5.1. Hovering Efficiency

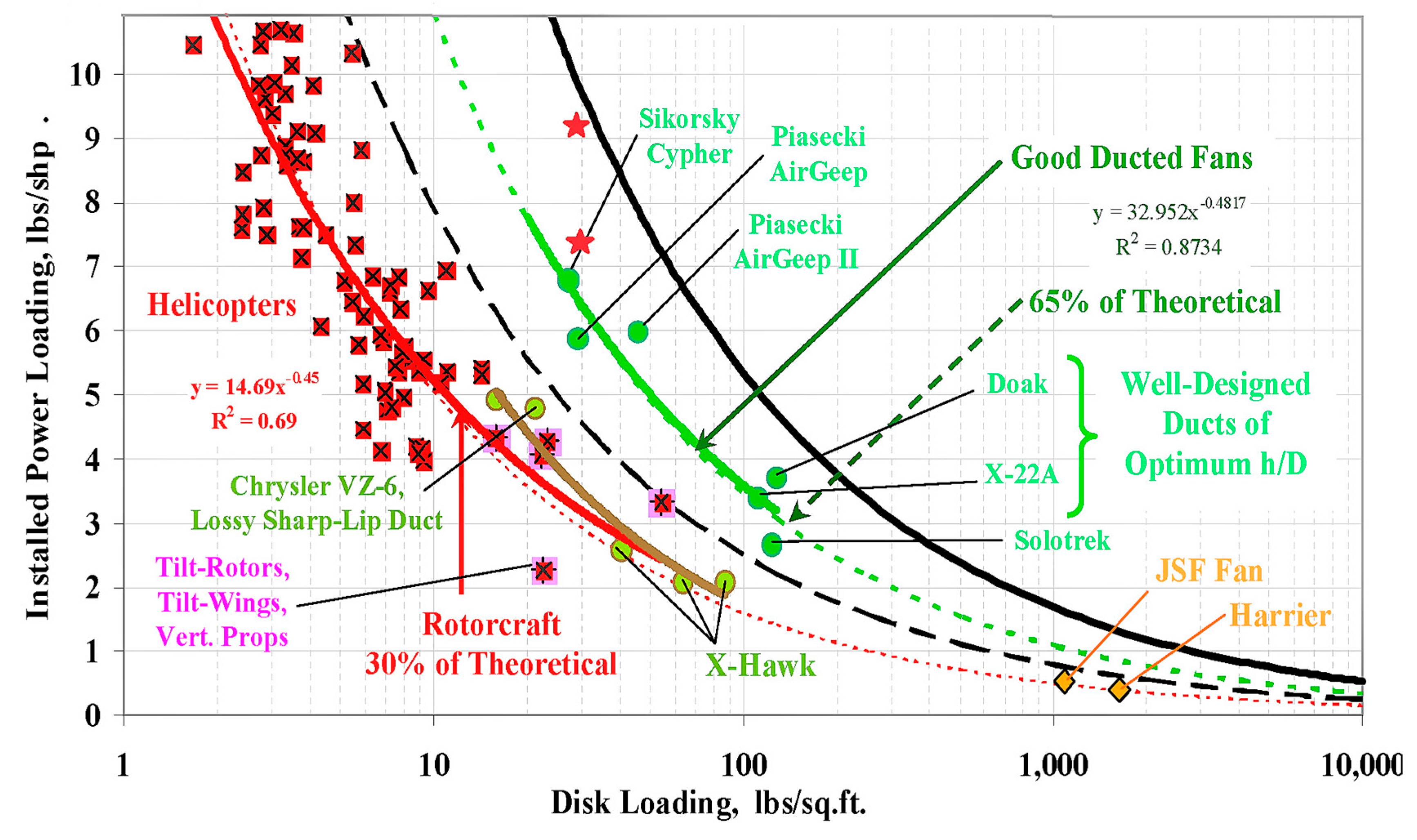

On the basis of optimization of parameters for hovering efficiency in the previous study [

2,

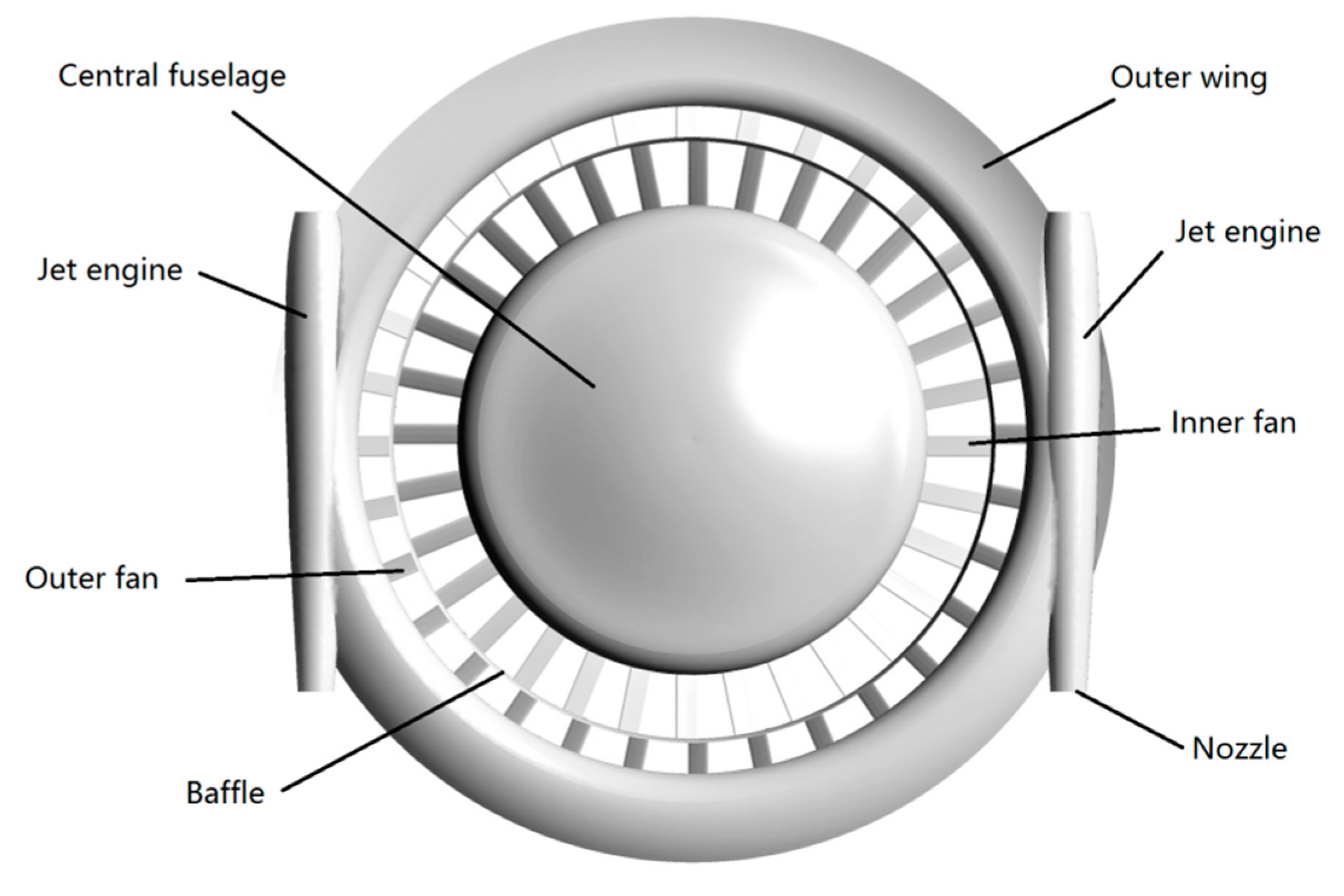

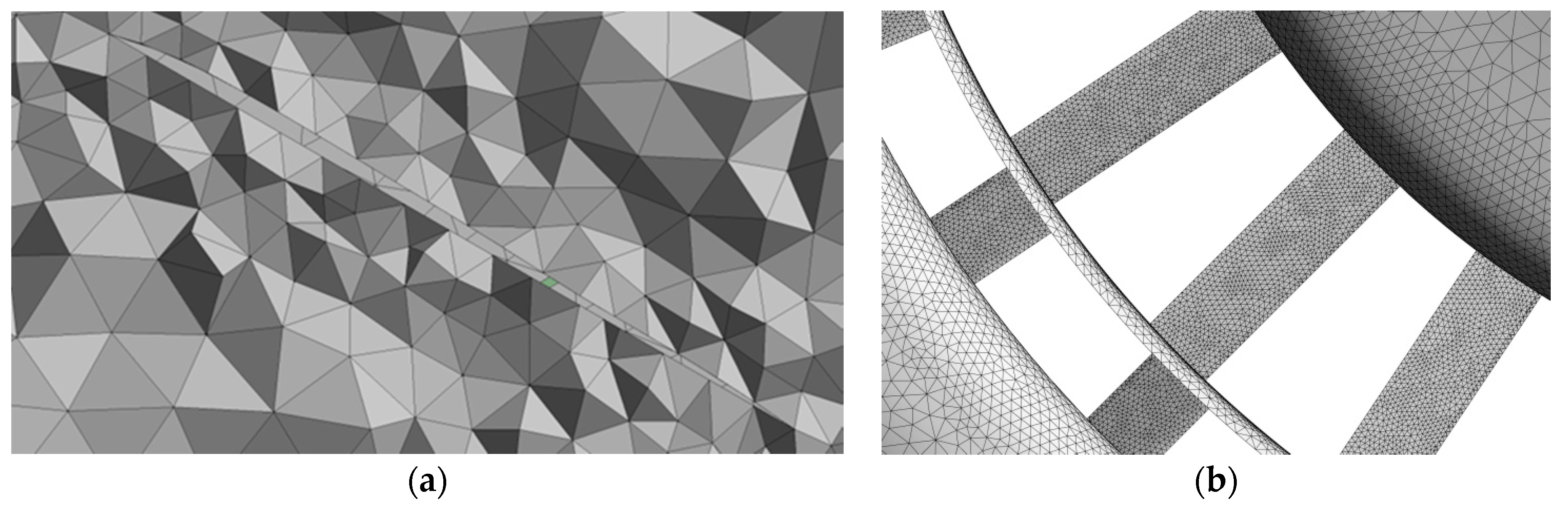

3], we further improved the annular duct walls to a complete half circle to maximize the inlet lip radius and the diffuser expansion angle. Therefore, the maximum inlet lip radius was 0.5 m, half of the duct thickness, and the final theoretical diffuser expansion angle was 180°. This was not a usual ducted fan with a Venturi type of duct. The diffusion factor σ value greatly increased, with more lift generated from the outer wing and less thrust directly from the fans, and the separations of flows from the duct walls happened very late (

Table 2,

Figure 5). The figure of merit (FM) and power loading increased as the power decreased (

Table 2). Inspired by the results, we further moved the location of fans lower from the throat of the duct to the diffuser area as shown in

Figure 4b, and the hovering performance was improved again. The σ value increased to 1.31, which means that only 38% of total lift comes directly from the fan thrusts and three fifths of lift comes from the duct, fuselage, and outer wing. We then found from this point that 2% blade thickness and a 30° pitch angle gave better results than the original 4% thickness and 27° pitch angle. A zero thickness of blades was also investigated, but the results were not better. Finally, the highest power loading achieved was 9.05 lbs/hp with a figure of merit of 0.772 without ground effect as shown in

Table 2. When the aircraft was close to the ground with the distance of 10 m (approximately the radius of the aircraft), the figure of merit and power loading continued to increase (

Table 2).

According to the momentum theory of ducted fan in hover mode [

2,

11,

12], duct diffusion ratio:

where

V1 is the velocity under the fan, and

V2 is the far wake velocity;

Ttotal is the total thrust, and

Tfan is the thrust directly from the fan. For a helicopter rotor, σ = 0.5. For a typical ducted fan, σ is about 1. Higher σ value leads to lower direct fan thrust.

The figure of merit was calculated as follows:

where

Pideal is the induced power,

A is the annular fan area; σ is the duct diffusion ratio; ρ is the density of air, ρ = 1.225 kg/m

3;

rF together is the moment of fan, and ω (rad/s) and

n (rpm) are the rotational speed.

Therefore, higher σ value reduces the ideal power. If the actual power remains the same, the figure of merit may decrease. Usually, higher σ value also reduces the actual power, with the FM increased.

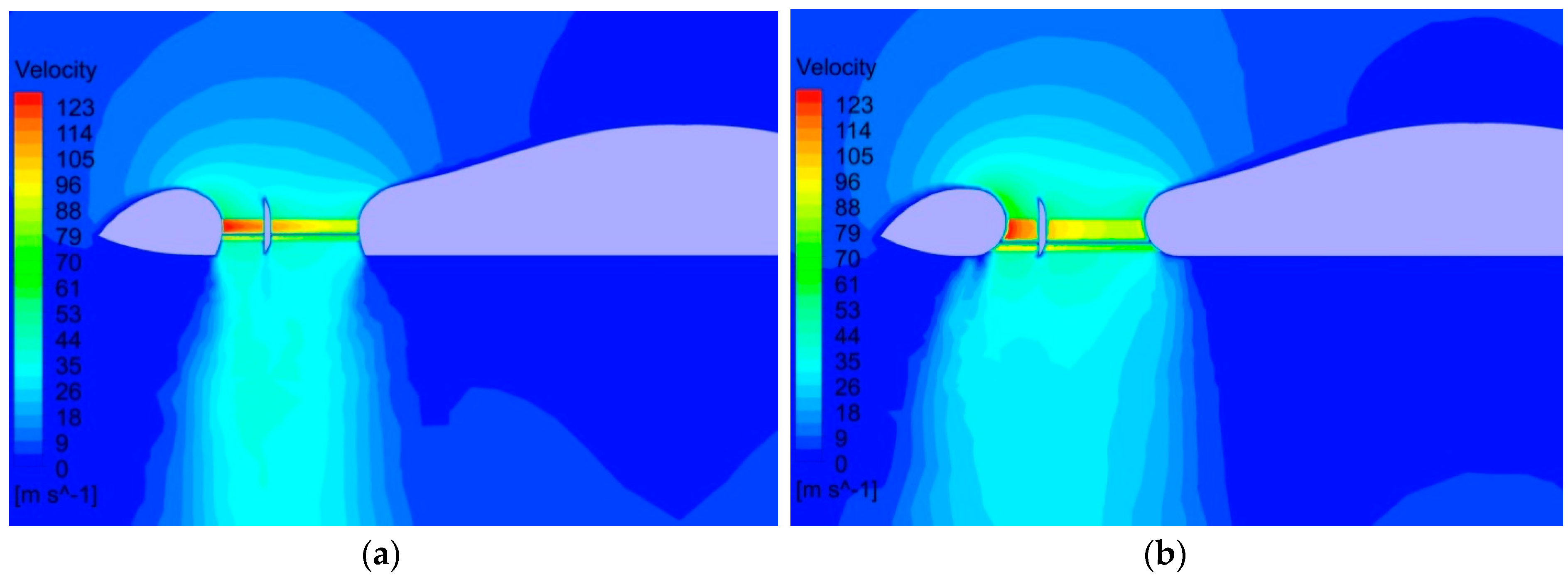

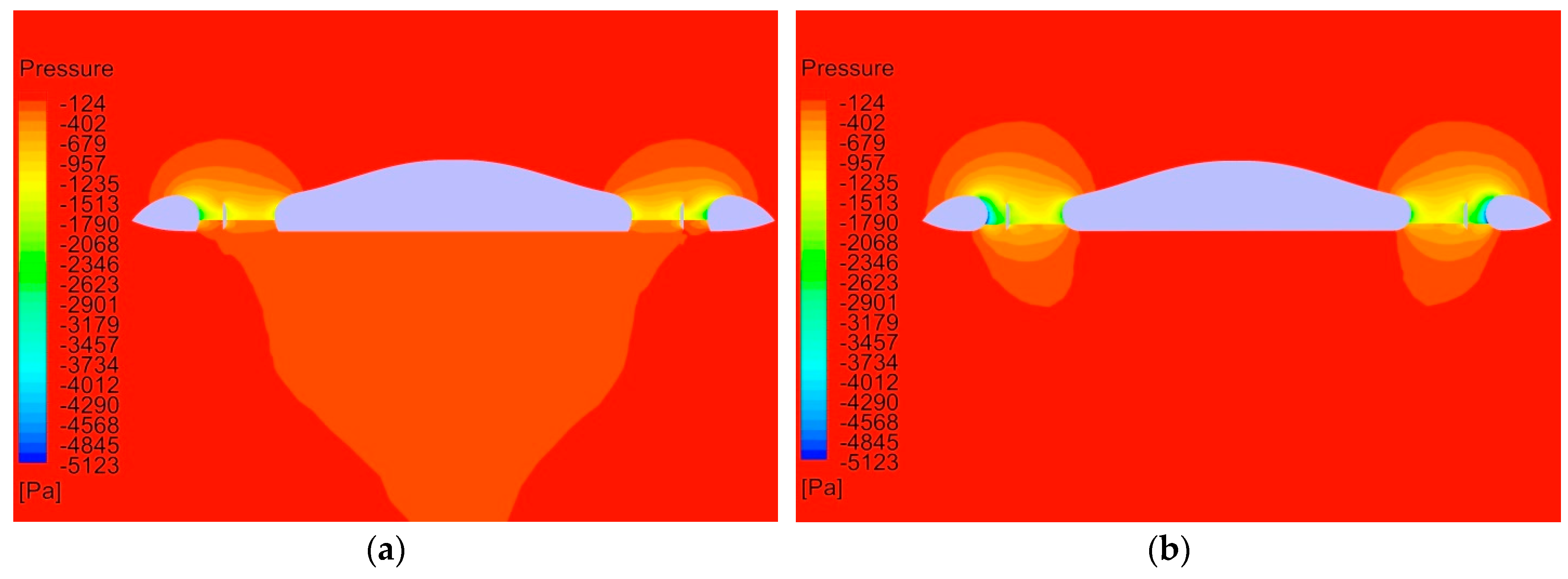

The reasons why the semicircle duct walls and the lower position of fans in the diffuser area promoted lift efficiency are probably due to lower pressure in the annular duct and lower thrusts directly from the fans. As shown in

Figure 6, when compared with the original fans, as the diffusion ratio σ increased, the downstream flow from the duct became much more diffused. The pressure in the duct became lower, while the pressure beneath the central fuselage became higher (

Figure 6). It is clear in

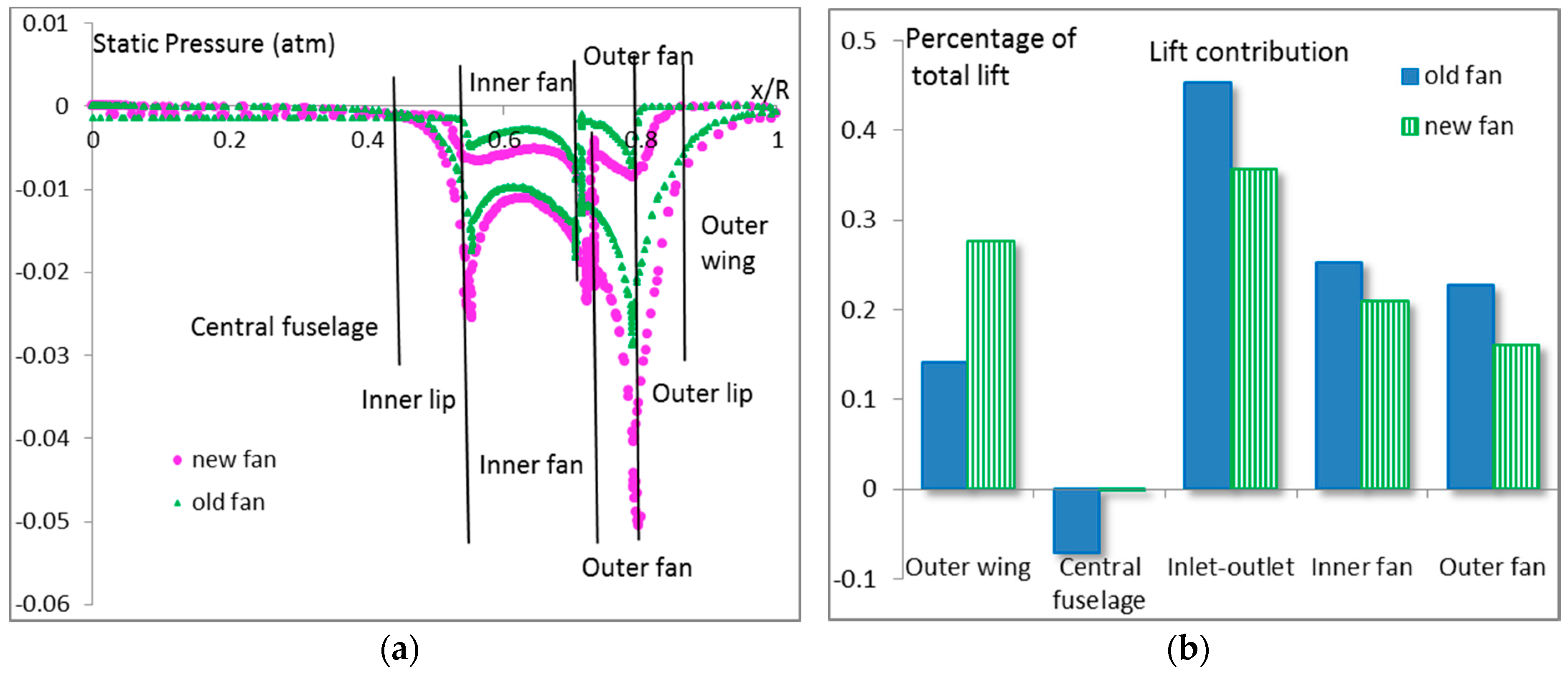

Figure 7 that the pressures on the upper and lower surfaces of the fans and the duct walls are much lower in the new fan configuration.

The low pressure in the duct resulted in low pressure on the top surface of the outer wing (

Figure 7a). As shown in

Figure 7b, compared with the original fan, less lifts came from the fans and duct walls (inlet–outlet), but more from the outer wing and less lift loss from the central fuselage. The lift from the outer wing almost doubled due to the lower pressure on the upper surface of outer wing. The negative lift beneath the central fuselage due to the low pressure was almost eliminated because of the increased pressure beneath the fuselage (

Figure 6 and

Figure 7). When the lifts directly from the fans decreased, if the lift to drag ratio did not change, the drags on the fan blades also decreased, thus leading to lower actual power and higher FM and power loading.

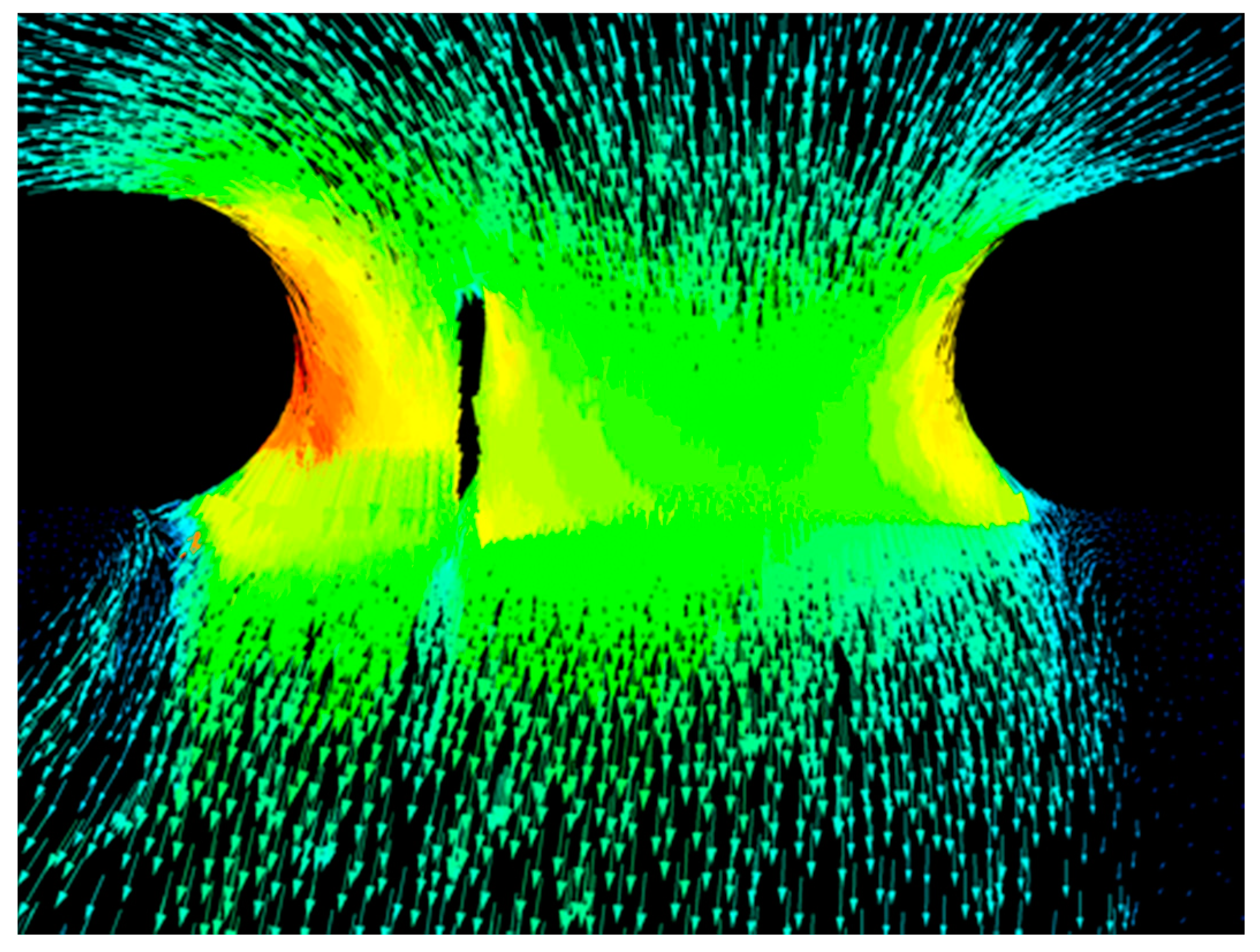

The key is the low pressure in the duct induced by the greater diffuser expansion effect. As shown in

Figure 8, the separation of flow from the duct walls happened very late, with the actual final diffuser angle at about 80° for the outer duct wall and 60° for the inner duct wall, by the average of 70°, much larger than the conventional optimum diffuser angle of 10° [

12]. The actual large diffuser expansion angle produced a much diffused downstream flow with a big diffusion ratio σ. As the inlet lip radius and outlet diffuser angle have been maximized by the semicircle duct walls and the other parameters have also been optimized, the lift efficiency probably has achieved the highest level.

The results were unexpected. In traditional ducted fans or shrouded rotors, the fans or rotors are usually placed at the narrowest throat position and the diffuser angle cannot be too large to avoid flow separation from the duct or shroud wall. In an investigation on a micro air vehicle (MAV) scale shrouded rotor by varying the diffuser expansion angle, diffuser length, inlet lip radius, and blade tip clearance, the results show that a small diffuser angle of 10° is more efficient than 20° or 0° [

12].

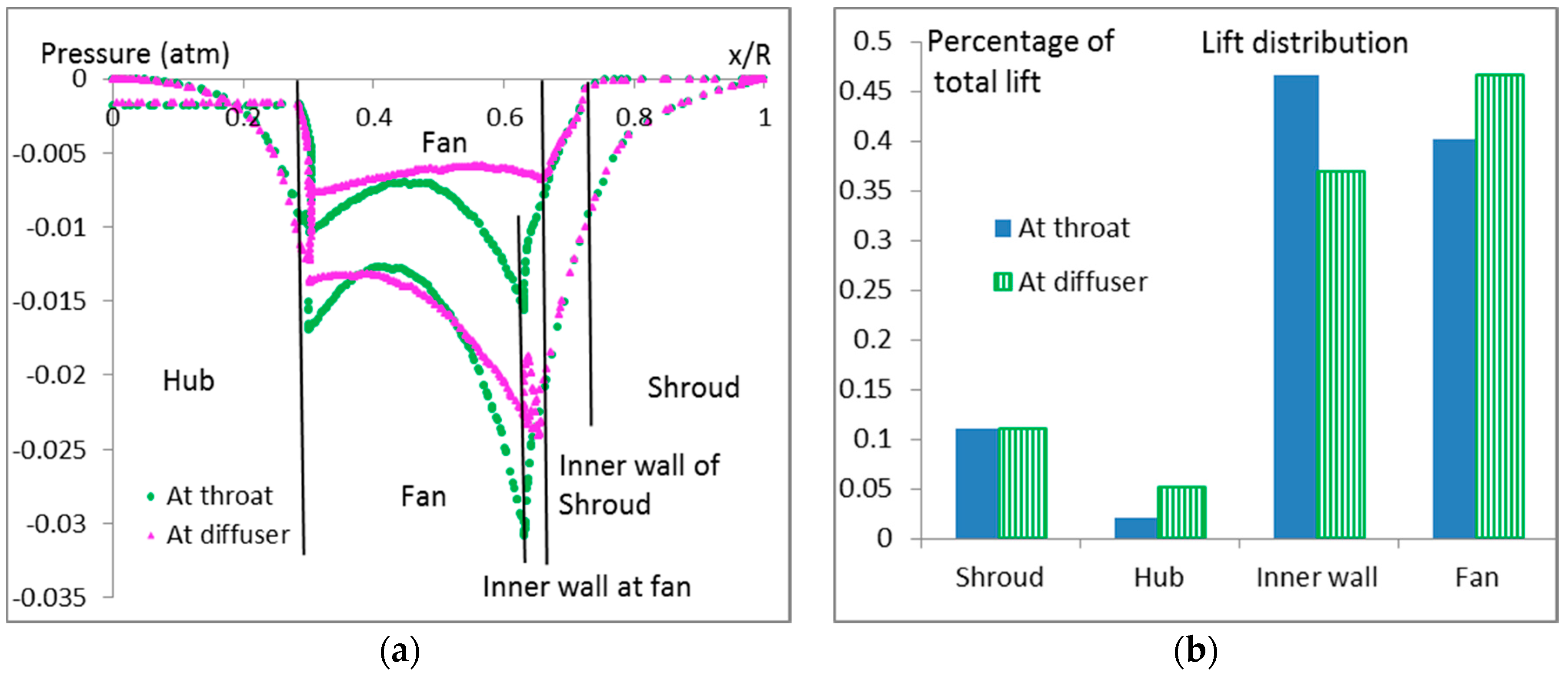

The advantage of the lower location of fans at the diffuser area only happened in the perfect semicircle duct walls. For the original fan configuration, although even most of the area of the duct walls was part of a circle, the lower location of fans did not result in higher lift efficiency. In order to explore the reason, a conventional Venturi type of the ducted fan was simulated as shown in

Figure 9. The separation happened early at the inner wall of the duct even at a small diffuser angle. The lower location of the fan in the diffuser area did not improve the separation and diffusion. As shown in

Table 3, the power loading and σ value of the fan at the throat are higher than that of the fan at the diffuser. This explains why most ducted fans are located at the throat.

It can be seen from

Figure 10 that, when the fan was moved to the diffuser area, the average pressure in the duct and on the surfaces of fan blades did not become lower and the pressure differences between the upper and lower surfaces of blades became even greater, leading to higher direct fan lift, which increased the drag on fan blades and the actual power. The pressure on the top surface of the shroud was not decreased to yield more lift (

Figure 10). The early separation of flow from the hub (

Figure 9) reduced the diffuser expansion effect while lower fan location could not improve it.

Therefore, only semicircle duct walls could prevent the flow from early separation and generate a strong diffusion effect, which made the pressure in the duct and on the upper surface of the outer wing very low, leading to less required fan lift and power. The value of σ reached the maximum with the semicircle duct walls because no diffuser angle can be greater than 180°.

For a conventional circular ducted fan with a ball hub and a semicircle duct wall, the separation of flow from the hub happens easily with a low diffusion ratio. Therefore, the semicircle duct walls only work for annular ducted fans with a very large hub.

5.2. Transition Characteristics

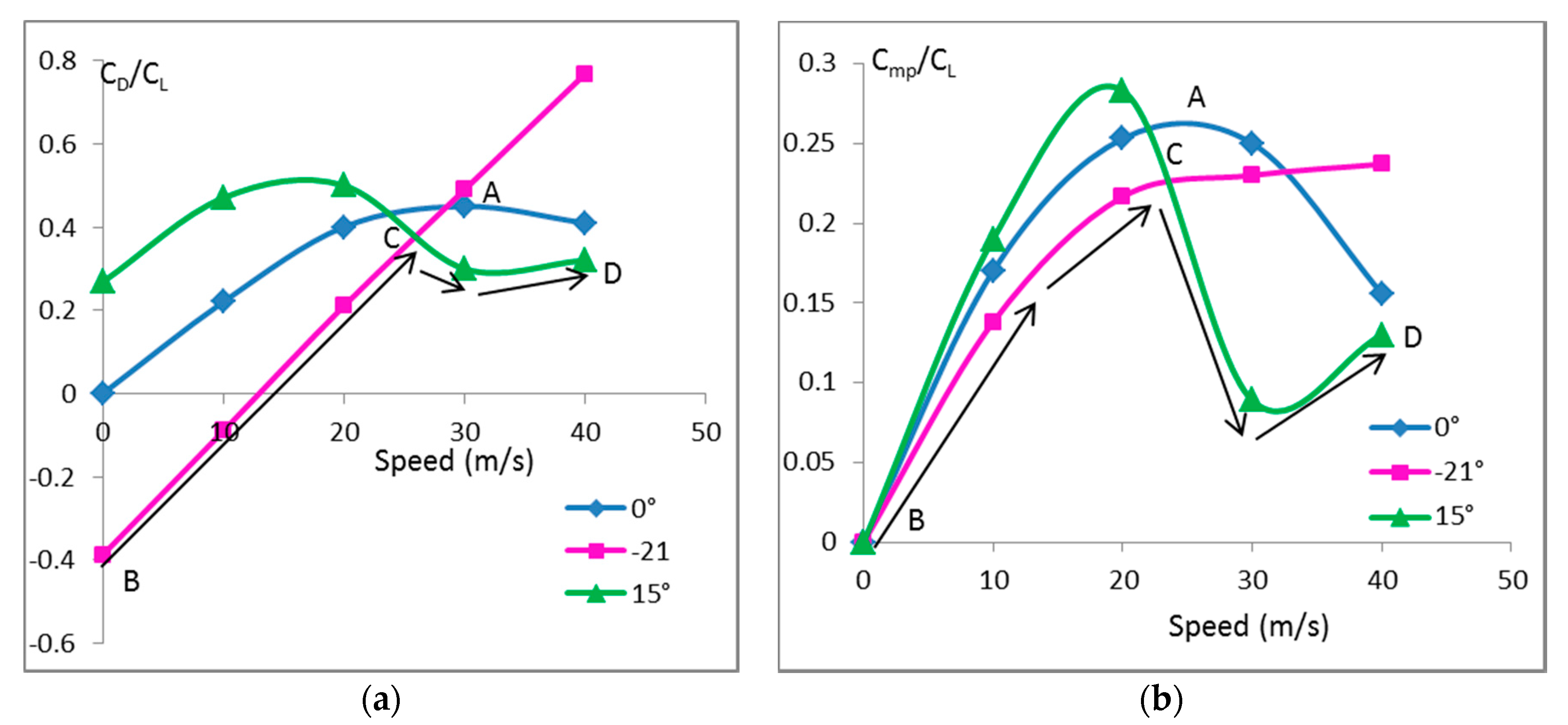

After the improvement of hovering efficiency, the transition characteristics of the new fan configuration were investigated. The drag, pitching moment and rolling moment were measured during the transition simulations while the rotational speeds of fans were adjusted to maintain the lift equal to the weight. The coefficients were calculated on the total lift, drag and moment, including the aerodynamic forces and forces generated by the lift fans. The reference area is the total disc area of diameter of 18 m. The results showed that the characteristics were deteriorated (

Figure 11). The yawing moment remained small after being eliminated by the counter rotating fans in hover mode and is not shown in

Figure 11. The momentum drag and nose up pitching moment increased significantly at all angles of attack, with the maximum drag increased from an original 0.397 [

4] to 0.45 at AOA of 0° (

Figure 11a, Spot A). Even with the recommended strategy to start transition from AOA of −21° along the arrows from B to C to D in

Figure 11, the peak of drag also increased from an original 0.29 [

4] to 0.38 (Spot C,

Figure 11a) at the forward speed of about 25 m/s. The peak of pitching moment also increased from 0.155 [

4] to 0.22 (Spot C,

Figure 11b), which needs upward thrusts from the jet nozzles of 0.55 of the aircraft weight to be eliminated (

Figure 12), much higher than the original 0.39. The total requirement for extra thrusts is 0.67 of the aircraft weight in transition.

The deterioration of transition characteristics is consistent with the phenomenon in helicopter design that high lift efficiency usually reduces the maximum forward speed of helicopter (“Whatever helps forward flight hurts hover, and whatever helps hover hurts forward flight.”) [

1].

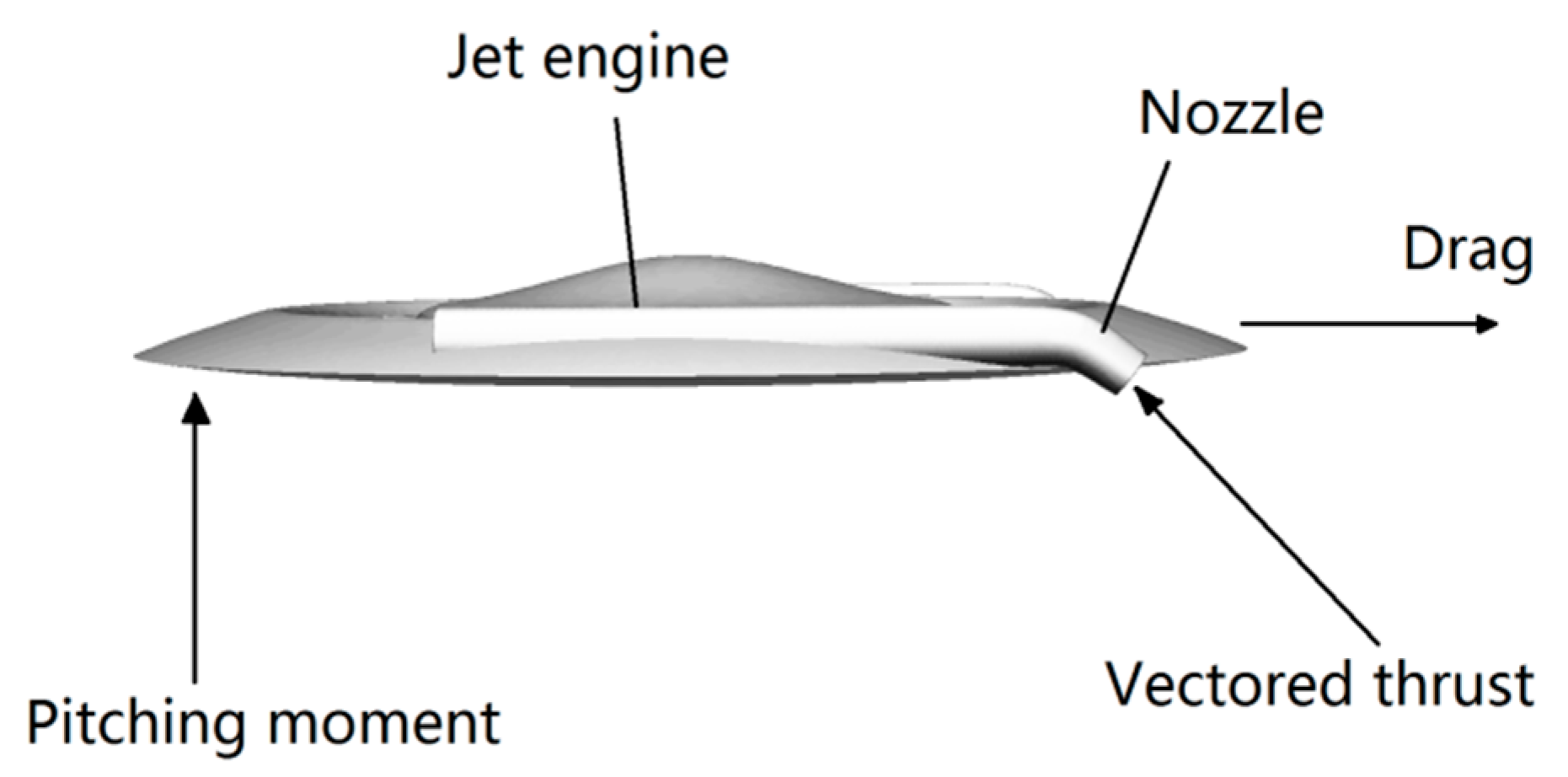

However, as the jet engines have to provide upward thrusts to eliminate the nose up pitching moment during the transition (

Figure 12), the lift fan only needs to provide part of the total lift at the same time. When the jet engines provided upward thrusts of 0.37 of the aircraft weight during the transition, the transition characteristics were improved as shown in

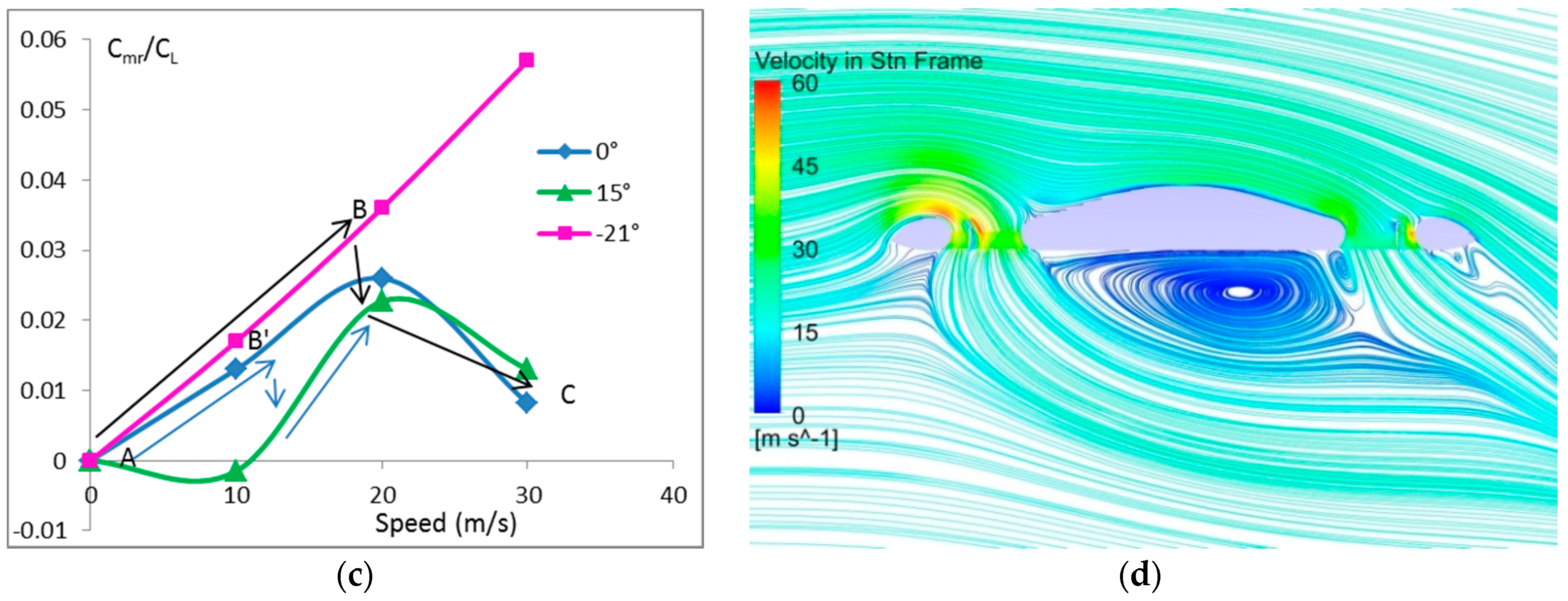

Figure 13. The rotational speeds of fans were adjusted to maintain the lift equal to 0.63 of the aircraft weight during the transition. The lift, drag and moment coefficients were calculated on the total lift, including the aerodynamic lift and those generated by the lift fans. As shown in

Figure 13, the starting transition from AOA of −21° still reduced the peak of drag and pitching moment (black arrows), but the advantage become quite small compared to starting transition directly from 0° (blue arrows). Therefore, starting from −21° is not very necessary. Starting the transition directly from 0° reduces the complexity of attitude control.

As shown in

Figure 13a, with the aid of jet lift, the peak of momentum drag was significantly reduced from 0.38 to 0.25 at spot Bʹ. The peak of pitching moment was also reduced from 0.22 to 0.15, which needs upward thrusts of 0.39 of the aircraft weight to be eliminated. The peak of rolling moment was only 0.023 (

Figure 13c, Spot Bʹ), which needs differential upward thrusts of 0.057 of aircraft weight to be eliminated. When the aircraft reaches the speed of 30 m/s, it can close the duct to start aerodynamic flight at AOA of 15° with 30% of the lift directly from the vectored jet thrusts.

The transition procedure should be like the following along the arrows from Aʹ or A to Bʹ to C (

Figure 13): at first, the aircraft rises from the ground and hovers in the air; then, the forward jet thrusts push the aircraft to speed up; after it reaches the speed of about 5 m/s and the nose up pitching moment becomes significant, the nozzles of jet engines turn downward to eliminate the pitching torque and provide part of the lift; when the speed reaches 12 m/s, then the attitude of aircraft is changed to AOA of 15°; the duct will be closed to start aerodynamic flight after the speed reaches 30 m/s. With the maximum upward thrust of 0.39 and forward thrust of 0.25 at spot Bʹ, total extra thrusts of 0.5 of the aircraft weight are enough for a successful transition. As the rotational speeds of the lift fans were lowered during the transition with the aid of jet lift (

Table 4), the power required by the lift fan at Spot Bʹ was also low (<0.2 of the aircraft weight). Thus, a total thrust to weight ratio of 0.7 would be enough for all the requirements, including the maximum cruise speed of 0.75 Mach based on aerodynamic drag prediction [

2,

4]. With the adjusted strategy to perform transition, the requirements of thrust to weight ratio remain the same as the original configuration, but with lift efficiency increased in hover mode.

The transition mode is the most inefficient period in a full flight with low forward speed and high power. However, since the transition phase only occupies a very short period of time with the speed up from 0 to 40 m/s, this is acceptable. The high efficiency in both hover and cruise flight ensures the high efficiency of the whole flight process. Since low speed patrol (0–40 m/s) is very inefficient for the annular lift fan aircraft due to the high momentum drag and pitching moment, this job should be done by helicopters.