A Review of Polymer Composites and Adhesives for Aircraft Landing Gear Applications

Abstract

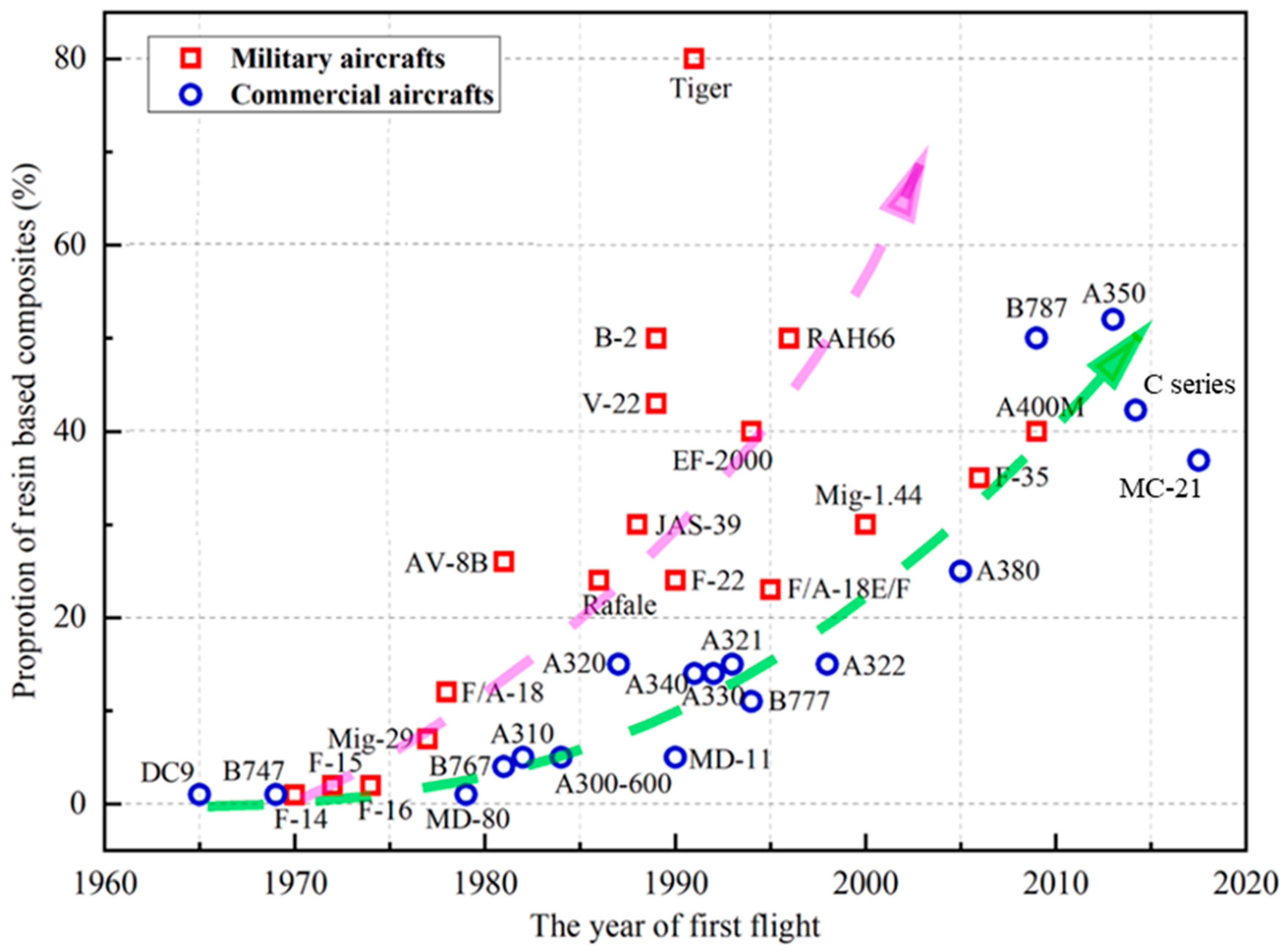

1. Introduction

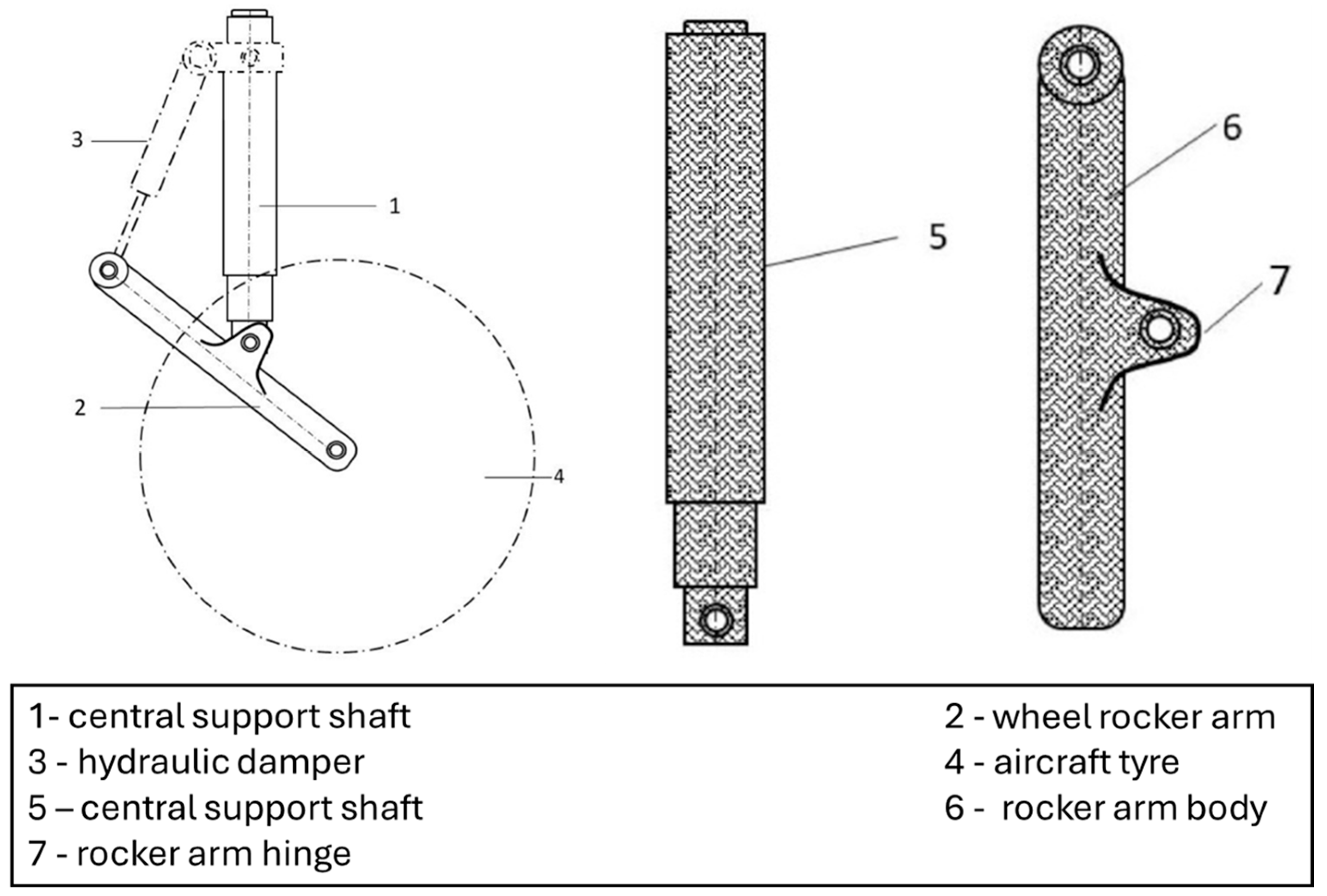

2. Polymer Composites Used in Landing Gear

3. Role of Adhesives in Enhancing Landing Gear Performance

- •

- Manufacturers aim to eliminate fasteners through welding and adhesive bonding while developing certifiable techniques like co-curing, friction joining, and refill friction stir spot welding (FSSW).

- •

- Research into self-healing adhesive joints and sustainable consumables for joining processes is prioritised.

- •

- Efforts focus on improving NDT methods for inspecting bonded interfaces and leveraging artificial intelligence (AI) to optimise joining processes and ensure quality.

- •

- Sustainability is a major trend, with autogenous welding emerging as a preferable option to minimise contamination in recycling metallic structures.

- •

- Digital twins are also highlighted for simulating manufacturing operations, enabling process optimisation and enhanced production efficiency.

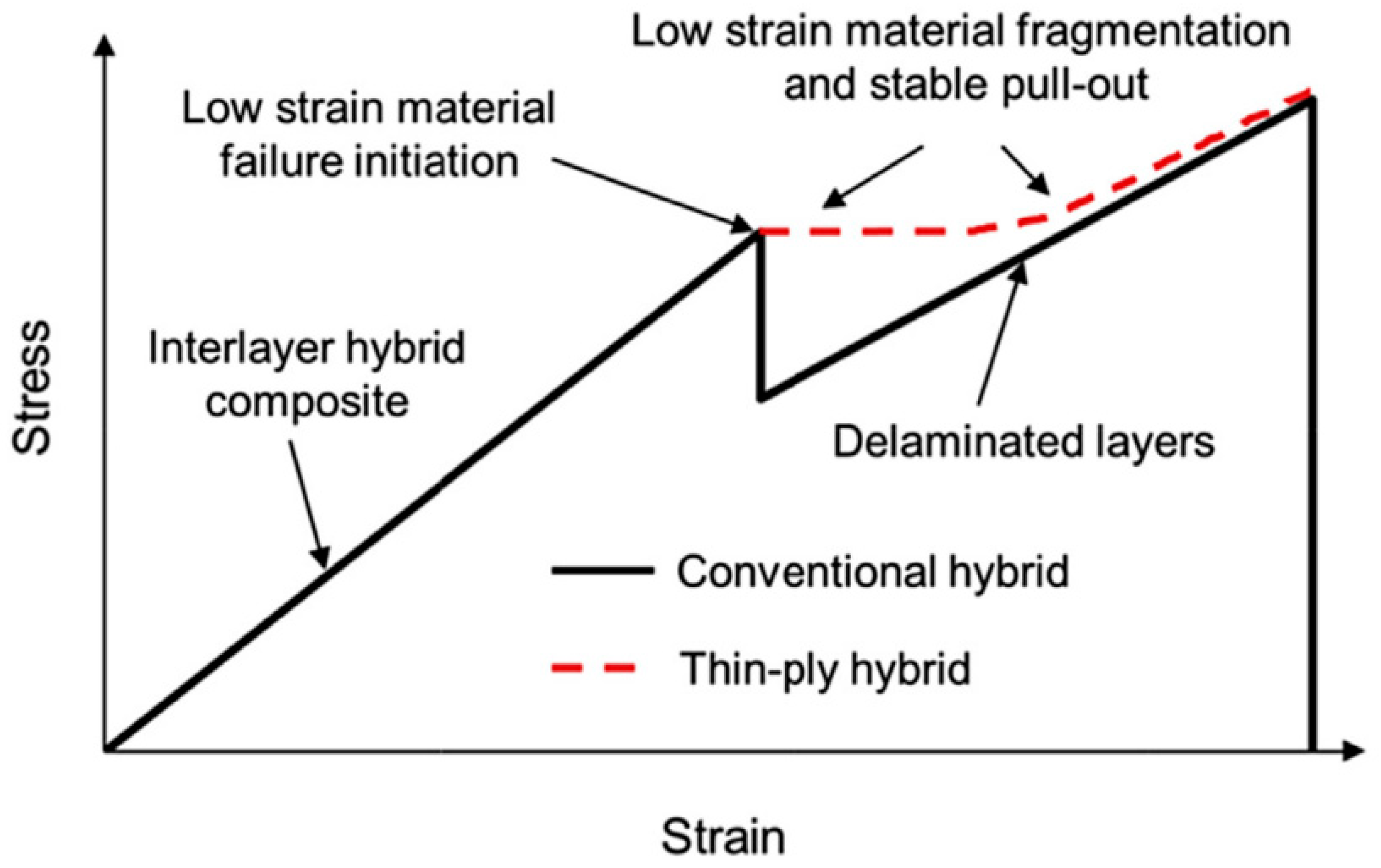

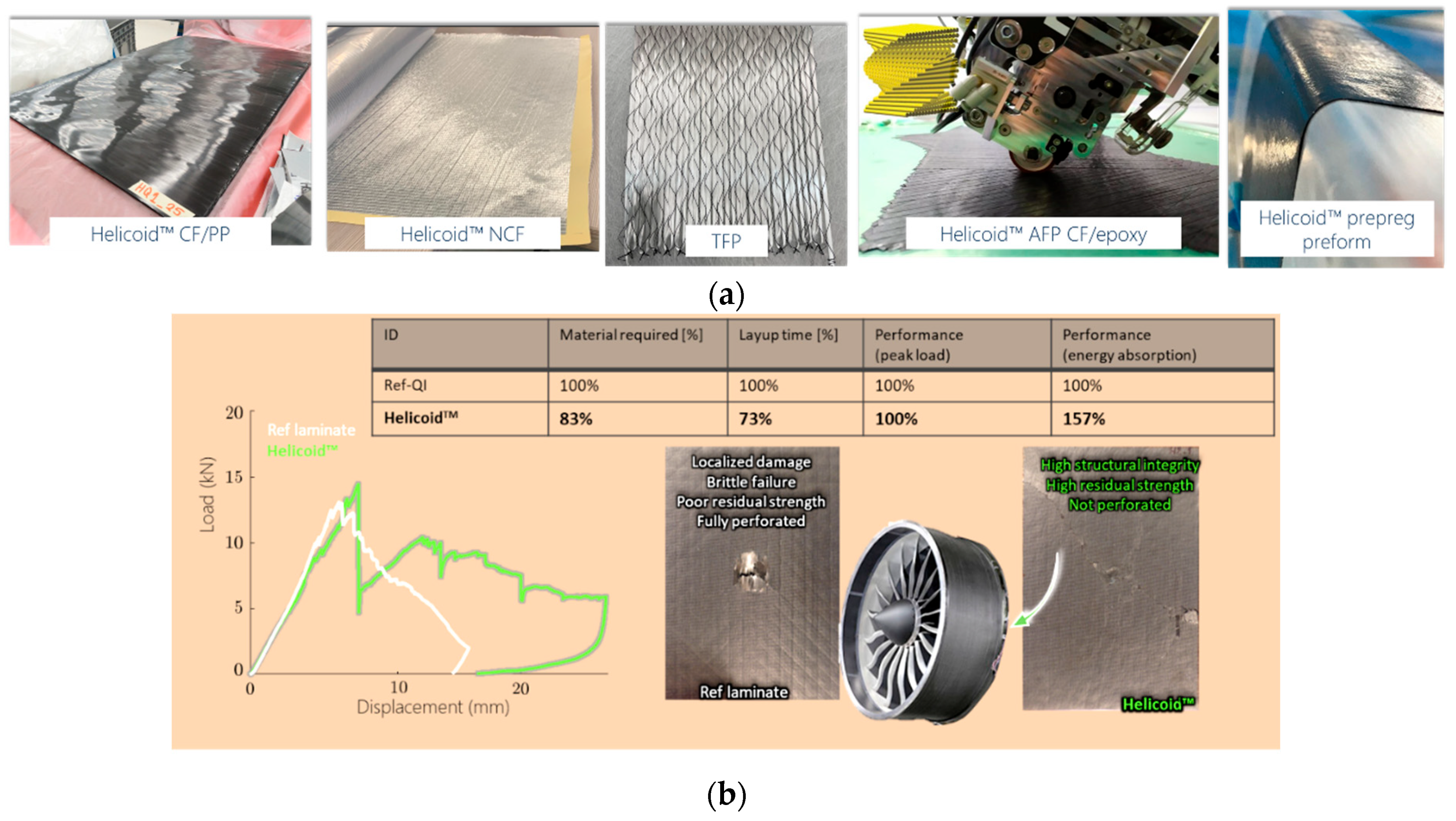

4. Innovative Materials and Hybrid Composites

5. Manufacturing Processes and Scalability

6. Conclusions and Future Outlook

Funding

Data Availability Statement

Conflicts of Interest

References

- Environmental Sustainability Status in the Aviation Maintenance and Production Organisation (M&P) Domain. Study—Assessment of the Environmental Sustainability Status in the Aviation Maintenance and Production Organisation (M&P) Domain. EASA. Available online: https://www.easa.europa.eu/en/document-library/research-reports/study-assessment-environmental-sustainability-status-aviation (accessed on 31 July 2024).

- Pierce, R.S.; Falzon, B.G. Simulating Resin Infusion through Textile Reinforcement Materials for the Manufacture of Complex Composite Structures. Engineering 2017, 3, 596–607. [Google Scholar] [CrossRef]

- Aerospace and Defense Thermoplastic Composites Market. Stratview Research. Available online: https://www.stratviewresearch.com/toc/299/aerospace-&-defense-thermoplastic-composites-market.html (accessed on 22 August 2025).

- Ejaz, H.; Awan, M.A.; Muzzammil, H.M.; Ullah, M.; Akhavan-Safar, A.; Dasilva, L.F.M.; Tanveer, A. Strength improvement/optimization methods in adhesively bonded joints: A comprehensive review of past and present techniques. Mech. Adv. Mater. Struct. 2024, 32, 4078–4106. [Google Scholar] [CrossRef]

- Xu, X.; Peng, G.; Zhang, B.; Shi, F.; Gao, L.; Gao, J. Material performance, manufacturing methods, and engineering applications in aviation of carbon fiber reinforced polymers: A comprehensive review. Thin-Walled Struct. 2025, 209, 112899. [Google Scholar] [CrossRef]

- Strategic Intelligence. Available online: https://intelligence.weforum.org/topics/a1G0X0000057NQgUAM/publications/c97caa99eab048338e0fa4cd84aa6c6c?utm_source=sfmc&utm_medium=email&utm_campaign=2837817_Prod-Si-WeeklyNewsletterV6&utm_term=&emailType=Strategic%20Intelligence%20Weekly&ske=MDAxNjgwMDAwMEdIbGFMQUFU (accessed on 3 December 2024).

- Jemioło, W. Life Cycle Assessment of Current and Future Passenger Air Transport in Switzerland. Master’s Thesis, University of Nordland, Bodø, Norway, 2015. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Cox, B.; Jemiolo, W.; Mutel, C. Life cycle assessment of air transportation and the Swiss commercial air transport fleet. Transp. Res. D Transp. Environ. 2018, 58, 1–13. [Google Scholar] [CrossRef]

- Scrap My Plane—The Aircraft Boneyard. Ace Breakers. Scrap My Car Kent. Available online: https://www.acebreakers.co.uk/aircraft-boneyard/ (accessed on 6 April 2025).

- Job, S.; Brocklehurst, H.; Kumar, N.; Minshull, J. Future Work on Climate Science and Material Impacts; Aerospace Technology Institute: London, UK, 2022. [Google Scholar]

- Annual Safety Review 2024; EASA: Cologne, Germany, 2024. [CrossRef]

- Wang, T.; Dong, Z.; Cao, C.; Zhou, J.; Meng, Y.; Quan, W. Characterization of aircraft landing impact loads: Effects on vertical tire-pavement contact characteristics and pavement performance. Constr. Build. Mater. 2024, 457, 139365. [Google Scholar] [CrossRef]

- N°156-May 2024-JEC Composites Magazine-JEC Composites Magazine Digital Edition. Available online: https://digital-magazine.jeccomposites.com/ (accessed on 6 June 2024).

- Aerospace Technology Institute. Aerospace Joining Technology Roadmap; Aerospace Technology Institute: London, UK, 2022. [Google Scholar]

- El-Chaikh, A.; Danzig, A.; Muenter, D.; Villechaise, P.; Appolaire, B.; Castany, P.; Dehmas, M.; Delaunay, C.; Delfosse, J.; Denquin, A.; et al. Effect of Microstructure on Fatigue Properties of Several Ti-Alloys for Aerospace Application. MATEC Web Conf. 2020, 321, 04015. [Google Scholar] [CrossRef]

- Hicks, C.; Tamimi, S.; Sivaswamy, G.; Pimentel, M.; McKegney, S.; Fitzpatrick, S. Hybrid manufacturing approach for landing gear applications: WAAM Ti–6Al–4V on forged Ti–5Al–5Mo–5V–3Cr. J. Mater. Res. Technol. 2024, 30, 6596–6608. [Google Scholar] [CrossRef]

- 300M Ultrahigh Strength Steel. Available online: https://www.matweb.com/search/datasheet.aspx?matguid=df0c08b0008749f0b84bf1fa44e49378&ckck=1 (accessed on 14 January 2025).

- Kasana, S.S.; Sharma, S.; Pandey, O.P. Influence of heat treatment (routes) on the microstructure and mechanical properties of 300M ultra high strength steel. Arch. Civ. Mech. Eng. 2022, 22, 126. [Google Scholar] [CrossRef]

- Caglar, H.; Aksoy, Y.A.; Idapalapati, S.; Caglar, B.; Sharma, M.; Sin, C.K. Debonding-on-demand Fe3O4-epoxy adhesively bonded dissimilar joints via electromagnetic induction heating. J. Adhes. 2024, 100, 734–764. [Google Scholar] [CrossRef]

- Vasanth, G.; Deepack, R.; Murali, S.; Magesh, S. Comprehensive analysis on mechanical behavior of airworthy raw materials for aircraft landing gear system. AIP Conf. Proc. 2020, 2283, 020096. [Google Scholar] [CrossRef]

- Aerospace Technology Institute. Composite Material Applications in Aerospace; Aerospace Technology Institute: London, UK, 2018. [Google Scholar]

- Speeding RTM with Heat-Flux Sensors. CompositesWorld. Available online: https://www.compositesworld.com/articles/speeding-rtm-with-heat-flux-sensors (accessed on 15 January 2025).

- GKN Aerospace on the Lockheed Martin F-35 Lightning II; GKN Aerospace: Filton, UK, 2018.

- Netherlands Aerospace Centre. Composites R&D e NLR-Royal Netherlands Aerospace Centre. Available online: https://www.nlr.org/wp-content/uploads/2025/03/E1661_Composites-Research-and-Development.pdf (accessed on 19 August 2025).

- Gurvich, M.R.; Zafiris, G.S.; Ganis, R.G. Manufacturing Method of Polymer Composite/Metal Load Transfer Joint for Landing Gear. U.S. Patent No. 10,556,673, 11 February 2020. [Google Scholar]

- Certification of Bonded Composite Primary Structures. CompositesWorld. Available online: https://www.compositesworld.com/articles/certification-of-bonded-composite-primary-structures (accessed on 13 April 2025).

- Paste Adhesives for Bonding in Aerospace Applications. Adhesives & Sealants Industry. Available online: https://www.adhesivesmag.com/articles/101211-paste-adhesives-for-bonding-in-aerospace-applications (accessed on 19 August 2025).

- A350 XWB Composite Bonded Repair. Available online: https://browserclient.twixlmedia.com/0ba7a0848114178ebac91fb18d85d314/root/d57374449245a3457532f74769334676 (accessed on 6 April 2025).

- Liu, J.; Quan, D.; Yang, X.; Zhou, C.; Zhao, G. Advances and Future Prospects of Adhesive Bonding and Co-Consolidation Technologies for Aviation Carbon Fiber Thermoplastic Composites. Appl. Compos. Mater. 2024, 32, 415–430. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, L.; Liu, Z.; Zhu, P. Research in failure behaviors of hybrid single lap aluminum-CFRP (plain woven) joints. Thin-Walled Struct. 2021, 161, 107488. [Google Scholar] [CrossRef]

- Yudhanto, A.; Alfano, M.; Lubineau, G. Surface preparation strategies in secondary bonded thermoset-based composite materials: A review. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106443. [Google Scholar] [CrossRef]

- Yang, K.; Feng, H.; Li, P.; Ji, S.; Lv, Z.; Liu, Z. The effects of environments and adhesive layer thickness on the failure modes of composite material bonded joints. Sci. Rep. 2024, 14, 22776. [Google Scholar] [CrossRef]

- Gleich, D.M.; Van Tooren, M.J.L.; Beukers, A. Analysis and evaluation of bondline thickness effects on failure load in adhesively bonded structures. J. Adhes. Sci. Technol. 2001, 15, 1091–1101. [Google Scholar] [CrossRef]

- Tserpes, K.; Barroso-Caro, A.; Carraro, P.A.; Beber, V.C.; Floros, I.; Gamon, W.; Kozłowski, M.; Santandrea, F.; Shahverdi, M.; Skejić, D.; et al. A review on failure theories and simulation models for adhesive joints. J. Adhes. 2022, 98, 1855–1915. [Google Scholar] [CrossRef]

- Caglar, H. Design for Disassembly of Adhesively Bonded Joints. Ph.D. Thesis, Nanyang Technological University, Singapore, 2022. [Google Scholar] [CrossRef]

- Murray, J.J.; Allen, T.; Bickerton, S.; Bajpai, A.; Gleich, K.; McCarthy, E.D.; Brádaigh, C.M.Ó. Thermoplastic rtm: Impact properties of anionically polymerised polyamide 6 composites for structural automotive parts. Energies 2021, 14, 5790. [Google Scholar] [CrossRef]

- Khan, T.; Ali, M.A.; Irfan, M.S.; Cantwell, W.J.; Umer, R. Visualization and investigation of healing mechanism in carbon fiber reinforced Elium® composites. J. Thermoplast. Compos. Mater. 2023, 36, 3966–3989. [Google Scholar] [CrossRef]

- Perrin, H.; Bodaghi, M.; Berthé, V.; Vaudemont, R. On the Addition of Multifunctional Methacrylate Monomers to an Acrylic-Based Infusible Resin for the Weldability of Acrylic-Based Glass Fibre Composites. Polymers 2023, 15, 1250. [Google Scholar] [CrossRef]

- Quan, D.; Alderliesten, R.; Dransfeld, C.; Murphy, N.; Ivanković, A.; Benedictus, R. Enhancing the fracture toughness of carbon fibre/epoxy composites by interleaving hybrid meltable/non-meltable thermoplastic veils. Compos. Struct. 2020, 252, 112699. [Google Scholar] [CrossRef]

- Perdana, A.S.; Jusuf, A.; Yudhanto, A.; Lubineau, G.; Tao, R.; Hadi, B.K. Extrinsic toughening in bonded joints with hybrid thermoset–thermoplastic bondline: Experimental evidence and modeling strategy. Compos. Part A Appl. Sci. Manuf. 2025, 190, 108686. [Google Scholar] [CrossRef]

- Reprocessable, Repairable and Recyclable Epoxy Resins for Composites. CompositesWorld. Available online: https://www.compositesworld.com/articles/reprocessable-repairable-and-recyclable-epoxy-resins-for-composites (accessed on 13 January 2025).

- Fureho. Available online: https://www.fureho.com/ (accessed on 21 October 2024).

- Das, S.; Kandan, K.; Kazemahvazi, S.; Wadley, H.; Deshpande, V. Deshpande, Compressive response of a 3D non-woven carbon-fibre composite. Int. J. Solids Struct. 2018, 136–137, 137–149. [Google Scholar] [CrossRef]

- Sinke, J. Manufacturing of GLARE Parts and Structures. Appl. Compos. Mater. 2003, 10, 293–305. [Google Scholar] [CrossRef]

- Garulli, T.; Katafiasz, T.J.; Greenhalgh, E.S.; Pinho, S.T. Damage deflection and subsequent damage diffusion in carbon–boron fibre hybrid composites under longitudinal compression. Compos. B Eng. 2025, 291, 112025. [Google Scholar] [CrossRef]

- Cho, J.; Park, J. Hybrid fiber-reinforced composite with carbon, glass, basalt, and para-aramid fibers for light use applications. Mater. Res. Express 2021, 8, 125304. [Google Scholar] [CrossRef]

- Zhao, S.; Yin, X.; Zhang, D. An investigation into the impact resistance of bio-inspired laminates with interlayer hybrid unidirectional/woven carbon fibers. Polym. Compos. 2023, 44, 7485–7498. [Google Scholar] [CrossRef]

- Galos, J. Thin-ply composite laminates: A review. Compos. Struct. 2020, 236, 111920. [Google Scholar] [CrossRef]

- Balaga, U.K.; Gargitter, V.; Yarlagadda, S.; Heider, D.; Crane, R.; Tierney, J.; Advani, S.G. Influence of ply thickness on transverse cracking onset, damage progression in thin ply composites and impact on mechanical performance. Compos. Struct. 2025, 354, 118827. [Google Scholar] [CrossRef]

- Czél, G.; Jalalvand, M.; Wisnom, M.R.; Czigány, T. Design and characterisation of high performance, pseudo-ductile all-carbon/epoxy unidirectional hybrid composites. Compos. B Eng. 2017, 111, 348–356. [Google Scholar] [CrossRef]

- AhmadvashAghbash, S.; Broggi, G.; Aydemir, A.; Argyropoulos, A.; Cugnoni, J.; Michaud, V.; Mehdikhani, M.; Swolfs, Y. Translaminar fracture in (non–)hybrid thin-ply fibre-reinforced composites: An in-depth examination through a novel mini-compact tension specimen compatible with microscale 4D computed tomography. Compos. Part A Appl. Sci. Manuf. 2025, 188, 108529. [Google Scholar] [CrossRef]

- Tsai, S.W. Double-Double: A New Perspective in the Manufacture and Design of Composites; JEC Group: Paris, France, 2022. [Google Scholar]

- Vermes, B.; Tsai, S.W.; Riccio, A.; Di Caprio, F.; Roy, S. Application of the Tsai’s modulus and double-double concepts to the definition of a new affordable design approach for composite laminates. Compos. Struct. 2021, 259, 113246. [Google Scholar] [CrossRef]

- Tsai, S.W. Double–double: New family of composite laminates. AIAA J. 2021, 59, 4293–4305. [Google Scholar] [CrossRef]

- Creating Stronger Composites Through Nature-Inspired, Helicoid Designs. CompositesWorld. Available online: https://www.compositesworld.com/articles/creating-stronger-composites-through-nature-inspired-helicoid-designs (accessed on 31 October 2024).

- Orlova, D.; Panchenko, A.; Omairey, S.; Berinskii, I. Computational homogenization of bio-inspired metamaterial with a random fiber network microstructure. Mech. Res. Commun. 2022, 124, 103930. [Google Scholar] [CrossRef]

- Mencattelli, L.; des Ouches, P.J.; Bert, A. Realising Impact Damage Tolerant Helicoid Bioinspired Composites with Automated Fiber Placement—From Coupon Testing to Three-Dimensional Preforms. In Proceedings of the Composites and Advanced Materials Expo, CAMX 2021, Dallas, TX, USA, 19–21 October 2021. [Google Scholar]

- Technology Behind FiberJoints. Available online: https://www.fiberjoints.com/technology (accessed on 19 August 2025).

- Jakobsen, J.; Endelt, B.; Shakibapour, F. Bolted joint method for composite materials using a novel fiber/metal patch as hole reinforcement—Improving both static and fatigue properties. Compos. B Eng. 2024, 269, 111105. [Google Scholar] [CrossRef]

- Cao, H.; Sun, X.; Kawashita, L.F.; Ivanov, D.S. New metal-epoxy-matrix carbon-fibre hybrids to tackle stress concentration. Compos. Part A Appl. Sci. Manuf. 2024, 184, 108272. [Google Scholar] [CrossRef]

- Hawkins, A.; Aravand, A.; Millen, S.; Tsai, S.W. Double-Double Laminates: Homogenisation, Mechanical Performance and Compression After Impact. In Proceedings of the 24th International Conference on Composite Materials 2025, Baltimore, MD, USA, 4–8 August 2025. [Google Scholar]

- Novel Insert Technology Enables Arc Stud Welding with Composites. CompositesWorld. Available online: https://www.compositesworld.com/articles/novel-insert-technology-enables-arc-stud-welding-with-composites (accessed on 6 December 2024).

- Deng, K.; Ompusunggu, A.P.; Xu, Y.; Skote, M.; Zhao, Y. A Review of Material-Related Mechanical Failures and Load Monitoring-Based Structural Health Monitoring (SHM) Technologies in Aircraft Landing Gear. Aerospace 2025, 12, 266. [Google Scholar] [CrossRef]

- Hassani, S.; Mousavi, M.; Gandomi, A.H. Structural health monitoring in composite structures: A comprehensive review. Sensors 2022, 22, 153. [Google Scholar] [CrossRef]

- Wang, D.; Dong, M.; Zhu, L.; Lou, X.; Yu, M.; Zhang, Y.; Deng, C.; Xin, J.; Zhu, Y.; Feng, K. Application of fiber-optic strain sensing technology in high-precision load prediction of aircraft landing gear. Opt. Laser Technol. 2025, 182, 112183. [Google Scholar] [CrossRef]

- Rocha, H.; Semprimoschnig, G.; Nunes, J.P. Sensors for process and structural health monitoring of aerospace composites: A review. Eng. Struct. 2021, 237, 112231. [Google Scholar] [CrossRef]

- Kanu, N.J.; Gupta, E.; Vates, U.K.; Singh, G.K. Self-healing composites: A state-of-the-art review. Compos. Part A Appl. Sci. Manuf. 2019, 121, 474–486. [Google Scholar] [CrossRef]

- Fan, J.; de Alegría, A.A.R.; Vassilopoulos, A.P.; Michaud, V. Healable adhesive paste development for thick adhesive joints. Constr. Build. Mater. 2024, 449, 138533. [Google Scholar] [CrossRef]

- Snyder, A.D.; Phillips, Z.J.; Turicek, J.S.; Diesendruck, C.E.; Nakshatrala, K.B.; Patrick, J.F. Prolonged in situ self-healing in structural composites via thermo-reversible entanglement. Nat. Commun. 2022, 13, 6511. [Google Scholar] [CrossRef] [PubMed]

- Easy Access Rules for Large Aeroplanes (CS-25). Revision from January 2023. EASA. Available online: https://www.easa.europa.eu/en/document-library/easy-access-rules/online-publications/easy-access-rules-large-aeroplanes-cs-25?page=22&utm_source=chatgpt.com (accessed on 19 August 2025).

- Easy Access Rules for Acceptable Means of Compliance for Airworthiness of Products, Parts and Appliances (AMC-20). Initial issue & Amendments 1–22. EASA. Available online: https://www.easa.europa.eu/en/document-library/easy-access-rules/online-publications/easy-access-rules-acceptable-means-1?page=20&utm_source=chatgpt.com (accessed on 19 August 2025).

- Upadhya, A.R.; Dayananda, G.N.; Kamalakannan, G.M.; Setty, J.R.; Daniel, J.C. Autoclaves for aerospace applications: Issues and challenges. Int. J. Aerosp. Eng. 2011, 2011, 985871. [Google Scholar] [CrossRef]

- Composite Material Undercarriage Adopting Three-Dimensional Weaving. CN209904017U. Available online: https://worldwide.espacenet.com/patent/search/family/069046686/publication/CN209904017U?q=pn%3DCN209904017U (accessed on 29 May 2024).

- Compression RTM for Production of Future Aerostructures. CompositesWorld. Available online: https://www.compositesworld.com/articles/compression-rtm-for-production-of-future-aerostructures (accessed on 7 January 2025).

- Potter, K. The early history of the resin transfer moulding process for aerospace applications. Compos. Part A Appl. Sci. Manuf. 1999, 30, 619–621. [Google Scholar] [CrossRef]

- Naik, N.; Sirisha, M.; Inani, A. Permeability characterization of polymer matrix composites by RTM/VARTM. Prog. Aerosp. Sci. 2014, 65, 22–40. [Google Scholar] [CrossRef]

- Huberty, W.; Roberson, M.; Cai, B.; Hendrickson, M. State of the Industry—Resin Infusion: A Literature Review; ROSA P, Online, 2024. Available online: https://rosap.ntl.bts.gov/view/dot/75056 (accessed on 19 August 2025).

- Cartié, D.D.; Dell’aNno, G.; Poulin, E.; Partridge, I.K. 3D reinforcement of stiffener-to-skin T-joints by Z-pinning and tufting. Eng. Fract. Mech. 2006, 73, 2532–2540. [Google Scholar] [CrossRef]

- Composite Landing Gear Brace for Boeing 787 Dreamliner—First in the Market for Messier-Bugatti-Dowty 1. Summary of the Impact (Indicative Maximum 100 Words). Available online: https://impact.ref.ac.uk/casestudies/CaseStudy.aspx?Id=17852 (accessed on 19 August 2025).

- Di Boon, Y.; Joshi, S.C.; Bhudolia, S.K. Review: Filament Winding and Automated Fiber Placement with In Situ Consolidation for Fiber Reinforced Thermoplastic Polymer Composites. Polymers 2021, 13, 1951. [Google Scholar] [CrossRef]

- Welsch, M.; Funck, R. Development of a Lightweight Strut Made of Composite Material for the Aviation Industry. Available online: https://www.circomp.de/downloads/circomp-paper-lightweight-strut.pdf (accessed on 19 August 2025).

- AIRSTRUT Lightweight Composite Strut. AEC. Available online: https://www.albint.com/engineered-composites/products/airstrut/ (accessed on 14 January 2025).

- Chen, Y.; Zhang, J.; Li, Z.; Zhang, H.; Chen, J.; Yang, W.; Yu, T.; Liu, W.; Li, Y. Manufacturing Technology of Lightweight Fiber-Reinforced Composite Structures in Aerospace: Current Situation and toward Intellectualization. Aerospace 2023, 10, 206. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Taylor, O. Understanding the Influence of Consolidation in Automated Fibre Placement and Its Effect on Design for Manufacture Decisions. Ph.D. Thesis, University of Bristol, Bristol, UK, 2022. Available online: http://research-information.bristol.ac.uk (accessed on 25 August 2025).

| Type | Material | Tensile Modulus (GPa) | Tensile Strength (MPa) | Density (g/cm3) | Specific Modulus (GPa/g/cm3) | Specific Strength (MPa/g/cm3) |

|---|---|---|---|---|---|---|

| Traditional materials | 45 Steel | 210 | 600 | 7.85 | 27 | 76 |

| 300M Steel | 205 | 2040 | 7.87 | 26 | 259 | |

| Ferrium® S53 | 205 | 1990 | 7.97 | 26 | 250 | |

| Ferrium® M54 | 196 | 2020 | 7.97 | 25 | 253 | |

| Aermet® 100 | 196 | 1970 | 7.84 | 25 | 251 | |

| Ti-6Al-4V | 117 | 971 | 4.5 | 26 | 216 | |

| Synthetic fibres | E-Glass fibre | 70–76 | 3100–3800 | 2.5–2.6 | 29 | 1102 |

| Aramid fibre | 124 | 3380 | 1.44 | 86 | 993 | |

| T300 | 230 | 3530 | 1.76 | 131 | 2006 | |

| T700 | 230 | 4900 | 1.80 | 128 | 2722 | |

| T800 | 294 | 5490 | 1.81 | 162 | 3033 | |

| Resin-based composites 1 | Glass fibre/epoxy | 48 | 1245 | 2.00 | 24 | 623 |

| Aramid fibre/epoxy | 78.4 | 1373 | 1.40 | 56 | 981 | |

| T300/epoxy | 128 | 1760 | 1.60 | 81 | 1100 | |

| T700/epoxy | 130 | 2100 | 1.60 | 81 | 1310 | |

| T800/epoxy | 154 | 2950 | 1.6 | 96 | 1814 | |

| T800/PEEK | 155 | 2200 | 1.57 | 98 | 1401 |

| Joint Type | Behaviour/Stiffness | Failure Load/Capacity | Failure Process/Mode | Performance Outcome |

|---|---|---|---|---|

| Bonded joint | Linear stiffness throughout loading | Complete load loss after adhesive fracture | Adhesive fracture | Lowest strength; lowest energy absorption |

| Riveted joint | Nonlinear at ~0.5–1.0 mm due to CFRP hole damage | Residual capacity ~5 kN post-failure | CFRP hole damage followed by rivet-only load bearing | Moderate strength; moderate energy absorption |

| Hybrid joint | Initial stiffness and peak load decrease with increasing bond line thickness; linear beyond ~1.0 mm until failure | Higher peak load than bonded or riveted joints; post-peak drops to ~5 kN (rivet-only behaviour) | (i) Adhesive + rivet share load; (ii) progressive adhesive fracture; (iii) rivet bears load alone | Superior strength and energy absorption |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caglar, H.; Ayre, D.; Mills, A.; Xu, Y.; Skote, M. A Review of Polymer Composites and Adhesives for Aircraft Landing Gear Applications. Aerospace 2025, 12, 794. https://doi.org/10.3390/aerospace12090794

Caglar H, Ayre D, Mills A, Xu Y, Skote M. A Review of Polymer Composites and Adhesives for Aircraft Landing Gear Applications. Aerospace. 2025; 12(9):794. https://doi.org/10.3390/aerospace12090794

Chicago/Turabian StyleCaglar, Hasan, David Ayre, Andrew Mills, Yigeng Xu, and Martin Skote. 2025. "A Review of Polymer Composites and Adhesives for Aircraft Landing Gear Applications" Aerospace 12, no. 9: 794. https://doi.org/10.3390/aerospace12090794

APA StyleCaglar, H., Ayre, D., Mills, A., Xu, Y., & Skote, M. (2025). A Review of Polymer Composites and Adhesives for Aircraft Landing Gear Applications. Aerospace, 12(9), 794. https://doi.org/10.3390/aerospace12090794