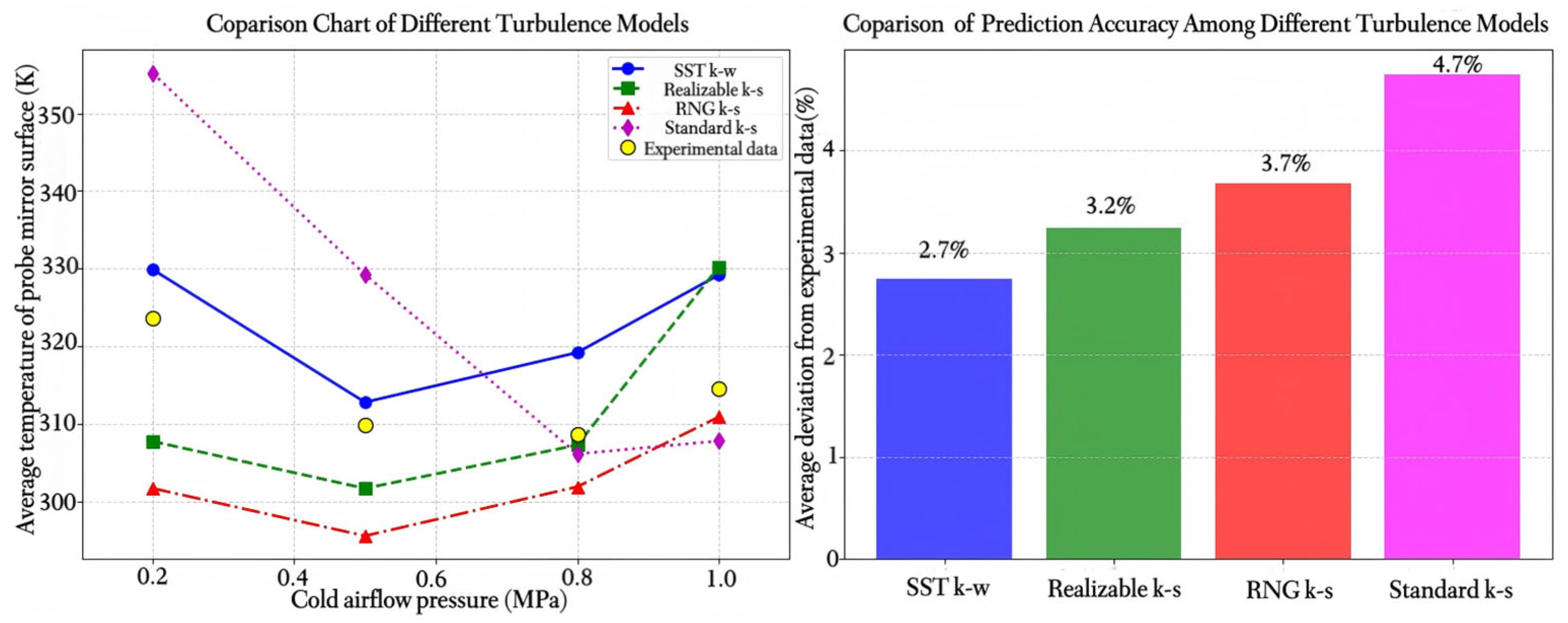

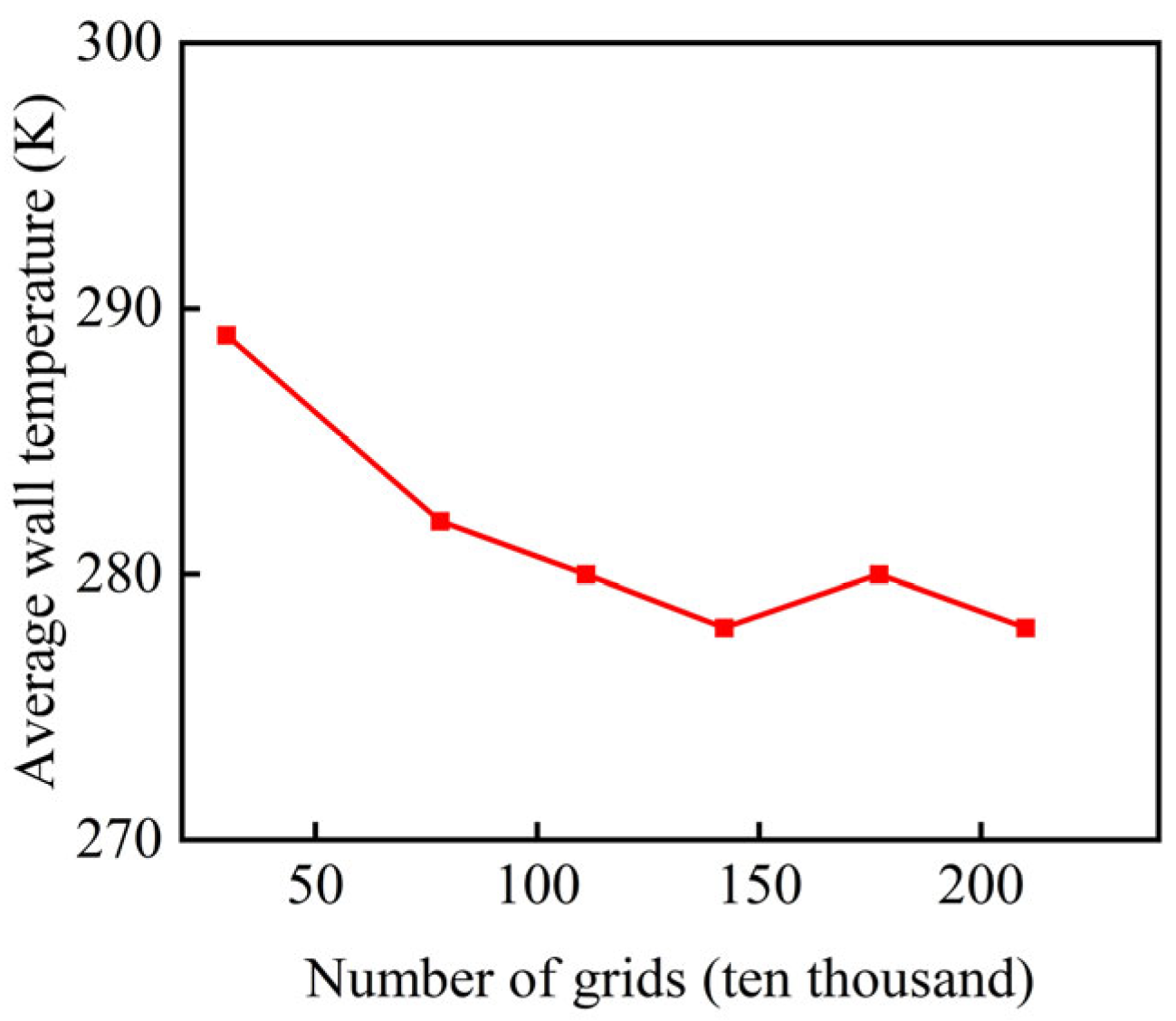

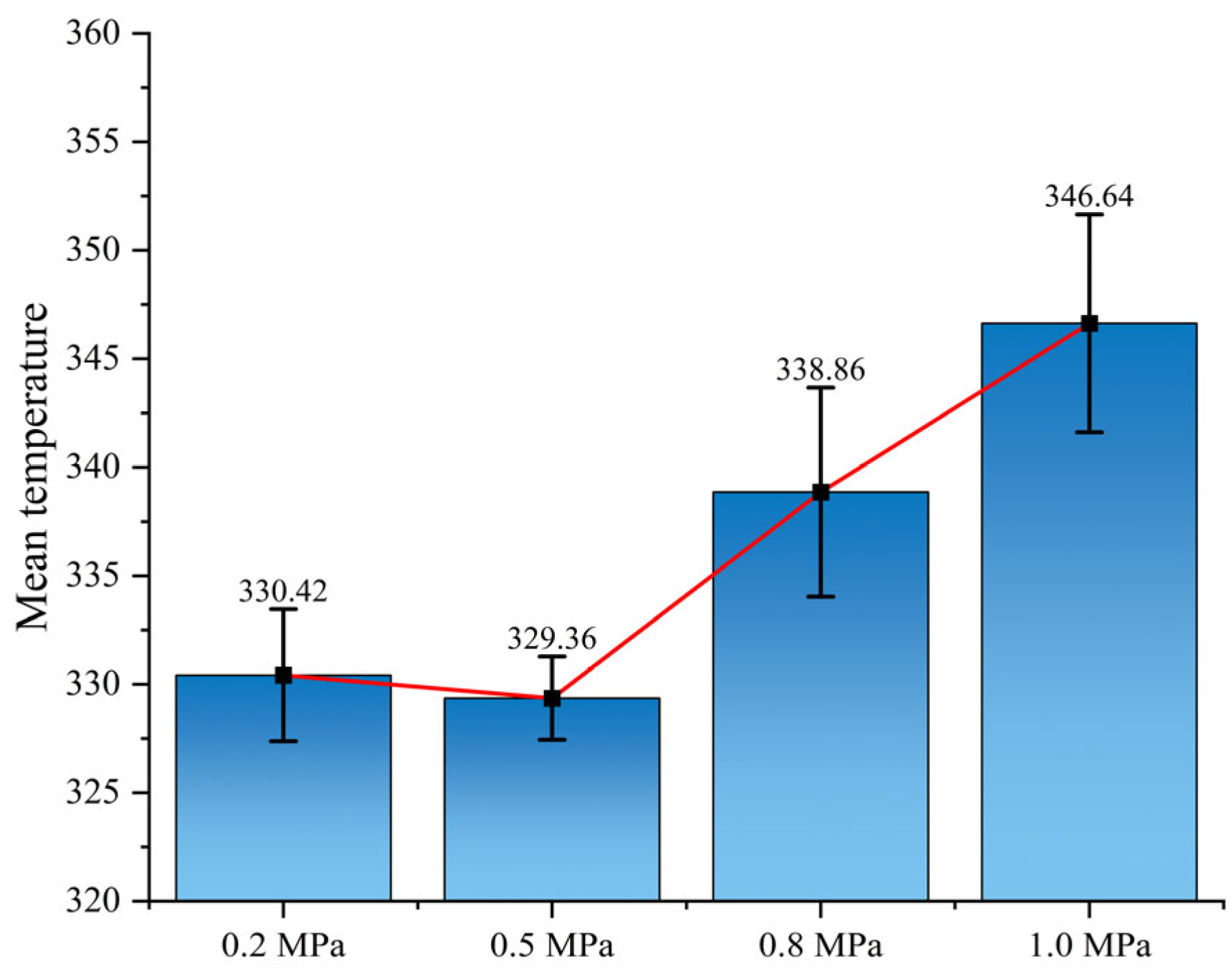

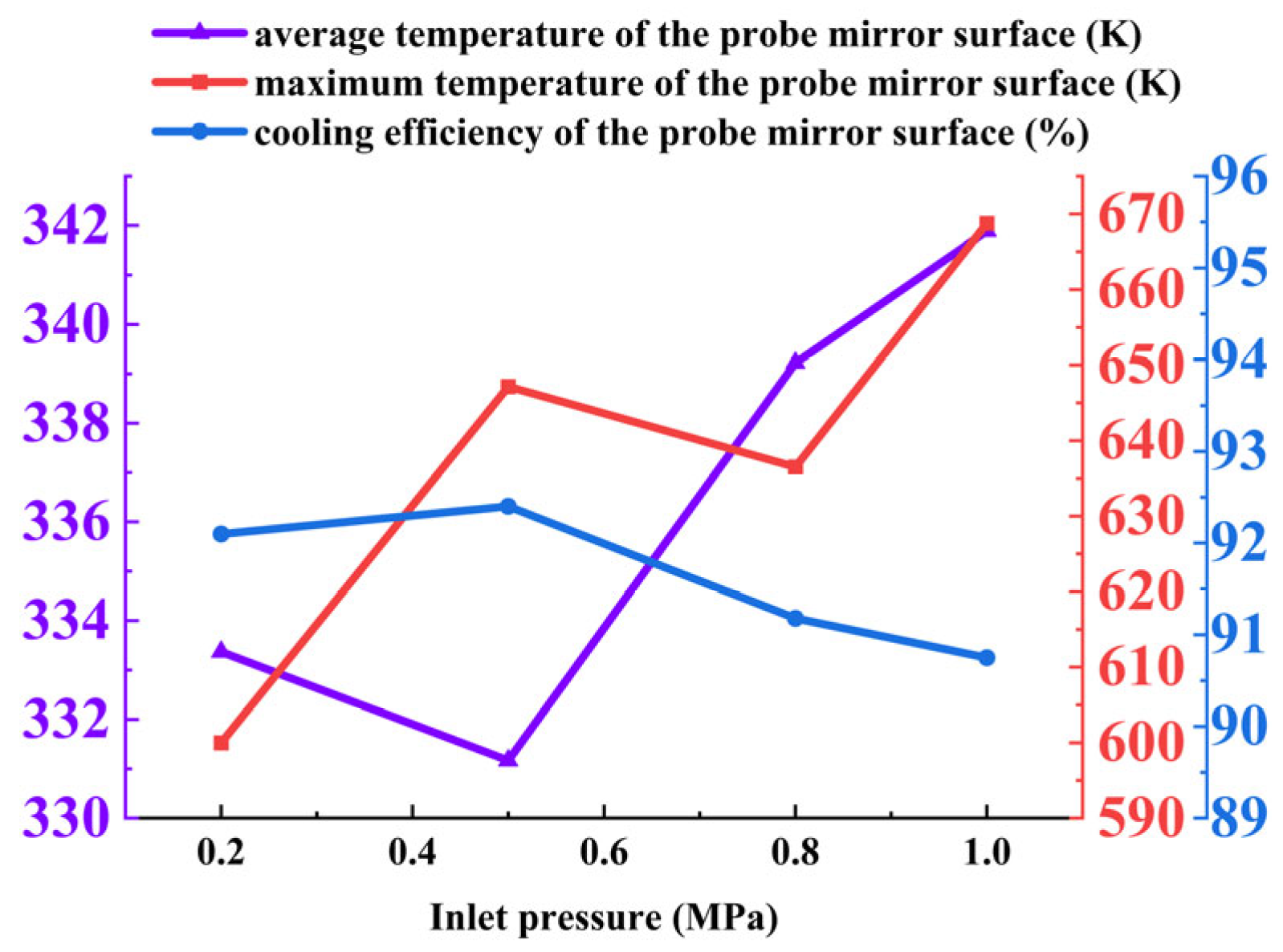

The results indicate that the inlet pressure has a significant impact on the average temperature of the probe mirror surface. In the annular cooling structure, the average temperature under the pressure condition of 0.5 MPa is the lowest (312.80 ± 0.92 K). Moreover, through one-way analysis of variance (ANOVA) and subsequent tests, it is confirmed that this value is significantly lower than those under other pressure conditions (p < 0.05); in contrast, the average temperature under 1.0 MPa is the highest (349.24 ± 0.87 K). The error bars in the figure represent the standard deviation of five independent measurement results (±1 SD), and all original data points are displayed in the figure. Validation results have proven the effectiveness of the simulation calculations and the reliability of the conclusions.

4.3.1. Ring Structure Cooling Flow Field Analysis

- (1)

Influence of Coolant Inlet Pressure

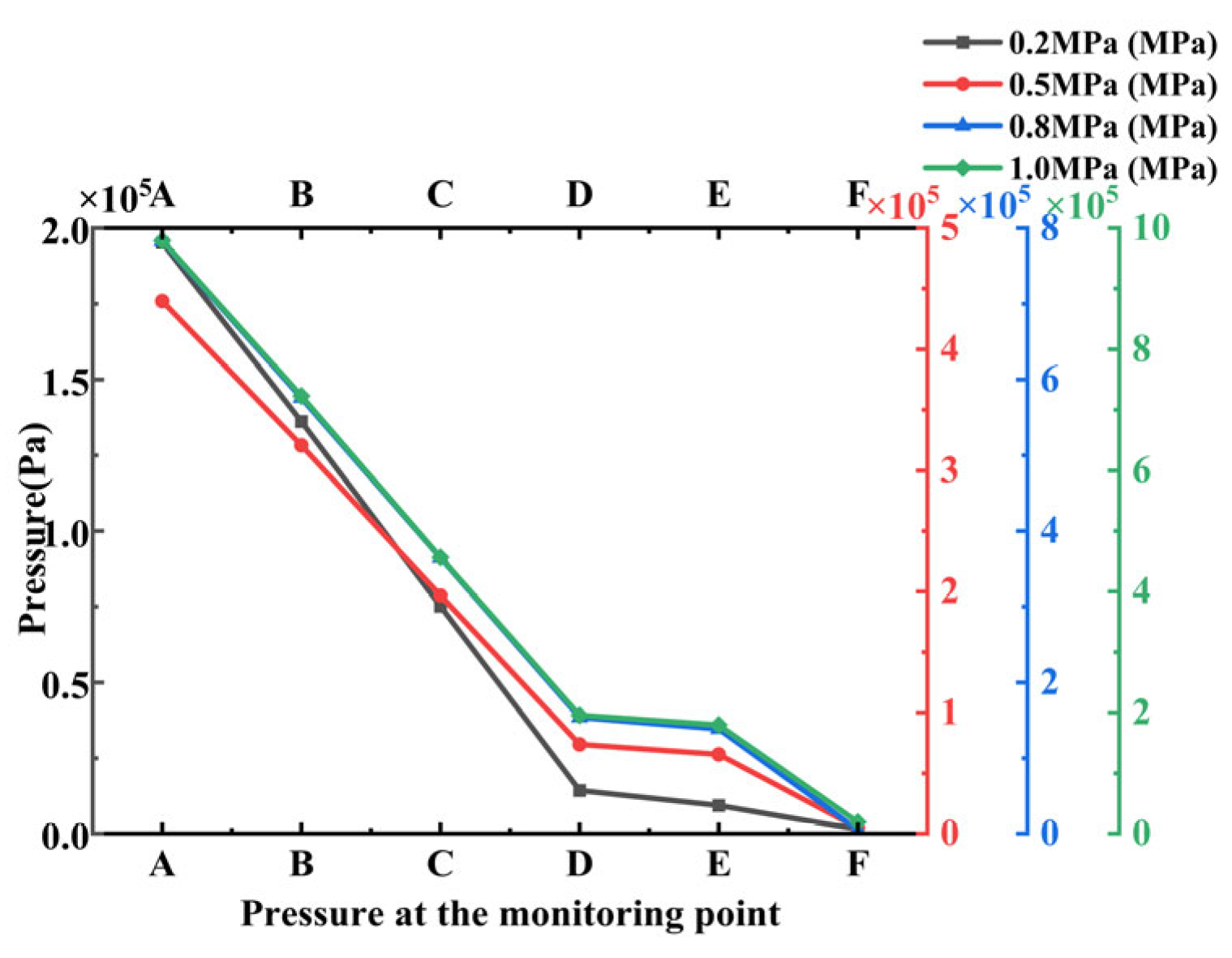

The cold flow inlet pressure significantly influences both the coolant flow rate and the cooling performance of the borescope probe. An excessively low pressure prevents the formation of a sufficiently thick cooling film, while an excessively high pressure leads to rapid coolant ejection and consumption, thereby reducing cooling effectiveness. In this study, four inlet pressures—0.2 MPa, 0.5 MPa, 0.8 MPa, and 1.0 MPa—were compared and analyzed.

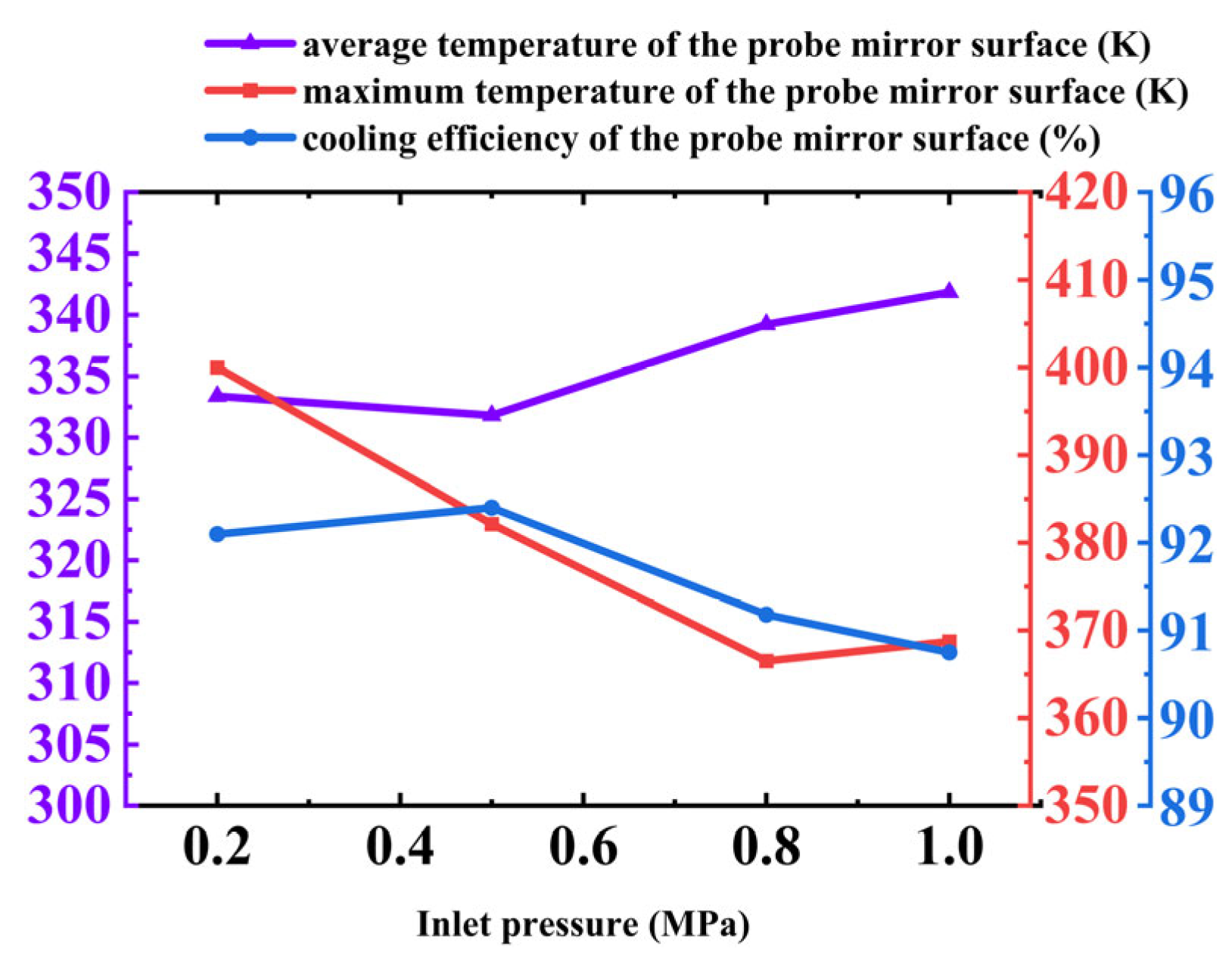

Figure 12 illustrates the variation in both the mirror surface temperature and average cooling efficiency of the probe under different cold flow pressures. As the inlet pressure increases, the flow rate of the cooling gas at the outlet of the annular structure rises correspondingly. The cooling effect initially improves and then deteriorates, reflected in the average mirror temperature, which first decreases from 333.50 K at 0.2 MPa to 331.81 K at 0.5 MPa, and then increases to 341.84 K at 1.0 MPa. The maximum mirror temperature follows a similar trend. Meanwhile, the cooling efficiency also increases initially before decreasing.

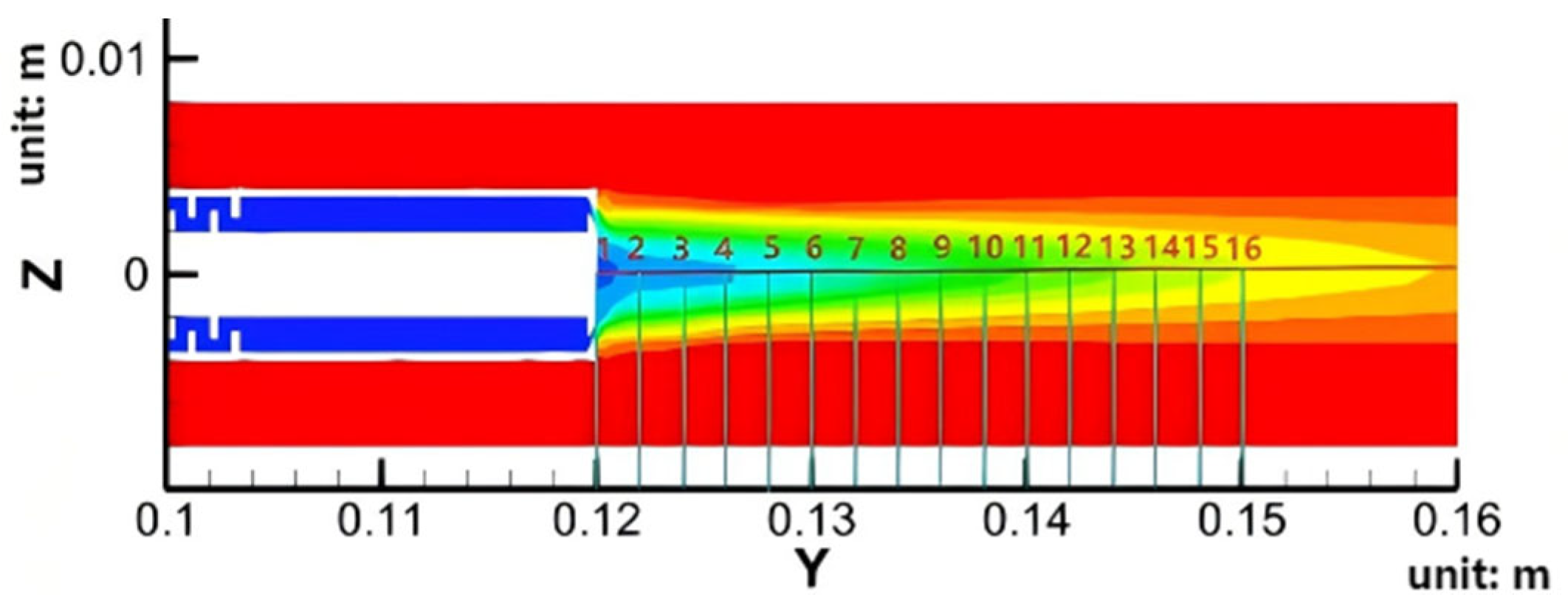

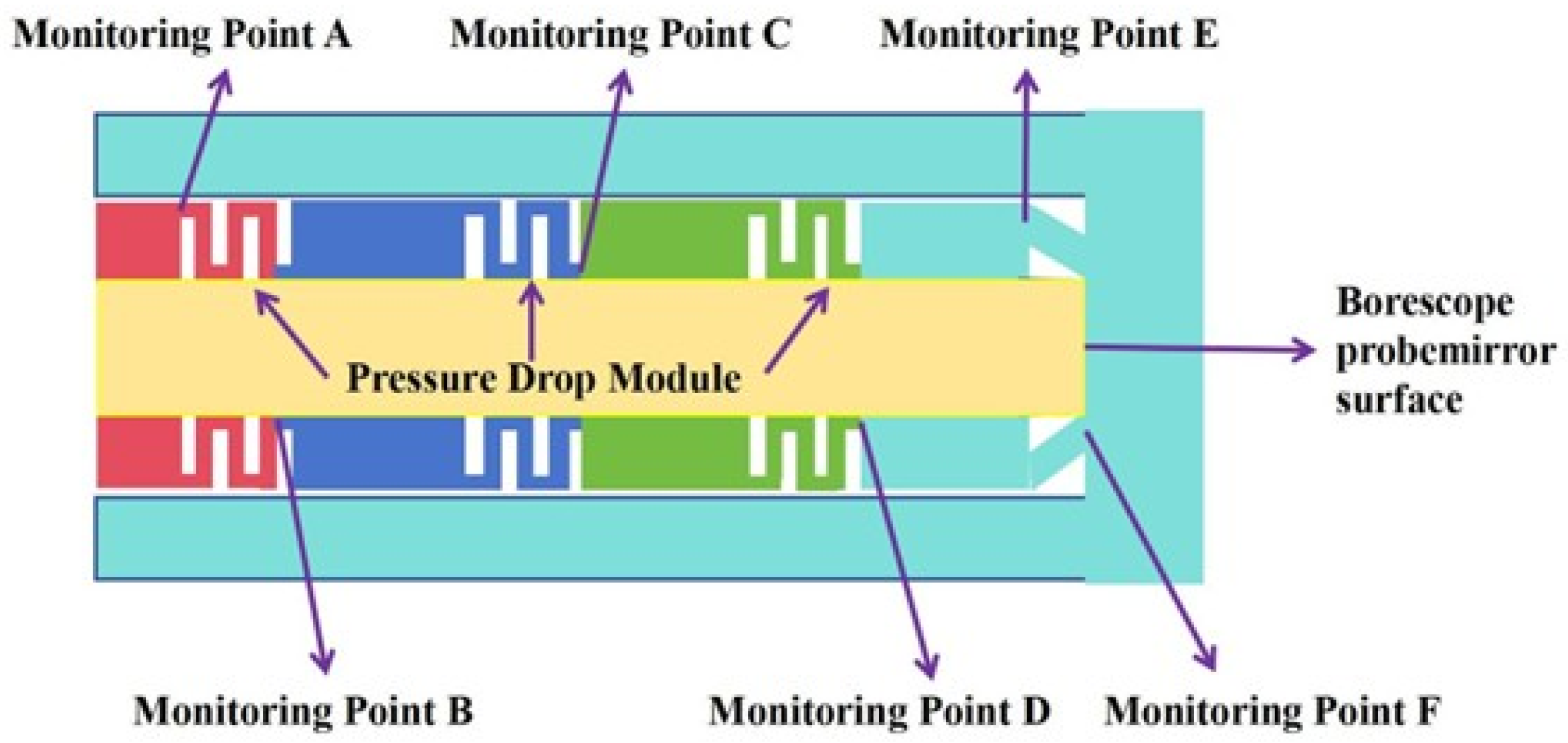

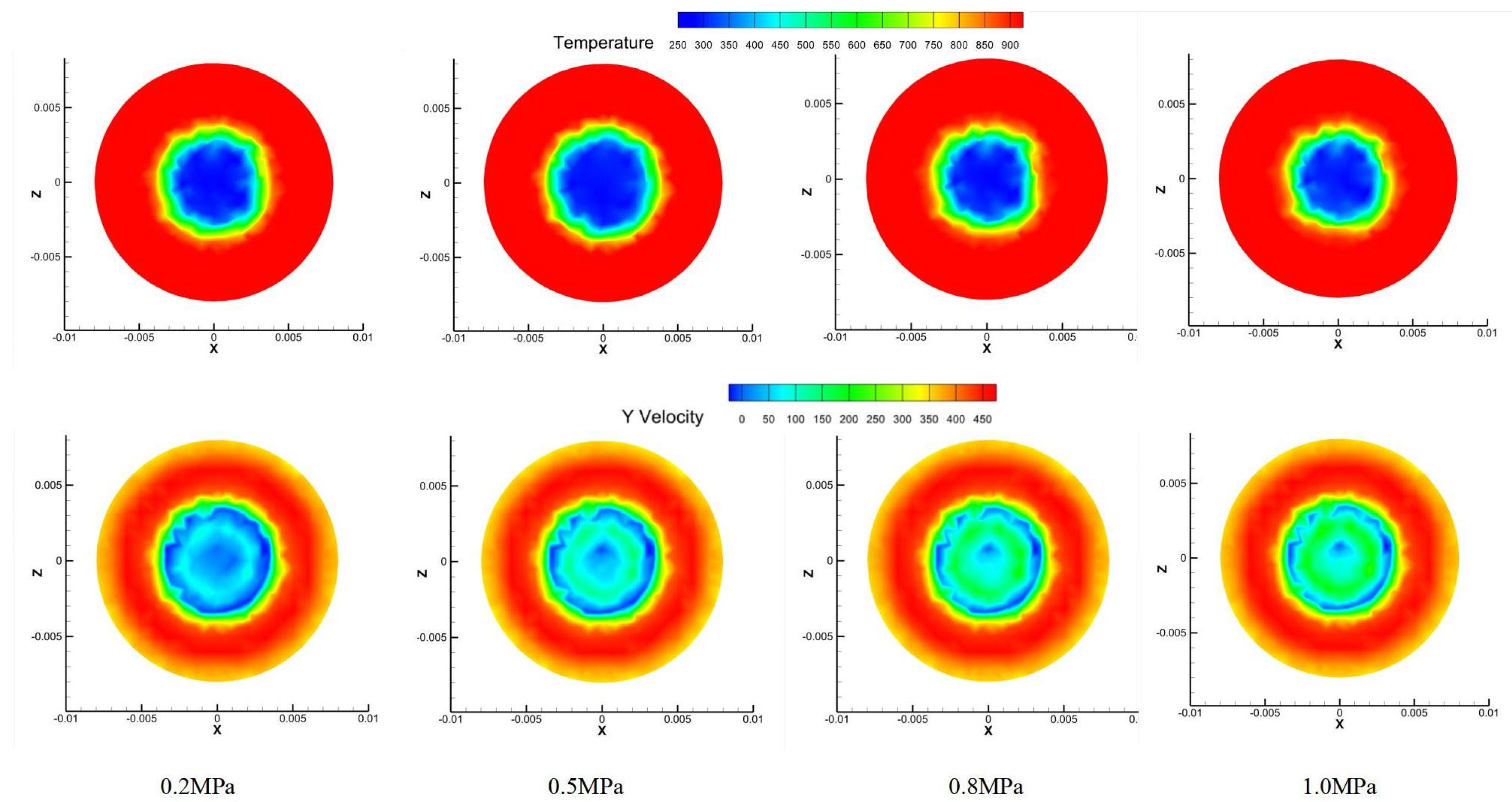

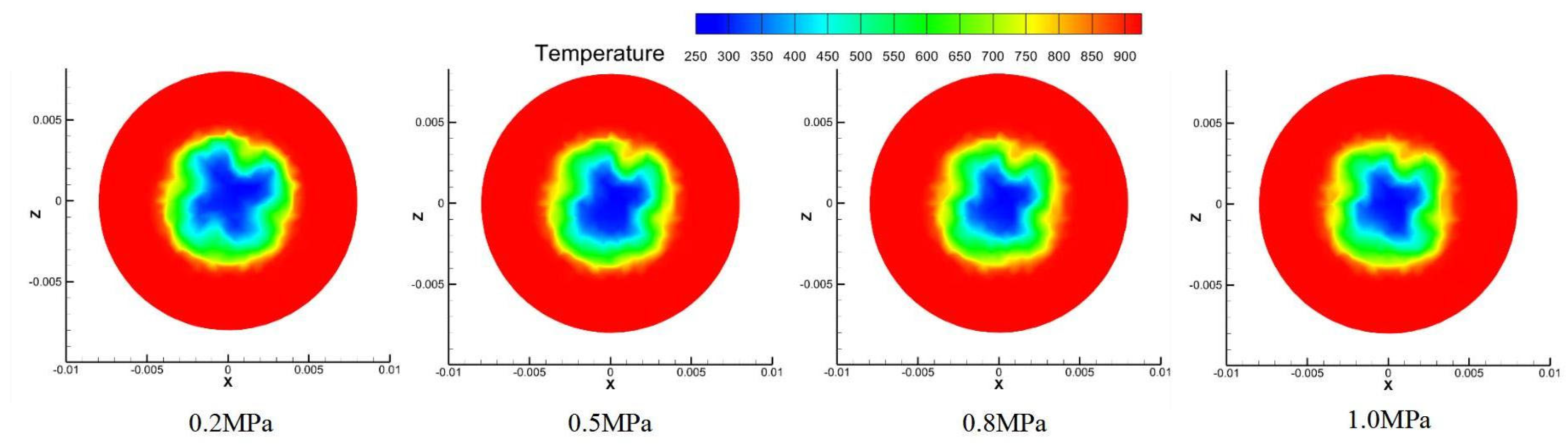

Figure 13 presents temperature contours at the 0.12 m cross-section where the probe mirror is located. The four comparative contour plots illustrate the temperature and flow velocity distributions under different inlet pressures. It can be observed that as the coolant pressure increases, the low-temperature region near the center of the mirror expands initially and then contracts. Meanwhile, the Y-velocity contours reveal that the high-velocity region on the mirror surface continuously expands with increasing coolant inlet pressure, and the central area becomes a pronounced high-speed flow zone beyond 0.8 MPa. This behavior is consistent with the previously noted trend of the average mirror temperature varying with inlet pressure and further demonstrates that the enlargement of the high-speed zone significantly enhances convective heat transfer, thereby improving the cooling performance around the mirror.

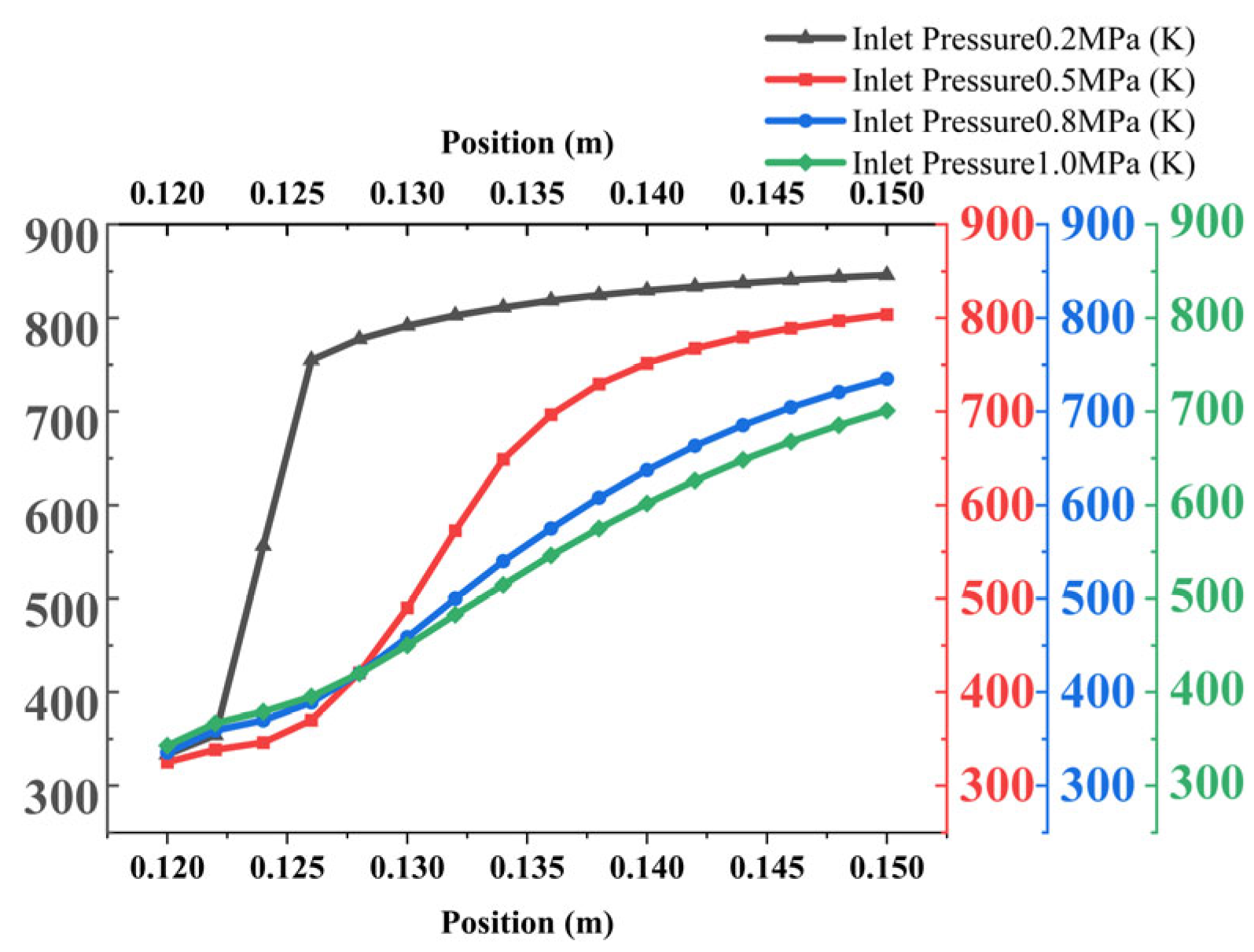

Figure 14 illustrates the variation in the cooling temperature field in front of the borescope probe under different cold flow inlet pressures. As the distance from the mirror increases, the temperature at each spatial monitoring point rises. The temperature increases rapidly up to the 0.135 m position, after which the rate of temperature rise slows, stabilizing by 0.15 m. As shown in the figure, a lower inlet pressure (e.g., 0.2 MPa) results in a more rapid temperature increase ahead of the probe; at 0.13 m, the temperature reaches approximately 800 K. In contrast, under higher inlet pressures, the temperature at the same location remains around 400–500 K. This difference is attributed to the formation of a more extensive cooling film at higher pressures, which enhances thermal protection in the region near the probe.

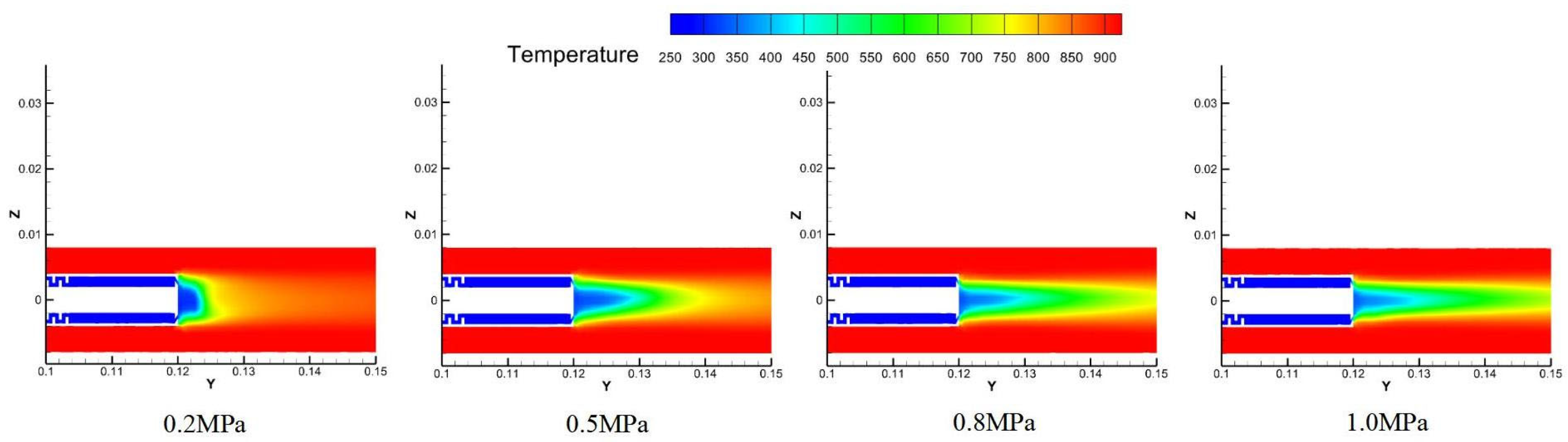

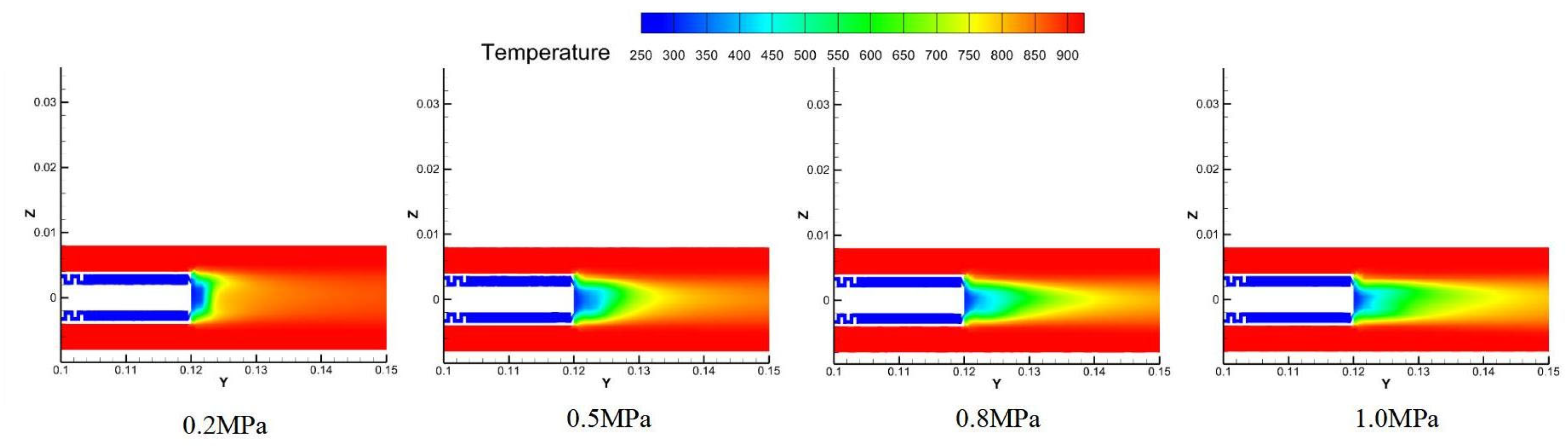

Figure 15 presents the temperature contour from the 0.1 m to 0.15 m cross-section. The cooling film formed by the coolant ejected from the impingement cooling ring is visible in front of the mirror. The low-temperature region is smallest at an inlet pressure of 0.2 MPa. As pressure increases, the cooling film coverage expands significantly until 0.8 MPa, beyond which no further noticeable expansion occurs. This behavior aligns with the previously observed influence of inlet pressure on the probe’s temperature distribution.

The influence of coolant inlet pressure on the thermal performance of an annular cooling structure was investigated under four pressure conditions: 0.2 MPa, 0.5 MPa, 0.8 MPa, and 1.0 MPa. The key findings are summarized as follows:

Mirror temperature and cooling efficiency: As shown in

Figure 12, both the average and maximum mirror temperatures exhibit a non-monotonic relationship with increasing inlet pressure. The average temperature decreases from 329.90 K at 0.2 MPa to 312.81 K at 0.5 MPa, then increases to 319.24 K at 1.0 MPa. Cooling efficiency follows a similar trend, initially improving before declining beyond the optimum pressure. This behavior is attributed to the trade-off between cooling film stability and coolant consumption rate. At moderate pressures, the coolant forms a continuous protective film, whereas excessive pressure induces high velocity and mixing, reducing residence time and cooling effectiveness.

Flow and temperature distribution:

Figure 13 illustrates that as pressure increases, the low-temperature region on the mirror initially expands and then contracts. Concurrently, the high-velocity zone continuously expands with pressure, becoming particularly pronounced above 0.8 MPa. This flow acceleration enhances convective heat transfer, corroborating the observed temperature trends.

Figure 14 and

Figure 15 further demonstrate that higher pressures significantly extend the cooling film’s spatial coverage, maintaining lower temperatures in regions farther from the mirror. The cooling film reaches its maximum coverage at 0.8 MPa, beyond which no notable expansion occurs.

Summary of optimal conditions: The annular cooling structure achieves optimal performance at a coolant inlet pressure of 0.5 MPa, yielding the lowest average mirror temperature (312.81 K) and highest cooling efficiency. This pressure balances coolant momentum and flow stability, promoting the formation of an effective insulating film without excessive consumption or mixing. Pressures below 0.5 MPa result in inadequate film coverage, while higher pressures diminish cooling performance due to reduced film adherence and increased mixing. For practical applications in aero-engine borescope cooling, 0.5 MPa is recommended to ensure efficient thermal protection and operational economy.

- (2)

Influence of Coolant Inlet Temperature

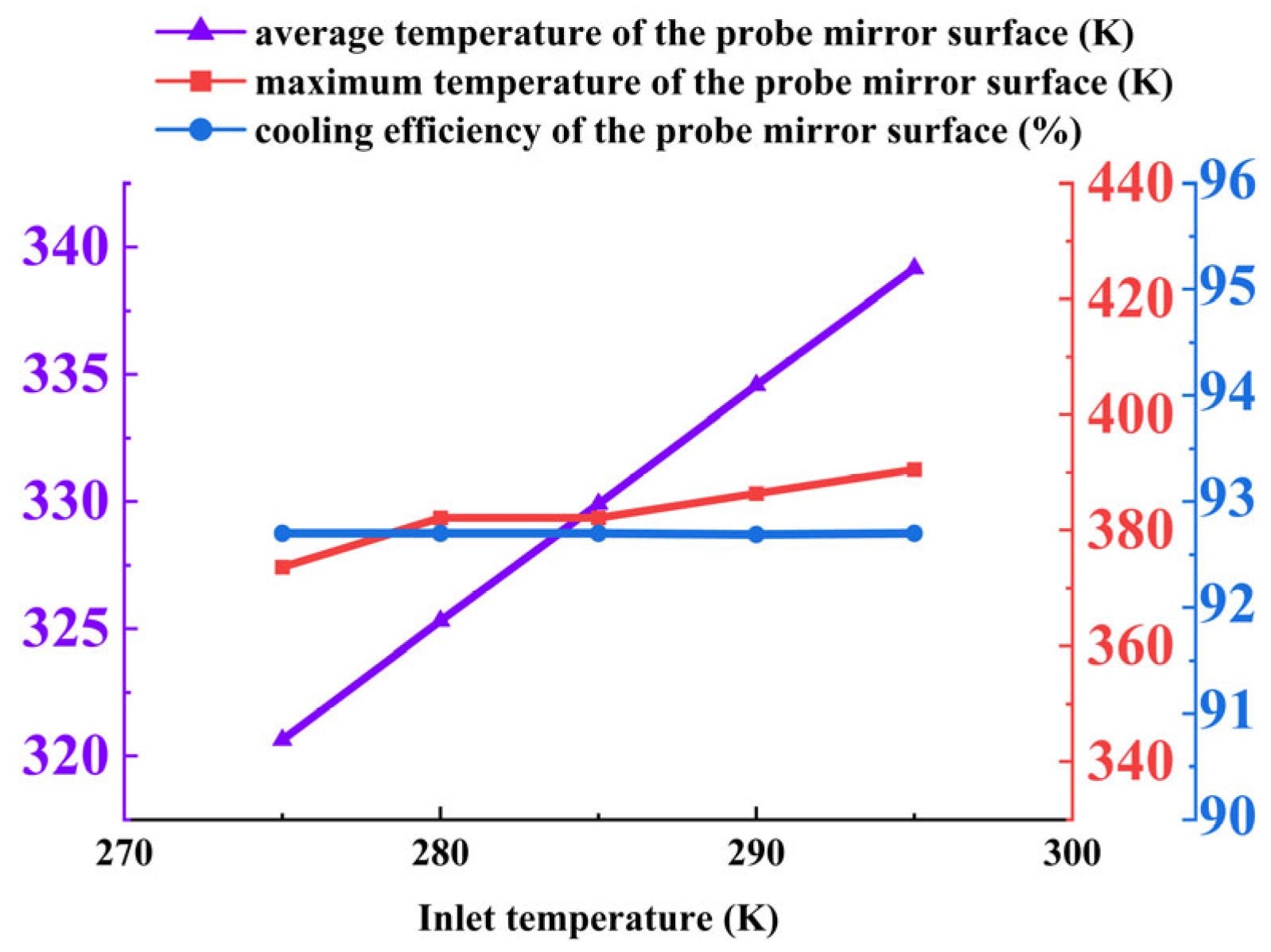

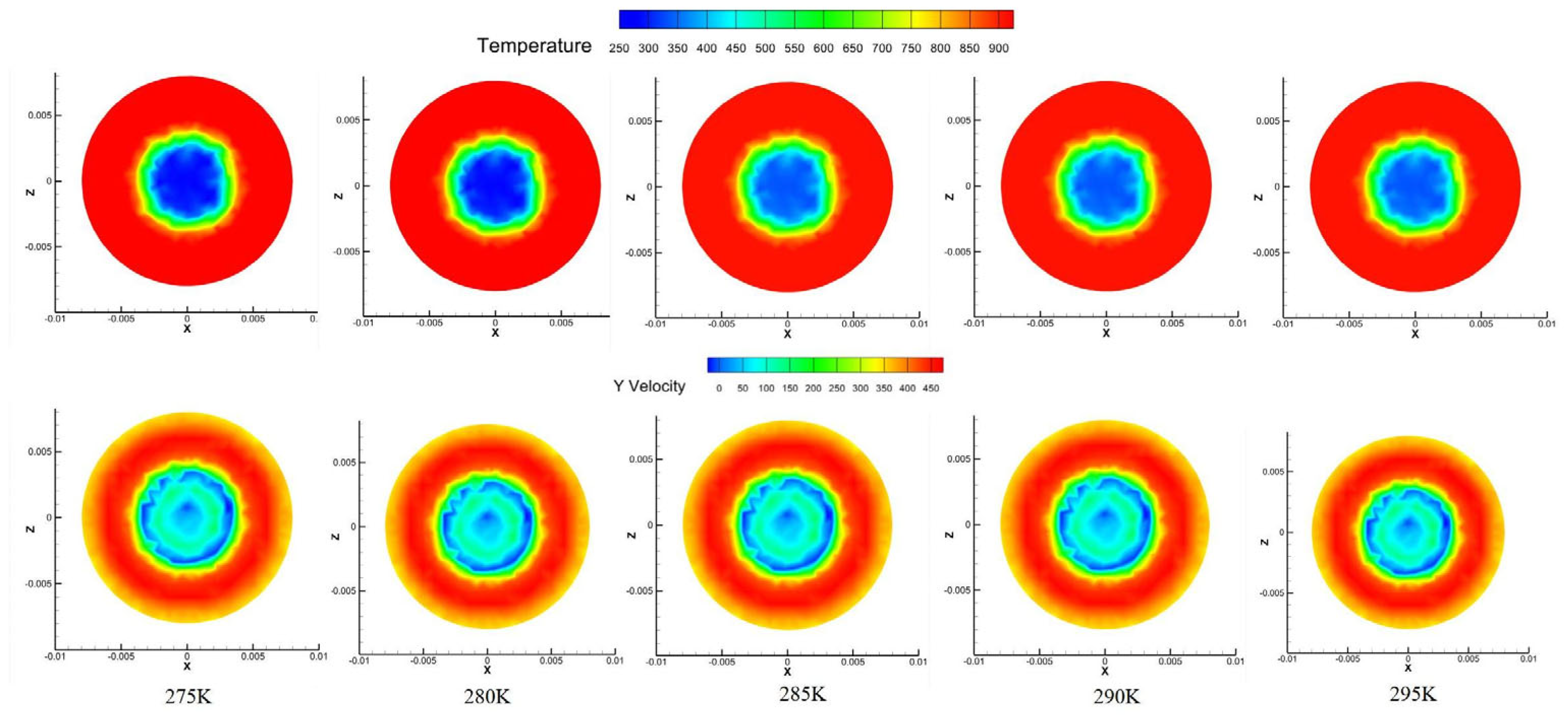

This section analyzes the influence of the coolant inlet temperature on the cooling characteristics of the borescope probe. Comparative analyses were conducted under five coolant temperature conditions: 275 K, 280 K, 285 K, 290 K, and 295 K.

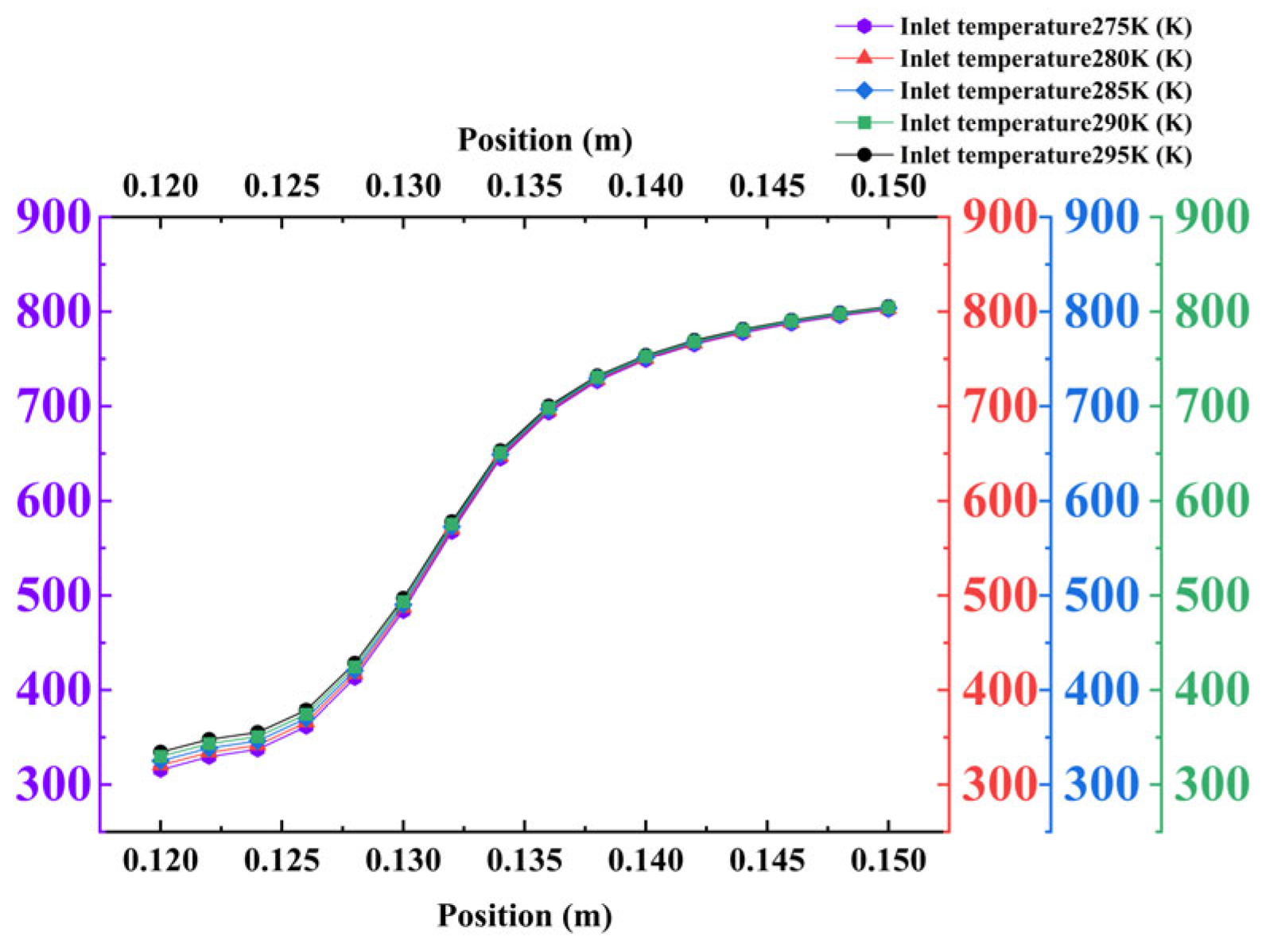

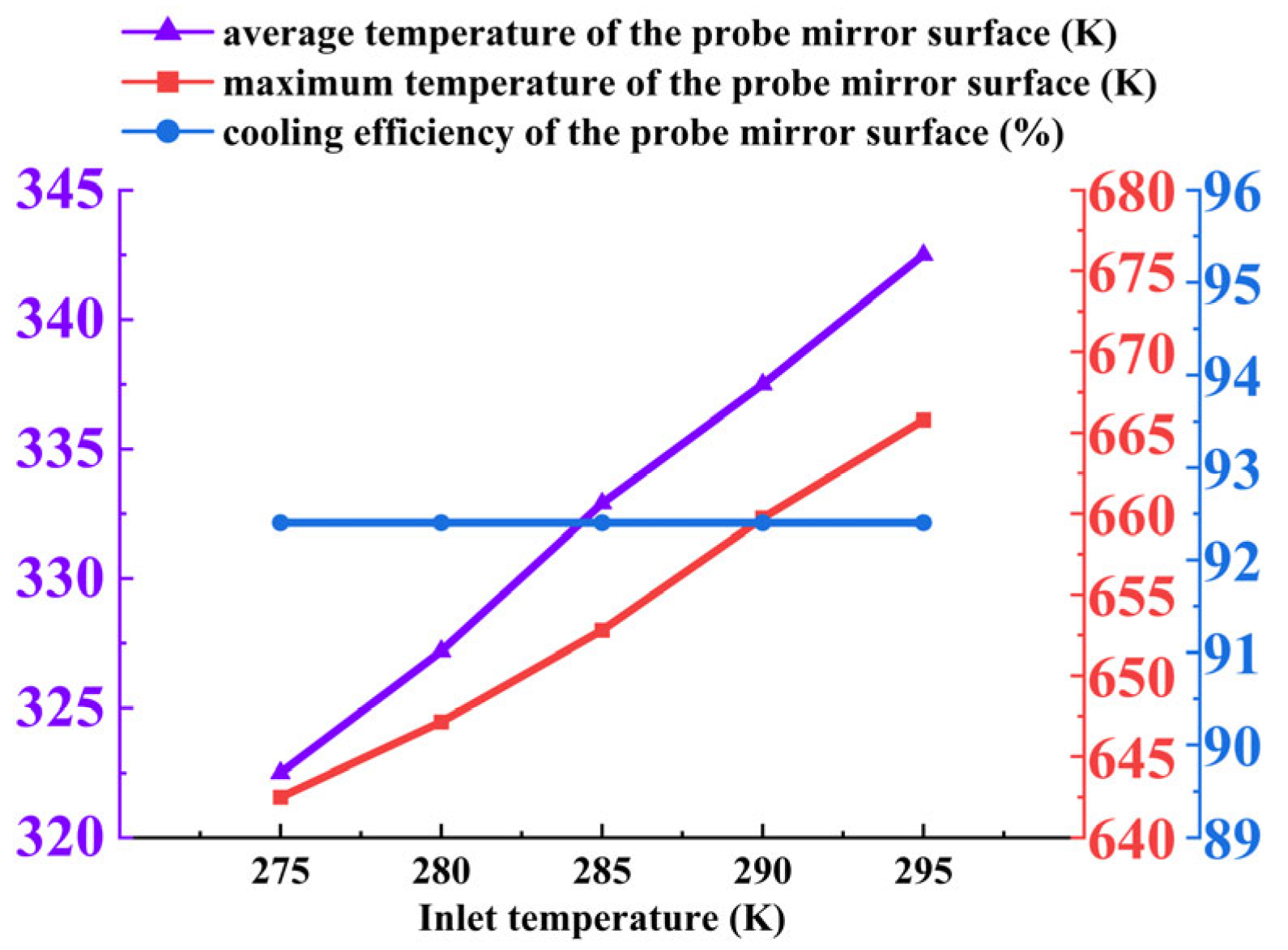

Figure 16,

Figure 17,

Figure 18 and

Figure 19 present the resulting mirror temperature, cooling efficiency, temperature distribution on the mirror surface, and cooling temperature field, respectively.

Variations in the coolant inlet temperature primarily affect the absolute temperature of the mirror surface while exerting negligible influence on the cooling efficiency and the distribution pattern of the downstream temperature field. The specific manifestations are as follows:

Mirror temperature and cooling efficiency: The average mirror temperature exhibits a strictly linear and proportional relationship with the inlet temperature, increasing from 320.63 K at 275 K to 339.16 K at 295 K. This occurs because the coolant acts as a “cold source”; an increase in its temperature directly raises the equilibrium wall temperature under steady-state heat transfer conditions. The cooling efficiency remains largely unchanged, indicating that the adiabatic effectiveness of the cooling film is unaltered, and both the flow structure and the coverage characteristics of the film remain stable.

Temperature field distribution: Under different temperature conditions, the contour morphology of the temperature field is highly consistent, indicating that the inlet temperature does not alter the flow behavior of the coolant or the spatial structure of the cooling film. Temperature variations result only in a uniform shift in the temperature values across the field, while the gradient and morphology remain unchanged. This is because, under a constant inlet pressure, temperature changes do not affect the momentum of the coolant, and thus the formation and coverage capability of the cooling film remain intact.

Summary of optimal conditions: Within the investigated parameter range, an inlet temperature of 275 K yields the lowest average mirror temperature (320.63 K), representing the optimum cooling condition. If cooling efficiency is used as the evaluation metric, the performance across temperature conditions is comparable. Therefore, the selection of the inlet temperature should consider practical engineering requirements: lower temperatures are preferable when minimizing mirror temperature is critical, whereas moderately higher temperatures may be adopted when economic efficiency is a priority without compromising the thermal insulation performance of the cooling film.

- (3)

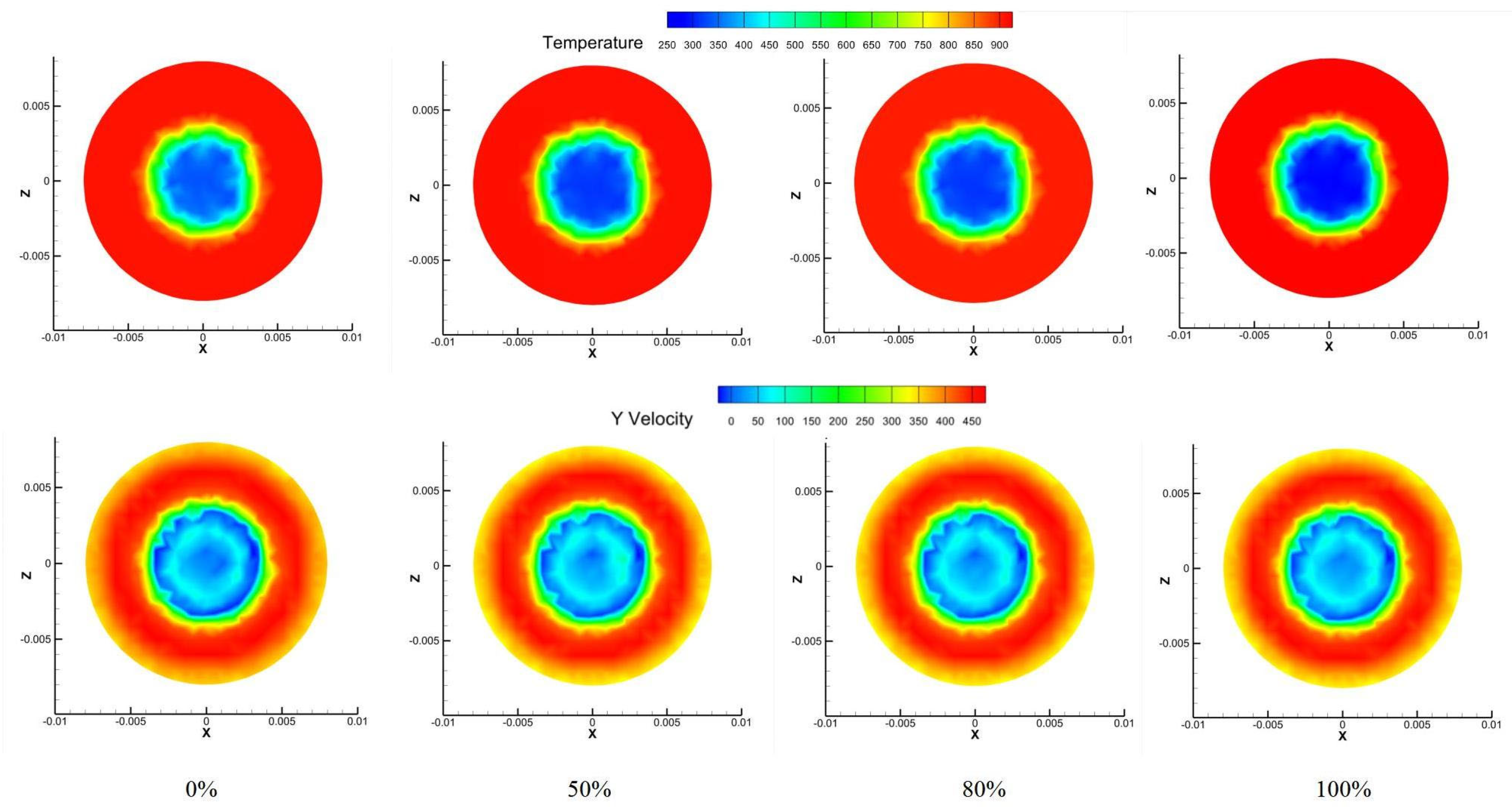

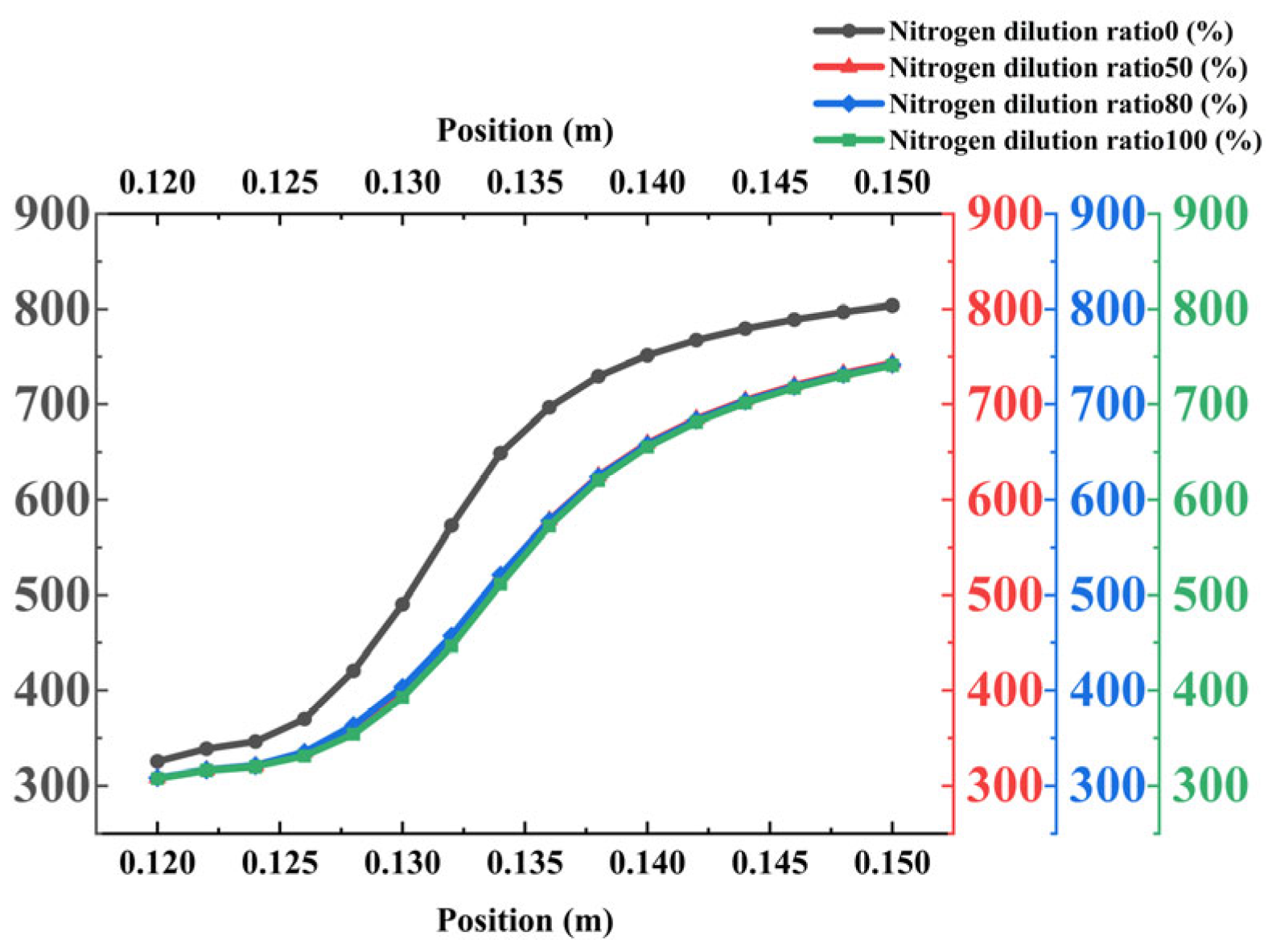

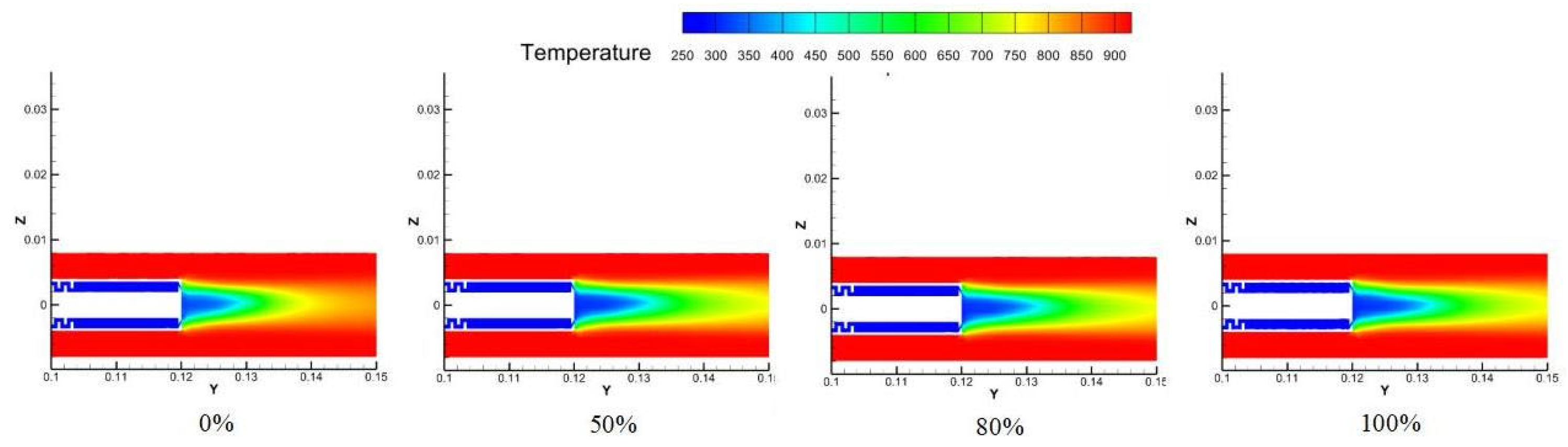

Influence of Coolant Nitrogen Mixing

This section investigates the influence of nitrogen concentration in the cooling air on the cooling performance of the borescope probe. Four nitrogen mixing ratios—0%, 50%, 80%, and 100%—were considered in this study. The corresponding results are shown in

Figure 20,

Figure 21,

Figure 22 and

Figure 23.

The influence of the nitrogen concentration in the coolant on the thermal performance of an annular cooling structure was investigated under four mixing ratios: 0%, 50%, 80%, and 100%. The key findings are summarized as follows:

Mirror temperature and cooling efficiency: As shown in

Figure 20, nitrogen doping significantly enhances cooling performance. The average mirror temperature decreases from 329.90 K (0% nitrogen) to 311.37 K (100% nitrogen), while the maximum temperature drops substantially from 382.14 K to 341.85 K. Correspondingly, the cooling efficiency shows notable improvement. This enhancement is attributed to nitrogen’s superior thermophysical properties, including higher specific heat capacity and improved thermal transport characteristics, which promote more efficient heat absorption and dissipation within the cooling film.

Flow velocity and temperature distribution:

Figure 21 demonstrates that nitrogen doping moderately reduces the flow velocity on the mirror surface due to the lower density of nitrogen compared to air. However, this velocity reduction is accompanied by improved flow uniformity and stability, contributing to more consistent cooling coverage. The temperature contours reveal that the low-temperature region expands significantly with increasing nitrogen concentration, particularly at a 50% mixing ratio.

Figure 22 and

Figure 23 further confirm that the spatial morphology of the temperature field remains consistent across different mixing ratios, with nitrogen primarily enhancing heat transfer efficiency rather than altering the fundamental flow structure. The improved thermal performance results from the enhanced convective heat transfer capabilities of the nitrogen-enriched mixture.

Summary of optimal conditions: The cooling performance of the annular structure is markedly improved by nitrogen doping, with a 50% nitrogen mixing ratio identified as optimal. This ratio achieves the best balance between heat transfer enhancement and flow characteristics, yielding the lowest mirror temperatures and highest cooling efficiency. Higher nitrogen concentrations (80–100%) do not provide additional benefits, indicating a saturation point in thermal performance improvement. The reduced flow velocity at higher nitrogen concentrations is compensated for by improved heat transfer efficiency, maintaining overall cooling effectiveness. For practical applications in aero-engine borescope systems, a 50% nitrogen mixture is recommended to maximize cooling performance while maintaining operational feasibility and economic efficiency.

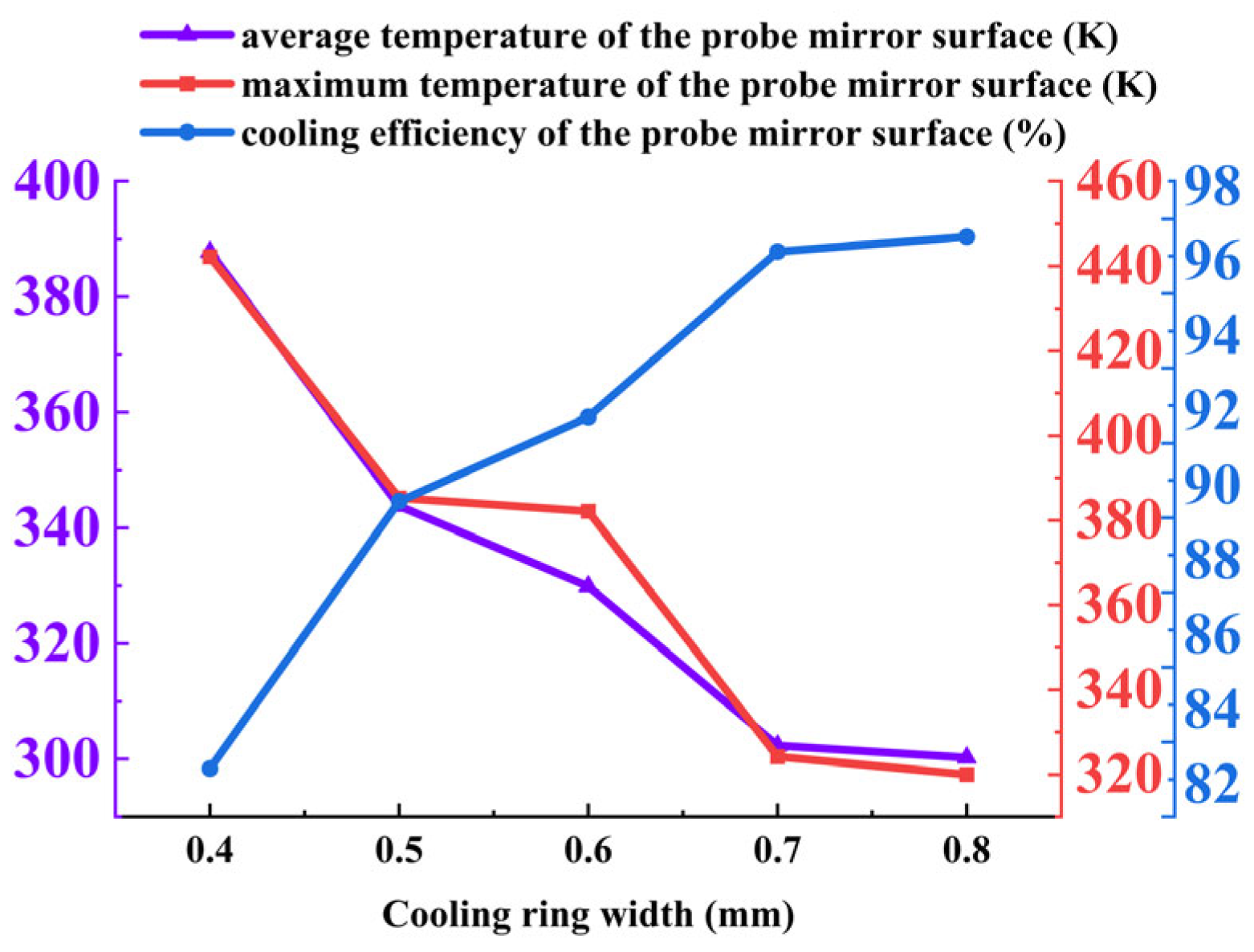

- (4)

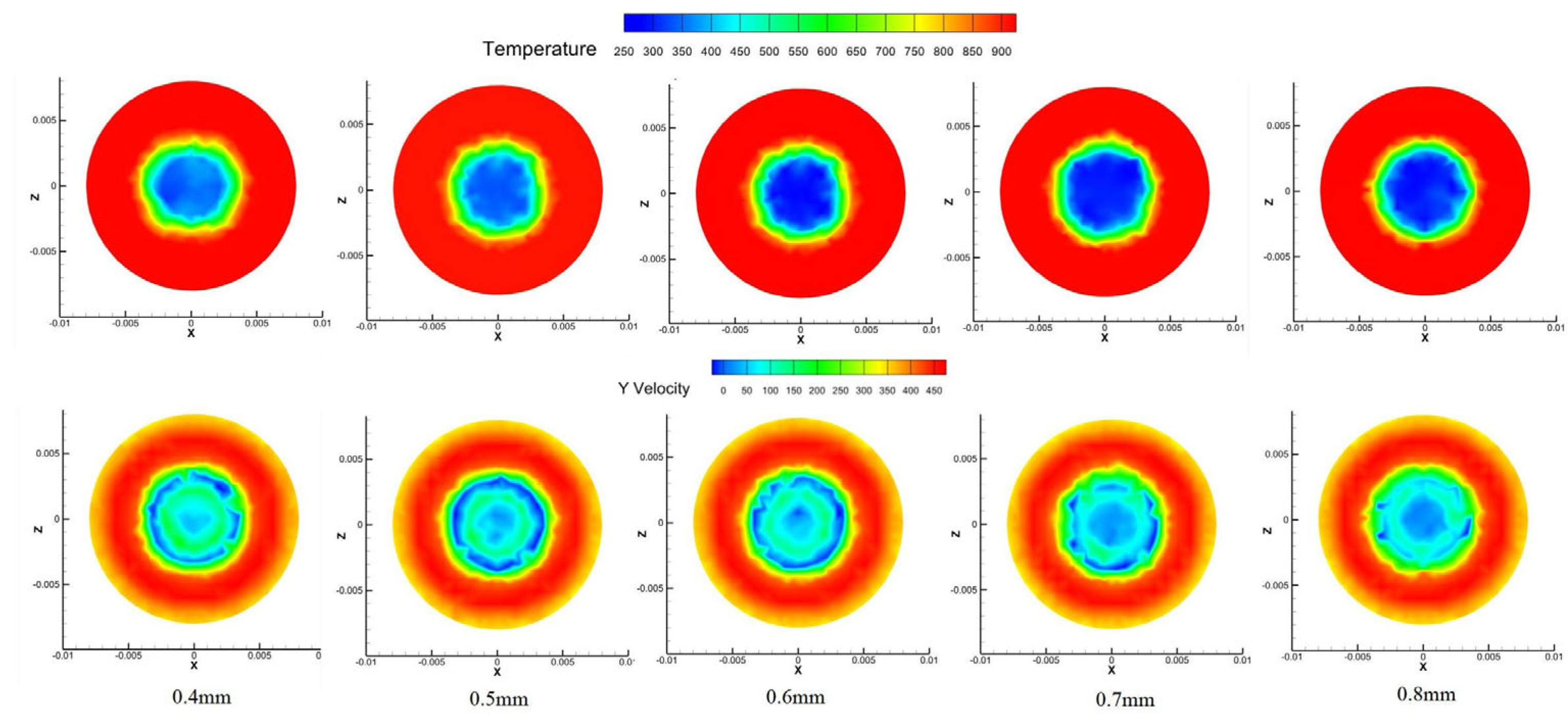

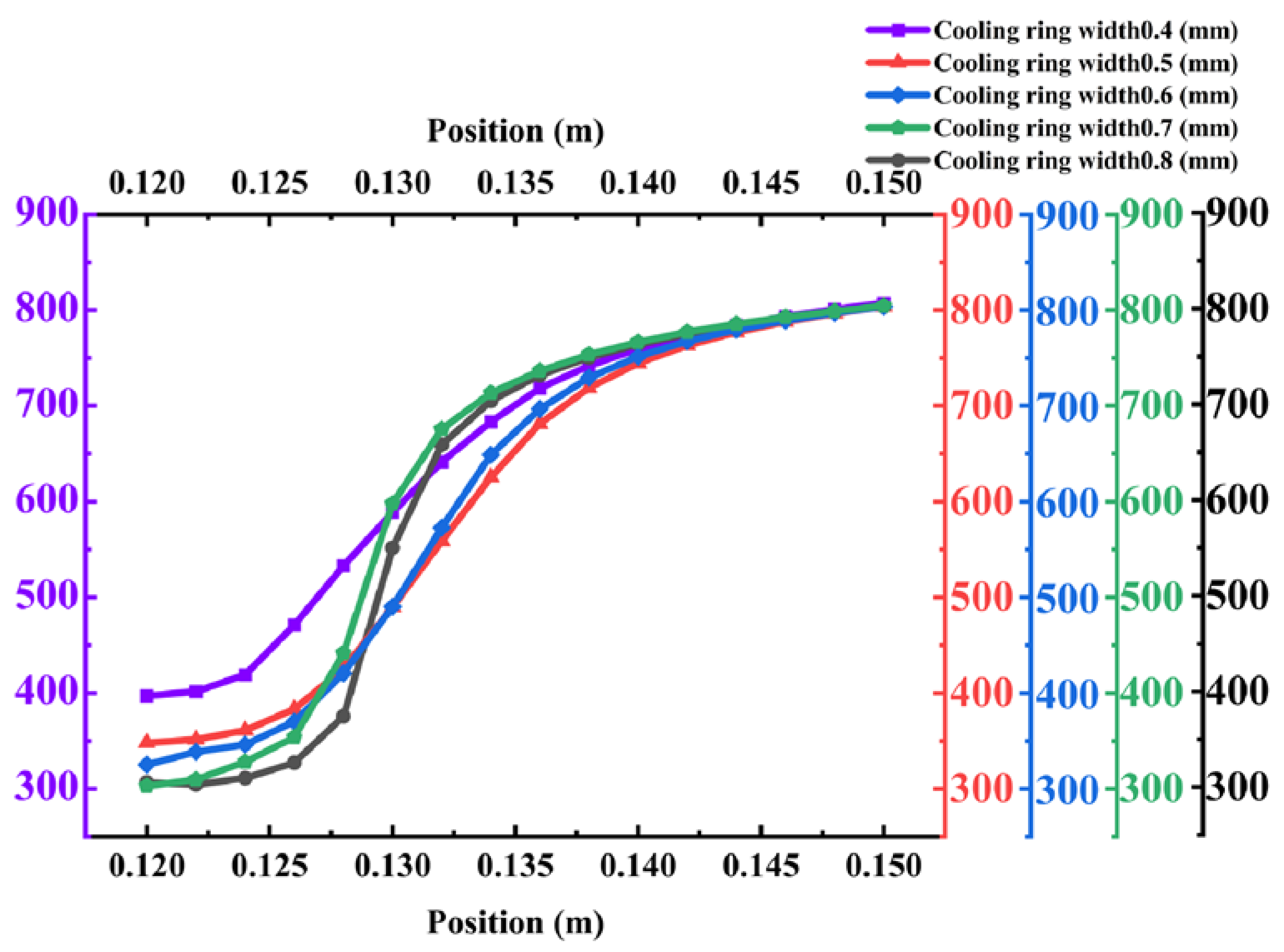

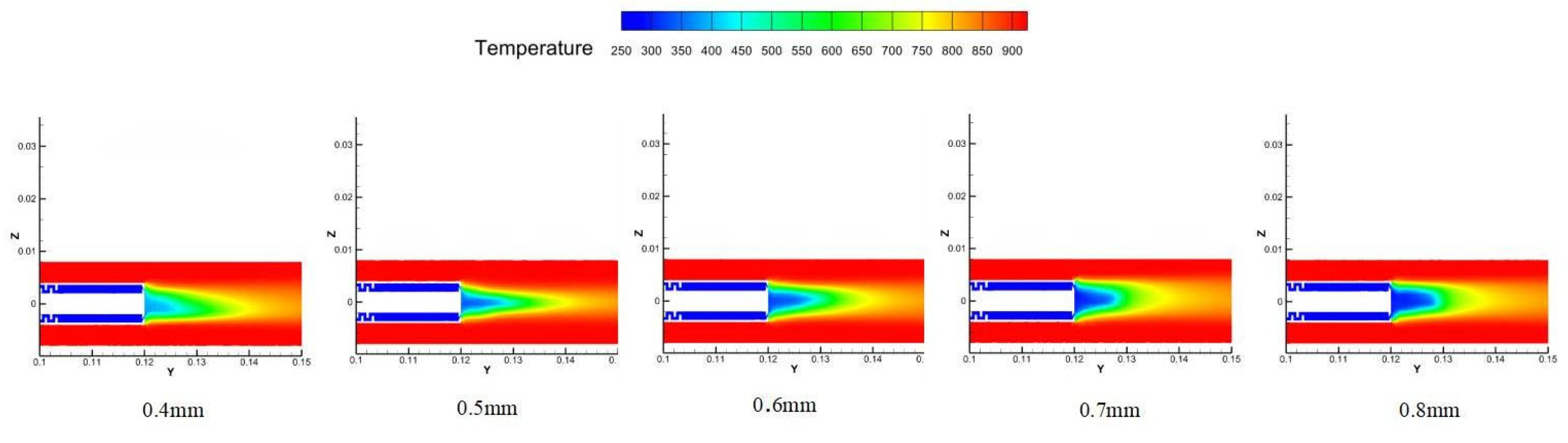

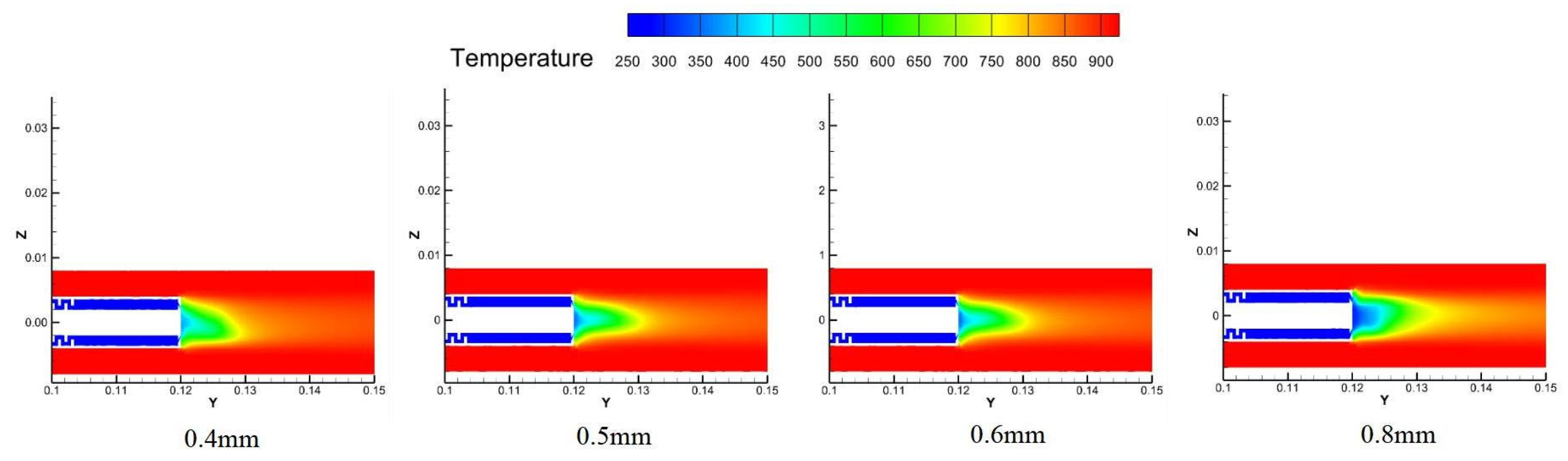

Influence of Cooling Ring Width

This section analyzes the influence of the cooling ring width on the cooling performance of the borescope probe. Five different cooling ring widths—0.4 mm, 0.5 mm, 0.6 mm, 0.7 mm, and 0.8 mm—were selected for comparative investigation. The corresponding results are presented in

Figure 24,

Figure 25,

Figure 26 and

Figure 27.

The influence of cooling ring width on the thermal performance of the annular cooling structure was investigated using five widths: 0.4 mm, 0.5 mm, 0.6 mm, 0.7 mm, and 0.8 mm. The key findings are summarized as follows:

Mirror temperature and cooling efficiency: As shown in

Figure 24, both the average and maximum mirror temperatures decrease significantly with increasing ring width. The average temperature declines from 387.77 K at 0.4 mm to 300.25 K at 0.8 mm, while the maximum temperature drops from 442.25 K to 320.05 K. Correspondingly, the cooling efficiency shows continuous improvement. This enhancement is attributed to the increased coolant mass flow rate at larger widths, which improves the coverage and heat transfer capacity of the cooling film.

Flow velocity and temperature distribution:

Figure 25 reveals that the flow velocity distribution on the mirror surface undergoes significant changes with increasing width. While larger widths enhance coolant flow rate, they also reduce the exit velocity due to the increased flow area. At smaller widths (0.4–0.5 mm), higher velocities are observed but with insufficient flow volume, resulting in poor cooling coverage. At a 0.6 mm width, an optimal balance is achieved between flow rate and velocity, providing both adequate coverage and sufficient momentum for effective heat transfer. Larger widths (0.7–0.8 mm) show further reduced velocities, compromising the cooling effectiveness in regions distant from the probe.

Figure 23 and

Figure 26 confirm that the temperature field distribution follows similar trends, with the most uniform thermal protection achieved at 0.6 mm width.

Summary of optimal conditions: The cooling ring width significantly affects the performance of the annular cooling structure. A width of 0.6 mm is identified as optimal, providing the best balance between coolant flow rate and exit velocity. This configuration keeps the average mirror temperature below 330 K while ensuring excellent lateral diffusion and thermal coverage. Smaller widths (0.4–0.5 mm) result in inadequate cooling due to limited flow volume, while larger widths (0.7–0.8 mm) suffer from reduced velocity, impairing cooling effectiveness in distal regions. For practical applications in aero-engine borescope systems, a cooling ring width of 0.6 mm is recommended to ensure comprehensive thermal protection while maintaining efficient coolant utilization.

4.3.2. Ring–Slit Structure Cooling Flow Field Analysis

- (1)

Influence of Coolant Inlet Pressure

For the ring–slit structure, this study employs the same pressure parameters as those used for the circular structure. Four coolant inlet pressures were applied: 0.2, 0.5, 0.8, and 1.0 MPa. The specific results of the analysis are presented below.

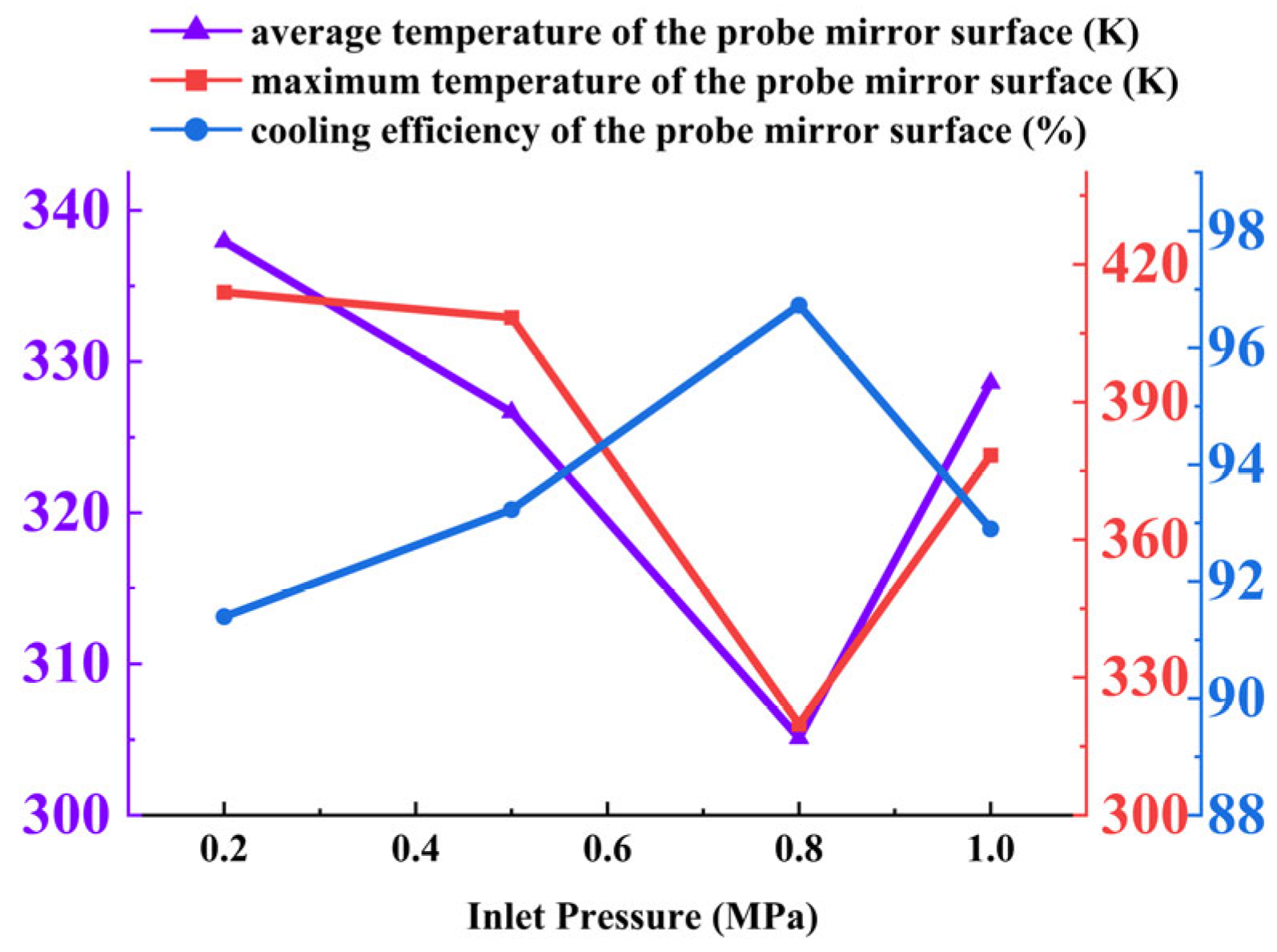

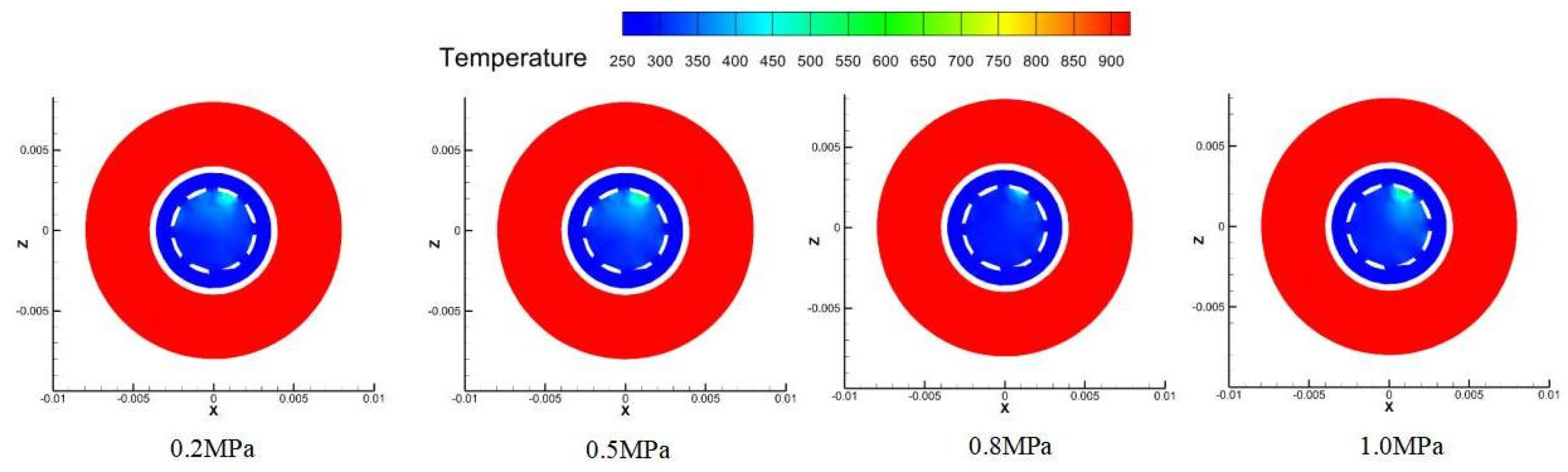

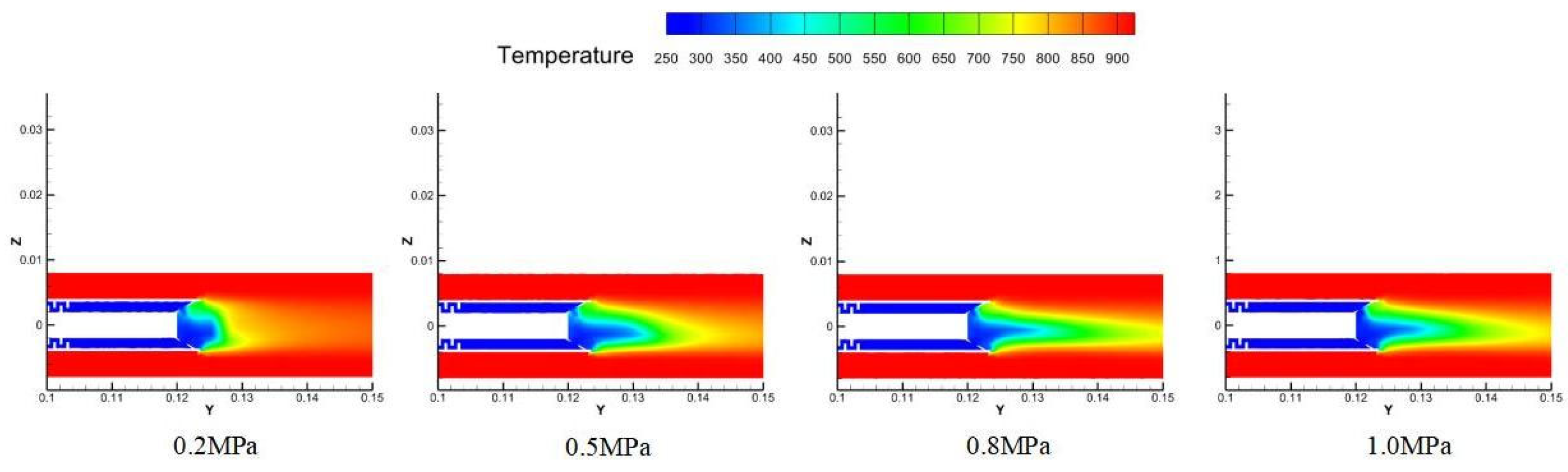

Mirror temperature and cooling efficiency: As shown in

Figure 28, the average mirror temperature decreases initially and then increases with rising coolant pressure, while the cooling efficiency first increases and then decreases. The optimal cooling performance occurs at 0.5 MPa, with an average mirror temperature of 331.37 K and a cooling efficiency of 92.4%. This trend is attributed to the requirement that the total pressure of the coolant must exceed that of the mainstream flow to effectively cover the probe surface. Excessively high pressure increases flow velocity, leading to intensified mixing and reduced residence time, thereby diminishing cooling effectiveness.

Temperature distribution characteristics:

Figure 29 reveals that the low-temperature region between the segmented ring slits expands as pressure increases, significantly improving cooling coverage. However, beyond 0.5 MPa, the expansion of the cooling region saturates. At lower pressures (e.g., 0.2 MPa), the cooling airflow fails to fully cover the areas between the slits, resulting in a cloverleaf-shaped cooling pattern. As pressure rises, the coolant undergoes sufficient heat exchange with the surrounding hot environment, causing the cooling zone to become more circular and uniform.

Temperature field evolution:

Figure 30 indicates that the temperature rise trend remains consistent across pressure conditions, but the rate of increase varies markedly. At 0.2 MPa, the temperature rises rapidly, reaching 750 K by 0.125 m. At 0.5 MPa and above, the temperature increase slows significantly, suggesting the formation of a stable and continuous cooling film.

Summary of optimal conditions: The ring–slit structure achieves optimal cooling performance at a coolant inlet pressure of 0.5 MPa, balancing high cooling efficiency (92.4%) and low mirror temperature (331.37 K). This pressure ensures sufficient coolant momentum to form a stable film without excessive velocity, which would promote mixing and reduce effectiveness. Lower pressures result in inadequate coverage and higher temperatures, while higher pressures offer no further improvement and increase coolant consumption. Thus, 0.5 MPa is recommended for practical applications to maximize cooling performance and operational efficiency.

- (2)

Influence of Coolant Inlet Temperature

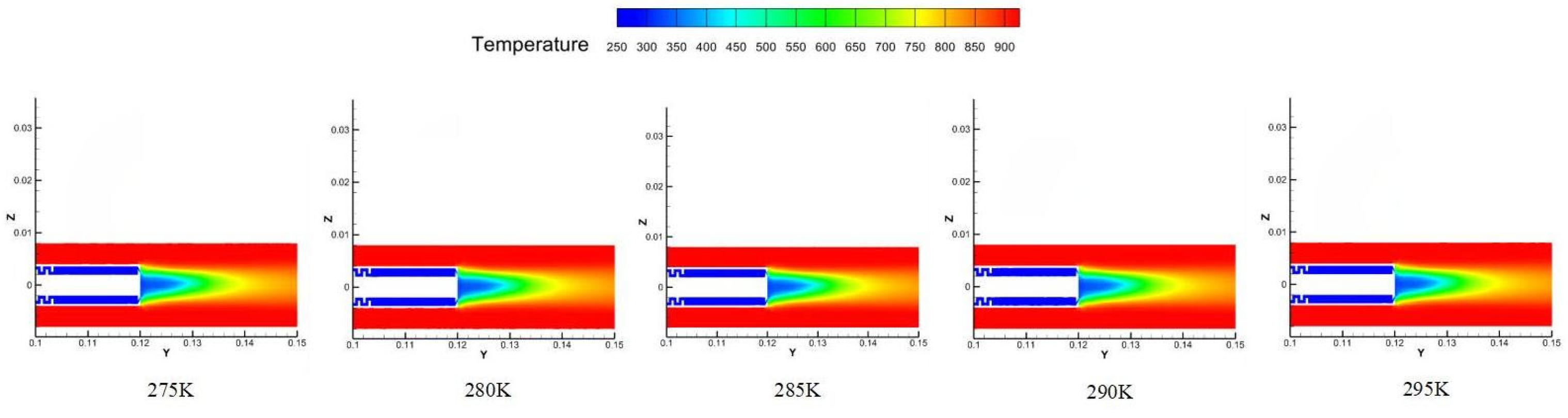

The influence of coolant inlet temperature on the cooling performance of the ring–slit structure was investigated under five temperature conditions: 275 K, 280 K, 285 K, 290 K, and 295 K. The key findings are summarized below:

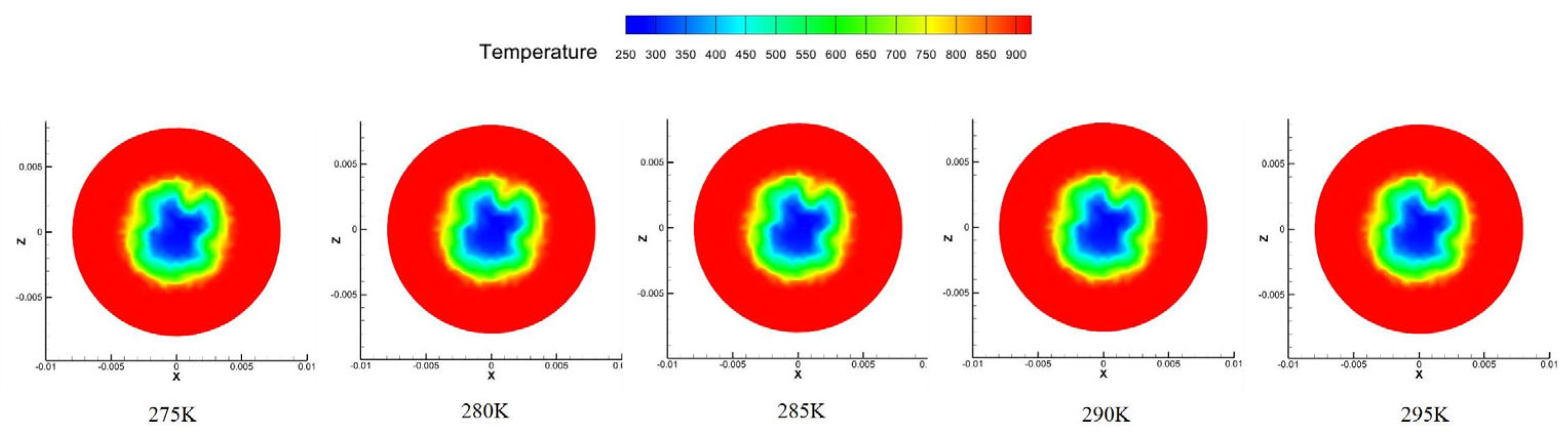

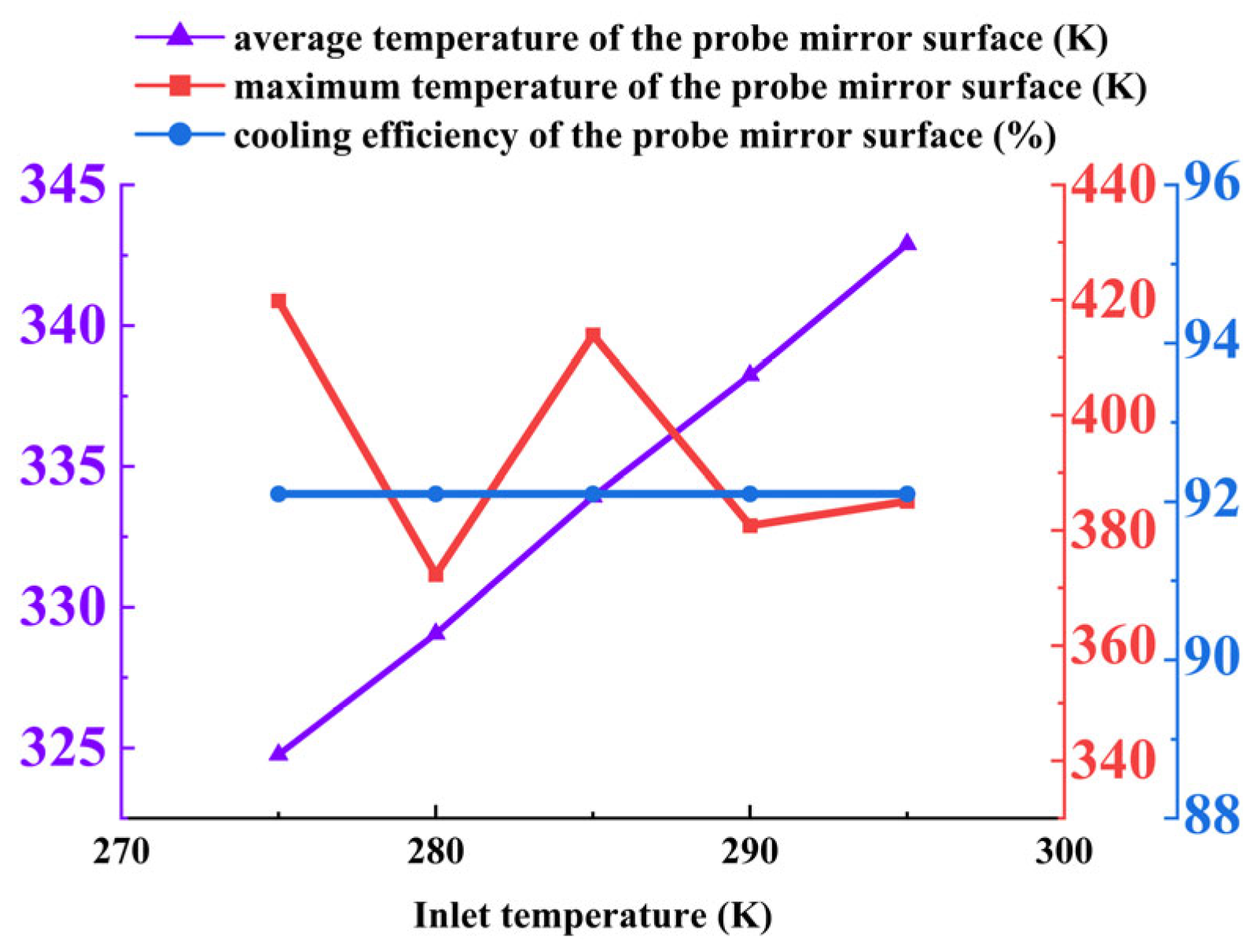

Mirror temperature and cooling efficiency: As shown in

Figure 31, the average temperature of the probe mirror exhibits a linear relationship with the coolant inlet temperature, increasing from 322.49 K at 275 K to 340.97 K at 295 K. In contrast, the cooling efficiency remains constant at 92.40% across all temperature conditions. This occurs because the coolant temperature directly influences the baseline temperature of the cooling source but does not alter the flow characteristics or the adiabatic effectiveness of the cooling film.

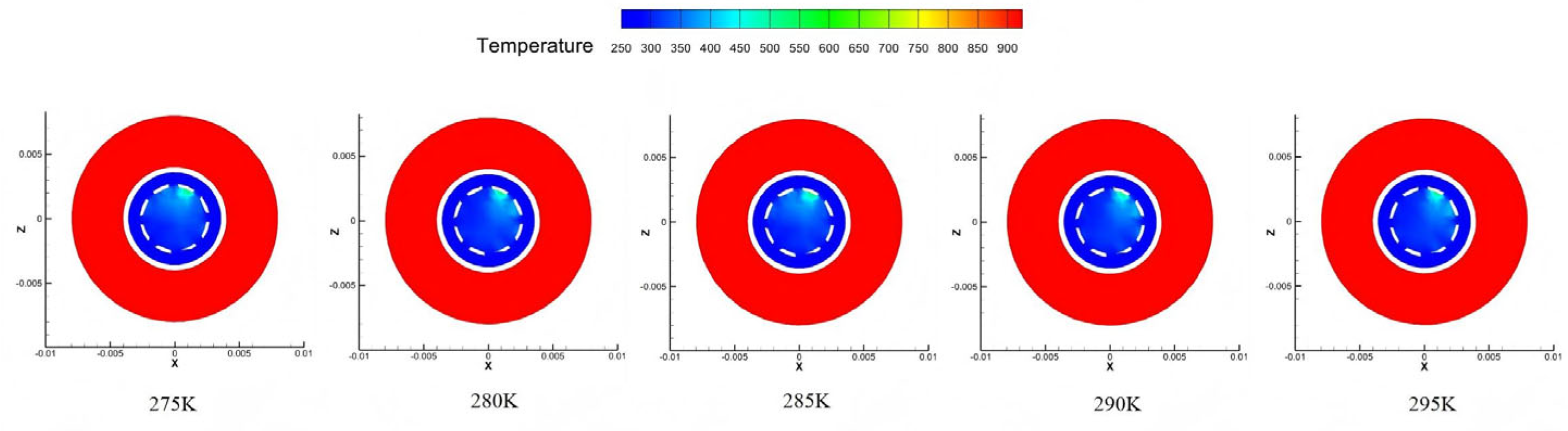

Temperature field distribution: Analysis of

Figure 32 indicates that variations in inlet temperature do not affect the spatial distribution of the temperature field. The morphology and gradient of the temperature contours remain consistent across all cases. The cooling film coverage, flow direction, and lateral diffusivity remain unchanged, confirming that temperature only shifts the absolute temperature values uniformly without impacting the flow structure or cooling mechanisms.

Summary of optimal conditions: The cooling performance of the ring–slit structure is primarily influenced by the absolute temperature of the coolant. While lower inlet temperatures, such as 275 K, yield the lowest mirror temperature (322.49 K), the cooling efficiency remains unaffected by temperature variations. Therefore, the selection of the optimal inlet temperature should be based on specific application requirements: lower temperatures are suitable when minimizing the absolute mirror temperature is critical, whereas higher temperatures may be used to reduce operational costs without sacrificing cooling efficiency.

- (3)

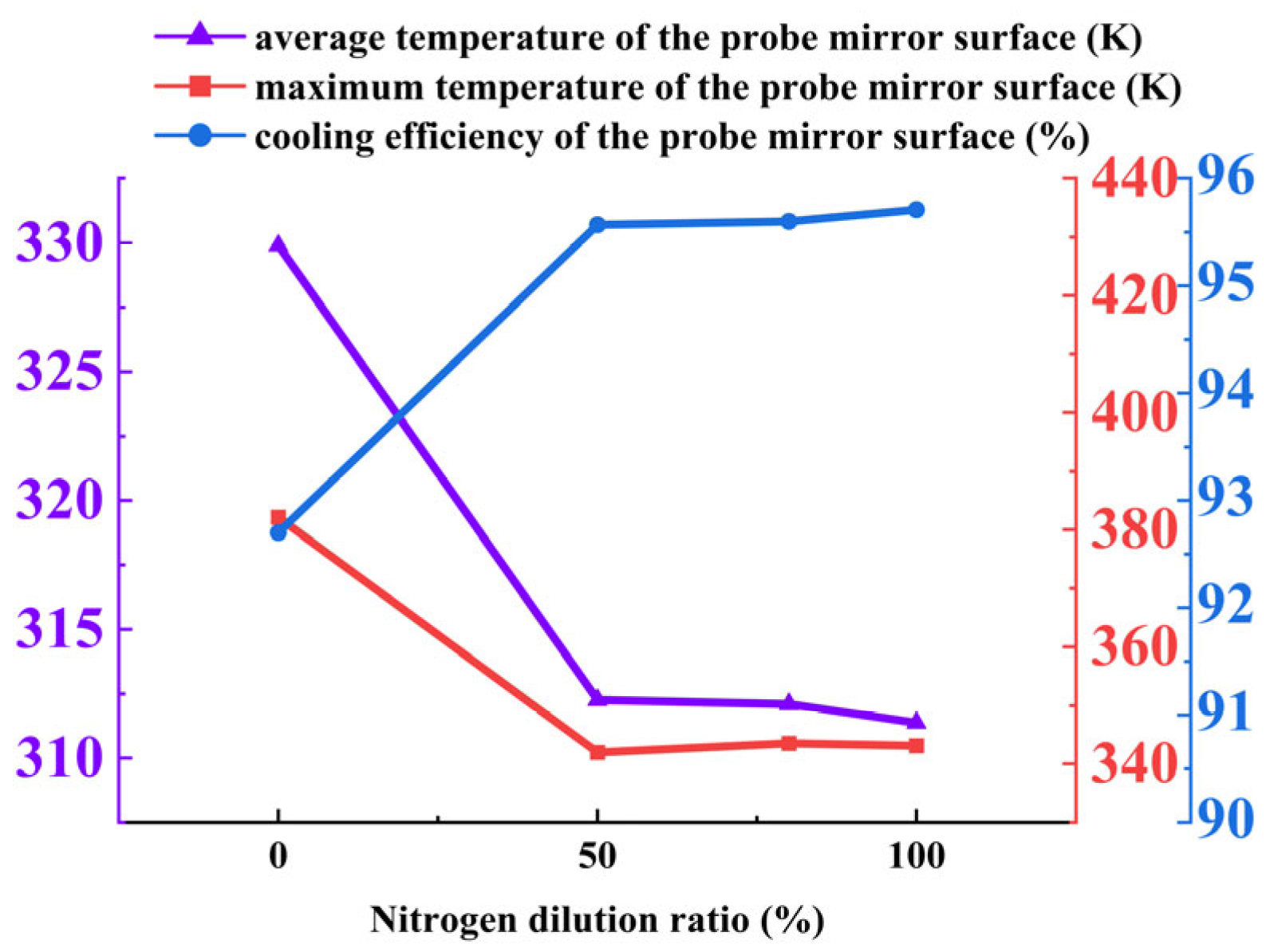

Influence of Coolant Nitrogen Mixing

The influence of the nitrogen concentration in the cooling air on the thermal performance of the borescope probe under the ring–slit configuration was investigated. Four nitrogen mixing ratios—0%, 50%, 80%, and 100%—were examined. The key findings are summarized as follows:

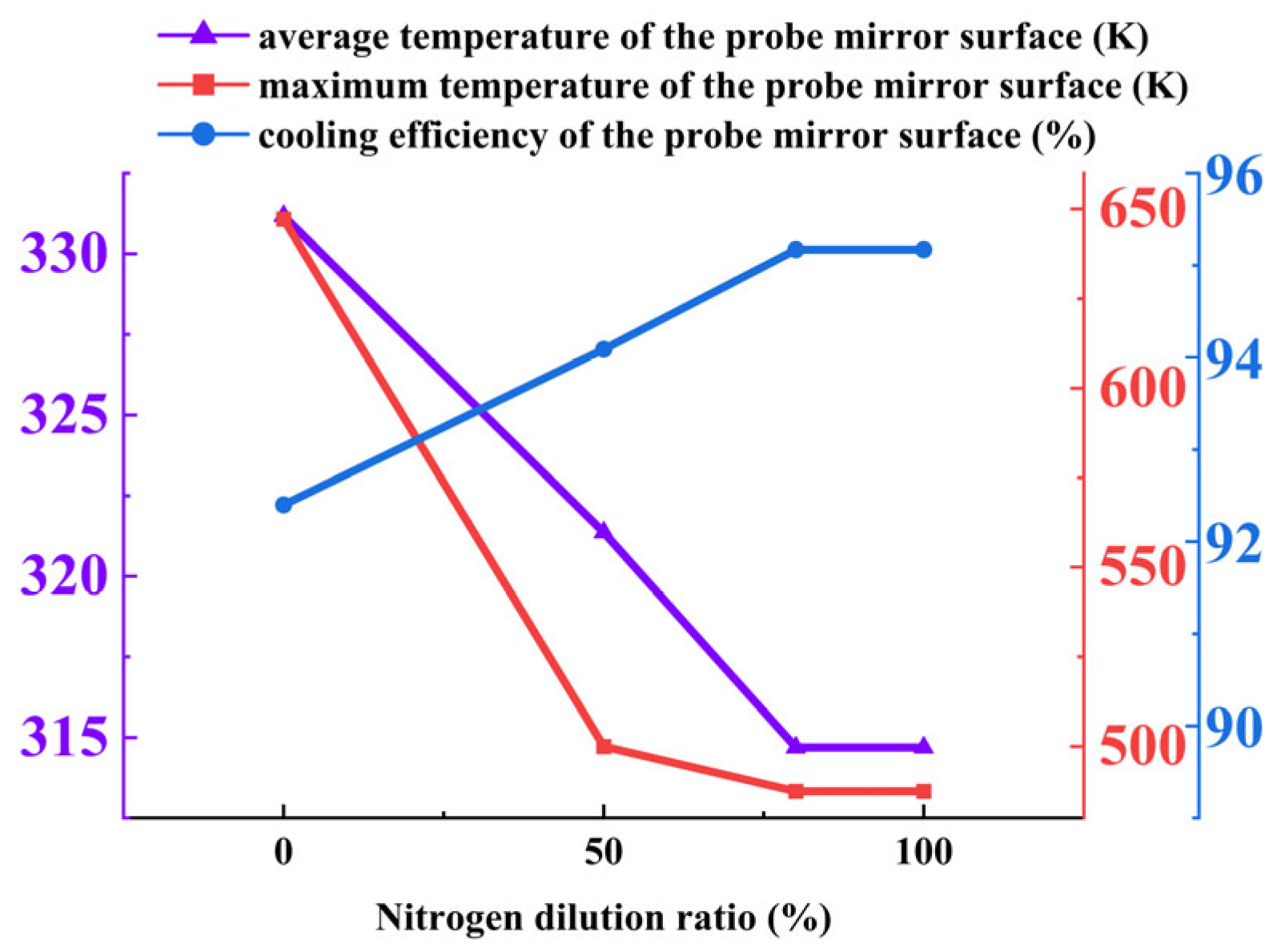

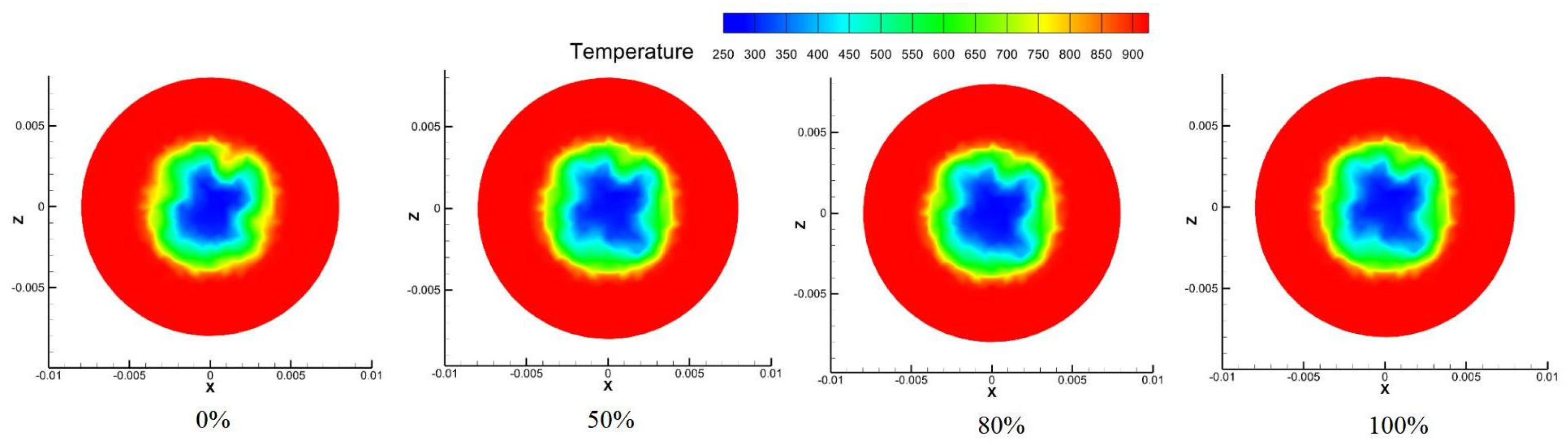

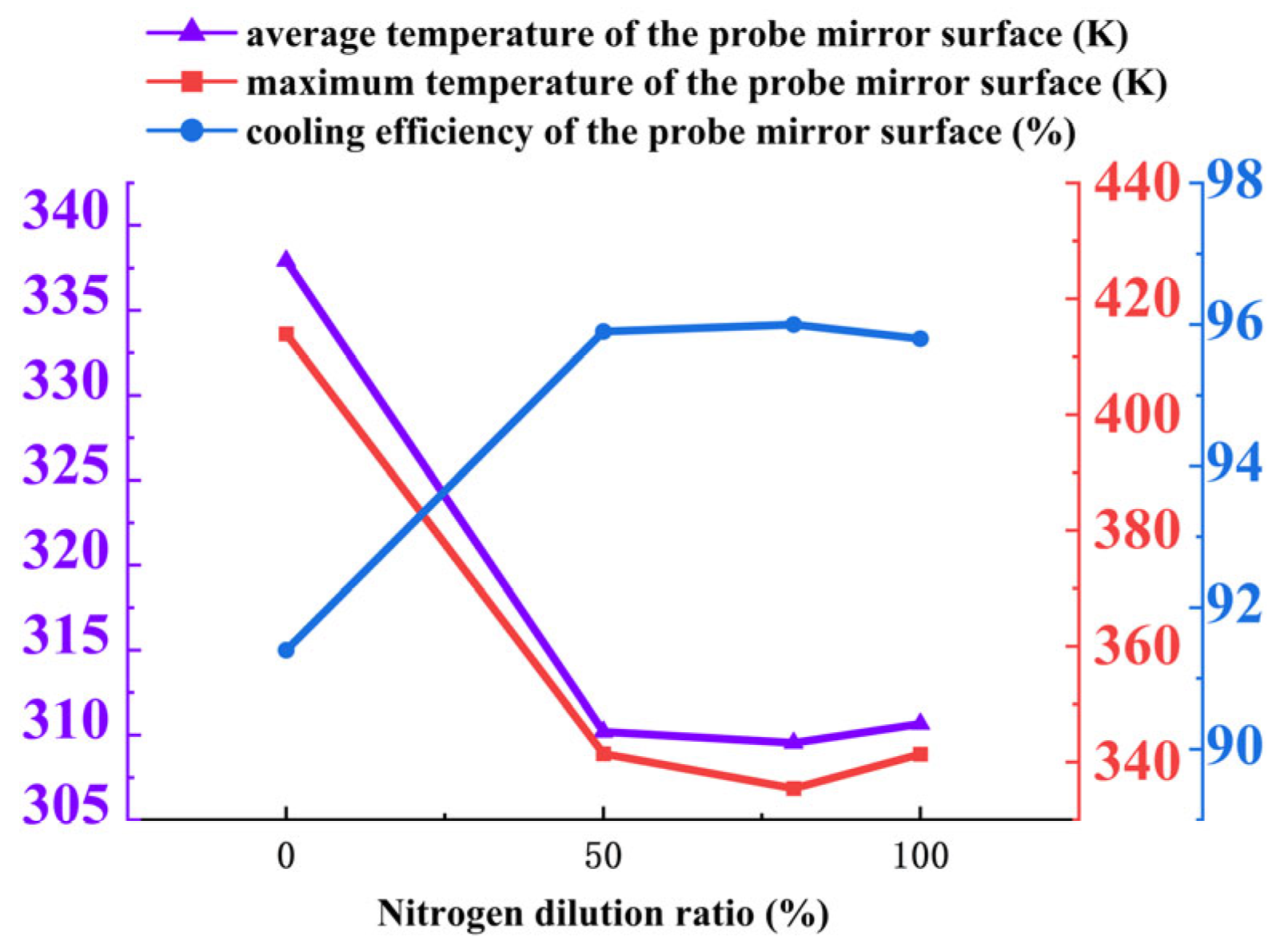

Mirror temperature and cooling efficiency: As illustrated in

Figure 33, nitrogen doping significantly enhances cooling performance. The average mirror temperature decreases from 331.17 K (0% nitrogen) to 314.69 K (100% nitrogen), while the maximum temperature drops substantially from 647.14 K to 487.50 K. Correspondingly, the cooling efficiency increases from 92.40% to 95.17%. This improvement is attributed to the superior thermophysical properties of nitrogen, including higher specific heat capacity and improved thermal transport characteristics, which enhance heat absorption and dissipation within the cooling film.

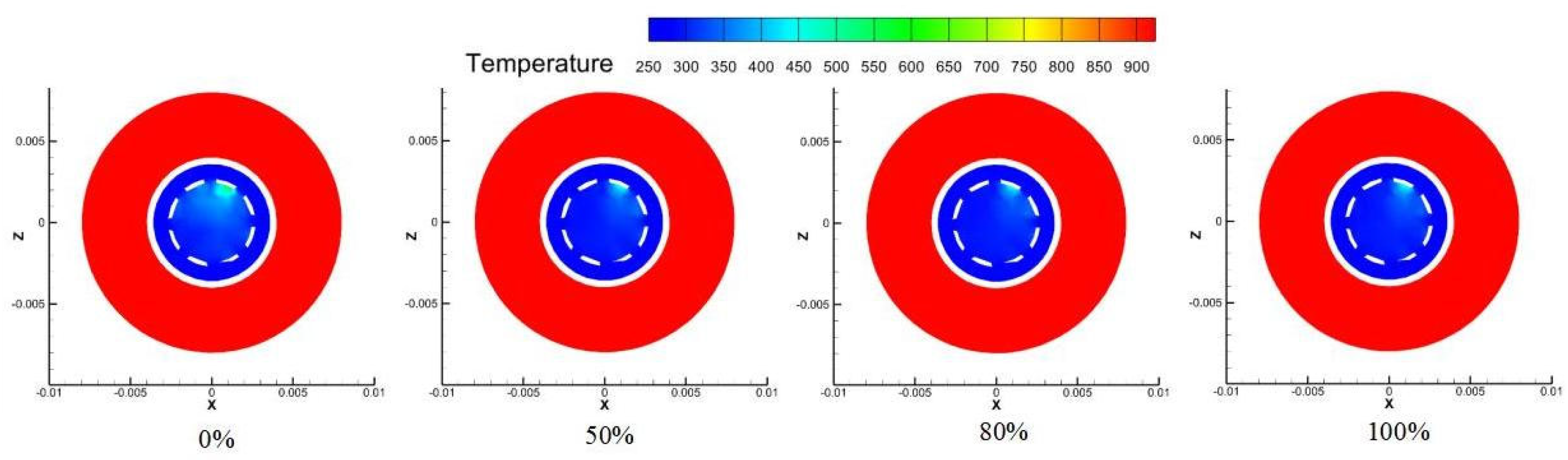

Temperature field distribution: Analysis of

Figure 34 indicates that nitrogen doping considerably expands the low-temperature region on the probe mirror. A notable enlargement of the cooling zone is observed as the nitrogen ratio increases from 0% to 50%. Beyond 50%, further increases yield diminishing returns, with the temperature field morphology remaining largely unchanged at 80% and 100% nitrogen.

Summary of optimal conditions: The introduction of nitrogen into the coolant markedly improves the cooling effectiveness of the ring–slit structure. A nitrogen mixing ratio of 50% is identified as the optimum ratio, providing the best balance between performance enhancement and practical applicability. At this ratio, the cooling effect is significantly improved without substantial additional gains at higher concentrations. These results suggest that nitrogen doping can be strategically used to enhance thermal protection in high-temperature environments, with 50% offering a cost-effective and efficient solution for borescope probe cooling applications.

- (4)

Influence of Cooling Slit Width

The influence of cooling slit width on the thermal performance of the borescope probe was investigated under the ring–slit configuration. Four slit widths—0.4 mm, 0.5 mm, 0.6 mm, and 0.8 mm—were compared. The key observations are summarized below:

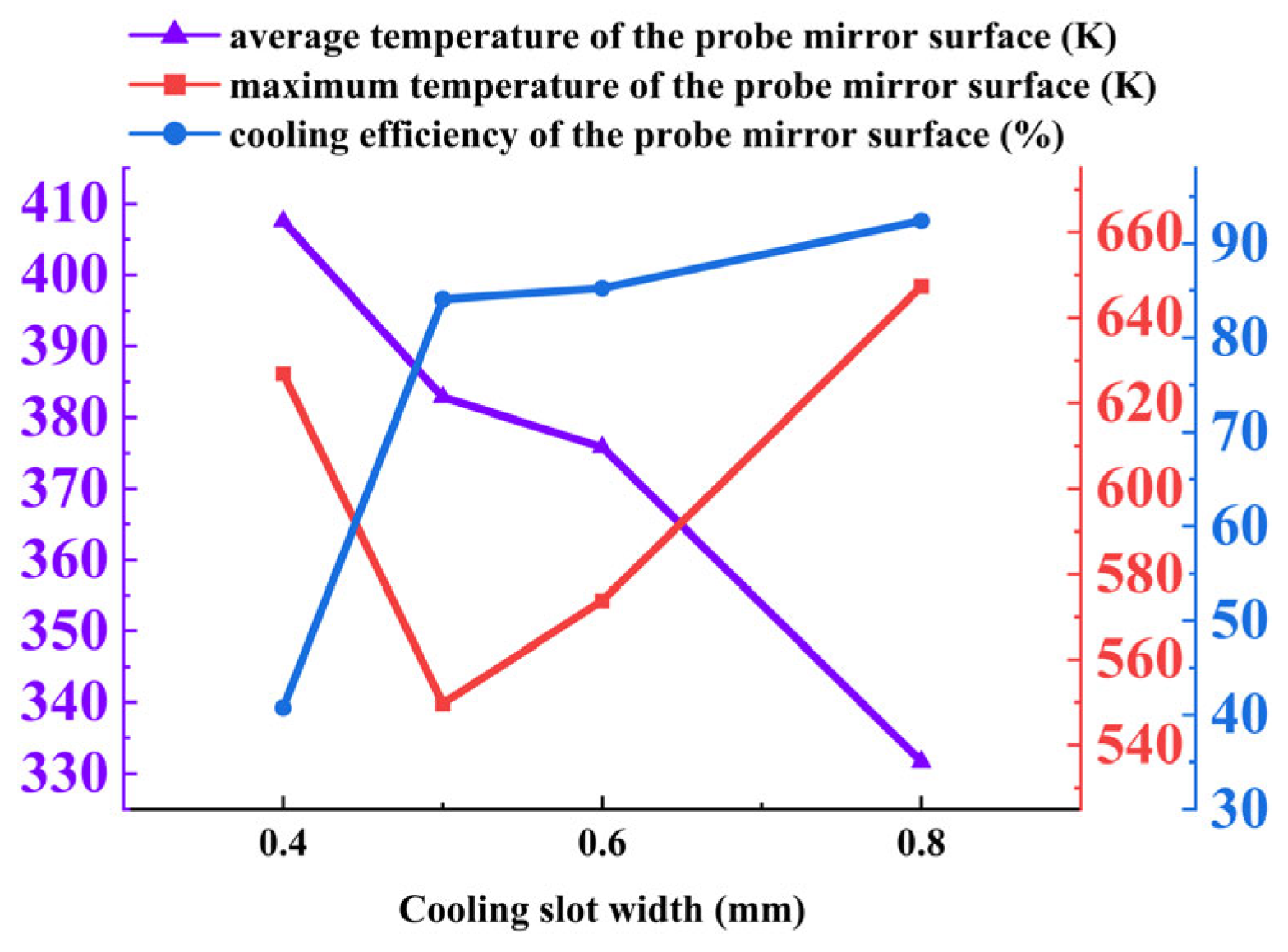

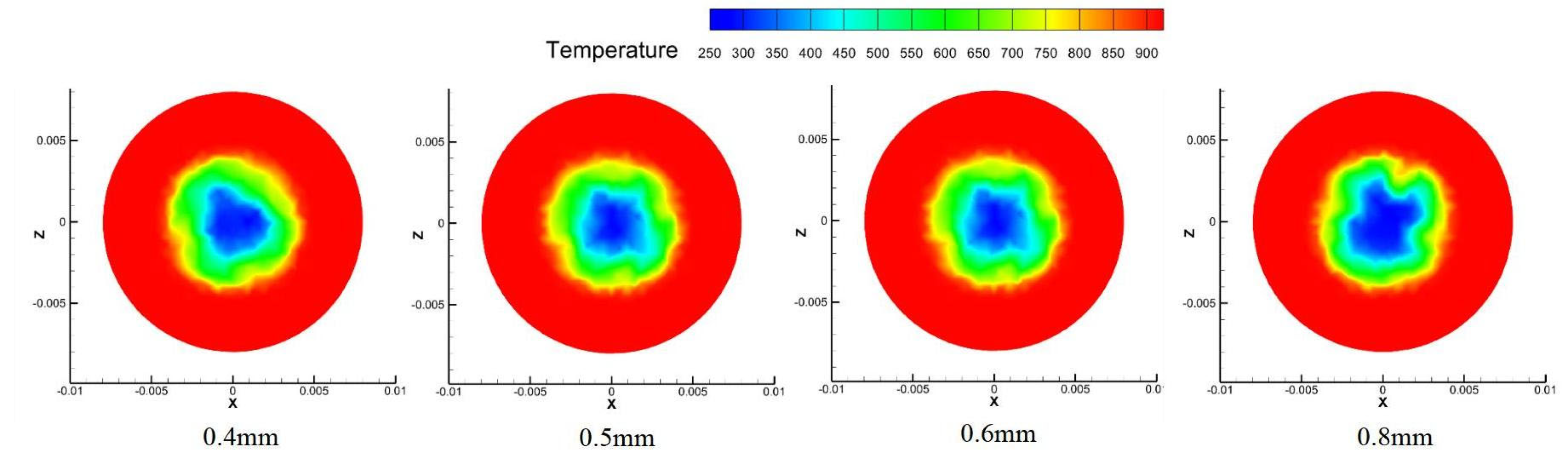

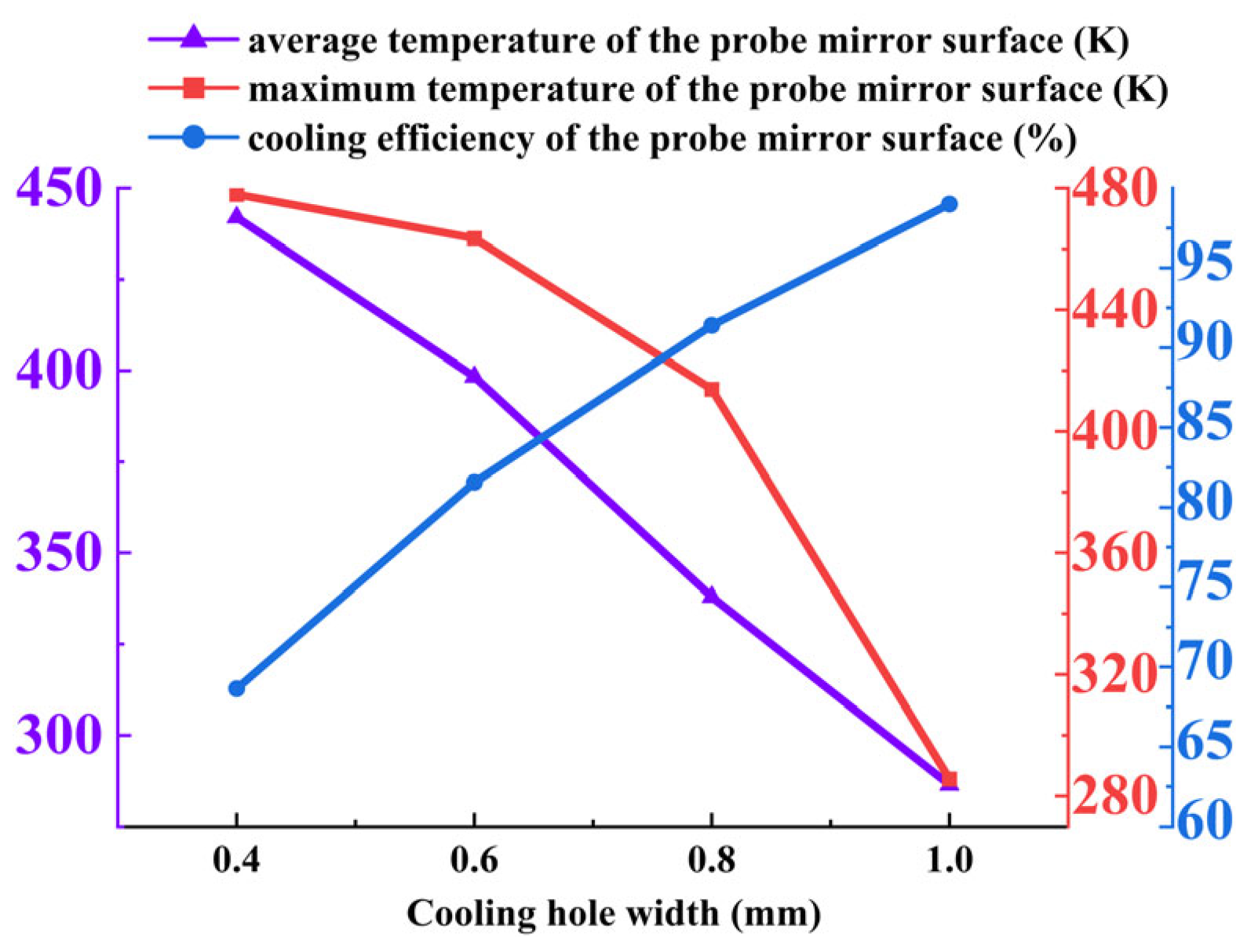

Mirror temperature and cooling efficiency: As shown in

Figure 35, increasing the slit width significantly improves cooling performance. The average mirror temperature decreases substantially from 407.54 K at 0.4 mm to 331.68 K at 0.8 mm, while the cooling efficiency increases markedly from 40.75% to 92.40%. However, the maximum mirror temperature exhibits a non-monotonic trend, reaching a minimum of 549.73 K at 0.5 mm and rising above 625 K at both 0.4 mm and 0.8 mm. This behavior is attributed to the trade-off between coolant flow rate and velocity: narrower slits provide insufficient flow for adequate cooling, while wider slits reduce flow velocity, compromising local heat transfer and resulting in incomplete cooling in certain regions.

Temperature field distribution: Analysis of

Figure 36 and

Figure 37 indicates that the cooling area on the mirror surface expands with increasing slit width due to higher coolant flow rate. The temperature field distribution ahead of the probe remains consistent across different slit widths, with temperature curves largely overlapping except for the 0.4 mm case, where temperatures are notably higher. This suggests that slit width has limited influence on the overall morphology of the temperature field but significantly affects the absolute temperature levels and local cooling uniformity.

Summary of optimal conditions: The cooling slit width has a profound impact on the performance of the ring–slit cooling structure. A width of 0.5 mm is identified as the optimum width, achieving the lowest maximum mirror temperature (549.73 K) while maintaining excellent average temperature reduction and cooling efficiency. Narrower widths (e.g., 0.4 mm) suffer from insufficient coolant flow, whereas wider widths (e.g., 0.8 mm) reduce flow velocity, leading to localized overheating. These findings highlight the importance of balancing flow rate and velocity to ensure efficient and uniform cooling. For practical applications, a slit width of 0.5 mm is recommended to maximize thermal protection and operational reliability.

4.3.3. Hole-Type Structure Cooling Flow Field Analysis

- (1)

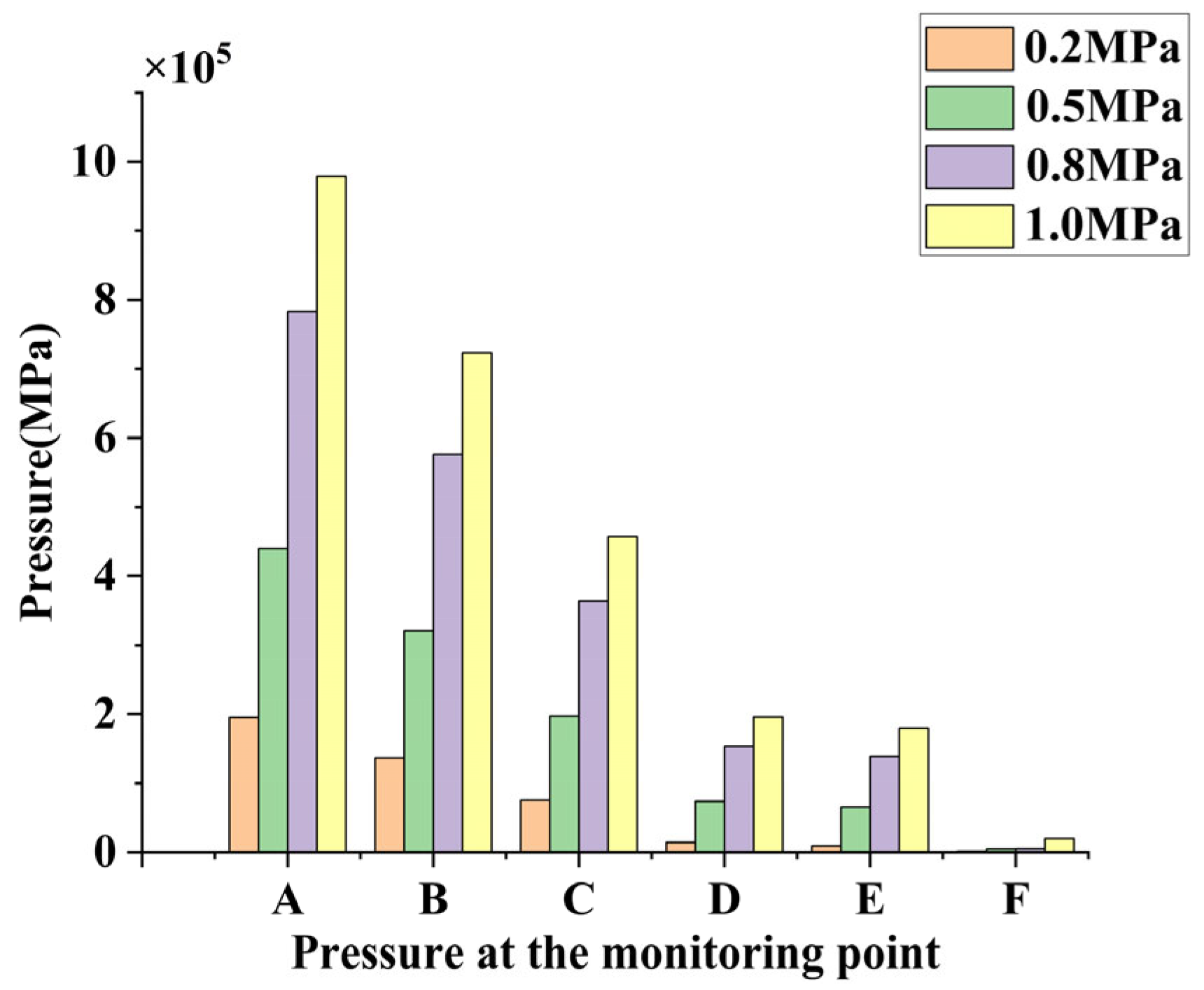

Influence of Coolant Inlet Pressure

The influence of coolant inlet pressure on the cooling performance of the hole-type structure was investigated. Key observations from

Figure 38,

Figure 39 and

Figure 40 are summarized as follows:

Mirror temperature and cooling efficiency: As shown in

Figure 38, the average and maximum temperatures of the probe mirror exhibit a non-monotonic relationship with the inlet pressure, initially decreasing and then increasing as the pressure rises from 0.2 MPa to 1.0 MPa. The optimum cooling performance occurs at 0.8 MPa, where the average and maximum mirror temperatures reach their lowest values of 305.10 K and 319.85 K, respectively, and the cooling efficiency peaks at 96.73%. This trend is attributed to the balance between coolant momentum and flow distribution: moderate pressure ensures sufficient penetration and formation of a continuous cooling film, while excessive pressure promotes mixing and reduces residence time.

Temperature field distribution: Analysis of

Figure 39 and

Figure 40 indicates that the inlet pressure has minimal impact on the temperature distribution very close to the mirror surface. However, as the distance from the mirror increases, higher pressures significantly expand the cooling coverage and enhance the effectiveness of the air film.

Summary of optimal conditions: The hole-type cooling structure demonstrates superior performance at a coolant inlet pressure of 0.8 MPa, achieving the lowest mirror temperatures and the highest cooling efficiency (96.73%). This pressure provides the ideal compromise between coolant momentum and flow stability, ensuring effective film formation without excessive mixing. Lower pressures result in inadequate cooling coverage, while higher pressures diminish performance due to reduced film adherence and increased mixing. For practical applications in aero-engine environments, 0.8 MPa is recommended to maximize cooling effectiveness and operational reliability.

- (2)

Influence of Coolant Inlet Temperature

Analysis of

Figure 41 and

Figure 42 indicates that the average temperature of the hole probe mirror in the circular hole structure changes linearly with the change in the coolant inlet temperature and the cooling efficiency is unchanged, which is consistent with the results of the circular ring and the ring–slit structure. In analyzing the distribution of the temperature field under the conditions of different temperature coolant inlet conditions in the circular hole structure, with a small increase in the coolant inlet temperature, the temperature increase in the temperature field also changes linearly and the trend of change is consistent; at this time, the distribution of the temperature field cloud diagram is basically the same.

- (3)

Influence of Coolant Nitrogen Mixing

The influence of the nitrogen concentration in the coolant on the thermal performance of the hole-type cooling structure was investigated. Four nitrogen mixing ratios—0%, 50%, 80%, and 100%—were examined. The key findings are summarized below:

Mirror temperature and cooling efficiency: As demonstrated in

Figure 43, nitrogen doping significantly enhances cooling performance, though the improvement is non-monotonic. Both the average and maximum mirror temperatures decrease initially and then increase slightly beyond an optimum point. The best performance is achieved at a nitrogen mixing ratio of 80%, where the average temperature is reduced from 337.93 K (0% nitrogen) to 309.55 K and the maximum temperature drops from 413.92 K to 335.43 K. Correspondingly, the cooling efficiency increases from 91.40% to 96.10%. This enhancement is attributed to the improved thermophysical properties of the nitrogen-enriched coolant, which promote more efficient heat absorption and dissipation within the cooling film.

Temperature field distribution: Analysis of

Figure 44 indicates that the cooling coverage area on the probe mirror expands as the nitrogen ratio increases up to 80%. The low-temperature region is most extensive at this ratio, confirming the optimal cooling effect. Beyond 80%, no significant further improvement is observed in the temperature field distribution, suggesting a saturation of the beneficial thermal effects. The overall morphology of the temperature field remains consistent, with nitrogen doping primarily influencing the absolute temperature levels rather than the flow structure.

Summary of optimal conditions: The cooling performance of the hole-type structure is markedly improved by nitrogen doping, with an 80% nitrogen mixing ratio identified as optimal. This ratio achieves the lowest mirror temperatures and the highest cooling efficiency, representing the best balance between performance enhancement and practical feasibility. Higher nitrogen concentrations do not yield additional benefits, indicating a performance plateau beyond 80%. These results suggest that nitrogen doping can be effectively employed to enhance cooling in high-temperature environments, with an 80% mixture offering the most efficient and economically viable solution for borescope probe applications.

- (4)

Influence of Cooling Hole Diameter

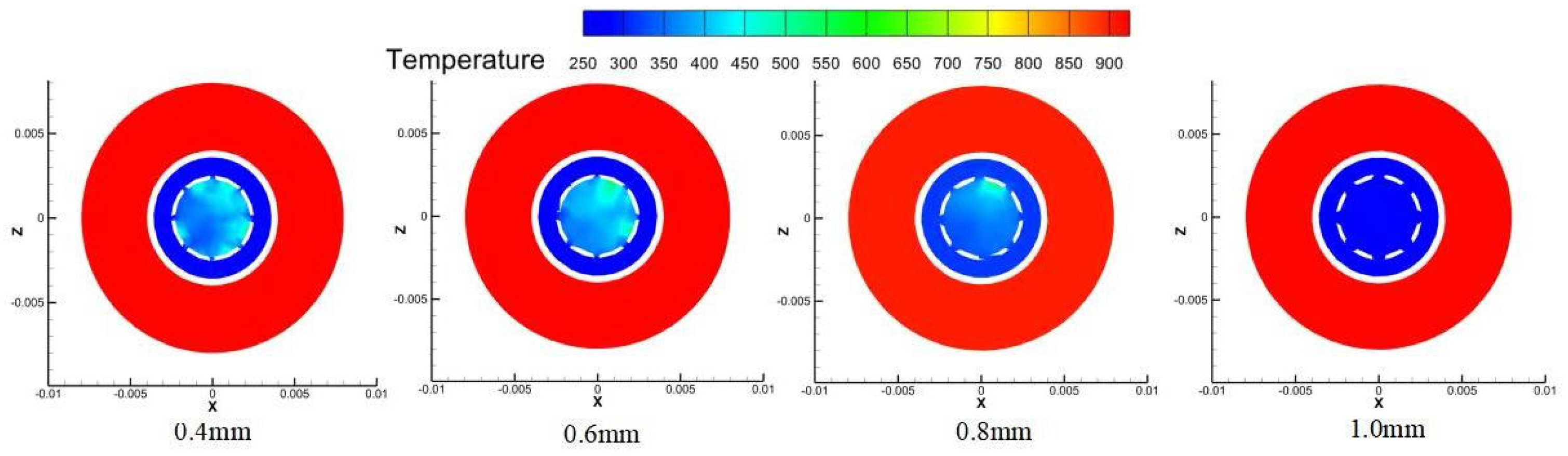

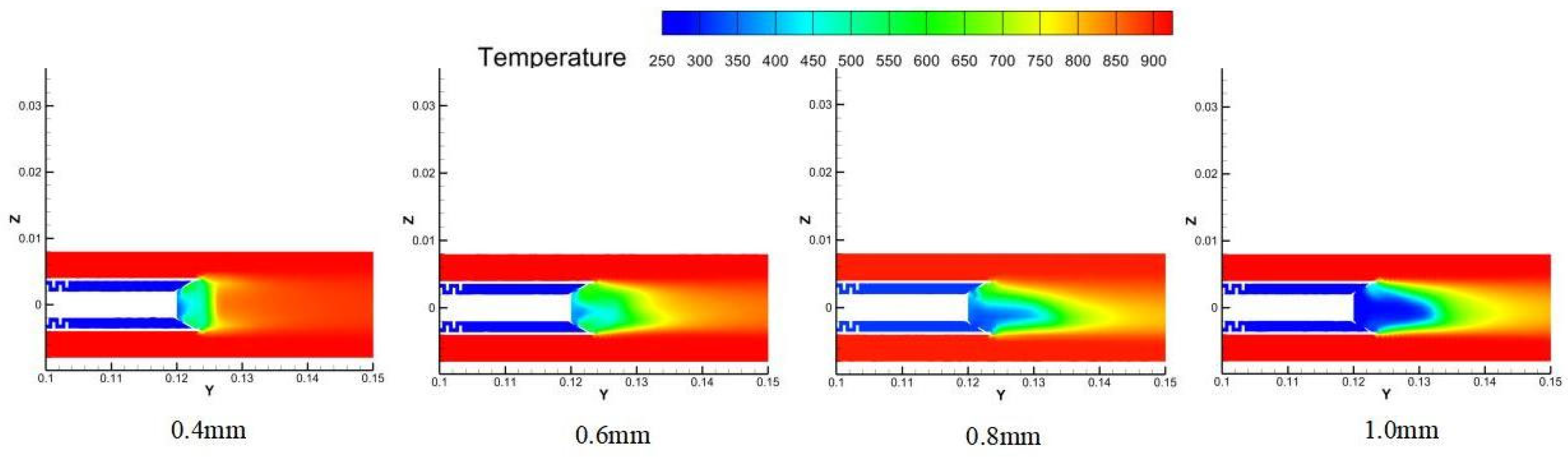

The influence of cooling hole diameter on the thermal performance of the borescope probe was investigated using four diameters: 0.4 mm, 0.6 mm, 0.8 mm, and 1.0 mm. The key findings are summarized as follows:

Mirror temperature and cooling efficiency: As shown in

Figure 45, both the average and maximum temperatures of the probe mirror decrease significantly with increasing cooling hole diameter, while the cooling efficiency improves progressively. The average temperature declines from 451.98 K at 0.4 mm to 286.20 K at 1.0 mm and the maximum temperature drops from 477.92 K to 289.64 K. At 1.0 mm, the mirror temperature approaches the coolant inlet temperature, indicating the formation of a complete and effective cooling protective film. This enhancement is attributed to the increased coolant mass flow and improved coverage capability at larger diameters.

Temperature field distribution: Analysis of

Figure 46 and

Figure 47 reveals that the cooling area on the mirror surface expands considerably with larger diameters, resulting in more uniform and efficient thermal protection. The temperature distribution curves ahead of the probe vary significantly with diameter. At 0.4 mm, the temperature rises rapidly near the 0.125 m cross-section, whereas at 1.0 mm, the temperature remains stable up to 0.130 m without a significant increase. This demonstrates that larger diameters facilitate the formation of a robust cooling film that effectively suppresses heat penetration from the high-temperature environment.

Summary of optimal conditions: The cooling hole diameter profoundly affects the performance of the hole-type cooling structure. A diameter of 1.0 mm is identified as optimal, achieving the lowest mirror temperatures (average: 286.20 K; maximum: 289.64 K) and the highest cooling efficiency. At this diameter, the coolant forms a complete protective film that provides near-ideal cooling performance. Smaller diameters (e.g., 0.4 mm) result in insufficient coolant flow and inadequate film formation, leading to poor cooling effectiveness. These results highlight the critical role of diameter selection in maximizing thermal protection. For practical applications in high-temperature environments, a cooling hole diameter of 1.0 mm is recommended to ensure reliable and efficient probe operation.

4.3.4. Underlying Physical Principles of Coolant Property Effects

The marked improvement in cooling performance observed with nitrogen-based coolants, as compared to conventional air, arises from fundamental differences in the thermophysical properties that govern heat transfer and fluid dynamic behavior. The underlying mechanisms can be systematically summarized as follows:

- (1)

Enhanced heat capacity:

The volumetric heat capacity of a coolant directly determines its capacity to absorb thermal energy per unit volume. Nitrogen possesses a higher specific heat capacity (Cp ≈ 1040 J/kg·K) than air (Cp ≈ 1005 J/kg·K). Under identical mass flow conditions, nitrogen absorbs a greater amount of heat from the probe’s mirror surface for the same temperature rise, resulting in a more pronounced temperature reduction.

- (2)

Improved thermal transport:

The thermal conductivity (k) of the coolant dictates the efficiency of heat transfer between the solid wall and the coolant gas. Nitrogen possesses a higher thermal conductivity (k ≈ 0.026 W/m·K at 300 K) than air (k ≈ 0.024 W/m·K at 300 K). This property facilitates a more effective conduction of heat from the hot surface into the coolant jet and the ensuing protective film, thereby improving the convective heat transfer coefficient and accelerating the cooling process.

- (3)

Improved cooling film stability:

Owing to its higher molecular weight and density, nitrogen exhibits greater momentum when injected into the crossflow. This reduces jet deflection and improves adhesion to the surface, forming a more continuous and stable cooling film. The cohesive film mitigates the entrainment of high-temperature mainstream gases, thereby maintaining lower adiabatic wall temperatures and significantly reducing surface heating.

- (4)

Synthesis of mechanisms:

The synergistic integration of these properties—increased heat absorption, improved heat conduction, and enhanced film stability—collectively contributes to an additional reduction of 20–30 K in the average mirror temperature. These findings underscore the potential of nitrogen-enriched coolants in advancing thermal protection strategies for borescope probes operating in high-temperature environments.