Advanced Fiber Optic Sensing Technology in Aerospace: Packaging, Bonding, and Calibration Review

Abstract

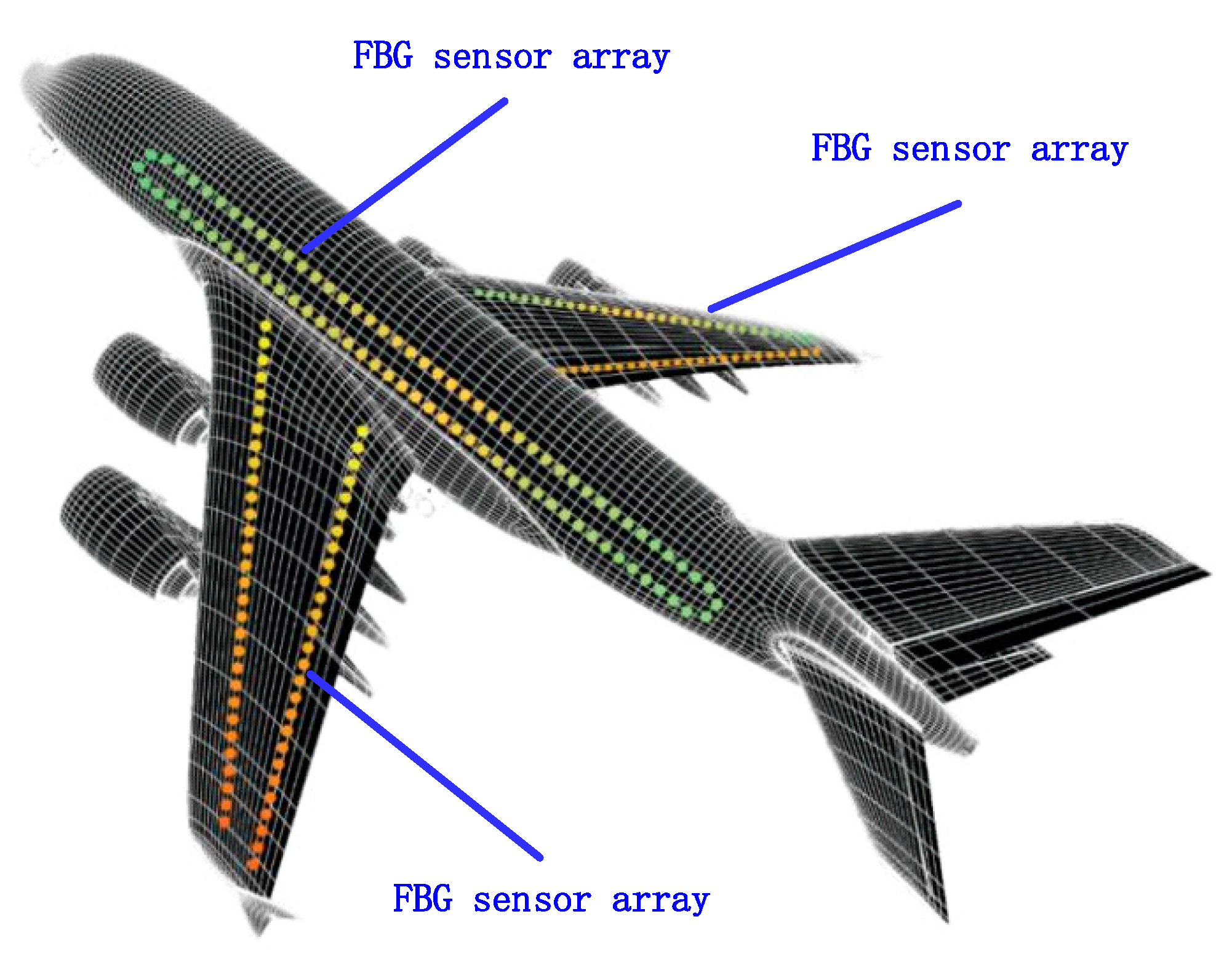

1. Introduction

2. Classification of Optical Fiber Sensors

2.1. FBG Sensor

2.2. Rayleigh Scattering

2.3. Brillouin Scattering

3. Packaging Forms of FBG Sensors

3.1. Tube-Packaged FBG Sensors

3.2. Embedded FBG Sensor

3.3. Surface-Attached FBG Sensor

4. Bonding Technology of FBG Sensor

4.1. Principle of Optical Fiber Bonding Technology

4.2. Influencing Factors

4.2.1. Effect of Bonding Thickness

4.2.2. Effect of Bonding Width

4.2.3. Effect of Bonding Length

5. Calibration Technology

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y. Recent progress in aircraft smart skin for structural health monitoring. Struct. Health Monit. 2022, 21, 2453–2480. [Google Scholar] [CrossRef]

- Krishnamoorthy, R.R.; Marius, D. Nondestructive inspection and structural health monitoring of aerospace materials. Aerosp. Mater. 2025, 159–206. [Google Scholar] [CrossRef]

- Giannakeas, I.N.; Khodaei, Z.S.; Aliabadi, M.H. Structural health monitoring cost estimation of a piezosensorized aircraft fuselage. Sensors 2022, 22, 1771. [Google Scholar] [CrossRef] [PubMed]

- Davis, C.; Tejedor, S.; Grabovac, I. High-strain fiber bragg gratings for structural fatigue testing of military aircraft. Photonic Sens. 2012, 2, 215–224. [Google Scholar]

- Miguel, G.C.; Zúñiga, S.J.; Sánchez, G.J. Demonstration and methodology of structural monitoring of stringer runs out composite areas by embedded optical fiber sensors and connectors integrated during production in a composite plant. Sensors 2017, 17, 1683. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Chen, X. Fiber Bragg gratings sensors for aircraft wing shape measurement: Recent applications and technical analysis. Sensors 2019, 19, 55. [Google Scholar] [CrossRef]

- DAYY Photonics. Fiber Bragg Grating Sensor (FBG); DAYY Photonics. Available online: https://dayyphotonics.com/applications/fiber-bragg-grating-sensor-fbg (accessed on 20 July 2025).

- Pena, F.; Richards, L.; Parker, A.R., Jr.; Piazza, A.; Chan, P.; Hamory, P. Fiber Optic Sensing System (FOSS) Technology—A New Sensor Paradigm for Comprehensive Structural Monitoring and Model Validation Throughout the Vehicle Life-Cycle. 2015. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20180007391.pdf (accessed on 20 July 2025).

- Pena, F.; Martins, B.L.; Richards, W.L. Active In-flight Load Redistribution Utilizing Fiber-Optic Shape Sensing and Multiple Control Surfaces; NASA/TM—2018–219741; NASA: Washington, DC, USA, 2018.

- Martins, B.L.; Kosmatka, J.B. Health Monitoring of Aerospace Structures via Dynamic Strain Measurements: An Experimental Demonstration. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 0701. [Google Scholar]

- Kim, J.H.; Lee, Y.G.; Park, Y. Temperature-compensated strain measurement of full-scale small aircraft wing structure using low-cost FBG interrogator. Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, Spie Smart Structures and Materials + Nondestructive Evaluation And Health Monitoring, San Diego, CA, USA, 10–14 March 2013. Volume 8692, p. 86922P. Available online: https://www.spiedigitallibrary.org/conference-proceedings-of-spie/8692/86922P/Temperature-compensated-strain-measurement-of-full-scale-small-aircraft-wing/10.1117/12.2011720.short?webSyncID=d49a2853-1ab0-d3a6-b03c-97c009b6bcd7&sessionGUID=46b80d8e-8abe-eaed-6ae0-5c117aac5a91 (accessed on 30 July 2025).

- He, Y.; Dong, M.; Sun, G. Shape monitoring of morphing wing using micro optical sensors with different embedded depth. Opt. Fiber Technol. 2019, 48, 179–185. [Google Scholar] [CrossRef]

- Ciminello, M.; Sikorski, B.; Galasso, B.; Pellone, L.; Mercurio, U.; Concilio, A.; Apuleo, G.; Cozzolino, A.; Kressel, I.; Shoham, S.; et al. Preliminary Results of a Structural Health Monitoring System Application for Real-Time Debonding Detection on a Full-Scale Composite Spar. Sensors 2023, 23, 455. [Google Scholar] [CrossRef] [PubMed]

- Pollock, L.; Wild, G. An Exploration of Structural Health Monitoring for Hypersonic Vehicles. In AIAA Aviation Forum and ASCEND Co-Located Conference Proceedings, Proceedings of the AIAA AVIATION Forum and ASCEND 2024, Las Vegas, NV, USA, 29 July–2 August 2024; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2024. [Google Scholar]

- Apuleo, G.; Ciminello, M.; Pellone, L.; Mercurio, U.; Concilio, A. Application of a Fiber Optic-Based SHM System to a Composite Aircraft Wing and Its Technological Maturity Evaluation. Eng. Proc. 2025, 90, 31. [Google Scholar]

- Krenz, A.; Koch, J.; Reimer, V.; Doering, A.; Guehlke, P.; Waltermann, C. Methods for FBG Sensor Integration for RTM Process Monitoring and SHM of the Final CFRP Component. In Proceedings of the 10th ECCOMAS Thematic Conference on Smart Structures and Materials, Patras, Greece, 3–5 July 2023; pp. 1839–1850. [Google Scholar]

- Pollock, L.; Kleine, H.; Neely, A.; Wild, G. Optical Fiber Bragg Grating-Based Measurement of Fluid-Structure Interaction on a Cantilever Panel in High-Speed Flow. IEEE Access 2024, 12, 101106–101120. [Google Scholar] [CrossRef]

- Ankita, R.; Ghorai, S.K.; Sengupta, S. Vehicle Flow Indication and Identification Using FBG Sensors. Phys. Scr. 2024, 99, 125543. [Google Scholar] [CrossRef]

- Aimasso, A.; Dalla Vedova, M.D.L.; Bertone, M.; Maggiore, P. Preliminary Design and Performance Evaluation of Optical Fiber-Based Load Sensor for Aerospace Systems. J. Phys. Conf. Ser. 2024, 2802, 012010. [Google Scholar] [CrossRef]

- Reimer, T.; Di Martino, G.; Petkov, I.; Dauth, L.; Baier, L.; Gülhan, A. Design, Manufacturing and Assembly of the STORT Hypersonic Flight Experiment Thermal Protection System. In Proceedings of the 25th AIAA International Space Planes and Hypersonic Systems and Technologies Conference, Bengaluru, India, 28 May 2023–1 June 2024; p. 3089. [Google Scholar]

- Parnika, G.; Amit, T.; Xiuyun, H.; Kamil, G.; Kafil, M.R.; Padraic, E.M.; Peter, O.B. Substrate integrated micro-thermoelectric coolers in glass substrate for next-generation photonic packages. J. Opt. Microsyst. 2024, 4, 011006. [Google Scholar]

- Lv, Z.; Zhu, B.; Lu, L.; Yuan, P.; Lou, X.; Dong, M.; Zhu, L. Miniature and low-power high-precision FBG interrogator with self-temperature compensation. Opt. Express. 2025, 33, 10289–10301. [Google Scholar]

- Luo, X.; Hu, R.; Xie, B. Thermal Management for Opto-Electronics Packaging and Applications; Wiley: Hoboken, NJ, USA, 2024. [Google Scholar]

- Rees, A.V.; Tsong, W.; Vlekkert, I.V.D.; Farjana, F.; Lammerink, R.E.M.; Visscher, I.; Roeloffzen, C.G.H.; Musa, S.; Geskus, D. High-Power 150 mW Extended Cavity Si3N4 Tunable Narrow-Linewidth Laser. In Optical Interconnects XXIV; SPIE: Bellingham, WA, USA, 2024; p. 128920J. [Google Scholar]

- Zhang, Z.; Huang, B.; Zhang, Z.; Chen, H. On-Chip Reconstructive Spectrometer Based on Parallel Cascaded Micro-Ring Resonators. Appl. Sci. 2024, 14, 4886. [Google Scholar]

- Yi, D.; Luan, J.; Wang, Y.; Tsang, H.K. Reconfigurable polarization processor based on coherent four-port micro-ring resonator. Nanophotonics 2023, 12, 4127–4136. [Google Scholar]

- Amanzadeh, M.; Aminossadati, S.M.; Kizil, M. Recent developments in fibre optic shape sensing. Measurement 2018, 128, 119–137. [Google Scholar] [CrossRef]

- Hill, K.O.; Fujii, Y.; Johnson, D.C. Photosensitivity in optical fiber waveguides: Application to reflection filter fabrication. Appl. Phys. Lett. 1978, 32, 647–649. [Google Scholar] [CrossRef]

- Dunphy, J.R.; Meltz, G. Optical Fiber Sensors for Composite Structures. In Optical Fiber Sensors; Optica Publishing Group: Washington, DC, USA, 1988; FCC1. [Google Scholar] [CrossRef]

- Malo, B.; Hill, K.O.; Bilodeau, F. Point-by-point fabrication of micro-Bragg gratings in photosensitive fibre using single excimer pulse refractive index modification techniques. Electron. Lett. 1993, 29, 1668–1669. [Google Scholar] [CrossRef]

- Hong, C.Y.; Zhang, Y.F.; Zhang, M.X. Application of FBG sensors for geotechnical health monitoring, a review of sensor design, implementation methods and packaging techniques. Sens. Actuators A Phys. 2016, 244, 184–197. [Google Scholar] [CrossRef]

- Zhou, T.; Chen, M.Y.; Hu, Z.Z.; Gong, T.Y.; Liang, Y. Research on ultra-wide joint bending angle detection based on transparent tubing structure. IEEE Sens. J. 2023, 24, 1511–1519. [Google Scholar] [CrossRef]

- Liang, Y.; Liang, H.; Kong, L.; Li, H.; Dai, Z.; Chen, M. Thin-diameter photonic crystal fiber magnetic field sensor based on controlled hole collapse and infiltration. IEEE Sens. J. 2023, 23, 27337–27342. [Google Scholar] [CrossRef]

- Liang, Y. Design of a Mach-Zehnder Interferometric Fiber Sensing System Based on PCA-Assisted OAM Interrogation for Simultaneous Measurement of Refractive Index and Temperature. J. Light. Technol. 2022, 40, 6310–6316. [Google Scholar] [CrossRef]

- Barnoski, M.K.; Rourke, M.D.; Jensen, S.M. Optical time domain reflectometer. Appl. Opt. 1977, 16, 2375–2379. [Google Scholar] [CrossRef]

- Eickhoff, W.; Ulrich, R. Optical frequency domain reflectometry in single-mode fiber. Appl. Phys. Lett. 1981, 39, 693–695. [Google Scholar] [CrossRef]

- Ippen, E.P.; Stolen, R.H. Stimulated Brillouin scattering in optical fibers. Appl. Phys. Lett. 1972, 21, 539–541. [Google Scholar] [CrossRef]

- Horiguchi, T.; Tateda, M. BOTDA-nondestructive measurement of single-mode optical fiber attenuation characteristics using Brillouin interaction: Theory. J. Light. Technol. 1989, 7, 1170–1176. [Google Scholar] [CrossRef]

- Shi, B.; Xu, X.J.; Wang, D. Study on BOTDR-based distributed optical fiber strain measurement for tunnel health diagnosis. Chin. J. Rock. Mech. Eng. 2005, 24, 2622–2628. [Google Scholar]

- Li, X.J.; He, F.; Wang, Y.B. Tunnel structure safety monitoring system based on BOTDA technology. Appl. Mech. Mater. 2014, 621, 281–284. [Google Scholar] [CrossRef]

- Li, W.; Bao, X.; Li, Y. Differential pulse-width pair BOTDA for high spatial resolution sensing. Opt. Express 2008, 16, 21616–21625. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, K.; Horiguchi, T.; Koyamada, Y. Coherent self-heterodyne detection of spontaneously Brillouin-scattered light waves in a single-mode fiber. Opt. Lett. 1993, 18, 185–187. [Google Scholar] [CrossRef]

- Rogers, A.J. Polarization-optical time domain reflectometry: A technique for the measurement of field distributions. Appl. Opt. 1981, 20, 1060–1074. [Google Scholar] [CrossRef] [PubMed]

- Ramirez-Hernandez, M.A.; Alonso-Murias, M.; Monzon-Hernandez, D. Polymer-Capped Fiber Fabry-Perot Interferometer for Large Range Displacement Sensing. J. Light. Technol. 2024, 42, 3430–3437. [Google Scholar] [CrossRef]

- Siwowski, T.; Rajchel, M.; Howiacki, T.; Sieńko, R.; Bednarski, Ł. Distributed fibre optic sensors in FRP composite bridge monitoring: Validation through proof load tests. Eng. Struct. 2021, 246, 113057. [Google Scholar] [CrossRef]

- Zhan, Y.; Han, M.; Wang, Z.; Xu, L.; Song, Z.; Lu, A.; Guo, X.; Deng, W.; Huang, S. Distributed strain monitoring for different composites structures with high resolution based on optical fiber sensing. Optik 2021, 248, 168113. [Google Scholar] [CrossRef]

- da Silva Falcão, B.; Giwelli, A.; Kiewiet, M.N.; Banks, S.; Yabesh, G.; Esteban, L.; Kiewiet, L.; Yekeen, N.; Kovalyshen, Y.; Monmusson, L.; et al. Strain measurement with multiplexed FBG sensor arrays: An experimental investigation. Heliyon 2023, 9, e18652. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Y.; Yang, S.; Zhang, D. All-sapphire fiber-optic sensor for the simultaneous measurement of ultra-high temperature and high pressure. Opt. Express 2024, 32, 14826–14836. [Google Scholar]

- Wang, F.; Zhan, W.; Zhang, X.; Lu, Y. Improvement of spatial resolution for BOTDR by iterative subdivision method. J. Light. Technol. 2013, 31, 3663–3667. [Google Scholar] [CrossRef]

- Almoosa, A.S.K.; Hamzah, A.E.; Zan, M.S.D.; Ibrahim, M.F.; Arsad, N.; Elgaud, M.M. Improving the Brillouin frequency shift measurement resolution in the Brillouin optical time domain reflectometry (BOTDR) fiber sensor by artificial neural network (ANN). Opt. Fiber Technol. 2022, 70, 102860. [Google Scholar] [CrossRef]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Small-diameter optical fibre sensor embedment for ambient temperature cure monitoring and residual strain evaluation of CFRP composite laminates produced by vacuum-assisted resin infusion. CEAS Space J. 2021, 13, 353–367. [Google Scholar] [CrossRef]

- Tserpes, K.I.; Karachalios, V.; Giannopoulos, I.; Prentzias, V.; Ruzek, R. Strain and damage monitoring in CFRP fuselage panels using fiber Bragg grating sensors. Part I: Design, manufacturing and impact testing. Compos. Struct. 2014, 107, 726–736. [Google Scholar] [CrossRef]

- Mao, X.; Zhou, X.; Ye, H.; Tan, Y.; Luo, Y. Fast interrogation of dynamic fiber Bragg grating using neighborhood average algorithm. Infrared Phys. Technol. 2023, 128, 104490. [Google Scholar] [CrossRef]

- Yi, X.; Chen, X.; Fan, H.; Shi, F.; Cheng, X.; Qian, J. Separation method of bending and torsion in shape sensing based on FBG sensors array. Opt. Express 2020, 28, 9367–9383. [Google Scholar] [CrossRef]

- Gong, Y.; Michael, O.L.C.; Hao, J.; Paulose, V. Extension of sensing distance in a ROTDR with an optimized fiber. Opt. Commun. 2007, 280, 91–94. [Google Scholar] [CrossRef]

- Yin, J.; Liu, T.; Jiang, J.; Liu, K.; Wang, S.; Wu, F.; Ding, Z. Wavelength-division-multiplexing method of polarized low-coherence interferometry for fiber Fabry–Perot interferometric sensors. Opt. Lett. 2013, 38, 3751–3753. [Google Scholar] [CrossRef]

- Kahandawa, G.C.; Epaarachchi, J.; Wang, H.; Lau, K.T. Use of FBG sensors for SHM in aerospace structures. Photonic Sens. 2012, 2, 203–214. [Google Scholar] [CrossRef]

- Cusano, A.; Antonello, C.; Jacques, A. Fiber Bragg Grating Sensors: Recent Advancements, Industrial Applications and Market Exploitation; Bentham Science Publishers: Sharjah, United Arab Emirates, 2011. [Google Scholar]

- Yang, X. A novel packaging method for FBG temperature sensors based on ultrasonic-assisted soldering technology. Sens. Actuators A Phys. 2024, 373, 115381. [Google Scholar] [CrossRef]

- Marco, B. Fiber-bragg-grating-based displacement sensors: Review of recent advances. Materials 2022, 15, 5561. [Google Scholar]

- Khan, R.Y.M.; Rahim, U.; Muhammad, F. Design and development of cost-effective fiber Bragg grating temperature sensor package. Meas. Sci. Technol. 2023, 34, 085122. [Google Scholar] [CrossRef]

- Huang, L.; Xiong, L.; Guo, Y.; Hu, Z. All-Silicon Packaging Technology for Fiber Bragg Gratings and Its Application in Tilt Sensor. IEEE Sens. J. 2022, 22, 22627–22636. [Google Scholar] [CrossRef]

- Grabovac, I.; Nuyens, T.; Davis, C. Packaging and Mounting of In-Fibre Bragg Grating Arrays for Structural Health Monitoring of Large Structures. Defense Science and Technology Organization Victoria (Australia) Maritime Platforms div. 2010. Available online: https://archive.org/details/DTIC_ADA536063/page/30/mode/2up?q=%22richard++muscat%22 (accessed on 20 July 2025).

- Floris, I.; Madrigal, J.; Sales, S. Experimental study of the influence of FBG length on optical shape sensor performance. Opt. Lasers Eng. 2020, 126, 105878. [Google Scholar] [CrossRef]

- Li, Y.; Wen, C.; Sun, Y. Capillary encapsulating of fiber Bragg grating and the associated sensing model. Opt. Commun. 2014, 333, 92–98. [Google Scholar] [CrossRef]

- Jinachandran, S.; Li, H.; Xi, J. Fabrication and characterization of a magnetized metal-encapsulated FBG sensor for structural health monitoring. IEEE Sens. J. 2018, 18, 8739–8746. [Google Scholar] [CrossRef]

- Zhang, Y.; Meng, F.; Song, Y. Characterization of metallic-packaging fiber Bragg grating sensors with coated and bare fibers. Appl. Opt. 2019, 58, 1426–1432. [Google Scholar] [CrossRef]

- Di Palma, P. Force sensor based on FBG embedded in silicone rubber. IEEE Sens. J. 2022, 23, 1172–1178. [Google Scholar] [CrossRef]

- Liao, M.H. The cooperative deformation test of an embedded FBG sensor and strain correction curve verification. Constr. Build. Mater. 2022, 342, 128029. [Google Scholar] [CrossRef]

- Zhao, J.R. Embedded Fiber Bragg Grating (FBG) Sensors Fabricated by Ultrasonic Additive Manufacturing for High-Frequency Dynamic Strain Measurements. IEEE Sens. J. 2023, 24, 2853–2862. [Google Scholar] [CrossRef]

- Ana, F.M. Embedded fiber Bragg grating sensors for monitoring temperature and thermo-elastic deformations in a carbon fiber optical bench. Sensors 2023, 23, 6499. [Google Scholar] [CrossRef] [PubMed]

- Qiang, B. Temperature and external strain sensing with metal-embedded optical fiber sensors for structural health monitoring. Opt. Express 2022, 30, 33449–33464. [Google Scholar] [CrossRef] [PubMed]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y. Overview of fiber optic sensor technologies for strain/temperature sensing applications in composite materials. Sensors 2016, 16, 99. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.P.; Wu, Y.B.; Chen, C.; Zhang, H.Y.; Jiang, H. Dynamic response of CFRP reinforced steel beams subjected to impact action based on FBG sensing technology. Sensors 2022, 22, 6377. [Google Scholar] [CrossRef] [PubMed]

- Shafighfard, T.; Magdalena, M. Experimental and numerical study of the additively manufactured carbon fibre reinforced polymers including fibre Bragg grating sensors. Compos. Struct. 2022, 299, 116027. [Google Scholar] [CrossRef]

- Fatemeh, M. Methods for embedding fiber Bragg grating sensors during material extrusion: Relationship between the interfacial bonding and strain transfer. Addit. Manuf. 2023, 68, 103497. [Google Scholar] [CrossRef]

- Grundmann, N.; Brüning, H.; Tserpes, K.; Strohbach, T.; Mayer, B. Influence of Embedding Fiber Optical Sensors in CFRP Film Adhesive Joints on Bond Strength. Sensors 2020, 20, 1665. [Google Scholar] [CrossRef]

- Murayama, H.; Kageyama, K.; Kamita, T. Structural health monitoring of a full-scale composite structure with fiber-optic sensors. Adv. Compos. Mater. 2002, 11, 287–297. [Google Scholar] [CrossRef]

- Baker, W.; McKenzie, I.; Jones, R. Development of life extension strategies for Australian military aircraft, using structural health monitoring of composite repairs and joints. Compos. Struct. 2004, 66, 133–143. [Google Scholar] [CrossRef]

- Botsis, J.; Humbert, L.; Colpo, F. Embedded fiber Bragg grating sensor for internal strain measurements in polymeric materials. Opt. Lasers Eng. 2005, 43, 491–510. [Google Scholar] [CrossRef]

- Li, H.N.; Zhou, G.D.; Liang, R. Strain transfer analysis of embedded fiber Bragg grating sensor under nonaxial stress. Opt. Eng. 2007, 46, 054402. [Google Scholar] [CrossRef]

- Takeda, N.; Minakuchi, S. Smart aircraft composite structures with embedded small-diameter optical fiber sensors. In Proceedings of the Third Asia Pacific Optical Sensors Conference, Sydney, Australia, 31 January–3 February 2012; Volume 8351, p. 83510I. [Google Scholar]

- Fang, L.; Chen, T.; Li, R. Application of embedded fiber Bragg grating (FBG) sensors in monitoring health to 3D printing structures. IEEE Sens. J. 2016, 16, 6604–6610. [Google Scholar] [CrossRef]

- Freydin, M.; Rattner, M.; Raveh, D.E. Strain-Based Aeroelastic Shape Sensing. In Proceedings of the 2018 AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 8–12 January 2018; p. 0190. [Google Scholar]

- Kwon, H.; Park, Y.; Kim, J.H. Embedded fiber Bragg grating sensor–based wing load monitoring system for composite aircraft. Struct. Health Monit. 2019, 18, 1337–1351. [Google Scholar] [CrossRef]

- He, Y.; Zhu, L.; Sun, G.; Meng, F.; Song, Y. Fiber Brag grating monitoring of a morphing wing based on a polyvinyl chloride reinforced silicone substrate. Opt. Fiber Technol. 2019, 50, 145–153. [Google Scholar] [CrossRef]

- Qu, X.; Li, J.; Shan, Y.; Yang, Z.; Yang, L.; Xu, H.; Zhao, S. Various static loading condition monitoring of carbon fiber composite cylinder with integrated optical fiber sensors. Opt. Fiber Technol. 2024, 83, 103685. [Google Scholar] [CrossRef]

- Waters, D.H.; Kumosa, M.; Hoffman, J. Evaluating strain limits of embedded FBG sensors in pultruded hybrid composite rods. IEEE Trans. Power Deliv. 2022, 37, 5025–5032. [Google Scholar] [CrossRef]

- Li, Y.; Wen, C.; Zhang, H. An electroplating method for surface mounting optical fiber sensors on the metal substrate. IEEE Photonics Technol. Lett. 2016, 28, 1811–1814. [Google Scholar] [CrossRef]

- Wang, H.P.; Gong, X.S.; Wang, X.Z.; Feng, S.Y.; Yang, T.L.; Guo, Y.X. Discrete curvature-based shape configuration of composite pipes for local buckling detection based on fiber Bragg grating sensors. Measurement 2022, 188, 110603. [Google Scholar] [CrossRef]

- Lee, G.; Hossain, O.; Jamalzadegan, S.; Liu, Y.; Wang, H.; Saville, A.C. Abaxial leaf surface-mounted multimodal wearable sensor for continuous plant physiology monitoring. Sci. Adv. 2023, 9, eade2232. [Google Scholar] [CrossRef]

- Kaya, B.M.; Esenturk, O.; Asici, C.; Sarac, U.; Dindis, G.; Baykul, M.C. Coating effects of a strain sensor on durability and sensitivity using the fiber loop ringdown spectroscopy technique. Physica Scripta. 2024, 99, 055511. [Google Scholar] [CrossRef]

- Hopf, B.; Koch, A.W.; Roths, J. Temperature dependence of glue-induced birefringence in surface-attached FBG strain sensors. J. Light. Technol. 2015, 34, 1220–1227. [Google Scholar] [CrossRef]

- Sirkis, J.S.; Haslach, H.W. Interferometric stain measurement by arbitrarily configured surface-mounted, optical fibers. J. Light. Technol. 1990, 8, 1497–1503. [Google Scholar] [CrossRef]

- Duncan, R.; Gifford, D.; Childers, B. A Distributed Sensing Technique for Aerospace Applications. In Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 5–8 January 2004; p. 544. [Google Scholar]

- Li, H.; Zhu, L.; Dong, M. Analysis on strain transfer of surface-bonding FBG on Al 7075-T6 alloy host. Optik 2016, 127, 1233–1236. [Google Scholar] [CrossRef]

- Goossens, S.; De Pauw, B.; Geernaert, T. Aerospace-grade surface mounted optical fibre strain sensor for structural health monitoring on composite structures evaluated against in-flight conditions. Smart Mater. Struct. 2019, 28, 065008. [Google Scholar] [CrossRef]

- Sodja, J.; De Breuker, R.; Meddaikar, Y.M. Ground Testing of the FLEXOP Demonstrator Aircraft. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 1968. [Google Scholar]

- Boateng, E.K.G.; Schubel, P.; Umer, R. Thermal isolation of FBG optical fibre sensors for composite cure monitoring. Sens. Actuators A Phys. 2019, 287, 158–167. [Google Scholar] [CrossRef]

- Guo, Z.S. Strain and temperature monitoring of asymmetric composite laminate using FBG hybrid sensors. Struct. Health Monitor. 2007, 6, 191–197. [Google Scholar] [CrossRef]

- Fernández, R.; Gutiérrez, N.; Jiménez, H.; Martín, F.; Rubio, L.; Jiménez-Vicaria, J.D.; Paulotto, C.; Lasagni, F. On the structural testing monitoring of CFRP cockpit and concrete/CFRP pillar by FBG sensors. Adv. Eng. Mater. 2016, 18, 1289–1298. [Google Scholar] [CrossRef]

- Xu, L.; Shi, S.; Yan, F.; Huang, Y.; Bao, Y. Experimental study on combined effect of mechanical loads and corrosion using tube-packaged long-gauge fiber Bragg grating sensors. Struct. Health Monit. 2023, 22, 3985–4004. [Google Scholar] [CrossRef]

- Kosaka, T.; Kurimoto, H.; Osaka, K.; Nakai, A.; Osada, T.; Hamada, H.; Fukuda, T. Strain monitoring of braided composites by using embedded fiber-optic strain sensors. Adv. Compos. Mater. 2004, 13, 157–170. [Google Scholar] [CrossRef]

- Jang, B.-W.; Park, S.-O.; Lee, Y.-G.; Kim, C.-G.; Park, C.-Y. Detection of impact damage in composite structures using high speed FBG interrogator. Adv. Compos. Mater. 2012, 21, 29–44. [Google Scholar] [CrossRef]

- Yi, L.; Zhenkai, W.; Jialu, L. Research on health monitor for three-dimensional braided composite material. In Proceedings of the 2011 Third International Conference on Measuring Technology and Mechatronics Automation, Shanghai, China, 6–7 January 2011; pp. 1150–1153. [Google Scholar]

- Kim, S.-W.; Kim, E.-H.; Jeong, M.-S.; Lee, I. Damage evaluation and strain monitoring for composite cylinders using tin-coated FBG sensors under low-velocity impacts. Compos. B Eng. 2015, 74, 13–22. [Google Scholar] [CrossRef]

- Frazão, O.; Oliveira, R.; Dias, I. A simple smart composite using fiber Bragg grating sensors for strain and temperature discrimination. Microw. Opt. Technol. Lett. 2008, 51, 235–239. [Google Scholar] [CrossRef]

- Rao, Y.J.; Yuan, S.F.; Zeng, X.K.; Lian, D.K.; Zhu, Y.; Wang, Y.P.; Huang, S.L.; Liu, T.Y.; Fernando, G.F.; Zhang, L.; et al. Simultaneous strain and temperature measurement of advanced 3-D braided composite materials using an improved EFPI/FBG system. Opt. Lasers Eng. 2002, 38, 557–566. [Google Scholar] [CrossRef]

- Zhao, X.; Jin, K.; Yan, M.; Nan, P.; Zhou, F.; Xin, G.; Lim, K.-S.; Ahmad, H.; Zhang, Y.; Yang, H. Inverse heat transfer for real-time thermal evaluation of aircraft thermal protection structure with embedded FBG sensors. Appl. Therm. Eng. 2025, 260, 124869. [Google Scholar] [CrossRef]

- Takeda, S.I.; Mizutani, T.; Nishi, T.; Uota, N.; Hirano, Y.; Iwahori, Y.; Nagao, Y.; Takeda, N. Monitoring of a CFRP-stiffened panel manufactured by VaRTM using fiber-optic sensors. Adv. Compos. Mater. 2008, 17, 125–137. [Google Scholar] [CrossRef]

- Mizutani, T.; Takeda, N.; Takeya, H. On-board strain measurement of a cryogenic composite tank mounted on a reusable rocket using FBG sensors. Struct. Health Monitor. 2006, 5, 205–214. [Google Scholar] [CrossRef]

- Basu, M.; Ghorai, S.K. Strain sensing in fiber-reinforced polymer laminates using embedded fiber Bragg grating sensor. Fiber Integr. Opt. 2014, 33, 279–298. [Google Scholar] [CrossRef]

- Sun, L.; Wang, J.; Hu, H.; Fu, C.; Wang, C.; Ni, A. A real-time NDT method based on FBG sensor spectrums to detect the transverse matrix cracks in composite materials. J. Nondestruct. Eval. 2020, 39, 44. [Google Scholar] [CrossRef]

- Pran, K.; Farsund, O.; Wang, G. Fibre Bragg grating smart bolt monitoring creep in bolted GRP composite. In Proceedings of the 15th Optical Fiber Sensors Conference Technical Digest, Portland, OR, USA, 10 May 2002; pp. 431–434. [Google Scholar]

- Wei, Z.; Song, D.; Zhao, Q.; Cui, H.-L. High pressure sensor based on fiber Bragg grating and carbon fiber laminated composite. IEEE Sensors J. 2008, 8, 1615–1619. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, X.; Wei, X.; Nan, P.; Zhou, F.; Xin, G.; Lim, K.-S.; Zhang, Y.; Yang, H. Real-Time Sensor for Measuring the Surface Temperature of Thermal Protection Structures Based on the Full-Time Domain Temperature Inversion Method. Sensors 2025, 25, 2227. [Google Scholar] [CrossRef]

- Papantoniou, A.; Rigas, G.; Alexopoulos, N.D. Assessment of the strain monitoring reliability of fiber Bragg grating sensor (FBGs) in advanced composite structures. Compos. Struct. 2011, 93, 2163–2172. [Google Scholar] [CrossRef]

- Kuang, K.S.C.; Kenny, R.; Whelan, M.P.; Cantwell, W.J.; Chalker, P.R. Embedded fibre Bragg grating sensors in advanced composite materials. Compos. Sci. Technol. 2001, 61, 1379–1387. [Google Scholar] [CrossRef]

- Minakuchi, S. In situ characterization of direction-dependent cure-induced shrinkage in thermoset composite laminates with fiber-optic sensors embedded in through-thickness and in-plane directions. J. Compos. Mater. 2015, 49, 1021–1034. [Google Scholar] [CrossRef]

- .Rajabzadeh, A.; Heusdens, R.; Hendriks, R.C.; Groves, R.M. Characterisation of transverse matrix cracks in composite materials using fibre Bragg grating sensors. J. Lightw. Technol. 2019, 37, 4720–4727. [Google Scholar] [CrossRef]

- Geng, X.; Jiang, M.; Gao, L.; Wang, Q.; Jia, Y.; Sui, Q.; Jia, L.; Li, D. Sensing characteristics of FBG sensor embedded in CFRP laminate. Measurement 2017, 98, 199–204. [Google Scholar] [CrossRef]

- Prusty, B.G. Failure investigation of top-hat composite stiffened panels. Ships Offshore Struct. 2013, 9, 186–198. [Google Scholar] [CrossRef]

- Yu, K.; Peng, Z.; Zhang, Y.; Zhu, P.; Chen, W.; Hao, J. Pipeline Elbow Corrosion Simulation for Strain Monitoring with Fiber Bragg Gratings. Micromachines 2024, 15, 1098. [Google Scholar] [CrossRef]

- Rebelo, F.J.; Oliveira, J.R.; Silva, H.M.; Oliveira e Sá, J. Material selection for efficient strain transfer in pavement monitoring using FBG sensors. Int. J. Pavement Eng. 2024, 25, 2440509. [Google Scholar] [CrossRef]

- Cheng, C.; Liu, Y.; Li, X.; Yang, J.; Tong, T.; Ke, Q. The strain transfer characteristics of SAW strain sensors and their impact on the sensor performance. Sens. Actuators A Phys. 2025, 389, 116575. [Google Scholar] [CrossRef]

- Wahab, M.M.A.; Ashcroft, I.A.; Crocombe, A.D. Prediction of fatigue thresholds in adhesively bonded joints using damage mechanics and fracture mechanics. J. Adhes. Sci. Technol. 2001, 15, 763–781. [Google Scholar] [CrossRef]

- Zhou, G.; Li, H.; Ren, L. Influencing parameters analysis of strain transfer in optic fiber Bragg grating sensors, Advanced Sensor Technologies for Nondestructive Evaluation and Structural Health Monitoring II. Int. Soc. Opt. Photonics 2006, 6179, 61790R. [Google Scholar]

- Hocker, G.B. Fiber-optic sensing of pressure and temperature. Appl. Opt. 1979, 18, 1445–1448. [Google Scholar] [CrossRef]

- Pak, Y.E. Longitudinal shear transfer in fiber optic sensors. Smart Mater. Struct. 1992, 1, 57. [Google Scholar] [CrossRef]

- Yuan, L.; Zhou, L. Sensitivity coefficient evaluation of an embedded fiber-optic strain sensor. Sens. Actuators A Phys. 1998, 69, 5–11. [Google Scholar] [CrossRef]

- Liang, Y.; Zhang, H.; Lin, W.; Liu, B.; Liu, H.F. Characterization of photo-isomerization-induced refractive index response for azobenzene solution based on capillary-assisted Mach-Zehnder interferometer under 473 nm laser excitation. Opt. Laser Technol. 2022, 151, 108045. [Google Scholar] [CrossRef]

- Liang, Y.; Zhang, H.; Huang, B.; Liu, B.; Lin, W.; Sun, J.J.; Wang, D.B. Ultrahigh-sensitivity temperature sensor based on resonance coupling in liquid-infiltrated side-hole microstructured optical fibers. Sens. Actuators A Phys. 2022, 334, 113358. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Wang, Y.; Zhang, Z. Analysis and experimental research on the principle of surface bonded FBG strain transfer. J. Funct. Mater. 2016, 47, 07046–07050. [Google Scholar]

- Her, S.C.; Huang, C.Y. Effect of coating on the strain transfer of optical fiber sensors. Sensors 2011, 11, 6926–6941. [Google Scholar] [CrossRef]

- Wang, Q.; Qiu, Y.; Zhao, H. Analysis of strain transfer of six-layer surface-bonded fiber Bragg gratings. Appl. Opt. 2012, 51, 4129–4138. [Google Scholar] [CrossRef]

- Wan, K.T.; Leung, C.K.Y.; Olson, N.G. Investigation of the strain transfer for surface-attached optical fiber strain sensors. Smart Mater. Struct. 2008, 17, 035037. [Google Scholar] [CrossRef]

- Wu, R.; Zheng, B.; Liu, Z. Analysis on strain transfer of a pasted FBG strain sensor. Optik 2014, 125, 4924–4928. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, Q.; Qiu, Y. Strain transfer of surface-bonded fiber Bragg grating sensors for airship envelope structural health monitoring. J. Zhejiang Univ. Sci. A 2012, 13, 538–545. [Google Scholar] [CrossRef]

- Xue, G.; Fang, X.; Hu, X. Measurement accuracy of FBG used as a surface-bonded strain sensor installed by adhesive. Appl. Opt. 2018, 57, 2939–2946. [Google Scholar] [CrossRef] [PubMed]

- Her, S.C.; Huang, C.Y. The effects of adhesive and bonding length on the strain transfer of optical fiber sensors. Appl. Sci. 2016, 6, 13. [Google Scholar] [CrossRef]

- Kwon, H.; Park, Y.; Shrestha, P. Signal characteristics of the surface bonded fiber Bragg grating sensors by bonding length under different load types. In Proceedings of the 2017 25th Optical Fiber Sensors Conference (OFS), Jeju, Republic of Korea, 24–28 April 2017; IEEE: New York, NY, USA, 2017; pp. 1–4. [Google Scholar]

- Eckstorm, C. Flight Loads Measurements Obtained from Calibrated Strain-Gage Bridges Mounted Externally on Skin of Low-Aspect-Ratio Wing; NASA TN D-8349; NASA: Washington, DC, USA, 1976.

- Jenkins, J.; DeAngelis, V. A Summary of Numerous Strain-Gauge Load Calibrations on Aircraft Wings and Tails in a Technology Format; NASA Technical Memorandum 4804; NASA: Washington, DC, USA, 1997.

- Lokos, W.; Stauf, R. Strain-Gage Calibration Parametric Study; NASA TM 212853; NASA: Washington, DC, USA, 2004.

- Monaghan, R.; Fields, R. Experiments to Study Strain-Gage Load Calibrations on Wing Structure at Elevated Temperatures; NASA TN D-7390; NASA: Washington, DC, USA, 1973.

- Hönisch, G. Der Einfluß der Dehnungsübertragung zwischen Bauteil und Meßdraht auf den k-Faktor von DMS. Maschinenbautechnik 1966, 15, 61–68. [Google Scholar]

- Ko, R. Standard Specification Format Guide and Test Proce-Dure for Single-Axis Interferometric Fiber Optic Gyros; IEEE: New York, NY, USA, 1972. [Google Scholar]

- VDI/VDE/GESA 2004 Experimentelle Strukturanalyse—Empfehlung zur Durchf¨uhrung von Dehnungsmessungen bei hohen Temperaturen. In Experimental Structural Analysis—Recommended Practice for High-Temperature Strain Measurements; VDI Richtlinie 2635 Blatt 2; VDI: Berlin, Germany, 2019.

- VDI/VDE/GESA 2007 Experimentelle Strukturanalyse—Dehnungsmessstreifen mit metallischem Messgitter—Kenngr¨oßen und Pr¨ufbedingungen. In Experimental Structure Analysis—Metallic Bonded Resistance Strain Gages—Characteristics and Testing Conditions; VDI Richtlinie 2635 Blatt 1; VDI: Berlin, Germany, 2024.

- Inaudi, D.; Glisic, B. Reliability and field testing of distributed strain and temperature sensors, Smart Structures and Materials 2006: Smart Sensor Monitoring Systems and Applications. Int. Soc. Opt. Photonics 2006, 6167, 61671D. [Google Scholar]

- Habel, W.R.; Schukar, V.G.; Kusche, N. Fibre-optic strain sensors are making the leap from lab to industrial use—Reliability and validation as a precondition for standards. Meas. Sci. Technol. 2013, 24, 094006. [Google Scholar]

- Roths, J.; Wilfert, A.; Kratzer, P. Strain calibration of optical FBG-based strain sensors, Fourth European Workshop on Optical Fibre Sensors. Int. Soc. Opt. Photonics 2010, 7653, 76530F. [Google Scholar]

- Habel, W.R.; Schukar, V.G.; Kusche, N. Calibration Facility for Quality Certification of Surface-Attached Fiber Optic and Electrical Strain Sensors. In Proceedings of the Sensors, 2011 IEEE, Limerick, Ireland, 28–31 October 2011; IEEE: New York, NY, USA, 2011; pp. 1337–1340. [Google Scholar]

- IEC 61757-1-1:2016; Fibre Optic Sensors-Part 1-1: Strain Measurement-Strain Sensors Based on Fibre Bragg Gratings. Available online: http://www.iec.ch/ (accessed on 10 February 2020).

- Lazarev, V.A.; Leonov, S.O.; Tarabrin, M.K.; Karasik, V.E.; Lehmann, P.; Osten, W.; Gonçalves, A.A. Fiber Bragg gratings strain measuring system and a sensor calibration setup based on mechanical nanomotion transducer, Optical Measurement Systems for Industrial Inspection X. Int. Soc. Opt. Photonics 2017, 10329, 103292F. [Google Scholar]

- Święch, Ł. Calibration of a Load Measurement System for an Unmanned Aircraft Composite Wing Based on Fibre Bragg Gratings and Electrical Strain Gauges. Aerospace 2020, 7, 27. [Google Scholar] [CrossRef]

- Ogunleye, R.O.; Rusnáková, S.; Javořík, J.; Žaludek, M.; Kotlánová, B. Advanced sensors and sensing systems for structural health monitoring in aerospace composites. Adv. Eng. Mater. 2024, 26, 2401745. [Google Scholar] [CrossRef]

- Pashaie, R.; Shokrieh, M.M.; Vahedi, M.; Mirzaei, A.H.; Akbari, S. A comparative study of residual stress measurement of laminated composites using FBG sensor, DIC technique, and strain gauge. Opt. Quantum Electron. 2024, 56, 1790. [Google Scholar] [CrossRef]

- Liu, B.; Pang, J.; Tu, X.; Zhou, Z. Three components strain-gauge type aircraft surface friction resistance sensor: Design, manufacturing, and calibration. Measurement 2023, 218, 113165. [Google Scholar] [CrossRef]

- Ibrar Jahan, M.A.; Honnungar, R.V.; Nandhini, V.L.; Malini, V.L.; Vohra, H.; Balaji, V.R.; Royc, S.K. Deciphering the sensory landscape: A comparative analysis of fiber Bragg grating and strain gauge systems in structural health monitoring. J. Opt. 2024, 1–9. [Google Scholar] [CrossRef]

- Ling, S.; Chen, X.; Miao, L.; Yin, J.; Jian, J.; Jin, Q. A novel semiconductor piezoresistive thin-film strain gauge with high sensitivity. IEEE Sens. J. 2024, 24, 13914–13924. [Google Scholar] [CrossRef]

- Deng, K.; Ompusunggu, A.P.; Xu, Y.; Skote, M.; Zhao, Y. A review of material-related mechanical failures and load monitoring-based structural health monitoring (SHM) technologies in aircraft landing gear. Aerospace 2025, 12, 266. [Google Scholar] [CrossRef]

- Güemes, A.; Fernandez-Lopez, A. Recent advances in loads/strain monitoring: A review. Struct. Health Monit. Manag. Aerosp. Struct. 2024, 101–113. [Google Scholar] [CrossRef]

- Lu, H.; Feng, Y.; Wang, S.; Liu, J.; Han, Q.; Meng, Q. A high-performance, sensitive, low-cost LIG/PDMS strain sensor for impact damage monitoring and localization in composite structures. Nanotechnology 2024, 35, 355702. [Google Scholar] [CrossRef] [PubMed]

- Meher, U.; Sunny, M.R. Localization and quantification of delamination/disbond inside a composite lap-joint using novel cross and drive point mechanical impedance based feature. Mech. Syst. Signal Process. 2024, 220, 111661. [Google Scholar] [CrossRef]

- Marinho, N.R.; Loendersloot, R.; Wiegman, J.W.; Grooteman, F.; Tinga, T. Evaluating sensor performance for impact identification in composites: A comprehensive comparison of FBGs with PZTs. Struct. Health Monit. 2024, 14759217241304644. [Google Scholar] [CrossRef]

- Xu, Z.E.N.G.; Deshuang, D.E.N.G.; Hongjuan, Y.A.N.G.; Zhengyan, Y.A.N.G.; Shuyi, M.A.; Lei, Y.A.N.G.; Zhanjun, W.U. Research progress in low-velocity impact monitoring technology for aircraft structures. Acta Aeronaut. Astronaut. Sin. 2024, 45, 030368. [Google Scholar]

- Verma, P.; Ubaid, J.; Varadarajan, K.M.; Wardle, B.L.; Kumar, S. Synthesis and characterization of carbon nanotube-doped thermoplastic nanocomposites for the additive manufacturing of self-sensing piezoresistive materials. ACS Appl. Mater. Interfaces 2022, 14, 8361–8372. [Google Scholar] [CrossRef]

- Chung, D.D.L. A critical review of piezoresistivity and its application in electrical-resistance-based strain sensing. J. Mater. Sci. 2020, 55, 15367–15396. [Google Scholar] [CrossRef]

- Carani, L.B.; Humphrey, J.; Rahman, M.M.; Okoli, O.I. Advances in embedded sensor technologies for impact monitoring in composite structures. J. Compos. Sci. 2024, 8, 201. [Google Scholar] [CrossRef]

- Krohn, D.; Rannow, R.K.; Westbrook, P.; Rochat, E.; Paul, D.; Arkwright, J. White Paper-Smart Infrastructure Using Distributed Fiber Optic Sensors. In Smart Infrastructure Using Distributed Fiber Optic Sensors; IEEE: Piscataway, NJ, USA, 2025; pp. 1–19. [Google Scholar]

- Grating, Sensors—Fiber Bragg, and Interrogator Standard—Terminonolgy. “P2067™/D32.” 2020. Available online: https://ieeexplore.ieee.org/abstract/document/9353446/ (accessed on 20 July 2025).

| Application Area | Function | Example | Ref. |

|---|---|---|---|

| Structural health monitoring | Real-time monitoring of structural integrity and detection of damage | FBG array in composite beam/wing box | [13,14,15,16] |

| Load/strain/vibration monitoring | Detect changes in load and vibration modes | FBG array for hypersonic aircraft | [17,18,19] |

| Thermal environment monitoring | Evaluate the temperature of the thermal protection system or the surface of the body | STORT aircraft thermal protection system monitoring | [20,21,22] |

| Photon system support | Support high-speed optical communication and modulation systems | FBG demodulator, tunable laser, filter | [23,24,25,26] |

| Spatial Resolution | Measurement Time | Temperature and Strain | Strain Accuracy | Dynamic Measurement | |

|---|---|---|---|---|---|

| DPP-BOTDA | 2 m | 2–5 min | Yes | 20 | Yes |

| BOTDR | ~1 m | 1–5 min | Yes | 60 | No |

| OFDR | ~1 mm | (0.01–3) s | Yes | 1 | 30 Hz |

| Phase OTDR | ~0.5 m | <1 ms | No | No | No |

| Sensor Technology | Application Scenario | Optimization Focus | Ref. |

|---|---|---|---|

| Extrinsic Fabry–Perot Interferometer (EFPI) | Curing strain monitoring of aviation composite laminates and axial strain detection of wings | Expanding the dynamic range by nine times through a hemispherical polymer cap to achieve sub-nanometer-resolution displacement measurement | [44] |

| OTDR | Distributed strain monitoring of composite material bridges and detection of debonding damage to wing bolt lines | Improve measurement accuracy and spatial resolution, achieve continuous strain/deflection distribution measurement of the entire length of the structure | [45] |

| BOTDR | Long-distance strain/temperature monitoring of large-area aircraft structures | Improving spatial resolution based on iterative subdivision method, up to 0.1 m of 1 km fiber can be achieved under 10 ns pulse | [46] |

| FBG | Micro-strain monitoring in the manufacturing process of composite materials and multi-parameter distributed monitoring during service life | 3D strain mapping achieved through ceramic coated FBG | [47] |

| Sapphire fiber EFPI | Strain monitoring of extreme high-temperature environment near the engine | Capable of withstanding temperatures exceeding 1000 °C and achieving synchronous measurement of high temperature and high pressure | [48] |

| Iterative subdivision BOTDR | Fine positioning of local strain in aircraft structure and optimization of long-distance monitoring | Can extract sub-Brillouin signals and optimize the ability to capture long-distance local damage | [49] |

| Artificial Neural Network BOTDR | Strain monitoring and dynamic data processing of aircraft structures under complex loads | Resolution can be increased from 21.13 MHz to 2.88 MHz under 60 ns pulse | [50] |

| Small diameter FBG | Strain monitoring of lightweight drone structures and damage detection of thin-walled composite materials | Reduce the impact on the mechanical properties of the substrate structure and adapt to the vacuum assisted resin infusion (VARI) process | [51] |

| High pressure vessel compatible with FBG (PTFE protection) | Strain monitoring during the manufacturing stage of aviation composite materials and microcrack detection during the curing process | Can resist high temperature and high pressure deformation, and can evaluate residual strain | [52] |

| Dynamic FBG Interrogation (FFT) | Real-time health monitoring of aircraft, rapid response to fluctuations and capture | Can improve wavelength scanning speed, with a resolution of 0.11 pm at a scanning frequency of 40 kHz | [53] |

| Anti torsional deformation FBG | Multi-directional load aircraft component strain monitoring and precise measurement of complex stress fields | Can reduce torsional deformation error, with a relative error of 0.86% in bending direction measurement | [54] |

| Distributed ROTDR | Monitoring of temperature field distribution on aircraft wings and thermal strain detection in wide-temperature environments | Can maintain constant Raman Stokes power reception and extend sensing distance | [55] |

| Wavelength Division Multiplexing FPI | Multi-area strain synchronous monitoring of aircraft and integration of multiple sensors | Can demodulate the length of each FPI cavity through a bandpass filter, breaking through the limitations of FPI multiplexing | [56] |

| Prestressed FBG | Monitoring of shrinkage strain in thick composite structures and control of deformation in laminated plates | Identifying spectral distortion caused by damage through a fixed FBG filtering decoding system | [57] |

| Characteristic | Tube-Packaged FBG | Embedded FBG | Surface-Attached FBG | Ref. |

|---|---|---|---|---|

| Core integration method | Place the bare FBG in the sleeve, apply pre tension and inject encapsulation adhesive to fix it, so that the FBG is embedded in the sleeve | Embedding reinforcing fiber layers during manufacturing, permanently embedded in composite laminates | Prepare composite laminates, and then use high-performance adhesives to stick FBG onto the surface of the cured laminates | [99,100,101] |

| Target sensing applications | Monitor structural strain and assist in long-term structural health monitoring | Monitor the internal strain and temperature during the curing/post curing stage of composite materials. Detect BVD and locate it | Detecting surface damage and locating it. Large-scale structural SHM (such as wind turbine blades) | [102,103,104] |

| Detecting physical parameters | Structural strain (dependent on strain transfer between sleeve encapsulation adhesive FBG) | Interlayer strain, interlayer temperature, impact, vibration, damage | Surface strain, surface temperature, impact, damage, vibration, pressure | [105,106] |

| Manufacturing process | To bare FBG casing, apply pre tightening force, and seal with adhesive. The casing material (metal, capillary, etc.) affects performance and may involve process validation such as VARTM | Select interlayer pre strain fixed FBG, operate before resin impregnation/curing. Preparation of laminated panels including manual layering, hot pressing, VARIM, etc. | Curing the surface of laminated panels, adhesive/matrix epoxy bonding pre strain FBG. Preparation of laminated panels including manual layering, hot pressing, VARTM, etc. | [107,108] |

| temperature sensitivity | Due to the influence of temperature characteristics of casing and encapsulation adhesive materials, attention should be paid to temperature–strain coupling | Sensitive to curing/chemical reaction temperature, affected by changes in fiber/matrix temperature | Easy to be affected by external environmental temperature, which may cause inaccurate sensing | [109,110,111] |

| Strain sensitivity | Dependent on encapsulation adhesive strain transfer, affected by sleeve constraints, it is necessary to optimize encapsulation parameters to ensure transfer efficiency | Axial strain disturbance detection is more sensitive | Surface measurement improves sensitivity, but the value may differ from the actual internal strain | [112,113] |

| Maintain characteristics | Replacement after damage requires removal of sleeves, which is relatively complex | Difficult to maintain and replace, requiring replacement of the entire intelligent composite material structure | Can be replaced and maintained for easy visual inspection | [114,115] |

| Defects related to laminated panels | If the compatibility between the encapsulation adhesive and the laminated board is poor, it may affect the local mechanical properties of the laminated board | Easy occurrence of resin-rich areas/bubbles, debonding, decreased mechanical properties, etc. | No obvious defects related to laminated panels | [116,117,118] |

| Defects of sensors | There is uneven strain transmission. Long-term use of encapsulation adhesive aging affects performance | There are angular offsets, residual strains, etc. | Poor bonding process may result in adhesive residue, weak bonding, and affect sensing | [119,120] |

| Long-term stability | When the packaging is good, the stability of the sleeve and packaging adhesive affects long-term performance. If the material is stable, it can work stably for a longer period of time | Due to the influence of internal stability of materials and manufacturing defects, long-term monitoring should pay attention to performance drift | Due to the influence of surface environment (humidity, external forces), long-term stability is prone to fluctuations and requires regular calibration | [121,122] |

| Strain transmission efficiency | Due to the influence of mechanical properties of packaging materials, optimize packaging parameters to ensure efficiency is needed | Transferred through the matrix material, close to the actual internal strain, but manufacturing defects can easily cause transmission deviation | Dependent on adhesive transfer, affected by adhesive properties and bonding processes, surface strain transfer is direct but may differ from the interior | [123,124,125] |

| Calibration Technology Dimension | FBG Sensor | Traditional Strain Gauges | Piezoresistive Sensor | Ref. |

|---|---|---|---|---|

| Core calibration principle | Based on the relationship between Bragg wavelength and strain/temperature variation | Based on the relationship between resistance change and strain change | Based on the relationship between resistance changes and strain/damage changes | [157,158] |

| Mainstream calibration methods | Static calibration, dynamic calibration, temperature–strain coupling calibration | Static calibration, dynamic calibration | Static calibration, damage calibration | [159,160] |

| Calibration accuracy | High (static calibration error ± 1 με, dynamic calibration relative standard deviation ≈ 0.16%) | Middle (static error ± 5–10 με, affected by lead resistance) | Low (error ± 5–10%, affected by CNT dispersion and interface damage) | [161,162] |

| Environmental interference factors | Encapsulation stress release, fiber eccentricity. Temperature cross-sensitivity requires specialized compensation calibration | Vulnerable to electromagnetic interference and changes in lead resistance | Affected by humidity, CNT aggregation, and fiber matrix interface state | [163,164] |

| Calibration equipment complexity | High | Low | Middle | [165,166] |

| Feasibility of on-site calibration | Low | High | Middle | [167,168] |

| Long term calibration stability | High | Middle | Low | [169,170] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Chen, X.; Cui, B.; Wang, X. Advanced Fiber Optic Sensing Technology in Aerospace: Packaging, Bonding, and Calibration Review. Aerospace 2025, 12, 827. https://doi.org/10.3390/aerospace12090827

Ma Z, Chen X, Cui B, Wang X. Advanced Fiber Optic Sensing Technology in Aerospace: Packaging, Bonding, and Calibration Review. Aerospace. 2025; 12(9):827. https://doi.org/10.3390/aerospace12090827

Chicago/Turabian StyleMa, Zhen, Xiyuan Chen, Bingbo Cui, and Xinzhong Wang. 2025. "Advanced Fiber Optic Sensing Technology in Aerospace: Packaging, Bonding, and Calibration Review" Aerospace 12, no. 9: 827. https://doi.org/10.3390/aerospace12090827

APA StyleMa, Z., Chen, X., Cui, B., & Wang, X. (2025). Advanced Fiber Optic Sensing Technology in Aerospace: Packaging, Bonding, and Calibration Review. Aerospace, 12(9), 827. https://doi.org/10.3390/aerospace12090827