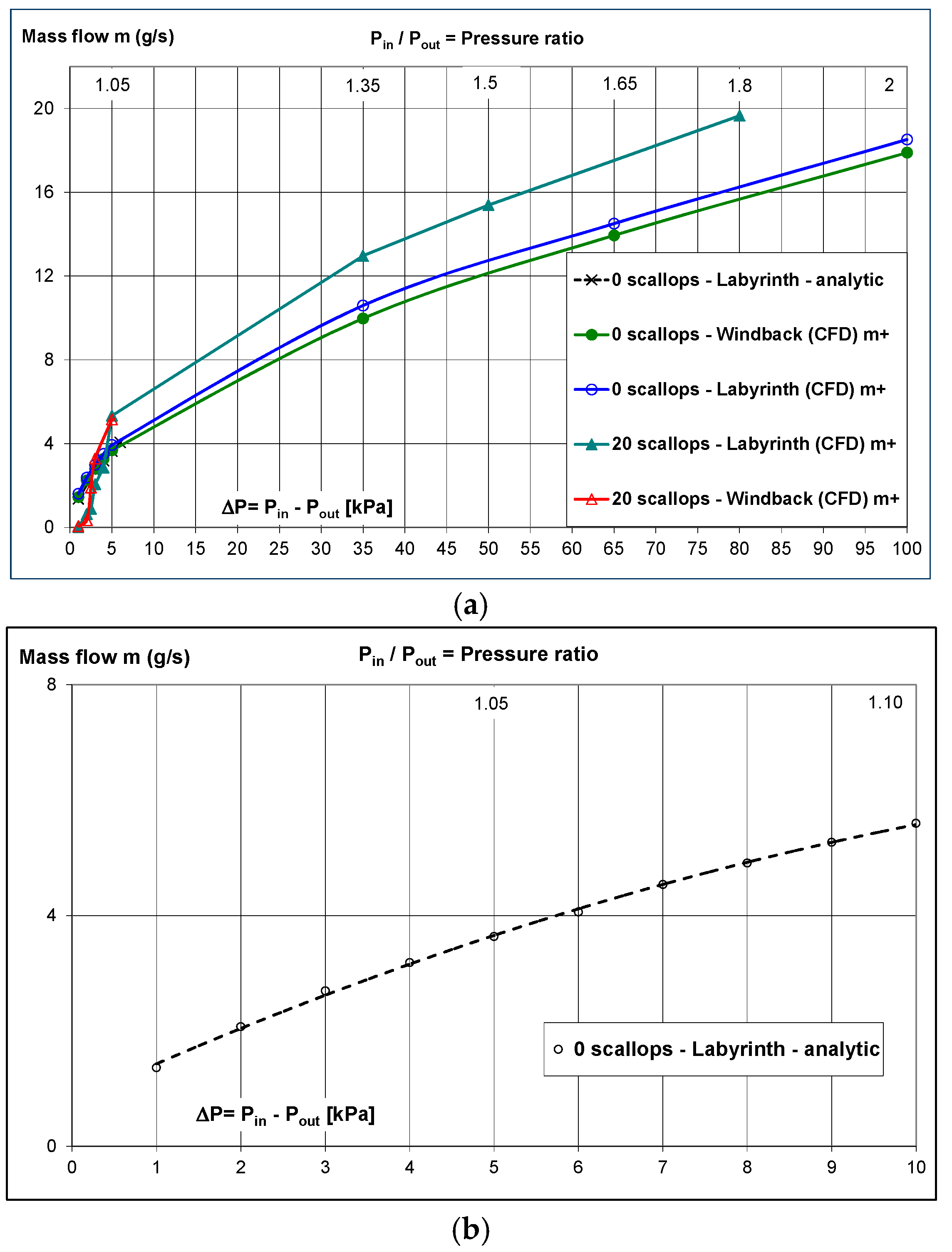

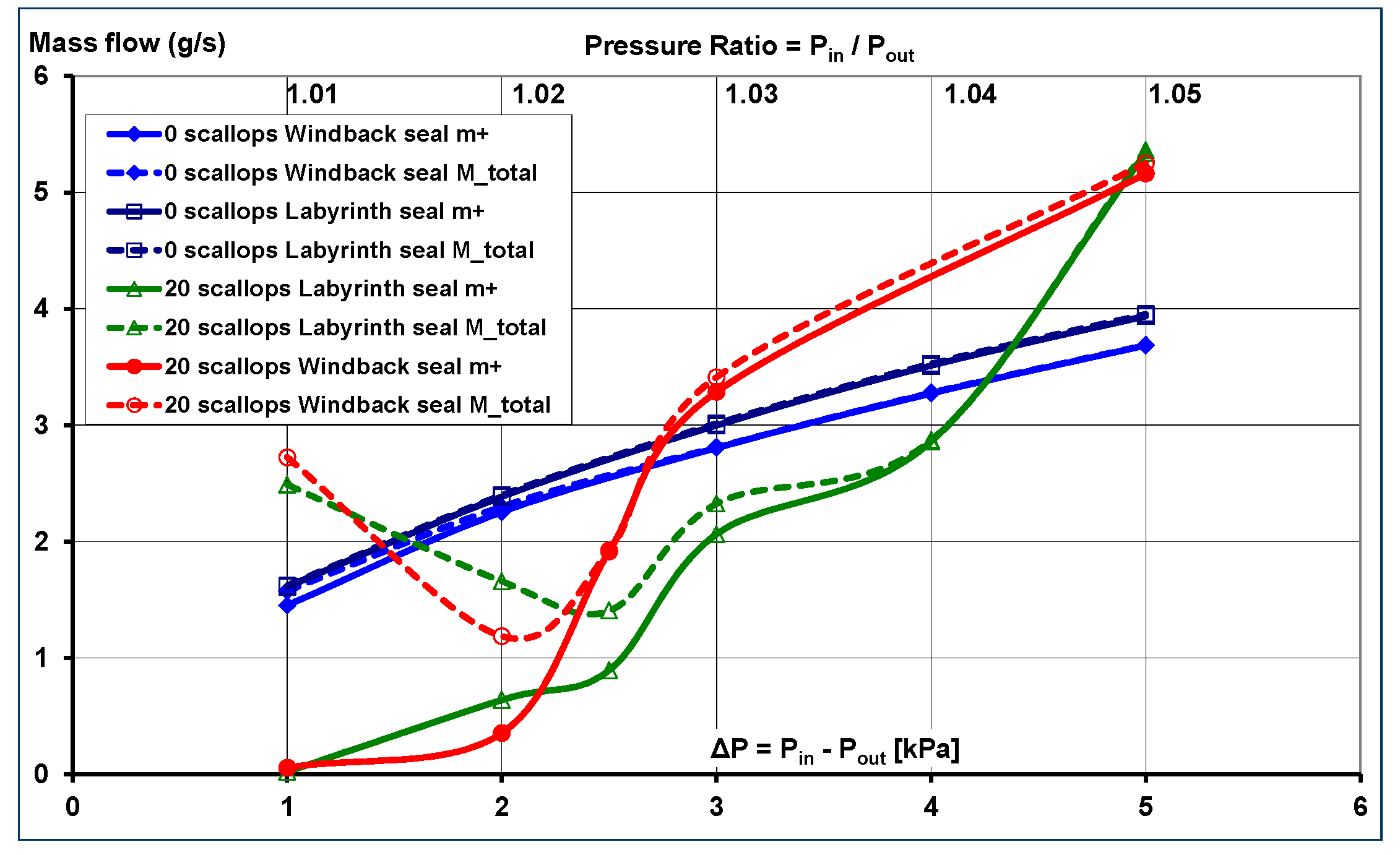

5.1. Comparison between Windback and Labyrinth Seal with a Scallop Free (Smooth) Rotor

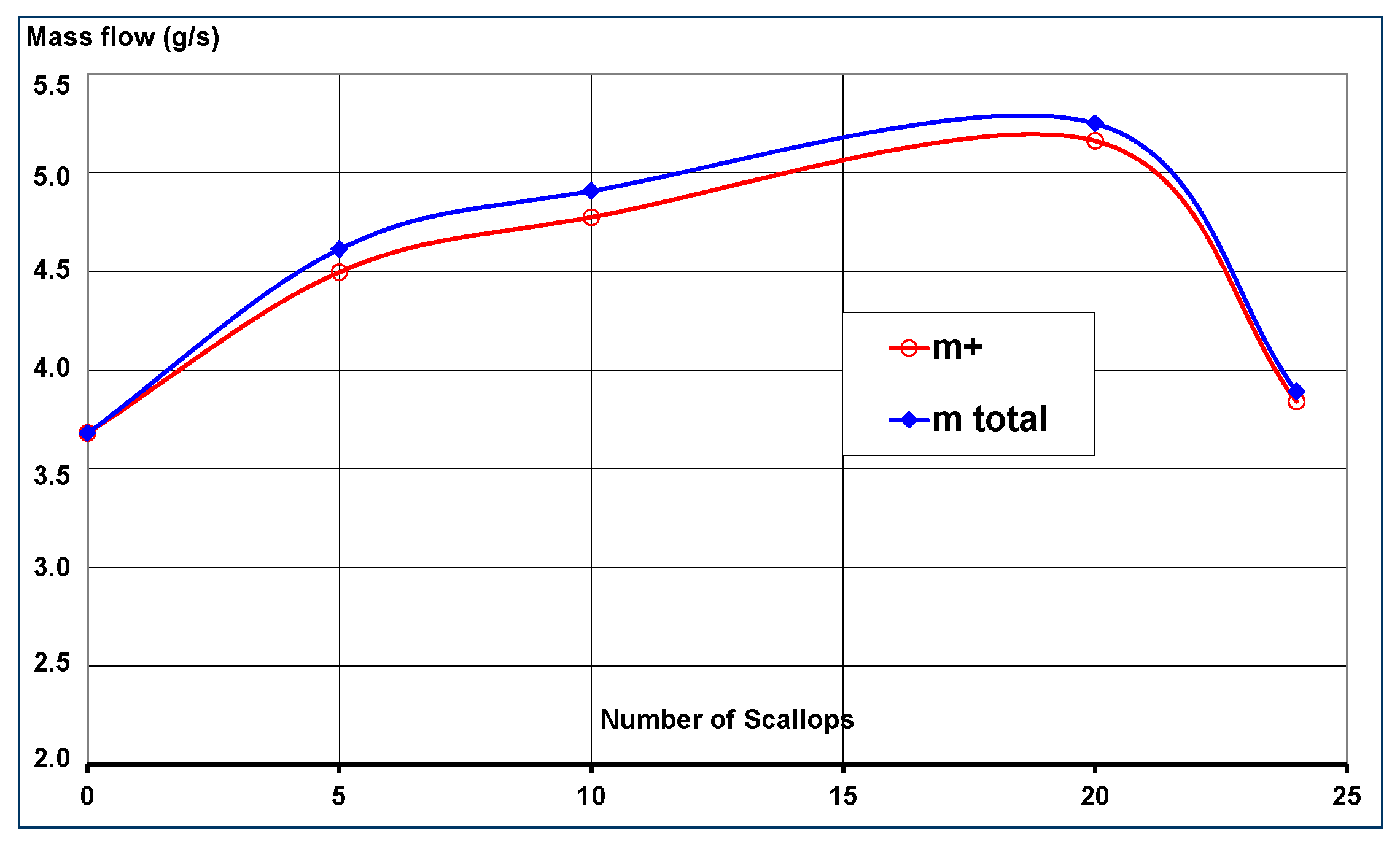

5.2. Impact of Rotor Scallops

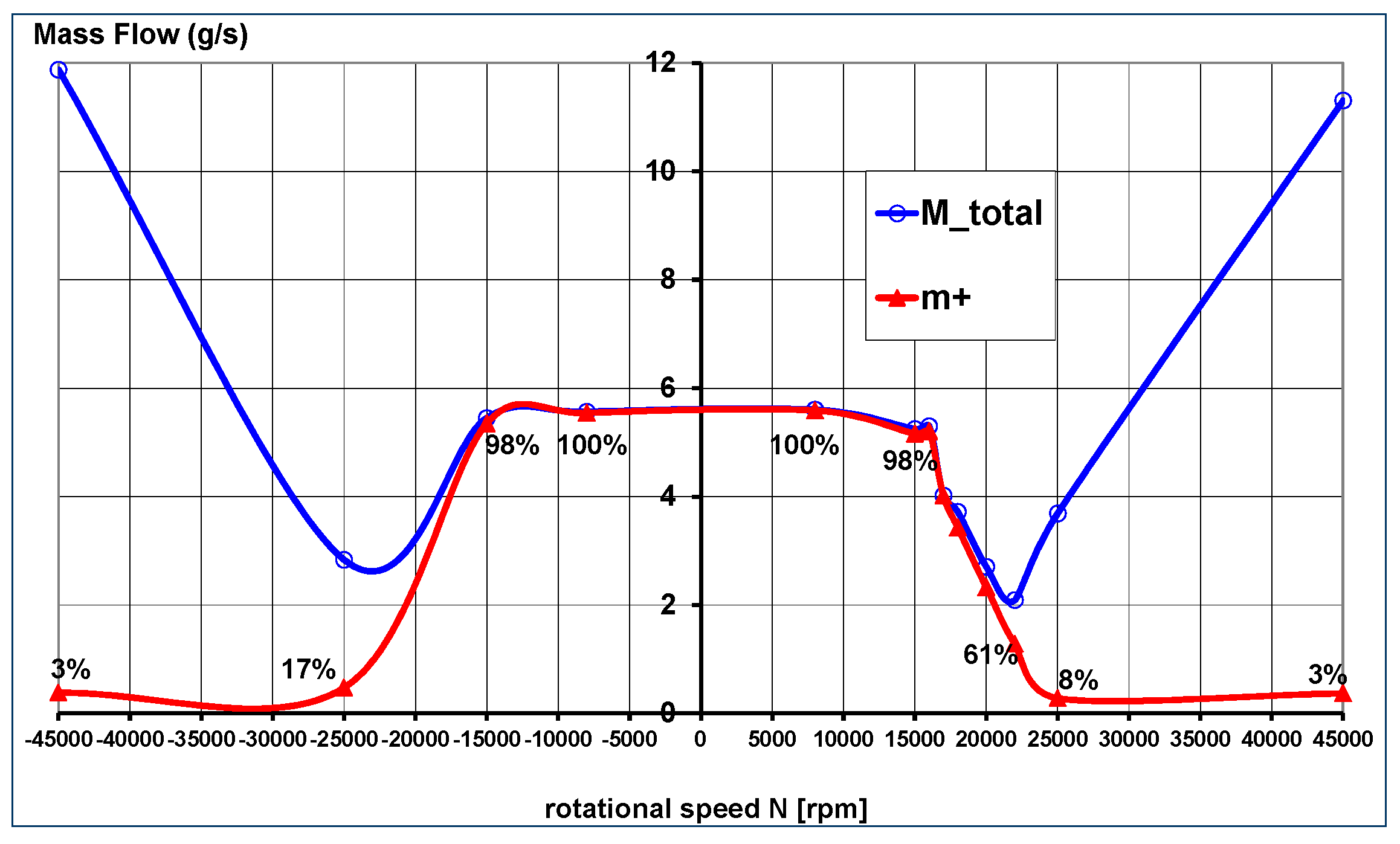

5.3. Impact of the Rotational Speed and Direction

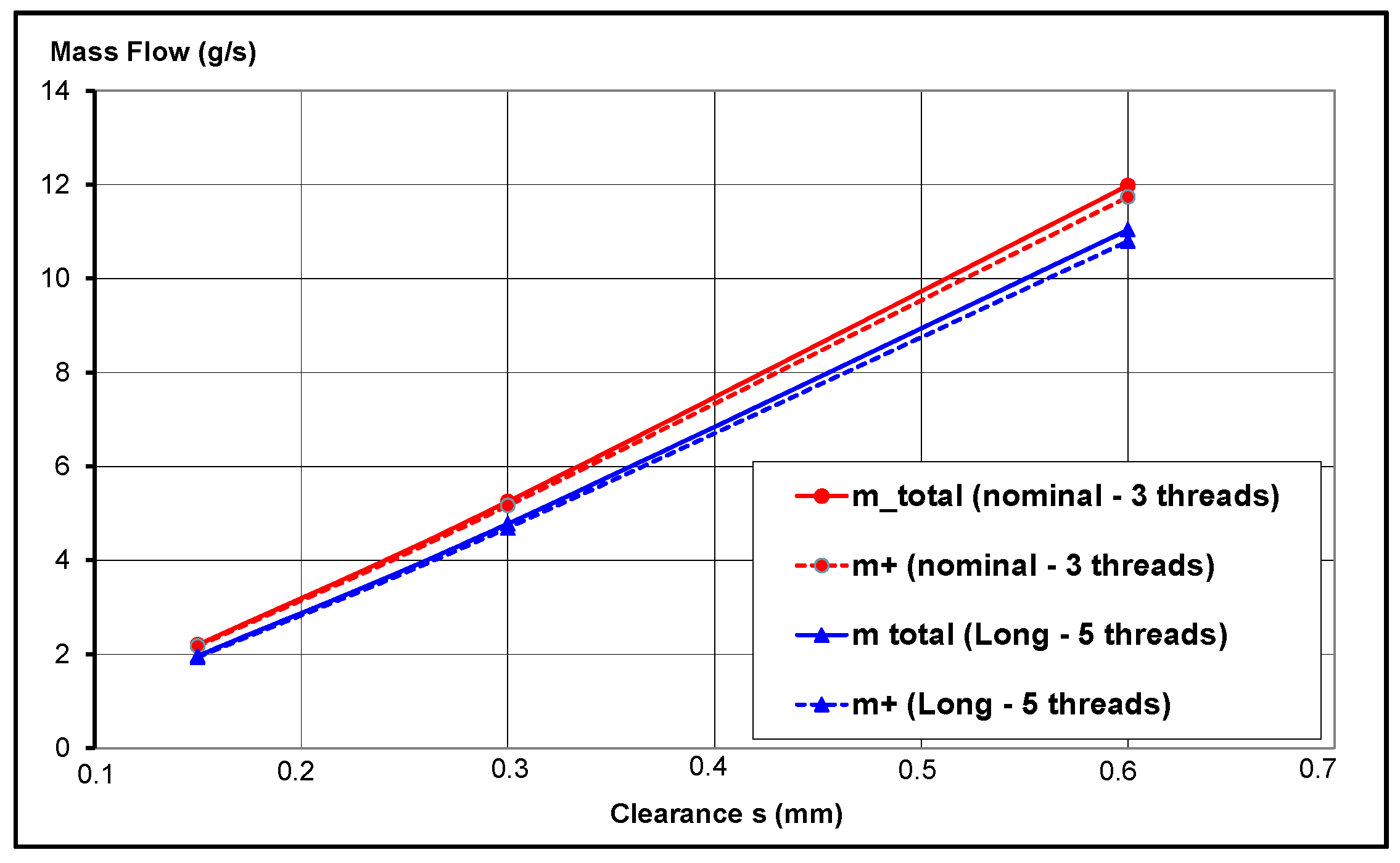

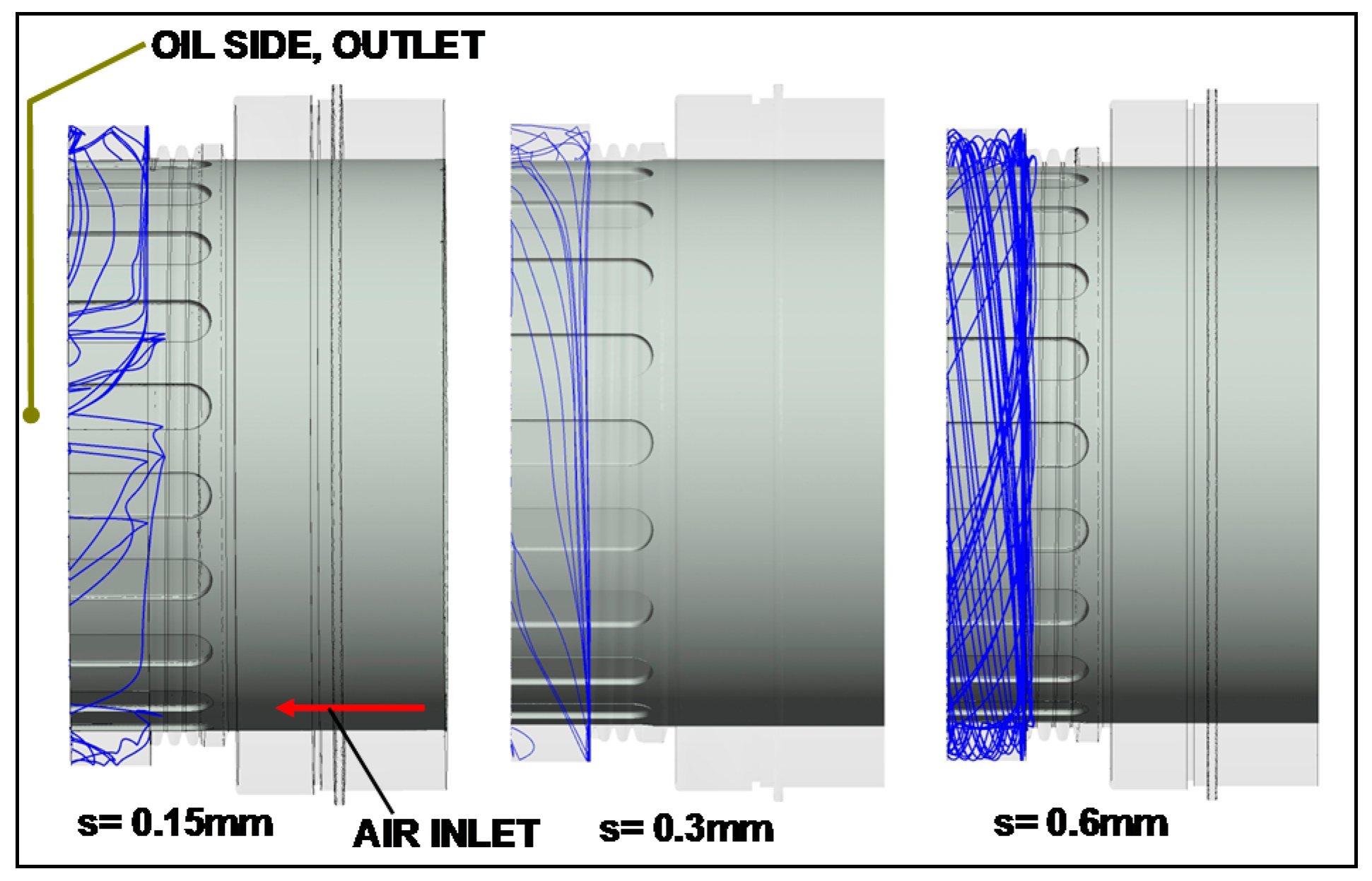

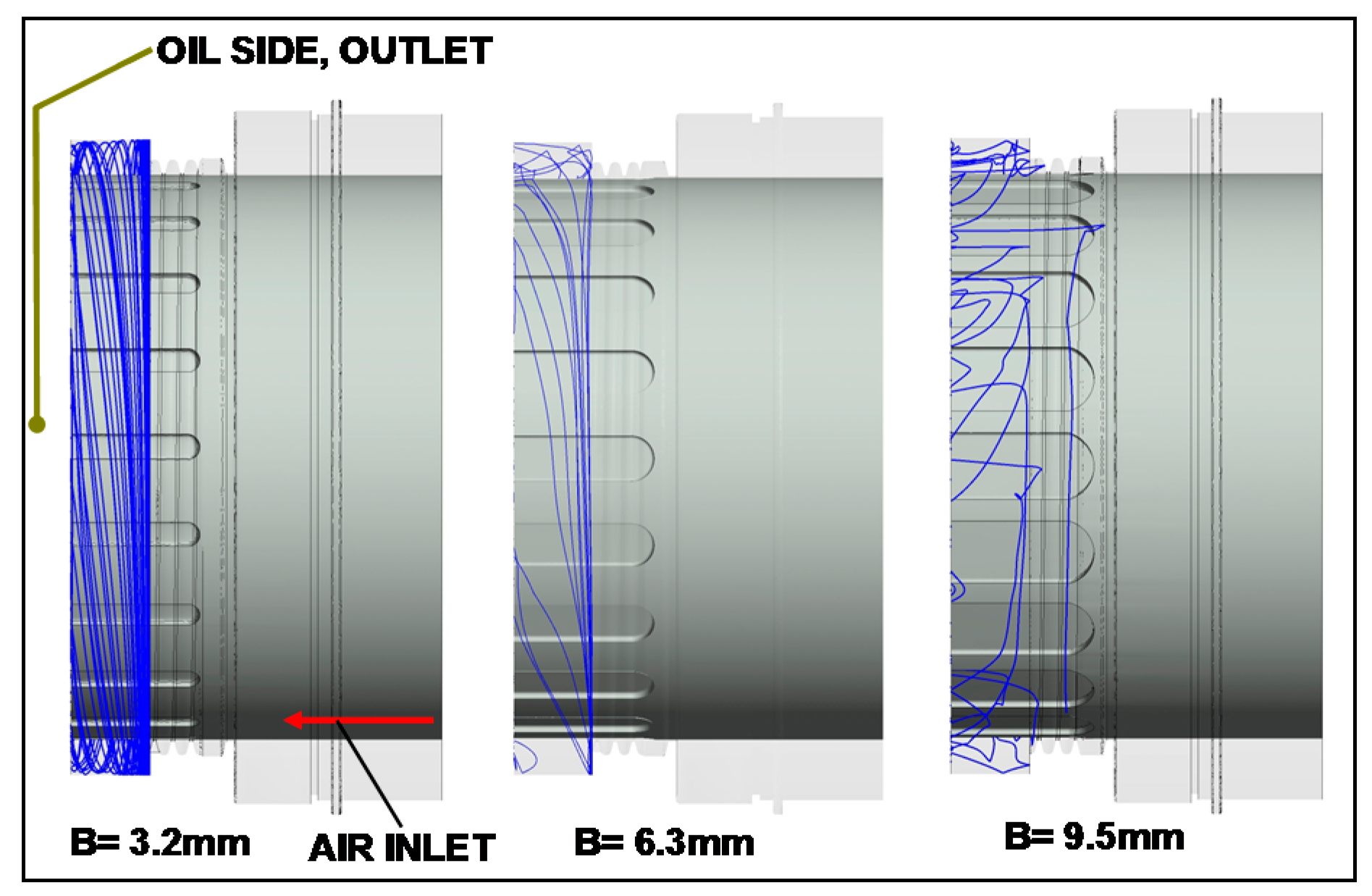

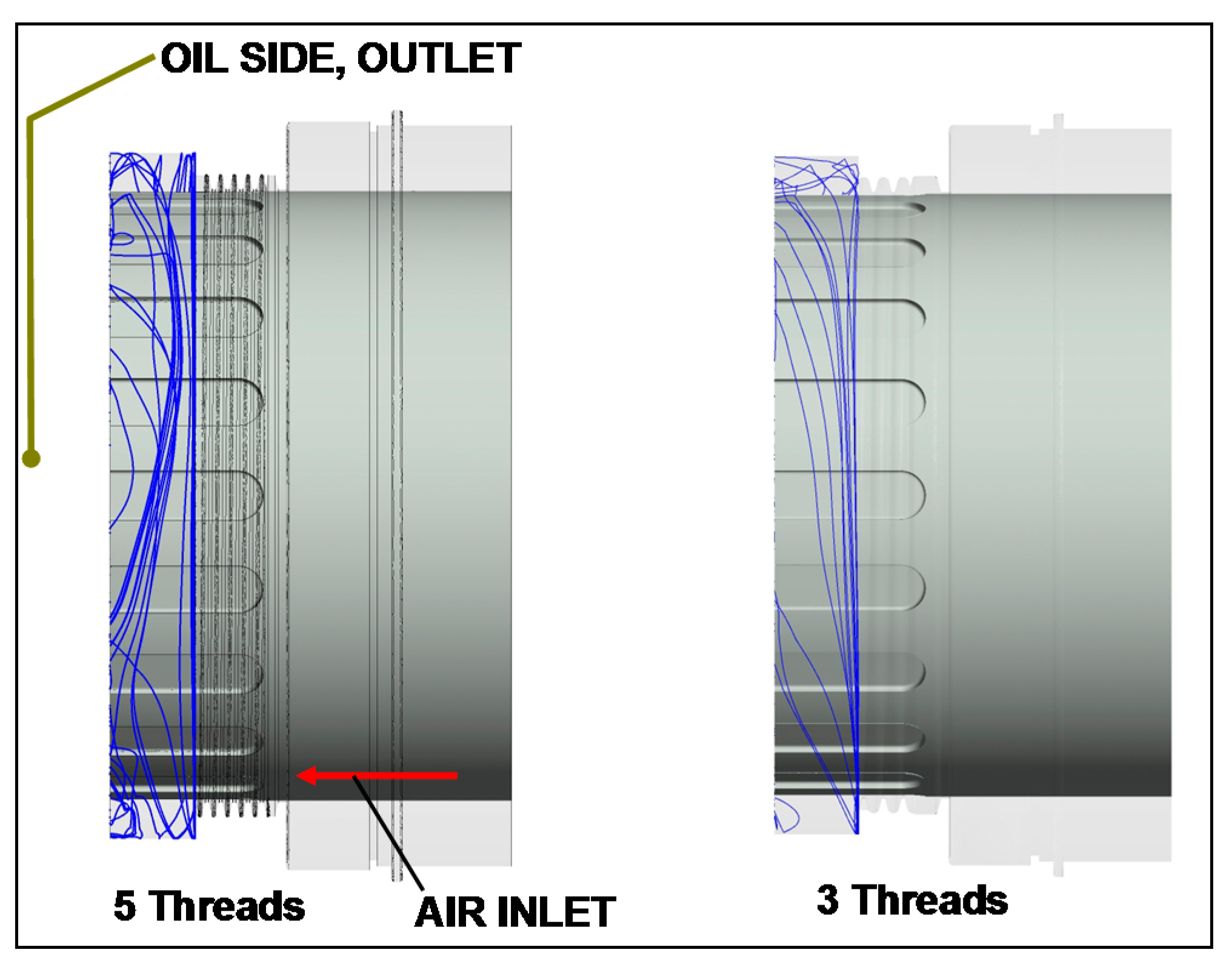

5.4. Impact of the Length of the Helical Thread and of the Clearance

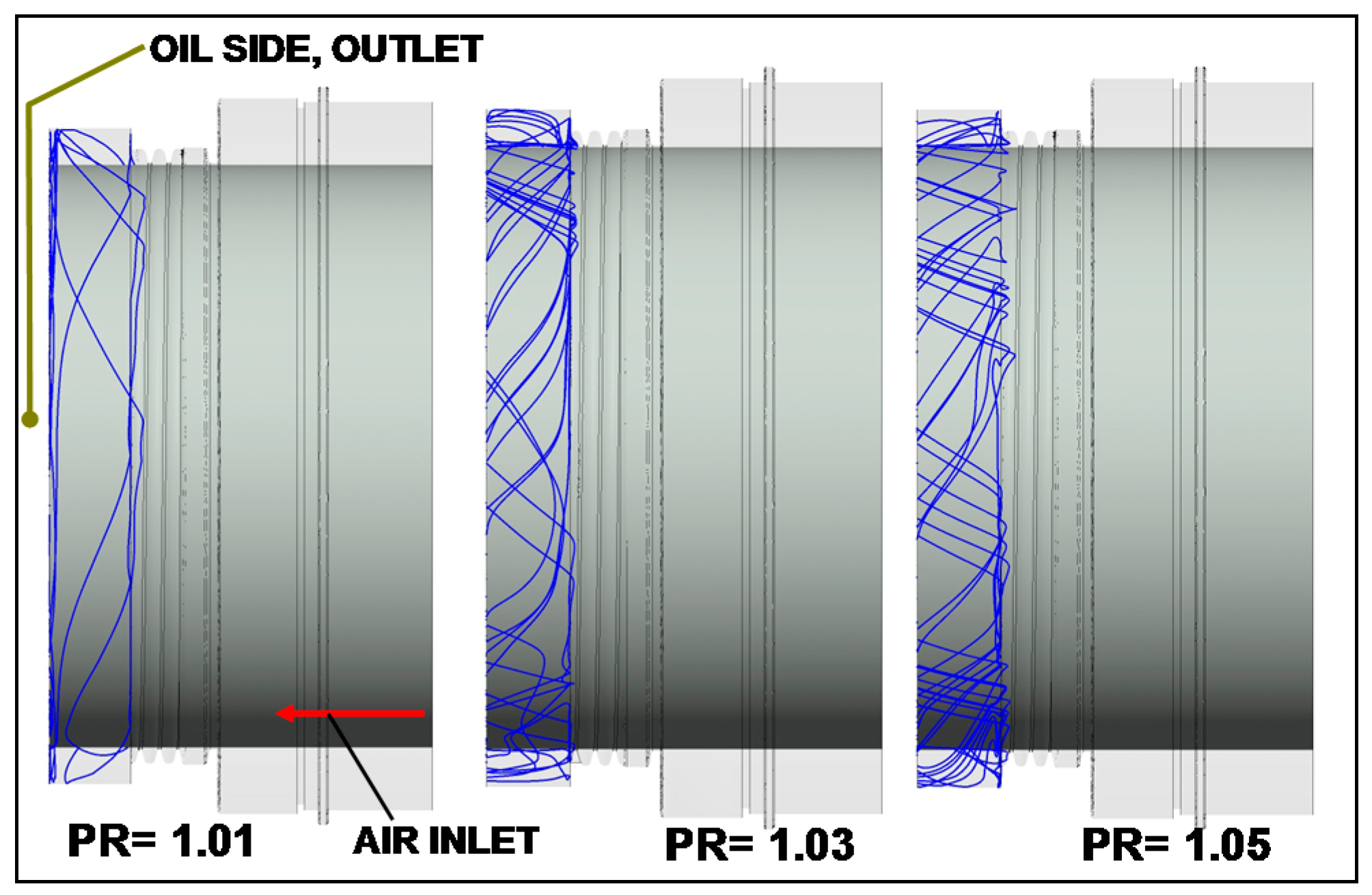

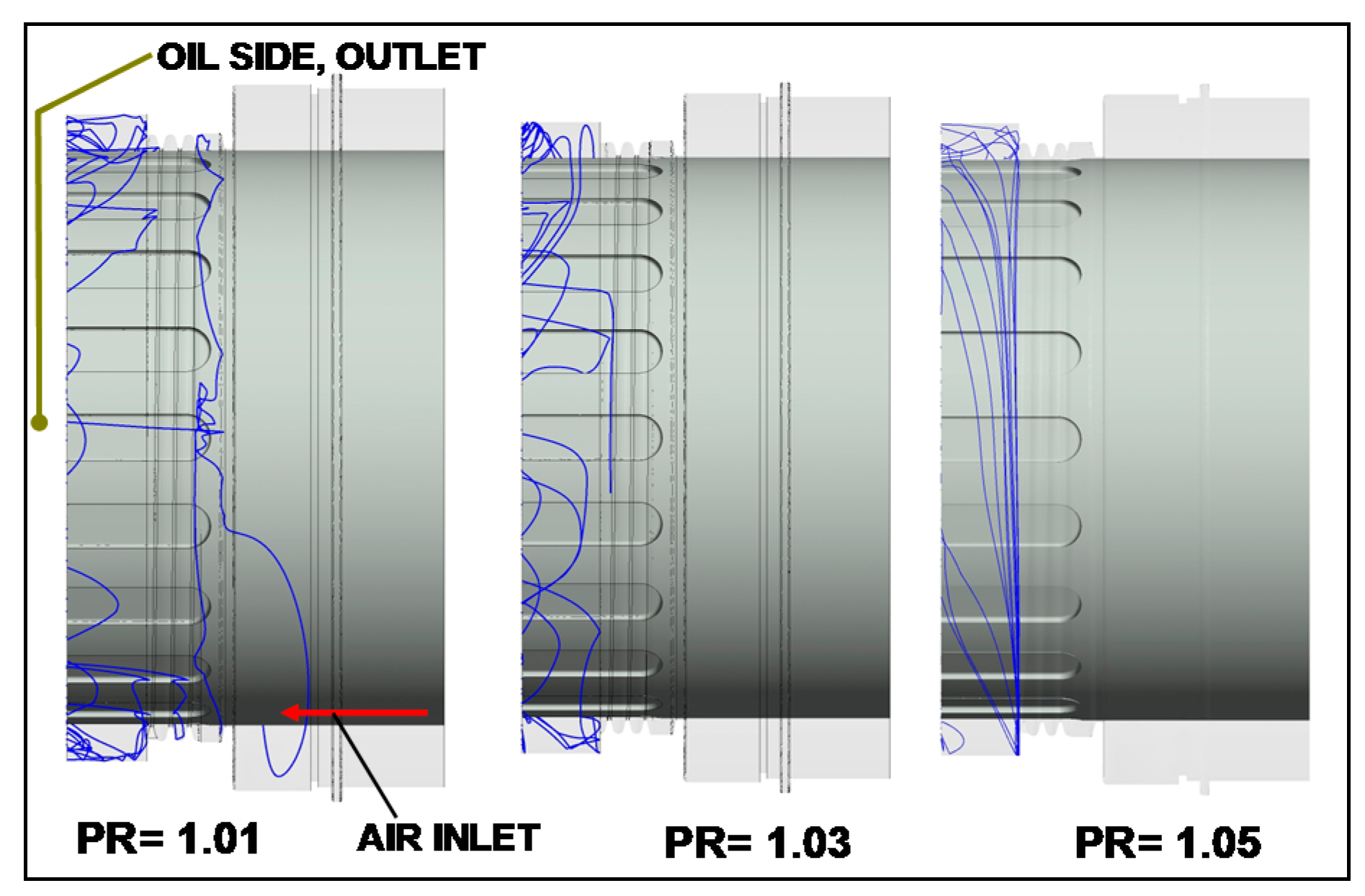

5.5. Oil Particle Tracing

6. Conclusions

- (1)

- A comparison of results between this CFD survey and Morrison et al. has shown deviations in mass flow rate and discharge coefficient.

- (2)

- At very low pressure ratios backflow is a problem particularly when scallops are engraved in the rotor.

- (3)

- No evidence for backflow has been observed for a windback seal combined with rotor without scallops. This is an issue which requires further investigation.

- (4)

- Nevertheless, scallops in the rotor increase the total mass flow rate through the windback seal.

- (5)

- There are limitations concerning scallop number and size, seal clearance and rotational speeds. Increase in scallop size compared to the baseline has had a negative impact on the seal’s performance. Increase or decrease in tip clearance showed no performance deterioration. Increase in rotor speed has led to a high instability and backflow above 22,000 rpm. Nevertheless, further investigations on these issues are necessary.

- (6)

- Operational pressure ratio should be above 1.05 for unproblematic seal operation. Nevertheless, even at a pressure ratio of 1.01 no massive oil migration out of the (baseline) seal was documented. This is an important information for the designer.

- (7)

- Further numerical and also rig investigations are planned in order to investigate further design and operational aspects of windback seals.

7. Outlook

Author Contributions

Conflicts of Interest

Nomenclature

| A | Area between the fin and the stator | m2 |

| a | Scallop depth | mm |

| B | Scallop width | mm |

| b | Fin tip width | mm |

| CAD | Computer Aided Design | |

| Cd | Discharge Coefficient | |

| D | Fin tip diameter | mm |

| d | Rotor diameter | mm |

| H | Enthalpy | J/kg K |

| h | Fin height | mm |

| kH | Hodkinson carry over factor | |

| kc | correction for carry over factor | |

| L | Total length of CFD entity | mm |

| Ls | Scallop length | mm |

| m+ | Effective mass flow rate | g/s |

| through seal | ||

| mair | Air mass flow rate | g/s |

| mtotal | Total mass flow rate | g/s |

| N | Rotational speed | rpm |

| Nt | Number of threads | |

| Ns | Number of scallops | |

| n | Number of fins | |

| P | Pressure | Pa |

| PR | Pressure Ratio | |

| Ps | Static pressure | Pa |

| Pt | Total pressure | Pa |

| R | Gas constant (air:287) | J/kg K |

| Re | Reynolds number | |

| S | Entropy | J/kg |

| s | Fin/Rotor clearance | mm |

| Tt | Total temperature | K |

| t | Pitch | mm |

| Utan | Tangential component of the velocity | m/s |

| URotor | Rotor circumferential | m/s |

| Velocity = π N d/60 | ||

| y | distance to node | mm |

| y+ | non-dimensional wall distance | |

| x | Axial coordinate | mm |

| Greek letters | ||

| γ | Particle diameter | mm |

| τw | Wall shear stress | N/m2 |

References

- Morisson, G.; Al-Ghasem, A. Experimental and Computational analysis of a gas compressor Windback seal. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007. [Google Scholar]

- Lim, C.H. A Numerical and Experimental Study of Windback Seals. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2009. [Google Scholar]

- ANSYS Inc. ANSYSVR CFX, release 11.0; ANSYS Inc.: Canonsburg, PA, USA, 2010.

- Schiller, L.; Naumann, Z. A Drag coefficient correlation. Z. Ver. Dtsch. Ing. 1935, 77, 318–320. [Google Scholar]

- Zimmermann, H.; Wolff, K.H. Air System Correlations: Part 1—Labyrinth Seals. In Proceedings of the ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition, Stockholm, Sweden, 2–5 June 1998. [Google Scholar]

- Hodkinson, B. Estimation of the leakage through a labyrinth gland. Proc. Inst. Mech. Eng. 1940, 141, 283–288. [Google Scholar] [CrossRef]

- Kutz, K.J.; Speer, T.M. Simulation of the Secondary Air System of Aero Engines. In Proceedings of the ASME 1992 International Gas Turbine and Aeroengine Congress and Exposition, Cologne, Germany, 1–4 June 1992. [Google Scholar]

- Farrall, M.; Simmons, K.; Hibberd, S. Experimental and numerical investigation of shear and gravity driven oil films in aero-engine bearing chambers. In Proceedings of the ASME Turbo Expo 2004: Power for Land, Sea, and Air, Vienna, Austria, 14–17 June 2004. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Flouros, M.; Cottier, F.; Hirschmann, M.; Salpingidou, C. Numerical Investigation on Windback Seals Used in Aero Engines. Aerospace 2018, 5, 12. https://doi.org/10.3390/aerospace5010012

Flouros M, Cottier F, Hirschmann M, Salpingidou C. Numerical Investigation on Windback Seals Used in Aero Engines. Aerospace. 2018; 5(1):12. https://doi.org/10.3390/aerospace5010012

Chicago/Turabian StyleFlouros, Michael, Francois Cottier, Markus Hirschmann, and Christina Salpingidou. 2018. "Numerical Investigation on Windback Seals Used in Aero Engines" Aerospace 5, no. 1: 12. https://doi.org/10.3390/aerospace5010012

APA StyleFlouros, M., Cottier, F., Hirschmann, M., & Salpingidou, C. (2018). Numerical Investigation on Windback Seals Used in Aero Engines. Aerospace, 5(1), 12. https://doi.org/10.3390/aerospace5010012